Page 1

OWNER’S MANUAL

Heat Transfer Machines

B-250 / B-250D Cap

FH-3000D Combo/Flat/Cube

FH-3000D

w/Cube Attachment

FH-3000D

w/Flat Attachment

D

B-250

For Customer Service, Call 1-800-835-0606

Visit www.hixcorp.com

ext. 209, ext. 211, ext. 220, ext.221 or

Receiving & Installation ............................................................................. 2

Temperature & Time Instructions .......................................................... 2-3

Pressure Adjustment ................................................................................. 3

Transfer Application Instructions............................................................... 4

Changing Combo Press Attachments ...................................................... 5

Maintenace ................................................................................................ 5

CONTENTS

Call 1-800-835-0606

BEFORE warranty repair you MUST get Prior Authorization:

Troubleshooting .....................................................................................6-7

Analog Thermostat Bypass ....................................................................... 8

Fuse Replacement ....................................................................................9

Toggle Adjustment................................................................................... 1 0

Microswitch Adjustment ........................................................................... 10

Parts Identification .............................................................................. 11-14

FAQ’s ....................................................................................................... 15

Warranty...................................................................................................16

(Effective January 1, 2007)

HIX will automatically register the equipment on the date it was shipped to you or your

WARRANTY

distributor. If the equipment was not purchased directly from HIX, but through a distributor

(either domestic or foreign), please keep a copy of their sales invoice showing the serial

number and date it was sold/shipped to you with this warranty. In this case, we will use the

distributor’s invoice date as the beginning warranty date. STAPLE A COPY OF YOUR RE-

CEIPT TO THIS WARRANTY and keep in a safe place to provide verification of your warranty

should a problem occur. Thank you.

Please fill in the following information and attach a copy of your receipt for your records.

Date Purchased: _____________________ From: _________________________________

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg,

Model #: ____________________________ Serial #: ________________________________

Kansas, U.S.A. HIX warrants to the original purchaser, its Conveyor Dryers, Heat Transfer

Presses, Mug Presses, Mug Glazer, Retensionable Screen Frames, Textile Printers, Spot

Heaters, and Exposure Units against defects in workmanship and material, except for wear

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item

and tear for a period of “One Year” from the date of purchase. HIX warrants its Accessories,

Reten Splines/Hardware/Tool Kit, and Shuttle for a period of 90 days from the date of pur-

chase. DoughXpress and Thermatrol products are covered under separate warranty.

In the case of heat transfer presses (except the Mug Press, Hobby Lite), HIX warrants the

at no cost during this period subject to the limitations of insurance and shipping costs stated

below.

heat casting for the “Life” of the machine for the original purchaser. If a part becomes obsolete

at the time for repair, and/or cannot be reasonably substituted for, HIX will credit, at half the

This warranty does not cover belts, pads, mug wraps, mug press liners, canvas, rubber

then current list price or last recorded price, only that part toward a new machine or any

product HIX offers. This credit offer shall be the sole responsibility of the HIX Corporation in the

event of an obsolete part.

blankets, bulbs, glass, PTFE or finish, rod ends, turn buckles on printers, or mug press or

damages due to accident, misuse/abuse, alterations or damage due to neglect, shipping or

lack of proper lubrication or maintenance. HIX shall not be responsible for repairs or alterations

made by any person without the prior written authorization by HIX. This warranty is the sole

E-Mail: sales@hixcorp.com • Fax: (866) 563-4600

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606

E-Mail: customerservice@hixcorp.com • Fax: (866) 561-0894

In the case of a problem with the equipment identified herein, HIX Corporation should be

and exclusive warranty of HIX and no person, agent, distributor, or dealer of HIX is authorized

to change, amend or modify the terms set forth herein, in whole or in part.

contacted during regular business hours to discuss the problem and verify an existing war-

ranty. HIX personnel will assist the customer to correct any problems which can be corrected

through operation or maintenance instructions, simple mechanical adjustments, or replace-

of the customer, and not that of HIX, and HIX shall not be responsible for improper handling or

ment of parts. In the event the problem cannot be corrected by phone, and upon the issuance

of a return authorization by HIX, the equipment shall be returned to HIX or an authorized

service representative. All insurance and shipment/freight costs are solely the responsibility

This expressed warranty is given in lieu of any and all other warranties, whether ex-

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair

This warranty gives you specific legal rights and you may also have other rights which

damage in transit. HIX offers a reconditioning service and a core exchange/credit policy on

some models. HIX customer service personnel may be contacted for complete return authori-

zation and reconditioning information.

pressed or implied, including but not limited to those of merchantability and fitness for a

particular purpose, and constitutes the only warranty made by HIX Corporation.

or replace the nonconforming goods. HIX shall not be liable for any other damages, either

incidental or consequential, or the action as brought in contract, negligence or otherwise.

Manufacturers of the Finest Quality Textile and Graphics Screen Printing and Heat Transfer Equipment

vary from state to state.

©2007 HIX Corp. 16 BDFHD081607

Page 2

FAQ ’S

PARTS IDENTIFICATION

Question: Can I transfer onto a 5 Panel Cap? Answer: Y es –

the front of the 5 Panel Cap has no seam running down the middle,

therefore you can easily transfer onto the cap front.

Tip: Keep all transfers 3/8” away from seams.

Question: Can I transfer onto a 6 Panel Cap? Answer: Y es –

but because of the seam running down center of front of cap you

will need to separate your art transfer or flock design to avoid trying to

transfer into the seam. Remember– separation must be 3/8” away

from seam. (both sides of seam)

Question: Are the lower platens interchangeable? Answer:

Yes there are three different sizes available – youth, golf and ball.

Question: What is the PTFE Blanket used for? Answer: It helps

prevent movement of your transfer while lowering the heat head. It

also helps prevent scorching of the nylon & poly fibers and stick-

ing. If applying adhesive backed patches it keeps the adhesive

from oozing from under the patch from getting on the heat head.

And helps to keep the edges from curling up after the heat head is

raised and while the adhesive is cooling.

Question: How do you adjust the Pressure? Where is the

Pressure Adjustment located? Answer: A small “thumb” type

adjustment control is located on the front of the machine. T urning

the wheel left offers more pressure. T urning the dial right offers

less pressure.

Question: How much pressure do I need? Answer: Time,

Temperature and Pressure for transfers vary – depending on the

transfer you are using. Please follow the directions provided by

15

your heat transfer/heat transfer paper manufacture for specific

instructions.

Tip: Always experiment when using a new supply of caps or

transfers to get best results.

Question: How do I load a hat in my press? Answer: Place the

back of the cap under the spring tensioned hold down, pull inside

liner (also known as the linger or sweat band) out against the bill of

the hat, slide the cap over lower platen and pull to snug on the

platen.

Tip: Make sure the bill of the cap and cord is clear of the platens.

Question; Can you do sleeves, pockets using the Cap Press?

What else? Answer: Although, the Cap press is designed primarily

for caps it can do sleeves, pockets, as well as, visors, socks and

under garments. The FH-3000D, which is a 3-3/4” x 6” flat press,

perfect for the other small items beyond hats.

DO NOT RISK COSTLY SHIPPING DAMAGE!

SHIP ONLY IN ORIGINAL BOX.

B250D (Digital) and FH-3000D (Ditigal).

Inspect your machine for hidden shipping damage. Contact

the delivery company immediately , should you find damage.

INSTALLATION / OPERATION

NOTE: Manual includes B-250 (Analog)-

INSPECTION

NOTE: Save all of your shipping/packing materials.

SHIPPING OR RETURNS

1. Fasten machine to plywood shipping base with bolts provided.

Fold in flaps and seal the box.

(Additional bottom boards, box and liners may be obtained

from your supplier for a nominal cost.)

2. Tie or tape handle securely to base.

3. Place in original box, and put side liner and top liner in place.

UNPACKING/SETUP

2

the desired setting that is noted; from off to 400°F. When the

set temperature has been reached, the heat indicating light

will turn off.

ga.-3 conductor . Maximum length, 25’ (7.62 m).

TEMPERATURE & TIME INSTRUCTIONS(ANALOG)

1. The B-250 Analog temperature control knob is turned to

1. Remove and save bolts attaching machine to base board.

OPERATION

2. Carefully cut tape/wrap holding machine closed.

3. Affix self-adhesive rubber feet.

4. Plug the machine into the correct grounded electrical outlet.

WARNING: When using an extension cord, use 12 or 14

with digital hand timer. Item#12718.

2. Time; see separate instructions that are included

Page 3

HIX Corporation

1201 E 27th Terrace, Pittsburg, KS 66762

Phone (620) 231-8568 Fax (620) 231-1598 Email: mail@hixcorp.com www.hixcorp.com

This document and the information contained herein is the sole property of HIX Corporation.

It will be held confidentially and may not be disclosed to third parties for any reason without prior

written consent of HIX Corporation (Copyright 2005).

Part Name

Project

Drawing Number

Rev

Material Specification

Drawn

Checked

Date

Date

Tolerance Unless Noted

.0

B250 New design

B250

K

dlane

12/6/2005

.060

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

MICROSWITCH ASSY

3182316

FUSE HOLDER

5711819

TERMINAL BLOCK72223110

RELAY 10A SS 3-32 VDC

INPUT

23057113

FUSE MDA-5 AMP720741

45

CLAMP CABLE .313

59765252

BLANKET HOLDER

2502213163

WASHER .281x.625x.063

ZPS

167742064

CONTROL TEMP PI BOARD

34711165

CONTROL TEMP CVC PDB

BOARD

34681166

CONTROL TEMP CVC

CABLE

34703167

SPACER .171X.375X.188

NYLON

36595468

6

1

9

1

45

1

13

1

52

2

10

1

63

1

68

4

65

1

66

1

67

1

OPERATION

TEMPERA TURE & TIME INSTRUCTIONS(DIGITAL)

The B-250D and FH-3000D use the following digital time and

temperature control instructions.

the digital control. The light next to “TEMP” will light. Press the

up ▲, or down ▼, button to your desired setting.

control. The light next to “TIME” will light. Press the up ▲, or

1. Turn on the machine by pushing the on/off switch.

2. To change or set the temperature, press the menu button on

3. To change or set the time, press the menu button on the digital

a third time to lock in your settings otherwise the previous.

settings will still be used.

Wait for the machine to reach your preset temperature by

monitoring the display temperature until it matches the set

down ▼, button to your desired setting.

temperature.

4. When you have your desired settings press the menu button

3

the lower platen. Set so that the heat head will lock down firmly,

with your substrate in place.

counter-clockwise and increased by turning it clockwise.

PRESSURE - B-250 (DIGITAL) AND (ANALOG)

1. There is a pressure control knob located on the front stem, holding

2. Pressure is reduced by turning knob (with machine open)

NOTE: Adjustments may be required from one item to another and

will vary to achieve the desired result.

CAUTION: Excessive pressure can cause structural damage,

voiding the machine warranty!

WARNING: For continued protection against risk of fire,

replace with the following fuses only:

120 Volt Unit s - Buss MDA-5; 220 Volt Units Buss MDA-3.

14

PARTS IDENTIFICATION

Page 4

HIX Corporation

1201 E 27th Terrace, Pittsburg, KS 66762

Phone (620) 231-8568 Fax (620) 231-1598 Email: mail@hixcorp.com www.hixcorp.com

This document and the information contained herein is the sole property of HIX Corporation.

It will be held confidentially and may not be disclosed to third parties for any reason without prior

written consent of HIX Corporation (Copyright 2005).

Part Name

Project

Drawing Number

Rev

Material Specification

Drawn

Checked

Date

Date

Tolerance Unless Noted

.0

B250 New design

CAP PRESS

B250

K

dlane

12/6/2005

060

Parts List

DESCRIPTION

PART NUMB

QTY

ITEM

FRAME WELDMENT

250000111

SWITCH ROCKER 120v3258114

ASSY, 400 ENCLOSURE

600100018

PLATEN FRAME

WELDMENT

2500005112

ADJUSTMENT KNOB

2505004115

250 CAP BRACKET PLATE

2507012126

B-250 BRACKET ROD

25542127

SPRING JONES No 9181901129

FOOT RUBBER

28010431

SPRING HIX #H-612 PLATED

64808133

DECAL TEMP-TIMER62944139

CORD GRIP

13250140

CORDSET

60590141

CENTER COVER

2502110158

1

1

4

1

8

1

15

1

26

1

29

1

31

4

39

1

40

1

41

1

58

1

12

1

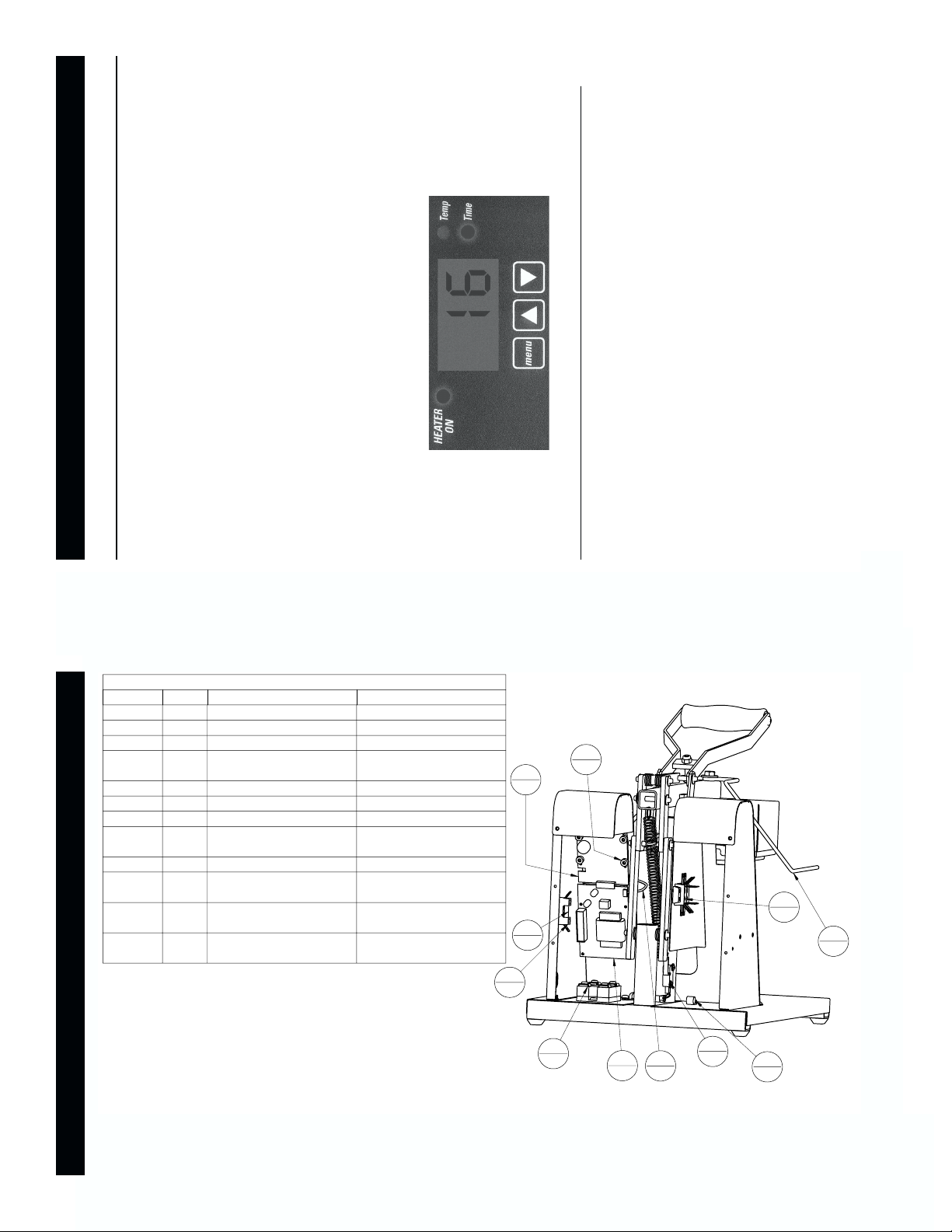

PARTS IDENTIFICATION

are available on-line.

parts ordering

Instructions and

or call 620-231-8568.

www.hixcorp.com

service, visit

For customer

13

and pressure to the desired

OPERATION

TRANSFER APPLICATION INSTRUCTIONS

settings as instructed on

1. Set the temperature, time,

pages 2-3.

and fold out the sweatband.

2. Remove cardboard (if any)

spring-loaded cap holder

spring-loaded cap holder .

over the lower platen.

3. Slip rear of cap under the

4. Pull the bill and cap up and

so that it just clears the upper

platen when the machine is

5. Position cap and sweat band

closed.

6. Align lettering or design.

contacts and locks down the

main arm. The timer begins

counting when the handle is

7. Pull handle until the toggle bolt

locked down.

raise the handle until the upper heat platen releases, peel transfer.

The timer will automatically reset for the next product.

8. At the completion of the cycle (indicated by the timer beeping),

NOTE: When applying die cut, cold-peel, or sublimation transfers, the optional

4

transfer hold-down should momentarily (3-5 seconds) remain in contact with

the transfer after the heat platen has been released. Y ou can also use high

temperature tape to hold these types of transfers to your substrate. This will

prevent the transfer paper from curling up on the ends and shifting the image.

For hot-split transfers, peel the transfer immediately after lifting handle. When

printing letters, the handle can be raised to its fully-open position at the end

of the time cycle.

Page 5

OPERATION

HIX Corporation

1201 E 27th Terrace, Pittsburg, KS 66762

Phone (620) 231-8568 Fax (620) 231-1598 Email: mail@hixcorp.com www.hixcorp.com

This document and the information contained herein is the sole property of HIX Corporation.

It will be held confidentially and may not be disclosed to third parties for any reason without prior

written consent of HIX Corporation (Copyright 2005).

Part Name

Project

Drawing Number

Rev

Material Specification

Drawn

Checked

Date

Date

Tolerance Unless Noted

.0

B250 New design

CAP PRESS

B250

K

dlane

12/6/2005

.060

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

FRAME WELDMENT

250000111

MAIN ARM250000212

HANDLE250000313

RELAY 10A SS 3-32 VDC

INPUT

23057113

ADJUSTMENT KNOB

2505004115

UPPER LINK2502106216

MIDDLE LINK2502109217

BOLT 1/4-20 x 1-1/4 ZP10686118

LINKAGE PIN LONG

2505006219

LINKAGE PIN MEDIUM

2505005220

LINKAGE PIN SHORT2505007221

PUSH NUT .25 SHAFT

716541222

NUT 1/4-20 NYLOCK

14154123

HANDLE GRIP FOAM

26840124

LOWER CASTING, GOLF2503201132

SPRING HIX #H-612 PLATED

64808133

GROMMET .563 IDx.750

GRV

17301234

WASHER 5/16 USS ZP16683235

BOLT 5/16-18x1-3/4

10793136

NUT HEX 4-40 ZP81224543

PAD CUT 3in14842146

SCREW HX WH THR CUT

.25-20x.50

50181249

HANDLE LINK

2502102156

BLANKET HOLDER2502213163

11

1

24

1

3

1

12

1

2

1

56

1

17

2

16

2

22

12

20

2

34

2

23

1

36

1

13

1

18

1

49

2

50

10

32

1

35

2

63

1

Adjustment Rod

MAINTENACE

512

FH-3000D/ CUBE COMBO PRESS ATT ACHMENTS

1. To switch the different attachments, just lift the attachment off,

replace with other attachment. Adjust screw to change height.

Tighten adjustment knob.

2. Load paper cube tight against the back and non moving side.

NOTE: For flat attachment, simply align article on pad and adjust the

pressure (at back, bottom of machine). For cube attachment, put product

in and adjust for width and pressure.

all moving parts.

1. Monthly, place drop of light oil (sewing machine oil or 3:1 oil) on

PARTS IDENTIFICATION

Page 6

Machine

overheats

Call

Technical

Service

NO

Does heat light remain on constantly

when overheating?

NO

Call

Technical

Service

NO

Check large tan

wires soldered to

back of heat casting.

Repair if needed.

Problem solved?

YES

Little or

no heat

Is power light on?

YES

Try another outlet.

NONO

Call

Technical

Service

Problem solved?

NO

Replace fuse. pg 7

Problem solved?

NO

Problem solved?

NO

Check power flow

with VOM meter

Repair if needed.

NO

Replace on\off switch.

NO

Problem solved?

Remove rear cover

and check for loose

or broken wires

Repair if needed.

Does the digital

display show

" C"?

Replace

thermocouple.

∗

∗

∗

Problem solved?

Is heat light on?

NO

YES

YES

Problem solved?

NO

Bypass

relay.

Replace

relay.

∗

Replace

Relay

Problem solved?

NO

∗

NO

Problem solved?

Machine

won't stay

closed.

Call

Technical

Service

NO

NO

Problem solved?

Problem solved?

Adjust pressure. pg 3

Adjust toggle bolt. pg 8

HIX Corporation

1201 E 27th Terrace, Pittsburg, KS 66762

Phone (620) 231-8568 Fax (620) 231-1598 Email: mail@hixcorp.com www.hixcorp.com

This document and the information contained herein is the sole property of HIX Corporation.

It will be held confidentially and may not be disclosed to third parties for any reason without prior

written consent of HIX Corporation (Copyright 2005).

Part Name

Project

Drawing Number

Rev

Material Specification

Drawn

Checked

Date

Date

Tolerance Unless Noted

0

ANALOG PARTS

B250

B-250 AP

A

L J WELLS

8/15/2007

060

Parts List

ITEM

QTY

PART NUMBER

DESCRIPTION

1 1 6001007 FRONT SHEET - ND

2 1 16772 TIMER

3 2 94854

KNOB ( THERMOSTAT)

4 1 14233 LAMP ID RED 120v

5

1 16764 TIMER DECAL

6 1 35394

ROCKER SWITCH HOLE

PLUG

7 1 16436

THERMOSTAT

8 1 2508003 HEATSHIELD

9 1 35157

DECAL TEMP 400 DEG

10 2 15438

SCREW TAP PH PHP 6x1/4

ZP

1

6

5

3

3

9

8

7

2

4

10

10

ANALOG ONL Y

PARTS IDENTIFICATION

Analog Parts List

11

TROUBLESHOOTING (DIGTIAL MODELS)

control knob to “OFF” and unplug machine!

WARNING:Before making repairs, turn temperature

10

6

*Customer Service Tech Sheets are available for this step.

Visit www .hixcorp.com to print or call 620-231-8568 and we

will send you one. Parts ordering is available on-line.

Page 7

control knob to “OFF” and unplug machine!

10

7

TROUBLESHOOTING (ANALOG MODELS)

WARNING:Before making repairs, turn temperature

T oggle Bolt Lock Nut

*Customer Service Tech Sheets are available for this step.

Visit www .hixcorp.com to print or call 620-231-8568 and we

will send you one. Parts ordering is available on-line.

10

REPAIRS

TOGGLE ADJUSTMENT

NOTE: If machine is hard to open, follow step 1. If machine will

ments clockwise as viewed from top. Lock handle down.

Repeat until machine operates comfortably and locks down

securely . Tighten toggle lock nut and check operation. If turned

too far, machine will not st ay locked when closed.

not stay locked down, follow step 2.

1. Loosen the toggle bolt lock nut. T urn toggle bolt in 1/4 incre-

sure is required on handle, reduce pressure by turning pres-

sure knob counterclockwise. Repeat. (See page 3, “Op-

erations”). If contact is made but handle won’t lock down, turn

toggle bolt 1/4 turn (counterclockwise as viewed from the

top). Repeat until handle locks down comfortably. Tighten

2. If toggle bolt does not contact main arm and excessive pres-

trol knob to “OFF” and unplug machine!

toggle lock nut and check for proper operation.

MICRO SWITCH ADJUSTMENT (see page 14, item #6)

If countdown timer will not activate.

WARNING: Before making repairs, turn temperature con-

1. Remove rear cover .

mounting screws

2. Using a screwdriver and a small wrench loosen micro switch

3. Adjust switch so it “clicks” only when machine is locked down.

4. Tighten mounting screws, replace rear cover and check operation.

Page 8

HIX Corporation

1201 E 27th T

Phone (620) 231-8568 Fax (620) 231-1598 Emai

This document and the information contained herein

It will be held confidentially and may not be disclose

written consent of HIX Corporation (Copyright 2005)

M

Drawn

Checked

Date

Date

Rev

Rev Date

Rev By

Description

M

A

Tolerance Unless Noted.0.00

.000

FRACTION

ANGLES

L J WELLS

8/30/2007

.060

.030

.010

1/32

1 DEGREE

Released for production.

Thermostat Wires

Thermost at Knob

Terminal Screws

Terminals

Washers

Thermostat Post

Attachment Screw

Attachment Screw

Set Screw

REPAIRS

Rear T erminal

Fig. 3

9

control knob to “OFF” and unplug machine!

FUSE REPLACEMENT (DIGITAL) AND (ANALOG)

WARNING: Before making repairs, turn temperature

holder on inside of the machine. (See page 14, item #9)

1. Remove back cover of the machine and locate internal fuse

2. Remove blown fuse. Replace with the proper fuse.

(120V) ...... MDA-5 ONLY

(220V).. .... MDA-3 ONL Y

3. Replace back cover of machine.

Fig. 2

8

REPAIRS

THERMOSTAT BYPASS (B-250 ANALOG ONLY)

If your machine is not heating (temperature light does not

control knob to “OFF” and unplug machine!

move knob by pulling knob upward. Fig. 3, Pg. 9

come on).

WARNING: Before making repairs, turn temperature

1. Loosen recessed set screw in the thermostat knob and re-

heat head down from the main arm. Remove heat shield

cover to gain access to the thermostat.

2. Remove casting retaining bolt (Fig. 1, Below) to drop the

Fig. 3, Pg. 9

3. Attach both “thermostat wires” on the “rear terminal”.

4. Plug machine in and turn temperature control to desired

temperature.

Fig. 1

If heat light comes on, and the machine starts heating, replace

thermostat.

NOTE: If you feel your temp calibration is off contact customer service.

Casting Retaining Bolt

Loading...

Loading...