Page 1

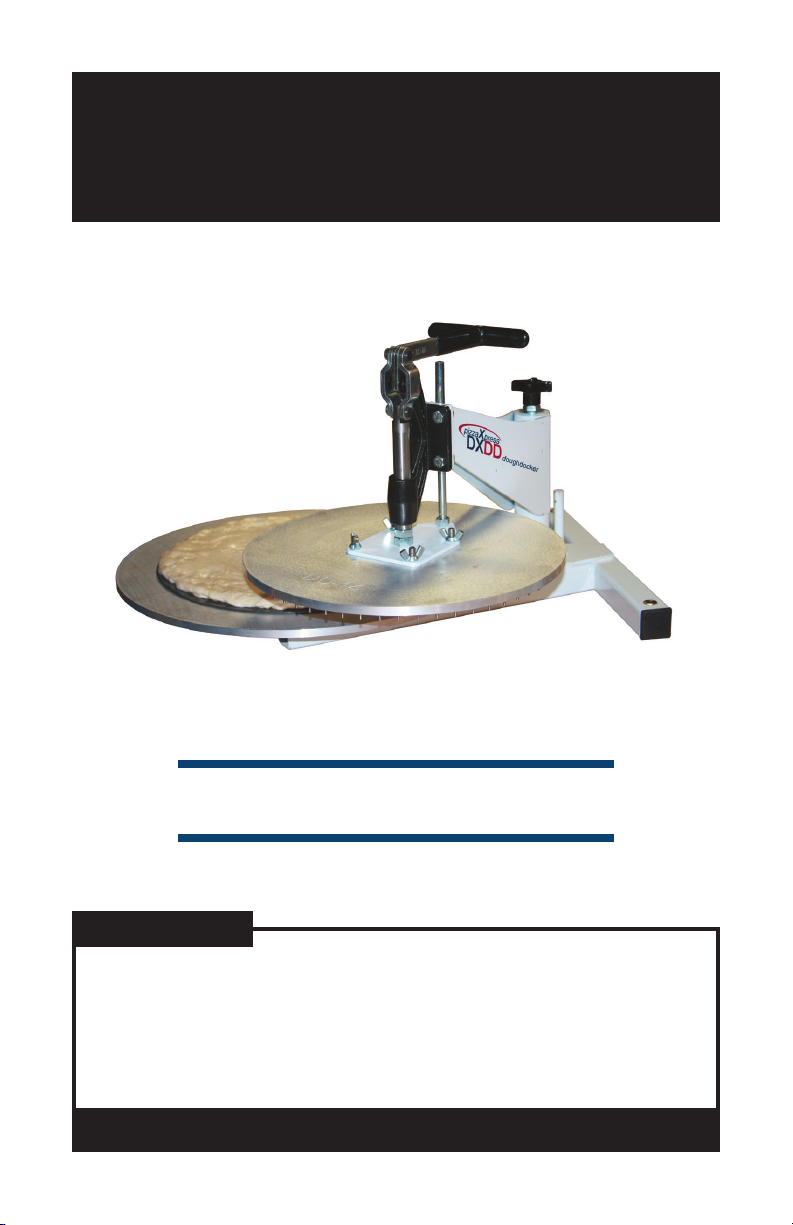

doughXpress

DXDD

Manual Dough Docking Press

OWNER’S MANUAL

DXDD with 14”

docking platen

shown

For Customer Service, Call 1-800-835-0606 ext. 205

or Visit www.doughXpress.com

CONTENTS

Receiving and Shipping 2

Operation 3-4

Cleaning / Maintenance 5

Parts Identication 6

Warranty 8

BEFORE warranty repair you MUST get Prior Authorization:

®

70272 RV B 090517

Page 2

RECEIVING & INSTALLATION

Please read this manual in its entirety before operating your press.

UNPACKING

Remember to save all packing materials - including box, liner and board.

You may need these for shipping your machine or if a repair is necessary

in the future.

INSPECTION

Inspect your machine for hidden shipping damage. Contact the delivery

company immediately, should you nd damage.

PLATEN SURFACE

Slight surface imperfections are a normal part of the aluminum casting

process for the platens on your press. These are not considered a defect

and do not affect the functionality of the machine in any way.

SHIPPING OR RETURNS

NOTE: Save all of your shipping/packing materials.

DO NOT RISK COSTLY SHIPPING DAMAGE!

SHIP ONLY IN ORIGINAL BOX.

1. Fasten machine to plywood shipping base with bolts provided.

2. Make sure handle is pressed down so that the upper platen will not

swing around during shipment.

3. Place in original box, and put side liner and top liner in place. Fold

in aps and seal the box.

(Additional bottom boards, box and liners may be obtained from your supplier

for a nominal cost.)

INSTALLATION

1. Lift press from box and place on cart or other sturdy surface.

2. If press is to be placed on counter top stick black plastic foot pad on

the bottom of the legs.

3. Place four set screws of the desired docking platen through the bottom

holes on the platen mount plate.

4. Place one at washer and wing nut on each set screw and tighten

with ngers.

CAUTION: Over tightening nuts can cause stripping on the set screws and/

or make future removal and assembly of the docking platen(s)

difcult.

NOTE: Upon receiving your new equipment, some debris or residue may

be present on the aluminum platen(s). Clean the platens per the

instructions provided prior to rst use.

2

Page 3

OPERATION

THICKER

PRESSURE

1. The pressure control knob, located at the top / rear of the machine,

should be set so that the teeth of the docking platen just touch the

lower platen.

THINNER

WARNING: Make all adjustments while press is open. Adjusting the

thickness while under pressure will result in damage to the

press.

2. Pressure is reduced by turning knob (with machine open) counter-

clockwise and increased by turning it clockwise.

NOTE: Adjustments may be required from one product to another and will

vary to achieve the desired result.

CAUTION: Excessive pressure can cause structural damage, voiding the

machine warranty!

3. To set the nished product thickness, turn the dial on the top of the

machine as indicated.

3

Page 4

OPERATION

DOCKING PRODUCT

Your doughXpress DXDD docking press is designed for easy use and will

reliably dock your dough.

Your DXDD docking press is designed to dock dough in diameters from 8”

up to 18” in steps of 2”.

1. Make sure the size of dough that will be docked matches that of the

docking platen. Interchange the docking platen if necessary.

2. Move the magnetic stoppers to the appropriate notch for docking the

size of dough you wish. [See Figure 1]

16”

14”

12”

10”

8”

NOTE: When docking an 18” dough, no stoppers will be used. Simply line

up the try with the lower platen.

3. Place the pressed dough on a baking tray.

4. Slide the baking tray on to the lower platen of the DXDD up to the

stoppers to assure dough and tray are perfectly centered under the

docking platen.

5. Make sure the docking platen is swung above dough. Docking arm

will reach a stop when it is directly above the lower platen. Using the

handle, lower the docking platen until the teeth of the docking platen

sufciently press the dough.

NOTE: Minimal pressure is needed to effectively dock dough. Pressing too

hard can break the teeth or damage the press in other ways and

void the warranty.

6. Lift the handle to the locked position and swing docking platen away

from lower platen.

Fig 1

4

Page 5

CLEANING / MAINTENANCE

CLEANING THE PLATENS

1. Swing the upper platen away for easier access.

2. Use a soap or detergent and nonmetallic scrubbing sponge to remove

any excess material from the platens.

WARNING: Do not use abrasives such as steel wool scrubbies, kitchen

cleansers, griddle cleaner, or griddle bricks or any other kind

of abrasive material. This will damage the coating.

CLEANING XYLAN COATED PLATENS

You may clean the Xylan coated platens with a mild soap and warm water.

Use a soft cloth or sponge. Do not use steel wool, scrubbies, kitchen

cleansers, or other abrasives. None abrasive oven cleaners are acceptable.

CLEANING OUTSIDE SURFACES OF MACHINE

Use a mild soap and warm water with a soft cloth or sponge. Do not use

steel wool, kitchen cleansers, or other abrasives.

LUBRICATION

Your press requires lubrication every 15,000 cycles or every 6 months.

Lubricate weekly in a heavy use production environment. Use NSF/NLG12

rated food grade grease (such as Bel-Ray No-Tox #2 or equivalent). A

general purpose food grade machine oil spray is also acceptable such as

CRC03055 lubricant (available from retailers such as Amazon). Lubricate

all moving or hinged points.

5

Page 6

PARTS IDENTIFICATION

6

Page 7

PARTS IDENTIFICATION

ITEM QTY PART NUMBER DESCRIPTION

1 1 14571 NUT HX 3/8-16 ZPS

2 8 24732 WASHER-0.344 x 0.6875 x 0.0625

3 1 35122 DECAL PANTHER PRESS PRESSURE

4 1 35181 TOGGLE CLAMP SWINGMAN METRIC

5 4 62685 SCREW SET 5/16-18x1.000 SS

6 1 62898 KNOB PHENOLIC SWINGMAN

7 2 63320 WASHER THRUST 00500x00875

8 1 63584 O-SWG15 PLATEN MNT PLATE

9 1 63622 BEARING, THRUST 1/2x7/8

10 4 68055 BOLT 5/16-18 x 1

11 4 68594 NUT, 5/16-18 NYLON INSERT LOCK

12 1 70175 DDM-8 DOUGH DOCKER MOLD

13 1 70175 DDM-10 DOUGH DOCKER MOLD

14 1 70177 DDM-12 DOUGH DOCKER MOLD

15 1 70178 DDM-14 DOUGH DOCKER MOLD

16 1 70178 DDM-16 DOUGH DOCKER MOLD

17 1 70180 DDM-18 DOUGH DOCKER MOLD

18 1 7050002 M-UNIV BASE PLATE ASSEMBLY

19 2 7051004 M-DD STOP PIN

20 4 7051500 M-DD SPACER 1/2”

21 4 84335 PLUG TUBE 1.50 SQ BLK PE

22 8 84806 NUT WING 5/16-18 ZPS

23 3 87056 NUT HEX JAM 1/2-13 NC ZP

24 4 87692 SCREW, SET 5/16-18x1.750 CPT

25 1 9141010 M-SMAN15 ELEVATION SCREW

26 2 9141500 M-TXM-15 CP LOWER PLATEN

27 1 9151002 M-UNIV FRAME WELDMENT

28 1 9151750 M-PIVOT ARM WELDMENT

29 1 9152500 M-BOLT ANTI ROTATION

30 1 70263 NUT HX M12x1.75 ZPS

7

Page 8

WARRANTY

BEFORE warranty repair you MUST get

Prior Authorization: Call 1-800-835-0606

Warranty will be voided otherwise.

NOTICE

Our system will automatically register the equipment on the date it was shipped. If the

equipment was not purchased directly from HIX, but through a distributor (either domestic

or foreign), please keep a copy of their sales invoice showing the serial number and date it

was sold/shipped to you with this warranty. In this case, we will use the distributor’s invoice

date as the beginning warranty date. STAPLE A COPY OF YOUR RECEIPT TO THIS

WARRANTY and keep in a safe place to provide verication of your warranty should a

problem occur. Thank you.

Please ll in the following information and attach a copy of your receipt for your records.

Date Purchased: _______________________ From:_____________________________

Model #: ______________________________ Serial #:___________________________

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pitts-

burg, Kansas, U.S.A. HIX warrants to the original purchaser its Dough, Tortilla and Poultry

Presses against defects in workmanship and material, except for wear and tear for a period

of “One Year” from the date of purchase. All dough press carts, compressors, and accessories are warranted for 90 days from the date of purchase.

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective

item at no cost during this period subject to the limitations of insurance and shipping costs

stated below.

This warranty does not cover normal wear and tear, damages due to accident, misuse/

abuse, alterations or damage due to neglect or lack of proper lubrication or maintenance.

HIX shall not be responsible for repairs or alterations made by any person without the prior

written authorization by HIX. This warranty is the sole and exclusive warranty of HIX and

no person, agent, distributor, or dealer of HIX is authorized to change, amend or modify the

terms set forth herein, in whole or in part.

In the case of a problem with the equipment identied herein, HIX Corporation should

be contacted during regular business hours to discuss the problem and verify an existing

warranty. HIX personnel will assist the customer to correct any problems which can be

corrected through operation or maintenance instructions, simple mechanical adjustments,

or replacement of parts. In the event the problem cannot be corrected by phone, and upon

the issuance of a return authorization by HIX, the equipment shall be returned to HIX or

an authorized service representative. All insurance and shipment/freight costs are solely

the responsibility of the customer, and not that of HIX, and HIX shall not be responsible for

improper handling or damage in transit. HIX customer service personnel may be contacted

for complete return authorization and reconditioning information.

This expressed warranty is given in lieu of any and all other warranties, whether ex-

pressed or implied, including but not limited to those of merchantability and tness for a

particular purpose, and constitutes the only warranty made by HIX Corporation.

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to

repair or replace the nonconforming goods. HIX shall not be liable for any other damages,

either incidental or consequential, or the action as brought in contract, negligence or otherwise.

This warranty gives you specic legal rights and you may also have other rights which

vary from state to state.

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

(620) 231-8568 • Fax: (620) 231-1598

E-Mail: mail@hixcorp.com • Website: www.doughxpress.com

8

©2010 HIX Corp.

Loading...

Loading...