OWNER’S MANUAL

INSTALLATION AND OPERATION

Model 55 Furnace

Model 82 Furnace

Model 55 Model 82

Save this Manual

· Operating Instructions and Maintenance Enclosed.

· Thoroughly Read and Understand Instructions.

· Always Leave this Manual with Stove Owner.

Warning

· Follow the instructions within this manual. If instructions are NOT followed, a fire

may result causing property damage personal injury, or death.

· Stove surfaces may become HOT while in operation. High stove temperatures may

ignite clothing or flammable material.

· For use of solid fuels, wood or coal only. Other fuel sources can result in poisonous

gas emission and/or fire.

· Carbon Monoxide and Smoke Detectors in home must be present and working

properly.

Page 1

Table of Contents

I. Welcome to the Hitzer Family

A. Safety Notice

II. Flue System

A. Existing Masonry Flue System

B. Factory Built Systems

C. Flue Requirements

1. Flue Size

2. 10 foot / 2 foot / 3 foot minimum rule

3. One Appliance per Chimney

III. Location and Installation

A. Typical Installation

B. Floor / Wall Protection

C. Clearance Reduction

IV. Basic Rules and Regulations for Safe and Efficiency Operations

A. Cautions

B. Local Codes

C. NFPA 211

V. Start Up, Operations, and Maintaining Appliance

A. Start Up

B. Basic Instructions

C. Ash Removal

Page 2

I. Welcome to Hitzer Family

Hitzer Inc. welcomes you to a proud and unified team of Hitzer stove owners. Thank

You for your recent purchase of a Hitzer Furnace. We can assure that your Hitzer stove

has the finest Swiss Amish Craftsmanship. The Hitzer Furnace is built with premier

quality materials to ensure safety, durability, and performance. These are all top

priorities in the Hitzer line of products.

We would like to personally thank you again and welcome you into our continually

growing Hitzer Family. We wish you and your family an extended amount of warmth and

comfort, provided by your new Hitzer Stove. Thanks for choosing Hitzer as “Our Stoves

Make Warm Friends.”

Safety Notice

Safety Notice: If this Hitzer Stove is not properly installed a house fire may result. For

your safety and to reduce the risk of fire, follow the installation instructions carefully.

Failure to follow these instructions may result in property damage, bodily injury, or even

death. Contact your local building inspector or fire officials about the need for a permit,

restrictions, or installation inspection required in your area. Save these instructions for

future reference.

UL Tested/Label: Follow the information and clearance charts located on each Hitzer

Stove Model. These stoves have been tested to UL 391-2006, approved, and labeled

on the rear of each stove.

It is strongly recommended to have this Hitzer Stove installed by an educated and

certified installation professional. Please refer to a NFI (National Fireplace Institute)

Certified Installer for your installation needs and questions. Locate an NFI professional

at www.nficertified.org.

II. Flue Systems

Page 3

Masonry Flue System: A good chimney is essential. A masonry chimney must be built

with a low heat masonry material. It is important to make sure that the masonry

chimney is structurally sound and on a solid foundation. The masonry chimney must

have a liner installed with in the chimney construction. An unlined chimney is not safe

with solid fuel systems, and may result in a house fire. The liner may be constructed

with a structurally sound clay liner or a stainless steel liner. If using an existing masonry

chimney, be sure to have the chimney examined and cleaned by a chimney

professional. The structural foundation of the chimney and liner is important. If existing

clay liner is cracked or damaged, it is recommended to re-line the chimney with a

stainless steel liner. Be sure the masonry chimney is compatible with the local building

codes and requirements. It is important to note that you can only have one solid fuel

appliance per chimney, and it is not permissible to connect the Hitzer Stove to a

chimney that is servicing another unit.

Factory Built System: A good chimney is essential. The factory built chimney must be

a Class A High Temperature UL tested chimney UL 103 HT. It is required for this Class

A chimney to be listed and labeled under the UL standards. If using an existing factory

built Class A chimney it must be inspected and cleaned by a certified chimney

professional, before use. With Factory Built Chimneys clearances and distance

requirements are required per chimney style. Be sure to follow the manufacturer’s

clearances and regulations. It is also important to abide by the rules and regulations of

local jurisdictions upon chimney installation. Like masonry chimneys, you can only have

one appliance per chimney, and it is not permissible to connect the Hitzer Stove to a

chimney that is servicing another unit.

Flue Requirements: It is required to have your chimney inspected and cleaned by a

certified chimney professional before Hitzer Stove installation, and at least twice

monthly during the heating season. If material has accumulated, it should be removed

immediately to reduce the risk of a chimney fire. If a chimney fire does occur the fire

department should be called immediately and the draft controls should be closed on the

stove. It is also required to have a chimney that is built according to the manufacturer’s

specifications and meet local building codes.

Flue Size: The proper flue size is very important. The proper flue size is essential in

order to have the correct amount of draft required to operate the Hitzer Stove. The

diameter of the flue size including chimney liner should never be less than the diameter

of the flue exhaust collar on the Hitzer Furnace. The flue size for the 55 furnace should

be a minimum of 6 inches in diameter. The flue size for the 82 furnace should be a

minimum of 7 inches in diameter.

Flue Size (Continued): The flue size also has a maximum size of inches in order to

sustain the desired draft. For an interior chimney the flue and chimney liner size

cannot be larger than 3 times the square inches of the flue exhaust collar on the Hitzer

stove. For an exterior chimney that has at least one side exposed to the exterior of the

house the flue and chimney liner cannot be more than 2 times the square inches of the

flue exhaust collar of the Hitzer Stove. Also keep in mind the warmer the chimney is the

better the draft.

Page 4

Model Flue Size (Sq. Inch) Minimum (Sq. inch) Maximum (Sq. Inch)Int/Ext

55 FA 6” 28 sq. in. 6” 28 sq. in. 84 sq. in. interior

55 FA 6” 28 sq. in. 6” 28 sq. in. 56 sq. in. exterior

82FA 7” 38.5 sq. in. 7” 38 sq. in. 115.5 sq. in. interior

82FA 7” 38.5 sq. in. 7” 38 sq. in. 77 sq. in. exterior

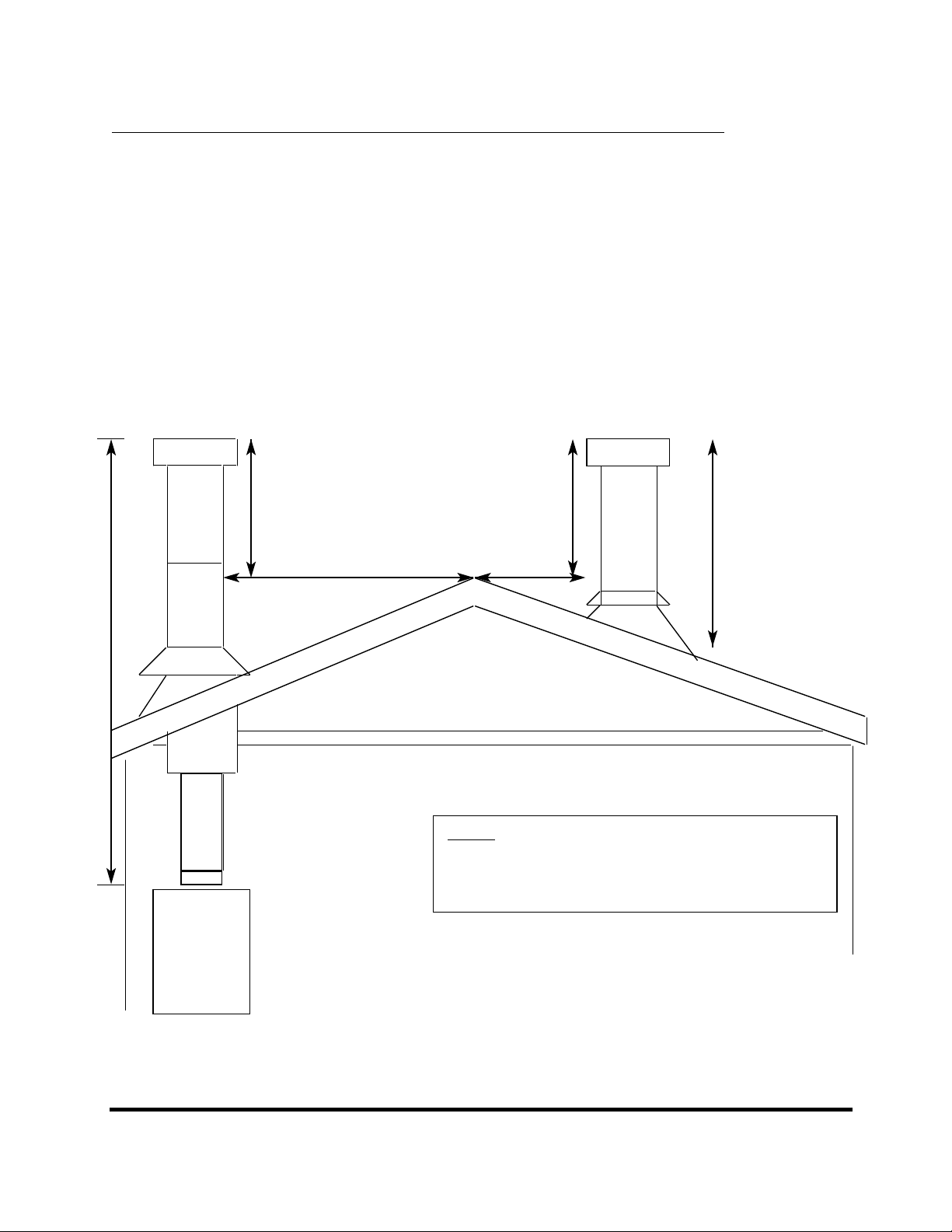

Chimney Height Requirements: The minimum height of a chimney system for the

Hitzer Stove is 15 feet. The chimney must exceed the roof of a house a minimum of 3

feet at any point of exit. In pitched roof installation the chimney must be 2 feet higher

than anything within a 10 foot radius of the chimney. It is important to have a chimney

draft of .03 - .06 It is required to abide by the manufacture’s instructions on class A

chimney’s as well as local building codes.

Note: All illustrations are for design purposes

only.

Actual installations may vary.

Illustrations are not drawn to scale.

III. Location of Stove and Installation

Page 5

The location of the stove is very important for optimum stove performance as well as

safety assurance. When searching for the location of the stove be sure to strictly follow

manufactures guidelines, clearance to combustible material requirements, local building,

and fire codes. Failure to follow manufacture’s instruction and local jurisdiction codes

may result in bodily injury, property damage, fire, or death. Locate the stove where

there is sufficient air supply for proper operation to occur. It is vitally important to locate

the stove next to existing forced air furnace as well as next to the chimney. The closer

placement to these two items the better the stove will perform, and achieve maximum

heat flow. The longer the chimney connector pipe (stovepipe) and farther away the

stove is from the chimney the less performance is achieved from the stove. Please

consider the construction and layout of the home to be heated and make placement of

the stove to achieve maximum heat benefit produced by the stove.

It is mandatory to abide by clearance to combustibles regulations provided by the Hitzer

Stove Manufacture. Failure to abide by the clearance requirements may result in a fire.

Clearance to Combustible Material: Floor Protection

Unit to Side Wall: 28” Front: 16”

Unit to Back Wall: 28” Side: 8”

Chimney Connecter to Back Wall: 18” Side: 8”

Chimney Connecter to Side Wall: 39” Rear: 8”

The installation of the Hitzer Stove Furnace is a vital part to performance and safety.

Requirements in regards to installation:

· Only one appliance is to be used per chimney, and cannot have multiply appliances per

chimney.

· Flue must be the same size as stove flue collar or within requirements of flue size

maximums (see page 5).

Page 6

· Chimney connector pipe (stove pipe) must be made of at least 24 gauge metal

U.L. tested pipe and be attached with crimped ends facing the stove. A minimum

of 3 screws is required at each connection point.

· Masonry or manufactured thimble must be longer than the thickness of the wall

and does not intrude into chimney more than 2”.

· Thimble may be constructed of approved clay liner thimble tested and labeled.

With a 12” non-combustible clearance zone on each side of thimble. Please use

NFPA 211 instructions and requirements in regarding thimble information.

· Thimble may be a manufactured thimble or class A chimney pipe. A

manufactured component must be installed with listed components accessories

and meet manufacturer’s specifications.

· It is required to have thimble clearances to combustible material as required by

manufacturer and NFPA 211.

· NFPA 211 codes must be followed and an 18” clearance to combustible material

is required for chimney connectors.

· At least 2” clearance of fireproof material is required for protection through the

wall thimble of Class A insulated chimney pipe and follow manufacturers

specifications.

· A protective and UL listed and labeled floor pad must be used if placed on a

combustible floor material. This protective floor pad must have an insulating

factor of K-0-84. A solid non-combustible material such as brick or concrete

does not require an additional pad.

· DO NOT install in a garage.

Connecting Stove to Chimney: Connection of stove to the chimney should be

made as direct as possible. Not recommended to use more then 2 elbows for

venting. The pipe connecting the stove to the chimney should be at least 24 gauge

single wall pipe. Thicker gauges and double wall pipe may be used. A ¼ inch slope,

back toward the stove, per foot of horizontal run is required. This allows any

condensation forming in the pipe to flow back toward the stove. The connection pipe

should be installed so the upper pipe fits inside the lower pipe. Horizontal run pipe

should have the seam turned up. Note the point at which the flue passes through a

wall to the chimney. This penetration should be made with a class A chimney pipe

and used with the listed proper accessories according to manufacturer’s instructions.

Chimney connector (stove pipe) CANNOT pass through a ceiling, wall, concealed

space, or enter the chimney. Three screws must be attached at each connection

point of the chimney connector. When the Class A chimney pipe connects to the

masonry, it must be cemented to the chimney, or a thimble must be connected to the

chimney and the pipe should be tightly inserted into the thimble without cementing.

WARNING: FIRE RISK

Follow Chimney Connector Manufacturer’s

Instructions for Proper Installation

Page 7

ONLY use connector within the same room between

appliance and ceiling or wall

Chimney Connector shall not pass through:

attic or roof

closet or concealed space

floor or ceiling

Typical Installations

Below are typical ways of approved installation formats. Note: these illustrations reflect

typical installations and are for design purposes only. Illustrations and diagrams are for

informational purposes only. These diagrams are not drawn to scale. Actual installation

procedures may vary

NOTE: It is always best to run the supply duct up. The supply duct must be

constructed of material with a minimum 250° temperature rating. In the case of a power

outage the stove can still be utilized. With the supply duct up, this will allow gravity heat

to still rise into the system. The plenum on the stove must be constructed of metal.

Page 8

Page 9

Typical Wrong Installation

Do not have supply hot air flow downward as this will not allow the Hitzer Furnace to

operate properly without electricity

Do not have the supply air flow back into the blower of existing oil or gas furnace. This

will damage the existing furnace controls and/or void any warranty.

Do not have hot air from gas or oil furnace flow downward into the Hitzer Furnace and

flow out the Hitzer Furnace to existing duct work.

Air Duct Calculation Chart

Page 10

It is important to have the correct size of duct work that corresponds with the Hitzer

Furnace in order to achieve maximum performance of the Hitzer Stove. The 82 FA can

be equipped with a 960 CFM Blower, and the 55 FA can be equipped with a 460 CFM

Blower. In order to achieve maximum performance and heat, it is important to make

sure the duct work is sized properly and not too large for the blower assembly. If the

duct work is too large the Hitzer Furnace won’t achieve full potential. NOTE: These

calculations are based on a .10 static pressure.

Supply Duct Size Shape Approximate Capacity(CFM)

6” round 120

8” round 240

10” round 420

12” round 680

8”x12” rectangle 480

8”x16” rectangle 700

8”x 20” rectangle 910

8”x 22” rectangle 1000

8”x 24” rectangle 1200

Note: Return duct should be 12% larger than the supply

Floor/Wall/Ceiling Protection

Floor: A protective and UL listed and labeled floor pad must be used if placed on a

combustible floor material. This protective floor pad must have an insulating factor of K0-84. See figures on page 6.

The floor protection must be placed underneath the stove and extend at least 8 inches

on each side of the stove and 16 inches from the front fuel door of the stove. See

figures on page 6.

The floor protection must also be placed underneath the chimney connector (stove pipe)

and extend at least 2 inches on either side of the chimney connector.

If the floor surface is constructed of non-combustible material with a K value of 0-84,

such as a concrete floor, masonry, marble, or ceramic tile then a protective floor pad is

not required.

Wall/Ceiling: Wall/Ceiling protection must be place on the wall or ceiling if chimney

connector pipe is less than 18 inches away from combustible material. The clearance

reduction chart must be followed (See Figure Below) for the required percentage

reduction per non-combustible protection.

Page 11

Clearance From Combustibles Reduction Chart:

Type of Protection As Wall Protector As Ceiling Protector

a.)3 ½ ” Masonry Wall

no ventilation 33% ----

b.)1/2 ” noncombustible

insulation board over 1”

glass fiber or mineral

wool batts, no ventilation 50% 33%

c.)Minimum 24 gage sheet

metal spaced out 1” 66% 50%

d,)3 ½ masonry wall spaced

out 1” 66% ----

e.)1/2” noncombustible wall

spaced out over 1” 66% 50

NOTE: After reduction of listed clearances, clearances shall not be less than 12

inches to combustible walls and not less than 18 inches to combustible ceiling.

IV. Basic Regulations for Safe Operations

Standard Cautions:

CAUTION- Hot Surfaces WARNING-Risk of Fire

-Keep children away Do NOT operate with fuel or ash door open

-Do not touch during operation Do NOT store fuel or other combustible

material within marked installation clearances

DANGER-Risk of Fire/Explosion

-Wood/Coal Only

-Do NOT burn garbage, gasoline, Do NOT connect this unit to a chimney flue

oil, or any other flammable liquids serving another appliance.

CAUTION WARNING

Use caution when opening loading door. Have chimney inspected. The chimney

Avoid opening loading door rapidly. This is a very important part of your heating

could cause flame to flash out door. This system. It must be the right size,

occurs when there is unburned gas at the properly constructed, and in good

top of the fire box. When the door is condition. Chimney must be at least 15’

opened, oxygen combines with gases high and exceed the roof a minimum of

and ignites. 3 feet.

WARNING-Risk of Fire WARNING-Over Fire Unit

-Comply with all minimum clearances to Do NOT over fire your unit.

Page 12

combustibles as specified. This will cause warping of fire box parts,

-Failure to comply may cause fire. damage the stove, and void all warranty.

Local Codes:

All local codes should be strictly followed and inspected by local officials. Please follow

local building codes, manufacture codes, and fire codes. Local codes vary depending

on location and regulations. Communication and inspection in accordance with local

building and fire officials must be present and installation must successfully pass the

local professional inspection.

NFPA 211:

Installation procedures must be followed and required with strict correlation with NFPA

211.

V. Stove Operation, and Maintaining Appliance

Start up:

After installation has occurred by a certified professional and local building inspection

are completed and passed, stove ignition may precede. Make sure chimney is clean

and clear upon start up. Check the stove to make sure all parts are correctly positions

and functioning, as they may have been moved around during the installation process.

Once this has occurred, you may now begin to build a fire in your Hitzer Furnace.

When setting up the stove with blower and filter it must be assembled together. The

blower box must be fastened to blower flange on back of the stove. When using filter(s)

place 20 x 20 x1 filter in at least one, preferably two, of the sides of the removable

blower filter box sides. Remove the metal sides and slide the 20 x 20 x1 filters in the

place of the metal sides. It is suggested when hooking cold air return straight to the

Hitzer Stove to cut a hole in the blower filter box side to the adequate return air duct

size.

Note: For the first fire in your new Hitzer Furnace, create a small hot fire to allow paint

to cure to the stove. This may create a slight odor as paint cures to the stove. Let this

small fire burn for at least 2 hours before you fully load the stove to maximum heating

potential. NEVER USE: gasoline, kerosene, charcoal lighter fluid, or any other type of

flammable liquid to start your fire.

Burning Wood:

Page 13

Begin by opening all air inlet draft controls to the fully open position. To start a wood fire

cover the whole grate area with newspaper and small dry kindling. Next light the

newspaper with a match or lighting device. Create a hot kindling fire by adding more

kindling the hotter and longer the fire burns. Once a good hot kindling fire is

established, proceed to add larger wood splits. Start with a couple log splits on top of

you kindling fire. As the fire progresses add more log splits until the fire box is full.

Over a span of time you should now have created a warm fire inside your Hitzer

Furnace capable of your heating needs. Once fire is at the desired temperature close

the air inlet drafts, to moderate the temperature desired. Continue to add wood when

the fuel supply decreases if continuous burn is preferred.

Burning Anthracite Coal: (See Attached Burning Coal Paper)

Begin by opening all air inlet draft controls to the fully open position. Create a hot

kindling fire that has high temperatures. Next, layer coal over the grate area layering

coal on the entire firebox grate surface. Allow this first layer of coal to begin to burn.

After the first layer of coal is burning successfully, add another layer of coal on top of

the first layer. Allow enough time for the second layer to burn successfully. Then add a

third layer of coal over the entire grate area. Once the third layer has successfully

begun to burn, you may now fill the grate area to the top of the fire brick. This creates a

deep bed of coal. When the coal is successfully burning you may now close the air

intakes down to moderate the temperature desired.

Basic Instruction:

In order for the fuel inside the furnace to burn properly it must have air flow for

combustion to occur. Air can enter the Hitzer Furnace in two ways.

1. The primary air for combustion enters through the draft air inlet box at the rear of the

stove. This air inlet is controlled by the Dial-Heat Regulator. The air that is drawn into

the stove flows up through the grate area and into the firebox from the bottom. This is

important for proper combustion to occur. With the Dial-Heat Regulator it will

automatically adjust itself to how much air it needs, to maintain the stove temperature

for the Dial-Heat Number setting. The higher the number the Dial-Heat Regulator is set

on the more air is drawn into the stove, creating a warmer fire.

2. The second air intake is located on the fuel door, via spinner knob. This air intake

insures complete combustion as secondary air enters through these intakes. This

secondary air mixes with unburned gases and completes the combustion process.

Direct Draft Damper:

In front of the fuel door is the operating handle for the direct damper. When this rod is

up the damper is open. This direct damper should normally be closed except when the

door is open for fueling. It may be suggested to leave the damper up and open at times

in the fall and early spring to help prevent creosote or soot. The direct damper’s

purpose is to reduce heat loss up the chimney.

Page 14

Adjusting Temperature or Control:

When the room temperature reaches the desired temperature, turn the control knob on

the draft regulator until the draft damper just barely closes. The heater should then

maintain a uniform temperature without further attention as long as fuel supply is

sufficient. Sudden changes in exterior temperature may make it necessary to turn the

control knob slightly toward warmer or cooler from time to time. We do not advise

turning the regulator more than one number a day as it takes a while for the house

temperatures to stabilize to the new stove temperature.

Ash Removal:

Ash removal is an essential part of the Hitzer Furnace Operation. Too much ash build

up can restrict the air flow, crippling the combustion process causing a weak fire or the

fire to go out. Too much ash build up may cause damage to the Hitzer Furnace and

warp the parts located within the fire box.

Ash Removal (continued):

Ash removal is essential when burning Anthracite Coal. Anthracite coal requires a clear

air flow up through the grate area and through the coal. This requires ash removal to be

quite frequent. It is recommended to remove ash with anthracite coal at least once

daily, and often times more frequently depending on the amount of coal used and the

exterior temperature.

When burning wood, ash removal is not quite as frequent, as the stove operates best

with a layer of ash on the grates. Ash removal is still essential! Too much ash can

cause damage to the Hitzer Furnace and warp the parts located within the fire box.

To remove ashes simply open the ash door. Shake the grates with the shaker handle.

Use short, fast, vigorous strokes. Watch the ash fall into the ash pan. Continue

shaking the grates until red hot coals fall into the ash pan about the length of each

grate. Close the ash door and let the ashes cool in the ash pan. Never let ash in ash

pan build up against bottom of grates. If left in this position the ability of the grates to

perform properly will dissipate because of the insulating properties of the ash. Leaving

in this position will cause the grates to warp and become unusable. Make sure grates

are never turned upside down (center rib facing upward) or in a vertical position causing

the fire to surround the whole grates. All of these situations will warp and destroy the

grates.

Once hot coals are cool and ash pan is full you can now safely remove the ash pan

from the Hitzer Furnace. Dump the ashes in a metal container with a lid, such as a

Hitzer Ash Tote, that is placed on a non-combustible surface. Replace the ash pan back

into the Hitzer Furnace for future ash removal.

CAUTION CAUTION

Never let ashes build up to grate level Never use anything but a metal

Page 15

from ash pan.This will reduce the life of grate. container to put ashes in.

CAUTION-Hot Contents

CAUTION-Hot Contents

Wear protective gloves when

removing ash, and emptying

ash pan.

Further Information:

You may also contact your Hitzer dealer or Hitzer Inc., for questions or more information

regarding stove installation and operation. Hitzer Inc.

269 E Main St.

Berne, IN 46711

(260) 589-8536

Page 16

Loading...

Loading...