D2 Drive User Guide v1.8

D2 Drive User Guide

Version 1.8

December 7, 2016

HIWIN Mikrosystem Corp.

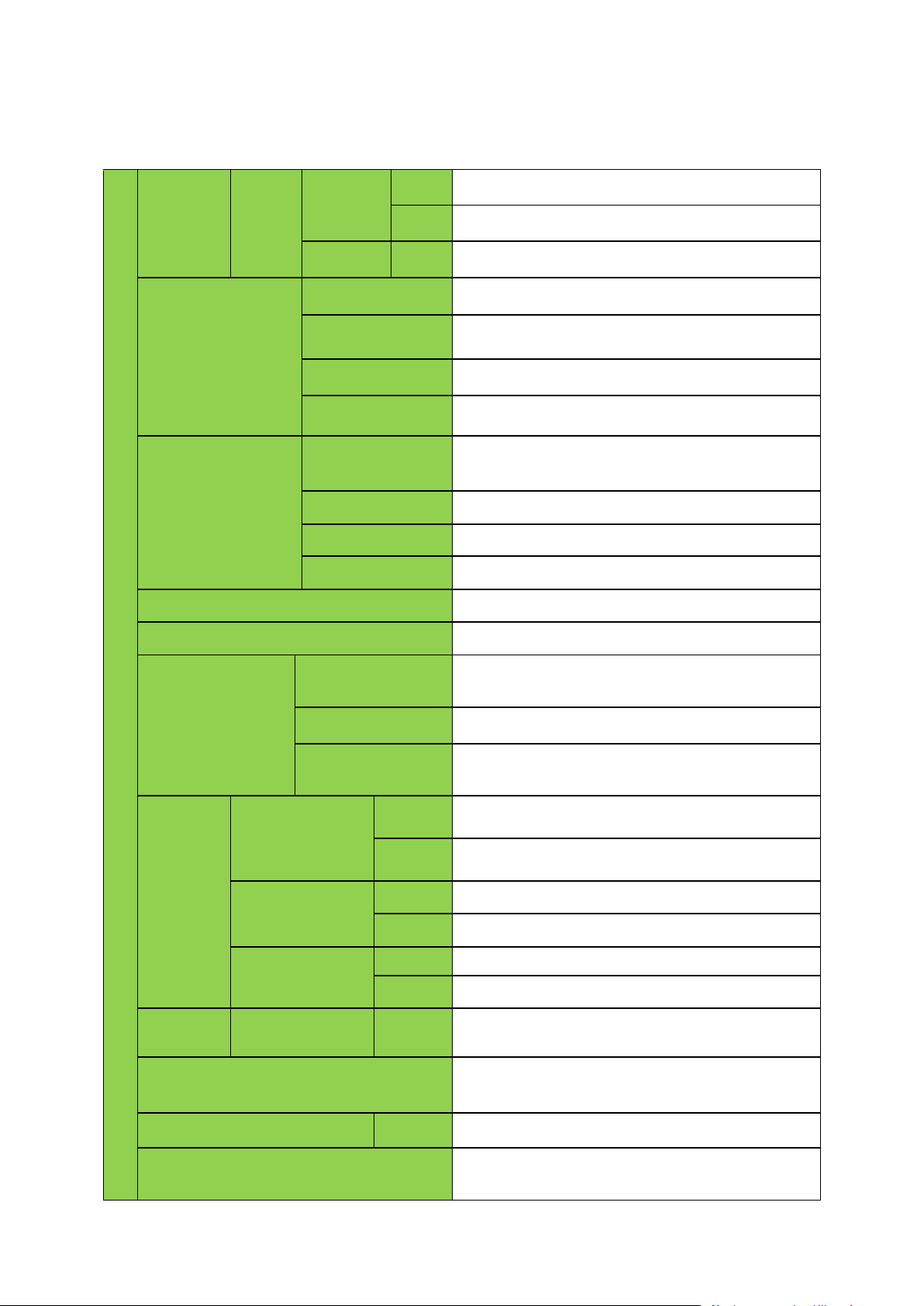

D2 Drive User Guide v1.8 Table of Contents

Table of Contents

1. About the User Guide ....................................................................................................... 1

1.1. Instructions before use ................................................................ ........................... 2

1.2. Safety instructions .................................................................................................. 4

2. Specifications ................................................................................................................... 7

2.1. Drive information .................................................................................................... 8

2.1.1. Safety certification ........................................................................................ 8

2.1.2. Nameplate information .................................................................................. 8

2.1.3. Model number ............................................................................................... 9

2.2. Drive specifications .............................................................................................. 10

2.3. Drive dimensions .................................................................................................. 14

2.4. Drive installation ................................................................................................... 21

2.5. Computer requirements ........................................................................................ 22

3. Operation Principles ....................................................................................................... 23

3.1. Operation modes .................................................................................................. 24

3.1.1. Position mode ............................................................................................. 24

3.1.2. Velocity mode ............................................................................................. 24

3.1.3. Force/torque mode ..................................................................................... 25

3.1.4. Stand-alone mode ...................................................................................... 25

3.2. Encoder type ........................................................................................................ 26

3.3. Encoder signal output ........................................................................................... 27

3.4. Path planning ....................................................................................................... 28

3.5. Servo loops and gains .......................................................................................... 30

3.6. Gain margin and phase margin ............................................................................ 31

3.6.1. Nyquist diagram .......................................................................................... 31

3.6.2. Bode diagram ............................................................................................. 32

3.7. Move and settling ................................................................................................. 34

3.8. Error compensation .............................................................................................. 35

3.9. Velocity ripple ....................................................................................................... 36

3.10. Enable .................................................................................................................. 37

3.11. Common physical quantities ................................................................................. 38

4. Wiring ............................................................................................................................. 39

4.1. System configuration and wiring ........................................................................... 40

4.1.1. System wiring diagram ............................................................................... 40

4.1.2. CN1 power ................................................................................................. 43

4.1.3. CN2 brake/motor power .............................................................................. 47

4.1.4. CN3 USB communication ........................................................................... 48

4.1.5. CN4 Modbus communication ...................................................................... 48

4.1.6. CN5 Modbus communication/safety function .............................................. 49

4.1.7. CN6 control signal ...................................................................................... 50

4.1.8. CN7 encoder .............................................................................................. 52

4.1.9. CN8 EtherCAT communication ................................................................... 52

4.1.10. CN13/CN14 extension I/O signal ................................................................ 53

4.2. Drive accessories ................................................................................................. 54

4.3. Main power wiring ................................................................................................ 58

4.3.1. AC power wiring (single-phase) .................................................................. 58

4.3.2. AC power wiring (three-phase) ................................................................... 59

4.4. Multiple drives connection .................................................................................... 60

4.5. I/O signal wiring .................................................................................................... 62

4.5.1. Digital input wiring....................................................................................... 62

4.5.2. Digital output wiring .................................................................................... 63

4.6. Wiring examples for control commands ................................................................ 65

HIWIN Mikrosystem Corp. ii

D2 Drive User Guide v1.8 Table of Contents

4.6.1. System wiring diagram for pulse command................................................. 65

4.6.2. System wiring diagram for voltage command .............................................. 73

4.6.3. System wiring diagram for PWM command ................................................ 75

5. Drive Configuration ......................................................................................................... 79

5.1. Installation and communication ............................................................................ 80

5.1.1. Setup files ................................................................................................... 80

5.1.2. Communication setup ................................................................................. 81

5.1.3. HMI main window ....................................................................................... 83

5.2. Configuration center ............................................................................................. 86

5.2.1. Motor configuration ..................................................................................... 86

5.2.2. Encoder configuration ................................................................................. 88

5.2.3. Operation mode configuration ..................................................................... 94

5.2.4. Modbus communication configuration ......................................................... 96

5.2.5. Completing configuration procedure ........................................................... 97

5.3. Auto phase center ................................................................................................ 98

5.3.1. Function description .................................................................................... 98

5.3.2. Pre-operation .............................................................................................. 98

5.3.3. Setting procedure ....................................................................................... 99

5.3.4. Troubleshooting ........................................................................................ 100

5.4. Auto tune center ................................................................................................. 101

5.4.1. Function description .................................................................................. 101

5.4.2. Announcements ........................................................................................ 104

5.4.3. Troubleshooting ........................................................................................ 104

5.5. I/O center ........................................................................................................... 106

5.5.1. Digital input ............................................................................................... 106

5.5.2. Digital output ............................................................................................. 117

5.5.3. Analog output ........................................................................................... 122

5.5.4. Extension I/O ............................................................................................ 123

5.6. In-position signal setting ..................................................................................... 124

5.7. Homing configuration ......................................................................................... 126

5.7.1. Go left and right for homing ...................................................................... 128

5.7.2. Use near home sensor/index for homing .................................................. 130

5.7.3. Use multi-turn absolute encoder for homing.............................................. 132

5.7.4. Use homing methods in CiA 402 protocol ................................................. 133

5.8. Save parameters to Flash and recover to factory default .................................... 138

5.8.1. Save parameters to Flash ......................................................................... 138

5.8.2. Recover to factory default ......................................................................... 138

5.9. Parameter setting examples via HMI .................................................................. 140

5.9.1. Position mode ........................................................................................... 140

5.9.2. Velocity mode ........................................................................................... 142

5.9.3. Force/Torque mode .................................................................................. 143

5.9.4. Stand-alone mode .................................................................................... 145

6. Drive Tuning ................................................................................................................. 147

6.1. Status display and quick view ............................................................................. 148

6.1.1. Status display ........................................................................................... 148

6.1.2. Quick view ................................................................................................ 148

6.1.3. Software shortcuts .................................................................................... 149

6.2. Performance center ............................................................................................... 150

6.3. Scope ................................ ................................................................ ................. 153

6.4. Data collection .................................................................................................... 155

6.4.1. Function description .................................................................................. 155

6.4.2. Data collection via PDL ............................................................................. 156

6.5. Plot view ............................................................................................................. 157

6.5.1. Graphic display mode ............................................................................... 157

6.5.2. Save/open file ........................................................................................... 161

HIWIN Mikrosystem Corp. iii

D2 Drive User Guide v1.8 Table of Contents

6.5.3. Mathematical operation ............................................................................ 162

6.6. Advanced gains .................................................................................................. 165

6.6.1. Filter ......................................................................................................... 165

6.6.2. Acceleration feed-forward ......................................................................... 167

6.6.3. Schedule gains and velocity loop gain ...................................................... 169

6.6.4. Analog input.............................................................................................. 172

6.6.5. Current loop .............................................................................................. 173

6.6.6. Vibration suppression feature ................................................................... 173

6.6.7. Friction compensation ............................................................................... 177

6.7. Loop constructor................................................................................................. 179

6.7.1. Load/Save file ........................................................................................... 180

6.7.2. Tool .......................................................................................................... 181

6.7.3. Filter ......................................................................................................... 184

6.7.4. Gain tuning ............................................................................................... 185

6.7.5. Spectrum analysis .................................................................................... 186

6.8. Encoder signal confirmation ............................................................................... 187

6.9. Error map function .............................................................................................. 188

6.9.1. Set error map ............................................................................................ 188

6.9.2. Enable error map ...................................................................................... 190

6.9.3. Save/open error map ................................................................................ 190

6.9.4. Change start position ................................................................................ 191

6.10. Backlash compensation ...................................................................................... 196

7. LCD Operation .............................................................................................................. 197

7.1. LCD function ...................................................................................................... 198

7.1.1. Panel description ................................................................ ...................... 198

7.1.2. Operation page description ....................................................................... 198

7.2. Parameter initialization via LCD .......................................................................... 200

7.3. Home page ......................................................................................................... 202

7.4. Display parameters page .................................................................................... 204

7.5. Change parameters page ................................................................................... 206

7.5.1. Save to Flash ............................................................................................ 207

7.5.2. Parameter edit function ............................................................................. 208

7.5.3. Advanced parameter zone ........................................................................ 211

7.6. Actions page ...................................................................................................... 219

7.6.1. Enable/Disable ......................................................................................... 220

7.6.2. JOG .......................................................................................................... 221

7.6.3. Absolute coordinate motion ...................................................................... 222

7.6.4. Auto tune .................................................................................................. 222

7.6.5. Set position to zero ................................................................................... 223

7.7. Parameter setting examples via LCD ................................................................. 224

7.7.1. Position mode ........................................................................................... 224

7.7.2. Velocity mode ........................................................................................... 227

7.7.3. Force/torque mode ................................................................................... 229

7.7.4. Stand-alone mode .................................................................................... 231

8. Protection Function ....................................................................................................... 233

8.1. Motion protection ................................................................................................ 234

8.2. Position and velocity errors protection ................................................................ 237

8.2.1. Position error limit ..................................................................................... 237

8.2.2. Position error and velocity error warnings ................................................. 237

8.3. Brake output ....................................................................................................... 238

8.4. Limit protection ................................................................................................... 242

8.4.1. Hardware limit protection ................................ .......................................... 242

8.4.2. Software limit protection............................................................................ 242

8.5. Over temperature protection ............................................................................... 244

8.5.1. Soft-thermal protection ............................................................................. 244

HIWIN Mikrosystem Corp. iv

D2 Drive User Guide v1.8 Table of Contents

8.5.2. Drive over temperature protection ............................................................. 244

8.6. Over voltage protection ...................................................................................... 245

9. Troubleshooting ............................................................................................................ 249

9.1. Drive’s status indicator ....................................................................................... 250

9.2. Drive’s errors and warnings ................................................................................ 251

9.2.1. Status display area on Lightening HMI ...................................................... 251

9.2.2. LCD status ................................................................................................ 251

9.2.3. Errors and warnings log ............................................................................ 252

9.2.4. Error at loading PRM file ........................................................................... 254

9.3. Error codes and troubleshooting ......................................................................... 255

9.4. Warning codes and troubleshooting ................................................................... 258

9.5. Troubleshooting for common issues ................................................................ ... 262

A. Axis Enable Setting ....................................................................................................... 265

A.1. Start enable method .............................................................................................. 266

A.2. Confirm enable status via HMI .............................................................................. 267

B. Parameter Comparison ................................................................................................. 269

B.1. Comparing parameters in RAM and Flash ............................................................ 270

C. Update Firmware & Load PDL ...................................................................................... 273

C.1. Update drive’s firmware ........................................................................................ 274

C.2. Load PDL program into drive ................................................................................ 277

D. Modbus Communication ............................................................................................... 279

D.1. Modbus communication specification .................................................................... 280

D.2. Function code ....................................................................................................... 281

D.3. Modbus objects ..................................................................................................... 285

D.3.1. Input register .............................................................................................. 285

D.3.2. Holding register .......................................................................................... 289

E. EMC Solution ................................................................................................................ 291

E.1. Common-mode motor filter .................................................................................... 292

E.2. Motor power cable with magnetic rings ................................................................. 295

HIWIN Mikrosystem Corp. v

D2 Drive User Guide v1.8 Table of Contents

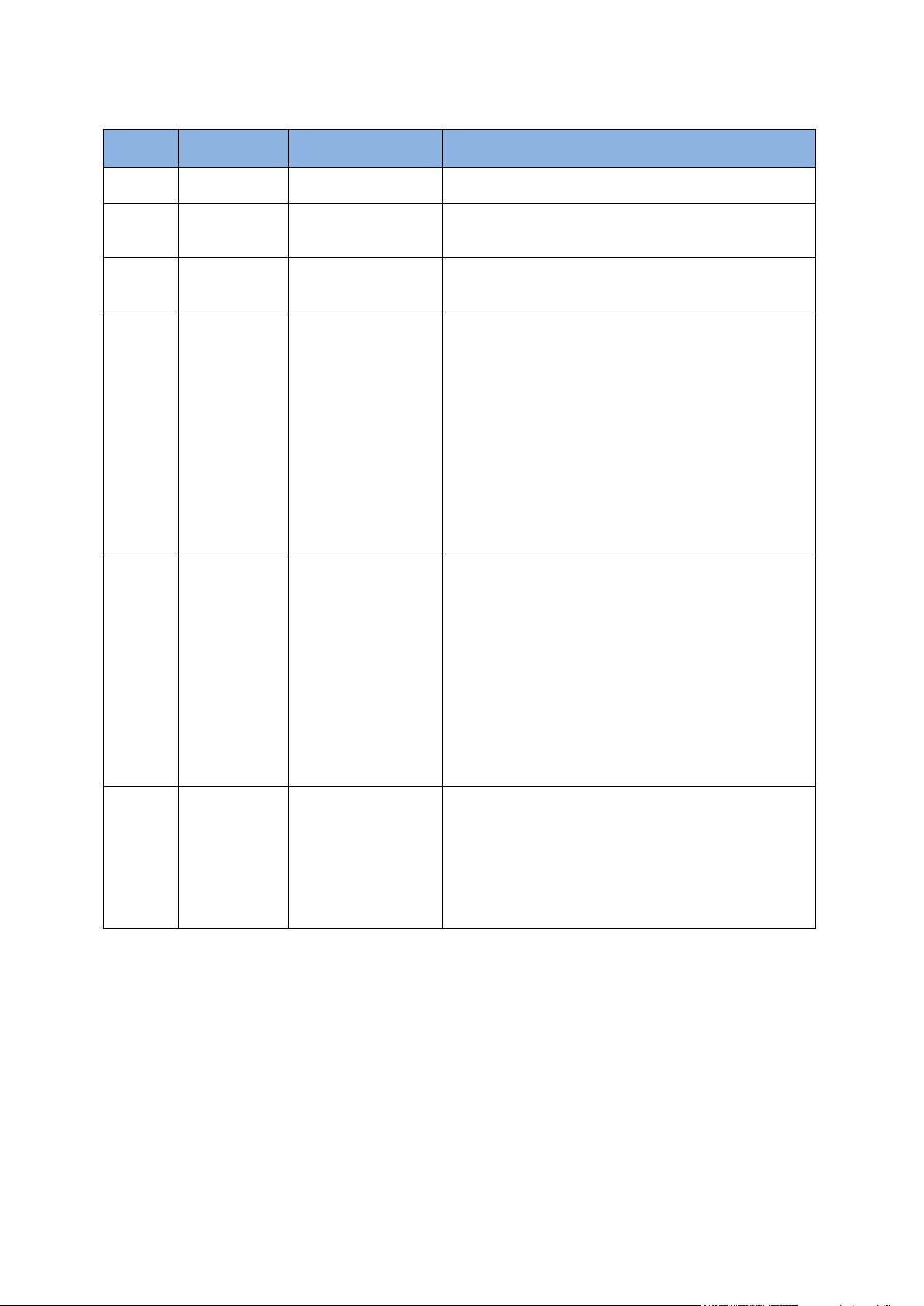

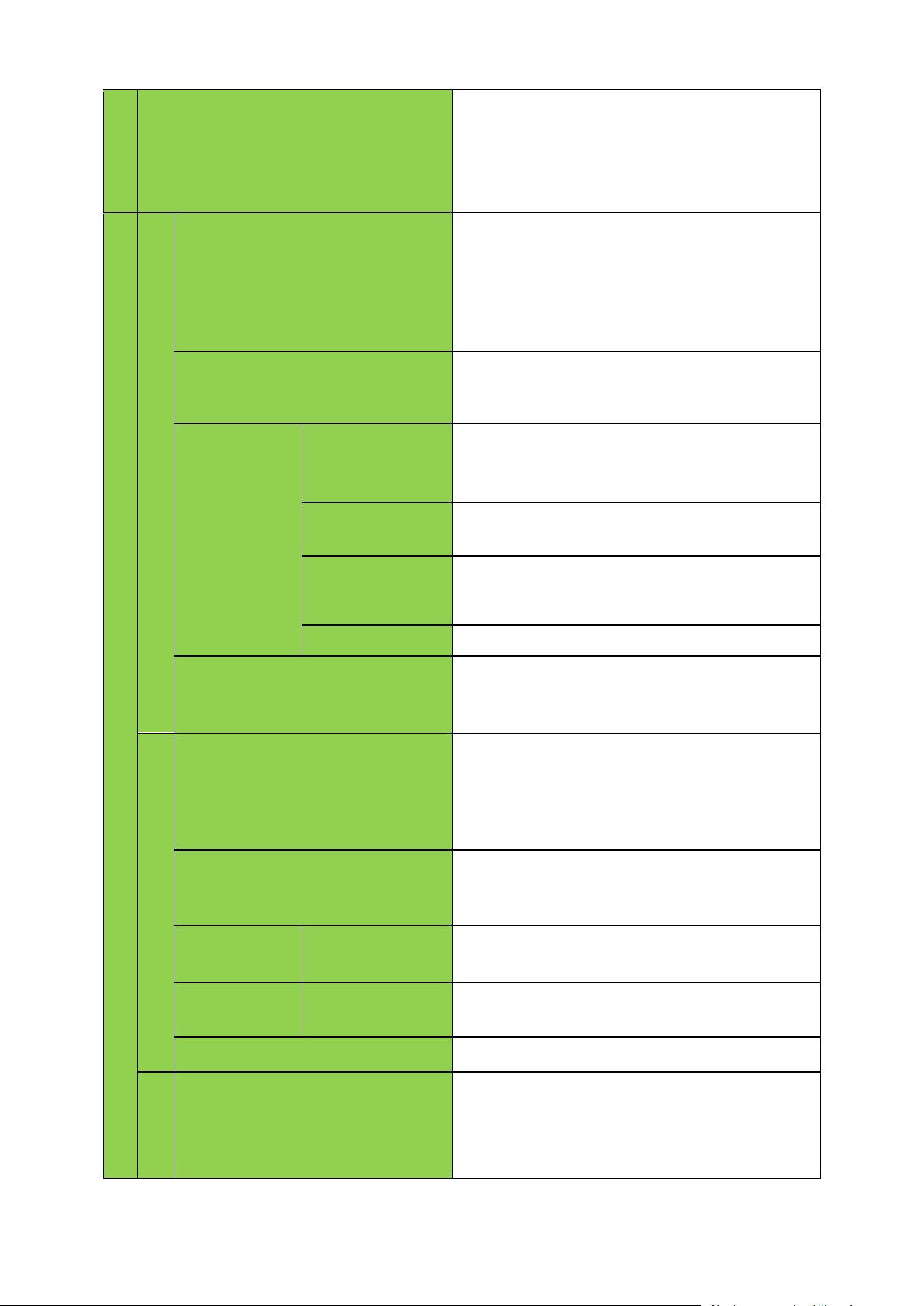

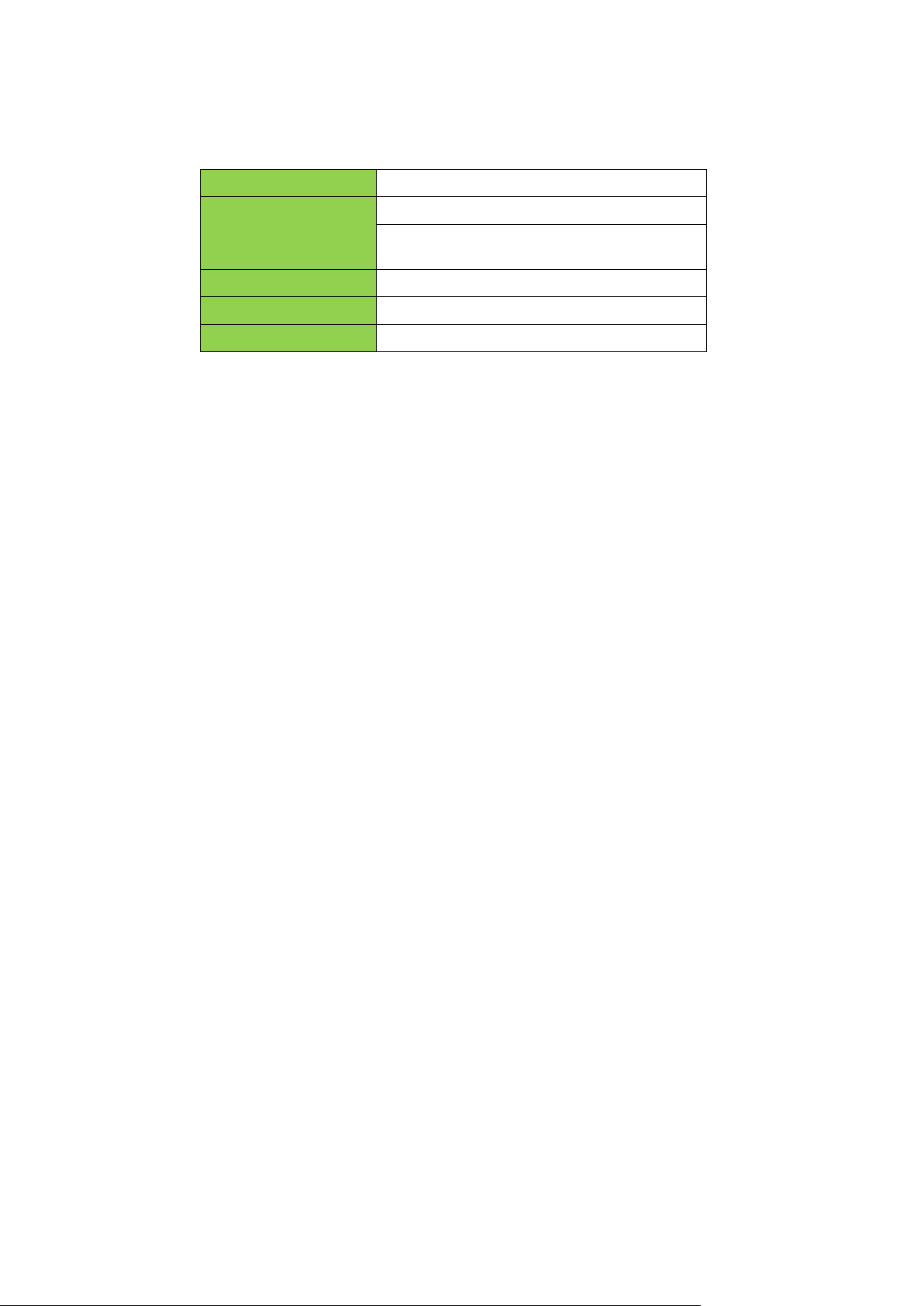

Version

Date

Applicability

Remarks

1.0

2012-06-05

D2-series drive

Frist release.

1.1

2012-08-30

D2-series drive

Renew Figure 2-1 and Figure 2-2.

Renew CN6 connector part number.

1.2

2014-05-15

D2-series drive

(1) Update the description of LCD operation.

(2) Update the description according to motor model.

1.3

2014-08-20

D2-series drive

(1) Add the information for D2T drive.

(2) Renew the dimension of D2 drive.

(3) Add the dimension of D2 drive with EtherCAT

(CoE/mega-ulink).

(4) Remove the brake wiring without a relay.

(5) Remove the input function of clear position error.

(6) Add the description of mega-ulink

communication.

(7) Add the description of using PDL to assist with

data capture.

(8) Add motor models with HIWIN 17 encoder to

Table 4.1.

1.4

2014-11-21

D2-series drive

(1) Modify the model number by combining

D2-model and D2T-model drives.

(2) Add the description of ZeroTune.

(3) Add the description of setting parameters to

factory default.

(4) Renew the description of LCD operation.

(5) Add LCD common parameters table.

(6) Add the input range of LCD parameters.

(7) Add the PDL information to drive specifications.

(8) Add the description of VSF operation.

1.8

2016-12-07

D2 MDP 0.043 or

above

D2COE MDP 0.119

or above

Lightening 0.189 or

above

Re-write and re-organize this User Guide based on

Chinese version of D2 Drive User Guide v1.8.

Revision History:

HIWIN Mikrosystem Corp. vi

D2 Drive User Guide v1.8 1. About the User Guide

1. About the User Guide

1. About the User Guide ....................................................................................................... 1

1.1. Instructions before use ................................................................ ........................... 2

1.2. Safety instructions .................................................................................................. 4

HIWIN Mikrosystem Corp. 1

D2 Drive User Guide v1.8 1. About the User Guide

Attention

‧Maximum ambient temperature for this series drives is 55 ℃.

‧This product can be installed only on the environment with the pollution level being

2.

‧The rated input voltage of drive is 240 V. Hence, the power supply voltage cannot be

over than 240 V. A short-circuit current shall not exceed 5,000 A.

‧The drive does not provide a motor over-temperature sensing, while not have a motor

over-temperature protection.

‧The short-circuit protection of drive cannot be used as a shunt-circuit protection. The

shunt-circuit protection must be chosen in accordance with US National Electrical

Code (NEC) and local regulations.

‧Before starting to inspect the product, turn off the power and wait at least five

minutes. Then, use a multi-meter or a similar instrument to check that the residual

voltage between P and N terminals has dropped to the safety level (50 Vdc or lower)

to avoid electric shock.

1.1. Instructions before use

This document is suitable for D2-series drives, included D2 model and D2T model. Read the

User Guide carefully before using the product. HIWIN Mikrosystem Corp. (“the Company”) will

not take any responsibility for damages, accidents, or injuries caused by the installation or use

that is not performed according to these instructions.

Do not dismantle or modify the product. The product has been subject to structural

calculations, computer simulations, and physical tastings to verify its design. Do not

dismantle or modify the product without the consent of the professional technician of the

Company. The Company does not take any responsibility for accidents or damages

resulting from such dismantling or modification.

Before installing or using the product, check the external appearance and ensure that there

is no damage on the product surface. If any damage is identified, contact the Company or

one of the Company’s distributors immediately.

Refer to performance specifications on the product label or manufacturer's document before

using the product. Install the product based on these performance limits and installation

instructions indeed.

Read the specification of power voltage on the label before using the product and confirm

that the power supply meets the product requirement. The Company does not take any

responsibility for product damages or personal injuries resulting from the incorrect power

supply.

Do not use the product over the rated load. The Company does not take any responsibility

for damages or injuries resulting from such misuse.

Do not use the product in an environment where shocks may occur. The Company does not

take any responsibility for damages, accidents, or injuries resulting from such shocks.

If the drive has any error, refer to Section 9.5. Troubleshooting for common issues. Follow

instructions to turn off drive’s power to perform troubleshooting. After the error is eliminated,

turn on drive’s power again.

Do not try to repair any produce’s malfunction. The product can only be repaired by the

qualified technician.

The warranty period is one year from the ex-factory date. The Company does not take any

responsibility for product replacement or repair caused by the inappropriate use or natural

disasters. (Refer to notes and installation instructions in the User Guide.)

HIWIN Mikrosystem Corp. 2

D2 Drive User Guide v1.8 1. About the User Guide

Warning

At installing or exchanging motor power

cables, if the correct sequence of

connection is not followed, the motor may

run abnormally. It is possible to cause injury

to persons or damage to equipment. Please

use correctly labelled cables.

Warning

Each motor model has its own rated

maximum payload. If applying more than

such payload to the motor, it may cause

abnormal motion, damage to equipment,

or injury to persons.

Warning

If users select to use own made motor

encoder cables, please check the User

Guide carefully or contact our service

department. The wrong connection of such

cable may cause abnormal motion or injury

to persons.

Warning

During the usage of motor, in case of the

careless removal of encoder connector

from the drive, please do not hot plug it

back to the drive. It may cause abnormal

motion, damage to equipment, or injury

to persons.

Warning

Applying the open type of optical feedback

system (e.g. optical scale), please note that

if the scale is stained or scratched, it may

cause abnormal motion, damage to the

motor or equipment, or injury to persons.

Warning

When the motor is regularly under the

operation, and careless touch or collision

to the encoder connector on the drive, it

is recommended to power cycle the

drive, or it may cause abnormal motion,

damage to equipment, or injury to

persons.

Warning

Applying the open type of magnetic

feedback system (e.g. magnetic scale),

please note that if the strong magnetic

object comes close to the scale, it may

cause abnormal motion, damage to the

motor or equipment, or injury to persons.

Warning

During the usage of motor, please do not

unplug the encoder connector when it is

not powered off, move the motor, and

then plug it back to the drive, or it may

cause abnormal motion, damage to

equipment, or injury to persons.

Risks specifically identified:

HIWIN Mikrosystem Corp. 3

D2 Drive User Guide v1.8 1. About the User Guide

Warning

Inappropriate operations may cause dangers resulting in the serious injury or death.

Inappropriate operations may cause dangers resulting in the disability, minor injury, or

material damage.

Attention

Actions marked Attention may have serious consequences under different situations.

All such instructions are important and must be followed.

Prohibited

Indicate that the action is forbidden and must not be done.

Required

Indicate that the action is compulsory and must be done.

Danger

‧

Always ensure that the drive is correctly earthed by using PE bar in the switch

cabinet as reference potential. Safety is not guaranteed if there is no low-ohm

earthing.

‧

Power connections may be live even if the motor does not move. Never disconnect

electrical connections of motor and drive as live. In the worst case, electric arcs

may form and cause personal injury and damage contacts.

‧

After disconnecting the drive from the power supply, wait at least five minutes

before touching live parts (e.g. contacts, threaded bolts etc.) or breaking

connections. For your own safety, measure the voltage in the intermediate circuit

and wait until it has fallen below 40 Vdc.

1.2. Safety instructions

Read the User Guide carefully before the installation, transportation, maintenance, and

inspection. Ensure that the product is used correctly.

Users should read the EM information, safety information, and all related instructions before

using the product.

The safety instructions in the User Guide are categorized into “Warning”, “Attention”,

“Prohibited”, and “Required”.

HIWIN Mikrosystem Corp. 4

D2 Drive User Guide v1.8 1. About the User Guide

Usage instructions

Warning

Do not touch the terminal or inside part when it is powered to

avoid electric shock.

Do not touch the terminal or inside within 10 minutes from the

power off. The residual voltage may cause electric shock.

Do not change the wiring when it is powered to avoid electric

shock.

Do not cut the cable, apply too much stress to it, or place heavy

objects on it. Laying the cable between objects may cause fire or

electric shock.

Attention

Do not install the product in the place exposed to moisture or

erosion, or in an environment containing ignitable gas. Do not

use the product close to any flammable objects.

Storage

Prohibited

Do not store the product in the place exposed to water, moisture,

direct sunlight, harmful gas, or liquids.

Handling

Attention

Be careful of handling the product and avoid damaging it.

Use appropriate handling methods and do not apply too much

pressure to the case.

The product shall not be stacked too high to avoid collapsing.

Installation location

Required

Do not install the product in the place exposed to high

temperatures, high humidity or flying dust, iron powder, or

cutting powder.

Install the product in the place where the ambient temperature

meets the specification of User Guide. Use one cooling fan if the

temperature is potentially high.

Do not install the product in the place exposed to direct sunlight.

Since the product does not have one waterproof or

moisture-proof case, do not use it outdoors or install it in the

place where water or other liquid exists.

Install the product in the place with the low vibration.

When the motor continues moving, the heat is generated due to

the use frequency. Use one cooling fan, or set to standby status

when the motor stops. So that, the ambient temperature of motor

does not exceed its specific value.

HIWIN Mikrosystem Corp. 5

D2 Drive User Guide v1.8 1. About the User Guide

Installation

Attention

Do not place any heavy objects on the product to avoid damage.

Do not mix with debris to avoid fire.

Ensure that the product is installed in the required direction to

avoid fire.

Protect the product from the strong impact to avoid collapse or

damage.

The weight of mounting body must be taken into account during

installation. Inappropriate installation may cause damage.

Install the product on a metal or noncombustible object to avoid

fire.

Wiring

Attention

Be correct and reliable wiring, otherwise it may cause motor to

out of control or burn out, and make damage or fire.

Operation and transportation

Attention

Ensure that the specification of power source is correct to avoid

damage or fire.

The motor may suddenly start after the power is recovered

instantly. Do not come too close to machine.

Required

Wire an external line for emergency stop to stop the operation

and to cut off the power at any time.

Maintenance

Prohibited

Do not dismantle or modify the product.

Do not attempt to repair any product malfunction. Please send it

back to the professional technician of the Company for repair.

HIWIN Mikrosystem Corp. 6

D2 Drive User Guide v1.8 2. Specifications

2. Specifications

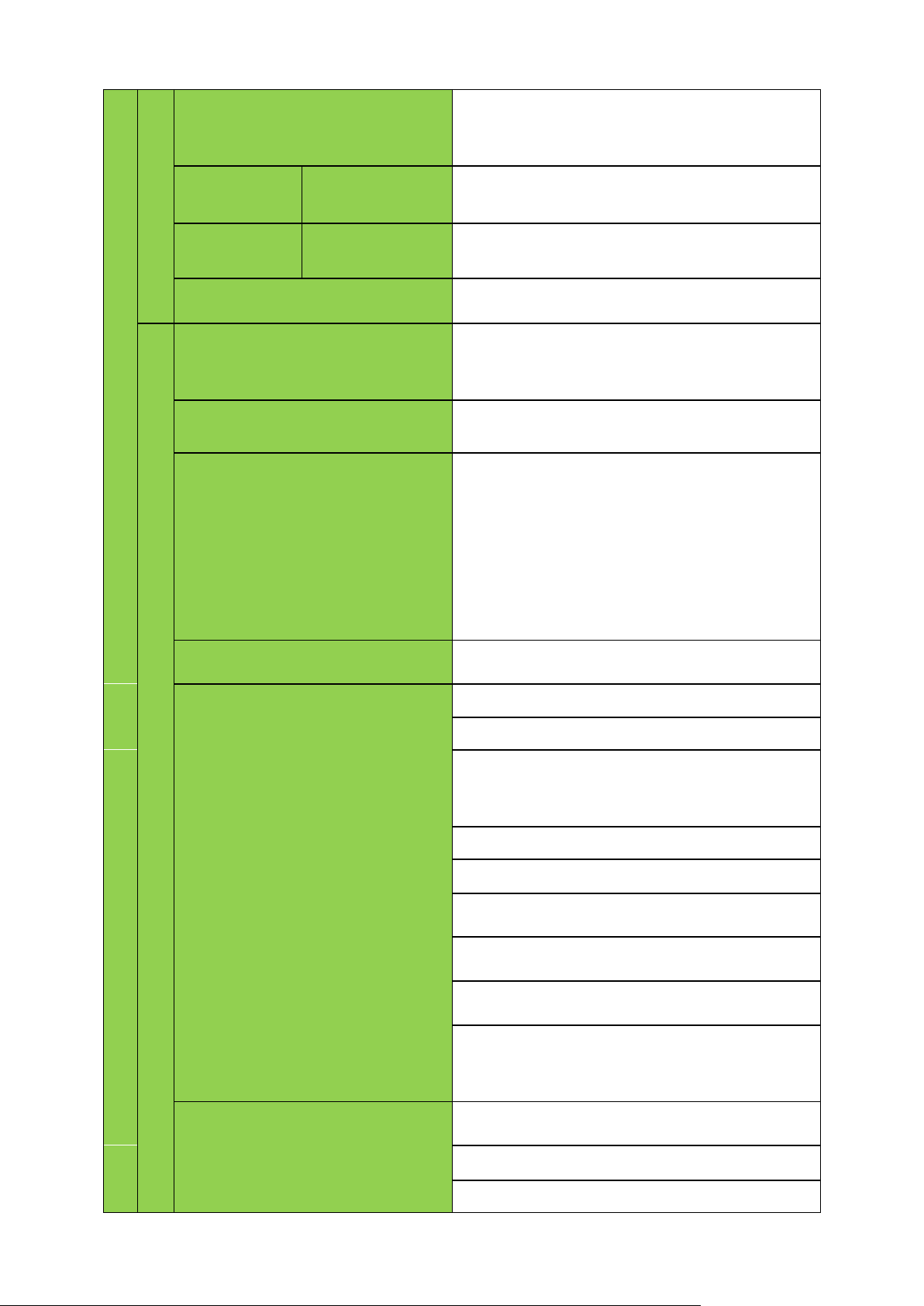

2. Specifications ................................................................................................................... 7

2.1. Drive information .................................................................................................... 8

2.1.1. Safety certification ........................................................................................ 8

2.1.2. Nameplate information .................................................................................. 8

2.1.3. Model number ............................................................................................... 9

2.2. Drive specifications .............................................................................................. 10

2.3. Drive dimensions .................................................................................................. 14

2.4. Drive installation ................................................................................................... 21

2.5. Computer requirements ........................................................................................ 22

HIWIN Mikrosystem Corp. 7

D2 Drive User Guide v1.8 2. Specifications

EMC

EN 61800-3: 2004 (Category C2)

EN 61000-3-2: 2006/A1: 2009/A2: 2009

EN 61000-3-3: 2008

IEC CISPR 11: 2009/A1: 2010

IEC 61000-4-2: 2008

IEC 61000-4-3: 2006/A1: 2007/A2: 2010

IEC 61000-4-4: 2004

IEC 61000-4-5: 2005

IEC 61000-4-6: 2008

IEC 61000-2-1: 1990

IEC 61000-2-4: 2003

IEC 60146-1-1: 1993

LVD

IEC 61800-5-1: 2007 (2nd Edition)

EN 61800-5-1:2007

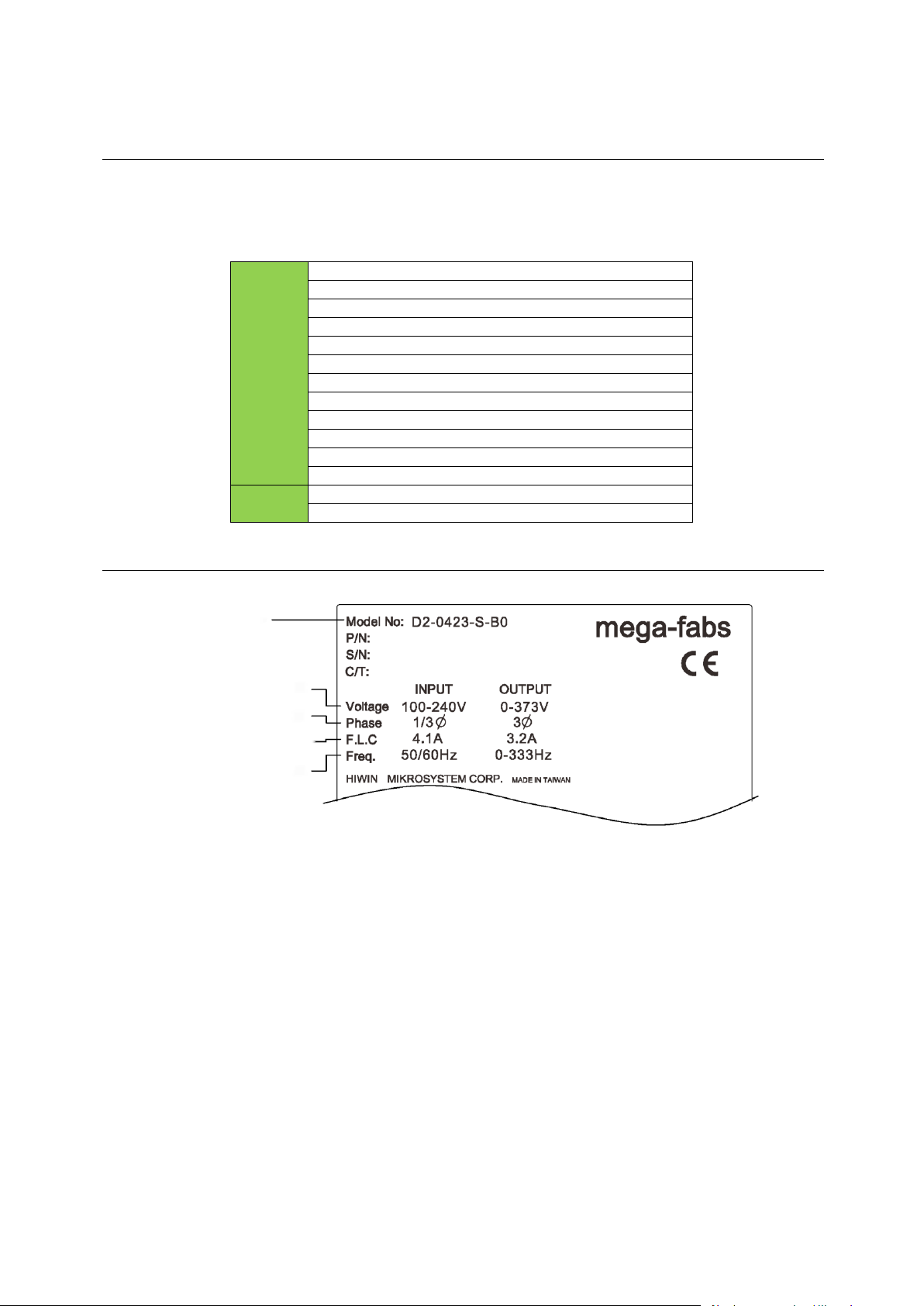

Model No.

Input/output voltage

Rated input/output current

Input/output frequency

Phases

2.1. Drive information

2.1.1. Safety certification

The drive complies with the following safety regulations.

CE Compliance

Table 2-1

2.1.2. Nameplate information

Fig. 2-1

HIWIN Mikrosystem Corp. 8

D2 Drive User Guide v1.8 2. Specifications

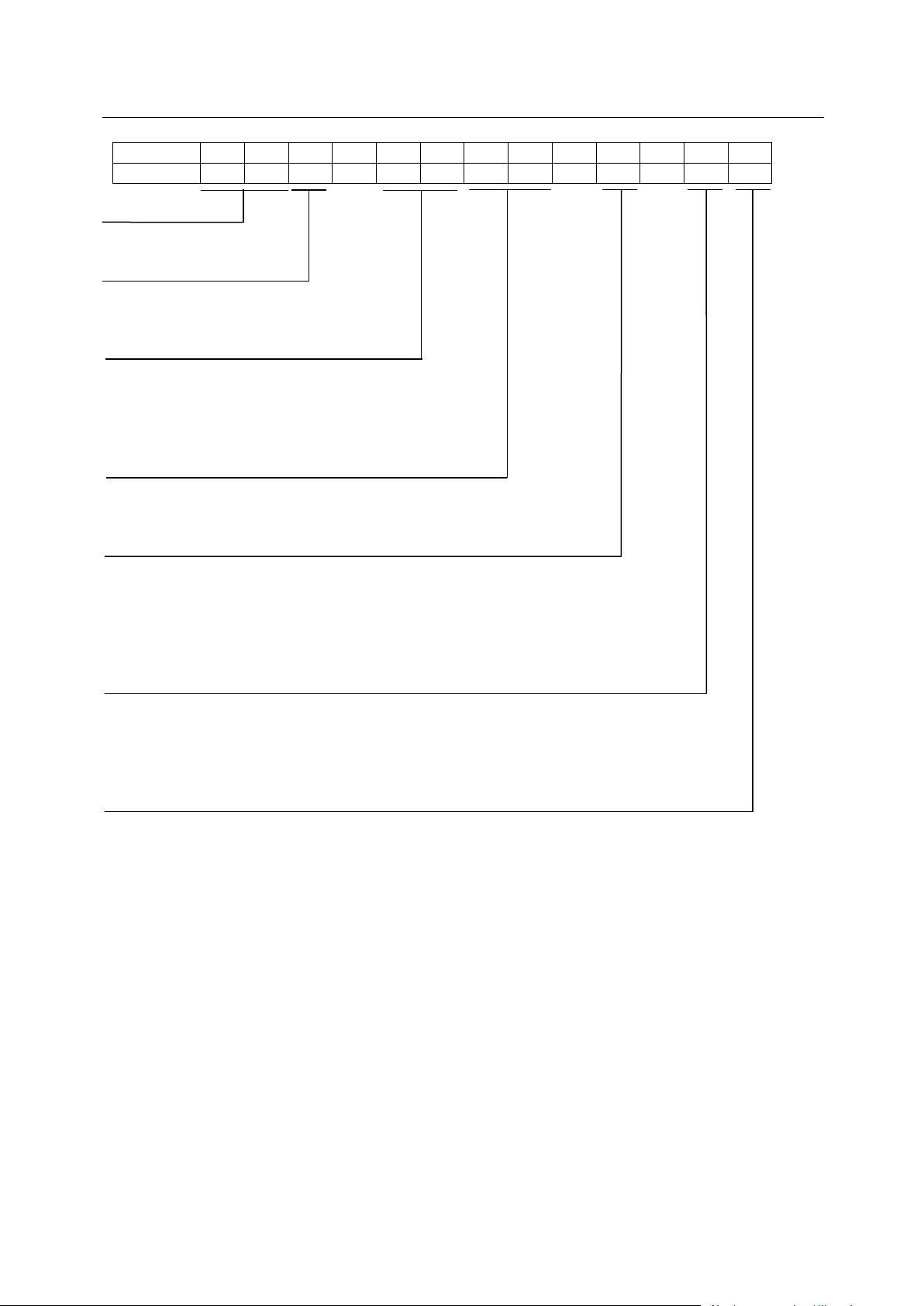

Column

1 2 2a 3 4 5 6 7 8 9 10

11

12

Example

D 2 - 0 4 2 3 - S - B 0

2.1.3. Model number

D2-series drives:

Product

D2-series drive…= D2

Type

17-bit encoder only…….= T

13-bit encoder only........=Blank

Rated output

100 W…………………...........………….= 01

400 W……………………...……………..= 04

1.0 KW………….……….…....................= 10

2.0 KW……………………………………= 20

Voltage range

1/3-phase 110/220 Vac….....………..…….…………..= 23

3-phase 220 Vac…………….……………..........……..= 32

Interface

Standard………………………………………………………………….= S

EtherCAT (CoE)………………………….…………….….….………...= E

EtherCAT (mega-ulink)…………………..…………………………..…= F

Standard with extension I/O module..….……..……………………....= K

Standard with Modbus………………………………………………….= T

Frame size

A frame (suggestion: 100 W rated output)…….…………..…………..…………..= A

B frame (suggestion: 400 W rated output)……….……………………..………....= B

C frame (suggestion: 1.0 KW rated output)…………………………..…………...= C

D frame (suggestion: 2.0 KW rated output)…………………………..…………...= D

Encoder type

13-bit less-wire incremental encoder...…..………………….…..…………….….……....= 0

17-bit serial incremental encoder (HIWIN17)……………………………………………..= 4

Dual loop (full closed loop) and 17-bit serial absolute encoder………..……………….= 5

Note:

(1) The standard model supports the pulse and +/- 10 V input interfaces.

(2) The EtherCAT (CoE) and EtherCAT (mega-ulink) models do not have the extension I/O

module and Modbus module.

(3) The frame D model requires the voltage range of 3-phase 220 Vac.

(4) D2 model does not support the extension I/O module and the rated output of 2.0 KW.

(5) D2T frame A, B, and C models do not have the Modbus module.

(6) For the dual-loop model, the rotary encoder should be the 17-bit serial absolute

encoder and the linear encoder should be the digital AqB encoder.

(7) The EtherCAT (CoE) model does not support the dual-loop control.

Fig. 2-2

HIWIN Mikrosystem Corp. 9

D2 Drive User Guide v1.8 2. Specifications

Basic specifications

Input power

220V

Main power

Frame

A-C

Single/three-phase, 200 - 240 Vac 50/60Hz

Frame

D

Three-phase, 200 - 240 Vac 50/60Hz

Control

power

Frame

A-D

Single-phase, 200 - 240 Vac 50/60Hz

Output power

Power

Frame A: 100 W; frame B: 400 W; frame C: 1.0 KW;

frame D: 2.0 KW.

Continuous current

Frame A: 0.9 A

rms

; frame B: 2.5 A

rms

;

frame C: 5.1 A

rms

; frame D: 11 A

rms

.

Peak current

Frame A: 2.7 A

rms

; frame B: 7.5 A

rms

;

frame C: 15.3 A

rms

; frame D: 33 A

rms

.

Sustainable duration

of peak current

1 second maximum.

Environment

Temperature

Operation temperature: 0°C to 45°C

(if over 55°C, the forced ventilation is needed)

Storage temperature: -20°C to 65°C

Humidity

0 to 90% RH (non-condensing)

Altitude

Below 1,000 meters

Vibration

1G (10 to 500Hz)

Installation pollution level

II

Control method

IGBT PWM space vector control

Encoder input

Resolution/Feedback

resolution

13-bit (10,000 count/rev) less-wire incremental encoder;

17-bit (131,072 count/rev) serial incremental encoder (5

lines).

Frequency

5M pulse/sec (Before Quadrature);

20M count/sec (After Quadrature).

Other

For the dual-loop model, the rotary encoder should be the

17-bit serial absolute encoder and the linear encoder

should be the digital AqB encoder.

Parallel I/O

connector

Control signal

Input

9 (general purpose) for D2 model

10 (general purpose) for D2T model

Output

4 (general purpose) for D2 model

5 (general purpose) for D2T model

Analog signal

Input

1 (12-bit A/D)

Output

2 (analog monitor: 2 outputs)

Pulse signal

Input

2 (low-speed channel, high-speed channel)

Output

4 (line driver: 3 outputs; open collector: 1 output)

Brake

connector

Control signal

Output

Used to connect with brake (1 Adc max). Also, it is

programmable for general-purpose output.

Dynamic brake

Frame D model has one built-in dynamic brake resistor

(line resistance: 2.6 Ω ± 5%; continuous power: 120 W;

peak power: 600 W).

Communication function

USB

Used to connect with PC, 115,200 bps

Front panel

LCD status display: dot matrix 8*2 characters with 4

buttons;

LED status indicator lights (green, red)

2.2. Drive specifications

Table 2-2 Drive specification

HIWIN Mikrosystem Corp. 10

D2 Drive User Guide v1.8 2. Specifications

Control mode

Switchable control modes

(1) Position control;

(2) Velocity control;

(3) Torque control ;

(4) Position/velocity control;

(5) Position/torque control ;

(6) Velocity/torque control;

Function specifications

Position control

Control input

(1) Inhibit pulse command;

(2) Axis enable;

(3) Switch between primary and secondary CG;

(4) Electronic gear selection;

(5) Left limit switch;

(6) Switch between primary and secondary mode;

(7) Clear error;

(8) Right limit switch, etc.

Control output

(1) Servo ready;

(2) Errors;

(3) In-position;

(4) Zero speed detected, etc.

Pulse input

Maximum input

pulse frequency

Photo-coupler interface (single-ended input): 500 Kpps;

Line driver interface (differential input): 4 Mpps (16M

count/s with AqB).

Signal format of

input pulse

(1) Pulse/direction (Pulse/Dir);

(2) Pulse up/pulse down (CW/CCW);

(3) Quadrature (AqB).

Electronic gear

(Division/

Multiplication of

command pulse)

Gear ratio: pulses/counts

Pulses: 1 - 2,147,483,647; counts: 1 – 2,147,483,647.

Smoothing filter

Smooth factor: 1 - 500 (0: no smoothing filter)

Vibration suppression feature (VSF)

VSF can remove the vibration frequency that occurs

during movement. It can reduce the vibration caused by

the system’s structure and improve the machine’s

productivity.

Velocity control

Control input

(1) Zero speed clamp;

(2) Axis enable;

(3) Switch between primary and secondary CG

(4) Left limit switch

(5) Switch between primary and secondary mode

(6) Clear error

(7) Right limit switch, etc.

Control output

(1) Servo ready;

(2) Errors;

(3) In-velocity;

(4) Zero speed detection, etc.

PWM input

Velocity command

input

Velocity commands can be provided by the duty cycle of

PWM input. Parameters are used to set the scale and

command direction.

Analog input

Velocity command

input

Velocity command can be provided by the analog voltage.

Parameters are used to set the scale and command

direction.

Zero speed clamp

The input of zero speed clamp is possible.

Torque

control

Control input

(1) Axis enable;

(2) Switch between primary and secondary CG;

(3) Left limit switch;

(4) Switch between primary and secondary mode;

(5) Clear error;

(6) Right limit switch, etc.

HIWIN Mikrosystem Corp. 11

D2 Drive User Guide v1.8 2. Specifications

Control output

(1) Servo ready;

(2) Errors;

(3) In-velocity;

(4) Zero speed detected, etc.

PWM input

Torque command

input

Torque commands can be provided by the duty cycle of

PWM input. Parameters are used to set the scale and

command direction.

Analog input

Torque command

input

Torque commands can be provided by the analog voltage.

Parameters are used to set the scale and command

direction.

Speed limit function

The parameter for speed limit can be set.

Common

Auto tune

The auto tune procedure runs automatically after start and

identifies the load inertia. Users do not set by themselves.

All necessary gains are set by clicking one button on the

LCD panel.

Emulated encoder feedback output

Can be arbitrarily set (The maximum frequency of frame A

- C models is 18M count/s; while that of frame D model is

9M count/s).

Protective function

(1) Motor short detected;

(2) Over voltage detected (> 390 Vdc ± 5%);

(3) Position error too big;

(4) Encoder error;

(5) Soft-thermal threshold reached;

(6) Motor maybe disconnected;

(7) Amplifier over temperature (IGBT > 80℃ ± 3℃);

(8) Under voltage detected;

(9) 5V for encoder card fail;

(10) Phase initialization error;

(11) Serial encoder communication error.

Error log

Errors and warnings are saved in the non-volatile memory.

Process description language (PDL)

Maximum code capacity: 32 KBytes

Variable storage capacity: 800 Bytes

Supported variable type:

(1) Float type: 32 bits;

(2) Integer type: 16 and 32 bits;

(3) Array and pointer supported.

Execution cycle: 66.67 us

4 tasks can be executed simultaneously.

Support if, else, while loop, for loop, goto, till, and other

commands to control program flow.

Support arithmetic operators, logical operators, and

comparison operators.

Support lock and unlock commands to control the

synchronization of multi-tasks.

Maximum length of user-defined name:

(1) variable: 17 characters

(2) label: 24 characters

(3) proc: 24 characters

Error mapping

Method: Establish compensation table to compensate the

encoder error by using the linear interpolation.

Samples: Maximum 5,000 points.

Storage location: Flash ROM; disc file.

HIWIN Mikrosystem Corp. 12

D2 Drive User Guide v1.8 2. Specifications

Unit: um, count.

Enable method: it is activated after the internal homing is

completed, or by an external input signal.

Regeneration

Resistor

Frame A - C: need external connection (option), and have

no built-in regenerative resistor.

Frame D: need external connection (option), and also

have one built-in regenerative resistor (resistance: 13 Ω ±

5%; continuous power: 120 W; peak power: 600 W).

Cut-in voltage

+HV > 370 VDC

Drop-out voltage

+HV < 360 VDC

DC link capacity

Frame A: 560 uF; frame B: 820 uF;

frame C: 1,410 uF; frame D: 2,000 uF.

Others

Friction compensation, backlash compensation.

HIWIN Mikrosystem Corp. 13

D2 Drive User Guide v1.8 2. Specifications

D2-DNN46A

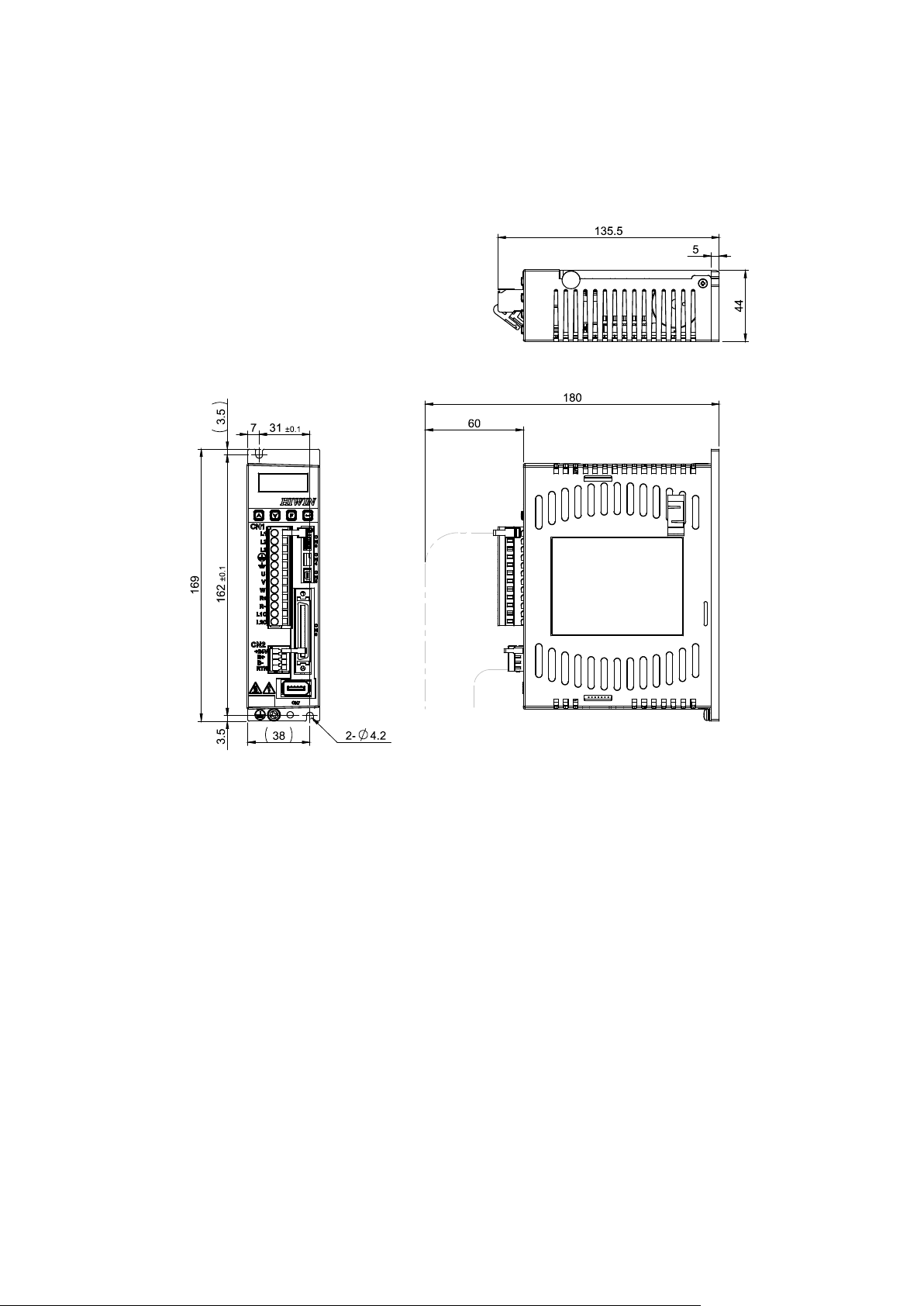

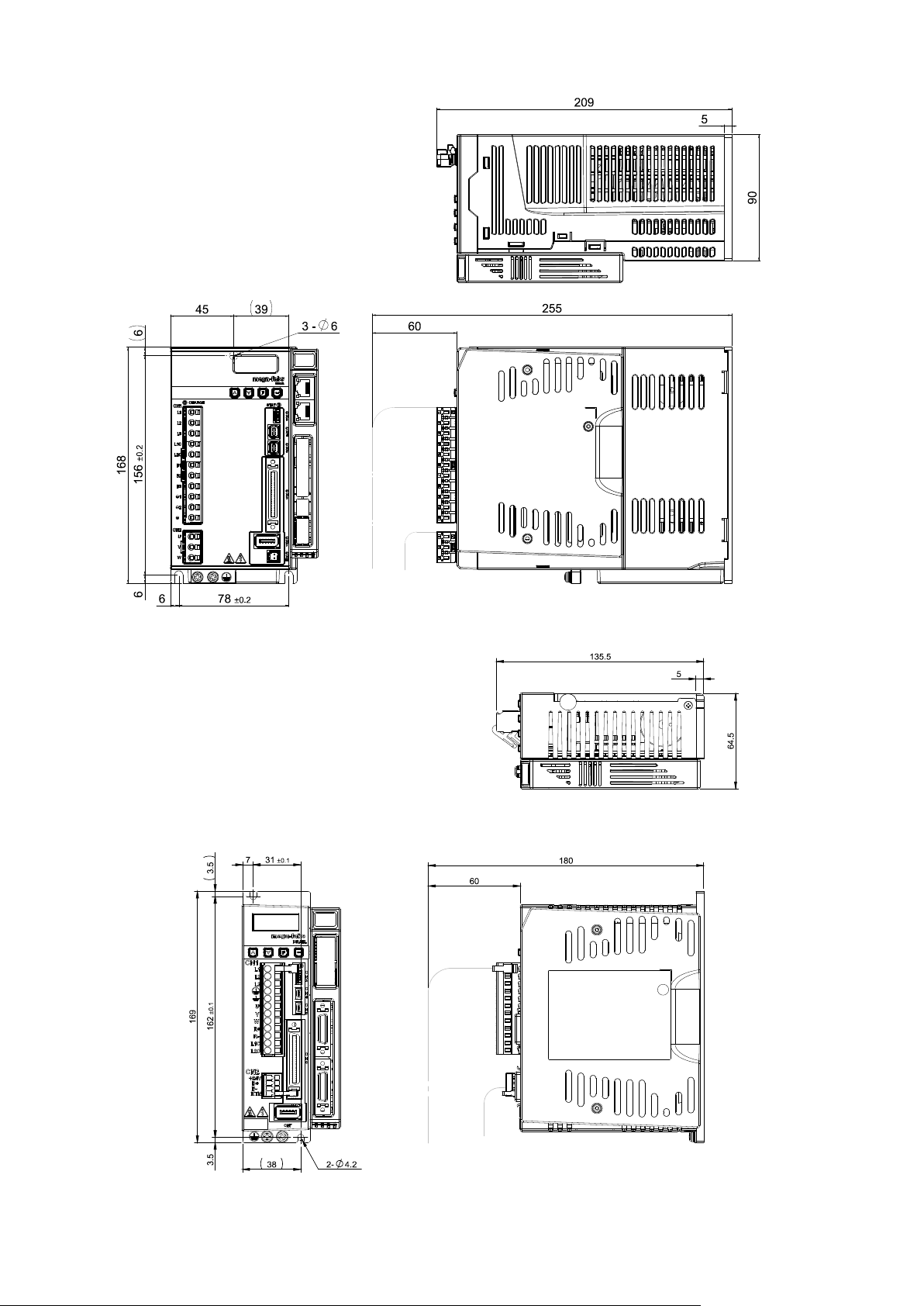

2.3. Drive dimensions

Dimensions and mounting holes of D2-series drives, D2-series drives with the EtherCAT

(CoE/ mega-ulink) module, and D2-series drives with the extension I/O module are shown in

the following figures. The dimension unit is in mm, and the diameter of mounting hole is 4 mm.

Fig. 2-3 Dimensions of frame A model

HIWIN Mikrosystem Corp. 14

D2 Drive User Guide v1.8 2. Specifications

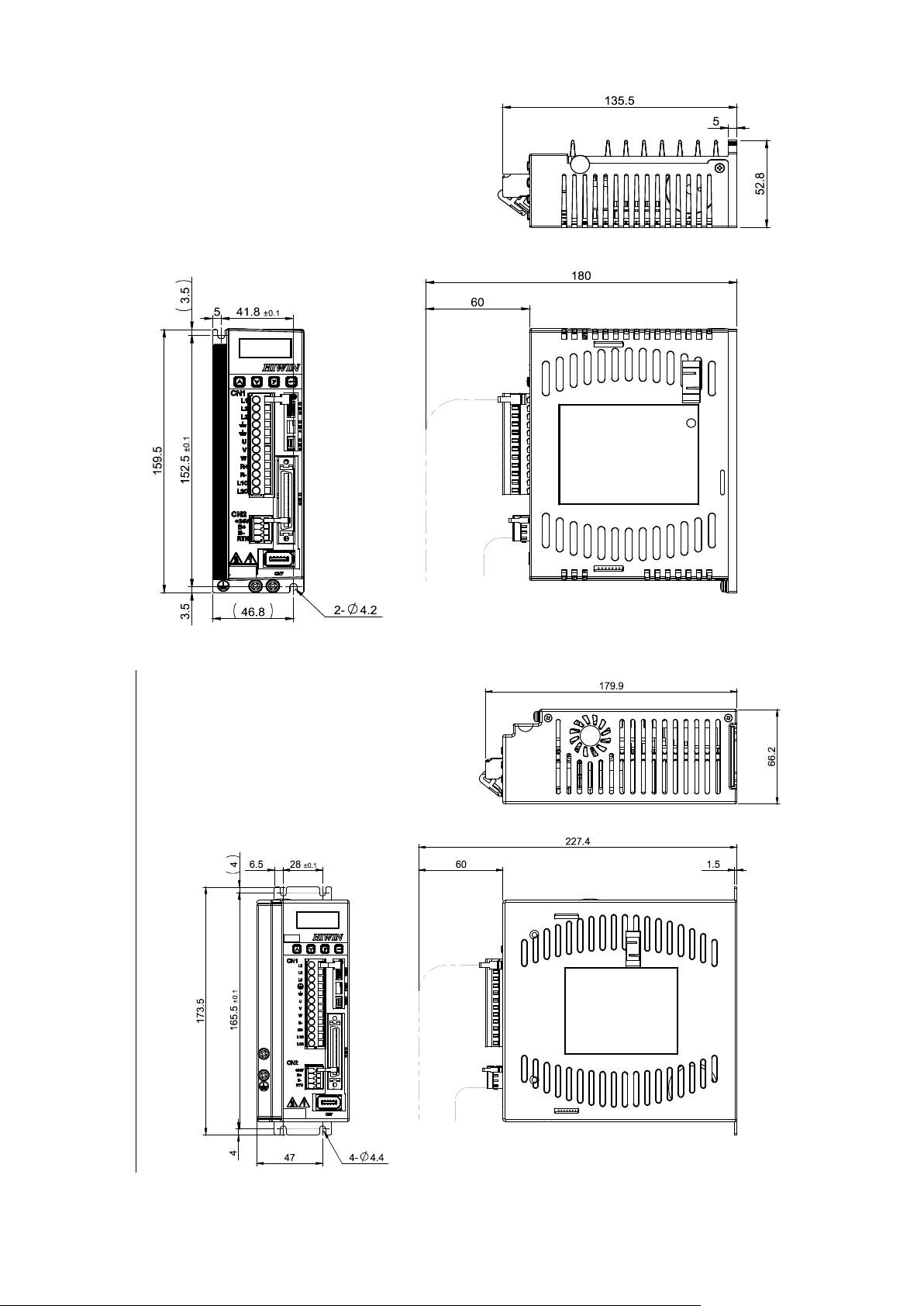

D2-DNN47A

D2-DNN48A

Fig. 2-4 Dimensions of frame B model

Fig. 2-5 Dimensions of frame C model

HIWIN Mikrosystem Corp. 15

D2 Drive User Guide v1.8 2. Specifications

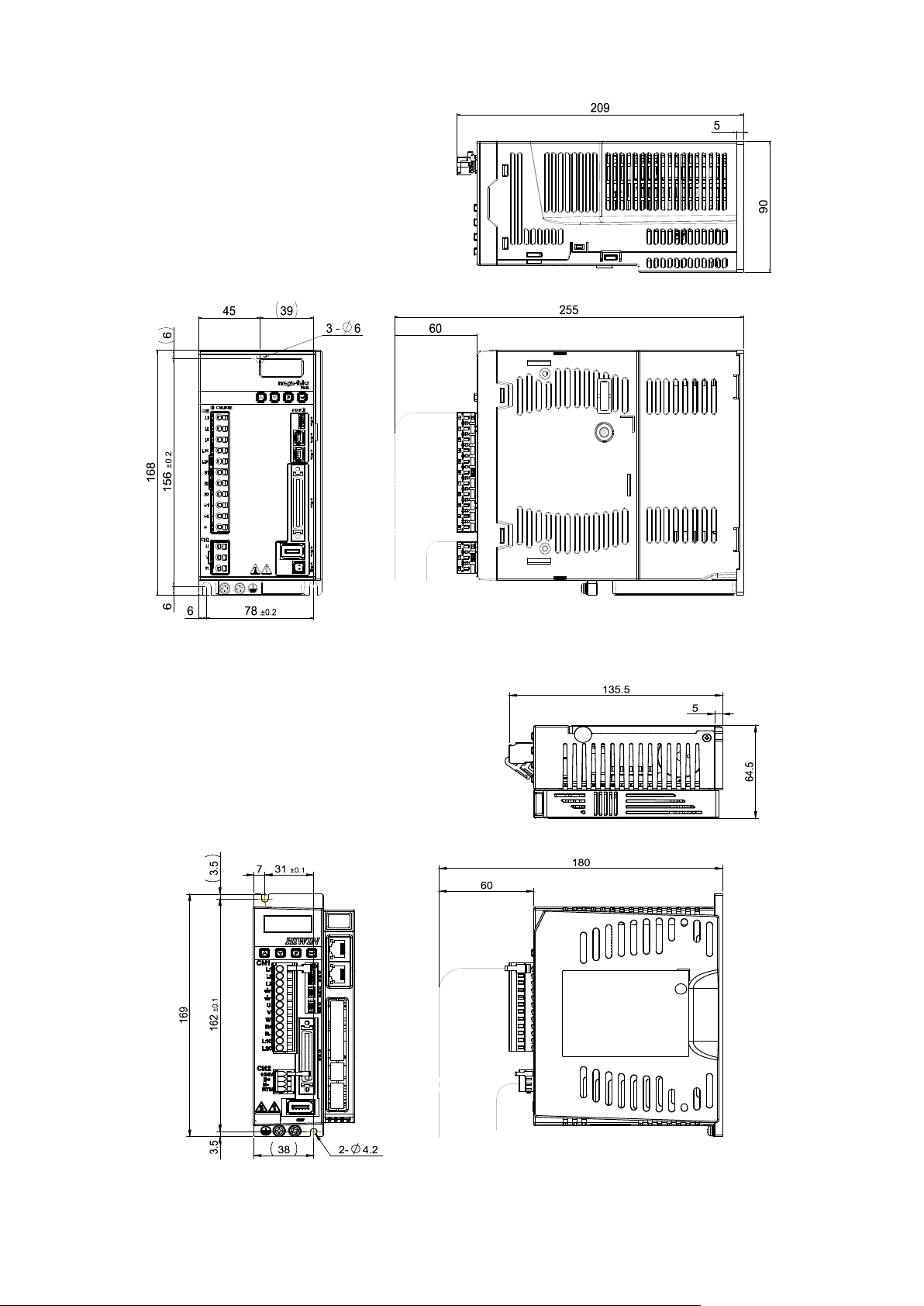

D2-DNN52A

D2-DNN43A

Fig. 2-6 Dimensions of frame D model

Fig. 2-7 Dimensions of frame A model with the EtherCAT module

HIWIN Mikrosystem Corp. 16

D2 Drive User Guide v1.8 2. Specifications

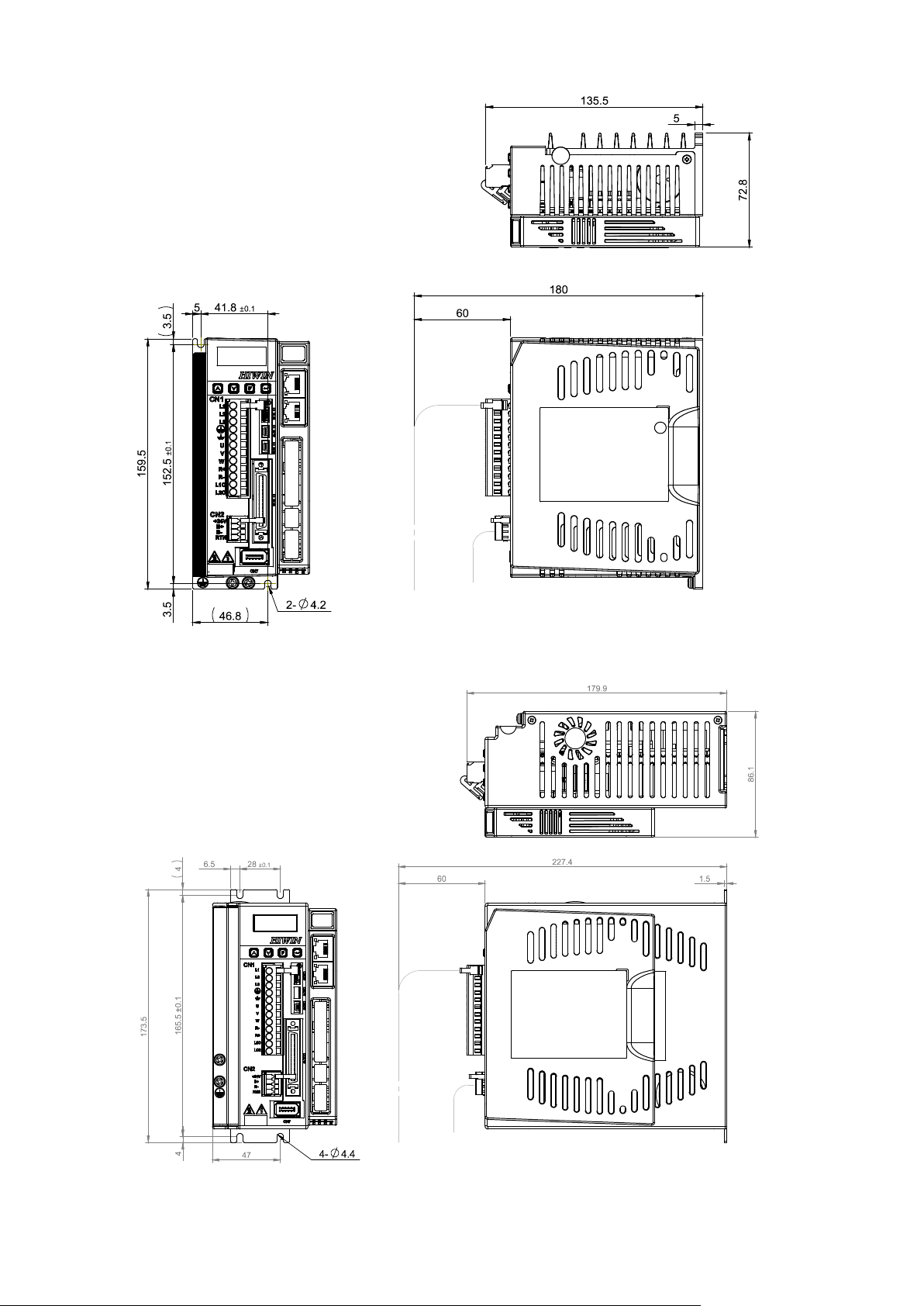

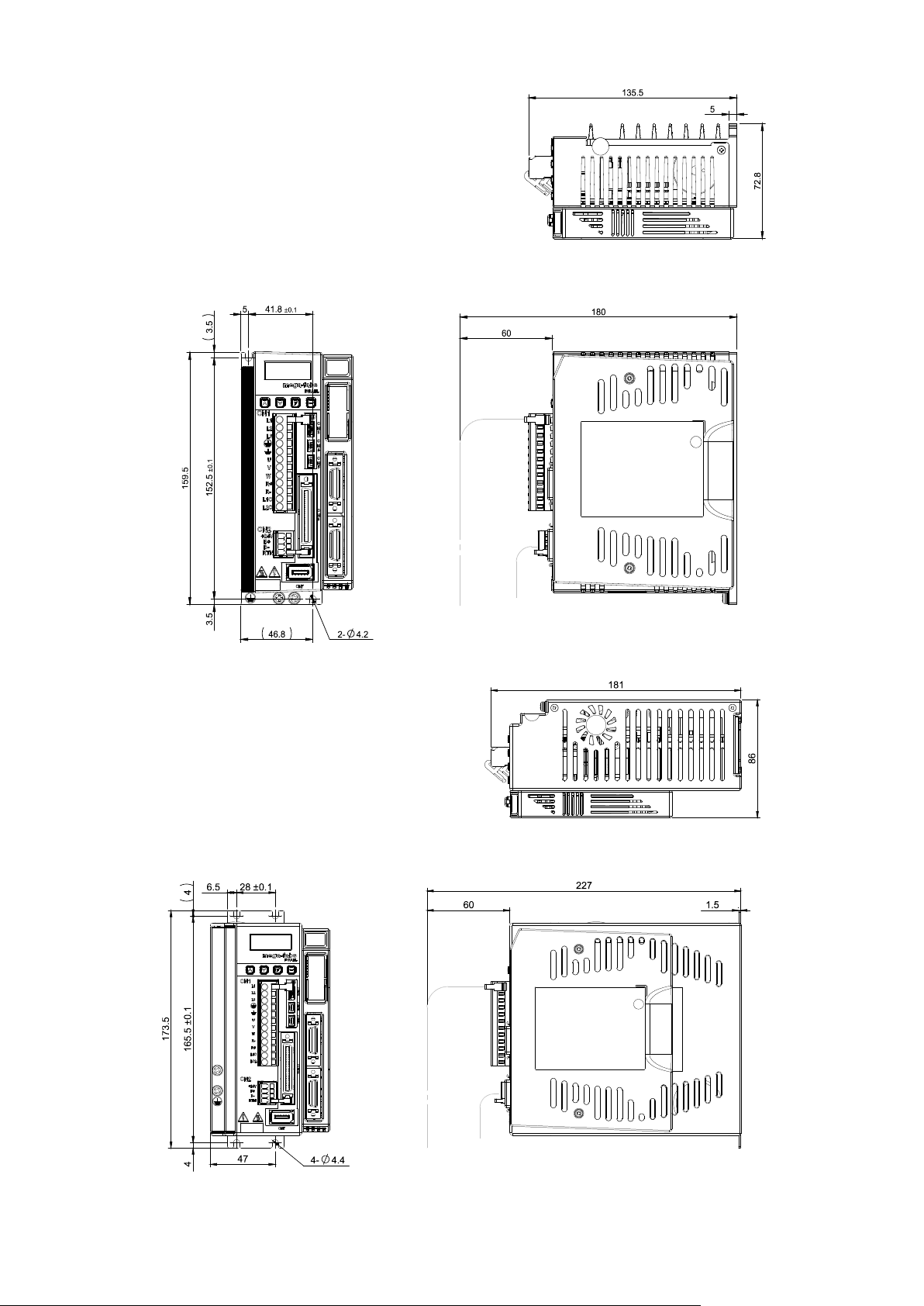

D2-DNN44A

D2-DNN45A

Fig. 2-8 Dimensions of frame B model with the EtherCAT module

Fig. 2-9 Dimensions of frame C model with the EtherCAT module

HIWIN Mikrosystem Corp. 17

D2 Drive User Guide v1.8 2. Specifications

D2-DNN57A

D2-DNN54A

Fig. 2-10 Dimensions of frame D model with the EtherCAT module

Fig. 2-11 Dimensions of frame A model with the extension I/O module

HIWIN Mikrosystem Corp. 18

D2 Drive User Guide v1.8 2. Specifications

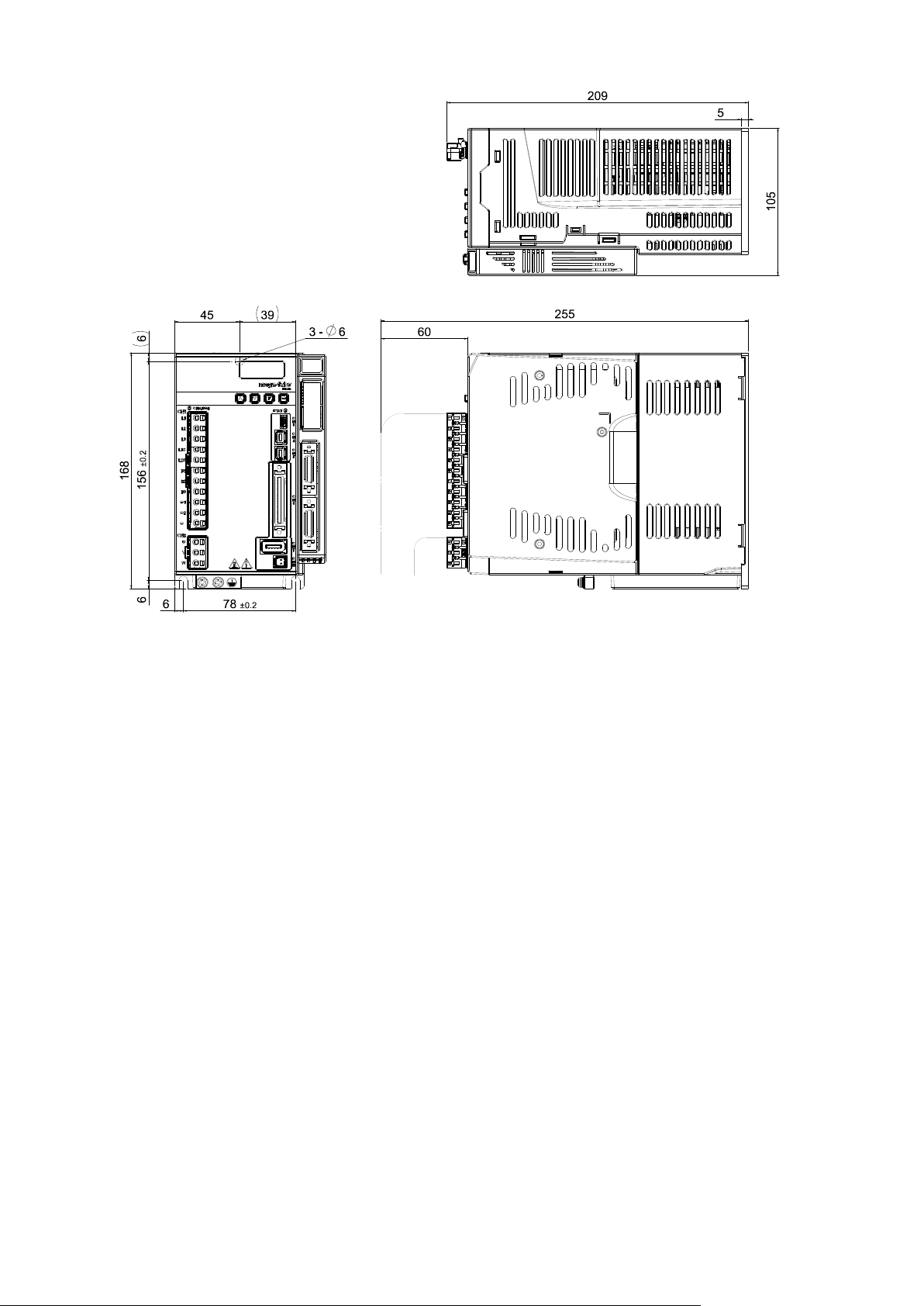

D2-DNN55A

D2-DNN56A

Fig. 2-12 Dimensions of frame B model with the extension I/O module

Fig. 2-13 Dimensions of frame C model with the extension I/O module

HIWIN Mikrosystem Corp. 19

D2 Drive User Guide v1.8 2. Specifications

D2-DNN53A

Fig. 2-14 Dimensions of frame D model with the extension I/O module

HIWIN Mikrosystem Corp. 20

D2 Drive User Guide v1.8 2. Specifications

50 mm

or more

20 mm

or more

20 mm

or more

50 mm

or more

Electric

cabinet

50 mm

or more

50 mm

or more

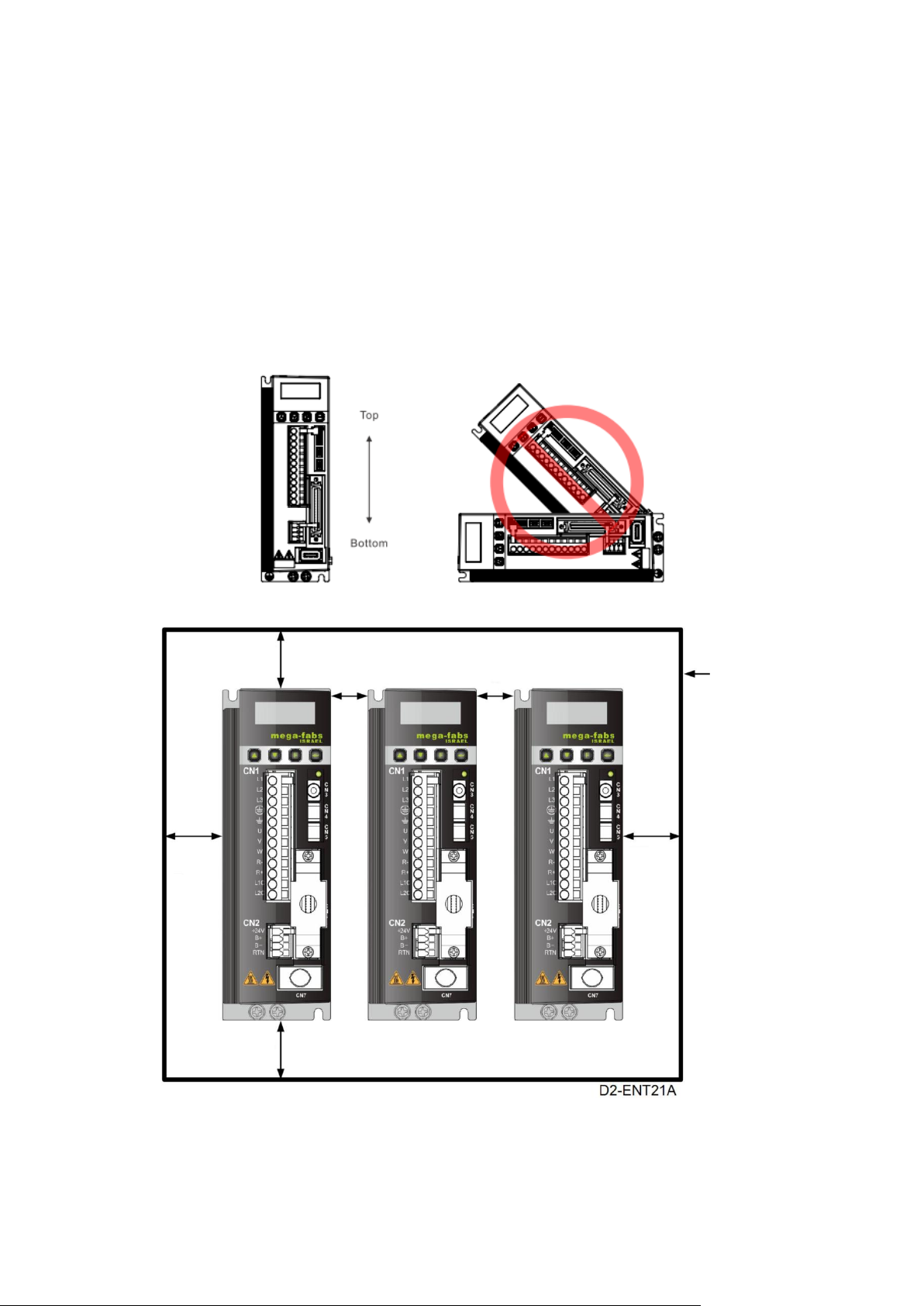

2.4. Drive installation

To fix drive in the used environment (e.g. electric cabinet), conductive screws must be used to

secure drive to electric cabinet. Moreover, insulating materials (e.g. paint) on the contact

surface of electric cabinet must be removed, so that the drive can connect to ground through

the machine. If the main power of drive is 220 V, the grounding resistance must be less than

50 Ω; if 110 V, it must be less than 100 Ω.

Installing drive must be careful, not to shut suction hole and vent, and not place it in the

inclined position. Otherwise, it will cause drive failure. In order to ensure that the effect of

cooling circulation is well, installing drive should keep an enough space between the drive and

the adjacent article or baffle. If more than one drive is installed, keep the space between

drives more than 20 mm, such that the drive has an enough space for heat dissipation. Fans

can be set in the electric cabinet to facilitate the heat dissipation of drives.

Fig. 2-15

Fig. 2-16 Space between drives

HIWIN Mikrosystem Corp. 21

D2 Drive User Guide v1.8 2. Specifications

CPU

1.0 GHz or more

RAM

512 MB or more

Available space on

the hard disk

50 MB or more

Communication port

USB

Operating system

Windows 2000, Windows XP, Windows 7

Screen resolution

1024 x 768 pixels or more

2.5. Computer requirements

Table 2-3

HIWIN Mikrosystem Corp. 22

D2 Drive User Guide v1.8 3. Operation Principles

3. Operation Principles

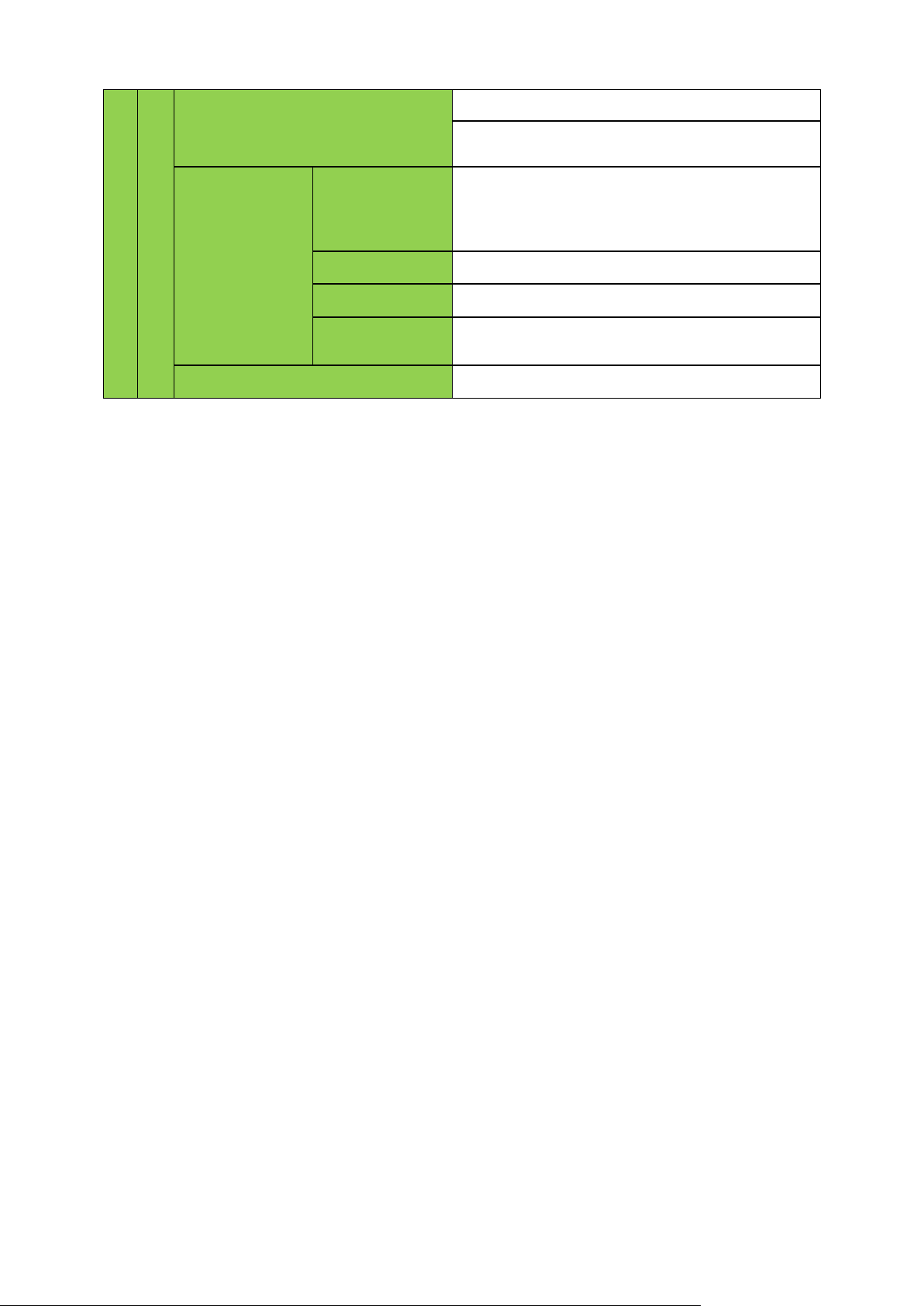

3. Operation Principles ....................................................................................................... 23

3.1. Operation modes .................................................................................................. 24

3.1.1.

3.1.2.

3.1.3.

3.1.4.

3.2. Encoder type ........................................................................................................ 26

3.3. Encoder signal output ........................................................................................... 27

3.4. Path planning ....................................................................................................... 28

3.5. Servo loops and gains .......................................................................................... 30

3.6. Gain margin and phase margin ............................................................................ 31

3.6.1.

3.6.2.

3.7. Move and settling ................................................................................................. 34

3.8. Error compensation .............................................................................................. 35

3.9. Velocity ripple ....................................................................................................... 36

3.10. Enable .................................................................................................................. 37

3.11. Common physical quantities ................................................................................. 38

Position mode ............................................................................................. 24

Velocity mode ............................................................................................. 24

Force/torque mode ..................................................................................... 25

Stand-alone mode ...................................................................................... 25

Nyquist diagram .......................................................................................... 31

Bode diagram ............................................................................................. 32

HIWIN Mikrosystem Corp. 23

D2 Drive User Guide v1.8 3. Operation Principles

Pulse input

Dir input

A-phase input

B-phase input

CCW input

CW input

Reversal

Forward

Forward

Forward

Reversal

Reversal

3.1. Operation modes

The following operation modes can be used to implement the interface between the standard

D2 drive and the host controller.

(1) Position mode;

(2) Velocity mode;

(3) Force/torque mode;

(4) Stand-alone mode.

Each mode is described as follows.

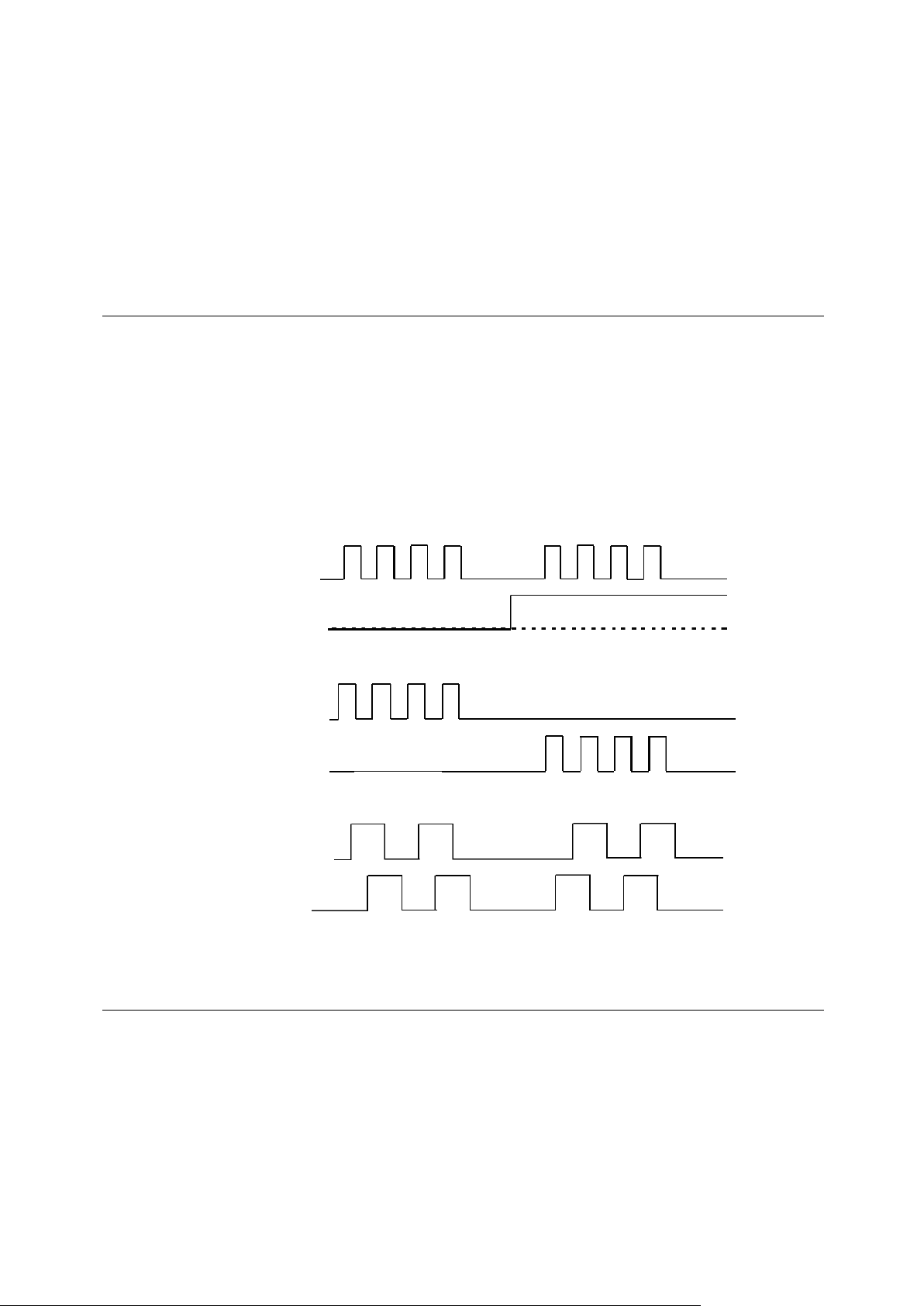

3.1.1. Position mode

The host controller sends pulses to drive. These pulses are equal to position commands.

When the drive receives a pulse, it moves the motor with a corresponding distance. The host

controller is responsible for path planning. The pulse is sent faster and faster at the

acceleration, and is sent with a fixed frequency at the constant speed. As shown in Fig. 3-1,

there are three formats of pulse signal: pulse/direction (pulse/dir), pulse up/pulse down

(CW/CCW), and quadrature (AqB). Based on the hardware wiring, the pulse signal can be

classified into the differential and single-end TTL logic signals.

The electronic gear can be set in the position mode. One input pulse is normally set to be

equal to one encoder count. For example, the gear ratio of 2:3 means that 2 input pulses is

equal to 3 encoder counts.

Fig. 3-1

3.1.2. Velocity mode

The drive can receive the command from the host controller via voltage, so as called V

command. The input voltage range is from -10 V to +10 V. The drive converts the received

external voltage to the corresponding velocity command to drive the motor. Besides the

voltage, the host controller can also send the velocity command via PWM signal, so as called

PWM command. It utilizes different duty cycles to correspond to different velocity commands.

There are two types of PWM command: single-line type (PWM 50%) and dual-line type (PWM

100%). The single-line type (PWM 50%) takes the duty cycle of 50% as the basis. If the duty

cycle of PWM command is less than 50%, the motor performs the reverse motion; while if

greater than 50%, the motor performs the forward motion. In addition to using one pin to

transmit PWM command, the dual-line type (PWM 100%) needs another pin to control motion

HIWIN Mikrosystem Corp. 24

D2 Drive User Guide v1.8 3. Operation Principles

direction.

(1) Use voltage command

The drive converts the analog voltage to the velocity command to control the speed of

motor movement. The higher the voltage is, the faster the output speed is. However, the

maximum output speed is limited by the maximum motor speed. The lower the voltage is,

the slower the output speed is. When the voltage value is negative, the output speed is

negative and the motor moves in the reverse direction. The drive can set the command

speed corresponding to the voltage per unit.

(2) Use PWM command

The drive converts the PWM signal to the velocity command to control the speed of motor

movement. It can set the command speed corresponding to “Full PWM”.

3.1.3. Force/torque mode

In the force/torque mode, the command from the host controller, which can be received by the

drive, is the same as that in the velocity mode. There are V command and PWM command.

After the drive receives these two commands, it converts them to the corresponding current to

drive the motor.

(1) Use voltage command

The drive converts the analog voltage to the current command. By controlling the output

current of drive, it can control the force or torque of motor movement. The higher the

voltage is, the larger the output current is. However, the maximum output current is limited

by the maximum motor current. The lower the voltage is, the smaller the output current is.

When the voltage value is negative, the output current is negative and the motor moves in

the reverse direction. The drive can set the command current corresponding to the

voltage per unit.

(2) Use PWM command

The drive converts the PWM signal to the current command to control the force or torque

of motor movement. It can set the command current correspond to “Full PWM”.

3.1.4. Stand-alone mode

There is one high-speed DSP on the inside of drive. Therefore, the drive can plan the motion

profile by itself. If the drive needs to do test alone or without any host controller (e.g. only the

servo motor and drive), the stand-alone mode can be selected to let drive be responsible for

all control loops.

HIWIN Mikrosystem Corp. 25

D2 Drive User Guide v1.8 3. Operation Principles

Resolution

Grating Period

3.2. Encoder type

The encoder usually plays an important role in the servo motor control. It provides the

information of drive position or angle to realize the servo-loop control. There are two types of

commonly used encoder: digital type and analog type. D2-series drives only support the

digital encoder presently, but not analog encoder.

(1) Digital type

The digital or so-called incremental encoder normally outputs the differential signal of TTL

RS422. The main feature of this signal is two digital pulses with the 90°-phase difference.

The definition of resolution for this signal is given in Fig. 3-2

(2) Analog type

The analog encoder has two-phase signals: sin and cos. The hardware normally takes

the differential signal of 1 Vpp. The main feature of this signal is two sinusoidal signals

with the 90°-phase difference. Its specification is normally represented by the grating

period. For example, the grating period of common linear analog scale is 40 um.

Fig. 3-2

Fig. 3-3

HIWIN Mikrosystem Corp. 26

D2 Drive User Guide v1.8 3. Operation Principles

Encoder

D2

Switchable

Signal

Processing

Emulated

Output

Buffered

3.3. Encoder signal output

The input signal of encoder is used to perform the servo control by the servo drive. When the

drive works with the host controller, the host controller also has the requirement of receiving

position signal. Normally, the drive will transmit the position or angle signal received from the

encoder to the host controller. D2 drive provides the following two modes of encoder output.

(1) Buffered encoder output

When this mode is selected, the drive sends the received encoder signal to the host

controller directly. Besides, if the invert of encoder signal is required, check the option of

invert function. At this time, the drive inverts the received encoder signal and sends it out.

(2) Emulated encoder output

When this mode is selected, the drive multiplies the received encoder position by a scale

and sends it out to the host controller. For some cases, if the host controller cannot

receive the encoder signal with a too high frequency, the scale can be set to lower the

frequency of encoder output. In addition, if the multiplier factor of analog encoder is set

too high, the scale can also be set to lower the resolution of encoder output.

Encoder

Output

Encoder

Fig. 3-4

HIWIN Mikrosystem Corp. 27

D2 Drive User Guide v1.8 3. Operation Principles

Time (t)

Position (p)

Velocity (v)

Acceleration (a)

3.4. Path planning

The main purpose of path planning is that the host controller calculates the suitable motion

command based on the user’s actual requirement of distance, velocity, acceleration, and

smooth factor, as shown in Fig. 3-5. This command (pulse or V command) is sent to the drive

by the host controller, or calculated by the drive itself (stand-alone mode). Different

configurations are adopted according to different applications.

Fig. 3-5

(1) Position

The encoder provides the position information of motor to the drive, such that the drive

can realize the current motor position. For the linear motion, common position units are

um, mm, and m; while for rotary motion, it is the encoder count. For D2 drive, “Reference

position” denotes the position command, which is calculated by the path generator based

on the related parameters. However, “Target position” is the target position set by the

user or host controller. After this parameter is sent to the drive, normally, it needs to be

calculated by the path generator so as to let motor move.

(2) Velocity

The velocity is defined as the difference of position per unit time. For linear motion,

velocity units are um/sec, mm/sec, m/sec; while for rotary motion, they are count/sec, rps,

and rpm.

(3) Acceleration

The acceleration is defined as the difference of velocity per unit time. For linear motion,

acceleration units are um/sec2, mm/sec2, and m/sec2; while for rotary motion, it is rps2.

(4) Smooth factor

When the acceleration is rapidly increased or decreased in a short time, it means that the

force applied to moving object is suddenly increased or decreased. Sometimes, to reduce

such impact, the technique of smooth motion is introduced to the motion control loop, so

as to enhance the performance. D2-serise drives adopt the technique of smooth factor to

achieve this effect. By using the smooth factor, the motion trajectory can be planned to

S-type or T-type curve. Its value can be set from 0 to 500. If this value is larger, the

trajectory is closer to S-Type curve and the impact is smaller. On the other hand, if this

value is smaller, the trajectory is closer to T-Type curve. As this value being 1, it means

that there is no effect of smooth function. When the value of smooth factor is increased, in

some case, the settling performance during positioning process will be enhanced, since

the impact of motor force is reduced. However, when the motion becomes smoother, the

move time of path planning is unavoidably increased. Tests on the practical machine are

needed to adjust the smooth factor, so as to get the balance between them. As the

smooth factor is set to 0, the motion protection of drive is disable.

HIWIN Mikrosystem Corp. 28

D2 Drive User Guide v1.8 3. Operation Principles

(5) Emergency stop

D2-series drives have the function of emergency stop. When the drive deactivates the

signal of “Axis enable” on the pin I3, this function is activated. At this moment, the drive

immediately stops the motor in any motion by using the deceleration for emergency stop

to guarantee safety.

HIWIN Mikrosystem Corp. 29

D2 Drive User Guide v1.8 3. Operation Principles

Common

Gain

Position

Loop

Velocity

Loop

Filter

Current

Loop

Filter

Motor &

Encoder

Actual Current

Feedback Velocity

Feedback Position

Target

Position

Reference

Position

Reference

Velocity

Command

Current

PWM

Output

0.1

……………………………………5……………………………………

1

Control rigidity

Response

High

Low

3.5. Servo loops and gains

(1) Servo loops

There are three types of control loop for D2 drive: current, velocity, and position control

loops to implement the servo motor control. The architecture of drive’s servo loop is

described in Fig. 3-6. In the position mode, three loops should be connected in sequence

to perform the position control for the motor. In the velocity mode, the velocity loop should

use the current loop to drive the motor. However, in the current mode, the current loop

only controls the phase commutation mechanism of motor, and its command is controlled

by the voltage command from the host controller. To simplify gain parameters of servo

loops, D2 drive only uses one common gain (CG) to set and adjust the overall

control-loop architecture.

Fig. 3-6

(2) Servo gains

D2 drive uses one high-speed DSP to implement the motor control. Generally, when the

servo loop is implemented by the digital method, it needs to adjust many servo gains.

However, this drive adopts an ingenious control design to simplify servo gains as one

common gain to significantly improve convenience.

Fig. 3-7

HIWIN Mikrosystem Corp. 30

D2 Drive User Guide v1.8 3. Operation Principles

)

( p j

G

0

p

G

Re

G

j

Im

Plane

j

G

Phase crossover

0

)(log

)(

log

p

p

jG

jG

1010

20

1

20

3.6. Gain margin and phase margin

3.6.1. Nyquist diagram

Gain margin (GM) is defined as that the loop gain, calculated by dB, can be increased before

the close-loop system becomes unstable. On the other hand, phase margin (PM) is defined as

that the phase delay can be increased before the close-loop system becomes unstable.

(1) Gain margin:

Denote G(jωp) as the relative distance from the intersection of Nyquist diagram and the

negative real axis to the point (-1, j0), where ωp is the frequency at the phase crossover.

The example of G(jωp) = 180° is shown in Fig. 3-8. For the transfer function G(s) in a

loop system,

gain margin = GM = dB.

Following results can be derived from Fig. 3-8 and characteristics of Nyquist diagram.

a. If G(jω) does not intersect with the negative real axis, |G(jωp)| = 0 and GM = dB.

When the Nyquist diagram does not intersect with the negative real axis at any

non-zero and finite frequency, GM = dB. Theoretically, the loop gain can be

increased to be infinite before the system becomes unstable.

b. If G(jω) intersects with the negative real axis between 0 and -1, 0 < |G(jωp)| < 1 and

GM > 0 dB. When the Nyquist diagram intersects with the negative real axis between

0 and -1 at any frequency, the system is stable as increasing loop gain.

c. If G(jω) is at the point (-1, j0), |G(jωp)| = 1 and GM = 0 dB. When the Nyquist diagram

G(jω) is at the point (-1, j0), GM = 0 dB. This means that the system reaches the

unstable boundary and the loop gain cannot be increased any more.

d. If G(jω) passes by the point (-1, j0), |G(jωp)| > 1 and GM < 0 dB. When the Nyquist

diagram G(jω) passes by the point (-1, j0), GM < 0 dB. At this time, GM must be

reduced to achieve the steady state of loop gain.

HIWIN Mikrosystem Corp. 31

Fig. 3-8 Gain margin of Nyquist diagram

D2 Drive User Guide v1.8 3. Operation Principles

40

20 0 -20

-40

-60

-360

0

-90

-180

-270

Gain crossover

gp

Phase crossover

Gain margin

Phase

margin

)()( dBjG

(deg)

)

( j G

sec)

/ ( rad

sec)

/ ( rad

0

g

G

Re G j

Im

Plane

j

G

Gain

crossover

0

1

-1

Phase margin

(2) Phase margin

Phase margin is defined as that the angle between the straight line passing through the

gain crossover and the negative real axis of G(jω)-plane, as shown in Fig. 3-9.

Phase margin = PM = G(jωg) -180°.

Fig. 3-9 Phase margin of Nyquist diagram

3.6.2. Bode diagram

The gain margin and phase margin of Bode diagram are given in Fig. 3-10.

Fig. 3-10 Gain margin and phase margin of Bode diagram

HIWIN Mikrosystem Corp. 32

D2 Drive User Guide v1.8 3. Operation Principles

0 dB

-3 dB

Bandwidth

Gain (dB)

f

The bandwidth of Bode diagram is defined as the frequency at -3 dB, as shown in Fig. 3-11.

Fig. 3-11 Bandwidth of Bode diagram

HIWIN Mikrosystem Corp. 33

D2 Drive User Guide v1.8 3. Operation Principles

Total time

Move time

Settling time

T

Position

- target radius

Reference

Feedback position

Position

Time

After entering the radius

“In-position” signal.

3.7. Move and settling

The motor moves based on the path planned by the host controller. When it arrives at the

target position, it is able to position accurately and stop motion. This is called move and

settling.

(1) Position error

In the servo system, there is a certain difference between the target position and the

encoder feedback position. This is called position error.

(2) Target radius

After the motor arrives at the target position, the difference between the feedback position

and the target position must be controlled and kept within a specific positive/negative

small range. This range is called target radius.

(3) Total time of move and settling

As shown in Fig. 3-12, after the motor arrives at the target position, the position error

should be smaller than the setting of target radius and keep for a certain time (debounce

time). After that, the “In-position” signal is set and called in position. If the position error is

continuously out the radius, it is called not yet in position. The total time spent from the

motion start to the settling achievement is the amount of move time and settling time.

position

arget

for a debounce time,

send out the

Fig. 3-12

HIWIN Mikrosystem Corp. 34

D2 Drive User Guide v1.8 3. Operation Principles

drive

Host Controller

Feedback position

input from encoder

Error map

Motor cable

Feedback

position output

Pulse command

input

Mapping effective area

+ position

+ position

index

Mapping effective area

Home offset

= 100

Drive coordinate = 0

Drive coordinate = -100

index

Drive coordinate = 0

3.8. Error compensation

Normally, the positioning accuracy of drive is determined by the performance of encoder. But

sometimes, the encoder cannot completely meet the requirement of accuracy. In this case,

instruments with the higher level of accuracy (e.g. laser interferometer) should be applied to

measure the system error. D2 drive has one high-performance control method. It saves the

measured error data into the error map of drive, as shown in Fig. 3-13, and uses this data

during motion. By adopting the method of linear interpolation between the fixed distance, it

calculates the value of error compensation to enhance the positioning accuracy.

Motor D2

Fig. 3-13

The mapping effective area is determined by the index signal. The area from the index

towards positive direction is the mapping effective area; while the area from the index towards

negative direction is the area without mapping. As shown in the following figure, the mapping

effective area for non-zero home offset is the same as that for zero home offset.

A. Home offset = 0

B. Home offset = 100

HIWIN Mikrosystem Corp. 35

Fig. 3-14

D2 Drive User Guide v1.8 3. Operation Principles

%,RippleVelocity 100

2

1

V

VV

target

minmax

(a)

(b)

Constant

Velocity

Constant

Velocity

V

V

V

target

V

V

target

V

3.9. Velocity ripple

Generally in the motion control, it is always desirable that the motion in the constant-speed

phase is as smooth as possible. The motion stability can be estimated by the index of velocity

ripple. Main factors causing the variation in the constant-speed phase are the motor cogging

force, cable chain, air pipeline, and guideway friction, and so on. This velocity ripple is usually

used for scanning or detecting machines required high stability in the constant-speed phase.

The equation of velocity ripple is:

where V

and V

is the target velocity, V

target

is the minimum velocity in the constant-speed phase. As shown in Fig. 3-15, the

min

is the maximum velocity in the constant-speed phase,

max

velocity ripple of (a) is larger indicated less steadiness; while (b) is smaller indicated better

steadiness.

Fig. 3-15

HIWIN Mikrosystem Corp. 36

D2 Drive User Guide v1.8 3. Operation Principles

3.10. Enable

The enable is a necessary step before the drive starts to receive any motion command. Only

at the enable state, the drive can receive the pulse or voltage command from the host

controller to do motion.

(1) Step motion mode

The step motion (SM) mode is an open-loop architecture. At this mode, the motor

behavior is similar as the stepper motor. The signal of feedback position is not adopted at

the enable. This mode is used to ensure that the force direction of motor is consistent with

the direction of encoder feedback. If not, it will cause the failure of phase initialization.

(2) Phase initialization

For the drive with the incremental encoder, it needs to find the electrical angle at the first

power-on, called phase initialization. For HIWIN servo motors, after the drive is booted, it

is able to successfully find the electrical angle almost without any movement at the first

enable process. The other common method of phase initialization is to add Hall sensor to

achieve the same effect. Generally, the host controller sends an output signal to the drive

(e.g. the input I3 of D2 drive) to complete the phase initialization and enable process.

HIWIN Mikrosystem Corp. 37

D2 Drive User Guide v1.8 3. Operation Principles

No.

Physical quantities

Description

1

Feedback Position

Feedback position

2

Reference Position

Position command

3

Target Position

Target position

4