T-40 AND T-70 BLOWER HEATERS

EQUIPPED WITH OIL BURNER

Instruction and user manual

Page 1/14

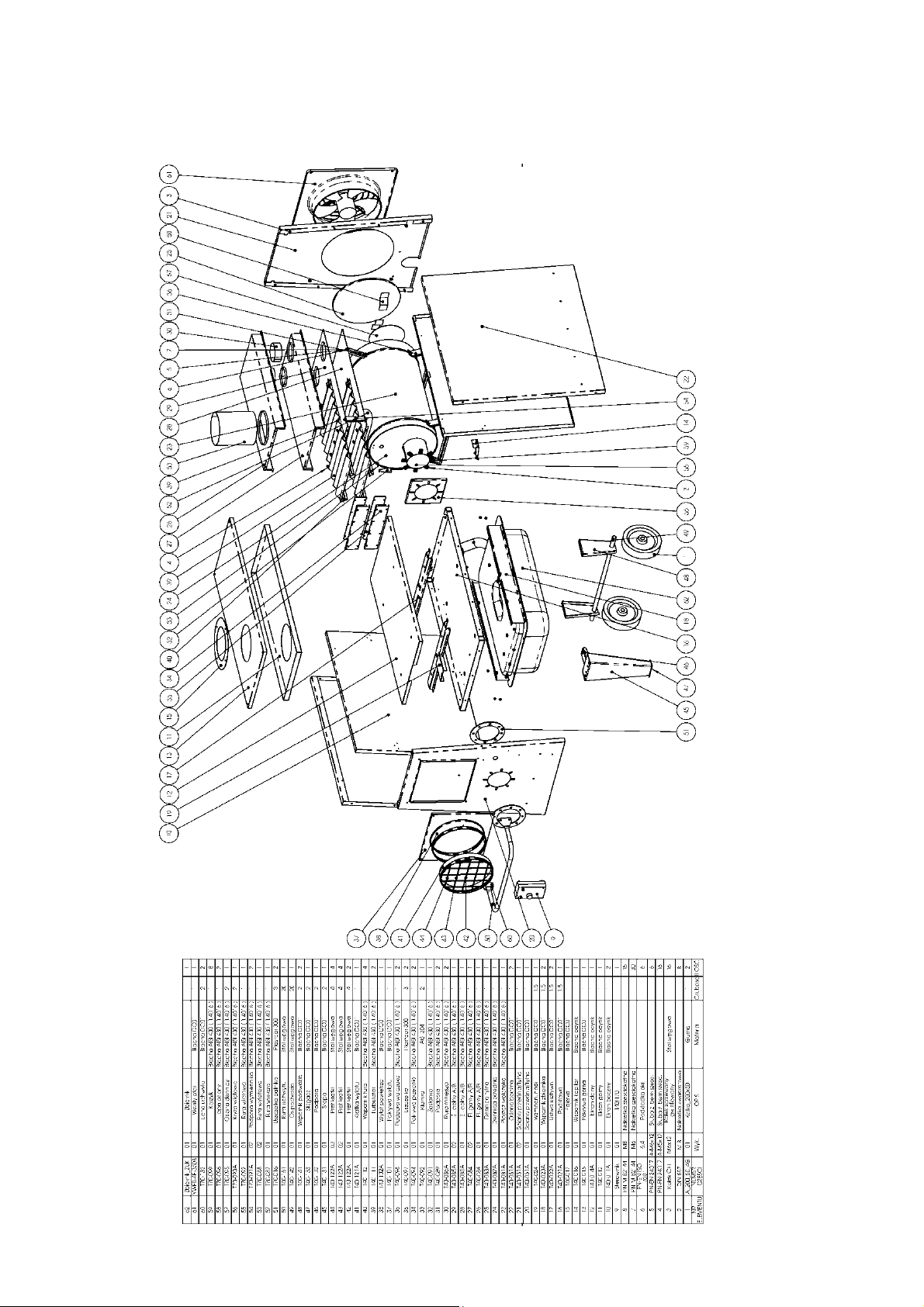

Fig.1 T40 construction

Page 2/14

PART

NO

DESCRIPTION

PART

NO

DESCRIPTION

1

Wheel_200x50

32

End cap

2

Screw cup

33

Clamp

3

Stud-bolt

34

Front cover

4

Hexagonal head screw

35

Insulating gasket

5

Hexagonal head screw

36

Combustion chamber support

6

Round washer

37

Air outlet cover

7

Hex cap screw

38

Air outlet point

8

Hex cap screw

39

Turbulator

9

T40/T70

40

Turbulator support

10

Side screen

41

Air outlet grille

11

Upper screen

42

Protective grille

12

Bottom screen

43

Protective grille

13

Upper cover

44

Protective grille

14

Support

45

Foot

15

Lid

46

Support

16

Footing

47

Slider

17

Cleat

48

Undercarriage support

18

Tank support

49

Undercarriage axis

19

Foot support

50

Handle pull

20

Front/rear panel

51

Insulating plate

21

Front/rear panel

52

Bigger flue

22

Side panel

53

Outlet pipe

23

Combustion chamber cover

54

Exchanger support

24

Front crown

55

Inlet pipe

25

Rear crown

56

Inlet flange

26

Upper part A/B

57

Crown cover

27

Upper part A/B

58

Cover flap

28

Bottom part A/B

59

Basket

29

Bottom part A/B

60

Handle end cap

30

Smaller flue

61

Fan

31

Support

62

Tank

Page 3/14

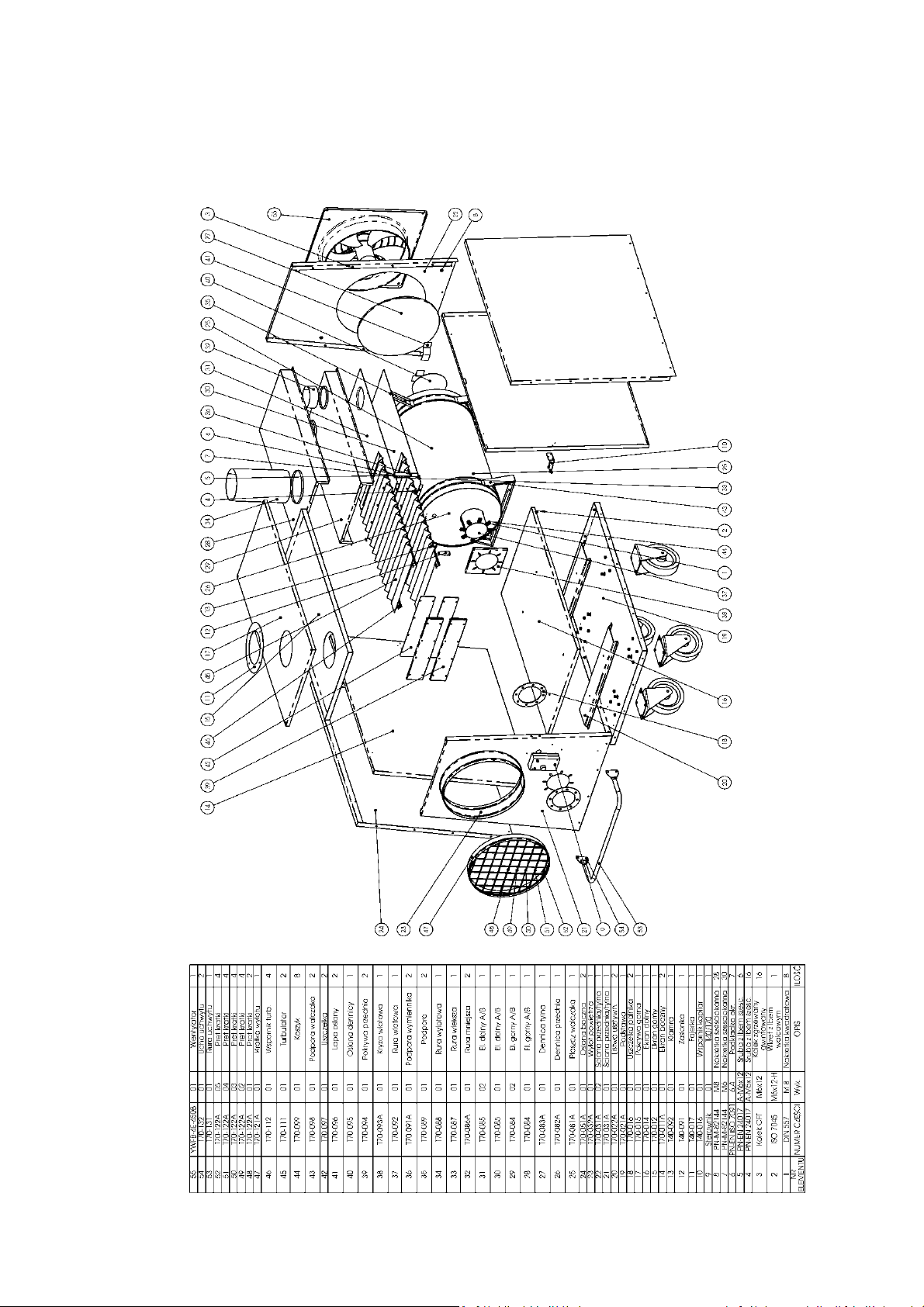

Fig.2 T70 construction

Page 4/14

PART

NO

DESCRIPTION

PART

NO

DESCRIPTION

1

Screw cup

29

Upper part A/B

2

Cheese head screw

30

Bottom part A/B

3

Stud-bolt

31

Bottom part A/B

4

Hexagonal head screw

32

Smaller flue

5

Hexagonal head screw

33

Bigger flue

6

Round washer

34

Outlet pipe

7

Hex cap screw

35

Support

8

Hex cap screw

36

Exchanger support

9

T40/T70

37

Inlet pipe

10

Support

38

Inlet flange

11

Lid

39

Front cover

12

End cap

40

Crown cover

13

Clamp

41

Cover flap

14

Side screen

42

Insulating gasket

15

Cover screen

43

Combustion chamber support

16

Bottom screen

44

Basket

17

Cover

45

Turbulator

18

Insulating plate

46

Turbulator support

19

Footing

47

Protective grille

20

Cleat

48

Protective grille

21

Front/rear panel

49

Protective grille

22

Front/rear panel

50

Protective grille

23

Air outlet point

51

Protective grille

24

Side panel

52

Protective grille

25

Combustion chamber

53

Handle pull

26

Front crown

54

Handle end cap

27

Rear crown

55

Fan

28

Upper part A/B

Page 5/14

Thank you for choosing Hiton blower heater which will provide heat almost

measurement

unit

T-40

T-70

Installed Power

kW

36

75

instantaneously. Low price of heating oil used for this device makes it even

more economical.

Our observations and experiences gained during production and sales of the

blower heaters show that if exploited according to this instruction manual, the

device causes no problems to their user and is almost failure-free.

We therefore strongly recommend strict adherence to this instruction

manual and we guarantee your satisfaction with this heater.

1. General information

Before installing the blower heater you should make sure there are no damages

caused during transportation and that the blower is complete with all parts.

2. Use

T range blower heaters should be used for heating all types of production

premises, warehouses, shops, residential buildings, chicken farms and others.

3. Fuel

The following fuel should be used: light EL heating oil (according to DIN

51603) or EKOTERM heating oil with the following parameters:

- density at 15oC < 0,86 kg/cm3

- kinematic viscosity at 20oC mm2/s < 6

- sulphur content < 0,3%

- ignition temperature 85oC

- calorific value > 42000 kJ/kg

This oil meets requirements of European quality and ecological norms.

In case of problems with purchasing fuel oil, diesel oil can also be used. If

diesel oil is used in place of the heating oil, the settings must be changed

accordingly (soot can start to deposit in combustion chamber and the heat

exchanger during burning).

Manufacturer's settings are set for the light heating oil.

4. Technical and exploitation parameters of the heater and burner

Blower heater range includes

Page 6/14

Burner's nozzle

0.85/60

o

1.75/60

o

Fuel pump pressure

bar

12

12

Burner power supply

V/Hz

220/50

220/50

Fan output

m3/h

2600

5000

Max. Air temperature

o

C

85

85

Fan power supply

V/Hz

220/50

220/50

Blower hole diameter

mm

280

440

Flue diameter

mm

180

180

Dimensions

Length

mm

1360

1550

Width

mm

590

720

Height

mm

1190

1305

Weight

kg

95

125

Tank

capacity

l

55

N/A

Average fuel consumption

l/h 2 4

T range heaters are portable devices. Each T-40 is equipped with a fuel tank

(external tanks of any capacity may be used). T-70 heaters are not equipped with

fuel tanks and can be fuelled from any plastic or metal tank meeting technical

requirements. Blower heater is used for producing air heated up to max

temperature of 850C. Basic component parts of the heater include cylindrical

combustion chamber made of acid-proof sheet and heat exchanger fitted with

turbulators. Heat of burned oil is absorbed by air which is ventilated by fan and

passes through heat exchanger and combustion chamber. Some of the heat is

transported outside through the flue in form of combustion fumes. Excellent

capacity of the heaters compensates for the heat losses and minimizes them.

Maximum air temperature at the outlet is 850 C. The temperature is controlled

by means of a thermostat with the range of 650C ÷ 850C. The device is

additionally equipped with safety thermostat set at 1100C. Both inlet and outlet

points are secured with protective screens. Outlet and inlet points should never

be obstructed. T range heaters require disposal of combustion fumes. Flue

connection should be made of insulated tin pipes and the flue should be in

vertical position 1m above the rooftop of the heated building. Chimney flue

diameter cannot be inferior to the diameter of the heaters' flue. Horizontal

connection between the heater and flue should be slightly inclined and not

longer than 2 meters. Flue can be fitted by means of elastic SPIRO pipes

provided that the above requirements are met.

T range heaters are powered by voltage rating 220 V (in case of heaters

Page 7/14

equipped with centrifugal fan the voltage is 380 V).

Chimney diameter cannot be inferior to the flue diameter.

Units are equipped with two-way fuel filers with shut off valves on the feed line

and return valve on fuel disposal (one-way filers are also in use).

For T range heaters connections between tank, filter and burner are made by the

manufacturer. T-70 heater does not have a tank and the feed line connection

between the filter and the tank should be installed by an authorized person

according to regulations regarding storage of light heating oil and depending on

the capacity of burner pump. All T range heaters are fitted with oil burners

with pumps.

Assembly

T-40 heaters are fitted with oil tanks and do not require assembly. Heaters

should be placed in appropriate location with respect to regulations regarding

flue and chimney connection. It also applies to T-70 units. When placing them,

regulations concerning connection of oil tank and storage of light heating oil

should be adhered to. Air outlet/inlet points should never be obstructed. If

heaters operate in conditions where contaminations occur or may occur (such as

dust, chemicals) or exhaust fans are in use (which may interfere by creating

negative pressure) air supply from a different source or from the outside should

be provided.

Fire regulations are also to be met.

Operation and maintenance manual

Prior to switching on the device, check the assembly and, if necessary, fill up

the oil tank. Heater cannot be switched on immediately after filling up the oil

tank. Allow the oil in the tank to settle for 15 minutes (if the device is switched

on too early, there is a risk of air getting into the oil feed line). Check if the

chimney is unobstructed and if there is sufficient air draught.

In 95 % of cases lack of air draught is the cause of failures of the device

(failure of flame sensor, electrodes, fuel nozzle, burner gasket, heat exchanger

gaskets).

Heater should be connected to the power outlet according to the following rule:

plug’s phase connects with the socket phase. Heater is fitted with two switches

(red switch activates heating and the blue switch triggers cooling) and a

thermostat.

Switching on

If you want to activate the heating mode, press the red button, the blue button

should be switched off.

If the blue button is switched on, the fan will work continuously without 3.5

Page 8/14

min cycles after the burner has been switched off.

The blue button should be switched on if you want to ventilate the device - the

red button should be switched off during this time.

Set the thermostat at a desired value.

Press the red button (the fan and burner will switch on simultaneously).

If the heater does not start, control diode on its casing will light up.

After one minute, control button should be pressed again, which will start the

burner.

If air gets into the oil feed line, for example when oil feed line is long, it is

necessary to repeat this operation 2-3 times (at 2 minute intervals).

If the burner still does not ignite, it is necessary to call an authorized service

to fix the failure.

Once the burner is activated, oil starts to burn automatically. Ignition spark

stops after a dozen or so seconds. Once the desired temperature has been

reached, the burner turns off and the fan continues to work (for about 3.5

minutes) cooling down the heat exchanger and combustion chamber and, at the

same time, absorbing their heat if the temperature of the heat exchanger located

near temperature sensors goes down to the value higher than or equal to the one

of the thermostat.

If during cooling down, the temperature goes down below the value set on the

thermostat the burner will start again with the fan still working.

It is possible to mount external thermostat, which will regulate the temperature

keeping it at a desired level.

Red button is used for turning the heater off. Safety feature of the control panel

does not allow turning the fan off while the burner is still working.

N O T E

The maintenance of the device should be carried out by an authorized

person.

Do not use the heater close to combustible materials their fumes or

explosives.

Do not use the heater if the air contaminations occur or may occur (dust,

chemicals) or if there are fans that can create negative pressure.

Do not allow the tank to be completely empty as this may cause the air to get

in.

Reset the burner if the supplier or type of fuel is changed. This should be

done by an authorized person.

Observe the fuel in filter (if the filter is clean and if there is no water in fuel).

Page 9/14

Fuel mixed with water looks like water with sugar on the filter; working

even for a few hours under such circumstances may cause damage to the

fuel pump.

Heater should operate in building/s with efficient air ventilation with the

inside temperature not lower than +50C.

Air inlet and outlet should never be obstructed.

Do not spill oil when filling up or cleaning the filer.

Supervise tightness of fuel installation and the quality of combustion fumes

(there should be no visible smoke coming out).

There should be no smell of oil.

Fire extinguisher should be placed close to the heater.

Maintenance

The device and the surrounding area should be kept clean.

Oil spill should be cleaned immediately.

Oil filter should be replaced regularly (transparent filter cover allows to see

contaminations).

Burner photocell should be cleaned regularly.

Oil tank should be cleaned every other season.

At least once a year, after the season and more often if necessary, clean the

combustion chamber and exchanger along with tulbulators and chimney flue.

Soot deposited in the flue isolates and decreases efficiency of the heater and

hinders its normal functioning.

In case of malfunctioning, i.e. visible dark fumes, it is necessary to turn the

heater off, clean it, set the burner and check fumes composition.

These are not covered by the warranty and are to be carried out by

authorized personnel.

Protect the heater against humidity.

Failures and their remedies

Turn the burner and power supply off.

Shut the fuel feed valves.

Use appropriate fire extinguisher.

Heating oil storage conditions

Oil should not be stored in temperature below -5C because this may cause

paraffin precipitation and block the filer.

Capacity of single tank without casing should not exceed 2000 l.

Tanks should not be placed closer than 1.5 m from the source of heat and

where oil is heated up to temperature higher by 150C than the room

Page 10/14

temperature where it is located.

Tanks should have minimum 32 mm diameter vent holes.

Mark the tank and place appropriate fire extinguisher next to it.

Possible remedies

Burner will not start

Damaged safety device of the network or the burner.

Faulty plug connection.

Loose connections (joints).

Thermostat damaged or set below room temperature.

Light from the outside reaches photocell.

Damaged control panel.

Blocked safety thermostat.

Damaged engine.

Blocked burner pump.

No fuel.

Burner starts but switches off after a while

No fuel supply - open fuel valves.

No ignition spark - too low fuel injection pressure.

Damaged pump or pump clutch.

Blocked fuel filter, pump filer or nozzle.

Damaged fuel line - not air-tight.

Damaged electro valve.

Damaged photocell.

No flame with proper fuel feeding

Worn-out nozzle.

Too big air valve opening - sparkle extinguishes.

Oiling up of the electrodes.

Damaged transformer.

Too big spaces between electrodes.

No flame with proper fuel feeding and proper ignition

Too low fuel injection pressure.

Wrong placement of the electrodes.

Spark bounces up to the casing.

Dirty nozzle.

Page 11/14

Water in fuel.

Air-locked fuel line.

No supply.

There is a flame but keeps on extinguishing

Leaking electromagnetic valve.

Damaged contacts of the control panel.

Improper angle of fuel nozzle injection.

Improper fitting of the disk.

Partly covered nozzle.

Dirty flame sensor.

Air-locked fuel line.

Disturbances during operation.

Improper ratio between air and fuel.

Too big fuel nozzle.

Unregulated fuel pressure.

Too high temperature of combustion fumes.

Too strong/weak chimney draught.

Combustion chamber and exchanger with soot.

Leaking fuel line.

Control panel

Bottom row of diodes signals the fuel level in the tank.

When the fuel tank is almost empty, intermittent sound is activated. This

means that the tank needs to be filled up.

When the fuel tank is empty, the red diode goes off (no fuel left) and

continuous sound is triggered. The device stops working. Once filled up, the

heater continues to work.

Each heater can be fitted with any temperature thermostat.

Fitting the thermostat:

In the bottom part of the control panel there is a short black wire next to two

white wires.

Remove wire sleeve at its end and cut the wire.

Join two wires obtained after cutting with wires of the external control panel.

Page 12/14

Set the heater knob at the maximum value.

Set the external thermostat to desired temperature.

NOTE: for thermostats powered by 220 V transmitters should be mounted.

NOTE

Failure to comply with the above instruction manual may cause damage to

the heater, which will result in the warranty to become void.

All repairs made under void warranty are subject to charges.

Page 13/14

Loading...

Loading...