Page 1

WARRANTY

HIX will automatically register the equipment on the date it was shipped to you or your distributor.

If the equipment was not purchased directly from HIX, but through a distributor (either domestic

or foreign), please keep a copy of their sales invoice showing the serial number and date it was

sold/shipped to you with this warranty. In this case, we will use the distributor’s invoice date as the

beginning warranty date. STAPLE A COPY OF YOUR RECEIPT TO THIS W ARRANTY and keep

in a safe place to provide verifi cation of your warranty should a problem occur. Thank you.

Please fi ll in the following information and attach a copy of your receipt for your records.

Date Purchased: From:

Model #: Serial #:

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg, Kansas, U.S.A. HIX warrants to the original purchaser, its Ovens and Dryers, Heat Transfer Presses,

Mug Presses, Mug Glazer, Retensionable Screen Frames, Textile Printers, Spot Heaters, and Exposure Units against defects in workmanship and material, except for wear and tear for a period of

“One Y ear” from the date of purchase. HIX warrants its Accessories, Reten Splines/Hardware/Tool

Kit, and Shuttle for a period of 90 days from the date of purchase. Thermatrol and doughXpress

products are covered under separate warranty.

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item at

no cost during this period subject to the limitations of insurance and shipping costs stated below.

In the case of heat transfer presses (except the Hobby Lite), HIX warrants the heat casting for

the “Life” of the machine for the original purchaser. If a part becomes obsolete at the time for repair ,

and/or cannot be reasonably substituted for, HIX will credit, at half the then current list price or last

recorded price, only that part toward a new machine or any product HIX offers. This credit offer

shall be the sole responsibility of the HIX Corporation in the event of an obsolete part.

This warranty does not cover belts, pads, mug wraps, canvas, rubber blankets, bulbs, glass, rod

ends, turn buckles on printers or damages due to accident, misuse/abuse, alterations or damage

due to neglect, shipping or lack of proper lubrication or maintenance. HIX shall not be responsible

for repairs or alterations made by any person without the prior written authorization by HIX. This

warranty is the sole and exclusive warranty of HIX and no person, agent, distributor, or dealer of

HIX is authorized to change, amend or modify the terms set forth herein, in whole or in part.

In the case of a problem with the equipment identifi ed herein, HIX Corporation should be con-

tacted during regular business hours to discuss the problem and verify an existing warranty. HIX

personnel will assist the customer to correct any problems which can be corrected through operation

or maintenance instructions, simple mechanical adjustments, or replacement of parts. In the event

the problem cannot be corrected by phone, and upon the issuance of a return authorization by

HIX, the equipment shall be returned to HIX or an authorized service representative. All insurance,

packaging and shipment/freight costs are solely the responsibility of the customer, and not that

of HIX, and HIX shall not be responsible for improper packaging, handling or damage in transit.

Contact HIX customer service for complete return authorization information. Correct shipping boxes

are available from HIX.

This expressed warranty is given in lieu of any and all other warranties, whether expressed or

implied, including but not limited to those of merchantability and fi tness for a particular purpose,

and constitutes the only warranty made by HIX Corporation.

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair or

replace the nonconforming goods. HIX shall not be liable for any other damages, either incidental

or consequential, or the action as brought in contract, negligence or otherwise.

This warranty gives you specifi c legal rights and you may also have other rights which vary from

state to state.

Manufacturers of the Finest Quality Textile and Graphics Screen Printing and Heat Transfer Equipment

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606 • Fax: 620-231-1598

E-Mail: customerservice@hixcorp.com • E-Mail: sales@hixcorp.com

(Effective September 1, 2010)

16

©2010 HIX Corp.

NP PRINTER

Manual Screen Printer

OWNER’S MANUAL

4 Color / 4 Station

NP Rotary shown

For Customer Service, Call 1-800-835-0606

or Visit www.hixcorp.com

CONTENTS

Printer/ Assembly 2-4

Set Printhead 5

Screen Installation & Adjustment 6

PrePress and Registering 7-11

King Pin Registration 11-12

Jacket Hold Down Set Up 13

Gas Spring Replacement 14-15

Warranty 16

BEFORE warranty repair you MUST get Prior Authorization:

70663 RV A_121310

Page 2

PRINTER ASSEMBLY

GAS SPRING REPLACEMENT

TOOLS REQUIRED:

(2) 9/16” Wrench

(2) 1/2” Wrench

(1) 7/8“ Socket and Ratchet

(1) Phillips Screwdriver

Assembly (if press is assembled/ partially assembled go to next step)

ARM ASSEMBL Y

Slide each arm under the fl ange nut on lower print wheel, and then 1.

tighten from the bottom.

Insert the additional (2) 1/2” bolts (Fig 1) to print arm fl anges and 2.

tighten.

BASE ASSEMBL Y

Empty the contents of ALL cartons on the fl oor.

NOTE: This will require two people.

Place leg assembly on fl oor, leveling pads down.1.

Align base with (4) holes on leg assembly. (2 people re quired)2.

Tighten the (4) 3/8” bolts down to leg assembly with 9/16” wrench.3.

To level printer adjust leveling pads and tighten jam nuts.4.

Remove the worn gas spring, 8.

and remove bushings.

Install bushings in new gas 9.

spring. (Fig. 40).

Install the top of the new gas 10.

spring following steps 5 then 4.

Check operation.11.

NOTE: To prolong the life of your

new gas spring, never

spray adhesive toward it.

Always spray the shirtboard from side-to-side

away from the gas spring.

(2) Bushings to

be retained for

use with new

gas spring

Fig. 40

Fig 1

PRINT HEAD ASSEMBLY

Remove the nut, bearing cap cardboard 1.

tube and plastic shrinkwrap from spindle

(Fig 2).

Remove the top bearing from spindle and 2.

set on a clean cloth.

Place print head wheel assembly over 3.

spindle.

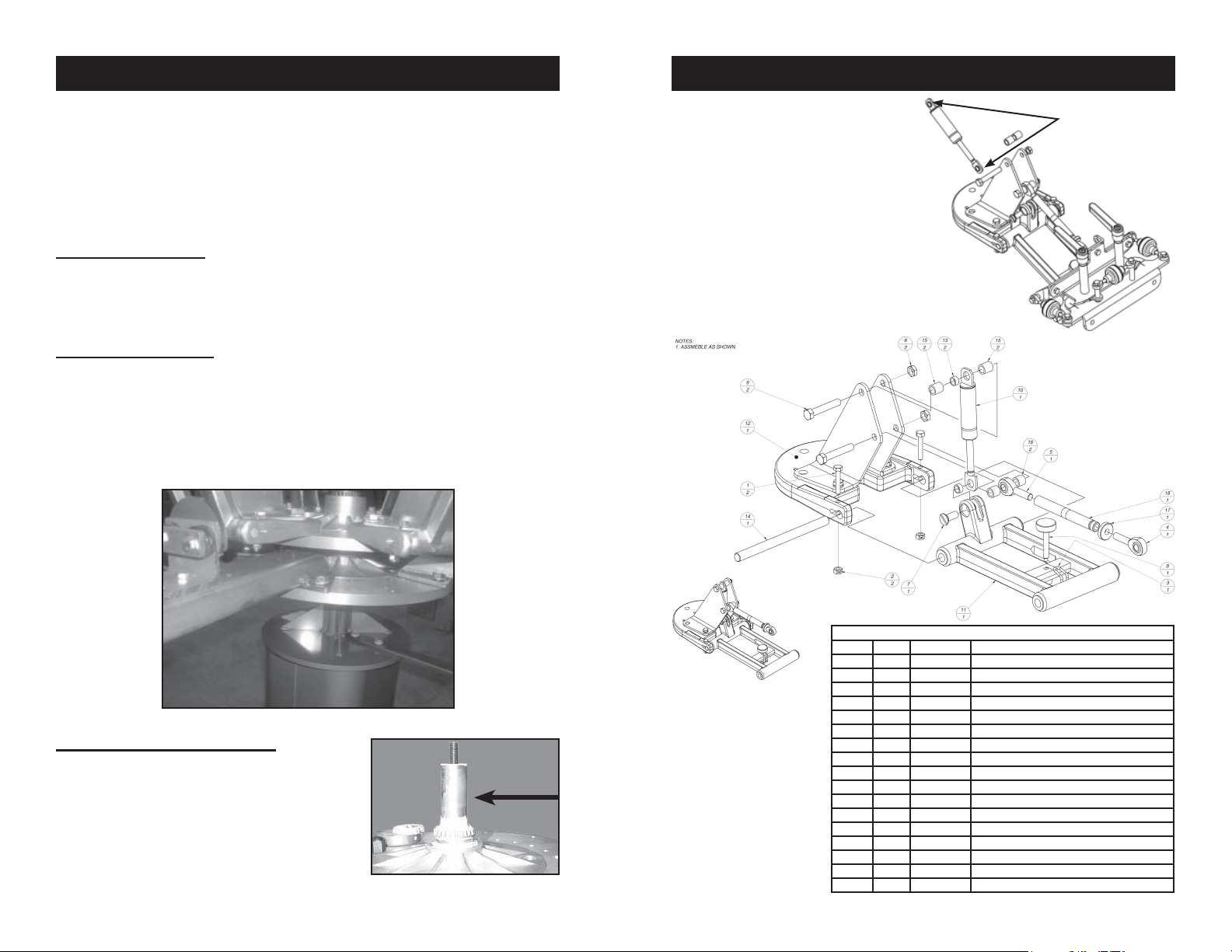

ITEM QTY PART # DESCRIPTION

1 2 10702 BOLT 1/4-20x1-1/2 ZPS

2 2 17111 Nut Hex 0420 NC ZP

3 1 18382 O-RING

4 1 29991 ROD END 3/8x3/8-24 RH

5 1 30007 ROD END 3/8x3/8-24 LH

6 2 47753 NUT HEX JAM 3/8-16 NC ZP

7 1 69302 SCREW MCH 3/8-16x1 FHSL

8 1 86017 KNOB, 5/16-18 CLAMPING

9 2 86850 BOLT 3/8-16 x 2-1/4

10 1 89326 SPRING, 150# GAS

11 1 1010600 ASSY, H-ARM

12 1 1010610 ASSY, PRINT HEAD BRACKET

13 2 1011032 BUSHING, GAS SPRING

14 1 1011033 SHAFT, H-ARM PIVOT

15 2 1011080 SPACER, GAS SPRING UPPER

16 2 1152004 SPACER, ROD END

17 1 1157002 ADJUSTMENT LOCK NUT

Fig 2

2

18 1 1157003 TUBE, KNURLED ADJUSTMENT

15

Page 3

GAS SPRING REPLACEMENT

PRINTER ASSEMBLY

PREMIER PRINTER GAS SPRING REPLACEMENT

Review pages Premier Printer exploded views and part identifi cation before

beginning. Drawings can be obtained though the manufacturer. Call tech

support 800-835-0606.

TOOLS REQUIRED

A. 9/16” box wrench

B. 9/16” socket & ratchet

C. Standard screwdriver

STEPS:

Rotate printhead wheel so that the printhead with the worn gas spring 1.

is centered between two shirtboard print stations.

Remove the shirtboards on both sides to allow for more work space 2.

while you change the worn gas spring.

Raise H-Arm to its most upright position (Fig. 38).3.

Fig. 38

(2) Spacers

H-Arm

Bolt

& Nut

NOTE: Make sure the bearing is seated evenly in the bearing race on the

bottom of the printwheel assembly such that wheel assembly turns

freely. 2 people required (Fig 3).

Fig 3

Place the tapered end of the bearing into the top race 4.

of the printwheel assembly and hand tighten the cap

on screw until snug. The cap on screw can then be

tightened an additional ¼ turn by inserting a rod into

the hole in the top of the bearing cap. (Fig 4)

Fig 4

SHIRTBOARD POSITION

Holding the bearing cap in place, tighten the nut fi rmly on the top of 5.

the spindle assembly.

NOTE: Spin and gently rock both upper and lower printwheels to assure

bearings are seated properly (Fig 5).

Remove bolt and Nut from top of 4.

gas spring with 9/16” box wrench

on one side and 9/16” socket

wrench on the other.

Remove (2) Spacers and (1) 5.

Bushing and retain for use with

new gas spring.

Once the top of gas spring has 6.

been released lower the H-Arm

to the lowest position and turn the

inclination link until the lower gas

spring pin is exposed out past the

printhead tower. (Fig. 39)

Take out fl athead screw.7.

(Fig. 39)

14

Flathead

screw

Inclination Link

Fig. 39

Fig 5

Attach shirtboards on the print arms, fl at

side in, push the shirtboard to the back

until they rest just under the print head and

tighten them using the knobs located on

the side FIRST. T ighten the bottom knob

second on the shirtboard clamps (Fig 6).

Fig 6

3

Page 4

PRINTER ASSEMBLY

JACKET HOLD DOWN SET-UP

REGISTRATION GUIDE ALIGNMENT

Lower 1. all print heads (Fig. 7). Tighten the (2) bolts (Fig. 8) that secure

the registration guide bracket to the arm.

Print Heads Down

Fig. 7

NOTE: This procedure must be done to ensure all print heads will register

for printing.

Two Bolts

Fig. 8

BRAKE WHEEL ADJUSTMENT

The brake wheel is mounted so as to allow the wheel to be raised or 1.

lowered to provide the braking action desired.

Loosen the retaining bolt and align brake wheel under a print arm.2.

Insert a Phillips screwdriver into the hole on the brake wheel shaft. 3.

(Fig. 9)

Raise or lower the brake wheel by moving the screwdriver to the desired 4.

brake resistance (Fig. 9).

1. Remove shirtboard and install the

jacket hold down board onto the

arm. Place the off-contact compensation cap over bolt head (Fig. 33).

NOTE: This cap compensates for the

height increase of the jacket

board over a standard board.

Fig. 33

2. Adjust the rubber grip blades so that

they are parallel with the edge of

the board. Gap adjustment will vary

depending on the jacket and liner

thickness. (Fig. 34)

Fig. 34

3. Center jacket over platen (Fig. 35)

with latch protruding.

NOTE: On small or youth size jackets, it

may be necessary to unzip the

jacket front fi rst.

Fig. 35

4. Lower the holddown into position

(Fig. 36) and lock the toggle latch.

Check the jacket position to ensure it

is centered properly before printing.

Reposition grip (step 2) as necessary.

Fig. 9

Tighten the retaining bolt and check the braking action. 5.

Re-adjust if needed.6.

4

5. Lock the toggle latch so the frame

will not tend to creep up (Fig. 37).

NOTE: It is wise to “pre-flash” each

jacket before the fi rst print is

made to prevent shrinking of

the jacket, which can cause

registration problems when doing multi-color prints.

13

Fig 36

Fig. 37

Page 5

KING PIN SYSTEM

Expose each screen one at a time (Fig. 31), washout, dry and prep for

printing.

Step 3: Align the docking hole in the exposed frame with the PIN on mounting plate bolted to the printer. (Fig. 32) Lock the screen in position with

back or side clamps on each print head. Add your ink to each screen and

proof the print. Check the print itself and the registration marks for correct

alignment and visual

Fig. 27 Fig. 28

SET PRINTHEAD

NOTICE: Failing to properly set up

printhead level will not allow

print to be registered.

YOUR HIX PRESS MUST BE REGISTERED ON CONTACT!

(Meaning the exposed screen is touching the shirtboard. )

Front to rear adjustment. Insert Screen into screen clamp (see 1.

page 6) and adjust the screen tilt adjustment (see page 9).

Adjust so that the screen is parallel with the shirt board front to back,

and make sure your screen sits totally fl at on the shirtboard. Or the

screen will slip when you tighten the ratchet handles. (See handles on

page 7 Fig. 13)

Left to right/ Parallel adjustment.2. Be sure the back screen clamp (or

cross tube holding side clamps) is level and parallel in relationship to

the shirtboard. (Left to right on the shirtboard) There are two bolts that

secure the back clamp (or crosstube) to the lower registration plate.

Slightly loosen nuts holding these bolts. The left side of the back

clamp (or crosstube) is oversized which allows you to move the clamp

(or crosstube) to align the screen parallel to the shirt board. Adjust to

parallel and tighten.

NOTE: If not level after tightening repeat steps 1 and 2 above.

WARNING: Failing to level this section of the printer will cause an un-even

contact from the left to the right or front to rear. This may

will cause the screen to “slip” or move when you tighten the

registration ratchet handles.

Fig. 29 Fig. 30

exposure plate docking pin

Fig. 31 Fig. 32

mounting plate docking pin

12

Not to scale

Back clamp

Screen not level

Screen Level

Front to Rear

Shirtboard

Cross tube that holds side clamps

Left to Right

Shirtboard

5

Page 6

SCREEN INSTALL. & ADJUST.

PREPRESS & REGISTRATION

FOR BACK CLAMPS: (FIG. 10)

1. Loosen both black knobs on the back clamp and center the screen 1.

in the clamp making sure the screen is all the way inside the clamp.

2. Tighten the black knobs so that they securely grip the screen.2.

FOR SIDE CLAMPS: (FIG. 11 AND 12)

(If the side clamp is not attached see Fig 12)

Loosen the two black adjustment knobs on each side clamp wide 1.

enough to accept the screen.

Loosen the angled back knob on the back of each side clamp and 2.

move clamps far enough apart on the cross tube so that the screen

will fi t into the clamps.

Insert the screen into the side clamps and press clamps inward so that 3.

they are against the sides of the screen frame and centered over the

shirtboard. Center on the crosstube.

Gently tighten the angled knobs on the cross tube.4.

NOTE: Do not overtighten.

Tighten the two black knobs on each side clamp to securely grip the 5.

screen.

Back Clamp Fig. 10

Slide this

side over

cross tube.

Fig. 12

NOTE: The bolt securing the left hand side of the cross tube is in an over-

sized hole allowing for adjustment if a screen is slightly warped

or twisted. Likewise, printers confi gured with the back clamp fea-

ture a similar slotted hole which exists to allow for leveling of the

screen.

Remember if you modify this adjustment for a warped screen, to

reset printhead for fl at screen (see page 5)

Loosen the nuts on the cross tube or the back clamp. Adjust up or

down so that the screen is parallel (right to left) to the shirt board.

6

Side Clamp Fig. 11

Allen screws

registration

take-up nut

Loosen the two Allen screws on the registration take-up nut.1.

Loosen the 1/4-20x0.750 bolt on the opposite side of main pivot 2.

pin as the registration take-up nut.

Turn the registration take-up nut clockwise to tighten the 3.

space and remove any play. BE CAREFUL NOT TO OVER

TIGHTEN.

Tighten the two Allen screws and bolt from steps 1 and 2.4.

H-Arm

bolt

KING PIN SYSTEM

The HIX King PIN™ registration system lets you go from art, to exposure,

to printer in 3 simple and very fast steps. This kit includes a precision hole

punching device, exposure plate and a pin mounting plate for each of your

print heads.

KING PIN™ REGISTRATION SYSTEM:

The King PIN™ system was designed to save additional set up time during

the pre press process. From fi lm positive alignment, to screen exposure,

to print set up and registration, the innovative King PIN™ system is very

easy to use.

Combine the King PIN™ system with the HIX Micro-registration print head

and your registration needs are covered. The King PIN™ system quickly

attaches to all HIX printers.

Step 1: After generating fi lm positives or vellums, line them up and tape

together (in registration). (Fig. 27)

Insert all and center the taped positives into the hole punching device and

punch holes. (Fig. 28) Remove the tape from the fi lm positives and attach

each individual positive to the King PIN™ exposure plate pins. (Fig. 29

and Fig. 30 )

Step 2: Position the exposure plate with the positive attached on your

exposure unit. Take your unexposed screen and position the frame (side

with the slotted hole) snug into the docking position PIN on the exposure

plate. (Fig. 30)

11

Page 7

PREPRESS & REGISTRATION

PREPRESS & REGISTRATION

If your clamps are too loose when you begin the adjustments (Fig.

23) your screen may jump out of registration during fi nal clamping.

(See page 5)

ratchet handles

registration

knobs

Fig. 23

Before proceeding to the next print head alignment, measure the dis-9.

tance between the end of the shirt board clamp and the registration

guide on the print arm. This distance should be the same for all the

other shirt boards in the setup process. (Fig. 24) Adjust if necessary

see shirtboard position pg. 3

NOTICE: Before printing follow these steps below.

The fi rst step involves setting all 1.

micro register heads to a neutral

position. This can be done by

loosening the ratchet handles approximately a 1/4 turn (Fig. 13) and

then turning the three registration

knobs (Fig. 14) until the arrow tab

points (Fig. 15) to the center of the

inscribed cross hairs.

Perform this adjustment on every

print head that takes a screen.

registration

knobs

Fig. 14

ratchet handles

Fig. 13

Fig. 24

NOTE: Over time the bushings (Fig. 25) between the micro-registration and

the H-Arm could become worn and create play in the print head.

This play can cause prints to fall out of registration. An adjustment

to the registration take-up nut (Fig. 26) on the micro-registration

will need to be made.

Fig. 25

Fig. 26

H-Arm

10

Fig. 15

7

Page 8

PREPRESS & REGISTRATION

PREPRESS & REGISTRATION

Center, level, and tape your art/2.

fi lm positive (normally the black

or trap) on one shirt board using

a T-Square and a ruler. Roughly

center or position to desired location. Make sure all printable

images lie within the boundary of the shirtboard. (Fig. 16)

Then register your screens to

the film positive (see page 9).

(film positive- Any artwork on

a clear fi lm that can be used to

expose a screen.

Optionally, if you do not have a positive or vellum; you can spray tack 3.

adhesive on the shirt board, then load a shirt or pellon onto the board.

Then “print” the black/darkest color or keyline positive directly onto the

shirt or pellon. Cure, then register your screens to this print (see page

9). (keyline positive- the outline that traps all other color separation

positives. pellon- test print material, so to not ruin usable material.)

NOTE: Slight adjustments to the shirtboard to improve alignment may be

necessary.

To adjust the shirtboard:4. (Fig.

17) Loosen the shirt board and

position so that it lines up with the

screen frame when it is lowered

into the horizontal position.

REMEMBER to tighten the side knob

fi rst and then the bottom/larger knob.

Lower the screen onto the shirt 5.

board with the taped artwork.

Loosen the screen clamps on back 6.

clamp models or angled back

knob on side clamp presses and

center the screens side to side if

needed.

Note: Keep

in mind you

still want the

screen to fit

tight against

the back of the

screen clamps

to improve support. (Fig. 18)

side to side

8

Fig. 16

Fig. 17

Fig. 18

Lower your screen all the way down to the shirt board. You may have 7.

to use the off contact adjustor (Fig. 19) and your screen leveler (Fig.

20) to achieve front to rear “contact” with the shirt board. Now slightly

loosen the ratchet handles. Y ou should be able to notice the movement

of the screen after adjusting the three adjustment nuts. (Fig. 14)

off contact adjustor screen leveler

Fig. 19

ShirtboardShirtboard

If not parallel left to right see page 5, step #2.

Looking through the screen (Fig. 21) use the adjustment knobs. (Fig. 22-23)8.

Fig. 21 Fig. 22

Once you have achieve perfect lineup with the screen and art, hold the

screen down with your hand and then working back and forth, gently

snug up the ratchet handles (Fig. 23) until the screen is fi rmly locked

in place. Recheck your registration then use the off contact and the

screen leveling adjustment to raise the screen approximately 1/16” off

the shirtboard surface.

NOTE: If your ratchet handles are too tight you may cause damage to the

adjustment nuts by forcing them. (Fig. 23)

9

Fig. 20

Loading...

Loading...