HiTi Digital P110S Service Manual

CONFIDENTIAL 1

P110S

Service Guide

Version: 1.11

CONFIDENTIAL 2

Revision History

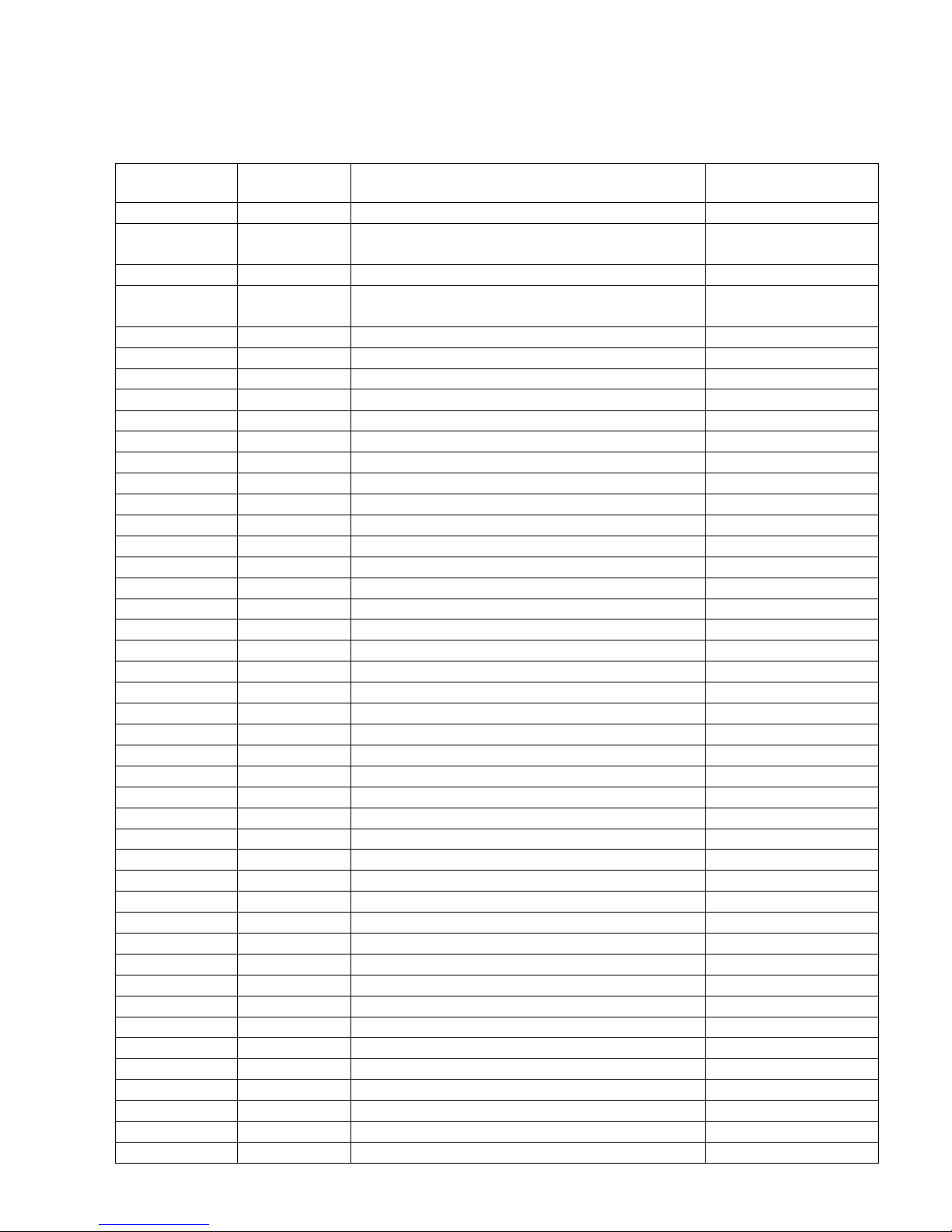

Date Revision Description Remark

2009/10 1.0.0 The first edition.

2010/6/25 1.0.1 1. Disassmbly out of warranty warning

2. Modified Error code list

Page 19

Page 59

2011/1/6 1.0.2 Disassmbly warning Page 19

2012/2/8 1.1 1. Added jitter pitch (interval)

2. Modified the Capstan Roller Info

Page 60

2012/4/11 1.11 Added precaution for TPH assembly Page 54

CONFIDENTIAL 3

Outlines:

CHAPTER 1: INTRODUCTION.......................................... 4

CHAPTER 2: SPECIFICATIONS ........................................ 5

CHAPTER 3: OPERATION THEORY................................ 6

CHAPTER 4: DISASSEMBLY & ASSEMBLY ................. 19

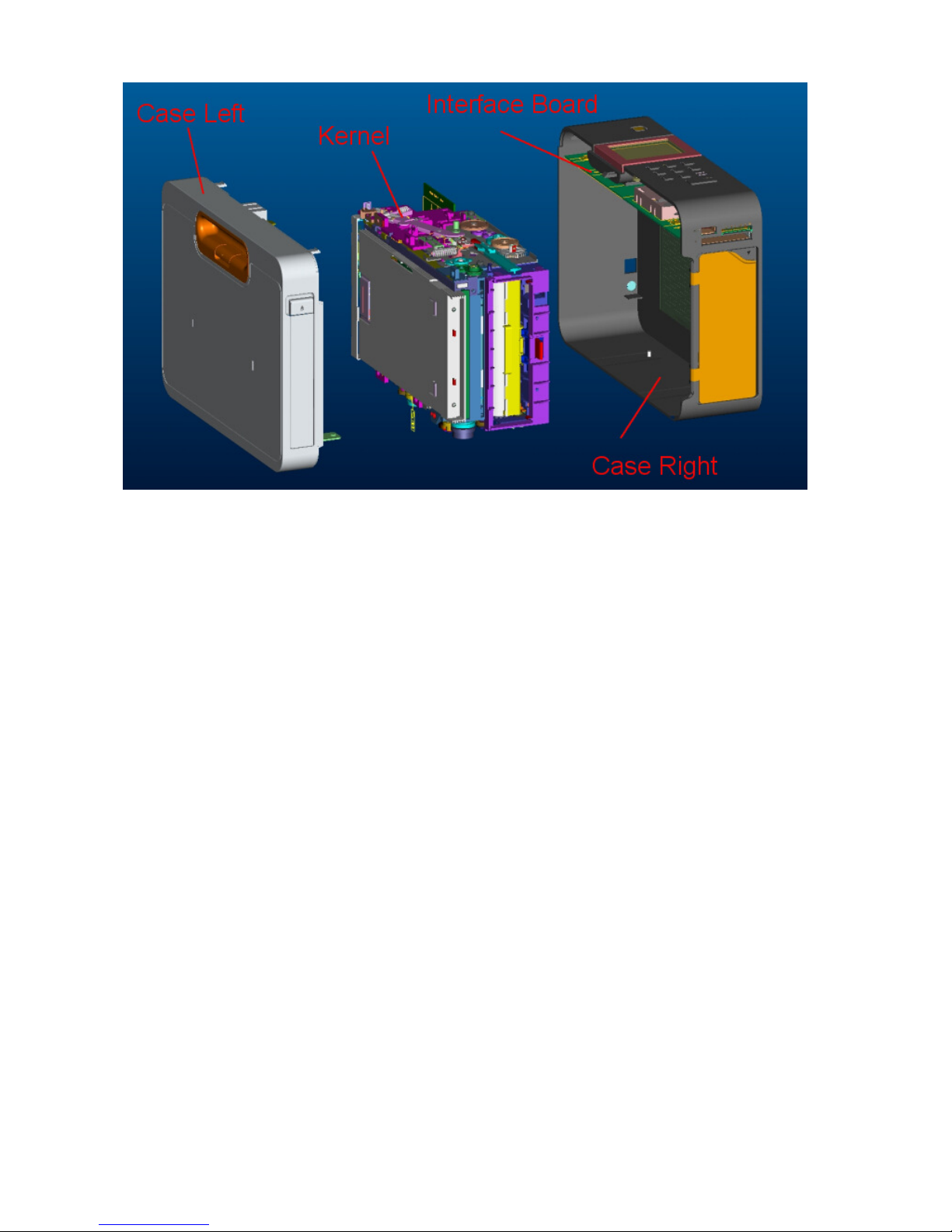

ASSY_CASE_LEFT, ASM_ID_CASE_RIGHT, CHASSIS ASSY .....20

LCD PANEL BD, ASM_LCD................................................................23

CARD BD ..............................................................................................25

MAIN BD...............................................................................................27

SMART CARD BD ................................................................................28

WIRE SNR JAM P110S.........................................................................30

WIRE SNR RIBBON P110S..................................................................32

WIRE SNR CAM P110S........................................................................33

WIRE MB TO SMART_CARD BD P110S ...........................................35

WIRE SNR RIBBON_TYPE P110S......................................................36

WIRE SNR PAPER_OUT P110S...........................................................38

WIRE SNR LE P110S ............................................................................40

ROLLER_CAPSTAN_TUK_P110........................................................45

ASSY ROLLER PINCH ........................................................................46

FAN 4010 12VDC ADDA 2-BALL SYSTEM ROHS ...........................48

MTR CAM PM 15 22OHM BIP P110S .................................................50

MTR PM 3.75 7OHM BIP P110S ROHS...............................................51

TPH 300DPI P110S TSB 6.3-DEGREE ROHS .....................................53

CHAPTER 5: ADJUSTMENT ............................................ 55

CHAPTER 6: GEAR LIST .................................................. 57

CHAPTER 7: ERROR MESSAGE..................................... 60

CONFIDENTIAL 4

Chapter 1: Introduction

This document contains

operation theory and

parts replacement procedure

s that are

intended

to ease the task of transportation, usage, maintenance and parts replacement.

CONFIDENTIAL 5

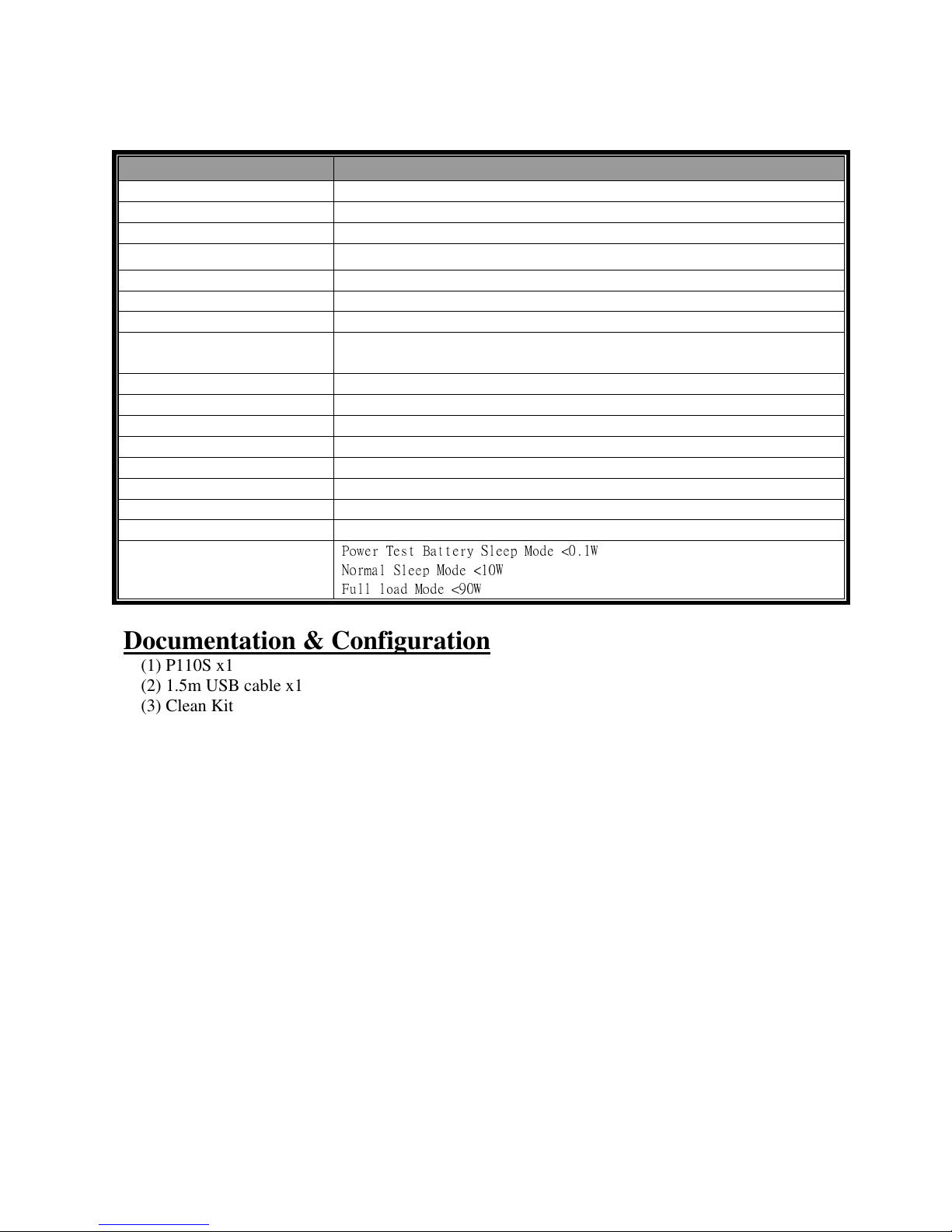

Chapter 2: Specifications

Item Description

Resolution

300 x 300 dpi

Max Prints Size

4 “x6 “

Printing time/ size

63 sec./ 4”x 6” photo paper and 1x1 sticker

Capacity

60 pieces

Ribbon Capacity

60 images for YMCO

Display

2.5” LCD 320x240 pixel

Memory Card Slot

CF Type I & II / SD / SDHC / MS / MS Pro / MMC / Micro Drive

Dimension & Weight

25cm (D) x 18.5cm (H) x 10cm (W) & 2.2 kg (excl. consumable,

battery & adapter)

File format support

JPEG

USB Host

USB mass-storage device support, PTP/PictBridge support

Computer Interface

USB 2.0 full speed interface with PC

LED Indicator

3 LED indicator (Printing, Charge, Error status)

Power Supply

100~240V Universal Power with 24V/90W Adapter

Support OS

Win2000/XP/VISTA, MAC OS x10.2 with Pentium PC

Bundle Software

ID quick désirée / ID Creator / eFrame convertor

Accessory option

Clean Kit, Battery, Carrying Bag

Power Consumption

Power Test Battery Sleep Mode <0.1W

Normal Sleep Mode <10W

Full load Mode <90W

Documentation & Configuration

(1) P110S x1

(2) 1.5m USB cable x1

(3) Clean Kit x1

(4) 3 M Power cord with adapter x1

(5) Driver, AP and electrical manual CD x1 in 10 languages

(6) Quick installation guide x1

(7) Warranty Card x1

CONFIDENTIAL 6

Chapter 3: Operation Theory

Hardware

P110S Circuit Theory

The circuit of P110S contain six parts: main board, card board, LCD board, motors and sensors

wires/cables. The power is supplied by adapter and Li-ion battery. Adapter is an AC to DC power

conversion device and it provides a 90W max. 19V, DC source to drive P110S photo printer. And the

Li-ion battery is five series-one parallel (5S1P) and the capacity is 2600 mAH. The voltage of battery is

from 21V (Full) to 13.75V (cutoff). And the normal voltage of battery for printing is from 21V to 18V.

Main board transforms (step-up) adapter or battery voltage to 24V for motors driver ICs and charger IC,

and also transforms (step-down) the input voltage to TPH necessary voltage (15V +/- 5%). In the mean

time, transform input voltage to 5V and 3.3V by voltage regulators for ASIC, Memory, and the I/Os. Main

board provides a connection to thermal print head, supports both Toshiba G5004 series. To the others, CF

card socket provides an interface for CompactFlash type, including CF type I, CF type II and MicroDrive;

MultimediaCard,SecurityDisk, and MemoryStick, are integrated in 4 in 1 card socket. Card board, which

consists the driver IC for the 2.5-inch TFT-LCD panel, the user buttons, and the control circuit, is to be

the user interface(UI). The input voltage from adapter or battery and the video signal from main board are

connected to card board. Besides, the TFT-LCD panel is to display images and messages for user

operations.

Motors and sensors wires are builts to motivation provided and detected whicth based on main board

controlled.

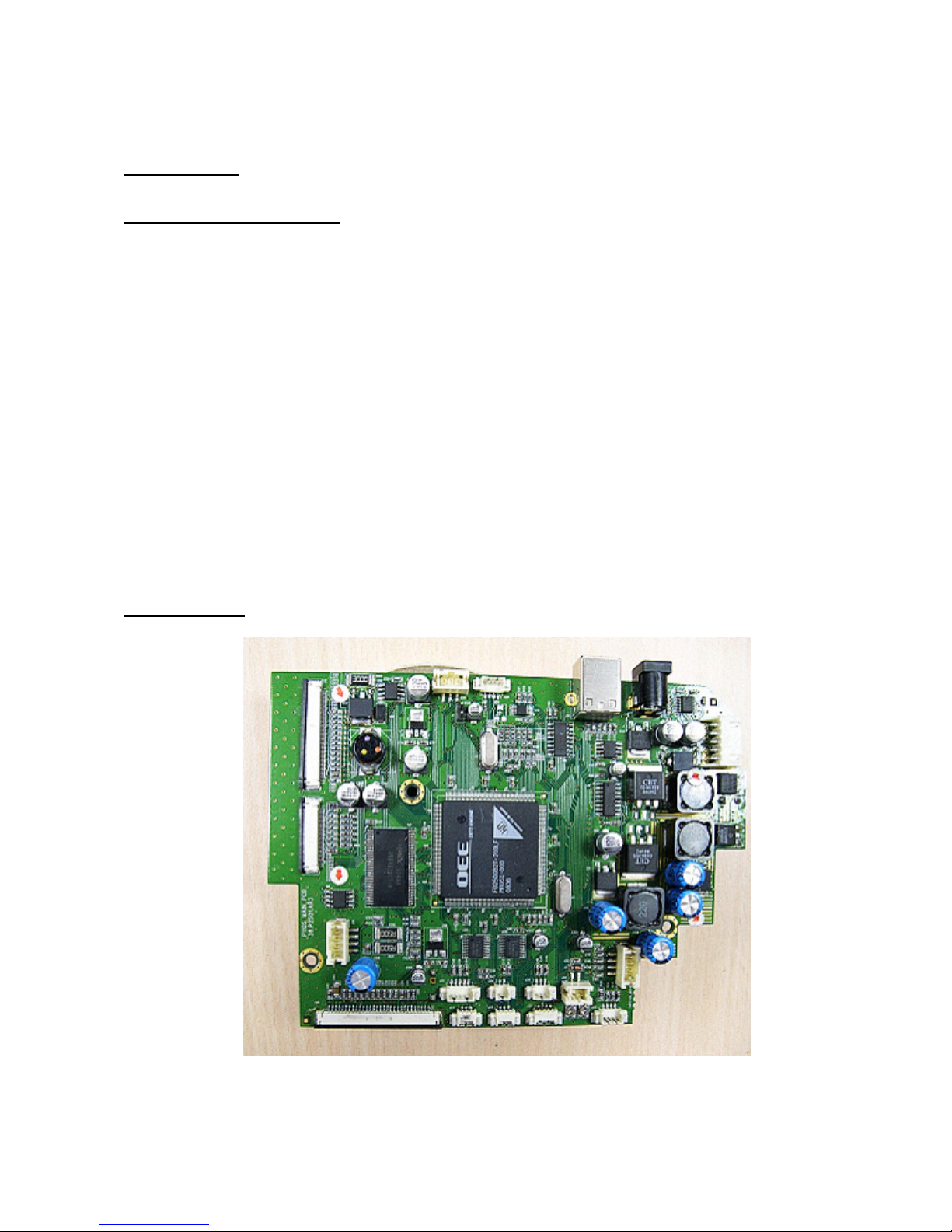

Main Board

The circuit theory of main board will be divided into six parts.

1. ASIC Architecture

The FD2500 (code name: Nexus), the successor of FD2680 (code name: ULTIMA), is a single-chip

integrated controllerfor the dye-diffusion thermal transfer photo printer and multimedia applications

based on a turbo 8032micro-controller, a fixed-point DSP, an Image Extension (iMX) data processing

accelerator, and an intelligent print engine. The Nexus engine is specifically designed for the digital

processing of imaging applications, and the dual cores (MCU-DSP) architecture provides benefits of

CONFIDENTIAL 7

parallel processing of control and computation operations, and the unified memory architecture (UMA)

eliminates the memory cost. Besides, versatile general peripherals are also to provide the data

communication capability.

2. Memory IC

a. SDRAM

This 256Mbit SDRAM on main board is to be the data buffer. The image file, print data, video frame

are temporarily stored during operation.

b.NOR Flash

This 8Mbit flash memory is applied as respective ASIC need which store the MCU code, the DSP

code,the logo, the OSD (On-Screen Display) map and etc.

c.NAND Flash

This 128MB flash memory is to store image related data for later image compounded using.

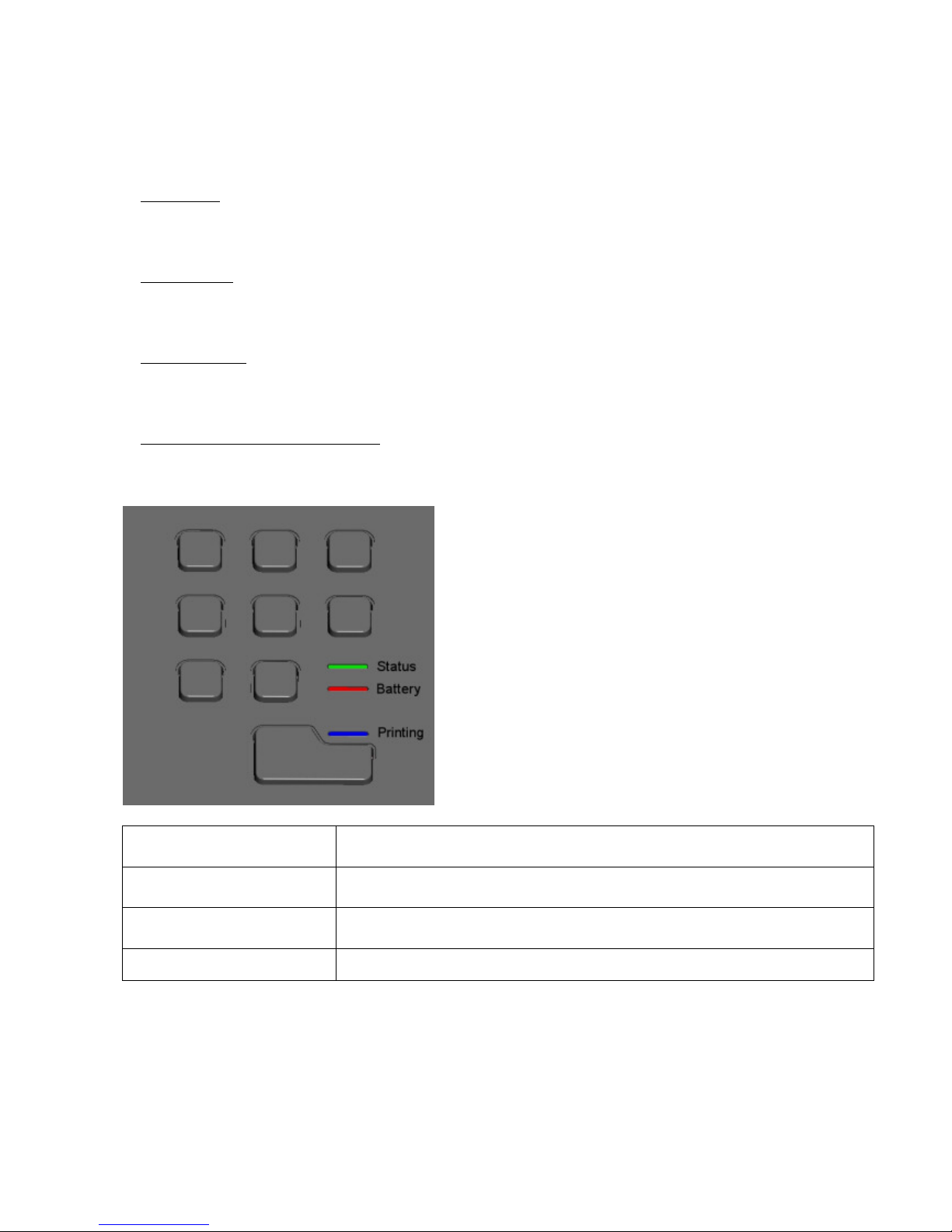

3. LED & Sensor

a. Status/Error LED/Indicate LED

Show printer status and error message. Green LED shining means printer ready. Green LED blinking

means printer busy. Rde LED blinking means error message. Orange LED shining means battery

charging. Blue LED blinking means push the print button. Blue LED shining means printing.

Printing LED (Blue)

On : Printing

Blinking : To hint user click the print button to print

Battery LED (Red)

On : Charging

Blinking : Battery low

Error status LED (Green)

On : Printer is ready for processing job

Blinking : Printer is processing job, or in power-up initialization state

Error status LED (Red)

Blinking : Indicate error

CONFIDENTIAL 8

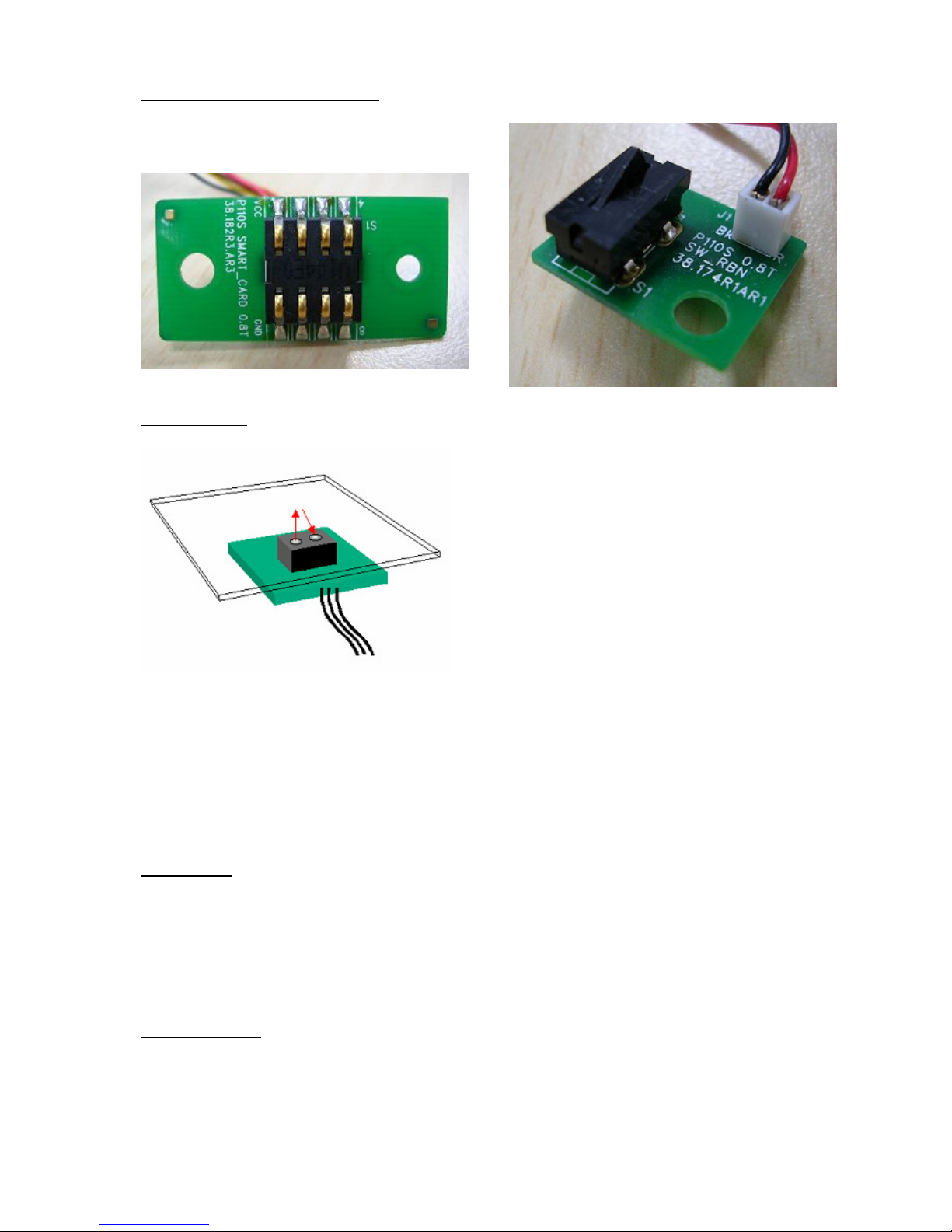

b. Cam sensor

Cam sensor (2 pcs) indicates the position of linkage. There are four position: P1-initial position,

P2-Load paper position, P3-ribbon search position, P4-print position.

Penetration Type Sensor

c. Paper out/ LE/ Jam sensor

Detect paper in paper cassette, Detect the existence of paper and paper length.

Reflective Type Sensor

Paper out sensor

Jam sensor

Smart card sensor

Ribbon sensor

Ribbon type sensor

LE sensor

Cam sensor

CONFIDENTIAL 9

d. Smart card/ Ribbon type sensor

Detect ribbon type and sheet and whether the ribbon install.

e. Ribbon LED

Detect ribbon color Y, M, C and O, which are index as black bar individually.

Reflective Type Sensor

4. TPH Interface

Print data will be shifted into TPH during each clock. After 256 shift clocks, one line data will be

shifted to TPH. Latch/ signal will latch the print data. Strobe/ signal will heat the corresponding heater

elements on TPH according to shift-in data. More the storbe/ time, more the dye of the ribbon is

transferred to paper.

5. Motor Interface

a.Cam motor

Cam motor is a bipolar motor and driven by driver IC L6219. L6219 is designed to drive both windings

of a bipolar stepping motor and includes pulse-width-modulation (PWM) control of ouput current to

750mA. For PWM control, the maximum output current is determined by user's selection of a reference

voltage and sensing resistor.

It controls printing function and position of ASSY LINKAGE.

b. Capstan motor

Capsten motor is a bipolar motor and driven by driver IC L6219. L6219 is designed to drive both

windings of a bipolar stepping motor and includes pulse-width-modulation (PWM) control of ouput

current to 750mA. For PWM control, the maximum output current is determined by user's selection of

a reference voltage and sensing resistor.

It controls Takeup Roller, Feeding Roller, Ribbon Take, Ribbon Rewind, Paper moving

6. Charging Interface

CONFIDENTIAL 10

Charging IC is MAXIM1640. There are three charging modes Top-off mode, Fast-charge mode, and

Pulsetrickle mode. Pulse-trickle mode is for battery in over-discharge situation. Fast-charge is for

battery in normal voltage. Top-off is after fast-charge mode for charging battery voltage upto full

voltage (21V).

Card Board

The circuit theory of card board can be divided into three parts.

1. CPU and serial EPROM

This card board uses an 80-series CPU with 64KB on-chip FLASH EPROM to do central control,

including LCD backlight control, button-pushed sensing, and communication with main board. The

serial EPROM stores setting data of LCD that is got from the calibration process. CPU will read the

serial EPROM and complete the initial setting for LCD after power on.

2. LCD and backlight LED

The 2.5-inch TFT LCD panel is used to display images and messages. It's backlight is low DC voltage

ultralight white-LED.

3. Memory Card Socket and Interface

CF card socket for CF memory card, and 4-in-1 card socket for SM, MMC, SD, and MS memory cards.

And CF control by ASIC, SM, MMC, SD, and MS control by PS3002.

CONFIDENTIAL 11

Mechanism & Movements

User Interface

CONFIDENTIAL 12

CONFIDENTIAL 13

CONFIDENTIAL 14

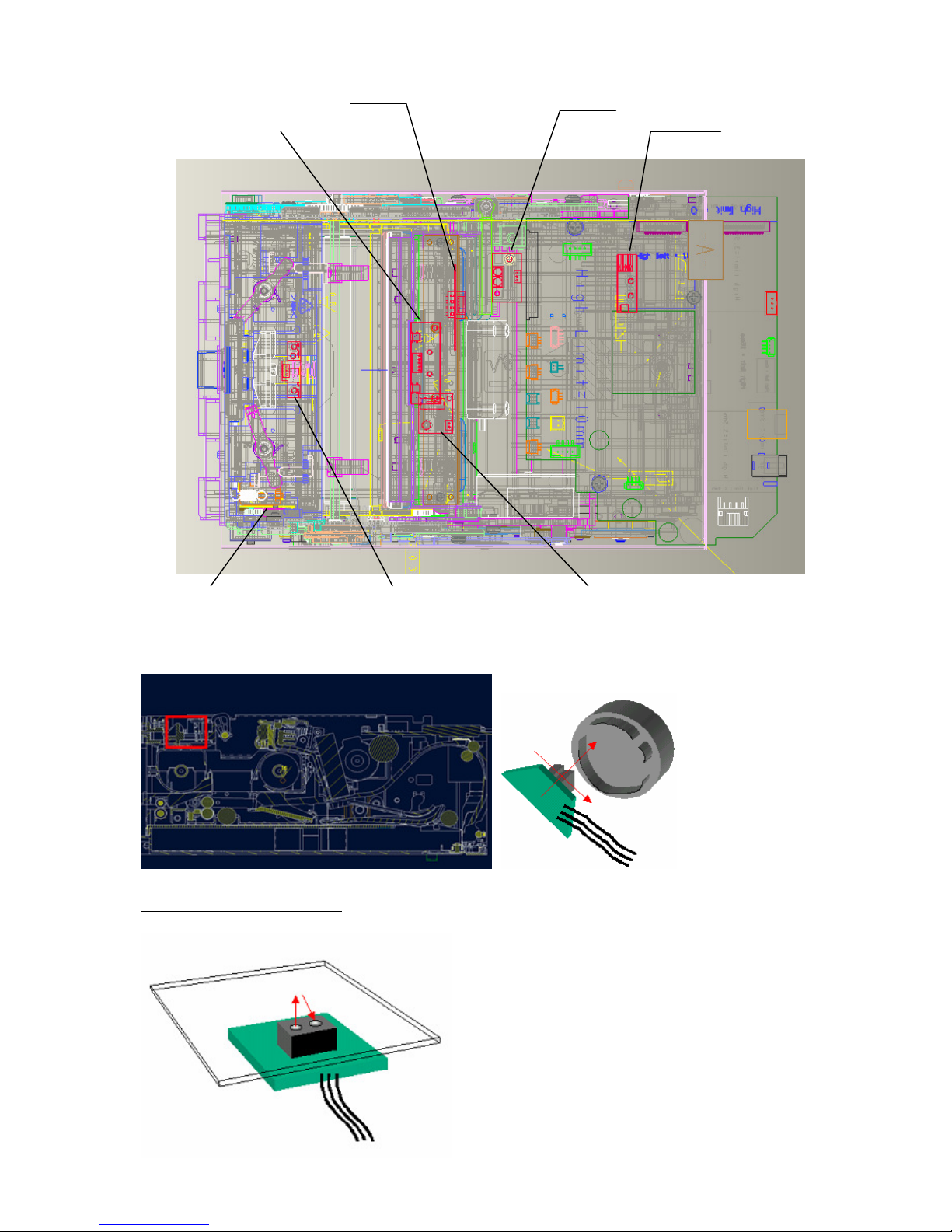

Function layout

Ribbon Lock

Module

ADF translation

parts

Supply TQL

Takeup TQL

Capstan Roller

Cam Motor

Capstan Motor

Main Board

Exit Paper gear

train

ASSY

LINKAGE

Linkage rotate axes

Lifter

Cam gear

train

CONFIDENTIAL 15

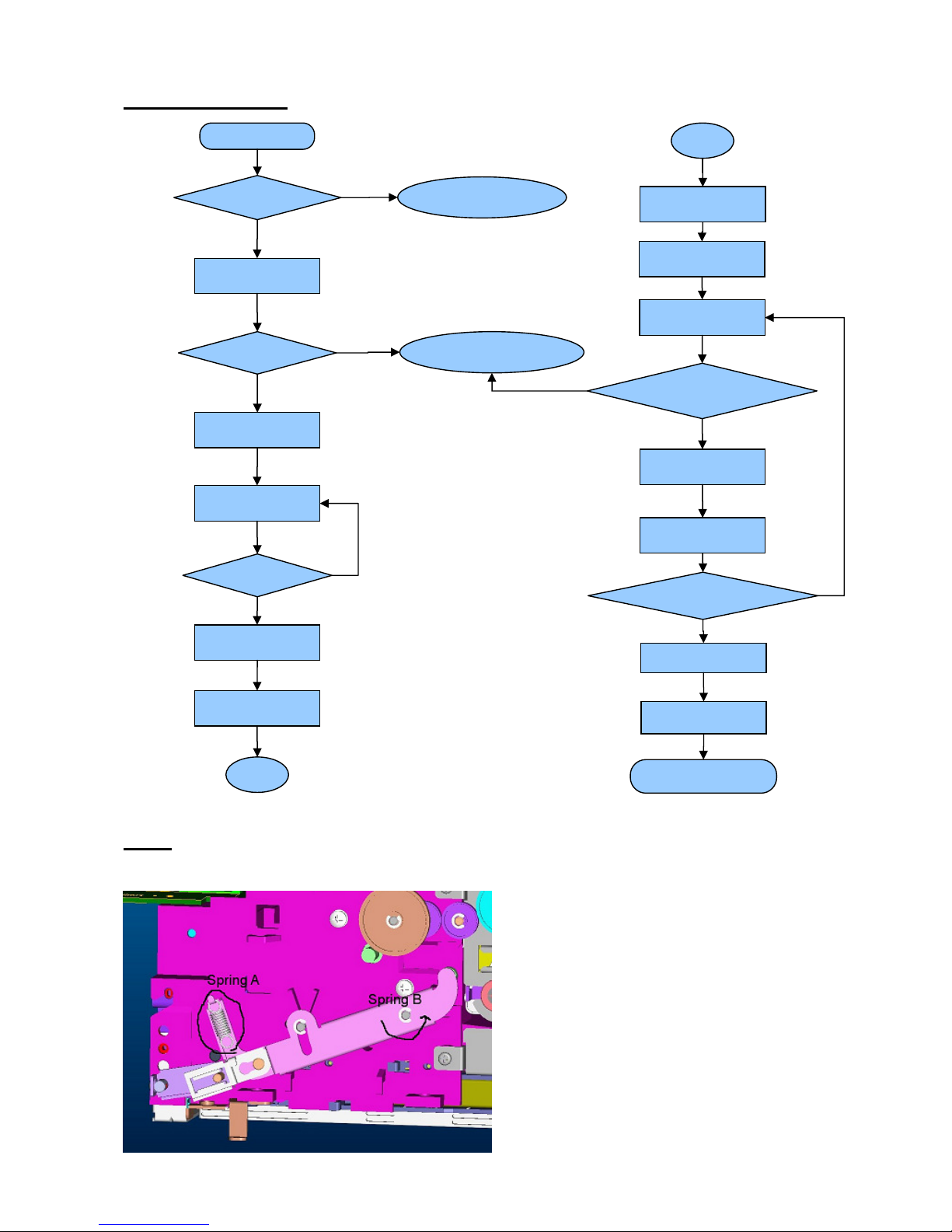

Printing Process

ADF

Spring A(500g~800g): The value too big --> Multi Feed; The value too small --> Miss Feed

Spring B(300g-cm): To make sure the lifter status is down

Search RBN Y

A

Job start

Paper exist ?

Error !!

Paper Out

Move Cam to P3

Error !!

Ribbon Out

Move Cam to P2

Paper

feeding

Sensor

Move Cam to P1

Position

Paper

A

Move Cam to P4

Print Y

Move Cam to P3

Search RBN

M,C,O

Move Cam to P4

Job finished ?

Move Cam to P1

Print

M,C,O

Exit

Paper

Job finished

CONFIDENTIAL 16

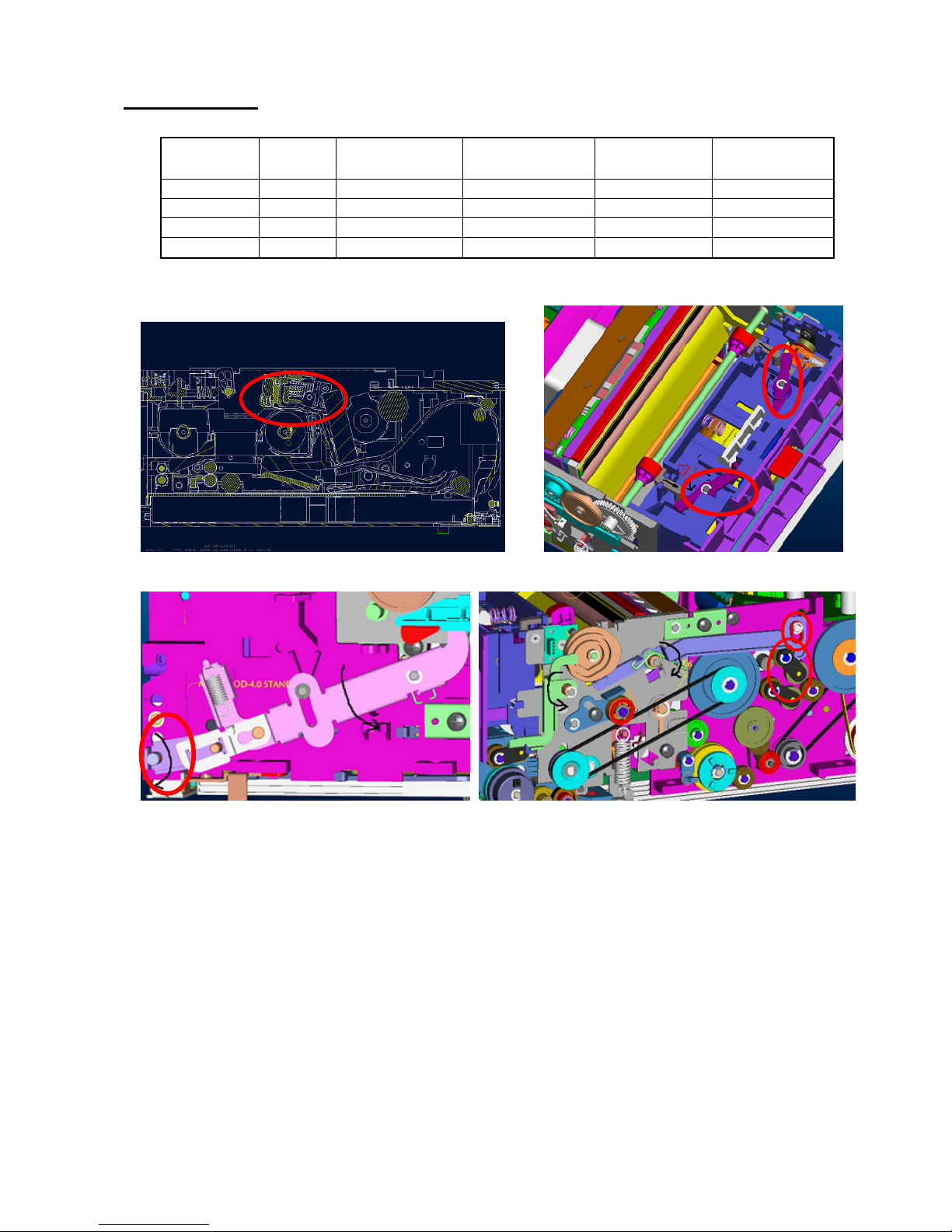

Cam Position

Function

Cam

(Linkage)

Ribbon Search

(TQL _Take)

Paper Feeding

(Roller_Pick-Up)

Paper Feeding

(Lifter)

Paper Moving

(Paper Guide)

Initial P1 Disable Disable Disable UP

Paper Feeding P2 Disable

Enable Enable

UP

Search Ribbon P3

Enable

Disable Disable Mid

Printing P4

Enable

Disable Disable Down

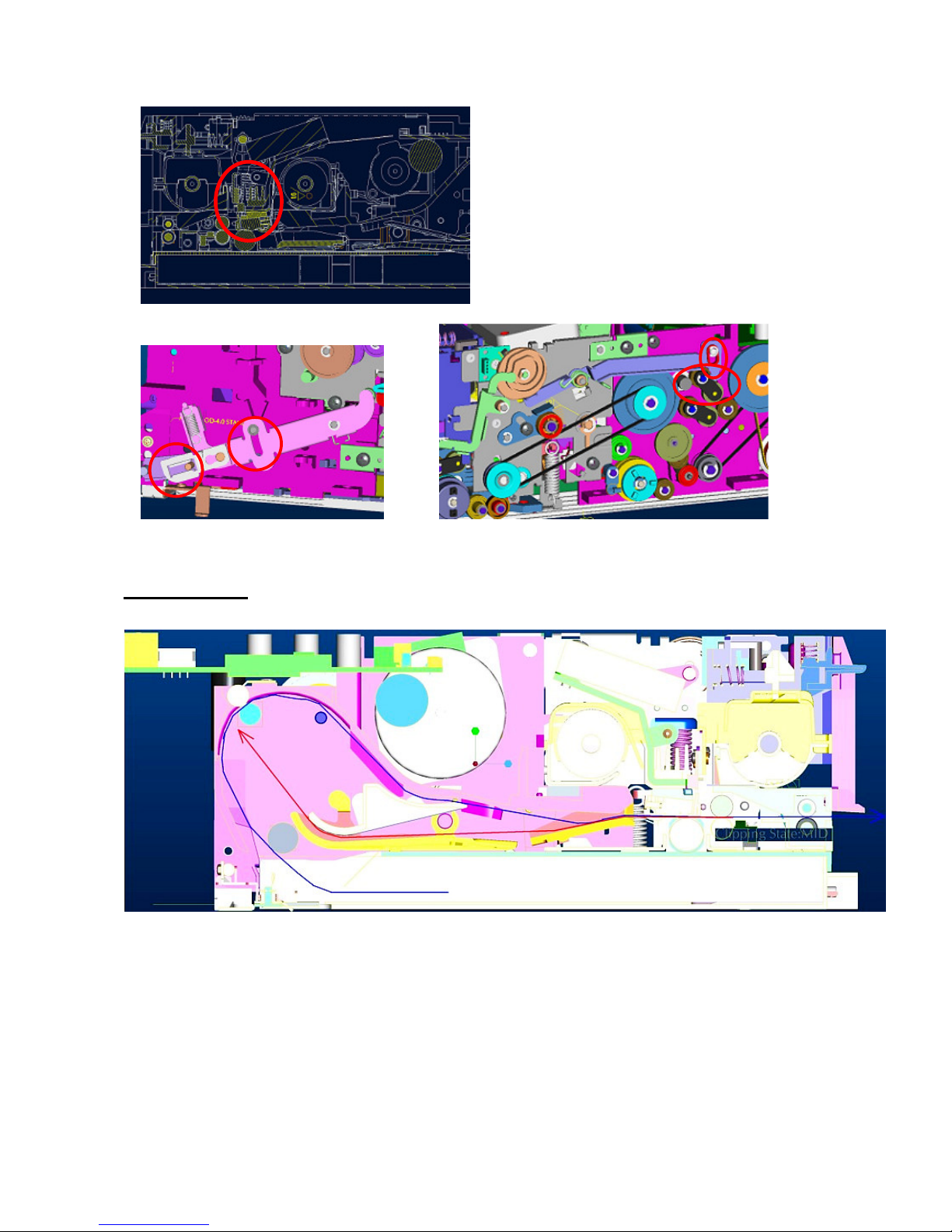

Initial (P1)

Ribbon cassette is released.

Lifter is down (to avoid paper feeding). Roller_Pick-Up is disable. TQL_Take is disable.

CONFIDENTIAL 17

Paper Feeding (P2)

Ribbon cassette is locked.

Lifter is up. Roller_Pick-Up is enable. TQL_Take is disable.

Search Ribbon (P3)

Lifter is down. Roller_Pick-Up is disable. TQL_Take is enable.

CONFIDENTIAL 18

Printing (P4)

Lifter is down. Roller_Pick-Up is disable. TQL_Take is enable.

Paper path

CONFIDENTIAL 19

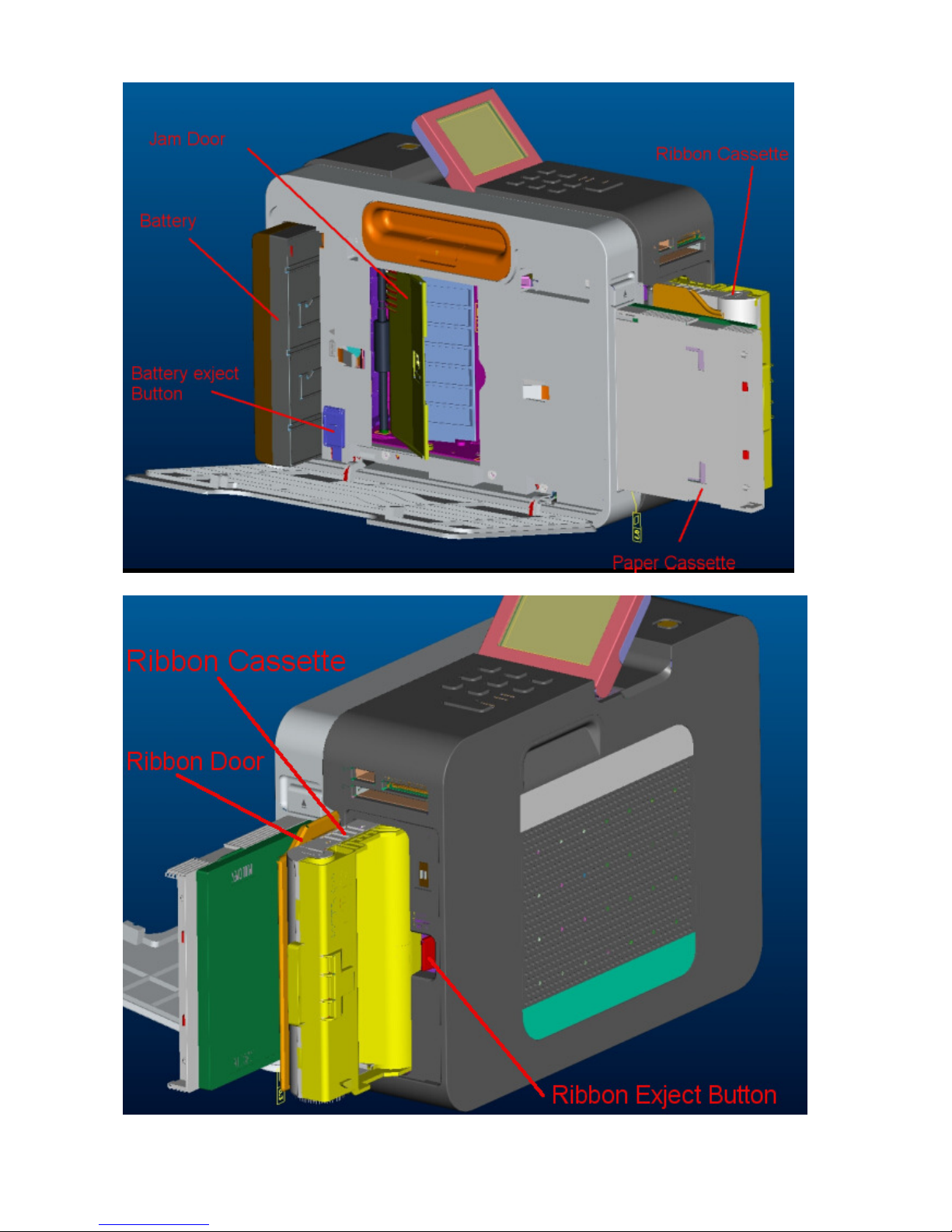

Chapter 4: Disassembly & Assembly

Safety Instructions

Read these instructions carefully. Save these instructions for future reference.

Follow all warnings and instructions marked on the printer.

Before disassembly, it should be off the switch and removed the

batter pack and plug of power cord. Any Main BD or Card BD

damage related to disassembly will be judged as “out-of-warranty”

after identification.

Do not place the printer on an unstable cart, stand, or table. The printer may get damaged by a

fall.

Openings in the chassis and the bottom are provided for ventilation purposes and to ensure

reliable operation of the printer by protecting it form overheating: these openings must not be

blocked or covered.

Placing the printer on a bed, sofa, rug, or other similar, not firm surfaces may block the openings.

The printer should never be placed near or over a radiator or heat register, proper ventilation and

cooling must be provided at all times.

The printer should only be operated with the type of power indicated on the marking label. If you

are not sure of the type of power available in your area, consult your dealer or local power

company.

If an extension cord is used with this product, make sure that the total ampere rating of the

equipment plugged into the extension cord does not exceed the extension cord ampere rating.

Also, make sure that the total rating of all products plugged into the wall outlet does not exceed

the fuse rating.

Tools Required

Name Model Q’ty

Screwdriver

- 1

Screwdriver (small)

- 1

Flat-blade screwdriver (small)

- 1

Spring hook

- 1

Nipper

- 1

Pliers

- 1

Please assemble carefully to avoid breaking two notches.

Loading...

Loading...