Hitecsa EKWXA 7002.4, EKWXA 8002.4, EKWXBA 7002.4, EKWXA 9002.4, EKWXBA 8002.4 Installation, Operation & Maintenance Manual

...Page 1

Installation, Operation

& Maintena

nce Manual

05.17 207646 Rev.103

EKWXA │ EKWXBA

AIR-COOLED WATER CHILLERS ─ AXIAL FANS

Models: 7002.4 │ 8002.4 │ 9002.4

Cooling Capacities: from 178,3 kW to 213,6 kW

Heating Capacities: from 194,9 kW to 244,2 kW

ONLY COOLING

HEATING PUMP

Page 2

Thank you for trusting the Hitecsa Products. Our company has been offering the market an extended range of specialized units for

air conditioning and cooling installations for over 35 years. Our approach is based on efficiency, adaptability, usability and practical

solutions. This has been the hallmark of our product catalogue.

The versatility of our factory allows us to contribute solutions, almost tailored to each project’s specifications, in search of a solution

to every problem that arises in design and implementation of air conditioning installations.

From all of us at Hiplus Aire Acondicionado, once again, thank you very much.

Page 3

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

EKWXA – EKWXBA – BIG KRONO II

INDEX

INTRODUCTION ................................................................................................................ 5

CONTENTS ........................................................................................................................... 5

REGULATIONS AND CERTIFICATIONS ................................................................................... 6

SAFETY PRECAUTIONS ...................................................................................................... 6

DESCRIPTION OF THE UNIT ............................................................................................... 7

TECHNICAL DATA ............................................................................................................. 8

RECEPTION ..................................................................................................................... 10

INSPECTION ....................................................................................................................... 10

RIGGING ............................................................................................................................ 10

STORAGE ........................................................................................................................... 10

INSTALLATION ................................................................................................................ 11

DIMENSIONS...................................................................................................................... 11

Model 7002.4 .................................................................................................................. 11

Models 8002.4 │ 9002.4 ................................................................................................. 12

WEIGHT DISTRIBUTION ..................................................................................................... 13

Model 7002.4 .................................................................................................................. 13

Models 8002.4 │ 9002.4 ................................................................................................. 13

INSTALLATION LOCATION .................................................................................................. 14

UNIT SETTLEMENT ............................................................................................................. 14

WATER DRAIN .................................................................................................................... 14

ELECTRICAL CONNECTIONS ............................................................................................... 14

SERVICE AREA .................................................................................................................... 15

Model 7002.4 .................................................................................................................. 15

Models 8002.4 │ 9002.4 ................................................................................................. 15

OPERATION .................................................................................................................... 16

OPERATING LIMITS ............................................................................................................ 16

Modo de Refrigeración 7002.4 │ 5002.4 │ 9002.4.......................................................... 16

Bomba de Calor 7002.4 │ 5002.4 │ 9002.4 ..................................................................... 16

BEFORE START-UP ............................................................................................................. 17

START UP ........................................................................................................................... 17

THERMOSTAT AND CONTROL......................................................................................... 17

MCX-15 CONTROL .............................................................................................................. 17

Main Functions of the Control System ............................................................................ 17

MCX-15 START UP .............................................................................................................. 18

Start Menu ...................................................................................................................... 18

Main Menu ..................................................................................................................... 18

Password Level ............................................................................................................... 19

Inputs/Outputs ............................................................................................................... 19

3

Page 4

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

Model 7002.4 .................................................................................................................. 20

Models 8002.4 │ 9002.4 ................................................................................................. 21

System Parameters ......................................................................................................... 22

Regulation Parameters ................................................................................................... 23

Compressors ................................................................................................................... 23

Alarms ............................................................................................................................. 24

HYDRONIC KIT ................................................................................................................ 26

TECHNICAL DATA ............................................................................................................... 26

OPERATING LIMITS ............................................................................................................ 27

MAINTENANCE ............................................................................................................... 27

CONSERVATION AND CLEANING ....................................................................................... 27

LUBRICANT ........................................................................................................................ 27

REFRIGERANT CHARGE ...................................................................................................... 28

OPTIONAL ...................................................................................................................... 28

ACCESSORIES / OPTIONAL ................................................................................................. 28

APPENDIX: SAFETY DATA R410A .................................................................................... 29

4

Page 5

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

This manual and the instruction documents of refrigeration lines, wiring diagrams and any other attached documents,

have been written to allow a correct installation, set up and maintenance of the unit. Therefore it is essential to read the

instructions with due attention. Verify all the necessary information for the correct installation of the system is included

in the manuals supplied with this unit and / or the rest of the indoor units, accessories, etc. Otherwise, the manufacturer

declines any responsibility for any damage to persons or things, as a result of improper use of the unit and/or failure to

observe these instructions.

Check that electrical network features are in accordance to data shown in the data nameplate of the unit.

The packaging material (plastic bags, insulating materials, nails, etc.) is a potential source of danger and should be kept

out of the reach of children and properly recycled according to local safety regulations. This product should not be mixed

with household waste at the end of its life. Due to the refrigerant, oil and other components contained in this product, it

must be dismantled by professional installers in accordance with current regulations.

Carry out periodic inspections to detect possible damaged or broken pieces. If they are not repaired it could result in

damage to people or stuff. Before executing any maintenance operation, cut off the unit power supply.

All operations must be carried out in accordance with local safety regulations.

Reparations should be always realized for trained personal authorized by the manufacturer using original spares. Failure

to comply with these warnings could affect the safety features of the unit.

INTRODUCTION

CONTENTS

Purpose of the Manual

Preservation Manual

This manual and the electric diagram of the unit must be retained and remain available to the operator for any further consultation.

Updating the Data

The continuous improvement in design and performance to which we are committed gives us the right to modify the specifications of our

products without prior notice.

Electrical Network

Local Safety Regulations

Observe and analyze all possible causes of accidents that may arise in the place or places of installation of the units, check means and

tools to use, etc. It is not possible to anticipate each and every one of the potential circumstances of danger in this manual. Respect the

local security standards during installation.

Principles of Security on Installation

The unit is designed and built in a way that does not pose a risk to the health and safety of people. Appropriate project solutions have

been adopted to eliminate the possible causes of risk in the installation.

Packaging and Replacement of Equipment

Use

The unit will be used only for the reason has been conceived. Any other use does not imply any kind of compromise or link for the

manufacturer.

Incorrect Operation

In case of breakdowns or operation faults, turn off unit.

Periodic Inspections and Maintenance

Repairs

Modifications

All manufacturer responsibility is declined when the warranty has been expired in case of electrical and/or mechanical modifications.

Alterations in general not expressly allowed and not respecting what is instructed here, they cause the warranty expiration.

Refrigerant

This product is hermetically sealed and contains R-410A which is a HFC fluorinated greenhouse gas.

5

Page 6

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

DANGER

ATTENTION!

WARNING!

WARNING!

INTRODUCTION

REGULATIONS AND CERTIFICATIONS

ISO 9001:2008 CERTIFICATION: HILPUS AIRE ACONDICIONADO S.L., trying always to find the customer satisfaction, has obtained

the ISO 9001:2008 Quality System referred to its production activity. This will results in a continuous determination to improve quality and

reliability of all our products; commercial activities, design, raw materials, production and after-sales service, are the means to reach our

goal.

CE MARKING: Our machines have got the CE mark, in conformity with the essential requirements of the applicable EC

directives and their last modifications as well as with the national legislation of each country.

CERTIFICACION EUROVENT: HITECSA participates in the EUROVENT Certification program. Check certified products on the web.

SAFETY PRECAUTIONS

Before starting installation, service or maintenance, turn off the main power switch in order to avoid

electrical shock that may cause personal damages.

To open the electrical panel and access the inside of the machine it is MANDATORY to disconnect the power supply hose from the

machine, it MUST BE FREE OF TENSION for this operation.

Do not touch or adjust the safety elements inside any unit of the system. In the repairs use only original spare parts and install them

properly in the same position where old parts were placed.

Installation and maintenance of air conditioning equipment can be dangerous because the system is under pressure, because some

of its elements have high temperatures and include electrical components.

Do not install the unit in explosive atmosphere.

Only qualified and trained service staff should install, commission and carry out maintenance works. Unqualified staff should only

carry out basic tasks such as cleaning and replacement of filters, etc.

Prevent access to children so they can not play with the appliances.

In every visit, all precautions should be taken into account: those recommended in the Installation, operation and maintenance

instructions, as well as the ones indicated in labels of the unit. Do not forget to strictly follow any other safety codes.

NO objects should be introduced into the air inlets or outlets that can be drawn into the fan, people, etc.

Use safety glasses, work gloves and any other safety accessory necessary.

For brazing operations use a quenching cloth and have at close distance a fire extinguisher.

This product contains fluorinated greenhouse gases, its leakage can cause displacement of air and cause insufficient oxygen to

breathe.

Must follow all safety recommendations.

6

Before starting the equipment, make sure that the water tank is completely full and that the installation

SECURITY OF THE OPTIONAL HYDRONIC KIT WITH ELECTRIC HEATERS.

is perfectly drained of air.

Page 7

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

DESCRIPTION OF THE UNIT

The EKWXA / EKWXBA units are compact reversible WATER / AIR units for the production of hot / cold water. They are designed for

outdoor installation. Supplied with R-410A refrigerant charge, ready for installation.

These units are manufactured under a strict quality control throughout their process and once finished are tested in the factory, verifying

the correct operation of all its components.

The unit is composed by:

Hermetic compressor, alternative, with wide operating limits. It incorporates thermal protection of the windings (without requiring

additional protection), the oil load for its perfect lubrication and internal damping system. The compressor is mounted on the chassis

with shock absorbers and is acoustically insulated. All this guarantees a silent operation and without vibration.

External coils built with copper tube without welds and expanded in aluminum fins. Incorporate distributor with neck and calibrated

orifice (nozzle) to improve distribution of the gas in Cold mode.

Coolant-water exchanger made from stainless steel plates (AISI 316) welded with bronze base. It is perfectly insulated with insulating

heat material to prevent the exchange of heat with the outside. It has built-in electrical heaters as an anti-ice protection to avoid the

risks of breaking it by freezing the water in case of lack of flow.

Fan motor mounted with a square base and circular inlet embouchure suitable for the aerodynamic performance of the flow driven

by the fan itself. Ready for outdoor installation, totally closed, with permanent lubrication. It consists of aluminum blades designed

to obtain a low sound level, inserted into the outer rotor of a high efficiency motor, with IP-54 protection and class F winding

insulation. It has internal thermal probes incorporated for its protection, as well as external security grid.

Thermostatic expansion valve with MOP at the plate exchanger inlet for cooling mode operation. The expansion in the external coil,

when necessary (operation in heating mode), is realized through a hole.

Safety pressure switch connected to the compressor output (maximum pressure point) of manual reset. Its cut is calibrated at a

pressure of 42 bars.

Bidirectional dehydrator filter type mounted on the liquid line. It consists of a solid desiccant core that minimizes vibration and friction

during the operation of the equipment besides absorbing excess moisture and filter any impurities.

Tank to contain the variations of the refrigerant charge required by the machine when changing its operation between Cool/Heat.

Check valves only on Heat Pump units to bypass the expansion system of the secondary exchanger block. Cold mode performs the

bypass to battery, in Heat mode, it is done to the expansion valve.

The sheet metal structure of these equipments is resistant to the weather and is formed by galvanized steel sheet which is applied

an oven painting process by polymerization of powder paint which provides excellent overall coating and especially in corners and

edges. The self-supporting base is constructed with highly rigid steel. The rest of the structure is galvanized steel. The design is

done for an easy maintenance. The finished set has RAL 1013 color.

7

Page 8

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

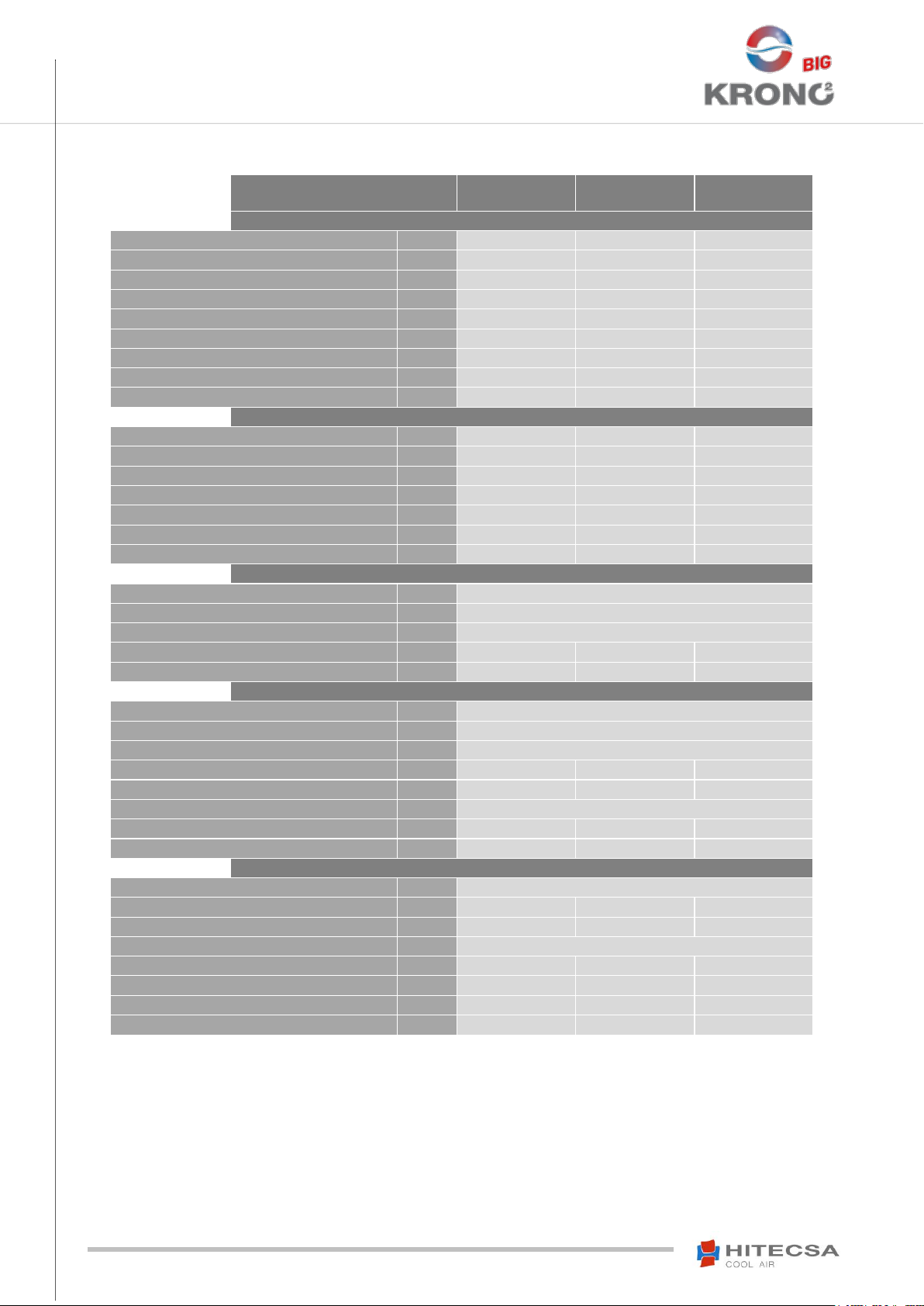

EKWXA/EKWXBA

7002.4

8002.4

9002.4

COOLING MODE

(1)

Cooling capacity

kW

178,3

200,1

213,6

Total absorbed capacity

(3)

kW

61,3

73,8

81,8

Total rated current

A

107,7

123,6

138,2

Compressor absorbed power

kW

54,2

65

72,8

Compressor rated current

A

94,3

111,8

125,2

Evaporator water flow

m³/h

33

35,5

37

Evaporator pressure drop

kPa

63

70,8

77,5

EER

2,91

2,71

2,61

ESEER

- -

-

HEATING MODE

(2)

Cooling capacity

kW

194,9

224,3

244,2

Total absorbed capacity

(3)

kW

60,7

74,5

86,9

Total rated current

A

112,1

129,1

142,4

Compressor absorbed power

kW

56,7

65,8

73,2

Compressor rated current

A

98,1

112,1

125,6

COP

3,21

3,01

2,81

SCOP

- -

-

REFRIGERANT

Number of circuits

2

Type

R-410A

Global warming potential (GWP)

(4)

2088

Refrigerant charge cooling only (no optional)

Kg

2 x 23

2 x 22

2 x 23

Refrigerant charge heating pump (no optional)

Kg

2 x 23

2 x 23.5

2 x 24

COMPRESSOR

Type

SCROLL

Number of compressors

4

Number of power stages

4

Maximum current for operating circuit

A

71

80

89

Locked rotor current

A

249

264

309

Oil type

POE 160 SZ

Oil volume

L

2 x (6,7 + 6,7)

2 x (6,7 + 6,7)

2 x (6,7 + 6,7)

Crankcase strength

W

2 x (75 + 75)

2 x (75 + 75)

2 x (75 + 75)

FANS

Type

AXIAL

Number of total fans

4 6

6

Rated air flow

m3/ h

91690

105398

105398

Available static pressure

Pa

0

Diameter

mm

800

710

710

Absorbed power (by fan)

kW

2,06 / 1,33

1,52/ 0,97

1,52/ 0,97

Rated current (by fan)

A

3,8 3 3

Speed

r.p.m.

910

914

914

TECHNICAL DATA

Note:

(1) COOLING MODE: Outdoor temperatura 35ºC, Water inlet temperature 12ºC, Water outlet temperature 7ºC.

(2) HEATING MODE: Outdoor temperature 7ºC D.B. / 6ºC W.B., Inlet temperature 40ºC, Water outlet temperature 45ºC.

(3) TOTAL ABSORBED CAPACITY: Absorbed power by the equipment in Cold or Heat conditions indicated above according to UNE-EN-14511-2: 2013.

(4) GWP: Global warming potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

(5) Measurement conditions on the free field, directivity 2 and 1,5 meters above the floor.

8

Page 9

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

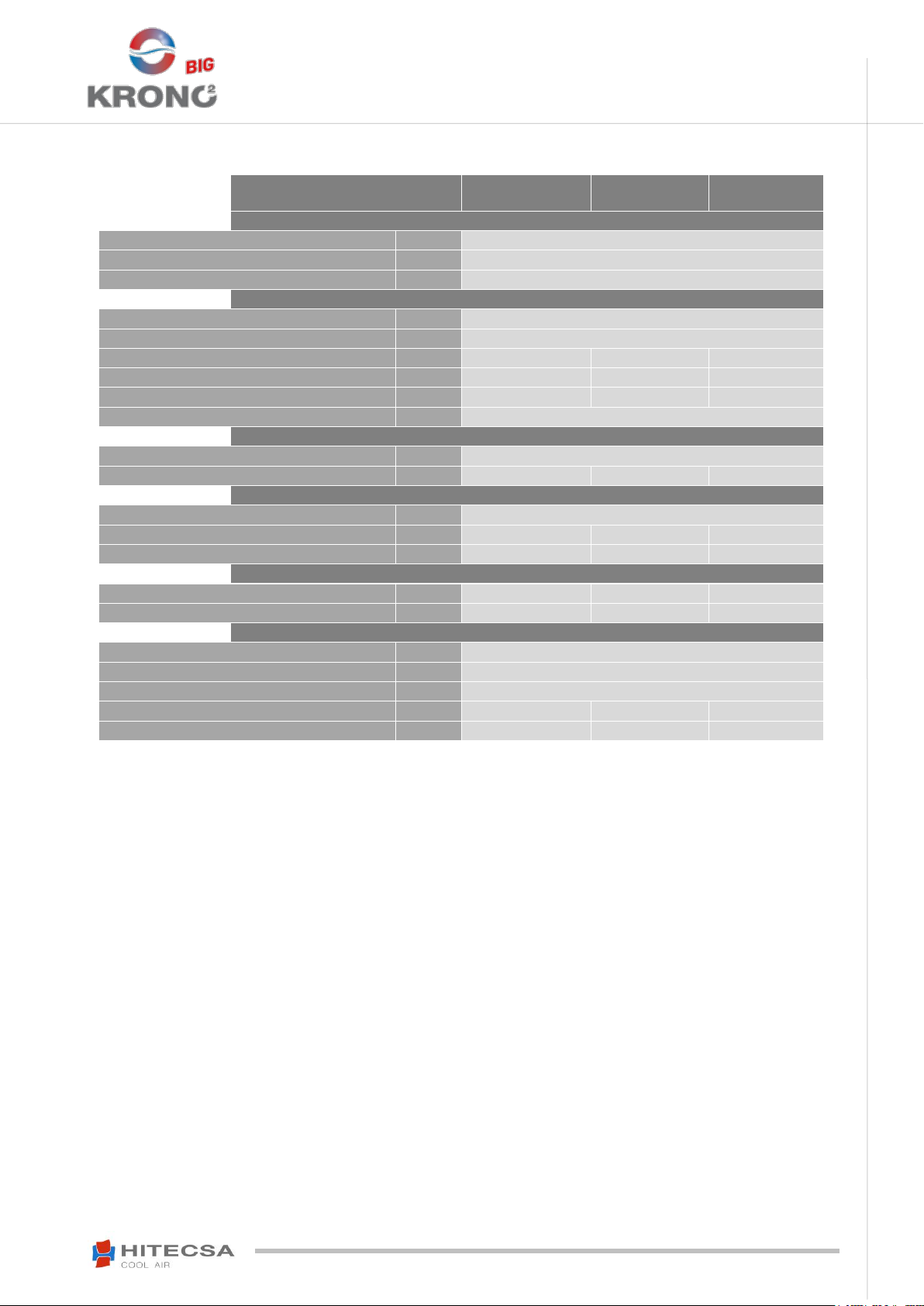

EKWXA/EKWXBA

7002.4

8002.4

9002.4

OUTDOOR HEAT EXCHANGER

Type

Aluminum fin coil and copper tubing

Quantity

2

Front surface of the exchanger

m2

5,18 + 5,18

INDOOR HEAT EXCHANGER

Type

PLATES (Water / Refrigerant)

Quantity

2

Evaporator water flow

m3/ h

33

35,5

37

Evaporator pressure drop

KPa

63

70,8

77,5

Water volume

L

8,4

8,4

8,4

Anti-ice resistance

W

100

WATER CONNECTIONS

Type

SLOTTED – Victaulic type

External diameter

(‘’)

3 ''

3 ''

3 ''

ELECTRIC SPECIFICATIONS

Supply voltage

V / ~F / Hz

400V - 3+N 50Hz

Maximum intensity

A

156,2

178,2

196,6

Starting current (AC)

A

334,7

362,1

416,3

SOUND LEVEL

Sound power

dB(A)

92,8

94,7

94,8

Sound pressure (5m)

(5)

dB(A)

71

72,9

73

WEIGHT AND DIMENSIONS

Large

mm

3200

Width

mm

2250

High

mm

2150

Net weight of heat pump units - EKWXBA

kg

1720

1753

1759

Net weight of cooling only units - EKWXA

kg

1686

1719

1725

TECHNICAL DATA

Note:

(1) COOLING MODE: Outdoor temperatura 35ºC, Water inlet temperature 12ºC, Water outlet temperature 7ºC.

(2) HEATING MODE: Outdoor temperature 7ºC D.B. / 6ºC W.B., Inlet temperature 40ºC, Water outlet temperature 45ºC.

(3) TOTAL ABSORBED CAPACITY: Absorbed power by the equipment in Cold or Heat conditions indicated above according to UNE-EN-14511-2: 2013.

(4) GWP: Global warming potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming potential.

(5) Measurement conditions on the free field, directivity 2 and 1,5 meters above the floor.

9

Page 10

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

RECEPTION

INSPECTION

At the time of equipment delivery it is advisable to examine it carefully.

Check that the equipment has not been damaged during transport and has been supplied complete with all parts specified in the

order and/or with the optionals specified in the order. If this is not the case contact the transport company immediately. (First 48h).

Verify the correct voltage of the nameplate and make sure it’s in accordance with local power supply.

In case of any flaw or anomaly detected, please contact HITECSA.

RIGGING

Before moving the unit, make sure that all panels are well fixed.

Raise and set down the equipment carefully.

Do not tilt the unit more than 15 degrees during transportation.

When lifting the unit, make sure that it’s balanced and stable; bear in mind that the heaviest part is where the compressor is installed.

Always transport the unit in its original packaging to the place of installation.

Lifting through crane.

STORAGE

If the equipment is going to be stored please follow the instructions below in order to avoid damages, corrosion or deterioration:

Do not place the machine in places exposed to ambient temperature above 50ºC and preferably keep the unit away from direct

sunlight.

Avoid prolonged storage, before installation, water inlet, dust and objects in general due to invasion or biological, meteorological

and/or human inclemencies.

Minimum storage temperature is 5ºC.

Maximum Relative Humidity: 90%.

It is also recommended:

10

Move it carefully.

Avoid placing other objects on top of the unit (unless it is done within the limits of the overlap planes indicated on the packaging).

Avoid placing the unit with heat-shrink protection under the sun, as the pressure of the circuits could assume values that could lead

to the intervention of the safety valves.

Page 11

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

1. Water inler Ø 3”

INSTALLATION

DIMENSIONS

Model 7002.4

2. Water outlet Ø 3”

3. Electrical panel

4. Main switch

5. Electrical connection input

6. Optional electrical connection input

7. Water inlet with Hydronic Kit Ø 3”

11

Page 12

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

1. Water inler Ø 3”

INSTALLATION

DIMENSIONS

Models 8002.4 │ 9002.4

2. Water outlet Ø 3”

3. Electrical panel

4. Main switch

5. Electrical connection input

6. Optional electrical connection input

7. Water inlet with Hydronic Kit Ø 3”

12

Page 13

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

WEIGHT DISTRIBUTION (kg)

R1

R2

R3

R4

R5

R6

R7

R8

TOTAL

7002.4

Heating

pump

233

246

194

181

185

187

248

246

1720

Cooling

only

234

247

181

173

176

184

244

247

1686

WEIGHT DISTRIBUTION (kg)

R1

R2

R3

R4

R5

R6

R7

R8

TOTAL

8002.4

Heating

pump

229

241

206

185

189

195

249

259

1753

Cooling

only

228

241

195

178

181

192

244

259

1719

9002.4

Heating

pump

229

242

206

185

189

196

250

262

1759

Cooling

only

229

242

195

178

181

193

246

262

1725

INSTALLATION

WEIGHT DISTRIBUTION

Model 7002.4

Models 8002.4 │ 9002.4

13

Page 14

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

WARNING!

Recommended siphon measures

INSTALLATION

INSTALLATION LOCATION

Consult and respect the rules and local regulations which regulate the installation of air conditioning systems.

Choose a site without dust and debris.

Respect the appropriate service area for the equipment wich will be installed.

Verify that the ground or structure on which the unit will be installed is able to support its weight in operation.

Fit shock absorbers throughout the installation to prevent the transmission of noise and vibration.

Check that the direction of the sound level is not going to disturb anyone.

UNIT SETTLEMENT

Be sure unit is correctly leveled.

The bed frame should have sufficient strength to support unit weight.

Be sure that after settlement the unit drain is working properly.

WATER DRAIN

The indoor drain (of condensate water) has connection 3/4’’ MPT.

Condensate evacuation line diameter should be equal or larger than unit drain

connection depending on the line length and general building configuration.

The condensate line should be pitched a minimum 2% for proper water evacuation.

When drain line is exposed to air temperatures below 0 grades is necessary to provide

thermal insulation or electrical heating wire to avoid water freezing and tube damage.

It is convenient to install the trap with proper dimensions.

ELECTRICAL CONNECTIONS

Before starting any type of operations put in position off main power switch.

Unit current supply should be within 10% of Volts indicated on the unit nameplate.

Unit star-up at incorrect voltage and resulted from its damages are not covered by Hitecsa guarantee.

When making electrical connections always use the unit wiring diagram.

Be sure that the compressor crankcase heater can be energized before unit start.

Do not operate at any different current from that is shown on the unit’s nameplate.

The installer has to install the line protection elements according to the local laws.

The interconnecting wires have to be in the protection tube or inside the groove channel.

14

Page 15

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

INSTALLATION

SERVICE AREA

Be sure to respect the measures for a proper operation of the unit.

Model 7002.4

Models 8002.4 │ 9002.4

15

Page 16

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

OPERATING LIMITS

7002.4

8002.4

9002.4

Nominal Water Flow

m3/h

33

35,5

37

Minimum Water Flow

m3/h

21,9

23,6

24,6

Maximum Water Flow

m3/h

49,5

53,3

55,5

Minimum Volume of Water

l

455

510

550

EKWXA - EKWXBA

6025 30 35 40

45

50

55

-15

-10

-5

0

5

10

15

20

LWT (°C)

Temperatura exterior / Outdoor temperature / Témperature éxterieur (°C)

-7

-10

-5

0

5

10 15 20 25

-20

-10

0

10

20

30

40

55

LWT (°C)

Temperatura exterior / Outdoor temperature / Témperature éxterieur (°C)

25

46

-20

-10

-5

0

5

-15

-10

0

10

20

30

40

46

LWT (°C)

Temperatura exterior / Outdoor temperature / Témperature éxterieur (°C)

55

18

-7

EKWXA - EKWXBA

+ Glicol

+ Glycol

EKWXA - EKWXBA

+ Control de condensación

+ Condensation Control

+ Contrôle de la Condensation

EKWXA - EKWXBA

EKWXA - EKWXBA

+ Glicol

+ Glycol

-15

OPERATION

OPERATING LIMITS

Modo de Refrigeración 7002.4 │ 5002.4 │ 9002.4

Bomba de Calor 7002.4 │ 5002.4 │ 9002.4

16

Page 17

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

Check the following points:

BEFORE START-UP

OPERATION

Electrical connections are well tightened.

Panels are firmly secured with screws.

There are no oil or refrigerant leaks.

The unit is correctly leveled.

There is enough space for service and maintenance.

Drainage is not blocked.

Check that the crankcase heater of each compressor is in operation for 24 hours prior to commissioning.

Air filters are cleaned and correctly mounted.

Grilles, air diffusers, air ducts and flexible connections are in good condition.

Electrical power source is in accordance with what is said in the nameplate.

Fans rotate in the right direction.

START UP

Start up has to be performed by a qualified service person.

It is necessary to take notes of the air inlet and outlet temperatures to the internal coil, the volts and amps of the compressor and

motor fan, as well as the suction and discharge pressure of each compressor.

It should be remembered that it is necessary to clean the air filters after the first 4 hours of operation.

Observe at least, 3 cooling cycle operations.

Due to the unit equips frequency converters, it is essential that the power is at least 300mA to prevent power cuts caused by the

activation of the circuit breaker.

THERMOSTAT AND CONTROL

MCX-15 CONTROL

The control is composed of a user interface and an electronic board.

Power supply 20/30 Vdc – 24 Vac.

Panel mounting type.

Screen with display that allows the inputs and outputs to be visualized.

Operating mode: 4 compressors, cooling only and heat pump.

Defrosting by pressure transducers.

Management of water circulating pump and hydraulic module.

Clock programming.

Programmable controller with 3 access levels: User, Maintenance and

Manufacturer.

Main Functions of the Control System

Regulates water temperature.

Service hour counter for compressors and water pumps

(optional).

Intake and outlet water temperature reading displays, as well

as, pressure reading displays in evaporator and condenser

stages.

Compressor start timers.

Pressure overload safety protection.

Electronic compressor protection.

External fan protection.

Water flow protection.

Anti-freeze active protection.

Remote ON/OFF.

Remote COOL/HEAT mode toggle

Condensing and evaporating pressure control by incorporating

2 ventilation stages

Check valve for cycle reversion (only available for Heat Pump

units)

Anti-frost feature. Anti-frost start and stop settings through

pressure readings.

Anti-frost duration time control.

17

Page 18

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

(UP) By pressing and holding this key for, at least, 3 seconds the unit will start up if it was shutdown or it shuts down

if it is running.

(DOWN) By pressing and holding this key, at least, 3 seconds the unit will toggle between cooling and heating mode.

If the unit is running, it needs to stop prior to switching modes and then it must be started up once again.

(ESC) Pressing this key leads to a shortcut to the ALARMS menu.

(RETURN) This key takes the user to the MAIN MENU screen if it is pressed in the START MENU screen. It is also

used to enter menus for other selected options.

(UP) Used to scroll UP between highlighted options.

(DOWN) Used to scroll DOWN between highlighted options.

(ESC) Returns to the previous screen of a highlighted

option.

(RETURN) Advances to the next screen or sublevel of a

highlighted option.

THERMOSTAT AND CONTROL

MCX-15 START UP

Start Menu

Keypad utility

Main Menu

Keypad utility

ON

Starts up the unit using the last settings.

OFF

Shuts off the unit according to the established time parameters.

HEAT/COOL

Toggles between operating modes.

18

Page 19

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

DISPLAY “A” DISPLAY “B” ALARMS/WARNINGS

COMPRE

SSOR

WATER PUMP

OUTDOOR FAN

ANTI-FREEZE HEATER

COOL/HEAT/ ANTI

- FROST MODE

DIGITAL OUTPUTS

1=ON

ANALOG

OUTPUTS

DIGITAL INPUTS

1= Acti

ve

ANALOG INPUTS

THERMOSTAT AND CONTROL

MCX-15 START UP

Password Level

There are 3 clearance levels for different parameters or system setting options.

Level L0: User Access, no password required.

Level L1: User-Maintenance Access.

Level L2: Manufacturer authorized Access ONLY.

Inputs/Outputs

0=No Active

0=OFF

19

Page 20

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

POSITION

ANALOG INPUTS

DIGITAL INPUTS

ANALOG OUTPUTS

DIGITAL OUTPUTS

1

Water inlet temperature

Differential pressure

switch/ Flow switch

Fans circuit 1

Compressor 1 circ.1

2

Water outlet temperature

circuit 1

Thermal Compressor 1

Fans circuit 2

Compressor 2 circ.1

3

Water outlet temperature

circuit 2

Thermal Compressor 2

4 ways valve, circuit 1 (only

heat pump)

4

Cond./evap pressure.

Cool/Heat circuit 1

Thermal outdoor fans

circuit 1

Antifreeze resistance circuit

1

5

Evap./cond pressure.

Cool/Heat circuit 1

Safety high pressure

switch circuit 1

Compressor 1 circ.2

6

Cond./evap pressure.

Cool/Heat circuit 2

Remote Start/Stop

Compressor 2 circ.2

7

Evap./cond pressure.

Cool/Heat circuit 2

Remote Cool/Heat selector

Water pump (KIT 1 pump)

8

Second SETPOINT

Antifreeze resistance circuit

2

9

Thermal Compressor 3

10

Thermal Compressor 4

11

Thermal outdoor fans

circuit 2

Fans circuit 1

12

Safety high pressure

switch circuit 2

Fans circuit 2

13

Thermal pump

14

4 ways valve, circuit 2 (only

heat pump)

15

THERMOSTAT AND CONTROL

MCX-15 START UP

Model 7002.4

20

Page 21

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

POSITION

ANALOG INPUTS

DIGITAL INPUTS

ANALOG OUTPUTS

DIGITAL OUTPUTS

1

Water inlet temperature

Differential pressure

switch/ Flow switch

Fans circuit 1

Compressor 1 circ.1

2

Water outlet temperature

circuit 1

Thermal Compressor 1

Fans circuit 2

Compressor 2 circ.1

3

Cond./evap pressure.

Cool/Heat circuit 1

Thermal Compressor 2

4 ways valve, circuit 1 (only

heat pump)

4

Evap./cond pressure.

Cool/Heat circuit 1

Thermal outdoor fans

circuit 1

Antifreeze resistance circuit

1

5

Cond./evap pressure.

Cool/Heat circuit 2

Safety high pressure

switch circuit 1

Compressor 1 circ.2

6

Evap./cond pressure.

Cool/Heat circuit 2

Remote Start/Stop

Compressor 2 circ.2

7

Water outlet temperature

circuit 2

Remote Cool/Heat selector

4 ways valve, circuit 2 (only

heat pump)

8

Second SETPOINT

Antifreeze resistance circuit

2

9

Thermal Compressor 3

10

Thermal Compressor 4

11

Thermal outdoor fans

circuit 2

Fans circuit 1

12

Safety high pressure

switch circuit 2

Fans circuit 2

13

Thermal pump

14

Water pump (KIT 1 pump)

15

THERMOSTAT AND CONTROL

MCX-15 START UP

Models 8002.4 │ 9002.4

21

Page 22

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

OFF: No reading shown.

IdOF: ON/OFF state.

Set: Set point value for current operating mode.

reg: (Varies according to the model of the unit)

AI1: Intake water temperature. (Default setting)

AI2: Outlet water temperature.

OFF: No reading shown.

IdOF: ON/OFF state.

Set: Set point value for current operating mode. (Default setting)

reg: (Varies according to the model of the unit)

AI1: Intake water temperature.

AI2: Outlet water temperature

OFF: The unit is set to Standby or OFF mode.

ON: The unit starts up.

EQUA: The unit resumes operation under the same settings as the last

time it was running before loss of power.

THERMOSTAT AND CONTROL

MCX-15 START UP

System Parameters

Display Screens

Display screen “A”.

Select the Reading to be shown in Display screen A when the unit is running. By default, the reading shown on Display screen A when

the unit is shut down is “OFF”.

Display screen “B”.

Select the Reading to be shown in Display screen B when the unit is running.

Password

Displays Installer-Maintenance password.

Setup

System ON/OFF.

Indicates whether the unit is running (ON) or if it is shutdown (OFF), it also allows starting up or shutting down the unit by selecting

ON/OFF.

Restart After Disconnection Mode.

Following a sudden power outage, this indicates the operational mode for restart.

System HEAT / COOL

Indicates current operating mode HEAT/COOL and, it also allows switching between modes.

If the unit is running, it stops before switching operating modes and then it is started up in the new mode.

Scheduler enable.

Enables/Disables Programming Mode.

22

Page 23

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

AI1: Regulation of INTAKE water.

AI2: Regulation of OUTLET water.

THERMOSTAT AND CONTROL

MCX-15 START UP

Regulation Parameters

Configuration

Temperature Regulation Entry

This is used to tell the system whether regulation will be applied to IN or OUT water temperature.

Calibration of the Regulation Probes.

Adjusts probe regulation values in the range between -99,9 and 99,9.

Set Point

Cooling Set point Temperature.

Sets the value of the operating Cooling Set point temperature in ºC, by default this value is set to 7ºC. Values can range between 6,0

and up to 17,0ºC.

Lower Limit Set point Temperature.

This is used to set the lowest limit of the Set point temperature in cooling more.

By default this value is 6,0ºC.

High Limit Set point Temperature.

This is used to set the highest limit of the Set point temperature in cooling more.

By default this value is 17,0ºC.

Heating Set point Temperature.

Sets the value of the operating Cooling Set point temperature in ºC, by default this value is set to 45ºC. Values can range between

35,0 and up to 55,0ºC.

Lower Limit Set point Temperature.

This is used to set the lowest limit of the Set point temperature in heating more.

By default this value is 35,0ºC.

High Limit Set point Temperature.

This is used to set the highest limit of the Set point temperature in heating more.

By default this value is 55,0ºC.

Compressors

Activation

Activation of compressor 1

Activates or disables compressor 1.

Activation of compressor 2

Activates or disables compressor 2.

23

Page 24

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

CODE

DESCRIPTION

RESET

TYPE

COMPRESSOR

WATER

PUMP

CONDENSER

FAN

ANTIFREEZE

HEATER

A03

Evaporator flow switch

Manual

OFF

OFF

OFF

OFF

A09

High temperature

Notification

- - -

-

A10

Evaporator pump service time limits

exceeded

Notification

- - -

-

A11

Evaporator pump 2 service time

limits exceeded

Notification

- - -

-

A12

Condenser fan service time limits

exceeded

Notification

- - -

-

A13

Maximum time of defrost exceeded

Notification

- - -

-

A50

General fan thermal protection

Automatic

OFF - OFF

-

A61

Maximum service hours for

compressor 1 exceeded

Notification

- - -

-

A62

Maximum service hours for

compressor 2 exceeded

Notification

- - -

-

A63

Service Hours For Compressor 3

Exceeded

Notification

- - -

-

A64

Service Hours For Compressor 4

Exceeded

Notification

- - -

-

A7A

Intake water probe

Automatic

OFF

OFF

OFF

OFF

A7B

Outlet Water Probe Circuit 1

Automatic

OFF C1

OFF

OFF

OFF

A7C

Outlet Water Probe Circuit 2

Automatic

OFF C2 - -

-

A7G

Discharge Transducer Probe Circuit

1

Automatic

OFF C1

OFF

OFF

OFF

A7H

Discharge Transducer Probe Circuit

2

Automatic

OFF C2 - -

-

A7V

Intake Transducer Probe Circuit 1

Automatic

OFF C1

OFF

OFF

OFF

A7W

Intake Transducer Probe Circuit 2

Automatic

OFF C2 - -

-

AC0

General Thermal Compressor Alarm

Manual

OFF - -

-

AC1

Thermal compressor 1 circuit 1

Manual

OFF - -

-

AC2

Thermal compressor 2 circuit 1

Manual

OFF - -

-

AC3

Thermal compressor 1 circuit 2

Manual

OFF - -

-

AC4

Thermal compressor 2 circuit 2

Manual

OFF - -

-

AE1

Anti-freeze circuit 1

Manual

OFF C1

ON - -

AE2

Anti-freeze circuit 2

Manual

OFF C2

ON - -

THERMOSTAT AND CONTROL

MCX-15 START UP

Alarms

24

Page 25

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

CODE

DESCRIPTION

RESET

TYPE

COMPRESSOR

WATER

PUMP

CONDENSER

FAN

ANTIFREEZE

HEATER

AF1

Thermal Protection Fan Circuit 1

Manual

OFF C1

-

OFF C1

-

AF2

Thermal Protection Fan Circuit 2

Manual

OFF C2

-

OFF C2

-

AH0

General High Pressure

Manual

OFF - -

-

AH1

High Pressure Circuit 1

Manual

OFF C1 - -

-

AH2

High Pressure Circuit 2

Manual

OFF C2 - -

-

AL0

General low water pressure

protection

Manual

OFF - -

-

AL1

Low Pressure Protection Circuit 1

3 times in 1

hour

OFF C1 - -

-

AL2

Low Pressure Protection Circuit 2

3 times in 1

hour

OFF C2 - -

-

AP0

General Evaporator Pump

Manual

OFF

OFF

OFF

OFF

AP1

Thermal protection water pump 1

Automatic

-

OFF - -

AP2

Thermal protection water pump 2

Automatic

-

OFF - -

AP9

Operation reserved pump

Notification

- - -

-

E10

EEV Connection Alarm Circuit 1

Manual

OFF C1 - -

-

E12

EEV Reheat Temperature Alarm

Circuit 1

Manual

OFF C1 - -

-

E14

EEV Evaporation Pressure Alarm

Circuit 1

Manual

OFF C1 - -

-

E16

EEV Refrigerant Not Selected Alarm

Circuit 1

Manual

OFF C1 - -

-

E17

EEV Valve Operation Alarm Circuit 1

Manual

OFF C1 - -

-

E18

EEV Low Battery Alarm Circuit 1

Manual

OFF C1 - -

-

E19

CAN EEV Communication Alarm

Circuit 1

Manual

OFF C1 - -

-

E20

EEV Connection Alarm Circuit 2

Manual

OFF C2 - -

-

E22

EEV Reheat Temperature Alarm

Circuit 2

Manual

OFF C2 - -

-

E24

EEV Evaporation Pressure Alarm

Circuit 2

Manual

OFF C2 - -

-

E26

EEV Refrigerant Not Selected Alarm

Circuit 2

Manual

OFF C2 - -

-

E27

EEV Valve Operation Alarm Circuit 2

Manual

OFF C2 - -

-

E28

EEV Low Battery Alarm Circuit 2

Manual

OFF C2 - -

-

E29

CAN EEV Communication Alarm

Circuit 2

Manual

OFF C2 - -

-

THERMOSTAT AND CONTROL

MCX-15 START UP

Alarms

25

Page 26

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

KRONO 2 series

7002.4

8002.4

9002.4

HYDRONIC KIT

Expansion Vessel Volume

l

50

Deposit Inertia Volume

l

300

Available Pressure Machine + H.K. Without Tank

kPa

104,2

118,4

129,2

Available Pressure Machine + H.K. With Tank

kPa

114

129,8

141,6

Water Flow

m3/h

33

35,5

37

Connection Type

Slotted - Victaulic

Connection Diameter

(“)

3

HEAT PUMP OPTION

Power Supply

V/~/Hz

400/3/50

Number of Heat Pump

2

Reserve Heat Pump Option

SI

Maximum weight: Heat Pump + H.K. (full of water)

kg

2245

2278

2284

LOW PRESSURE PUMP

Model

CEA 370/2

Rated Power (per unit)

kW

1,5

Maximum Current (One Pump Operation)

A

3,4

Locked Rotor Current (One Pump)

A

28

Available Pressure Machine + H.K. Without Tank

kPa

66

46,4

32,2

Available Pressure Machine + H.K. With Tank

kPa

56,2

35,1

19,9

HIGH PRESSURE PUMP

Model

CEA 370/5

Rated Power (per unit)

kW

3

Maximum Current (One Pump Operation)

A

5,9

Locked Rotor Current (One Pump)

A

51,2

Available Pressure Machine + H.K. Without Tank

kPa

157,9

139,2

125,5

Available Pressure Machine + H.K. With Tank

kPa

148,1

127,8

113,2

HYDRONIC KIT

TECHNICAL DATA

26

Page 27

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

OPERATING LIMITS

7002.4

8002.4

9002.4

Coefficient of thermal expansion Water between 7-50°C / 2 bar

ΔV/V

0,0125

Coefficient of thermal expansion Water between 7-55°C / 2 bar

ΔV/V

0,015

Expansion vessel

l

50

Maximum water volume (7-50)ºC

l

1992

Maximum water volume (7-55)ºC

l

1672

WARNING!

HYDRONIC KIT

OPERATING LIMITS

MAINTENANCE

CONSERVATION AND CLEANING

Before performing any service or maintenance of the unit, it is mandatory to disconnect and lock the system

main switch to prevent anyone other than the technician from connecting the unit and causing personal

It is advisable to do maintenance works every 1.000 operating hours as well as at the beginning of each cooling season.

Coils: At least once a year, clean condenser coils with water and detergent, then dry with air at a low pressure. Never clean with wire

brush.

Drainage system: Verify condition and good operation of the drainage tray and siphon.

Refrigeration circuit: Check for oil refrigerant leaks, noises or system’s vibrations. Take measurements of temperatures and

pressures of components and record them on the maintenance form.

Electrical circuit: Make sure that all electrical connections -wires, contactors and terminals- are properly tight. Record the readings

for volts and amperes of each compressor and fan motor. Verify the starting current. Check the good operation of all relays, pressure

switches and phase sequence relay of Scroll compressor.

injury.

LUBRICANT

R-410A refrigerant compressors use synthetic polyolester oil. Each compressor manufacturer has a specific oil for your product.

The compressor or system should not remain open to atmosphere for more than 15 minutes.

Synthetic ester-type lubricants (POE, Polyol Ester) having high solubility with R-410A are used. Since these types of oils are very

hygroscopic, it should be more careful handling them than with conventional ones. Moreover, when these synthetic oils are mixed with

minerals or alkylbenzenes, they deteriorate causing capillary blockage or failure in the compressor.

Do not mix under any circumstances.

27

Page 28

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

CONDENSATION CONTROL

STANDARD, IC y SIL: Outdoor AC fan with variable speed drive

SS: Serial Built-in Speed Control

POWERED FAN

Incorporation of EC Electronic Fans of bionic profile with higher available pressure

With this accessory is included the control of condensation of the equipment

SOFT STARTER

Soft starter to minimize peak currents at the compressor start

ELECTRONIC EXPANSION

Expansion of electronic injection valve

HYDRONIC KIT

Option 1: Pump + Tank + Expansion vessel

Option 2 : Pump + Tank with electrical heater + Expansion vessel

In HEAT mode for low outdoor temperatures, the electric heater is activated as a compressor

support, as long as the compressor is operational

Option 3 : Pump + Expansion vessel

WATER MANOMETERS

Incorporation of manometers for reading the inlet and outlet pipes

AGGRESSIVE

ENVIRONMENTS

Coils with Blygold coating of finned pack

Coils with Aluzinc flap type

Coils with copper fins

COIL PROTECTION

Incorporation of protection grids to prevent impact on the condenser coils

SUPERVISION

External monitoring system

MULTIPLE UNITS

MANAGEMENT

Modular control system via master/slave

WARNING!

WARNING!

MAINTENANCE

REFRIGERANT CHARGE

Never use oxygen to pressurize system or purge lines for leak test. Oxygen reacts violently with

oil, which can cause an explosion resulting in damage, personal injury or death.

In case it is necessary to add or recover refrigerant, use an electronic scale that is suitably reinforced and prepared to withstand the

handling of the refrigerant bottle.

The charge must be made in LIQUID condition.

The inlet of liquid refrigerant R-410A in the empty tubes causes temperatures below 0ºC until the internal pressure reaches 7 bars.

If it is necessary to make brazing operation, first fill the circuit with dry nitrogen. Burning

refrigerant 410A results in toxic gas emissions.

Leaks should be repaired immediately.

Never overcharge the system.

Never use compressor as vacuum pump.

If leakage symptoms appear during the operation, it is necessary to leak test.

To find small leaks, you will need a detector for HCF.

If gas leak is detected is necessary to remove and recuperate complete refrigerant charge. Pressurize system with dry nitrogen. If

leakage has been not detected break a vacuum, dehydrate and charge with refrigerant.

Do not reintroduce used refrigerant, send it to an authorized recycling location.

OPTIONAL

ACCESSORIES / OPTIONAL

* In addition to these optional consult with our Commercial department for any other configuration or function not described as available.

28

Page 29

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

Refrigerant Data

Safety Data: R410A

Toxicity

Low

Contact with Skin

R410A vapours can irritate the skin and eyes. In liquid form, it can freeze skin on

contact. If contact with skin occurs, flush the exposed area with lukewarm water until

all of the chemical is removed. If there is evidence of frostbite, bathe in lukewarm

water.

Contact with Eyes

If contact with eyes occurs, immediately flush with large amounts of lukewarm water

for at least 15 minutes, lifting eyelids occasionally to facilitate irrigation. Seek medical

attention as soon as possible.

Ingestion

Very unlikely - should something happen, it will cause frost burns. Do not induce

vomiting. Only if the patient is conscious, wash out mouth with water and give some

250 ml of water to drink. Then, obtain medical attention.

Inhalation

Inhalation of the R410A vapour may cause irritation. Vapour inhalation at high

concentrations may result in asphyxiation or the heart may become sensitized,

causing cardiac arrhythmia. When concentration of R410A reach levels which reduce

oxygen to 14-16% by displacement, symptoms of asphyxiation will occur. An

individual exposed to high concentrations of R410A must be given medical attention

immediately. Adequate ventilation must be provided at all times.

Recommendations

Semiotics or support therapy is recommended. Cardiac sensitisation has been

observed that, in the presence of circulating catecholamines such as adrenalin, may

cause cardiac arrhythmia and accordingly, in case of exposure to high

concentrations, cardiac arrest.

Prolonged Exposure

R410A: a study on the effects of exposure to 50,000 ppm during the whole life of rats

has identified the development of benign testicle tumour.

This situation should therefore be negligible for personnel exposed to concentrations

equal to or lower than professional levels.

Professional Levels

R410A: Recommended threshold: 1000 ppm v/v - 8 hours TWA.

Stability

R410A: is stable under normal operating conditions.

Conditions to Avoid

Do not use in the presence of high temperatures, flames, burning surfaces and

excess humidity.

Hazardous Reactions

Contact with certain red-hot metals may result in exothermic or explosive reactions

and yield toxic and/or corrosive decomposition products. Specific materials to avoid

include freshly abraded aluminium surfaces and active metals such as sodium,

potassium, calcium, powdered aluminium, magnesium and zinc.

Hazardous Decomposition

Products

R410A: Halogen acids produced by thermal decomposition and hydrolysis.

APPENDIX: SAFETY DATA R410A

29

Page 30

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

Refrigerant Data

Safety Data: R410A

General Precautions

Do not inhale concentrated vapours. Their concentration in the atmosphere should

not exceed the minimum preset values and should be maintained below the

professional threshold. Being weightier than the air, the vapour concentrates on the

bottom, in narrow areas. T here fore, the exhaust system must work at low level.

Respiratory System Protection

If you are in doubt about the concentration in the atmosphere, it is recommended to

wear a respirator approved by an accident prevention Authority, of the independent

or oxygen type.

Storage

Cylinders must be stored in a cool, dry and properly ventilated storage area away

from heat, flames, corrosive chemicals, flumes, explosives and be otherwise

protected from damage. Keep a temperature below 52°C.

Protective Clothing

Wear overalls, protective gloves and goggles or a mask.

Accidental Release Measures

IIt is important to wear protective clothing and a respirator. Stop the source of the

leak, if you can do this without danger. Negligible leaks can be left evaporating under

the sun, providing that the room is well ventilated. Considerable leaks: ventilate the

room. Reduce the leak with sand, earth or other absorbing substances. Make sure

that the liquid does is not channelled into gutters, sewers or pits where the vapours

are likely to create a stuffy atmosphere.

Disposal

The best method is recovery and recycling. If this method is not practicable, dispose

according to an approved procedure, which shall ensure the absorption and

neutralization of acids and toxic agents.

Fire Fighting Information

R410A: Not flammable in the atmosphere.

Cylinders

The cylinders, if exposed to fire, shall be cooled by water jets; otherwise, if heated,

they may explode.

Protective Fire Fighting Equipment

In case of fire, wear an independent respirator and protective clothing.

APPENDIX: SAFETY DATA R410A

30

Page 31

05.17 207646 Rev.103

EKWXA│EKWXBA

AIR-COOLED WATER CHILLERS

AXIAL FANS

We reserve the right to add modifications without prior notice.

31

Loading...

Loading...