Page 1

Drill

Taladro

Berbequim

FD 10VB • FD 10SB

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Antes de usar, leia com cuidado para assimilar estas instruções.

Handling instructions

Instrucciones de manejo

Instruções de uso

Page 2

1

2

2

3

8

7

4

5

6

1

3

4

!

0

@

9

#

5

$

%

1

Page 3

English Español Português

1

Trigger switch Interruptor de gatillo Interruptor de gatilho

2

Adjusting knob

3

High speed Alta velocidad

4

Low speed Baja velocidad Baixa rotação

5

Stopper Tope Obturador

6

Lever Palanca Alavanca

7

Right (clockwise)

8

Left (counterclockwise)

9

Drill chuck Portabrocas

0

Chuck wrench Llave Chave do mandril

!

Tighten (clockwise)

@

Loosen (counterclockwise)

When the point appears, turn lumber

#

over.

$

Lumber to be drilled Madera que va a taladrar Madeira a ser perfurada

%

Extra lumber Madera adicional Madeira extra

Mando de ajuste Botão de ajuste

Alta rotação

Derecha (en el sentido de las

agujas del reloj)

Izquierda (en el sentido contrario a

las agujas del reloj)

Apretar (en el sentido de las agujas

del reloj)

Afl ojar (en el sentido contrario a las

agujas del reloj)

Cuando aparezca la punta, dele la

vuelta a la madera.

Direita (sentido horário)

Esquerda (sentido anti-horário)

Mandril

Apertar (sentido horário)

Afrouxar (sentido anti-horário)

Quando a ponta aparecer, vire a

madeira ao contrário.

2

Page 4

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fi re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep

children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or

medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear

eye protection.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off -position before connecting to

power source and/or

carrying the tool.

3

pipes, radiators, ranges and

power tool outdoors, use an

battery pack, picking up or

Carrying power tools with your fi nger on the switch or

energising power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and

away from moving parts.

Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and safer

at the rate for which it was designed.

b) Do

not use the power tool if the switch does not

turn it on and off .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may aff ect the power

tools’

If damaged, have the power tool repaired before

Many accidents are caused by poorly maintained

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

g) Use the power tool, accessories and tool bits

Use of the power tool for operations diff erent from those

5) Service

a) Have your

This will ensure that the safety of the power tool is

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach of

children and infi rm persons.

operation.

use.

power tools.

edges are less likely to bind and are easier to

control.

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed.

intended could result in a hazardous situation.

person using only identical replacement parts.

maintained.

power tool serviced by a qualifi ed repair

of the reach of children

gloves

Page 5

English

DRILL SAFETY WARNINGS

1. When mounting the drill bit or driver bit, insert it fully into

the drill chuck and completely tighten the drill chuck with

the chuck wrench.

If mounting is not done properly, it is very dangerous as

the drill bit may slip or loosen during operation.

2. Do not wear gloves made of stuff liable to roll up such as

cotton, wool, cloth or string, etc.

3. Do not touch the bit during or immediately after operation.

The bit becomes very hot during operation and could

cause serious burns.

4. When placing the drill on the fl oor, make sure that the drill

has stopped completely.

5. Before drilling into a wall, fl oor or ceiling, thoroughly

confi rm that no items such as electric cables or conduits

are buried inside.

6. When working in high position, take care of downward

direction.

SPECIFICATIONS

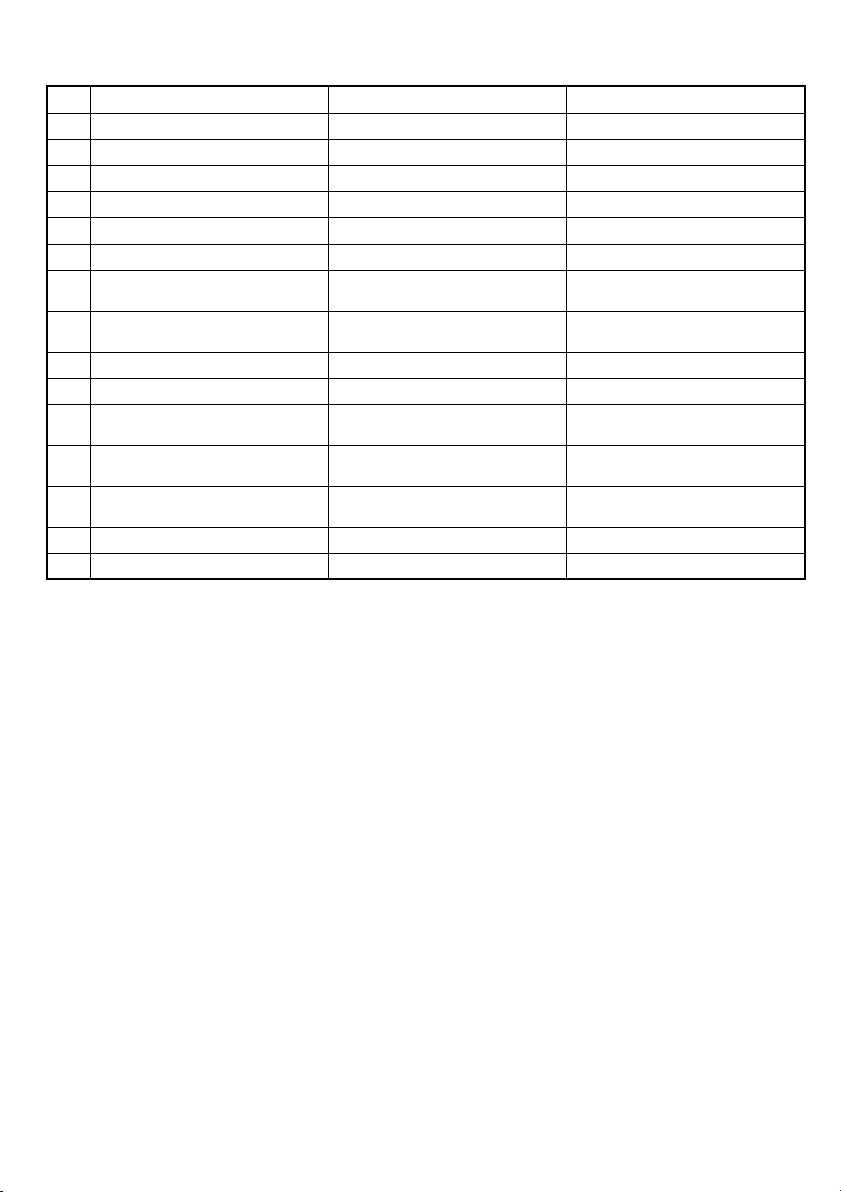

Model FD10VB FD10SB

Voltage (by areas)* (110 V, 115 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Power input 420 W*

No-load speed 0 – 2800/min 2800/min

Capacity

Weight (without cord) 1.4 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

APPLICATIONS

1. Drilling various materials

○ Drilling metal

Use a metal-working drill bit

○ Drilling wood

Use a wood-working drill bit (However, a metal-

2. Tightening wood screws (Only model FD10VB)

Use the driver bit. Use a Phillips screw for easy

tightening.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If the

plug is connected to a receptacle while the power switch

is in the ON position, the power tool will start operating

immediately, inviting serious accident.

3. Extension cord

When the work area is removed from the power source.

Use an extension cord of suffi cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

4. Check the tightening of the drill chuck

The drill chuck has been tightened at the factory, but

check again that it is in order before use.

Turn the drill chuck clockwise to tighten.

HOW TO USE

1. Operation of switch

Pulling the trigger of switch and push the stopper, it

keeps, the switched-on condition and it is convenient for

the continuous running. When switched off , the stopper

can be disconnected by means of pulling the trigger

again.

Steel

Wood 25 mm

2. Adjustment of speed

[FD10SB]

The maximum speed can be obtained by pulling the

trigger switch.

[FD10VB]

(1) The speed is adjustable from zero to maximum speed

according to the extent the trigger switch is pulled.

working drill bit to make pilot holes for wood screws

or holes smaller than 6.5 mm.)

(2) The maximum speed is adjustable from zero to 2800/

min. with the rotation of adjusting knob.

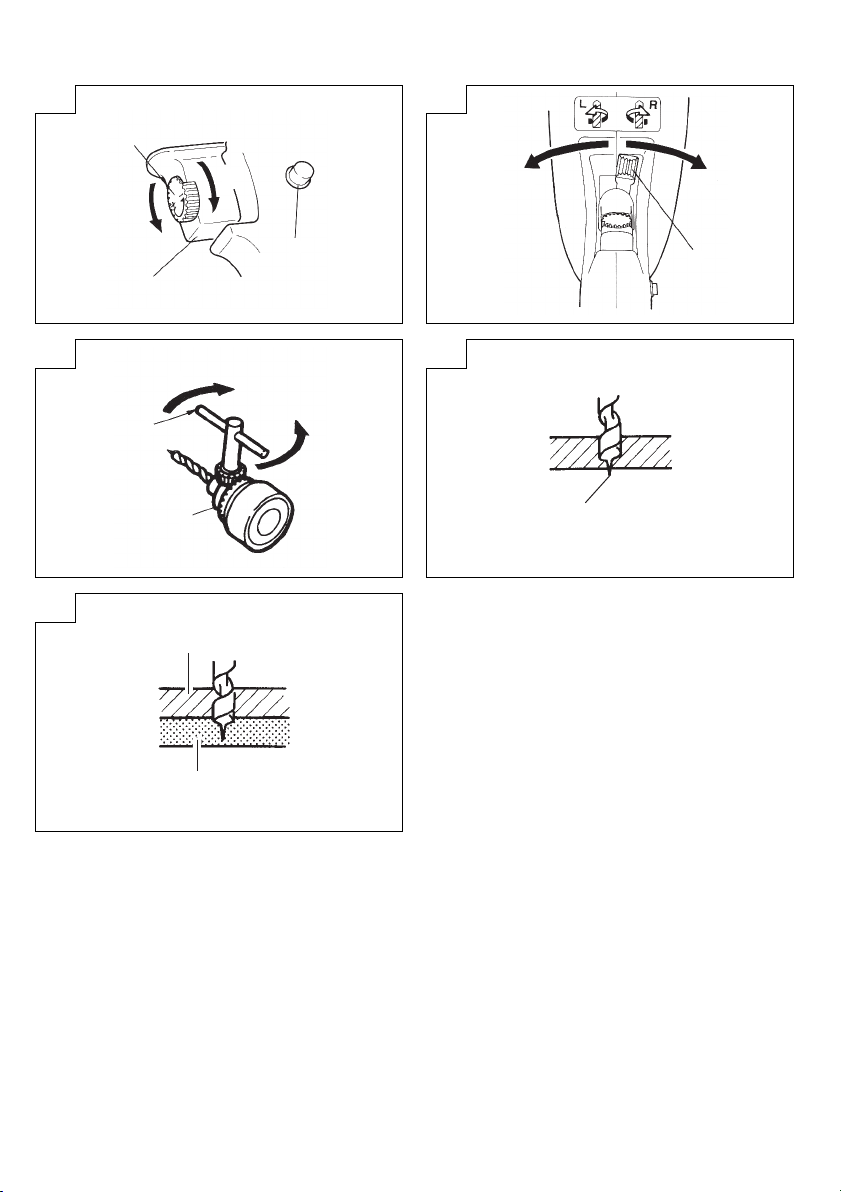

(3) Turn the adjusting knob clockwise for higher speed and

counterclockwise for lower speed. (Rotate the adjusting

knob approximately 1-2/3 turns.) (Fig. 1)

(4) The switch can be locked with the stopper at any required

position irrespective as to how far the adjusting knob has

been rotated. Select a proper position according to the

required speed for each work.

3. Confi rm the direction of bit rotation (Fig. 2)

The bit rotates clockwise (viewed from the rear

side) by pushing the R-side of the reversing switch

lever. The L-side of the lever is pushed to turn the bit

counterclockwise.

CAUTION

Never change the direction of bit rotation during

operating.

Turn the power switch OFF before changing the direction

of bit rotation.

4. For use as a drill

(1) Mounting drill bit

Tighten drill bit with the chuck wrench. There are three

holes in which the chuck wrench should be inserted.

Tighten them equally in turn at three holes, without

tightening them only at one hole. The drill bit can be

removed in the opposite method as mentioned above.

(Fig. 3)

(2) How to drill

1 To use for drilling lumber

○ Apply the point of the drill bit to the desired drilling

position, hold the drill perpendicular to the workpiece

surface and turn on the switch.

○ When drilling a through hole in lumber, remove the drill

from the material as soon as the tip of the drill bit protrudes

from the opposite surface. Then, turn the workpiece over

and complete the drilling from the opposite side to obtain

a clean hole. (Fig. 4)

10 mm

4

Page 6

English

If extra lumber is applied under the lumber you want to

drill and it is drilled together, a fi ne hole will also be made.

(Fig. 5)

○ A wood-working drill need not be pressed strongly since it

penetrates using the screw at the point. Even if excessive

force is used, a hole will not be made quickly.

2 To use for drilling metal

○ In case you drill metal with a metal-working drill, apply in

advance a center punch in the drilling position. You can

drill metal stably since the point of the drill does not slip.

○ If you apply sewing machine oil or soapy water to the drill

with a brush or an old tooth brush, the drill will last long.

○ Even if more-than-necessary force is used, a hole will not

be made quickly.

On the contrary, the edge of the drill will be damaged.

This will decrease operational effi ciency and shorten the

life of this tool.

CAUTION

Do not expose the motor to water as it may cause motor

malfunction and electric shock.

5. To use the driving wood screws (FD10VB)

(1) Driver bit

○ For driving a slotted head wood screw, the driver bit

detaches easily. So use cross-recessed head wood

screws as often as possible.

○ Select a driver bit matching the cross-recessed and the

slotted groove of the wood screw.

(2) Pilot hole

If a pilot hole is made with a drill a little smaller than the

diameter of the wood screw, the lumber will not be split

and the wood screw will be driven with ease.

(3) Driving operation

Put the wood screw lightly in the pilot hole, apply the bit to

the screw head groove, turn on the switch and drive the

screw.

6. Caution to be taken immediately after operation

When placing the drill in dusty places before the rotating

parts has stopped completely, make sure the machine

does not suck in dust and swarf.

This Parts List will be helpful if presented with the tool to

the Hitachi Authorized Service Center when requesting

repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATION

Hitachi Power Tools are constantly being improved

and modifi ed to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifi cations herein are subject to change

without prior notice.

MAINTENANCE AND INSPECTION

CAUTION

Be sure to switch power OFF and disconnect the plug during

maintenance and inspection.

1. Inspecting the drill bits and driver bit

Since use of an abraded drill bit will cause motor

malfunctioning and degraded effi ciency, replace the drill

bit with a new one or resharpening without delay when

abrasion is noted. If you use a driver bit of which point

is worn or broken, it will be dangerous since it slips. So

replace it with a new one.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Servicing

Consult a Hitachi Authorized Service Center in the event

of power tool failure.

4. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modifi cation and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized Service

Center.

5

Page 7

Español

ADVERTENCIAS DE SEGURIDAD GENERAL DE

LA HERRAMIENTA ELÉCTRICA

ADVERTENCIA

Lea todas las instrucciones y advertencias de

seguridad.

Si no se siguen las advertencias e instrucciones, podría

producirse una descarga eléctrica, un incendio y/o daños

graves.

Guarde todas las advertencias e instrucciones para

futura referencia.

El término “herramienta eléctrica” en las advertencias hace

referencia a la herramienta eléctrica que funciona con la red

de suministro (con cable) o a la herramienta eléctrica que

funciona con pilas (sin cable).

1) Seguridad del área de trabajo

a) Mantenga la zona de trabajo limpia y bien

iluminada.

Las zonas desordenadas u oscuras pueden provocar

accidentes.

b) No utilice las herramientas eléctricas en entornos

explosivos como, por ejemplo, en presencia de

líquidos infl

Las herramientas eléctricas crean chispas que

pueden infl amar el polvo o los humos.

c) Mantenga a los niños y transeúntes alejados

cuando utilice una herramienta eléctrica.

Las distracciones pueden hacer que pierda el

control.

2) Seguridad eléctrica

a) Los enchufes de las herramientas eléctricas

tienen que ser adecuados a la toma de

corriente.

No modifi que el enchufe.

No utilice enchufes adaptadores con

herramientas eléctricas conectadas

Si no se modifi can los enchufes y se utilizan tomas

de corriente adecuadas se reducirá el riesgo de

descarga eléctrica.

b) Evite el contacto corporal con superfi cies

conectadas a tierra como tuberías, radiadores y

frigorífi cos.

Hay mayor riesgo de descarga eléctrica si su cuerpo

está en contacto con el suelo.

c) No exponga las herramientas eléctricas a la

lluvia o a la humedad.

La entrada de agua en una herramienta eléctrica

aumentará el riesgo de descarga eléctrica.

d) No utilice el cable incorrectamente. No utilice el

cable para transportar, tirar de la

eléctrica o desenchufarla.

Mantenga el cable alejado del calor, del aceite,

de bordes afi lados o piezas móviles.

Los cables dañados o enredados aumentan el riesgo

de descarga eléctrica.

e) Cuando utilice una herramienta eléctrica al aire

libre, utilice un cable prolongador adecuado

para utilizarse al aire libre.

La utilización de un cable adecuado para usarse al

aire libre reduce el riesgo de descarga eléctrica.

f) Si no se puede evitar el uso de una herramienta

eléctrica en un lugar húmedo, utilice un

suministro protegido mediante un dispositivo

de corriente residual (RCD).

El uso de un RCD reduce el riesgo de descarga

eléctrica.

amables, gases o polvo.

a tierra.

herramienta

3) Seguridad personal

a) Esté atento, preste atención a lo que hace y

utilice el sentido común cuando utilice una

herramienta eléctrica.

No utilice una herramienta eléctrica cuando esté

cansado o esté bajo la

alcohol o medicación.

La distracción momentánea cuando utiliza

herramientas eléctricas puede dar lugar a importantes

daños personales.

b) Utilice un equipo de protección. Utilice siempre

una protección ocular.

El equipo de protección como máscara para el

polvo, zapatos de seguridad antideslizantes, casco

o protección para oídos utilizado para condiciones

adecuadas reducirá los daños personales.

c) Evite un inicio involuntario. Asegúrese de que

el interruptor está en “off ” antes de conectar la

herramienta a una fuente de alimentación y/o

batería, cogerla o transportarla.

El transporte de herramientas eléctricas con el dedo

en el interruptor o el encendido de herramientas

eléctricas con el interruptor encendido puede

provocar accidentes.

d)

Retire las llaves de ajuste antes de encender la

herramienta eléctrica.

Si se deja una llave en una pieza giratoria de la

herramienta eléctrica podrían producirse daños

personales.

e) No se extralimite. Mantenga un equilibrio

adecuado en todo momento.

Esto permite un mayor control de la herramienta

eléctrica en situaciones inesperadas.

f) Vístase adecuadamente. No lleve prendas

sueltas o joyas. Mantenga el pelo, la ropa y los

guantes alejados de las piezas móviles.

La ropa suelta, las joyas y el pelo largo pueden

pillarse en las piezas móviles.

g) Si se proporcionan dispositivos

de extracción de polvo e instalaciones de

recogida, asegúrese de que están conectados y

se utilizan adecuadamente.

La utilización de un sistema de recogida de polvo

puede reducir los riesgos relacionados con el polvo.

4) Utilización y mantenimiento de las herramientas

eléctricas

a) No fuerce la herramienta eléctrica. Utilice

la herramienta eléctrica correcta para su

aplicación.

La herramienta eléctrica correcta trabajará mejor y

de forma más segura si se utiliza a la velocidad para

la que fue diseñada.

b) No utilice la herramienta eléctrica si el interruptor

no la enciende y apaga.

Las herramientas eléctricas que no pueden

controlarse con el interruptor son peligrosas y deben

repararse.

c) Desconecte el enchufe de la fuente eléctrica y/o

la batería de la herramienta eléctrica antes de

hacer ajustes, cambiar accesorios o almacenar

herramientas eléctricas.

Estas medidas de seguridad preventivas reducen el

riesgo de que la herramienta eléctrica se ponga en

marcha accidentalmente.

d) Guarde las herramientas eléctricas que no se

utilicen para que no las cojan los niños y no

permita

que utilicen las herramientas eléctricas

personas no familiarizadas con las mismas o

con estas instrucciones.

infl uencia de drogas,

para la conexión

6

Page 8

Español

Las herramientas eléctricas son peligrosas si son

utilizadas por usuarios sin formación.

e) Mantenimiento de las herramientas eléctricas.

Compruebe si las piezas móviles están mal

alineadas o unidas, si hay alguna pieza rota u otra

condición que pudiera afectar al funcionamiento

de las herramientas eléctricas.

Si la herramienta eléctrica está dañada, llévela a

reparar antes de utilizarla.

Se producen muchos accidentes por no realizar

un mantenimiento correcto de las herramientas

eléctricas.

f) Mantenga las herramientas

limpias.

Las herramientas de corte correctamente mantenidas

con los bordes de corte afi lados son más fáciles de

controlar.

g) Utilice la herramienta eléctrica, los accesorios

y las brocas de la herramienta, etc. de acuerdo

con estas instrucciones, teniendo en cuenta las

condiciones laborales y el trabajo que se va a

realizar.

La utilización de la herramienta eléctrica para

operaciones diferentes a aquellas pretendidas podría

dar lugar a una situación peligrosa.

5) Revisión

a) Lleve su herramienta a que la

cualifi cado que utilice sólo piezas de repuesto

idénticas.

de corte afi ladas y

revise un experto

Esto garantizará el mantenimiento de la seguridad de

la herramienta eléctrica.

PRECAUCIÓN

Mantenga a los niños y a las personas enfermas

alejadas.

Cuando no se utilicen, las herramientas deben

almacenarse fuera del alcance de los niños y de las

personas enfermas.

ADVERTENCIAS DE SEGURIDAD DEL

TALADRO

1. Cuando monte la broca en el taladro, insértela

completamente en el portabrocas y ajuste el portabrocas

con la llave.

Un montaje incorrecto puede ser muy peligroso, puesto

que la broca puede resbalar o afl ojarse durante la

operación.

2. No utilice guantes hechos de un material que se pueda

enrollar, como algodón, lana, paño, cordón, etc.

3. No toque la broca durante o inmediatamente después

de su operación puesto que se calienta mucho y puede

ocasionar quemaduras graves.

4. Cuando deje el taladro en el suelo, asegúrese de que la

broca ha parado completamente.

5. Antes de taladrar en la pared, suelo o techo, compruebe

que tras ellos no hay cables eléctricos ni conductos.

6. Cuando trabaje en lugares altos, tenga en cuenta la

caída.

ESPECIFICACIONES

Modelo FD10VB FD10SB

Voltaje (por áreas)* (110 V, 115 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Acometida 420 W*

Velocidad de marcha en vacío 0 – 2800/min 2800/min

Capacidad

Peso (sin cable) 1,4 kg

* Verifi car indefectiblemente los datos de la placa de características de la máquina, pues varían de acuerdo al país de

destino.

APLICACIONES

1. Taladrar distintos materiales

○ Taladrar metal

Use una broca para metal

○ Taladrar madera

Use una broca para madera. No obstante, use una

2. Apretar tornillos de madera (sólo el modelo

FD10VB)

Use la broca atornilladora. Use un tornillo de estrella para

un ajuste más fácil.

ANTES DE LA PUESTA EN MARCHA

1. Alimentación

Asegurarse de que la acometida de red que ha de ser

utilizada es conforme a las exigencias de corriente

espacifi cadas en la placa de características del

producto.

Acero

Madera 25 mm

2. Conmutador de alimentación

Asegurarse de que el conmutador de acometida

está en posición OFF (desconectado). Si el enchufe

está conectado a la caja del enchufe mientras el

conmutador de acometida está en posición ON

(conectado) la herramienta eléctrica empezará a trabajar

inmediatamente, provocando un serio accidente.

broca para metal para hacer los orifi cios guía para

tornillos de madera o para los orifi cios inferiores a 6,5

mm.)

3. Cable de prolongación

Cuando está alejada el área de trabajo de la red de

acometida, usar un cable de prolongación de un grosor

sufi ciente y potencia nominal. El cable de prolongación

debe ser mantenido o más corto posible.

4. Compruebe que el portabrocas se ajusta bien

El portabrocas viene ajustado de fábrica, pero vuelva a

comprobar que está en su sitio antes de usarlo.

Para ajustarlo, gire el portabrocas a la derecha.

10 mm

7

Page 9

Español

COMO SE USA

1. Operación del interruptor

Accione el gatillo del interruptor y pulse el bloqueador.

Ello mantendrá el taladro encendido y es recomendable

si lo va a usar varias veces. Cuando está apagado, el

bloqueador se puede desconectar accionando el gatillo

de nuevo.

2. Ajustar la velocidad

[FD10SB]

La velocidad máxima se obtiene accionando el interruptor

del gatillo.

[FD10VB]

(1) La velocidad se puede ajustar de cero a velocidad

máxima dependiendo del grado en el que se accione el

gatillo.

(2) La velocidad máxima se puede ajustar de cero a 2800 en

menos de un minuto girando el mando de ajuste.

(3) Gire el mando de ajuste a la derecha para aumentar

la velocidad y a la izquierda para disminuirla. (Gire el

mando de ajuste aproximadamente 1-2/3 vueltas.)

(Fig. 1)

(4) El interruptor se puede bloquear con el bloqueador en

cualquier posición independientemente de la posición a

la que se haya girado el mando de ajuste. Seleccione

la posición adecuada dependiendo de la velocidad

necesaria para cada trabajo.

3. Confi rme la dirección de la broca (Fig. 2)

La broca gira hacia la derecha (vista desde atrás) al

pulsar el lado derecho (R) de la palanca reversa. Pulse el

lado izquierdo (L) de la palanca para hacer girar la broca

a la izquierda.

PRECAUCIÓN

Nunca cambie la dirección de rotación de la broca

durante su operación.

Apague el interruptor de corriente antes de cambiar la

dirección de rotación de la broca.

4. Para uso como taladro

(1) Montaje de la broca

Ajuste la broca con la llave. Hay tres orifi cios en los que

deberá insertar la llave. Ajuste los tres orifi cios de igual

forma. No ajuste únicamente un orifi cio. La broca se retira

siguiendo el proceso inverso al descrito anteriormente.

(Fig. 3)

(2) Cómo taladrar

1 Taladrar madera

○ Aplique la punta de la broca en la posición de taladro

deseada. Sujete el taladro perpendicularmente a la

superfi cie de trabajo y encienda el interruptor.

○ Cuando taladre orifi cios en madera, retire el taladro del

material tan pronto como la punta de la broca salga por

el otro lado. A continuación, dele la vuelta a la pieza de

trabajo y complete el orifi cio desde la otra parte para

obtener un orifi cio limpio. (Fig. 4)

Si se aplica madera adicional bajo la madera que desea

taladrar y se taladra a la vez, el orifi cio será igualmente

válido. (Fig. 5)

○ No se necesita ejercer presión sobre el taladro cuando

se taladre madera, ya que se taladra usando el tornillo

de la punta. El exceso de presión no acelerará el taladro

del orifi cio.

2 Taladrar metal

○ Si está taladrando metal con la broca para metal,

practique una hendidura en el punto donde desea hacer

el orifi cio. Esto le permitirá taladrar más fácilmente, ya

que el taladro no resbalará.

○ Si aplica aceite para máquinas de coser o agua jabonosa

al taladro con un cepillo o un cepillo de dientes el taladro

se conservará mejor.

○ El exceso de presión no acelerará el taladro del orifi cio.

Por el contrario, la punta del taladro se dañará. Esto

disminuirá la efi cacia y acortará la vida útil de la

herramienta.

PRECAUCIÓN

No exponga el motor al agua, puesto que podría

ocasionar un funcionamiento defectuoso o una descarga

eléctrica.

5. Para atornillar en madera (FD10VB)

(1) Broca atornilladora

○ La broca atornilladora baila cuando se usan tornillos

planos. Se recomienda usar tornillos de estrella siempre

que sea posible.

○ Seleccione una broca atornilladora que se ajuste bien a

la cabeza del tornillo.

(2) Orifi cio guía

Si se emplea una broca un poco inferior al diámetro del

tornillo para hacer el orifi cio guía, la madera no se partirá

y el tornillo entrará fácilmente.

(3) Atornillado

Coloque el tornillo sobre el orifi cio guía, sitúe la broca

sobre la cabeza del tornillo, encienda el interruptor y

atornille.

6. Precauciones tras la operación

Cuando coloque el taladro en lugares con polvo antes

de que las partes rotadoras hayan parado, asegúrese de

que la máquina no succiona polvo ni rebabas.

MANTENIMIENTO E INSPECCIÓN

PRECAUCIÓN

Asegúrese de que el interruptor de corriente está

desconectado y desconecte el enchufe durante las tareas

de mantenimiento e inspección.

1. Inspeccionar las brocas taladradoras y

atornilladoras

Para evitar un mal funcionamiento o una degradación de la

efi cacia del motor como resultado de una broca gastada,

sustitúyala inmediatamente por una nueva o afílela si

advierte indicios de abrasión. Puede ser peligroso usar

una broca atornilladora con la punta gastada o rota ya

que puede resbalar. Le recomendamos que la sustituya

por una nueva.

2. Inspeccionar la broca de taladro y el macho de

roscar

Como el uso continuado de una broca o macho de roscar

desgastados disminuye la efi ciencia operativa y causa

un posible recalentamiento del motor, reemplazar o afi lar

la broca o el macho sin demora si se nota un excesivo

desgaste.

3. Averías

Consulte con un servicio técnico autorizado por Hitachi

si experimenta un funcionamiento defectuoso de la

herramienta.

4. Lista de repuestos

A: N° ítem

B: N° código

C: N° usado

D: Observaciones

PRECAUCIÓN

La reparación, modifi cación e inspección de las

herramientas eléctricas Hitachi deben ser realizadas por

un Centro de Servicio Autorizado de Hitachi.

Esta lista de repuestos será de utilidad si es presentada

junto con la herramienta al Centro de Servicio Autorizado

de Hitachi, para solicitar la reparación o cualquier otro

tipo de mantenimiento.

En el manejo y el mantenimiento de las herramientas

eléctricas, se deberán observar las normas y reglamentos

vigentes en cada país.

8

Page 10

Español

MODIFICACIONES

Hitachi Power Tools introduce constantemente mejoras

y modifi caciones para incorporar los últimos avances

tecnológicos.

Por consiguiente, algunas partes (por ejemplo, números

de códigos y/o diseño) pueden ser modifi cadas sin

previo aviso.

NOTA

Debido al programa continuo de investigación y desarollo de

HITACHI estas especifi caciones están sujetas a cambio sin

preaviso.

9

Page 11

Português

ADVERTÊNCIAS GERAIS DE SEGURANÇA

PARA A FERRAMENTA ELÉTRICA

ADVERTÊNCIA

Leia todas as instruções e advertências de segurança.

Deixar de seguir as instruções e as advertências pode

provocar um choque elétrico, incêndio e/ou ferimentos

graves.

Guarde todas as advertências e instruções para futuras

consultas.

O termo “ferramenta elétrica” em todas as advertências

refere-se à sua ferramenta conectada à corrente (com um

cabo de alimentação) ou à ferramenta elétrica alimentada

por bateria (sem um cabo de alimentação).

1) Segurança da área de trabalho

a) Mantenha a área de trabalho limpa e bem

iluminada.

As áreas escuras ou cheias de material são propícias

a acidentes.

b) Não trabalhe com ferramentas elétricas em

ambientes explosivos, tais como na presença

de líquidos infl amáveis,

As ferramentas elétricas criam faíscas que podem

infl amar os gases ou pó.

c) Mantenha as crianças e outras pessoas afastadas

quando trabalhar com uma ferramenta elétrica.

As distrações podem fazer com que perca controle.

2) Segurança elétrica

a) Os plugues da ferramenta elétrica devem

corresponder às tomadas.

Nunca modifi que o plugue.

Não use plugues de adaptação com ferramentas

elétricas conectadas à terra.

Os plugues inalterados e tomadas correspondentes

reduzirão o risco de choques elétricos.

b) Evite o

Existe um risco maior de choque elétrico se o seu

c) Não exponha ferramentas elétricas à chuva ou

A entrada de água numa ferramenta elétrica

d) Não abuse do cabo de alimentação. Nunca use

Mantenha o cabo afastado do

Fios danifi cados ou entrelaçados podem aumentar o

e) Quando trabalhar com uma ferramenta elétrica

O uso de um cabo adequado para uso ao ar livre

f) Se não for possível evitar o uso de uma máquina

O uso de um RCD reduz o risco de choques

3) Segurança pessoal

a) Mantenha-se alerta, esteja atento ao que estiver

contato corporal com superfícies

conectadas à terra, tais como canos, radiadores,

fogões e geladeiras.

corpo estiver conectado à terra.

condições de umidade.

aumentará o risco de choques elétricos.

o cabo para transportar, puxar ou desligar a

ferramenta elétrica.

agudas ou peças móveis.

risco de choques elétricos.

ao ar livre, use uma extensão adequada para

uso em exteriores.

reduz o risco de choques elétricos.

elétrica num local úmido, use uma fonte de

alimentação protegida por um

corrente residual (RCD).

elétricos.

fazendo e use o bom senso ao trabalhar com

uma ferramenta elétrica.

gases ou pó.

calor, óleo, bordas

dispositivo de

Não use uma ferramenta elétrica quando estiver

cansado ou sob a infl uência de drogas, álcool

ou medicamentos.

Um momento de desatenção enquanto trabalha com

ferramentas elétricas pode resultar em ferimentos

pessoais graves.

b) Use o equipamento

sempre protetores para os olhos.

O equipamento de proteção, tal como uma máscara

de pó, sapatos de segurança antiderrapantes,

capacete ou protetores auditivos usados para

condições adequadas reduzirá os ferimentos

pessoais.

c) Evite ligar a ferramenta acidentalmente.

Certifi que-se de que o interruptor esteja na

posição de desligado antes de conectar a

fonte de alimentação e/ou bateria, levantar ou

transportar a ferramenta.

Transportar ferramentas elétricas com o dedo

no interruptor ou ativar ferramentas que estão

com o interruptor ligado é perigoso e aumenta a

probabilidade de acidentes.

d) Remova qualquer chave de parafusos ou chave

de

aperto antes de ligar a ferramenta.

Uma chave de aperto ou de parafusos instalada

na parte rotativa da ferramenta pode provocar

ferimentos pessoais.

e) Não se estique. Mantenha sempre o controle e

equilíbrio adequados.

Isso lhe permite obter um melhor controle da

ferramenta em situações inesperadas.

f) Vista-se adequadamente. Não use roupas largas

ou jóias. Mantenha o cabelo, roupas e luvas

afastados das peças móveis.

As roupas largas, jóias ou cabelo comprido podem

ser apanhados em peças móveis.

g) Se forem fornecidos componentes para a

conexão de dispositivos de extração

de pó, certifi que-se de que os mesmos sejam

conectados e usados adequadamente.

O uso de um coletor de pó pode reduzir os perigos

relacionados com o pó.

4) Uso da ferramenta e manutenção

a) Não force a ferramenta elétrica. Use a ferramenta

correta para a sua aplicação.

A ferramenta correta fará o trabalho melhor e

com mais segurança à velocidade para a qual foi

concebida.

b) Não use a ferramenta elétrica se o interruptor

não a ligar ou desligar.

Qualquer ferramenta que não possa ser controlada

pelo interruptor é perigosa e deve ser reparada.

c) Desligue o plugue da rede elétrica e/ou a

bateria da ferramenta elétrica antes de efetuar

quaisquer ajustes, mudar os acessórios ou

guardar a ferramenta elétrica.

Tais medidas preventivas de segurança reduzem o

risco de ligar a ferramenta elétrica acidentalmente.

d) Guarde as ferramentas elétricas fora do alcance

de crianças e não permita que pessoas não

habituadas à ferramenta elétrica ou estas

instruções trabalhem

As ferramentas elétricas são perigosas nas mãos de

usuários inexperientes.

e) Efetue a manutenção de ferramentas elétricas.

Verifi que a existência de desalinhamentos ou

curvaturas das peças móveis, rupturas de peças

e quaisquer outras condições que possam afetar

o funcionamento das ferramentas elétricas.

de proteção pessoal. Use

e coleta

com a ferramenta.

10

Page 12

Português

Se encontrar qualquer dano, solicite o conserto

da ferramenta antes de usá-la.

Muitos acidentes são causados por ferramentas com

manutenção inadequada.

f) Mantenha as ferramentas de corte afi adas e

limpas.

As ferramentas de corte com uma manutenção

adequada e extremidades afi adas são menos

propensas a curvar-se e mais fáceis de controlar.

g) Use a ferramenta elétrica, acessórios e

brocas de ferramentas, etc., de acordo com

estas instruções, levando em consideração

as condições de trabalho e o

efetuado.

O uso de uma ferramenta elétrica para operações

diferentes das concebidas pode resultar num mau

funcionamento.

5) Manutenção

a) A manutenção da sua ferramenta elétrica deve

ser realizada por pessoal técnico qualifi cado e

somente peças idênticas devem ser usadas para

substituição de peças defeituosas.

Isso garantirá que a segurança da ferramenta elétrica

seja mantida.

trabalho a ser

PRECAUÇÃO

Mantenha afastadas das crianças e pessoas

debilitadas.

Quando não estiverem sendo usadas, as ferramentas

devem ser guardadas fora do alcance de crianças e

pessoas debilitadas.

ADVERTÊNCIAS DE SEGURANÇA PARA O

BERBEQUIM

1. Ao montar a broca de perfuração ou a broca de

aparafusamento, insira-a completamente no mandril

e aperte o mandril completamente com a chave de

mandril.

Se a montagem não for feita adequadamente, será

perigoso usar a ferramenta, pois a broca poderia sair de

posição ou soltar-se durante a operação.

2. Não use luvas feitas com material que possa se enrolar

como, por exemplo, algodão, tecido ou malha, etc.

3. Não toque na broca durante ou logo após a operação.

A broca fi ca muito quente durante a operação e poderia

causar sérias queimaduras.

4. Ao colocar a ferramenta no chão, certifi que-se de que a

ferramenta tenha parado completamente.

5. Antes de perfurar uma parede, assoalho ou teto,

certifi que-se de que não haja coisas como cabos

elétricos ou encanamentos embutidos no material a ser

perfurado.

6. Ao trabalhar num lugar alto, tome cuidado com o que

está debaixo da área de trabalho.

ESPECIFICAÇÕES

Modelo FD10VB FD10SB

Voltagem (por áreas)* (110 V, 115 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Potência de entrada 420 W*

Rotação sem carga 0 – 2800/min 2800/min

Capacidade

Peso (sem cabo) 1,4 kg

* Certifi que-se de verifi car a placa de identifi cação no produto, já que existe a possibilidade de alterações de acordo com a

área.

APLICAÇÕES

1. Perfuração de diversos tipos de materiais

○ Perfuração de metais

Use uma broca de trabalho em metal

○ Perfuração de madeira

Use uma broca de trabalho em madeira (No entanto,

2. Aperto de parafusos para madeira (Somente modelo

FD10VB)

Use a broca de aparafusamento. Use um parafuso

Phillips para um aperto fácil.

ANTES DA OPERAÇÃO

1. Fonte de energia

Certifi que-se de que a fonte de energia que será usada

satisfaça as exigências especifi cadas na placa de

identifi cação do produto.

Aço

Madeira 25 mm

2. Interruptor de alimentação

Certifi que-se de que o interruptor de alimentação

use uma broca de trabalho em metal para fazer furospiloto para parafusos para madeira ou furos menores

que 6,5 mm.)

3. Cabo de extensão

Quando o local de trabalho não possuir uma fonte de

4. Verifi que o aperto do mandril

O mandril é apertado antes que a ferramenta saia

Gire o mandril no sentido horário para apertá-lo.

esteja na posição de desligado (OFF). Se o plugue for

conectado a uma tomada elétrica com o interruptor na

posição de ligado (ON), a ferramenta elétrica começará

a funcionar imediatamente, podendo provocar um grave

acidente.

energia, utilize um cabo de extensão de espessura e

de potência nominal sufi cientes. A extensão deve ser

mantida o mais curta quanto possível.

da fábrica, mas certifi que-se de que o aperto esteja

adequado antes de usar a ferramenta.

10 mm

11

Page 13

Português

MODO DE USAR

1. Operação do interruptor de gatilho

Puxar o interruptor de gatilho e pressionar o detentor

mantém a ferramenta na condição ligada, sendo

conveniente para um trabalho contínuo. Para desligar,

desconecte o detentor puxando o interruptor de gatilho

de novo.

2. Ajuste da velocidade

[FD10SB]

A velocidade máxima pode ser obtida puxando-se o

interruptor de gatilho até o fundo.

[FD10VB]

(1) A velocidade é ajustável de zero até a velocidade

máxima de acordo com a extensão em que o interruptor

de gatilho é puxado.

(2) A velocidade máxima é ajustável de zero a 2800/min

com a rotação do botão de ajuste.

(3) Gire o botão de ajuste no sentido horário para uma

velocidade mais alta, e no sentido anti-horário para

uma velocidade mais baixa. (Gire o botão de ajuste

aproximadamente 1-2/3 volta.) (Fig. 1)

(4) O interruptor pode ser bloqueado com o detentor em

qualquer posição requerida, independentemente de

quanto o botão de ajuste tiver sido girado. Selecione

uma posição apropriada de acordo com a velocidade

requerida para cada trabalho.

3. Confi ra a direção de rotação da broca (Fig. 2)

A broca gira no sentido horário (visto de trás) quando

se pressiona o lado R da alavanca do interruptor de

inversão. O lado L da alavanca é pressionado para girar

a broca no sentido anti-horário.

PRECAUÇÃO

Nunca altere a direção de rotação da broca durante a

operação.

Coloque o interruptor de alimentação na posição de

desligado (OFF) antes de alterar a direção de rotação da

broca.

4. Para usar como um berbequim

(1) Montagem da broca

Aperte a broca com a chave de mandril. Há três orifícios

nos quais a chave de mandril deve ser inserida. Aperte

igualmente em ordem nos três orifícios, sem apertar

somente em um orifício. Realize o procedimento acima

na ordem inversa para retirar a broca. (Fig. 3)

(2) Como perfurar

1 Para perfurar madeira

○ Aplique a ponta da broca na posição desejada para a

perfuração, segure a ferramenta perpendicularmente à

superfície da peça de trabalho e ligue a ferramenta com

o interruptor de alimentação.

○ Ao perfurar um orifício atravessante na madeira, retire

a broca do material assim que a ponta da broca sair

pela superfície oposta. Logo, vire a peça de trabalho ao

contrário e complete a perfuração desde o lado oposto

para obter um orifício de corte limpo. (Fig. 4)

Se for aplicada uma madeira extra sob a madeira que

será perfurada e a mesma for perfurada junto, também é

possível obter um orifício fi no. (Fig. 5)

○

Um berbequim de trabalho em madeira não precisa

ser pressionado fortemente, pois o mesmo penetra na

madeira usando o parafuso na ponta. A aplicação de

uma força excessiva não acelerará a perfuração.

2 Para perfurar metal

○ Para perfurar metal com um berbequim de trabalho

em metal, aplique previamente um punção centrador

na posição de perfuração. Assim, o metal poderá ser

perfurado com estabilidade, já que a ponta da broca não

escorregará.

○ Se você aplicar óleo de máquina de costura ou água

ensaboada no berbequim com uma escova ou escova

de dentes usada, a ferramenta durará mais tempo.

○ A aplicação de uma força maior do que a força necessária

não realizará uma perfuração mais rápida.

Pelo contrário, a borda da ferramenta poderá sofrer

danos. Isso reduzirá a efi cácia operacional e encurtará

a vida útil da ferramenta.

PRECAUÇÃO

Não exponha o motor à água, pois isso pode causar um

mau funcionamento do motor e choques elétricos.

5. Para aparafusar parafusos para madeira (FD10VB)

(1) Broca de aparafusamento

○ Para aparafusar um parafuso para madeira de cabeça

fendida, a broca de aparafusamento sai de posição

facilmente. Portanto, sempre que possível, use parafusos

para madeira de fenda cruzada.

○ Selecione uma broca de aparafusamento compatível

com a fenda cruzada e a ranhura fendida do parafuso

para madeira.

(2) Furo-piloto

Se for feito um furo-piloto com um berbequim um pouco

menor que o diâmetro do parafuso para madeira, a

madeira não rachará e o parafuso para madeira poderá

ser aparafusado com facilidade.

(3) Operação de aparafusamento

Coloque o parafuso para madeira ligeiramente no furo-

piloto, aplique o berbequim na ranhura da cabeça do

parafuso, ligue a ferramenta e aparafuse o parafuso.

6. Precaução logo após a operação

Ao colocar o berbequim em lugares poeirentos antes

que as peças rotativas tenham parado completamente,

certifi que-se de que a ferramenta não aspire a poeira e

serragem.

MANUTENÇÃO E INSPEÇÃO

PRECAUÇÃO

Certifi que-se de desligar (OFF) a ferramenta e de

desconectar o plugue da rede elétrica para a manutenção

e inspeção.

1. Inspeção das brocas de perfuração e brocas de

aparafusamento

Como o uso de uma broca desgastada causará o

mau funcionamento do motor e deteriorará a efi cácia

operacional, troque a broca por uma nova ou afi e a

broca sem demora quando perceber qualquer desgaste.

Se você usar uma broca de aparafusamento com uma

ponta desgastada ou quebrada, isso será perigoso pois

a broca poderá escorregar. Portanto, troque a broca por

uma nova.

2. Inspeção dos parafusos de montagem

Inspecione regularmente todos os parafusos de

montagem e certifi que-se de que estejam corretamente

apertados. Se algum deles estiver frouxo, reaperte-o

imediatamente. Caso isso não seja feito, pode resultar

em perigo grave.

3. Serviço

Consulte um Centro de Serviço Autorizado da Hitachi no

caso de qualquer defeito da ferramenta elétrica.

4. Lista de peças para conserto

A: N° do item

B: N° do código

C: N° da peça usada

D: Observações

PRECAUÇÃO

Os consertos, modifi cações e inspeção de Ferramentas

Elétricas da Hitachi devem ser realizados por uma

Ofi cina Autorizada da Hitachi.

12

Page 14

Português

Esta lista de peças pode ser útil se for apresentada com

a ferramenta na Ofi cina Autorizada da Hitachi ao solicitar

conserto ou manutenção.

Na operação e na manutenção das ferramentas

elétricas, devem-se observar as normas de segurança e

os padrões estabelecidos por cada país.

MODIFICAÇÕES

As Ferramentas Elétricas da Hitachi estão sempre sendo

aperfeiçoadas e modifi cadas para incorporar os mais

recentes avanços tecnológicos.

Dessa forma, algumas peças (isto é, números de código

e/ou design) podem sofrer modifi cações sem aviso

prévio.

NOTA

Devido ao contínuo programa de pesquisa e desenvolvimento

da HITACHI, as especifi cações contidas aqui estão sujeitas

a modifi cações sem aviso prévio.

13

Page 15

1 980057 1

ABCD

FD10VB

2 950292 1 “1”

3 312368 1

4 6202VV 1 6202VVCMPS2L

5 939544 1

6 994721 1

7 954789 1

8 608VVM 1 608VVC2PS2L

10 340228E 1 220V-230V

9A 360456E 1 220V-230V

11 626VVM 1 626VVC2PS2L

13 ———— 1

14 302086 7 D4×20

12-1 312386 1 (MOSS GREEN)

12-2 312387 1 (OFF BLACK GREEN)

15 930483 2

16 999041 2

17 981373 2

18 303665 1

19 303656 1

20 312388 1

21 303657 1

22 303666 1

23 ———— 1

24 ———— 1

26 960266 1

27 305812 2 D4×16

28 ———— 1

29 303654 1

30 303655 1

31 994273 1

25-1 307217 1 D7.2

25-2 303662 1 D8.8

32 302488 1

14

Page 16

1 980057 1

ABCD

FD10SB

2 950292 1 “1”

3 312368 1

4 6202VV 1 6202VVCMPS2L

5 939544 1

6 994721 1

7 954789 1

8 608VVM 1 608VVC2PS2L

10 340228E 1 220V-230V

9A 360455E 1 220V-230V

11 305808 1

12 312371 1

13 626VVM 1 626VVC2PS2L

15 ———— 1

16 302086 7 D4×20

17 305807 1

14-1 312372 1 (MOSS GREEN)

14-2 312373 1 (OFF BLACK GREEN)

18 312370 1

19 930483 2

20 999041 2

22 994734 1

23 994273 1

24 960356 2 M3.5

25 302488 1

26 ———— 1

28 960266 1

29 305812 2 D4×16

21-1 960356 2 M3.5

21-2 980063 2

27-1 307217 1 D7.2

27-2 303662 1 D8.8

30 ———— 1

15

Page 17

161718

Page 18

Page 19

Page 20

Issued by

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo 108-6020, Japan

Distributed by

Francisco Petrarca No. 239 Local A

Col. Chapultepec Morales C. P. 11570

Mexico, D. F.

Avenida Balboa, Edif. BBVA,

Piso 21 B-1, Panamá, Rep. de Panamá

904

Code No. C99182241 G

Printed in China

Loading...

Loading...