INDUSTRIE 4.0 Best Partner

Multi Axis Robot

Pick-and-place / Assembly /

Array and packaging / Semiconductor /

Electro-Optical industry /

Automotive industry / Food industry

ßArticulated Robot

ßDelta Robot

ßSCARA Robot

ßWafer Robot

ßElectric Gripper

ßIntegrated Electric Gripper

ßRotary Joint

Single Axis Robot

Precision / Semiconductor /

Medical / FPD

ßKK, SK

ßKS, KA

ßKU, KE, KC

Ballscrew

Precision Ground / Rolled

ßSuper S series

ßSuper T series

ßMini Roller

ßEcological & Economical

lubrication Module E2

ßRotating Nut (R1)

ßEnergy-Saving & Thermal-

Controlling (C1)

ßHeavy Load Series (RD)

ßBall Spline

Medical Equipment

Hospital / Rehabilitation centers /

Nursing homes

ßRobotic Gait Training System

ßHygiene System

ßRobotic Endoscope Holder

Direct Drive

Rotary Table

Aerospace / Medical / Automotive industry /

Machine tools / Machinery industry

ßRAB Series

ßRAS Series

ßRCV Series

ßRCH Series

Linear Guideway

Automation / Semiconductor / Medical

ßBall Type--HG, EG, WE, MG, CG

ßQuiet Type--QH, QE, QW, QR

ßOther--RG, E2, PG, SE, RC

Bearing

Machine tools / Robot

ßCrossed Roller Bearings

ßBall Screw Bearings

ßLinear Bearing

ßSupport Unit

AC Servo Motor & Drive

Semiconductor / Packaging machine

/SMT / Food industry / LCD

ßDrives-D1, D1-N, D2T

ßMotors-50W~2000W

Linear Motor

Automated transport / AOI application

/ Precision / Semiconductor

ßIron-core Linear Motor

ßCoreless Linear Motor

ßLinear Turbo Motor LMT

ßPlanar Servo Motor

ßAir Bearing Platform

ßX-Y Stage

ßGantry Systems

Driven Tool Holders

All kinds of turret

ßVDI Systems

Radial Series, Axial Series, MT

ßBMT Systems

DS, NM, GW, FO, MT, OM, MS

Torque Motor

(Direct Drive Motor)

Inspection / Testing equipment /

Machine tools / Robot

ßRotary Tables-TMS,TMY,TMN

ßTMRW Series

ßTMRI Series

C18UE001-1804

Warranty Terms and Conditions

The period of warranty shall commence at the received date of HIWIN product

(hereafter called “product”) and shall cover a period of 12 months. The warranty does

not cover any of the damage and failure resulting from:

The damage caused by using with the production line or the peripheral

equipment not constructed by HIWIN.

Operating method, environment and storage specifications not specifically

recommended in the product manual.

The damage caused by changing installation place, changing working

environment, or improper transfer after being installed by the professional

installer.

Product or peripheral equipment damaged due to collision or accident caused by

improper operation or installation by the unauthorized staff.

Installing non-genuine HIWIN products.

The following conditions are not covered by the warranty:

Product serial number or date of manufacture (month and year) cannot be

verified.

Using non-genuine HIWIN products.

Adding or removing any components into/out the product without authorized.

Any modification of the wiring and the cable of the product.

Any modification of the appearance of the product; removal of the components

inside the product. e.g., remove the outer cover, product drilling or cutting.

Damage caused by any natural disaster. i.e., fire, earthquake, tsunami, lightning,

windstorms and floods, tornado, typhoon, hurricane etc.

HIWIN does not provide any warranty or compensation to all the damage caused by

above-mentioned circumstances unless the user can prove that the product is defective.

For more information towards warranty terms and conditions, please contact the

technician or the dealer who you purchased with.

Improper modification or disassemble the robot might reduce

the robot function, stability or life.

The end-effector or the cable for devices should be installed

1.

Safety Information

Safety Responsibility and Effect

This chapter explains how to use the robot safely. Be sure to read this

C18UE001-1804

and designed by a professional staff to avoid damaging the

robot and robot malfunction.

Please contact the technician for special modification coming

from production line set up.

For the safety reason, any modification for HIWIN product is

strictly prohibited.

Safety Precautions

chapter carefully before using the robot.

The user of the HIWIN industrial robot has responsibility to design and

install the safety device meeting the industrial safety regulations in order to

ensure personal safety.

2.

Description Related to Safety

I. Safety Symbols

Carefully read the instructions in the user manual prior to robot use. The

following shows the safety symbols used in this user manual.

Symbol Description

Failure to follow instructions with this symbol may result

in serious hazard or personal injury. Please be sure to

comply with these instructions.

Failure to follow instructions with this symbol may result

in personal injury or product damage. Please be sure to

comply with these instructions.

Failure to follow instructions with this symbol may result

in poor product performance. Please be sure to comply

with these instructions.

II. Working Person

The personnel can be classified as follows

Operator:

3.

C18UE001-1804

Turns robot controller ON/OFF

Starts robot program from operator’s panel

Reset system alarm

Programmer or teaching operator:

Operates the robot

Teaches robot inside the safety fence

Maintenance engineer:

Operates the robot

Teaches robot inside the safety fence

Does maintenance, adjustment, replacement

Programmer and the maintenance engineer must be trained for proper robot

operation.

Warning

3.1 Common Safety Issues

All operating procedures should be assessed by

professional and in compliance with related

industrial safety regulations.

When operating robot, operator needs to wear

safety equipment, such as smock for working

environment, safety shoes and helmets.

When encountering danger or other emergency or

abnormal situation, please press the emergency stop

button immediately and move the arm away with

low speed in manual mode.

When considering safety of the robot, the robot and

the system must be considered at the same time. Be

sure to install safety fence or other safety equipment

and the operator must stand outside the safety fence

while operating the robot.

A safety zone should be established around the

robot with an appropriate safety device to stop the

unauthorized personnel from access.

While installing or removing mechanical

components, be aware of a falling piece which may

cause injury to operator.

C18UE001-1804

Ensure the weight of workpiece does not exceed the

rated load or the tolerable torque. Exceeding these

values could lead to the driver alarm or malfunction

of the robot.

Do not climb on robot.

The personnel installing robot should be trained and

licensed.

To ensure personal safety, robot installation must

comply with this manual and related industrial

safety regulations.

The control cabinet should not be placed near high

voltage or machines that generate electromagnetic

fields to prevent interference that could cause the

robot to deviation or malfunction.

Using non-HIWIN repair components may cause

3.2 Operation

3.3 Maintenance

robot damage or malfunction.

Beware of the heat generated by the controller and

servo motor.

Do not overbend the cable to avoid poor circuit

contact.

Programming should be done outside of the safety

fence. If it is inevitable to enter the safety fence, be

prepared to press the emergency stop button

whenever necessary. Operation should be restricted

at low speed and beware of surrounding safety.

Please contact us if the procedure not specified by

HIWIN is needed.

Please contact us if the replacement of the

component not specified by HIWIN is needed.

Be sure to carry out regular maintenance, otherwise

it will affect the service life of the robot or other

unexpected danger.

3.4 End Effector

C18UE001-1804

Prior to repair and maintenance, please turn off

power supply.

Maintenance and repair should be performed by a

qualified operator with a complete understanding of

the entire system to avoid risk of robot damage and

personal injury.

When replacing the components, avoid foreign

material going into the robot.

More attention must be paid to the design of the end

effector to prevent power loss or any other errors

that could lead to workpiece falling or damage.

The tool-type end effector is usually equipped with

high voltage, high temperature and active rotary

3.5 Pneumatic, Hydraulic System

3.6 Emergency Stop

shaft. Special attention should be paid to the

operating safety.

The end effector should be mounted firmly on the

robot to avoid workpiece release during operation

which may cause personal injury or hazard.

The end effector may be equipped with its own

control unit. Be sure the control unit does not

interfere with robot operation.

When using the pneumatic or hydraulic system, the

gripped workpiece may fall due to insufficient

pressure or gravity.

The robot or other control component should have

at least one device for immediate halt of n function,

such as an emergency stop switch.

The emergency stop button must be installed in an

easily accessible location for quick stop.

While executing an emergency stop, power to the

C18UE001-1804

servo motor will be cut, and all movements will be

stopped. And the control system will be shut down.

Emergency stop should be reset if the restoration of

operating procedure is wanted.

Avoid using emergency stop to replace a normal

stop procedure. This could lead to unnecessary loss

to robot.

C18UE001-1804

1.Transportation and Installation

1.1 Transportation

1.2 Installation

1.3 Connection with the Controller

1.4 Grounding

1.5 Operating Ambient Conditions

1.6 Standard and Optional Equipment List

2.Basic Specifications

2.1 Description of Serial Number

2.2 Labels

2.3 Robot Specifications

Content

2.4 Outer Dimensions and Motion Range

2.5 Wrist Moment Conditions

3.Equipment Mounting Surface and Interface

3.1 Mounting Surface for End Effector

3.2 Pneumatic Interface

3.3 I/O Interface

4.Zero-Position

4.1 Zero Position Setting

5.Maintenance and Inspection

5.1 Periodic Inspection Items

5.2 Repair

5.2.1 Backup Batteries Replacement

5.2.2 Timing Belt Replacement

5.2.3 Grease Replenishment

C18UE001-1804

Version Date Product Note

1.0.0 2017.12.18

RT605-710-GB

RT605-710-GB

First edition

Manual specification updated

2.0.0 2018.01.08

RT605-909-GB

RT605-909-GB

C18UE001-1804

1. Transportation and Installation

1.1 Transportation

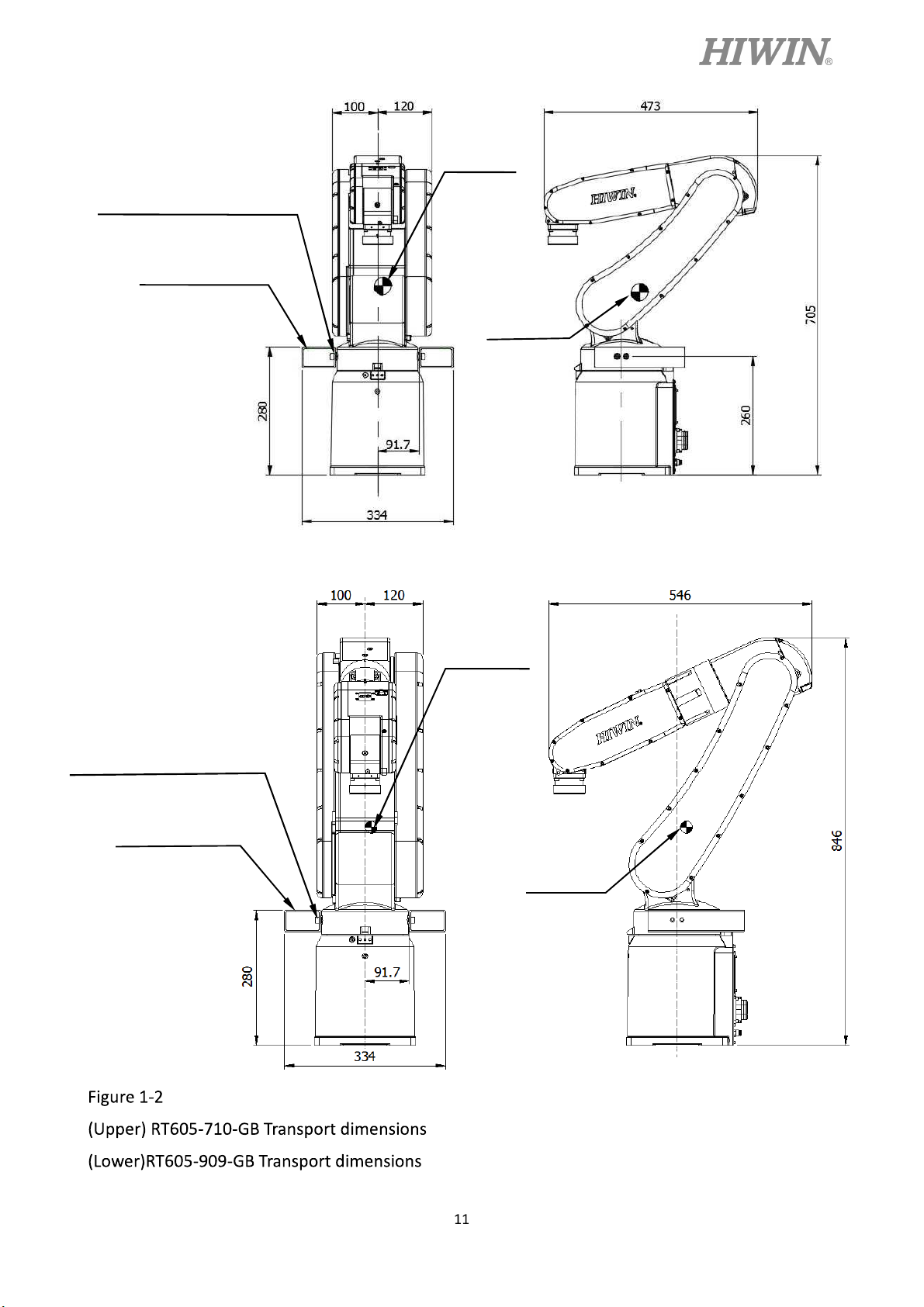

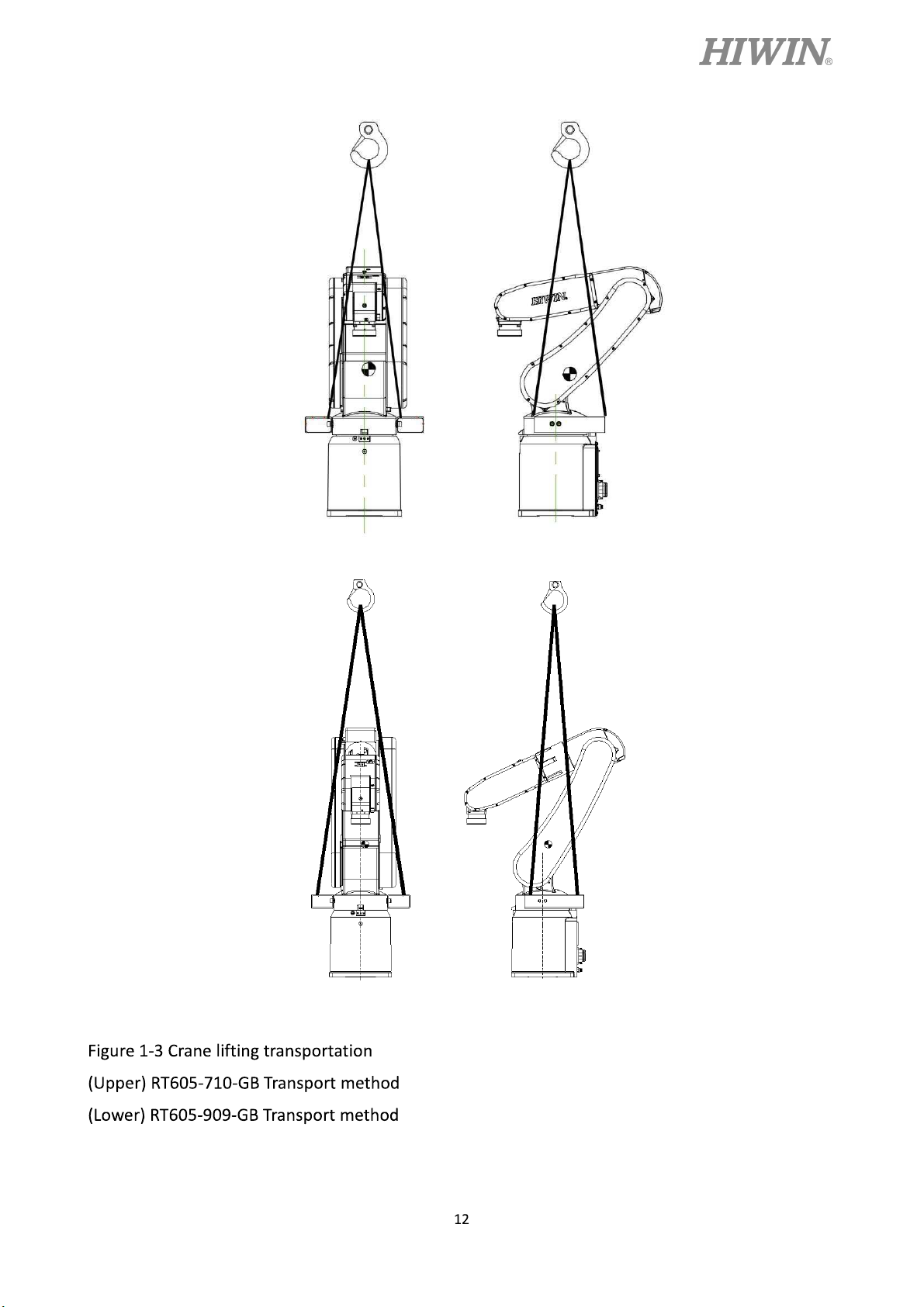

Sling can be used to transport the robot. The transportation procedure is as follows:

Step1. Move the robot into its transport posture and the angle of each joint is shown in the table

of Figure 1-1.

Step2. Secure the suspension plate to the robot with four M8×1.25P×12L screws as shown in

Figure 1-2. Make the sling go through the suspension plate to keep the center of gravity

under the hanging point shown as Figure 1-3. Please ensure the robot is in stable

condition to avoid overturning.

Step3. Move the robot to the desired position by using sling.

Step4. Remove the suspension plate.

C18UE001-1804

RT605-710-GB

Transport posture

J1 0°

J2 45°

J3 -55°

J4 0°

J5 -80°

J6 0°

RT605-909-GB

Transport posture

J1 0°

J2 30°

J3 -55°

J4 0°

J5 -65°

J6 0°

Figure 1-1 Transport posture

Before carrying the robot, be sure to remove the end

effector which changes the center of gravity.

Please keep stable, slow down and avoid excessive

vibration or shock during transportation.

While placing the robot be sure to avoid the robot and the

installation surface collision.

After removing the suspension plate, please maintain it

properly for re-transportation.

Before operation, remove the suspension plate to avoid

danger.

C18UE001-1804

Hexagon socket cap screw

M8x1.25Px12L

Suspension plate

Center of

gravity

Center of

gravity

Hexagon socket cap screw

M8x1.25Px12L

Suspension plate

Center of

gravity

Center of

gravity

C18UE001-1804

C18UE001-1804

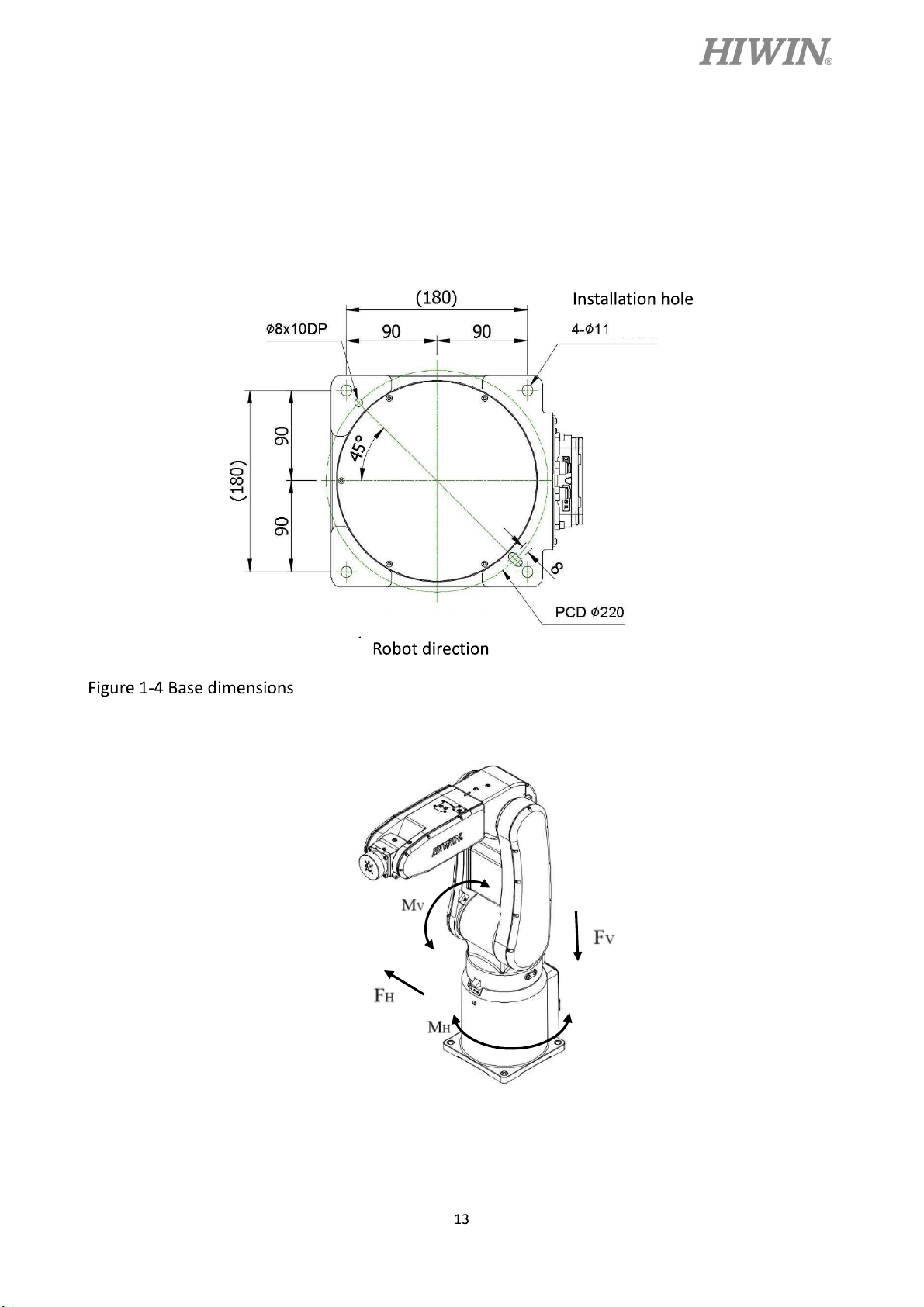

1.2 Installation

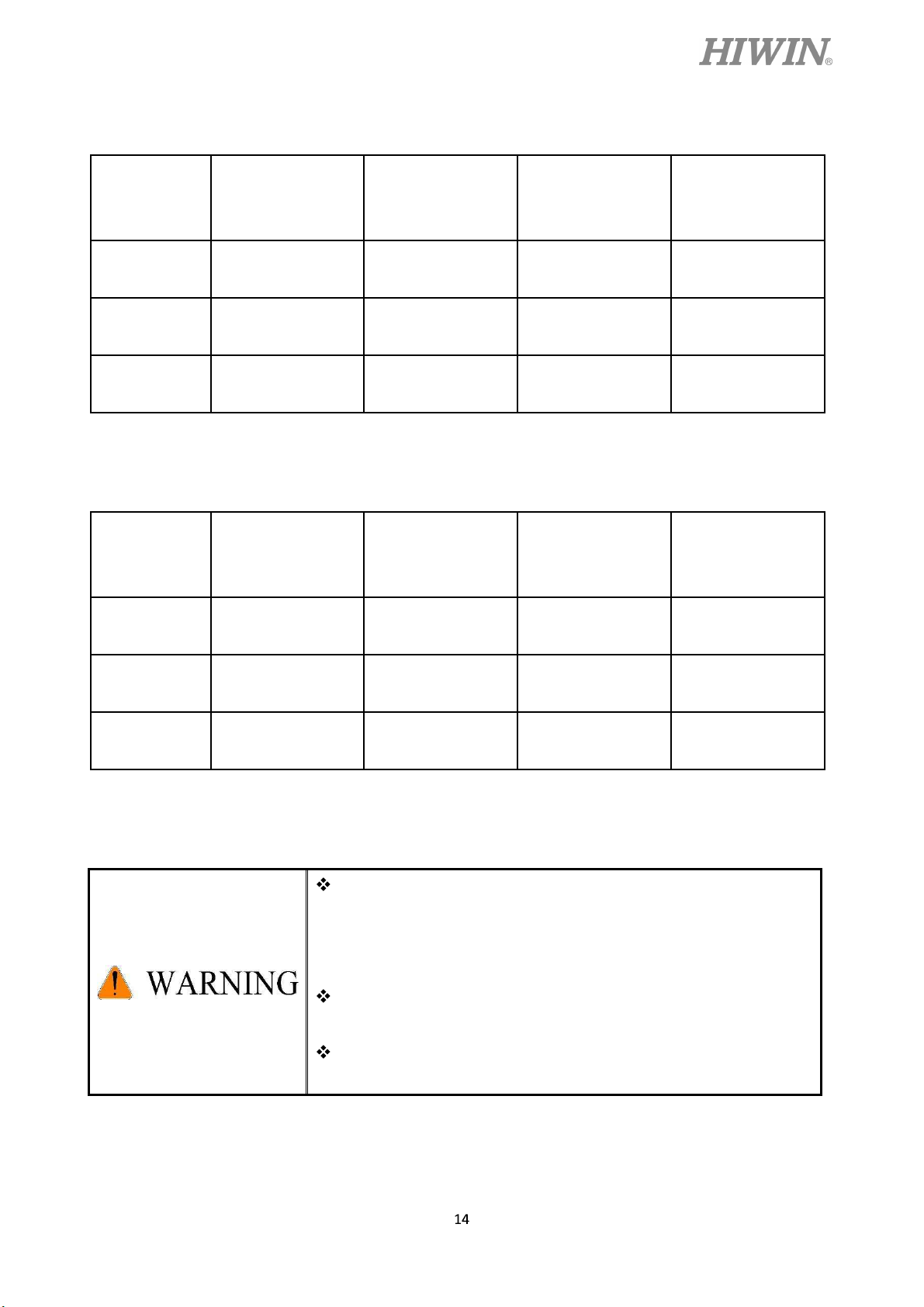

Figure 1-4 shows the installation dimensions of the robot. According to the dimensions, fix

the robot on the installation surface with M10 screws. Figure 1-5, table 1-1 and table 1-2 show

the forces and moments acting on the installation surface during operation. The strength of

surface must be considered when installing the robot.

Figure 1-5 Forces and moments acting on the installation surface

C18UE001-1804

Table 1-1 RT605-710-GB Value of forces and moments acting on the installation surface

Vertical moment

Vertical force

Horizontal moment

Horizontal force

Mv (Nm)

Fv (N)

MH (Nm)

Stop 144 441 0 0

Acceleration

382 1009 149 456

/Deceleration

Power cut stop

462 1199 248 760

Table 1-2 RT605-909-GB Value of forces and moments acting on the installation surface

Vertical moment

Vertical force

Horizontal moment

Horizontal force

Mv (Nm)

Fv (N)

MH (Nm)

Stop 160 490 0 0

FH (N)

FH (N)

Acceleration

/Deceleration

Power cut stop

526 1205 244 748

660 1467 407 1246

Ensure the installation surface is smooth plane which is

recommended to be 6.3a or less for the roughness. If the

installation surface is rough, the robot could produce the

position shift during the operation.

Ensure the position of the installation surface for the robot will

not shift owing to the movement.

Ensure the strength of the installation surface for the robot will

not be damaged owing to the movement.

C18UE001-1804

+

+

-

+

+

+

+

-

1.3 Connection with the Controller

Figure 1-6 shows the structure drawing of the robot. Figure 1-7 shows the connection

between robot, controller, teach pendant and power source. Figure 1-8and Figure 1-9 show the

interface of J1 and the pin assignment of CN2 connector.

Joint 4

Joint 5

Joint 6

J6

J5

Joint 3

Joint 2

J4

-

J2

-

J1

-

J3

Joint 1

Figure 1-6 Drawing of robot structure

Teach pendant

Power source

CN2

Controller

Figure 1-7 Robot and controller connection

C18UE001-1804

Battery box

Air out socket

Power/signal socket

Air in socket

Figure 1-8 Interface at the rear of J1

Figure 1-9 Pin assignment of CN2 connector

When connecting the cable, be sure to turn off power supply

first.

C18UE001-1804

1.4 Grounding

Figure 1-10 shows the grounding connection of the robot with the screw (M5×0.8P×8L).

Grounding wire

Washer

Figure 1-10 Grounding method

1.5 Operating Ambient Conditions

The robot operating ambient conditions is shown in Table 1-3.

Table 1-3 Ambient conditions

Ambient temperature 0~45 [Note 1]

Ambient relative humidity 75% R.H. or less

Altitude Up to 1000 m above mean sea level

Vibration 0.5G or less

Ambient conditions

Screw

No condensation permissible

Environment

Do not use under corrosive environment

Do not use under flammable environment

Do not use under explosive environment

Do not use under radiative environment

[Note 1]: When the robot is stopped for a long period of time at the temperature near 0 , the robot

operation may have greater resistance in the beginning and then an overload alarm may be raised. It

is recommended to warm up the robot at low speed for a few minutes.

1.6 Standard and Optional Equipment List

Standard and optional equipment list is shown in Table 1-4.

Table 1-4 Standard and optional equipment list

C18UE001-1804

Item

HIWIN

Part No.

Teach pendant AH301401

Calibration tool set 4C201EK1

End effector I/O connector 4CA30008

Connector set 4C201701

Suspension plate set 4C201E41

Robot base (GB) 4C300F42

J2 belt 45310141

J2 belt 453100X8

J3 belt 453100QN

RT605-710-GB

RT605-909-GB

Standard

Optional

Optional

Refer to section

Refer to section

Refer to section

Refer to section

Refer to section

Refer to section

Remark

4.1

3.3

1.1

5.2.2

5.2.2

5.2.2

J3 belt 453100X9

J5 J6 belt

453100MY

J1~J4 grease (16KG) 47110035

J5~J6 grease (16KG) 47110037

Encoder battery 462600LN

CN3 Emergency stop set

4C7013F2

5M

External input/output

4C201DY1

wiring set

External input/output

4C201DZ2

expansion module

Cotton filter 4657003Y

Battery 462C0097

Refer to section

Refer to section

Refer to section

Refer to section

Refer to section

5.2.2

5.2.2

5.2.3

5.2.3

5.2.1

2. Basic Specifications

2.1 Description of Serial Number

There is a serial number on the specification label of each robot. The explanation of serial

number and model name are shown in Figure 2-1.

C18UE001-1804

Figure 2-1 Description of serial number

2.2 Labels

The labels on the robot are shown in Table 2-1.

Table 2-1 Labels description

Labels Name Description

Collision

Grounding

Keep safety distance from robot

system, and prevent colliding to

operator during operation.

Make sure grounding is

completed, or it will cause electric

shock.

Electric shock

Pay more attention that the robot

may have a risk of electric shock.

C18UE001-1804

Be aware of transport posture

Transport

posture

when transporting robot, please

refer to section 1.1 for detailed

information.

Robot specification and serial

Specification

number.

The connection port of air tube for

Air in

air input.

The connection port of air tube for

Air out

air output.

Grease in The hole for grease in.

Grease out The hole for grease out.

2.3 Robot Specifications

The robot specifications are shown in Table 2-2.

Table 2-2 Robot specification

Item Specification

Model name RT605-710-GB RT605-909-GB

Degrees of freedom 6

C18UE001-1804

Installation

Floor slope (wall mounting, ceiling mounting) [Note 1]

Load capacity 5kg [Note 2] 5kg [Note 2]

Maximum reach radius 710 mm 909 mm

Cycle time 0.5 s [Note 3]

Repeatability ±0.03 mm ±0.04 mm

J1 ±165°

J2 +85°~ -125°

J3 +185°~ -55°

±165°

+85°~ -125°

+185°~ -55°

Motion range

J4 ±190°

J5 ±115°

J6 ±360°

J1 360°/ s

J2 288°/ s

J3 420°/ s

±190°

±115°

±360°

250°/ s

200°/ s

300°/ s

Maximum speed

J4 444°/ s

J5 450°/ s

444°/ s

450°/ s

J6 720°/ s

Allowable load

moment at

wrist

J4 8.40 N-m

J5 8.40 N-m

J6 5.56 N-m

J4

0.36 kg-

Allowable load

J5

0.36 kg-

inertia at wrist

J6

0.13 kg-

Weight 40 kg (Manipulator only) 45 kg (Manipulator only)

Tool wiring 6 input / 4 output

Tool pneumatic pipes

Two channels of tracheal connection (apply with M5 thread 4

tracheal caliber connector)

Protection rating IP32

Noise level Less than 75 dB [Note 4]

720°/ s

8.40 N-m

8.40 N-m

5.56 N-m

0.36 kg-

0.36 kg-

0.13 kg-

C18UE001-1804

[Note 1]: Compared to mounting on the ground, the performance of the robot may be different

when mounting on the wall or ceiling. Please contact HIWIN if there’s any demand for this

application.

[Note 2]: For details about load capacity, please refer to section 2.5.

[Note 3]: The cycle time is the time that the robot moves forward and backward in the vertical

height 25mm and the horizontal distance 300mm with 1 kg load, as shown in Figure 2-2.

Figure 2-2 Cycle time trajectory

[Note 4]: The noise level is measured at maximum speed and maximum load according to

ISO11201.

2.4 Outer Dimensions and Motion Range

The motion range is shown in Figure 2-3 and Figure 2-4.

C18UE001-1804

Figure 2-3 RT605-710-GB Motion range

C18UE001-1804

Figure 2-4 RT605-909-GB Motion range

C18UE001-1804

2.5 Wrist Moment Conditions

The load capacity of the robot is not only limited by the weight of the load, but also

limited by the center of gravity of the load. Figure 2-5 shows allowable center of gravity of the

load when the robot is loaded 1~5kg.

Figure 2-5 Wrist moment diagram

3. Equipment Mounting Surface and Interface

3.1 Mounting Surface for End Effector

The mounting surface for end effector on the wrist end is shown in Figure 3-1.

C18UE001-1804

Figure 3-1 Mounting surface for end effector

3.2 Pneumatic Interface

Pneumatic holes (AIR IN & AIR OUT) are installed on the rear of J1 as shown in Figure

3-2. The outer diameter of the air tube in the robot is 4mm and the secure holes for the nozzle

are M5×0.8P.

Figure 3-2 Pneumatic interface

C18UE001-1804

3.3 I/O Interface

I/O interface for end effector on J5 and the pin assignment of I/O connector are shown in

Figure 3-3. Figure 3-4 to Figure 3-7 show the wiring diagram of I/O interface.

A

A side view

Figure 3-3 Pin assignment of the I/O connector (Power output: 24V/1A)

Figure3-4 Wiring diagram of input (Standard: Sinking type)

C18UE001-1804

Figure 3-5 Wiring diagram of input (Optional: Sourcing type)

Figure 3-6 Wiring diagram of output (Standard: Sinking type)

C18UE001-1804

Figure 3-7 Wiring diagram of output (Optional: Sourcing type)

Pin 1 and pin 9, which are 24V/1A, are used for signal,

not for power input of end effector.

The maximum output current at each pin is 100mA.

C18UE001-1804

4. Zero-Position

4.1 Zero Position Setting

The calibration tools for setting Zero-position are shown in Figure 4-1. The robot is

adjusted to the minimum speed during the calibration, and aligns the pinhole with the

calibration tool to set up the Zero-position. The procedure of resetting Zero-position with the

calibration tools is shown below.

Figure 4-1(a) 4-1(b) 4-1(c)

Calibration tool (A) Calibration tool (B) Calibration tool (C)

Figure 4-1 The calibration tool set

J1-axis Zero-position setting

Step1. Secure the calibration tool (A) on J1-axis by using positioning pin and screws.

Step2. Operate J1 at low speed to align the positioning surface of J2 with the calibration

tool (A).

Step3. Finish calibration and remove the calibration tool (A).

Step4. Clear encoder by HRSS. (Refer to page 34)

Step5. Zero position etting of J1-axis is completed.

Calibration tool(A)

Hexagon socket cap screw

M5x0.8Px6L (Nickel plated)

Positioning pin

Figure 4-2 Illustration of J1-axis Zero-position setting

Positioning surface

J2-axis Zero-position setting

Step1. Operate J2 at low speed to align the pinhole of J3 with the pinhole of J2.

Step2. Insert the calibration tool (B) to the pinhole to calibrate Zero-position.

Step3. Finish calibration and remove the calibration tool.

Step4. Clear encoder by HRSS. (Refer to page 34)

Step5. Zero position etting of J2-axis is completed.

C18UE001-1804

Calibration tool(B)

Pinhole

Figure 4-3 Illustration of J2-axis Zero-position setting

J3-axis Zero-position setting

Step1. Operate J3 at low speed to align the pinhole of J4 with the pinhole of J3.

Step2. Insert the calibration tool (B) to the pinhole to calibrate Zero-position.

Step3. Finish calibration and remove the calibration tool.

Step4. Clear encoder by HRSS. (Refer to page 34)

Step5. Zero-position setting of J3-axis is completed.

Calibration tool(B)

Pinhole

Figure 4-4 Illustration of J3-axis Zero-position setting

J4-axis Zero-position setting

RT605-710-GB J4-axis Zero-position setting

Step1. Operate J4 at low speed to align the keyway of J5 with the keyway of J4.

Step2. Insert the calibration tool (C) to the keyway to calibrate Zero-position.

Step3. Finish the calibration and remove the calibration tool.

Step4. Clear encoder by HRSS. (Refer to page 34)

Step5. Zero-position setting of J4-axis is completed.

C18UE001-1804

Calibration tool(C)

Keyway

Figure 4-5 Illustration of J4-axis Zero-position setting

RT605-909-GB J4-axis Zero-position setting

Step1. Operate J4 at low speed to align the keyway of J5 with the keyway of J4.

Step2. Insert the calibration tool (C) to the keyway to calibrate Zero-position.

Step3. Finish the calibration and remove the calibration tool.

Step4. Clear encoder by HRSS. (Refer to page 34)

Step5. Zero-position setting of J4-axis is completed.

Calibration tool(C)

Keyway

C18UE001-1804

J5-axis Zero-position setting

Step1. Operate J5 at low speed to align the pinhole of J6 with the pinhole of J5.

Step2. Insert the calibration tool (B) to the keyway to calibrate Zero-position.

Step3. Finish the calibration and remove the calibration tool.

Step4. Clear encoder by HRSS. (Refer to page 34)

Step5. Zero-position setting of J5-axis is completed.

Calibration tool(B)

Pinhole

Figure 4-6 Illustration of J5-axis Zero-position setting

J6-axis Zero-position setting

Step1. Operate J6 at low speed to align the calibration mark of end effector with the

mark of J6.

Step2. Clear encoder by HRSS. (Refer to page 34)

Step3. Zero-position setting of J5-axis is completed.

Calibration mark

Figure 4-7 Illustration of J6 -axis Zero-position setting

Clear encoder by HRSS

Step1. Select the “JOINT” as the coordinate system.

Step2. Move the robot to the Zero-position. (Refer to section 4.1)

Step3. Click Main Menu>>Start-up>>Master>>Clear Encoder.

(As shown in Figure 4-8)

Step4. Double click the axis to clear encoder. (As shown in Figure 4-8)

C18UE001-1804

Figure 4-8 Clear encoder by HRSS

C18UE001-1804

5. Maintenance and Inspection

This chapter presents the maintenance and periodical inspection procedures to maintain the robot

for a reasonable service life. It includes the cover removal and installation, inspection and

replacement of the timing belt, lubrication position, the procedures for replacing the battery, and other

notes.

[Note 1] The operating time of the robot is defined as 3840 hours per year. When using the robot

beyond this operating time, correct the maintenance frequencies shown in this chapter by calculation

in proportion to the difference between the actual operating time and 3840 hours per year.

5.1 Periodic Inspection Items

The daily inspection items before the robot operation are shown in Table 5-1.

Table 5-1 Daily Inspection Items

Are any of the robot installation screws,

1

cover installation screws and end effector

installation screws loose?

Are all the cables securely connected? Such

as the power and signal cable, grounding

2

cable, the cable for teach pendant and the

cable connected the robot and other

equipment.

Is the pneumatic system normal? Are there

3

any air leak, drain clogging or hose damage?

Is the air source normal?

Inspection item Remedy

Before turning power ON

After turning power ON

Securely tighten the screws.

Securely connect.

Drain the drainage system and replace the

leaking component.

1. The robot installation screws might not be

securely tightened to the installation surface.

Securely tighten the screws.

2. If the roughness of the installation surface is

uneven, modify the installation surface to the

Check whether the robot moves smoothly

1

without vibration and noise.

reasonable surface roughness.

3. The base might not be sufficiently rigid.

Please replace the base to make it more

rigid.

4. There might be foreign material between the

robot and the installation surface. Please

remove it.

C18UE001-1804

5. Some operating positions might exceed the

mechanism limit. Please reduce the load,

speed or acceleration.

6. The timing belt might loosen or not be in

correct position. Please replace or adjust the

timing belt. (Refer to section 5.2.2)

7. If the grease of the reducer has not been

changed for a long period. Please change the

grease. (Refer to section 5.2.3)

8. If the bearing or the reducer has been

damaged by the rolling surface or the gear

tooth surface. Please contact HIWIN directly.

1. The Zero-position of the robot might be

rewritten. Please set the Zero-position. (Refer

to section 4.1)

2. The Zero-position data will be lost if the

backup batteries is dead. Please replace the

2 The repeatability is not within the tolerance.

backup batteries (Refer to section 5.2.1) and

set the Zero-position. (Refer to section 4.1)

3. The Robot J1 base retaining bolt might

loosen. Please apply LOCTITE and tighten it

to the appropriate torque.

The project and time of periodic inspection refer to Table 5-2.

Table 5-2 Periodic inspection items

Inspection item Remedy

Inspection item A (1 month / 320 hours)

Check if there are any cracks and flows on

1

Clean and check each part of the robot.

the robot.

Inspection item B (3 months / 960 hours)

Check the ventilation system of the

If it is dusty, turn off the power and clean the

1

controller.

ventilation system of the controller

Inspection item C (6 months / 1920 hours)

Adjust the tension of the timing belt. If the

1 Check whether the timing belt is normal.

friction at the timing belt is severe, replace it.

Refer to section 5.2.2.

Inspection item D (1year / 3840 hours)

C18UE001-1804

1 Replace the backup battery in the robot.

Replace the backup battery. Refer to section

5.2.1

Inspection item E (3years/11520hours)

1 Change the lubrication grease of the reducer. Change the grease. Refer to section 5.2.3.

It is normal that the belt produces debris during operation,

but if it happens right after cleaning the belt, it is

recommended to replace the belt.

Table 5-3 Inspection schedule

C18UE001-1804

5.2 Repair

5.2.1 Backup Batteries Replacement

The absolute encoder of the motor is used to record the position of the robot. When the

controller power is turned off, the position data of each -axis is preserved by the backup batteries.

The batteries are installed when the robot is delivered from the factory. If the batteries are in use,

the annual change of batteries is needed. The service life of the batteries depends on the operating

conditions of the robot. In order to avoid the loss of position data, the batteries need to be

changed by the user periodically. The procedure for replacing the batteries of the robot is shown

in Figure 5-1 and described as below.

Step1. Press the emergency stop button to prohibit the movement of the robot motion.

Step2. Ensure the robot and controller are connected with the cables. Keep the power ON.

Step3. Please remove the battery cover. the screws for battery cover are hexagon socket

screws (M3×0.5P×6L) and the four batteries are 3.6V.

Step4. Replace the battery one by one. If all batteries are removed in the same time, the

position data will be lost. If so, please reset the robot to the Zero-position. All batteries

should be changed at one time. Please prevent the old batteries are included.

Step5. After replacing the battery, ensure to install the battery cover to prevent the robot being

damaged by dust and grease.

All batteries should be changed at one time. If the old

batteries are included, the service life of the batteries may

be reduced.

Battery cover

Rubber seal

Cover screw

Figure 5-1 The backup batteries replacement

C18UE001-1804

5.2.2 Timing Belt Replacement

The timing belt is used in the robot for the driver system of the J5 and J6 -axis. Although the

belt tension has been adjusted before the robot delivery, the timing belt will wear depending on the

working conditions. The belt tension might be lower than the standard after operating for a long time.

The timing belt should be periodically checked, maintained and replaced.

Timing Belt replacement period

Check the timing belt about every 6 months. The timing belt must be replaced if the belt teeth is

found cracked, worn to approximately half of the tooth width, or broken.

When replacing the belt, the robot system origin may deviate.

In this case, the position data must be rechecked if the origin

is offset. Please refer to section 4.1 for Zero-point setting.

Belt Tension

It is very important to keep proper belt tension. The belt tooth jumping will happen if the belt

tension is too loose. If the belt tension is too tight, it will cause damage to the motor or bearing.

Measuring methods of the belt by using fingers or tools are shown in Figure 5-2. The sonic tension

meter is used to measure the belt tension. The specifications and standard tension of belt are shown

in Table 5-4.

Belt width

Span

Sonic tension meter

Figure 5-2 Belt tension measurement

It is normal that the belt produces debris during operation,

but if it happens right after cleaning the belt, it is

recommended to replace the belt.

Table 5-4 The belt specifications

Axis Model name Belt type Width(mm) Span(mm) Tension(N)

C18UE001-1804

2

RT605-909-GB 375-5GT-9

RT605-710-GB 440-5GT-9

RT605-710-GB 365-5GT-9

3

RT605-909-GB 635-5GT-9

5

6

Common 285-3GT-6

Common

117.5

9

116.9

154.9

9

254.9

6

285-3GT-6

If the belt of J1 and J4 need to be replaced, please contact

HIWIN.

6

100.3

100.3

55

55

29

29

Cover removal

Before replacing the belt, remove the cover of J3 and J5 as shown in Figure 5-3.

C18UE001-1804

Figure 5-3 Cover removal diagram

Inspection, maintenance and replacement of timing belt in J2-axis.

Figure 5-4 shows the structure of J2-axis.

Screws for motor flange

Tension adjusting nut

Tension adjusting screw

Belt pulley

Belt

Figure 5-4 J2-axis structure diagram

Belt pulley

C18UE001-1804

Inspect J2-axis timing belt

Step1. Ensure the power of controller is switched off.

Step2. Remove the cover of J3.

Step3. Check whether the timing belt is normal.

Step4. If the timing belt is abnormal, refer to the following paragraph to replace the

timing belt.

Step5. If the belt tension is lower than the standard, refer to the following paragraph to

adjust the belt tension.

Adjust J2-axis timing belt

Step1. Loose the two fixing screws on motor flange, so that the motor can be move.

No need to remove the screws.

Step2. Refer to Table 5-4, loosen or tighten the adjusting screw to adjust the tension of

the belt.

Step3. Tighten the two fixing screws on motor flange.

Replace J2-axis timing belt

Step1. Remove the two fixing screws on motor plate.

Step2. Loose the adjusting screw to replace the timing belt.

Step3. After replacing the belt, refer to the paragraph “Adjust J2-axis timing belt”

above to adjust the tension of the belt.

Inspection, maintenance and replacement of timing belt in J3-axis.

Figure 5-5 shows the structure of J3-axis.

Tension adjusting screw

Tension adjusting nut

Belt pulley

belt

Screws for motor flange

Belt pulley

Figure 5-5 J3-axis structure diagram

C18UE001-1804

Inspect J3-axis timing belt

Step1. Ensure the power of controller is switched off.

Step2. Remove the cover of J3.

Step3. Check whether the timing belt is normal.

Step4. If the timing belt is abnormal, refer to the following paragraph to replace the

timing belt.

Step5. If the belt tension is lower than the standard, refer to the following paragraph to

adjust the belt tension.

Adjust J3-axis timing belt

Step1. Loose the two fixing screws on motor flange, so that the motor can be move.

No need to remove the screws.

Step2. Refer to Table 5-4, loosen or tighten the adjusting screw to adjust the tension of

the belt.

Step3. Tighten the two fixing screws on motor flange.

Replace J3-axis timing belt

Step1. Remove the two fixing screws on motor plate.

Step2. Loose the adjusting screw to replace the timing belt.

Step3. After replacing the belt, refer to the paragraph “Adjust J3-axis timing belt”

above to adjust the tension of the belt.

Inspection, maintenance and replacement of timing belt in J5-axis.

Figure 5-6 shows the structure of J5-axis.

Belt pulley

Belt

Belt pulley

Screws for motor flange

Figure 5-6 J5-axis structure diagram

Tension adjusting screw

C18UE001-1804

Inspect J5-axis timing belt

Step1. Ensure the power of controller is switched off.

Step2. Remove the cover of J5.

Step3. Check whether the timing belt is normal.

Step4. If the timing belt is abnormal, refer to the following paragraph to replace the

timing belt.

Step5. If the belt tension is lower than the standard, refer to the following paragraph to

adjust the belt tension.

Adjust J5-axis timing belt

Step1. Loose the two fixing screws on motor flange, so that the motor can be move.

No need to remove the screws.

Step2. Refer to Table 5-4, loosen or tighten the adjusting screw to adjust the tension of

the belt.

Step3. Tighten the two fixing screws on motor flange.

Replace J5-axis timing belt

Step1. Remove the two fixing screws on motor plate.

Step2. Loose the adjusting screw to replace the timing belt.

Step3. After replacing the belt, refer to the paragraph “Adjust J5-axis timing belt”

above to adjust the tension of the belt.

Inspection, maintenance and replacement of timing belt in J6-axis.

Figure 5-7 shows the structure of J6-axis.

Screws for motor flange

Tension adjusting screw

Belt pulley

Belt

Belt pulley

Figure 5-7 J6-axis structure diagram

C18UE001-1804

Inspect J6-axis timing belt

Step1. Ensure the power of controller is switched off.

Step2. Remove the cover of J5.

Step3. Check whether the timing belt is normal.

Step4. If the timing belt is abnormal, refer to the following paragraph to replace the

timing belt.

Step5. If the belt tension is lower than the standard, refer to the following paragraph to

adjust the belt tension.

Adjust J6-axis timing belt

Step1. Loose the two fixing screws on motor flange, so that the motor can be move.

No need to remove the screws.

Step2. Refer to Table 5-4, loosen or tighten the adjusting screw to adjust the tension of

the belt.

Step3. Tighten the two fixing screws on motor flange.

Replace J6-axis timing belt

Step1. Remove the two fixing screws on motor plate.

Step2. Loose the adjusting screw to replace the timing belt.

Step3. After replacing the belt, refer to the paragraph “Adjust J6-axis timing belt”

above to adjust the tension of the belt.

5.2.3 Grease Replenishment

The grease inlets and the air vents are shown in Figure 5-8.

Bevel gear air outlet

J6-axis air outlet

C18UE001-1804

J5-axis air outlet

J4-axis air outlet

J3-axis air outlet

J3-axis grease inlet

J2-axis grease inlet

J2-axis air outlet

J1-axis grease inlet

J1-axis air outlet

J6-axis grease inlet

Bevel gear grease inlet

J4-axis grease inlet

J5-axis grease inlet

A side view

Figure 5-8 Lubrication and air inlet/outlet positions

Grease specification

Table 5-5 shows the specification of grease.

Table 5-5 Grease specification

C18UE001-1804

Part

Lubrication grease Quantity

nipple

J1 reduction gear M6 SK-1A 93.3 ml

J2 reduction gear M5 SK-1A 66.6 ml

J3 reduction gear M5 SK-1A 33.3 ml

J4 reduction gear M5 SK-1A 20 ml

J5 reduction gear M5 SK-2 6.1 ml

J6 reduction gear M5 SK-2 6.1 ml

Bevel gear M5 SK-2 11.2 ml

[Note1] If the robot is not used for 2 years, replace the grease of each axis.

[Note2] The J3 cover needs to be removed for J2 grease replacement.

Grease

Procedure of grease replenishment

Step1. The grease inlets and the air outlets of the robot are shown in Figure 5-9.

Step2. Remove the screw of the grease inlet, and install the grease nipple.

Step3. Remove the screw of the air outlet.

Lubrication

interval

3Year

/11520Hr

Step4. Replenish the grease from the grease inlet by the grease gun.

Step5. Refer to Table 5-4 for the amount of grease.

Step6. Install the screw of the air outlet.

Step7. Remove the grease nipple, and install the screw of the grease inlet.

Grease nipple

Grease gun

Grease inlet

Figure 5-9 Grease replenishment

Loading...

Loading...