Page 1

Logic 2

and

Logic 3

Two Wire Irrigation Controllers

P.O. Box 929, 556 S. Mirage Avenue

Lindsay, CA 93247

For Technical Assistance: 800-468-0071 ext. 331

MADE IN THE USA

UPDATED 3/03/03

Read Entire Instruction Booklet Before Installation

Page 2

TABLE OF CONTENTS

1. Installing the Logic 2 and Logic 3, Valve Wiring

2. Valve Wiring

3. Selecting Proper Wire Size

4. Wire Connections

5. Testing Controller Surge Protect ion Board

6. Controller Lightning Protection

7. Features and Programming the Logic 2 and the Logic 3

8. Pre Wet, Fertigation and Setting Pause

9. Start Times, Total Run Times and Calendar

10. Definitions and Looping Program 6

11. Program/Master Valve ON/OFF, Test Cycle

12. Semi/Manual/Program Clear, Rain Delay, Run

13. Programming of Logic Receivers / Diamond Settings

14. Receiver Programming Instructions

15. Receiver Number Identification Tags, “Do’s & Don’ts”

16. Rain OFF Wiring Instructions

17. Rain OFF Diagram

18. Wire Chart

19. Wire Chart

20. Common Field Wiring Example

21. Field Wire Example-Pump Start Relay

22. Field Lightning and Surge Protection Wiring Diagram

Installation and field wiring instructions.

Read booklet completely before beginning installation.

NOTICE: Before installation, receivers must all be

programmed. See page 14 for receiver programming

instructions

Page 3

INSTALLING THE LOGIC

Mounting the controller. . .When seleting the controller installation location, make

sure controller and all related wiring is a minimum of 15 feet from any high

voltage control boxes, pumps or any high voltage equipment. This

irrigation controller is a computer and should be installed accordingly.

When mounting the LOGIC indoors, notice the "keyhole" shaped mounting slot

as well as 2 mounting holes on the back of the controller. Use the template

provided to locate mounting screw locations. Remove the four face plate screws

and two lower panel screws to access enclosure mounting screws. To attach to

wall studs, use a #10 screw, leaving 1/4" of the shank exposed to slip into the

"keyhole" slot. To additionally secure the controller, drive additional screws

through the bottom mounting holes into the stud or cross bracing.

When mounting the LOGIC outdoors, use the same procedure as above. When

attaching the controller to hollow walls, masonry, or cinder blocks, use

appropriate toggle bolts, masonry shields or compression drive bolts. For

additional weatherproofing, run a silicon bead around the case between the

controller and the wall. It is also recommended to fill mounting holes with silicon

as well, to prevent water or insects from entering the controller.

The LOGIC should be hard wired to the transformer by a qualified electrical

technician. Use an approved GFI device and utilize proper grounding

techniques using the green wire from controller transformer. This will help

assure safety as well as performance and reliability of the Logic controller.

The manufacturer’s warranty becomes invalid without proper grounding as

per local code. See enclosed “Installation Diagram for Primary Wiring”.

Warning! When connecting the field receivers, make sure there is no

power to the printed circuit board, controller and/or the receivers; this will

prevent the shorting of receivers and controller.

Unscrew the LOGIC bottom terminal plate and route two (or four) field wires

through the hole at the bottom of the controller. Secure each 2-wire run under the

appropriate terminal on the terminal strip labeled “Line 1” and “Line 2”. If using

both outputs “Line 1” and “Line 2”, keep each 2 wire set independent. Do not mix

output “Line 1” with output “Line 2”. It is strongly suggested to use different

colored wires for each wire used.

The Logic 2 an d Logic 3 Terminal Strip is labeled as follows:

1

Page 4

VALVE WIRING

Wire

The field wiring from the controller to the receivers consists of either one or two, 2-wire

runs, which connect, in series, to each valve location. Each 2-wire run is totally

independent of the other relative to wire size requirements and the number of valves

operating simultaneously. Both 2-wire runs receive and output the exact same

information. The purpose of 2 independent 2 wire runs are for reducing the potential

amount of “back tracking” when valves are located in more than one general direction

from the controller. Theoretically, with the Logic controller located in the center of an

irrigation project, one 2-wire run would go one direction and the other 2-wire run could

go the other direction. “Line 1” is one 2-wire run; “Line 2” is the second available 2-wire

run. The 2-wire runs start at the controller and end at the last receiver/valve for that wire

run. Do not loop or make a complete connected circle.

For the main 2-wire runs, it is very important to size the wire properly.

Consideration for designing the proper wire size includes the total wire distance

from controller to the farthest receiver and how many valves will be operating

simultaneously. Wire size must be designed using Ohm’s law for any

application.

The field wiring should consist of one or two continuous main 2 wire runs starting at the

controller terminal labeled “Line 1” or “Line 2” continuing to the last receiver/valve of

that wire run. If using the dual output feature, use one continuous length of wire

independently from each output “Line 1” and the second independent 2 wire run from

“Line 2”. Every receiver is to be connected directly anywhere on one of your main two wire continuous runs. Do not tee or branch the main two wire runs. To access remote

valve(s), attach the two red receiver wires (one red wire to each field wire) of the main

two wire run. Extend the black solenoid leads from the receiver and attach to the solenoid

at the valve. The distance from a receiver to the solenoid is limited only by standard wire

sizing/distance and voltage drop parameters. From the controller to the solenoid the

voltage can not exceed 7 voltage loss. The last receiver installed is the end of the main

two wire run. You may operate a maximum of four of the same numbered receivers or

four valves maximum of any random numbered receivers at any one time. This will

affect the wire size, as more power draw will be needed. (See wire-sizing guide.)

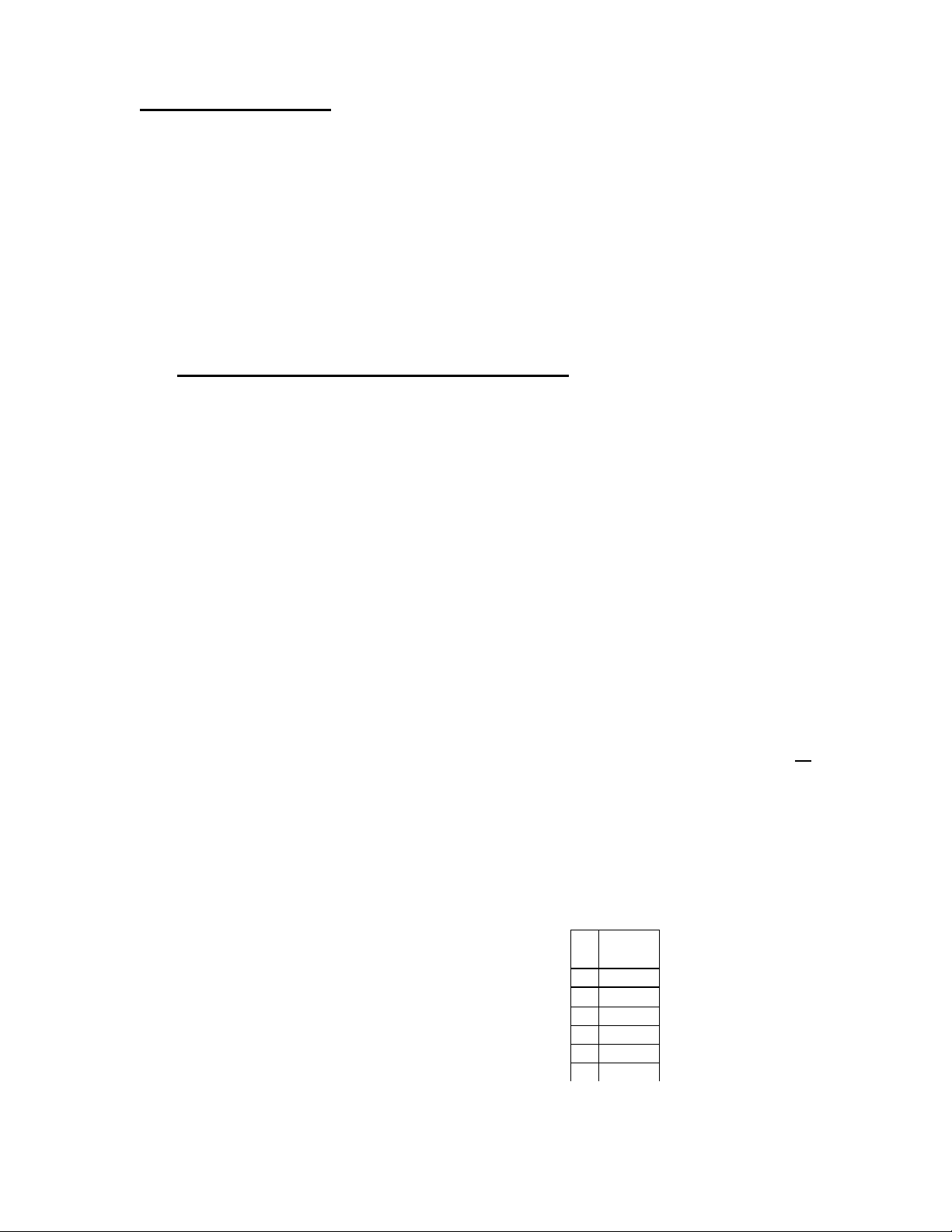

Use the following formula when designing your wire size for each Logic 2 wire run.

Consult attached wire charts to insure proper wire gage. Minimum wire size and type is

14 Ga. Always use direct bury, heavy jacket, solid core copper wire

.

Wire Size Formula is: VD = C x R x (2L) / 1000

"Ohms Law" Voltage Drop = Current x Resistance in Ohms

VD = Voltage Drop

C = Current (Solenoid Amperage Draw)

R = Resistance (Wire Size “Voltage Loss” Factor)

L = Length of distance between controller and valve in feet

2

Ohms Per

Size

1,000 Ft.

14 2.580

12 1.620

10 1.020

8 0.641

6 0.403

4 0.253

Page 5

The Logic is designed to allow for a 7 volt loss in the field wiring. By increasing

the wire size you decrease the voltage loss. The rule is the bigger the wire, the

smaller the voltage loss. Use only solid copper wire manufactured for Direct

Bury Applications. To calculate the voltage drop, use the charts on pages 18 and

19. For a maximum of one valve only operating simultaneously, the following

chart applies.

Total Length of Valves Operating Wire Size

Each 2 Wire Run Simultaneously Gauge MM2

Feet Meters

0-2,500 0-762 1 Valve #14 2.5

2,500-5,000 762-1,525 1 Valve #12 4

5,000-7,500 1,525-2,286 1 Valve #10 6

Calculating Voltage Drop and Proper Wire Sizing

Figure the wire distance from the controller to the farthest valve. Find that

distance by adding the distances on the chart and subsequent voltage drops.

Add these voltage drops to figure the total voltage drop at that wire size. Should

the voltage drop exceed 7.0 volts, the next larger sized wire should be calculated

until the voltage drop is equal to or less than 7.0 volts. For multiple valves

operating simultaneously, you must calculate and add the loss at each valve.

See example 1 and 2 below.

Example 1

Logic to V1 (Valve 1)

PROGRAM RECEIVER

1000´

PRE WET / FERTIGATION

MASTER ON

FERTIGATION ON

CALENDAR ODD / EVEN

MASTER CLEAR

Logic 1

To Valve

Controller

to V1

Total Voltage Drop 1.290 O.K. use 14 Ga

24 Volts less 1.290 = 22.71 Volts

Chart 1

.35 amps inrush charts Voltage Loss .25 amps holding chart Voltage Loss

Length 1 Valve 2 Valves 3 Valves 4 Valves Length 1 Valve 2 Valves 3 Valves 4 Valves

Wire Size 14 2.58 R factor Wire Size 14 2.58 R factor

100 0.181 0.361 0.542 0.722 100 0.129 0.258 0.387 0.516

200 0.361 0.722 1.084 1.445 200 0.258 0.516 0.774 1.032

300 0.542 1.084 1.625 2.167 300 0.387 0.774 1.161 1.548

400 0.722 1.445 2.167 2.890 400 0.516 1.032 1.548 2.064

500 0.903 1.806 2.709 3.612 500 0.645 1.290 1.935 2.580

600 1.084 2.167 3.251 4.334 600 0.774 1.548 2.322 3.096

700 1.264 2.528 3.793 5.057 700 0.903 1.806 2.709 3.612

800 1.445 2.890 4.334 5.779 800 1.032 2.064 3.096 4.128

900 1.625 3.251 4.876 6.502 900 1.161 2.322 3.483 4.644

1000 1.806 3.612 5.418 7.224 1000 1.290 2.580 3.870 5.160

14 Ga

Table

1000´@1

valve

Voltage drop

from Chart

1.290 V.D.

Page 6

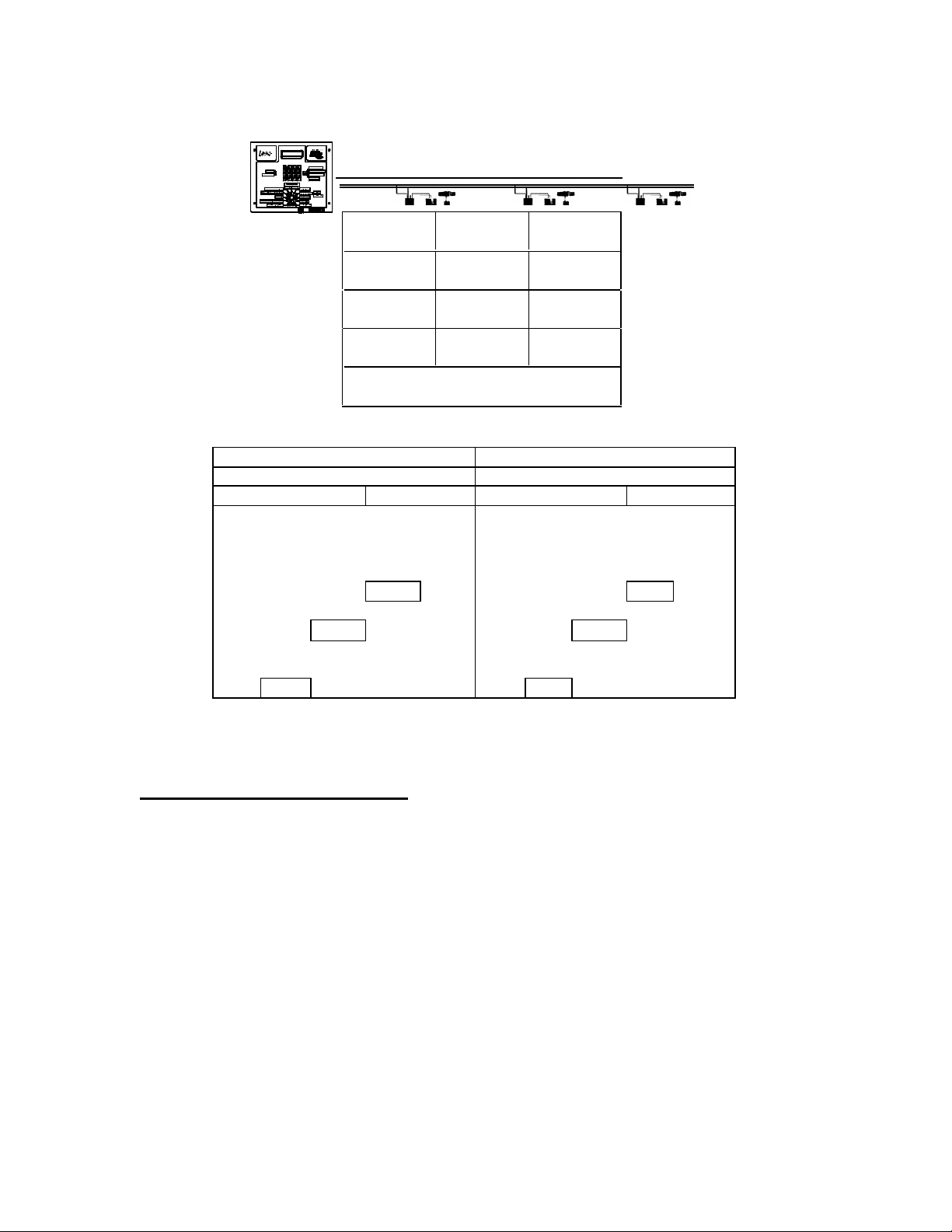

Example 2

Logic to V1 V1 to V2 V2 to V3

500´ 700´ 1000´

Chart 2

Logic 1

To Valve

Controller to

V1

V1 to V2 700´@ 2

V2 to V3 1000´@ 1

Total Voltage drop 3.159 O.K. use 12 Ga

24 Volts less 3.159 = 20.841 Volts

12 Ga

Table

500´@ 3

valves

valves

valve

Voltage drop

from Chart

1.215 V.D.

1.134 V.D.

0.810 V.D.

.35 amps inrush charts Voltage Loss .25 amps holding chart Voltage Loss

Length 1 Valve 2 Valves 3 Valves 4 Valves Length 1 Valve 2 Valves 3 Valves 4 Valves

Wire Size 12 1.62 R factor Wire Size 12 1.62 R factor

100 0.113 0.227 0.340 0.454 100 0.081 0.162 0.243 0.324

200 0.227 0.454 0.680 0.907 200 0.162 0.324 0.486 0.648

300 0.340 0.680 1.021 1.361 300 0.243 0.486 0.729 0.972

400 0.454 0.907 1.361 1.814 400 0.324 0.648 0.972 1.296

500 0.567 1.134 1.701 2.268 500 0.405 0.810 1.215 1.620

600 0.680 1.361 2.041 2.722 600 0.486 0.972 1.458 1.944

700 0.794 1.588 2.381 3.175 700 0.567 1.134 1.701 2.268

800 0.907 1.814 2.722 3.629 800 0.648 1.296 1.944 2.592

900 1.021 2.041 3.062 4.082 900 0.729 1.458 2.187 2.916

1000 1.134 2.268 3.402 4.536 1000 0.810 1.620 2.430 3.240

WIRE CONNECTIONS:

One of the most critical installation requirements of a Logic 2 wire system is the quality

of your wire connections. If you follow these directions you will have a reliable,

dependable control system for many years. It is suggested to soldier all receiver (red

wire) connections to your main two-wire run. Next install the soldiered two-wire

connection in a waterproof underground connector housing. When soldering is

impractical, a waterproof “dry-type” connection such as the Hit Products DBC-Y or

DBC-R or 3M DBY™ or DBR™ wire connector is required. Either of the above

mentioned products will provide an uncontaminated, dry connection and then the splice is

submerged in a waterproof gel-filled housing.

4

Page 7

Do not use pre-filled wire nut connectors as they will impede the transfer

of the signal through the wire splice.

TEST BEFORE BACK-FILLING TRENCH.

To easily test for communication and wire integrity, connect each receiver to the

field wiring at each planned location. It is not necessary for receiver to be

attached to solenoid/valve for test, but O.K. if already connected. Do not allow

black receiver wires to touch each other (short or ground) when testing.

Manually sequence controller through each station number for minimum of 30

seconds, checking each activated receiver in the field for a continuously

activated bright LED light on each receiver. A continuously activated bright LED

light on receiver during station activation confirms satisfactory communication.

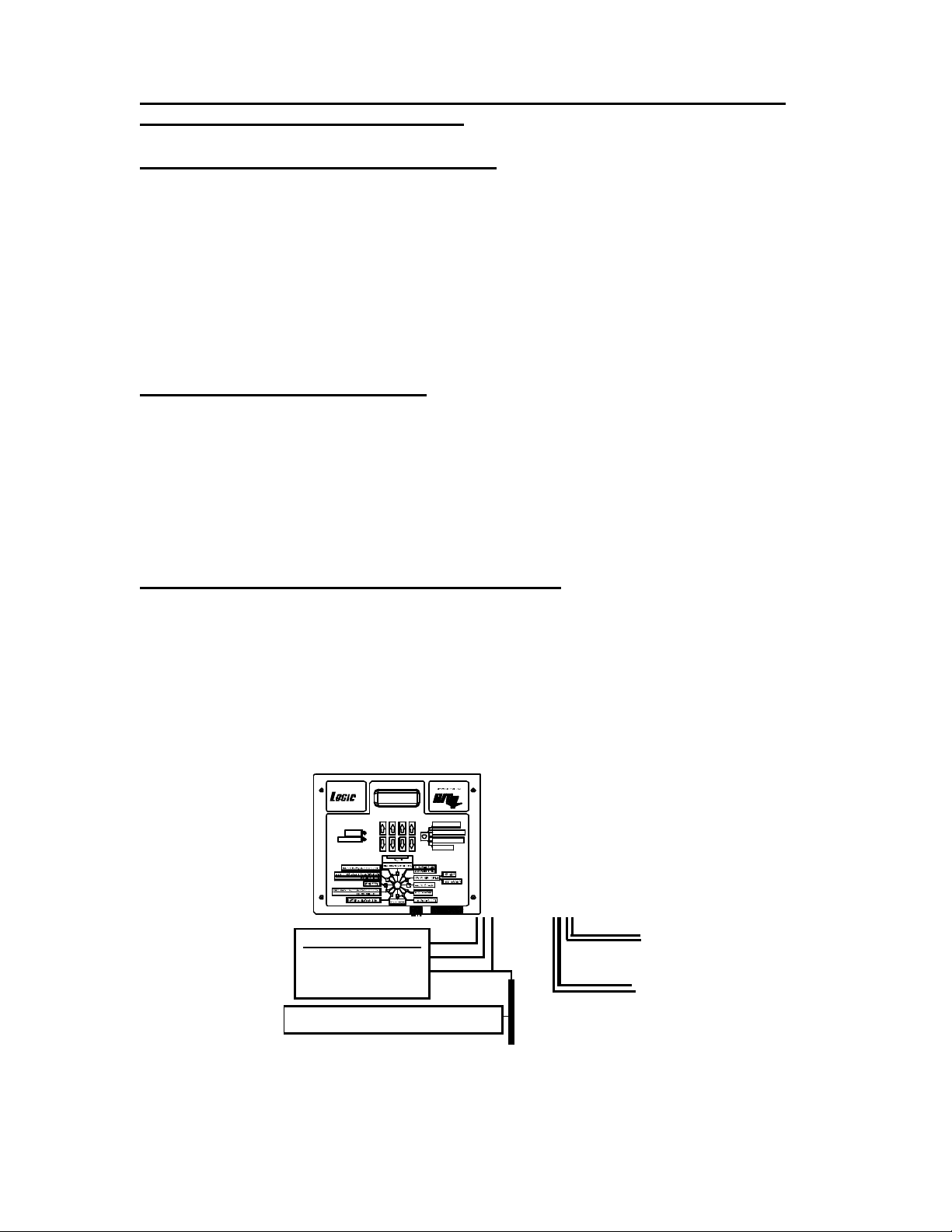

Modular Surge Protection Board

The surge protection board is attached directly underneath the large main

controller printed circuit board. This board and its components are like a

sophisticated fuse. It will blow in an attempt to save the main circuit board from

destruction by line surges mainly created by lightning. It is connected to the main

board with a simple plug for easy removal for testing and replacement if

necessary.

LOGIC 2 and LOGIC 3 Internal Surge Protection

The terminal connectors for the field and ground wires located on the internal

surge protection board will accept up to 10 gage wire allowing the field wiring to

be directly connected. Access is made by removing the stainless steel panel

held by two screws directly below the face plate. Note : Make sure all wiring

connectors are tight and it is recommended to use only soldered connections or

dry-type DBC waterproof connectors for all main 2-wire splices.

PROGRAM RECEIVER

MASTER ON

FERTIGATION ON

GFI CIRCUIT 110 VAC

THIS CONNECTION

SHOULD BE MADE BY A

QUALIFIED TECHNICIAN.

10´ GROUND ROD -Keep ground moist.

PRE WET / FERTIGATION

CALENDAR ODD / EVEN

MASTER CLEAR

BLACK

WHITE

GREEN

5

BLUE LINE 2

BLUE LINE 2

RED LINE 1

RED LINE 1

?

?

?

?

Page 8

Controller Lightning Protection

It is recommended that, in environments where either power surges or direct lightning

strikes are possible, the following installation of grounding protection be followed on the

primary input power supply. Every Logic controller is supplied with a heavy duty-surge

protection kit that will protect yo ur controller against power surges on the primary side.

To activate, it must be installed per local grounding codes. In case a power surge exceeds

the limitations of the board, the surge protection kit will blow and a new surge protection

replacement kit can easily be installed without the need to replace the whole controller

(Part #L-SPD-F).

Field Wiring/Receiver Lightning Protection

As with any electronic equipment buried in the field, it is recommended to use

surge protection devices every 300 – 500 feet along the main 2 wire run and at

the end. These model #L-SPD-F, field surge protection kits are to be installed at

same convenient location as any receiver. Each L-SPD-F does require a

grounding rod-not included with the Hit Products model #L-SPD-F. Attach the

green #L-SPD-F wire to the grounding rod. See diagram on page 22.

Pump Start Relay

When using a pump start relay, the relay shall be a 24 VAC coil with a maximum

inrush of .35 amps and holding .25 amps. The relay will act as a slave to the

magnetic relay to control the pump motor. You can use up to a 5hp Hit Products

pump start relay attached directly to the relay terminal. See diagram on page 21.

Fertigation

The controller is fitted with a separate relay to operate a 24VAC system with a

maximum inrush of .35 amps and holding .25 amps at 24VAC, for application of

fertilizer or other material injection systems. A slave relay should be used to

operate any auxiliary pumps or injection systems exceeding the above power

requirements.

Read This First! The LOGIC Controllers are so easy to program because the four

sets of black up/down buttons correspond to whatever is directly above them in the

display. You can toggle between ON and OFF, set hours, minutes, and seconds, or

even select program numbers, valve numbers, and start times simply by using these

up/down buttons located directly under their functions. For more advanced special

feature functions look to right of up/down buttons. These advanced features may be

accessed by having dial in corresponding number to that number in box to the left of function.

**************************************************************************************

“NOTE”

When you first install your LOGIC 2 or LOGIC 3 controller, press Master Clear to clear

all possible information stored in the unit. Put dial in position 10, Press top right

Up/Down key under “CLR” OFF. Push Advanced Feature button. Controller will

automatically clear ALL programmable data except current date and time.

6

Page 9

FEATURES LOGIC 2 LOGIC 3

Stations Available 1-42 1-128

Programs Available 8 16

Run Time Per Station 0-10 hours, 59 min. Max. 0-10 hours, 59 min. Max.

Programs 5 & 6 0-59 min., 59 sec. 0-59 min., 59 sec.

Calendar 0-28 days Max.,ODD/EVEN 0-28 days Max.,ODD/EVEN

Water Budget 0-250% 0-250%

Rain OFF Days 0-31 days Max. 0-31 days Max.

Pause 0-59 sec. 0-59 sec.

PROGRAMMING THE LOGIC 2 and LOGIC 3 CONTROLLERS

The Logic controller is a very simple controller to program. It has built in features

and automatic programming that will be explained throughout these instructions.

Please read the entire operational manual before starting to program the Logic

controller. The controller programming consists of 8 buttons to control the

display, a twelve position rotary switch and a special function key for more

special options. The 8 buttons that control the display are located directly below

the portion of the display they control. Each set (two buttons) of buttons operates

the display up or down for ease of getting to the function, number, valve or time

desired. For ease of explanation, the following terminology will be used

throughout these instructions. The set of buttons to the far left will be button set

1, directly right of these will be set 2, directly right of set 2 will be set 3 and the

last set or far right set will be set 4, the special feature button in the upper right of

the control panel, will be referred to as set 5.

The main rotary dial has 12 positions just like the numbered hour positions on a

clock 1-12. The rotary switch consists of the following positions and functions:

Position 1

CurrentDate/ Current Time

Current Date: Set today’s Date, use set 2 to set month, use set 3 to set day of

month, use set 4 to set year, i.e.: 5/30/01

Current Time: Set time of day, use set 1 to change display from date to time, use

set 2 to set hour (this will set A.M. or P.M.), use set 3 to set minutes, use set 4 to

“Zero out” seconds.

Position 2

Pre Wet – Special Feature Button

Valve Run Times

Fertigation – Special Feature Button

Set Valve Run Times:

Use set 1 to choose the program, use set 2 to choose the valve number, use set

3 to set hours, use set 4 to set minutes. Input the total irrigation run time desired

for each valve, including pre wet and fertigation time.

7

Page 10

Pre Wet and Fertigation option:

Press set 5, the display will now be the same, except with the following changes, a “P”

will show in front of Hours. Use set 3 or 4 to set amount of hours and minutes for the prewet time. Press set 5, again the display will stay the same except for a “F’ that will show

in front of hours, use sets 3 or 4 to set the amount of hours and minutes for fertigation.

NOTE: At no time will the controller permit the total time of pre-wet and fertigation to

exceed the total run time programmed. No pre-wet run times need to be programmed in

order to run the fertigation mode.

NOTE: Programs 5 and 6 can only be set in minutes and seconds, as all other programs

can be set in hours and minutes. The maximum run times can be set from 1 minute to 10

hours and 59 minutes on all programs except 5 and 6, which can be set for a minimum of

10 seconds to a maximum of 59 minutes and 59 seconds. With the water budget feature

(position 8) these run times can be increased or decreased from 0% to 250% in 5%

increments.

Definitions:

Pre-wet will run concurrently at the start of the valve run time.

Fertigation will start at the conclusion of the programmed pre wet cycle and will

automatically activate the fertigation relay (terminals located on the bottom of the

controller board). If only fertigation time is programmed and no pre-wet time is

programmed, fertigation will start at the commencement of the valve run time

programmed. This relay will remain activated for as long as the fertigation is

programmed. If the total valve run time is 15 minutes, pre wet for 3 minutes and

fertigation for 5 minutes, then there will be 7 minutes remaining of valve run time after

the fertigation cycle ends.

Note: A maximum of any 4 receivers/valves (any combination) may be operated

simultaneously. Wire size must be designed for simultaneous multi-valve operation on

same 2 wire run.

Position 3

Pause

Pause: Use set 1 to choose the program, use set 2 or 3 to set desired time, use set 4 to turn

master valve or pump start function ON or OFF during pause function.

Definitions:

Pause: Amount of time delay between sequential valve openings in a program

Master: Master ON will keep the master valve or pump relay ON during pause. Master

OFF: Will turn master valve or pump relay OFF during pause.

Note: In order for this option to function, the master valve must be activated (see

position 8 below) for that specific program.

8

Page 11

Position 4

Start Time

To set start times, use set 1 to choose the desired program, use set 2 to choose

the start number, (always use start 1 for the first start time after midnight and so

on through start 8 (Logic II) start 16 (Logic III) use set 3 to set the hour of the

start time, use set 4 to set the minutes of the start time.

Note: The start time is part of the first leg of a preprogrammed function

called “Diamond Settings” Refer to Diamond settings at the end of this

programming guide for full details.

Position 5

Total Run Time

To review the total run time in a specific program, use set 1 to choose the

program number. The total run time of that specific program is shown in the lower

right hand position of the display. You can review the water budget setting along

with the total run time in this position. If the water budget is changed from the

default of 100%, the total run times will change in this position, but in position 2,

the valve run times will stay as inputted. The actual running of the valve is

determined by the input in position 2 multiplied by the water budget setting in

position 8.

To review the numbered day of the calendar the controller is currently on, use set

1 to choose the program desired. The day of the calendar will be displayed

directly right of the word “DAY” in the upper display. You can change the day of

the calendar by using set 3 buttons. This will or can bring all days of all programs

to the same day for calendar purposes.

Note: By adjusting the budget up or down (0% to 250%) it will change the total

run time. See position 8 for further discussion. The budget is the second leg of

the Diamond Setting.

Position 6

Calendar

The calendar is the third leg of the Diamond Setting. After programming the run

times and the start times, the calendar will automatically establish the minimum

calendar period. You can manually change the calendar to any desired period,

longer than the minimum “Auto-calendar” period, but not shorter. By pressing set

1 to select the program, press set 2 to change the number of days desired in the

calendar, (if the total run time exceeds one day, the calendar can not be set

backwards. Press set 3 to review the days of the calendar. By pressing set 3

repetitively, the display above set 4 will show one of the following events: Strt

(start), run or off for each da y of the calendar. Note: The calendar automatically

resets all programs to Day 1, today, for all programs when “Master Clear” is

activated. The calendar automatically resets to Day 1, today, whenever a

“Program Clear” function is activated for that specific program. The calendar

automatically resets to today, Day 1, when any value in “Calendar” (Position 6) is

changed. The calendar can be manually changed to any day being today in

Position 5, “Total Run Time”. Day value has to be equal to or less than

“calendar” number of days.

9

Page 12

Definitions:

Start: This is the day of the calendar that the program will start. This will be

automatically set upon initial programming or set by the user. This is day 1 of the

calendar, the day you set up the calendar or programmed the program or let the autocalendar set up the calendar.

Run: The total run time of the program has carried over into the second or more days

and the program will be running these days to complete.

Off: The user has programmed in additional da ys that the program will not be active.

Odd/Even: May be accessed by pressing Feature Key #6. Runtime must not go beyond

11:59p.m.

Note: The number of days that the calendar automatically sets up is determined as

follows: The number of hours from 12:00 mi dnight to the first start time plus the

total run time, divided by 24 hours will equal the number of calendar days.

Example: If a start time is 8:00am, then the first calculation would be 8 hours plus a

total run time of 56 hours for a grand total of 64 hours, divided by 24 hours would equal a

2.67 day calendar, the display would show a 3 day calendar, as follows, day 1 STRT, day

2 RUN, and day 3 RUN. If you wanted to irrigate every 4th day, use set 2 to expand the

calendar from 3 days to 4 days, day 4 wo uld show OFF. Another example would be to

run a program Monday, Wednesday and Friday. The auto-calendar would set up as 1

day, set the calendar to 7 days. If Tuesday were the day you set up the program, this

would be day 1 of the calendar. Therefore you would change day 1 from STRT to Off,

and then set up day 2 (Wed.) as a STRT (start) and day 3 off, day 4 STRT (Fri), day 5

off, day 6 off and day 7(Mon) STRT.

Note: To further understand the Diamond setting for calendar, read the Diamond

setting on page 13.

Position 7

Looping Program 6

Any valve run times and start times set in program 6 can be looped if desired.

There must be individual run times for each valve and one start time in program 6 for

looping to be activated. Use set 3 and set 4 to establish the total amount of loop time

desired. Use set 2 to turn looping feature ON or OFF.

Hints for using Looping: Looping will run a program continuously for the amount of

time set in position 7 looping. For example: If looping is set for 6 hours and the start

time is 8:00 am, program 6 will start at 8:00 am and run for 6 hours. A new lawn can be

irrigated for 5 minutes every hour by doing the following. Valves 1, 2 and 3 operate the

new lawn, set run times for 5 minutes each on valves 1, 2 and 3, then go to a valve that is

not being used and set run time for 45 minutes. You want to irrigate from 10 am until 5

pm. Set start time for program 6 at 10:00 am and go to position 7, set loop for 7 hours and

turn looping ON. The program will start at 10 am and run va lve 1 for 5 minutes, then

valve 2 for 5 minutes and then valve 3 for 5 minutes and then the valve that is not being

used for 45 minutes and then back to valve 1 and so on until 7 hours runs out, which will

be 5:00 PM.

Caution! If operating with a pump, the 45 minutes will cause “Dead

Heading” on the pump and may damage the pump or pipelines

10

Page 13

Note: Program 6 can be sensor activated, such as a temperature sensor. The

terminals for remote operation are located on the terminal board and marked

pr6trg (program 6 trigger). Program the amount of run times per valve in program

6, do not put in a start time, make sure the program is ON in position 8 and whether

or not the master should run with program 6.

Program the amount of loop time in position 7. The co ntacts on the board are “Normally

Open”, when the remote sensor activates and closes the contacts for more than 30

seconds, program 6 will operate for the looping time programmed.

If for any reason the remote sensor contact opens during the looping cycle, the looping

cycle will continue until the programmed time is completed. The sensor must open and

close the contacts to operate the looping cycle a second time. If, for any reason, the

contacts open and close during the preprogrammed length of looping, the looping

program will reset at that time and start over again.

Position 8

Program/Master Valves ON/OFF

Pump Start

Water Budget %

Use set 1 to choose the program desired, use set 2 to turn a program ON or OFF (a fully

programmed program can be disabled by the this function) use set 3 to turn the master

valve or pump start ON or OFF during the program running, use set 4 to increase or

decrease the budget feature of the program. (The amount of time in position 2 will not

change in the display but the actual run time will be increased or decreased by the amount

of budget %). The new “water budgeted” run times can be viewed in position 5.

Note: The water budget is the fourth leg of the Diamond Settings (see page 13 for more

on the Diamond Settings).

Position 9

Test Cycle

Use set 1 to set run time in minutes, use set 2 to set run time of seconds for test

cycle, and use set 4 to turn ON or OFF test cycle.

The controller will immediately run each valve in sequence for the predetermined run

time for visual review of the systems operation.

Note: The pause setting in position 3 for program 1 will determined the amount of pause

between stations during the test cycle operation.

11

Page 14

Position 10

Semi/ Manual/ Program Clear

Master Clear – Special Feature Button

Semi- use set 1 to choose the program you want to activate for one cycle, use

set 2 to activate that program ON. At the conclusion, the controller will revert to

automatic after 30 minutes, without putting the rotary switch back to "Run".

Manual — Press set 3 to activate manual mode, use set 1 to choose the specific

valve number to be operated manually for a predetermined time, use set 2 to set

amount of hours to run, use set 3 to set amount of minutes, use set 4 to tell the

controller whether or no t you want the master valve or the pump start on during

this manual operation. Valve will immediately be activated for that period of time.

At the conclusion, the controller will go back to “RUN” mode without turning the

rotary switch back to the “RUN” position. You can activate up to 4 valves at the

same time in manual mode.

Note: In running semi or running a valve manually, position 8 will dictate

whether the master valve or the pump start will run with that program or

valves(s).

Program Clear/Program: Use set 4 to choose program clear, use set 1 to

choose the program that you desire to clear all the information from, use set 4 to

answer yes. Note: By clearing the program all information for that program is

deleted.

Master Clear will clear all the information in the controller by way of the

following: Turn rotary switch to position 10, press set 4, and then press the

special function set 5, “Master Clear”. All programming data in all programs will

be deleted. Only the current time and date will remain.

Position 11

Rain Delay Auto/On/Off

To set days of delay (controller will not run for the number of days set) press set

1 for the number of days of delay, remember the new day starts at midnight. To

turn controller ON or OFF press set 4 to turn controller ON or OFF. In the OFF

position, controller will keep time but no output will be made to activate valves on

any program. See pages 16 and 17.

Position 12

Program Receiver – Special Feature Button

In the run position controller will execute all that you have instructed it to do. The

controller can be programmed while running an automatic program. While

programming, the operation will stop; after programming turn dial back to position

12 (Run). If today is a start day the controller will resume operation. If it is a run

day, the controller will wait until the next start time or start day. Note: If position

10 is used and left in position 10, the controller will automatically revert to

position 12 (Run) after 30 minutes and resume any automatic programmed

functions.

12

Page 15

DIAMOND SETTINGS

The DS as we call it, is an automatic calendar setting after run times and start

times are entered. The DS will set the minimum days of the irrigation calendar.

This is to protect against overlapping within a program. After initial programming

of the Logic, run times and start times, the DS will not allow you to enter

additional run times or increase the budget so that it will exceed the current

calendar days set.

If you are unable to increase run times, check your “total run time” in position 5. If the

“total run time” for that program is close to the number of current calendar days for that

program you may have to increase the number of calendar days to get the controller to

accept increased run times, increased water budget or adding more valves with run times

to that program. The same is true of increasing the water budget, the calendar may have

to be extended to accommodate the extended run times to allow the program to complete

its cycle.

The DS sets the calendar automatically as follows. The start time entered is

calculated as to how many hours past 12 midnight it is, for example an 8AM start

time would be 8 hours from midnight or the start of that day, then the DS looks at

total run times including pause time and adds the time from midnight to the start

time together. If the total time exceeds 24 hours the calendar is set for two

days, if the total time exceeds 48 hours the calendar is set to a three-day

calendar and so on. The first day will be set as a STRT day (Start) the following

day will be “run” days. The day you programmed this program, automatically

becomes day 1 of the calendar, for example a three-day calendar programmed

on Monday would look like the following:

Day 1 STRT would be Monday

Day 2 RUN would be Tuesday

Day 3 RUN would be Wednesday

Day 1 STRT would be Thursday

Day 2 RUN would be Friday

And so on; please note that any calendar not divisible by 7 will run on different days of

the week as the year progresses. If the above example were changed to a five-day

calendar the days 4 and 5 would show OFF.

It is important to remember if the total run time of a program is under 23 hours and

59 minutes, the DS automatically sets the calendar to one day. Even if the start time

is set to allow the program to run past midnight into the next day. The same is true if

multiple start times are used in the same program and the total runtime of the program

multiplied by the number of start times is under 23 hours and 59 minutes. The DS wi ll

not allow multiple start times that total more than 23 hours and 59 minutes.

13

Page 16

To Program Receivers, the following must happen. Rotate dial to position 12,

press set 5, the display will change to “set receiver ID”, press set 2 or 3 to set the

receiver number desired, press set 4 to program the receiver. The receiver will

blink 3 times. To check receiver, go to position 10 and follow the manual valve

instructions above to test receiver if desired. Be sure to attach the receiver

identification number tag immediately so as to know the receiver’s/valve number

in the system.

Note: Before programming receiver, disconnect the two sets of field wires from

controller. Connect red wires from receiver to programming port on the controller

board. Proceed to program as many receivers as required. After programming the

receivers re-connect the two sets of field wires.

Logic Receiver Programming Instructions

When programming a receiver with a controller that is installed with the field

wires connected:

1. Set the controller in the OFF position. Turn the rotary switch to position 11

(Rain Off/Auto On/Off) use the top right arrow key to turn the setting from ON to

OFF.

2. Disconnect the 2 sets of field wires.

3. Set the Rotary switch to the “Run” position. Position 12.

4. Press the “Feature” key to access the “Set Decoder ID” screen.

5. Connect the red wires of the receiver to the “Programming Port” at the bottom

of the controller board; one red wire in each position.

6. Be sure black receiver wires are not touchi ng.

7. Using the arrow keys corresponding directly underneath the ID number in the

display (second from right) and select the desired number for that receiver.

8. Press the arrow key corresponding to “Enter” on the display (right down

arrow).

9. The LED on the receiver will flash three (3) times.

10. Remove the red leads.

11. Install “Receiver Number Identification Tag” (see below listed instructions).

If programming more receivers repeat from step 5. (see “Receiver

Programming Leads” below.)

12. To end programming press “Feature” key to return to run. Controller will not

resume “Run” automatically.

13. Re-connect field wires.

14. If the controller was set to “OFF” in step 1 repeat the procedure to set the

controller back to “ON.”

Receiver Programming Leads Using Alligator Clips (these may be used

when programming multiple receivers.)

1. Disconnect the 2 sets of field wires.

2. Insert the wire end into the screw terminal of the “Programming Port”. One

wire per screw terminal.

3. Attach one alligator clip to one receiver red wire.

DO NOT ALLOW THE ALIGATOR CLIPS OR RECEIVER BLACK WIRES TO

TOUCH (SHORT) WHILE PROGRAMMING.

14

Page 17

Programmable Receiver Number Identification Tags

Hit Products has developed a user friendly, flexible means to identify the number

of the field-programmed receivers during the receiver programming process.

Inside every box of programmable receivers, you will find one set of identification

tags numbered 1-128. You will use these receiver identification tags as follows:

1. Every time a receiver is programmed, find the corresponding numbered identification

tag and immediately attach to receiver.

2. To attach identification tag to receiver, insert one red receiver wire into the hole (from

front to back) to the left of the appropriate numbered tag as you are looking at the

number. Pull red wire all the way through the hole until identification tag is

approximately one inch from body of receiver.

Note: This will leave the engraved number unobstructed by the wire.

3. Insert same end of same red wire back through hole (from back of tag towards front)

and continue to pull wire through until tight. The number on the tag should now be

readily visible and the black wire positioned on back (blank side of tag). See above.

4. Should receiver ever be reprogrammed to a different number, make sure to replace the

identification tag with the appropriately numbered identification tag. Failure to do so can

create extreme confusion!

Installation “Do’s & Don’ts” with Logic 2 Wire Controllers

1. Proper wire sizing is a must. Use Ohm’s law for determining proper 2 wire run wire

size. See instruction booklet.

2. Each 2-wire run must be a continuous run, no tees, no branches, and no loops. Each

2-wire run must have one beginning (at the controller ter minal) and one end only (at

the last valve).

3. Logic receivers must be directly attached to the 2-wire run; red to field wires, black

to solenoid.

4. All wire connections must be waterproof, using “dry type” wire connectors (DBC

Series by Hit Produc ts or DBY/DBR Series™, 3M™) and/or soldered and then

installed in waterproof housings.

*****Do not use pre- filled gel type wire nuts.*****

5. Do not install Logic Controller, its receivers or any Logic field wire within 15 ft. of

any high voltage electrical panels, meters, pumps, equipment or controls.

6. Use with standard 24 VAC solenoids only. Do not use with low power/diode

bridge type solenoids.

7. Use different colored wires for each wire in each 2 wire run.

8. “Line 1” is one pair of wires for a 2 wire run. “Line 2” is the second two wire run.

Do not mix “Line 1” and “Line 2”. This controller is a computer, install it accordingly

and it will serve you well. If you have any questions, please don’t hesitate to call the

factory at (800) 468-0071, ext. 331 for help, 8a m-5pm, Mon-Fri.

15

Page 18

Logic “RAIN OFF” Switch Wiring Instructions

Location:

The rain off terminal is located on the bottom right of the Controller board labeled

“RAIN OFF”. These two terminal screws must be jumped with a wire to close the

circuit and enable normal operation. This jumper wire is factory installed. It is to

be removed if utilizing a “Rain Off” switch.

Function:

This is a normally closed, dry contact circuit. When the circuit is open the unit will

display RAIN and turn off all station output. When the contact is closed the

program will resume running where it would have been at that time during normal

operating mode.

Important Note:

Do not apply live power directly to these contacts.

Tips:

Problem example 1: When using a rain off switch at distances from the controller,

the controller sometimes does not receive the on/off signal from the sensor.

Remedy: A) Relocate the sensor near the controller. B) Use a larger wire size to

eliminate the resistance from the long distance of the run. C) For sensors

requiring an isolation relay, Example: Rain guard type (see drawing). Relocate

the relay to inside the Logic controller cabinet. The sensor itself may be at a

remote location.

Problem example 2:

The LCD display alternates from the normal text to the word RAIN. This is

caused from application of 24VAC to the sensor input. Note: 24VAC will not

permanently damage the sensor, but proper wiring must be completed to restore

normal operation.

Remedy:

This input is a dry contact only. A single wire from one terminal screw to a

normally closed contact with a single return wire to the second terminal is

required. Use care that neither wire is connected to the common or other power

line. When acquiring a relay check the schematic that the actuator/coil is isolated

from the contacts in the output section (no common connections are made

internally). Most solid-state block relays have a Triac connected to the common

internally and are not suitable for this application. Suggested 24VAC relays are:

Omron LY2-AC24, Potter & Brumfield KHAU-17A11-24, NTE /Mauser 526R11A10-24. Another source for relays (24VAC Coil, DPDT/SPDT contacts) is

your local Radio Shack store.

P.O. Box 929, 556 S. Mirage Avenue

Lindsay, CA 93247

For Technical Assistance: 800-468-0071 ext. 331

16

Page 19

CALENDAR ODD / EVEN

PRE WET / FERTIGATION

MASTER CLEAR

PROGRAM RECEIVER

FERTIGATION ON

MASTER ON

FERTIGATION ON

MASTER ON

CALENDAR ODD / EVEN

PRE WET / FERTIGATION

MASTER CLEAR

PROGRAM RECEIVER

17

Page 20

For Wire Size Formula is: VD = C x R x

"Ohms Law" Voltage Drop = Current x

Resistance in Ohms

VD = Voltage

Drop

C = Current (Solenoid

Amperage Draw)

R = Resistance (Wire Size “Voltage Loss”

Factor)

L = Length of distance between controller

and valve in feet

.35 amps inrush charts Voltage Loss .25 amps holding chart Voltage Loss

Length 1 Valve 2 Valves 3 Valves 4 Valves Length 1 Valve 2 Valves 3 Valves 4 Valves

Wire Size 4 0.253 R factor Wire Size 4 0.253 R factor

100 0.018 0.035

200 0.035 0.071

300 0.053 0.106

400 0.071 0.142

500 0.089 0.177

600 0.106 0.213

700 0.124 0.248

800 0.142 0.283

900 0.159 0.319

1000 0.177 0.354

Wire Size 6 0.403 R factor Wire Size 6 0.403 R factor

100 0.028 0.056

200 0.056 0.113

300 0.085 0.169

400 0.113 0.226

500 0.141 0.282

600 0.169 0.339

700 0.197 0.395

800 0.226 0.451

900 0.254 0.508

1000 0.282 0.564

Wire Size 8 0.641 R factor Wire Size 8 0.641 R factor

100 0.045 0.090

200 0.090 0.179

300 0.135 0.269

400 0.179 0.359

500 0.224 0.449

600 0.269 0.538

700 0.314 0.628

800 0.359 0.718

900 0.404 0.808

1000 0.449 0.897

0.053 0.071 100 0.013

0.106 0.142 200 0.025

0.159 0.213 300 0.038

0.213 0.283 400 0.051

0.266 0.354 500 0.063

0.319 0.425 600 0.076

0.372 0.496 700 0.089

0.425 0.567 800 0.101

0.478 0.638 900 0.114

0.531 0.708 1000 0.127

0.085 0.113 100 0.020

0.169 0.226 200 0.040

0.254 0.339 300 0.060

0.339 0.451 400 0.081

0.423 0.564 500 0.101

0.508 0.677 600 0.121

0.592 0.790 700 0.141

0.677 0.903 800 0.161

0.762 1.016 900 0.181

0.846 1.128 1000 0.202

0.135 0.179 100 0.032

0.269 0.359 200 0.064

0.404 0.538 300 0.096

0.538 0.718 400 0.128

0.673 0.897 500 0.160

0.808 1.077 600 0.192

0.942 1.256 700 0.224

1.077 1.436 800 0.256

1.211 1.615 900 0.288

1.346 1.795 1000 0.321

18

0.025 0.038 0.051

0.051 0.076 0.101

0.076 0.114 0.152

0.101 0.152 0.202

0.127 0.190 0.253

0.152 0.228 0.304

0.177 0.266 0.354

0.202 0.304 0.405

0.228 0.342 0.455

0.253 0.380 0.506

0.040

0.081

0.121

0.161

0.202

0.242

0.282

0.322

0.363

0.403

0.064

0.128

0.192

0.256

0.321

0.385

0.449

0.513

0.577

0.641

0.060 0.081

0.121 0.161

0.181 0.242

0.242 0.322

0.302 0.403

0.363 0.484

0.423 0.564

0.484 0.645

0.544 0.725

0.605 0.806

0.096 0.128

0.192 0.256

0.288 0.385

0.385 0.513

0.481 0.641

0.577 0.769

0.673 0.897

0.769 1.026

0.865 1.154

0.962 1.282

Page 21

For Wire Size Formula is: VD = C x R x

.35 amps inrush charts

Voltage Loss

.25 amps holding chart

Voltage Loss

"Ohms Law" Voltage Drop = Current x

Resistance in Ohms

VD = Voltage

Drop

C = Current (Solenoid

Amperage Draw)

R = Resistance (Wire Size “Voltage Loss”

Factor)

L = Length of distance between controller

and valve in feet

Length 1 Valve 2 Valves

Wire Size 10 1.02 R factor Wire Size 10 1.02 R factor

100

200

300

400

500

600

700

800

900

1000

100

200

300

400

500

600

700

800

900

1000

100

200

300

400

500

600

700

800

900

1000

0.071

0.143

0.214

0.286

0.357

0.428

0.500

0.571

0.643

0.714

Wire Size 12 1.62 R factor Wire Size 12 1.62 R factor

0.113

0.227

0.340

0.454

0.567

0.680

0.794

0.907

1.021

1.134

Wire Size 14 2.58 R factor Wire Size 14 2.58 R factor

0.181

0.361

0.542

0.722

0.903

1.084

1.264

1.445

1.625

1.806

0.143

0.286

0.428

0.571

0.714

0.857

1.000

1.142

1.285

1.428

0.227

0.454

0.680

0.907

1.134

1.361

1.588

1.814

2.041

2.268

0.361

0.722

1.084

1.445

1.806

2.167

2.528

2.890

3.251

3.612

3 Valves 4 Valves Length 1 Valve 2 Valves

0.214 0.286

0.428 0.571

0.643 0.857

0.857 1.142

1.071 1.428

1.285 1.714

1.499 1.999

1.714 2.285

1.928 2.570

2.142 2.856

0.340 0.454

0.680 0.907

1.021 1.361

1.361 1.814

1.701 2.268

2.041 2.722

2.381 3.175

2.722 3.629

3.062 4.082

3.402 4.536

0.542 0.722

1.084 1.445

1.625 2.167

2.167 2.890

2.709 3.612

3.251 4.334

3.793 5.057

4.334 5.779

4.876 6.502

5.418 7.224

100 0.051

200 0.102

300 0.153

400 0.204

500 0.255

600 0.306

700 0.357

800 0.408

900 0.459

1000 0.510

100 0.081

200 0.162

300 0.243

400 0.324

500 0.405

600 0.486

700 0.567

800 0.648

900 0.729

1000 0.810

100 0.129

200 0.258

300 0.387

400 0.516

500 0.645

600 0.774

700 0.903

800 1.032

900 1.161

1000 1.290

0.102

0.204

0.306

0.408

0.510

0.612

0.714

0.816

0.918

1.020

0.162

0.324

0.486

0.648

0.810

0.972

1.134

1.296

1.458

1.620

0.258

0.516

0.774

1.032

1.290

1.548

1.806

2.064

2.322

2.580

19

3 Valves 4 Valves

0.153

0.306

0.459

0.612

0.765

0.918

1.071

1.224

1.377

1.530

0.243

0.486

0.729

0.972

1.215

1.458

1.701

1.944

2.187

2.430

0.387

0.774

1.161

1.548

1.935

2.322

2.709

3.096

3.483

3.870

0.204

0.408

0.612

0.816

1.020

1.224

1.428

1.632

1.836

2.040

0.324

0.648

0.972

1.296

1.620

1.944

2.268

2.592

2.916

3.240

0.516

1.032

1.548

2.064

2.580

3.096

3.612

4.128

4.644

5.160

Page 22

20

Page 23

21

Page 24

FIELD RUN AND AT THE END OF

NOTE: INSTALL SPD-F EVERY

300 TO 500 FEET ALONG THE

THE RUN AS SHOWN.

FERTIGATION ON

MASTER ON

CALENDAR ODD / EVEN

PRE WET / FERTIGATION

MASTER CLEAR

PROGRAM RECEIVER

22

Loading...

Loading...