Hitecsa ACVA STD 351, ACVBA STD 351, ACVA STD 501, ACVA STD 711, ACVBA STD 401 Installation, Operation And Maintenance Instructions

...Page 1

ACVA - ACVBA

Installation, operation and maintenance instructions

1

Installation, operation and maintenance instructions

ACVA – Cooling Only

ACVBA – Heat Pump

SELF-CONTAINED VERTICAL UNITS

MONOBLOC AIR-AIR

Page 2

ACVA - ACVBA

Installation, operation and maintenance instructions

2

INDEX

INTRODUCTION ................................................................................

3

SAFETY PRECAUTIONS

................................................................................

4

RECEPTION

................................................................................

5

INSTALLATION LOCATION

................................................................................

6

START UP

................................................................................

8

TECHNICAL DATA

................................................................................

11

DIMENSIONS

................................................................................

14

REFRIGERANT CHARGE

................................................................................

18

MAINTENANCE

................................................................................

19

Page 3

ACVA - ACVBA

Installation, operation and maintenance instructions

3

INTRODUCTION

The contents of this manual are designed to assure the correct installation, adjustment and

maintenance of the unit, therefore:

• Read the instructions with due care and attention.

• The appliance must be installed, tested and serviced by properly qualified staff

licensed in accordance with the established legislation.

• The manufacturer declines all liability and warranty coverage is automatically waived,

if electrical and/or mechanical modifications to the unit. Tampering and unauthorized

repairs or modifications to the unit will automatically void the warranty.

• Observe the safety regulations in force at the time of installation.

• Make sure that the characteristics of the mains network conform to the data on the

serial number plate placed on the unit.

• Keep this manual and the wiring diagram with care and make sure that they are

available for consultation by the operator whenever necessary.

• Packing materials (plastic wrappings, expanded polystyrene, etc) are potentially

hazardous and must be kept out of reach of children. Recycle packing materials in

accordance with local legislation.

• The units must be used only for the purpose for which they are designed .The

manufacturer bears no responsibility in the case of applications other than the

specified use.

• Disconnect the unit in the event of breakdowns or malfunctions.

• If repairs are necessary, use only HITECSA approved service centres and always insist

on original spare parts. The use of non-original parts and/or unauthorized service

centres may result in unsafe operation of the unit.

REGULATIONS AND CERTIFICATIONS

ISO 9001:2008 certification: HITECSA AIRE ACONDICIONADO S.L.U., trying always to find the

customer satisfaction, has obtained the ISO 9001:2008 Quality System referred to its

production activity. This will results in a continuous determination to improve quality and

reliability of all our products; commercial activities, design, raw materials, production and

after-sales service, are the means to reach our goal.

CE marking: our machines have got the CE mark, in conformity with the essential requirements

of the applicable EC directives and their last modifications as well as with the national

legislation of each country.

Page 4

ACVA - ACVBA

Installation, operation and maintenance instructions

4

SAFETY PRECAUTIONS

• Installation and maintenance of air conditioning equipment can be dangerous because the

system is under pressure, because some of its elements have high temperatures and

include electrical components.

• Only qualified and trained service staff should install,commission and carry out

maintenance works. Unqualified staff should only carry out basic tasks such as cleaning

and replacement of filters, etc.

• In every visit, all precautions should be taken into account: those recommended in the

Installation, operation and maintenance instructions, as well as the ones indicated in labels

of the unit. Do not forget to strictly follow any other safety codes.

• Use safety glasses, work gloves and any other safety accessory necessary.

• For brazing operations use a quenching cloth and have at close distance a fire extinguisher.

WARNING!

Before starting installation, service or maintenance, turn off the main power switch in order

to avoid electrical shock that may cause personal damages.

• When repairing the unit, use only original spare parts and install them properly in the

same position where old parts were placed.

These units are designed to work with 100% recirculated air. The installation with 100% outdoor air

is prohibited. See application limits.

•

Do not install the unit in explosive atmosphere.

•

Page 5

ACVA - ACVBA

Installation, operation and maintenance instructions

5

RECEPTION

INSPECTION UPON RECEIPT

• Units are delivered with special protective packing; therefore when it arrives, please

inspect it carefully to check that no damage has occurred during transport and that the

unit has been supplied complete with all parts specified in the order. If any damage is

found, immediately file a claim with the transport company.

• Verify the correct voltage of the nameplate and make sure it’s in accordance with local

power supply.

• In case of any flaw or anomaly detected, please contact HITECSA

RIGGING

• Before moving the unit, make sure that all panels are well fixed.

• Raise and set down the equipment carefully.

• Do not tilt the unit more than 15 degrees during transportation.

• When lifting the unit, make sure that it’s balanced and stable; bear in mind that the

heaviest part is where the compressor is installed.

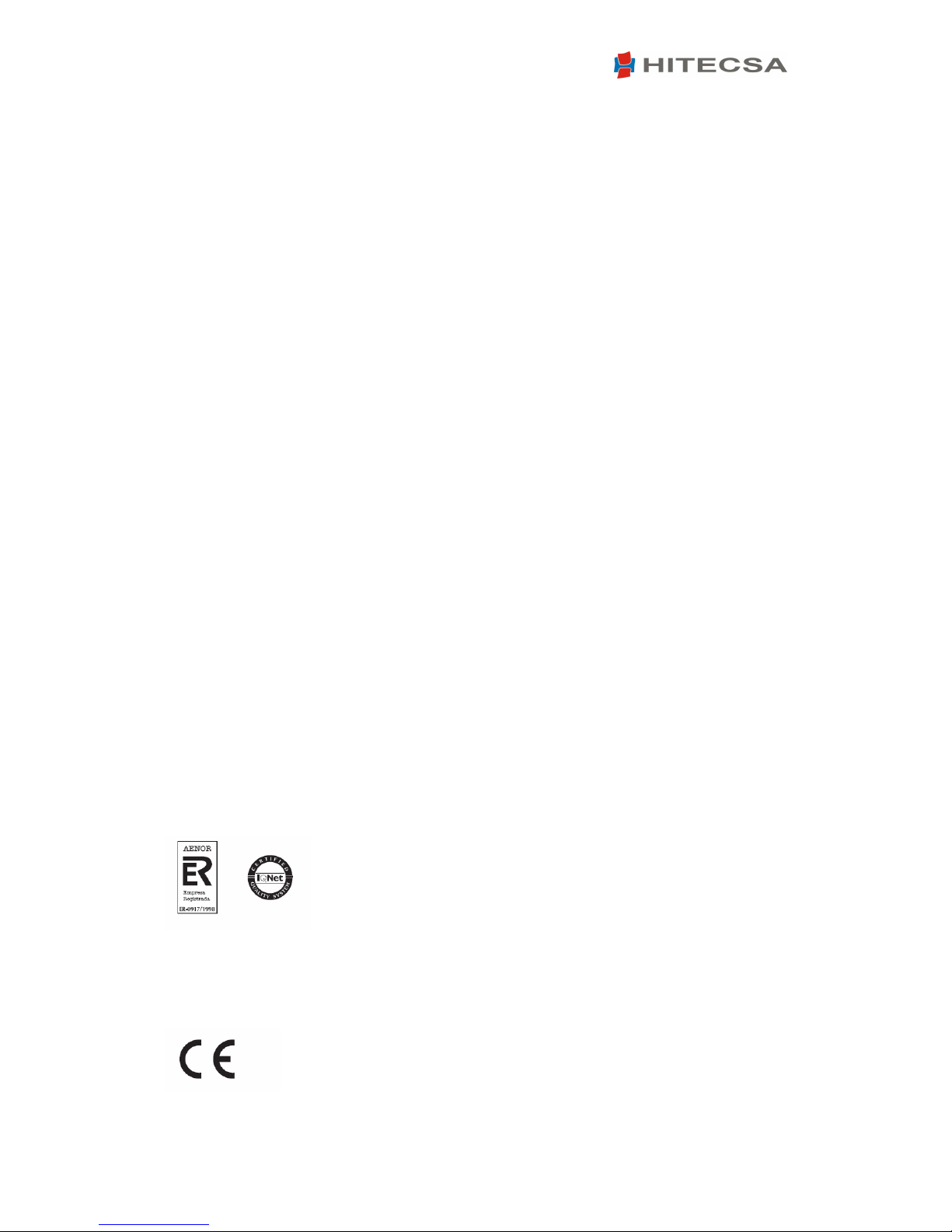

• Check minimum length of wire raising (Fig.1)

Fig

.1

Page 6

ACVA - ACVBA

Installation, operation and maintenance instructions

6

STORAGE

If the equipment is going to be stored please follow the instructions below in order to avoid

damages, corrosion or deterioration:

• Keep the unit away from direct sunlight, rain, sand, wind or temperatures above 50ºC

• Storage temperature: maximum 50ºC, minimum -10ºC

• Maximum humidity: 90%

INSTALLATION LOCATION

• Check if the base is able to support the weight of unit during operation.

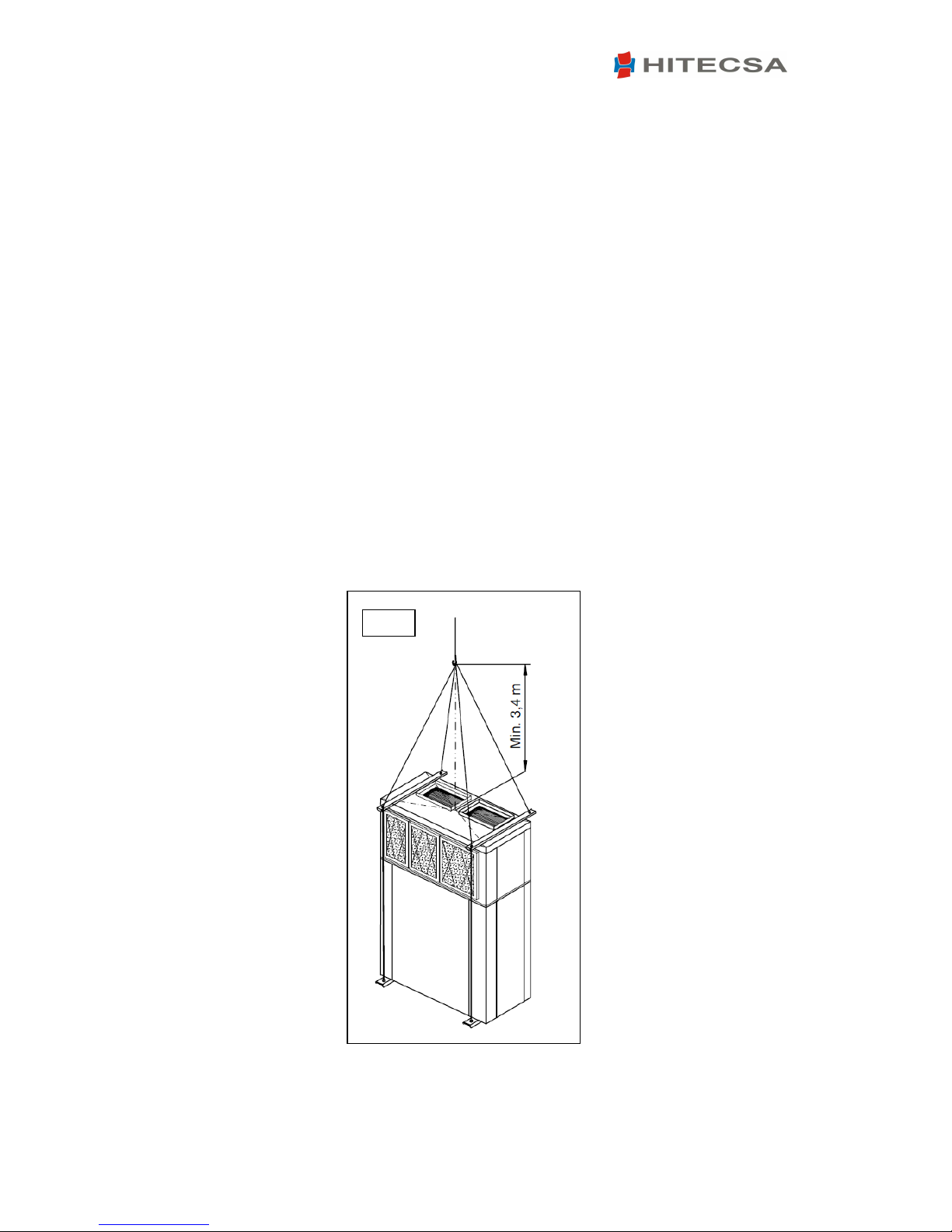

• Reserve a minimum service area according to Fig. 2.

• Choose a place free of dust or any other foreign material that could clog or damage the

condenser coil. The location should also be a place that cannot be flooded.

• Consult and respect all regulations concerning installation of air conditioning systems.

• Check if sound waves do not disturb anyone.

SERVICE AREA (mm)

Fig

.2

Page 7

ACVA - ACVBA

Installation, operation and maintenance instructions

7

UNIT SETTLEMENT

• Make sure that the unit is correctly levelled.

• The bed frame should be strong and solid enough to support the weight of the machine.

• Verify that the indoor drain is working properly.

WEIGHT DISTRIBUTION (Kg)

Page 8

ACVA - ACVBA

Installation, operation and maintenance instructions

8

BEFORE START UP

• Check the following points:

o Wires are well tightened.

o Panels are firmly secured with screws.

o There are no oil or refrigerant leaks.

o The unit is correctly levelled.

o There is enough space for service and maintenance.

o Drainage is not blocked.

o Crankcase heater has been working at least 24 hours prior to the start-up.

o Air filters are clean and correctly mounted.

o Grilles, air diffusers, air ducts and flexible connections are in good condition.

o Electrical power source is in accordance with what is said in the nameplate.

o Fans rotate in the right direction.

.

START UP

• Start up should be performed by qualified technical people.

• Use a start up check list: record inlet and outlet temperatures and pressures, outdoor air

temperature, volts and amps of each compressor and each fan motor, suction and

discharge pressure of each compressor.

• Use a similar check list for service and maintenance works.

• Remember that after 4 hours of operation, it is necessary to clean the filters.

• Monitor at least 3 cooling cycle operations.

OPERATION LIMITS

COOLING MODE

TEMPERATURE MINIMUM MAXIMUM

Outdoor ambient 19ºC 46ºC

Indoor dry bulb 19ºC 32ºC

Indoor wet bulb 15ºC 23ºC

HEATING MODE

TEMPERATURE MINIMUM MAXIMUM

Indoor dry bulb 18ºC 26ºC

Outdoor wet bulb -7ºC 18ºC

*For temperatures of less than 19ºC it is necessary

to use the condensation control optional.

*

Page 9

ACVA - ACVBA

Installation, operation and maintenance instructions

9

ELECTRIC CONNECTIONS

Legend

1. Main power 400/3/50 + neutral

2. Earth

3. Crankcase heater (230/1/50)

4. Time-delay fuses or circuit breaker (MCB) curve D

5. Main power switch

6. Remote control

WARNING!

Before starting installation, service or maintenance, turn off the main power switch in order

to avoid electrical shock that may cause personal damages.

• Main power supply of the unit should agree with the data shown on the nameplate.

HITECSA will not be held responsible for damages resulted from non observance of the

above.

• Always use the wiring diagram sent with the unit to make electrical connections.

• Check that the crankcase heater has been working at least 24 hours prior to the start up of

the unit.

• Current supply should be within 10% of Volts and Amperes indicated on the unit

nameplate.

• Do not operate the unit at different current from that shown on the unit nameplate.

• The installer should put line protection elements in compliance with current legislation.

• The interconnecting wires should be protected with a tube or put inside a groove channel.

2

1

4

5

3

6

Page 10

ACVA - ACVBA

Installation, operation and maintenance instructions

10

DRAINAGE

• Indoor drainage (of condensate water) has a 3/4” MPT connection.

• Condensate drain line diameter should be equal or larger than the unit connection

depending on line length and general building configuration.

• Drainage line should have a minimum inclination of 2% for proper water evacuation.

• When drainage line is exposed to temperatures below 0ºC, it is necessary to provide

thermal insulation or electrical heating wire to avoid water freezing and tube damages

•

It is advisable to install a trap with proper dimensions.

Page 11

ACVA - ACVBA

Installation, operation and maintenance instructions

11

TECHNICAL AND ELECTRIC DATA

CAPACITIES

Cooling capacity

kW

9,8

12,5

14,4

18,9

19,6

Heating capacity

kW

10,4

13,7

15,0

20,0

21,0

EER efficiency

2,2

2,2

2,0

2,3

2,1

COP efficiency

2,5

2,7

2,3

2,6

2,6

Number of refrigerant circuits

11111

REFRIGERANT

Charge

Kg

3,50 4,20 4 6,20 5,80

COMPRESSOR

Type

Rotary

Scroll

Scroll

Scroll

Scroll

Quantity

11111

Type of oil

PVE

PVE

PVE

PVE

PVE

Volume of oil

l

1,3

1,7

1,7

1,7

2,8

Type

FV60S

FV68S

FV68S

FV68S

FV68S

OUTDOOR FAN

Type

Nominal airflow

m3/h

4300

3950

4900

6800

6800

Available static pressure

Pa5050505050Model

10/10 SS

12/12 SS

12/12 SS

15/15 SS

15/15 SS

Capacity

kW

0,75

0,55

0,75

1,1

1,1

Speed

r.p.m.

1083

825

829

746

746

INDOOR FAN

Type

Nominal airflow

m3/h

2315

2600

3540

4720

4720

Available static pressure

Pa4350605555Model

10/10 DD

10/10 SS

10/10 SS

12/12 SS

12/12 SS

Capacity

kW

0,25

0,55

0,55

0,75

0,75

Speed

r.p.m.

872

870

1032

809

809

Voltage

Total input power cooling

kW

4,6

5,7

7,3

8,4

9,27

Total input current cooling

A

9,2

10,5

13,3

16,0

17,8

Total input power heating

kW

4,2

5,1

6,5

7,9

8,16

Total input current heating

A

8,4

9,7

11,8

14,7

15,8

Max. Input power cooling

kW

5,4

7,3

9,5

11,0

11,10

Max. Input current cooling

A

9,7

12,3

15,0

19,3

19,5

Max. Input power heating

kW

5,0

6,3

7,5

9,0

9,21

Max. Input current heating

A

8,9 10,9 12,6 15,6 16,5

Starting current

A

48,0

63,0

66,0

67,0

102,0

DIMENSIONS AND WEIGHT

Lenght

mm

937

937

1087

1130

1130

Width

mm

750

750

750

800

800

Height

mm

1603

1603

1603

1900

1900

Weight

Kg

251

276

290

367

392

400V-~3N-50Hz

GENERAL SPECIFICATIONS FOR ELECTRIC INSTALLATION

Centrífugal, double suction

R-410A

1725

Type

Global warming potential (GWP)

Centrífugal, double suction

701 721

ACVA STD

351 501

ACVBA STD

401

Page 12

ACVA - ACVBA

Installation, operation and maintenance instructions

12

CAPACITIES

Cooling capacity

kW

22,7

24,2

30,1

34,9

37,8

Heating capacity

kW

23,9

25,3

31,7

38,2

39,5

EER efficiency

2,1

2,2

2,3

2,4

2,3

COP efficiency

2,3

2,6

2,6

2,9

2,6

Number of refrigerant circuits

11112

REFRIGERANT

Charge

Kg

7,20

7,70

9,50

10,50

2 x 6,5

COMPRESSOR

Type

Quantity

11112

Type of oil

PVE

PVE

PVE

POE

PVE

Volume of oil

l

2,8

2,8

2,8

3,3

2 x 1,7

Type

FV68S

FV68S

FV68S

160SZ

FV68S

OUTDOOR FAN

Type

Nominal airflow

m3/h

7400

7714

10000

12500

13600

Available static pressure

Pa5057505088Model

15/15 SS

15/15 SS

15/11 G2L

15/11 G2L

2 x 15/15 SS

Capacity

kW

1,5

1,5

1,5

2,2

2 x 1,1

Speed

r.p.m.

834

808

686

760

718

INDOOR FAN

Type

Nominal airflow

m3/h

5133

5125

6277

8000

8000

Available static pressure

Pa53837391

130

Model

12/12 SS

12/12 SS

12/12 G2L

12/12 G2L

12/12 G2L

Capacity

kW

1,1

1,1

1,1

1,5

1,5

Speed

r.p.m.

891

910

800

896

862

Voltage

Total input power cooling

kW

10,9

10,9

13,4

14,4

16,6

Total input current cooling

A

20,2

20,4

24,5

27,8

31,0

Total input power heating

kW

10,3

9,6

12,4

13,2

15,9

Total input current heating

A

19,3

18,3

22,3

25,6

28,4

Max. Input power cooling

kW

13,8

13,6

16,5

17,8

14,2

Max. Input current cooling

A

23,5

23,2

28,0

30,9

37,4

Max. Input power heating

kW

12,3

12,0

15,8

16,4

18,3

Max. Input current heating

A

21,2

20,5

26,0

28,5

30,1

Starting current

A

102,0

102,0

102,0

158,0

67,0

DIMENSIONS AND WEIGHT

Lenght

mm

1130

1130

1700

1700

2000

Width

mm

800

800

870

870

939

Height

mm

1900

1900

1900

1900

1997

Weight

Kg

423

440

553

558

730

Scroll

400V-~3N-50Hz

GENERAL SPECIFICATIONS FOR ELECTRIC INSTALLATION

1201 1402

ACVBA STD

Type R-410A

ACVA STD

751 801 1001

Centrífugal, double suction

Global warming potential (GWP) 1725

Centrífugal, double suction

Page 13

ACVA - ACVBA

Installation, operation and maintenance instructions

13

CAPACITIES

Cooling capacity

kW

49,6

50,2

63,1

73,6

78,5

Heating capacity

kW

51,2

51,9

65,5

81,9

81,9

EER efficiency

2,6

2,5

2,4

2,6

2,3

COP efficiency

3,0

2,9

2,9

3,0

2,8

Number of refrigerant circuits

22222

REFRIGERANT

Charge

Kg

2 x 6,3

2 x 6,6

2 x 8,0

2 x 10,3

2 x 9,0

COMPRESSOR

Type

Quantity

22222

Type of oil

PVE

PVE

PVE

POE

POE

Volume of oil

l

2 x 2,8

2 x 2,8

2 x 2,8

2 x 2,3

2 x 3,3

Type

FV68S

FV68S

FV68S

160SZ

160SZ

OUTDOOR FAN

Type

Nominal airflow

m3/h

15600

16000

22000

23000

23000

Available static pressure

Pa

110

110

123

142

142

Model

2 x 15/15 SS

2 x 15/15 SS

2 x 18/18 SS

2 x 18/18 SS

2 x 18/18 SS

Capacity

kW

2 x 1,5

2 x 1,5

2 x 2,2

2 x 3

2 x 3

Speed

r.p.m.

808

808

671

734

787

INDOOR FAN

Type

Nominal airflow

m3/h

10000

10000

11000

12000

12000

Available static pressure

Pa

145

145

175

160

160

Model

12/12 G2L

12/12 G2L

15/11 G2L

15/11 G2L

15/11 G2L

Capacity

kW

2,2

2,233

3

Speed

r.p.m.

913

913

734

787

734

Voltage

Total input power cooling

kW

19,8

20,8

27,0

28,3

34,2

Total input current cooling

A

36,0

37,0

48,1

56,1

57,2

Total input power heating

kW

17,5

18,6

23,7

27,0

28,9

Total input current heating

A

34,8

35,8

44,1

52,7

52,7

Max. Input power cooling

kW

25,4

26,6

33,2

33,5

42,7

Max. Input current cooling

A

41,9

43,0

55,0

58,8

63,9

Max. Input power heating

kW

21,3

22,6

30,2

30,6

36,2

Max. Input current heating

A

38,2

39,3

51,4

55,0

58,7

Starting current

A

102,0

102,0

158,0

179,0

158,0

DIMENSIONS AND WEIGHT

Lenght

mm

2000

2000

2600

2600

2600

Width

mm

939

939

980

980

980

Height

mm

1997

1997

2174

2174

2174

Weight

Kg

810

820

1080

1115

1135

400V-~3N-50Hz

Scroll

GENERAL SPECIFICATIONS FOR ELECTRIC INSTALLATION

Centrifugal, double suction

R-410A

Global warming potential (GWP)

Centrifugal, double suction

ACVA STD

1502 1602 2002 2302 2402

ACVBA STD

Type

(1) COOLING: Outdoor temperature: 35 °C. Indoor WB temperature 19 °C.

DIMENSIONS

(1) COOLING: Outdoor temperature: 35

°

C. Indoor WB temperature 19

°

C.

(2) HEAT PUMP: WB outdoor temperature.: 6 °C. Indoor temperature: 20 °C.

Page 14

ACVA - ACVBA

Installation, operation and maintenance instructions

14

DIMENSIONS

ACVA

–

ACVBA

351 -

501

Page 15

ACVA - ACVBA

Installation, operation and maintenance instructions

15

ACVA

–

ACVBA

701 - 801

Page 16

ACVA - ACVBA

Installation, operation and maintenance instructions

16

ACVA

–

ACVBA

1001

- 1201

Page 17

ACVA - ACVBA

Installation, operation and maintenance instructions

17

ACVA

–

ACVBA

1

402 – 1502

-

1602

Page 18

ACVA - ACVBA

Installation, operation and maintenance instructions

18

ACVA

–

ACVBA

2002

– 2302 - 2402

Page 19

ACVA - ACVBA

Installation, operation and maintenance instructions

19

REFRIGERANT CHARGE

WARNING!!!

Never use oxygen to carry out leak tests. Oxygen reacts violently when in contact with oil

and could cause an explosion resulting in damage, personal injuries or even death.

• Should it be necessary to add or recover refrigerant, do it always in LIQUID phase, never in

gas or vapour phase since this would cause wrong mixing conditions.

• Due to its high pressure and quick evaporation, refrigerant R410A cannot be kept in liquid

phase inside charge cylinder because bubbles would form, making reading difficult.

WARNING!!!

If it’s necessary to make welding operations, you must fill the circuit with dry nitrogen.

Combustion of R410a refrigerant generates toxic gases.

• Repair immediately any refrigerant leak.

• Never overcharge the system.

• Never use compressor as a vacuum pump.

• If symptoms of refrigerant loss appear during operation, it’s necessary to carry out a leak

test. Leak detectors usually employed with CFC and HCFC cannot be used with R410a, due

to chlorine in its composition. A leak detector for R134a may be used but the sensibility

will be lower (when sensibility is 1 for R134a, it falls to 0,6 for R410a).

• To find small leaks, you will need a detector for HCF. Sensibility for R410A is approx. 23

grams per year.

• If a gas leak is found, it will be necessary to remove and completely recover the refrigerant

charge. Pressurize the system with dry nitrogen. If no leakage is detected, then do the

vacuum and charge again with refrigerant.

Page 20

ACVA - ACVBA

Installation, operation and maintenance instructions

20

MAINTENANCE

WARNING!!!

Before performing any service or maintenance operation, turn off the main power switch of

the system to avoid any personal injuries. Block the power switch so that nobody other than

a qualified technician can switch on electrical power.

• It is advisable to do maintenance works every 1.000 operating hours as well as at the

beginning of each cooling season.

• Coils: at least once a year, clean condenser coils with water and detergent, then dry

with air at a pressure of 600 kPa. Never clean with wire brush.

• Fans and motors: adjust transmission belt at least twice during the first month of

operation and then check every 1.000 hours. Fan and motors do not need additional

lubrication.

• Drainage system: verify condition and good operation of the drainage tray. Make sure

that holes at the base of the unit are not blocked so that evacuation can be properly

done.

• Refrigeration circuit: check for oil refrigerant leaks, noises or system’s vibrations. Take

measurements of temperatures and pressures of components and record them on the

maintenance form.

•

Electrical circuit: make sure that all electrical connections -wires, contactors,

terminals- are properly tight. Record the measurements (volts and amperes) of each

compressor and fan motor. Verify the starting current. Check the good operation of all

relays, pressostats and phase sequence relay of Scroll compressor.

Page 21

ACVA - ACVBA

Installation, operation and maintenance instructions

21

www.hitecsa.com

HITECSA AIRE ACONDICIONADO S.L.U.

Masia Torrents, 2

08800 Vilanova i la Geltrú (Barcelona)

SPAIN

Tel. +34 93 893 49 12

Fax. +34 93 893 96 15

info@hitecsa.com

Loading...

Loading...