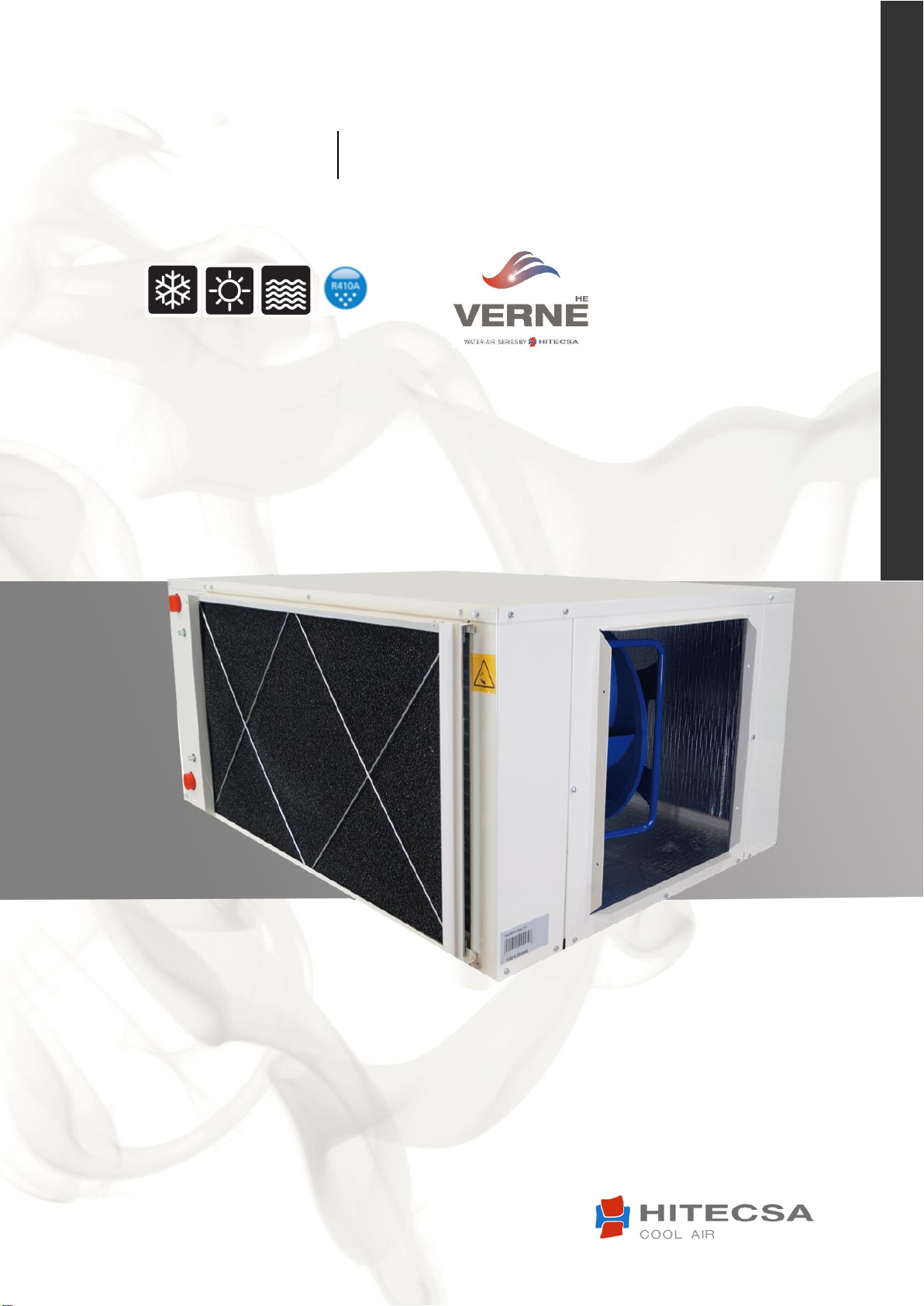

Hitecsa Verne WPHA HE 251, Verne WPHA HE 351, Verne WPHA HE 401, Verne WPHA HE 501, Verne WPHA HE 70 Installation, Operation And Maintenance Manual

...

1

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

INSTALLATIO

N,

OPERATION AND MAINTENANCE MANUAL

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

Models: 091│121│141│171│201│251│351│401│501│ 701│751│1001│1201

Cooling capacity: 2.4 a 41.0 kW

Heating capacity: 2.3 a 37.9 kW

WPHA HE WPHBA HE

Cooling only Heat pump

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

2

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Thank you for trusting the Hitecsa Products. Our company has been offering the market an extended range of specialized

units for air conditioning and cooling installations for over 35 years. Our approach is based on efficiency, adaptability,

usability and practical solutions. This has been the hallmark of our product catalogue.

The versatility of our factory allows us to contribute solutions, almost tailored to each project’s specifications, in search of

a solution to every problem that arises in design and implementation of air conditioning installations.

From all of us at Hiplus Aire Acondicionado, once again, thank you very much.

3

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

INDEX

INTRODUCTION ............................................................................................................................ 4

REGULATIONS AND CERTIFICATIONS....................................................................................... 5

SAFETY PRECAUTIONS ............................................................................................................... 6

TECHNICAL SPECIFICATIONS .................................................................................................... 8

TRANSPORT & RECEPTION ...................................................................................................... 14

INSPECTION AT RECEPTION ........................................................................................................................................... 14

RIGGING ......................................................................................................................................................................... 14

STORAGE ........................................................................................................................................................................ 14

INSTALLATION............................................................................................................................ 15

INSTALLATION LOCATION .............................................................................................................................................. 15

UNIT SETTLEMENT ......................................................................................................................................................... 15

SERVICE AREA ................................................................................................................................................................ 15

WEIGHT DISTRIBUTION (KG) ........................................................................................................................................... 15

DIMENSIONS AND WEIGHT ............................................................................................................................................ 16

WATER DRAIN ................................................................................................................................................................ 21

AIR DUCTS ...................................................................................................................................................................... 21

INSTALLATION OF WATER PIPES .................................................................................................................................... 22

Preliminary information ............................................................................................................................................. 22

Components................................................................................................................................................................ 22

Safety elements .......................................................................................................................................................... 22

Risk of frost ................................................................................................................................................................. 22

Glycol additions .......................................................................................................................................................... 22

WPHA / WPHBA HYDRAULIC CIRCUIT AND ITS COMPONENTS ...................................................................................... 23

ELEMENTS AND HYDRAULIC CONNECTIONS OF THE INSTALLATION DIAGRAM ............................................................. 24

ELECTRICAL CONNECTIONS ........................................................................................................................................... 25

Thermostat connections. ............................................................................................................................................ 25

OPERATION ................................................................................................................................ 27

BEFORE START UP .......................................................................................................................................................... 27

START UP ....................................................................................................................................................................... 27

OPERATING LIMITS ........................................................................................................................................................ 28

Cooling cycle ............................................................................................................................................................... 28

Heating cycle .............................................................................................................................................................. 28

TH TUNE CONTROL ........................................................................................................................................................ 29

ON-OFF CONTROL .......................................................................................................................................................... 29

TEMPERATURE ADJUSTMENT ........................................................................................................................................ 29

SYSTEM MODES .......................................................................................................................................................... 29

Indoor Fan Modes:...................................................................................................................................................... 29

Warnings and Information signals ............................................................................................................................. 29

Description of the Warning Codes .............................................................................................................................. 29

Alarms ........................................................................................................................................................................ 29

Alarm Codes Reset ...................................................................................................................................................... 29

Description of the Alarm Codes .................................................................................................................................. 30

MAINTENANCE ........................................................................................................................... 31

REFRIGERANT CHARGE .................................................................................................................................................. 33

FAN WITH EC MOTOR .................................................................................................................................................... 33

Diagnosis / Failures .................................................................................................................................................... 34

APPENDIX: SAFETY DATA R410A ............................................................................................. 36

4

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

This manual and any other instructive document attached as refrigeration lines design, electrical diagrams,

etc. have been written to allow a correct installation, commissioning and maintenance of the unit. Therefore

it is essential to read the instructions with due attention.

Verify that all the necessary information for the correct installation of the system is included in the manuals

supplied with this unit and/or the rest of the indoor units, accessories, etc. Otherwise, the manufacturer

declines any responsibility for any damage to persons, animals or things, as a result of improper use of the

unit and/or failure to observe these instructions.

In case of different interpretations and/or errors the documentary priority will be: 1. Characteristics plate of

the unit, 2. IOM (this document), 3. EDM, technical catalogue, 4. UM user manuals.

Check that the electrical network features are in accordance to data shown in the data nameplate of the unit.

The material of the package (plastic bags, insulating materials, nails, etc.) is a potential source of danger. Consequently,

it should be kept out of the reach of children and properly recycled according to the valid local safety regulations.

This product should not be mixed with household waste at the end of its life. Due to the refrigerant, oil and other

components contained in this product, it must be dismantled by professional installers, all waste should be

sent, according to its nature to recycling, composting or treatment plants, or an authorized management agency in

accordance with current local legislations.

INTRODUCTION

Purpose of this Manual

Conservation of the Manual

This manual and the electric diagram of the unit must be retained and remain available to the operator for any further consultation.

Updating the Data

The continuous improvement in design and performance to which we are committed gives us the right to modify the specifications of our

products without prior notice.

Electrical Supply

Local Safety Regulations

Observe and analyse all possible causes of accidents that may arise in the place or places of installation of the units, check means and

tools to use, etc. It is not possible to anticipate each and every one of the potential circumstances of danger in this manual. Respect the

valid local security standards during installation.

Principles of Security on Installation

The unit is designed and built in a way that does not pose a risk to the health and safety of people. Appropriate solutions for the project

have been adopted to eliminate the possible causes of risk in the installation.

Packaging and Replacement of Equipment

Utilization

The unit will be used only for the reason it has been conceived. Any other use does not imply any kind of compromise or link for the

manufacturer.

5

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Carry out periodic inspections to detect possible damaged or broken pieces. If they are not repaired it could cause

damage to people or stuff. Before executing any maintenance operation, cut off the unit power supply.

Make sure to leave the maintenance areas open. If these areas have to be necessarily invaded by the construction of

air supply and/or lateral return ducts. Verify that the design of the ducts allow the access to the fans and the change of

the filters or that these are accessible from the other lateral.

All operations should be carried out in accordance with local safety regulations.

The reparations should be always and exclusively made by trained personal authorized by the manufacturer using

original spares. The safeties of the unit could be affected due to the failure to comply with these warnings.

INTRODUCTION

Incorrect Operation

In case of breakdowns or operation faults, turn off unit.

Periodic Inspections and Maintenance

Repairing Operations

Modifications

The manufacturer will not respond to the warranty and to the possible damages of the unit in case of electrical and/or mechanical

modifications. The unauthorized manipulation, reparation or modification of the unit will automatically invalidate the warranty.

Refrigerant

This product is hermetically sealed and contains R-410A which is a HFC fluorinated greenhouse gas.

This product is hermetically sealed and its operation depends on the use of R-410A which is a HFC fluorinated greenhouse gas.

REGULATIONS AND CERTIFICATIONS

ISO 9001 CERTIFICATION: HIPLUS AIRE ACONDICIONADO S.L., trying always to find the maximum satisfaction of

costumers, has obtained the ISO 9001:2015 Quality System referred to its production activity. This will result in a

continuous determination to improve quality and reliability of all our products; commercial activities, design, raw materials,

production and after-sales service, are the means to reach our goal.

CE MARKING: Our machines have got the CE mark, in conformity with the essential requirements of the applicable EC

directives and their last modifications as well as with the national legislation of each country.

EUROVENT CERTIFICATION: HITECSA participates in the EUROVENT Certification program. Check certified products

on the web.

6

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

The warranty of the unit will not respond to the damages caused by frozen water.

WARNING!

SAFETY PRECAUTIONS

Before starting any installation, service or maintenance operation, turn off the main power switch in

order to avoid electrical shock that may cause personal damages.

In case of folding electrical panels, before folding them up in order to access to the interior of the

machine, it is MANDATORY to disconnect the power supply hose from the electrical voltage, IT MUST

ALWAYS BE FREE OF VOLTAGE for this operation

DANGER

Do not touch or adjust the safety elements inside of any unit of the system. In repairs use only original spare parts

and install them properly in the same position where old parts were placed.

The installation and maintenance of air conditioning equipment could be dangerous because the system is under

pressure, some of its elements have high temperatures and include electrical components.

Do not install the unit into an explosive atmosphere.

If it was necessary to open the electrical panel and access the inside of the machine it is MANDATORY to

disconnect the power supply hose from the machine. It MUST BE FREE OF VOLTAGE for this operation.

It is generally forbidden to carry out work on electrical live parts. Protection class of the device when it is complete

opened is IP00! Be careful, do not touch hazardous voltages directly.

Check the safe isolation from the supply using a two-pole voltage detector.

Even after disconnecting the main voltage, life-threatening charges can appear between the protective ground

“PE” and the main connection.

Units with water-air, water-water or refrigerant-water heat exchangers must be conveniently protected from breaks

by freezing when the room temperature can reach values lower than 5 ºC.

In this case, it is mandatory heat, remove completely the water or add antifreeze to ensure that the freezing point

is always lower than the room temperature.

When the motor runs independently due to air flowing through or if it continues to run down after being

turned off, dangerous voltages of over 50 V can arise on the internal connections of the motor through operation

of the generator.

When there are EC motors or motors with variable speed control, the protective earth is conducting high discharge

currents (depending on the switching frequency, current source voltage and motor capacity). Earthing in

compliance with EN specifications shall therefore be observe even for testing and trial conditions (EN 50 178, Art.

5.2.11). Without earthing, dangerous voltages can be present on the motor housing.

Through use of capacitors, danger of death exists even after switching off the device in case of direct contact with

conductive parts or with parts that carry voltage due to fault condition. It is only allowed remove or open the

housing of the controller when the power supply cable is disconnected and after a waiting time of 3 minutes.

7

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

ATTENTION!

will be on the person or operating company of the unit, and will not be on its manufacturer.

WARNING!

SAFETY PRECAUTIONS

Only qualified and trained service staff (technical service) must make the installation, commissioning and carry

out maintenance works. Unqualified personnel can only make basic tasks such as cleaning and replacement of

filters, etc.

Prevent access to children so they cannot play with the appliances.

In every visit, all precautions must be taken into account: those recommended in the installation, operation and

maintenance instructions, as well as the ones indicated in labels of the unit. Do not forget to strictly follow any

other safety precautions.

DO NOT introduce objects into the air inlets or outlets that can be drawn into the fan, people, etc.

Use safety glasses, work gloves and any other safety accessory necessary.

The fan / motor may switch on and off automatically for functional reasons.

After power failure or main disconnection an automatic restart of the fan takes place after voltage return!

Wait for the fan to come to a complete standstill before approaching it!

In the AC external rotor motor the external rotor turns during operation!

For brazing operations use a quenching cloth and take precautions to have at close distance a fire extinguisher.

This product contains fluorinated greenhouse gases, its leakage can cause displacement of air and cause

insufficient oxygen to breath.

The decomposition of fluorinated gases when being burned due to e.g. brazing operations, may cause the

existence of highly toxic and corrosive gases.

Must follow all safety recommendations.

The responsibility of all personal and material damages caused by an unplanned or inappropriate use

Product precautions

The equipment accomplishes the current technical standards at the moment of its delivery and basically it is considered

secure. The unit and its corresponding accessories should only be assembled and operate if they are in perfect conditions

and in agreement with the instructions manual of the manufacturer. Utilizations which are not in accordance with the

technical specifications of the unit (Name plate and appendix / technical data) might cause defects and other kind of

damages.

8

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

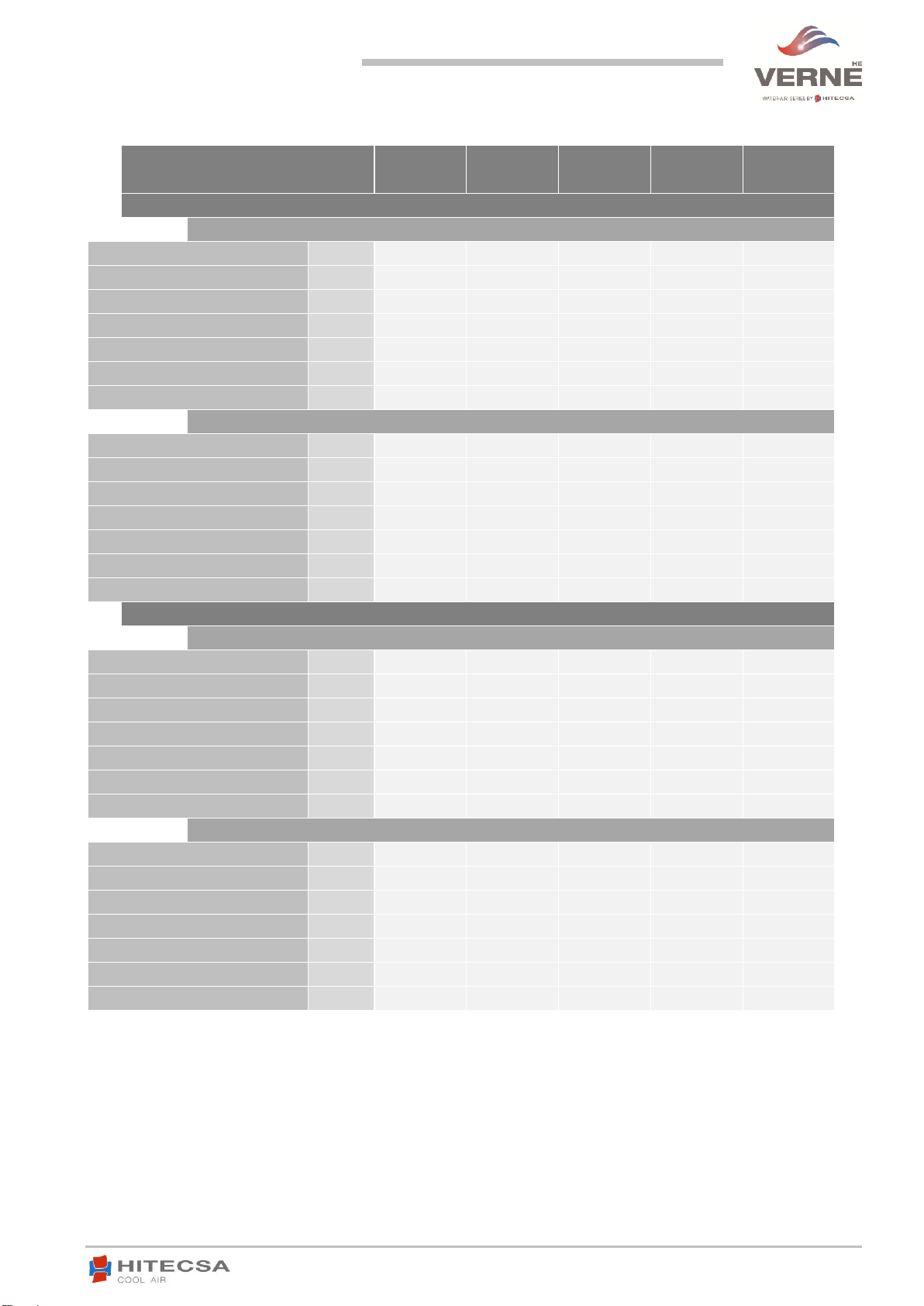

VERNE HE SERIES

091

121

141

171

201

WPHA / WPHBA

COOLING CAPACITIES (1)

Nominal cooling capacity (1)

kW

2.36

3.18

3.86

4.82

5.83

Power input (1)

kW

0.72

0.94

1.06

1.11

1.56

EER Coefficient (1)

kW / kW

3.3

3.37

3.64

4.35

3.75

SEER Coefficient (1)

kW / kW

2.94

3.06

3.03

3.74

3.35

η

s,c

(1) 109.5

114.4

113.3

141.8

126.1

Water flow

m³/h

0.5

0.67

0.81

1.01

1.23

Differential pressure

kPa

8.3

14.3

20.3

17.3

24.9

COOLING CAPACITIES (2)

Nominal cooling capacity (2)

kW

2.64

3.56

4.33

5.38

6.51

Power input (2)

kW

0.52

0.68

0.76

0.83

1.12

EER Coefficient (2)

kW / kW

5.11

5.24

5.69

6.49

5.82

SEER Coefficient (2)

kW / kW

3.7

3.87

3.82

4.55

4.23

η

s,c

(2) 139.8

146.7

144.6

174.2

161.2

Water flow

m³/h

0.56

0.75

0.91

1.13

1.37

Differential pressure

kPa

10.3

17.6

25.2

21.3

30.4

WPHBA (Heat pump units)

HEATING CAPACITIES (3)

Heating capacity (3)

kW

2.26

3.16

3.86

4.56

5.75

Power input Heat (3)

kW

0.68

0.85

1.12

1.04

1.44

COP Coefficient (3)

kW / kW

3.31

3.72

3.46

4.37

4.0

SCOP Coefficient (3)

kW / kW

2.87

3.22

2.99

3.78

3.22

η

s,h

(3) 106.7

120.8

111.5

143.4

130.7

Water flow

m³/h

0.47

0.66

0.8

0.96

1.23

Differential pressure

kPa

7.4

13.9

19.9

15.8

24.9

HEATING CAPACITIES (4)

Heating capacity (4)

kW

1.76

2.47

3.03

3.57

4.49

Power input Heat (4)

kW

0.6

0.75

0.99

0.96

1.28

COP Coefficient (4)

kW / kW

2.91

3.27

3.05

3.72

3.52

SCOP Coefficient (4)

kW / kW

2.52

2.83

2.63

3.22

3.05

η

s,h

(4) % 92.8

105.2

97.1

120.7

113.9

Water flow

m³/h

0.36

0.51

0.62

0.75

0.97

Differential pressure

kPa

4.5

8.6

12.4

10.0

16.1

TECHNICAL SPECIFICATIONS

1) Nominal conditions. Refrigeration tower: Indoor air 27/19 ºC. Condenser water: inlet 30 ºC / outlet 35 ºC (Inlet

partial loads 26/22/18).

2) Geothermal conditions: Indoor air 27/19 ºC. Condenser water: inlet 10 ºC / outlet 15 ºC (Inlet partial loads

10/10/10).

3) Underground water conditions: Indoor air 20 ºC. Evaporator water: inlet 10 ºC, unit water flow 100 % outlet 7

ºC.

4) Brine conditions: Indoor air 20 ºC. Evaporator water: inlet 0 ºC, unit water flow 100 % outlet -3ºC.

9

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

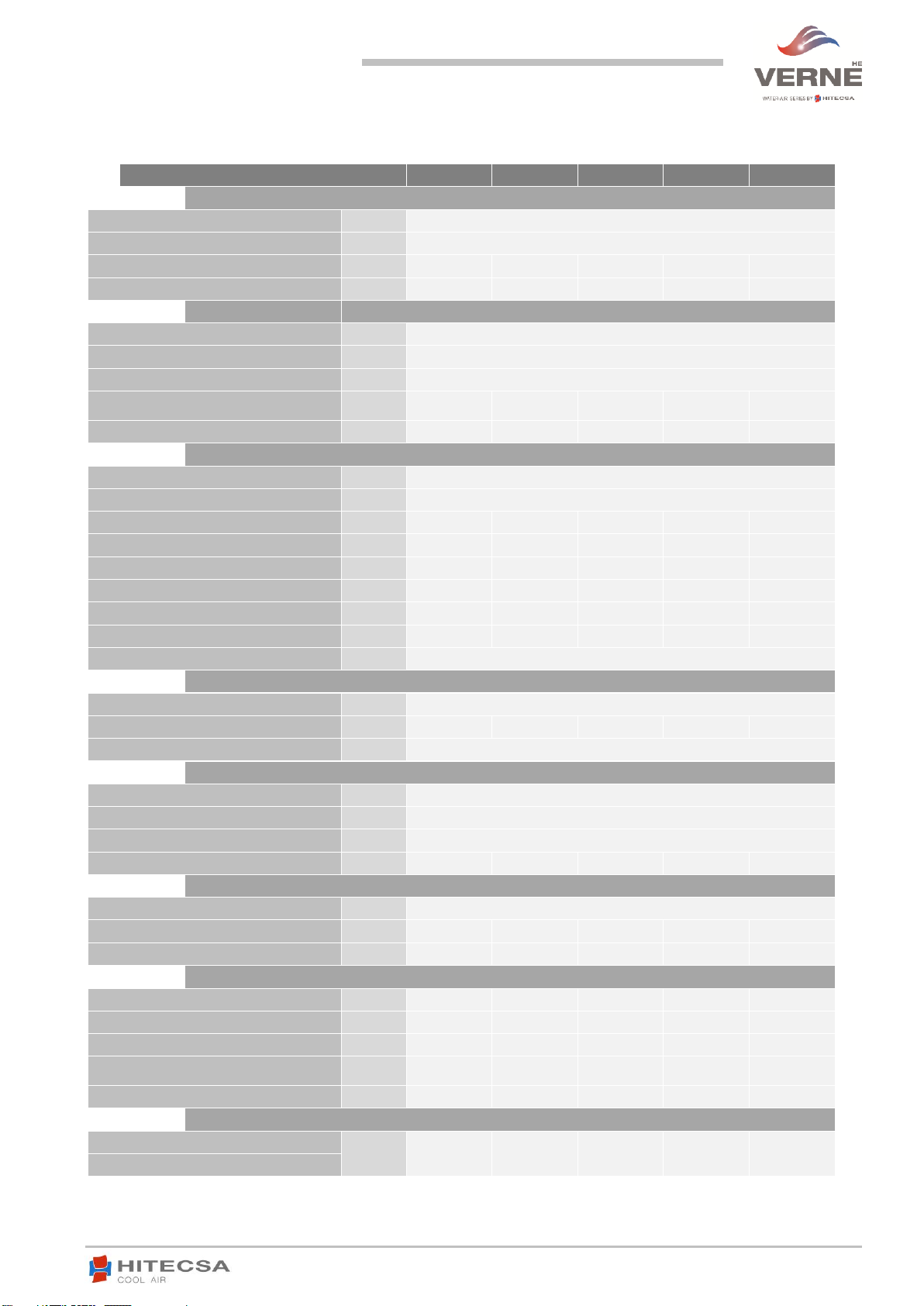

VERNE HE SERIE

091

121

141

171

201

REFRIGERANT

Type

R-410A

Global warming potential (GWP) (5)

2088

Refrigerant load WPHA

kg

0.4

0.4

0.4

0.5

0.55

Refrigerant load WPHBA

kg

0.7

0.6

0.9

1.5

1.2

COMPRESSOR

Type

Rotary

Quantity

1

Voltage

V / ~ / Hz

230 / I / 50

Oil type

ESTER

VG74

ESTER

VG74

POE

ESTER

VG74

ESTER

VG74

Oil quantity in compressor

L

0.35

0.40

0.44

0.48

0.62

EVAPORATOR FAN

Type

Radial with EC motor

Quantity

1

Size

mm

190

190

190

250

250

Nominal air flow

m³/h

500

600

700

900

1100

Static pressure available

Pa

25

25

25

25

25

Maximum pressure available

Pa

515

410

300

760

700

Motor nominal Capacity

kW

0.2

0.2

0.2

0.5

0.5

Nominal speed

r.p.m.

2500

2924

3365

1368

1640

Power supply

V / ~ / Hz

230 / I / 50

INDOOR HEAT EXCHANGER

Type

Coil with aluminium fins and copper pipes

Frontal area

m²

0.165

0.165

0.165

0.188

0.188

Fin spacing

mm - (")

2.1 - 3/8”

OUTDOOR HEAT EXCHANGER

Type

Brazed plates

Quantity

1

Water connections (gas male screw)

(")

¾”

Number of plates

16

16

16

22

22

ELECTRICAL DATA

Voltage

V / ~ / Hz

230 / I + N / 50

Maximum current input

A

5.78

7.18

8.28

9.63

12.63

Start-up current

A

20.98

22.98

35.68

28.13

45.03

DIMENSIONS AND WEIGHT

Length

mm

1055

1055

1055

1055

1055

Width

mm

560

560

560

560

560

Height

mm

410

410

410

470

470

Conduit

mm x

mm

225x225

225x225

225x225

236x296

236x296

Weight

kg

60

62

65

75

77

SOUND LEVEL

Sound pressure at 2 m

dB (A)

55

55

56

57

59

Total sound power (Lw)

dB (A)

71.5

72

72.5

73.5

75.5

TECHNICAL SPECIFICATIONS

5) GWP: Global warming potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms

of 100-year warming potential.

10

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

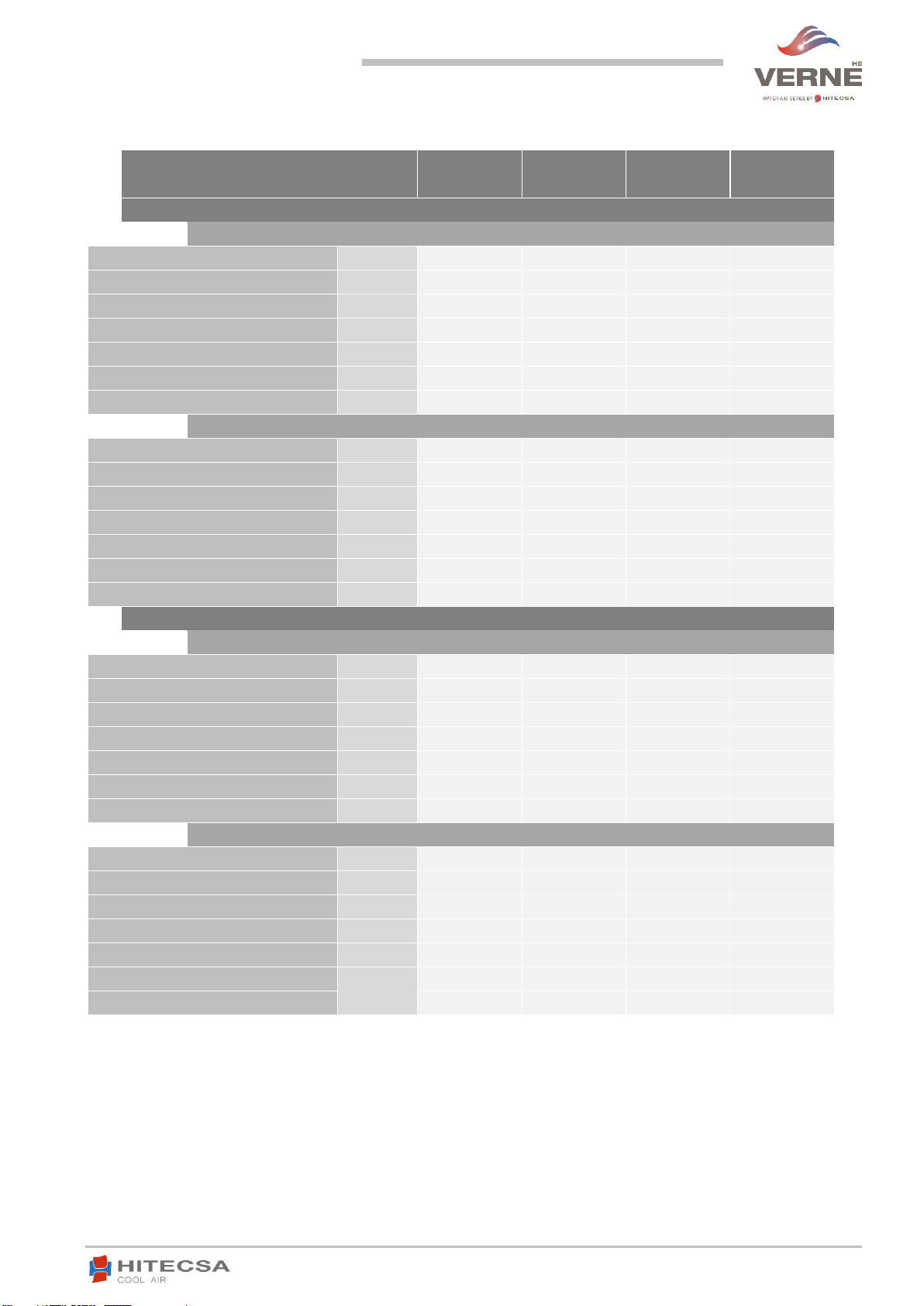

VERNE HE SERIE

251

351

401

501

WPHA / WPHBA

COOLING CAPACITIES (1)

Nominal cooling capacity (1)

kW

7.47

11.31

13.06

16.61

Power input (1)

kW

1.78

2.85

3.24

3.44

EER Coefficient (1)

kW / kW

4.19

3.97

4.03

4.82

SEER Coefficient (1)

kW / kW

3.77

3.61

3.6

4.5

η

s,c

(1) 142.7

136.4

136

172.2

Water flow

m³/h

1.57

2.38

2.75

3.5

Differential pressure

kPa

14.5

31.3

40.9

21.3

COOLING CAPACITIES (2)

Nominal cooling capacity (2)

kW

8.35

12.66

14.62

18.55

Power input (2)

kW

1.33

2.05

2.33

2.49

EER Coefficient (2)

kW / kW

6.3

6.18

6.29

7.46

SEER Coefficient (2)

kW / kW

4.63

4.58

4.56

5.69

η

s,c

(2) 177.2

175.1

174.6

219.8

Water flow

m³/h

1.76

2.67

3.08

3.91

Differential pressure

kPa

17.9

38.8

50.5

26.2

WPHBA (Heat pump units)

HEATING CAPACITIES (3)

Heating capacity (3)

kW

7.47

11.61

13.44

15.22

Power input Heat (3)

kW

1.71

3.33

3.08

3.17

COP Coefficient (3)

kW / kW

4.38

3.48

4.36

4.8

SCOP Coefficient (3)

kW / kW

3.8

3.02

3.77

4.16

η

s,h

(3) 144

112.9

142.8

158.6

Water flow

m³/h

1.54

2.4

2.8

3.5

Differential pressure

kPa

14.0

31.8

42.3

21.3

HEATING CAPACITIES (4)

Heating capacity (4)

kW

5.86

9.11

10.55

11.89

Power input Heat (4)

kW

1.56

2.97

2.74

2.82

COP Coefficient (4)

kW / kW

3.76

3.07

3.84

4.22

SCOP Coefficient (4)

kW / kW

3.26

2.66

3.32

3.66

η

s,h

(4) 122.2

98.3

124.7

138.4

Water flow

m³/h

1.2

1.88

2.2

2.76

Differential pressure

kPa

8.8

20.3

27.1

13.7

TECHNICAL SPECIFICATIONS

1) Nominal conditions. Refrigeration tower: Indoor air 27/19 ºC. Condenser water: inlet 30 ºC / outlet 35 ºC (Inlet

partial loads 26/22/18).

2) Geothermal conditions: Indoor air 27/19 ºC. Condenser water: inlet 10 ºC / outlet 15 ºC (Inlet partial loads

10/10/10).

3) Underground water conditions: Indoor air 20 ºC. Evaporator water: inlet 10 ºC, unit water flow 100 % outlet 7

ºC.

4) Brine conditions: Indoor air 20 ºC. Evaporator water: inlet 0 ºC, unit water flow 100 % outlet -3ºC.

11

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

VERNE HE SERIE

251

351

401

501

REFRIGERANT

Type

R-410A

Global warming potential (GWP) (5) 2088

Refrigerant load WPHA

kg

0.7

0.8

0.8

2

Refrigerant load WPHBA

kg

1.7

1.8

2.8

3.8

COMPRESSOR

Type Rotatory

Scroll

Quantity

1

Voltage

V / ~ / Hz

230/1/50

400/3/50

230/1/50

400/3/50

Oil type ESTER VG74

PVE

PVE

PVE

Oil quantity in compressor

L

0.62

1.33

1.57

1.57

EVAPORATOR FAN

Type

Radial with EC motor

Quantity

1

Size

mm

310

310

310

400

Nominal air flow

m³/h

1500

2000

2300

2800

Static pressure available

Pa

25

37

50

50

Maximum pressure available

Pa

1050

1630

1580

1150

Motor nominal Capacity

kW

147

0,2

0,245

0,55

Nominal speed

r.p.m

1190

1558

1777

1044

Power supply

V / ~ / Hz

230/1/50

400/3/50

INDOOR HEAT EXCHANGER

Type

Coil with aluminium fins and copper pipes

Frontal area

m²

0.252

0.252

0.252

0.45

Fin spacing

mm - (")

1.8 - 3/8”

1.8 - ¾”

1.8 - 3/8”

2.1 - 3/8”

Oil type PVE

PVE

PVE

POE

Oil quantity in compressor

L

1.57

2.46

2.46

3.31

OUTDOOR HEAT EXCHANGER

Type

Brazed plates

Quantity

1

Water connections (gas male screw)

"

¾”

1 1/4

Number of plates

42

42

42

32

ELECTRICAL DATA

Voltage

V / ~ / Hz

230/1/50-400/3/50

230/1/50-400/3/50

400/3+N/50

400/3+N/50

Maximum current input

A

17.4 -10.9

23.5 - 11.0

9.24

13.39

Start-up current

A

65.3- 31.0

92.0 - 52.84

62.04

73.79

DIMENSIONS AND WEIGHT

Length

mm

1135

1135

1135

1385

Width

mm

670

670

670

940

Height

mm

530

530

530

620

Conduit

mm x mm

350x350

350x350

350x350

450x500

Weight

kg

90

110

115

160

SOUND LEVEL

Sound pressure at 2 m

dB (A)

60

61

61

62

Total sound power (Lw)

dB (A)

76.5

77.5

78.0

78.5

TECHNICAL SPECIFICATIONS

5) GWP: Global warming potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

12

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

VERNE HE SERIE

701

751

1001

1201

WPHA

COOLING CAPACITIES (1)

Nominal cooling capacity (1)

kW

20.11

25.44

34.06

40.05

Power input (1)

kW

4.43

5.81

7.32

8.92

EER Coefficient (1)

kW / kW

4.54

4.38

4.66

4.49

SEER Coefficient (1)

kW / kW

4.27

4.05

4.28

4.11

η

s,c

(1) % 162.7

154

163

156.4

Water flow

m³/h

4.23

5.36

7.17

8.43

Differential pressure

kPa

30.3

46.9

34.4

46.5

COOLING CAPACITIES (2)

Nominal cooling capacity (2)

kW

22.46

28.44

38.09

44.8

Power input (2)

kW

3.2

4.18

5.42

6.39

EER Coefficient (2)

kW / kW

7.02

6.81

7.03

7.01

SEER Coefficient (2)

kW / kW

5.4

5.14

5.28

5.23

η

s,c

(2) % 208

197.7

203.3

201.1

Water flow

m³/h

4.73

5.99

8.02

9.43

Differential pressure

kPa

37.2

57.6

42.4

57.2

WPHBA (Heat pump units)

HEATING CAPACITIES (3)

Heating capacity (3)

kW

18.57

24.79

32.42

37.9

Power input Heat (3)

kW

3.96

5.63

7.27

8.59

COP Coefficient (3)

kW / kW

4.69

4.41

4.46

4.41

SCOP Coefficient (3)

kW / kW

4.07

3.82

3.86

3.81

η

s,h

(3) % 154.9

144.7

146.3

144.6

Water flow

m³/h

4.31

5.73

7.45

8.68

Differential pressure

kPa

31.3

53.1

37.0

49.0

HEATING CALORÍFICAS (4)

Heating capacity (4)

kW

14.51

19.4

25.41

29.73

Power input Heat (4)

kW

3.52 5 6.66

7.65

COP Coefficient (4)

kW / kW

4.13

3.88

3.82

3.89

SCOP Coefficient (4)

kW / kW

3.58

3.36

3.3

3.35

η

s,h

(4) % 135.1

126.2

123.9

126.1

Water flow

m³/h

3.4

4.53

5.97

7.04

Differential pressure

kPa

20.2

34.4

24.5

33.3

TECHNICAL SPECIFICATIONS

1) Nominal conditions. Refrigeration tower: Indoor air 27/19 ºC. Condenser water: inlet 30 ºC / outlet 35 ºC (Inlet

partial loads 26/22/18).

2) Geothermal conditions: Indoor air 27/19 ºC. Condenser water: inlet 10 ºC / outlet 15 ºC (Inlet partial loads

10/10/10).

3) Underground water conditions: Indoor air 20 ºC. Evaporator water: inlet 10 ºC, unit water flow 100 % outlet 7

ºC.

4) Brine conditions: Indoor air 20 ºC. Evaporator water: inlet 0 ºC, unit water flow 100 % outlet -3ºC.

13

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

VERNE HE SERIE

701

751

1001

1201

REFRIGERANT

Type

R-410A

Global warming potential (GWP) (5) 2088

Refrigerant load WPHA

kg

1.6

1.7

2.4

3

Refrigerant load WPHBA

kg 4 4.2

6.1

6.3

COMPRESSOR

Type

Scroll

Quantity

1

Voltage

V / ~ / Hz

400/3/50

Oil type PVE

PVE

PVE

POE

Oil quantity in compressor

L

1.57

2.46

2.46

3.31

EVAPORATOR FAN

Type

Radial with EC motor

Quantity

1

Size

mm

400

400

450

450

Nominal air flow

m³/h

3400

4300

6200

7000

Static pressure available

Pa

50

62

75

75

Maximum pressure available

Pa

1100

975

580

400

Motor nominal Capacity

W

2.4

2.4

2.0

2.0

Nominal speed

r.p.m.

1242

1509

1476

1643

Power supply

V / ~ / Hz

400/3/50

INDOOR HEAT EXCHANGER

Type

Coil with aluminium fins and copper pipes

Frontal area

m²

0.45

0.45

0.84

0.84

Fin spacing

mm - "

2.1 - 3/8”

OUTDOOR HEAT EXCHANGER

Type

Brazed plates

Quantity

1

Water connections (gas male screw) " 1 ¼”

Number of plates

32

32

52

52

ELECTRICAL DATA

Voltage

V / ~ / Hz

400 / 3+N / 50

Maximum current input

A

17.89

19.64

23.01

26.12

Start-up current

A

90.79

128.74

128.51

150.42

DIMENSIONS AND WEIGHT

Length

mm

1385

1385

1930

1930

Width

mm

940

940

1040

1040

Height

mm

620

620

690

690

Conduit

mm x mm

450x500

450x500

550x550

550x550

Weight

kg

160

180

230

250

SOUND LEVEL

Sound pressure at 2 m

dB (A)

65

65

66

67

Total sound power (Lw)

dB (A)

81.5

82.0

82.5

83.5

TECHNICAL SPECIFICATIONS

5) GWP: Global warming potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms

of 100-year warming potential.

14

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Fig. 1

Fig. 2

TRANSPORT & RECEPTION

INSPECTION AT RECEPTION

It is advisable to examine the equipment carefully at the time of its reception.

Check that the equipment has not been damaged during transport and has been supplied complete with all parts

specified in the order and/or with the optional specified in the order. If this is not the case contact the transport

company immediately. (First 48h)

Verify the correct voltage of the nameplate and make sure it is in accordance with local power supply.

In case of any flaw or anomaly detected, please contact HITECSA.

RIGGING

Before moving the unit, make sure that all panels are well fixed.

Raise and set down the equipment carefully.

Do not tilt the unit more than 15 degrees during transportation. (Fig. 1) (Fig. 2)

Always transport the unit in its original packaging to the place of installation.

All units come with a particular rigging diagram of that model, similar to the one shown below. Be sure to hoist

the machine through the points indicated in the diagram.

Make sure that the unit is balanced, stable and without any deformations when it is lifted.

STORAGE

If the equipment is going to be stored before the installation, please follow the instructions below in order to avoid damages,

corrosion or deterioration:

Move it carefully.

Do not place the machine in places exposed to ambient temperature above 50ºC and preferably keep the unit away

from direct sunlight.

Avoid placing the unit with plastic wrapping protection under the sun, as the pressure of the circuits could assume

values that could lead to the intervention of the safety valves.

- In addition, when cooling, water condensation occurs inside the machine and the plastic wrap.

Avoid placing other objects on top of the unit (unless it is done within the limits of the overlap planes indicated on the

packaging, etc. Follow these indications).

Avoid prolonged storage, before installation, water inlet, dust and objects in general due to invasion or biological,

meteorological and/or human inclemencies.

Minimum storage temperature: 5ºC.

Maximum relative humidity: 90%.

15

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

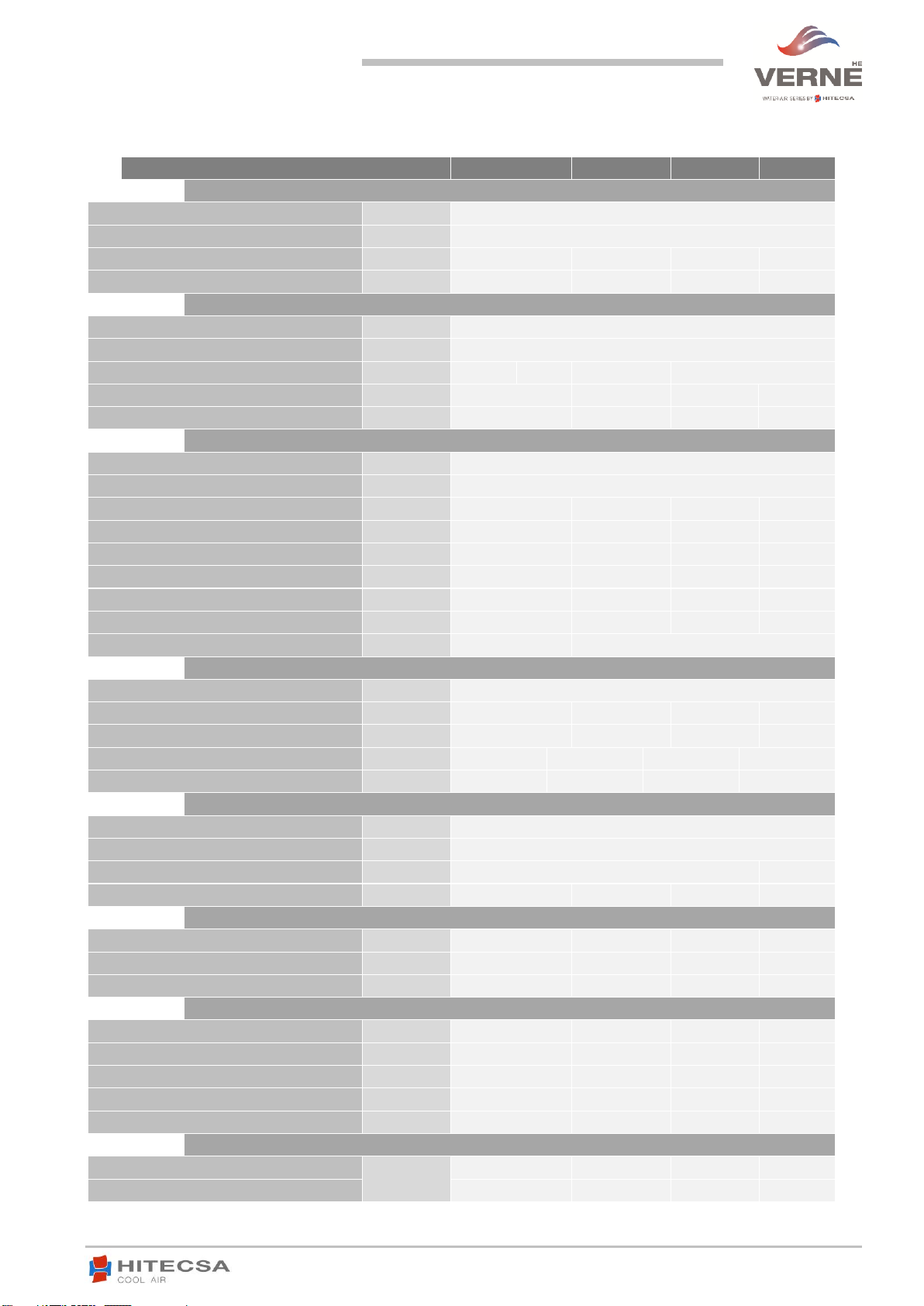

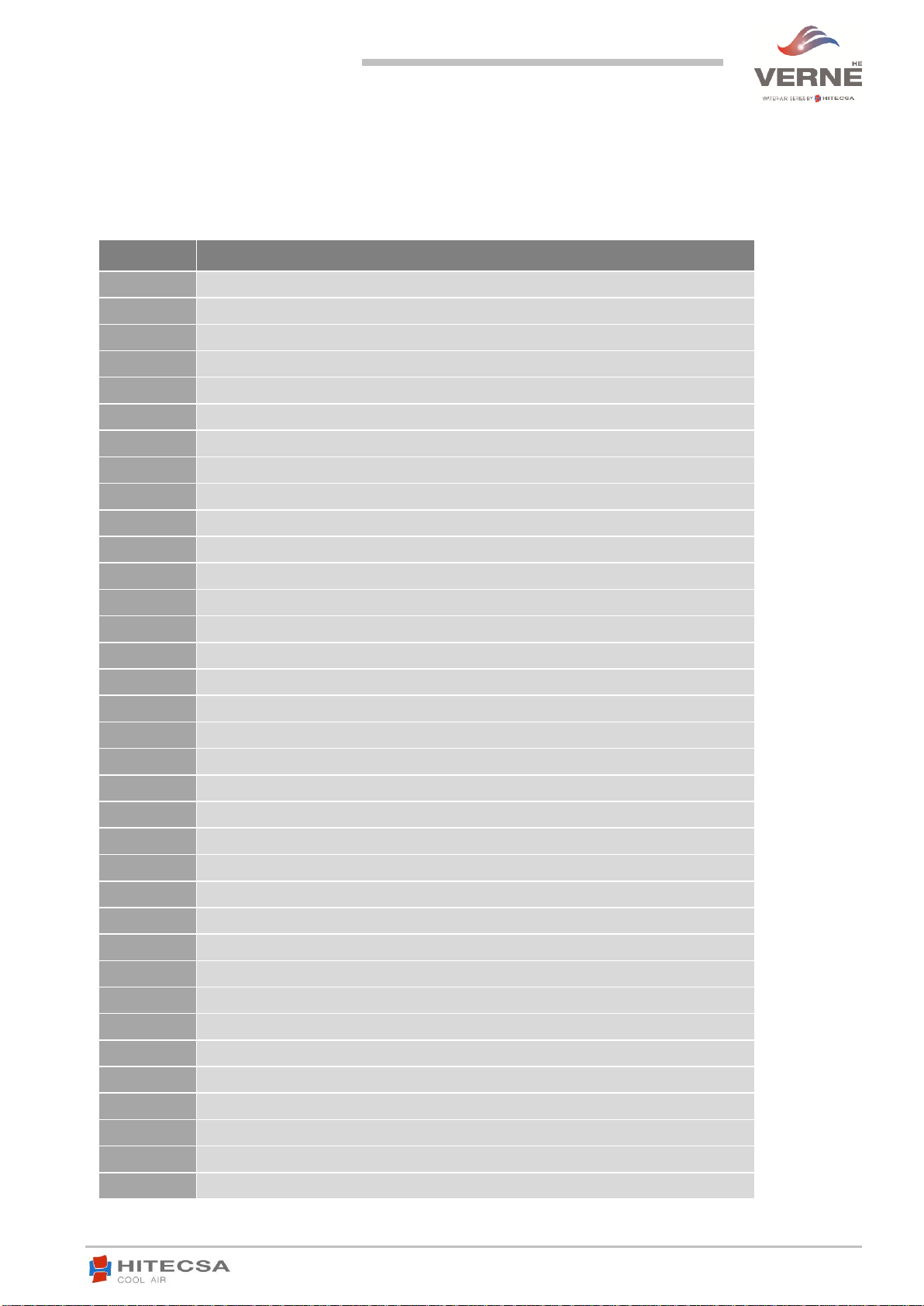

MODEL

1 2 3

4

091

13

13

16

18

121

14

14

16

18

141

14

15

17

19

171

16

17

20

22

201

16

19

20

22

251

21

22

22

25

351

24

26

29

31

401

26

27

30

32

501

38

38

41

43

701

38

38

41

43

751

43

44

46

47

1001

55

56

59

60

1201

61

61

63

65

(3 – 4): Electrical panelboard side

INSTALLATION

INSTALLATION LOCATION

- Consult and respect the rules and local regulations which regulate the installation of air conditioning

systems.

- Choose a site without dust and debris.

- Respect the appropriate service area for the equipment which will be installed.

- Verify that the ground or structure on which the unit will be installed is able to support its weight in

operation.

- Fit shock absorbers throughout the installation to prevent the transmission of noise and vibration.

- Check that the direction of the sound level is not going to disturb anyone.

UNIT SETTLEMENT

Be sure unit is correctly balanced.

The bed frame should have sufficient strength to support unit weight.

Be sure that after settlement the unit drain is working properly.

SERVICE AREA

Make sure to respect the following measurements for the correct operation of the unit.

WEIGHT DISTRIBUTION (kg)

16

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

APROX. WEIGHT(Kg)

MODEL

Net Weight

Packaged Weight

091

60

75

121

62

77

141

65

80

Legend:

1. Power supply input

2. Water inlet

3. Outdoor water drain Ø 3/4” male

4. Water outlet

5. Air filter

6. Manoeuvre

7. Compressor

8. EC fan

9. Condenser heat exchanger

10. Evaporator coil

11. Presostatic valve connection (option)

AA Access panel

INSTALLATION

DIMENSIONS AND WEIGHT

Models 091 – 141

17

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

APROX. WEIGHT (Kg)

MODEL

Net Weight

Packaged Weight

171

75

90

201

77

92

Legend:

1. Power supply input

2. Water inlet

3. Outdoor water drain Ø 3/4” male

4. Water outlet

5. Air filter

6. Manoeuvre

7. Compressor

8. EC fan

9. Condenser heat exchanger

10. Evaporator coil

11. Presostatic valve connection (optional)

AA Access panel

INSTALLATION

DIMENSIONS AND WEIGHT

Models 171 – 201

18

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

APROX. WEIGHT (Kg)

MODEL

Net Weight

Packaged Weight

251

90

105

351

110

115

401

115

130

Legend:

1. Power supply input

2. Water inlet

3. Outdoor water drain Ø 3/4” male

4. Water outlet

5. Air filter

6. Manoeuvre

7. Compressor

8. EC fan

9. Condenser heat exchanger

10. Evaporator coil

11. Presostatic valve connection (optional)

12. Main switch

AA Access panel

INSTALLATION

DIMENSIONS AND WEIGHT

Models 251 – 451

19

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

APROX. WEIGHT (Kg)

MODEL

Net Weight

Packaged Weight

501

160

175

701

160

175

751

180

195

Legend:

1. Power supply input

2. Water inlet

3. Outdoor water drain Ø 3/4” male

4. Water outlet

5. Air filter

6. Manoeuvre

7. Compressor

8. EC fan

9. Condenser heat exchanger

10. Evaporator coil

11. Presostatic valve connection (optional)

12. Main switch

AA Access panel

INSTALLATION

DIMENSIONS AND WEIGHT

Models 501 – 751

20

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

APROX. WEIGHT (Kg)

MODEL

Net Weight

Packaged Weight

1001

230

245

1201

250

265

Legend:

1. Power supply input

2. Water inlet

3. Outdoor water drain Ø 3/4” male

4. Water outlet

5. Air filter

6. Manoeuvre

7. Compressor

8. EC fan

9. Condenser heat exchanger

10. Evaporator coil

11. Presostatic valve connection (optional)

12. Main switch

AA Access panel

INSTALLATION

DIMENSIONS AND WEIGHT

Models 1001 – 1201

21

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Recommended drain trap

measures

INSTALLATION

WATER DRAIN

The indoor drain unit (of condensate water) has a 3/4” gas (ISO 228-1, BSPP) male connection.

Condensate drain pipe diameter should be equal or larger than the unit connection depending on the line length

and general building configuration.

The drainage line should be inclined a minimum 2% for proper water evacuation.

When drain line is exposed to air temperatures below 0 degrees, it is necessary to cover with thermal insulation

or electrical heating wire to avoid water freezing and tube damage.

It is convenient to install the drain trap with proper dimensions (see diagram).

AIR DUCTS

Air duct dimensions will be determined according to the airflow and available pressure of the unit.

Ducts must be designed by qualified technical people.

Use ducts made of non-inflammable materials in order to avoid any risk of fire as a consequence of the

deflagration of gases. It is advisable to use metal sheet duct with insulation.

Use flexible ducts to connect air ducts into the unit and thus avoid vibration and noise transmission.

A bad design of the ducts will reduce the performance of the machine and may block access to maintenance or

change filters, fans, etc., especially when there is only one access.

22

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

INSTALLATION

INSTALLATION OF WATER PIPES

Preliminary information

The selection and installation of the components of the installation have to be done by a qualified installer, respecting the

current legislation of the place of the work and standards of good practice.

The design and calculations of the pipes will be made in a way that the pressure drop of the installation never surpass the

one that could beat the incorporated pump of the unit. Moreover, a bad design of the pressure drops of the pipes that

connect with the indoor units may cause the wrong operation of some of them.

Components

- Shut-off valves: Installed at the entry and exit of every component, they allow to do the maintenance operations

without emptying the installation.

- Thermometers and manometers: Installed at the entrance and the exit of the principal elements. Ease the

maintenance and control operations.

- Steam traps: Installed at the highest points of the installation. Allow the air purge of the circuit.

- Drain keys: Install them in all low points of the circuit to allow their emptying.

- Supports: The weight of the pipes must not be supported by the connections of the unit. Therefore, flexible elements

will be installed to prevent it.

- Expansion tank: Keeps the correct pressure of the installation. It is recommended to fill it at 2.15 bars, when the

water temperature changes from cold to pump and vice-versa. The expansion tank has to be sized depending on the

content of water of the installation.

In special circumstances may be necessary to install one or more additional tanks even when the unit has already one.

Safety elements

The installation of the following safety elements is MANDATORY when they ARE NOT incorporated as standard at the

unit. Its non-compliance will cause the LOSS OF WARRANTY.

Water filter

The water filter will be installed and must contain a mesh inside to retain particles with a diameter not greater than

Ø> 0.5mm

At the water inlet of the unit, to protect the heat exchanger or other critical components from obstructions.

Flow switch or differential pressure switch

Water heat exchanger protection from breaks due to an insufficient water flow and can cause the total disqualification

of the unit.

It is mandatory to install the flow switch at the water outlet of the unit, with a horizontal stretch of 6Ø inlet and 5Ø

posterior of horizontal length, without section changes at the stretch to ensure the laminar regime of the water/fluid

flow. In case of placing flow switches that are not supplied by HITECSA, follow the manufacturer instructions, provided

that the aforementioned lengths do not decrease.

Risk of frost

If the unit or the corresponding hydraulic connection depend on the temperatures close to 4 ºC, take the convenient

measures to prevent the risk of frosts.

For example:

Mix the installation water with glycol.

Protect the pipes with warming cables placed below the insulation

Empty the installation checking that:

There is no closed keys that may retain water even after the emptying.

There is no low points which water can hold back even after the emptying, make a blowing if necessary.

Glycol additions

Take into account the use of glycol solutions increases the pressure drop. Make sure the type of glycol used is compatible

with the components of the hydraulic circuit (pumps, filter keys, etc.).

23

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Element contained in

water

Concentration by mg/l

Effects of a higher value

Effects of a lower value

Suspended solids

Variable

Can deteriorate the material

No effects are observed

Conductivity

≤ 500 µs/cm

No effects are observed

-

> 500 µs/cm

-

Not recommended

NH3

Must be between 2 and 20

Not recommended

No effects are observed

Chlorides

≤ 300

-

No effects are observed

> 300

Corrosion

-

Iron

≤ 10

No effects are observed

-

> 10

-

Incrustations

Carbonic acids

Must be between 20 and 50

Corrosion

Not recommended

PH

Must be between 6 and 9

Incrustations

Corrosion

Sulphates

Must be between 70 and 300

Corrosion

No effects are observed

Langelier

Must be between -0,5 and +0,5

Water with tendency to create

incrustations

Water with corrosive

tendency

1. Antivibratory coupling

2. Shut off valve

3. Presostatic valve

4. Solenoid valve ON/OFF

5. Flow switch

6. Mesh filter

7. Condensates drainage network /

Empty

8. Solenoid valve ON/OFF with the

compressor

9. Manometer

10. Drain valve

INSTALLATION

WPHA / WPHBA HYDRAULIC CIRCUIT AND ITS COMPONENTS

Within the hydraulic circuit and its components, the plate heat exchanger is the most delicate affected part, and as a result

must follow at least these guidelines:

- The installation must be made according to the diagram of hydraulic connections (see below).

- The maintenance of both the filter and the flow switch must be done within periods in which the locking dressings

are avoided.

- The inlet and outlet water of the unit must be respected and install, if necessary, a bypass valve.

The units that incorporate a plate heat exchanger must work in both an open hydraulic circuit and a thermal ring within the

control values in the attached table.

Surpassing the Langelier index below or above can generate corrosive or fouling water, so the component would be at risk

and the equipment warranty would be denied. In this case, you should work with a secondary exchanger, adapted to the

quality of the water.

WATER CONNECTIONS WITH OPTIONAL PRESOSTATIC VALVE

Install the Bypass solenoid valve with presostatic valve option in the heat pump units.

NOTE: The pressure tap of the presostatic valve must be connected to the high pressure outlet of the unit. Graphs show connections for heat pump units. In

case of cooling only units, do not mount the solenoid valve. While mounting the presostatic valve, the performance of the flow switch on the compressor startup must be timed during 1 minute, to let de valve act.

24

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Mesh filter

Flexible connection

3

4

7

8

11

12

Condensates

drainage

Dry cooler

Automatic purge

Manometer

Water pump

15

Flow switch

1

2

5

6

9

10

WPHA/BA unit

Shut off valve

Water line

Thermometer

13

14

Drainage

Expansion tank

Air duct

It is mandatory to install the flow switch in the water inlet of the machine with a previous section which

length is 6 times the Ø of the inlet and 2 times the Ø of the outlet of horizontal lenght without any section

change in order to ensure that the flow rate of water/fluid is laminar. In case of installing flow switches that

are not supplied by HITECSA, follow the instructions of the manufacturer, provided that the

abovementioned lengths do not decrease. Failure to comply these guidelines causes loss of the equipment

warranty.

ATTENTION!

INSTALLATION

ELEMENTS AND HYDRAULIC CONNECTIONS OF THE INSTALLATION DIAGRAM

25

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

1. Power Supply :

* 091- 251 Single-phase

** 351-1201 Three-phase+Neutral

2. Ground

3. Delayed-action fuses or circuit

breaker D curve.

4. Main switch

5. Th TUNE Control

Th-TUNE CONNECTION:

- Two power supply cables 230 VAC

(L+N)

- A shielded twisted pair cable AWG

20/22 with drain wire to GND.

PGD CONNECTION (Option):

- Connection through 6 wire

telephonic cable for lines greater

than 50m intersperse with TCONN

(4 wire twisted and shielded, see

diagram).

INSTALLATION

ELECTRICAL CONNECTIONS

Thermostat connections.

26

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

- Do not forget that at least

one of the safety devices

must be installed and the

terminals of the unused

safety element must be

bypassed.

- The option solenoid cut-off

valve (Y3) and the optional

alarm can not be selected

at the same time.

INSTALLATION

ELECTRICAL CONNECTIONS

Electrical connection of the hydraulic accessories for maneuver with TH-TUNE and µPC

27

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

OPERATION

BEFORE START UP

Start up has to be performed by a qualified service personnel in air conditioning.

Make sure that panels are firmly secured with screws.

Check that there is no leakage of oil or refrigerant.

Ensure that the unit is evenly levelled.

Check if there is enough space for operation and maintenance.

Before opening the electrical panel and having access to the inside of the machine it is MANDATORY to

disconnect the power supply hose of the machine which MUST BE FREE OF VOLTAGE for this operation.

Check that the drainage is not blocked.

Verify if there are losses of water. Check that the valves work correctly.

Check the water circuit allows its emptying for repairs or stop and its correct air purge.

Always use the electrical diagram of the unit to make the connections.

Make sure that all electrical connections are properly tight.

The power supply of the unit must be as indicated on the serial plate. Damage caused by the start-up of the unit

in an incorrect voltage line is not covered by Hitecsa’s warranty.

The unit must not be supplied with any other voltage than that indicated on the serial plate. The power supply to

the unit must be within 10% of the voltage indicated on the serial plate.

Check the correct rotation direction of the fans.

The installer must place line protection elements in accordance with current legislation.

Wiring of electrical connections must be protected by a tube or other cable conduits.

Make sure if the crankcase heater of each compressor has been operating during 24 hours prior the Start Up.

Check that the air filters are clean and correctly fitted.

Check the condition and placement of grilles, diffusers, air ducts, tarpaulins, etc.

START UP

It is very important to evacuate air from the system and clean dirt particles of the water circuit. The two

operations must be done at the same time.

At first start up the water pump for a few minutes.

Stop the water pump and notice if the automatic purge is working. Repeat this operation 10 times. If it proceeds

in this way, all the existing air will go out from the system and the water circuit will be filled.

The next step is to remove the water mesh filter and clean it. The performance of the system will improve since

the dirty mesh filter has a high pressure drop.

It is necessary to take notes of the air inlet and outlet temperatures to the internal coil, the volts and amps of the

compressor and motor fan, as well as the suction and discharge pressure of each compressor.

It should be remembered that it is necessary to clean the air filters after the first 4 hours of operation.

Observe, at least, 3 cooling cycle operations.

28

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

INPUT TEMPERATURE

MINIMUM

MAXIMUM

Dry indoor air

19ºC

31ºC

Wet indoor air

15ºC

21ºC

Water inlet

15ºC *

45ºC **

TEMPERATURE

MINIMUM

MAXIMUM

Dry air inlet

18ºC

24ºC

Water inlet

12ºC

27ºC

OPERATION

OPERATING LIMITS

Cooling cycle

*For water inlets lower than 25ºC, it is necessary to install the presostatic valve accessory.

** On request units can be manufactured to 50 ºC.

Heating cycle

29

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

CODE

DESCRIPTION

AVFS

Warning of Dirty Filter

IFAb

No water flow Info.

OFFd

The remote contact On-off is open.

OFFs

Stoppage through supervisor (Modbus, Bacnet, etc.)

Security stoppage

Press the central button several times until RES

appears (only available when there is at least one

active alarm).

All alarms, whose causes have disappeared or

have been solved, are cancelled.

Turn the central button to change from 0 to 1.

Press the central button once.

When the reset has been made, the text will

change to OK.

OPERATION

TH TUNE CONTROL

This controller, comes as standard with 2 compressor units (until model 4502.2)

ON-OFF CONTROL

Press and hold the button (On / Off) for two seconds to turn the thermostat on or off. The word "OFF" will be displayed on the thermostat

screen when it is off.

NOTE: The thermostat will show "OFFd" if the remote on-off contact is open and "OFFs" when the shutdown is done through Modbus.

TEMPERATURE ADJUSTMENT

Adjust the setpoint temperature rotating the central button.

SYSTEM MODES

Press (Mode) button to alternate between the available operations modes.

Available system modes:

Cooling Mode – Display will show the icon: and in the down-Right corner: .

Heating Mode – Display will show the icon: & . This mode is not available for cooling only machines.

Automatic Mode – Display will show: “Auto”. This mode is not available for cooling only machines. This operating

mode will change between cold and heat depending on the selected temperature setpoint. The mode that is active at

each moment will be indicated in the lower right part of the display: Heating, Cooling.

Only Fan – Display will show two icons at the same time: . The fan will operate in continuous mode and will

not take into account the temperature value introduced in the setpoint.

NOTE: When the outdoor temperature is very low and you want the machine to operate in cooling mode, either by

selecting this mode or by selecting the Auto mode. If the machine does NOT have condensation control then it could

stop due to the activation of an alarm.

Beware of always leaving Auto mode active! The conditions that lead to the previous error could be given.

Indoor Fan Modes:

“Fan / Autofan” with Ventilation “Continuous / Auto”

Press (Fan) button, to alternate between automatic or continuous ventilation modes.

With automatic fan - The icon on the screen will show "Auto".

The fan only works when there is a request for cold or heat.

Without automatic fan - The word "Auto" disappears from the icon.

The fan operates in continuous mode.

Warnings and Information signals

On the Th-tune screen, some 4-letter alphanumeric characters (AL01) may appear,

When the ( ) symbol also appears then it is an alarm, otherwise it is a warning or an information signal. The warnings

disappear automatically when the cause disappears, however the alarms have to be reset.

Description of the Warning Codes

Alarms

All alarms are serious, cause the unit stoppage and activate an output signal through a relay.

Alarm Codes Reset

After the reset, the thermostat will return automatically to its normal state, displaying the ambient or return temperature as configured.

30

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

CODE

DESCRIPTION

AL01

Alarm B1 probe disconnected (Outdoor temperature)

AL02

Alarm B2 probe disconnected (Air supply temperature)

AL03

Alarm B3 probe disconnected (Discharge temperature comp.1)

AL05

Alarm B5 probe disconnected (Return humidity)

AL06

Alarm B6 probe disconnected (Return humidity)

AL07

Alarm B7 probe disconnected (Outdoor humidity)

AL08

Alarm B8 probe disconnected (Inlet water temperature circuit 2)

AL09

Alarm B9 probe disconnected (Outlet water temperature circuit 3)

AL11

Alarm B11 probe disconnected (Low pressure C1, only 2 circuits units)

AL12

Alarm B12 probe disconnected (Low pressure C2, only 2 circuits units)

ALb1

Alarm B1 probe disconnected (Outdoor temperature)

ALb2

Alarm B2 probe disconnected (Air supply temperature)

ALb3

Alarm B3 probe disconnected (Discharge temperature comp.1)

ALb5

Alarm B5 probe disconnected (Return humidity)

ALb6

Alarm B6 probe disconnected (Return humidity)

ALb7

Alarm B7 probe disconnected (Outdoor humidity)

ALb8

Alarm B8 probe disconnected (Inlet water temperature circuit 2)

ALb9

Alarm B9 probe disconnected (Outlet water temperature circuit 3)

ALF6

Thermic alarm compressor

ALF7

Thermic alarm indoor fan

ALH1

Anti-icing alarm 1 (Water inlet below 12ºC)

ALH2

Anti-icing alarm 2 (Water outlet below 6ºC)

ALH3

Anti-icing alarm 3 (Water inlet < 15ºC and ΔT > 8ºC)

ALH4

Anti-icing alarm 4 (Compressor ON and ΔT Water Inlet/Outlet below 1,5ºC)

ALIF

Flow switch alarm

ALPA

Alarm high pressure switch circuit 1

ALPB

Alarm low pressure switch circuit 1

ALPM

Minimum pressure switch alarm

ALRF

Lack of refrigerant alarm

A2F7

Thermic alarm compressor 2 (2 circuit unit)

A2F8

Thermic alarm indoor fan 2 (2 circuit unit)

A2PA

Alarm high pressure switch circuit 2

A2PB

Alarm low pressure switch circuit 2

A2PM

Minimum pressure switch alarm circuit 2

A2RF

Lack of refrigerant alarm circuit 2

OPERATION

TH TUNE CONTROL

Description of the Alarm Codes

31

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Before performing any service or maintenance operation it is mandatory to turn off the main power switch of

the system to avoid any personal injuries. Locked it so that nobody other than a qualified technician can

switch on electrical power.

Read the SAFETY PRECAUTIONS!

WARNING!

MAINTENANCE

It is advisable to do maintenance works every 1.000 operating hours as well as at the beginning of each cooling season.

Refrigeration circuit: Check for oil or refrigerant leaks, noises or system’s vibration. Take measurements of

temperatures and pressures of components and record them on the maintenance form.

Electrical circuit: Make sure that all electrical connections –wires, contactors and terminals- are properly tight.

Record the readings for volts and amperes of each compressor and fan motor. Verify the starting current. Check

the good operation of all relays, pressure switches and phase sequence relay of Scroll compressor.

Fans: Check the direction of rotation of the fans and examine the support of them. Verify the operating status.

- Before handling the fan, make sure that it is completely stopped and disconnected from the mains, even if it is

already stopped and no one can start it during the intervention.

- Regular inspection of the device is necessary. The frequency of it, must be taken based on the degree of dirt in

propellers, turbines or impellers. The dirt in impellers (propellers or turbines), motors and grids can involve risks

and shortens significantly the life of the fan.

- Keep the fan's air circulation paths clear of obstacles - danger due to shot out objects!

- It is necessary to check the free passage of condensation water evacuation holes (if they exist) suitable for the

assembly position.

- In cleaning operations be very careful not to unbalance the propeller or turbine.

- If the cleaning work is carried out improperly, in the case of non-painted / painted fans, no guarantee is assumed

as regards the formation of corrosion or adhesion of the paint.

- To prevent humidity accumulation in the motor, before the cleaning process, the fan must operate for at least 1 hour

between 80 and 100% of the maximum number of revolutions!

- After the cleaning process, the fan must work for 2 hours between 80 and 100% of the maximum number of

revolutions to dry!

- Check the fan for mechanical vibrations at regular intervals (recommended every 6 months). Be aware of the limit

values indicated in ISO 14694 and carry out relief measures in case of exceeding these (e.g., the subsequent

balancing by expert personnel).

- Check if there are cracks in the impeller (propeller or turbine), especially in the welding seams.

- Motors and fans do not need any additional lubrication "thanks" to the use of lubrication for life. After the useful life

of the grease expires (30-40,000 h approx.) a change of bearings is required. In view of that, as for any fault (e.g.

in the winding or in electronic systems), please contact our technical assistance department.

Air filters: Clean air filters after 4 hours of system operation and every 3 months (or more depending on application).

Filters can be cleaned by immersion in warm water with soap, later washed in clean water and dry.

Coils: At least once a year, clean condenser coils with water and detergent, then dry with air at low pressure. Never

clean with a wire brush, water and/or air at high pressure.

Drainage system: Verify condition and good operation of the drainage tray and drain trap. It is necessary to clean

the condensates trays after the first day of operation. Then, clean it at least once a year. Take into account the

meteorological conditions, e.g. in places where falling leaves or the flight of seeds can plug the drain trap, it will

also be necessary to clean them at mid and late spring and autumn. The dates are approximate and will depend on

the blooming, falling leaves, seeds, etc. of the plants of the zone or the human activity or any other cause.

Hydraulic Circuit: Check for water leaks, as well as noise and vibrations of the system elements. Record water

pressure values at the inlet and outlet of the pump.

- Clean the filter and the flow switch, it should be done frequently enough to avoid deposits that could block them.

- Make sure you know and comply with all local laws and regulations that affect the maintenance of water facilities.

32

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Legend

5. Water circuit stock pops

MAINTENANCE

Plate heat exchanger: it is necessary to clean the plate heat exchanger of the evaporator at least once a year.

The plate exchanger is cleaned by circulating the cleaning liquid inside. A deposit with acid (5% phosphorus acid

should be used, and if it is necessary to clean more frequently, use 5% oxalic acid). Introduce the cleaning liquid

through the heat exchanger. To achieve an effective cleaning, the acid should be circulated at least 1.5 times the

normal flow rate of water, and if possible in the opposite direction. Then the circuit must be cleaned with a large

amount of water to remove traces of acid. Put new water and start.

1. Plate heat exchanger

2. Cleaning liquid (Water + Acid)

3. Circulating pump

4. Cleaning circuit stock pops

Compressor: Check regularly the lubricant oil level, the presence of vibrations or noises and the insulation of the

motor.

DO NOT FORGET to stop the crankcase resistance for 24 hours before starting up the compressor.

COMPRESSOR LUBRICATION

- Compressors with R-410A refrigerant use synthetic polyester lubricant oils. Each compressor manufacturer has a

specific lubricant oil for its product.

- The compressor or system must not be open to the air for more than 15 minutes.

- The synthetic polyol-ester lubricant oil has the capacity to absorb humidity 100 times more than the mineral oil used

with the R22 refrigerant.

33

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

WARNING!

WARNING!

Do not disconnect the mains voltage so that the fan can start again!

The safe starting of fans is not guaranteed if they are driven in the opposite direction. If the

application requires a safe start, the manufacturer of the installation or the user has to take

the appropriate measures to prevent a reverse drive.

MAINTENANCE

REFRIGERANT CHARGE

Never use oxygen to pressurize system or purge lines for leak test. Oxygen reacts violently with

oil, which can cause an explosion resulting in damage, personal injury or death.

In case it is necessary to add or recover refrigerant, use an electronic scale that is suitably reinforced and prepared to

withstand the handling of the refrigerant bottle.

The charge must be made in LIQUID condition.

The inlet of liquid refrigerant R-410A in the empty tubes causes temperatures below 0ºC until the internal pressure

reaches 7 bars.

If it is necessary to make brazing operation, first fill the circuit with dry nitrogen. Burning

refrigerant 410A results in toxic gas emissions.

Leaks should be repaired immediately.

Never overcharge the system.

Never use compressor as vacuum pump.

If leakage symptoms appear during the operation, it is necessary to leak test.

To find small leaks, you will need a detector for HCF.

If gas leak is detected is necessary to remove and recuperate complete refrigerant charge. Pressurize system with

dry nitrogen. If leakage has been not detected break a vacuum, dehydrate and charge with refrigerant.

Do not reintroduce used refrigerant, send it to an authorized recycling location.

FAN WITH EC MOTOR

Rotation caused by an Air Flow in the opposite direction

When the fan is stopped (no signal, no power supply, etc. ...), the motor control does not intervene if the fan rotates in the

opposite direction (due, for example, to an air flow).

If we put the fan in operation while turning in the opposite direction, first the control will reduce the rotations in a controlled

manner until it reaches the value "0" (stop of the fan). Then the control will make a new start in the proper direction of

rotation.

The higher the number of turns in the opposite direction, the longer the control will be needed to stop the fan.

In the event that the fan rotates strongly in the opposite direction, the control may not be able to start the fan in the proper

direction of rotation.

Information

34

IOM_WPHBA HE-WPHA HE_091a1201_207815_180701_EN

HORIZONTAL WATER-AIR COMPACT PACKAGED UNITS

WPHA HE / WPHBA HE

Type of

failure

Possible Cause

Solution

The fan

does not

rotate

Power supply blackout. Cut of a

phase. Overvoltage or very low

voltage.

Check the power supply.

Short circuit to ground.

Check the motor connections and the power supply.

Short circuit in winding.

Replace the fan.

The thermal protection of the motor

has been switched off (the motor is

overheated).

Check that the air passages; if it is necessary to remove the

foreign bodies "The drive wheel is blocked or dirty" check the

temperature of supply air. Check the voltage.

The drive wheel is blocked or dirty.

Switch off power to the motor and secure against switching

back on.

Check safe isolation from supply.

Remove safety grille.

Remove foreign bodies or soiling.

Remount the safety grille.

The fan

does not

start

The temperature is very low for the

bearing grease.

Insert bearing with cold greasing.

The airflow circulates in the wrong

direction (the motor moves with

many revolutions in the wrong

direction).

Check the air flow.

In cases where the air flow is very strong, it is possible that the fan

will not start up.

The fan

rotates very

slowly

Rotor / blade drags / rubs.

Remove foreign bodies / dirt on the fan, if necessary.

Temperature management