Hitecsa VERNE WPHBA 171, VERNE WPHBA 251, VERNE WPHBA 201, VERNE WPHA Series, VERNE WPHBA 351 Series Manual

...

INSTALLATION, OPERATION & MAINTENANCE MANUAL

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

WPHBA │ WPHA

Heat pump Cooling only

PACKAGED HORIZONTAL WATER-TO-AIR CONDITIONERS

Models: 091│121│141│171│201│251│351│401│501│701│751│1001│1201

Cooling Capacities: from 2.4 to 41.0 kW

Heating Capacities: from 2.8 to 46.4 kW

Thank you for trusting the Hitecsa Products. Our company has been offering the market an extended range of specialized units for

air conditioning and cooling installations for over 35 years. Our approach is based on efficiency, adaptability, usability and practical

solutions. This has been the hallmark of our product catalogue.

The versatility of our factory allows us to contribute solutions, almost tailored to each project’s specifications, in search of a solution

to every problem that arises in design and implementation of air conditioning installations.

From all of us at Hiplus Aire Acondicionado, once again, thank you very much.

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

WPHBA │ WPHA

INDEX

INTRODUCTION ........................................................................................................................... 5

CONTENTS ................................................................................................................................... 5

REGULATIONS AND CERTIFICATIONS ........................................................................................... 6

SAFETY PRECAUTIONS ................................................................................................................. 7

TECHNICAL SPECIFICATIONS ........................................................................................................ 8

OPCIONAL MOTOR EC ................................................................................................................ 14

TRANSPORT & RECEPTION ........................................................................................................ 15

INSPECTION AT RECEPTION ....................................................................................................... 15

RIGGING ..................................................................................................................................... 15

STORAGE .................................................................................................................................... 15

INSTALLATION ........................................................................................................................... 16

INSTALLATION LOCATION .......................................................................................................... 16

UNIT SETTLEMENT ..................................................................................................................... 16

SERVICE AREA (MM) .................................................................................................................... 16

WEIGHT DISTRIBUTION (KG) ....................................................................................................... 16

DIMENSIONS AND WEIGHT ........................................................................................................ 17

Standard Fan ........................................................................................................................ 17

EC RADIAL FAN ..................................................................................................................... 22

DRAINAGE .................................................................................................................................. 27

AIR DUCTWORK ......................................................................................................................... 27

HYDRAULIC INSTALLATION ....................................................................................................... 28

WATER FILLING .................................................................................................................... 28

Risk of frost .......................................................................................................................... 28

Glycol additions ................................................................................................................... 28

THE HYDRAULIC CIRCUIT AND ITS COMPONENTS ...................................................................... 29

Security devices .................................................................................................................... 29

INSTALLATION OF THE FLOW SWITCH AS AN OPTION ....................................................... 30

WATER CONNECTIONS WITH THE OPTIONAL PRESSOSTATIC VALVE ......................................... 32

ELEMENTS AND HYDRAULIC CONNECTIONS OF THE INSTALLATION DIAGRAM ......................... 33

ELECTRICAL CONNECTIONS ....................................................................................................... 34

Thermostats connection. ..................................................................................................... 34

INSTALLATION ...................................................................................................................... 35

Electrical connection of the hydraulic accessories for control with TH-TUNE and µPC ..... 35

3

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

OPERATION ............................................................................................................................... 35

BEFORE START UP ...................................................................................................................... 35

START UP ................................................................................................................................... 36

OPERATING LIMITS .................................................................................................................... 37

Cooling cycle ........................................................................................................................ 37

Heating cycle ........................................................................................................................ 37

INDOOR FAN TRANSMISSION ADJUSTMENT.............................................................................. 37

TH TUNE CONTROL .................................................................................................................... 39

Start / Stop ........................................................................................................................... 39

Temperature Adjustment ..................................................................................................... 39

System Modes ...................................................................................................................... 39

Indoor Fan: “Fan / Autofan” with ventilation “Continuous / Auto” ..................................... 39

Alarms .................................................................................................................................. 39

MAINTENANCE .......................................................................................................................... 41

COMPRESSOR LUBRICANT ......................................................................................................... 42

REFRIGERANT CHARGE .............................................................................................................. 43

OPTIONAL ................................................................................................................................. 44

EC MOTOR FANS ........................................................................................................................ 44

Safety instructions ................................................................................................................ 44

Working on device................................................................................................................ 45

Modifications / interventions in the device .......................................................................... 47

Diagnosis / Faults ................................................................................................................. 48

Status Out with flash code ................................................................................................... 49

Rotation caused by an air flow in false direction ................................................................. 50

Maintenance and repairs ..................................................................................................... 50

Cleaning ............................................................................................................................... 51

APPENDIX: SAFETY DATA R-410A .............................................................................................. 52

4

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

This manual and any other instructive document attached as refrigeration lines design, electrical diagrams,

etc. have been written to allow a correct installation, commissioning and maintenance of the unit. Therefore

it is essential to read the instructions with due attention.

Verify that all the necessary information for the correct installation of the system is included in the manuals

supplied with this unit and/or the rest of the indoor units, accessories, etc. Otherwise, the manufacturer

declines any responsibility for any damage to persons, animals or things, as a result of improper use of the

unit and/or failure to observe these instructions.

In case of different interpretations and/or errors, the priority order of validity of the given documents will be:

1. Name plate of the unit stating the specifications. 2. IOM (the present document), 3. EDM, technical

catalogue, 4. UM user manuals.

Check that the electrical network features are in accordance to data shown in the data nameplate of the

unit.

The material of the package (plastic bags, insulating materials, nails, etc.) is a potential source of danger.

Consequently, it should be kept out of the reach of children and properly recycled according to the valid

local safety regulations.

This product should not be mixed with household waste at the end of its life. Due to the refrigerant, oil and

other components contained in this product, it must be dismantled by professional installers in accordance

with current regulations.

INTRODUCTION

CONTENTS

Purpose of this Manual

Preservation Manual

This manual and the electric diagram of the unit must be retained and remain available to the operator for any further

consultation.

Updating the Data

The continuous improvement in design and performance to which we are committed gives us the right to modify the

specifications of our products without prior notice.

Electrical Network

Local Safety Regulations

Observe and analyse all possible causes of accidents that may arise in the place or places of installation of the units, check

means and tools to use, etc. It is not possible to anticipate each and every one of the potential circumstances of danger in

this manual. Respect the valid local security standards during installation.

Principles of Security on Installation

The unit is designed and built in a way that does not pose a risk to the health and safety of people. Appropriate solutions

for the project have been adopted to eliminate the possible causes of risk in the installation.

Packaging and Replacement of Equipment

Utilization

The unit will be used only for the reason it has been conceived. Any other use does not imply any kind of compromise or

link for the manufacturer.

Incorrect Operation

In case of breakdowns or operation faults, turn off unit.

5

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

Carry out periodic inspections to detect possible damaged or broken pieces. If they are not repaired it could

cause damage to people or stuff. Before executing any maintenance operation, cut off the unit power

supply.

All operations should be carried out in accordance with local safety regulations.

The reparations should be always and exclusively realized for trained personal authorized by the

manufacturer using original spares. The safeties of the unit could be affected due to the failure to comply

with these warnings.

INTRODUCTION

CONTENTS

Periodic Inspections and Maintenance

Repairs

Modifications

The manufacturer will not respond to the warranty and to the possible damages of the unit in case of electrical and/or

mechanical modifications. The unauthorized manipulation, reparation or modification of the unit will automatically invalidate

the warranty.

Refrigerant

This product is hermetically sealed and contains R-410A which is a HFC fluorinated greenhouse gas.

REGULATIONS AND CERTIFICATIONS

ISO 9001:2015 CERTIFICATION: HIPLUS AIRE ACONDICIONADO S.L., trying always to find the customer satisfaction,

has obtained the ISO 9001:2015 Quality System referred to its production activity. This will result in a continuous

determination to improve quality and reliability of all our products; commercial activities, design, raw materials, production

and after-sales service, are the means to reach our goal.

CE MARKING: Our machines have got the CE mark, in conformity with the essential requirements of the applicable EC

directives and their last modifications as well as with the national legislation of each country.

6

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

ATTENTION!

the person or operating company of the unit, and will not be on its manufacturer.

WARNING!

SAFETY PRECAUTIONS

DANGER

Do not touch or adjust the safety elements inside of any unit of the system. In the repairs use only original spare

parts and install them properly in the same position where old parts were placed.

The installation and maintenance of air conditioning equipment could be dangerous because the system is under

pressure, some of its elements have high temperatures and include electrical components.

Do not install the unit in explosive atmosphere.

Before starting any installation, service or maintenance operation, turn off the main power switch in order

to avoid electrical shock that may cause personal damages.

To open the electrical panel and access the inside of the machine it is MANDATORY to disconnect the power

supply hose from the machine. It MUST BE FREE OF TENSION for this operation.

It is generally forbidden to carry out work on electrical live parts. Protection class of the device when it is complete

opened is IP00! Be careful, do not touch hazardous voltages directly.

Check the safe isolation from the supply using a two-pole voltage detector.

Even after disconnecting the main voltage, life-threatening charges can appear between the protective ground

“PE” and the main connection.

Only qualified and trained service staff (technical service) must make the installation, commissioning and

carry out maintenance works. Unqualified staff can only make basic tasks such as cleaning and

replacement of filters, etc.

Prevent access to children so they can not play with the appliances.

In every visit, all precautions must be taken into account: those recommended in the installation, operation and

maintenance instructions, as well as the ones indicated in labels of the unit. Do not forget to strictly follow any

other safety precautions.

DO NOT introduce objects into the air inlets or outlets that can be drawn into the fan, people, etc.

Use safety glasses, work gloves and any other safety accessory necessary.

This product contains fluorinated greenhouse gases, its leakage can cause displacement of air and cause

insufficient oxygen to breath.

Must follow all safety recommendations.

The responsibility of all personal and material damages caused by an unplanned or inappropriate use will be on

7

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

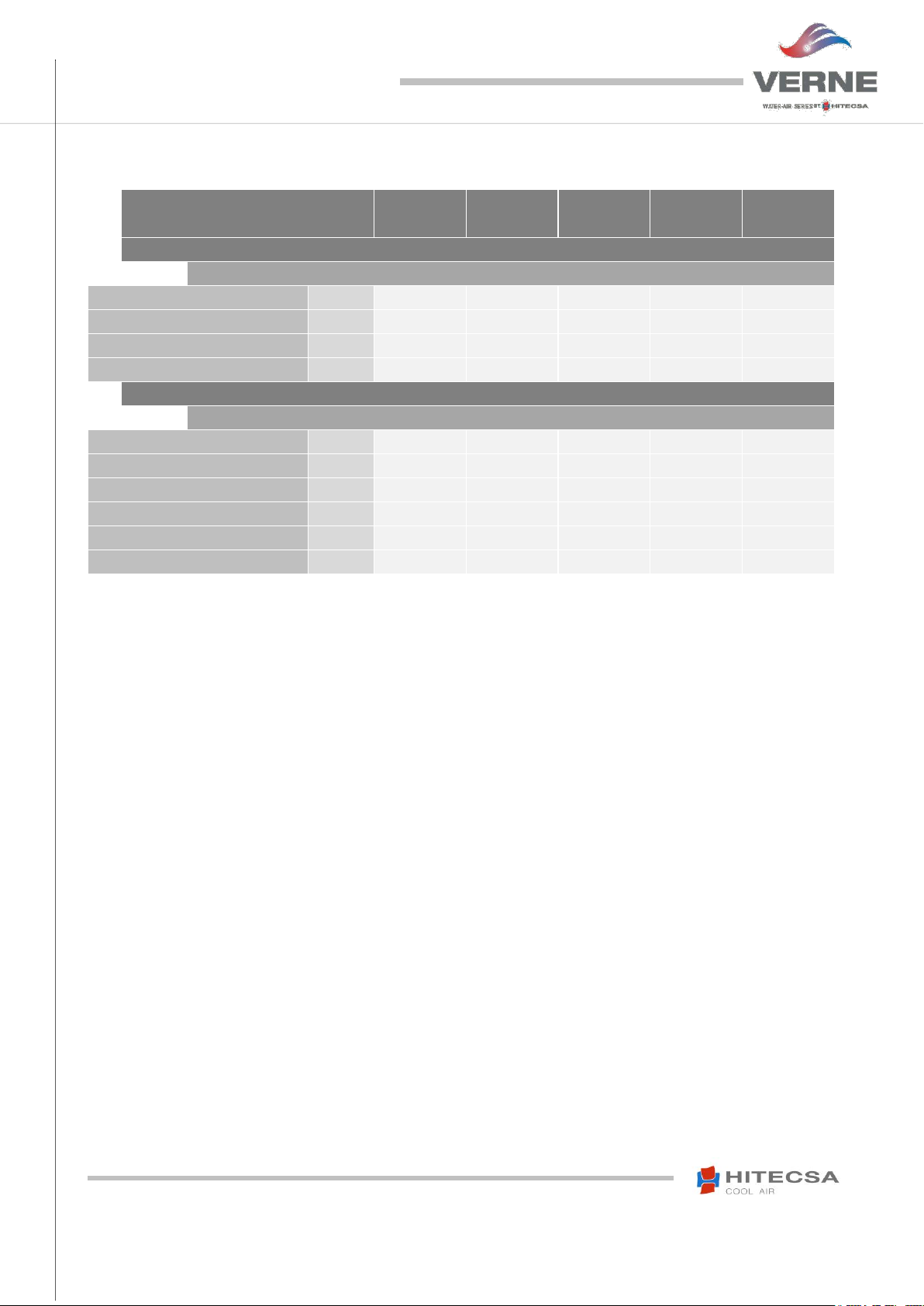

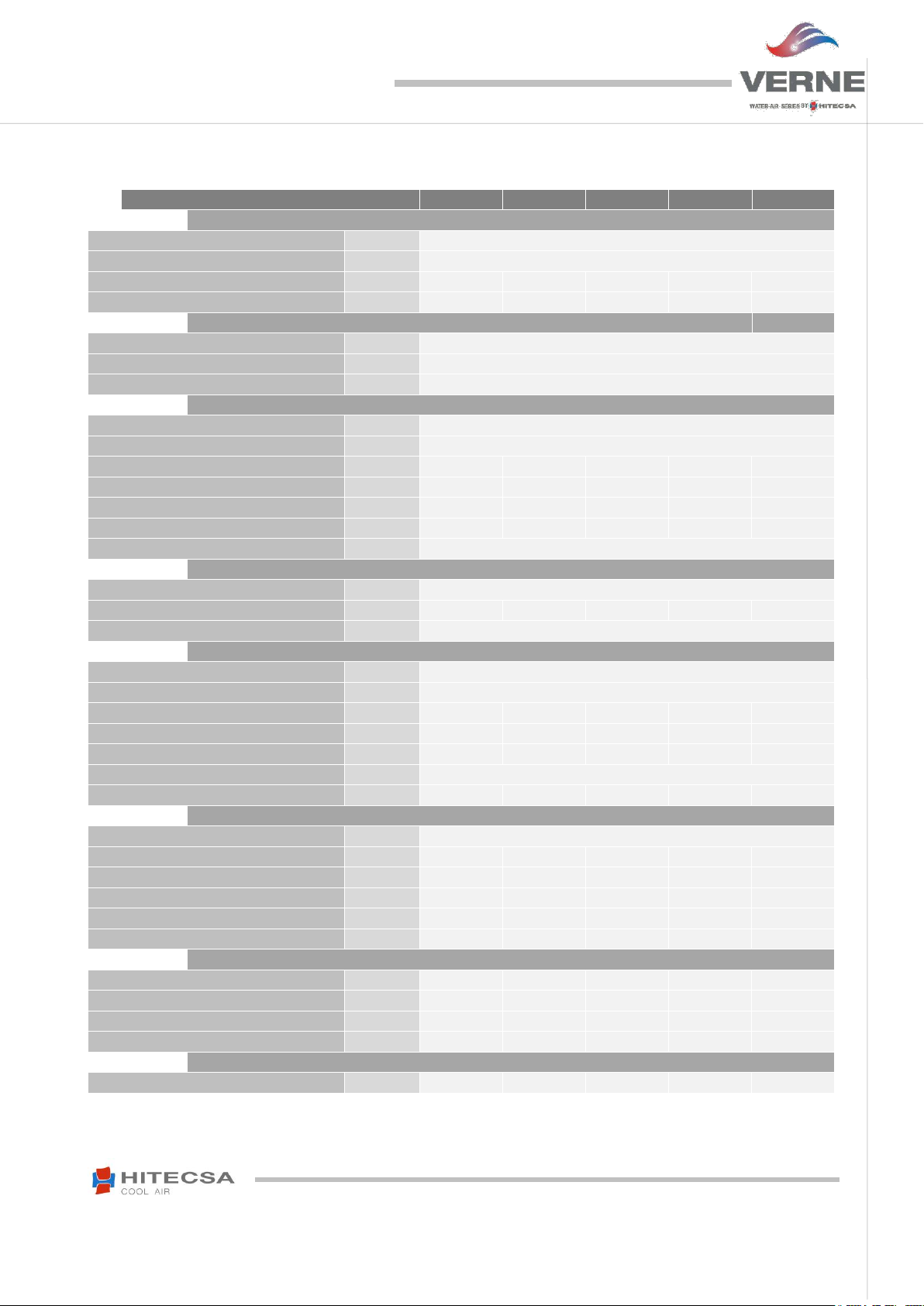

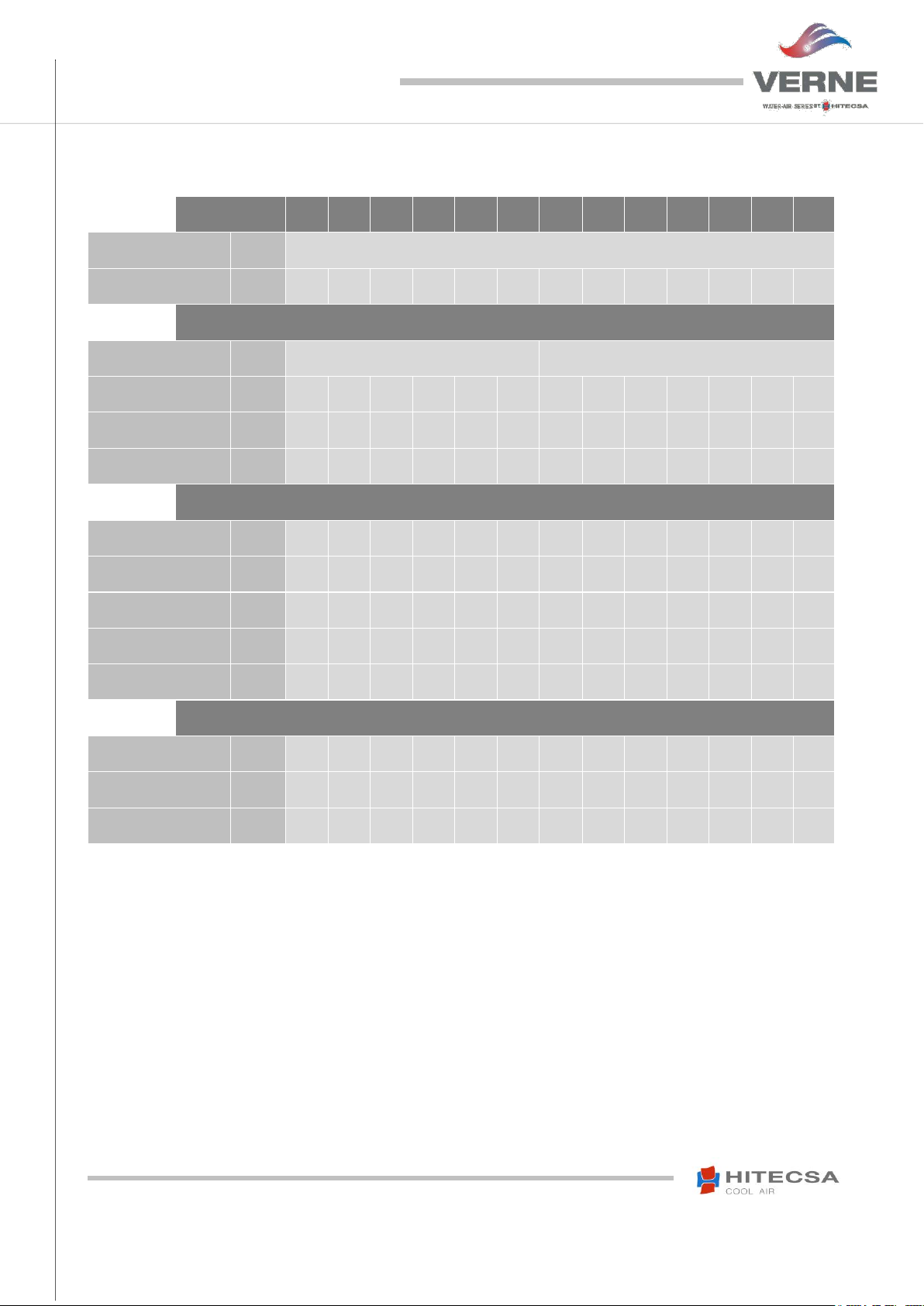

VERNE RANGE

091

121

141

171

201

WPHBA / WPHA

COOLING CAPACITIES

Nominal Cooling Capacity (1)

kW

2.33

3.15

3.88

4.79

5.76

Power Input (3)

kW

0.75

1.00

1.14

1.18

1.64

EER Coefficient

kW / kW

3.12

3.15

3.39

4.05

3.51

Energy Class

A A A A

A

WPHBA (Heat Pump Units)

HEAT CAPACITIES

Heat Capacity (2)

kW

2.83

3.87

4.7

5.56

7.11

Heat Power Input (3)

kW

0.8

1.05

1.31

1.26

1.79

COP Coefficient

kW / kW

3.56

3.69

3.59

4.41

3.97

Water flow

m³/h

0.6

0.7

0.9

1.0

1.3

Pressure Drop

kPa

8.72

15.46

22.42

17.9

26.81

Energy Class

A A A A

A

TECHNICAL SPECIFICATIONS

1) Nominal Cold Conditions, calculated according to UNE-EN 14511:2013 standard, 35ºC of outdoor temperature, 12ºC of inlet water temperature

and 7ºC of outlet water temperature.

2) Nominal Heat Conditions (mean temperatures), calculated according to UNE-EN 14511:2013 standard, 7ºC dry bulb / 6ºC wet bulb of outdoor

temperature, 30ºC of inlet water temperature and 35ºC of outlet water temperature.

3) Total power input at nominal conditions. Calculated according to UNE-EN 14511:2013 regulation.

4) GWP: Global Warming Potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

8

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

VERNE RANGE

091

121

141

171

201

REFRIGERANT

Type

R-410A

Global Warming Potential (GWP) (4) 2088

Refrigerant load WPHA

kg

0.4

0.4

0.4

0.5

0.55

Refrigerant load WPHBA

kg

0.7

0.6

0.9

1.5

1.2

COMPRESSOR

Type

Rotational

Quantity

1

Voltage

V / ~ / Hz

230 / I / 50

EVAPORATOR FAN

Type

Centrifugal. double aspiration (integrated motor)

Quantity

1

Model 180 / 184

180 / 184

7 / 7

7 / 7

180 / 184

Air flow

m³/h

500

600

700

900

1100

Available Pressure

Pa

25

25

54

25

25

Motor power

W

115

115

72

72

150

Voltage

V / ~ / Hz

230 / I / 50

INDOOR HEAT EXCHANGER

Type

Coil with aluminium fins and copper tube

Frontal area

m²

0.165

0.165

0.165

0.188

0.188

Fin spacing

mm - (")

2.1 - 3/8

EXTERNAL HEAT EXCHANGER

Type

Brazed plates

Quantity

1

Water flow WPHA

m³/h

0.5

0.7

0.9

1.0

1.3

Water flow WPHBA

m³/h

0.6

0.7

0.9

1.0

1.3

Pressure Drop

kPa

8.72

15.46

22.42

17.9

26.81

Water connections (male gas thread)

(")

3/4

Number of plates

16

16

16

22

22

GENEREAL FEATURES FOR THE ELECTRICAL INSTALLATION

Voltage

V / ~ / Hz

230 / I + N / 50

Max. Power Input (Cold)

kW

1.0

1.3

1.5

1.5

2.2

Max. Current Input (Cold)

A

4.4

5.8

7.0

8.0

11.3

Max. Power Input (Heat)

kW

0.9

1.2

1.4

1.4

1.9

Max. Current Input (Heat)

A

4.0

5.4

6.0

7.2

10.0

Start up current

A

19.6

21.6

34.4

26.5

43.7

DIMENSIONS AND WEIGHT

Length

mm

1055

1055

1055

1055

1055

Width

mm

560

560

560

560

560

Height

mm

410

410

410

470

470

Weight

kg

60

62

65

75

77

SOUND LEVEL

Sound pressure at 2 m

dB (A)

58

58

59

60

62

TECHNICAL SPECIFICATIONS

(4) GWP: Global Warming Potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

9

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

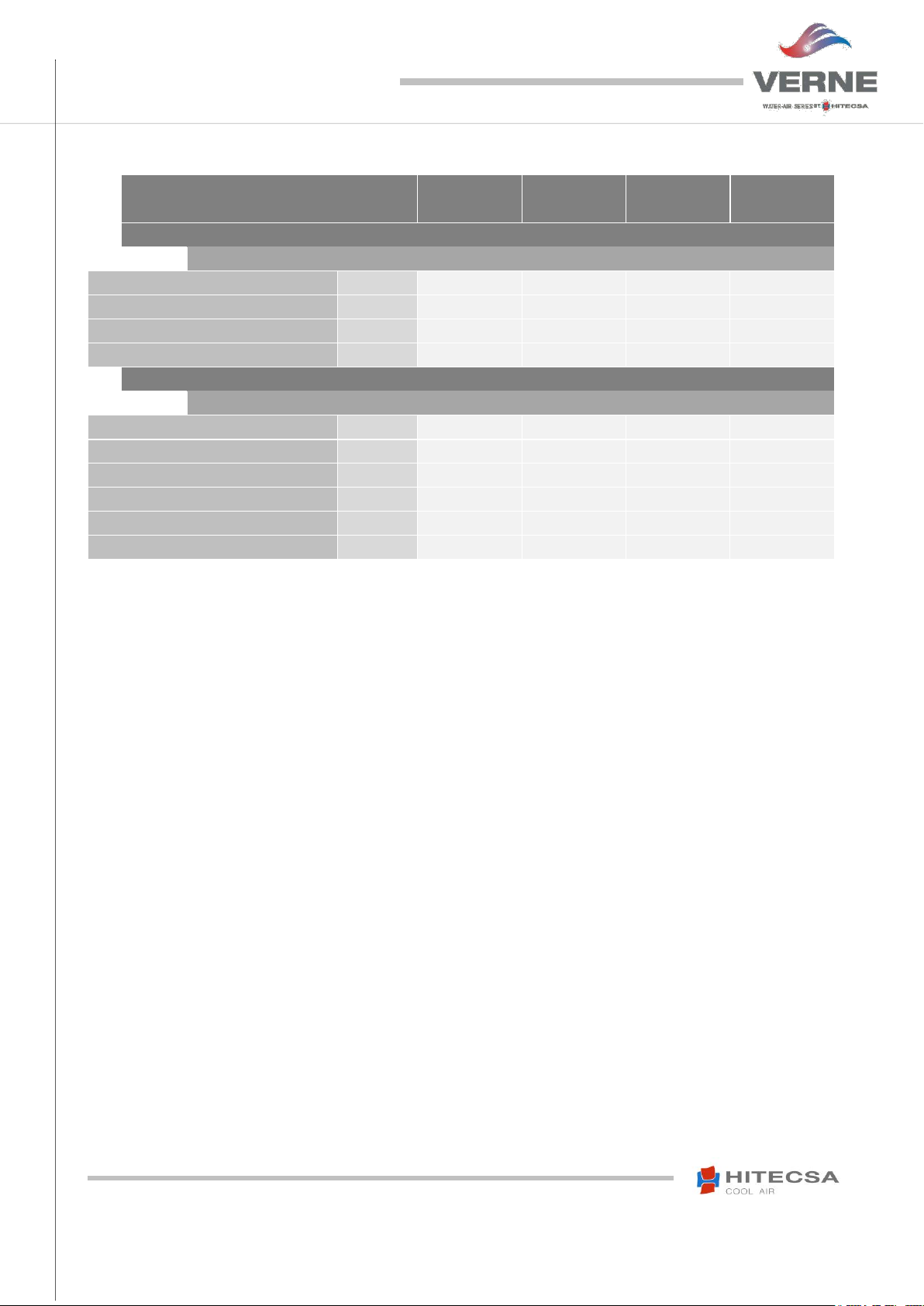

VERNE RANGE

251

351

401

501

WPHBA / WPHA

COOLING CAPACITIES

Nominal cooling capacity (1)

kW

7.42

11.3

13.08

16.35

Power Input (3)

kW

1.87

2.99

3.44

3.48

EER Coefficient

kW / kW

3.97

3.78

3.8

4.7

Energy class

A A A

A

WPHBA (Heat Pump Units)

HEATING CAPACITIES

Heating capacity (2)

kW

9.22

14.15

16.34

18.89

Heat Power Input (3)

kW

1.86

3.1

3.6

3.96

COP Coefficient

kW / kW

4.96

4.56

4.54

4.77

Water flow

m³/h

1.6

2.6

2.9

3.5

Pressure Drop

kPa

15.07

34.3

44.8

21.25

Energy class

A A A

A

TECHNICAL SPECIFICATIONS

1) Nominal Cold Conditions, calculated according to UNE-EN 14511:2013 standard, 35ºC of outdoor temperature, 12ºC of inlet water temperature

and 7ºC of outlet water temperature.

2) Nominal Heat Conditions (mean temperatures), calculated according to UNE-EN 14511:2013 standard, 7ºC dry bulb / 6ºC wet bulb of outdoor

temperature, 30ºC of inlet water temperature and 35ºC of outlet water temperature.

3) Total power input at nominal conditions. Calculated according to UNE-EN 14511:2013 regulation.

4) GWP: Global Warming Potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

10

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

VERNE RANGE

251

351

401

501

REFRIGERANT

Type

R-410A

Global Warming Potential (GWP) (4) 2088

Refrigerant load WPHA

kg

0.7

0.8

0.8

2.0

Refrigerant load WPHBA

kg

1.7

1.8

2.8

3.8

COMPRESSOR

Type Rotative

Scroll

Quantity

1

Voltage

V / ~ / Hz

230/1/50

400/3/50

230/1/50

400/3/50

400/3/50

EVAPORATOR FAN

Type Centrifugal. double aspiration (integrated motor)

Centrifugal.

transmission motor

Quantity

1

Model 7 / 7

9 / 9

10 / 10

10 / 10

Air flow

m³/h

1500

2000

2300

2800

Available Pressure

Pa

37

37

60

50

Motor power

W

147

200

245

550

Voltage

V / ~ / Hz

230/1/50

400/3/50

230/1/50

400/3/50

400/3/50

INDOOR HEAT EXCHANGER

Type

Coil with aluminium fins and copper tube

Frontal area

m²

0.252

0.252

0.252

0.45

Fin spacing

mm - (")

1.8 - 3/8

2.1 - 3/8

EXTERNAL HEAT EXCHANGER

Type

Brazed plates

Quantity

1

Water flow WPHA

m³/h

1.6

2.6

2.9

3.5

Water flow WPHBA

m³/h

1.6

2.6

2.9

3.5

Pressure Drop

kPa

15.07

34.3

44.8

21.25

Water connections (male gas thread)

(")

3/4

1 1/4

Number of plates

42

42

42

32

GENEREAL FEATURES FOR THE ELECTRICAL INSTALLATION

Voltage

V / ~ / Hz

230/1/50

400/3+N/

50

230/1/50

400/3+N/

50

400/3+N/50

Max. Power Input (Cold)

kW

2.6

5.2

5.0

6.3

Max. Current Input (Cold)

A

13.4

6.9

19.3

9.0

8,5

10,9

Max. Power Input (Heat)

kW

2.6

4.8

4.6

5.4

Max. Current Input (Heat)

A

11.3

13.4

6.9

19.3

Start up current

A

61.3

27.0

88.0

50.8

61,3

71,3

DIMENSIONS AND WEIGHT

Length

mm

1135

1135

1135

1385

Width

mm

670

670

670

940

Height

mm

530

530

530

620

Weight

kg

90

110

115

160

SOUND LEVEL

Sound pressure at 2 m

dB (A)

63

64

64

65

TECHNICAL SPECIFICATIONS

11

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

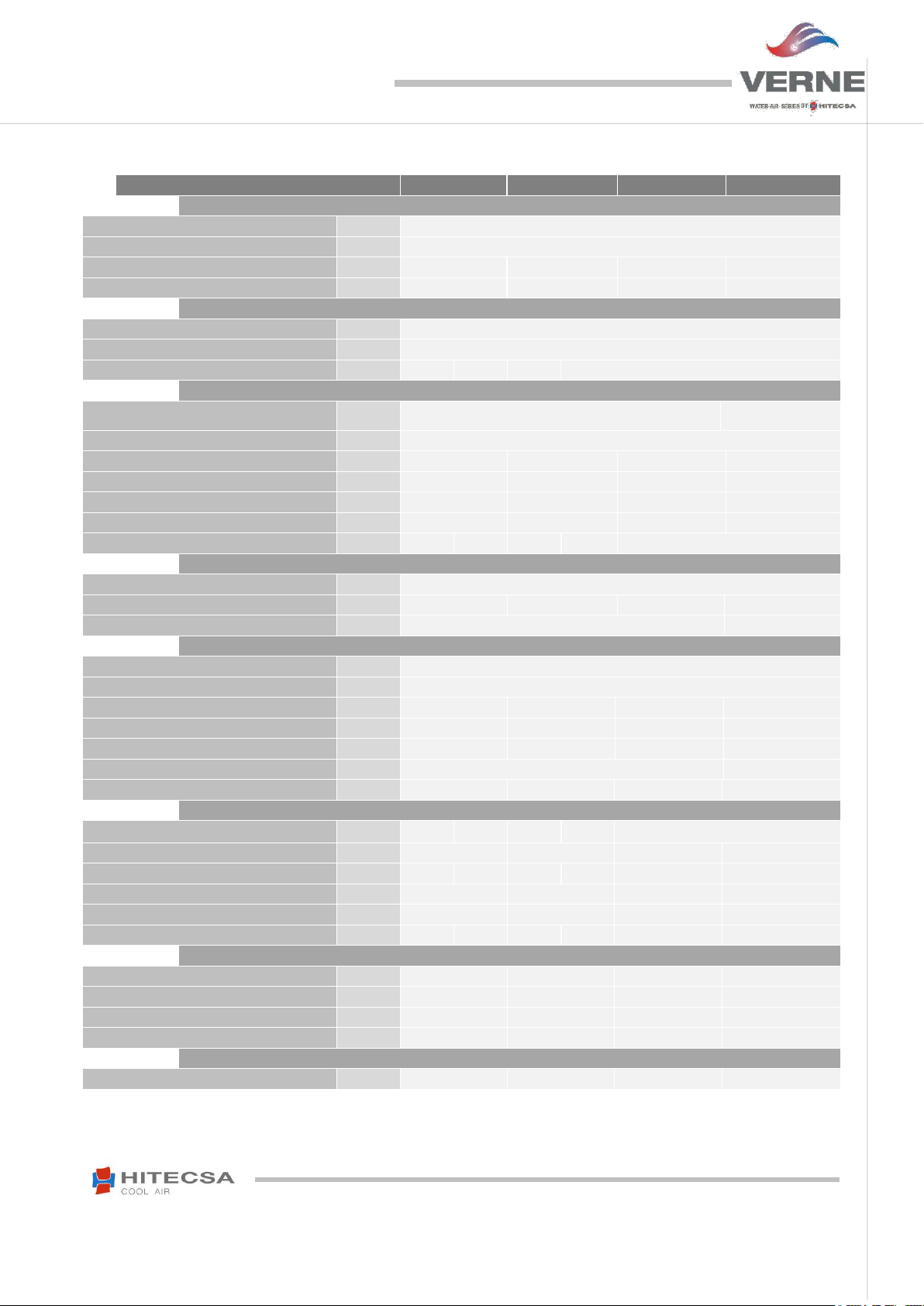

VERNE RANGE

701

751

1001

1201

WPHA

COOLING CAPACITIES

Nominal cooling capacity (1)

kW

19.77

25.18

33.9

39.96

Power Input (3)

kW

4.46

6.11

7.78

9.25

EER Coefficient

kW / kW

4.44

4.12

4.36

4.32

Energy class

A A A A

WPHBA (Heat Pump Units)

HEATING CAPACITIES

Heating capacity (2)

kW

23.11

30.6

39.82

46.41

Heat Power Input (3)

kW

4.94

7.01

8.37

10.1

COP Coefficient

kW / kW

4.68

4.37

4.76

4.6

Water flow

m³/h

4.3

5.5

7.6

8.7

Pressure Drop

kPa

30.9

49.03

37.1

49.35

Energy class

A A A A

TECHNICAL SPECIFICATIONS

1) Nominal Cold Conditions, calculated according to UNE-EN 14511:2013 standard, 35ºC of outdoor temperature, 12ºC of inlet water temperature

and 7ºC of outlet water temperature.

2) Nominal Heat Conditions (mean temperatures), calculated according to UNE-EN 14511:2013 standard, 7ºC dry bulb / 6ºC wet bulb of outdoor

temperature, 30ºC of inlet water temperature and 35ºC of outlet water temperature.

3) Total power input at nominal conditions. Calculated according to UNE-EN 14511:2013 regulation.

4) GWP: Global Warming Potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

12

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

VERNE RANGE

701

751

1001

1201

REFRIGERANT

Type

R-410A

Global Warming Potential (GWP) (4) 2088

Refrigerant load WPHA

kg

1.6

1.7

2.4

3.0

Refrigerant load WPHBA

kg 4 4.2

6.1

6.3

COMPRESSOR

Type

Scroll

Quantity

1

Voltage

V / ~ / Hz

400/3/50

EVAPORATOR FAN

Type

Centrifugal. transmission motor

Quantity

1

Model 10 / 10

12 / 9

12 / 12

15 / 15

Air flow

m³/h

3400

4300

6200

7000

Available Pressure

Pa

50

62

75

75

Motor power

W

550

750

1500

1100

Voltage

V / ~ / Hz

400/3/50

INDOOR HEAT EXCHANGER

Type

Coil with aluminium fins and copper tubes

Frontal area

m²

0.45

0.45

0.84

0.84

Fin spacing

mm - (")

2.1 - 3/8

EXTERNAL HEAT EXCHANGER

Type

Brazed plates

Quantity

1

Water flow WPHA

m³/h

4.3

5.5

7.5

8.7

Water flow WPHBA

m³/h

4.3

5.5

7.6

8.7

Pressure Drop

kPa

30.9

49.03

37.1

49.35

Water connections (male gas thread)

(")

1 1/4

Number of plates

32

32

52

52

GENEREAL FEATURES FOR THE ELECTRICAL INSTALLATION

Voltage

V / ~ / Hz

400 / 3+N / 50

Max. Power Input (Cold)

kW

8.9

10.2

13.4

14.8

Max. Current Input (Cold)

A

15.4

17.5

23.0

25.3

Max. Power Input (Heat)

kW

7.7

8.5

12.0

13.0

Max. Current Input (Heat)

A

15.4

17.5

23.0

25.3

Start up current

A

88.3

126.6

128.5

149.6

DIMENSIONS AND WEIGHT

Length

mm

1385

1385

1930

1930

Width

mm

940

940

1040

1040

Height

mm

620

620

690

690

Weight

kg

160

180

230

250

SOUND LEVEL

Sound pressure at 2 m

dB (A)

68

68

69

70

TECHNICAL SPECIFICATIONS

(4) GWP: Global Warming Potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

13

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

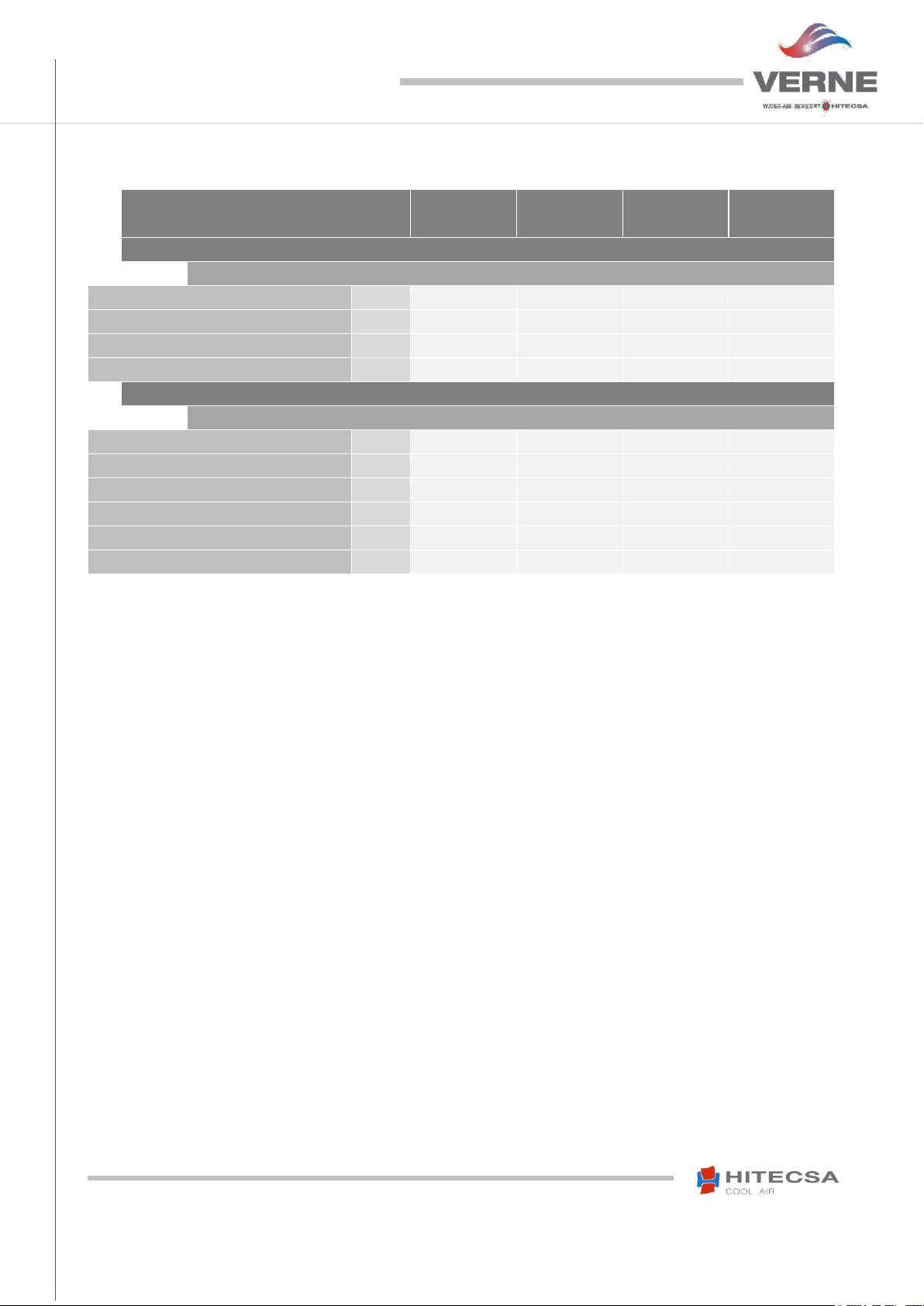

WPHBA EC Fan

91

121

141

171

201

251

351

401

501

701

751

1001

1201

Type

RADIAL with EC motor (Plug-Fan type)

Quantity / Size

- / mm

1/190

1/190

1/190

1/250

1/250

1/310

1/310

1/310

1/400

1/400

1/400

1/450

1/450

Nominal Electrical Specifications (for a fan)

Power supply

V/~/Hz

230V / 1~ / 50Hz

400V / 3~ / 50Hz

Motor nominal power

kW

0.2

0.2

0.2

0.5

0.5

1.4

2.5

2.5

2.4

2.4

2.4

2.0

2.0

Max. Current

(400V)

A

1.9

1.9

1.9

2.2

2.2

6.0

3.8

3.8

3.7

3.7

3.7

3.2

3.2

Max. Speed

r.p.m.

4240

4240

4240

3080

3080

2920

3640

3640

2400

2400

2400

1880

1880

Nominal Operation Conditions

Nominal air flow

m3/h

500

600

700

900

1100

1500

2000

2300

2800

3400

4300

6200

7000

Available Pressure

Pa

25

25

25

25

25

25

37

50

50

62

62

75

75

Total power input

kW

0.04

0.059

0.084

0.057

0.084

0.113

0.226

0.309

0.2

0.307

0.513

0.827

1.107

Speed

rpm

2500

2924

3365

1368

1640

1190

1558

1777

1044

1242

1509

1476

1643

Total sound power

(Lw)

dBA

70

74

77

63

67

65

73

76

67

71

77

81

84

Operating Limits Values

Max. available

pressure

Pa

515

410

300

760

700

1050

1630

1580

1150

1100

975

580

400

Max. sound power

dBA

77

77

78

82

80

89

94

93

90

88

87

84

86

Sound power at 400Pa

dBA

75

76 - 73

74

75

78

80

74

76

79

82

86

TECHNICAL SPECIFICATIONS

OPCIONAL MOTOR EC

14

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

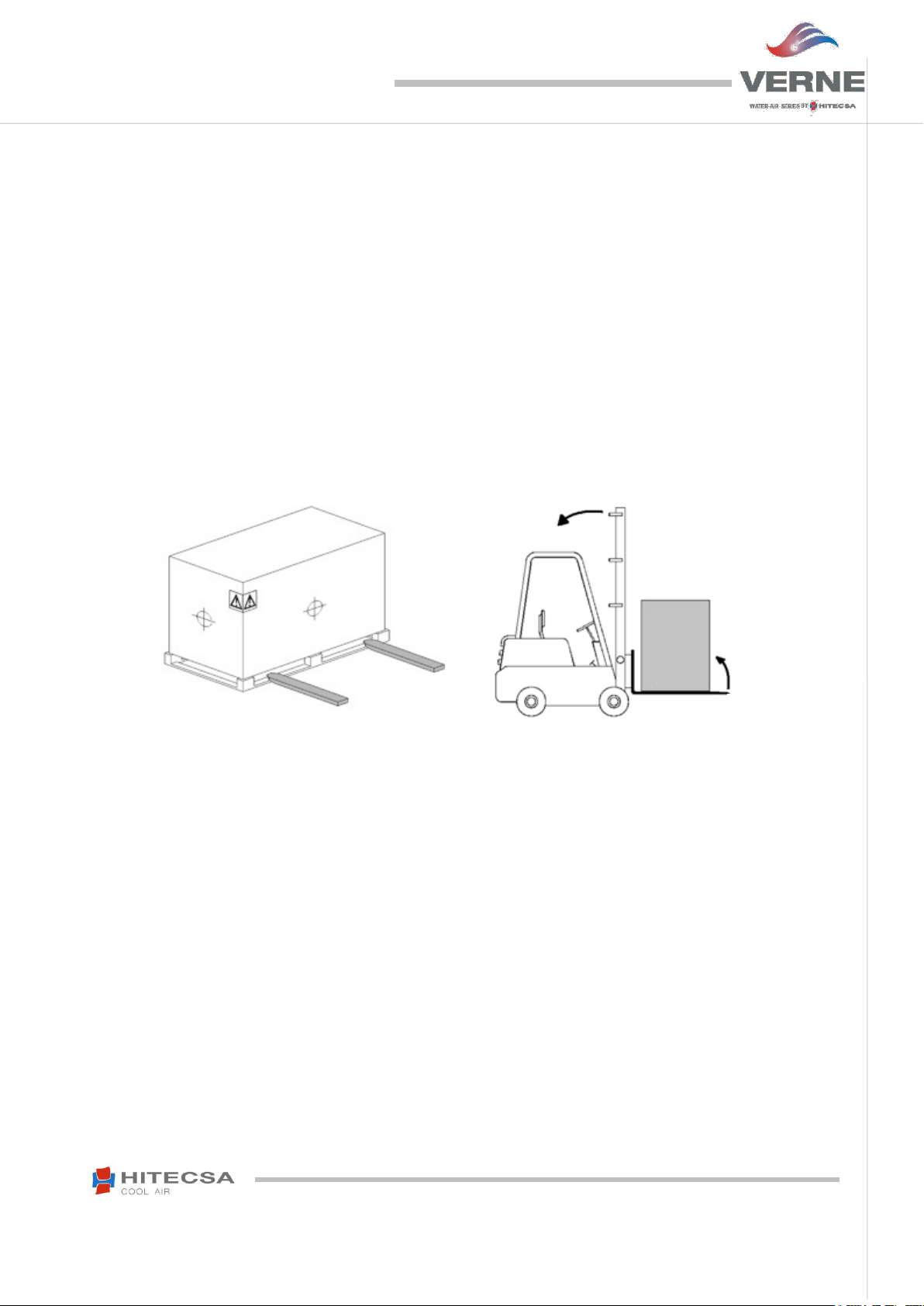

Fig.2

Fig.1

TRANSPORT & RECEPTION

INSPECTION AT RECEPTION

It is advisable to examine the equipment carefully at the time of its reception.

Check that the equipment has not been damaged during transport and it has been supplied complete with all

parts specified in the order and/or with the options specified in the order. If this is not the case, contact the

transport company immediately. (First 48h).

Verify the correct voltage of the nameplate and make sure it is in accordance with local power supply.

In case of any flaw or anomaly detected, please contact HITECSA.

RIGGING

Before moving the unit, make sure that all panels are well fixed.

Raise and set down the equipment carefully.

Do not tilt the unit more than 15 degrees during transportation. (Fig. 2).

Always transport the unit in its original packaging to the place of installation.

All units come with a particular rigging diagram of that model, similar to the one shown below. Be sure to hoist

the machine through the points indicated in the diagram.

Make sure that the unit is balanced, stable and without any deformations when it is lifted.

STORAGE

If the equipment is going to be stored before the installation, please follow the instructions below in order to avoid damages,

corrosion or deterioration:

Move it carefully.

Do not place the machine in places exposed to ambient temperature above 50ºC and preferably keep the unit away

from direct sunlight.

Avoid placing the unit with plastic wrapping protection under the sun, as the pressure of the circuits could assume

values that could lead to the intervention of the safety valves.

In addition, when cooling, water condensation occurs inside the machine and the plastic wrap.

Avoid placing other objects on top of the unit (unless it is done within the limits of the overlap planes indicated on the

packaging, etc. Follow these indications).

Avoid prolonged storage, before installation, water inlet, dust and objects in general due to invasion or biological,

meteorological and/or human inclemencies.

Minimum storage temperature is: 5ºC.

Maximum relative humidity: 90%.

15

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

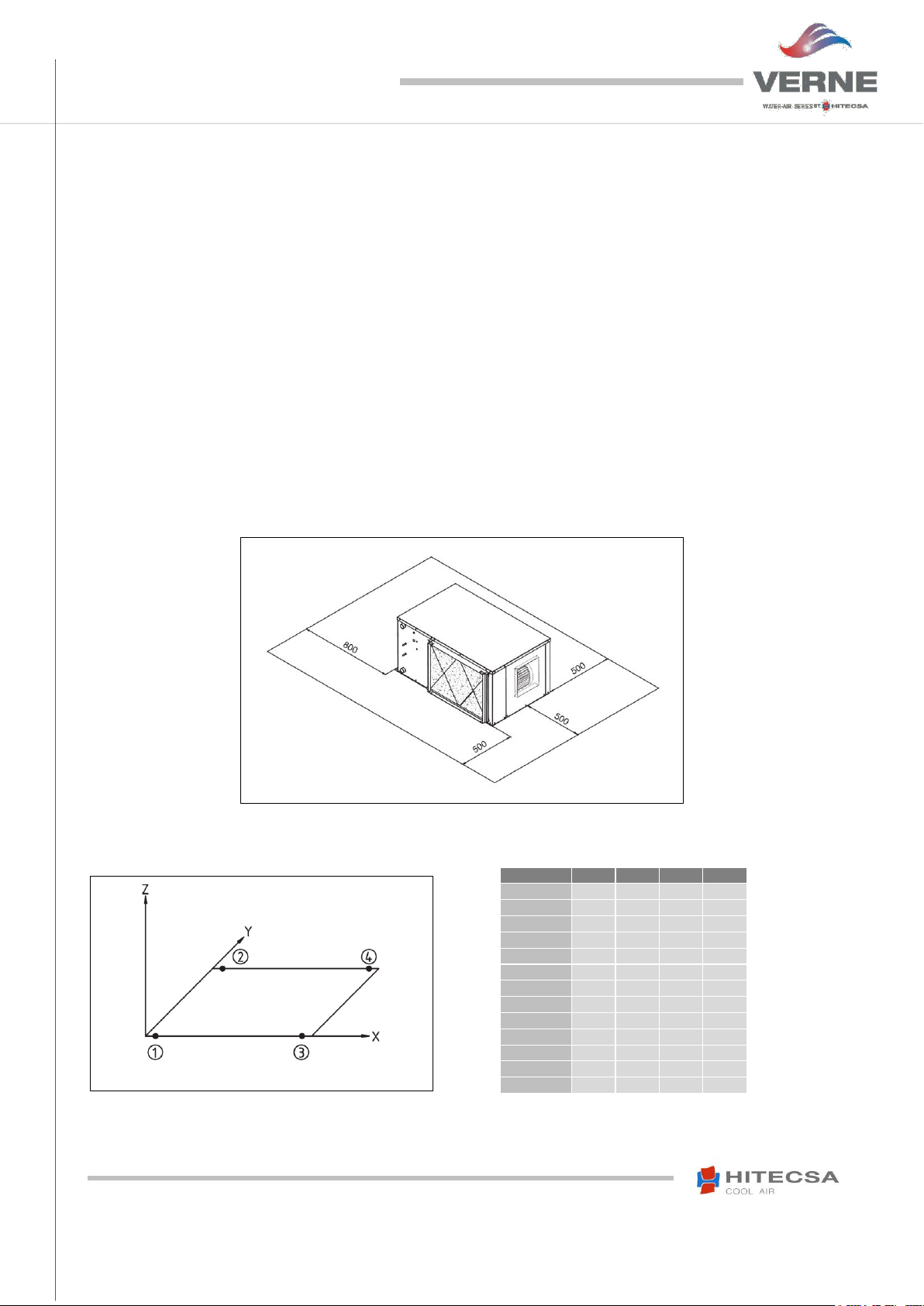

MODELS

1 2 3

4

091

13

13

16

18

121

14

14

16

18

141

14

15

17

19

171

16

17

20

22

201

16

19

20

22

251

21

22

22

25

351

24

26

29

31

401

26

27

30

32

501

38

38

41

43

701

38

38

41

43

751

43

44

46

47

1001

55

56

59

60

1201

61

61

63

65

(3 – 4): Electrical Panel side

INSTALLATION

INSTALLATION LOCATION

Consult and respect the rules and local regulations which regulate the installation of air conditioning systems.

Choose a site without dust and debris.

Respect the appropriate service area for the equipment which will be installed.

Verify that the ground or structure on which the unit will be installed is able to support its weight in operation.

Fit shock absorbers throughout the installation to prevent the transmission of noise and vibration.

Check that the direction of the sound level is not going to disturb anyone.

UNIT SETTLEMENT

Be sure that the unit is correctly levelled.

The bed frame should have the area and the strength to support the weight of the unit.

Be sure that after settlement the unit drain is working properly.

SERVICE AREA (mm)

Make sure to respect the following measurements for the correct operating of the unit.

WEIGHT DISTRIBUTION (kg)

16

IOM_WPHBA-WPHA_091a1201_207954_180610_EN

COMPACT HORIZONTAL PACKAGED WATER-TO-AIR UNITS

WPHBA / WPHA

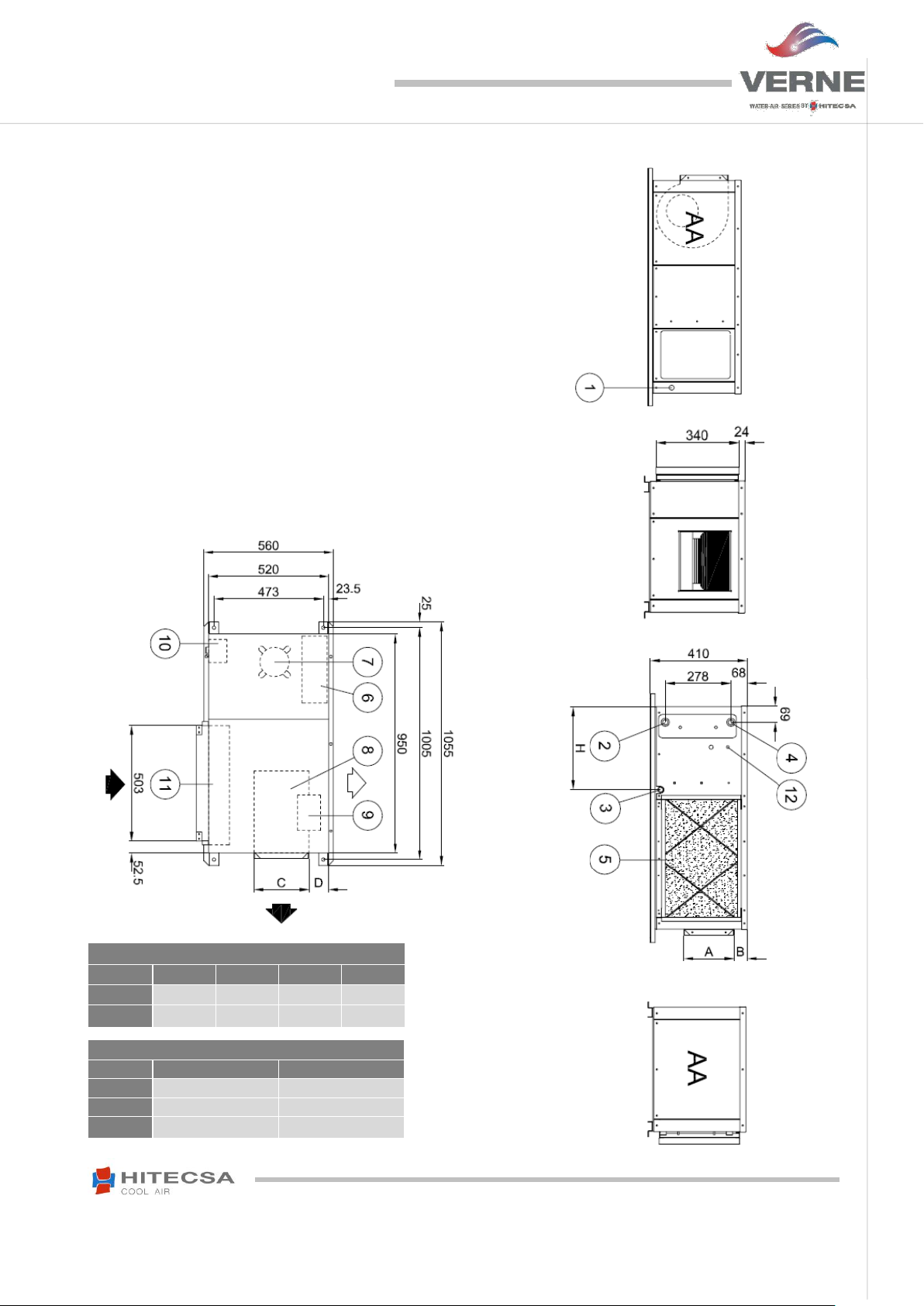

Legend

8 Evaporator turbine

DIMENSIONS (mm)

MODEL A B C D

091-121

131

108

232

86

141

213

56

238

86

WEIGHT (kg)

MODEL

NET WEIGHT

PACKAGED WEIGHT

091

60

75

121

62

77

141

65

80

INSTALLATION

DIMENSIONS AND WEIGHT

Standard Fan

Models 091 – 141

1 Electrical connections input

2 Water inlet

3 External drainage 3/4’’ male

4 Water outlet

5 Air filter

6 Electrical panel

7 Compressor

9 Turbine engine

10 External coil

11 Internal coil

12 Pressure valve connection (optional)

AA Panel access

17

Loading...

Loading...