Page 1

Page 2

Page 3

TABLE OF CONTENTS

Introduction

Table of Contents

What’s New?

Projuct Support

Safety Information

Warnings

Hitec 2.4GHz System Set-up

2.4GHz Module Features

Optima Series Receiver Features

Set-up and Use

Range Check Function

Scanmode Set-up

Failsafe

Telemetry System

SPC(Supplementary Power Connection) System

Charging the Eclipse 7 Ni-Mh Batteries

Operating With A Trainer Cord

Other Adjustments

Adjustable length control sticks

Stick lever tension adjustment

Throttle ratchet change

Changing the Eclipse 7 transmitter’s mode

Factory Service Repair Information

Eclipse 7 Controls and Switch Assignments

Mode II

Transmitter Input Buttons

Receiver - Servo Connection List

Warning Displays

Model Setup Functions

MODL - Model Select

VER - Version

REST - Data Reset

TIME -Timer Function Setup

COPY - Copy Model

ACRO, HELI, GLID - Model Type Select

Wing & Swashplate Type Selection

Model Name

MODE - Mode 1,2,3,4, Changeable

Telementry Display Function

AIRCRAFT (ACRO) MENU FUNCTIONS

Simple Transmitter Setup Aerobatic Airplane (ACRO)

Eclipse 7 Pro Aircraft Controls

and Switch Assignments 1

Airplane Model Function Descriptions

EPA - End Point Adjust

D/R - Dual Rates

EXP - Exponential

FLT.C - Flight Condition Menu

STRM - Subtrim Settings

REV - Servo Reversing

T.CUT - Throttle Cut(Engine Shut off)Function

PMX1 to PMX5 - Programmable Mixes

1, 2, 3, 4, & 5

LAND - Landing Function

FLPT - Flap Trim Function

E->F - Elevator Flap Mixing

A->R - Aileron Rudder Mixing

ELVN - Elevon Mixing

VTAL - V-Tail Mixing

FLPN - Flaperon Mixing

AILV - Ailevator (2Elevon Aileron Mixing)

MX.SS - Mix Switch Select

Aircraft Flight Trimming Chart

Glider (GLID) Menu Functions

2

Eclipse 7 Glider Controls

and Switch Assignments

2

3

6

12

12

12

13

13

Competition Glider Quick Setup Instructions

Glider Model Function Descriptions

ADIF - Aileron Differential

VTAL - V-Tail Programming

E->F - Elevator Flap mixing

A->R - Aileron Rudder mixing

F->A - Flap Aileron mixing

F->E - Flap Elevator mixing

CROW - Crow mixing (airbrakes)

S.TM1, 2 - Speed Flap Trim offsets 1, 2

AIL.T - Aileron trim

A->F - Aileron Flap mixing (4WNG only)

DFL.T - Dual Flap Trim (4WNG only)

MX.SS - Mix Switch Select

SAILPLANE TRIMMING CHART

Eclipse 7 Helicopter (HELI) Programming

Eclipse 7 Helicopter Controls

and Switch Assignments

Helicopter Setup Instructions

Menu Descriptions - Helicopter

14

16

16

18

19

19

19

19

20

20

20

21

22

22

22

Flight Conditions

R->T - Rudder Throttle Mixing

GYRO - Gyro settings

HOLD - Throttle Hold

THCV - Throttle Curve

PTCV - Pitch Curve

RVMX - Revolution mixing

SWAH - Swashplate adjust (120’,140’, 180’)

MX.SS - Mix Switch Select

Hovering Throttle Adjustment Knob

Hovering Pitch Adjustment Knob

Helicopter Flight Trimming Chart

Adjust Hovering Pitch and

Hovering Throttle

24

24

30

29

29

29

32

33

33

34

34

34

35

35

36

36

37

37

38

39

39

40

42

43

45

47

48

48

48

48

48

48

49

50

50

50

51

52

53

56

54

56

59

59

59

59

60

60

60

62

61

61

61

61

62

62

Page 4

What’s New?

Many of you have owned or used earlier model Hitec transmitters. Here are four “new” Hitec transmitter features that set the

Eclipse 7 Pro apart from all other Hitec products.

1. Signal Protocol

Using Hitecs AFHSS 2.4GHz module to link with Hitec Optima AFHSS 2.4GHz receivers.

2. Gimbals

Feel the silky smooth action of the new four ball bearing supported gimbals in the Eclipse 7 Pro. These new gimbals were created to give you the smoothest action demanded by the highest performance aircraft.

3. Switch Assignments

During the model programming steps you will be asked to select what stick, switch or slider controls the features you want to

use with your model. This gives you unlimited exibility to choose the most comfortable and practical way for you to use the

Eclipse 7 Pro..

4. Channel and Control Assignments

The Eclipse 7 Pro will automatically select the channel and control assignments based on the model you have. There is the

option to change them if you wish, allowing you a wider choice of receivers that can be used with the Eclipse 7 Pro..

Safety Information

Flying models can be dangerous if proper safety precautions are not followed. Here are a few critical safety

suggestions to keep you and others safe.

Are you experienced?

Flying models is not an intuitive process. Most accomplished model pilots were taught by another modeler. We encourage

you to seek help during your early ight experiences and if required, during the building and gear installation process. Unlike

some other hobbies, model airplane ying has evolved into a social event. There are approximately 2,500 model aircraft clubs

in America. Friendship and help could be right around the corner. Ask your local hobby shop about clubs in your area.

Where to Fly

Having enough land for your own model airport is rare. Most of us y at club administrated model elds. The local ball eld

can be tempting but rarely has the space needed and your liability is high should you damage property or hurt an innocent

person. We recommend you y at a sanctioned model aircraft eld.

Join the AMA

In America, the Academy of Model Aeronautics (AMA) is an organization of model enthusiasts that provide resources and

insurance to modelers. The AMA also lobbies the Government concerning legislation that impact modelers.

Visit their web site for more information, www.modelaircraft.org.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, Indiana 47302

Toll Free : 800 435-9262

Fundamental Guidelines for Safe Flying

1. Don’t y over people or personal property.

2. Make sure you do a range and pre-ight check on your aircraft.

3. Check for others ying on your frequency. (No need with 2.4GHz)

4. Know your batteries condition. Keep them charged.

5. The equipment we use in the R/C hobby is sensitive electronic gear. Have receivers checked after a crash before using

them in another aircraft.

6. Use the Fail-Safe function in AFHSS mode to lower the throttle in case of a signal “lock-out”.

7. Don’t y alone.

2

Page 5

Hitec 2.4GHz System Set-up

TRAINER

2.4GHz Module Features

The following contains the complete instructions on how to use the Optima 2.4GHz series receivers and Eclipse 7 Pro set for a

trouble free 2.4GHz signal. We encourage you to review this information before using these products.

1. Dual Blue and Red Status indicator LED’s

Indicates the set-up process codes and use status..

2. Function Button

Used for Linking(ID -Setting) the Eclipse 7 Pro to a receiver, entering the power down mode for range checks and the Nomal /

Scan Mode set-up.

3. Sensor Data Output and System Upgrade Connector Port

A 3 pin servo plug connector port is featured on back side of Eclipse 7 Pro . Using the HPP-22 PC interface accessory this

port serves to facilitate upgrading the devices software and downloading information from Optima 7,9 receiver if using

optional onboard sensor station..

2. Function Button

1. LED

3. Sensor Date Output &

System Update Port

3

Page 6

Hitec 2.4GHz System Set-up

Optima Series Receiver Features

As of this writing, there are three Optima 2.4GHz receivers that are compatible with the Eclipse 7 Pro .The Optima 6, Optima 7

and the Optima 9 channel products are loaded with a variety of functions that are sure to deliver a satisfying R/C experience.

1. Telemetry Sensor and System Port

A three pin servo plug connector port is featured on the Optima 7 and 9 ch receivers. Using the HPP-22 PC interface acces

sory this port serves to facilitate upgrading the devices software and interfacing the optional onboard sensor station.

2. Function Button

Used for Linking(ID-Setting) the receiver to a Eclipse 7 Pro , entering Fail-Safe / Hold mode setup function.

3. Dual LED Status Indicator

Indicates the set-up process codes and use status

4. SPC Supplementary Power Connection

Power the Optima receiver function with up to a 35V. motor battery. Details about the SPC system can be found on page 9.

5. Channel Output and Battery Input Ports

The ports for battery power, servos, gyros and other accessories are located at each end of the streamlined Optima receivers.

6. Jumpers

The jumper is installed at the factory and is used when the receiver is powered by an electronic speed control, a commercially

available B.E.C. (battery eliminator circuit), dedicated 4.8 to 6V. NiMH battery pack, or *2S Li-Po/Io/Fe batteries. The jumper is

removed when the receiver is powered using the SPC feature as described in more detail on page 9.

(*Verify your servos are rated for use with these higher voltage batteries or use a regulator.)

Normal / Scan Mode Selectable

Select between two operational signal types. See page 6 for details.

FAIL-SAFE Option

Servos and other accessories may be programmed with a FAIL-SAFE point in the event power to the receiver is interrupted.

See page 7 for details..

Onboard Receiver Battery Warnings

Know when your on-board battery is low with direct telemetry feedback to your transmitter. See page 8 for details.

1

1. Function Button

2. Dual LED Status Indicator

3. Channel Output and Battery Input Ports

4. SPC (Supplementary Power Connection)

5. Telemetry Sensor and System Port

2

4

3

5

1

4

2

3

4

Page 7

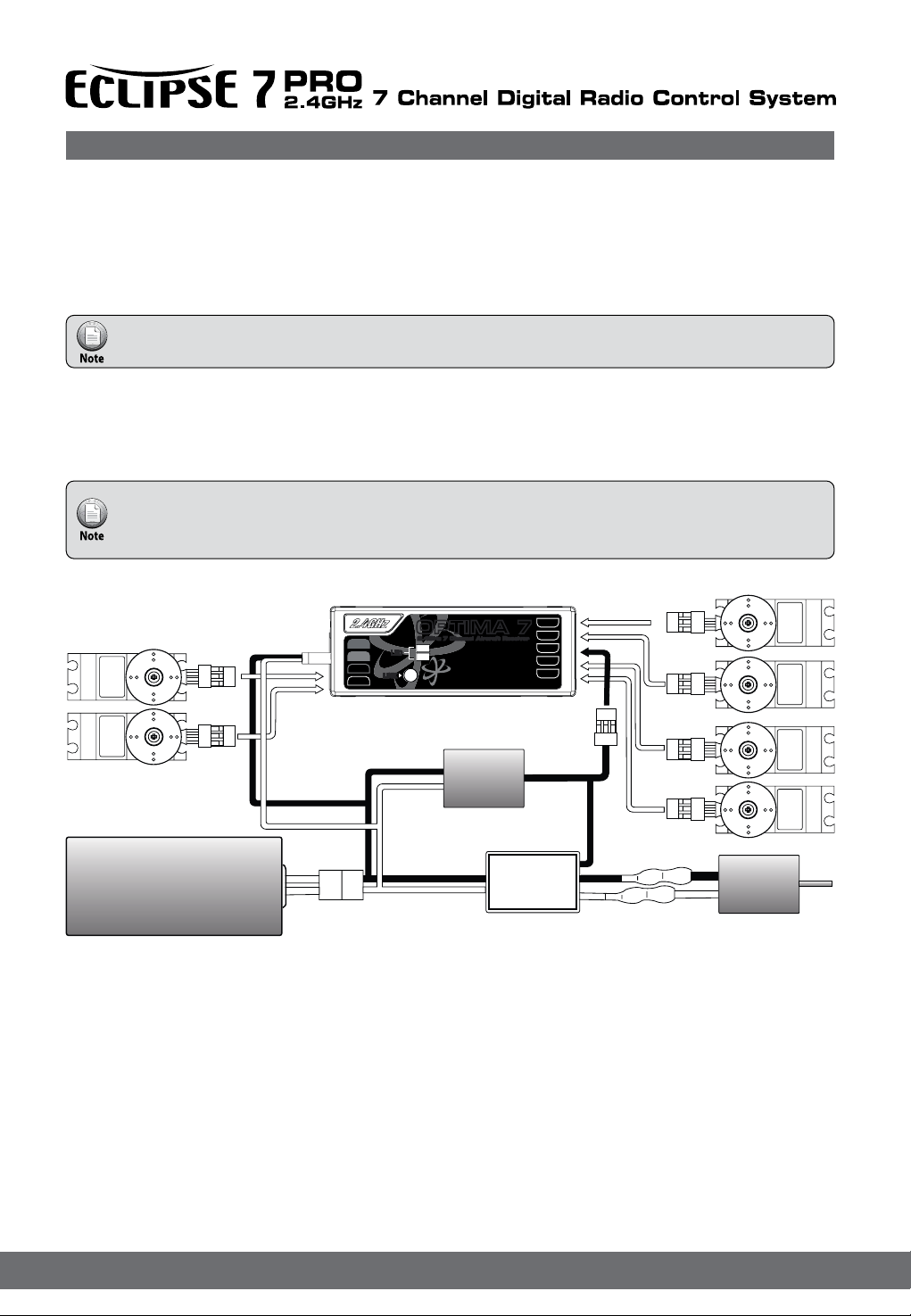

Hitec 2.4GHz System Set-up

Optima Receiver Connection Diagrams

Glow, gas or electric powered aircraft using a separate receiver battery supply.

Follow this connection diagram when using a dedicated 4.8 to 6V. NiMH battery pack, or *2S Li-Po/Io/Fe batteries

Verify your servos are rated for use with these higher voltage batteries or use a regulator.

SERVO

ADAPTIVE

FREQUENCY HOPPING

SPREAD SPECTRUM

CH1

CH2

CH3

CH4

CH5

DATA

SPC

BAT/CH7

CH6

OPTIMA 7OPTIMA 7

2.4GHz 7 Channel Aircraft Receiver2.4GHz 7 Channel Aircraft Receiver

LED

LINK

LINK

LED

2.4GHz

Telemetric

AFHSS

SERVO

Receiver

Battery

Electric powered aircraft with Electronic Speed Control

Use this method on electric planes using ESC’s providing power to the receiver and servo functions

SERVOSERVO

DATA

SPC

BAT/CH7

CH6

OPTIMA 7OPTIMA 7

2.4GHz 7 Channel Aircraft Receiver2.4GHz 7 Channel Aircraft Receiver

LED

LINK

LINK

LED

2.4GHz

Telemetric

AFHSS

ADAPTIVE

FREQUENCY HOPPING

SPREAD SPECTRUM

CH1

CH2

CH3

CH4

CH5

SERVO SERVO

SERVOSERVO

Engine

SERVO SERVO

BEC

Power Battery

Optional BEC shown in diagram is used if the servo power requirements exceed that which the ESC provides.

ESC

5

SERVOSERVO

Motor

Page 8

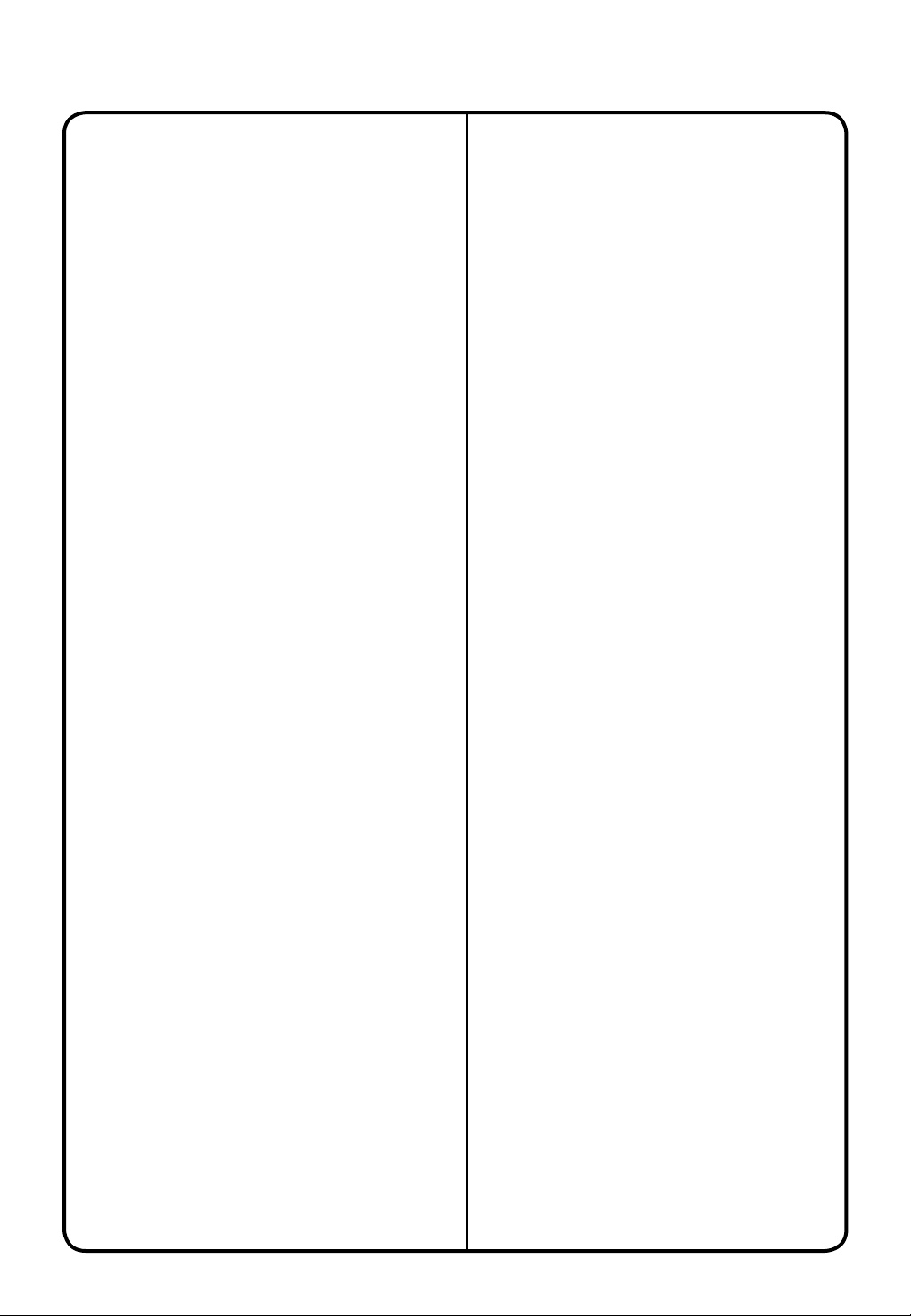

Set-up Use of the Hitec 2.4GHz System

General Use Guidelines

To turn the system on and off, use the following sequence at all times

Turning On -Turn on the transmitter, then turn on the receiver. Turning Off -Turn off the receiver, then turn off the transmitter.

Range Check Function

It is critical that before each ight session you perform a range check that conrms the signal between the receiver and transmitter is appropriate. Unlike the FM/PPM or PCM signal radios, 2.4GHz systems use a xed shorter, stubby transmitter antenna, so

called rubber duck antenna. So the traditional method of range check, lowering the transmitter antenna, is not applied.

The Hitec 2.4GHz System uses a power-down mode to reduce the transmitter signal strength.

Once the power-down mode is activated it runs for about 90 seconds, effectively shortening the range to 30 meters, or 100

feet. During this power-down mode that you should walk away from the secured aircraft carrying the transmitter to a minimum

distance of approx. 30 meters or 100 feet, testing the effective range.

How to use Power-Down

- Before each ying session, conrm the radio system is working properly.

- Before the engine or motor is started, turn on the system as explained above.

Then make sure all the servos and control surfaces are working properly.

If any control surface is not moving properly, do not y the aircraft until the problem is solved.

- If you are unable to accomplish a successful range check of 30 meters or 100 feet,

DO NOT ATTEMPT TO FLY.

Link Guidelines

- Link must be done within 15ft.(5m) of the transmitter and receiver.

- Transmitter and receiver need to be at least 18in.(50cm) from each other to link properly.

6

Page 9

Set-up Use of the Hitec 2.4GHz System

R

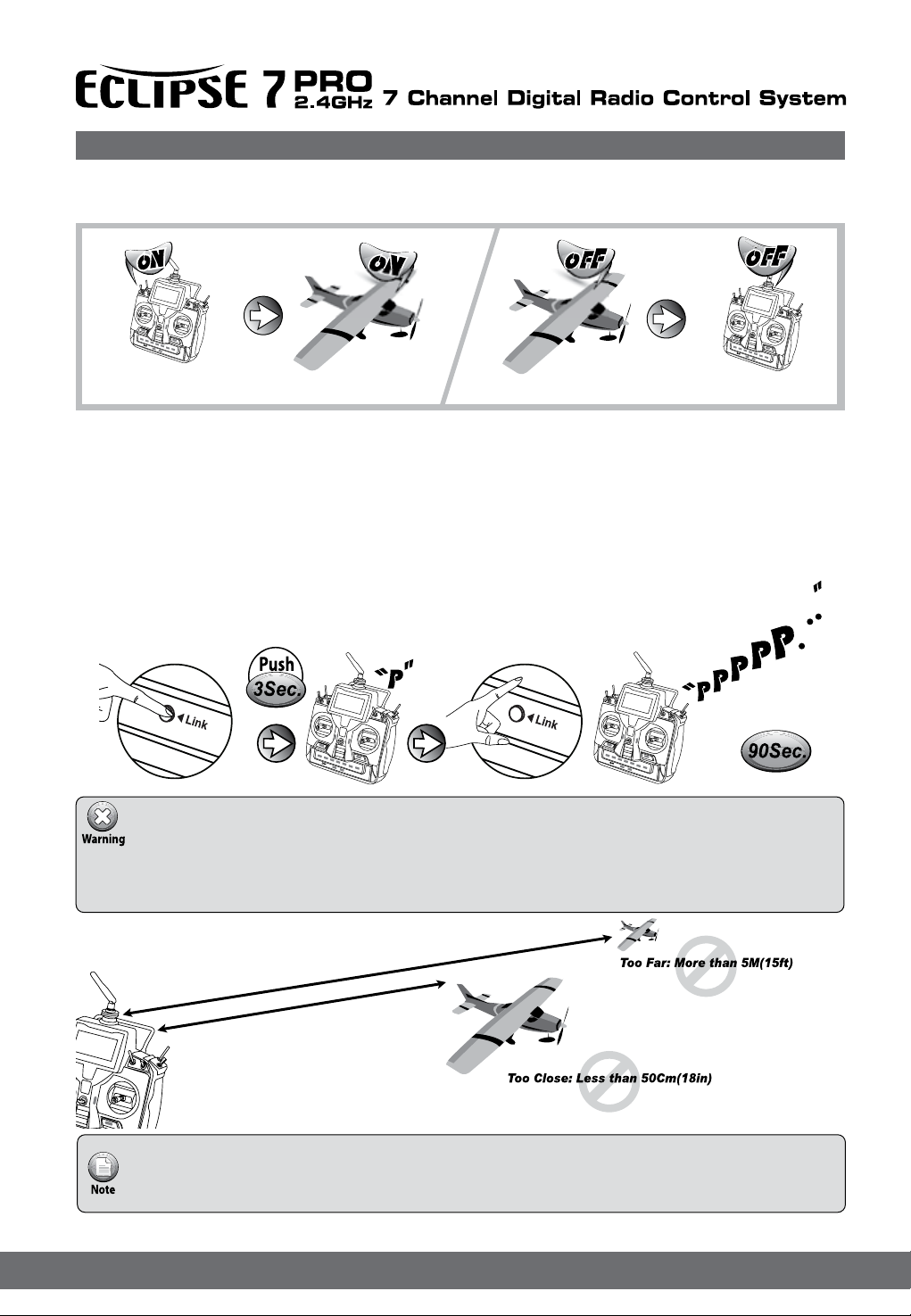

ID-Setup A.K.A, Link or Bind

Press and hold the Link button, and turn on the transmitter.

Release the link button.

Check if BLUE LED is blinking.

If RED LED is blinking, press

the link button for 2 sec., so

that LED changes to the BLUE.

Check if RED LED is blinking.

If BLUE LED is blinking,

press the link button for 2 sec.,

so that LED changes to the RED.

Press and hold the link button on Receiver and turn on the power.

l

e

n

r

n

e

a

v

i

h

e

C

c

e

6

R

z

t

H

f

a

G

r

4

.

c

2

ir

A

Both RED, BLUE LEDs will blink rapidly

to nd the transmitter signal.

Release the link button when

RED LED on receiver glows steady.

When the link is completed, BLUE LED

Transmitter will blink.

l

e

n

r

n

e

a

v

i

h

e

C

c

e

6

R

z

t

H

f

a

G

r

4

.

c

r

2

i

A

Release the link button.

When the link is completed, BLUE LED

Transmitter will blink while RED LED

Transmitter glows steady.

To save the setting, please reboot (Turn Off & On) both transmitter and

receiver.

When they are turned on again, RED LED Transmitter

and BLUE LED on the receiver will glow steady.

When they are turned on again, you can hear continuous

beep sound. Both RED LEDs transmitterand receiver will

glow steady in normal status.

l

e

n

r

n

e

a

iv

h

e

C

c

e

7

Page 10

Set-up Use of the Hitec 2.4GHz System

SmartScan Function

Turn on the transmitter.

Press and hold the LINK button on the ECLIPSE 7 PRO for about 6 sec.

Release the LINK button when you hear two continuous beeps.

The ECLIPSE 7 PRO will automatically scan the frequency to nd the cleanest and the most

stable frequency in any area. (The BLUE LED on the transmitter will blink during the scanning for 3sec.)

When the scan is completed, the BLUE LED on the transmitter stops blinking and glows steady.

Re-boot the transmitter (turn Off and On) and follow the link process with your receiver.

Push

6Sec.

After “Scanning,” you need to do the link process again for all your receivers as receivers need new

frequency hopping codes from the Spectra 2.4 module.

FAIL-SAFE and Hold Mode

If you use the FAIL-SAFE function, and set it up properly, should the receiver signal somehow be interrupted or interference

were to occur, the servos will move to your pre-set FAIL-SAFE point you previously stored in the receiver during the FAIL-SAFE

set-up process.

If FAIL-SAFE has not been activated, the signal is switched off after the HOLD period of 1 sec. This means that the servos

become “soft” and remain in their last commanded position under no load (this may equate to full-throttle!), until a valid signal is

picked up again.

In the interests of safety, we recommend that FAIL-SAFE should always be activated, and the FAIL-SAFE settings should be

selected so as to bring the model to a non-critical situation (e.g. motor idle / electric motor OFF, control surfaces neutral,

airbrakes extended, aero-tow release open, etc).

8

Page 11

Channel

Receiver

C

h

a

n

n

e

l

R

e

c

e

iv

e

r

C

hannel

R

eceiver

C

h

a

n

n

e

l

R

e

c

e

iv

e

r

Set-up Use of the Hitec 2.4GHz System

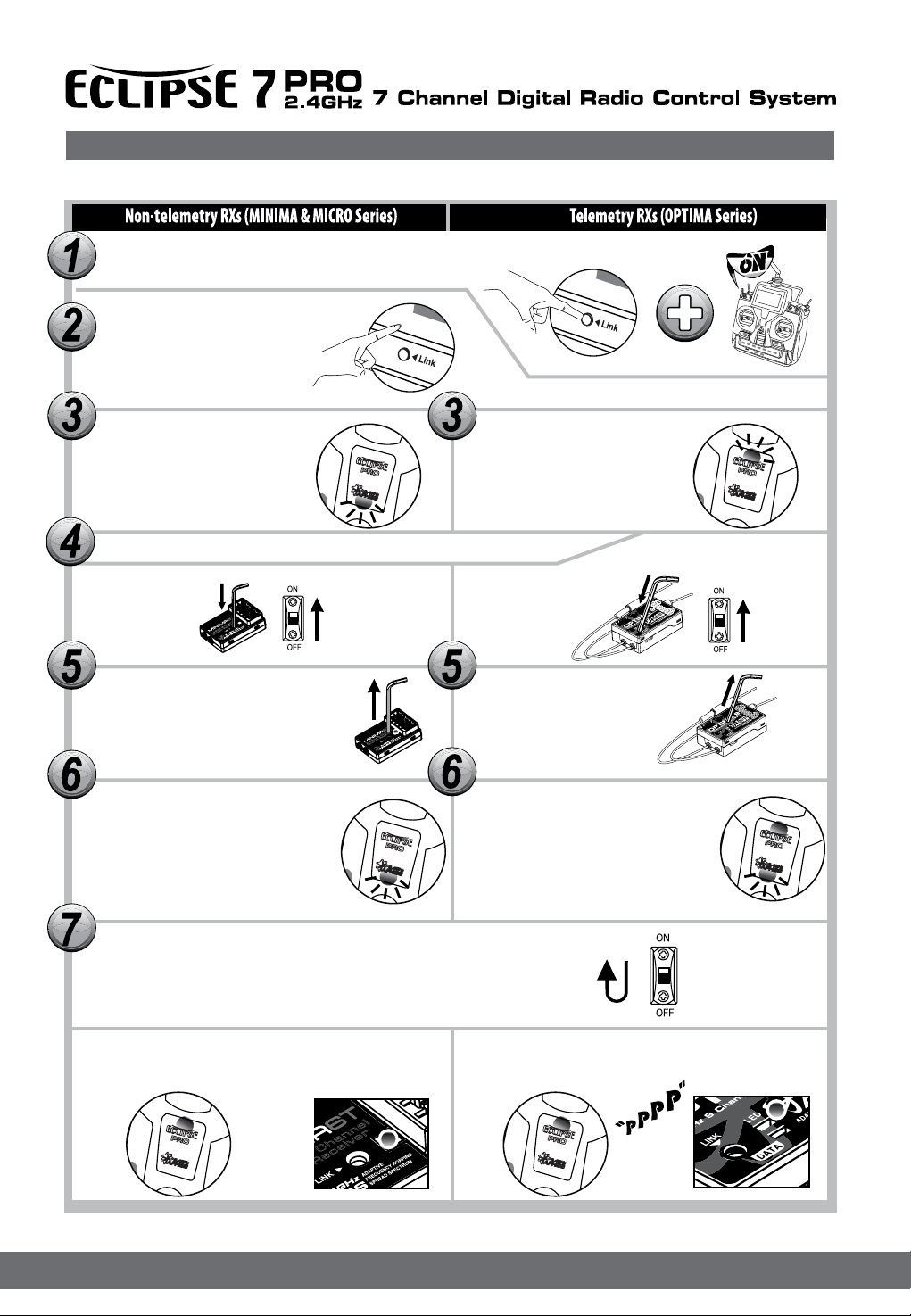

FAIL-SAFE Setup

Non-telemetry RXs (MINIMA & MICRO Series)

Switch on both.

Wait for the system to boot and control over the model.

l

e

n

r

n

e

a

v

i

h

e

C

c

e

6

R

z

t

H

f

a

G

r

4

.

c

r

2

i

A

Push the link button for 6 sec.

Push

l

e

n

r

n

e

a

v

i

h

e

C

c

e

6

R

z

t

H

f

a

G

r

4

.

c

r

2

i

A

6Sec.

Release the link button when LED is turned off.

You will see that both RED & BLUE LEDs will start blinking.

Wait

1Sec.

l

e

n

r

n

e

a

v

i

h

e

C

c

e

6

R

z

t

H

f

a

G

r

4

.

c

r

2

i

A

Telemetry RXs (OPTIMA Series)

Push

6Sec.

Release the link button when LED is turned off.

You will see that both RED & BLUE LEDs will start blinking.

Wait

2Sec.

Both RED & BLUE LEDs will blink alternately for 8sec.

During that time, move concerned transmitter sticks to

the desired FAIL-SAFE positions.

Fail-Safe position

Blinking

8Sec.

BLUE LED will glow steady once the setting

process is completed during above 8sec.

Both RED & BLUE LEDs will blink alternately for 5sec.

During that time, move concerned transmitter sticks to

the desired FAIL-SAFE positions.

Fail-Safe position

Blinking

5Sec.

RED LED will glow steady once the setting

process is completed during above 5sec.

Turn off both transmitter and receiver to save the Fail-Safe position. Now, Fail-Safe process is completed.

l

e

n

n

a

h

r

e

C

v

i

6

e

c

z

e

H

R

G

t

4

f

.

a

2

r

c

r

i

A

9

Page 12

Set-up Use of the Hitec 2.4GHz System

FAIL-SAFE Setup

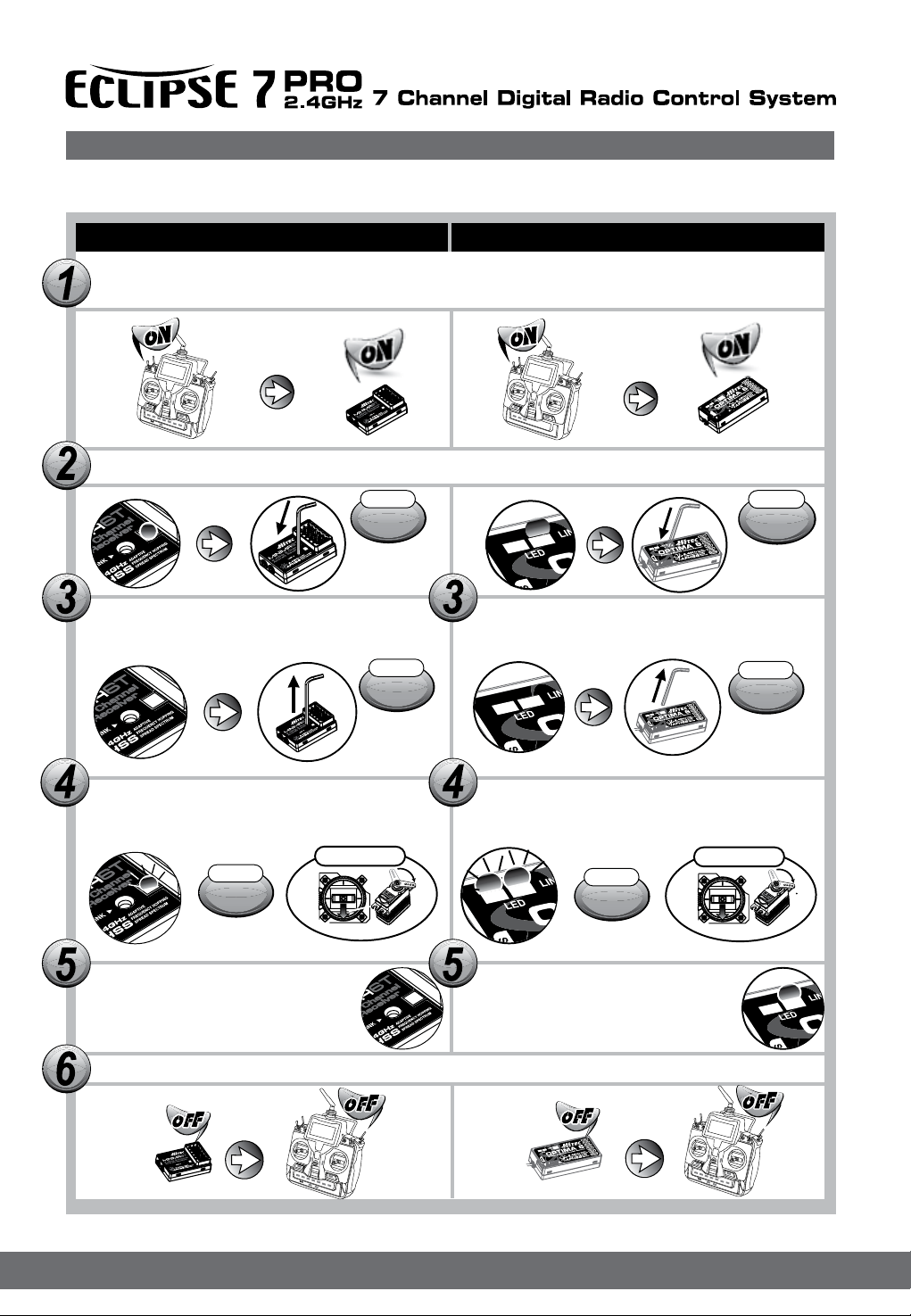

a. Switch on the transmitter, then the receiver, wait for the system to boot and you have control over the model.

b. Press and hold the receiver function button for 6 seconds, release the button. After 2 more seconds both red and blue

LEDs blink rapidly.

c. From the moment you release the button, the receiver will count 5 seconds during that time move all the transmitter

sticks and other controls to the desired FAIL-SAFE positions (e.g. motor idle, control surfaces neutral), and hold them

there.

d. After 5 seconds the system will save the FAIL-SAFE position. Relax all the control sticks.

e. Turn off the receiver, then the transmitter.

f. Turn on the system to use it. FAIL-SAFE is now activated.

Testing the FAIL-SAFE Setting

Move the sticks to positions other than the FAIL-SAFE settings, and then switch off the transmitter. The servos should now

move to the FAIL-SAFE positions previously stored, after the HOLD period (1 sec.) has elapsed.

How to turn FAIL-SAFE Off and reactivate the Hold Mode

a. Switch on the transmitter, then the receiver. Wait for the system to boot and you have control over the model.

b. Press and hold the receiver function button for 6 seconds and release it. After 2 seconds the red and blue LEDs will

blink rapidly.

c. Immediately press the button and release it.

d. FAIL-SAFE Mode is now deactivated and HOLD mode is activated.

e. Turn the transmitter off, then the receiver off.

f. Turn the system back on to use it..

If FAIL-SAFE is deactivated, the FAIL-SAFE position settings are also deleted!

The FAIL-SAFE settings should be checked every time before you run the engine/motor.)

Range Check Function

It is critical that before each ight session you perform a range check that conrms the signal between the receiver and transmitter is appropriate. Unlike the FM/PPM or PCM signal radios, 2.4GHz systems use a xed shorter, stubby transmitter antenna so

the traditional method of range checking your system by lowering the transmitter antenna will not work.

We instead use a power-down mode to reduce the transmitter signal strength. Once the power-down mode is activated it runs

for about 90 seconds, shortening the effective range 100 feet (30 m). During this power-down mode that you should walk away

from the secured aircraft carrying the transmitter to a distance of approx. 30 meters, testing the effective range

How to use Power-Down

a. Press the button on the module for 3 seconds, then both the blue and red LEDs will turn on with single beep sound.

Release the button. The 90-second countdown starts from the time the button released.

b. Walk away from the secured aircraft carrying the transmitter to a distance of approx. 100 feet (30 m), testing the ef

fective range.

c. To exit the power-down mode before the 90 seconds, press the button again to escape.

If you are unable to accomplish a successful range check of 90 feet, DO NOT ATTEMPT TO FLY.

Telemetry System

Currently there is a direct feedback telemetry function available in your Hitec 2.4 system. Plans are to have many more devices

available in the future.

Check the Hitec website at www.hitecrcd.com for more up-to-dated information.

The Hitec Eclipse 7 Pro and Optima Series receivers feature full telemetry capabilities (except Optima 6) and include a Low

Receiver Battery Warning as a basic function.

10

Page 13

Set-up Use of the Hitec 2.4GHz System

Low Battery Warning

The 2.4GHz system will automatically recognize the receiver battery voltage among 4 and 5 cell NiMH or NiCd batteries and

warns you, and also 2S LiPo/lo/Fe battery packs can be used with battery warning level customization.

- When battery level is high(4cell > 4.5V, 5cell > 5.6V): The red module LED glows constantly.

- When battery level is low(4cell < 4.5V, 5cell < 5.6V): Blue LED glows constantly and the red LED will blink fast. You will

hear a continuous loud beep from the module as a low receiver battery warning. Upon hearing the alarm, we advise

you to bring back the aircraft and land at once.

That you can adjust RX battery voltage warning level in B.WAR menu. Also via HPP-22 warning level can be adjusted.

SPC (Supplementary Power Connection) System

Hitecs exclusive optional receiver power system allows you to directly power the receiver from the main motor power battery of

an electric powered aircraft. Up to 35 Volts can be fed directly into the receiver to power JUST THE RECEIVER FUNCTION. It

will not power the servos. Almost all servos will burn-up if more than 6 Volts are used over a short period of time.

some Hitec servos are rated to be used at 7.4Volts. You will still need to supply power for your servos with a four or

ve cell NiMH receiver battery, 2 cell Li-Po and regulator set-up, or a commercially available BEC.

The SPC system was partially created to be integrated into future Hitec telemetry system devices.

Note Check the Hitec web site for more information on the availability of telemetry systems in the future.

SERVOSERVO

Power Battery

DATA

SPC

BAT/CH7

CH6

OPTIMA 7OPTIMA 7

2.4GHz 7 Channel Aircraft Receiver2.4GHz 7 Channel Aircraft Receiver

LED

LINK

LINK

LED

2.4GHz

Telemetric

AFHSS

BEC

ADAPTIVE

FREQUENCY HOPPING

SPREAD SPECTRUM

ESC

CH1

CH2

CH3

CH4

CH5

SERVO SERVO

SERVOSERVO

Motor

11

Page 14

Charge the Batteries!

Charging the Eclipse 7 Pro Ni-MH Batteries

Connect the transmitter charging cord into

the charging socket (on the rear of the case,

left side) and airborne Ni-MH batteries to the

receiver connector on the charger.

Connect the receiver battery to the

charging cord.

Plug the charger into a wall socket.

The charger’s LEDs should light,

indicating charging current is

owing. The batteries should be

left on charge for about 15 hours.

TRAINER

Try to charge the batteries with the

charger supplied

with your system exclusively.

The use of a fast-charger may

damage the batteries by overheating

anddramatically reduce their lifetime.

If you need to remove or replace the transmitter battery,do

not pull on its wires to remove it. Instead, gently pull on the

connector’s plastic housing where it plugs in to the transmitter.

The battery must be removed to charge it properly with a

“peak” charger.

PUSH

Operating With A Trainer Cord

An optional training cord is available from your dealer.

The cord may be used to help a beginning pilot learn to

f ly easily by allowing a second transmitter, operated by

an experienced instructor, to be connected to this system.

The instructor may override the beginning pilot at any

time to bring the model back under safe control. For

training

To use the trainer cord:

Set up both the student’s and instructor’s transmitters

to have identical trim and control motions.

Plug it into each transmitter, with power

switched off. The trainer jack is

on the back of the transmitter.

Turn the connector until its notches

line up and it ts without having

to be forced.

Turn on the instructor’s transmitter.

DO NOT turn on the student

PUSH

transmitter power.

Move the controls on the instructor’s transmitter, and verify

each control moves the proper direction.

Now verify that the student’s trims and control travels match

the instructor’s by using the trainer switch (the momentary

Trainer switch on the top left of the transmitter case) and

switching back and forth while leaving the control sticks and

trims alone, then moving the control sticks.

TRAINER

The instructor’s transmitter has normal control over

the model unless the trainer switch is pulled, passing

control to the student’s transmitter. If the student loses

control, the instructor can quickly “take over” by releasing

the trainer switch and controlling the model.

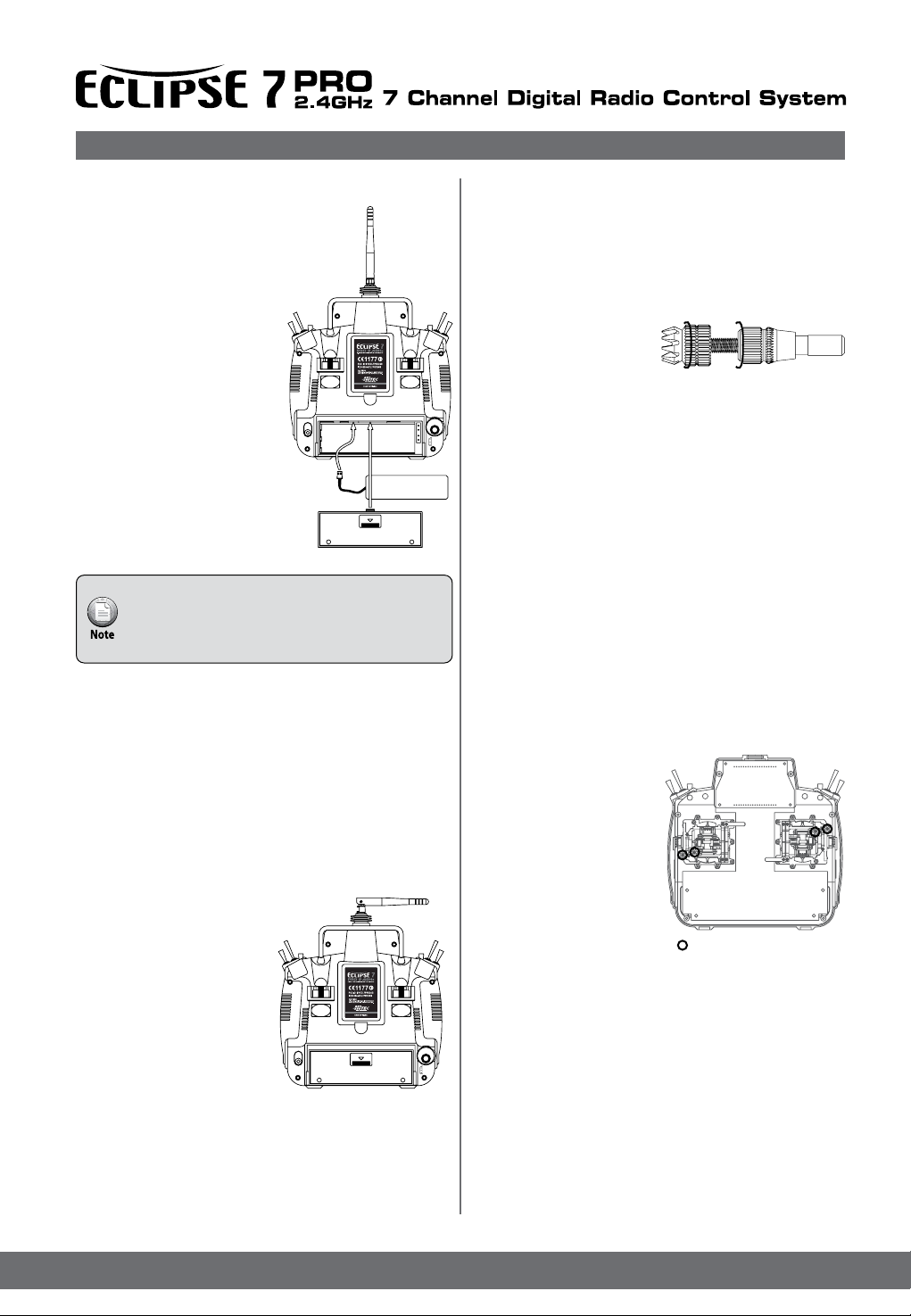

Other Adjustments

Adjustable length control sticks

You may change the length of

the control sticks to make your

transmitter more comfortable to

hold and operate.

A B

To lengthen or shorten your transmitter sticks, rst

unlock the stick tip by holding locking piece B and turning

stick tip A counterclockwise. Next, move the locking

piece B up or down (to lengthen or shorten).

When the length feels comfortable, lock the position by

turning locking piece B counterclockwise.

Stick lever tension adjustment

You may adjust the stick tension of your sticks to provide

the “feel” that you like for ying. To adjust your springs,

you’ll have to remove the rear case of the transmitter.

Using a screwdriver, remove the six screws that hold the

transmitter rear cover into position, and put them in a

safe place. Place some padding under the front of the

transmitter and place it face-down on the pad. Gently

ease off the transmitter rear cover and move it to the

right side of the transmitter, carefully turning it as you

would turn the page of a book. Now you’ll see the

view shown. Using a small cross-point screwdriver,

rotate the adjusting screw for each stick for the desired

spring tension. The tension increases when the adjusting

screw is turned clockwise, and

decreases for counterclockwise

motion. When you are satised

with the spring tensions, you

may close the transmitter.

Very carefully reinstall the rear

cover. When the cover is

properly in place, tighten the six

screws.

Tension Adjust Screw

Ratchet change

Some pilots, especially those ying helicopters, prefer a

“softer” or “smoother” ratchet action on the throttle stick.

An alternate ratchet that provides a smoother ratcheting

action is included as an accessory with your Eclipse 7 Pro

system. To change the throttle ratchet, remove the back

of the transmitter case as directed above in the “stick lever

tension adjustment” section. Then, unscrew the ratchet

retaining screw, remove the old ratchet, and replace

with the new one. Tighten the retaining screw gently but

rmly. Then, replace the transmitter rear cover.

12

Page 15

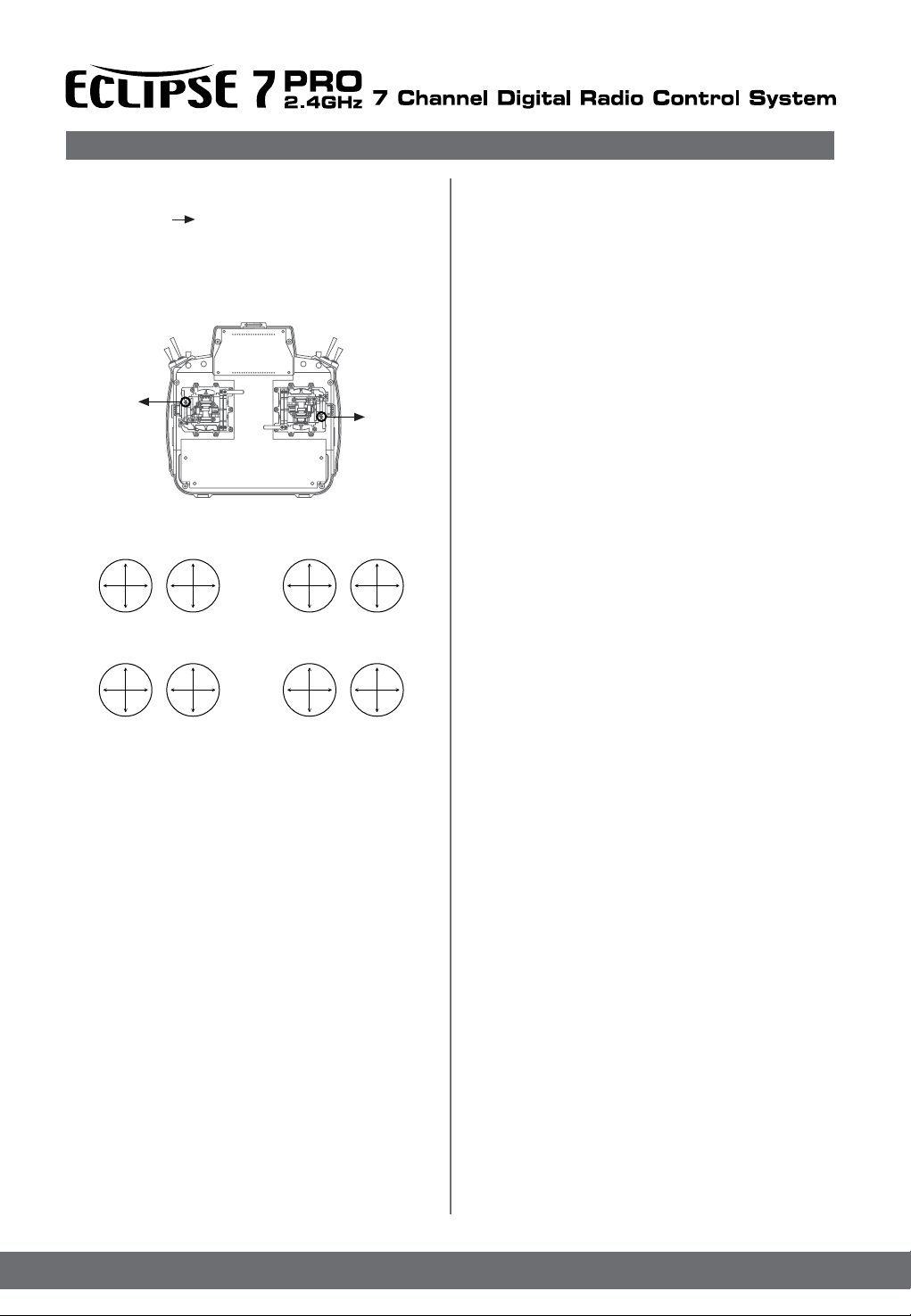

Factory Service Repair Information

Changing the Eclipse 7 Pro transmitter’s mode

If you wish to change current system’s Mode from the factory

installed (Mode 2 1, 3 or 4)

Please remove the Transmitter Battery rst, after that remove

all backside screws carefully, and then lift back case gently.

In order to change mode , please adjust Tension Screws and

Mode Screws according to below gures.“

Mode

Change

Screw

Mode

Change

Screw

MODE 1 MODE 2

ELEV THRO

RUDD RUDD

ELEV THRO

AILE AILE

THRO ELEV

AILE AILE

MODE 3 MODE 4

THRO ELEV

RUDD RUDD

Hitec-RCD, Inc.

12115 Paine St.

Poway, CA 92064

TEL: 1-858-748-6948

FAX: 1-858-748-1767

Web site: http://www.hitecrcd.com

Factory Service Repair Information

(for U.S.& Canada only)

Please read the warranty card supplied with your system,

and return it so your system will be under warranty.

Before you decide to have your system repaired, if there

is no apparent physical damage, read this instruction

manual again and check to be sure that you are operating

the system as it is supposed to be operated. If you

are still having trouble, pack up your system in its original

shipping materials and send it to the factory or the nearest

authorized Hitec R/C Service Center.

Be sure to include a note in your package that describes

the trouble in as much detail as possible, including:

Symptoms of the problem in as much detail as you can

provide, including any unusual mounting conditions

or equipment orientation

A list of items you are sending, and what you want to

be repaired.

Your name, address, and telephone number

If you have any questions regarding this product, please

consult with Hitec’s service center. The address and

telephone numbers of our service center is given below.

Telephone inquiries are accepted from 8:00 AM to

4:30 PM weekdays (closed on holidays).

13

Page 16

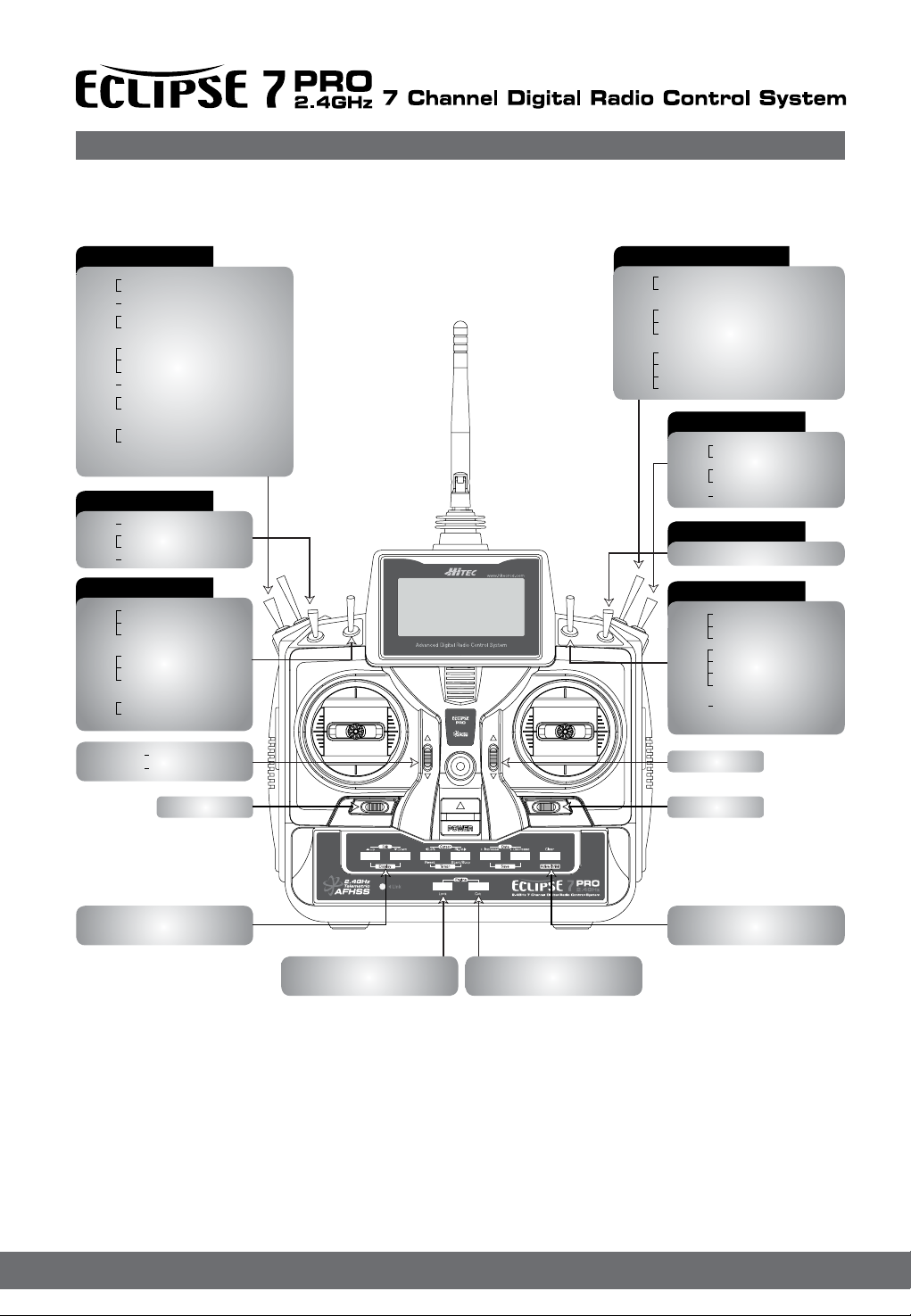

Eclipse 7 Pro “Mode2” Control and Switch Assignments

ECLIPSE 7 PRO MODE 2 TYPE

SWITCH CONFIGURATION LIST FRONT

Flight Mode Switch

ACRD Elevator to Flap Mix

Condition Mix 1 Trim, D/R, EXP

Nomal Trim, D/R, EXP

Condition Mix 2 Trim, D/R, EXP

Landing Mix

Glider Condition Mix 1

4-Wing Speed Flap Trim Offset 1

Elevator to Flap Mix

Normal Trim, D/R, EXP

Condition Mix 2

4-Wing Speed Flap Trim Offset 2

HELI Rudder to Throttle Mix

Nomal Trim, D/R, EXP, Gyro Gain

ldle UP 1 Trim, D/R, EXP, Throttle Curve

ldle UP 2 Trim, D/R, EXP, Pitch Curve

Elev. D/R

ACRD Elevator D/R

Elevator D/R

Motor ON/OFF CH3

Elevator D/R

Rudder D/R

ACRD

P-Mix 4 ON/OFF

Aileron to Rudder Mix On/OFF

Rudder D/R

Glider P-Mix 4 ON/OFF

Aileron to Rudder Mix

Rudder D/R

HELI P-Mix 2 ON/OFF

Rudder D/R

ACRD/HELI Throttle Trim

Glider Flap Trim

Flight Condition Switch

ACRD P-Mix 5 ON/OFF

Condition 3 Trim, D/R, Exp (Ail, Elev, rudd)

Glider P-Mix 5 ON/OFF

Condition 3 Trim, D/R, Exp (Ail, Elev, rudd)

4-wing Aileron to Flap Coupling Mix

HELI Throttle Hold

Condition 3 Trim, D/R, Exp (Ail, Elev, rudd)

Gyro Gain

Hold Pitch Curvo

Gear

ACRD Landing Gear ON/OFF

P-Mix3 ON/OFF

Glider P-Mix3 ON/OFF

Crow Mix ON/OFF

HELI P-Mix 1

Elev. D/R

ACRD/Glider/HELI Aileron D/R

CH7 Switch

ACRD P-MIX 1 ON/OFF

P-MIX 2 ON/OFF

Glider P-MIX 1 ON/OFF

P-MIX 2 ON/OFF

Flap to Aileron Mix

Flap to Elevator Mix

HELI CH 7 Control

(Heading lock ON/OFF)

Elevator Trim

Rudder trim

Select to Voltage

Trim Data

Model Name

Acro/HELI Engine Low Position Hold

Glider X

Acro/HELI Engine Cut off

Glider X

This gure shows the assignments for a Mode 2 system as supplied by the factory in North America.

Note that some of the functions will not operate until activated in the mixing menus.

14

Aileron Trim

Integral Timer Data Reset

Page 17

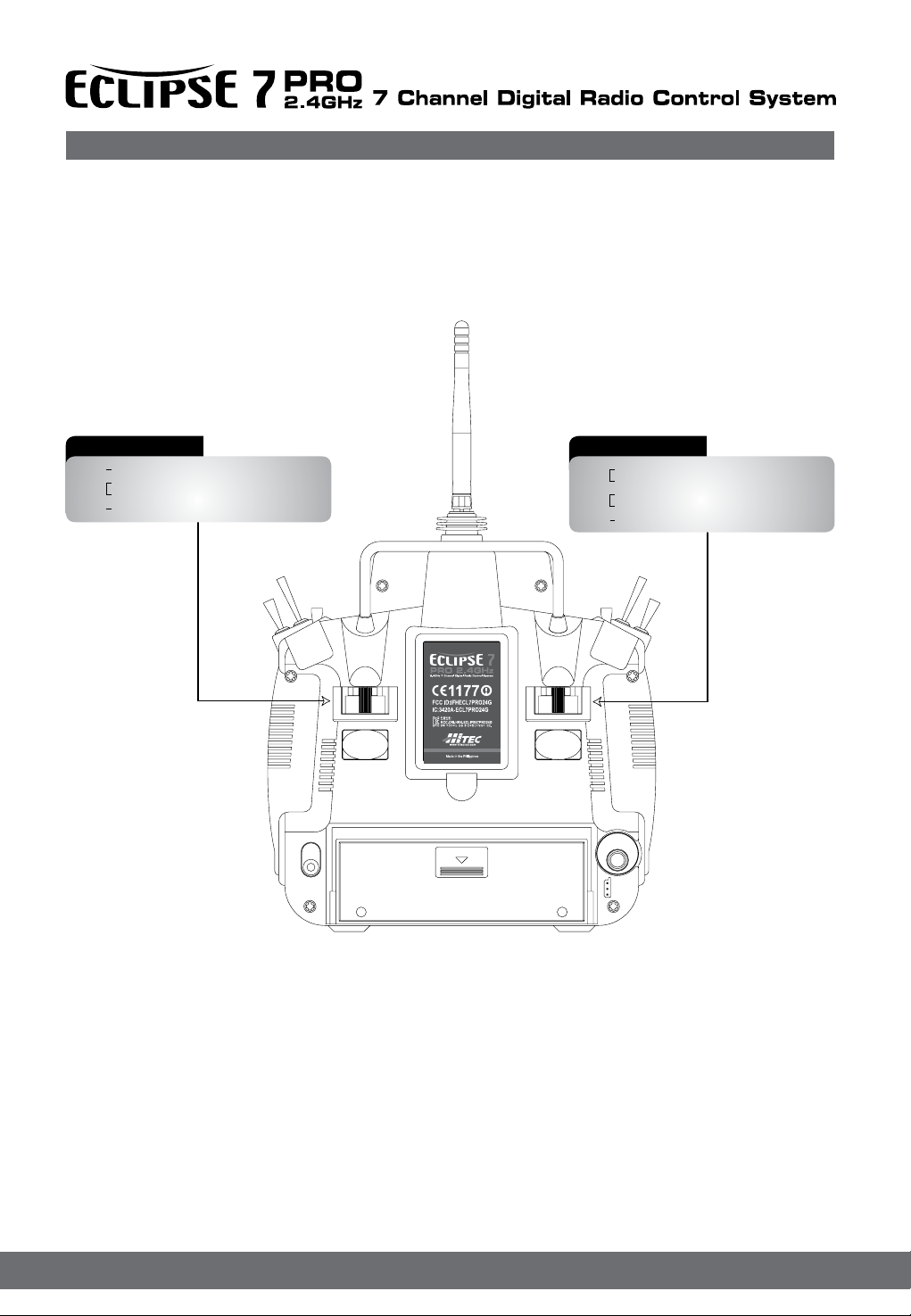

Eclipse 7 Pro “Mode2” Control and Switch Assignments

ECLIPSE 7 PRO MODE 2 TYPE

SWITCH CONFIGURATION LIST REAR

VR2

ACRD CH7 Control

Glider 2-Wing Ch7 Control

4-Wing 2nd-Flap Aileron Trim

HELI Hovering Pitch

PUSH

VR1

ACRD Flap Trim Control

Glider Flap Control

Flap to Aileron Mix Control

Flap to Elevator Mix Control

HELI Hovering Throttle Control

TRAINER

15

Page 18

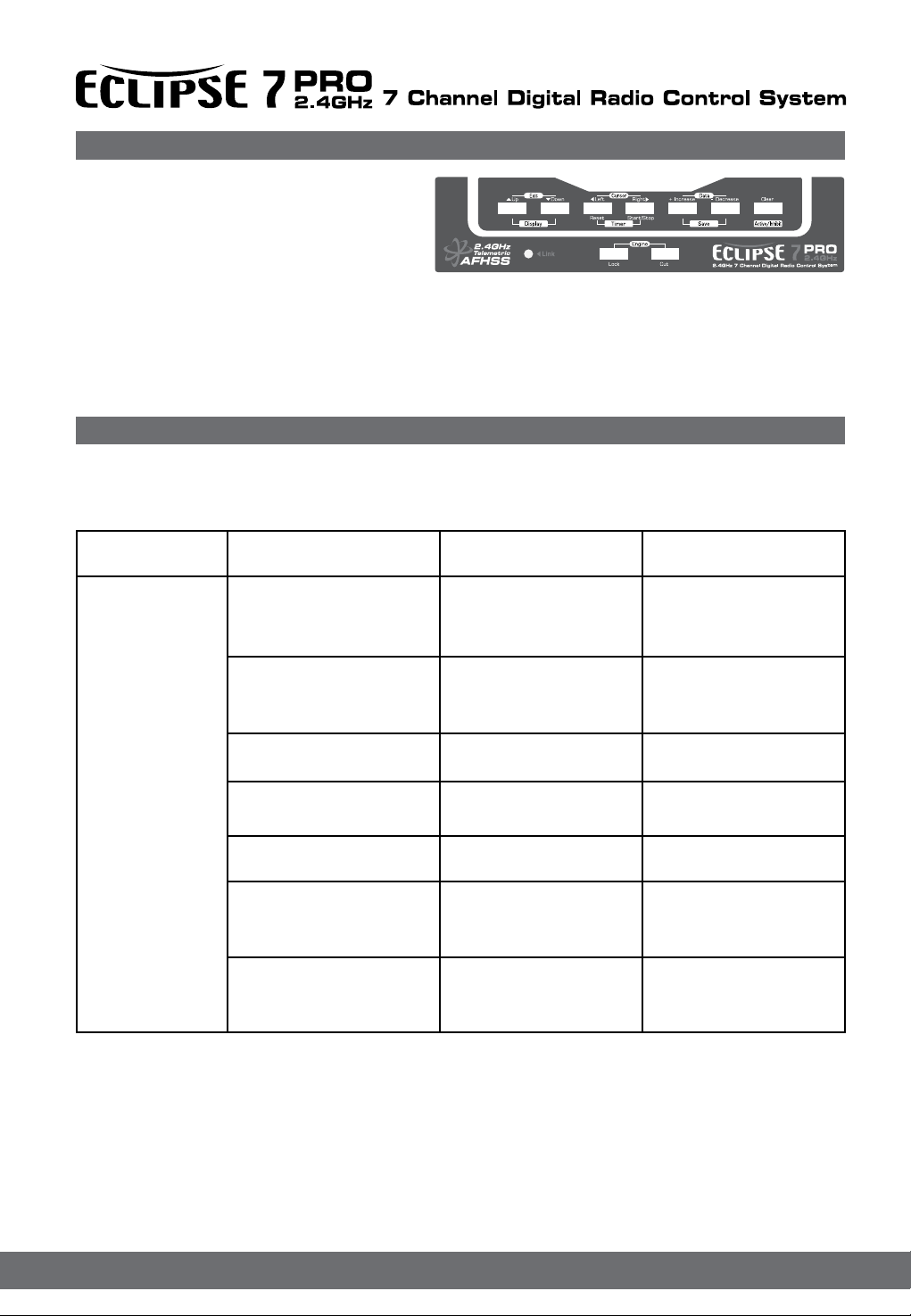

Transmitter Input Buttons

The buttons are used for different things as follows:

1.The Edit/Display Up & Down buttons (1)allow

you to move up and down within the model

menus, and move within the regular display.

select options within a particular function,

and control the timer function.

2.The Data +Increase & -Decrease buttons (3)allow you to increase or decrease the numerical settings for a function.

3.The Clear Active/Inhibit button (4)resets numbers, and turns functions on and off.

4.The Engine Lock button (5)holds the throttle channel while other channels may respond to the transmitter.

5.The Engine Cut button (6)closes the throttle so that you can kill the engine without touching the trim lever.

You'll learn how to use these buttons in the setup sections that follow

6.The link button Can be used for that link process between ECLIPSE 7 PRO to a Optima or Minima series receivers, entering

the power down mode for range checks, and the Normal/Scan Mode set-up

Receiver - Servo Connection List

The table below shows the hookups that should be used for each of the model types. Note that some functions shown will not

operate until they are activated in the transmitter.

Receiver channel Aircraft (ACRO) Glider (GLID) Helicopter (HELI)

aileron or right aileron

1

2

3

4

5

6

7

The servo response varies with the selected function. Standard options are shown rst.

or right aperon (FLPN)

or right elevon (ELVN)

Elevator or V-tail right side

(VTAL) or left elevon (ELVN)

or left Elevator(AILV)

throttle

rudder or V-tail left side

(VTAL)

landing gear left aileron gyro sensitivity

ap (controlled by VR1) or

left aperon (FLPN) or left

aileron

optional, controlled by VR2

or right Elevator(AILV)

right aileron(or rudder for

rudder-elevator models)

elevator or V-tail right side

(VTAL)

spoiler, throttle (on-off

controlled by Gear switch)

rudder or V-tail left side

(VTAL)

right ap (4WNG) or single

ap

(2WNG)

left ap (4WNG) or proportional

channel, controlled by VR2

(2WNG)

roll

or swash servo 1 (120’)

or swash servo 1 (140’)

or swash servo 1 (180’)

Elevator

or swash servo 2 (120’)

or swash servo 2 (140’)

or swash servo 2 (180’)

throttle

yaw

pitch

or swash servo 3 (120’)

or swash servo 2 (140’)

or swash servo 2 (180’)

optional, controlled by Gear

switch

16

Page 19

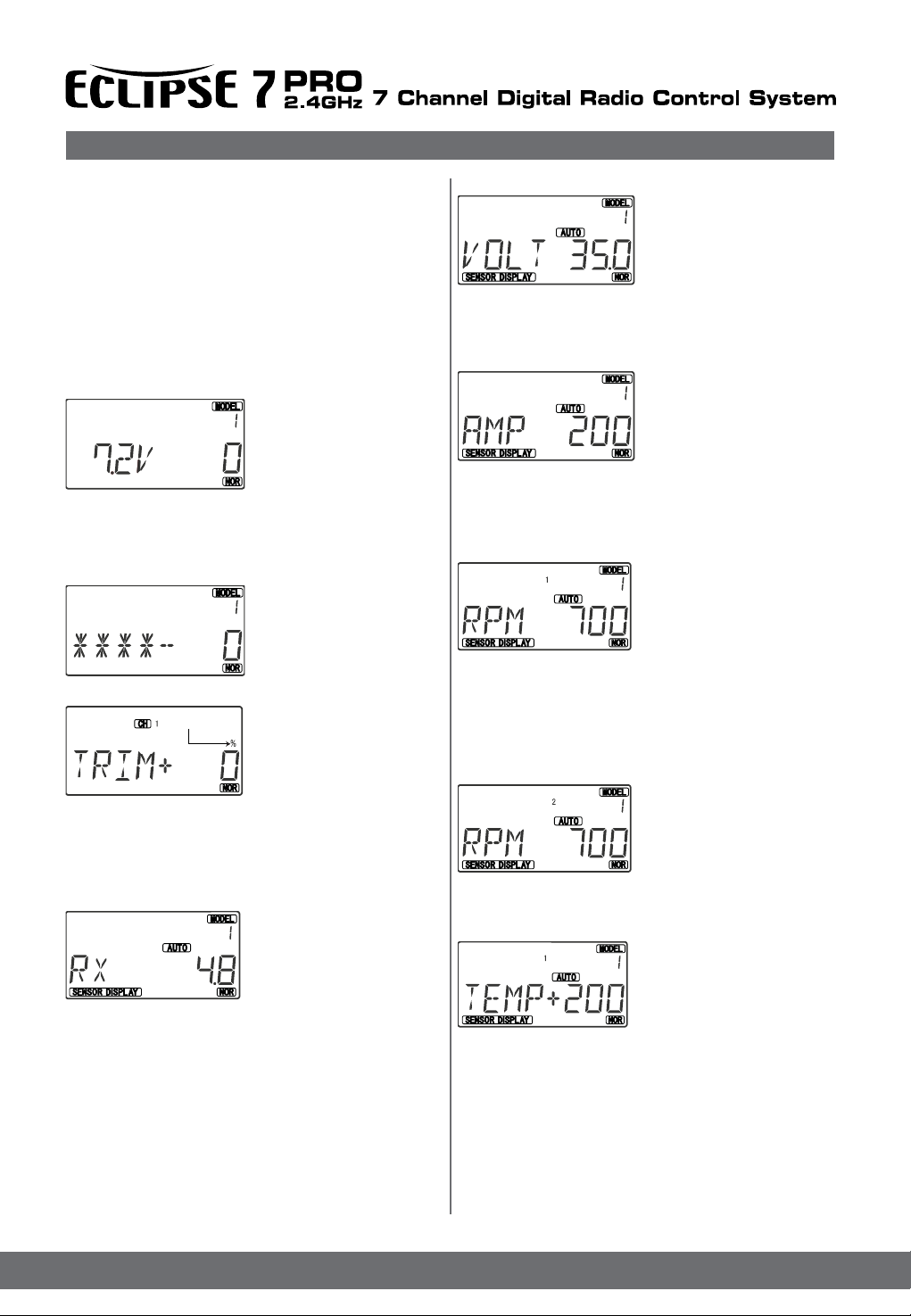

Telemetry system Information

When you rst turn on your transmitter, the rst screen

shown below appears on the LCD display. Before ying,

or even starting the engine, BE SURE that the model

number appearing in the higher right of the display

matches the model that you are about to y!

If you don’t, reversed servos and incorrect trims will lead

to an immediate crash.

You can scroll up and down through the startup screen

by pressing one of the two Edit keys (the two keys on the

far left). If you press timer or engine cut or lock keys, you

go directly to those functions regardless of the display.

This screen appears at

startup. The model

memory number is shown

by state in gures.

Battery voltage is shown in

time is on the lower right. You can reset the operating time

display by hitting the Clear button (the one on the farthest

right).

Do this after each charge to keep track of your operating time

on a single charge.

Flashing

is, you have to move it! Be sure to move it back to where it

was. Note that the CH3 trim only moves downward, so if you

need more engine RPM, set up idle with the trim at -25% so

you can increase it if needed.

by in lower right of the display. Display can be shown 0v to 35v

You can check all Telemetry information by select to Auto or

Normal. If you select Auto ,by pressing Cursor right ,display

will showing all Telemetry information in every 2sec rotationally

. If you select Normal , you have to select what you want to

see the Telemetry information by pressing the Cursor .

the bottom left, and operating

Pressing the Down button

gives the Model Name display

you can check the current

Model name by this screen

Pressing the Down button

gives the Trim display

(different numbers may

appear depending on the

model type). To see where

the trim for a certain channel

Pressing the Down button

gives the Telemetry information

display when you use Optima

series receivers(Hitec Telemetry

capable receivers)

you can check receiver voltage

VOLT

BLUE with HTS-VOLT which

attached receiver or Electric

powered aircraft’s main battery.

Voltage value appears in lower

right in the display as you see

left diagram . voltage range

is 0v to 99.9v. ( If you not use HTS-SS, Numeral 0 will appear

in lower right of the display )

AMP

You can check Current of your

battery using HTS-SS BLUE

with HTS-C50/C200 which

attached receiver or Electric

powered aircraft’s main battery.

Current value appears in lower

right in the display . As you see left diagram. Current range

is 0 to 200.( If you not use HTS-SS, Numeral 0 will appear in

lower right of the display )

RPM

You can check the RPM of your

aircraft using HTS-SS BLUE

with HTS-RPM .

Hitec have two types of RPM

sensors, one is O-RPM(Optical

RPM Sensor ,Optimized Heli),

the other is M-RPM(Magnetic RPM Sensor, all aircraft using

props). RPM value appears in lower right in the display .As

you see above diagram, you can see the small numeral 1, this

information coming from HTS-SS BLUE RPM Sensor rst slot.

Real RPM value can be calculated by X100 displaied value.

Ex) if you see 700 in the display, actual RPM is 70,000 .

As you see to left diagram, this

information coming from HTS-

SS BLUE RPM sensor second

slot.

You can see small numeral 2 in

the display

This is showing second RPM sensor information.

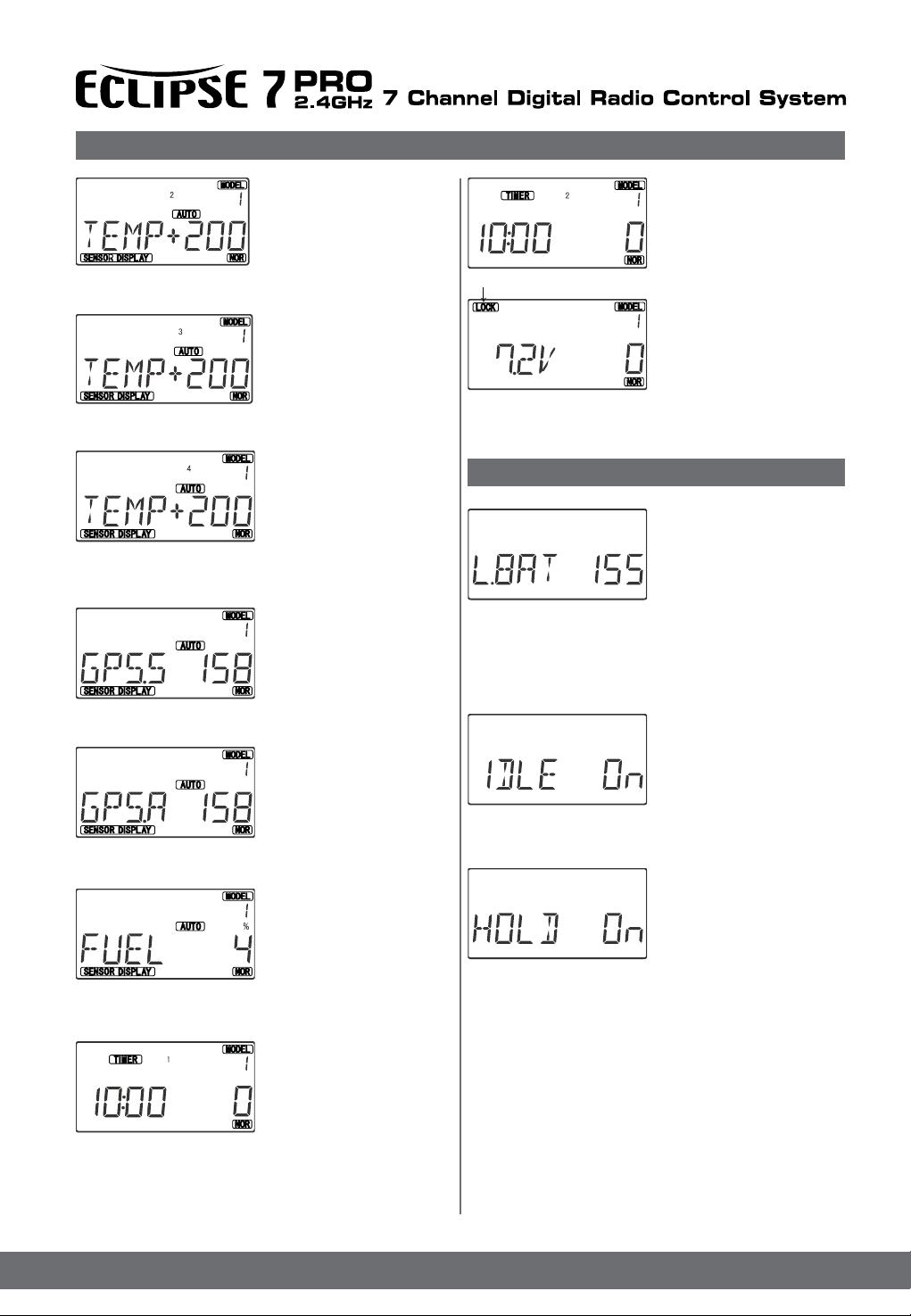

TEMPERATURE

You can check the temperature

of your aircraft’s engine , mufer

, ESC , batteries and etc. that

using HTS-SS BLUE, HTS-SS

with HTS-TEMP(You can use

maximum 4 temperature sensors).

Temperature value appears in lower right in the display .As

you see left diagram, you can see the small numeral 1, this

information coming from HTS-SS BLUE, HTS-SS Temperature

sensor rst slot. Temperature range is -40 to 200 .

17

Page 20

Telemetry system Information

As you see to left diagram, this

information coming from HTSSS BLUE ,HTS-SS temperature

sensor second slot.

You can see small numeral 2 in

the display This is showing

second TEMP sensor information.

As you see to left diagram, this

information coming from HTSSS BLUE ,HTS-SS temperature

sensor third slot.

You can see small numeral 3 in

the display This is showing third

TEMP sensor information.

As you see to left diagram, this

information coming from HTSSS BLUE ,HTS-SS temperature

sensor fourth slot.

You can see small numeral 4 in

the display

This is showing fourth TEMP sensor information.

GPS SPEED

You can check the Speed of

your aircraft using HTS-SS

BLUE, HTS-SS with HTS-GPS

. GPS Speed value appears in

lower right in the display . GPS

Speed range is 0 to 999 Km/h.

GPS ALTITUDE

You can check the Altitude of

your aircraft using HTS-SS

BLUE, HTS-SS with HTS-GPS.

GPS Altitude value appears in

lower right in the display. GPS

Altitude range is 0 to 999m

left diagram shows second

TIMER of the DUAL TIMER

LOCK indicator

Pressing the Lock buttonlocks

the throttle servo and holds it

where you last commanded it.

This may be used as a safety

feature when you are carrying

the model and transmitter to

ensure you don’t accidentally give throttle. It is shown by the

LOCK indicator

Warning Displays

The LOW BATTERY warning is

displayed when the transmitter

battery voltage drops below 6.6

volts, and a beeper sounds.

The operating time is still shown

on the right. If you reset this

each time you charge the system, you will have a good idea of

how long you can safely operate.

WHEN THE BEEPER SOUNDS, LAND YOUR MODEL AS

SOON AS POSSIBLE BEFORE LOSS OF CONTROL DUE

TO A DEAD TRANSMITTER BATTERY

The IDLE ON warning is

displayed when the transmitter

is powered up with the Idle-up

switch on in the helicopter mode

only.

You can turn this off by moving

the Flt. Mode switch back. For your safety, the transmitter will

not broadcast until this alarm is ended.

FUEL

you can check the fuel amount

of your model using HTS-SS

with HTS-FUEL, fuel level can

be checked by appears numeral

0 to 4.(this function only can use

HTS-SS. HTS-SS BLUE cannot

provide this function)

DUAL TIMER

Pressing the two Timer button at

the same time that

gives the Timer display .you can

start the timer pressing Start

button . Stop and Reset also

same function as like key name.

You can nd out rst TIMER of the DUAL TIMER that seeing

small numeral 1 in the display . you may move to second

TIMER pressing UP or Down button.

The HOLD ON warning is

displayed when the transmitter

is powered up with

the Throttle hold switch on

in the helicopter mode only

when throttle hold values are

programed. You can turn this off by moving the Flt. Cond.

Switch back. For your safety, the transmitter will not broadcast

until this alarm is ended.

18

Page 21

Model Setup Functions

This section describes the model setup functions that are used to choose all of the operating features of a particular model

memory. These functions are used to select the model memory, the model type (from airplanes, gliders, and helicopters), set

the Timer, and other useful functions. These functions are used to set up a new model or a new model memory, to switch

between memories, and to change transmit shift.

Map of Basic Menu Functions

M.SEL Model select

VER- 1.010

RESET Reset Memory

TIME Timer1, 2 setup

COPY Data Copy

ACRO Acrobatic model mode

HELI Helicopter model mode

GLID Glider model mode

2WING Two Servo Wing (GLID only)

4WING Four Servo Wing (GLID only)

NOR Normal swashplate (HELI only)

120` 120` swashplate (HELI only)

140` 140` swashplate (HELI only)

180` 180` swashplate (HELI only)

**** Model Name (four Letters +

Up to three numbers)

MODE Mode 1, 2, 3, 4 changeable

IMP Unit Select

RPM RPM Check

AMP AMP Check

B,WAR Rx Battery Warning

Model select ( M.SEL )

Version ( VER- 1.010 )

Reset Memory ( RESET )

Timer1, 2 setup ( TIME )

Data Copy ( COPY )

Acro, Heli, Glide Model Select ( Heli )

SWASH /120 /140 /180 /NOR Select ( NOR)

Model Name Select ( ACRO 001 )

Mode 1, 2, 3, 4 changeable ( MODE )

Unit Select ( IMP )

RPM Check ( RPM )

AMP Check ( AMP)

Rx Battery Warning ( B,WAR )

PowerOnWhilePressing

bothEdit/Displaykeys

Model Setup Functions

MODL – Model Select

. Your Eclipse 7 PRO system can store up to sixteen independent sets of model data in its memory. The Model Select

(MODL) function allows you to choose from any of the

seven sets of model data.

You can assign a four-character name to each model memory.

The model names are not visible when you wish to switch

memories. There are several ways to keep track of which

model is in each memory. You may attach a small piece of

white tape to the transmitter and write the model’s name along

with the model setup number (and its channel number), or you

may use a notebook, or label the model with its memory number prominently near its on-off switch inside the fuselage.

Choosing a model memory to load

Flashing

you into the model select (M.SEL) menu.

3. Select the desired model number by pressing the Cursor

Right or Left button. At this time, the selected model number

will blink on and off.

4. Switch power off.

5. Switch power back on. The previously-selected model

number is indicated by the arrow above the model numbers

in the display.

1. Start with the transmitter

switched off.

2. Turn on your transmitter

while pressing both of the

two Edit keys (the two keys

on the far left). This gets

VERSION

Left diagram shows current software version of Eclipse 7 Pro.

The software can be upgraded

by using HPP-22 device.

RESET –Data Reset

The Reset function is used to clear out an existing set of

model data within a single model memory, the current one.

This function resets all data to the factory default values, and

may be used to get a “fresh start” so that you may begin with

a clear memory before you input new model settings into a

memory that had been used for another model.

Flashing

The model select (M.SEL) menu will be displayed.

2. Press the Up or Down arrow key until you get into the Reset

(REST) menu.

This display has the word “REST” ashing on and off.

(If you’re already in the setup menus, you can just press the

Up or Down arrow key to get here.)

3. IF YOU ARE SURE YOU WANT TO RESET and clear

out the current model memory, press both the +Increase

and -Decrease Data keys at the same time. The transmitter

Resetting the memory

1. With the transmitter switched

off, turn on your transmitter

while pressing both of the two

Edit keys(the two keys on the

far left).

19

Page 22

Charge the Batteries!Model Setup Functions

will beep twice to indicate a successful reset.

4. Press the Up or Down arrow keys to get to another

setup menu, or switch power off.

5. Switch power back on. You may now set up the details

of your model in the Edit mode.

CAUTION: WHEN YOU COMMAND RESET, YOU’LL ERASETHE MEMORY YOU’RE IN AND LOSE ANY PROGRAMMINGYOU HAVE ENTERED. DON’T DO THIS UNLESS YOU

ARE

POSITIVE YOU WANT TO FLUSH OUT THAT MEMORY

ANDSTART FROM SCRATCH WITH THE FACTORY DEFAULTSETTINGS.

TIME – Timer Function Setup

1. With the transmitter switched

off, turn on your transmitter

Flashing

while pressing both of the two

Edit keys(the two keys

on the far left).

The model select (M.SEL) menu

will be displayed

Flashing

2. Press the Up or Down

arrow key until you get into

the Reset (TIME) menu. The

word “TIME” will ashing on and

off. (If you’re already in the set-up menus, you can just press

the Up or Down arrow key to get here.)

3. To change the number of minutes shown, press the

+Increase and -Decrease Data keys until you see the

amount you desire. You may select from 0 to 60 minutes.

4.Pressing the cursor will bring you to get second timer .

5. Press the Up or Down arrow keys to get to another

setup menu, or switch power off.

6. Switch power back on. You may now set up the

details of your model in the Edit mode.

COPY-Copy Model

The COPY function is used to copy the model data stored

in the current model memory into another model memory.

This function is handy to use to start a new model that’s

Copying from one model memory to another

2. Press the Up arrow key.

This gets you into the model

copy (COPY) menu. (If

you’re already in the setup

menus, you can just press

the UP or Down arrow key to get here.)

3. The source model memory (the memory that will be

similar to one you have already

programmed, and is also

handy for copying the current

model data into another

model memory as a backup.

1. With the transmitter switched

off, turn on your transmitter

while pressing both of the two

Edit keys (the two keys

on the far left). The model select

(M.SEL) menu will be displayed.

duplicated) is the current one, indicated by the numeral (located higher right)

. To select your destination model number,

press the Left or Right Cursor keys. The selected destination

memory number is shown by the ashing numeral .

4. Press the +Increase and -Decrease Data keys at the

same time. The transmitter beeps twice rapidly, indicating

the copy has been completed. THIS WILL ERASE ALL

THE OLD SETTINGS IN THE SLAVE MODEL MEMORY,

SO BE SURE YOU’RE IN THE CORRECT MODEL

BEFORE YOU COPY MODEL!

5. Switch power off.

6. Switch power back on. If you wish to go to the newly saved

memory, repeat step 1.

ACRO, HELI, GLID - Model Type Select

This function is used to select the type of model to be

programmed in the current model memory. You may

select from aircraft (ACRO), gliders (GLID), and helicopters

(HELI). If you select glider or helicopter types, you

will need to set the wing type (for a glider) or the swash

type (for a helicopter). These settings are covered below.

Flashing

Flashing

Flashing

type or swash type in the GLID and HELI model settings, see

the sections below.]

4. If you wish to change the model type from that displayed,

press on the Left or Right Cursor buttons until the model type

you want, either ACRO,GLID, or HELI, appears.

5. To select your desired model type, press both the

+Increase and -Decrease Data keys simultaneously.

Two beeps tell you that the new model type is now registered.

THIS WILL ERASE ALL THE OLD SETTINGS IN THE

MODEL MEMORY, SO BE SURE YOU’RE IN THE CORRECT

MODEL MEMORY BEFORE YOU CHANGE MODEL TYPE!

6. Press the Up or Down arrow keys to get to another

setup menu, or switch power off.

7. Switch power back on. You may now set up the details

of your model in the Edit mode.

Selecting the Model Type

1. With the transmitter switched

off, turn on your transmitter

while pressing both of the two

Edit keys (the two keys

on the far left). The model select

(M.SEL) menu will be

displayed.

2. Press the Down arrow key.

This gets you into the type

select menu. The current

model type will be ashing on

and off. (If you’re already

in the setup menus, you can just

press the Up or Down arrow key

to get here.)

3. If the model type you want is

displayed, you’re done.

[If you wish to change the wing

20

Page 23

Model Setup Functions

Wing & Swashplate Type Selection

If you are using the glider (GLID) or helicopter (HELI)

setting menus, you must tell the Eclipse 7Pro system what

type of model you are using. In the case of a glider, you have

to specify whether it has two (2WNG) or four (4WNG)

wing servos (most slope gliders use two wing servos, and

competition gliders use four wing servos, two each for

outboard and inboard ailerons and aps). Helicopters may

have one servo each for blade angle, roll and pitch(NOR)

or they may use three servos in concert on the swash to

provide these functions (120’, 140`,180’). Note that these

menus will not be available unless you have selected the

GLID or HELI model types.

Selecting the Wing or Swashplate Type

setup menu, and WING will be highlighted: If you’re in HELI

mode, SWASH will be highlighted and you can select from

three swashplate types: NOR, 120’,140` and 180’

If you’re happy with the wing or swash type that is

displayed, go on to the next step. If you wish to change

the wing or swashplate type from that displayed, press on

the Left or Right Cursor buttons until the wing/swash

type you want appears. CAUTION: if you change types,

you may lose settings in the menus.

4. Press the Up or Down arrow keys to get to another

setup menu, or switch power off.

5. Switch power back on. You may now set up the

details of your model in the Edit mode.

1. Select the GLID or HELI

model type in the Model Type

Select menus (see above).

2. With the transmitter

switched off, turn on your

transmitter while pressing

both of the two Edit keys

(the two keys on the far left).

The model select (M.SEL)

menu will be displayed.

3. Press the Up or Down

arrow keys: In the GLID

mode, you’ll enter the wing

21

Page 24

Model Setup Functions

Model Name

The Model Name function is used to create an alphanumeric

name which is stored in the model memory along with the rest

of the model settings. You will nd it useful to help keep track

of multiple models. The model name can be four alphabetic

characters, along with up to three numbers following.

The letters may be used to abbreviate the model’s name, and

the numbers may be used for the memory number, or you

may wish to store that model’s channel number so you can

remember easier.

Flashing

left). The model select (M.SEL) menu will be displayed,

with “stars” to represent letters to be chosen.

2. Press the Up or Down arrow key until you get into the model

name menu. You’ll see the display as shown to the right.

The rst character of the name will be ashing on

and off. (If you’re already in the setup menus, you can

just press the Up or Down arrow key to get here.)

3. To change the rst character, press the +Increase and

-Decrease Data keys until you see the character you desire.

You may select from the upper case letters A ~ Z, ,

+, -, /, and the numbers 0 ~ 9.

4. Press the Right Cursor key to move to the next character.

5. Press the +Increase and -Decrease Data keys until

you see the character you desire.

6. Repeat the previous two steps to input the third and

fourth characters of the display.

7. Press the Right Cursor key to move to the number

displays on the right.

8. Press the +Increase

10. Switch power back on. You may now set up the details of

your model in the Edit mode.

Mode – Mode Select

will be displayed . You can change the Mode 2 to Mode 1,

Mode 2 to Mode 3 or 4.

but If you want to change mechanically , please send this

Eclipse 7 Pro to service center. This

change procedure only can change the software of Eclipse 7

Pro.

Inputting a Model Name

1. With the transmitter

switched off, turn on your

transmitter while pressing

both of the two Edit keys

(the two keys on the far

and -Decrease Data keys

until you get to a number

that you like. This can be

any number from 0 to 199.

9. Press the Up or Down arrow

keys to get to another setup

menu, or switch power off.

1. With the transmitter switched

off, turn on your transmitter

while pressing both of the two

Edit keys

(the two keys on the far left).

The Mode select (MODE) menu

2.Press the Up or Down arrow

keys to get to another setup

menu, or switch power off.

3. Switch power back on. You

may now set up the details of

your model in the Edit mode.

MET(Metric), IMP(Imperial) – Unit Select

1. With the transmitter switched

off, turn on your

Flashing

transmitter while pressing both

of the two Edit keys

(the two keys on the far left).

The Imperial select (IMP) menu

will be displayed .

2. Press the Right or Left Cursor

key to select MET or IMP .

Flashing

* Metric = °C m Km

* Imperial = °F ft mile

3. Press the Up or Down arrow

keys to get to another setup

menu, or switch power off.

4. Switch power back on. You may now set up the

details of your model in the Edit mode.

RPM - RPM Check

Flashing

will be displayed . you can check aircraft RPM using RPM sensor (You can use maximum 2 RPM sensors).

Flashing

3. Press the Right Cursor key to select RPM1 or RPM2 .

4. Press the Up or Down arrow keys to get to another

setup menu, or switch power off.

5. Switch power back on. You may now set up the

details of your model in the Edit mode

1. With the transmitter switched

off, turn on your

transmitter while pressing both

of the two Edit keys

(the two keys on the far left).

The RPM select (RPM) menu

2. To change the

propeller(prop), press the +In-

crease and

-Decrease Data keys until you

see the type of prop you desire.

There are 3 kinds of props- 2-b

(blades) ,3-b , 4-b.

AMP- Amperage Check

1. With the transmitter switched off, turn on your transmitter

while pressing both of the two Edit keys (the two keys on the

far left). The Amperage select (AMP) menu will be displayed

Flashing

2. Press the Right Cursor key to

select 50 or 200

This numerals means AMP. 50

is 50AMP.

3. Press the Up or Down arrow

keys to get to another setup

menu, or switch power off.

22

Page 25

Model Setup Functions

Flashing

4. Switch power back on. You

may now set up the details of

your model in the Edit mode.

B,WAR - Rx Battery Warning

Flashing

menu will be displayed . this is very useful for knowing the battery recharging timing.

2.To change the Battery warning point, press the +Increase

and

-Decrease Data keys until you see the voltage value you

desire.

Set up range is from 4v to 35v.

1. With the transmitter switched

off, turn on your

transmitter while pressing both

of the two Edit keys

(the two keys on the far left).

The B.WAR select (B.WAR)

23

Page 26

AIRCRAFT (ACRO) MENU FUNCTIONS

This section describes the menu functions for xed-wing aircraft, provides a detailed setup example, and then describes the

functions individually. Functions relating specically to gliders and helicopters may be found in the following sections.

ACRO Functions Map

Simple Aerobatic Airplane Transmitter Setup

EPA End Point Adjust (servo travels)

D/R Dual Rates

EXP Exponential Settings

FLT.C Flight Condition Select

S.TRM Subtrim

REV Servo Reverse

T.CUT Throttle Cut (engine shut off)

PMX1-5 Programmable Mixer #1 - #5 (ve total)

LAND Landing function settings

FLPT Flap trim

E->F Elevator Flap mixing

A->R Rudder Coupling

ELVN Elevon mixing (tailless models)

VTAL V-tail mixing

FLPN Flaperon (combined aps & ailerons)

AILV Ailevator (2Elevon Aileron mixing)

MX.SS Mix Switch Select

Aircraft Trimming Chart

Voltage / Timer Display

Normal Display Mode

End Point Adjust ( EPA )

Dual Rates ( D/R )

Exponential Settings ( EXP )

Flight Condition Select ( FLT.C )

Subtrim ( S.TRM )

Servo Reverse ( REV )

Throttle Cut ( T.CUT )

Programmable Mixer #1 - #5 ( PMX- )

Landing function settings ( LAND )

Flap trim ( FLPT )

Elevator Flap mix ( E->F )

Rudder Coupling ( A->R )

Elevon mix ( ELVN )

V-tail mix ( VTAL )

Flaperon mix ( FLPN )

Ailevator mix ( AILV )

Mix Switch Select ( MX.SS )

Press both

Edit/Display key

Simple Transmitter Setup – Aerobatic Airplane (ACRO)

The following pages will take you step-by-step through the setup process for a sport or aerobatic airplane in the ACRO menu.

Going through this complete section will help you learn how to use your system quickly and easily. If you need to set up a

helicopter or glider, please refer to the quick setup instructions in the helicopter and glider sections.

AIRCRAFT SETUP INSTRUCTIONS

(AEROBATIC PLANE)

The aircraft setup procedure presented below uses an

aerobatic model as an example and assumes that there

are two aileron servos, one in each wing. You can use a

similar procedure to set up your own model; your setting’s

numbers and percentages will probably be different.

If your model only has one aileron servo, skip the instructions

referring to aperon.

1. Be sure that all of your servos are plugged into the

proper receiver channels:

CH1 – Right aileron CH4 – Rudder CH7 – Optional

CH2 – Elevator (Left Elevator) (Right Elevator)

CH3 – Throttle CH5 – Gear CH6 – Left aileron

2. We recommend that you do this programming exercise

with the servos installed in the model and connected to

the respective control surfaces. This will enable you to

immediately see the effect of each programming step.

3. Turn on your transmitter while holding down the two

Edit keys (the two keys on the far left). This gets you into

the model select (M.SEL) menu. Press the Cursor Right

button to move to a new model memory. The selected

model memory you select is indicated by the little ashing

arrow pointing down. Memory #2 is shown here.

4. Press the Up arrow until the word ACRO appears,

ashing on and off. If it does, you’re ready to proceed

on to the next step. If not, press the Left or Right

Cursor keys until it appears. You must press both Data

keys to “Save” the setting, after which the radio will beep

twice. This is how you select the type of model you wish

to use, either ACRO, HELI, or GLID.

5. WARNING: selecting a different model type will erase

the settings in the model memory. BE SURE you’re in the

correct model memory before selecting a new model type,

or you might accidentally erase a model you’re using. (The

other memories will not be affected.)

6. Press the Down arrow once. This gets you into the

model name mode (note the words “MODEL” and

“NAME” in the upper left of the display).

7. Now you can select four letters to identify your model.

With the rst of the four letters ashing, press the Data

+Increase or -Decrease key to change the letter that is

displayed. Stop when the rst letter is the one you want.

8. Press the Right Cursor key once to get to the second

letter. Repeat the previous step to choose the second

letter.

9. Repeat two more times to ll out the remaining two

letters. If you like, you can hit the right cursor button one

more time and select a number between 0 and 999 for

24

Page 27

Simple Transmitter Setup – Aerobatic Airplane (ACRO)

further identication. It can be handy to use this to store

the plane’s channel number.

1O. Press the Up arrow twice. This gets you into the

Timer menu (TIME). If you want, you can use the Data

+Increase or -Decrease keys to select the amount of

time you want the stopwatch to count down.

12. Now turn power ON.

The transmitter should display the model number and battery

voltage as shown. The number on the right is the elapsed

time, which will vary depending on how long the transmitter

has been left on.

15. Be sure that you connect the right aileron servo to

receiver CH1 and the left aileron servo to receiver CH6.

16. Later, you can get differential by adjusting the up and

Flashing

if they don’t. Go to the Reversing menu (REV) by hitting the

Downarrow.

17. We’ll start by setting the right aileron servo direction.

This is channel 1, and the 1 should be ashing for this

command. When you move the right-hand stick to the

right, the aileron on the right wing should move upwards,

and the aileron on the left should move downward.

Check that the right aileron moves the correct way!

LEFT

18. If it does not, activate the opposite direction for the

CH1 aileron servo by pressing the Active/Inhibit (Clear)

key. Each press switches from Reversed to Normal and

RIGHT

11. This completes the initial

part of the setup.

Now, we’ll go ahead and customize the ACRO settings

for your model. Switch transmitter power OFF.

13. Press both Edit keys to

get to the regular programming

menu. The end-point

adjust menu.(EPA) should

appear. Press the Down

arrow three times to get to the

aperon menu (FLPN).

The display should show that it

is inhibited (INH).

14. Turn on the Flaperon

function by pressing the

Active/Inhibit button

(Clear) until “On” appears

in the display.

down motion of the two servos

in the FLPN menu. Now we’ll

set the servo throw directions.

Now check that each servo

moves the proper direction.

We’ll use the Reversing function

RIGHT

LEFT

from Normal to Reverse. In the display, NOR for Normal is

chosen when the little triangle is above the channel

Flashing

The display shows Channel 1 reversed.

19. Next we’ll set the direction of the elevator servo,

channel 2. When you move the right-hand stick towards

the BOTTOM of the transmitter, the elevator should move

up. Check to make sure it moves in the proper direction!

(More planes are crashed due to reversed controls than

for any other reason.)

UP

DOWN

20. If the elevator control moves in the wrong direction,

move over to Channel 2 by pressing the Cursor Right

key. Now the ‘2’ should be ashing in the display.

Activate the opposite direction for the elevator servo by

pressing the Active/Inhibit (Clear) key. Move the right-hand

stick up-and-down again and verify the elevator

moves the right direction.

21. Now we’ll set the direction of the throttle servo. When

you move the left-hand stick towards the BOTTOM of the

transmitter, the throttle should close, meaning that the

hole in the carburetor should close. Check to make sure

that the throttle lever on the engine moves in the proper

direction!

HIGH

number, and REV for Reverse is

chosen when ashing numeral

the channel

number. Move the right-hand

stick again and verify

the right aileron moves in the

right directions.

DOWN

UP

HIGH Throttle :

carburetor fully opened

LOW Throttle :

carburetor at idle position

LOW

22. If the throttle servo moves in the wrong direction,

move over to Channel 3 by pressing the Cursor Right

key. Now the 3 should be ashing in the display.

Activate the opposite direction for the throttle servo by

pressing the Active/Inhibit (Clear) key. Verify the throttle

stick makes the servo move the carburetor opening in the

correct direction.

23. Now we’ll set the direction of the rudder servo. When

you move the left-hand stick towards the CENTER of the

transmitter (to the right), the trailing edge or rear rudder

should move to the right. Check to make sure!

(not fully closed)

25

Page 28

Simple Transmitter Setup – Aerobatic Airplane (ACRO)

RIGHT

RIGHTLEFT

LEFT

If the rudder moves in the wrong direction, move over to

Channel 4 by pressing the Cursor Right key. Now the

‘4’ should be ashing in the display. Activate the opposite

direction for the rudder servo by pressing the Active/

Inhibit (Clear) key. Move the left-hand stick left-and right

again and verify the rudder moves the right direction.

If your model has retracts, set the correct response direction

when commanded by the Gear switch, using the

same procedure. If you’re using a second aileron servo,

you’ll now set the left aileron servo direction (otherwise skip

this and the next step). This is channel 6, and the ‘6’

should be ashing for this command. When you move

the right-hand stick to the right, the aileron on the left wing

should move downwards. Check that the left aileron

moves the correct way! If it does not, activate the opposite

direction for the left aileron servo using the above

procedures. Move the right-hand stick again and verify

the left aileron moves in the proper directions.

Press the Up or Down

Flashing

arrow keys to the Flap Trim

function (FLPT), and input

a percentage of FLPT value

using the Data -Decrease

key(default is 30).

This temporarily disables the ap knob (VR1) so that you can

set aileron neutrals without regard to the ap knob position.

Later we’ll turn it back on.

24. Before we set the servo neutrals, we need to be sure

that all the trims are centered. Press both Edit keys to get

to the main menu, where voltage and time are displayed.

Press the Up arrow until the word TRIM appears.

By moving each of the four trim levers around, you can

see their positions, and move them back to zero for the

next step.

25. Once you have centered all the trims, unscrew the

screws holding the servo arms onto the elevator, aileron,

and rudder (we’ll set the throttle travel later). You will

want to place the servo arms on the output shaft so they

are near neutral - that is, about 90 to

the servo case sides or, if the servo is

90˚

mounted sideways, 90 to the pushrod

(sideways mounting is not recommended)

This way you won’t run out of subtrim

authority. Remove

all the arms that are in the way or

interfere with your pushrods.

Adjust the clevises on each servo pushrod to get the

position of each control to be as close as you can to

neutral (lined up with the adjacent portion of wing or tail).

Flashing

Setting Subtrims. Now

we’ll adjust all the subtrims

to electronically set the

desired neutral locations.

To do so, go back to the

programming menu by pressing both Edit keys, then

press the Up or Down arrow key repeatedly until STRM

appears.

26. Set the right aileron subtrim rst. If the channel 1 is not

ashing, press one of the Cursor

Left or Right buttons until it is (see gure). Then, adjust

the subtrim amount by adding or subtracting with the

Data +Increase or -Decrease keys. When you reach a

place where the right aileron matches up with the xed

portion of the wing, you are done. If you can’t get both

to match up, then set the subtrim back to zero and

mechanically adjust the clevis to get as close as you can,

then readjust the subtrim if necessary.

27. Note 1: you should NOT use subtrims instead of

mechanically adjusting the pushrods to be close. This

is because you can reduce the travel of the servo, especially

if you have to set the subtrim near 100%. As we

stated before, get the pushrods close mechanically rst,

then use the subtrim adjustment to get it just right.

28. Note 2: if you mess up the number you’ve entered

or nd the percentage the wrong direction, you can get

back to zero quickly by pressing the Active/Inhibit

(Clear) button.

29. Repeat the subtrim

Flashing

adjustment with the elevator

servo (CH2). First set

the pushrod length mechanically

to get as close to neutral as

possible, then set the subtrim to

get the elevator lined up to be parallel with the

stabilizer portion. For full-ying surfaces, use an incidence

meter or another method to get the incidence angle

recommended by the kit manufacturer or model designer.

30. For the throttle, we recommend not setting a subtrim

at this time. You will use the trim tab on the transmitter

for setting your idle RPM. To shut off the motor you will

use the Engine Cut function. In this way, you don’t lose

your carefully-set idle position.

31. Most people set up their engines to idle with the

throttle trim near center, so that there is room for changes

due to humidity and other factors.

32. The Eclipse 7 Pro provides a special throttle trim function

which allows the throttle trim lever to work at low throttle

levels, but disables it at high throttle.

33. Repeat the subtrim adjustment with the rudder (CH4),

gear (CH5), 2nd aileron channel (CH6), and the CH7

function if used. As before, rst set them mechanically,

then adjust the electronic settings. Be sure you have

selected the appropriate channel number each time.

26

Page 29

Simple Transmitter Setup – Aerobatic Airplane (ACRO)

34. Servo EPA (End Point Adjustment). Now we’ll go

through and set the servo travels for each channel.

This is both helpful and important, because you can set

the throw of each servo, in each direction, so that there is