Page 1

R2R

Reel to Reel Care Label Heat Press

OWNERS MANUAL

R2R shown

For Customer Service, Call 1-800-835-0606

or Visit www.hixcorp.com

CONTENTS

Receiving and Shipping 2

Set Up 3-6

Operation 7

Sensor Setting 8-9

Temperature and Time 10

Trouble Shooting/Maintance 11

Warranty 12

BEFORE warranty repair you MUST get Prior Authorization:

Call 1-800-835-0606

1

RV A_102609

Page 2

RECEIVING AND SHIPPING

UNPACKING

Remember to save all packing materials - including box,

liner and board. You may need these for shipping your

machine or if a repair is necessary in the future.

INSPECTION

Inspect your machine for hidden shipping damage. Contact

the delivery company immediately , should you find damage.

SHIPPING OR RETURNS

NOTE: Save all of your shipping/packing materials.

DO NOT RISK COSTLY SHIPPING DAMAGE!

SHIP ONLY IN ORIGINAL BOX. HIX will not be

responsible for freight damage repairs.

1. Place in original crate.

2. Fasten machine to shipping base with bolts provided.

3. Make sure crate top is securely fastened to base.

2

Page 3

SET UP

SET UP

1. Unpack - Remove nails located at base of crate and carefully remove

top portion of crate. Unfasten machine from shipping base and place

on secure, sturdy table. Reattach crate top to shipping base.

2. Keep crate for secure shipping in the event return shipment is required.

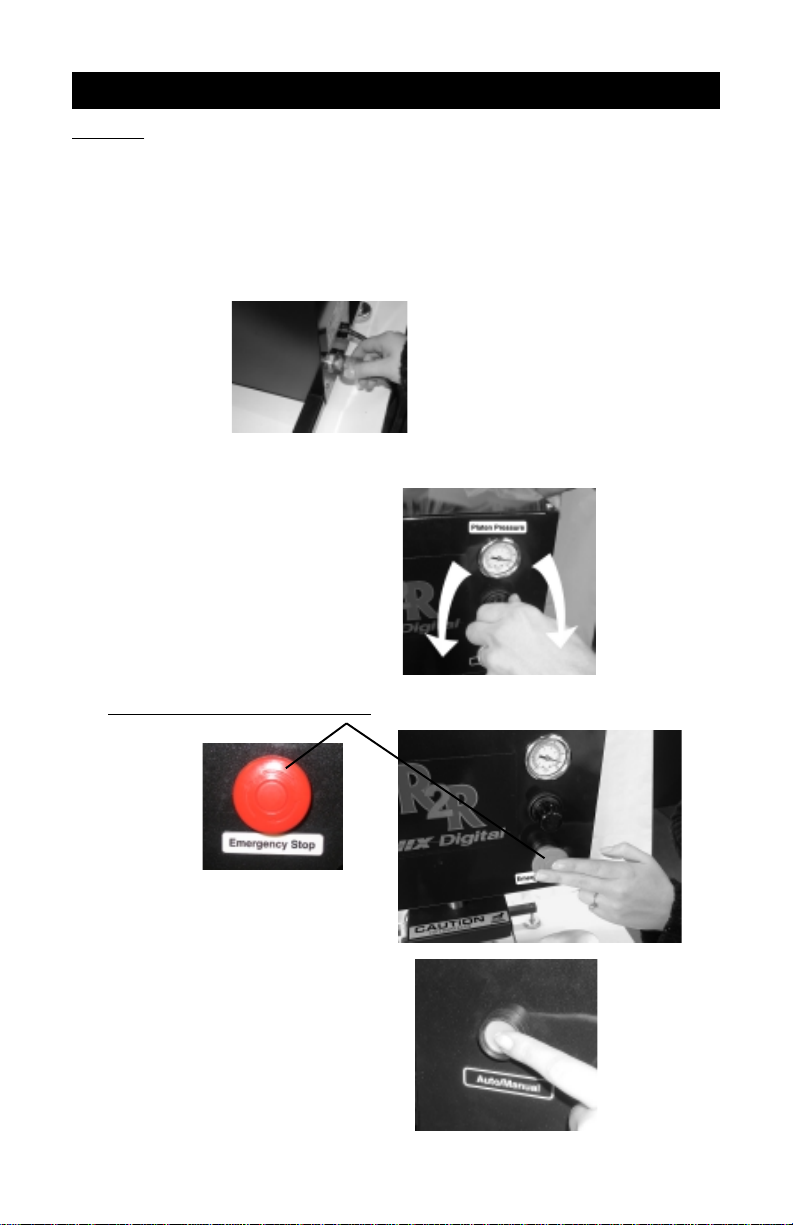

3. Connect air supply to brass air intake fitting 3/8”.

Note: pressure requires 4 CFM@ 70 PSI compressed air.

4. Set pressure Turn Knob below air

gauge right to increase pressure.

Left to decrease pressure.

Note: air pressure will not decrease

until machine cycles. Set starting

pressure to 40-50 PSI.

5. Push Emergency stop button.

6. Make sure auto/manual button is

in the “out” manual position.

(Press and release to change

button position)

3

Page 4

SET UP

7. Plug in machine.

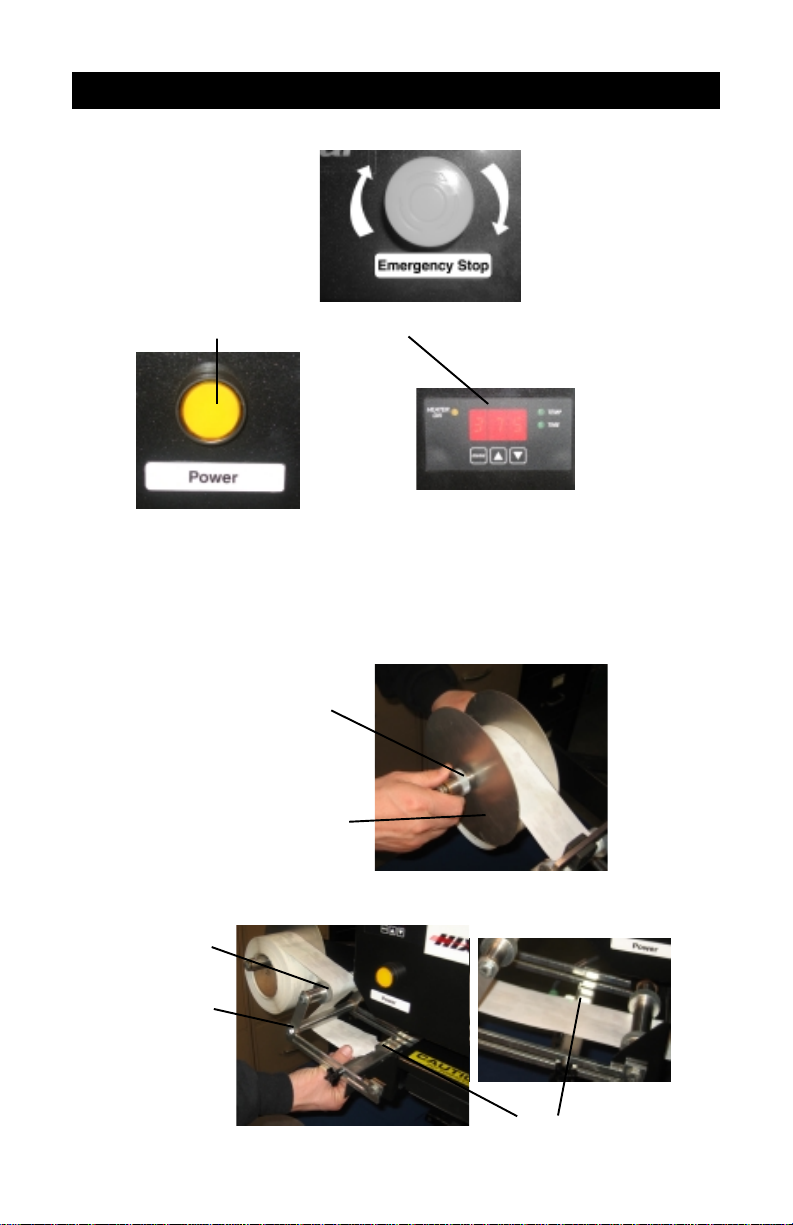

8. Now rotate Emergency

stop button to the right

(clockwise) to release.

9. Push Yellow power button. Time/Temp display will light.

10. Set your desired time and temp. (See Page 10 )

11. Remove Reel Quick Knob and reel face flange

(non motor side).

Note: Quick Knobs can be slid off after rotating approximately one turn.

12. Load full reel on supply side (non motor side)

Reel Quick Knob

Reel Face Flange

13. Feed Label over top guide rod, under elbow rod and over the sensor.

T op Guide Rod

Elbow Rod

Sensor

4

Page 5

SET UP

Continue web underneath heat platen and underneath right elbow web

guide. Feed over top guide rod and through slot in drive roller mount.

Top Guide Rod

Right Elbow Web

Guide

Drive Roller Mount

For effective web tracking labels should be fed between drive roller

and pinch roller then back over top of pinch roller.

Pinch Roller

Pinch Roller

Drive Roller

5

Page 6

SET UP

Simply place lead

edge of label web

between four fingers

of take up real and let

hang free.

14. Take up slack by pressing

and releasing Jog button on

left side of control box.

15. Set sensor position and sensitivity . (See sensor section p age 8)

16. Position label on platen then move sensor to align its light beam on the

index mark.

Index Mark

17. Push manual/auto button to “In” position to set in auto mode.

6

Page 7

OPERATION/SENSOR SETTING

OPERATION

1. Visually check and confirm label is in centered position.

(Note: If it is NOT repeat sensor setting Page 8)

2. Position Garment into desired position

3. Place finger in each optical control switch, heat head will come down

and then rise after set time, take up roll will automatically index to next

label. Warning: Watch Hands!

SENSOR SETTING

1. Jog label by depressing and releasing the Jog button to move the label

index mark such that the light beam is aimed on the Index mark. (or

hand move)

Index Mark

7

Page 8

SENSOR SETTING Cont.

2. Reposition guides on guide rod to maintain front to rear centering of

label. Do not adjust left to right position at this time.

Guides on

guide rods

3. Depress manual/auto button to the “out” position or manual mode

4. Position sensor light on eye mark printed on label web.

5. Turn small phillips head adjusting screw, such that small faint arrow

points to “TM” - Sensor light will flash for 2-4 seconds, then turn back to

“S”. The sensor stops flashing and is now set to the index point.

TD

TM

S

TB

8

Page 9

SENSOR SETTING Cont.

6. Now reposition label such that the light beam is between index marks

and on a non-printed (or white area) of the label.

7. Now turn phillips head adjusting screw on sensor to “TB” for 2-4 seconds.

Sensor lights will flash, then turn back to “S” flashing stops. Sensor is

now set to recognize background fields.

8. Put machine in Auto Mode (button in ) and activate optical control switch,

the label will advance to next index mark and stop. Position label front

to rear if necessary (Step 2 of sensor setting) and right to left on lower

platen, using jog button.

Optical Control Switch

9. Now adjust position of sensor head such that the light beam is just

above the Index mark (approx. 3mm) and tighten.

Sensor Settings Abbreviations

(also printed on sensor)

S - Switching Mode

TM - Teach In Mark

TD - T each In Dynamic

(not required in this application)

TB - Teach In Background

9

Page 10

TEMP & TIME INSTRUCTIONS

TEMPERATURE & TIME INSTRUCTIONS

1. Turn on the machine by pushing the power button.

2. To change or set the temperature, press the menu button on

the digital control. The light next to “TEMP” will light. Press the

up ▲, or down ▼, button to your desired setting.

3. To change or set the time, press again, the menu button on

the digital control. The light next to “TIME” will light. Press the

up ▲, or down ▼, button to your desired setting.

4. When you have your desired settings press the menu button

a third time to lock in your settings otherwise the controller

will revert to the previous settings.

5. Wait for the machine to reach your preset temperature by

monitoring the display temperature until it matches the set

temperature. The heater On light will also cycle On and Off.

10

Page 11

TROUBLE SHOOTING/MAINTENCE

Symptom Cause Solution

1. Machine does not

index properly .

2. Labels do not

transfer properly.

3. Upper Platen does

not move.

4. Unit does not come

on

Press set to Manual

Sensor not set

properly

Not enough heat, time

or pressure.

No air pressure.

E-Stop button is on.

Breaker Tripped

Blown Fuse

De-Press Manual/

Auto button

First make sure label

is aligned properly .

Re-Teach sensor . See

“Sensor Section” pg 8.

Please refer to

transfer specifications

while most transfer

target times range

from 1-2 seconds.

Pressure and Temperature settings may

vary depending on

fabric limitations.

Check that air connection is secure.

Check that air supply

has not been interrupted.

Turn E-S top clockwise

and press Power

button.

Locate main breaker

panel and flip tripped

breaker to on position.

See Diagram on page

12 for location of fuse.

11

Page 12

WARRANTY

(Effective May 1, 2008)

HIX will automatically register the equipment on the date it was shipped to you or your distributor.

If the equipment was not purchased directly from HIX, but through a distributor (either domestic or

foreign), please keep a copy of their sales invoice showing the serial number and date it was sold/

shipped to you with this warranty. In this case, we will use the distributor’s invoice date as the

beginning warranty date. STAPLE A COPY OF YOUR RECEIPT TO THIS WARRANTY and keep

in a safe place to provide verification of your warranty should a problem occur. Thank you.

Please fill in the following information and attach a copy of your receipt for your records.

Date Purchased: ______________________ From:__________________________________

Model #: ____________________________ Serial #: ________________________________

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg, Kansas, U.S.A. HIX warrants to the original purchaser, its Ovens and Dryers, Heat Transfer Presses,

Mug Presses, Mug Glazer, Retensionable Screen Frames, Textile Printers, S pot Heaters, and Exposure Units against defects in workmanship and material, except for wear and tear for a period of “One

Year” from the date of purchase. HIX warrants its Accessories, Reten S plines/Hardware/Tool Kit, and

Shuttle for a period of 90 days from the date of purchase. DoughXpress and Thermatrol products are

covered under separate warranty.

In the event of a defect, HIX, at its option, will repair , replace or substitute the defective item at no

cost during this period subject to the limitations of insurance and shipping costs stated below.

In the case of heat transfer presses (except the Mug Press, Hobby Lite), HIX warrants the heat

casting for the “Life” of the machine for the original purchaser. If a part becomes obsolete at the time

for repair, and/or cannot be reasonably substituted for , HIX will credit, at half the then current list price

or last recorded price, only that part toward a new machine or any product HIX offers. This credit offer

shall be the sole responsibility of the HIX Corporation in the event of an obsolete part.

This warranty does not cover belts, pads, mug wraps, mug press liners, canvas, rubber blankets,

bulbs, glass, rod ends, turn buckles on printers, or mug press or damages due to accident, misuse/

abuse, alterations or damage due to neglect, shipping or lack of proper lubrication or maintenance.

HIX shall not be responsible for repairs or alterations made by any person without the prior written

authorization by HIX. This warranty is the sole and exclusive warranty of HIX and no person, agent,

distributor, or dealer of HIX is authorized to change, amend or modify the terms set forth herein, in

whole or in part.

In the case of a problem with the equipment identified herein, HIX Corporation should be contacted during regular business hours to discuss the problem and verify an existing warranty. HIX

personnel will assist the customer to correct any problems which can be corrected through operation

or maintenance instructions, simple mechanical adjustments, or replacement of parts. In the event

the problem cannot be corrected by phone, and upon the issuance of a return authorization by HIX,

the equipment shall be returned to HIX or an authorized service representative. All insurance and

shipment/freight costs are solely the responsibility of the customer, and not that of HIX, and HIX shall

not be responsible for improper handling or damage in transit. Contact HIX customer service for

complete return authorization information.

This expressed warranty is given in lieu of any and all other warranties, whether expressed or

implied, including but not limited to those of merchantability and fitness for a particular purpose, and

constitutes the only warranty made by HIX Corporation.

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair or

replace the nonconforming goods. HIX shall not be liable for any other damages, either incidental or

consequential, or the action as brought in contract, negligence or otherwise.

This warranty gives you specific legal rights and you may also have other rights which vary from

state to state.

Manufacturers of the Finest Quality Textile and Graphics Screen Printing and Heat Transfer Equipment

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606

E-Mail: customerservice@hixcorp.com • Fax: (866) 561-0894

E-Mail: sales@hixcorp.com • Fax: (866) 563-4600

©2009 HIX Corp.

Loading...

Loading...