Page 1

SV 8SA • SV 12SF

ORBITAL SANDER

SCHWINGSCHLEIFER

PONCEUSE ORBITALE

LEVIGATRICE ORBITALE

VLAKSCHUURMACHINE

LIJADORA ORBITAL

LIXADEIRA ORBITAL

ΠΑΛΜΙΚΟ ΤΡΙΒΕΙΟ

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

Lire soigneusement et bien assimiler ces instructions avant usage.

Prima dell’uso leggere attentamente e comprendere queste istruzioni.

Deze gebruiksaanwijzing s.v.p. voor gebruik zorgvuldig doorlezen.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Antes de usar, leia com cuidado para assimilar estas instruções.

∆ιαβάστε προσεκτικά και κατανοήσετε αυτές τις οδηγίες πριν τη χρήση.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni per l’uso

Gebruiksaanwijzing

Instrucciones de manejo

Instruções de uso

Οδηγίες χειρισµού

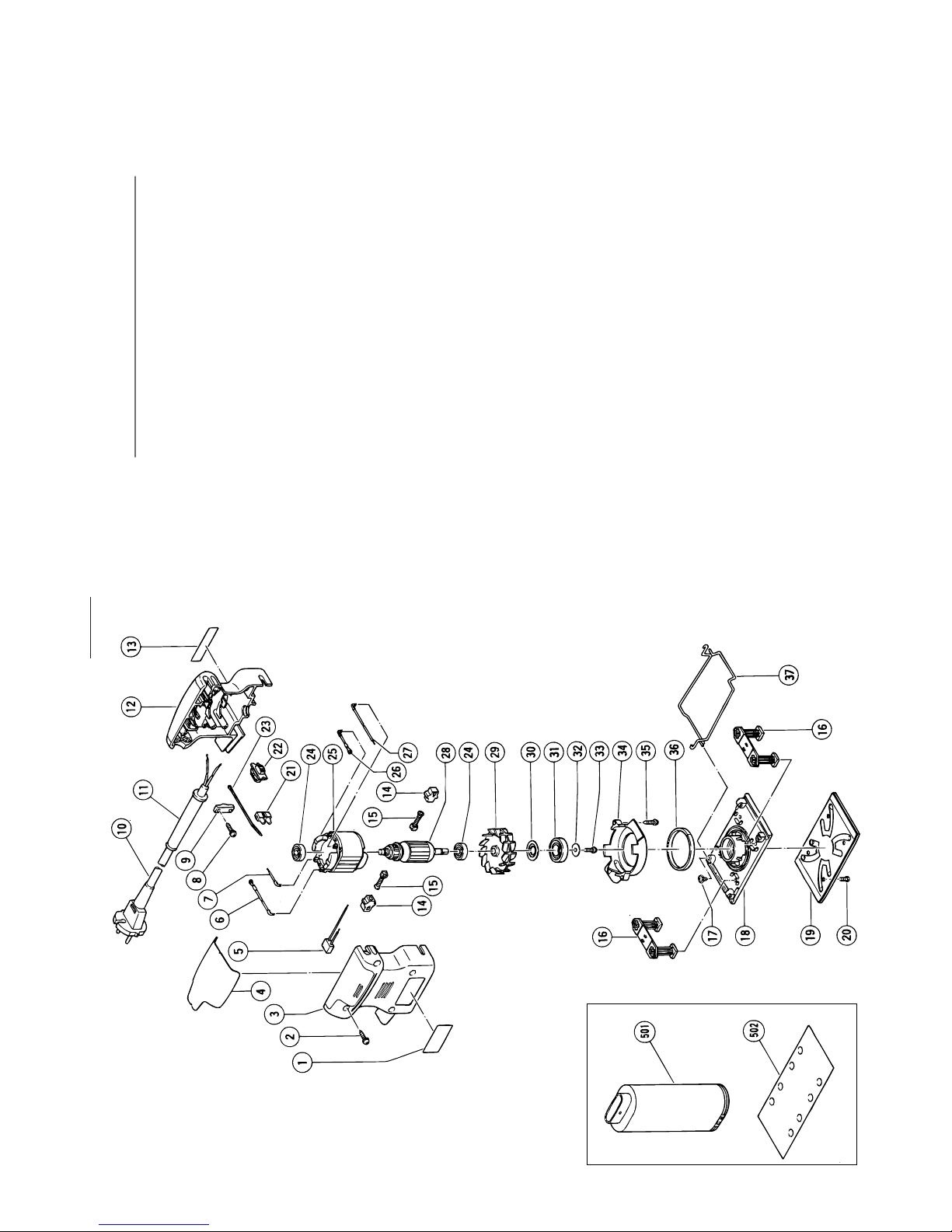

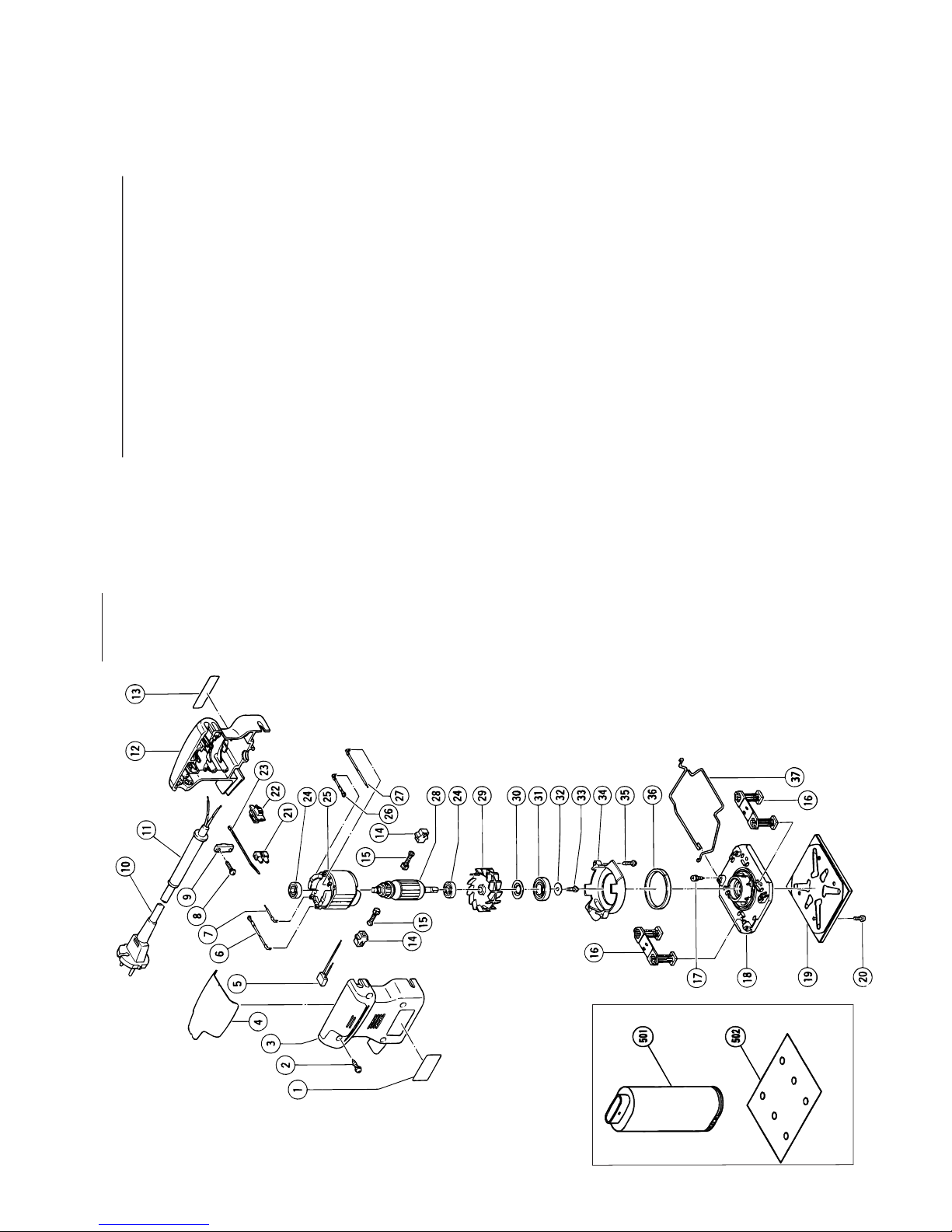

Page 2

12

1

2

3

4

5

6

7

8

43

1

2

3

4

5

6

7

8

5

6

7

1

2

Page 3

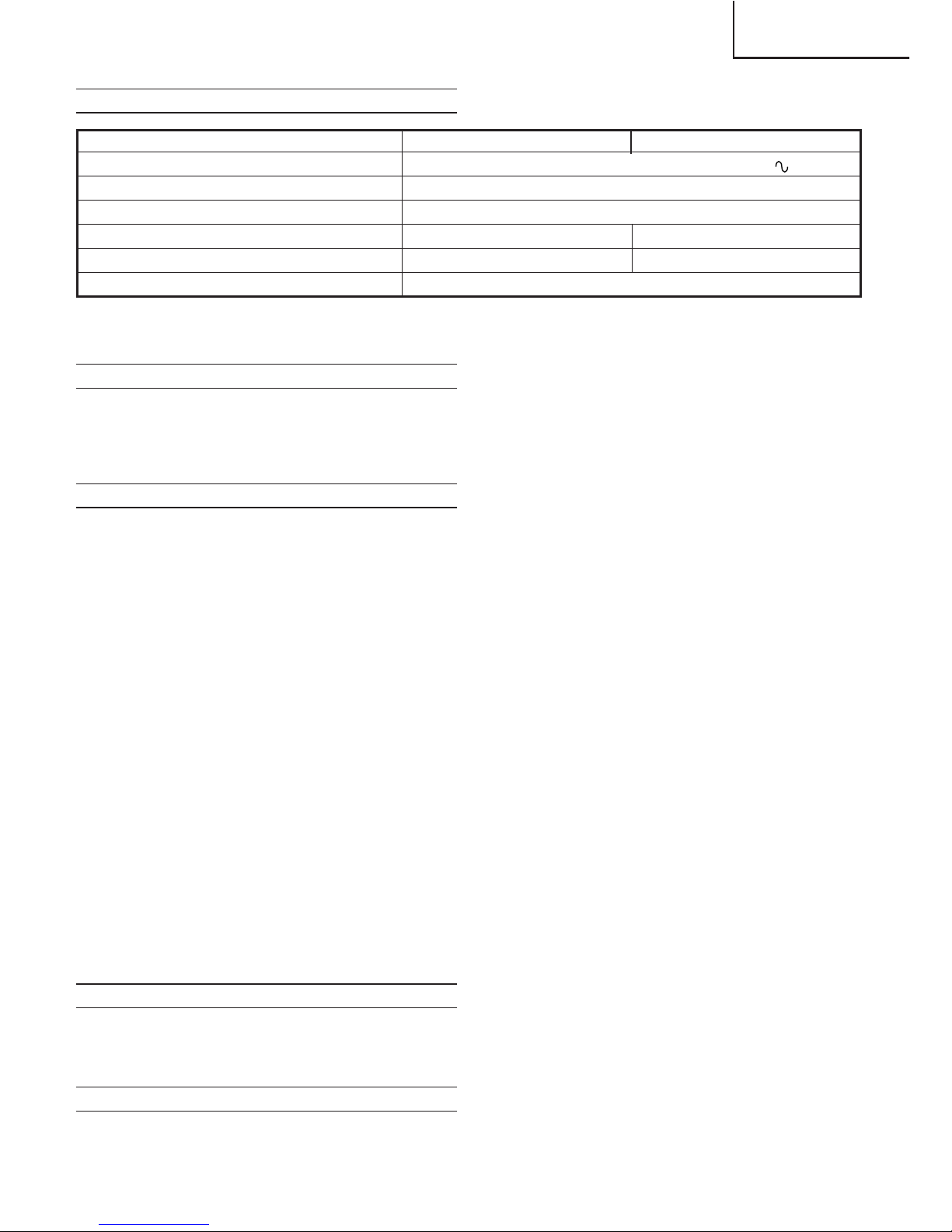

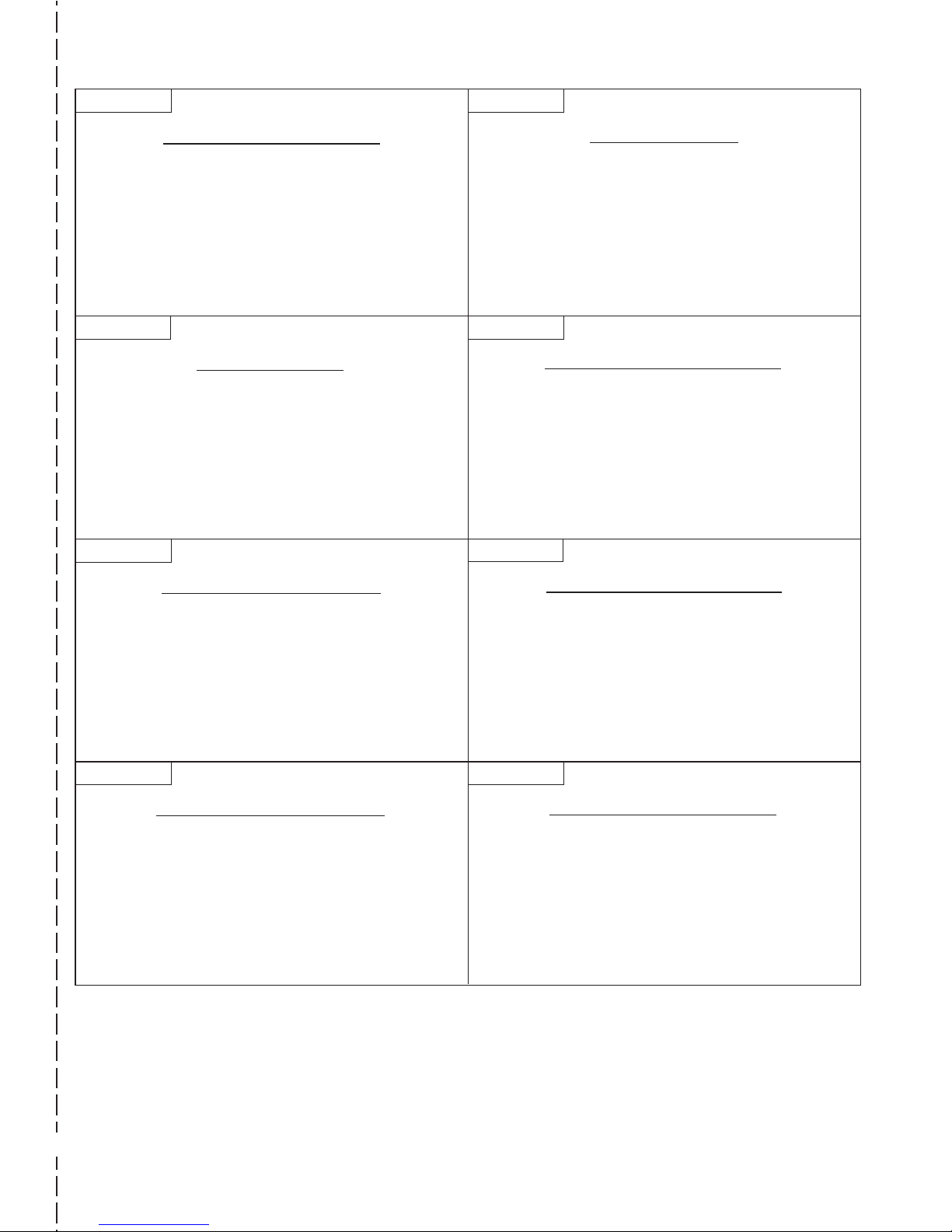

1

Sanding paper

Dust gate

2

3

Dust bag

4

Dust outlet

5

Dust collector

6

Adapter

7

Hose

8

Punch plate

Nederlands Español Português Ελληνικά

Schuurpapier

1

Stofschuif

2

Stofzak

3

Stof-uitlaatopening

4

Stof-verzamel

5

Adapter

6

Slang

7

Doorslagplaat

8

English Deutsch Français Italiano

Schleifpapier

Staubausgang

Staubsack

Staubauslaß

Staubsauger

Adapter

Schlauch

Stanzplatte

Papel eseneril

Boca de salida del

serrín

Bolsa celector de polvo

Salida del polvo

Colector de polvo

Adaptador

Manguera

Placa perforadora

Papier de verre

Volet à poussière

Sac à poussière

Déversoir de poussière

Collecteur à poussière

Adaptateur

Tuyau

Plaque de poiçonnage

Lixa

Boca de saída da poeira

Bolsa coletora de poeira

Saída da poeira

Coletor de poeira

Adaptador

Mangueira

Placa perfuradora

Carta abrasive

Uscita polvere

Sacca di raccolta della

polvere

Uscita polvere

Raccglipolvere

Adattatore

Manicotto

Punzone

Γυαλχαρτο

Είσοδος σκνης

Σάκος σκνης

Έξοδος σκνης

Συλλέκτης σκνης

Προσαρµογέας

Ελαστικς σωλήνας

Πλάκα διατρύπησης

2

Page 4

3

English

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including

the following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to

cause fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should

be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for

example, do not use circular saw to cut tree limbs

or logs.

8. Dress properly. Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protecting hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask

if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by

the cord or yank it to disconnect it from the

receptacle. Keep the cord away from heat, oil and

sharp edges.

12. Secure work. Use clamps or a vise to hold the

work. It is safer than using your hand and it frees

both hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades,

bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a

plugged-in tool with a finger on the switch. Ensure

switch is off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, free running

of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not

use the tool if the switch does not turn it on and

off.

21. Warning

The use of any accessory or attachment, other

than those recommended in this handling

instructions, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

Page 5

4

English

*Be sure to check the nameplate on product as it is subject to change by areas.

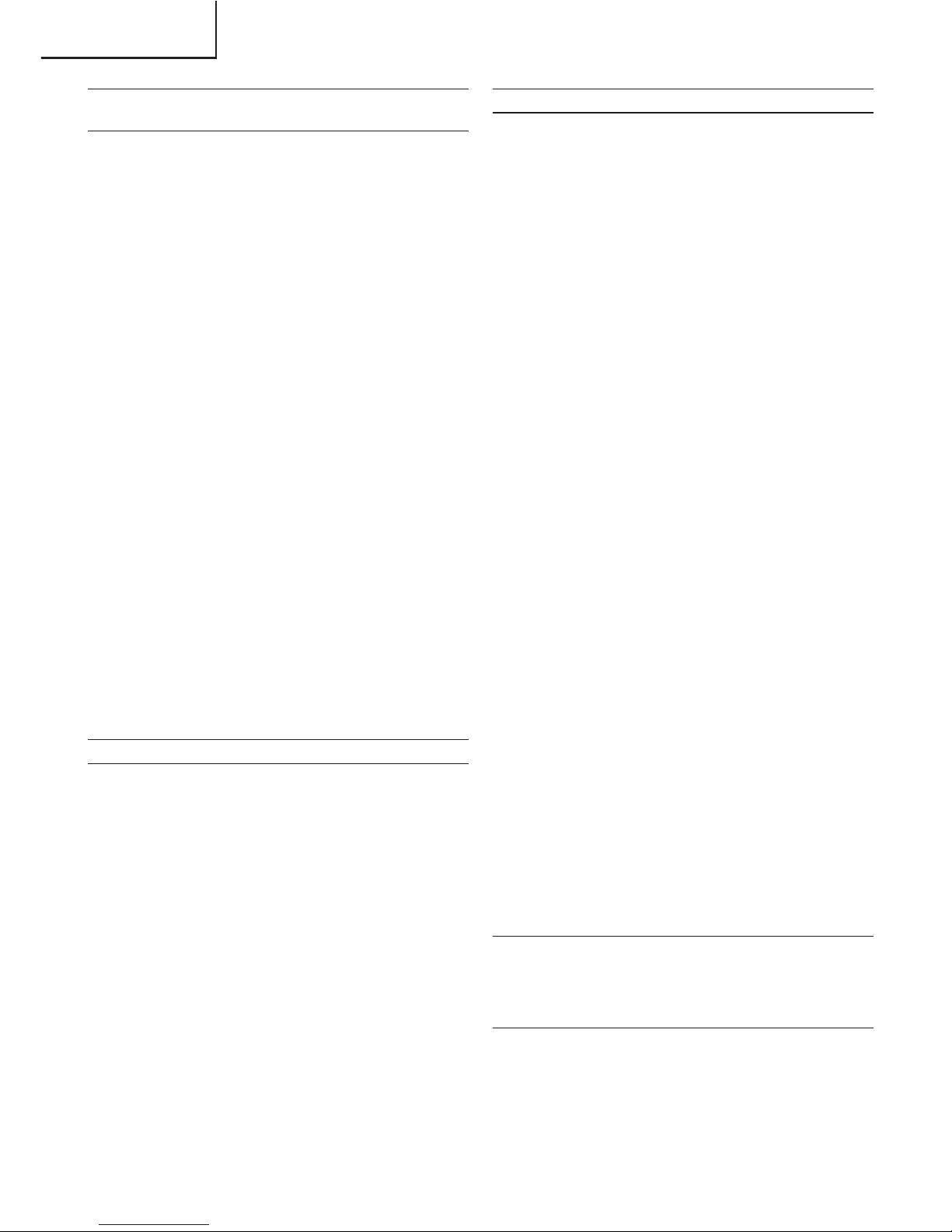

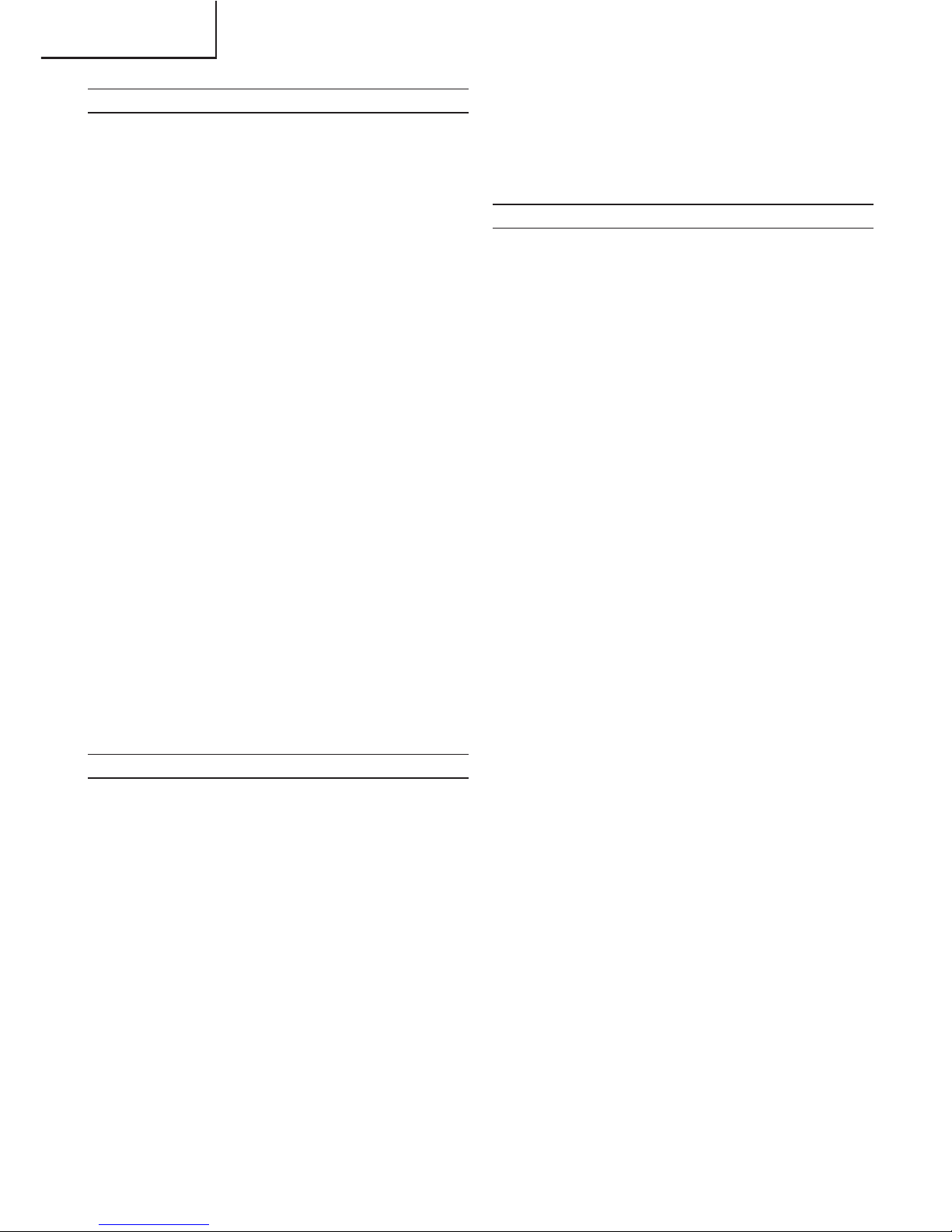

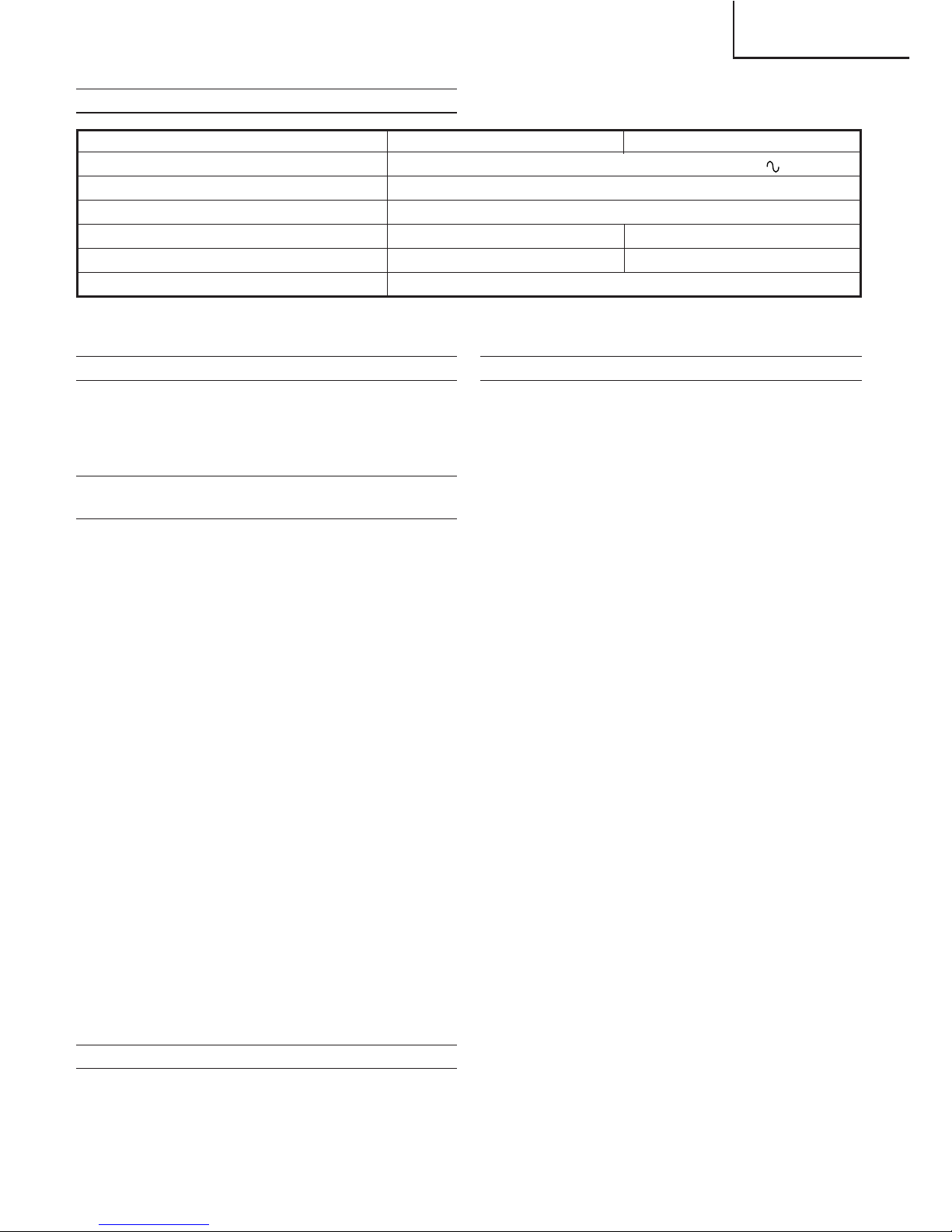

SPECIFICATIONS

Model SV8SA SV12SF

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power Input 200W*

No-load speed 14000/min.

Sanding pad size 80 mm × 130 mm 110 mm × 100 mm

Sanding paper size 80 mm × 170 mm 114 mm × 140 mm

Weight (without cord) 1.1 kg

STANDARD ACCESSORIES

䡬 Sanding paper (Grain: AA 100) ............................... 1

䡬 Dust bag ..................................................................... 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

1. Sanding paper

<For SV8SA use>

䡬 80 × 170 mm paper clip type sanding paper

Grain: AA60, AA100, AA150

䡬 80 × 130 mm Velcro type sanding paper

Grain: AA60, AA100, AA150

<For SV12SF use>

䡬 114 × 140 mm paper clip type sanding paper

Grain: AA60, AA100, AA150

䡬 110 × 100 mm Velcro type sanding paper

Grain: AA60, AA100, AA150

䡬 110 × 100 mm stick-on type sanding paper

Grain: AA60, AA80, AA100, AA120, AA150, AA180

䡬 Outer diameter 125 mm stick-on type sanding paper

Grain: AA60

2. Sanding pad

<For SV8SA use>

䡬 80 × 130 mm sponge pad (Velcro type)

<For SV12SF use>

䡬 110 × 100 mm sponge pad (Velcro type)

䡬 110 × 100 mm stick-on pad

䡬 Outer diameter 125 mm stick-on pad

3. Dust collector (Model WDE-1200)

4. Punch plate

Optional accessories are subject to change without notice.

APPLICATIONS

䡬 Finish polishing of woodwork surfaces

䡬 Sanding surfaces of woodwork or sheet metal prior

to painting, etc.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF positon.

If the plug is connected to a power receptacle while

the power switch is in the ON position, the power

tool will start operating immediately, which could

cause a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

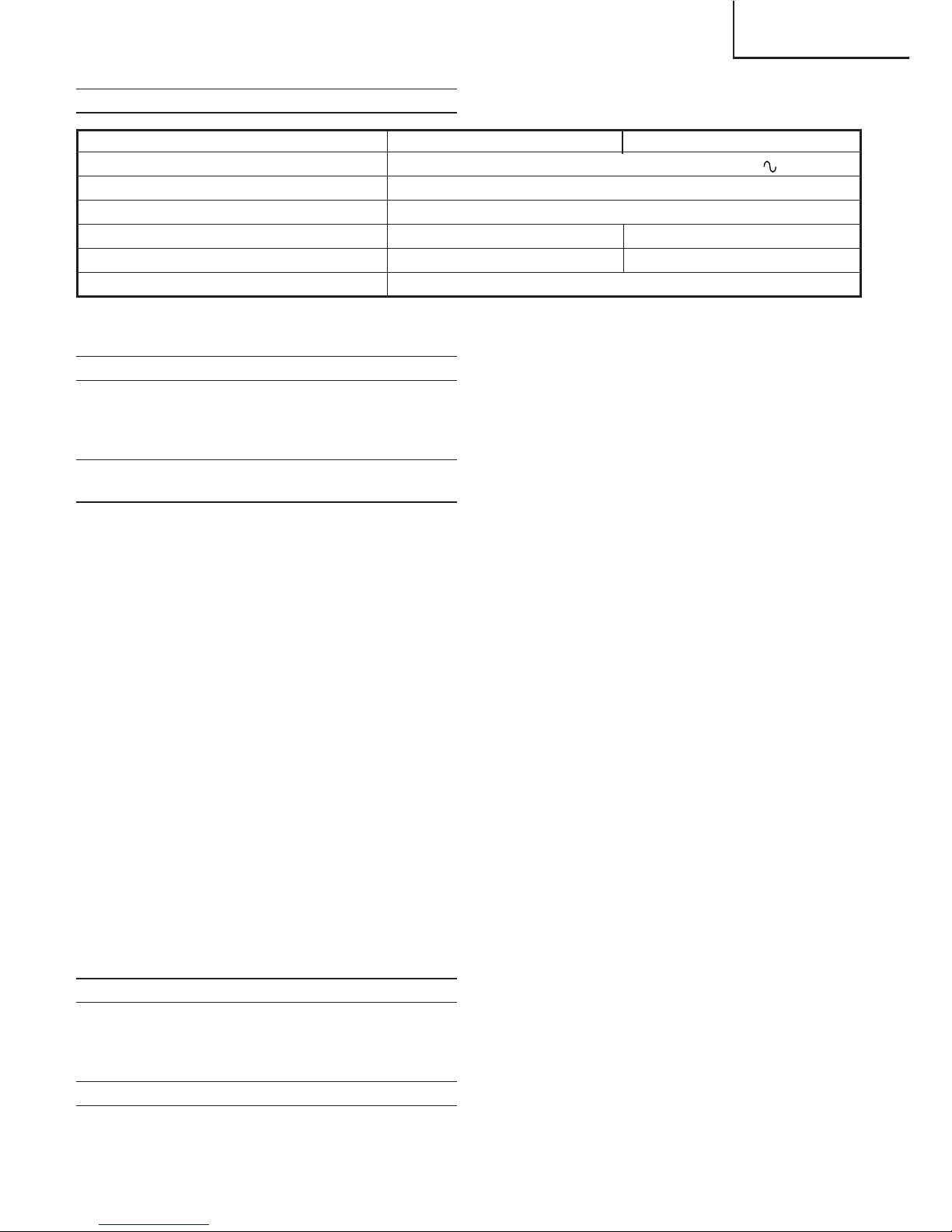

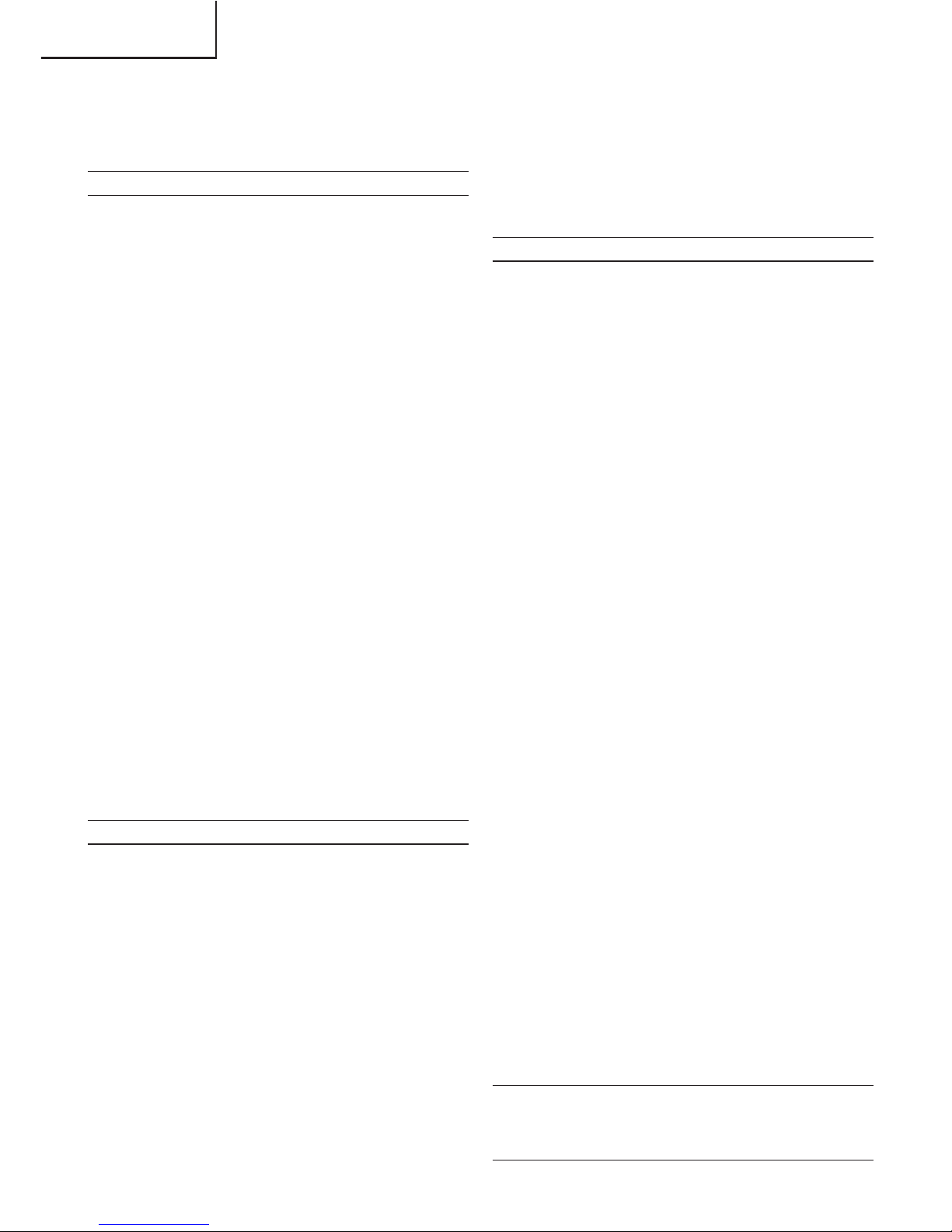

4. Installing the sanding paper

(1) Bending the sanding paper:

Position the sander with its pad side facing upward

as shown in Fig. 1. Place the sanding paper on the

pad so that the center of the sanding paper is

aligned with the center of the pad, and bend both

ends of the sanding paper at a 90° angle. Then,

bend both ends again in the manner shown in Fig.

2. The sanding paper is now ready to be installed

on the sander.

(2) Installing the sanding paper:

While ensuring that the cord is not bent, place the

sander on a workbench as shown in Fig. 3, and

insert one end of the sanding paper (bent section).

Next, insert the remaining bent section in the same

manner.

CAUTION

The sanding paper must be precisely installed on

the pad, ensuring that there is ample tension (leaving

no slack). Loosely installed sanding paper could

result in unevenly sanded surfaces and/or damage

to the sanding paper itself.

5. Attaching and Removing the Dust Bag

(1) Attaching the Dust Bag

As shown in Fig. 4, hold the dust gate and push

it in the direction of Arrow A to attach it to the

dust outlet.

(2) Removing the Dust Bag

As shown in Fig. 4, hold the dust gate and pull it

in the direction of Arrow B to remove it from the

dust outlet.

PRACTICAL OPERATING PROCEDURES

CAUTION

Never apply water or grinding fluid when sanding.

This could result in electrical shock.

Page 6

5

English

1. Switching the sander ON and OFF

The power can be turned on by setting the lever

to ON (1) and turned off by setting the lever to OFF

(0).

CAUTION

Never turn the power switch ON when the sander

is contacting the surface to be sanded. This is

necessary to preclude damage to the material. The

same applies when switching the power OFF.

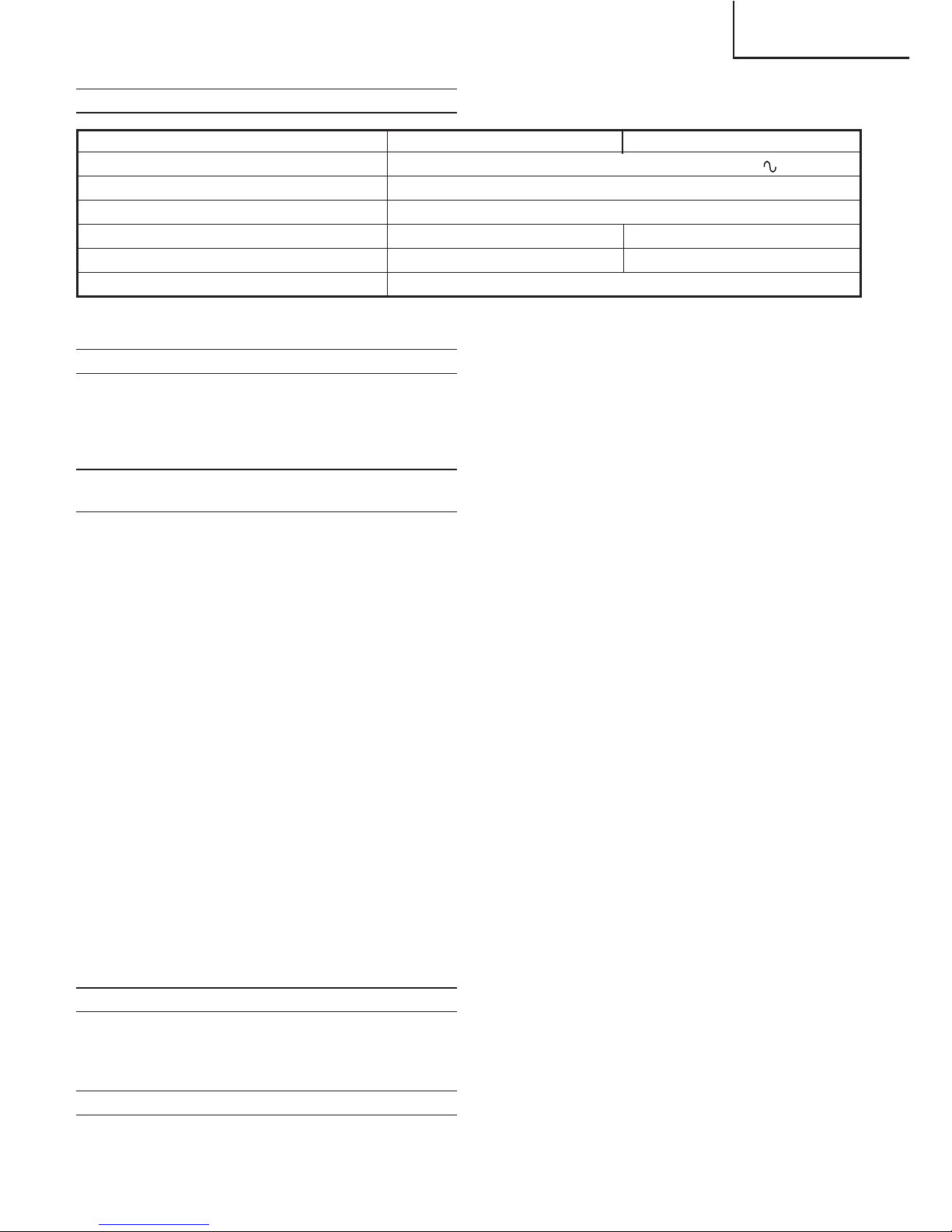

2. How to hold the orbital sander

While gripping the housing, lightly press the sander

against the surface to be sanded so that the sanding

paper uniformly contacts the surface, as shown in

Fig. 5. DO NOT apply excessive pressure to the

sander while sanding. Excessive-pressure may cause

overload of the motor, reduced service life of the

sanding paper, and lowered sanding or polishing

efficiency.

3. How to move the orbital sander

For optimum operating efficiency, alternately move

the sander forward and backward at a constant

speed and balance.

4. After installing new sanding paper

Movement of the sander may tend to become

unsteady after new sanding paper has been installed,

because of the new, coarse grain of the paper. This

can be avoided by slightly tilting the sander forward

or backward during sanding or polishing. Sander

movement will become steady as the sanding paper

surface becomes properly abraded.

MOUNTING THE OPTIONAL ACCESSORIES

1. Attaching a Sponge Pad (Velcro type) or a Stickon pad

Loosen the M4 × 10 screws (4) and remove the

attached pad. Next, attach a sponge pad (Velcro

type) or a stick-on pad.

CAUTION

Replace the pad only. Use the other parts without

removing them.

2. Attaching Velcro Type Sanding Paper or Stick-on

Type sanding Paper

Match the sanding paper’s hole with the pad’s hole

and strongly push the sanding paper with the palm

of your hand to fasten it securely in place.

3. When collecting dust with the Dust Collector (Model

WDE-1200)

By attaching the Dust Collector (Model WDE-1200),

it is possible to carry out clean sanding.

As shown in Fig. 6, attach the adapter, hose and

dust collector in order to the dust outlet.

4. Making a Hole in the Sanding Paper with the Punch

Plate (Fig. 7)

When using sanding paper without holes in it, punch

holes in it with the punch plate to improve dust

collecting capacity.

MAINTENANCE AND INSPECTION

1. Empting and cleaning the Dust Bag

If the dust bag contains too much saw dust, dust

collection will be affected. Empty the dust bag when

it gets full.

Remove the dust bag, open the fastener, and dispose

of the contents.

2. Inspecting the sanding paper

Since use of worn-out sanding paper will degrade

efficiency and cause possible damage to the pad,

replace the sanding paper as soon a excessive

abrasion is noted.

3. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

4. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the sinding does not

become damaged and/or wet with oil or water.

5. Servicing

Consult an authorized Service Agent in the event

of power tool failure.

6. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools,

the safety regulations and standards prescribed in

each country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance

with the following code:

Blue: -Neutral

Brown: -Live

As the colours of the wires in the main lead of this tool

may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal

marked with the letter N or coloured black. The wire

coloured brown must be connected to the terminal

marked with the letter L or coloured red. Neither core

must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH

STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except The United Kingdom.

Page 7

6

English

Information concerning airborne noise and vibration

The measured values were determined according to

EN50144.

The typical A-weighted sound pressure level: 85 dB (A).

Wear ear protection.

The typical weighted root mean square acceleration

value does not exceed 2.5 m/s2.

Page 8

7

Deutsch

ALLGEMEINE VORSICHTSMASSNAHMEN

WARNUNG! Bei der Verwendung von Elektrowerkzeugen

müssen immer die grundlegenden Vorsichtsmaßnahmen

befolgt werden, um das Risiko von Feuer, elektrischem

Schlag und persönlicher Verletzung und den

nachfolgenden Punkten zu vermeiden.

Lesen Sie diese Anweisungen völlig, bevor Sie dieses

Erzeugnis verwenden, und bewahren Sie diese

Anweisungen auf.

Für sicheren Betrieb:

1. Der Arbeitsplatz sollte sauber gehalten werden.

Unaufgeräumte Arbeitsplätze und Werkbänke

erhöhen die Unfallgefahr.

2. Die Betriebsbedingungen beachten.

Elektrowerkzeuge sollten nicht dem Regen

ausgesetzt werden.

Ebenfalls sollten Sie nicht an feuchten oder nassen

Plätzen gebraucht werden.

Der Arbeitsplatz sollte gut beleuchtet sein.

Verwenden Sie Elektrowerkzeuge nicht an Orten,

an denen die Gefahr von Feuer oder Explosion

besteht.

3. Schutzmaß nahmen gegen elektrische Schläge

treffen. Darauf achten, daß das Gehäuse nicht in

Kontakt mit geerdeten Flachen kommt, z. (z.B.

Rohre, Radiatoren, Elektroherde, Kühlschränke).

4. Kinder sollten vom Gerät ferngehalten werden.

Vermeiden, daß andere Personen mit dem

Werkzeung oder Verlängerungskabel in Kontakt

kommen.

5. Nicht benutzte Werkzeuge sollten sicher aufbewahrt

werden. Sie sollten an einem trockenen und

verschließbaren Ort aufbewahrt werden, damit

Kinder sie nicht in die Hände bekommen.

6. Werkzeuge sollten nicht mit übermäßiger Gewalt

verwendet werden. Ihre Leistung ist besser und

sicherer, wenn sie mit der vorgeschriebenen

Geschwindigkeit verwendet werden.

7. Nur die korrekten Werkzeuge verwenden. Niemals

ein kleineres Werkzeug oder Zusatzgerat für

Arbeiten verwenden, die Hochleistungsgerate

erfordern. Nur Werkzeuge verwenden, die dem

Verwendungszweck entsprechen, d.h. niemals eine

Kreissäge zum Sägen von Ästen oder

Baumstämmen verwenden.

8. Die richtige Kleidung tragen. Keine lose Kleidung

oder Schmuck tragen, da sich lose Kleidungsstücke

in den bewegenden Teilen verfangen kònnen. Bei

Arbeiten im Freien sollten Gummihandschuhe und

rutschfeste Schuhe getragen werden.

9. Es sollte eine Sicherheitsbrille getragen werden.

Bei Arbeiten mit Staubentwicklung sollte eine

Gesichtsoder Staubmaske getragen werden.

10. Schließen Sie eine Staubabsaugvorrichtung an.

Wenn Vorrichtungen für den Anschluß von

Staubabsaug- und -sammelvorrichtungen

vorhanden sind, so stellen Sie sicher, daß diese

angeschlossen sind und richtig verwendet werden.

11. Niemals das Kabel mißbrauchen. Ein Werkzeug

niemals am Kabel tragen oder bei Abtrennung

von der Steckdose das Kabel harausreißen. Das

Kabel sollte gegen Hitze, Öl und scharfe Kanten

geschützt werden.

12. Den Arbeitsplatz gut absichern. Zwingen oder einen

Schraubstock zur Befestigung des Werkstücks

verwenden. Das ist sicherer als die Benutzung der

Hände und macht beide Hände zur Bedienung des

Werkzeugs frei.

13. Sich niemals weit überbeugen. Immer einen festen

Stand und ein sicheres Gleichgewicht bewahren.

14. Die Werkzeuge sollten sorgfältig behandelt werden.

Für einen einwandfreien und sicheren Betrieb

sollten sie stets scharf sein und saubergehalten

werden. Die Anleitungen für schmierung und

Austausch des Zuehörs unbedingt einhalten. Die

Kabel der Geräte regelmäßig überprüfen und bei

Beschädigung durch eine autorisierte

Kundendienststelle reparieren lassen.

Ebenfalls die Verlägerungskabel regelmäßig

überprüfen und bei Beschadigung auswechseln.

Die Handgriffe sollten stets trocken und sauber

sein, sowie keine Ol- oder Schmierfett stellen

aufweisen.

15. Werkzeuge vom Netz trennen, wenn sie nicht

benutzt werden, vor Wartungsarbeiten und beim

Austausch von Zubehörteilen wie z.B. Blätter,

Bohrer und Messer.

16. Alle Stellkeile und Schraubenschlüssel entfernen.

Vor Einschaltung des Gerätes darauf achten, daß

alle Stellkeile und Schraubenschlüssel entfernt

worden sind.

17. Ein unbeabsichtigtes Einschalten sollte vermieden

werden. Niemals ein angeschlossenes Werkzeug

mit dem Finger am Schalter tragen. Vor Anschluß

überprüfen, ob das Gerät ausgeschaltet ist.

18. Im Freien ein Verlängerungskabel verwenden. Nur

ein Verlängerungskabel verwenden, das für die

Verwendung im Freien markiert ist.

19. Den Arbeitsvorgang immer unter Kontrolle haben.

Das Gerät niemals in einem abgespannten Zustand

verwenden.

20. Beschädigte Teile überprüfen. Vor Benutzung des

Werkzeugs sollten beschädigte Teile oder

Schutzvorrichtungen sorgfältig überprüft werden,

um festzustellen, ob sie einwandfrei funktionieren

und die vorgesehene Funktion erfüllen,

Ausrichtung, Verbindungen sowie Anbringung sich

bewegender Teile überprüfen. Ebenfalls

uberprufen, ob Teile gebrochen sind. Teile oder

Schutzvorrichtungen, die beschädigt sind, sollten,

wenn in dieser Bedienungsanleitung nichts anderes

erwähnt ist, durch eine autorisierte

Kundendienststelle ausge wechselt oder repariert

werden. Dasselbe gilt für defekte Schalter.

Wenn sich das Werkzeug nicht mit dem Schalter

einoder ausschalten läßt, sollte das Werkzeug nicht

verwendet werden.

21. Warnung

Die Verwendung von anderem Zubehör oder

anderen Zusätzen als in dieser Bedienungsanleitung empfohlen kann das Risiko einer

Körperverletzung einschließen.

22. Lassen Sie Ihr Werkzeug durch qualifiziertes

Personal reparieren. Dieses Elektrowerkzeug

entspricht den zutreffenden Sicherheitsanforderungen. Reparaturen sollten nur von

qualifiziertem Personal unter Verwendung von

Originalersatzteilen durchgeführt werden, da sonst

beträchtliche Gefahr für den Benutzer auftreten

kann.

Page 9

8

Deutsch

*Vergessen sie nicht, die Produktangaben auf dem Typenschild zu überprüfen, da sich diese je nach Verkaufsgebiet

ändern.

TECHNISCHE DATEN

Modell SV8SA SV12SF

Spannung (je nach Gebiet)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Leistungsaufnahme 200W*

Leerlaufdrehzahl 14000/min.

Größe des Schleifschuhs 80 mm × 130 mm 110 mm × 100 mm

Größe des Schleifpapiers 80 mm × 170 mm 114 mm × 140 mm

Gewicht (Ohne Kabel) 1,1 kg

STANDARDZUBEHÖR

䡬 Schleifpapier (Körnung: AA100) .............................. 1

䡬 Staubsack ....................................................................1

Das Standardzubehör kann ohne vorherige

Bekanntmachung jederzeit geändert werden.

SONDERZUBEHÖR (separat zu beziehen)

1. Schleifpapier

<Für Verwendung mit dem SV8SA>

䡬 80 × 170 mm Schleifpapier mit Papierclip

Körnung: AA60, AA100, AA150

䡬 80 × 130 mm Schleifpapier mit Klettenband

Körnung: AA60, AA100, AA150

<Für Verwendung mit dem SV12SF>

䡬 114 × 140 mm Schleifpapier mit Papierclip

Körnung: AA60, AA100, AA150

䡬 110 × 100 mm Schleifpapier mit Klebschicht

Körnung: AA60, AA80, AA100, AA120, AA150, AA180

䡬 Außendurchmesser 125 mm Schleifpapier mit

Klebschicht

Körnung: AA60

2. Schleifschuh

<Für Verwendung mit dem SV8SA>

䡬 80 × 130 mm Haftschuh (Klettenbandtyp)

<Für Verwendung mit dem SV12SF>

䡬 110 × 100 mm Haftschuh (Klettenbandtyp)

䡬 110 × 100 mm Schleifpapier mit Klebschicht

䡬 Außendurchmesser 125 mm mit Klebschicht

3. Staubsauger (Modell WDE-1200)

4. Stanzplatte

Das Sonderzubehör kann ohne vorherige

Bekanntmachung jederzeit geändert werden.

ANWENDUNGSGEBIETE

䡬 Fertigpolieren von Holzoberflächen

䡬 Schleifen von Holz oder Blech vor dem Anstreichen

usw.

VOR INBETRIEBNAHME

1. Netzspannung

Prüfen, daß die zu verwendende Netzspannung der

Angabe auf dem Typenschild entspricht.

2. Netzschalter

Prüfen, daß der Netzschalter auf “AUS” steht. Wenn

der Stecker an das Netz angeschlossen wird,

während der Schalter auf “EIN” steht, beginnt das

Werkzeug sofort zu laufen, was gefährlich ist.

3. Verlängerungskabel

Wenn der Arbeitsbereich nicht in der Nähe des

Netzanschlusses liegt, ist ein Verlängerungskabel

ausreichenden Querschnitts und ausreichender

Nennleistung zu verwenden. Das Verlängerungskabel

sollte so kurz wie möglich gehalten werden.

4. Anbringen des Schleifpapiers

(1) Falten des Schleifpapiers:

Den Schleifer wie in Abb. 1 gezeigt mit dem

Schleifschuh nach oben hinlegen. Das Schleifpapier

auf den Schleifschuh legen, so daß die Mitte des

Schleifpapiers mit der Mitte des Schleifschuhs

übereinstimmt, und beide Enden des Schleifpapiers

um 90° falten. Dann beide Enden noch einmal auf

die in Abb. 2 gezeigte Weise falten. Jetzt kann das

Schleifpapier angebracht werden.

(2) Anbringen des Schleifpapiers:

Darauf achten, daß das Kabel nicht geknickt wird,

und den Schleifer wie in Abb. 3 gezeigt auf eine

Werkbank legen. Ein Ende des Schleifpapiers

(gefalteter Teil) einführen und danach den anderen

gefalteten Teil auf die gleiche Weise einführen.

ACHTUNG

Das Schleifpapier muß präzise und mit ausreichender

Spannung (nicht zu lose) an den Schleifschuh

angebracht werden. Lose angebrachtes Schleifpapier

kann zu ungleichmäßig geschliffenen Flächen und/

oder Beschädigungen des Schleifpapiers führen.

5. Anbringen und Abnehmen des Staubsaugers

(1) Anbringen des Staubsaugers

Wie in Abb. 4 gezeigt, die Staubverbindung halten

und in Richtung des Pfeils A drücken, um sie am

Staubauslaß anzubringen.

(2) Abnehmen des Staubsaugers

Wie in Abb. 4 gezeigt, die Staubverbindung halten

und in Richtung des Pfeils B drücken, um sie vom

Staubauslaß abzunehmen.

PRAKTISCHE ARBEITSWEISE

ACHTUNG

Niemals Wasser oder Schleifflüssigkeit beim

Schleifen verwenden. Das kann zu elektrischen

Schlägen führen.

1. Ein-und Ausschalten des Schleifers

Durch Einstellung des Hebels auf ON (1) wird der

Schleifer ein- und durch Einstellung auf OFF (0)

ausgeschaltet.

Page 10

9

Deutsch

ACHTUNG

Den Schleifer niemals einschalten, wenn die

Maschine die zu schleifende Fläche berührt, um

Beschädigungen des Werkstücks zu verhindern. Das

gleiche gilt beim Ausschalten.

2. Halten des Schwingschleifers

Das Gehäuse halten und den Schleifer leicht gegen

die zu schleifende Fläche drücken, so daß das

Schleifpapier einen gleichmäßigen Kontakt hat, siehe

Abb. 5. Beim Schleifen keine übermäßigen Druck

auf den Schwingschleifer ausüben, weil dadurch

der Motor überlastet, die Nutzungsdauer des

Schleifpapiers verkürzt und die Schleif- oder

Polierleistung vermindert wird.

3. Bewegen des Schwingschleifers

Zur Erzielung einer optimalen Arbeitsleistung den

Schwingschleifer mit konstanter Geschwindigkeit

und mit gleichbleibendem Druck abwechselnd vor

und zurück bewegen.

4. Nach Einsetzen von neuem Schleifpapier

Nach Einsetzen von neuem Schleifpapier kann der

Schwingschleifer wegen des anfänglich gröberen

Korns des Papiers zu ungleichmäßiger Bewegung

tendieren. Dies läßt sich vermeiden, wenn der

Schleifer beim Schleifen oder Polieren leicht nach

vorne oder hinten geneigt wird. Die Bewegung des

Schwingschleifers wird stetig, wenn das

Schleifpapier etwas abgeschliffen ist.

ANBRINGEN VON SONDERZUBEHÖRTEILEN

1. Einen Haftschuh (Klettenbandtyp) oder einen Schuh

mit Klebschicht anbringen.

Die M4 × 10 Schrauben (4) lösen, und den

vorhandenen Schuh abnehmen. Danach einen

Haftschuh (Klettenbandtyp) oder einen Schuh mit

Klebschicht anbringen.

ACHTUNG

Nur den Schuh austauschen. Die anderen Teile so

verwenden, wie vorhanden.

2. Anbringen von Klettenband-Schleifpapier oder

Klebschicht-Schleifpapier.

Das Loch im Schleifpapier mit dem Loch im Schuh

anpassen, und das Schleifpapier mit der Handfläche

zum Befestigen fest andrücken.

3. Staubsammeln mit dem Staubsammler

(Modell WDE-1200).

Durch Anbringen des Staubsammlers (Modell WDE-

1200) wird sauberes Schleifen ermöglicht. Wie in

Abb. 6 gezeigt, den Adapter, den Schlauch und den

Staubsauger der Reihe nach am Staubauslaß

anbringen.

4. Mit der stanzplatte ein Loch im Schleifpapier machen

(Abb. 7)

Bei Verwendung von Schleifpapier ohne Löcher mit

der Stanzplatte löcher einstanzen, um die

Staubsammelfähigkeit zu steigern.

WARTUNG UND INSPEKTION

1. Leeren und Reinigen des Staubsacks

Die Aufnahmefähigkeit verringert sich, wenn der

Staubbeutel bereits zu viel Staub enthält. Der

Staubbeutel soll geleert werden noch bevor dieser

ganz voll ist. Den Staubbeutel abnehmen, die

Halterung öffnen und den lnhalt ausleeren.

2. Inspektion des Schleifpapiers

Die Weiterverwendung von abgenutztem

Schleifpapier führt zu verminderter Leistung und

kann eine Beschädigung des Schleifschuhs

verursachen. Daher sollte das Schleifpapier erneuert

werden, sobald übermäßiger Abrieb festgestellt wird.

3. Inspektion der Befestigungsschrauben:

Alle Befestigungsschrauben werden regelmäßig

inspiziert und geprüft, ob sie gut angezogen sind.

Wenn sich eine der Schrauben lockert, muß sie

sofort wieder angezogen werden. Geschieht das

nicht, kann das zu erheblichen Gefahren führen.

4. Wartung des Motors:

Die Motorwicklung ist das “Herz” des

Elektrowerkzeugs. Daher ist besonders sorgfältig

darauf zu achten, daß die Wicklung nicht beschädigt

wird und/oder mit Öl oder Wasser in Berührung

kommt.

5. Instandhaltung

Im Falle eines Versagens eine autorisierte

Wartungswerkstatt zu Rate ziehen.

6. Liste der Wartungsteile

A: Punkt Nr.

B: Code Nr.

C: Verwendete Anzahl

D: Bemerkungen

ACHTUNG

Reparatur, Modifikation und Inspektion von HitachiElektrowerkzeugen müssen durch ein autorisiertes

Hitachi-Kundendienstzentrum durchgeführt werden.

Dq=se Teileliste ist hilfreich, wenn sie dem

autorisierten Hitachi-Kundendienstzentrum

zusammen mit dem Werkzeug für Reparatur oder

Wartung ausgehändigt wird.

Bei Betrieb und Wartung von Elektrowerkzeugen

müssen die Sicherheitsvorschriften und Normen

beachtet werden.

MODIFIKATIONEN

Hitachi-Elektrowerkzeuge werden fortwährend

verbessert und modifiziert, um die neuesten

technischen Fortschritte einzubauen.

Dementsprechend ist es möglich, daß einige Teile

(z.B. Codenummern bzw. Entwurf) ohne vorherige

Benachrichtigung geändert werden.

ANMERKUNG

Aufgrund des ständigen Forschungs-und Entwicklungsprogramms von HITACHI sind Änderungen der hierin

gemachten technischen Angaben nicht ausgeschlossen.

Information über Betriebslärm und Vibration

Die Meßwerte wurden entsprechend EN50144 bestimmt.

Der typische A-gewichtete Schalldruckt ist 85 dB (A).

Bei der Arbeit immer einen Ohrenschutz tragen.

Der typische gewichtete Effektiv-Beschleunigungswert

überschreitet nicht 2,5 m/s2.

Page 11

10

Français

PRECAUTIONS GENERALES DE TRAVAIL

ATTENTION! Lors de l’utilisation d’un outillage électrique,

les précautions de base doivent être respectées de manière

à réduire les risques d’incendie, de secousse électrique et

de blessure corporelle, y compris les précautions

suivantes.

Lire ces instructions avant d’utiliser le produit et conserver

ces instructions pour référence.

Pour assurer un fonctionnement sûr:

1. Maintenir l’aire de travail propre. Des ateliers ou

des établis en désordre risquent de provoquer des

accidents.

2. Tenir compte de l’environnement de l’aire de tra

vail. Ne pas exposer les outils électriques à la

pluie.

Ne pas les utiliser dans des endroits humides.

Travailler dans un endroit bien éclairé.

Ne pas utiliser d’outillage électrique s’il existe un

risque d’incendie ou d’explosion.

3. Protection contre une décharge électrique. Eviter

tout contact corporel avec des surfaces de mise

à la terre telles que les tuyaux, radiateurs,

cuisinières et réfrigérateurs.

4. Tenir les enfants éloignés. Ne pas laisser les

visiteurs toucher l’outil ou son cordon

d’alimentation. Il est préférable de tenir les visiteurs

à l’écart de l’aire de travail.

5. Ranger les outils non utilisés. Quand on ne les

utilise pas, il est recommandé de ranger les outils

dans un endroit sec, verrouillé ou hors de portée

des enfants.

6. Ne pas forcer l’outil. Il fonctionnera mieux et plus

sûrement à la vitesse pour laquelle il a été con

cu.

7. Utiliser l’outil approprié. Ne pas essayer de faire

avec un petit outil le travail prevu pour un outil

plus important. Toujours utiliser l’outil adéquat;

par exemple, ne pas se servir d’une scie circulaire

pour couper des branches d’arbres ou des billots

de bois.

8. Porter des vêtements appropriés. Ne pas mettre

de vêtements flottants ou de bijoux qui risquent

d’être pris dans les pièces mobiles. Si l’on travaille

à l’extérieur, il est recommandé de porter des

gants de caoutchouc et des chaussures à semelles

antidérapantes. Veiller à s’attacher les cheveux ou

à mettre un bonnet si on a les cheveux longs.

9. Porter des lunettes protectrices. Mettre un masque

si l’opération de coupe crée de la poussière.

10. Relier l’équipement d’extraction de poussière.

Si des dispositifs sont prévus pour le raccordement

d’installations d’extraction et de collection de

poussière, s’assurer qu’ils sont correctement

raccordés et utilisés.

11. Prendre soin du fil. Ne jamais transporter l’outil

en le tenant par le fil et ne pas le débrancher en

tirant sur le fil d’un coup sec. Tenir le fil à l’abri

de la chaleur, l’éloigner de l’huile ou de bords

tranchants.

12. Fixer fermement la piêce à travailler. Utiliser des

agrafes ou un étau pour la maintenir, C’est plus

sûr que d’utiliser ses mains et cela les libêre pour

faire fonctionner l’outil.

13. Ne pas présumer de ses forces. Essayer de garder

son équilibre en toute circonstance.

14. Entretenir les outils avec soin. Les conserver bien

aiguisés et les nettoyer afin d’en obtenir les

meilleures performances et de pouvoir les utiliser

sans danger. Suivre les instructions pour le

graissage et le changement des accessoires.

Vérifier régulièrement les fils et cordons et s’ils

sont endommagés, les faire réparer par une

personne compétente. Vérifier régulièrement les

rallonges et les remplacer si elles sont

endommagées. Veiller à ce que les poignées soient

toujours sèches et propres, sans huile ni graisse.

15. Debrancher les outils lorsqu’on ne les utilise pas,

avant toute opération d’entretien et lors du

changement d’accessoire; comme par exemple

quand on change les lames, les forets, le fraises,

etc.

16. Retirer les clés de réglage. Prendre l’habitude de

toujours vérifier que les clés de réglage sont bien

retirées de l’appareil avant de le mettre en marche.

17. Eviter toute mise en marche accidentelle. Ne pas

transporter l’outil branché avec un doigt sur

l’interrupteur. S’assurer que l’interrupteur est sur

la position d’arrêt quand on branche l’outil.

18. Utilisation de rallonges à l’extérieur. Quand on

utilise l’outil à l’extérieur, ne se servir que des

rallonges prévues pour l’extérieur et portant une

marque distinctive.

19. Soyez vigilant. Regardez bien ce que vous faites.

Faites appel à votre bon sens. N’utilisez pas l’outil

quand vous êtes fatigué.

20. Vérifier les pièces endommagées. Avant d’utiliser

davantage l’outil, vérifier attentivement toute pièce

endommagée afin de déterminer si l’outil peut

fonctionner correctement et effectuer le travail

pour lequel il est prévu. Vérifier l’alignement et

la flexion des piêces mobiles, la cassure des pièces,

le montage et toute autre condition risquant

d’affecter le bon fonctionnement de l’outil. Un

protecteur ou toute autre pièce endommagée devra

être correctement réparé ou remplacé par un

service d’entretien autorisé, sauf autre indication

dans ce mode d’emploi. Faire remplacer les

interrupteurs défectueux par un service d’entretien

autorisé. Ne pas utiliser l’outil si l’interrupteur ne

permet pas de le mettre en marche ou de l’arrêter.

21. Précaution

L’utilisation d’un accessoire ou dispositif annexe

autre que ceux conseillés dans ce mode d’emploi

peut entraîner un risque de blessure corporelle.

22. Confier la réparation d’un outil à un technicien

qualifié. Cet outil électrique a été conçu

conformément aux règles de sécurité en usage.

Les réparations doivent être effectuées par du

personnel qualifié utilisant des pièces d’origine.

Dans le cas contraire, l’utilisateur s’expose à des

risques graves.

Page 12

11

Français

*Assurez-vous de vérifier la plaque signalétique se trouvant sur le produit, car elle peut changer suivant les régions.

CARACTERISTIQUES

Modèle SV8SA SV12SF

Tension (par zone)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Puissance d’entrée 200W*

Vitesse sans charge 14000/min.

Dimension du coussinet 80 mm × 130 mm 110 mm × 100 mm

Dimension du papier du verre 80 mm × 170 mm 114 mm × 140 mm

Poids (sans fil) 1,1 kg

ACCESSOIRES STANDARD

䡬 Papier de verre (Grain: AA100) ............................... 1

䡬 Sac à poussière ......................................................... 1

L’accessoire standard est sujet à changement sans préavis.

ACCESSOIRES EN OPTION

(vendus séparément)

1. Papier de verre

<Pour SV8SA>

䡬 Papier de verre type agrafage 80 × 170 mm

Grain: AA60, AA100, AA150

䡬 Papier de verre type Velcro 80 × 130 mm

Grain: AA60, AA100, AA150

<Pour SV12SF>

䡬 Papier de verre type agrafage 114 × 140 mm

Grain: AA60, AA100, AA150

䡬 Papier de verre type Velcro 110 × 100 mm

Grain: AA60, AA100, AA150

䡬 Papier de verre type adhésif 110 × 100 mm

Grain: AA60, AA80, AA100, AA120, AA150, AA180

䡬 Papier de verre type adhésif de diamètre extérieur

125 mm

Grain: AA60

2. Patin de ponçage

<Pour SV8SA>

䡬 Patin en caoutchouc 80 × 130 mm (type Velcro)

<Pour SV12SF>

䡬 Patin en caoutchouc 110 × 100 mm (type Velcro)

䡬 Patin adhésif 110 × 100 mm

䡬 Patin adhésif de diamètre extérieur 125 mm

3. Collecteur à poussière (Modèle WDE-1200)

4. Plaque de poiçonnage

Les accessoires en option sont sujets à changement

sans préavis.

APPLICATIONS

䡬 Polissage de finition des surfaces en bois.

䡬 Ponçage des surfaces en bois ou métalliques avant

peinture, etc..

AVANT LA MISE EN MARCHE

1. Source de puissance

S’assurer que la source de puissance à utiliser

correspond à la puissance indiquée sur la plaque

signalétique du produit.

2. Interrupteur de puissance

S’assurer que l’interrupteur de puissance est en

position ARRET. Si la fiche est branchée alors que

l’interrupteur est sur MARCHE, l’outil démarre

immédiatement et peut provoquer un grave accident.

3. Fil de rallonge

Lorsque la zone de travail est éloignée de la source

de puissance, utiliser un fil de rallonge d’une

épaisseur suffisante et d’une capacité nominale

suffisante. Le fil de rallonge doit être aussi court

que possible.

4. Mise en place du papier de verre

(1) Pliage du papier de verre:

Placer la ponceuse avec le coussinet dirigé vers le

haut, comme indiqué par la Fig. 1, puis placer le

papier de verre sur le coussinet en prenant soin

de faire coincider la ligne médiane du papier avec

celle du coussinet. Ensuite, plier les deux extrémités

du papier à 90°, puis les plier à nouveau, comme

indiqué par la Fig. 2. Le papier de verre est alors

prêt à être mis en place sur la ponceuse.

(2) Mise en place du papier de verre:

Placer la ponceuse sur un établi, comme indiqué

par la Fig. 3, tout en faisant bien attention à ne

pas plier le cordon d’alimentation et insérer l’une

des extrémités du papier de verre (Partie pliée).

Insérer ensuite l’autre extrémité pliée en procédant

de la même manière.

ATTENTION

Le papier de verre doit être mis en place sur le

coussinet avec beaucoup de précision. Vérifier qu’il

soit suffisamment tendu (sans partie lâche). Si le

papier de verre n’est pas tendu suffisamment, les

surfaces pourraient ne pas être poncées

uniformément et/ou le papier de verre pourrait être

endommagé.

5. Fixation et retrait du sac à poussière

(1) Fixation du sac à poussière

Tenir l’entonnoir de poussière et le pousser dans

le sens de la flèche A pour le fixer au déversoir

de poussière, comme indiqué par la Fig. 4.

(2) Retrait du sac à poussière

Tenir l’entonnoir de poussière et le tirer dans le

sens de la flèche B pour le détacher du déversoir

de poussière, comme indiqué par la Fig. 4.

Page 13

12

Français

MARCHE A SUIVRE POUR L’UTILISATION DE

LA PONCEUSE

ATTENTION

Ne jamais utiliser d’eau ou de fluide de ponçage

au cours des opérations de ponçage. Cela peut

entraîner un risque de commotion électrique.

1. Mise en MARCHE et ARRET de la ponceuse

La ponceuse peut être mise sous tension en mettant

le levier sur la position MARCHE (ON) (1) et hors

tension en mettant ce levier sur ARRET (OFF) (0).

ATTENTION

Ne jamais mettre l’interrupteur d’alimentation sur

MARCHE (ON) lorsque la ponceuse est en contact

avec la surface à poncer. Cette précaution est

nécessaire pour éviter d’endommager la pièce à

travailler. La même précaution doit être prise lorsque

l’interrupteur d’alimentation est mis sur ARRET (OFF).

2. Comment tenir la ponceuse orbitale

Tenir l’enveloppe et presser légèrement la ponceuse

sur la surface à poncer de manière à ce que le

papier de verre soit uniformément en contact avec

la surface à poncer, comme indiqué par la Fig. 5.

NE JAMAIS appliquer une pression excessive sur

la ponceuse au cours du ponçage. Une pression

excessive peut provoquer une surchage du moteur,

réduire la durée de vie du papier de verre et diminuer

l’efficacité du ponçage ou du polissage.

3. Comment déplacer la ponceuse orbitale

Pour obtenir une efficacité de fonctionnement

optimale, déplacer la ponceuse alternativement vers

l’avant et vers l’arrière tout en maintenant la vitesse

et l’équilibre constants.

4. Après la mise en place d’un papier de verre neuf

Le mouvement de la ponceuse a tendance à devenir

irrégulier après la mise en place d’un papier de

verre neuf, le grain d’un papier neuf étant toujours

grossier. Ce phénomène peut être évité en inclinant

légèrement la ponceuse vers l’avant ou vers l’arrière

pendant le ponçage ou le polissage. Le mouvement

de la ponceuse deviendra de plus en plus régulier

au fur et à mesure que la surface du papier de verre

s’use.

MONTAGE DES ACCESSOIRES EN OPTION

1. Fixation d’un patin en caoutchouc (type Velcro) ou

d’un patin adhésif

Desserrer les vis M4 × 10 (4) et enlever le patin

en place. Ensuite, attacher un patin en caoutchouc

(type Velcro) ou un patin adhésif.

ATTENTION

Remplacer uniquement le patin. Ne pas enlever les

autres pièces.

2. Fixation d’un papier de verre type Velcro ou type

adhésif

Faire correspondre l’orifice sur le papier de verre

avec l’orifice sur le patin et appuyer fermement de

la paume de la main sur le papier de verre pour

le fixer.

3. Aspiration de la poussière avec le dépoussiéreur

(Modèle WDE-1200)

Le dépoussiéreur (Modèle WDE-1200) permet permet

d’effectuer un ponçage proprement.

Comme indiqué par la Fig. 6, fixer l’adaptateur, le

tuyau et le dépoussiéreur au déversoir de poussière

dans cet ordre.

4. Perçage du papier de verre à l’aide d’une plaquette

de perforation (Fig. 7)

Si le papier de verre utilisé ne contient pas d’orifice,

percer des trous à l’aide de la plaquette de

perforation afin d’améliorer la capacité d’aspiration

de la poussière.

ENTRETIEN EN CONTROLE

1. Vidage et nettoyage du sac à poussière

Si le sac à poussière contient trop de sciure de bois,

la récupération de poussière sera difficile. Vider le

sac lorsqu’il est plein.

Enlever le sac à poussière, ouvrir la fermeture et

jeter le contenu.

2. Vérification du papier de verre

Remplacer le papier de verre dès que des traces

d’usure excessive sont visibles, car l’utilisation d’un

papier de verre trop usé diminuera l’efficacité des

opérations et risque, de plus, d’endommager le

coussinet.

3. Contrôle des vis de montage:

Vérifier régulièrement les vis de montage et s’assurer

qu’elles sont correctement serrrées. Resserrer

immédiatement toute vis desserrée. Sinon, il y a

danger sérieux.

4. Entretien du moteur:

Le bobinage de l’ensemble moteur est le “coeur”

même de l’outil électro-portatif. Veiller

soigneusement à ce que ce bobinage ne soit pas

endommagé et/ou mouillé par de l’huile ou de

l’eau.

5. Entretien

Consulter un agent agréé en cas de panne.

6. Liste des pièces de rechange

A: No. élément

B: No. code

C: No. utilisé

D: Remarques

ATTENTION

Les réparations, modifications et inspections des

outils électriques Hitachi doivent être confiées à un

service après-vente Hitachi agréé.

Il sera utile de présenter cette liste de pièces au

service après-vente Hitachi agréé lorsqu’on apporte

un outil nécessitant des réparations ou tout autre

entretien.

Lors de l’utilisation et de l’entretien d’un outil

électrique, respecter les règlements et les normes

de sécurité en vigueur dans le pays en question.

MODIFICATIONS

Les outils électriques Hitachi sont constamment

améliorés et modifiés afin d’incorporer les tous

derniers progrès technologiques.

En conséquence, il est possible que certaines pièces

(c.-à-d. no. de code et/ou dessin) soient modifiées

sans avis préalable.

NOTE

Par suite du programme permanent de recherche et de

développement HITACHI, ces spécifications peuvent faire

l’objet de modifications sans avis préalable.

Page 14

13

Français

Au sujet du bruit et des vibrations

Les valeurs mesurées ont été déterminées en fonction

de la norme EN50144.

Le niveau de pression acoustique pondérée A type est

de 85 dB (A)

Porter un casque de protection.

L’accélération quadratique pondérée typique n’excède

pas 2,5 m/s2.

Page 15

14

Italiano

PRECAUZIONI GENERALI

ATTENZIONE!

Quando si usano elettroutensili, bisogna sempre seguire

le precauzioni basilari di sicurezza per ridurre il rischio di

incendi, scosse elettriche e lesioni alle persone, tra cui

quanto segue.

Leggere tutte queste istruzioni prima di usare questo

prodotto e conservare le istruzioni.

Per un funzionamento sicuro:

1. Mantenere sempre pulita l’area dove si lavora.

Un’area di lavoro sempre pulita aiuta ad evitare

incidenti.

2. Tenere nella dovuta considerazione le condizioni

dell’ ambiente di lavoro.

Non esporre gli elettroutensili alla pioggia.

Non usare gli elettroutensili in luoghi molto umidi

o bagnati.

Mantenere ben illuminata l’area di lavoro.

Non usare elettroutentsili dove ci sia il rischio di

causare incendi o esplosioni.

3. Fare attenzione alle scosse elettriche. Evitare il

contatto del corpo con superfici collegate a terra

(p.es. tubi, caloriferi, fornelli, frigoriferi)

4. Tenere lontano i bambini. Non permettere che

persone estranee ai lavori tocchino gli elettrouten

sili o i cavi della corrente elettrica. Le persone non

addette al lavoro non dovrebbero nemmeno

avvicinarvisi.

5. Riporre gli elettroutensili non usati in luogo adatto.

Quando non utilizzati, gli elettroutensili vanno

tenuti in un luogo asciutto, chiusi a chiave o in

alto, fuori dalla portata dei bambini.

6. Non forzare mai gli elettroutensili. Qualsiasi lavoro

viene eseguito meglio e più velocemente alla

velocità per la quale l’elettroutensile è stato

formulato.

7. Scegliere sempre l’utensile elettrico adatto. Non

forzare un piccolo elettroutensile o un accessorio

a fare un lavoro di un utensile o accessorio più

grande. Non usare gli elettroutensili per dei lavori

per i quali non sono stati formulati (non usare,

per esempio, una sega circolare per tagliare grossi

tronchi).

8. Vestirsi in modo adatto. Non portare abiti larghi

o gioielli, che potrebbero impigliarsi nelle parti in

movimento degli elettroutensili. Lavorando all'ester-no, si raccomanda l’uso di guanti di gomma

e di scarpe antisdrucciolo. Chi porta capelli lunghi

dovrebbe utilizzare un’apposita cuffia protettiva.

9. Usare occhiali protettivi. Esegundo dei lavori di

taglio che producono molta polvere, usare anche

una mascherina antipolvere.

10. Collegare apparecchiature di rimozione della

polvere. Se sono forniti dispositivi per il

collegamento di apparecchiature di rimozione e

raccolta della polvere, assicurarsi che siano

collegati e usati correttamente.

11. Non maltrattare il cavo della corrente elettrica.

Non trasportare gli elettroutensili prendendoli per

il cavo della corrente e non scollegarli dalla presa

in tal modo. Tenere il cavo della corrente lontano

dal calore, olio ed oggetti taglienti.

12. Lavorare su oggetti fermi. Fissare saldamente

l’oggetto in una morsa. Èpiù sicuro che non

tenendolo fermo con le mani, che restano libere

per maneggiare l’elettroutensile.

13. Non squilibrare il corpo durante l’esecuzione di

un lavoro. Stare sempre su due piedi, in equilibrio

stabile.

14. Trattare gli utensili elettrici con cura. Tenerli sempre

puliti ed affilati per un funzionamento migliore e

più sicuro. Seguire le istruzioni date per la

lubrificazione e la sostituzione degli accessori.

Controllare periodicamente le condizioni del cavo

della corrente. Se dovesse essere rovinato, farlo

sostituire presso un Centro Assistenza. Non usare

cavi di prolungamento rovinati. Mantenere le

impugnature sempre pulite, libere soprattutto da

olio e grasso.

15. Quando non si usa, prima di eseguire una qualsiasi

operazione di manutenzione e prima di

intraprendere qualsiasi sostituzione di accessori

(lama, punte, ecc.), scollegare sempre

l’elettroutensile.

16. Togliere sempre le chiavi di regolazione

dall’attrezzo. E’buona abitudine controllare siste

maticamente che nessuna chiave di regolazione

sia più attaccata all’elettroutensile, prima di

metterlo in funzione.

17. Evitare che l’elettroutensile possa inavvertitamente

essere messo in funzione. Non trasportare gli elet

troutensili mantenendo il dito sull’interruttore,

mentre sono collegati alla rete. Prima di collegarli,

controllare che l’interruttore sia in posizione di

spento.

18. Fare uso di cavi di prolungamento per esterni. In

questo caso, controllare che il cavo sia adatto per

l’uso all’esterno.

19. Stare sempre attenti. Guardare sempre nel punto

in cui si esegue il lavoro. Non usare utensili

elettrici se si è stanchi.

20. Controllare qualsiasi parte che sembra danneggiata. Prima di riprendere l’uso degli elettroutensili,

controllare attentamente che la parte

apparentemente danneggiata possa ancora essere

usata in modo da assolvere la sua funzione.

Controllare che le parti mobili siano nella loro

posizione corretta, che nessun pezzo sia rotto, che

tutti i pezzi siano montati correttamente, e

controllare altri punti importanti per il

funzionamento dell’ utensile elettrico. Qualsiasi

pezzo danneggiato deve essere ripa rato o sostituito

da un Centro Assistenza autorizzato, a meno che

dettagliate istruzioni in proposito siano date nel

presente manuale.

Non usare l’elettroutensile se non può e acceso

o spento per mezzo del suo interruttore.

21. Attenzione

L’uso di qualsiasi accessorio o attacco diverso da

quelli citati nel presente manuale di istruzioni può

presentare il rischio di lesioni alle persone.

22. Far riparare l’elettroutensile da personale

qualificato. Questo elettroutensile è in conformità

con le relative norme di sicurezza. Le riparazioni

devono essere eseguite solo da personale

qualificato usando ricambi originali, altrimenti ne

possono derivare considerevoli rischi per

l’utilizzatore.

Page 16

15

Italiano

*Accertatevi di aver controllato bene la piastrina perché essa varia da zona.

CHARATTERISTICHE

Modello SV8SA SV12SF

Voltaggio (per zona)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Potanza assorbita 200W*

Velocità senza carico 14000/min.

Misura del cuscino abrasivo 80 mm × 130 mm 110 mm × 100 mm

Misura della carta abrasiva 80 mm × 170 mm 114 mm × 140 mm

Peso (escluso il cavo) 1,1 kg

ACCESSORI STANDARD

䡬 Carta abrasiva (Grana: AA100) ................................ 1

䡬 Sacca di raccolte della polvere ................................ 1

L’accessorio standard può essere modificato senza

preavviso.

ACCESSORI DISPONIBILI A RICHIESTA

(Venduti separatamente)

1. Carta vetrata

<Per l’uso con lo SV8SA>

䡬 Carta abrasiva di tipo fermacarta 80 x 170 mm

Grana: AA60, AA100, AA150

䡬 Carta abrasiva di tipo Velcro 80 x 130 mm

Grana: AA60, AA100, AA150

<Per l’uso con lo SV12SF>

䡬 Carta abrasiva di tipo fermacarta 114 x 140 mm

Grana: AA60, AA100, AA150

䡬 Carta abrasiva di tipo Velcro 110 x 100 mm

Grana: AA60, AA100, AA150

䡬 Carta abrasiva di tipo adesivo 110 x 100 mm

Grana: AA60, AA80, AA100, AA120, AA150, AA180

䡬 Carta abrasiva di tipo adesivo

diametro esterno 125 mm

Grana: AA60

2. Cuscinetto abrasivo

<Per l’uso con lo SV8SA>

䡬 Cuscino a spugna 80 × 130 mm (tipo Velcro)

<Per l’uso con lo SV12SF>

䡬 Cuscino a spugna 110 × 100 mm (tipo Velcro)

䡬 Cuscino adesivo 110 × 100 mm

䡬 Cuscino adesivo diametro esterno 125 mm

3. Raccglipolvere (Modello WDE-1200)

4. Punzone

Gli accessori disponibili a richiesta possono essere

modificati senza preavviso.

APPLICAZIONI

䡬 Levigatura di rifinimento di lavori di falegnameria.

䡬 Smerigliatura di superfici nei lavori di falegnameria

o di metalli in fogli prima della verniciatura.

PRIMA DI INIZIARE LE OPERAZIONE

1. Alimentazione

Assicurarsi che la rete di alimentazione che si vuole

usare sia compatibile con le caratteristiche relative

all’alimentazione di corrente specificate nella

piastrina dell’apparecchio.

2. Interruttore di corrente

Mettere l’interruttore in posizione SPENTO. Se la

spina è infilata in una presa mentre l’interruttore

è acceso, l’utensile elettrico si mette immediatamente

in moto, facilitando il verificarsi di incidenti gravi.

3. Prolunga del cavo

Quando l’ambiente di lavoro è lontano da una presa

di corrente, usare una prolunga del cavo di sufficiente

spessore e di prestazione adeguata. La prolunga

deve essere più corta possibile.

4. Montaggio della carta abrasiva

(1) Come piegare la carta abrasiva:

Sistemare la sabbiatrice con il lato del cuscino

rivolto verso l’alto come illustrato nella Fig. 1.

Disporre la carta abrasiva sul cuscino in modo che

il suo centro corrisponda al centro del cuscino e

piegarne i lati cosi da formare un angolo di 90°.

Quindi, piegarne entrambi i lati come illustrato nella

Fig. 2. La carta abrasiva è ora pronta per essere

montata sulla sabbiatrice.

(2) Montaggio della carta abrasiva:

Assicurarsi che il cavo non sia piegato e sistemare

la sabbiatrice sul banco da lavoro come é illustrato

nella Fig. 3 e inserire un capo della carta abrasiva

(la parte piegata). Quindi inserite la sezione piegata

che resta nello stesso modo.

ATTENZIONE

La carta abrasiva deve essere montata esattamente

sul cuscino assicurandosi che sia sempre ben tesa

(che non sia allentata). Se la carta abrasiva non

fosse montata ben tesa, la lavorazione potrebbe

risultare perfetta e/o la carta stessa potrebbe essere

danneggiata.

5. Applicazione e rimozione della sacca di raccolta

della polvere

(1) Applicazione della sacca di raccolta della polvere

Come mostrato nella Fig. 4, trattenere l’ingresso

polvere e spingerlo in direzione della freccia A per

applicarlo all’uscita polvere.

(2) Rimozione della sacca di raccolta della polvere

Come mostrato nella Fig. 4, trattenere l’ingresso

polvere e tirarlo in direzione della freccia B per

staccarlo dall’uscita polvere.

Page 17

16

Italiano

PROCEDIMENTI DI FUNZIONAMENTO

PRATICO

ATTENZIONE

Non aggiungere mai acqua o fluido abrasivo mentre

si smeriglia. Ne può causare una folgorazione.

1. Accendere o spegnere della sabbiatrice (posizioni

ON e OFF)

L’utensile viene acceso ponendo la levetta su ON

(1) e spenta ponendo la levetta su OFF (0).

ATTENZIONE

Non accendere mai l’interruttore mentre la

sabbiatrice è a contatto con la superficie da

smerigliare. Ciò è necessario per evitare danni

all’ogetto da lavorare. La stessa cosa vale quando

si spegne l’interruttore.

2. Come afferrare la levigatrice orbitale

Afferrando l’utensile, premere leggermente la

sabbiatrice contro la superficie da levigare in modo

che la carta abrasiva sia uniformemente a contatto

con la superficie Fig. 5. NON esercitare una pressione

eccessiva sulla sabbiatrice mentre si sta

smerigliando. Una eccessiva pressione può causare

sovracarico al motore, vita limitata alla carta abrasiva

e una minore efficacia di smerigliatura o levigatura.

3. Come muovere la levigatrice orbitale

Per un’ottima efficacia di funzionamento, muovere

alternativamente la levigatrice avanti e indiatro a

velocità constante e in piano.

4. Dopo aver messo una nuova carta abrasiva

Il movimento della sabbiatrice può tendere a

diventare irregolare dopo aver messo una nuova

carta abrasiva, a causa della nuova, grossa grana

della carta. Ciò puó essere evitato inclinando

lievemente avanti e indietro la levigatrice durante

la smerigliatura o la levigatura. Il movimento di

levigatura diventerà costante quando la superficie

della carta si sarà convenientemente ridotta.

MONTAGGIO DEGLI ACCESSORI SPECIALI

1. Applicazione un cuscino spugna (tipo Velcro) o un

cuscino adesivo

Allentare le viti M4 × 10 (4) e rimuovere il cuscino

applicato. Quindi applicare il cuscino spugna (tipo

Velcro) o il cuscino adesivo.

ATTENZIONE

Sostituire solo il cuscino. Usaer la altre parti senza

rimuoverle.

2. Applicazione di carta abrasiva tipo Velcro o carta

abrasiva di tipo adesivo

Far corrispondere il foro sulla carta abrasiva con

il foro del cuscino e premere con forza la carta

abrasiva con il palmo della mano per fissarla

saldamente in posizione.

3. Raccolta della polvere con il Raccoglipolvere

(Modello WDE-1200)

Applicando il Raccoglipolvere (Modello WDE-1200)

è possibile eseguire la smerigliatura senza sporcare.

Come mostrato nella Fig. 6, applicare l’adattatore,

il manicotto e il raccoglipolvere all’uscita polvere.

4. Perforazione della carta abrasiva con la piastra di

perforazione (Fig. 7)

Quando si usa carta abrasiva priva di fori, perforarvi

dei fori con la piastra di perforazione per migliorare

la capacità di raccolta polvere.

MANUTENZIONE E CONTROLLI

1. Svuotamente e pulitura del sacco per la polvere:

Se il portapolvere contiene troppa segatura, la

raccolta di polvere sarà ostacolata. Svuotare il

portapolvere quando si riempie.

Rimuovere il portapolvere, aprire la chiusura e

gettare via il contenuto.

2. Controllo della carta abrasiva

Poiché l’uso di carta abrasiva logora diminuisce

l’efficacia di lavoro e causa danni al cuscino,

sostituire la carta abrasiva non appena si nota un

eccessivo logoramento.

3. Controllo delle viti di tenuta:

Controllare regolarmente tutte le viti di tenuta e

assicurarsi che siano esclusìvamente serrate. Nel

caso che una di queste viti dovesse allentarsi

riserrarla immediatamente. Se si non ottiene di

farlo, si puó causare un grave incidente.

4. Manutenzione del motore:

L’avvolgimento del motore il vero e proprio “cuore”

degli attezzi elettrici. Fare attenzione a non

danneggiare l’avvolgimento e/o non bagnarlo con

olio o acqua.

5. Manutenzione

In caso di mancato funzionamento di un utensile

elettrico, rivolgersi ad una officina autorizzata.

6. Lista dei pezzi di ricambio

A: N. voce

B: N. codice

C: N. uso

D: Note

CAUTELA

Riparazioni, modifiche e ispezioni di utensili elettrici

Hitachi devono essere eseguite da un centro

assistenza Hitachi autorizzato.

Questa lista dei pezzi torna utile se viene presentata

con l’utensile al centro assistenza Hitachi autorizzato

quando si richiedono riparazioni o altri interventi

di manutenzione.

Nell’uso e nella manutenzione degli utensili elettrici

devono essere osservate le normative di sicurezza

e i criteri prescritti in ciascun paese.

MODIFICHE

Gli utensili elettrici Hitachi vengono continuamente

migliorati e modificati per includere le più recenti

innovazioni tecnologiche.

Di conseguenza, alcuni pezzi (p.es. numero di codice

e/o design) possono essere modificati senza

preavviso.

NOTA

A causa del continuo programma di ricerca e sviluppo

della HITACHI, le caratteristiche riportate in questo foglio

sono soggette a cambiamenti senza preventiva

comunicazione.

Page 18

17

Italiano

Informazioni riguardanti i rumori trasmessi dall’aria e

le vibrazioni

I valori misurati sono stati determinati in conformitá a

EN50144.

Il livello di pressione sonora pesato A tipico è di 85 dB (A)

Indossare protezioni per le orecchie.

Il valore tipico di accelerazione quadrata media a radice

pesata non supera 2,5 m/s2.

Page 19

18

Nederlands

ALGEMENE VOORZORGMAATREGELEN

WAARSCHUWING! Bij gebruik van elektrisch

gereedschap moet u altijd de normale basisvoorzorgen

voor de veiligheid in acht nemen om de kans op brand,

elektrische schokken en letsel te verminderen. Let tevens

op de volgende punten.

Lees al de aanwijzingen door alvorens het gereedschap

in gebruik te nemen. Bewaar deze aanwijzingen.

Voor een veilige werking:

1. Houd de plaats waar gewerkt wordt schoon. Niet

opgeruimde werkplaatsen en werkbanken

verhogen het gevaar van ongelukken.

2. Kies een geschikte omgeving om te werken. Stel

electrisch gereedschap niet aan regen bloot.

Gebruik electrisch gereedschap niet op vochtige

of natte plaatsen.

Zorg dat de werkplaats goed verlicht is.

Gebruik elektrisch gereedschap niet op plaatsen

waar brand- of explosiegevaar is.

3. Vermijd een electrische schok. Let er daarom op

dat er geen contact is met geaarde oppervlakken

zoals pijpen, radiators, keukenfornuis of ijskast.

4. Houd kinderen uit de buurt. Laat bezoekers het

gereedschap of snoer niet aanraken. Alle bezoekers

moeten een veilige afstand tot de werkplaats

aanhouden.

5. Ruim overbodig gereedschap op. Gereedschap dat

niet gebruikt wordt moet op een droge,

hooggelegen of af te sluiten plaats buiten het

bereik van kinderen opgeborgen worden.

6. Forceer het gereedschap niet. Het levert een betere

en veiligere prestatie op de snelheid waarvoor zij

werd ontworpen.

7. Gebruik het juiste gereedschap. Gebruik een klein

gereedschap of hulpstuk niet voor werkzaamheden

waarvoor een apparaat met groot vermogen vereist

is. Gebruik het gereedschap niet voor doeleinden

waarvoor dit niet bestemd is (bijvoorbeeld gebruik

van de cirkelzaag voor het zagen van bomen).

8. Draag de juiste kleding. Draag geen loszittende

kleren of armbanden e.d. daar deze in de

bewegende delen verstrikt kunnen raken. Bij het

werken buitenshuis wordt het gebruik van rubber

handschoenen en stevige, niet glijdende schoenen

aanbevolen.

9. Draag een veiligheidsbril. Ontstaat er veel stof

tijdens het werken, draag dan eveneens een

gezichtsbeschermer en/of stofmasker.

10. Sluit apparatuur voor het verzamelen van stof

aan.

Indien apparatuur voor het verzamelen van stof

is bijgeleverd, moet u deze apparatuur op de

vereiste wijze verbinden en gebruiken zoals wordt

beschreven.

11. Behandel het snoer voorzichtig. Draag het gereed

schap nooit door dit bij het snoer vast te houden.

Bescherm het snoer tegen hitte, olie en scherpe

hoeken.

12. Neem de uiterste veiligheid in acht. Gebruik

klemmen of een bankschroef om het werkstuk

vast te zetten. Hierdoor heeft u uw handen vrij

om het gereedschap te bedienen.

13. Buig u nooit te ver naar voren. Kies een goede

plaats en behoud altijd uw evenwicht.

14. Behandel het gereedschap voorzichtig. Zorg ervoor

dat het gereedschap scherp en schoon is zodat

een goed en veilig prestatievermogen wordt

verkregen. Volg de gebruiksaanwijzing voor het

smeren en het verwisselen van toebehoren.

Inspecteer de snoeren regelmatig op beschadiging

en laat deze zonodig door een erkend servicecenter

repareren. Controleer de verlengsnoeren ook

regelmatig en vervang deze bij beschadiging. Houd

alle handgrepen droog en schoon en vrij van olie

en vet.

15. Trek de stekker uit het stopcontact als het gereed

schap niet wordt gebruikt en ook bij

onderhoudsbeurten, het verwisselen van

toebehoren zoals bladen, boren, messen e.d.

16. Verwijder sleutels en moersleutels. Maak er een

gewoonte van voor het inschakelen te controleren

of alle sleutels en moersleutels verwijderd zijn.

17. Schakel het gereedschap niet onverwacht in. Draag

geen aangesloten gereedschap met de vinger op

de schakelaar. Controleer altijd of het gereedschap

uitgeschakeld staat alvorens dit aan te sluiten.

18. Bij het werken buitenshuis dient een verlengsnoer

te worden gebruikt. Gebruik dan alleen

verlengsnoeren die geschikt zijn voor het werken

buitenshuis en desbetreffend gemerkt zijn.

19. Let altijd goed op tijdens het werken. Kijk uit wat

u doet en gebruik het gereedschap niet als u moe

bent.

20. Bij beschadiging van een van de onderdelen dient

dit nauwkeurig te worden nagekeken en gerepa

reerd alvorens het gereedschap opnieuw in gebruik

wordt genomen. Let erop dat het betreffende on

derdeel zijn functie goed vervult. Controleer of de

bewegende delen goed zijn gemonteerd en vrij

kunnen bewegen. Dit om een foutief functioneren

van het gereedschap te voorkomen. Bij de

beschadiging van een onderdeel dient de reparatie

altijd te worden overgelaten aan een erkend ser

vice-center, tenzij in deze gebruiksaanwijzing an

ders wordt voorgeschreven. Laat ook defekte

schakelaars vervangen door een erkend servicecenter. Gebruik het gereedschap niet als de aan/

uit-schakelaar niet werkt.

21. Waarschuwing

Het gebruik van toebehoren of verlengstukken

waarvan het gebruik niet in deze

gebruiksaanwijzing is aangegeven, veroorzaakt

mogelijk letsel.

22. Laat het elektrisch gereedschap door een vakman

repararen.

Dit elektrisch gereedschap voldoet aan de vereiste

eisen voor de veiligheid. Voorkom mogelijk zeer

ernstige ongelukken en laat derhalve reparatie

over aan een erkend vakman die de originele

reserve-onderdelen gebruikt.

Page 20

19

Nederlands

*Controleer het naamplaatje op het apparaat daarhet apparaat afhankelijk van het gebied waar het verkocht wordt

gewijzigd kan worden.

TECHNISCHE GEGEVENS

Model SV8SA SV12SF

Voltage (verschillend van gebied tot gebied)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Opgenomen vermogen 200W*

Toerental onbelast 14000/min.

Afmetingen schuurzool 80 mm × 130 mm 110 mm × 100 mm

Afmetingen schuurpapier 80 mm × 170 mm 114 mm × 140 mm

Gewicht (zonder kabel) 1,1 kg

STANDAARD TOEBEHOREN

䡬 Schuurpapier (Korrel: AA100) .................................. 1

䡬 Stofzak ......................................................................... 1

De standaard toebehoren kunnen zonder aankondiging

ieder moment worden veranderd.

EXTRA TOEBEHOREN (los te verkrijgen)

1. Schuurpapier

<Voor gebruik met de SV8SA>

䡬 80 × 170 mm schuurpapier, papierklem-type

Korrel: AA60, AA100, AA150

䡬 80 × 130 mm schuurpapier, klitteband-type

Korrel: AA60, AA100, AA150

<Voor gebruik met de SV12SF>

䡬 114 × 140 mm schuurpapier, papierklem-type

Korrrel: AA60, AA100, AA150

䡬 110 × 100 mm schuurpapier, klitteband-type

Korrel: AA60, AA100, AA150

䡬 110 × 100 mm schuurpapier, zelfklevend type

Korrel: AA60, AA80, AA100, AA120, AA150, AA180

䡬 Buitendiameter 125 mm schuurpapier, zelfklevend

type

Korrel: AA60

2. Schuurzool

<Voor gebruik met de SV8SA>

䡬 80 × 130 mm spons-schuurzool, klitteband-type

<Voor gebruik met de SV12SF>

䡬 110 × 100 mm spons-schuurzool, klitteband-type

䡬 110 × 100 mm schuurzool, zelfklevend type

䡬 Buitendiameter 125 mm schuurzool, zelfklevend type

3. Stof-verzamel (Model WDE-1200)

4. Doorslagplaat

De extra toebehoren kunnen zonder aankondiging op

ieder moment worden veranderd.

TOEPASSINGEN

䡬 Napolijsten van houtoppervlakken.

䡬 Schuren van het oppervlak van hout of plaatwerk

alvorens te gaan verven e.d.

VOOR HET GEBRUIK

1. Netspanning

Controleren of de netspanning overeenkomt met de

opgave op het naamplaatje.

2. Netschakelaar

Controleren of de netschakelaar op “UIT” staat.

Wanneer de stekker op het net aangesloten is, terwijl

de schakelaar op “AAN” staat, t gevouwen gedeelte)

van het schuurpapier naar binnen en ga daarna op

dezelfde wijze te werk voor het insteken van het

andere gevouwen gedeelte.

3. Verlengsnoer

Wanneer het werkterrein niet in de buurt van een

stopcontact ligt, dan moet men gebruik maken van

een verlengsnoer, dat voldoende dwarsprofiel en

voldoende nominaal vermogen heeft. Het

verlengsnoer moet zo kort mogelijk gehouden

worden.

4. Aanbrengen van het schuurpapier

(1) Vouwen van het schuurpapier:

Leg de schuurmachine met de schuurzool naar boven

gericht neer, zoals aangegeven in Afb. 1. Leg het

schuurpapier op di schuurzool en wel zodanig dat

het midden van het schuurpapier tegenover het

midden van de schuurzool is. Vouw nu beide

uiteinden van het schuurpapier 90° om. Vouw beide

uiteinden vervolgens nogmaals zoals aanegeven in

Afb. 2. Het schuurpapier is nu klaar om aan de

schuurmachine te worden bevestigd.

(2) Bevestigen van het schuurpapier:

Zet de schuurmachine op een werkbank zoals

aangegeven in Afb. 3. en let er hierbij op dat het

snoer niet klem zit. Steek het ene uiteinde (het

gevouwen gedeelte) van het schuurpapier naar

binnen en ga daarna op dezelfde wijze te werk voor

het insteken van het andere gevouwen gedeelte.

LET OP

Zorg ervoor dat het schuurpapier correct en

voldoende gespannen (het papier mag niet bolzitten)

op de schuurzool wordt aangebracht. Als het

schuurpapier te los is bevestigd, kan dit resulteren

in ongelijkmatig schuren en/of beschadigiging van

het schuurpapier.

5. Aanbrengen en verwijderen van de stofzak

(1) Aanbrengen van de stofzak

Houd de stofpoort zoals aangegeven in Afb. 4 en

druk deze in de richting van pijl A op de

stofuitlaatopening aan.

(2) Verwijderen van de stofzak

Pak de stofpoort vast zoals aangegeven in Afb. 4

en trek deze in de richting van pijl B van de

stofuitlaatopening af.

Page 21

20

Nederlands

PARAKTISCHE WERKWIJZE

LET OP

Gebruik nooit water of slijpvloeistof bij

werkzaamheden met de vlakschuurmachine. Dit kan

namelijk een electrische schok veroorzaken.

1. In-en uitschakelen van de vlakschuurmachine

Zet de hendel op ON (1) voor het inschakelen en

op OFF (0) voor het uitschakelen van de

vlakschuurmachine.

LET OP

Schakel de vlakschuurmachine nooit in wanneer de

machine in contact is met het te schuren oppervlak.

Dit om beschadiging van het werkstuk te voorkomen.

Hetzelfde geldt bij het uitschakelen.

2. Vasthouden van de vlakschuurmachine

Pak de vlakschuurmachine bij de behuizing vast en

druk de machine lichtjes tegen het te schuren

oppervlak, zodat het schuurpapier het oppervlak

gelijkmatig aanraakt. Zie Afb. 5. Bij het schuren

moet geen overmatige druk op de

vlakschuurmachine worden uitgeoefend. Dit kan

namelijk leiden tot overbelasting van de motor, een

kortere levensduur van het schuurpapier en een

geringer schuuren polijsteffect.

3. Bewegen van de vlakschuurmachine

Om een optimaal arbeidseffect te verkrijgen, moet

de vlakschuurmachine met constante snelheid en

gelijkmatige druk afwisselend naar voren en achteren

worden bewogen.

4. Na het inzetten van nieuw schuurpapier

Na het aanbrengen van nieuw schuurpapier kan de

nieuwe, grove korrel van het papier leiden tot een

ongelijkmatige beweging van de vlakschuurmachine.

Dit kan vermeden worden door de

vlakschuurmachine tijdens het schuren of polijsten

licht naar voren of achteren te kantelen. De beweging

van de vlakschuurmachine wordt constanter zodra

het papier voldoende is afgeschuurd.

BEVESTIGEN VAN DE EXTRA TOEBEHOREN

1. Aanbrengen van een spons-schuurzool (klittebandtype) of een zelfklevende schuurzool

Draai de M4 × 10 schroeven (4) los en verwijder