Hitecsa BSW 1, BSW 2, BSW 3, BSW 5, BSW 4 Installation, Operation And Maintenance Manual

...Page 1

06.18 Ref. 207483 Rev.102

1

BSW

Cooling only

FAN-COIL HIGH PRESSURE

Models 1 | 2 | 3 | 4 | 5 | 6 | 7

Cooling capacities: from 3.8 to 50.6 kW

Heating capacities: from 5.0 to 60.9 kW

06.18 Ref. 207483 Rev.102

INS

TALL

ATION, OPER

ATION

AN

D MAINTENANC

E MANUAL

Page 2

BSW

FAN-COIL HIGH PRESSURE

2

06.18 Ref. 207483 Rev.102

Page 3

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

3

INDEX

INTRODUCTION 4

RECOMMENDATIONS 4

IDENTIFICATION OF THE UNIT 4

TRANSPORTATION, RECEIVING, HANDLING 4

SAFETY PROVISIONS 4

GENERAL DIMENSION UNIT 1÷5 5

TECHNICAL DATA UNIT 1÷5 5

GENERAL DIMENSION UNIT 6÷7 6

TECHNICAL DATA UNIT 6÷7 6

RECOMMENDATIONS FOR INSTALLATION 7

INSTALLATION OF THE AIR TREATMENT UNIT 7

EXAMPLE OF ACCESSORIES USE AND COMPATIBILITY 8

ASSEMBLY DIAGRAM

PAM (SUPPLY PLENUM) ASSEMBLY DIAGRAM 9

PAM (INTAKE PLENUM) ASSEMBLY DIAGRAM 9

RAM (SUPPLY PLENUM) ASSEMBLY DIAGRAM 10

RAM (INTAKE PLENUM) ASSEMBLY DIAGRAM 10

PAM MOUNTING BRACKET ASSEMBLY DIAGRAM 11

RAM MOUNTING BRACKET ASSEMBLY DIAGRAM 11

GAM ASSEMBLY DIAGRAM 12

SRE ASSEMBLY DIAGRAM 12

SRA ASSEMBLY DIAGRAM 13

USG ASSEMBLY DIAGRAM 13

SSP ASSEMBLY DIAGRAM 14

ALUMINIUM DAMPER ASSEMBLY DIAGRAM 14

BAM ON PAN ASSEMBLY DIAGRAM 15

BAM ON RAM ASSEMBLY DIAGRAM 15

SUPPLY GRILL ON PAM ASSEMBLY DIAGRAM 16

SUPPLY GRILL ON RAM ASSEMBLY DIAGRAM 16

INTAKE GRILL ON PAM ASSEMBLY DIAGRAM 17

INTAKE GRILL ON RAM ASSEMBLY DIAGRAM 17

HYDRAULIC CONNECTION 18

ELECTRICAL CONNECTIONS 18

CONNECTIONS TO THE TERMINAL BOARD 18

WIRING DIAGRAM

WIRING DIAGRAM (MOD. 1-3) 19

WIRING DIAGRAM (MOD. 4-5) 20

WIRING DIAGRAM (MOD. 6-7) 21

TURNING THE COIL 22

CLEANING AND MAINTENANCE 22

WHAT TO DO IF... 23

DISMANTLING THE UNIT 23

FOR INS

TALLAR

FOR

USER

Page 4

BSW

FAN-COIL HIGH PRESSURE

4

06.18 Ref. 207483 Rev.102

INTRODUCTION

This installation and maintenance booklet should always accompany the air treatment unit for ready consultation by the installer or user if necessary. The unit

should be installed in compliance with the regulations in force in each country

and according to the manufacturer’s or qualified person’s instructions. The manufacturer cannot be held liable for any damage to property or injury to persons

and animals caused by incorrect installation of the unit. Only qualified persons

should install the unit and connect it to the mains electricity supply. Before carrying out any work on the unit, ensure that it is disconnected from the electricity

supply. Read this instruction booklet prior to installation.

RECOMMENDATIONS

This unit is easy to use, but it is important to read all the contents of this guide

before using it for the first time. This will help you to:

- use the unit in all safety

- obtain best performance

- avoid incorrect actions

- respect the environment

- Do not allow children or unassisted handicapped persons to use the unit.

- Do not touch the unit with wet parts of the body or if barefoot.

- Do not tug, pull or twist electrical cables attached to the unit, even when disconnected from the electricity supply.

- Do not open the flaps giving access to the internal parts of the unit without

having first put the system on-off switch to “off”.

- Do not introduce sharp pointed objects through the air intake and outlet grilles.

- Do not leave packing material (boards, staples, plastic bags, etc.) within reach

of children since they could be a source of danger. Dispose of correctly.

- Do not spray or throw water directly on the unit.

- Do not use the unit in places with suspended dust/powder or in potentially

explosive atmospheres, in very damp environments or in the presence of oil in

suspension or in particularly aggressive atmospheres.

- Do not cover the unit with objects or drapes that even partially obstruct the

air flow.

The unit works by electricity at mains voltage (230 Vac, 50 Hz). Always bear in

mind that mains voltage is potentially dangerous and any appliance connected

to it should be used with caution. Before carrying out any work on the unit,

disconnect it from the electricity supply (by pulling out the plug from the mains

socket or isolating the supply line by putting the on-off switch OFF. If the unit is

not be used for long periods, make sure that the controls are in the position 0

(off). If the unit is not going to be used in winter when temperatures are near to

freezing, drain the system and ensure that the unit heat exchanger has no water

in it in order to prevent the formation of ice and consequent breakage. To make

the unit inoperable, disconnect it totally from the electricity supply. It is unsafe

to alter or try to alter the characteristics of this product. Any tampering or alteration in any case makes the warranty null and void. In the event of malfunction

or failure, do not try to repair the unit yourself; contact a qualified technician.

Repairs carried out by incompetent persons could cause damage or accidents.

Always keep the unit clean. In particular clean the air filter periodically (at least

once a month).

FAILURE TO COMPLY WITH THE ASSEMBLY INSTRUCTIONS GIVEN IN

THIS GUIDE RELIEVES THE PRODUCER OF ALL AND ANY LIABILITY.

INCORRECT INSTALLATION COULD CAUSE MALFUNCTIONING OR FAILURE OF THE UNIT. IT COULD ALSO REPRESENT A HAZARD FOR THE

USER.

IDENTIFICATION OF THE UNIT

The air treatment units come with a rating plate, which shows:

- The manufacturer's address; - Supply voltage in "V";

- "CE" marking; - Supply frequency in “Hz”;

- Model; - Number of phases, indicated with "Ph";

- Lot number; - Total cooling capacity in “W”;

- Date of production; - Sensible cooling capacity in “W”;

- Rated absorbed current in "A"; - Heat output.

- Input in “W”;

TRANSPORTATION, RECEIVING, HANDLING

The units and their accessories are enclosed in cardboard boxes up to size 50,

while the other sizes are palletised. The packs should be kept intact until positioned in the final place of installation. Use suitable handling equipment according

to the weight of the unit, as provided for by directive 89/391/EEC and subsequent amendments. The weight of each single machine is given in this guide

(table 2). Upon receiving the unit, check all the parts for any damage caused in

transit. Any damage should be reported to the carrier by affixing an accepted

with reservation on the accompanying note, specifying the type of damage. In

the event of prolonged storage, keep the units protected against dust and far

from sources of vibration or heat. The number of units that may be positioned

on one pallet are given in the table (table 1).

THE PRODUCER CANNOT BE HELD LIABLE FOR DAMAGE DUE TO INCORRECT HANDLING OR LACK OF PROTECTION AGAINST THE ELEMENTS.

SAFETY PROVISIONS

Secure packs during transportation.

Do not expose to the elements.

Do not tread on packs.

Protect hands with work gloves when dismantling the unit.

Work in PAIRS if the appliance weighs more than 25 kg.

Page 5

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

5

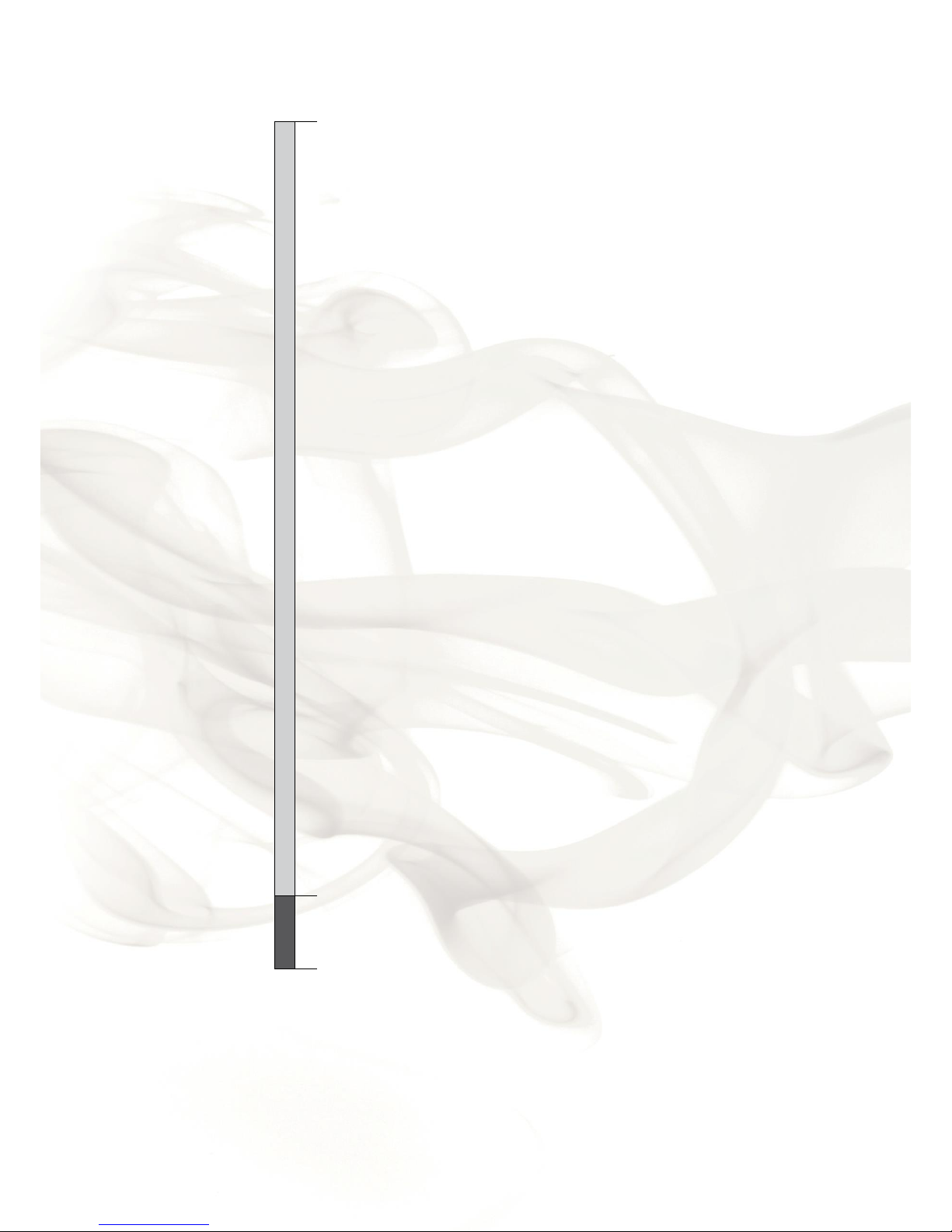

GENERAL DIMENSIONS UNIT 1÷5

GENERAL TECHNICAL DATA

MOD. 1 2 3 4

5

L

mm

770

1070

1270

1420

1520

H

mm

297

297

347

372

397

P

mm

643

643

643

770

770

A

mm

656

956

1156

1306

1406

B

mm

253

253

303

328

353

M

mm

680

980

1180

1330

1430

C

mm

247

247

297

322

347

D

mm

237

237

237

300,5

300,5

E

mm

118

118

118

195

195

F

mm

93,5

93,5

118,5

131

143,5

G

mm

233

233

233

310

310

I

mm

83,5

83,5

108,5

121

133,5

N

mm

193

193

193

270

270

Fittings

(male)

2 rows coil Ø 1/2”

1/2”

3/4”

3/4”

1”

4 rows coil Ø 1/2”

3/4”

3/4”

1”

1”

6 rows coil Ø 3/4”

3/4”

1”

1”

1” 1/4

Net weight

kg

28

38

49

62

72

Page 6

BSW

FAN-COIL HIGH PRESSURE

6

06.18 Ref. 207483 Rev.102

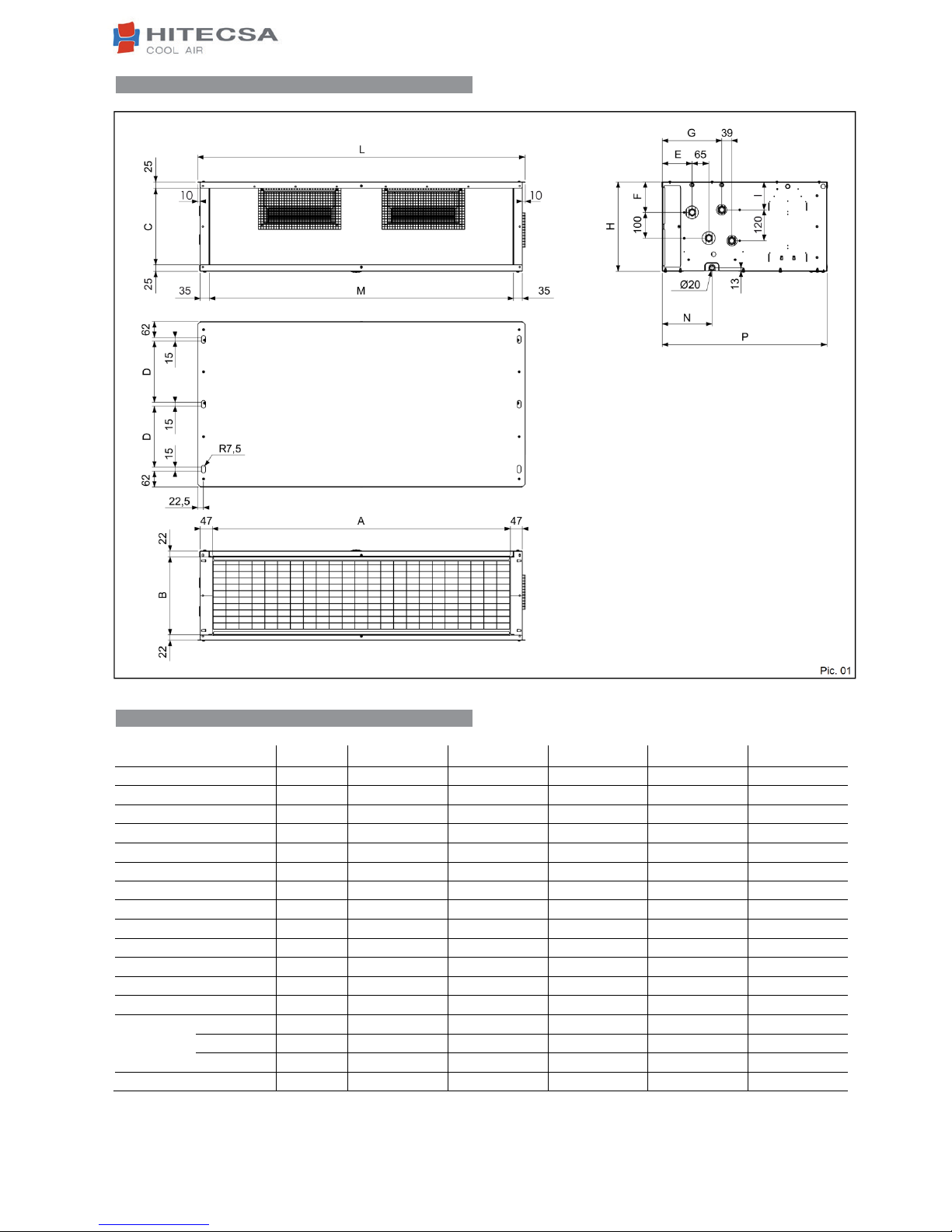

GENERAL DIMENSION UNIT 6 ÷ 7

TECHNICAL DATA UNIT 6÷7

MOD.

6

7

L

mm

2190

2190

H

mm

373

398

P

mm

770

770

A

mm

2076

2076

B

mm

328

353

M

mm

2100

2100

C

mm

323

348

D

mm

300,5

300,5

E

mm

201,5

201,5

F

mm

131,5

144

G

mm

311

311

I

mm

121,5

134

N

mm

270

270

Fittings

(male)

2 rows coil

Ø

1”

1”

4 rows coil

Ø

1” 1/4

1” 1/2

6 rows coil

Ø

1” 1/2

1” 1/2

Net weight

kg

127

Pic. 02

Page 7

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

7

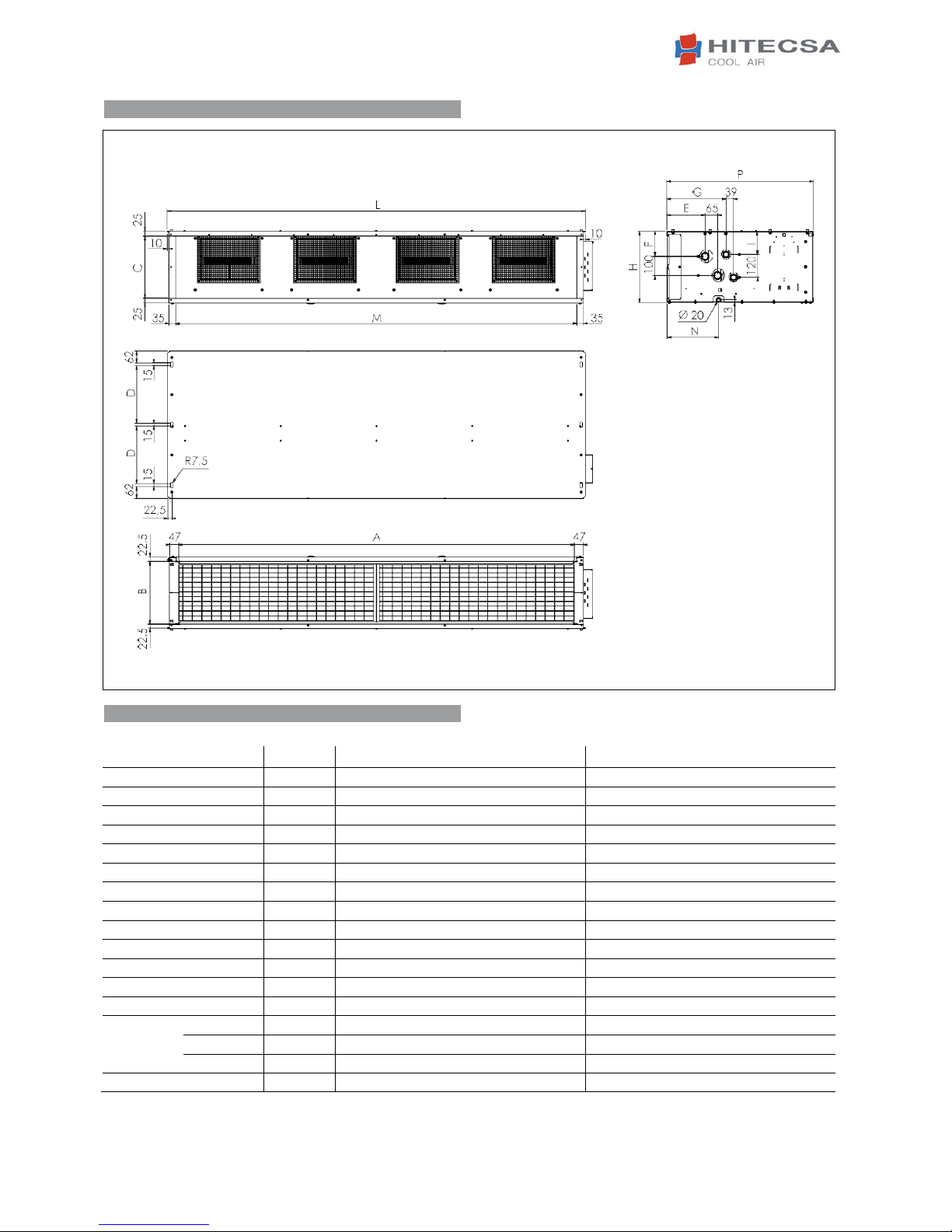

RECOMMENDATIONS FOR INSTALLATION

Before installing the unit, ensure that:

1) The place of installation has sufficient space for carrying out installation as

well as routine and extraordinary maintenance work (see Pic. 3). If the unit is

installed behind a suspended ceiling, an access should be provided;

2) There are no obstructions for air intake and delivery;

3) The water fittings are of the sizes, in the position and spaced apart as required by the unit;

4) The system pressure does not exceed 8 bar for the water-filled versions;

5) The electricity supply corresponds to the data on the unit rating plate and that

there is a circuit breaker switch readily accessible to the user to cut off the power

supply whenever necessary;

6) The circuit breaker is in the OFF position so that there is no voltage on the

unit supply line.

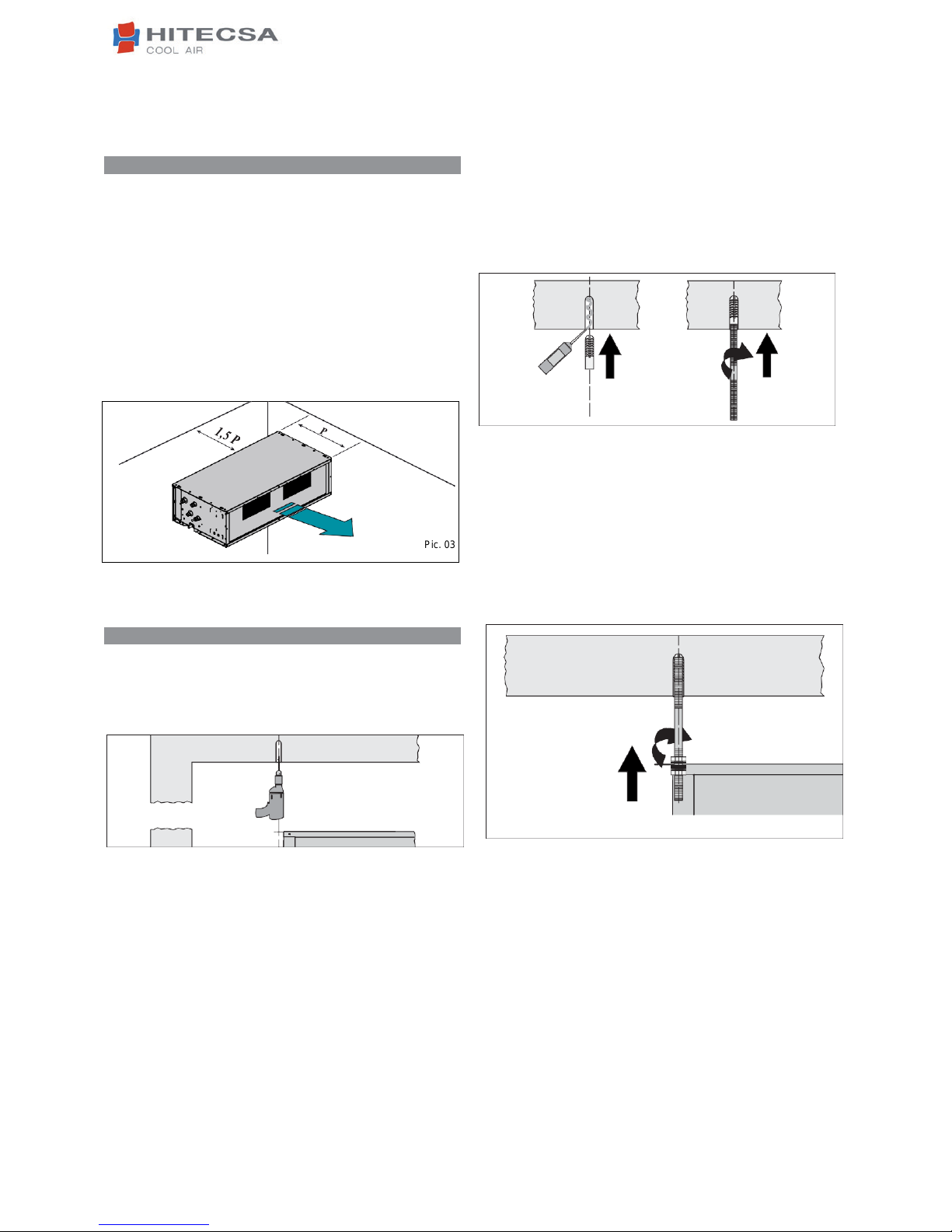

Drill the holes in line with the relative slots for the 6 unit screw anchors (Pic.

4). Inject thermosetting resin into the holes and then insert the screw anchors

(Pic. 5).

Fix the threaded rods of the correct length to the screw anchors (Pic. 5) and

insert them into the relative slots (Pic. 6). After having created a slope (max. 3

cm/m) in the direction of the condensate outlet, lock the threaded rod with a nut

and check nut. To prevent possible noise being created by vibrations from the

unit, it is advisable to insert a vibration-damping joint.

Note: the screw anchors, threaded rods and whatever else is necessary

for accomplishing the installation are NOT included in the supply of the

air treatment unit.

INSTALLATION OF THE AIR TREATMENT UNIT

PRELIMINARY OPERATIONS

- check that the various unit components are perfectly intact;

- check that the installation accessories and documentation are in the pack;

- place the packed section as close as possible to the place of installation;

- Do not place tools or weights of any kind on the packed unit.

Pic. 06

Pic. 04

Pic. 05

Pic. 03

Page 8

BSW

FAN-COIL HIGH PRESSURE

8

06.18 Ref. 207483 Rev.102

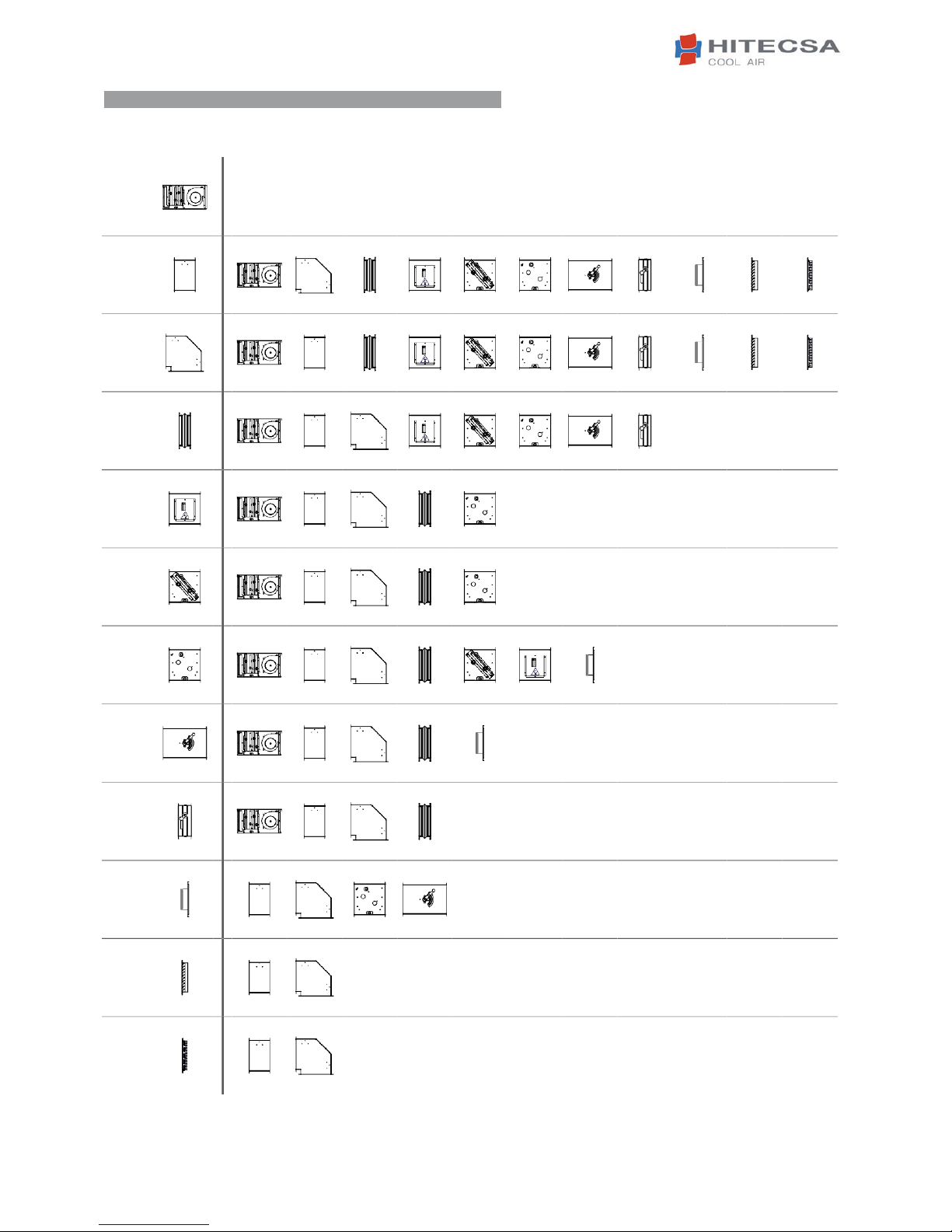

EXAMPLE OF ACCESSORIES USE AND COMPATIBILITY

UNIT

PAM

RAM

GAM

SRE

SRA

USG

SSP

Aluminium

damper

BAM

Air intake

grill

Air supply

grill

Depending on the requirements, the air filter can have a thickness of 12/25/48 mm

Page 9

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

9

PAM (SUPPLY PLENUM) ASSEMBLY DIAGRAM

PAM (INTAKE PLENUM) ASSEMBLY DIAGRAM

SCREWS LEGEND PAM 1÷5

x8 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

SCREWS LEGEND PAM 6÷7

x10 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flangiato with corrugated washer DIN4161

Pic. 07

Page 10

BSW

FAN-COIL HIGH PRESSURE

10

06.18 Ref. 207483 Rev.102

RAM (SUPPLY PLENUM) ASSEMBLY DIAGRAM

RAM (INTAKE PLENUM) ASSEMBLY DIAGRAM

SCREWS LEGEND RAM 1÷5

x5 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

x3 Screw TE M5x12 UNI 5739

TE M5x12

SCREWS LEGEND RAM 6÷7

x6 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

x4 Screw TE M5x12 UNI 5739

Pic. 09

SCREWS LEGEND RAM 1÷5

x7 Screw TC+M5x12 UNI7687

TE M5x12

x6 Hex nut M5 flanged with corrugated washer DIN4161

x1 Screw TE M5x12 UNI 5739

SCREWS LEGEND RAM 6÷7

x8 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

x2 Screw TE M5x12 UNI 5739

Pic. 10

Page 11

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

11

PAM MOUNTING BRACKET ASSEMBLY DIAGRAM

RAM MOUNTING BRACKET ASSEMBLY DIAGRAM

SCREWS LEGEND 1÷5

x6 Self-drilling screw with tip TC+3,9x9,5 UNI6954

Pic. 11

SCREWS LEGEND 1÷5

x6 Self-drilling screw with tip TC+3,9x9,5 UNI6954

Pic. 12

Page 12

BSW

FAN-COIL HIGH PRESSURE

12

06.18 Ref. 207483 Rev.102

GAM ASSEMBLY DIAGRAM

SRE ASSEMBLY DIAGRAM

SCREWS LEGEND SRE 1÷5

x8 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

SCREWS LEGEND SRE 6÷7

x10 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

Page 13

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

13

SRA ASSEMBLY DIAGRAM

USG ASSEMBLY DIAGRAM

SCREWS LEGEND SRA 1÷5

x8 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

SCREWS LEGEND SRA 6÷7

x10 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

Pic. 15

Page 14

BSW

FAN-COIL HIGH PRESSURE

14

06.18 Ref. 207483 Rev.102

SSP ASSEMBLY DIAGRAM

ALUMINIUM DAMPER ASSEMBLY DIAGRAM

CANALIZABLE SIDE

Lined up to the edge

SCREWS LEGEND SSP 1÷5

x8 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

UNIT + ACCESSORIES

SIDE

Shorter to mix the air flow

SCREWS LEGEND SSP 6÷7

x10 Screw TC+M5x12 UNI7687

x6 Hex nut M5 flanged with corrugated washer DIN4161

Pic. 17

Page 15

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

15

BAM ON PAN ASSEMBLY DIAGRAM

BAM ON RAM ASSEMBLY DIAGRAM

SCREWS LEGEND 1÷5

x8 Screw TC+M5x12 UNI7687

x8 Hex nut M5 flanged with corrugated washer DIN4161

SCREWS LEGEND 6÷7

x10 Screw TC+M5x12 UNI7687

x10 Hex nut M5 flanged with corrugated washer DIN4161

Pic. 19

Page 16

BSW

FAN-COIL HIGH PRESSURE

16

06.18 Ref. 207483 Rev.102

SUPPLY GRILL ON PAM ASSEMBLY DIAGRAM

SUPPLY GRILL ON RAM ASSEMBLY DIAGRAM

SCREWS LEGEND 1÷5

x6 Self-drilling screw TC+4,2x13 UNI8118

SCREWS LEGEND 6÷7

x8 Self-drilling screw TC+4,2x13 UNI8118

Pic. 21

SCREWS LEGEND 1÷5

x6 Self-drilling screw TC+4,2x13 UNI8118

SCREWS LEGEND 6÷7

x8 Self-drilling screw TC+4,2x13 UNI8118

Pic. 22

Page 17

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

17

INTAKE GRILL ON PAM ASSEMBLY DIAGRAM

INTAKE GRILL ON RAM ASSEMBLY DIAGRAM

SCREWS LEGEND 1÷5

x6 Self-drilling screw TC+4,2x13 UNI8118

SCREWS LEGEND 6÷7

x8 Self-drilling screw TC+4,2x13 UNI8118

Pic. 23

SCREWS LEGEND 1÷5

x6 Self-drilling screw TC+4,2x13 UNI8118

SCREWS LEGEND 6÷7

x8 Self-drilling screw TC+4,2x13 UNI8118

Pic. 24

Page 18

BSW

FAN-COIL HIGH PRESSURE

18

06.18 Ref. 207483 Rev.102

HYDRAULIC CONNECTION

MAIN HYDRAULIC CONNECTION

CAUTION! Always use a wrench and counter-wrench for connection of the

coil to the pipes (pic. 25). If the valve is installed, suitably insulate the valve

body with insulating material (pic. 26).

Connect the water inlet and outlet pipes, observing the indications given on the

side of the unit. Correctly insulate the water supply pipes to prevent dripping

during the cooling mode of operation. A shutoff valve should be inserted on the

water supply pipe and a balancing valve on the outlet pipe. The valve body and

balancing valve should also be properly insulated to prevent dripping. It is the

installer’s responsibility to insulate properly and the manufacturer cannot be held

liable for any insulation work.

NOTE: It is always advisable to install the valve. In the heating mode of

operation the valve reduces consumption because upon reaching the set

temperature the circulation of water is stopped to avoid wasting energy

(the fan coil would otherwise continue to heat like a radiator, even with the

motor at a standstill). In the cooling mode of operation the valve stops the

circulation of water when the set temperature is reached, this stopping the

internal exchanger from continuing to condense water with possible

undesirable dripping onto the floor. It also reduces chiller operation with

consequent energy saving.

CONDENSATE WATER DRAINAGE

The condensate drain pipe should slope downwards by at least 3 cm/m and

should not have ascending or throttled sections in order to ensure a regular flow

of water. It is advisable for a trap to be fitted. The condensate drain pipe should

be connected to a rainwater drainage system. Do not use sewage systems to

avoid possible rising of smells in the event of evaporation of the water in the

trap. Upon completion of work, check that the condensate flows out properly by

pouring water into the tray. The condensate water drainage system should be

fabricated in a workmanlike manner and should be periodically checked.

The manufacturer cannot be held liable for any damage caused by dripping in

the absence of a valve or of periodic maintenance of the drainage system.

ELECTRICAL CONNECTIONS

RECOMMENDATIONS!

Before carrying out electrical connections, ensure that the electricity supply to

the supply line has been cut off, checking that the on-off switch is in the OFF

position.

- Only qualified electricians should carry out the electrical connections.

- Check that the mains supply is single-phase 230 Vac/1/50 Hz (± 10%).

- Operating the unit with voltages outside the above limits could cause malfunction and renders the warranty null and void.

- The power supply line should be fitted with at least a switch isolator in conformity with European standard EN60947-3.

- Make sure that the electrical system is suitable for providing not only the working current required by the unit, but also the necessary current for powering

household and other electrical appliances already in use. Any electrical and

mechanical alterations or tampering render the warranty null and void.

The cables should be sufficiently long so that they are not permanently taut or

create throttling or compression on metal parts.

The power cables should be sufficiently long so that in the event of accidental

tugging the active wires are subjected to stress before the earth wire. Connect

the earth wire to the relative terminal marked with the symbol . Comply with

the safety regulations in force in the country of installation.

CONNECTIONS TO THE TERMINAL BOARD

The electrical connections should be made to the terminal boards on the side of

the appliance. Each terminal is identified by the label to be found on the terminal

boards.

CAUTION! FAILURE TO COMPLY WITH THE INDICATED CONNECTIONS

MAY CAUSE MOTOR BURNOUT!

Pic. 26

Pic. 25

Page 19

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

19

WIRING DIAGRAM (MOD. 1-3)

Page 20

BSW

FAN-COIL HIGH PRESSURE

20

06.18 Ref. 207483 Rev.102

WIRING DIAGRAM (MOD. 4-5)

Page 21

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

21

WIRING DIAGRAM (MOD. 6-7)

Page 22

BSW

FAN-COIL HIGH PRESSURE

22

06.18 Ref. 207483 Rev.102

TURNING THE COIL

CAUTION

The fan wheels may reach the speed of 1,000 rpm. Do not insert objects into the

electric fan and certainly not hands. The motor becomes hot during operation;

wait for it to cool before touching it. During the heating mode of operation the

exchanger and the connecting pipes may become very hot (80°C). Wait for the

exchanger to cool before touching it or protect hands with suitable gloves. The

heat exchange water coils are suitable for working up to a maximum pressure

of 8 bar.

To turn the coil, proceed as follows:

1. Disconnect the terminal board (6) from the side of the unit.

2. Remove the condensate collecting tray (2).

3. Remove the coil fixing screws (5).

4. Take out the coil (3), being careful not to be cut by the fins and not to damage them.

5. Remove the knockouts (1) on the opposite side of the unit (using a screwdriver) to allow the coil connections to pass through.

6. Position the coil, turning it without tipping it upside down, so that the fittings

are in line with the holes left by the knockouts.

7. Fix the coil using the previously removed screws (5).

8. Shift the terminal board (fixing it to the side opposite the water fittings) and

the motor cables, fixing them with their clamps. Ensure that the cables pass

through the hole in the side of the unit, protecting them with the relative grommet. If it proves easier to carry out this operation by separating the wires from

the terminal board, mark the positions of the wires to avoid making mistakes

when reconnecting.

9. Reconnect the wires to the relative terminal board (6), taking care that they

are correctly positioned.

10. Replace the condensate collecting tray (2).

CLEANING AND MAINTENANCE

CAUTION

Before carrying out any cleaning or maintenance work, disconnect the

unit from the mains electricity supply!

ROUTINE MAINTENANCE

The user is duty bound to have all maintenance operations carried out by trained and qualified personnel only. If the unit has to be dismantled, protect hands

with work gloves.

Monthly checks:

- Ensure that the fan impellers are clean. If they are dirty, clean them by suction

so as not to damage them.

- Check the whole of the electrical part and in particular that the electrical connections are tight.

Yearly checks:

- Check the whole of the electrical part and in particular that the electrical connections are tight.

- Check the tightness of all the bolts, nuts and whatever else may be loosened

by the constant vibrations of the unit.

- Check the motor for dust, dirt or other impurities. Periodically check that the

motor works without unusual vibrations or noise and that the fan inlet is not obstructed, which could otherwise leading to overheating of the windings.

- Check the fans for dirt or any foreign matter.

CLEANING THE AIR FILTER

The unit is fitted with an air filter on the fan inlet. During normal operation the

filter holds back impurities in the air.

The filter should be cleaned periodically to keep its filtering properties and the

airflow to the fan unchanged.

It is advisable to clean the filter at least once a month, proceeding as follows.

1. Take out the filter.

2. Place the filter on a flat, dry surface and remove the accumulated dust with

a vacuum cleaner.

3. Wash the filter with water and detergent (no solvents).

4. Leave the filter to dry in a ventilated place in the sun.

5. Replace the filter when it is perfectly dry.

Please clean the air filter every working season of the unit or more frequently considering the unit activity.

NOTE: the filter may also be taken out from the side or from the top.

INS

T

ALL

A

TION, OPER

A

TION

AN

D

MAINTENANC

E MANUAL

Page 23

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

23

WHAT TO DO IF...

There is little outflowing air

Possible cause: incorrect speed setting on the control panel

Possible remedy: select the right speed

Possible cause: clogged filter

Possible remedy: clean the filter

Possible cause: obstruction of the airflow on the intake or delivery

line

Possible remedy: remove obstruction

The motor does not turn? Check that…

... the power supply is switched on

... the switches or thermostats are in the correct

operating position

... there is no foreign matter jamming the rotation of

the fan

The unit does not heat/cool as before? Check that…

... the filter and the coil are clean

... no air has entered the water circuit by bleeding from

the relative valve

... the installation is correctly balanced

... the boiler/chiller is in proper working order

DISMANTLING THE UNIT

This unit is made to last for many years. Qualified personnel are needed to

dismantle it in all safety. The first operation to be carried out before dismantling

the unit is to disconnect it once and for all from the electricity supply.

This unit has been made using recyclable materials (copper, aluminum, brass,

plastic) and assembled by screws and push-fits to make separation of the parts

easy.

Contact a firm specialized in differentiated waste disposal; it is the only way to

be certain of correct recycling and thereby contribute to protection of the

environment.

Page 24

BSW

FAN-COIL HIGH PRESSURE

24

06.18 Ref. 207483 Rev.102

NOTES

Page 25

BSW

FAN-COIL HIGH PRESSURE

06.18 Ref. 207483 Rev.102

25

HIPLUS AIRE

ACONDICIONADO S.L.

Masia Torrents, 2

Tel. +34 93 893 49 12

Fax. +34 93 893 96 15

08800 Vilanova i la Geltrú

Barcelona, Spain

www.hitecsa.com

We reserve the right to change specification without notice.

Loading...

Loading...