Page 1

OWNER’S MANUAL

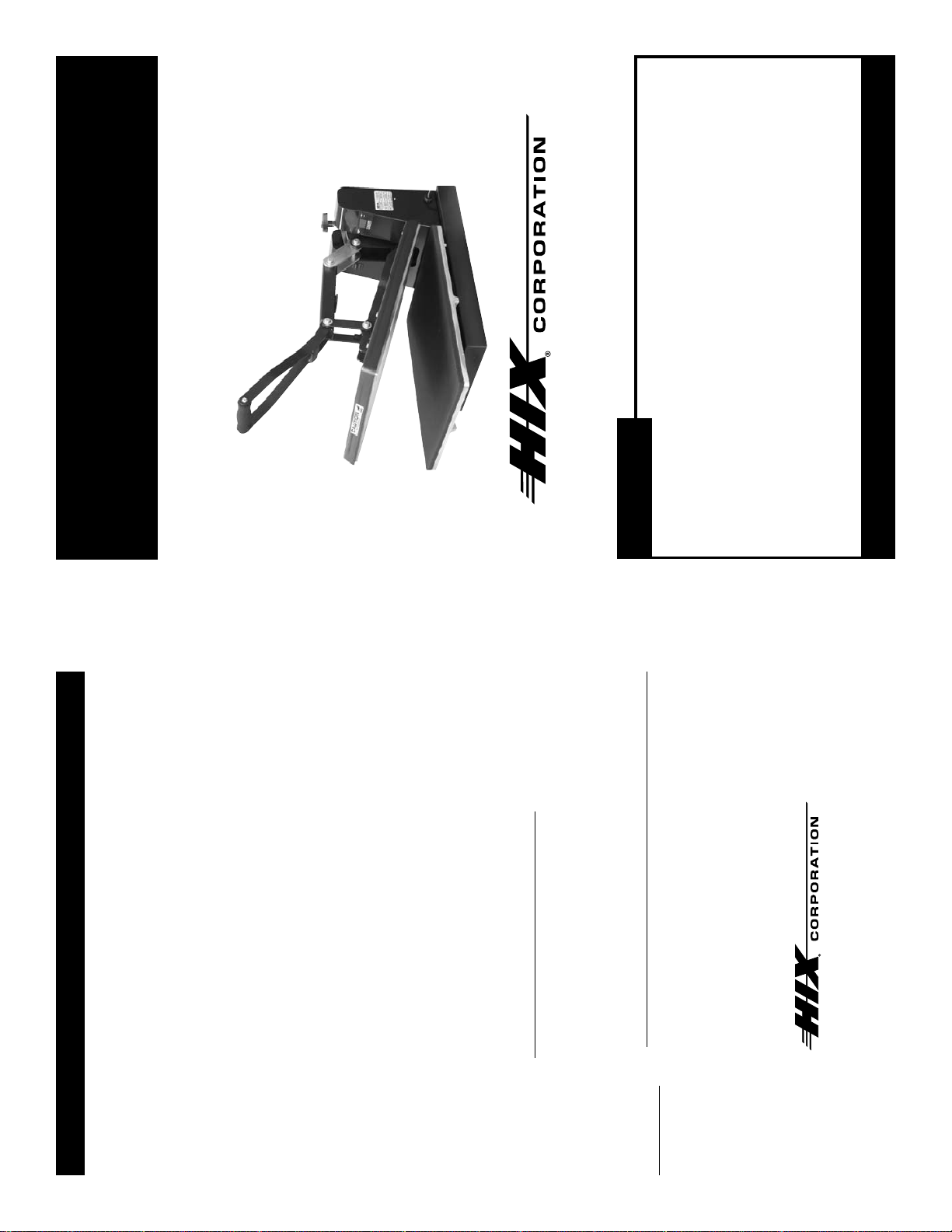

HT-600D

Visit www.hixcorp.com

HT-400D/HT-600D

15”x15” / 16”x20” Heat Transfer Machines

ext. 209, ext. 211, ext. 220, ext.221 or

For Customer Service, Call 1-800-835-0606

Receiving and Shipping ............................................................................ 2

Temperature & Instructions ....................................................................... 3

CONTENTS

BEFORE warranty repair you MUST get Prior Authorization:

Pressure....................................................................................................3

Transfer Application ................................................................................... 4

Troubleshooting ........................................................................................5

Fuse Replacement ....................................................................................6

Relay Bypass ............................................................................................. 7

Maintenance ..............................................................................................8

Parts Identification ............................................................................... 9-10

Warranty...................................................................................................12

(Effective January 1, 2007)

HIX will automatically register the equipment on the date it was shipped to you or your

WARRANTY

distributor. If the equipment was not purchased directly from HIX, but through a distributor

(either domestic or foreign), please keep a copy of their sales invoice showing the serial

number and date it was sold/shipped to you with this warranty. In this case, we will use the

distributor’s invoice date as the beginning warranty date. STAPLE A COPY OF YOUR RE-

CEIPT TO THIS WARRANTY and keep in a safe place to provide verification of your warranty

should a problem occur. Thank you.

Please fill in the following information and attach a copy of your receipt for your records.

Date Purchased: _____________________ From: _________________________________

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg,

Model #: ____________________________ Serial #: ________________________________

Kansas, U.S.A. HIX warrants to the original purchaser, its Conveyor Dryers, Heat Transfer

Presses, Mug Presses, Mug Glazer, Retensionable Screen Frames, Textile Printers, Spot

Heaters, and Exposure Units against defects in workmanship and material, except for wear

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item

and tear for a period of “One Year” from the date of purchase. HIX warrants its Accessories,

Reten Splines/Hardware/Tool Kit, and Shuttle for a period of 90 days from the date of pur-

chase. DoughXpress and Thermatrol products are covered under separate warranty.

In the case of heat transfer presses (except the Mug Press, Hobby Lite), HIX warrants the

at no cost during this period subject to the limitations of insurance and shipping costs stated

below.

heat casting for the “Life” of the machine for the original purchaser. If a part becomes obsolete

at the time for repair, and/or cannot be reasonably substituted for, HIX will credit, at half the

This warranty does not cover belts, pads, mug wraps, mug press liners, canvas, rubber

then current list price or last recorded price, only that part toward a new machine or any

product HIX offers. This credit offer shall be the sole responsibility of the HIX Corporation in the

event of an obsolete part.

blankets, bulbs, glass, PTFE or finish, rod ends, turn buckles on printers, or mug press or

damages due to accident, misuse/abuse, alterations or damage due to neglect, shipping or

lack of proper lubrication or maintenance. HIX shall not be responsible for repairs or alterations

made by any person without the prior written authorization by HIX. This warranty is the sole

E-Mail: sales@hixcorp.com • Fax: (866) 563-4600

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606

E-Mail: customerservice@hixcorp.com • Fax: (866) 561-0894

In the case of a problem with the equipment identified herein, HIX Corporation should be

and exclusive warranty of HIX and no person, agent, distributor, or dealer of HIX is authorized

to change, amend or modify the terms set forth herein, in whole or in part.

contacted during regular business hours to discuss the problem and verify an existing war-

ranty. HIX personnel will assist the customer to correct any problems which can be corrected

through operation or maintenance instructions, simple mechanical adjustments, or replace-

of the customer, and not that of HIX, and HIX shall not be responsible for improper handling or

ment of parts. In the event the problem cannot be corrected by phone, and upon the issuance

of a return authorization by HIX, the equipment shall be returned to HIX or an authorized

service representative. All insurance and shipment/freight costs are solely the responsibility

This expressed warranty is given in lieu of any and all other warranties, whether ex-

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair

This warranty gives you specific legal rights and you may also have other rights which

damage in transit. HIX offers a reconditioning service and a core exchange/credit policy on

some models. HIX customer service personnel may be contacted for complete return authori-

zation and reconditioning information.

pressed or implied, including but not limited to those of merchantability and fitness for a

particular purpose, and constitutes the only warranty made by HIX Corporation.

or replace the nonconforming goods. HIX shall not be liable for any other damages, either

incidental or consequential, or the action as brought in contract, negligence or otherwise.

Manufacturers of the Finest Quality Textile and Graphics Screen Printing and Heat Transfer Equipment

vary from state to state.

©2007 HIX Corp. 12 HT120205

Page 2

PARTS IDENTIFICATION

# DESCRIPTION Part # Qty.

fuses only: 120 Volt Units - Buss MDA-15; 220 Volt Units - Buss MDA-10.

31. Assembly Doghouse ............................................................ 1

30. Cordset ............................................................................... 1

29. Cord Grip ...............................................................13250 1

28. Fuse Holder ........................................................... 57118 1

27. Fuse ...................................................................................

26. Timer .................................................................................. 1

25. Dohouse Back ..................................................................... 1

24. EMI Filter ............................................................................ 1

46. Pin Handle Link ...................................................... 42129 1

47. Screw #14x1-1/4 Tap PHPH ....................................59816 2

48. Assembly Handle Grip & Dowel ...............................26856 1

WARNING: For continued protection against risk of fire, replace with the following

11

RECEIVING AND INSTALLATION

DO NOT RISK COSTLY SHIPPING DAMAGE!

SHIP ONLY IN ORIGINAL BOX.

Remember to save all packing materials - including box,

liner and board. You may need these for shipping your

machine or if a repair is necessary in the future.

UNPACKING

Inspect your machine for hidden shipping damage. Contact

the delivery company immediately , should you find damage.

INSPECTION

NOTE: Save all of your shipping/packing materials.

SHIPPING OR RETURNS

1. Fasten machine to plywood shipping base with bolts provided.

Fold in flaps and seal the box.

2. Tie or tape handle securely to base.

3. Place in original box, and put side liner and top liner in place.

2

(Additional bottom boards, box and liners may be obtained

from your supplier for a nominal cost.)

INST ALLATION

1. Remove plywood shipping base.

CAUTION: Handle must be tied to base before moving or

shipping.

The HT-600 requires a 20 amp receptacle.

2. Plug the machine into the correct grounded electrical outlet.

WARNING: When using an extension cord, use 12 or 14

ga.-3 conductor. Maximum length, 25’ (7.62 m).

Page 3

OPERATIONPARTS IDENTIFICATION

the digital control. The light next to “TEMP” will light. Press the

up ▲, or down ▼, button to your desired setting.

TEMPERATURE & TIME INSTRUCTIONS

1. Turn on the machine by pushing the on/off switch.

2. To change or set the temperature, press the menu button on

control. The light next to “TIME” will light. Press the up ▲, or

down ▼, button to your desired setting.

3. To change or set the time, press the menu button on the digital

a third time to lock in your settings otherwise the previous

settings will still be used.

4. When you have your desired settings press the menu button

the display temperature until it matches the set temperature.

5. Wait for the machine to reach your preset temperature by monitoring

PRESSURE

3

should be set so that the heat head will lock down firmly .

counter-clockwise and increased by turning it clockwise.

1. The pressure control knob, located on the top of the machine,

2. Pressure is reduced by turning knob (with machine open)

NOTE: Adjustments may be required from one garment to

another and will vary to achieve the desired result.

CAUTION: Excessive pressure can cause structural

damage, voiding the machine warranty!

10

# DESCRIPTION Part # Qty.

1. Assembly HT400/600 Handle .................................. 10499 1

2. Assembly Link/Pin Main Arm .................................. 42110 1

3. Assembly Main Arm ............................................... 42404 1

4. Link Rocker........................................................... 10502 2

5. Pin Rocker Link ..................................................... 42137 1

6. Nut 1/2" Push ........................................................ 20214 12

7. Knob Plastic .......................................................... 25143 1

8. Nut Jam 1/2-20 ...................................................... 25151 3

9. Block 2-1/2" Adj. Threaded ......................................25526 1

10. Pin Rocker Link Pivot ............................................. 41384 1

11. Assembly Top Adusting Rod ................................... 25208 1

12. Relay .................................................................................. 1

23. Terminal Board ....................................................... 72231 1

22. Screw #8x1/2 Tap-B PHPH ...................................... 21482 8

21. Bolt Lower Platen ................................................................. 2

20. Washer Spring ....................................................... 12378 12

19. Pin Main Arm Link .................................................. 41384 1

18. Spring #105 ........................................................... 49122 2

17. Nut 1/4-20 Hex ....................................................... 14548 4

16. Bolt 1/4-20x1-3/4 .................................................... 10710 2

15. Switch ................................................................................ 1

14. Nut 1/2-20 Nyloc .................................................... 89078 1

13. Assembly Frame ....................................................41384 1

35. Washer 3/8" Hard ................................................... 86504 4

36. Spacer Heatshield .................................................. 41384 4

37. Casting 1620 Lower ................................................ 82768 1

38. Pad 1/2" 1620 ........................................................ 50542 1

39. Casting Upper Heated .......................................................... 1

40. Heatshield ............................................................. 41384 1

41. Thermostat .......................................................................... 1

42. Thermometer ......................................................... 40345 1

43. Assembly Thermostat Cover .................................... 22640 1

44. Thermostat Knob .................................................... 14217 1

45. Spacer Haysite ...................................................... 41384 2

34. Switch Rocker ..................................................................... 1

33. Lamp Red ........................................................................... 1

32. Decal Overlay ........................................................ 09970 1

Page 4

Exploded V iew

9

as instructed on page 3. Always consult your specfic transfer

recommendations. Typical settings are: Cold Peel - 350°F

(177°C), 15 seconds and Hot Split - 375°F (190°C),

OPERATION MAINTENANCE

TRANSFER APPLICATION

1. Set the temperature, time, and pressure to the desired settings

10-12 seconds.

2. Align garment on the lower platen and smooth out the wrinkles.

NOTE: Wrinkles may be removed by bringing heated platen in

contact with the garment before the transfer is positioned.

3. Position the transfer and close the machine.

the designated time has elapsed, open the machine.

4. Pull operating handle down locking the machine closed. After

garment). NOTE: Do not fold the transfer back on itself.

Successful transfer work depends on the correct balance

of time, temperature and pressure. The type and thickness

of the material and the kind of transfer being used will

determine what settings are necessary.

5. Continuously peel the paper off the transfer (away from your

4

If a hot peel/split transfer is being applied, immediately peel

the paper after the machine has opened. DO NOT allow

the transfer to cool. If a cold peel transfer is being applied,

rub the transfer with an eraser or cloth and allow to cool for

5-10 seconds before removing the release paper.

Specific application instructions are enclosed with each

transfer .

Page 5

W ARNING: Before making repairs, be sure on/off switch

is off and machine is unplugged!

58

*Customer Service Tech Sheets are available for this step.

Visit www .hixcorp.com to print or call 620-231-8568 and we

will send you one. Parts ordering is available on-line.

MAINTENANCE TROUBLESHOOTING

Lubrication

Y our press requires lubrication every 6 months. Using 3-in-1 oil (avail-

able from your hardware store), add one to two drops of oil at all

moving parts.

NOTE: Unplug the machine before lubricating.

Cleaning The Heat Platen

You may clean the heat platen with steel wool, scrubbing aluminum

sponge, or fine wire brush.

Page 6

REPAIRSREPAIRS

7

wire #12 under terminal #1.

RELAY BYPASS

WARNING: Before making rep airs, be sure on/off switch is

off and machine is unplugged!

1. Remove the back cover of the machine.

2. Remove wire #26 from terminal #2 on relay .

3. Loosen terminal #1 on relay and replace wire #26 along with

4. Tighten the connection.

5. Plug machine in and turn the power switch on.

NOTE: Replace the relay if the machine starts heating. This is a

test only . Do not operate machine with relay bypassed.

6

holder on inside of the machine.

FUSE REPLACEMENT

WARNING: Before making rep airs, be sure on/off switch is

off and machine is unplugged!

1. Remove back cover of the machine and locate internal fuse

HT-400: 120V=MDA-15; 220V=MDA-8

HT-600: 120V=MDA-15; 220V=MDA-10

2. Remove blown fuse. Replace with the proper fuse.

3. Replace back cover of machine.

Loading...

Loading...