www.hiwin.tw

User Manual

SCARA Robot

- RS403

INDUSTRIE 4.0 Best Partner

Multi Axis Robot

Pick-and-place / Assembly /

Array and packaging / Semiconductor /

Electro-Optical industry /

Automotive industry / Food industry

• Articulated Robot

• Delta Robot

• SCARA Robot

• Wafer Robot

• Electric Gripper

• Integrated Electric Gripper

• Rotary Joint

Single Axis Robot

Precision / Semiconductor /

Medical / FPD

• KK, SK

• KS, KA

• KU, KE, KC

Direct Drive

Rotary Table

Aerospace / Medical / Automotive industry /

Machine tools / Machinery industry

• RAB Series

• RAS Series

• RCV Series

• RCH Series

Ballscrew

Precision Ground / Rolled

• Super S series

• Super T series

• Mini Roller

• Ecological & Economical

lubrication Module E2

• Rotating Nut (R1)

• Energy-Saving & Thermal-

Controlling (C1)

• Heavy Load Series (RD)

• Ball Spline

Linear Guideway

Automation / Semiconductor / Medical

• Ball Type--HG, EG, WE, MG, CG

• Quiet Type--QH, QE, QW, QR

• Other--RG, E2, PG, SE, RC

Medical Equipment

Hospital / Rehabilitation centers /

Nursing homes

• Robotic Gait Training System

• Hygiene System

• Robotic Endoscope Holder

Bearing

Machine tools / Robot

• Crossed Roller Bearings

• Ball Screw Bearings

• Linear Bearing

• Support Unit

AC Servo Motor & Drive

Semiconductor / Packaging machine

/SMT / Food industry / LCD

• Drives-D1, D1-N, D2

• Motors-50W~2000W

Driven Tool Holders

All kinds of turret

• VDI Systems

Radial Series, Axial Series, MT

• BMT Systems

DS, NM, GW, FO, MT, OM, MS

Linear Motor

Automated transport / AOI application

/ Precision / Semiconductor

• Iron-core Linear Motor

• Coreless Linear Motor

• Linear Turbo Motor LMT

• Planar Servo Motor

• Air Bearing Platform

• X-Y Stage

• Gantry Systems

Torque Motor

(Direct Drive Motor)

Inspection / Testing equipment /

Machine tools / Robot

• Rotary Tables-TMS,TMY,TMN

• TMRW Series

• TMRI Series

II

C07UE001-1804

Company: HIWIN Technologies Corp.

Address: No.7, Jingke Road, Taichung Precision Machinery Park,

Taichung 40852, Taiwan

Date: November 2017

Version: 2.0

Tel: +886-4-23594510

Fax: +886-4-23594420

E-mail: business@hiwin.tw

Website: http://www.hiwin.tw

Copyright: The contents in this manual are used for the authorized customers and

suppliers. This manual should not be copied, reproduced, transmitted in any form or

distributed on Internet without HIWIN’s authorization.

All Rights Reserved

© HIWIN Technologies Corp. All rights reserved

III

C07UE001-1804

Revision History

Version

Date

Remark

Ver1.0

2017/08

First issuance

Ver1.1

2017/11

Added the Ball Screw /Spline

lubrication

Ver1.2

2018/04

Added End-extending load

IV

C07UE001-1804

Table of Content

Table of Content ....................................................................................................... IV

Foreword .................................................................................................................... 6

About Manual ............................................................................................................ 6

Warranty ..................................................................................................................... 7

Notice Symbol ........................................................................................................... 8

Contact ....................................................................................................................... 9

Customer Service ....................................................................................................... 9

About Safety ............................................................................................................ 10

1 About Safety ......................................................................................................... 11

1-1 Operation ..................................................................................................... 11

1-2 Safety Symbol .............................................................................................. 12

1-3 Operation Notice .......................................................................................... 14

1-3-1 Run Alert Area ........................................................................................ 14

1-3-2 Temperature Error .................................................................................. 14

1-3-3 Flammability Alert.................................................................................. 14

1-3-4 Humidity Error ....................................................................................... 15

1-3-5 High Voltage ........................................................................................... 15

1-4 Emergency Stop ........................................................................................... 15

1-4-1 Robot Operation in Emergency Stop ...................................................... 15

2 Specifications........................................................................................................ 17

2-1 Features ...................................................................................................... 17

2-2 Model Name ................................................................................................ 17

2-3 Part Name and Dimensions .......................................................................... 18

2-4 Specification Table ....................................................................................... 21

3 Operating Environment ........................................................................................ 22

3-1 Install Robot ................................................................................................. 23

V

C07UE001-1804

3-2 Disassemble Package and Transport ............................................................ 24

4 Install End Effector ............................................................................................... 25

4-1 Installation Notice ........................................................................................ 25

4-2 Overview for Calculating Static Torque and Rotation Inertia ..................... 26

4-2-1 Calculate Static Torque ........................................................................... 26

4-2-1Calculate Rotation Inertia........................................................................ 29

Maintenance ............................................................................................................. 31

5 Robot Maintenance ............................................................................................... 32

5-1 Cover ............................................................................................................ 32

5-1-1 Disassemble Cover ................................................................................. 33

5-1-2 Install Cover ........................................................................................... 34

5-2 J3 & J4 Axes ................................................................................................ 35

5-2-1 Check J3 & J4 Belts ............................................................................... 36

5-3 Grease Lubrication ....................................................................................... 39

5-3-1 Lubrication of Ball Screw Spline ........................................................... 39

5-3-2 Decelerator Lubrication .......................................................................... 43

5-4 Wiring Panel ................................................................................................ 44

5-4-1 Replace Battery ...................................................................................... 44

5-5 Maintenance Period ..................................................................................... 46

6 Troubleshooting .................................................................................................... 47

6-1 Offset ............................................................................................................ 47

6-2 Overheat 47

6-3 Noise from Machine .................................................................................... 47

6-4 Jog Vibration ................................................................................................ 47

Opinion Response .................................................................................................... 49

6

C07UE001-1804

Foreword

Thank you for purchasing the Selective Compliance Assembly Robot Arm or

Selective Compliance Articulated Robot Arm (SCARA). This manual will provide the

method for installing and maintaining the machine, and protect a user life from

improper operation. A user should carefully read the description prior to the operation.

If the regulations are not followed to cause the machine damage or injury, a user must

take the related responsibilities. After you read this manual, please keep it well so that

can be read any time.

About Manual

This manual describes the SCARA Robot developed by HIWIN, whose structure

includes the body, the control panel, the Teaching Pendant (optional), the connection

cable and the software. A user who purchases the robot can operate and maintain the

robot via this manual.

This manual is suitable for the SCARA Robot only, which can be operated under

the ambient environment, but is not suitable for the related equipment and the

operating environment not mentioned in this manual, such as vacuum condition and

equipment involved in personal life.

7

C07UE001-1804

Warranty

The SCARA Robot is strictly tested and examined, and delivered to a customer

after its performance meets our requirements.

Warranty Period:

The product provides one-year warranty period from the day since it is delivered.

For the detailed terms and clauses of maintenance and repair, please contact the agent.

Warranty Content:

Disclaimer:

Even in the warranty period above-mentioned, the service will be charged when the

following items are met.

Guarantee the equipment delivered to customer.

In the warranty period, we provide free maintenance for failure during the

normal operation. The failure after the warranty period is expired will be

charged.

Failure and damage caused by incorrect operation different from the manual.

Reconstruct or remove the robot by yourself.

Failure and damage caused by improper adjustment/maintenance.

Failure and damage caused by act of God/fire/other factor.

If you operate the robot in the conditions or specifications beyond the manual,

we will not guarantee the basic performances.

We should not take any responsibility for human body (death or serious

injury)/damage incident/failure caused by not following “WARNINNG” and

“CAUTION” in this manual.

We can’t completely forecast all conditions for danger and failure. Such ability to

forecast shows the limit. Therefore, “WARNINNG”, “CAUTION” and other items in this

manual belong to the forecasting scopes.

8

C07UE001-1804

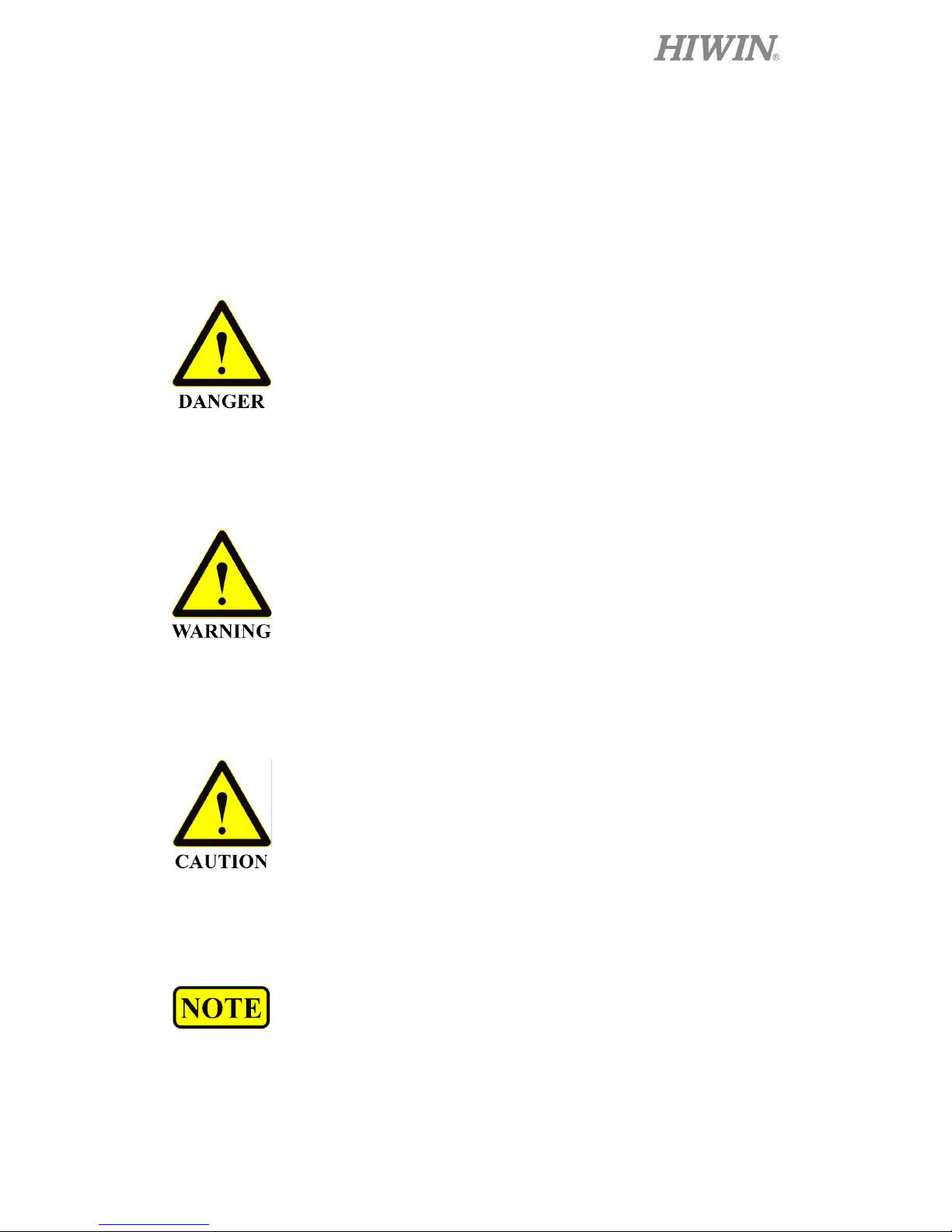

Notice Symbol

The symbols and warnings on the robot represent the danger in different extents

to remind a user of the safety concern during the operation, described as follows.

※DANGER symbol: represents an urgent danger. If it can’t be stopped and avoided

in time, the death or serious injury could take place.

※WARNING symbol: represents a potential danger condition. If it can’t be solved in

time, the injury or death could take place.

※CAUTION symbol: represents a potential danger. If it can’t be solved, the injury or

the intermediate incident will take place.

※NOTE symbol: represents a special purpose or a remark on the product, including

the mark qualified by the QC engineer.

9

C07UE001-1804

Contact

For the maintenance/examination/adjustment on the SCARA Robot, please contact

customer service.

Please prepare the following information when you contact us:

Customer Service

Customer hotline: +866-4-23594510

E-mail: business@hiwin.tw

System name/series number

Software name/version

Issue on the system

10

C07UE001-1804

About Safety

11

C07UE001-1804

1 About Safety

This chapter mainly describes the operation regulations about the SCARA Robot,

which not only provide the detailed operation information for a user and explain the

meaning for each alert symbol one by one, but also inform a user of the risk and the

emergency response during the operation.

1-1 Operation

For the sake of human body, the following regulations must be obeyed:

The robot can be operated or maintained by the trained and qualified operators.

Please carefully read the description in this manual, so that can efficiently and

safely operate the robot.

The operators must be familiar with the position, the function and operation for

safety switches.

Please ensure there are no obstacles stacked around the robot prior to the

operation.

Don’t open or remove the shelter on the robot.

Please ensure the circuit systems have been indeed grounded prior to the

operation.

Before you replace any circuit, all power must be disconnected to avoid electric

shock.

Please immediately disconnect the main switch during the power failure or

disconnection.

Don’t stain, scratch or move the warning label and product nameplate.

12

C07UE001-1804

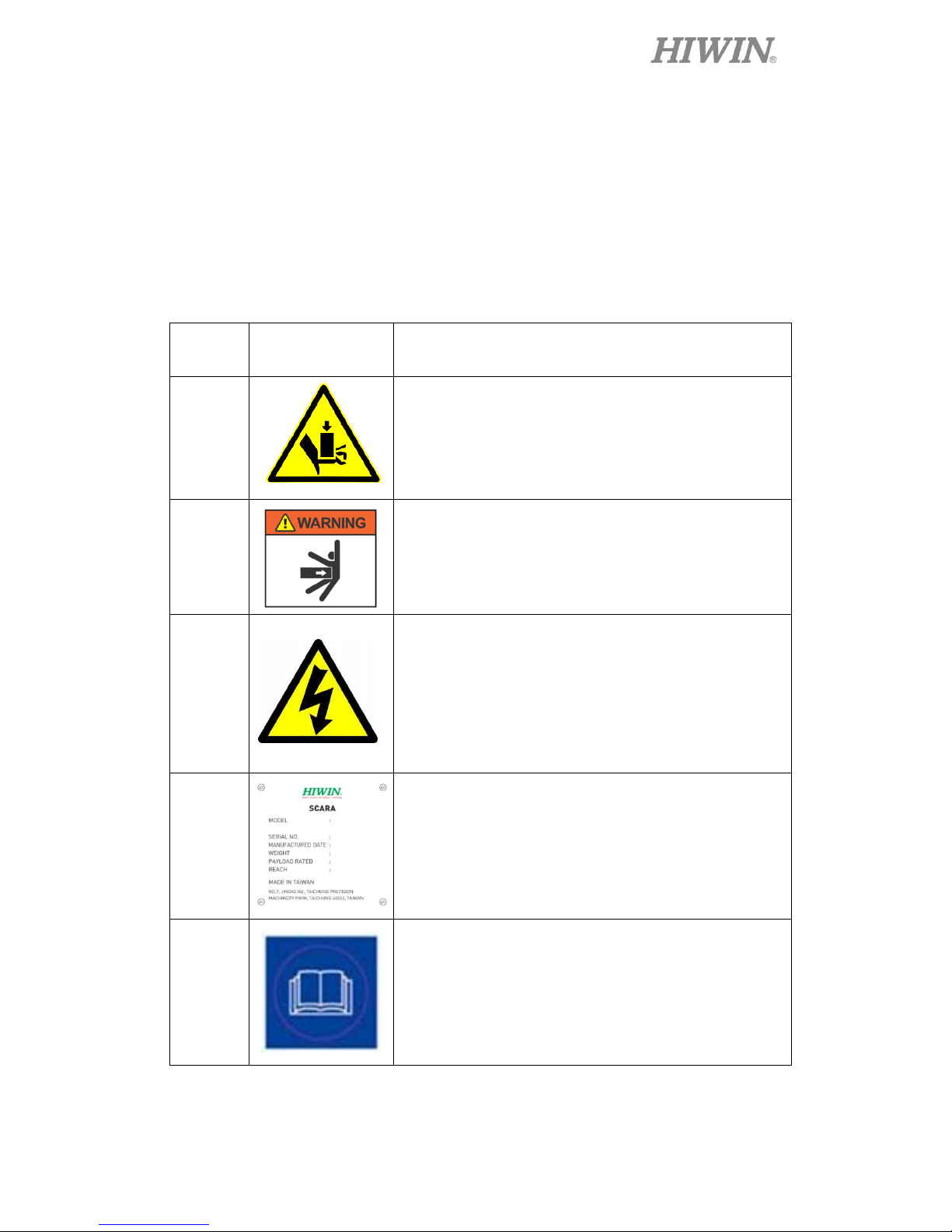

1-2 Safety Symbol

Each type of warning label is stuck on the robot and the control panel to remind a

user of operational safety. If the labels are stained or fallen, they must be indeed

cleaned or replaced.

Table 1-1 Safety Symbol

Sticking

position

Label pattern

Remark

A

The pinch label is stuck on the SCARA Robot. There are many

articulated joints on the robot. Please pay attention to your safety

during the operation and avoid pinch by accident.

B

There is a hit label on the SCARA Robot. Don’t enter the

operating area to avoid damage or injury when the robot is

operated.

C

There is a high voltage label on the SCARA Robot. Permissible

voltage and the maximum current for the robot are 1P

200~240VAC and 10A. A user needs to note the circuit has been

indeed grounded or there is any damage. When the robot is

removed or any pipe is replaced, please disconnect the power and

unplug the power connector to avoid electric shock.

D

Robot record. When the robot fails, you can provide the

information for the supplier.

E

If you have any problems on the robot, please carefully

read the Maintenance Manual, Software Manual or

contact our customer service. If the property loss and

life safety are caused by the personal factors, a user

must take responsibility.

13

C07UE001-1804

RS403-400-150-N

Figure 1-1 Illustration for Safety Symbol

Don’t remove the safety symbol. If it is lost, please contact

us or the agent.

14

C07UE001-1804

1-3 Operation Notice

1-3-1 Run Alert Area

The robot is a machine operating at high speed, whose maximum revolution radius

depends on the fixture size installed on the end. Before you operate the robot, please

ensure there is no any obstacle within the motion range, and indeed perform the

calibration to avoid collision and damage. When the robot is operated, the operator

should pay attention to the motion range for damage.

1-3-2 Temperature Error

When the robot is operated, the heat source comes from the electronic parts in the

control panel. There are the cooling fans on two side of the panel. The operator should

note the cooling fans normally run to prevent shutdown from overheating.

1-3-3 Flammability Alert

If you wipe the robot with volatile detergent or volatile chemicals are used in the

process, please ensure the temperature and the fan condition at any time to avoid a fire.

15

C07UE001-1804

1-3-4 Humidity Error

Electronic components in the robot and the control panel are made of metal materials,

which are more sensitive to the relative humidity of the operating environment.

Higher humidity will accelerate to oxidize the contacts of metal part and electronic

component, and loosen the assembly structure and cause poor contact; lower humidity

will easily generate static electricity and damage electronic components. It is

recommended the relative humidity in the ambient environment should be less than

50%.

1-3-5 High Voltage

1P 200~240VAC is supplied to the robot. Once electric leakage or touch by accident

takes place, it will cause serious injury or death. When you install the robot, you need

to check each connector is indeed connected, and ensure all circuits are not

excessively bent, even broken or damaged.

1-4 Emergency Stop

If you feel the robot failed during the operation, please immediately press the

EMERGENCY STOP button. When you press the EMERGENCY STOP button, the

arm will stop in the shortest distance by the controller and the motor brake.

Don’t press the EMERGENCY STOP button when the arm normally operates. If

you press EMERGENCY STOP button during the operation, it could hit the

peripherals and internal hardware to cause damage.

16

C07UE001-1804

The EMERGENCY STOP button is pressed in the urgent condition, not for

pause/run. If you want to stop the robot in the normal operation and the working path,

please operate it according to the software manual.

1-4-1 Robot Operation in Emergency Stop

When you press the EMERGENCY STOP button, please move the robot

according to the following methods. When you perform the operations abovementioned, please ensure the EMERGENCY STOP button on the robot is pressed and

indicated in flash.

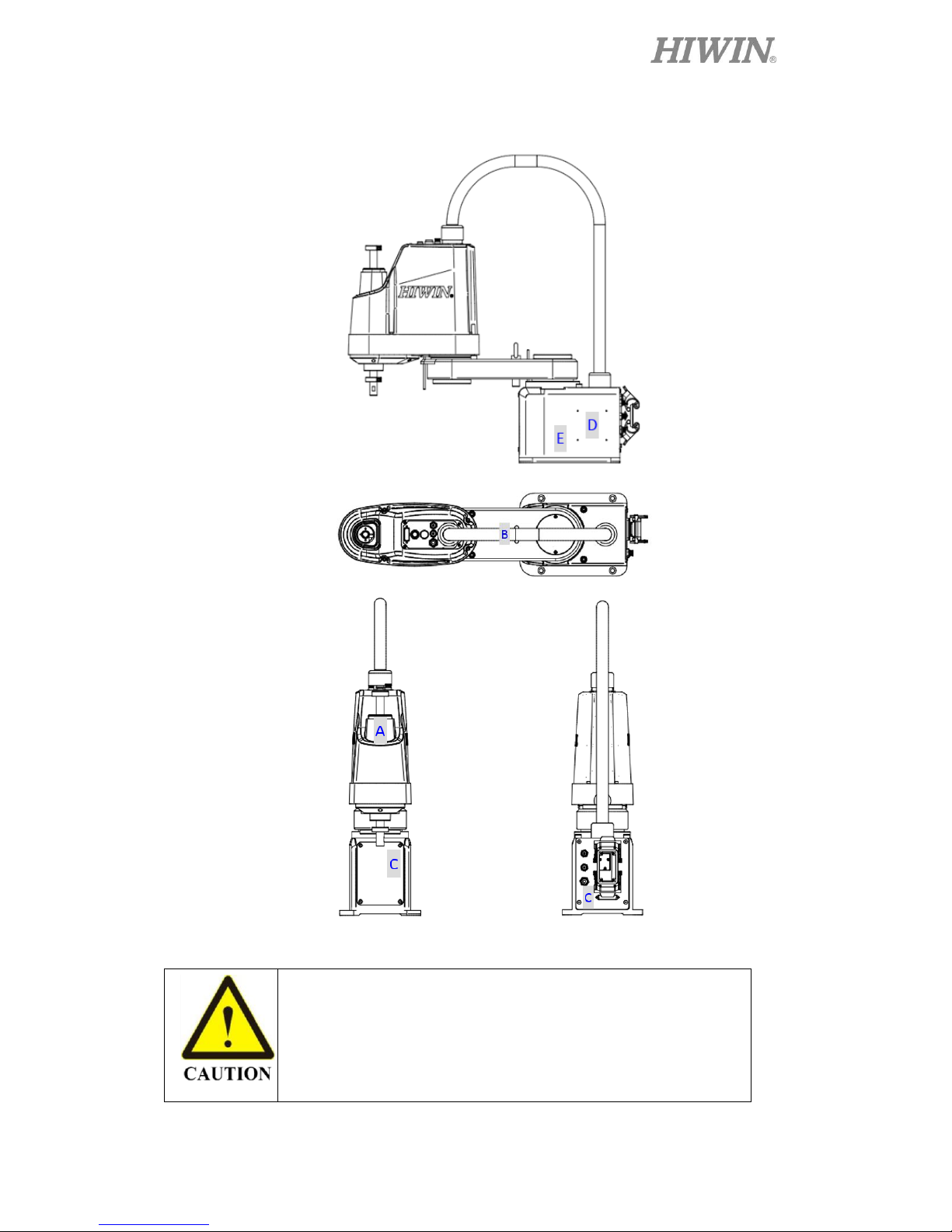

Figure 1-2 Illustration for Robot Axes

J1 axis: Move Arm A after you press the BRAKE RELEASE button.

J2 axis: Move Arm B after you press the BRAKE RELEASE button.

J3 axis: Rotate ball screw spline after you press the BRAKE RELEASE button.

J4 axis: Pull ball screw spline after you press the BRAKE RELEASE button.

Don’t apply excessive force to move the robot or quickly

rotate the parts after you press the EMERGENCY STOP

button. This condition could damage the robot.

Press the BRAKE RELEASE button after you press the

EMERGENCY STOP button to simultaneously release the

brake for four axes. Note that the object loaded on the end

could drop and cause injury or death owing to its weight.

J2 axis

BRAKE RELEASE button

Ball screw spline

J4 axis

J3 axis

Arm A

Arm B

17

C07UE001-1804

2 Specifications

2-1 Features

The SCARA Robot, suitable for the ambient environment, can be applied for

delivering and assembling the components, such as electronic parts. The maximum

permissible inertia can reach 0.05 kg-m2.

2-2 Model Name

RS403-400-150-N

The robot is operated in the standard environment. The

accessories with additional coating are installed on the

robot to prevent dust accumulation, which can be used

for food industry.

Model

:HIWIN

J4-axis stroke

150

:150 mm

Arm length

:400 mm

03

Maximum load

:3 kg

N

400

18

C07UE001-1804

2-3 Part Name and Dimensions

RS403-400-150-N

Figure 2-1 Part Names on Robot

Figure 2-2 Illustration from the Direction A of Figure 2-1

Arm A

Arm B

BRAKE

RELEASE

button

Status

Indicator

ψ4 pneumatic connector

ψ6 pneumatic connector

Ball screw spline

View from

Direction A

Base

ψ4 pneumatic connector

ψ6 pneumatic connector

power/signal line socket

19

C07UE001-1804

RS403-400-150-N

Figure 2-3 Part Dimensions for Robot

This dimension diagram is used for the reference, based

on the approved ones or the actual ones.

20

C07UE001-1804

RS403-400-150-N

Figure 2-4 Motion Range for Robot

All motion ranges in this diagram is used for the

reference. The dimensions are based on the approved

diagrams or the delivered machines.

The working range in this diagram doesn’t include the

end effector.

21

C07UE001-1804

2-4 Specification Table

This manual takes RS403-400-150-N for example, and describes the

performance and the specification of the robot, as shown in the following table.

Table 2-1 Specification Table for RS403-400-150-N

Specification Table

Model Number

RS403-400-150-N

Degree of Freedom

4

Payload

Rated

kg

1

Maximum

3

Maximum arm length

(Arm A, and Arm B)

mm

400

Maximum motion

range

J1

deg

±128

J2

deg

±130

J3

deg

±360

J4

mm

150

Cycle time

sec

0.42

Repeatability

J1+J2

mm

±0.01

J3

deg

±0.01

J4

mm

±0.01

Maximum axial speed

J1

deg/sec

600

J2

600

J3

2000

J4

mm/sec

890

Permissible rotation inertia

Rated

kg-m2

0.005

Maximum

0.05

Arm I/O

3 Output Point

3 Input Point

Pneumatic connector quantity/dimension

Ø 4 x 2

Ø 6 x 1

Arm weight (not including the control

panel)

kg

17

Input power

V/A

AC 220V

1P 50 / 60 Hz

Maximum pneumatic

input

Input pressure

kg / cm2

7

Vacuum pressure

1

22

C07UE001-1804

3 Operating Environment

Before you operate the robot, you must ensure the operating environment can

meet the related requirements to maintain the stability and lifetime.

Table 3-1 Operating Environment

Environmental

condition

Operating environment

Storage environment

Temperature

5℃~40℃

5℃~40℃

Relative humidity

Less than 50%

Less than 50%

Assembly platform

Table

None

Power system

1P 200~240VAC

None

Notice

Install indoors to keep away from direct sunlight.

Keep away from dust, mist, salt, metal powder or other

pollutants.

Keep away from flammable or corrosive solution and gas.

Keep away from the environment with water and high

moisture.

Keep away from impact or vibration.

Keep away from a source of electromagnetic interference.

The robot is not suitable in the coating environment. If it is

operated at the place where doesn’t meet the conditions

above-mentioned, please contact us or the agent.

The robot is operated only under the ambient environment.

The surface of the robot for the special condition must be

resistant to grease. If it could be stained with special grease,

please contact us or the agent to confirm in advance.

If the robot is operated in the environment with larger

temperature and humidity change, water condensation

could take place inside. When it is used to move food,

please contact us or the agent to ensure it will not pollute

food.

The robot can’t be operated in the acid or corrosive

environment. In addition, the body could be corroded in the

salty environment.

23

C07UE001-1804

3-1 Install Robot

When you install the robot, please lock with M8 bolts. The bolt specifications

need to meet ISO898-1:10.9 or 12.9. The base is installed on the lock surface. It is

recommended the thickness be 20mm or more, and be made of the steel material to

reduce the operating vibration. It is suggested the surface roughness be 25µm or less

than 25µm. The other assemblies are installed with appropriate tools in accordance

with the operating manual to avoid injury or damage by the improper operation.

When you install the robot, the working range must be taken into account. If the

end effector is installed, the maximum motion range will vary (depending on the

position and overhang of the end effector). Therefore, the safety area or the safety

fence will be changed, and the operators should not enter the area to avoid injury or

death when the robot operates.

Figure 3-1 Working Range for Robot

When you install the robot, please consider the motion

range (including the distance of end effector), and set up the

warning or safety fence.

The operators should not enter the area to avoid injury or

death when the robot operates.

Maximum motion range

(including the overhang distance of end effector)

Arm operating range

(not including end effector)

24

C07UE001-1804

3-2 Disassemble Package and Transport

The robot must be installed by the authorized engineer, and complied with the

national regulations. After you remove the package and take out the robot with a

protective bag, please transport it to the installation position by appropriate facilities.

The robot must be properly fixed during the transportation. The operator must note

the personal safety to prevent pinch or hurt from strong vibration or object.

The authorized staff can operate crane or forklift only.

When those without authorization perform the

operations above-mentioned, the surrounding operators

could be injured or the robot could be damaged.

Transport the robot with a cart.

The robot must be delivered by two operators or more

when transported with bard hands. The base, Arm A or

Arm B are held with two hands. Don’t pull black flexible

conduit or any connector.

When you adjust the position to install the robot, please

hold it with two hands so that it drops to pinch the

operator.

The robot must be indeed fixed on the transportation

facility to avoid collision, falling and damage when

transported in long distance.

25

C07UE001-1804

4 Install End Effector

4-1 Installation Notice

When you install the end effector, please obey the following items.

Figure 4-1 Recommended Installation Illustration for Ball End Effector

1. Don’t remove or change any mechanical stopper on the robot by yourself.

2. When you install the end effector on ball screw spline, please install it at

30mm on the lower end of ball screw spline and fix with the threaded

structure over M4.

3. When you install the end effector, please note weight, static torque and

rotation inertia are in the motion range. For the method to calculate static

torque and rotation inertia, please refer to 4-2 Overview for Calculating

Static Torque and Rotation Inertia.

If there are some doubts on weight, static torque and

rotation inertia, please contact us or the agent.

(30 mm End

effector clamp)

(Threaded structure)

26

C07UE001-1804

4-2 Overview for Calculating Static

Torque and Rotation Inertia

4-2-1 Calculate Static Torque

The permissible static torque for this robot is 90N.m, determined by M (torque)

= F (force) × L (end fixture/effector overhang plus total arm length), and must be less

than 90N.m. Please obey the operating condition. If the torque exceeds this value, the

performance and lifetime will be reduced.

Formula to calculate static torque:

M (torque) = F (force) × L (overhang plus total arm length)

Figure 4-2 Illustration for Calculating Static Torque of Robot End

Please calculate if permissible static torque is greater than

90N.m prior to the operation.

If the torque is greater than this value, the performance and

lifetime will be reduced.

Overhang

Total arm length

27

C07UE001-1804

Calculate Rotation Inertia

Rotation inertia is quantity used to indicate a force is against the rotation of an

object. When a fixture/an end effector are installed on the end of ball screw spline,

rotation inertia for the loaded device must be taken into account.

Please calculate if total rotation inertia at the end of ball

screw spline is within rated/maximum permissible inertia.

If rotation inertia is greater than the value, the performance

and lifetime will be reduced.

Rotation axis of ball screw spline

Fixture/end effector

Workpiece a

Workpiece b

Total rotation inertia at

the end of ball screw

=

Rotation inertia of

fixture/end effector

+

Rotation inertia

of Workpiece a

+

Rotation inertia

of Workpiece b

28

C07UE001-1804

The methods to calculate rotation inertia of an object are as shown in (a), (b) and

(c). Please refer to the methods to calculate rotation inertia for the basic shape, and

determine rotation inertia of the object.

(a) Rotation inertia of rectangle

(b) Rotation inertia of cylinder

(c) Rotation inertia of sphere

Mass

Center-of-gravity

position of

Offset distance

Rotation axis

Mass

Mass

Offset distance

Rotation axis

Center-of-gravity

position of cylinder

Rotation axis

Center-of-gravity

position of sphere

29

C07UE001-1804

End-extending load

The calculation of the end-extending load will vary depending on the shape of the

load. It is recommended that the actual calculation of the inertia be done.

Figure 4-3、 RS403-400-150-N arm end extension load diagram

Figure 4-4、 Load center of gravity and motor speed for 1KG load, spline length

330mm

Load center distance

30

C07UE001-1804

Figure 4-5、 Load center of gravity and motor speed for 3KG load, spline length

330mm

31

C07UE001-1804

Maintenance

32

C07UE001-1804

5 Robot Maintenance

In order to ensure the robot can efficiently operate and protect the operator safety,

please periodically maintain the robot according to the following sections. Don’t

disassemble the motor, decelerator and ball screw spline for the maintenance by

yourself to influence the accuracy of the robot. If there is any failure, please contact

the agent.

5-1 Cover

The cover is locked on the upper side of Arm B, which includes J2, J3 and J4

motors and three drive belts. You can remove the cover to check there are foreign

objects in Arm B, ball screw spline is damage and the belts are worn.

Please disconnect the power on the control panel and

unplug the power prior to the maintenance. Don’t make

any maintenance when the robot operates, so that can

avoid electric shock or improper operation.

In the period of maintenance, the robot should not contact

any objects to prevent electronic components from short

circuit or damage ball screw spline. Otherwise, the robot

could damage when the power is distributed.

Figure 5-1 Illustration of Part Name for Robot

Ball screw spline

Cable

Cover

Communication

Arm A

Arm B

Base

33

C07UE001-1804

5-1-1 Disassemble Cover

Step 01. Turn off the power on the control panel.

Step 02. Remove the external M4 and M3 screws.

Step 03. Disassemble the robot cover from down to up.

Step 04. Keep the screws well to avoid missing or damage.

Figure 5-2 Illustration of Dissembling Cover for Robot

Don’t force to disassemble the cover. Otherwise, it could

cause poor cable contact or damage as well as electric

shock or robot failure.

Don’t remove the cable sleeve when you disassemble the

cover, and avoid excessively pulling it so that the circuit

drops or breaks to cause the robot failure.

Don’t continuously apply force and heavily press/push to

the cover protrusion. Otherwise, it could break or

damage.

4-M3 flat washer

4-M4 flat washer

34

C07UE001-1804

5-1-2 Install Cover

Note that the internal circuits are excessively bent when

you install the cover. Otherwise, it could cause poor cable

contact or damage.

Note that ball screw spline is interfered with the cover

when you install the cover, and the screws are fastened

to complete the installation.

Step 01. Turn off the power on the control panel.

Step 02. Install the robot cover from up to down.

Step 03. Ensure the cover doesn’t interfere with any parts and pipes.

Step 04. Fasten the external M4 and M3 screws.

35

C07UE001-1804

5-2 J3 & J4 Axes

J3 & J4 axes employ 100W servo motors. With the link of the belt wheel and the

belt, the rotational and linear motions of ball screw spline are controlled. A user can

remove the cover to check there is any failure inside the Arm B.

Please press the Emergency Stop button before the

maintenance. Don’t make any maintenance when the

robot runs, so that the operators could be hit or the

incorrect run could take place.

Don’t remove J3 & J4 motors without the authorization

to influence the running accuracy of the robot.

36

C07UE001-1804

5-2-1 Check J3 & J4 Belts

There are three drive belts, 2 for J3 axis and one for J4 axis, installed in the robot,

which are used to link the servo motor and ball screw spline. A user must periodically

check the belts are worn, and confirm the belt tension meets the requirements to

ensure the robot can efficiently run.

Table 5-1 J3 and J4 Belts

Name

Quantity

Remark

Part

J3 Belt (ball end)

Width:

15mm

1

150-S2M-300

J3 Belt (motor end)

Width:

10mm

1

100-S2M-172

J4 Belt

Width:

10mm

1

100-S3M-396

Tool

Allen wrench

1

M4 screw

(recommended torque: 55kgf-

cm)

Tension meter

1

Belt tension

J3 (motor end): 30~40N,

J3 (ball end): 45~55N,

J4: 45~55N

Parameter

J3 Belt (ball end)

M=1.3 g/m, W=15mm, S= 86 mm (Note 1)

J3 Belt (motor end)

M=1.3 g/m, W=10mm, S= 44 mm (Note 1)

J4 Belt

M=1.9 g/m, W=10mm, S=124 mm (Note 1)

Note: M (unit mass), W (belt width), and S (line length)

Step 01. Turn off the power on the control panel.

Step 02. Disassemble the robot cover (Please see 5-1-1 Disassemble Cover.).

Step 03. Press the Emergency Stop button after the power is supplied.

Step 04. Slightly release the screws for J3 and J4 plates.

Step 05. Adjust the motor plate.

Step 06. Use the tension meter to measure the belt tension

37

C07UE001-1804

J3 (motor end): 30N~40N, J3 (ball end): 45N~55N, J4: 45N~55N.

Step 07. Hold the Release Brake button, and push ball screw spline upwardly and

backwardly to ensure the tension in each section meets the requirement.

Step 08. Check the motors of J3 and J4 axes as well as screws for middle wheel.

Step 09. Turn off the power on the control panel.

Step 10. Install the robot cover.

RS403-400-150-N Belt Tension Adjustment

Figure 5-3 Illustrations for Adjusting Belt Tension

J4 plate

Direction to adjust belt tension

Direction to adjust

belt tension

Direction to adjust

belt tension

J3 plate

Middle wheel of

J3 plate

38

C07UE001-1804

5-3 Grease Lubrication

There are many movable joints and parts on the SCARA Robot. The decelerator

and ball screw spline must be periodically serviced and maintained. Because ball

screw spline is exposed in the open environment for long time to easily accumulate

dust or insufficiently lubricate, a user must pay more attention so that the robot can

efficiently operate.

5-3-1 Lubrication of Ball Screw Spline

Ball screw spline is used for the rotation (J3-axis) and linear (J4-axis) motion of

the robot, supported by two sets of nut respectively. The bearing in the nut needs to be

periodically greased with HIWIN (G04), and the external grooves of ball screw spline

must be kept clean. It is recommended ball screw spline be cleaned and maintained

every three months to keep smoothly running.

Please press the Emergency Stop button and disconnect

the power prior to the maintenance. Don’t make any

maintenance when the robot operates, so that can avoid

electric shock or improper operation.

Don’t remove ball screw spline without the authorization

to influence the running accuracy of the robot.

Table 5-2 Lubrication of Ball Screw Spline

Lubrication part

Item

Check

Operation

Roller spline

bearing

Lubrication

Check once per

three month

when the

running distance

reaches 200km.

Fill new lubricant into the nut

nozzle (M3), and remove old

grease.Recommended fill: 2c.c.

Flat spline bearing

Fill new lubricant into the nut

nozzle (M3), and remove old

grease.Recommended fill: 2c.c.

Ball screw spline

Uniformly apply grease on the

screw surface in the grooves.

39

C07UE001-1804

Illustration for RS403-400-150-N Lubrication of Ball Screw Spline

Figure 5-4 Illustration for Lubricating Ball Screw Spline

4-M3 flat washer

4-M4 flat washer

Lubricate the surface

of ball screw spline

and the grooves with

HIWIN (G04)

Roller screw nut

Filler

Grease HIWIN (G04)

Straight screw nut

Filler

Grease HIWIN (G04)

40

C07UE001-1804

Table 5-3 Lubrication of Ball Screw Splin

Figure 5-5 Illustration for Lubricating Ball Screw Spline

Lubrication

part

Item

Check

Operation

Roller

spline

bearing

Lubrication

Check once per

three month

when the

running

distance

reaches

200km.

Fill new lubricant into the nut opening (Ø 1.5),

and remove old grease.Recommended fill: 2c.c.

Flat spline

bearing

Fill new lubricant into the nut opening (Ø 1.5),

and remove old grease.Recommended fill: 2c.c.

Ball screw

spline

Uniformly apply grease on the screw surface in

the grooves.

41

C07UE001-1804

5-3-2 Decelerator Lubrication

The base, the Arm A and the Arm B of the robot are linked by the decelerator to

provide the rotation motion for J1 and J2 axes. Because the lubricant is fully covered

in the decelerator, the insufficient lubrication will not take place. However, the tear

and wear of the mechanical structure could make noise from the decelerator, even

poor position accuracy, please contact the agent as soon as possible.

The decelerator should be disassembled by he trained or

authorized engineers only to avoid the accuracy and lifetime of

the robot.

The lubricant should be replaced by the trained or authorized

engineers only to avoid the accuracy and lifetime of the robot.

Table 5-4 Decelerator Lubrication

Area to

apply

grease

Operation

Reference Diagram

Flexible

bearing

grooves

Fill the roller space with grease.

Decelerator

body

1. Remove old grease in the

wall of the flexible wheel,

and fill in new one.

2. Fill new grease in the groove

of the rigid wheel (fill via the

gear gap).

3. For grease filling, please

refer to Table 5-4.

Maintenance Item

Period

Operation

Replacement of

decelerator lubricant

Running up to 6000 hours

or per 18 months

Described as Table 5-3

Check on back

clearance of

decelerator

Per 2.5 years

New parts should be replaced

if the clearance is greater than

the permissible value.

Wheel groove

Ball groove

Inner wall of

Wheel(fill by

tandard)

42

C07UE001-1804

Table 5-5 Grease Fill

Specification

Grease capacity

Unit

J1

J2

Inner wall of flexible wheel

g

21~27

21~27

Groove of rigid wheel

g 6 6

A (reference dimension)

mm 3 3

L (reference dimension)

mm

38~41

38~41

Description to disassemble RS403-400-150-N decelerator

Steps to disassemble the decelerator

Step 01. Turn off the power on the control panel.

Step 02. Remove the screws on the Arm A.

Step 03. Remove the M6 screws and washer for Arm A.

Step 04. Remove the M5 screws and washer for the decelerator and the motor plate.

Step 05. Disassemble the decelerator upwardly in the vertical direction.

Figure 5-6 Illustrations of Dissembling Decelerator for Robot J1

Please keep each origin part and component when you

disassemble the decelerator. Don’t assemble the decelerator with

non-origin parts.

The decelerator should be disassembled and installed by the

trained or authorized engineer.

M3 screw

M5 screw

Arm A

Decelerator

Cover

Washer

Washer

M6 screw

M5 screw

Wave generator

43

C07UE001-1804

Disassemble the decelerator for Arm B

Step 01. Turn off the power on the control panel.

Step 02. Remove the screw cover on the Arm A.

Step 03. Remove M6 screws on the bottom of Arm A.

Step 04. Remove the Arm B.

Step 05. Remove the M5 screws and washer for the decelerator and the Arm B.

Step 06. Disassemble the decelerator upwardly in the vertical direction.

Figure 5-7 Illustrations of Dissembling Decelerator for Robot J2

Please keep each origin part and component when you

disassemble the decelerator. Don’t assemble the decelerator

with non-origin parts.

The decelerator should be disassembled and installed by the

trained or authorized engineer.

M5 screw

M3 screw

M6 screw

Flat washer

Decelerator

Wave generator

Screw cover

Safety washer

44

C07UE001-1804

5-4 Wiring Panel

There are the communication cables, pneumatic pipes and driver batteries in the

wiring panel. A user can replace the batteries by removing the cover, so that can

maintain the memory of the robot coordinate.

5-4-1 Replace Battery

The batteries, located on the internal side of the wiring panel, are used to record

the value of the driver at each axis after power failure takes place. A user must

periodically replace them to ensure the robot coordinates can be memorized.

Please press the emergency button and disconnect the

power prior to the maintenance. Don’t make any

maintenance when the robot operates, so that can avoid

hit or improper operation.

If the batteries are replaced when the power on the

control panel is not supplied, the coordinates at each axis

can’t be recorded. The robot home must be recalibrated.

The industrial lithium batteries are used for memory.

Don’t replace them with commercial alkaline or

rechargeable one.

45

C07UE001-1804

Step 01. Remove the wiring panel.

Step 02. Turn on the power on the control panel, and press the Emergency Stop button.

Step 03. Take out 4 batteries in order.

Step 04. Install new batteries in order (primary lithium battery 3.6V/2.4AH for

TADIRAN No. 3).

Step 05. Turn off the power on the control panel.

Step 06. Install Wiring Panel (please see).

Step 07. Turn on the power on the control power to test the coordinates at each axis.

Figure 5-8 Illustration for replace batteries

3.6 V battery

M4 screw

Front cover

46

C07UE001-1804

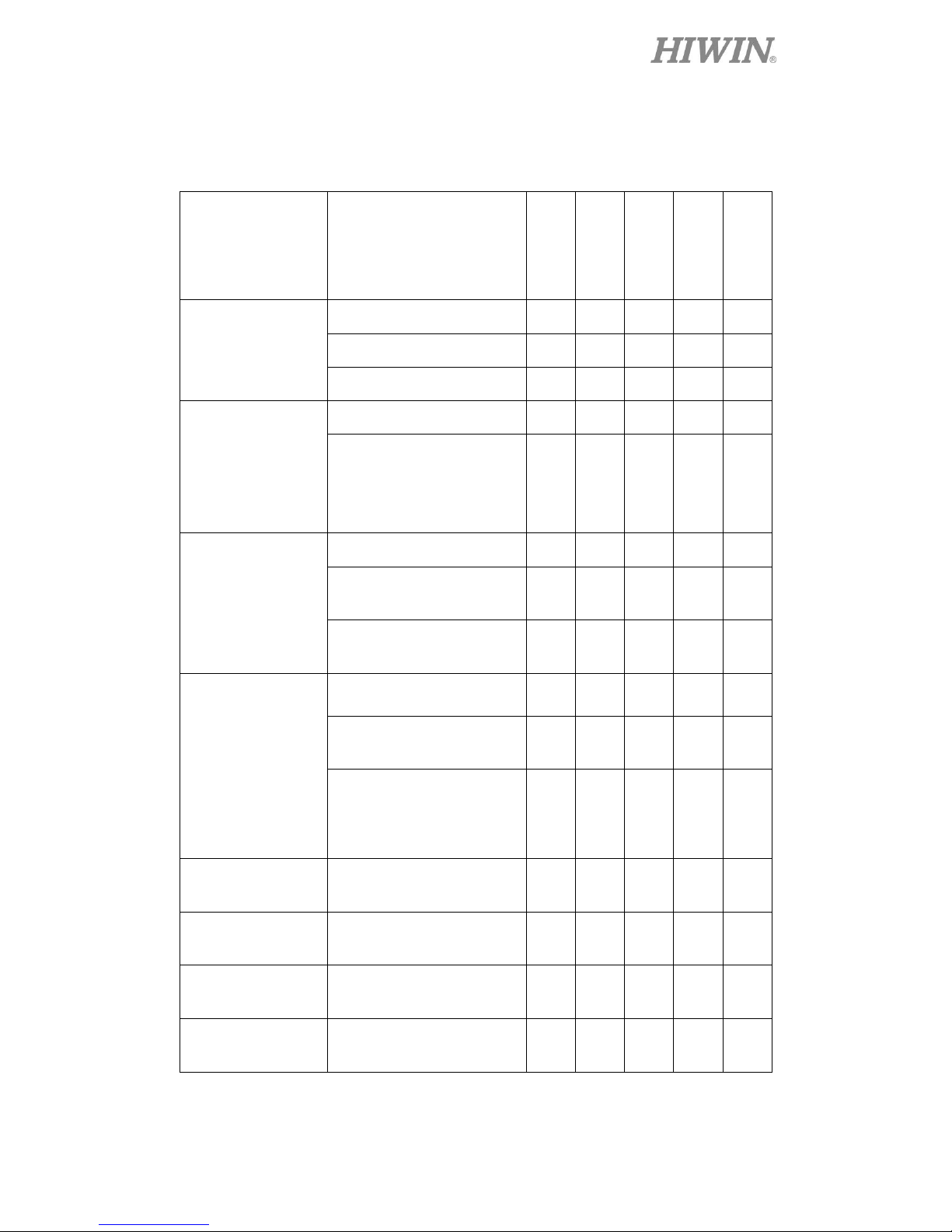

5-5 Maintenance Period

Contents related to service and maintenance

Check Item

Part Name

Daily Monthly Quarterly Twice a year Yearly

Check the

screws/bolts are

loose.

Base bolts

˅ ˅ ˅ ˅ ˅

Robot bolts

˅

Bots for ball screw spline

˅

Check the

communication

cables/power

cable connectors

are loose.

Communication cable

˅ ˅ ˅ ˅ ˅

Power cable connectors

for control panel

˅ ˅ ˅ ˅

Check the

appearance is

dirty or damaged,

and clean and

wipe it.

Robot appearance

˅ ˅ ˅ ˅ ˅

Appearance of

communication cable

˅ ˅ ˅ ˅ ˅

Appearance of control

panel

˅ ˅ ˅ ˅ ˅

Check the

communication

cables/power

cables/pneumatic

pipes are

excessively bent

or broken

Communication cables

˅ ˅ ˅ ˅ ˅

Power cables on control

panel

˅ ˅ ˅ ˅ ˅

Pneumatic cables

˅ ˅

Check belt tension

J3 and J4 axes (See:5-2-

1)

˅ ˅

Grease

Lubrication

ball screw spline (See:53-1)

˅ ˅ ˅

Grease

Lubrication

Decelerator (See:5-3-2)

*1

Replace Battery

Driver battery (See:5-4-

1)

˅

*1: For the maintenance time in each item, please follow 5-3-2.

47

C07UE001-1804

6 Troubleshooting

6-1 Offset

Upon the position is offset when the robot operates, please immediately stop all

operations and execute the home command, so that the robot can read the relative

position at each station. If the condition for the serious position offset can’t be

modified by resetting the home, please contact customer service for calibration.

6-2 Overheat

The robot is equipped with a mechanism of temperature protection. The incorrect

working temperature will influence the operations. A user must maintain the

appropriate environment temperature. As soon as the temperature rise in the system

takes place owing to the fan failure, the robot will stop the operation. Please contact

customer to replace the fan.

The motor drivers at each axis are equipped with a protection mechanism. The

high temperature or acceleration/deceleration will stop the operation of the robot. You

must recover the system setting by restarting it. A user can keep the robot normally

operating by changing the system setting.

Lower acceleration and velocity when the robot runs.

Reduce the time when the robot continuously runs.

6-3 Noise from Machine

The robot comprises several slide and rotation parts and components. It is

recommended a user periodically lubricate each part and component, so that the robot

can smoothly operate. As soon as noise is generated when the robot operates, please

contact customer service for check and maintenance.

48

C07UE001-1804

6-4 Jog Vibration

When you evaluate to operate the robot, please carefully read the specifications.

The efficiency of the robot depends on the fixtures or objects loaded on ball screw

spline. If the loads exceed the requirements, a user can maintain the normal operation

of the robot by changing the system setting or seek the assistance from customer

service.

Reduce acceleration and velocity when the robot operates.

Modify the fixture dimension and weight.

49

C07UE001-1804

Opinion Response

Issue

Actual condition

Use Advice:

E-mail: business@hiwin.tw

Customer hotline: +866-4-23594510

1. HIWIN is the registered trademark of HIWIN Technologies Corp.. For your protection; To avoid

counterfeit products, be certain you are buying genuine HIWIN products before purchase.

2. Actual products may be different from the specifications and photos in this catalog. The differences

in appearances or specifications may be caused by, among other things, product improvements.

3. HIWIN will not sell or export those techniques and products restricted under the "Foreign Trade

Act" and relevant regulations. Any export of restricted products should be approved by competent

authorities in accordance with relevant laws, and shall not be used to manufacture or develop

nuclear, biochemical, missile and other military weapons.

4. HIWIN website for patented product directory: http://www.hiwin.tw/Products/Products_patents.aspx

Publication Date:April 2018, first edition

SCARA Robot - RS403 User Manual

Copyright © HIWIN Technologies Corp.

Copyright © HIWIN Technologies Corp.

©2018 FORM C07UE001-1804 (PRINTED IN TAIWAN)

The specifications in this catalog are subject to change without notification.

Subsidiaries & R&D Centers

HIWIN Schweiz GmbH

JONA, SWITZERLAND

www.hiwin.ch

info@hiwin.ch

HIWIN s.r.o.

BRNO, CZECH REPUBLIC

www.hiwin.cz

info@hiwin.cz

HIWIN SINGAPORE

SINGAPORE

www.hiwin.sg

info@hiwin.sg

HIWIN KOREA

SUWON‧MASAN, KOREA

www.hiwin.kr

info@hiwin.kr

HIWIN CHINA

SUZHOU, CHINA

www.hiwin.cn

info@hiwin.cn

Mega-Fabs Motion System, Ltd.

HAIFA, ISRAEL

www.mega-fabs.com

info@mega-fabs.com

HIWIN GmbH

OFFENBURG, GERMANY

www.hiwin.de

www.hiwin.eu

info@hiwin.de

HIWIN JAPAN

KOBE‧TOKYO‧NAGOYA‧NAGANO‧

TOHOKU‧SHIZUOKA.HOKURIKU‧

HIROSHIMA‧FUKUOKA‧KUMAMOTO,

JAPAN

www.hiwin.co.jp

info@hiwin.co.jp

HIWIN USA

CHICAGO‧SILICON VALLEY, U.S.A.

www.hiwin.com

info@hiwin.com

HIWIN Srl

BRUGHERIO, ITALY

www.hiwin.it

info@hiwin.it

HIWIN TECHNOLOGIES CORP.

No. 7, Jingke Road,

Taichung Precision Machinery Park,

Taichung 40852, Taiwan

Tel: +886-4-23594510

Fax: +886-4-23594420

www.hiwin.tw

business@hiwin.tw

Loading...

Loading...