HiTi Digital 630PS Service Manual

Ver. Ex.1.1 Confidential 2003/7/8

630PS

Service Guide

Ver. Ex.1.1 Confidential 2003/7/8

Copyright

The information contained in this document is subject to change without notice.

Hi-Touch Imaging Technologies makes no warranty of any kind with regard to

this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Hi-Touch Imaging Technologies shall not be liable for any errors or for

incidental or consequential damages in connection with the furnishing,

performance, or usage of this material.

Reproduction, adaptation, or translation of this manual is prohibited without

prior written permission of Hi-Touch Imaging Technologies, except as allowed

under the copyright laws.

Hi-Touch Imaging Technologies, HiTi, HiTi corporation logo, PhotoDesiree,

"Digital mini-lab just for you" and HiTi name (written in Simplified Chinese or

Traditional Chinese) are trademarks or registered trademarks in Taiwan, China

and other countries of Hi-Touch Imaging Technologies.

Disclamer

This document is suitable to field site engineers, but not end-user. Field site

engineers should read both “Service Guide” and “User’s Manual” to service

end-user. Any comments or suggests, please email csd@hi-ti.com

.

Ver. Ex.1.1 Confidential 2003/7/8

Chapter 1. Overview

“HiTi Photo Printer 630PS” is aimed at the most cost effective standalone

photo finish machine for digital camera and photography. With a supreme

specification and cost effective design structure, 630PS will surely provide a

real photo quality output solution and one-touch photo finish machine for users

to print with fun and ease.

“HiTi Photo Printer 630PS” is a popular printer with high-speed, high-quality

and compact size. This printer is focused on printing “photos”, including of the

application on photo (4”x 6”), ID photo (1” or 2”), business card, greeting card

and more.

“HiTi Photo Printer 630PS” is a standalone printer. You don’t need to

communicate with host PC for printing. You can print instantly whenever you

want. “HiTi USB Photo Printer 630PS” also supports USB interface to

communicate with host PC, which meets the standard of USB 1.1 version. It’s

compatible with USB 2.0 host device. Any win32-based photo printing

application such as “HiTi PhotoDesiree”, “Adobe PhotoShop”, “Jasc Paint

Shop Pro” and “Newsoft Mr. Photo”, or vectors based applications such as

“Corel Draw!” are applicable in this printer.

“HiTi Photo Printer 630PS” includes of the following functions:

9 Printing Process

YMCO 4 passesΰYellow, Magenta, Cyan, and Over-coatingα

Over coating ensures that HiTi’s printouts can be kept longer than

inkjet printer’s printouts.

9 High Quality Resolution

300x300 dpi

Equal to 4800x4800 dpi ΰcompare with inkjet system.α

9 Convenience

Dual memory card support. HiTi Photo Printer 630PS provides two

types of card slot to let user print instantly.

Ver. Ex.1.1 Confidential 2003/7/8

Stand-alone operation & PC link. Could preview what you want to

print instantly.

630PS can be your card reader(images only).

F/W code and template could be downloaded by USB.

Offer large data buffer (32MB SDRAM).

HiTi Photo Printer provides an application “PhotoDesiree”, designed

especially for printing 4”x6” photos, ID photos, calendars, photo

business cards, photo greeting cards and more.

Application “PhotoDesiree” extends more functions for photo printer.

It makes photo creation easily, and it is very handy to use!

Ver. Ex.1.1 Confidential 2003/7/8

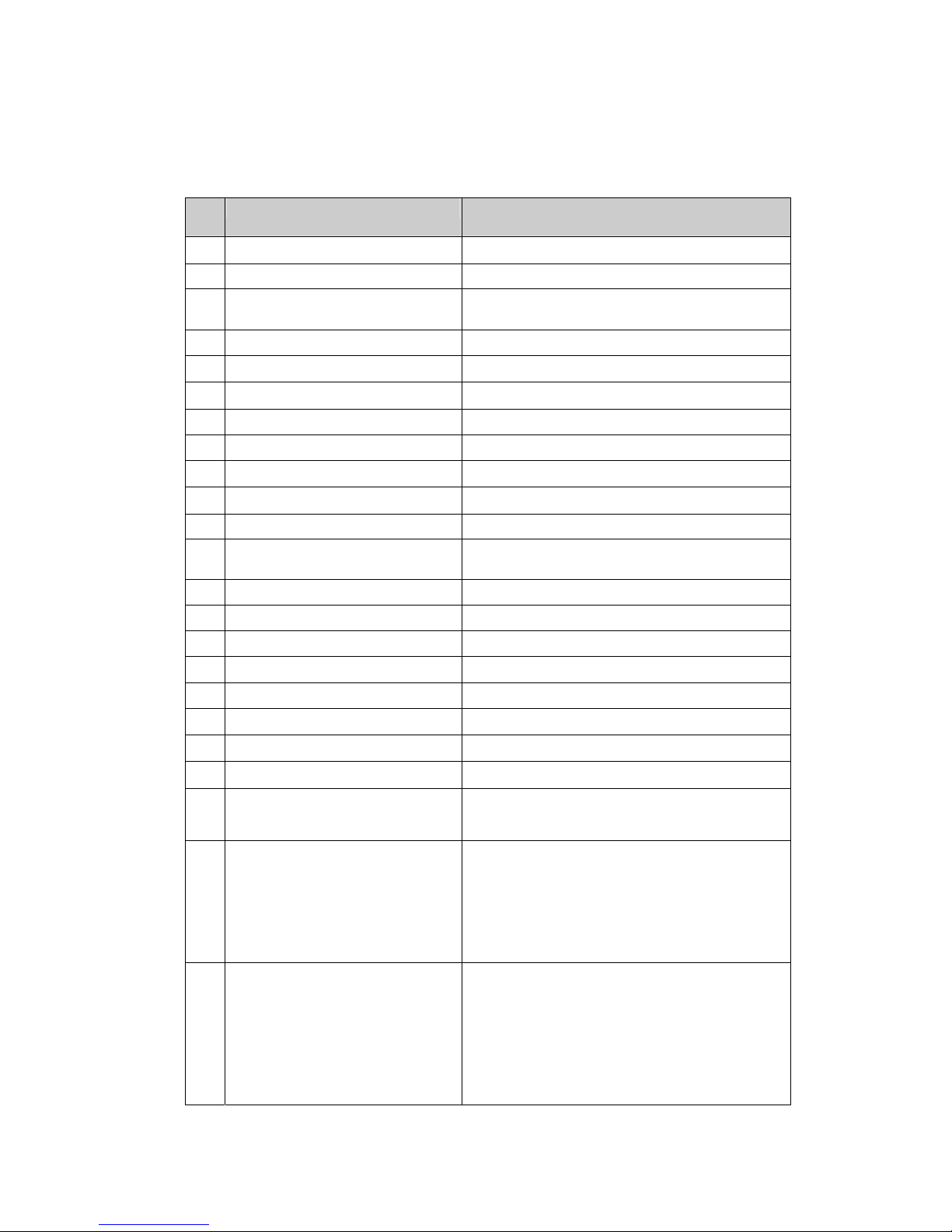

Chapter 2. Specification

No Item Description

1 Model HiTi 630 PS

2 Printing Method Dye Diffusion Thermal Transfer (D2T2)

3 Color Continuous-tone output, 256-level each

color

4 Paper Feed Cassette type automatic feeder.

5 Resolution 300x300dpi

6 Pixel 1200x1800 pixels

7 Printing Size 4”x 6”

8 Paper Size 4”x 7” with detachable boundary

9 Paper Cassette Capacity 25 sheets

10 Ribbon Cassette Capacity 50 images YMCO

11 Interface USB 1.1

12 Card Socket CompactFlash card Type 2 x1

SmartMedia card x1

13 File Format Support EXIF, JPEG, DPOF

14 Power Supply 100~240V, 50/60 Hz,75W

15 Printer Dimension 218(W) x 210(H) x 140(L) mm

16 Controller Dimension 60(W) x 23(H) x 130(L) mm

17 LCD Size 1.6” TFT LCD

18 Image Dimension in LCD TBD (small footprint)

19 Weight 2.0 kg

20 OS Windows 98/ME/2000

21 Minimum System

Requirement

Win 98/MEΚ64MB RAM, Pentium PC

Win 2000Κ128MB RAM, Pentium PC

22 Package kit Power Cord, USB Cable, CD (630 PS

Driver, PhotoDesiree, Acrobat Reader

5.0, Mr. Photo 3.1 and Manual), 10

images YMCO Ribbon, 8 images photo

paper, 1 image 4 x 4 sticker, 1 image

composite (4/2/4) sticker

23 Options 50 images YMCO Ribbon, 50 images

photo kit, 50 images 4 x 4 sticker kit, 50

images composite (4/2/4) sticker kit, 25

images photo and 25 images 4x4 sticker

kit, 25 images photo and 25 images 4/2/4

sticker kit, 25 images 4x4 sticker and 25

images 4/2/4 sticker kit

Ver. Ex.1.1 Confidential 2003/7/8

Chapter 3. Hardware

630PS Circuit Theory

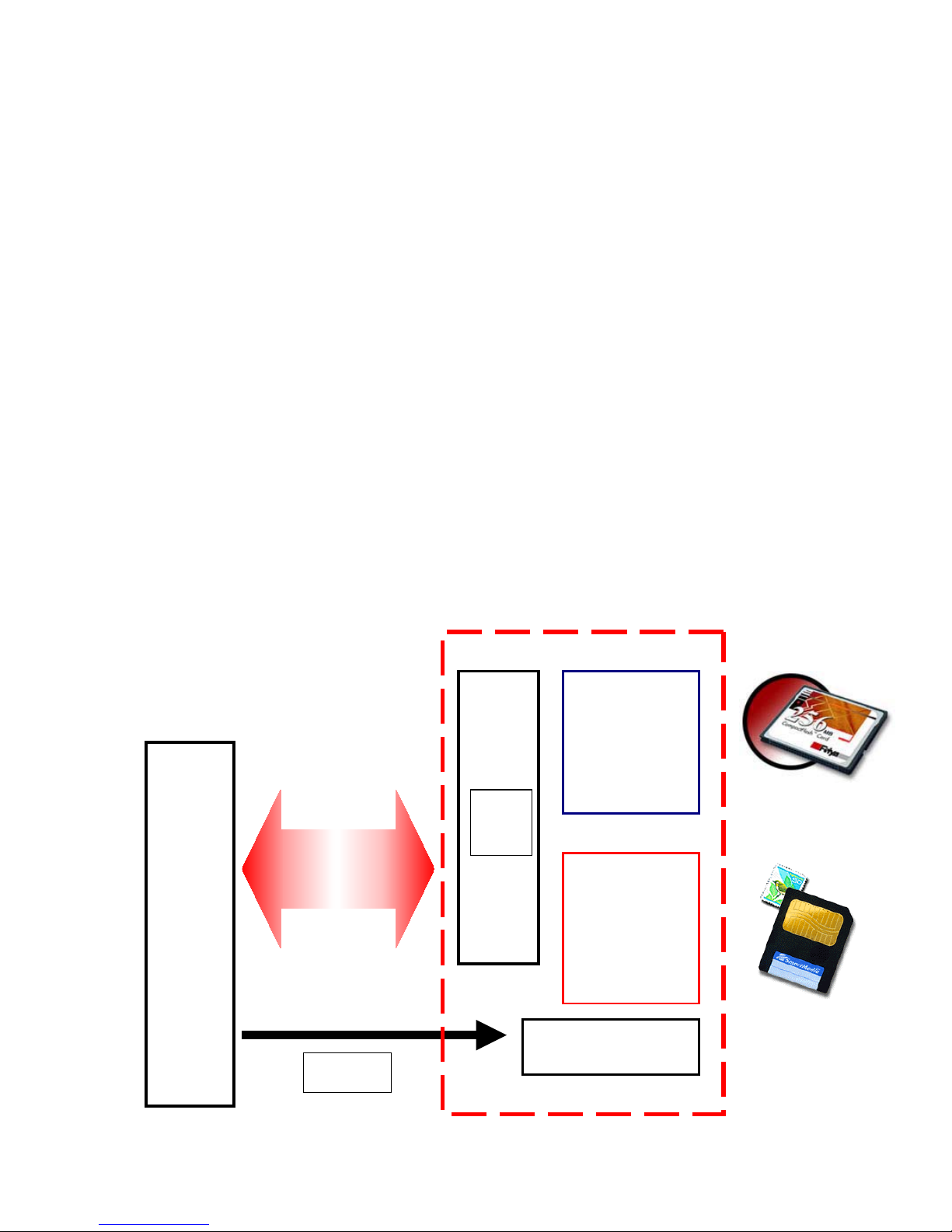

The circuit of 630PS contains five parts: main board, power board, card board,

controller board, wires & cables. Functionally, power board is an AC to DC

power conversion device, and it provides a 75W, 18V, DC source to drive the

630PS photo printer. Main board adopts 18VDC from power board to drive

motor driver ICs and fan, and also transforms the input 18V to 5V and 3.3V by

voltage regulators for ASIC, Memory, Video IC, and the I/Os. Card board,

which adopts 3.3V DC from main board, provides an interface for main board

to control CompactFlash and SmartMedia memory card, it is connected with

main board by a 3 pins power wire and a 50 pins signal cable. Controller board,

which consists of a 1.6-inch TFT-LCD panel, the user buttons, and the control

circuit, is to be the user interface (UI). The 18V DC from power board and the

video signals from main board are connected to controller board. Besides, The

TFT-LCD panel on controller board is to display images and messages for user

operations.

Ver. Ex.1.1 Confidential 2003/7/8

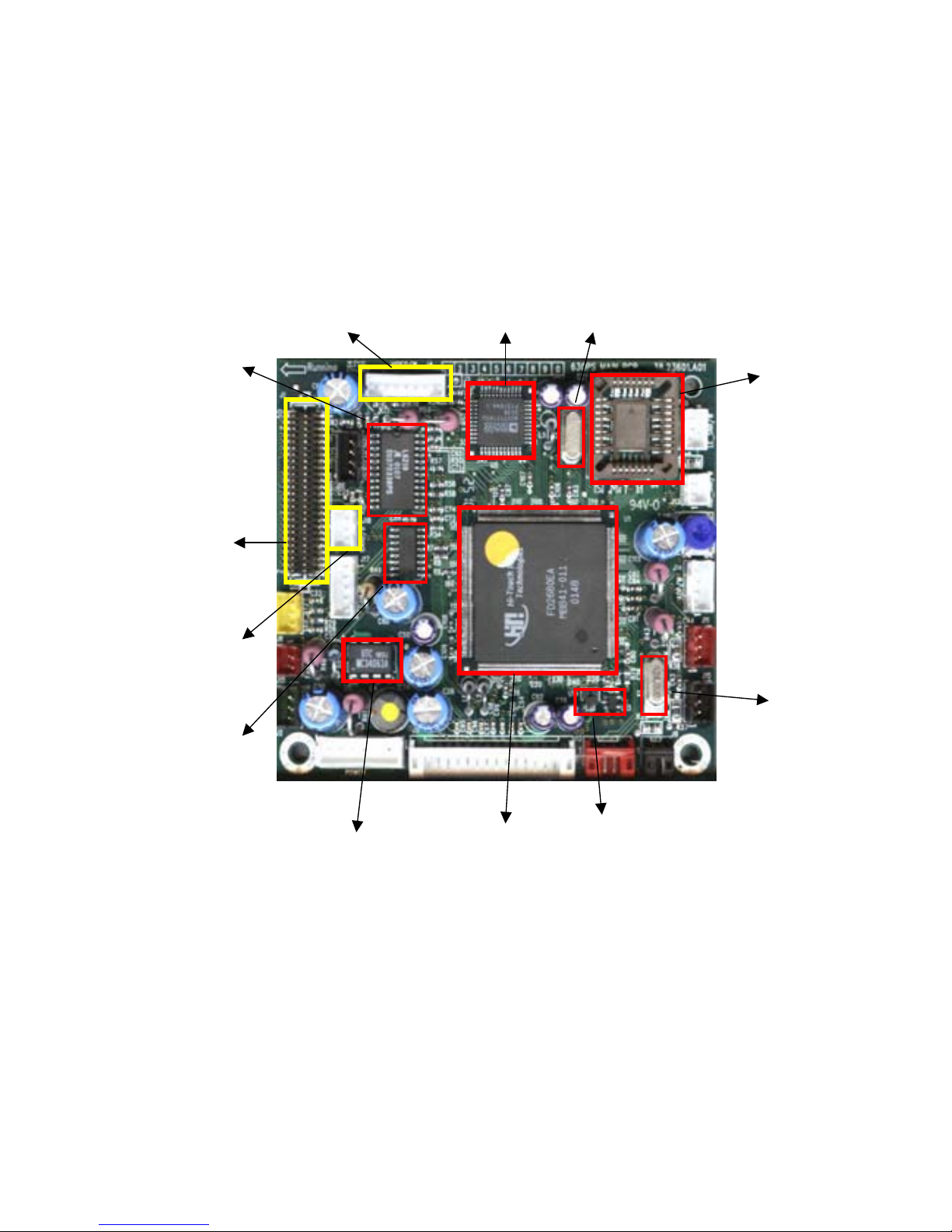

3.1 Main Board

The circuit theory of main board will be divided into seven parts.

Fig 2. Main Board

FlashRo

m

24MHz

Power low

d

etec

t

ASIC F2680EA

34063

Cam motor

Driver ULN2003

Card b/d

p

owe

r

Card b/d interface

Capstan Motor

Driver 6219

Controller

AD7171 27MHz

Ver. Ex.1.1 Confidential 2003/7/8

Fig 4. Main Board

3.1.1 ASIC Architecture

The most important IC on the main board is FD2680E, which is designed by

HITI. This ASIC contains a DSP core, a 8032 MCU, a SDRAM controller, a

CCIR601/656 Video controller, a CompactFlash card controller, a SmartMedia

card controller, a multi-type thermal print engine, an USB controller, the

embedded SRAM, an ADC, and IOs. Firmware can control the action of printer

via the versatile interfaces of FD2680E ASIC.

3.1.2 Memory IC

a) SDRAM

This 256Mbit SDRAM on main board is to be the data buffer. The image

file, print data, video frame are temporarily stored during operation.

N

AND flash

3.3V

256Mb

ADF motor

Driver

Ver. Ex.1.1 Confidential 2003/7/8

b) NOR Flash

This 4Mbit flash memory is to stored the MCU code, the DSP code, the

logo, the OSD (On-Screen Display) map and etc.

c) NAND Flash

This 64Mbit NAND flash memory is to stored the template for image

processing.

3.1.3 Video Encoder

This chip is used to convert the CCIR601/656 digital interface signals to

NTSC/PAL video signals.

3.1.4 Memory Card Interface

To control the CF and SM memory cards which are inserted on card board via

cable.

PCMCIA

CF/SM

Interface

Main

B/D

CF socket

50 pin

SM socke

t

22 pin

Power switch

3.3 Volt

50 pin

header

Ver. Ex.1.1 Confidential 2003/7/8

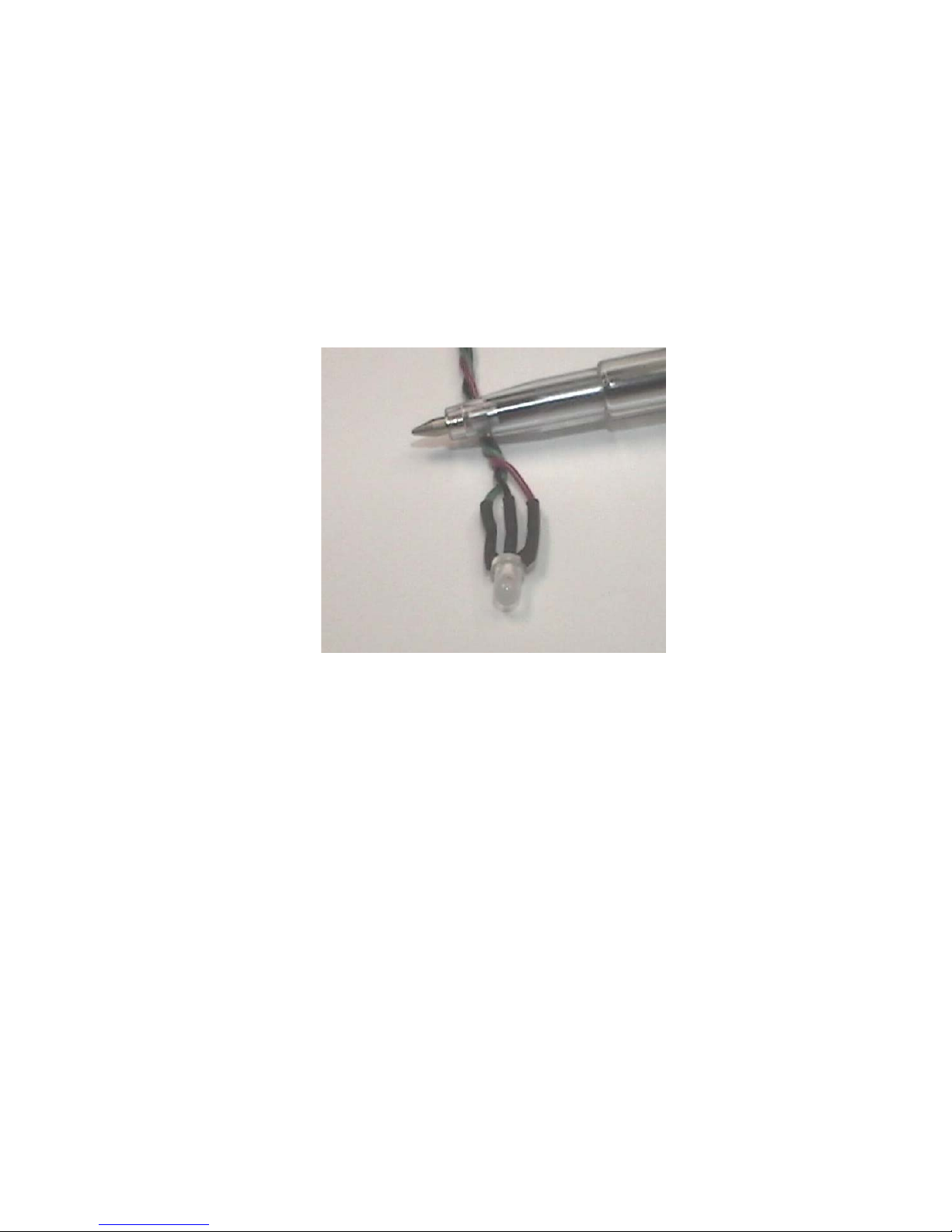

3.1.5 LED & Sensor

3.1.5.1 Status/Error LED

Show printer status and error message. Green shining LED means printer is

ready. Green blinking LED means printer is busy. Orange blinking LED means

error message. (See “Chapter 7. Troubleshooting” for more information about

error message.)

Fig 6. Status/Error Sensor

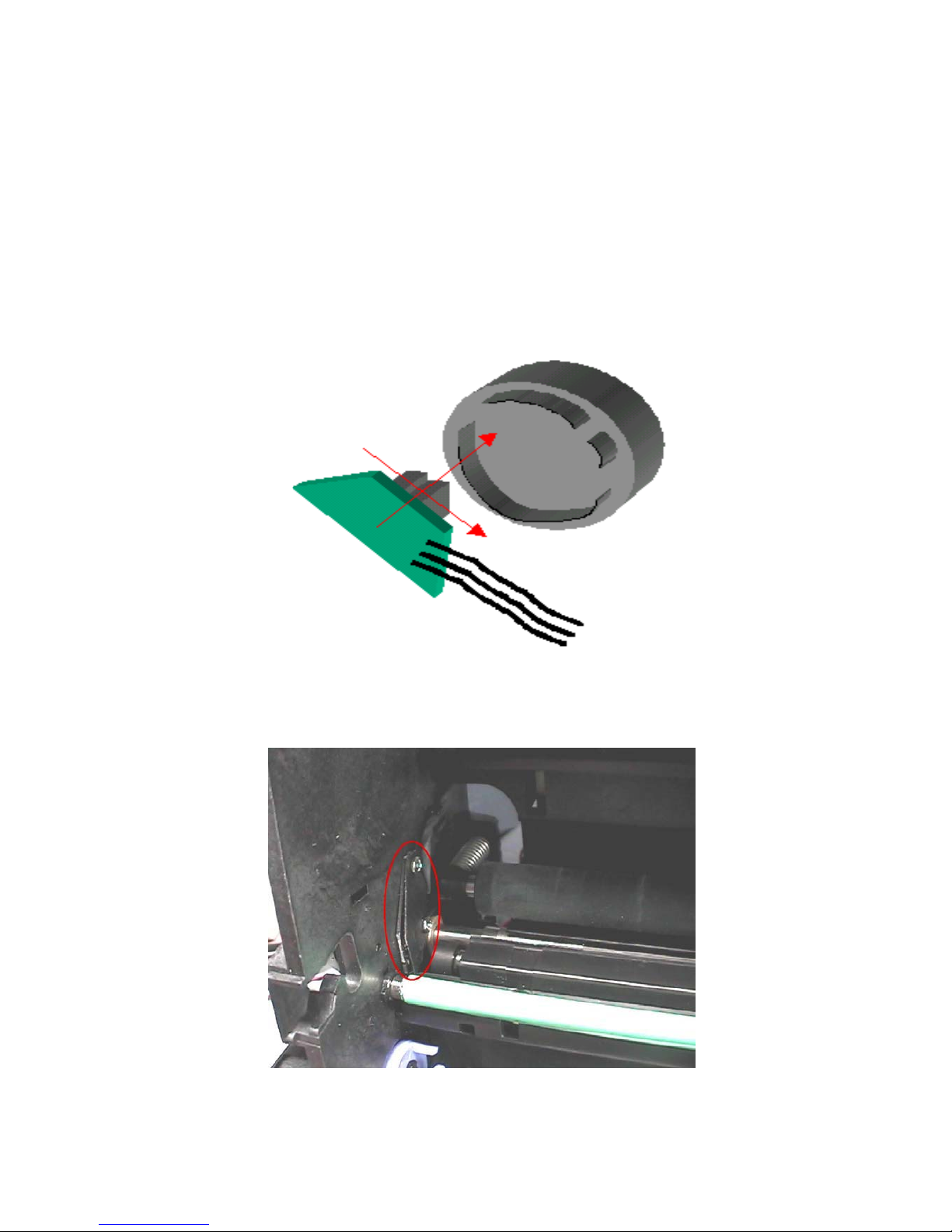

3.1.5.2 CAM Sensor

Under different status, the position of platen roller is different. Cam sensor

indicates the position of platen roller and pinch roller. It has three positions, P1:

initial position, P2: load position, and P3: print position. The CAM controls the

platen roller moving between these positions, and the CAM sensor detects &

feedback the position information to firmware.

P1 = Initial Position

At this position, the gap between platen roller & TPH is largest. While

printer power on or reset, it will be at this position. The large gap

between platen roller & TPH enable paper moving through the gap.

At this position, the pinch roller is releasing as well.

Ver. Ex.1.1 Confidential 2003/7/8

P2 = Load Position

At this position, the gap between platen roller & TPH is not as large as

P1. But still has gap to enable ribbon scrolling through the gap. The

pinch roller touches capstan roller to enable paper loading.

P3 = Print Position

Platen roller close to TPH, paper unmovable. No gap between platen

roller & TPH.

Fig 7. Cam Sensor Drawing

Fig 8. Cam Sensor

Ver. Ex.1.1 Confidential 2003/7/8

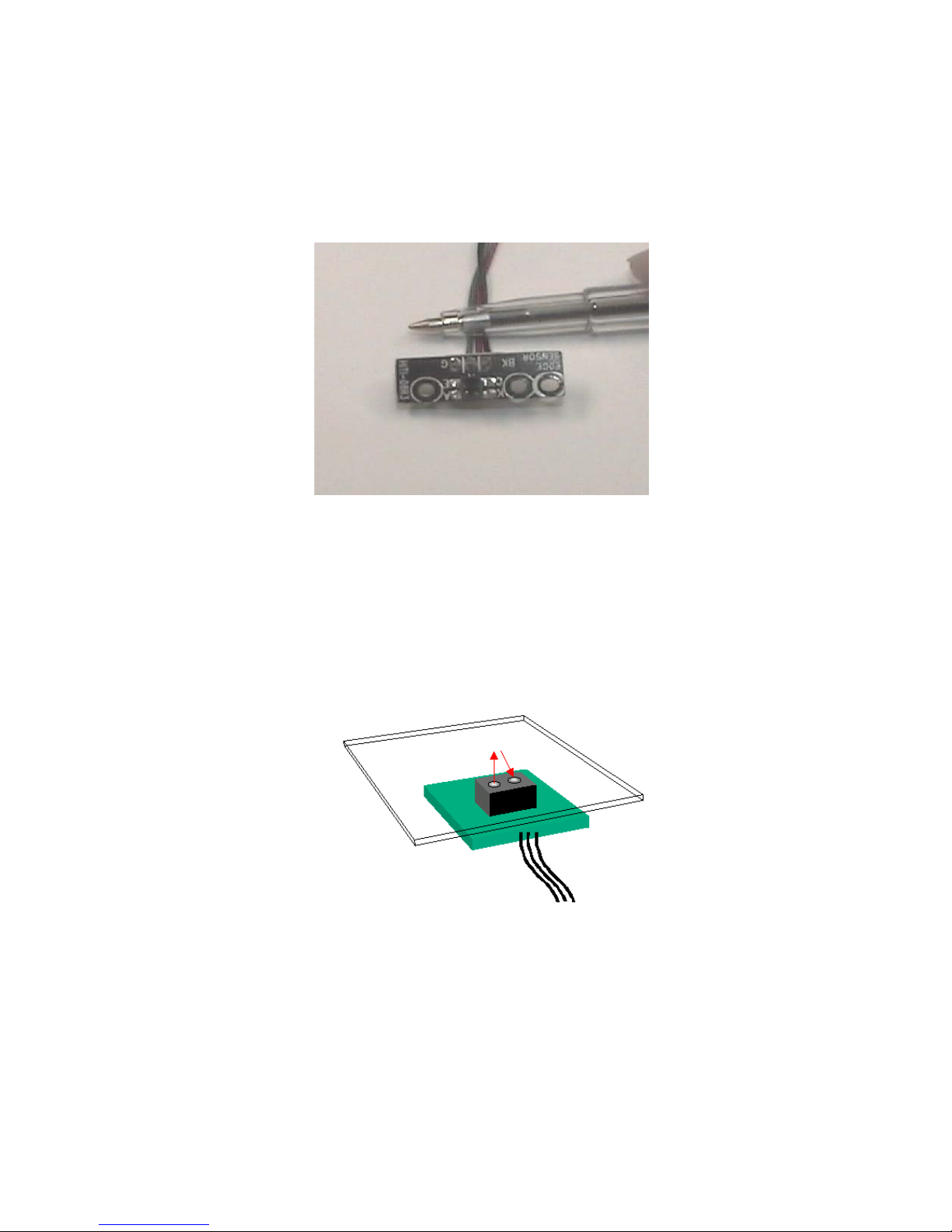

3.1.5.3 Leading Edge Sensor

It’s used to detect the status of paper. Leading Edge will be on when it detects

paper loading; Leading Edge will be off when it doesn’t detect paper loading.

Fig 9. Leading Edge Sensor

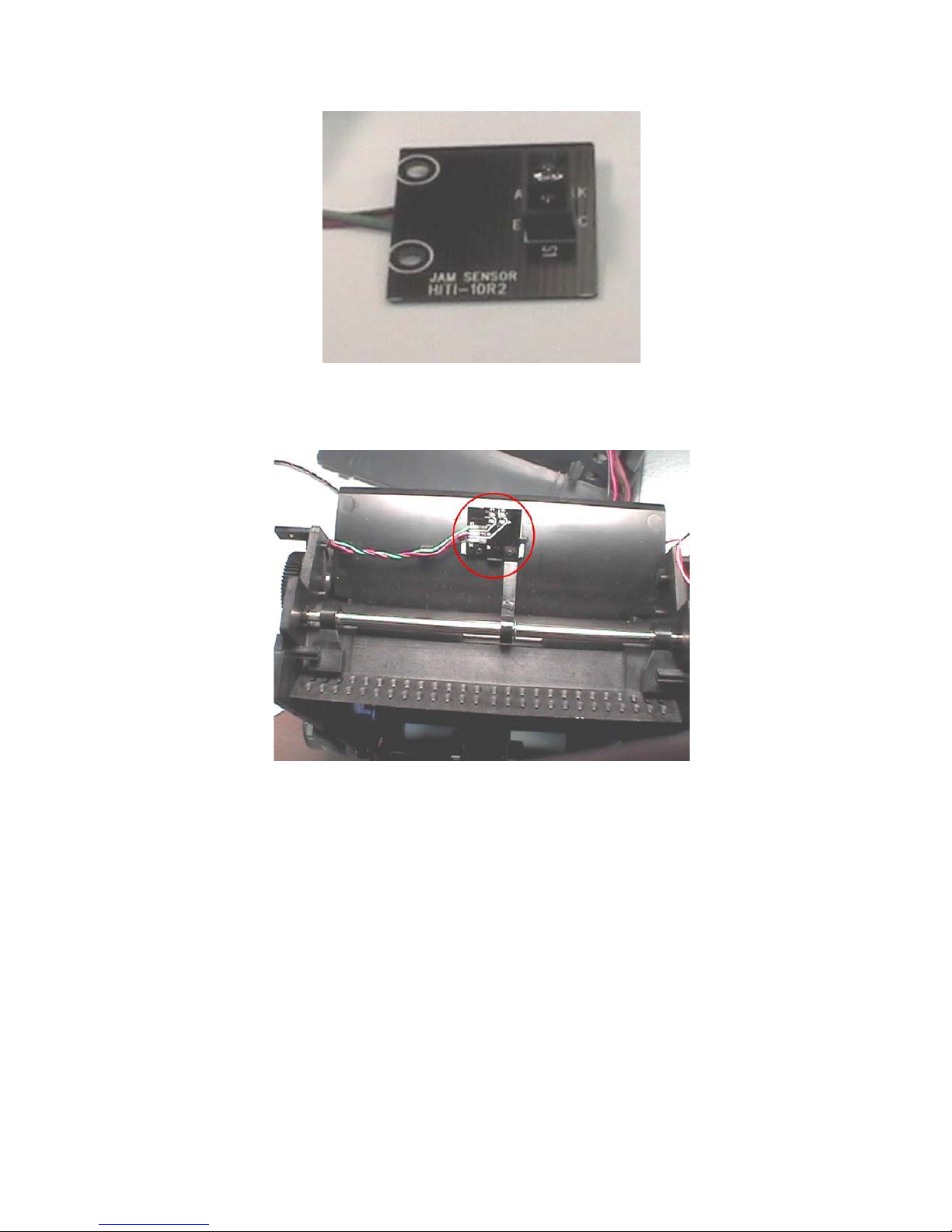

3.1.5.4 Jam Sensor

It’s used to detect the status of paper. Jam Sensor will be on when it detects

paper passing; Jam Sensor will be off when it detects paper jam.

Fig 10. Jam Sensor

Ver. Ex.1.1 Confidential 2003/7/8

Fig 11. Jam Sensor

Fig 12. Jam Sensor

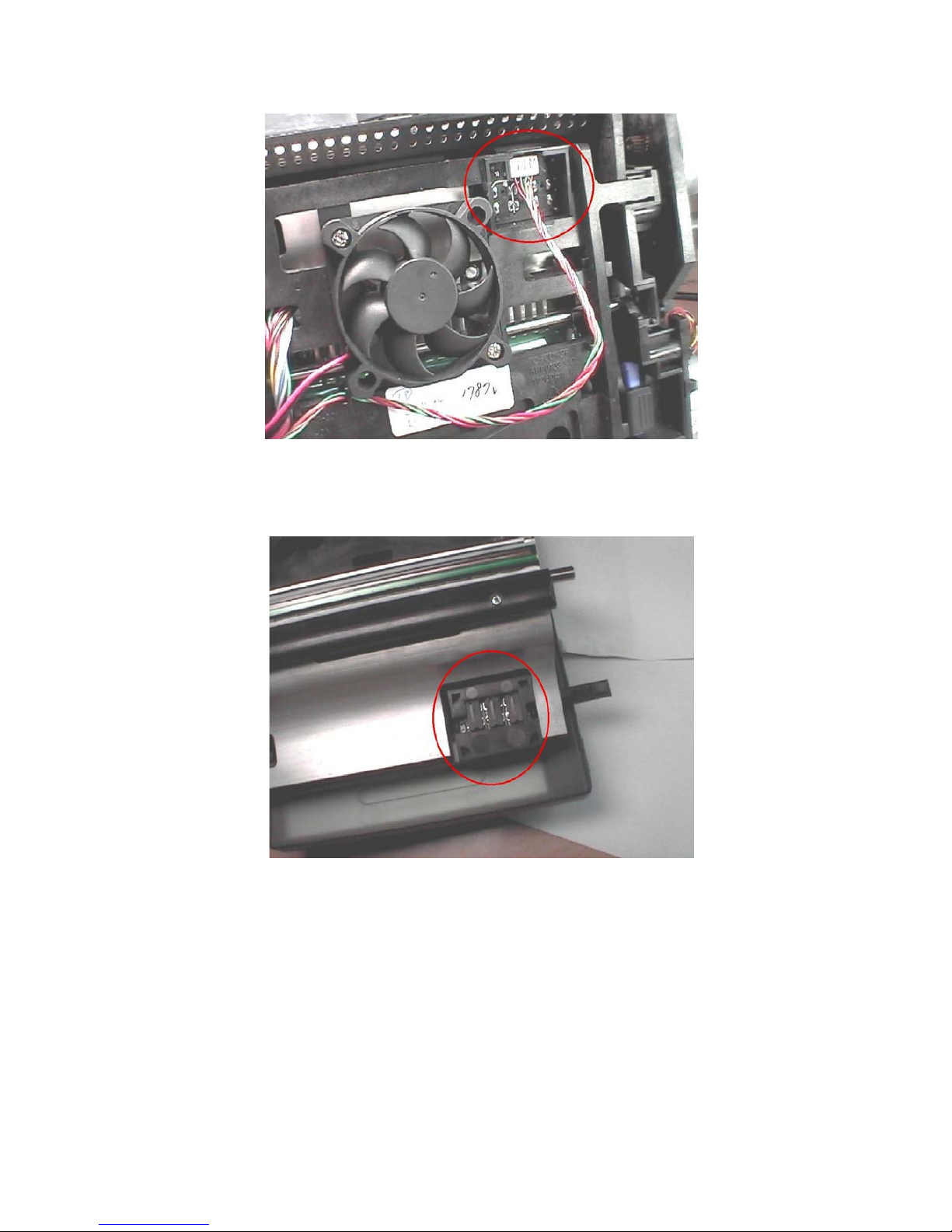

3.1.5.5 Ribbon Cassette Sensor

It’s used to detect the type of ribbon cassette and the status of ribbon door.

Ribbon Cassette Sensor will be on if the type of ribbon cassette is correct;

Ribbon Cassette Sensor will be off if the type of ribbon cassette is wrong. In

addition, Ribbon Cassette Sensor will be on if it detects ribbon door is closed;

Ribbon Cassette Sensor will be off if it detects ribbon door is open.

Ver. Ex.1.1 Confidential 2003/7/8

Fig 13. Ribbon Cassette Sensor (Front View)

Fig 14. Ribbon Cassette Sensor (Back View)

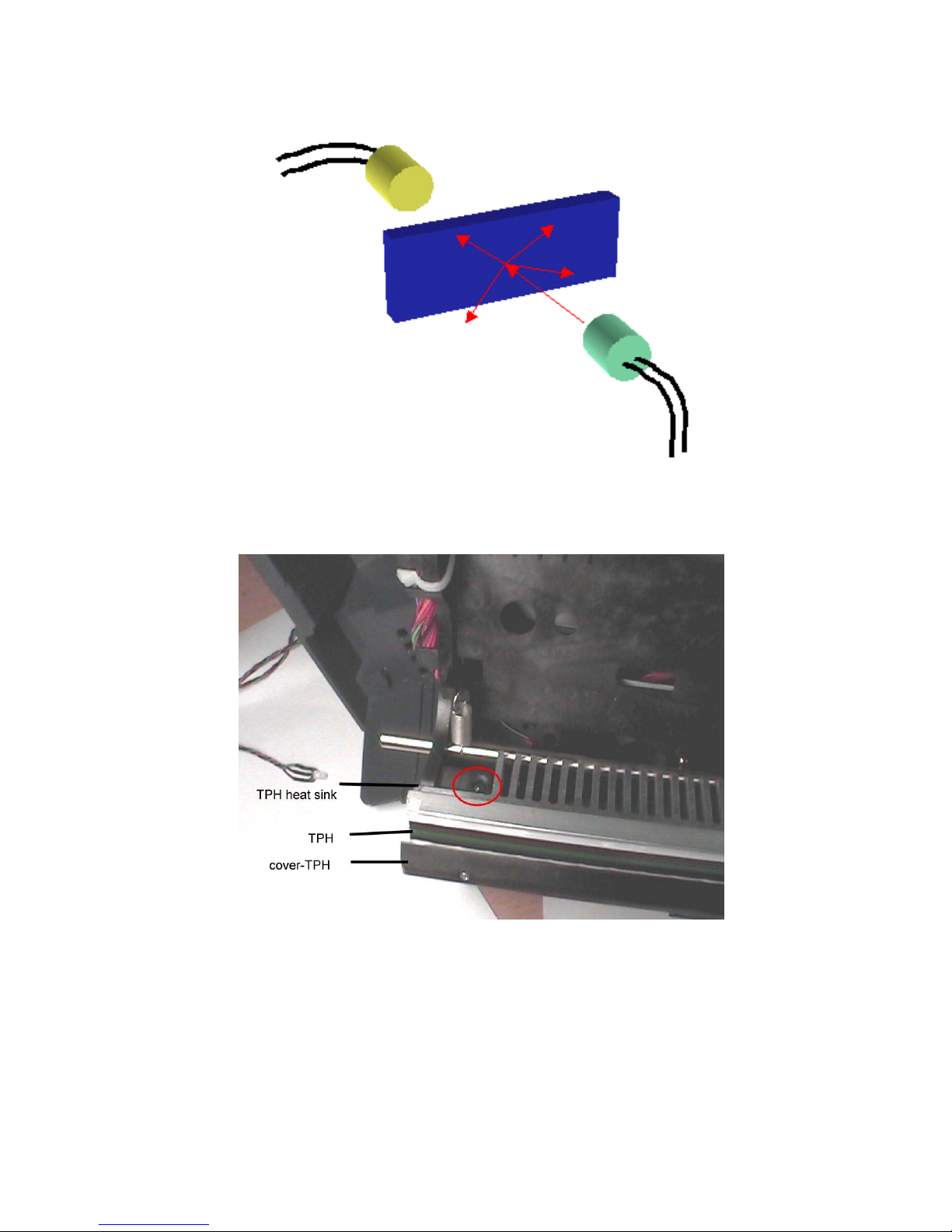

3.1.5.6 Ribbon LED/Ribbon Sensor

It’s used to detect the ribbon status, enable printer to control the ribbon scrolling

correct. Detect ribbon color. In yellow or overcoat layer, ribbon sensor senses

HIGH. In magenta and cyan layer, ribbon sensor senses LOW.

Ver. Ex.1.1 Confidential 2003/7/8

Fig 15. Ribbon LED/Sensor

Fig 16. Ribbon LED

Ver. Ex.1.1 Confidential 2003/7/8

Fig 17. Ribbon Sensor

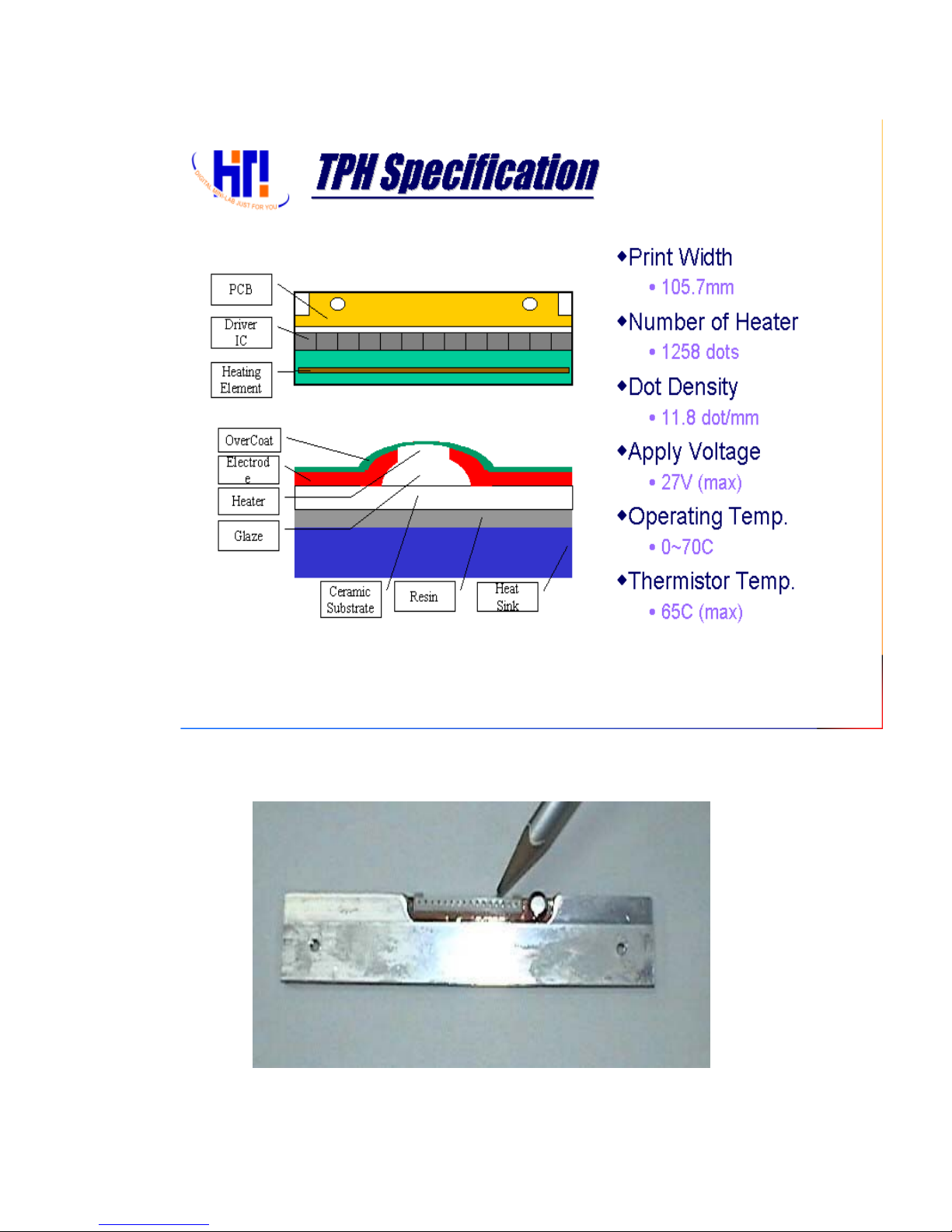

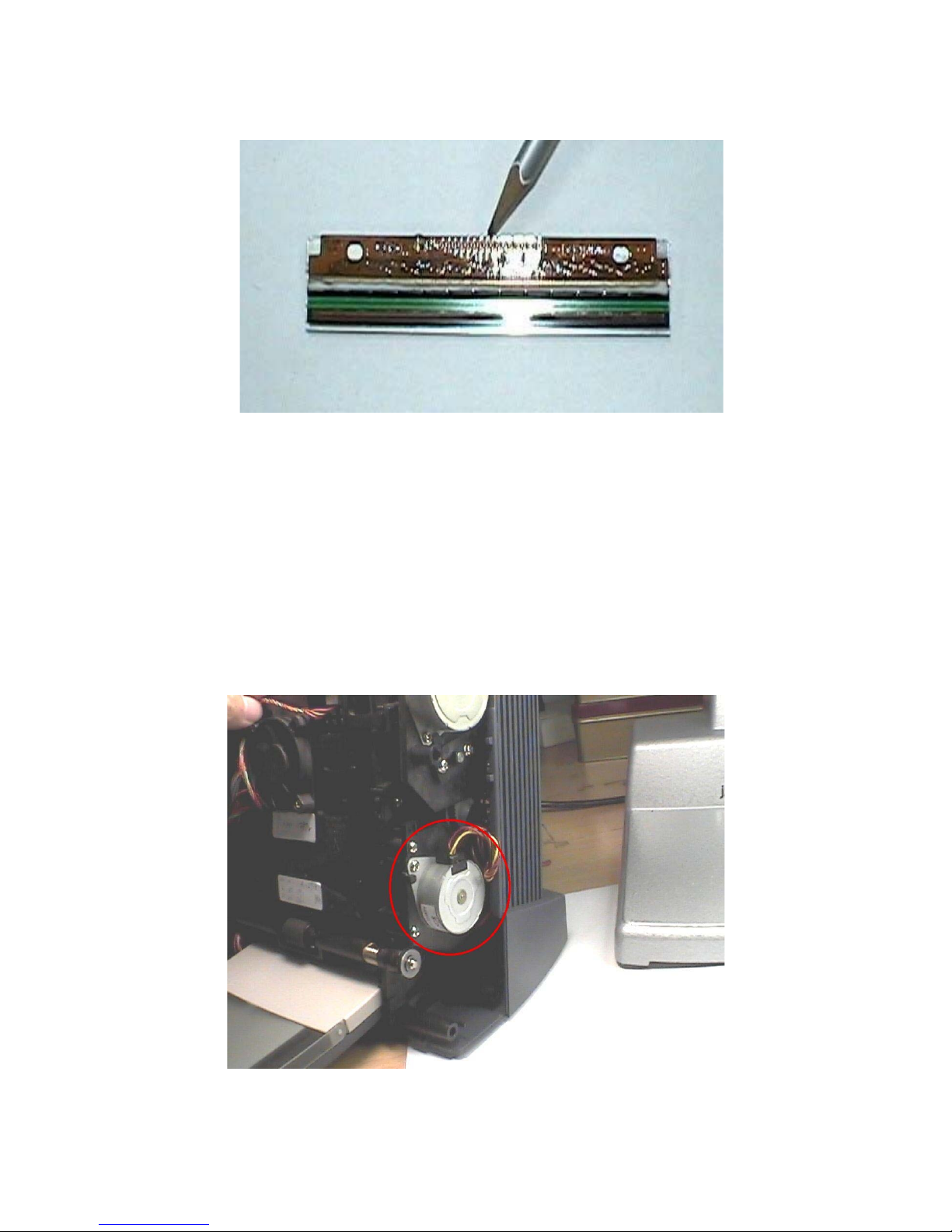

3.1.6 TPH

3.1.6.1 Specification

TPH(Thermal Print Head) is the key component for D2T2 printer, like the inkjet

printing head for inkjet printer. Print data will be shifted into TPH during each

clock. After 384 shift clocks, one line data will be shifted to TPH. Latch/ signal

will latch the print data. Strobe/ signal will heat the corresponding heater

elements on TPH according to shift-in data. More the strobe/ time, more the

dye of the ribbon transfers to paper.

Ver. Ex.1.1 Confidential 2003/7/8

Fig 18. TPH Specification

Fig 19. TPH (Back View)

Ver. Ex.1.1 Confidential 2003/7/8

Fig 20. TPH (Front View)

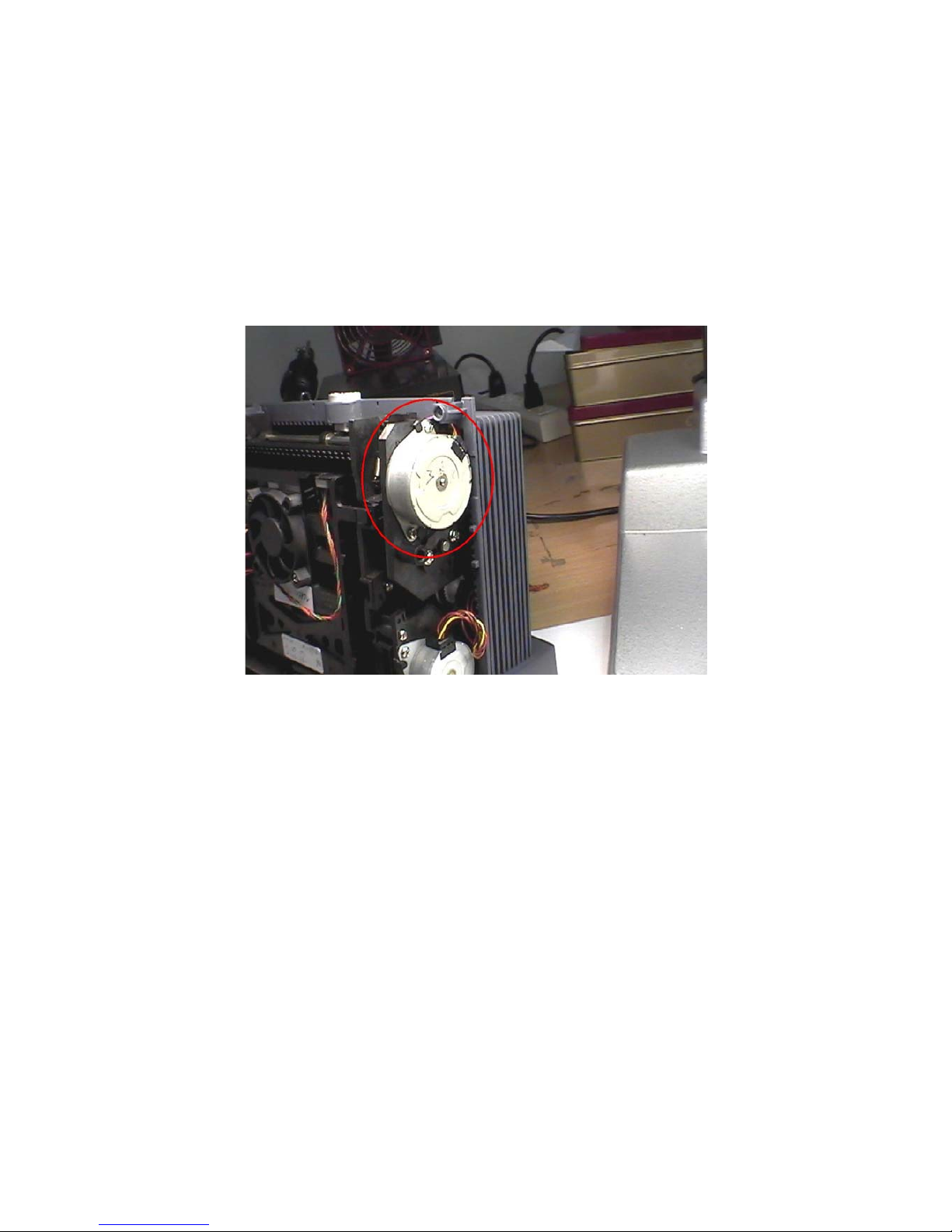

3.1.7 Motor

3.1.7.1 Cam motor

Cam motor is a unipolar motor. It’s driven by driver IC “ULN2003”. ULN2003

has high voltage and high current Darlington arrays. Therefore, it can support

continuous load of current rating to 500 mA.

Fig 21. Cam motor

Ver. Ex.1.1 Confidential 2003/7/8

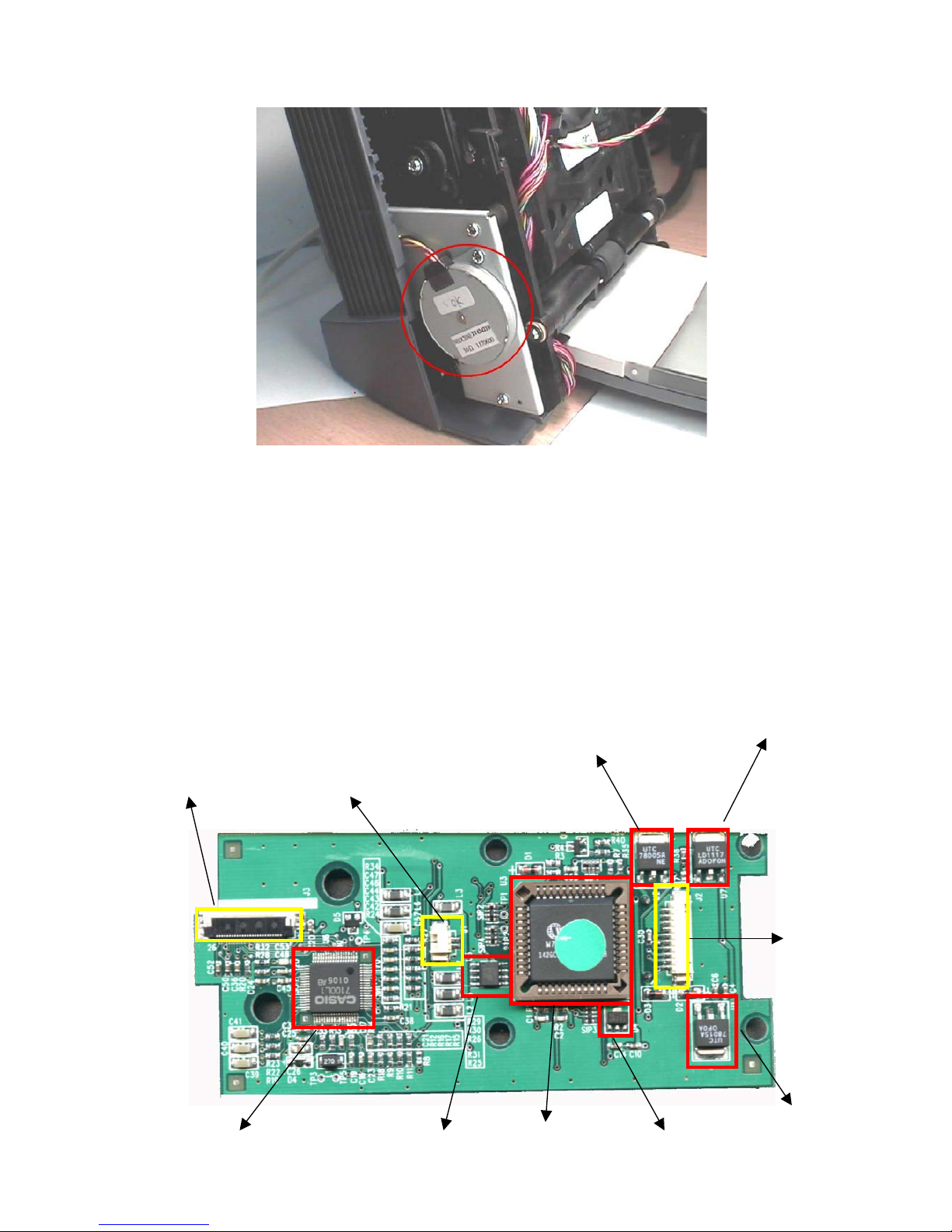

3.1.7.2 Capstan motor

Capstan motor is a bipolar motor. It’s driven by driver IC “L6219”. L6219 is

designed to operate both windings of bipolar stepping motor. It supports

Pulse-Width-Modulation (PWM) control of output current to 750 mA. For PWM

control, the maximum output current is determined by user’s selection of a

reference voltage and sensing resister.

Fig 22. Capstan Motor

3.1.7.3 Ribbon/ADF motor

Ribbon/ADF motor is a bipolar motor. It’s driven by driver IC “A3966”. A3966 is

designed to operate both windings of bipolar stepping motor. It supports

Pulse-Width-Modulation (PWM) control of output current to 650 mA. For PWM

control, the maximum output current is determined by user’s selection of a

reference voltage and sensing register.

Ver. Ex.1.1 Confidential 2003/7/8

Fig 23. Ribbon/ADF Motor

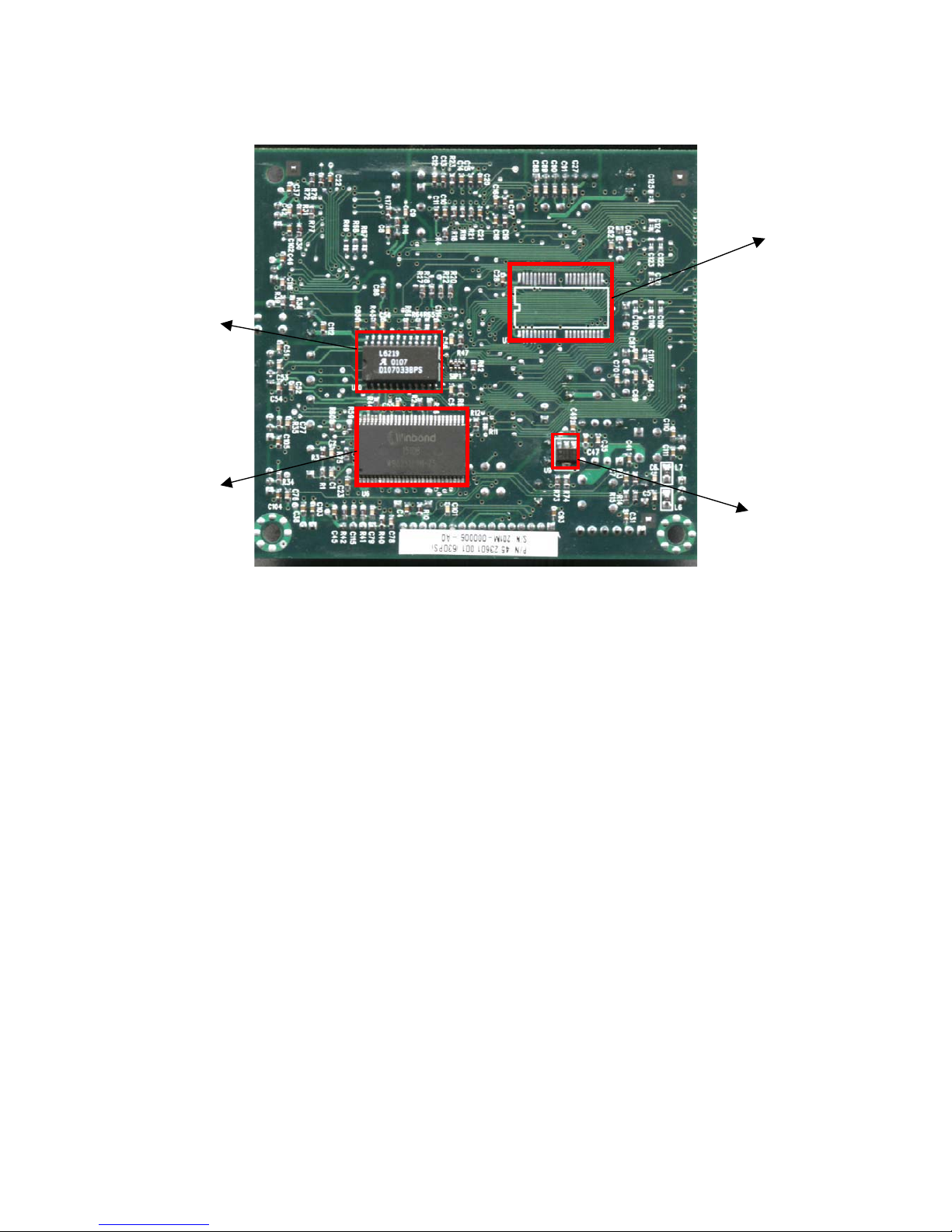

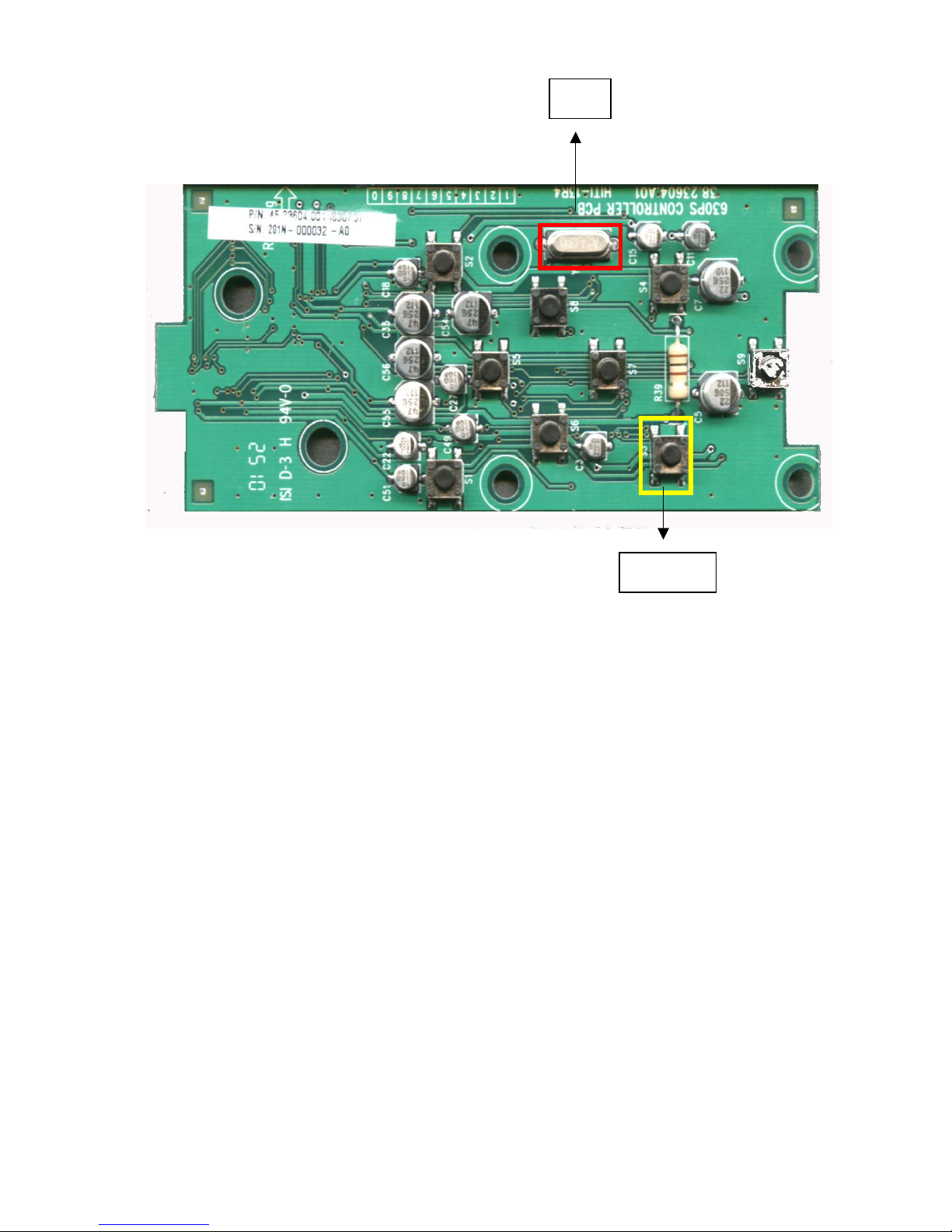

3.2 Controller Board

The circuit theory of controller board can be divided into four parts.

a) Power Circuit

b) CPU and serial EPROM

c) LCD driver

d) LCD and backlight LED

LCD control CHIP

Serial EEPROM

24C02

78E51 3.3V regulator

LED fixed

Curren

t

Control

Controller I/F

78D15

78D05

LCD’s back light control

LCD I/F

Ver. Ex.1.1 Confidential 2003/7/8

3.2.1 Power circuit

The input power of controller board is 18V. The power circuit uses voltage

regulators to provide15V, 5V and 3.3V for other components. The 13.5V is got

from 15V after the voltage drop of two diodes – 1N4148 . The LED backlight

require a 13.6V--19mA power source. Constant current will keep constant

lightness. The adjustable regulator – LD1117 can fulfil this requirement and

another NPN transistor – 2N3904 are used to switch ON/OFF the backlight.

3.2.2 CPU and serial EPROM

This controller board uses a 80-series CPU with 4KB on-chip FLASH EPROM

to do central control -- including initial setting of LCD driver IC, LED backlight

control, button-pushed sensing and communication with main board. The

serial EPROM stores setting data of LCD which is got from the calibration

process. CPU will read the serial EPROM and complete the initial setting for

LCD after power on.

24MH

Tact switch

Ver. Ex.1.1 Confidential 2003/7/8

3.2.3 LCD driver

The CM7100 is a video interface IC for TFT color LCD that accept RGB signal

inputs on a single chip. It supports a serial data control which can set image

quality adjust circuit.

3.2.4 LCD and backlight LED

The 1.6-inch TFT LCD panel is used to display images and messages. This

panel is driven by a specific LCD driver and its backlight is low DC voltage

white-LED.

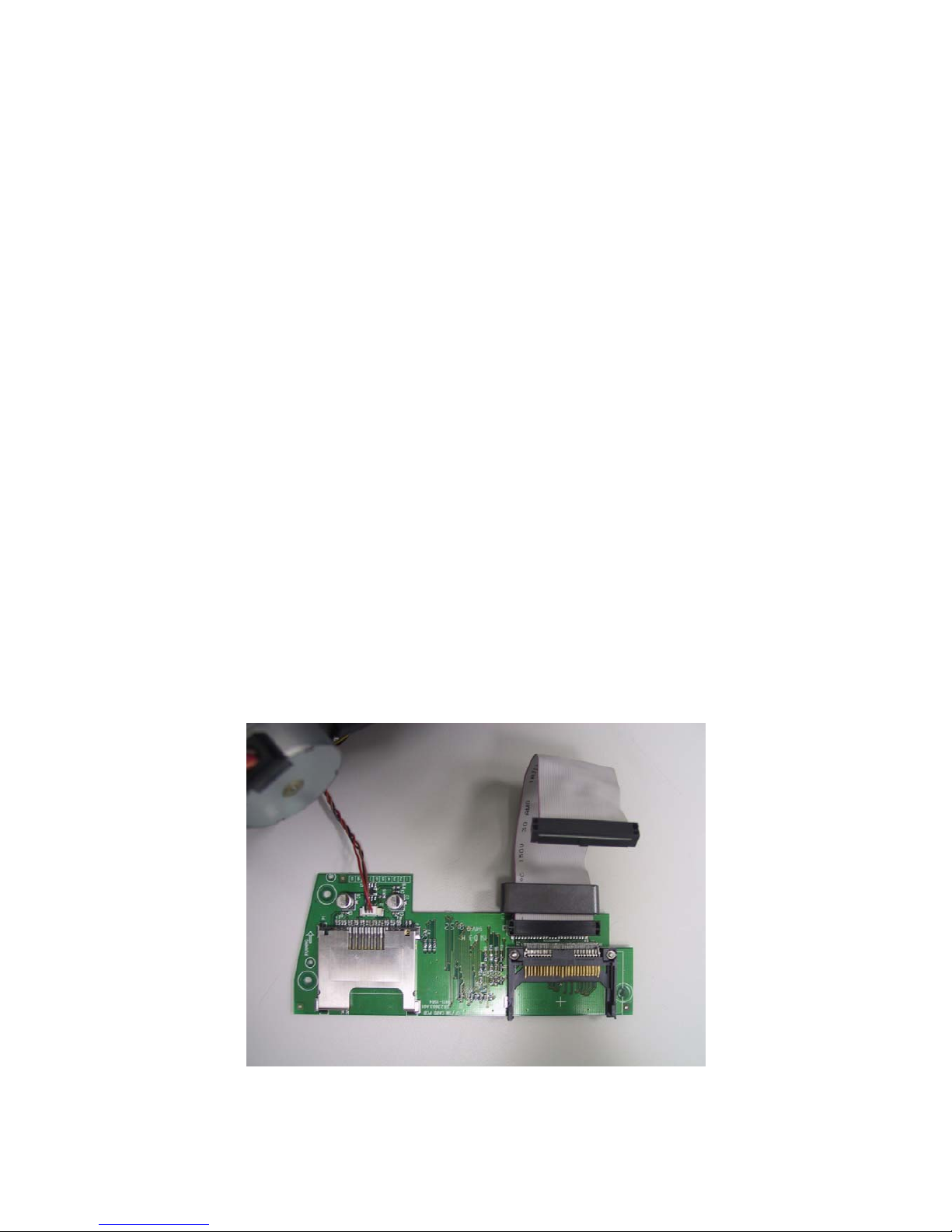

3.3 Card Board

The only one IC on card board is RT9701 -- a power switch. This switch is to

disable power supply of memory card sockets when no cards are inserted.

After either one of the sockets is inserted a CompactFlash card or a

SmartMedia card, the CD(card detection) is pulled low and the power switch

will be turned on by ASIC.

Fig 24. Card Board

Ver. Ex.1.1 Confidential 2003/7/8

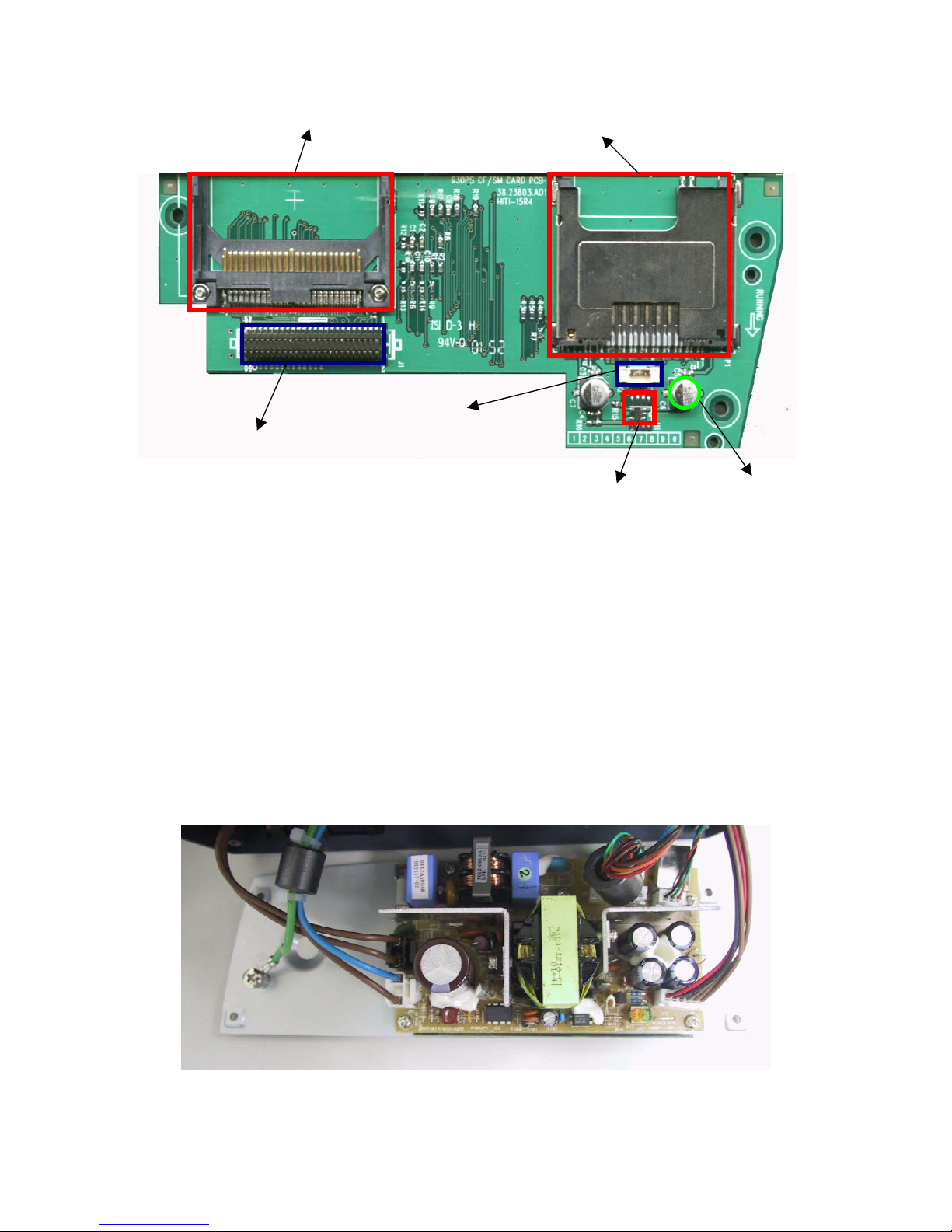

3.4 Power Board

It contains the Transformer, Snubber Circuit, and Power MOS. The function of

Sunbber Circuit is reducing the transient Spike Voltage Power MOS produces

when MOS be turned off. It prevents the Power MOS to be destroyed by the

transient Spike Voltage. Transformer is the component which transforms

energy. It is also separateness of the primary and secondary. It can use

proportion of coils to change the voltage between primary and secondary. The

Power MOS is controlled with UC3842A to switch energy of Transformer so

that is able to regulate Output Voltage.

Fig 25 Power Board

Card b/d powe

r

Power control IC EL Cap.(SMD

)

Card b/d I/F

Ver. Ex.1.1 Confidential 2003/7/8

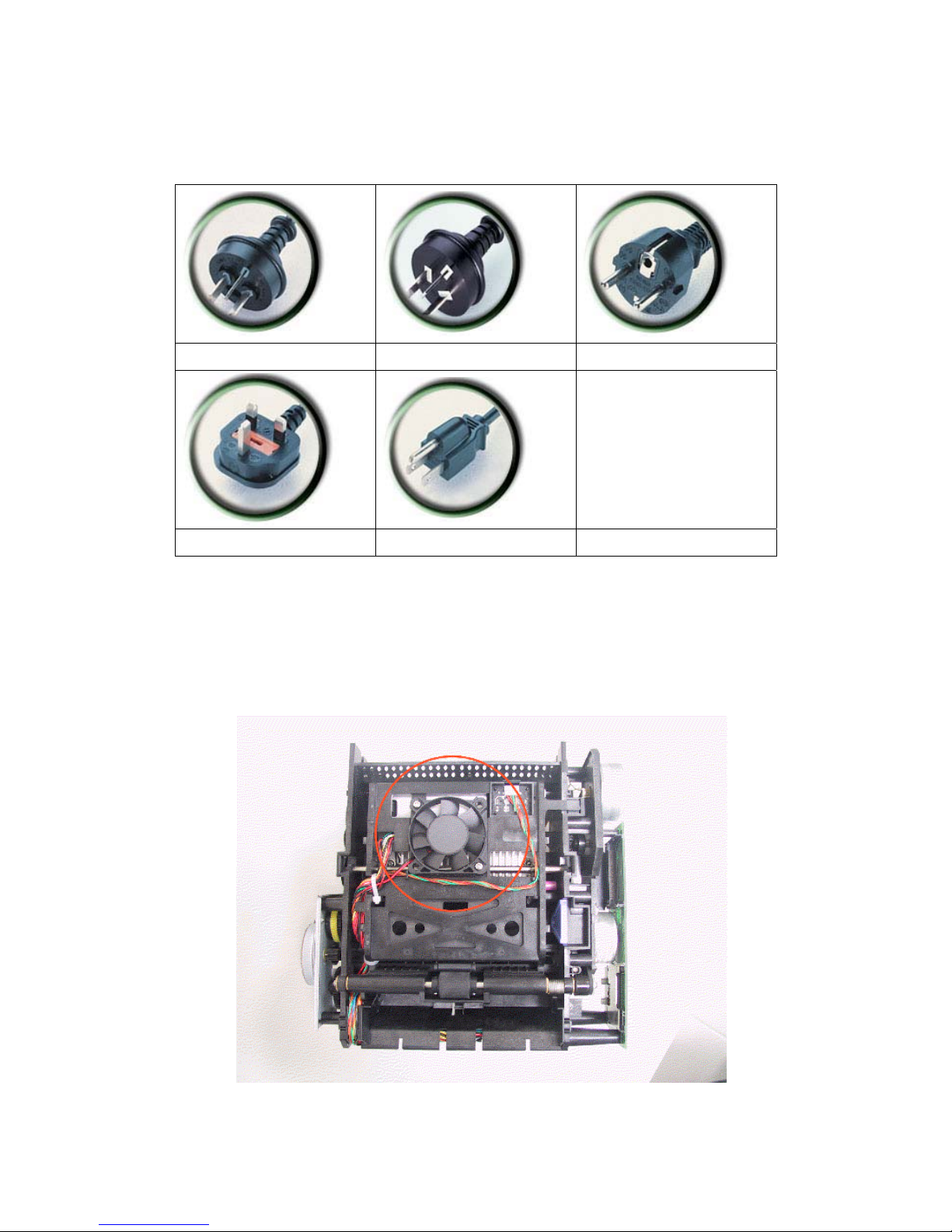

3.5 Power Cord

Australia China Europe

UK US

Fig 26 Power Cord

3.6 Fan

It’s used to reduce the temperature of the TPH (Thermal Print Head).

Fig 27. Fan

Loading...

Loading...