Hiwin RA610-GB, RT610-GB User Manual

Articulated Robot

- R A610 -GB

RT610 -GB

User Manual

Original Instruction

www.hiwin.tw

INDUSTRIE 4.0 Best Partner

Multi-Axis Robot

Pick-and-place / Assembly /

Array and packaging / Semiconductor /

Electro-Optical industry /

Automotive industry / Food industry

• Articulated Robot

• Delta Robot

• SCARA Robot

• Wafer Robot

• Electric Gripper

• Integrated Electric Gripper

• Rotary Joint

Single-Axis Robot

Precision / Semiconductor /

Medical / FPD

• KK, SK

• KS, KA

• KU, KE, KC

Ballscrew

Precision Ground / Rolled

• Super S series

• Super T series

• Mini Roller

• Ecological & Economical

lubrication Module E2

• Rotating Nut (R1)

• Energy-Saving & Thermal-

Controlling (Cool Type)

• Heavy Load Series (RD)

• Ball Spline

Bearing

Machine tools / Robot

• Crossed Roller Bearings

• Ballscrew Bearings

• Linear Bearing

• Support Unit

Torque Motor

Rotary Table

Aerospace / Medical / Automotive industry /

Machine tools / Machinery industry

• RAB Series

• RAS Series

• RCV Series

• RCH Series

Linear Guideway

Automation / Semiconductor / Medical

• Ball Type--HG, EG, WE, MG, CG

• Quiet Type--QH, QE, QW, QR

• Other--RG, E2, PG, SE, RC

DATORKER® Robot Reducer

Robots / Automation equipment /

Semiconductor equipment / Machine tools

• WUT Type-Combination Type (P)

• WUI Type-Component Type (C)

• WTI Type-Combination Type (P)

• WTI Type-Sealed type (A)

AC Servo Motor & Drive

Semiconductor / Packaging machine

/SMT / Food industry / LCD

• Drives-D1, D1-N, D2T

• Motors-50W~2000W

Linear Motor

Automated transport / AOI application

/ Precision / Semiconductor

• Iron-core Linear Motor

• Coreless Linear Motor

• Linear Turbo Motor LMT

• Planar Servo Motor

• Air Bearing Platform

• X-Y Stage

• Gantry Systems

Medical Equipment

Hospital / Rehabilitation centers /

Nursing homes

• Robotic Gait Training System

• Hygiene System

• Robotic Endoscope HolderS

Torque Motor &

Direct Drive Motor

Inspection / Testing equipment /

Machine tools / Robot

• Rotary Tables-TMS,TMY,TMN

• TMRW Series

• TMRI Series

C13UE001-1903

Warranty Terms and Conditions

The period of warranty shall commence at the received date of HIWIN product

(hereafter called “product”) and shall cover a period of 12 months. The warranty does

not cover any of the damage and failure resulting from:

The damage caused by using with the production line or the peripheral

equipment not constructed by HIWIN.

Operating method, environment and storage specifications not

specifically recommended in the product manual.

The damage caused by changing installation place, changing working

environment, or improper transfer after being installed by the

professional installer.

Product or peripheral equipment damaged due to collision or accident

caused by improper operation or installation by the unauthorized staff.

Installing non-genuine HIWIN products.

The following conditions are not covered by the warranty:

Product serial number or date of manufacture (month and year) cannot

be verified.

Using non-genuine HIWIN products.

Adding or removing any components into/out the product without

authorized.

Any modification of the wiring and the cable of the product.

Any modification of the appearance of the product; removal of the

components inside the product. e.g., remove the outer cover, product

drilling or cutting.

Damage caused by any natural disaster. i.e., fire, earthquake, tsunami,

lightning, windstorms and floods, tornado, typhoon, hurricane etc.

HIWIN does not provide any warranty or compensation to all the damage caused

by above-mentioned circumstances unless the user can prove that the product is

defective.

For more information towards warranty terms and conditions, please contact the

technician or the dealer who you purchased with.

1

in serious hazard or personal injury. Please be sure to

in personal injury or product damage. Please be sure to

effector or the cable for devices should be installed

professional staff to avoid damaging the

Improper modification or disassemble the robot might reduce

the robot function, stability or life.

The end-

and designed by a

C13UE001-1903

robot and robot malfunction.

Please contact the technician for special modification coming

from production line set up.

For the safety reason, any modification for HIWIN product is

strictly prohibited.

Safety Precautions

1. Safety Information

Safety Responsibility and Effect

This chapter explains how to use the robot safely. Be sure to read this

chapter carefully before using the robot.

The user of the HIWIN industrial robot has responsibility to design and

install the safety device meeting the industrial safety regulations in order

to ensure personal safety.

2. Description Related to Safety

I. Safety Symbols

Carefully read the instructions in the user manual prior to robot use. The

following shows the safety symbols used in this user manual.

Symbol Description

Failure to follow instructions with this symbol may result

comply with these instructions.

Failure to follow instructions with this symbol may result

comply with these instructions.

2

in poor product performance. Please be sure to comply

Failure to follow instructions with this symbol may result

with these instructions.

II. Working Person

The personnel can be classified as follows

Operator:

Turns robot controller ON/OFF

Starts robot program from operator’s panel

Restore system alarm status

Programmer or teaching operator:

Operates the robot

Teaches robot inside the safety fence

Maintenance engineer:

C13UE001-1903

Operates the robot

Teaches robot inside the safety fence

Does maintenance, adjustment, replacement

Programmer and the maintenance engineer must be trained for proper robot

operation

3

All operating procedures should be assessed by

emergency or

abnormal situation, please press the emergency stop

When considering safety of the robot, the robot and

ystem must be considered at the same time. Be

with an appropriate safety device to stop the

While installing or removing mechanical

Ensure the weight of workpiece does not exceed the

defined by the system integrator in accordance

with ISO 10218-1/-2.

To ensure personal safety, robot installation must

The control cabinet should not be placed near high

voltage or machines that generate electromagnetic

3. Warning

3.1 Common Safety Issues

professional and in compliance with related industrial

safety regulations.

When operating robot, operator needs to wear safety

equipment, such as smock for working environment,

safety shoes and helmets.

When encountering danger or other

button immediately and move the arm away with low

speed in manual mode.

the s

sure to install safety fence or other safety equipment

C13UE001-1903

and the operator must stand outside the safety fence

while operating the robot.

A safety zone should be established around the robot

unauthorized personnel from access.

components, be aware of a falling piece which may

cause injury to operator.

rated load or the tolerable torque. Exceeding these

values could lead to the driver alarm or malfunction

of the robot.

Do not climb on robot.

The installation for emergency functions shall be

The personnel operating robot should be trained and

licensed.

comply with this manual and related industrial safety

regulations.

4

fields to prevent interference that could cause the

pair components may cause

Beware of the heat generated by the controller and

Do not overbend the cable to avoid poor circuit

be done outside of the safety

Please contact us if the replacement of the

Be sure to carry out regular maintenance,

Prior to repair and maintenance, please turn off

When replacing the components, avoid foreign

robot to deviation or malfunction.

Using non-HIWIN re

robot damage or malfunction.

servo motor.

contact.

3.2 Operation

Programming must

C13UE001-1903

3.3 Maintenance

fence. If it is inevitable to enter the safety fence,

the emergency stop button must be pressed.

Please contact us if the procedure not specified by

HIWIN is needed.

component not specified by HIWIN is needed.

otherwise it will affect the service life of the robot

or other unexpected danger.

power supply.

Maintenance and repair should be performed by a

qualified operator with a complete understanding

of the entire system to avoid risk of robot damage

and personal injury.

material going into the robot.

5

More attention must be paid to the design of the

effector to prevent power loss or any other

errors that could lead to workpiece falling or

type end effector is usually equipped

with high voltage, high temperature and active

The end effector may be equipped with its own

control unit. Be sure the control unit does not

the pneumatic or hydraulic system,

the relief valve, so that can be applied in an

emergency.

at least one device for immediate halt of n

servo motor will be cut, and all movements will

be stopped. And the control system will be shut

down. Emergency stop should be reset if the

Avoid using emergency stop to replace a normal

stop procedure. This could lead to unnecessary

3.4 End Effector

end

damage.

The tool-

rotary shaft. Special attention should be paid to the

operating safety.

The end effector should be mounted firmly on the

robot to avoid workpiece release during operation

which may cause personal injury or hazard.

interfere with robot operation.

C13UE001-1903

3.5 Pneumatic, Hydraulic System

When using

the gripped workpiece may fall due to insufficient

pressure or gravity.

The pneumatic system must be equipped with

3.6 Emergency Stop

The robot or other control component should have

function, such as an emergency stop switch.

The emergency stop button must be installed in an

easily accessible location for quick stop.

While executing an emergency stop, power to the

restoration of operating procedure is wanted.

6

loss to robot.

4. Intended use

HIWIN robots are industrial robots and intended for pick-and-place,

C13UE001-1903

handling, assembling, deburring, grinding and polishing. Use is only permitted

under the specified environment, for more detailed information please see

section 1.5 environmental conditions.

Use is not permitted under the following conditions:

Use in potentially explosive environments

Use without performing risk assessments

Transportation of people and animals

Operation outside the allowed operating parameters

5. Disposal

The disposal of HIWIN robot shall be in accordance with the local

environmental regulations.

7

C13UE001-1902

Content

1. TRANSPORTATION AND INSTALLATION .......................................................................... 10

1.1 TRANSPORTATION ....................................................................................................................... 10

1.2 INSTALLATION ............................................................................................................................. 19

1.3 CONNECTION WITH THE CONTROLLER ......................................................................................... 21

1.4 GROUNDING ................................................................................................................................. 23

1.5 OPERATING AMBIENT CONDITIONS .............................................................................................. 23

1.6 STANDARD AND OPTIONAL EQUIPMENT LIST ............................................................................... 24

2. BASIC SPECIFICATIONS ........................................................................................................ 25

4.1 DESCRIPTION OF MODEL NAME ................................................................................................... 25

4.2 LABELS ........................................................................................................................................ 26

4.3 ROBOT SPECIFICATIONS ............................................................................................................... 28

4.4 OUTER DIMENSIONS AND MOTION RANGE .................................................................................. 30

4.5 WRIST LOAD CONDITIONS ........................................................................................................... 34

3. EQUIPMENT MOUNTING SURFACE AND INTERFACE ..................................................... 38

3.1 MOUNTING SURFACE FOR END EFFECTOR ................................................................................... 38

3.2 MOUNTING SURFACE ON THE ROBOT ........................................................................................... 38

3.3 INTERFACE OF AIR SUPPLY .......................................................................................................... 41

3.4 R-I/O INTERFACE ......................................................................................................................... 43

4. CALIBRATION ......................................................................................................................... 47

4.1 ZERO-POSITION SETTING ............................................................................................................. 47

5. MANUAL BRAKE RELEASE DEVICE (OPTIONAL) ............................................................ 51

5.1 SAFETY PRECAUTIONS ................................................................................................................. 51

5.2 CONFIRMATION BEFORE USING .................................................................................................... 52

5.3 OPERATION .................................................................................................................................. 54

6. MAINTENANCE AND INSPECTION ...................................................................................... 56

6.1 PERIODIC INSPECTION ITEMS ....................................................................................................... 56

6.2 MAINTENANCE ............................................................................................................................ 60

6.2.1 Backup Batteries Replacement .................................................................................................... 60

6.2.2 Timing Belt Replacement ............................................................................................................ 61

6.2.3 Grease Replenishment ................................................................................................................. 65

8

C13UE001-1903

Edition Date Robot type Remark

1.0.0 2018.05.25

1.0.1 2019.01.03

1.0.2 2019.02.19

RA610-GB

RT610-GB

RA610-GB

RT610-GB

RA610-GB

RT610-GB

First edition released

Added new chapter 5 manual brake

release device

Modified chapter 2.2 labels

9

C13UE001-1903

1. Transportation and Installation

1.1 Transportation

Sling, crane or forklift truck can be used to transport the robot. The transportation

procedure is as follows:

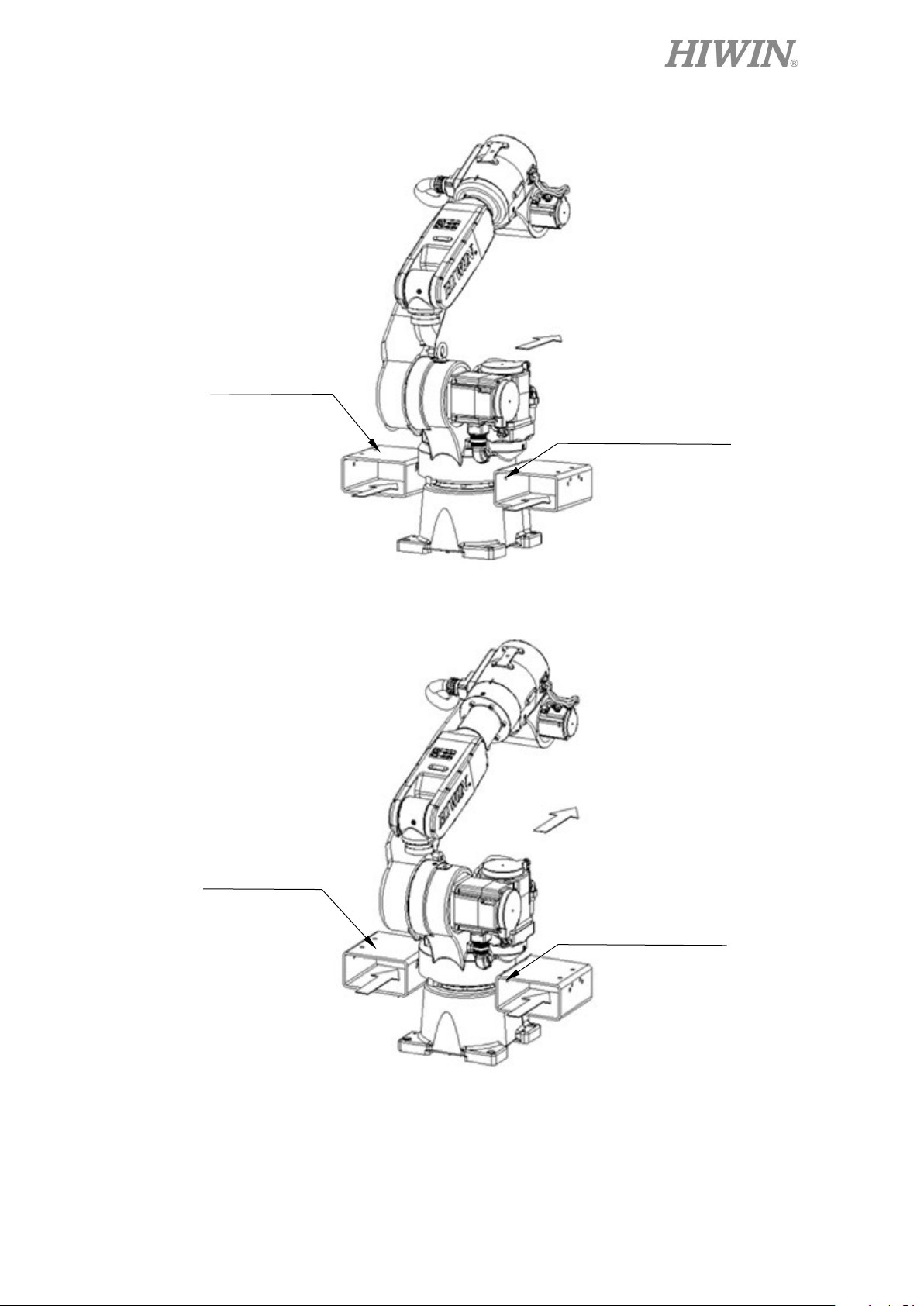

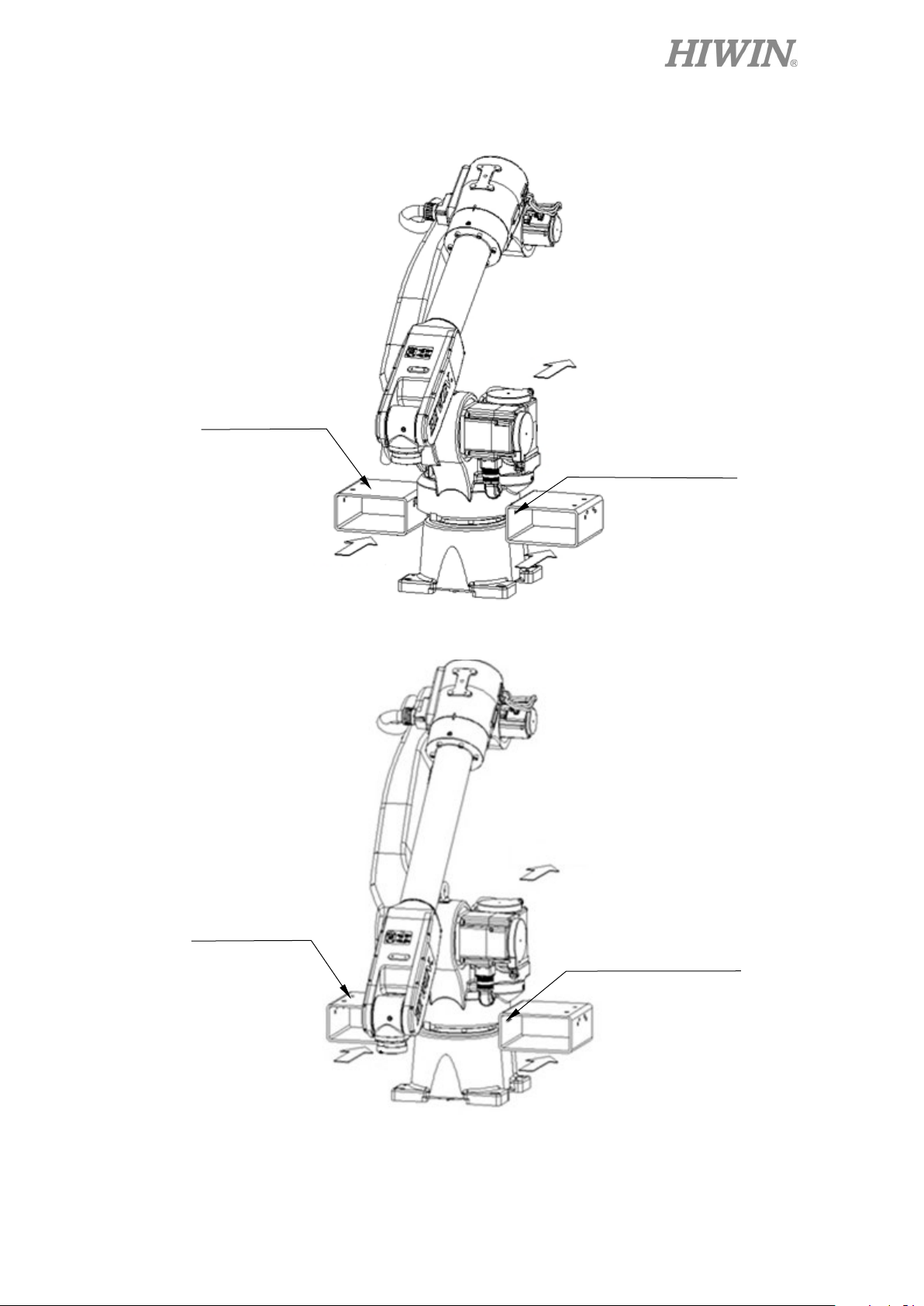

Transport by forklift truck:

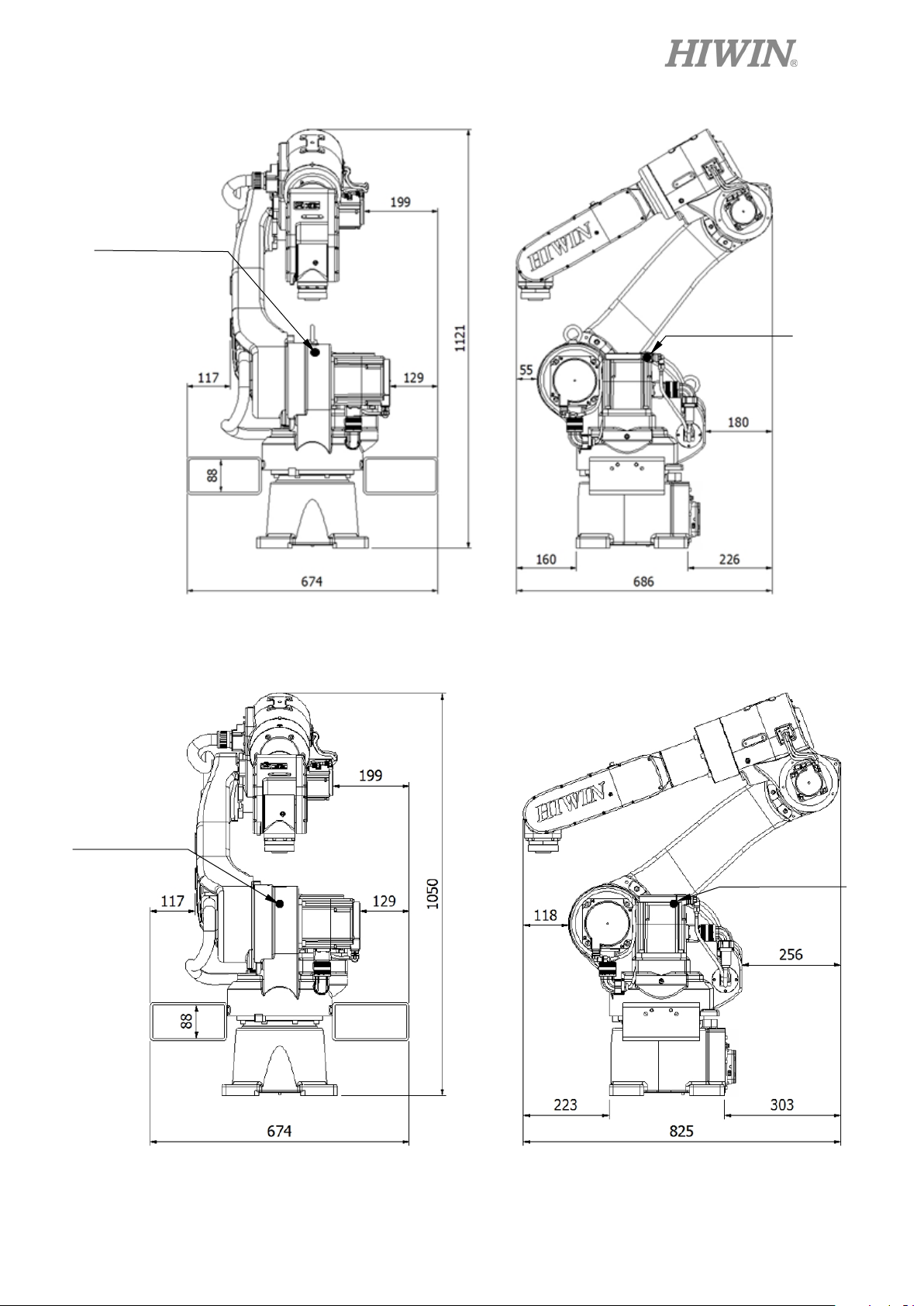

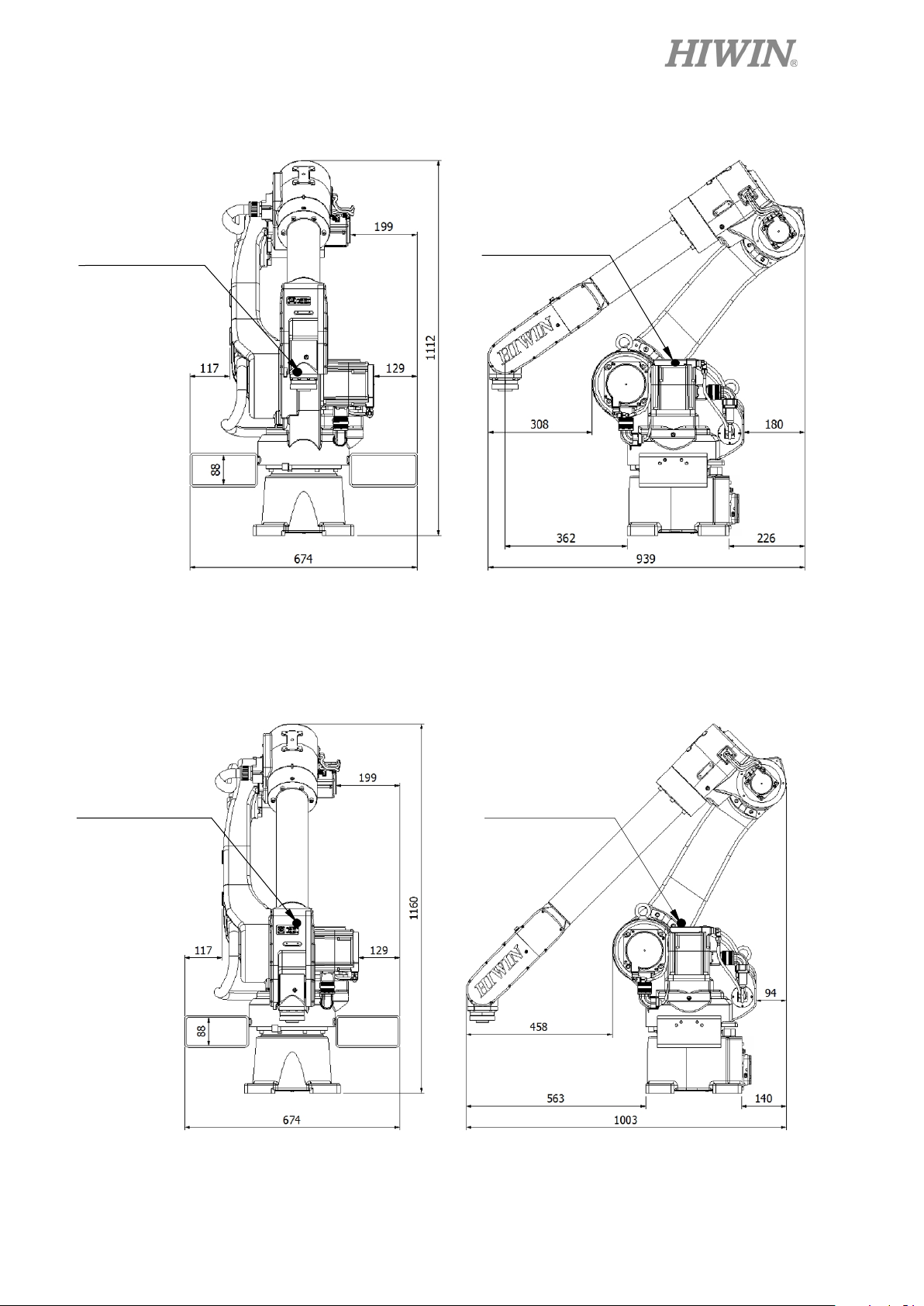

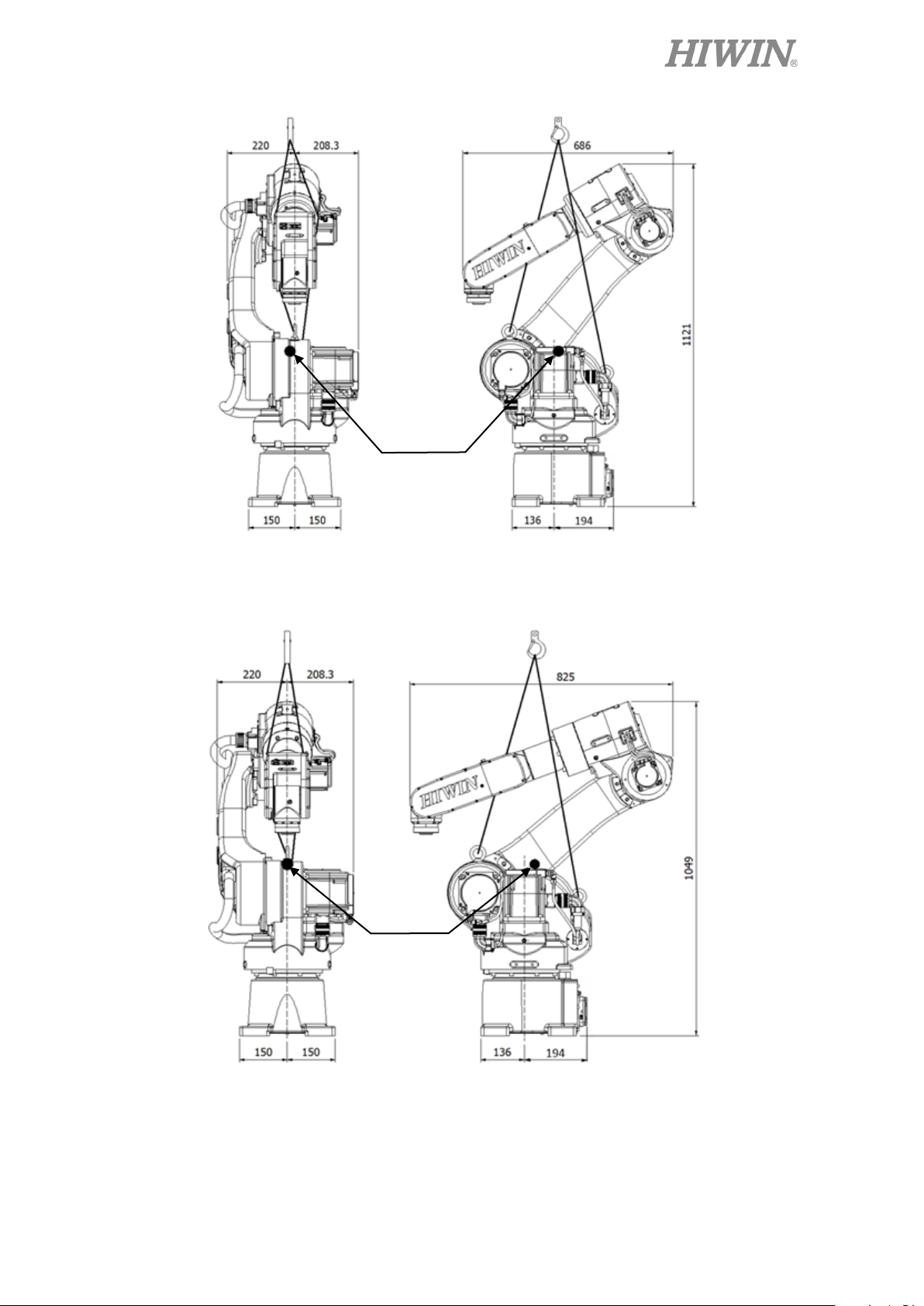

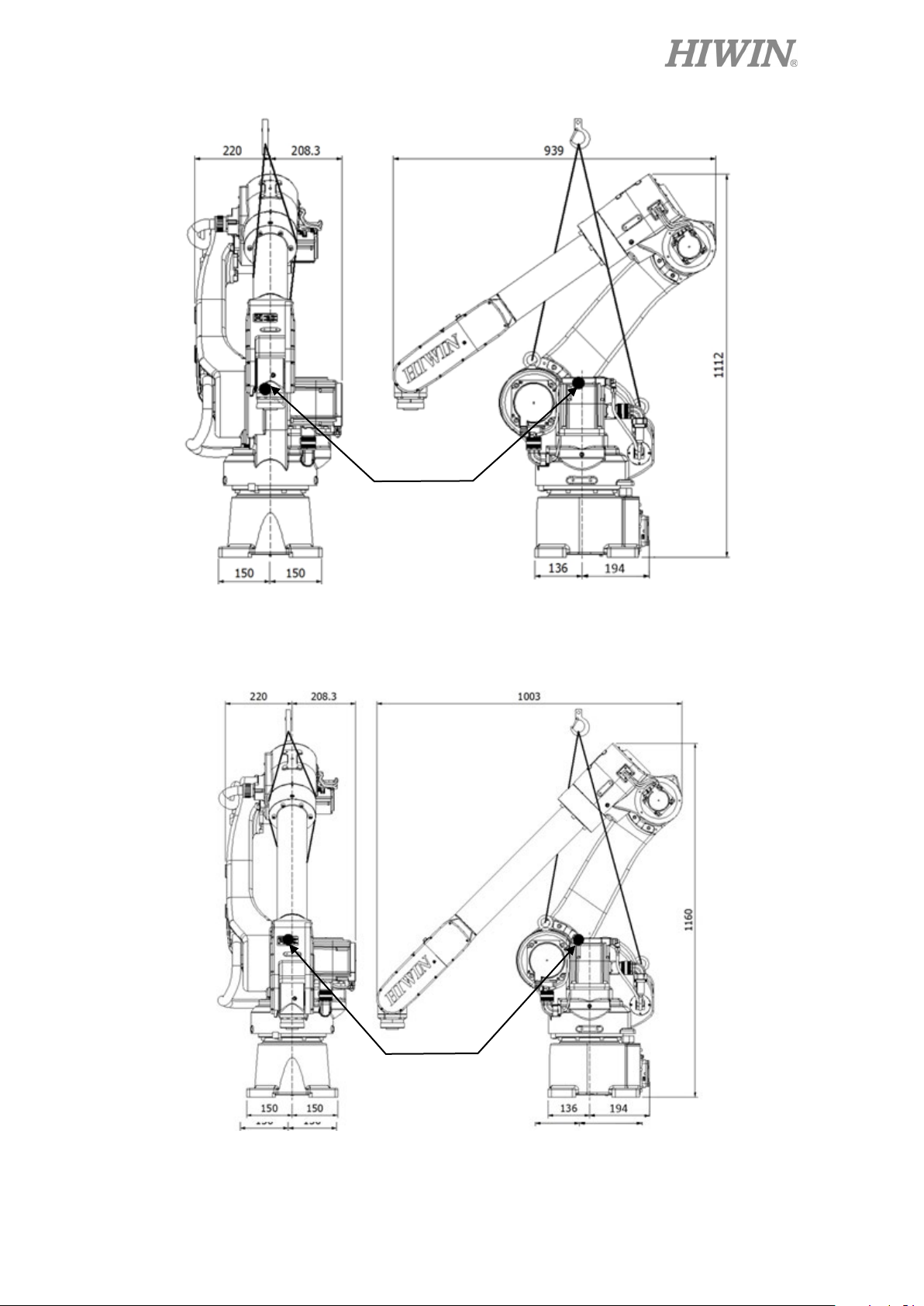

Step1. Move the robot into its transport position and the angle of each joint is shown in

the table of Figure 1-1. Transport dimensions are shown in Figure 1-2(a)~(d).

Step2. Secure the suspension plate to the robot with four M8x1.25Px20L head screw as

shown in Figure 1-3(a)~(d).

Step3. Move the robot to the desired position by forklift truck.

Step4. Remove the suspension plate and firmly secure the robot.

Transport by sling and crane:

Step1. Move the robot into its transport position and the angle of each joint is shown in

the table of Figure 1-1. Transport dimensions are shown in Figure 1-2(a)~(d).

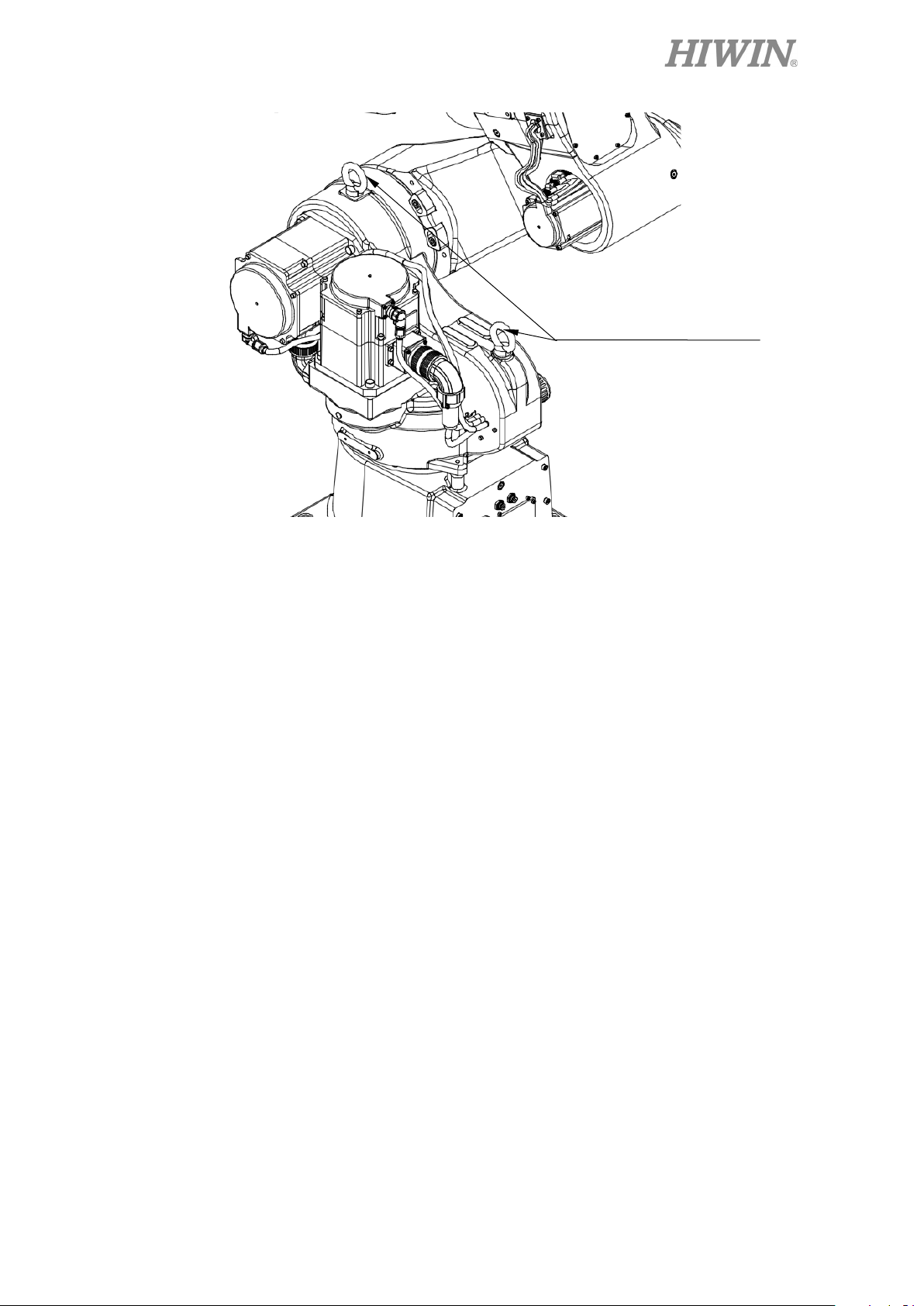

Step2. Secure two M12x1.75Px22L eye bolts to the robot as shown in Figure 1-4

(a)~(e).

Step3. Move the robot to the desired position by sling and crane.

Step4. Remove the eye bolts and firmly secure the robot.

(The transportation of RA610-GB and RT610-GB are the same. The following

figures only show the transportation of RA610-GB.)

Please refer to section 1.2~1.5 for robot installation and precautions.

10

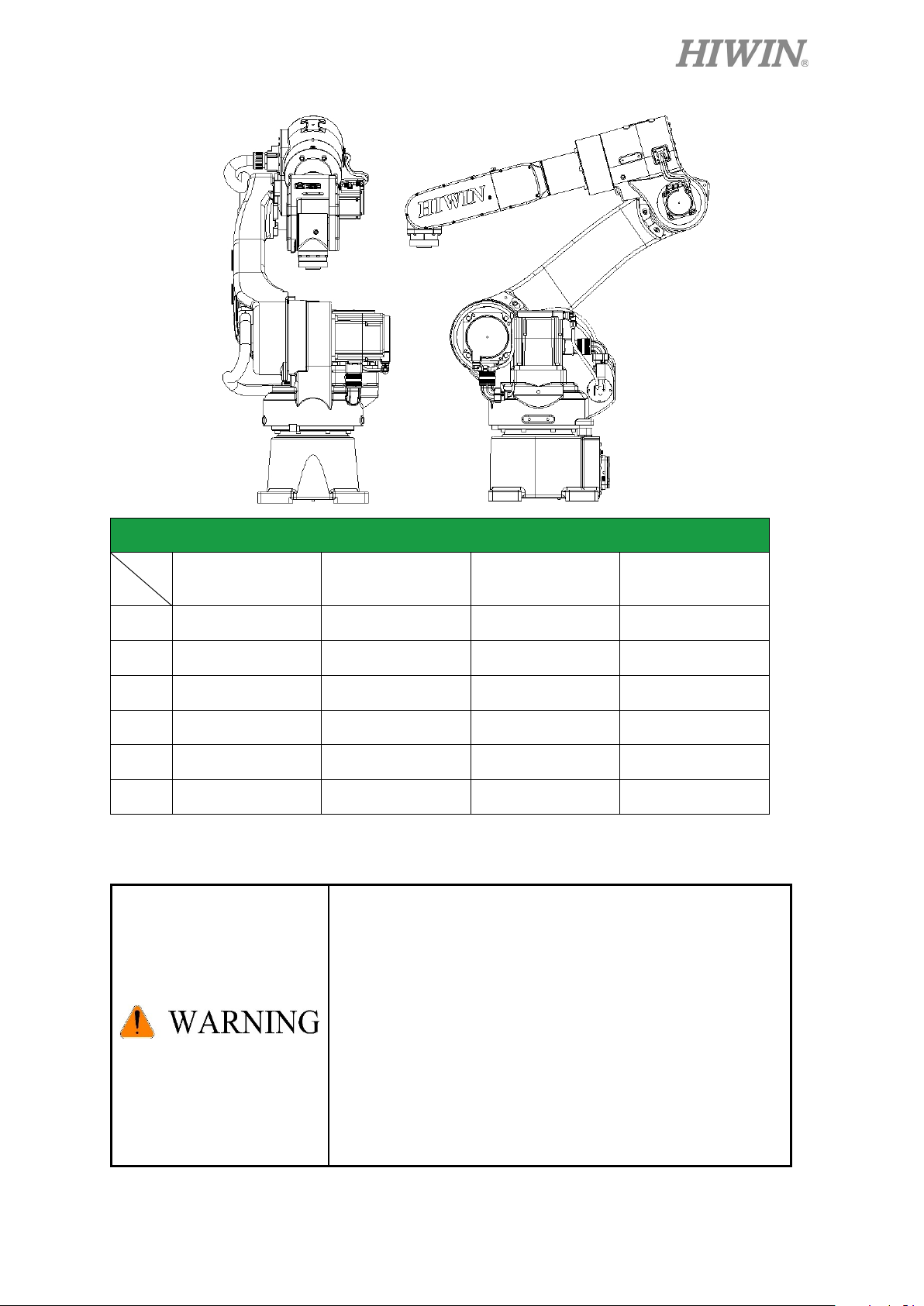

Transport position

RA610-1355-GB

RA610-1476-GB

RA610-1672-GB

RA610-1869-GB

0˚

0˚

0˚

0˚

45˚

55˚

45˚

35˚

J3

-75˚

-75˚

-80˚

-80˚

0˚

0˚

0˚

0˚

-60˚

-70˚

-55˚

-45˚

0˚

0˚

0˚

0˚

Before carrying the robot, be sure to remove the end

Please keep stable, slow down and avoid excessive

C13UE001-1903

RT610-1355-GB

RT610-1476-GB

J1

J2

J4

J5

J6

Figure 1-1 Transport position

effector which changes the center of gravity.

vibration or shock during transportation.

While placing the robot be sure to avoid the robot and

the installation surface collision.

RT610-1672-GB

RT610-1869-GB

After removing the suspension plate, please maintain it

properly for re-transportation.

Before operation, remove the suspension plate to avoid

danger.

11

Center of gravity

C13UE001-1903

Center of gravity

Center of gravity

Figure 1-2(a) RA610-1355-GB Transport dimensions

RT610 -1355-GB Transport dimensions

Center of gravity

Figure 1-2(b) RA610-1476-GB Transport dimensions

RT610-1476-GB Transport dimensions

12

C13UE001-1903

Center of gravity

Center of gravity

Figure 1-2(c) RA610-1672-GB Transport dimensions

RT610-1672-GB Transport dimensions

Center of gravity

Center of gravity

Figure 1-2(d) RA610-1869-GB Transport dimensions

RT610-1869-GB Transport dimensions

13

Direction for forklift

C13UE001-1903

Suspension plate

Screw: 4-M8x1.25Px20L

Washer: 4-M8

Figure 1-3(a) RA610-1355-GB Transport by forklift truck

RT610-1355-GB Transport by forklift truck

Suspension plate

Direction for forklift

Screw: 4-M8x1.25Px20L

Washer: 4-M8

Figure 1-3(b) RA610-1476-GB Transport by forklift truck

RT610-1476-GB Transport by forklift truck

14

C13UE001-1903

Suspension plate

Direction for forklift

Screw: 4-M8x1.25Px20L

Washer: 4-M8

Figure 1-3(c) RA610-1672-GB Transport by forklift truck

RT610-1672-GB Transport by forklift truck

Suspension plate

Direction for forklift

Screw: 4-M8x1.25Px20L

Washer: 4-M8

Figure 1-3(d) RA610-1869-GB Transport by forklift truck

RT610-1869-GB Transport by forklift truck

15

gravity

gravity

Center of

C13UE001-1903

Figure 1-4(a) RA610-1355-GB Transport by sling

RT610-1355-GB Transport by sling

Center of

Figure 1-4(b) RA610-1476-GB Transport by sling

RT610-1476-GB Transport by sling

16

Center of gravity

C13UE001-1903

Figure 1-4(c) RA610-1672-GB Transport by sling

RT610-1672-GB Transport by sling

Center of gravity

Figure 1-4(d) RA610-1869-GB Transport by sling

RT610-1869-GB Transport by sling

17

Sling installation position

C13UE001-1903

2-M12 Eyebolt

Figure 1-4(e) Eye bolt securement

18

C13UE001-1903

1.2 Installation

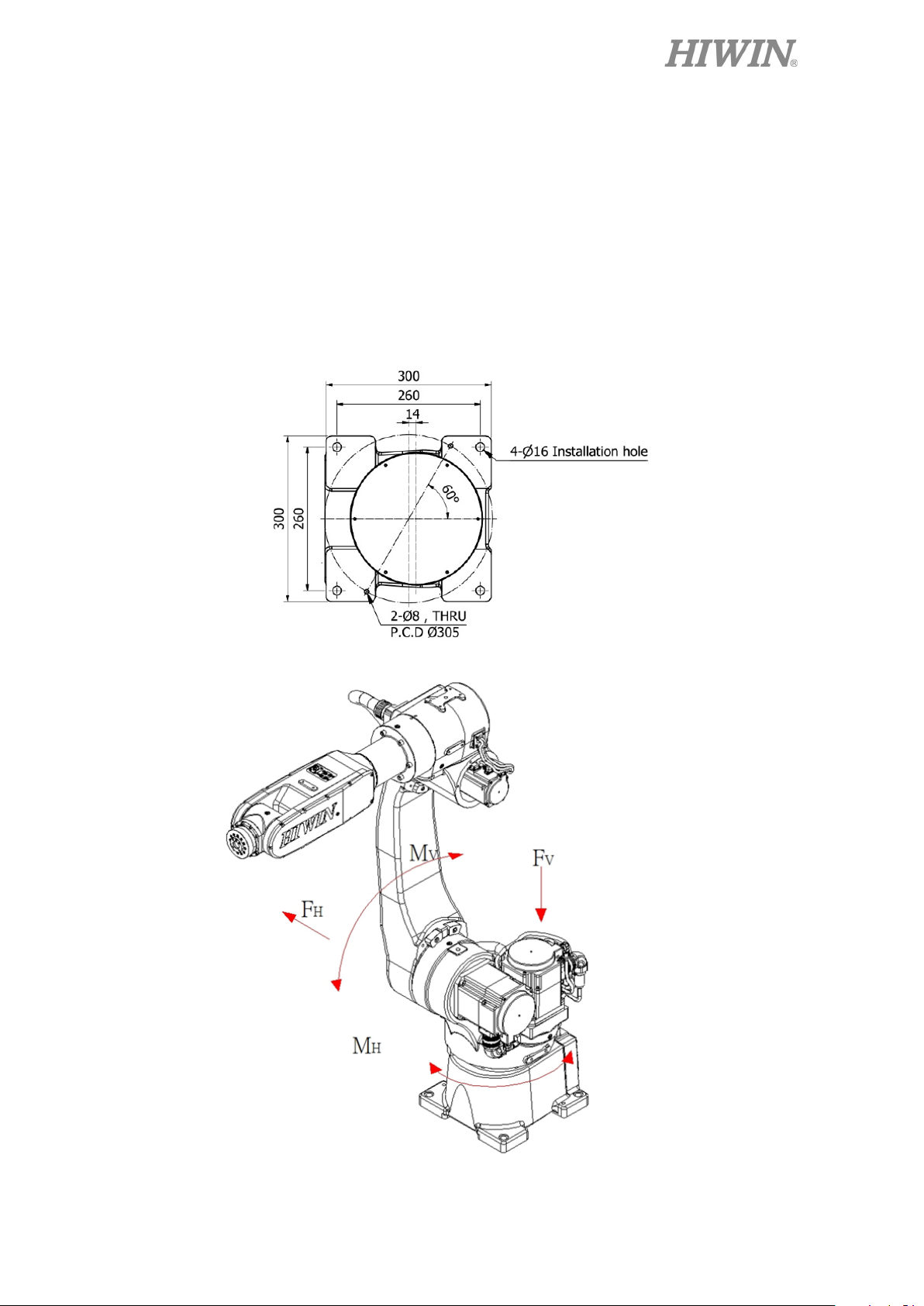

Figure 1-5 shows the installation dimensions of the robot. According to the

dimensions, fix the robot with M14 installation bolt on the installation surface. Figure 1-6

and Table 1-1 show the forces and moments acting on the installation surface. The

installation surface must have sufficient strength to withstand the dynamic movement of

the robot when operating at maximum speed.

(The installation interface of RA610-GB and RT610-GB are the same. The following

figure only shows the base dimensions of RA610-GB.)

Figure 1-5 Base dimension

Figure 1-6 Forces and moments acting on the installation surface

19

Loading...

Loading...