INDUSTRIE 4.0 Best Partner

Multi Axis Robot

Pick-and-place / Assembly /

Array and packaging / Semiconductor /

Electro-Optical industry /

Automotive industry / Food industry

ßArticulated Robot

ßDelta Robot

ßSCARA Robot

ßWafer Robot

ßElectric Gripper

ßIntegrated Electric Gripper

ßRotary Joint

Single Axis Robot

Precision / Semiconductor /

Medical / FPD

ßKK, SK

ßKS, KA

ßKU, KE, KC

Ballscrew

Precision Ground / Rolled

ßSuper S series

ßSuper T series

ßMini Roller

ßEcological & Economical

lubrication Module E2

ßRotating Nut (R1)

ßEnergy-Saving & Thermal-

Controlling (C1)

ßHeavy Load Series (RD)

ßBall Spline

Medical Equipment

Hospital / Rehabilitation centers /

Nursing homes

ßRobotic Gait Training System

ßHygiene System

ßRobotic Endoscope Holder

Direct Drive

Rotary Table

Aerospace / Medical / Automotive industry /

Machine tools / Machinery industry

ßRAB Series

ßRAS Series

ßRCV Series

ßRCH Series

Linear Guideway

Automation / Semiconductor / Medical

ßBall Type--HG, EG, WE, MG, CG

ßQuiet Type--QH, QE, QW, QR

ßOther--RG, E2, PG, SE, RC

Bearing

Machine tools / Robot

ßCrossed Roller Bearings

ßBall Screw Bearings

ßLinear Bearing

ßSupport Unit

AC Servo Motor & Drive

Semiconductor / Packaging machine

/SMT / Food industry / LCD

ßDrives-D1, D1-N, D2T

ßMotors-50W~2000W

Linear Motor

Automated transport / AOI application

/ Precision / Semiconductor

ßIron-core Linear Motor

ßCoreless Linear Motor

ßLinear Turbo Motor LMT

ßPlanar Servo Motor

ßAir Bearing Platform

ßX-Y Stage

ßGantry Systems

Driven Tool Holders

All kinds of turret

ßVDI Systems

Radial Series, Axial Series, MT

ßBMT Systems

DS, NM, GW, FO, MT, OM, MS

Torque Motor

(Direct Drive Motor)

Inspection / Testing equipment /

Machine tools / Robot

ßRotary Tables-TMS,TMY,TMN

ßTMRW Series

ßTMRI Series

C19UE101-1804

1.

Safety Information

Safety Responsibility and Effect

This safety information neither contains how to design, install and

Users of HIWIN robot have the responsibility to design and install

In compliance with the safety information on industrial robot

Safety and Notice

run a complete workstation or production line, nor ensure the whole

system safety. In order to guarantee personal safety, all machines

must be designed and installed according to the industrial safety

regulations.

the safety devices in compliance with the industrial safety

regulations, used to protect personal safety.

HIWIN robot will not

occur any safety accident.

Safety Operation Principle

Emergency Stop button (on Teach Pendant or from external

emergency stop switch) must be pressed before turning off the

power, and then disconnect the power switch.

After turning off the power switch, the operator must wait for green

indicator (PC indicator) to disappear then remove or turn off the

main power.

After turning off the power switch, do not restart it immediately.

Please wait for 30 seconds to restart.

The controller contains lead-acid battery. It may cause the lack of

electricity by natural wearing and will not be able to be turned on

successfully. If it is idle for a long time, please maintain the power

transmission at least every 3 months and keep it on lasting for 24

hours. Or take out the battery and keep the voltage of the battery

over 13V.

When the voltage of the battery is too low causing failure to turn on

the controller, please take out the battery and charge it with the

external power source until the voltage is over 13V. Or replace the

battery with a new one and then try to turn it on again.

Flipping it 90 degrees on the side or turning it over 180 degrees are

forbidden while installing the controller. This is to protect the

internal battery component.

While connecting to the external I/O or the signal, please operate in

the condition that the power switch is turned off to prevent from a

shortcut caused by mistaken touch in the process, and resulting in

damage.

2. Description Related to Safety

I. Safety Symbol

Please carefully read and make sure to follow this manual before

operating the robot. The following are the safety symbol used in this

manual.

C19UE101-1804

Symbol Description

DANGER

WARNING

CAUTION

II. Safety Grade

The following symbols are frequently used for safety notice. Please

Failure to follow the description of this symbol will cause

serious personal injury. Please make sure to follow those

requirements to ensure safety.

Failure to follow the description of this symbol will cause

personal injury or product damage. In order to guarantee

the safe use of this product, please follow this regulation

strictly.

Failure to follow the description of this symbol will result

in improper operation. In order to guarantee the safe use

of this product, please make sure to follow this regulation.

carefully read the following notices and always follow them before

operating the robot.

C19UE101-1804

Do not operate the machine in potentially explosive

environment.

Do not store the machine in the environment with

corrosive gas, with flammable gas or close to the

flammable object.

Do not operate the machine in the environment with

moisture, water or grease.

Do not operate the machine at the place where

vibration or the strong impact occurs.

Do not immerse the electric wires into grease or

water.

Do not connect or operate the machine with wet

hands.

DANGER

Please ensure the controller is grounded.

Keep hands away from the inner part of the controller

while it is connecting to the power or during

operating.

Do not touch the heat sink, regenerative resistance,

the power supply or the computer inside the

controller. While it is operating due to its high

temperature.

Be sure power is disconnected prior to move, connect,

check and maintain the controller, and ensure to

operate under the condition of no electrical shock risk.

The emergency stop switch must be installed in an

appropriate location where it can be operated easily.

When the robot acts abnormally, it could immediately

stop the robot from causing serious safety accident.

Do not open the controller cover without permission.

Do not stand on the product or put heavy objects on

it.

C19UE101-1804

WARNING

Do not block the vent or put foreign objects into it.

Please ensure the controller is fixed on the base.

Do not pull the connector violently or twist the

electric wires excessively.

Do not frequently switch the power switch and the

control button.

Please ensure that the robot, the emergency stop

switch and the controller are functioning properly

before performing any work.

Do not turn off the power switch during the

operation.

Do not open, modify, disassemble and maintain the

machine without permission.

The power must be disconnected when the machine

does not operate in a long time.

All operations must be executed by the trained staff.

The controller must be kept away from high voltage

When the robot is used to demonstrate, the operation

CAUTION

Do not turn off the power of the controller when

or components that may generate electromagnetic

field which will lead to robot malfunction or damage.

speed should keep low and always keep an eye on the

operating condition to prevent the workpiece from

dropping or causing danger to operator.

modifying the program or parameter. Otherwise, the

data stored in the controller will be damaged or lost.

C19UE101-1804

3.

Safety Notice

I. Safety Risk

i. Installation

Ordinary Risk

Risk without electric shock

The installation procedures must follow this manual.

The emergency stop switch must be installed in an appropriate

location where it can be operated easily, so that the operator can

immediately stop the robot system in an emergency.

The person who installs the robot must be trained and

authorized.

Always follow the installation and safety requirements

described in this manual to ensure personal safety.

A safety area must be set outside the working range of the robot,

and a safety device must be used to prevent the personnel

entering without permission.

After the brake of a servo motor is released, the robot will move

due to the gravity and it may injure the operator.

When installing or disassembling any mechanical parts, be

aware of falling parts which may injure the operator.

Be aware of high temperature produced by the controller.

Do not allow any action of climbing on the robot.

ii. End effector

The end effector can be classified as two types:

A. Gripper: Used to load and unload, such as pneumatic

B. Tool: Used to process, such as welding, cutting and

The gripper-type end effector should prevent the workpiece

from dropping or damaging when the robot experiences a power

gripper, electric gripper and vacuum sucker.

surface treatment.

error or other errors. More attention should be paid at the design

stage.

The end effector could be equipped with the control unit. The

position must be noted to avoid the robot interference when the

end effector is installed.

The tool-type end effector is usually equipped

C19UE101-1804

WARNING

iii.

Pneumatic and Hydraulic Systems

with high voltage, high temperature or active

shaft. Special attention should be paid during the

operation.

More attention should be paid to the pressure remained in the

pneumatic and hydraulic systems after the power is

disconnected.

The internal pressure must be released before the pneumatic and

hydraulic systems are maintained.

When the pneumatic and hydraulic systems are operated, the

clamped workpiece could drop owing to the insufficient

pressure or gravity.

The pneumatic and hydraulic systems must be equipped with

the relief valve, so that the operator can be applied in an

WARNING

iv.

Risk caused by the working environment

emergency.

More attention should be paid to the pressure in

the pneumatic and hydraulic systems which are

usually several times more than the atmosphere

pressure.

The industrial robots can be applied for the different industrial

environments.

All operating procedures must be specified by the professional

evaluation and according to the industrial safety regulations.

Maintenance must be conducted by the trained personnel who

clearly understand the procedures for the whole system and

other possible risks.

C19UE101-1804

When the operating procedures are interrupted, the special

attention should be paid during the troubleshooting.

II.

Emergency Stop

Emergency Stop Definition

When the emergency stop is executed, the power supplied from

the servo driver to the motor will be disconnected and all

actions will be stopped.

If the procedures are recovered, the emergency stop switch

should be reset.

Avoid using the emergency stop instead of the normal stop

procedure to shut down the robot system. Otherwise, it may

cause unnecessary damage to the robot system.

Emergency Stop Switch

The HIWIN robot is equipped with two emergency stop

switches, where one is installed on the teach pendant and the

other is directly connected to the controller via the cable. If

additional emergency stop switches are required, other

connection can be applied for the same purpose.

Based on the relevant industrial safety regulations, the

emergency stop switch is directly connected to the controller of

the robot via the physical wires.

4. Warranty Terms and Conditions

The period of warranty shall commence at the received date of

of 12 months. The warranty does not cover any of the damage and

failure resulting from:

The damage caused by using with the production line or the

peripheral equipment not constructed by HIWIN.

Operating method, environment and storage specifications

not specifically recommended in the product manual.

The damage caused by changing installation place, changing

working environment, or improper transfer after being

installed by the professional installer.

Product or peripheral equipment damaged due to collision or

C19UE101-1804

accident caused by improper operation or test by the

unauthorized staff.

Installing non-genuine HIWIN products.

The following conditions are not covered by the warranty:

Product serial number or date of manufacture (month and

year) cannot be verified.

Using non-genuine HIWIN products.

Adding or removing any components into/out the product

without authorized.

Any modification of the wiring and the cable of the product.

Any modification of the appearance of the product; removal

of the components inside the product. e.g., removal of the

cover, product drilling or cutting.

Damage caused by any natural disaster. i.e., fire, earthquake,

tsunami, lightning, windstorms, floods, tornado, typhoon and

hurricane etc.

C19UE101-1804

HIWIN does not provide any warranty or compensation to all the

damage caused by above-mentioned circumstances unless the user can

prove that the product is defective.

For more information towards warranty terms and conditions, please

contact the technician or the dealer who you purchased with.

Improper modification or disassemble the

robot might reduce the robot function,

stability or lifespan.

The end-effector or the cable for devices

should be installed and designed by a

professional staff to avoid damaging the robot

or robot malfunction.

WARNING

Please contact the technical support for

special modification coming from production

line set up.

For the safety reason, any modification for

HIWIN product is strictly prohibited.

Content

1. Specifications

1.1 Standard Specification

1.2 Standard and Optional Equipment

1.3 Serial Specification

1.4 Appearance Dimensions

1.5 Appearance Component

1.6 Operating Environment

1.7 Sticker and Label

2. Installation

2.1 Installation Dimensions

2.2 Multifunctional Installation Frame

2.3 Basic Connection Structure

2.4 Instruction of Controller ON/OFF Procedure

2.5 Motor Cable Connection (CN2)

C19UE101-1804

2.6 Emergency Stop Switch Connection (CN3)

3. External Input/ Output

3.1 Function I/O

3.2 Digital I/O

3.3 Example of Connection

3.4 Encoder Capture Module (CN5)

3.5 RS-232 Port

4. Teach Pendant

5. Maintenance

5.1 Lead-Acid Battery

5.2 Fan Cotton Filter

5.3 Fuse

Version Update

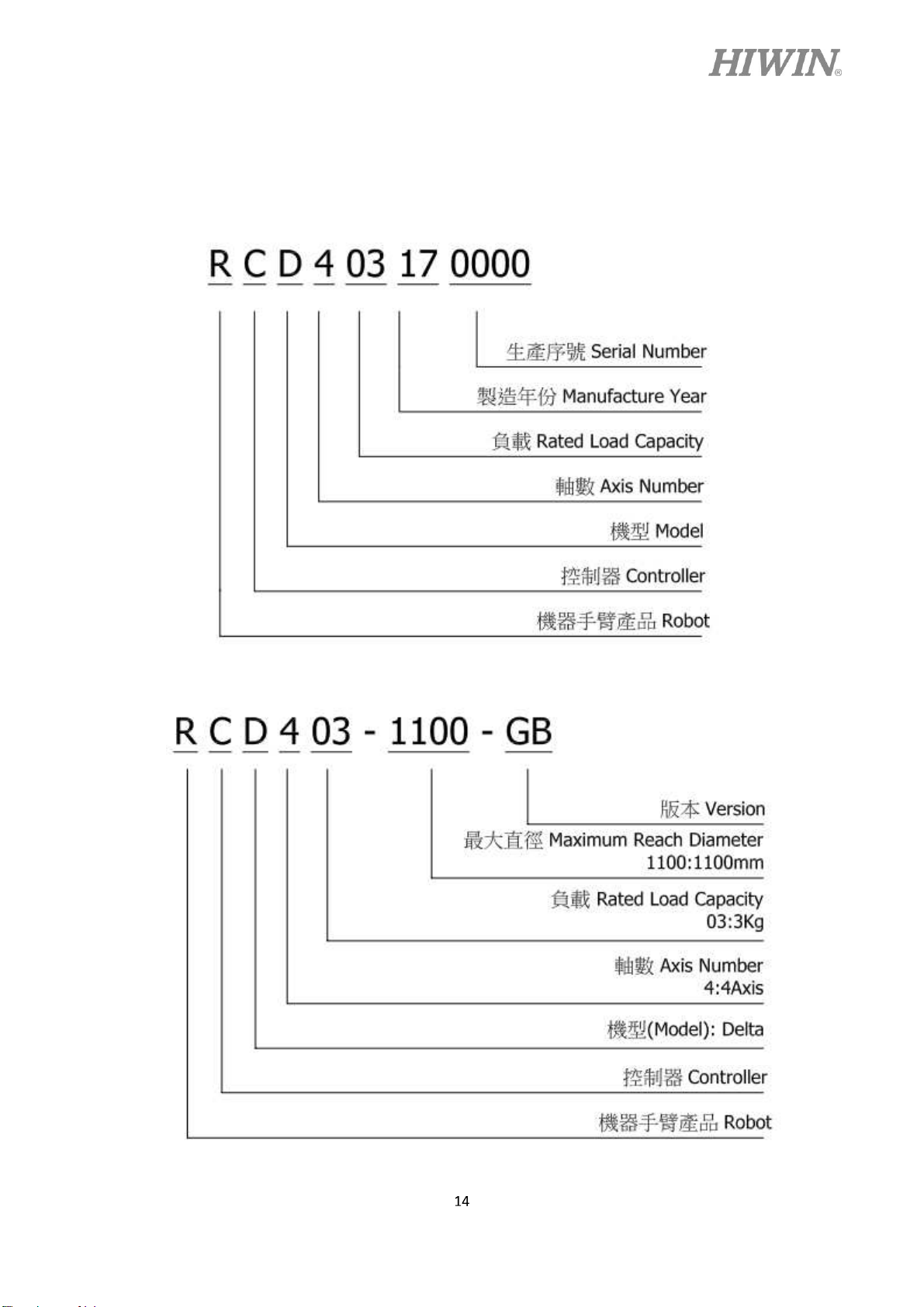

Version Date Applicable Scope Note

1.0.0 2018.01.08 RCD403-GB First release

1. Add leakage

current mark

2. Modify 3.4

C19UE101-1804

1.0.1 2018.03.05 RCD403-GB

Encoder Capture

Module

3. Add 2.6 & 3

warning sign

1. Specifications

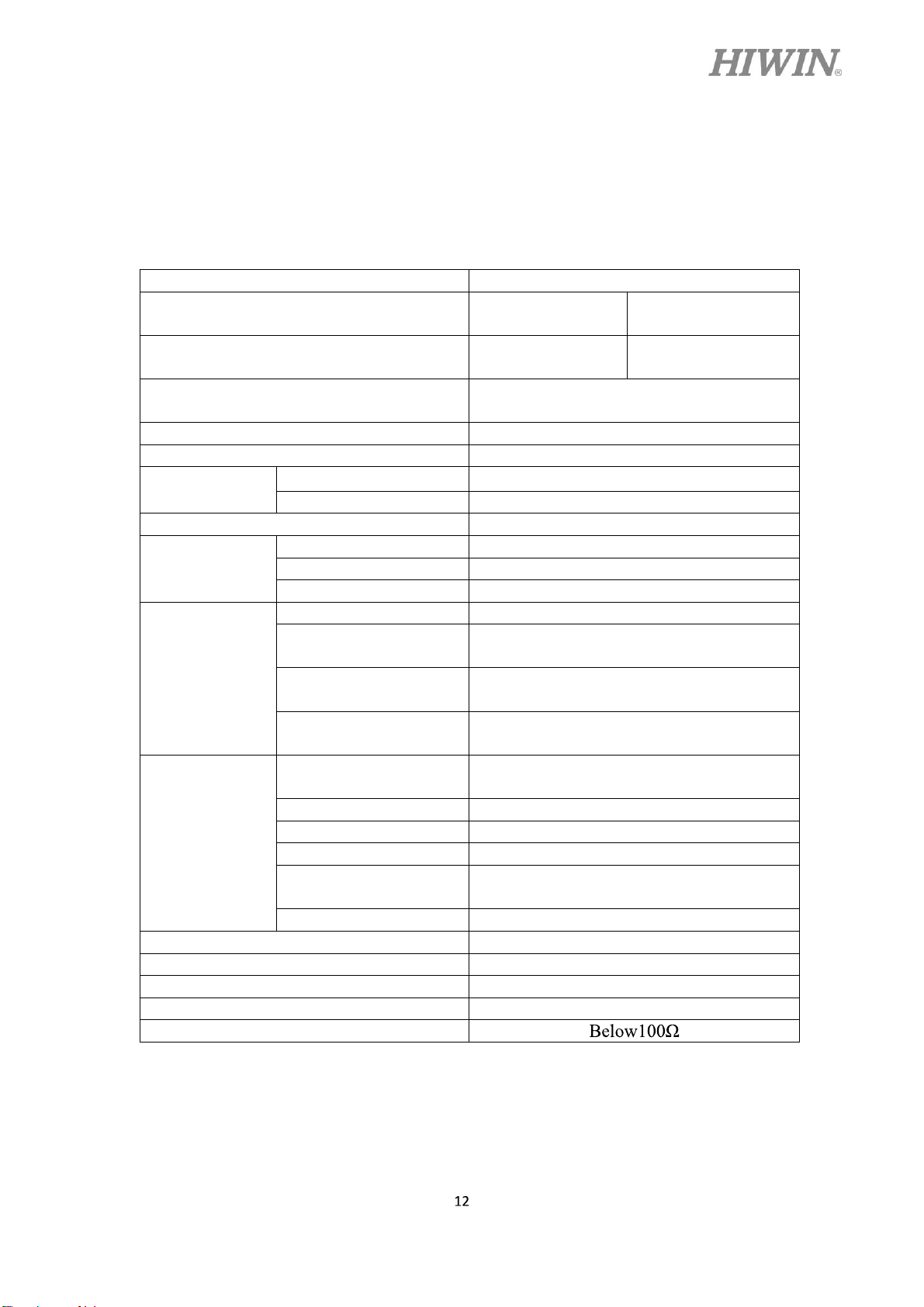

1.1 Standard Specification

The following table shows the standard specifications of the robot controller.

Item HIWIN Robot Controller

Model No. RCD403-1100-GB

Controlled Manipulator RD403-1100-GB

Positioning control

Joint control AC servo control

Operating system HRSS

Memory

capacity

Teaching method Teach pendant

Communication

interface

External I/O

Power

Weight (kg) 34

IP grade 20

Temperature range for workplaces (oC) 0~45

Relative humidity (%RH) 20~75 (non-condensing)

Grounding

Fixed point 5000

Step number 10000

RS232 1

Ethernet 2

USB 2

Emergency stop input Input : 1

Function I/O

Digital I/O

Encoder capture

module

Input power range

(VAC)

Power capacity (KVA) 1.5

Power frequency (HZ) 50/60

Voltage drop (msec) 10 or less

Rating output current

(A)

Current leakage (mA) 30

PTP (point-to-point)

CP (continuous path)

Output : 24

Three Phase AC 200-240

RCD403-1100-PR-

GB

RD403-1100-PR-

GB

Input : 8

Output : 8

Input : 24

4 Channel

4.5

C19UE101-1804

C19UE101-1804

1.2 Standard and Optional Equipment

The following table shows the items of the standard equipment for the robot

controller.

Item HIWIN Part No. Remark

CN1, Main Power Cable 4C7018Y1 Refer to CH2.3

CN2, Motor Power Signal Cable 5M AH301A01 Refer to CH2.5

Connector Accessory Kit 4C201M91

The following table shows the items of robot controller optional equipment.

Item HIWIN Part No. Remark

Teach Pendant AH301401 Refer to CH 4

CN3 Emergency Stop Switch Unit 5M 4C7013F2 Refer to CH 2.6

External I/O Wiring Kit 4C201DY1

Cotton Filter 4657003Y Refer to CH 5.2

Lead-Acid Battery 462C0097 Refer to CH 5.1

Refer to CH 2.6

and CH3

Refer to CH 3

1.3 Serial Specification

Serial Number:

C19UE101-1804

Model Number:

1.4 Appearance Dimensions

C19UE101-1804

The following show the appearance dimensions of the robot controller (unit: mm).

As a complete installation dimension, some space

CAUTION

needs to be reserved for the cables. Please refer to

CH2.1.

1.5 Appearance Component

The function of each connector outside the controller

C19UE101-1804

No. Item Description

1 Power Switch Switch power ON/OFF

2 Main Power Source Inlet three phase AC220V

3 Motor Connector (CN2) Connect robot controller to the robot

manipulator

C19UE101-1804

4 Teach Pendant Connector

(CN4)

5 Emergency Stop Connector

(CN3)

6 Network Connector Ethernet signal transmission

7 USB Connector USB signal transmission

8 RS232 Connector RS232 signal transmission

9 I/O Connector I/O signal transmission

10 Controller Power Indicator

Green Light

11. Encoder Capture Connector

(CN5)

Teach pendant signal transmission

Connect to external emergency stop device

Display ON/OFF status

Capture external encoder value

1.6 Operating Environment

The robot controller employs the IEC protection rating as IP20 (open). In addition, IP20

indicates the protection rating for the solid, not for grease and water.

The controller should not be placed at the

environment with moisture, with high

temperature, under direct sunlight or potentially

explosive environment.

Please keep the controller away from the strong

WARNING

electric field or the magnetic field.

Because the vents are set on the right side of the

controller, please ensure a space of 50mm from

the right.

Please place the controller at flat surface, and

avoid shaking.

C19UE101-1804

1.7 Sticker and Label

The following shows the appearance stickers and labels on the robot controller.

C19UE101-1804

No. Illustration Description

1

2

3

4

Controller specification

Beware of electric shock

Grounding

Transport by multiple people

5

Danger: authorized professionals

only

C19UE101-1804

2. Installation

2.1 Installation Dimensions

The following shows the connector installation space. Please reserve some space for

the connecting wires to avoid interference as they bend. ( unit: mm)

CAUTION

Controller should keep upright while installing as

the illustration shows. Flipping it 90 degrees on the

side and turning it over 180 degrees are forbidden

while installing the controller. This is to protect the

internal battery component.

C19UE101-1804

2.2 Multifunctional Installation Frame

This controller is attached with two groups of multifunctional fixing frame while

delivering (as shown below). The fixing frame can be installed on the controller

with the handle, used for transportation. Or the controller can be fixed on other

machines to use. The assembly method of the fixing frame and the handle is shown

below. The specification of the screws is M6X1PX8L flat-head screw.

Multifunctional fixing frame can be installed on the controller. The assembly drawing

is shown below. The specification of the screws is M6X1PX8L.

C19UE101-1804

Multifunctional fixing frame can be installed under the controller. The assembly

drawing is shown below. The specification of the screws is M6X1PX8L. This

configuration is convenient for the operator to fix the controller on other machines.

The corresponding dimensions of multifunctional fixing frame

C19UE101-1804

2.3 Basic Connection Structure

The picture below is an example of basic connection structure. This controller needs to

be supplied with single-phase AC200-240V, and the ground connection should be

separated from main power breaker. Do not connect the ground by devices or system

ground, the best way is to connect to power ground directly, and high-quality wires

which diameters are 14AWG or more should be used. The power can be turned on and

tested after connecting the main components mentioned below.

No. Item

1 CN1 Main Power Cable

2 CN2 Motor Signal Cable

3 CN3 Emergency Stop Switch

4 CN4 Teach Pendant

Do not connect any switch and breaker to the

ground wire.

C19UE101-1804

Please ensure the robot is firmly installed before

CAUTION

starting the operation test to prevent the robot

topples during the test.

2.4 Instruction of Controller ON/OFF Procedure

Item Illustration Instruction

Controller ON:

After the power is connected, turn the

Controller OFF:

(1) Operate the robot to a safe posture,

and then stop the motion.

Power

Switch

(2) Press the emergency stop button.

(3) Turn the power switch on the

WARNING

the controller starts its shut down

procedure. Before cutting off the

power, make sure the controller is

entirely turned off. (Refer to CH1.4,

wait for the indicator [10] to

disappear)

If you want to stop a moving robot, you should go

through the normal procedure and press the stop

button instead of the emergency stop.

Please stop the robot and press the emergency stop

button before turning it off. Directly cut off the

power while robot is moving may cause an

unexpected danger.

2.5 Motor Cable Connection (CN2)

Description:

The motor cable connects the robot and the

controller with a 5m cable.

Connection method:

The motor connection port on the

controller is CN2 connector

which is designed mistake-

proofing. If it cannot be plugged

C19UE101-1804

in, please rotate and connect it

again.

Plug the motor cable into CN2

connector, and buckle up the

safety lock indeed.

Plug the connector in the direction parallel to the

WARNING

pins to avoid the internal pins being crooked and

deformed.

According to different operating condition, the

temperature of the cable would rise slightly.

Remove plastic cover before connection.

Please avoid severe impact while installation.

C19UE101-1804

cause a severe damage or loss of life and property.

2.6 Emergency Stop Switch Connection (CN3)

Description:

Connector CN3 is a female DSUB-15 connector for

emergency stop.

Emergency stop switch (optional equipment) is a button box

with a 5m wire. It should be placed at the position, which is

easy to reach. DSUB-15 soldering connector is included in

the connector kit.

Emergency stop switch wiring diagram

Controller emergency stop connector is a dual circuit contact, which should be

connected with an external dual circuit emergency stop device additionally. This

device should be a dry contact (uncharged) switch. Ensure the connector is connected

correctly and the emergency stop device is accessible to the operator before the robot

functions.

The emergency stop device must be connected with

the controller and be placed at the position

accessible to operator. Wrong method of using can

DANGER

Connection Method:

The connector of emergency stop

device on controller is CN3 which is

designed mistake-proofing. If it

cannot be plugged in, please rotate

and connect it again.

Plug the connector into CN3 and

C19UE101-1804

secure the screws indeed.

CAUTION

Please ensure this emergency stop switch and

the emergency stop on the teach pendant are

all reset before the robot functions.

The external device connected to the

emergency stop switch circuit should be dry

contact (uncharged) switch. The charged

circuit is forbidden.

C19UE101-1804

3. External Input/ Output

Description:

External Input/ Output consists of two DSUB-37, including FI8/FO8 and DI24/DO24.

An external I/O wiring kit (optional equipment) contains connecting wire and

terminal block. Connector kit contains DSUB-37 soldering connector. External I/O

expansion module (optional equipment) can be expanded 16 more input and 16 more

output.

There are two types of controller external I/O:

(1) Function I/O (FI/O) specific function I/O

(2) Digital I/O (DI/O)

C19UE101-1804

3.1 Function I/O

Description:

Standard equipment has function I/O of 8IN/8OUT, which are all in the D37PIN-1

connector.

Function I/O List

INPUT

Pin Parameter Function

2 START Execute program

3 HOLD Pause program

4 STOP Stop program

5 ENBL Enable Function I/O

6 RSR1/PNS1 Robot service request 1 / program selection 1

7 RSR2/PNS2 Robot service request 2 / program selection 2

8 RSR3/PNS3 Robot service request 3 / program selection 3

9 RSR4/PNS4 Robot service request 4 / program selection 4

OUTPUT

Pin Parameter Function

21 RUN Program running

22 HELD Program pausing

23 FAULT Controller failure

24 READY Controller ready

25 ACK1/SNO1 RSR 1 feedback signal / selection program No. 1

26 ACK2/SNO2 RSR 2 feedback signal / selection program No. 2

27 ACK3/SNO3 RSR 3 feedback signal / selection program No. 3

28 ACK4/SNO4 RSR 4 feedback signal / selection program No. 4

3.2 Digital I/O

Description:

Standard equipment has 24IN/24OUT digital I/O, distributed in D37PIN-1 and

D37PIN-2 connectors.

Digital I/O List

C19UE101-1804

D37PIN-1

Pin Parameter Pin Parameter

10 DI[1] 29 DO[1] 2 DI[9] 21 DO[9]

11 DI[2] 30 DO[2] 3 DI[10] 22 DO[10]

12 DI[3] 31 DO[3] 4 DI[11] 23 DO[11]

13 DI[4] 32 DO[4] 5 DI[12] 24 DO[12]

14 DI[5] 33 DO[5] 6 DI[13] 25 DO[13]

15 DI[6] 34 DO [6] 7 DI[14] 26 DO[14]

16 DI[7] 35 DO [7] 8 DI[15] 27 DO[15]

17 DI[8] 36 DO [8] 9 DI[16] 28 DO[16]

10 DI[17] 29 DO[17]

11 DI[18] 30 DO[18]

12 DI[19] 31 DO[19]

13 DI[20] 32 DO[20]

14 DI[21] 33 DO[21]

15 DI[22] 34 DO[22]

Pin Parameter Pin Parameter

D37PIN-2

16 DI[23] 35 DO[23]

17 DI[24] 36 DO[24]

C19UE101-1804

The maximum current at the single output

3.3 Example of Connection

1. External OUTPUT are all NPN (current sinking) output and OUTPUT signal is 0V.

Pin20 (0V) and pin37 (24V) are supply voltage for OUTPUT which is supplied by

external power source and the power connection cannot be reversed.

2. External INPUT can be NPN (current sinking) or PNP (current sourcing) input,

adjusted with pin18 (COM). Pin19 (0V) is supply voltage for INPUT which is

supplied by external power source and the power connection cannot be reversed.

3. Pin20 (0V) and pin37 (24V) of OUTPUT in the same DSUB-37 connector are the

supply voltage, which should be connected to the same power supply.

4. Pin 18 (COM) and pin19 (0V) of INPUT in the same DSUB37 connector should be

connected to the same power supply. The COM voltage level, which is the same, cannot

be separated.

5. OUTPUT and INPUT in the same DSUB-37 connector can be connected to different

power supplies to provide reference voltage level.

6. D37PIN-1 and D37PIN-2 can be connected to different power supplies to provide

reference voltage level.

supplied by external output is 100mA.

The OUTPUT supplied by controller is all NPN

output, which cannot be modified. The INPUT

CAUTION

can be modified into NPN or PNP type by

adjusting COM voltage.

D37PIN-1

INPUT: NPN OUTPUT: NPN

C19UE101-1804

D37PIN-1

INPUT: PNP OUTPUT: NPN

C19UE101-1804

D37PIN-2

INPUT: NPN OUTPUT: NPN

C19UC101-1801

34

D37PIN-2

INPUT: PNP OUTPUT: NPN

C19UC101-1801

35

Connection method:

There are two I/O connectors

(DSUB-37) on the controller which is

designed mistake-proofing. If it

cannot be plugged in, please rotate

and connect it again.

C19UC101-1801

Plug the connector in and secure the

screw indeed.

No signal or power supply should be close to or

in contact with any metal case. Wrong method of

using can cause a severe damage or loss of life

DANGER

and property.

To prevent the internal component from damage,

WARNING

any wiring operation must be done only when the

controller is disconnected.

Please make sure the screws on the connector are

CAUTION

secured.

36

C19UC101-1801

3.4 Encoder Capture Module (CN5)

Description:

There are four channels in the encoder, CH1~CH4, the channel Latch signals are

IDI0~IDI3. IDICOM can change the input to NPN or PNP according to operation.

37

Encoder List

maximum current at the single output

C19UC101-1801

Pin Parameter Pin Parameter

1 GND 20 CH1A-

2 CH1A+ 21 CH1B-

3 CH1B+ 22 CH1Z-

4 CH1Z+ 23 CH2A-

5 CH2A+ 24 CH2B-

6 CH2B+ 25 CH2Z-

7 CH2Z+ 26 CH3A-

8 CH3A+ 27 CH3B-

9 CH3B+ 28 CH3Z-

10 CH3Z+ 29 CH4A-

11 CH4A+ 30 CH4B-

12 CH4B+ 31 CH4Z-

13 CH4Z+ 32 GND

14 IDICOM 33 IDI1

15 IDI0 34 IDI3

16 IDI2 35 GND

17 GND

The

supplied is 50mA.

CAUTION

38

C19UC101-1801

Actual Wiring Example

Take OMRON E6B2-CWZ1X as an example, the encoder required extra supply of

5V, CH1 as an input example.

Color Terminal

Brown Power supply(+Vcc)

Blue 0V(common)

Black Output phase A

White Output phase B

Orange Output phase Z

Black/red stripes

White/red stripes

Orange/red stripes

Output phase

Output phase

Output phase

39

3.5 RS-232 Port

Description:

The following figure shows the pin assignment of RS-232 controller.

Pin Description

C19UC101-1801

2 RXD-Receiver

3 TXD-Transmit

5 GND -Ground

The following figure shows the connection method with external device.

40

Connection method:

The I/O connector of controller is

COM1, which is designed mistake-

proofing. If it cannot be plugged in,

please rotate and connect it again.

Plug the connector in and secure the

screw indeed.

C19UC101-1801

No signal or power supply should be close to or

in contact with any metal case. Wrong method of

using can cause a severe damage or loss of life

DANGER

and property.

To prevent the internal component from damage,

WARNING

CAUTION

any wiring operation must be done only when the

controller is disconnected.

Please make sure the screws on the connector are

secured.

41

C19UC101-1801

4. Teach Pendant

Description:

The Teach Pendant provides the program edit, program management and motion

the Emergency Stop Switch and the Enable Switch

Teach Pendant Specification:

Item HIWIN Robot Teach Pendant

Model No. TP02

Dimensions 318x245x107 mm3

Weight 2.5kg

Protection Rating IP20

Display

Resolution 1024x768 pixels

Mode Manual, Auto and Lock

Physical Button

Cable Length 5m

20keys Enable Switch Emergency Stop Switch + Key Switch

It is forbidden to use Teach Pendant in the high

WARNING

dust concentration and high grease concentration

environment since its protection rating is IP20.

To ensure the Teach Pendant functions normally,

any impact and fall are forbidden.

42

Names and functions on Teach Pendant

Button Definition:

C19UC101-1801

No. Item Function Description

1 Emergency Stop

Disable servo and directly stop the robot.

Switch

2 Mode Switch Switch mode among Manu, Auto and Lock

3 XY-Axis T1 Key In the T1 mode, control the movement in XY-axis.

4 Z-Axis T1 Key In the T1 mode, control the movement in Z-axis.

5 Speed Key Adjust the robot speed

6 T1 Key Adjust the value in each axis in the different mode.

When pressing one of the switches, the robot can start

7 Enable Switch

(note 1)

to move; the robot will stop directly when releasing this

switch or pressing it to the end.

*note 1: instruction on enable switch:

In T1 and T2 mode, the enable switch must be held at center position to start the

robot. In Auto mode (AUT) and External Auto mode (EXT), the enable switch

should be held at center position only in the moment it starts, and then release.

The Enable Switch has three positions:

(1) Not pressed

(2) Center position The robot can move and teach

(3) Fully pressed

In addition, the enable switch on both side has the same function.

43

C19UC101-1801

5. Maintenance

5.1 Lead-Acid Battery

-acid battery in the controller which lifespan is about 3 to 5 years.

Please replace the battery when the voltage is too low to turn on or insufficient power.

Battery Replacement Steps:

(1) Remove 11 pieces of M4X0.7PX12L Phillips screws on the cover and remove

the cover.

(2) The battery is located on the right side in the cabinet. Remove the power cable

connected to the battery.

(3) Remove the Volero which fixes the battery; then take out and replace the battery.

(4) After ensuring the battery is fixed, connect it with the power cable. Install the

cover in order after confirm that all the cable is connected securely.

44

C19UC101-1801

After replacement, please ensure the polarities

of battery and power cable are connected

negative (black) to negative.

CAUTION

Ensure to shut down the controller before

replacing the battery.

5.2 Fan Cotton Filter

Every air inlet outside the cabinet contains cotton filter, which has the function of

blocking external foreign material, enhancing the air convection and promoting heat

dissipation. Please decide the frequency of cotton filter replacement according to

working environment.

(1) Remove M4X0.7PX12L Phillips screws on the cover.

(2) Replace internal cotton filter.

(3) Install the cover in order.

correctly; positive (red) to positive and

If poor convection occurs due to the foreign

CAUTION

material accumulated in cotton filter, it may

cause internal overheat and crash.

45

C19UC101-1801

5.3 Fuse

If encountered the following two situations, please try to open the controller cover and

check whether the internal fuse has melted:

1. If unable to start the controller, please follow the steps below to

replace the fuse:

1. Remove 11 pieces of M4X0.7PX12L Phillips screws on the

cover and remove the cover.

2. Check FUSE1, FUSE2, FUSE3 on RCBCDZ023.

3. Remove the protective cover of the fuse, if the fuse is melted,

replace a new fuse.

4. The specification of FUSE1, FUSE2, FUSE3 are 15A 5*20mm

glass fuse.

5. After replacing a new fuse, cover the fuse with protective cover.

6. Check FUSE1 on RCBCDZ033, if the fuse is melted, please

replace a new fuse LITTELFUSE 0297005 5A

7. Close the cover and secure the screws.

46

RCBCDZ023

C19UC101-1801

2. If abnormal sound is produced during the operation of the arm or an

error code 02-02-11 appeared during automatic running

1. Remove 11 pieces of M4X0.7PX12L Phillips screws on the

cover and remove the cover.

2. Check FUSE2 on RCBCDZ033, if the fuse is melted, please

replace a new fuse LITTELFUSE 0297002 2A

3. Close the cover and secure the screws.

RCBCDZ033

47

C19UC101-1801

Make sure the controller is disconnected to the

power supply before replacing the fuse.

WARNING

Replacing fuses with different ampere or other

conductive materials (Iron wire, Iron sheet) are

forbidden.

48

Loading...

Loading...