HiTi Digital 640PS, 641PS Service Manual

Confidential

1

64xPS/ID

Service Guide

Version: 1.1

The Service Guide was written mainly for engineers.

Please Do Not reproduce and duplicate.

Confidential

2

Chapter 1:

Overview

Chapter 2:

Theory of Operation, Mechanism, Firmware

Chapter 3:

Disassembly, Index of Parts, Tools required

Chapter 4:

Adjustments

Chapter 5:

Contact Information

Confidential

3

Chapter 1: Overview

Overvie w

HiTi Photo Printer 640PS and 641PS are popular printers able to print in high-speed &

high-quality. HiTi p hoto printers are sty lish and compact. HiTi printers can print 6x4”

(10x15cm) photos, ID photos (various sizes), name cards, post cards, greeting cards,

season cards, calendars, and stickers.

There are 2 different ways to operate the HiTi Photo Printer 640PS and 641PS:

1. The printer can be connected to a personal computer via a USB cable. HiTi photo

printers meet the USB 1.1 standard and are fully compatible with any USB device (USB

1.0 to 2.0).

2. The HiTi Photo Printer 640PS and 641PS can also be operated without a direct or

indirect connection to a personal computer. This printing style is called standalone

printing. In this mode, images are being selected with the handheld TFT monitor. The

640PS and the 641PS both feature ‘onboard’ multi-card readers. A memory card can be

inserted into the card slot. Image can be selected on the handheld TFT monitor.

In addition to a multi card memory card slot, the 641PS also features a LinkPrint

connector. LinkPrint is an advancement of the Picture Bridge standard, which allows

compliant cameras to be directly connected to the 641PS printer. LinkPrint also allows

external hard drives or storage drives, such as USB memory sticks, to be directly

connected to the printer.

The 640PS and 641PS include one of the following functions:

Printing Process

640PS

641PS

Confidential

4

YMCO 4 passes (Yellow, Magenta, Cyan, and Over-coating)

Over coating ensures that HiTi’s printouts can be kept a longer time than inkjet

printer’s printouts.

High Quality Resolution

640PS and 641PS: 403x403 dpi

Convenience

All HiTi Photo Printer ship with “Photo Desiree”, a photo editing program

designed for printing 4”x6” photos, id photos, calendars, photo name cards, and

photo greeting cards.

HiTi “Photo Desiree” enhances and enables very easy usage for your photo

printer. It allows you to turn your 640PS or 641PS into a digital mini lab you

can operate from home.

You can download the latest firmware and other software from the HiTi website

to your computer. Firmware is being updated per USB cable.

Multi-memory card support. HiTi Photo Printer 640PS and 641PS p rovide two

types of memory card slots.

Stand-alone operation & PC link: You can instantly p review what you want to

print.

640PS and 641PS can be used to read y our images from a memory card (it has

the functions of a card reader).

(641PS onl y:)

641PS can accept any USB device (Camera, USB memory stick, USB memory

card adaptors, External HDD). This technology is known as LinkPrint.

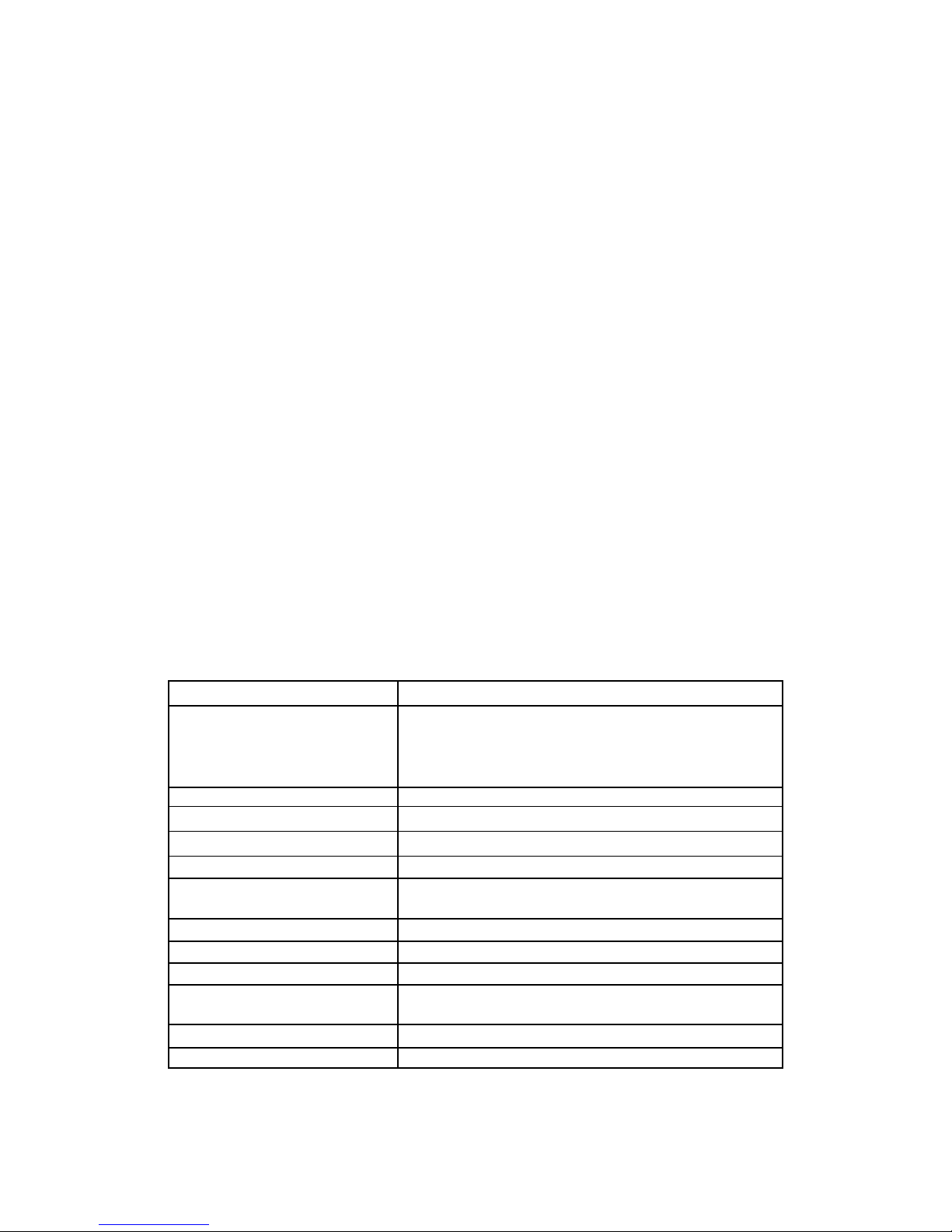

Specifications

Model Name HiTi Photo Printer 640PS & 641PS

Printing Method

Dy e Diffusion Thermal Transfer continuous tone

printing

Gradations

256 levels per Yellow, M agenta, Cyan color (8 bits),

total 16.77 million true colors

Resolution 403×403 dpi

Paper Size 4 in.×7 in. with detachable boundary

Printing Size 4 in.×6 in., (100mm×152mm)

Paper Fe e d Cassette type automatic feeder, 25 sheet capacity

Printing S peed

Approx. 60 sec. per sheet (excludin g data transmission

time)

Operating Temperature 59˚ ~90˚F (15˚ ~32˚C)

Operating Humidity 20 ~75% RH

Computer Interface USB Ver. 1.1

Card S ocket

Twin slot support CF, SM, SD, MMC, MS and Micro

Drive

File Format Support EXIF, JPEG, DPOF

Power Supply 100~240V, 50/ 60 Hz

Confidential

5

Operating Syste m

Windows 98/ ME/ 2000/ XP

Linux & Mac OS 10.2 and above

Mi nimum S ystem

Requireme nt

Win 98/ME: 64MB RAM , Pentium PC

Win 2000/ XP: 128MB RAM, Pentium PC

Certification UL, TUV-GS, FCC, CE, BSM I, CCC, C-Tick, VCCI

Accessories Included

Paper Cassette, USB cable, CD-ROM (with printer

drivers, bundle software and electronic manual), AC

power cord, Sample print kit (8 sheets of photo paper,

1 sheet of 4×4 sticker, 1 sheet of 4/2/4 sticker plus 1

YMCO ribbon cartridge for 10 prints

Chapter 2: Theory of Operation

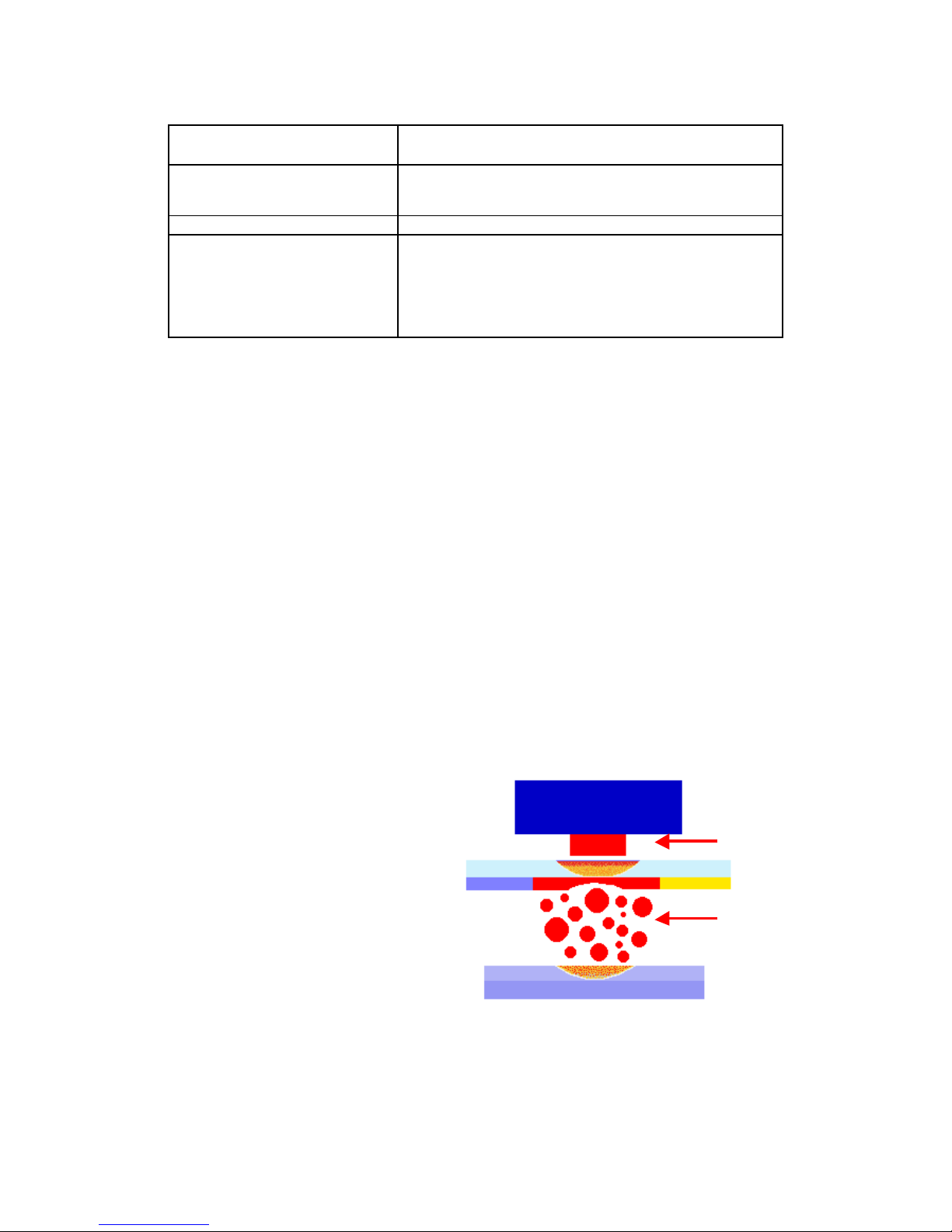

Dye Diffusion Thermal Transfer (D2T2)

Dye Diffusion Thermal Transfer (D2T2), the world’s leading technology in photo

printing processes, uses a thermal printing head (TPH) to sequentially heat three ribbon

panels that are coated with yellow, magenta and cyan dye. The heat process turns the dye

into gas that diffuses into a thin receiving layer on top of the paper. An overcoat is then

layered down on top of the paper to protect the color against water and ultraviolet rays

and to prevent it from fading.

Compared with some other photo-capable printing technologies, such as Thermal

Autochrome (Fujifilm), Variable Dot (Fujicopian) and Inkjet (Canon, Epson and HP),

Dye Diffusion Thermal Transfer creates the most realistic photo quality. To the naked

eye it is indistinguishable from photographic prints. Its continuous-tone printing produces

256 color gradation levels in each p ixel independently while other technologies, like

Variable Dot and Inkjet, have to make different dot sizes to increase the resolution in

half-tone to achieve similar effects.

The Thermal Print Head (TPH)

sequentially heats three ribbon panels

that are coated with dye in yellow,

magenta and cyan. The heat process

turns the dye into gas that diffuses into

a thin receiving layer on top of the

paper. An overcoat is then layered

down on top of the paper to p rotect the

color against water and ultraviolet and

to p revent it from fading.

TPH

Paper

Ribbon

Heat

Dye

Confidential

6

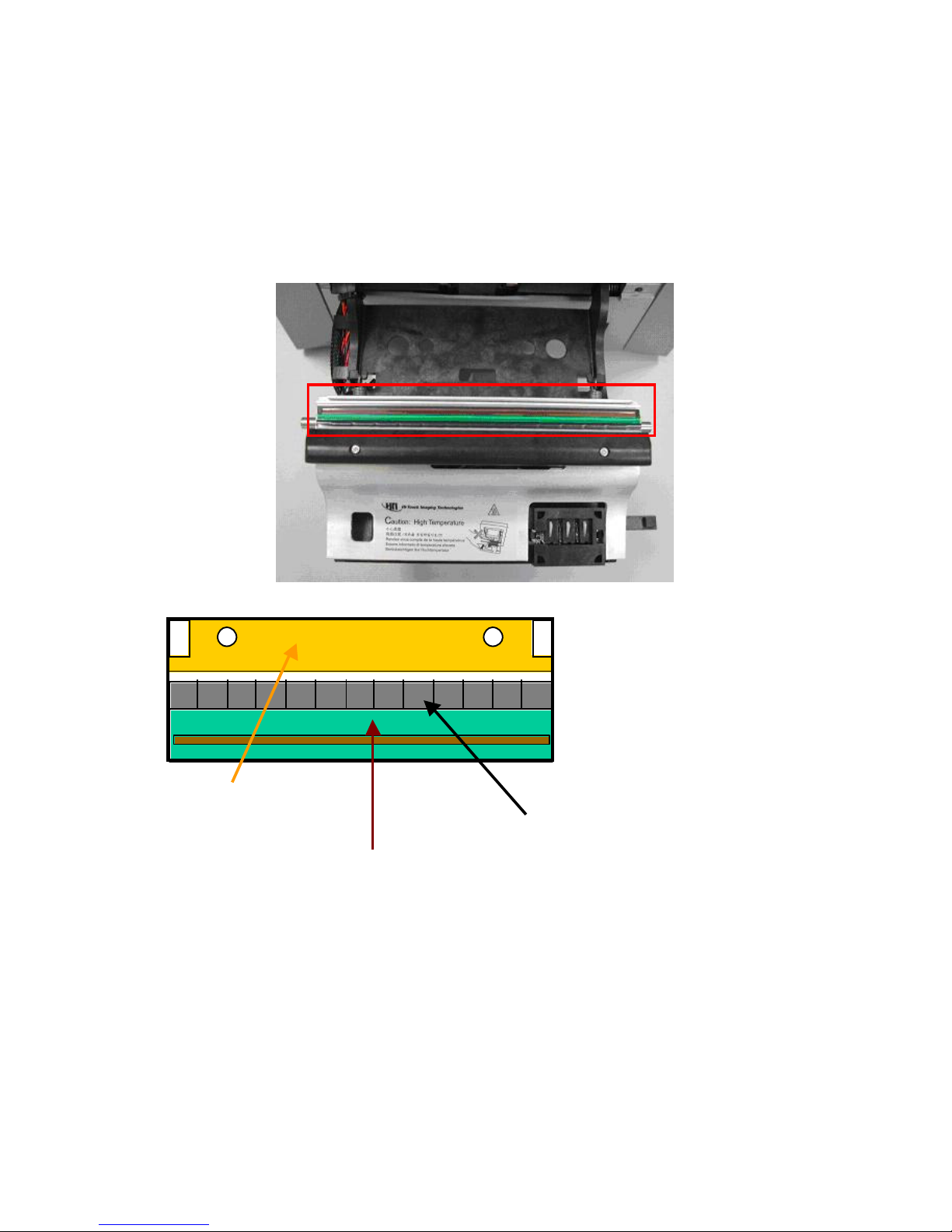

Hardware

Therma l Print Head (TPH)

Thermal Print Head (TPH) is the key component for D2T2 printer, like the inkjet printing

head for inkjet printer.

Heating Ele ment

Driver IC

PCB

Confidential

7

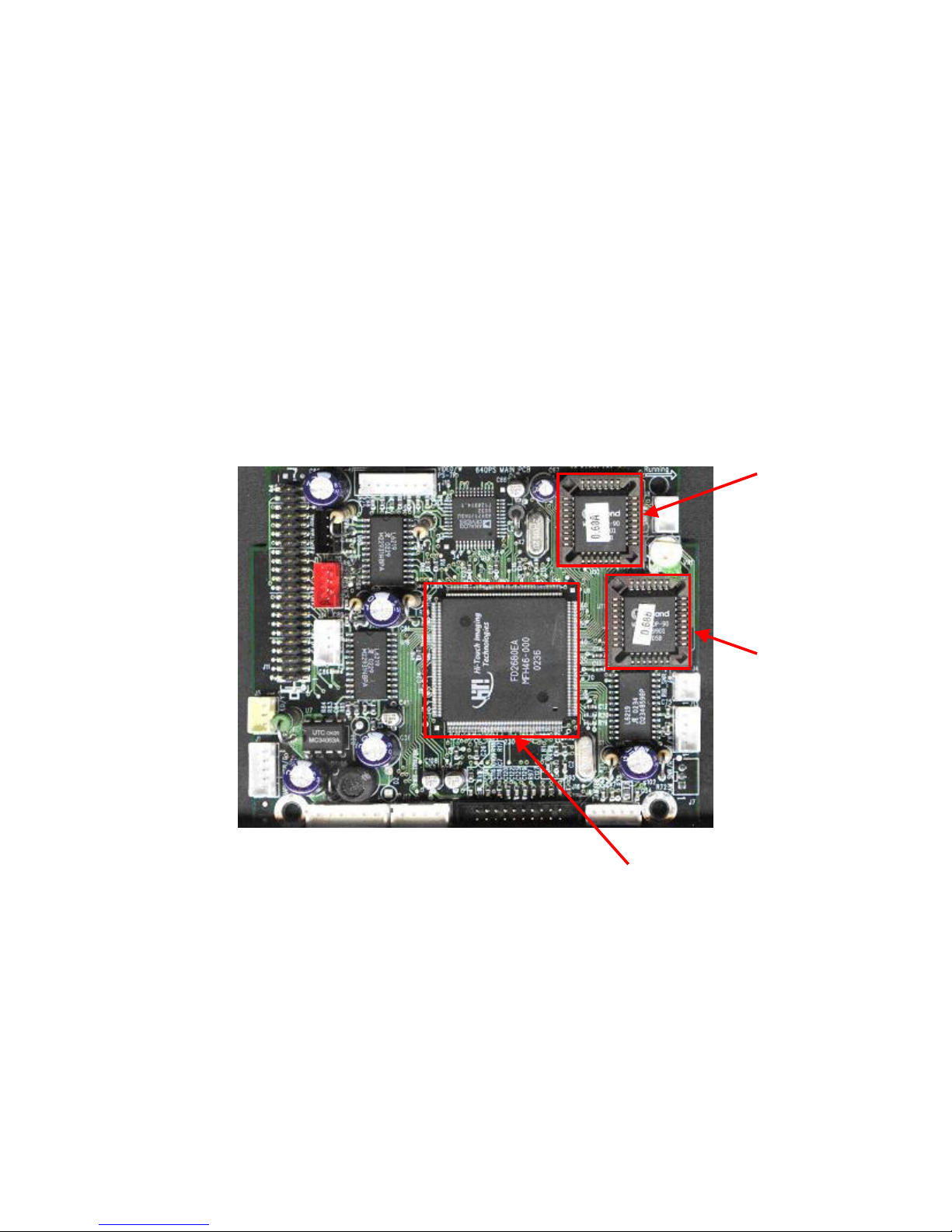

Main Board & ASIC

Note: Main Board = Mother board; ASIC = HiT i CPU

The ASIC is an IC (Integrated Chip) located on the Main Board. The ASIC was designed

by the HiTi R&D dep artment and features an 8032 MCU. The ASIC drives the USB

controller, controls the embedded SDRAM, MCU I/F, USB I/F, memory I/F, and GIO

interface.

The Firmware (located on IC-A and IC-B) controls the actions of the printer by reading

and writing the registers. Please note IC-B is a back up to IC-A.

The VR (Variable Resistance) on the main board is used to adjust the voltage of the

ribbon sensor. (M ore details located in the VR adjustment section).

The 640PS and 641PS have 2 ICs located on the mai nboard. The FW (firmware) i s

stored in IC-A and IC-B.

The picture below illustrates the mainboard of the 640PS.

On the 641PS main board IC-B is soldered onto the main board.

ASIC

IC - A

IC - B

Confidential

8

Power Board

It contains a universal AC input, DC +18V/7V outp ut and a USB interface.

The VR (variable resistance) on the power board is used to adjust the voltage of the THP.

This controls the color density of the printout.

The illustration below shows the image of a 640PS power board.

Note: If the color density is too light, a voltage adjustment (VR on the power board) can adjust the

lightness. More explanation will be given later.

VR

Confidential

9

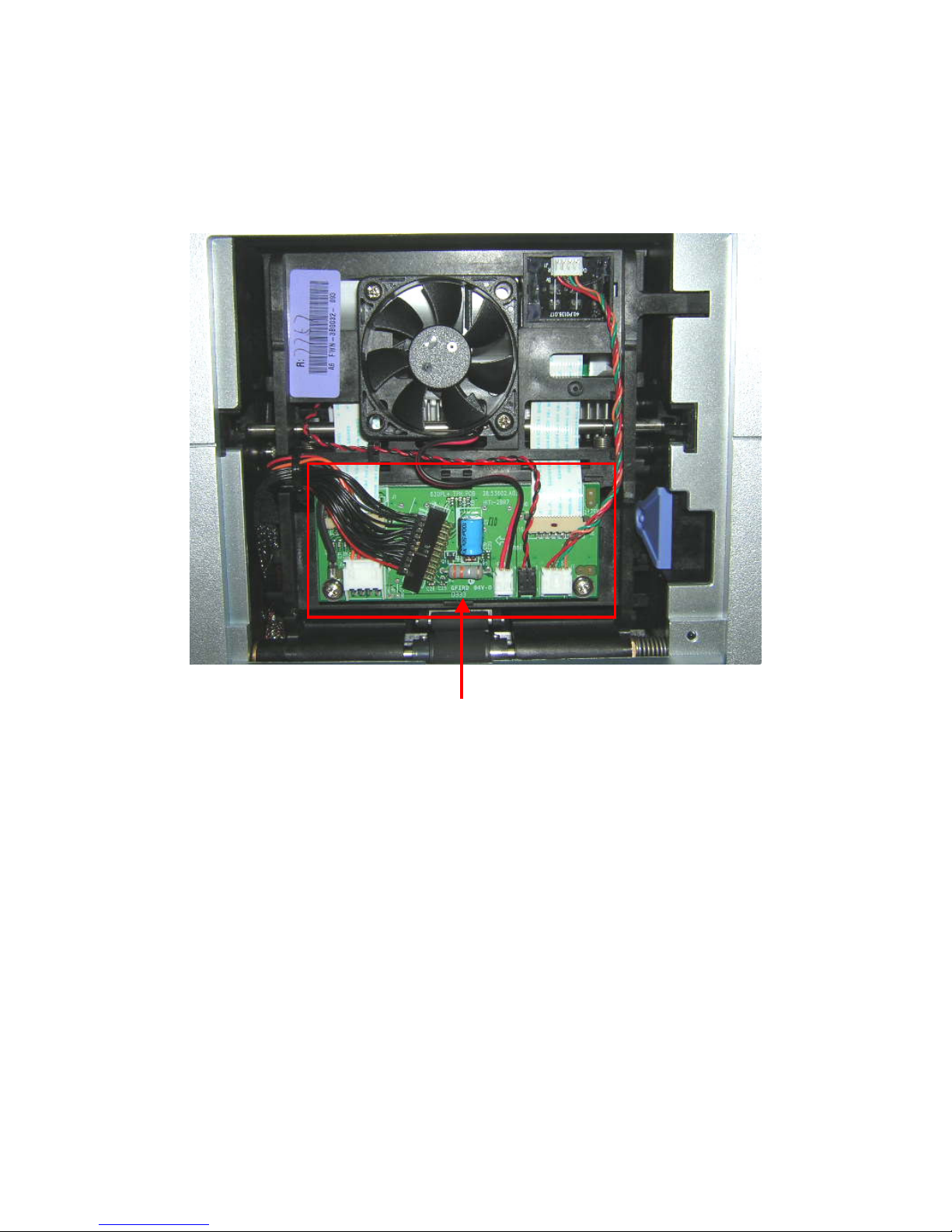

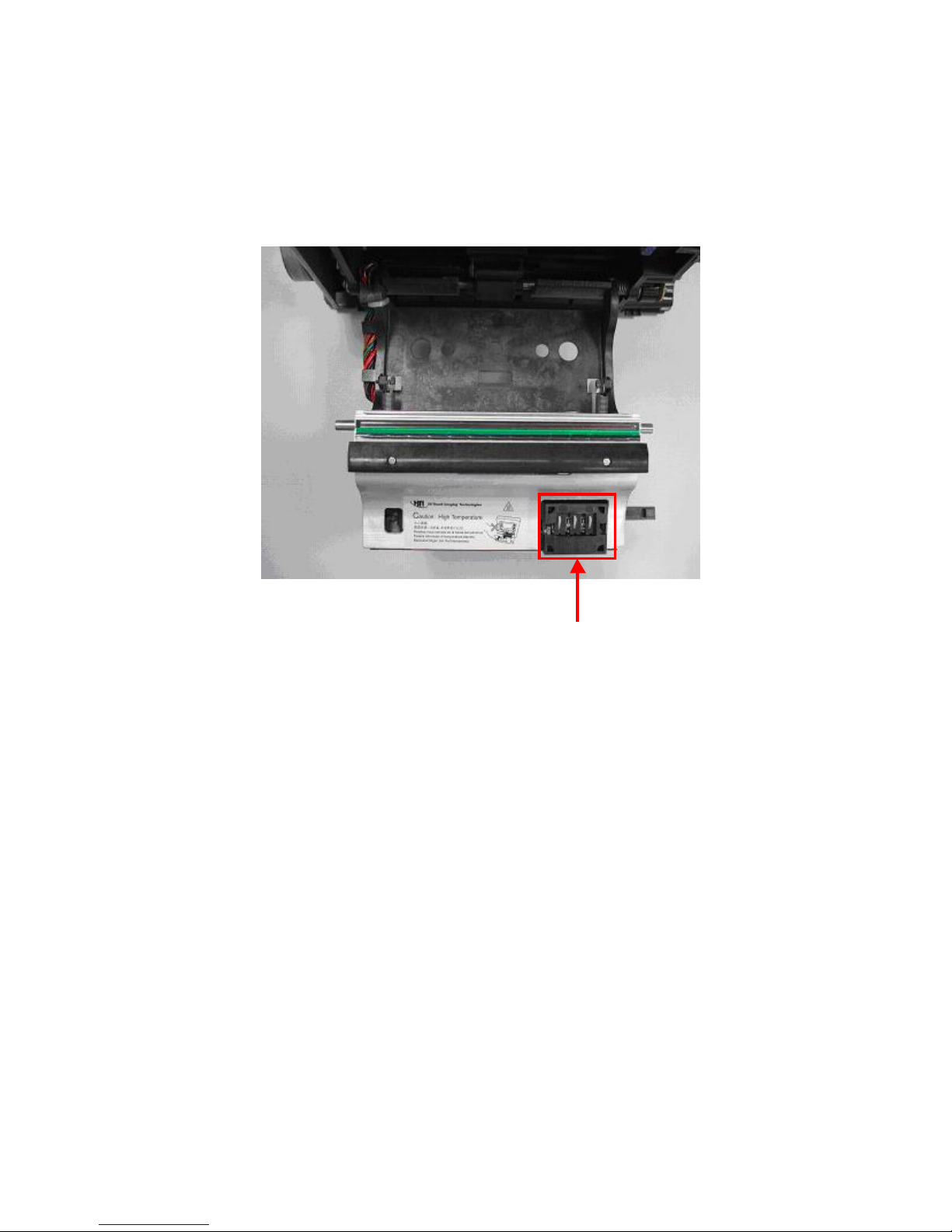

TPH Board

The TPH Board connects the cables (Ribbon LED cable, TPH Cable, Cassette Sensor

Cable, Fan Cable). The TPH board connects then to the motherboard.

TPH Board

Confidential

10

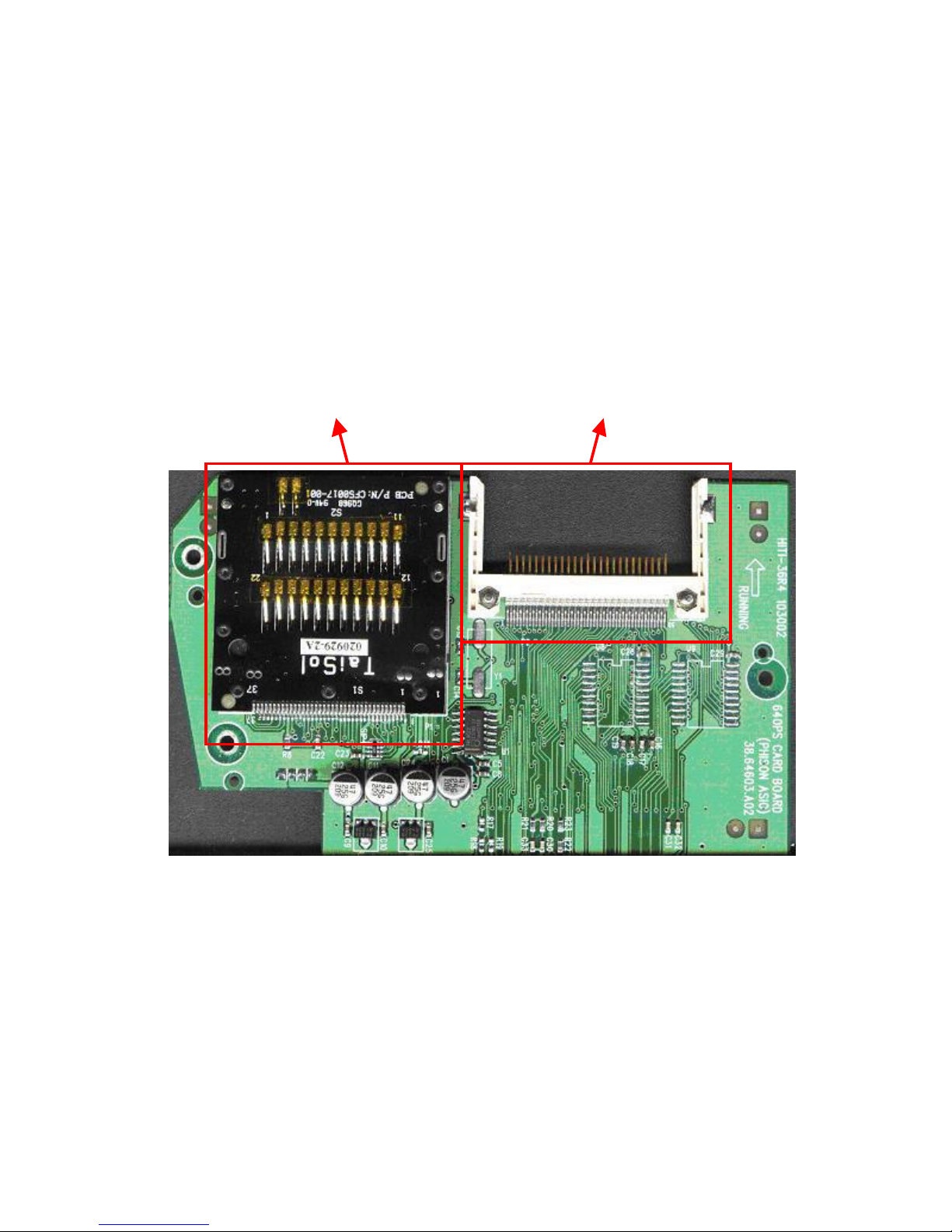

Card Board (640PS and 641PS)

640PS : There are 2 memory card sockets on the card board. One is for Compact Flash

and the other is for Smart M edia/ Multi-Media-Card/ Secure Digital Card/Memory Stick.

641PS : The 641 PS card board features an enh anced USB Connector. This USB

Connector connects Picture Bridge compatible cameras, external hard-drives and storage

cards such as USB memory sticks to the printer. As it is more advanced then Picture

Bridge it is called Link Print.

The illustration below shows the 640PS card board

Compact

Flash

socket

4 in 1 memory card

socket

Confidential

11

The illustration below shows the 641 PS card board

4 in 1 memory card

socket

CompactFlash

socket

USB DataLink

Socket

Confidential

12

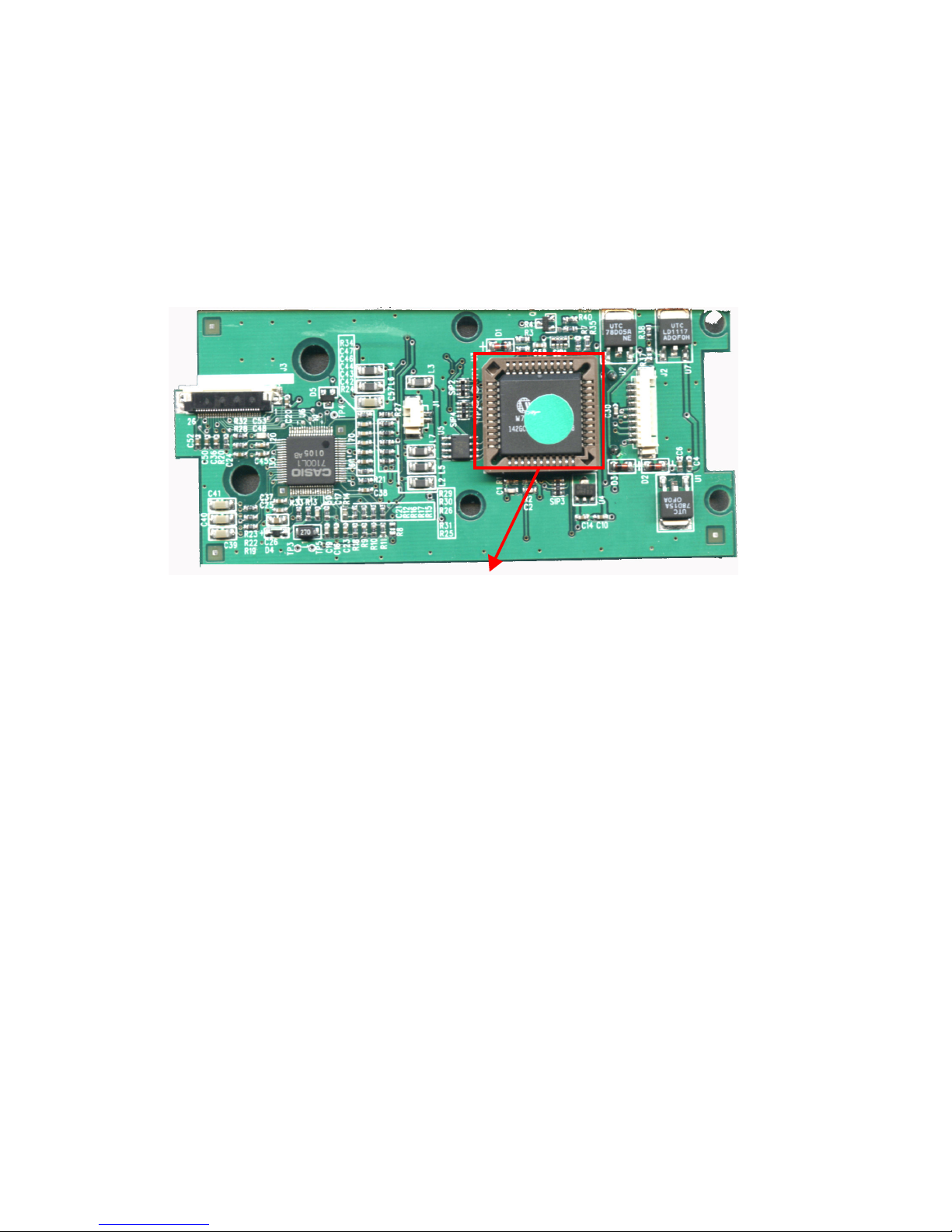

Controller Board (640PS and 641PS)

This controller board uses an 80-series CPU with 4KB on-chip FLASH EPROM for the

central control – this would include an initial setting of the LCD driver IC, the LED

backlight control, the button-pushed sensing and communication with the main board.

The serial EPROM stores the setting data of the LCD that was received at the calibration

process. The CPU will read the serial EPROM and complete the initial setting for LCD

after it has been powered on.

EPROM

Confidential

13

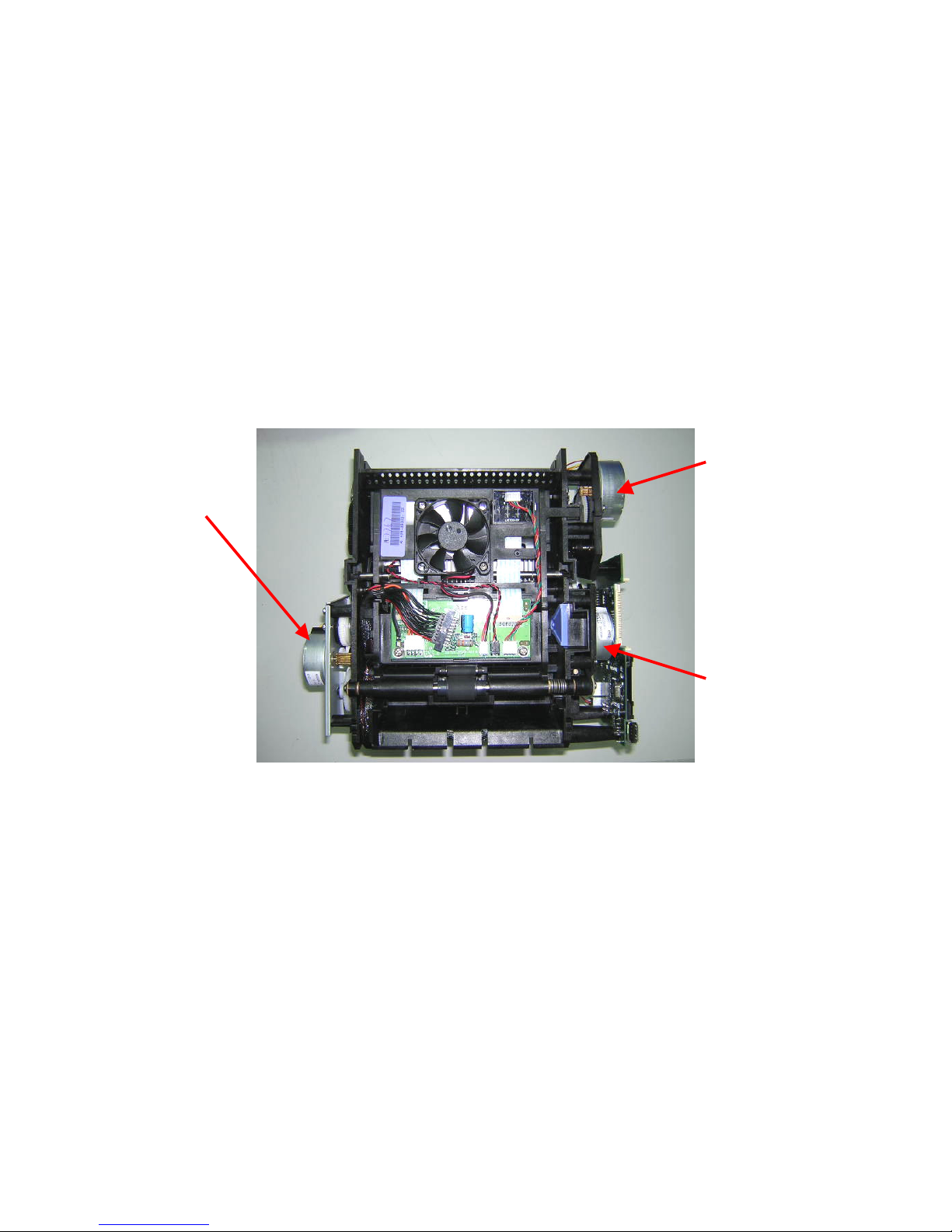

Motor

Cam mo tor

The Cam motor is a bipolar motor which ddrives the CAM to control the Platen roller’s &

Pinch roller’s position.

Capstan motor

The Capstan motor is a bipolar motor which drives the Capstan roller to control the

movement of the paper.

Ribbon/ ADF motor

The Ribbon/ ADF motor is a bipolar motor which feeds paper into the printing path and

then rolls the ribbon to the right starting position.

Cam

motor

Ribbon/ ADF

motor

Capstan

motor

Confidential

14

LED & Sensor Status/ Error LED

The Status/Error LED indicates the status of the printer. It also communicates any error

messages.

For example: The steadily shining Green LED indicates the ready stage of the printer.

The blinking Green LED indicates that the printer is busy. The blinking Orange LED

indicates that an error has happened.

(More in fo about Error messages later in this document)

Status/ Error

LED

Confidential

15

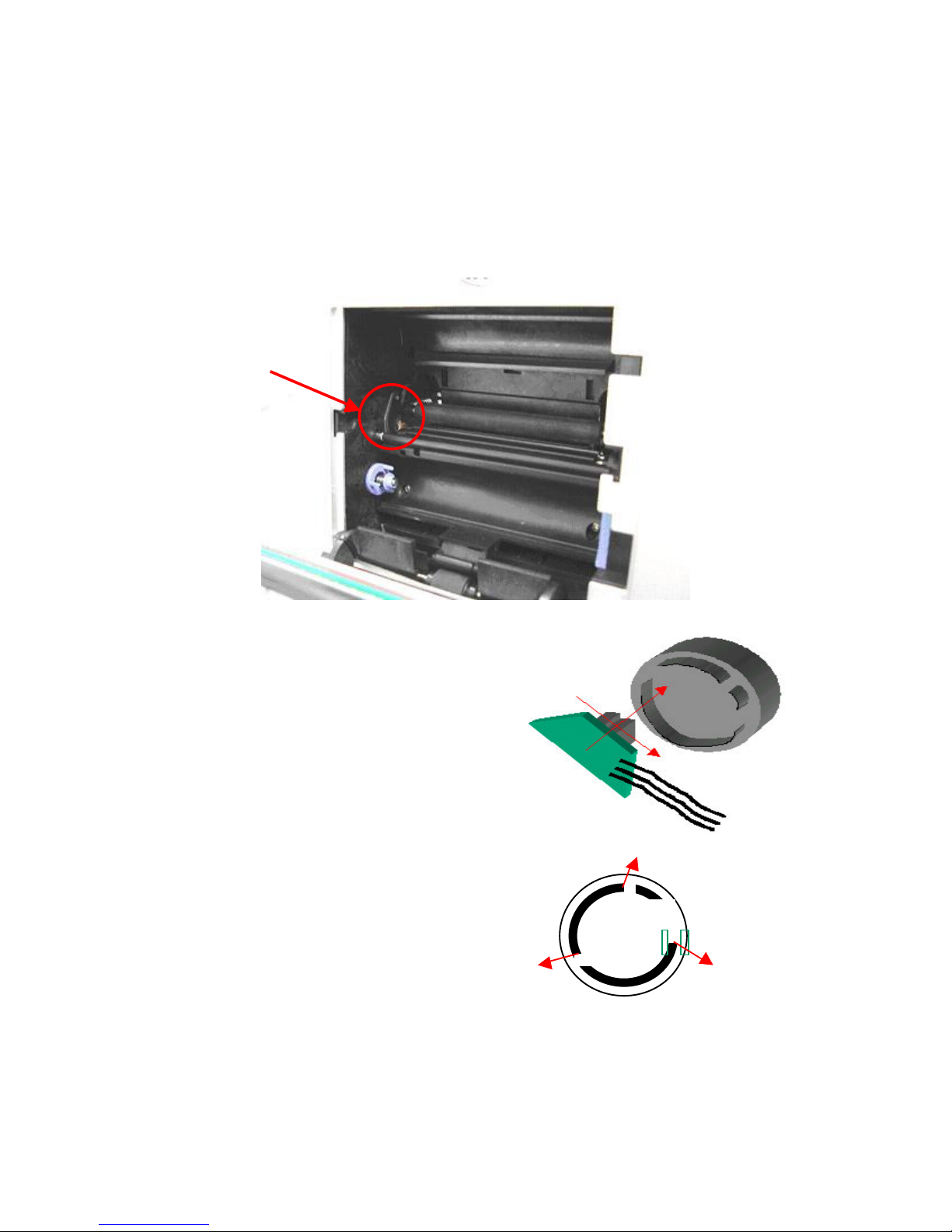

Cam Sensor

Depending on the printer’s status, the positions of the platen roller and the pinch roller

stay different. The Cam controls the movement of the platen roller between these

positions, and the Cam sensor detects & feeds the position’s information back to the

firmware. There are three different platen roller positions:

P1 = Initial Position

The gap between the platen roller & TPH is at

its largest, and the pinch roller is relaxed. The

printer is at this position when the printer

powers on or resets.

P2 = Loa d Position

The gap between platen roller & TPH is not as

large as at P1. The gap enables the ribbon to

wind. The pinch roller touches the capstan

roller and enables the loading of the p aper.

P3 = Print Position

The platen roller is close to the TPH,

and the pinch roller touches the capstan

roller which enables paper to move

forward and backward.

Cam

IINNIITTIIAALLLLOOAADDPPRRIINN

TT

Confidential

16

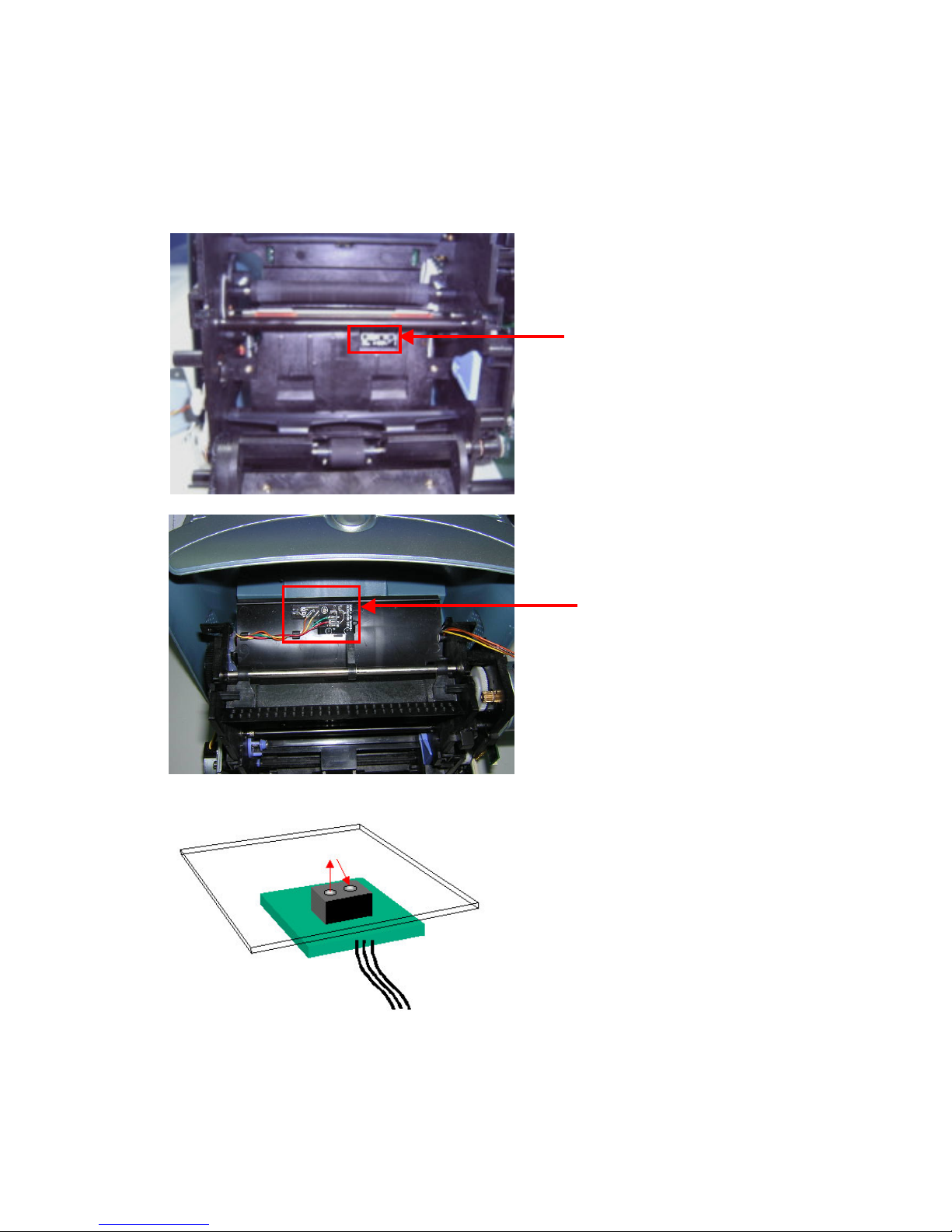

Leading Edge (LE) Sensor and Jam Sensor

The purpose of both sensors is to detect the status of paper. The sensor will be on when it

detects the loading of paper. The LE Sensor will be off if it does not detect paper loading.

Leading Edge

sensor

Jam sensor

Confidential

17

Ribbon Cassette (Door) Sensor

It is used to detect the status of the ribbon cassette and the ribbon door. The ribbon

cassette sensor will be on if the ribbon cassette type is correct; the Ribbon Cassette

Sensor will be off if the ribbon cassette type is wrong.

Ribbon Cassette sensor

Confidential

18

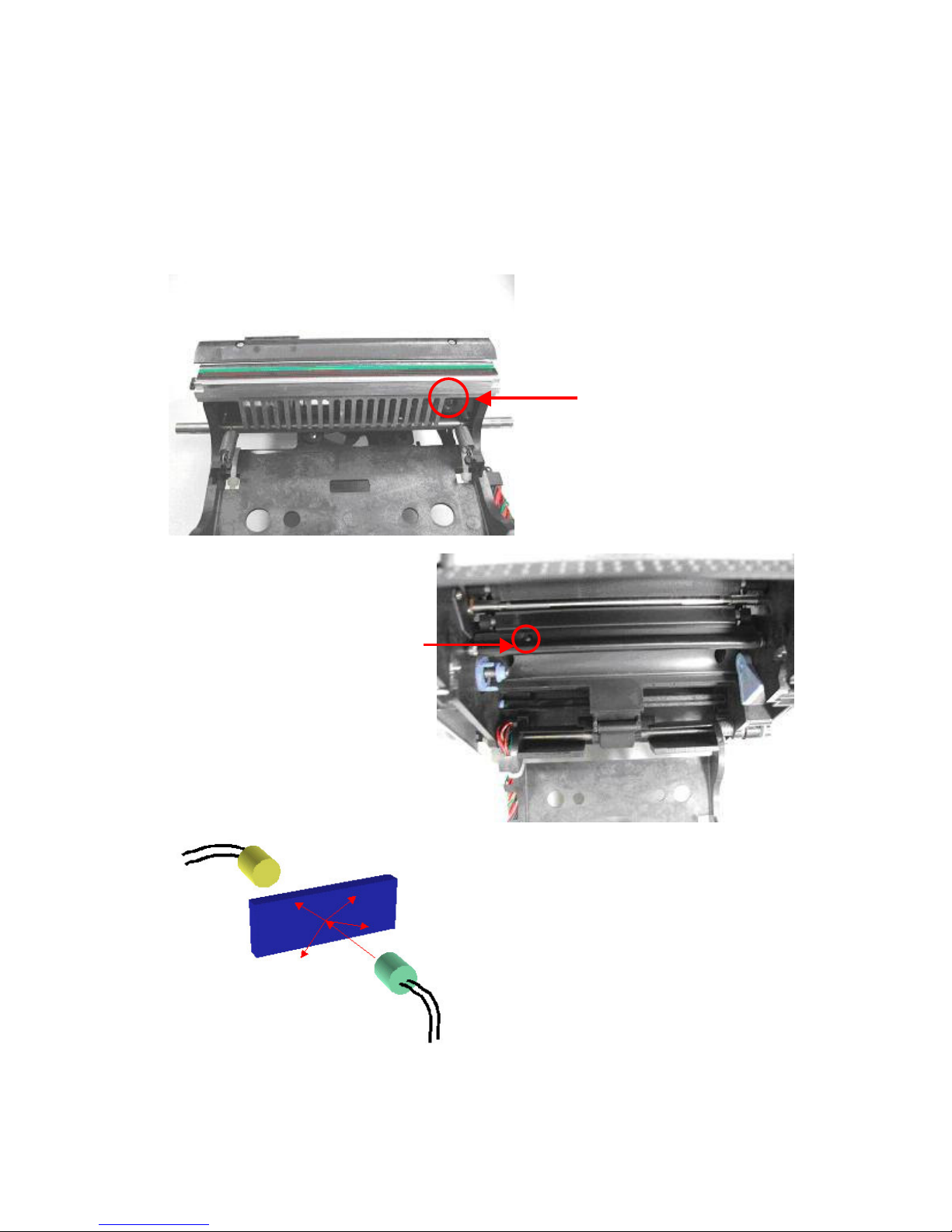

Ribbon LED/ Ribbon Sensor

The Ribbon LED and Ribbon Sensor is used to detect the ribbon status, it enables the

printer to detect the correct ribbon color. At the yellow or overcoat layer, the ribbon sensor

detects a HIGH value. In the magenta and cyan layer, the ribbon sensor detects a LOW

value.

Ribbon LED

Ribbon sensor

Confidential

19

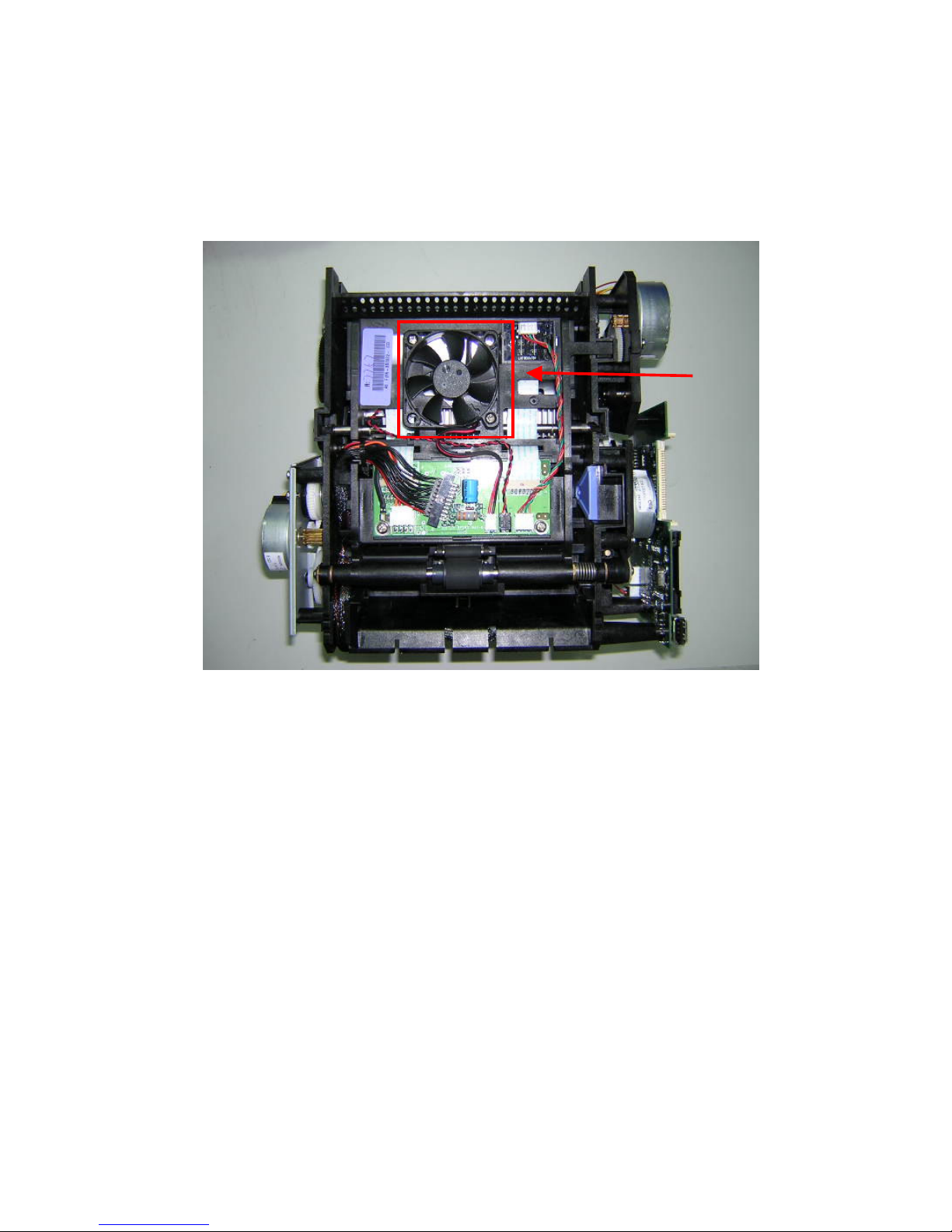

Fan

The Fan reduces the temperature of the TPH (Thermal Print Head). The fan only starts to

operate as soon as the temperature reaches a certain degree.

Fan

Confidential

20

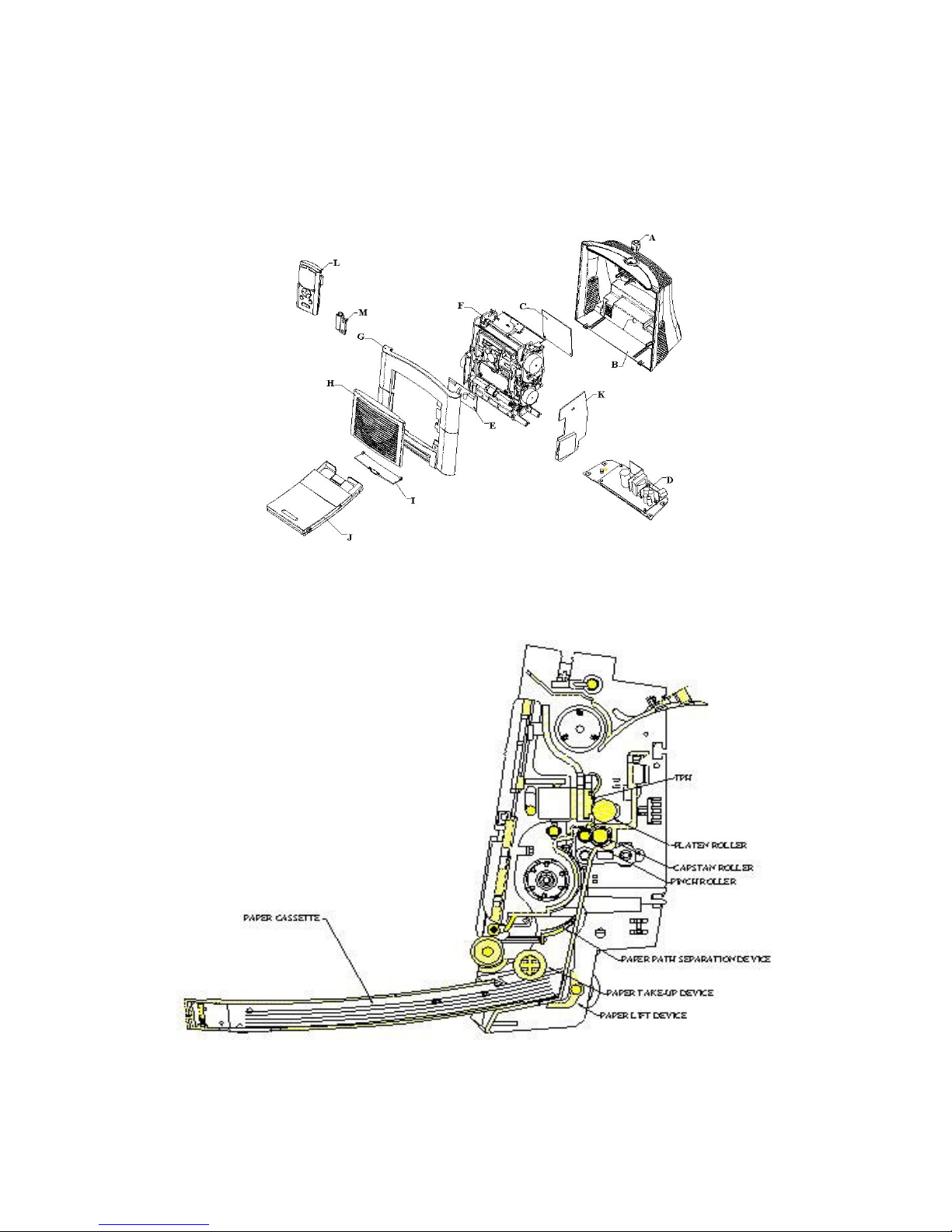

Mechanism

Basic Anatomy

A: Eject button B: Case back C: Main board

D: Bracket and power-board E: TPH board F: Chassis

G: Case front H: Ribbon door I: Paper door J: Paper cassette

K: Card board L: Controller M: Controller holder

Transmission

The Auto Document Feed (ADF)/ Ribbon search device

Confidential

21

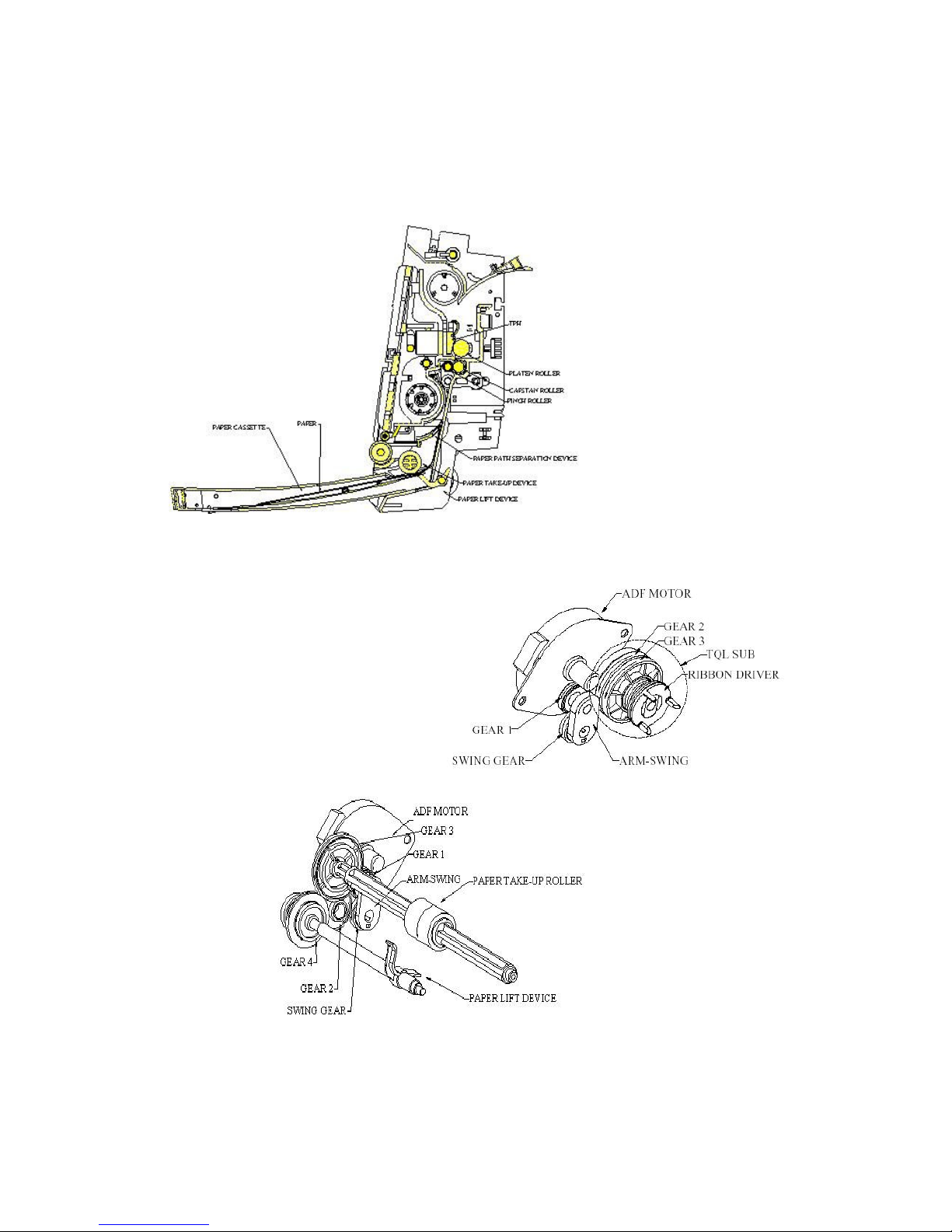

1. When the ADF Motor rotates the paper lifter gearing chain, the Paper Lifter device

starts lifting the elevator plate in the paper cassette up. The paper which lies at the top

position will then be in contact with the paper take up roller.

2. Now the photo p aper is

in contact with the

paper take up roller.

The pap er take-up roller

will grab the top paper

and lead the paper into

the p re-set p aper path.

3. The paper now passes

the leading edge (LE)

sensor. The p aper will

then be grabb ed by the capstan and pinch rollers. From this point onwards, the

paper’s movement is controlled by the capstan and pinch rollers.

4. While the capstan roller

controls the paper, the ADF

releases the paper lift device,

switches to operate the ribbon

gear chain and winds the

ribbon to the prop er frame.

Confidential

22

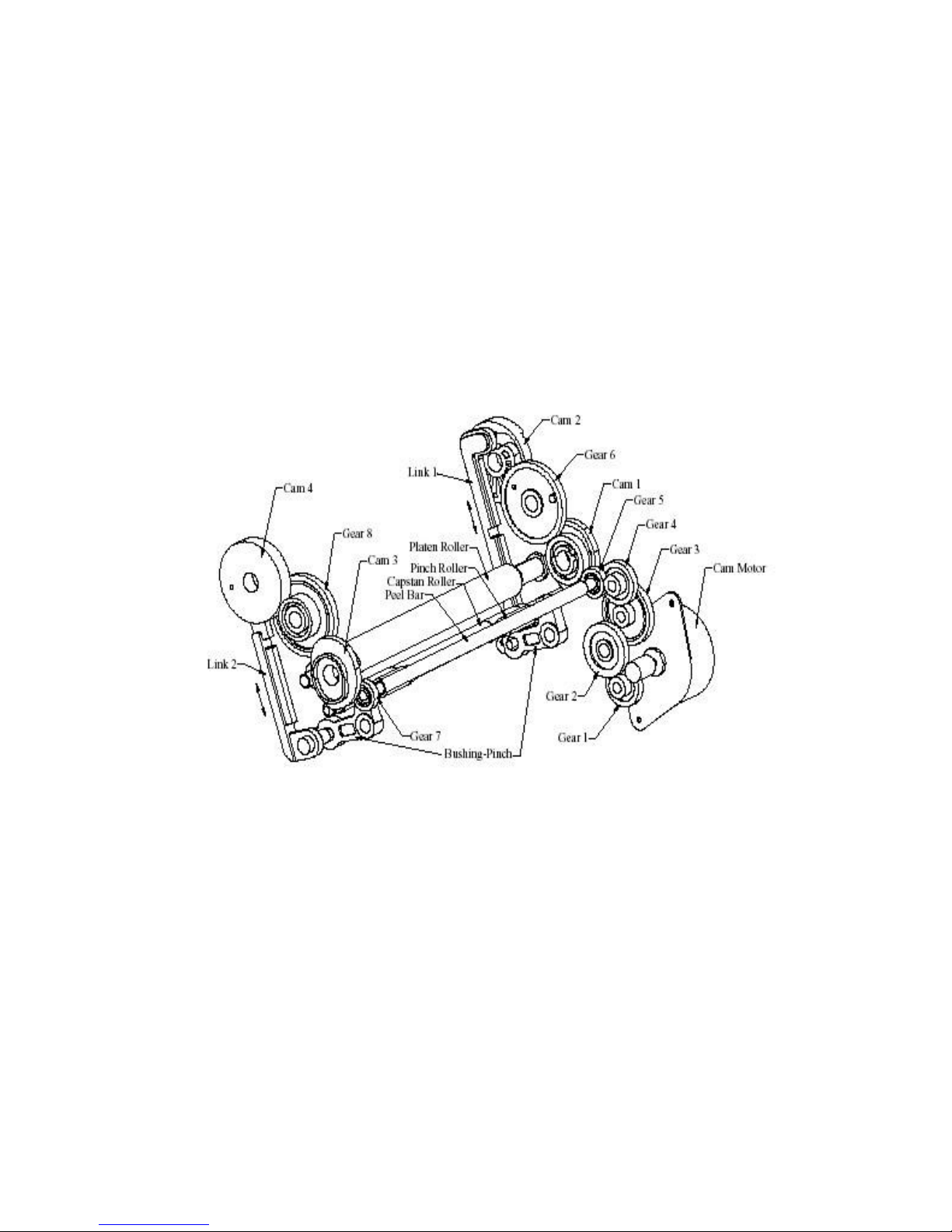

Cam position:

i. When the Cam M otor rotates, it will continue to operate Gear 1, Gear 2, Gear 3,

Gear 4, and Gear 5 in sequence.

ii. It will transfer power to another side of the Peel Bar after it receives p ower by

Gear 5. Both gear sides will then rotate synchronously.

iii. The process of the power transmission will go to Gear 5, Gear 7 Cam 1, Cam 3

Gear 6, Gear 8 Cam 2 and Cam 4.

iv. The internal cam design of Cam 2 and Cam 4, Link 1 and Link 2 can move in

and move out to operate the rotation of the Bushing-Pinch, and then separate

the Pinch Roller and the Capstan Roller.

Confidential

23

Firmware

Firmware update:

As the firmware is stored in the IC of the main board, you need to use the easy to use

BurnFW.exe application in order to update the printer’s firmware. Firmware updates can

easily be downloaded from the HiTi support website:

Go to www.hi-ti.com, then find the ‘Support’ se ction.

Firmware updates are always recommended and help to increase the printer’s lifetime and

efficiency.

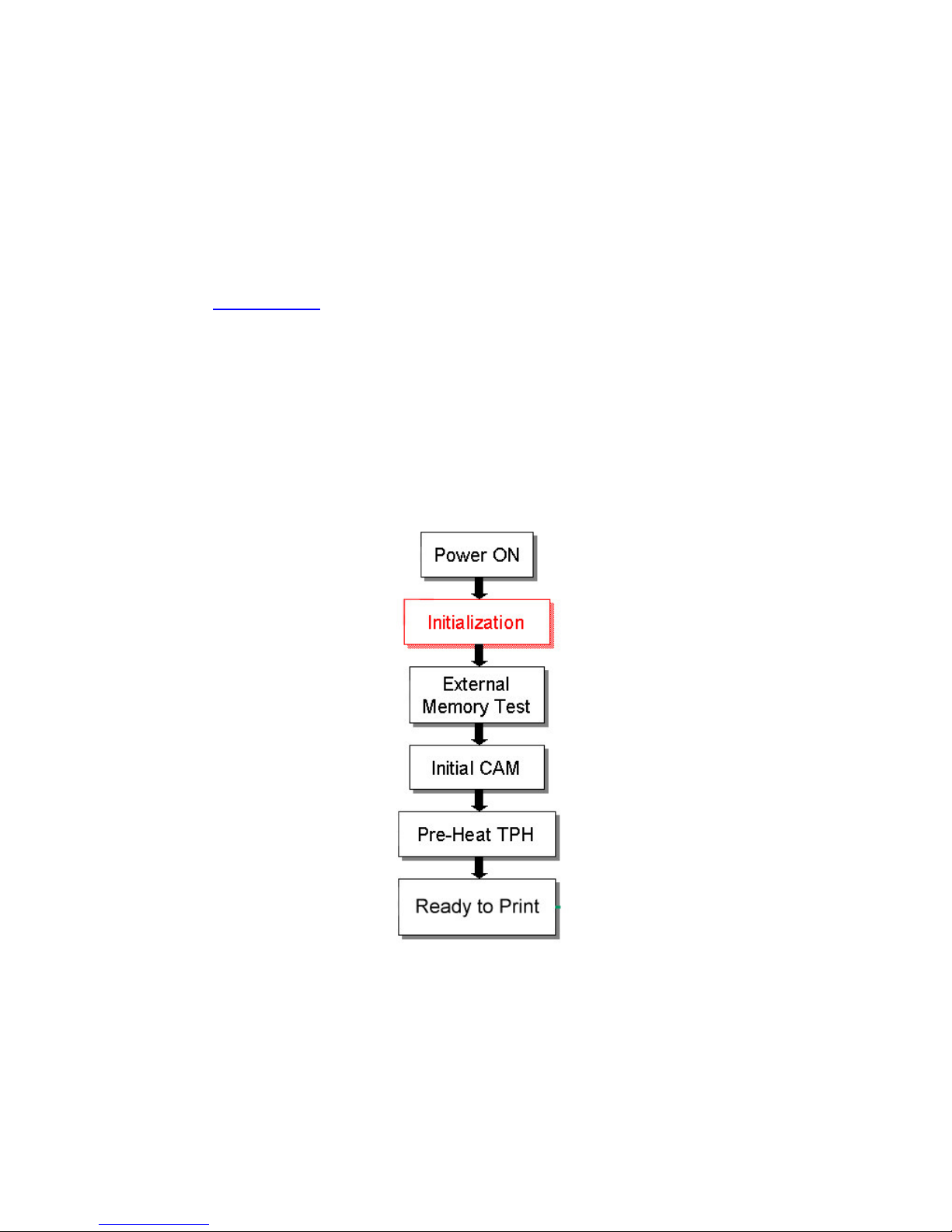

Initialization:

When the printer powers on, the initialization process will go through various stages.

(See below illustration). The status LED will keep blinking until the initialization process

has concluded.

Confidential

24

Host job flow:

After the printer is powered on, the firmware will control the printer’s operation.

Printing Step

Related Motor

Related Sensor

1 Check Ri bbon Cassette type Ribbon Cassette

2 Cam load to print position Cam Cam

3 Load pape r Capstan Jam

4 Ribbon registration (Y) ADF Ribbon

5 Print Yellow Capstan LE, Jam

6 Cam print to load position Cam Cam

7 Ribbon registration (M) ADF Ribbon

8 Back paper Capstan LE, Jam

9 Cam load to print position Cam Cam

10 Pri nt Magenta Capstan LE, Jam

11 Cam print to load position Cam Cam

12 Ribbon re gistration (C) ADF Ribbon

13 Back paper Capstan LE, Jam

14 Cam load to print position Cam Cam

15 Pri nt Cyan Capstan LE, Jam

16 Cam print to l oad position Cam Cam

17 Ribbon re gistration (O) ADF Ribbon

18 Back paper Capstan LE, Jam

19 Cam load to print position Cam Cam

20 Pri nt O vercoat Capstan LE, Jam

21 Eject paper Capstan

22 Cam print to i ni t position Cam Cam

Confidential

25

Error messages:

The firmware controlled Status LED shows the error status:

Green Signal Li ght:

Stable : Printer is ready for processing job

Blinking slowly: Printer is processing job or initializing after power on

Blinking fast: Printer is writing firmware

IMPORTAN T: N EVER TURN THE PRINTER OFF WHILE ANY LIGHT I S

BLINKING OR WHILE YOU CAN STILL HEAR OPERATIONAL SOUNDS FROM

THE PRINTER

Orange Signal Light:

Model LED blinking

ti mes

Error description

640PS 641PS

1 Cove r open

3 Ribbon out

4 Paper out

5 Paper jam

6 Paper mismatch

8 Cam error

9 Nvram error

11 Asi c error

12 Adc e rror

13 Fw checksum error

16 Write flash error

Confidential

26

Chapter 3: Disassembly

Safety Instructions for all HiTi products: Printers

• Read these instructions carefully. Save these instructions for future reference.

• Follow all warnings and instructions marked on the printer.

• Unplug the printer from the wall outlet before disassembly.

• Do not place the printer on an unstable cart, stand, or table. The printer may get

damaged by a fall.

• Openings in the chassis and the bottom are provided for ventilation purposes and

to ensure reliable operation of the printer by protecting it form overheating: these

openings must not be blocked or covered.

• Placing the printer on a bed, sofa, rug, or other similar, not firm surfaces may

block the openings. The printer should never be placed near or over a radiator or

heat register, proper ventilation and coolin g must be provided at all times.

• The printer should only be operated with the type of power indicated on the

marking label. If you are not sure of the type of power available in your area,

consult your dealer or local power comp any.

• If an extension cord is used with this product, make sure that the total ampere

rating of the equipment plugged into the extension cord does not exceed the

extension cord ampere rating. Also, make sure that the total rating of all products

plugged into the wall outlet does not exceed the fuse rating.

Confidential

27

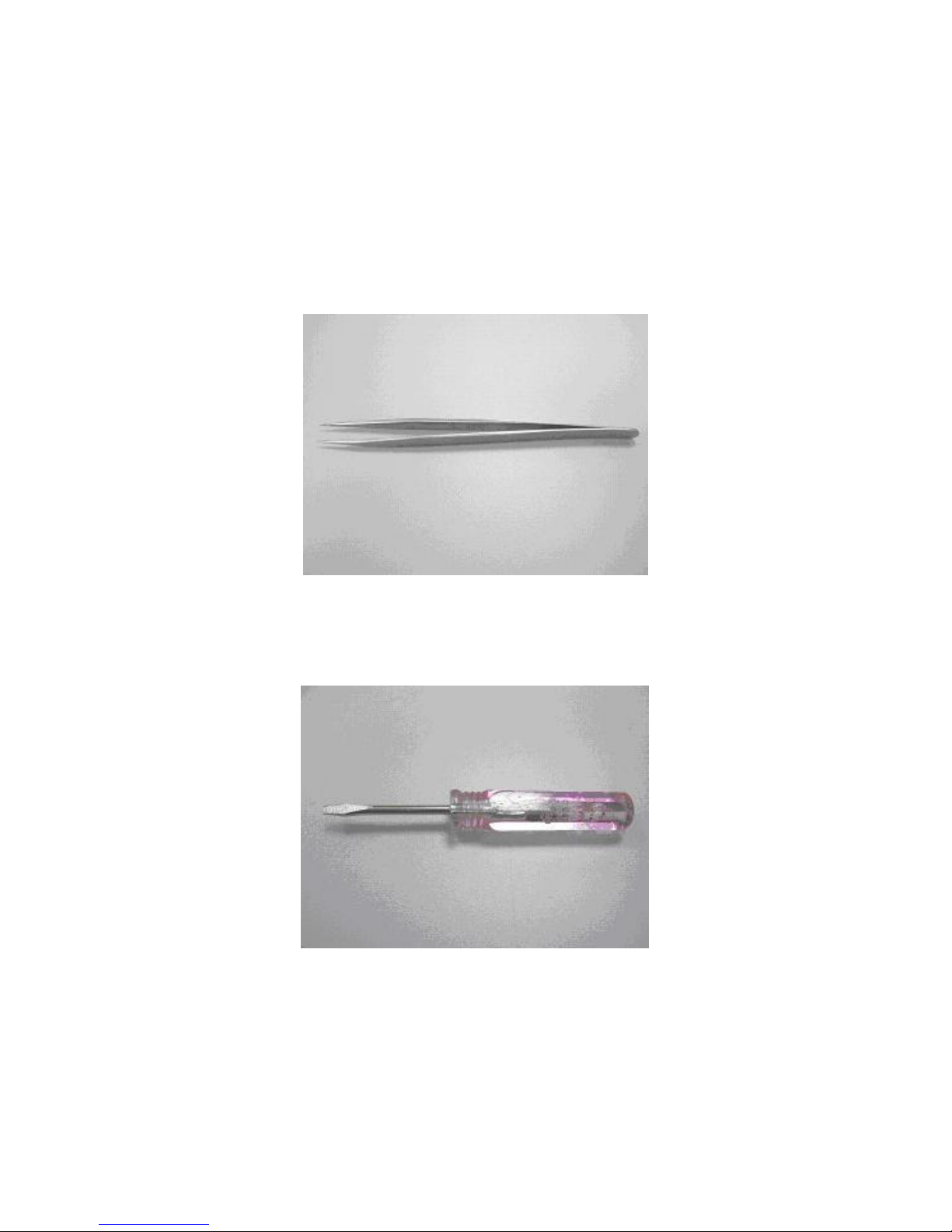

Tools

Tweezers

Screwdriver – minus

Confidential

28

Screwdriver – plus

IC Clamp

Confidential

29

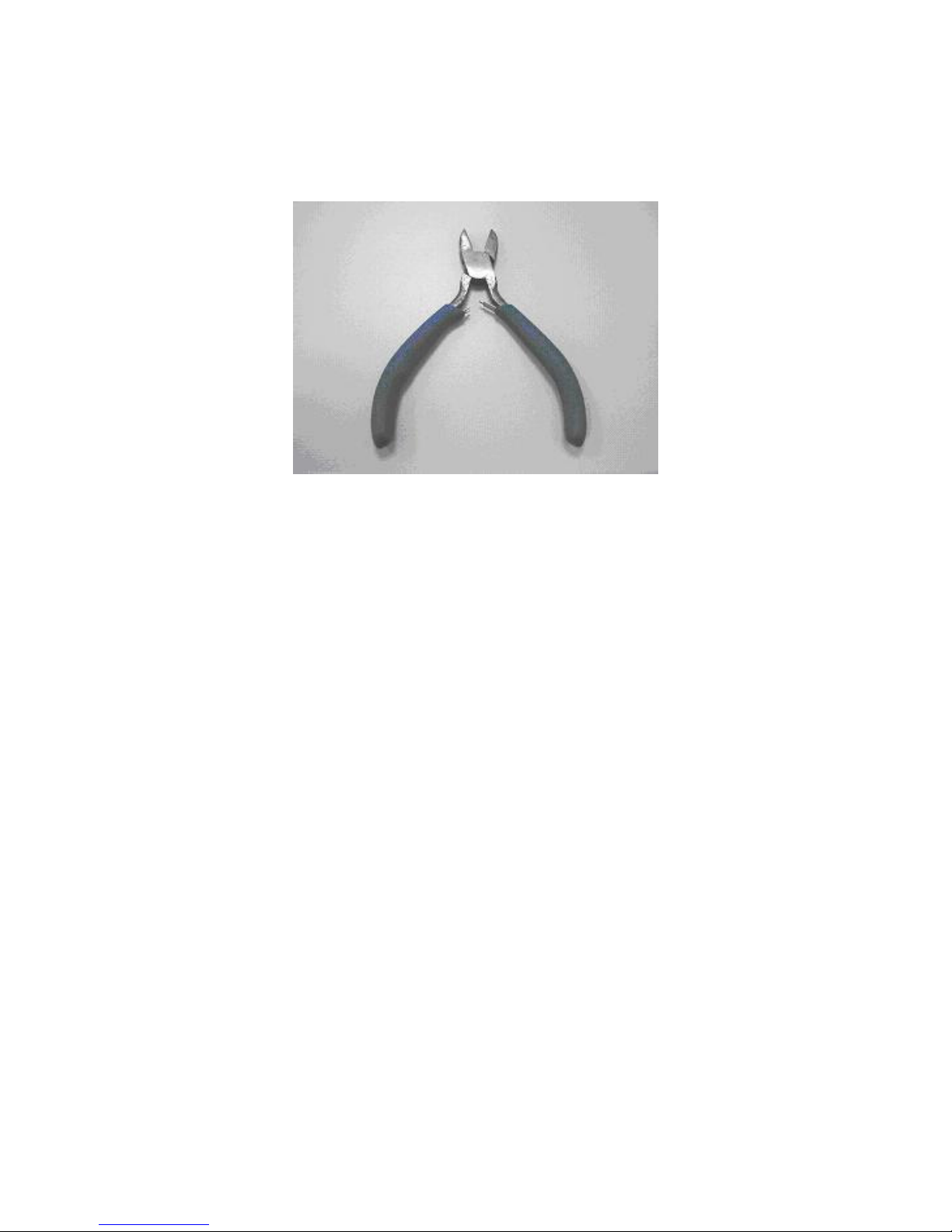

Wire Cutter

Confidential

30

Do not disassemble these Parts:

HiTi stri ctly prohibits anyone to disassemble the TPH (Thermal Print Head) and

the Bracket-idle . Both parts need to be cal ibrated by a spe cific calibration device

and cannot be repaired on site:

Bracket-idle:

Loading...

Loading...