Page 1

High Pressure Washer

Hochdruckreiniger

Nettoyeur haute pression

Idropulitrice ad alta pressione

Arandela de alta presión

Anilha de alta pressão

Myjka wysokoci nieniowa

Magasnyomású mosó

Basinçli yikama makinesi

M a

M a

AW 150

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

Lire soigneusement et bien assimiler ces instructions avant usage.

Prima dell’uso leggere attentamente e comprendere queste instruzioni.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Antes de usar, leia com cuidado para assimilar estas instruções.

Przed u ytkowaniem nale y dok adnie przeczyta niniejsz instrukcj i zrozumie jej tre .

Használat el tt olvassa el fi gyelmesen a használati utasítást.

Aleti kullanmadan önce bu kılavuzu iyice okuyun ve talimatları anlayın.

, , , .

.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni per l’uso

Instrucciones de manejo

Instrukcja obs ugi

Kezelési utasítás

Kullanım talimatları

Instruções de uso

Page 2

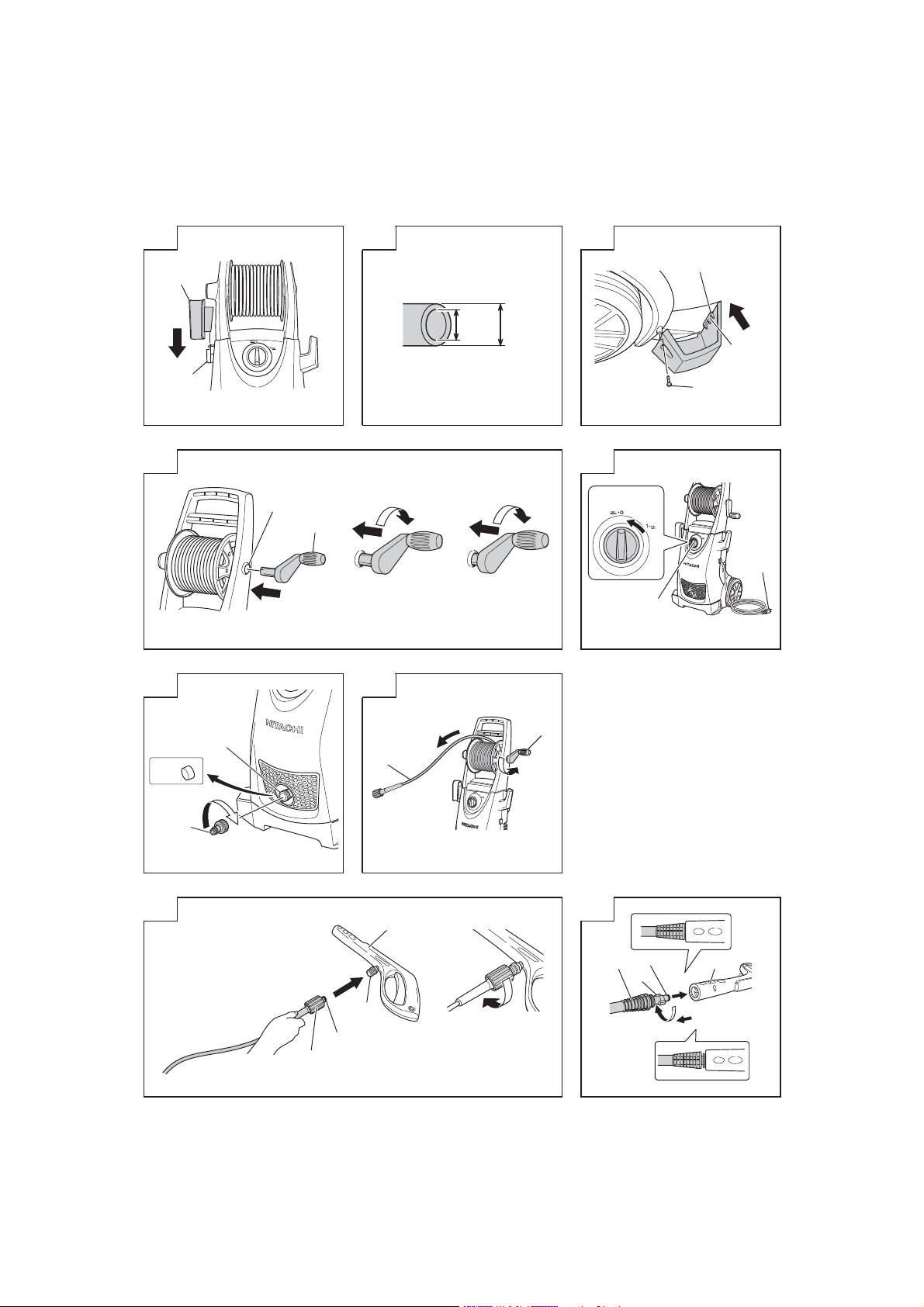

1 2 3

ï

í ì

î

4 5

ð

ç

(1)

(2) (3)

6 7

ê

é

ë

è

ÿ

ª

ç

ý

à

û

ü

8 9

Â

ï

ú

î

ö

ø

2

÷

¯

ö

î

Â

ï

í

Page 3

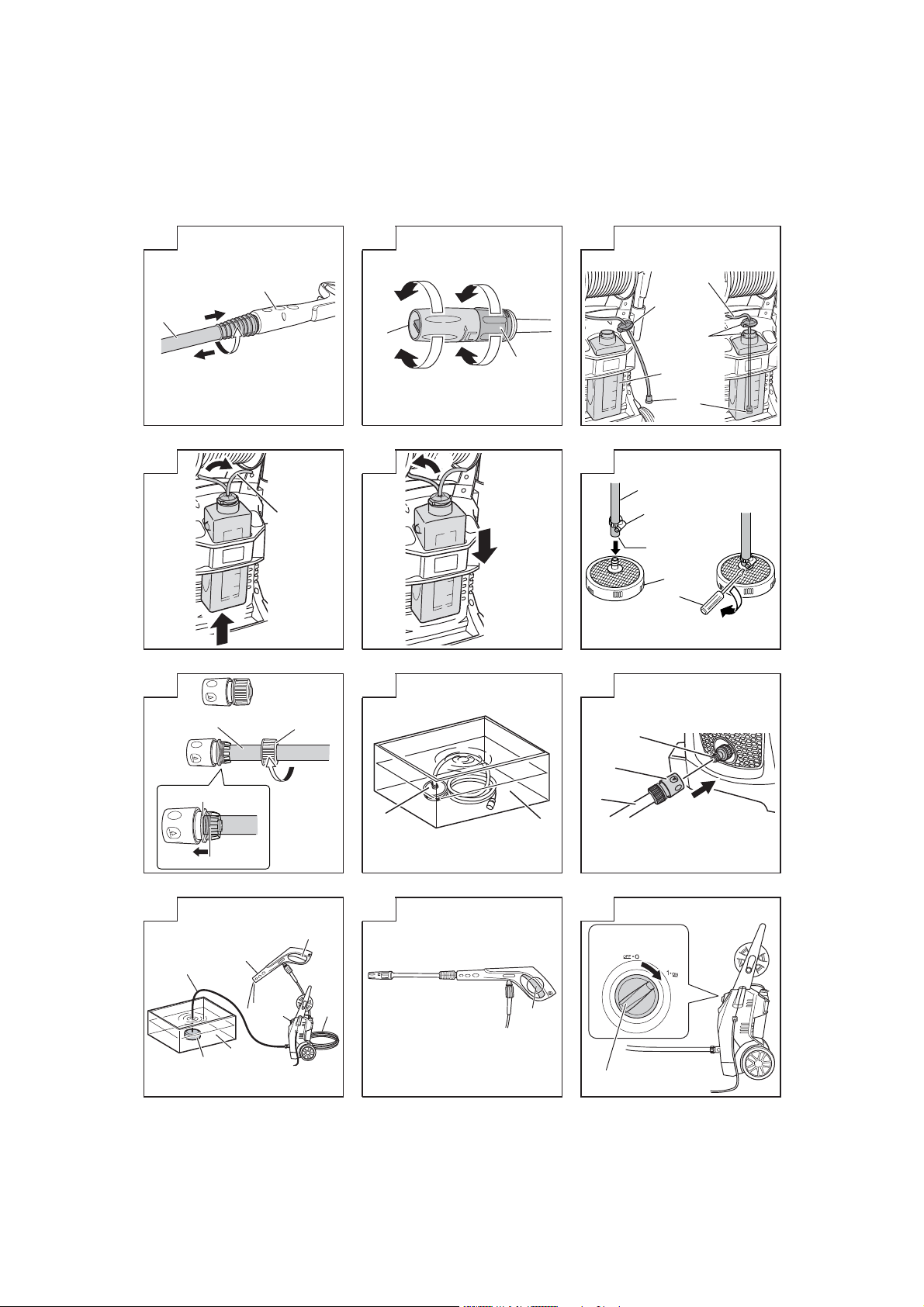

10 11 12

Â

®©

ï

÷

î

í

13 14 15

§

»

«

¬

ë

ï

ì

î

16 17 18

¶

¸

µ

·

ï

î

±

°

¿

¼

º

¹

ü

å

´

º

-

¨

¦

19 20 21

¾

º

¨

Â

ª

û

²

-

¸

½

³

ª

3

Page 4

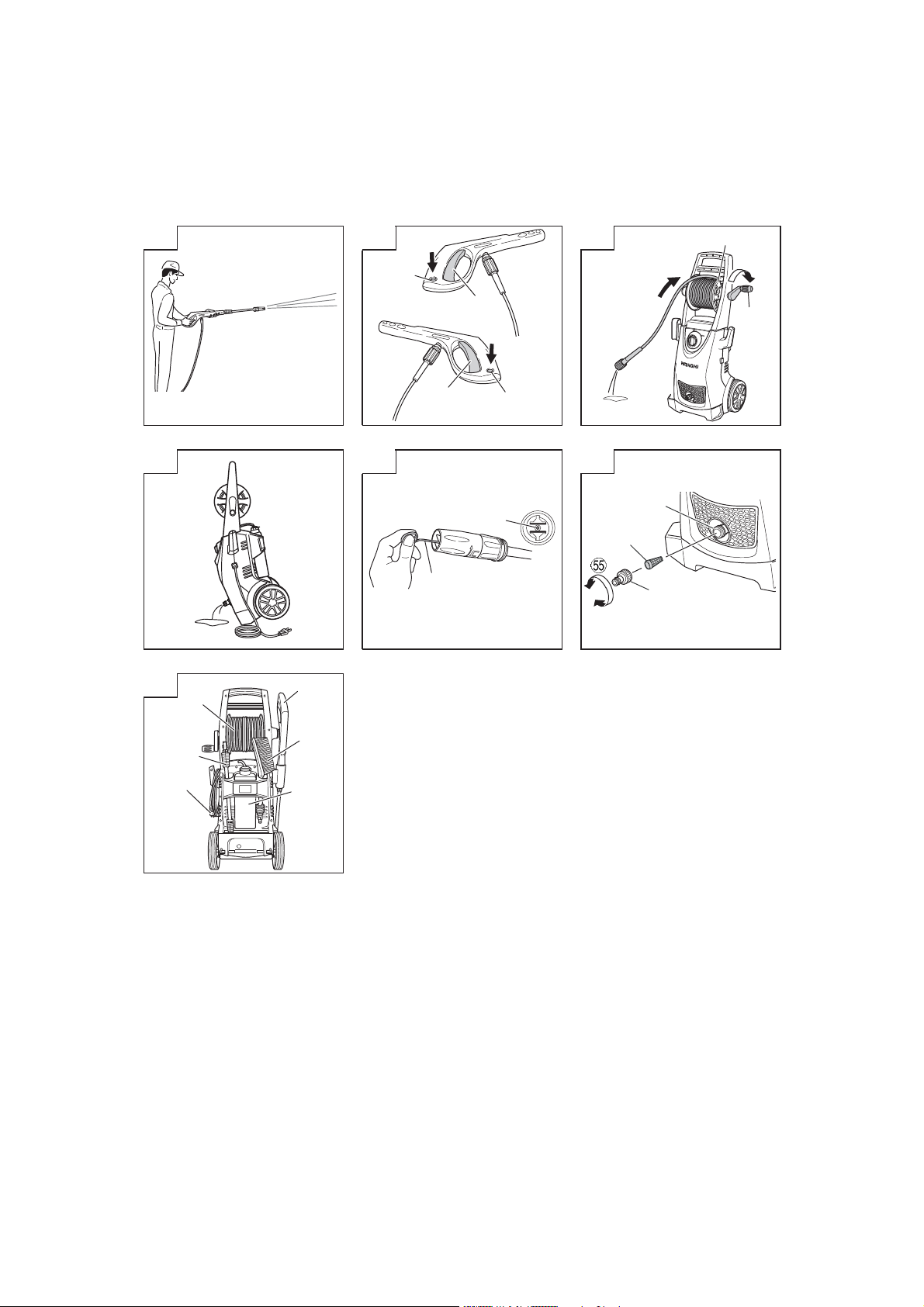

22 23 24

ò

ô

•

¾

ñ

¾

ô

25 26 27

~

}

´

28

Â

û

j

y

Ž

à

º

ü

ÿ

4

±

Page 5

English Deutsch Français Italiano

Gun holder Pistolenhalter Porte-pistolet Supporto della pistola

ï

î Washer protrusion Reinigervorsprung Saillie du nettoyeur Sporgenza dell'idropulitrice

í 14 to 15 mm 14 bis 15 mm 14 à 15 mm 14 - 15 mm

ì 20 mm or less 20 mm oder weniger 20 mm au maximum 20 mm o meno

ë Gun support protrusion

Vorsprung der

Pistolenhalterung

Support du pistolet en

saillie

Sporgenza del supporto

della pistola

ê Washer long hole Langes Loch des Reinigers Trou profond du nettoyeur Foro lungo dell'idropulitrice

Press fi rmly Fest drücken Appuyez fermement Premere saldamente

é

Screw supplied Mitgelieferte Schraube Vis fournie Vite in dotazione

è

ç Hose handle Schlauchgri Poignée du tuyau Manovella avvolgitubo

ð Attachment hole Befestigungsloch Trou de fi xation Foro di attacco

ÿ Power plug Netzstecker Fiche d'alimentation Spina di alimentazione

Water feed inlet Wasserzulaufö nung

à

ý Water feed inlet cap

Kappe für

Wasserzulaufö nung

ü Water feed connector Wasserzulaufanschluss

Entrée d'alimentation en

eau

Bouchon de l'alimentation

en eau

Connecteur d'alimentation

en eau

û High-pressure hose Hochdruckschlauch Tuyau à haute pression

Trigger gun Auslöserpistole Pistolet à gâchette Pistola a grilletto

Â

Connector Anschluss Connecteur Connettore

ú

Ingresso di alimentazione

dell'acqua

Tappo dell'ingresso di

alimentazione dell'acqua

Connettore di

alimentazione dell'acqua

Tubo fl essibile ad alta

pressione

ö O-ring O-Ring Joint torique O-ring

ø Ring Ring Joint Anello

÷ Nozzle Düse Buse Ugello

¯ Protrusion Vorsprung Saillie Sporgenza

© Jet Strahl Jet Getto

Spray Sprühen Vaporisateur Spruzzo

»

Low-pressure Niederdruck Basse pression Bassa pressione

®

¬ High-pressure Hochdruck Haute pression Alta pressione

§ Nozzle tip Düsenspitze Pointe de la buse Punta dell'ugello

« Pressure adjuster Druckregler Régulateur de pression Regolatore di pressione

Water supply pipe Wasserversorgungsrohr

·

Conduite d'alimentation

en eau

Tubo di alimentazione

acqua

± Detergent bottle Reinigungsmittelfl asche Flacon de détergent Flacone del detergente

Filter on the tip of the water

°

feed pipe

Hose band Schlauchklemme Collier de serrage du tuyau Fascetta fermatubo

¿

- Suction hose Ansaugschlauch Tuyau d'aspiration

Moisten the inside with

¼

water

Filter an der Spitze des

Wasserversorgungsrohrs

Die Innenseite mit Wasser

befeuchten

Filtre à l'extrémité du tuyau

d'alimentation en eau

Humidifi ez l'intérieur à l'eau

Filtro all'estremità del tubo

di alimentazione dell'acqua

Tubo fl essibile di

aspirazione

Inumidire l'interno con

acqua

º Strainer Siebfi lter Crépine Filtro

¹ Slotted screwdriver Flachkopfschraubenzieher Tournevis à tête plate Cacciavite a testa piatta

¸ One-touch joint Gelenk auf Knopfdruck Raccord rapide Raccordo rapido

Insert the suction hose

¶

µ Pass it through the ring fi rst

Den Ansaugschlauch

einschieben

Zuerst durch den Ring

führen

Insérez le tuyau

d'aspiration

Commencez par le passer

dans le joint

Inserire il tubo fl essibile di

aspirazione

Inserirlo prima nell'anello

´ Tighten Festziehen Serrez Serrare

Hose end Schlauchende Extrémité du tuyau Estremità tubo fl essibile

å

5

Page 6

English Deutsch Français Italiano

¦ Insert it past this point

¨ Accumulated water Angesammeltes Wasser Réservoir d'eau Acqua accumulata

½ Insert directly Direkt einschieben Insérez directement Inserire direttamente

ª Switch Schalter Interrupteur Interruttore

¾ Trigger Auslöser Gâchette Grilletto

Center of the trigger Mitte des Auslösers Centre de la gâchette Centro del grilletto

²

Switch ON Einschalten Interrupteur ON Interruttore su ON (acceso)

³

ô Trigger stopper Auslöserstopper Sécurité de la gâchette Fermo del grilletto

ò Lock Verriegeln Verrou Blocco

ñ Release Entriegeln Relâchez Rilascio

• Hose reel Schlauchaufroller Dévidoir Tamburo avvolgitubo

Ž Hose handle Schlauchgri Poignée du tuyau Manovella avvolgitubo

} Nozzle cleaner pin Düsenreinigungsstift

Nozzle hole Düsenloch Orifi ce de la buse Foro dell'ugello

~

Loosen Lockern Desserrez Allentare

y Turbo nozzle Turbodüse Buse turbo Ugello turbo

j Cleaning brush Reinigungsbürste Brosse de nettoyage Spazzola per pulizia

Über diesen Punkt hinaus

einschieben

Insérez au-delà de ce point Inserirlo oltre questo punto

Broche de nettoyage de

la buse

Pulitore dell'ugello

6

Page 7

English Deutsch Français

Symbols

WARNING

The following show

symbols used fo r the

machine. Be sure that you

understand their meaning

before use.

Read all safety

warnings and all

instructions.

Failure to follow

the warnings and

instructions may result

in electric shock, fi re

and/or serious injury.

Only for EU countries

Do n ot dispose of electric

tools together with

household waste material!

In observance of European

Directive 2002/96/EC

on waste electrica l and

electr onic equipment

and its implementation in

accordance with nation al

law, electric tools that

have reached the end of

their life must be colle cted

separately and returned

to an environmentally

compatible recycling facility.

High-pressure water

can be dangerous if

used incorrectly. Highpressure water jets

must not be directed

at people, electrical

equipment or the

washer itself.

Water that has passed

through the backfl ow

valve cannot be used

for drinking.

Alternating current Wechselstrom Courant alternatif Corrente alternata

Symbole

WARNUNG

Die folgenden Sym bole

werden für diese Maschine

verwendet. Achten Sie

darauf, diese vor der

Verwendung zu verstehen.

Lesen Sie säm tliche

Sicherhe itshinwe ise und

Anweis ungen durch .

Wenn die Warnungen

und Anweisungen nicht

befolgt we rden, kann es

zu Stro mschlag , Brand

und/oder ern sthaften

Verletzungen kommen.

Nur für EU-Länder

Werfen Sie

Elektrowerkzeuge nicht

in den Hausmüll!

Gemäss Europäischer

Richtlinie 2002/96/EG

über Elektro- und

Elektronik- Altgeräte

und Umsetzung in

nationales Recht

müssen verbrauchte

Elektrowerkzeuge

getrennt gesammelt und

einer umweltgerechaten

Wieder ververtung

zugeführt werden.

Wasser unter hohem

Druck kann bei falscher

Benutzung gefährlich

sein. Der Ho chdruckstrahl

darf nicht auf Menschen,

elektrische Anlagen,

oder den Reiniger selbst

gerichtet werden.

Wasser, das durch

das Rückfl ussventil

gefl ossen ist, ist nicht

trinkbar.

Symboles

AVERTISSEMENT

Les symboles suivants

sont utilisés pour l’outil.

Bien se familiariser

avec leur signifi cation

avant d’utiliser l’outil.

Lir e tous les

aver tisseme nts de

séc urité e t toute s les

instru ctions.

Tout manquement

à observer ces

avertissements et

instruction s peut en gendrer

des chocs électriques,

des incen dies et/ou des

blessures graves.

Pour les pays européen s

uniquement

Ne pas jeter le s appareils

électriques dans les ordures

ménagères!

Con formément à la directive

européenne 20 02 /9 6/EG

relative aux déchets

d’équipements électriques

ou électroniques (DEEE),

et à sa transposition dans

la législation nationale,

les appareils électriques

doivent être collectés à

part et être soumis à un

recyclage respectueux de

l’enviro nnem ent.

L'eau sous haute pression

peut être dangereuse

si elle n'est pas utilisée

correctement. Un jet

d'eau sous haute pression

ne doit pas être dirigé

vers des personnes, des

équipements électriques ou

le nettoyeur.

L'eau qui est passée à

travers le clapet antiretour n'est pas potable.

Italiano

Simboli

AVVERTENZA

Di seguito mostriamo

i simboli usati per la

macchina. Assicurarsi

di comprenderne il

signifi cato prima dell’uso.

Leggere tutti gli

avvertimenti di

sicurezza e tutte le

istruzioni.

La mancata osservanza

degli avvertimenti e

delle istruzioni potrebbe

essere causa di scosse

elettriche, incendi e/o

gravi lesioni.

Solo per Paesi UE

Non gettare le

apparecchiature elettriche

tra i rifi uti dom estici.

Secondo la Direttiva

Europea 2002/96/CE sui

rifi uti di apparecchiature

elettr iche ed elettroniche

e la sua attuazione

in conformità alle

norme nazionali, le

apparecchiature elettriche

esauste devono essere

raccolte separatamente, al

fi ne di essere reimpieg ate in

modo eco-compatibile.

L'acqua ad alta pressione

può essere pericolosa,

se utilizzata in modo

scorretto. Non puntare il

getto ad alta pressione

dell'idropulitrice verso

persone, apparecchiature

elettriche o l'idropulitrice

stessa.

L'acqua che ha

attraversato la valvola

antirifl usso non è

potabile.

V

A

Hz

W

kg

MPa

Class II tool Werkzeug der Klasse II Outil classe II Attrezzo di Classe II

Warning Warnung Avertissement Avvertenza

Volts Volt Volts Volt

Amperes Ampere Ampères Ampere

Hertz Hertz Hertz Hertz

Watts Watt Watts Watt

Kilograms Kilogramm Kilogrammes Kilogrammi

Megapascals Megapascal Mégapascals Megapascal

11

Page 8

English

(Original instructions)

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric

shock, fi re and/or serious injury.

Save all warnings and instructions for future referen ce.

1. Make sure the work area is always kept neat and

tidy.

Failure to observe this may result in accidents.

2. Take the surrounding environment into

consideration when using the washer.

Make sure the work area is brightly lit.

Do not use the washer near fl ammable liquid or gas.

3. Beware of electric shocks.

Do not touch anything that is earthed (grounded) when

using the High Pressure Washer. (For example, pipes,

heaters, microwave ovens, refrigerators, etc.)

4. Do not use the washer near children.

People other than the person using the washer must not

be allowed to touch the washer or the cord.

People other than the person using the washer must not

come near the work area.

5. Store the washer in a safe place when not in use.

Store the washer in a dry, high location or protected with

a lock out of the reach of children.

6. Do not use the washer in inappropriate ways.

Use the High Pressure Washer within the limits of its

capabilities to ensure safe and e cient results.

Do not use the washer for any purpose other than that for

which it was designed.

7. Wear safe clothing when using the washer.

Use safety boots, gloves, helmets with visors and

earplugs in accordance with necessity.

8. Use protective goggles and dust-protection masks

when using the washer.

There is a chance that splashes and dust may enter the

eyes and mouth when using the washer.

9. Do not handle the power cord roughly.

Do not carry the High Pressure Washer with only the

power cord or pull the plug from the socket while holding

the power cord.

Keep the power cord away from heat, oil and sharp

corners.

10. Make sure the item being cleaned is fi rmly fi xed in

place.

There are cases in which the power of the water pressure

will cause light objects to fl y o . Do not use the washer on

light objects that cannot be fi xed in place.

11. Maintain a proper stance when using the washer.

Make sure your feet are always placed fi rmly on the

ground to maintain balance.

12. Pay close attention to maintaining the High Pressure

Washer.

Clean the washer regularly to ensure safe and e cient

use.

Refer to the instruction manual when replacing supplied

parts.

Regularly check the power cord and ask your dealer for

repairs in the event of it being damaged.

If using an extension cord, check it regularly and replace

it in the event of it being damaged.

Make sure the grip is always kept dry and clean, and do

not allow oil of grease to come into contact with it.

13. Switch o and unplug the High Pressure Washer in

the following situations:

When it is not in use and when it is being repaired.

When attaching or detaching supplied or purchased

parts.

In other situations in which risks seem apparent.

14. Always remove equipment used for adjustment

purposes.

Check to make sure that all equipment used for

adjustment purposes has been removed before switching

on the power.

15. Avoid accidentally switching on the power.

Make sure you do not accidentally switch on the power to

the washer when it is plugged in.

Check to make sure that the washer is switched o

before plugging it into the power supply.

16. Use extension cords designed for outdoor use.

When using extension cords outdoors, make sure they

are cab-tire cords or cables.

17. Pay attention at all times when using the washer.

Pay attention to the methods of use stipulated in the

instruction manual and the surrounding environment

when using the High Pressure Washer.

Do not use the washer when tired.

18. Only use specifi ed accessories and attachments.

Using accessories and attachments other than those

specifi ed in the instruction manual or in Hitachi catalogs

may result in accidents or injuries and must be avoided at

all costs.

19. High Pressure Washer repairs to be performed only

by experts.

The High Pressure Washer conforms to all relevant

safety regulations and must not be modifi ed.

All repairs must be requested to Hitachi authorized

service centers. Attempting to carry out repairs without

the correct skills may result in accidents or injuries.

20. Check to make sure there are no damaged parts.

Carry out thorough inspections before using the washer

to make sure that no parts are damaged, and check to

ascertain that the washer is functioning properly.

Check that all moving parts or correctly positioned, have

been tightened in place and are correctly attached,

and then check all areas to confi rm that there are no

abnormalities that could a ect operations.

Refer to the instruction manual when replacing or

repairing damaged parts.

Request repairs to Hitachi authorized service centers

if details on repairs are not specifi ed in the instruction

manual.

Request repairs to Hitachi authorized service centers if

the switch is damaged.

Do not use the High Pressure Washer if the switch

becomes inoperable or cannot be turned o .

21. Use a power supply that conforms to the voltage

listed on the name plate.

Failure to observe this may result in the washer operating

at higher speeds than normal, leading to overheating

and the outbreak of smoke and fi re, which may cause

damage or injuries.

14

Page 9

English

22. Use an independent power socket with a rated value

of 15 A or more.

Sharing a power socket with other equipment may result

in the breaker shutting down.

23. Hold the trigger gun fi rmly in both hands when

using the washer.

Failure to observe this may result in injury.

24. High-pressure water can be dangerous if used

incorrectly.

High-pressure water jets must not be directed at people,

animals, easily-broken items, electrical equipment or the

washer itself.

25. Do not use gasoline, oil, organic solvents or

other infl ammable or toxic liquids, or any other

inappropriate liquid.

Failure to observe this may result in explosions, the

outbreak of fi re or smoke, or other accidents, which may

cause damage or injury.

26. When washing automobile tires, make sure that the

tip of the nozzle is kept at least 50cm distant from

the surface being washed.

Failure to observe this may result in damage to the tire or

brakes, which may cause serious accidents.

27. Do not touch the power plug or power socket with

wet hands.

Failure to observe this may result in electric shocks.

28. When the washer is being used by people (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

they must be supervised and guided by people

capable of operating it safely.

29. Make sure that a backfl ow valve is used without fail

when connecting the washer to a drinking water

faucet.

Water that has passed through the backfl ow valve cannot

be used for drinking.

30. Make sure that water is not splashed onto the High

Pressure Washer, power cord, extension cable,

power plug, power socket or other areas. Also,

neither exposes it to rain nor use it in the rain.

Failure to observe this may result in electric shocks.

31. Do not hold the trigger gun when fi xing it in place.

32. If the washer is not functioning normally or is

emitting strange noises or vibrations switch it o

immediately and contact Hitachi authorized service

centers to request inspections or repairs.

Continued use may result in injury.

33. If the washer is accidently dropped or banged into

something solid, inspect it for damage, cracks and

malformation.

Failure to observe this may result in injury.

CAUTION

1. Purge all of the pressure within the washer before

disconnecting the high-pressure hose.

2. Attach all supplied accessories correctly in

accordance with the instruction manual.

Failure to observe this may result in the accessories

becoming detached or in injury.

3. Check to make sure that no foreign matter is

adhering to the object being washed.

Failure to observe this may result in the matter fl ying o

and causing unexpected injury.

4. Do not spray a jet of water at the areas surrounding

labels on the object being washed.

Failure to observe this may result in the labels peeling o .

5. Grip the handle fi rmly when carrying the washer.

6. Do not use any accumulated water other than clean

water from the faucet (water containing dirt, mud,

sand, etc.) when using the auto-suction function.

SPECIFICATIONS

Model AW150

Voltage (by areas)*

Power input*

1

1

Max. discharge pressure (1MPa: 10.2 kgf/cm2) 11.0 MPa

Max permissible pressure 15.0 MPa

Max feed pressure 0.7 MPa

Max water discharge 6.67 L/min

Permissible temperature 40°C or less

Dimensions (Length x Width x Depth)

2

Weight*

(Including the hose handle, power cord holder, gun holder,

*1 Be sure to check the nameplate on product as it is subject to change by areas.

*2 Weight: Excluding the power cord, weight consists of trigger gun, high-pressure hose, variable nozzle, water feed connector

and accessory holder.

Single-phase AC 50/60 Hz

Voltage 220 V to 240 V

2000 W

425 mm x 345 mm x 905 mm

gun support and water feed connector)

12.4 kg

15

Page 10

English

STANDARD ACCESSORIES

(1) Trigger gun ..................................................................1

(2) High-pressure hose (10 m) ..........................................1

(3) Variable nozzle (with pressure adjuster) ......................1

(4) Turbo nozzle ...............................................................1

(5) Detergent bottle (stored inside the unit) ......................1

(6) One-touch joint (black)

(For use with the strainer hose) ...................................1

(7) Water feed connector ..................................................1

(8) Nozzle cleaner pin .......................................................1

(9) Gun holder ..................................................................1

(10)

Hose handle ................................................................1

(11)

Gun support (with 1 attachment screw) .......................1

(1) (2)

(3) (4)

(5) (6)

(7) (8)

(9) (10)

(11)

16

Page 11

English

OPTIONAL ACCESSORIES (sold separately)

Items shown in are sold separately. Contact Hitachi authorized service centers for replacements if the standard

accessories become damaged or broken.

Variable nozzle

(With pressure adjuster)

[Standard accessory]

Trigger gun

[Standard accessory]

Turbo nozzle

[Standard accessory]

Cleaning brush

Washes away dirt that has

been dislodged with the

brush.

Rotary brush

The central brush is rotated

by water pressure for cleaning

the windows and other items

with large surfaces.

Angle nozzle (variable)

Used for cleaning di cultto-reach places, such as

the underneath of cars and

ceilings, etc.

High-pressure extension hose

(10 m)

Extends the length of the highpressure hose supplied.

High-pressure hose

[Standard accessory]

Water feed connector

[Standard accessory]

One-touch joint (black)

[Standard accessories]

Pipe cleaning kit

(7.5 mm hose)

High-pressure water jets

from the front of the hose are

reversed to clean the inside

of the pipe.

Strainer hose set

Accumulated

water

17

Page 12

English

APPLICATIONS

Cleans screen doors, window glass, fl oors, walls, etc.

Cleans automobiles, motorbikes, etc.

Cleans mud o gardening equipment and agricultural

equipment.

PRIOR TO OPERATION

1. Installation of an earth leakage circuit breaker

It is recommended that an earth leakage circuit breaker

is connected to the washer to shut o the power if leaking

current exceeds 30 mA for 30 milliseconds in order to

prevent electric shocks.

2. Keep the work area neat and tidy

Dirty water will be sprayed about when using the washer.

It is therefore necessary to check the area to make sure

there are no hindrances, and keep the work area neat

and tidy.

3. Situating the washer

Select fl at locations where the washer will not be

splashed with water when cleaning.

4. Using extension cords

Make sure the cord is thick enough to provide a constant

supply of electricity, and use cords that are as short as

possible.

Acceptable cord thicknesses (Nominal cross sectional

area cable) and cord length are indicated in the table

below.

ݱ®¼ ̸·½µ²»-- ø³³î÷ ݱ®¼ Ô»²¹¬¸ ø³÷

ï ïîòë

ïòë îð

îòë íð

5. Attaching the gun holder (Fig. 1)

Align the groove on the gun holder with the protrusion on

the washer and push until it clicks into place.

6. Prepare a water feed hose (Fig. 2)

Prepare the following when using water feed hoses:

Hoses that can withstand pressure (equipped with

meshes)

Hoses with an inner diameter of 14 to 15 mm.

Hoses with an outer diameter of 20 mm or less.

7. Attaching the gun support (Fig. 3)

(1) Press the protrusion on the gun support into the long hole

on the washer at an angle shown in the illustration.

(2) Firmly screw the screw supplied into the screw hole with

a Phillips screwdriver.

8. Attaching the hose handle (Fig. 4)

(1) Insert the hose handle into the attachment hole on the

washer.

(2) Press down while rotating it until it reaches a position

approximately 15 mm deep.

(3) Continue to press down and rotate it until it clicks into

place at approximately 15 mm deep.

INSPECTIONS PRIOR TO USE

WARNING

Check the following before using the washer. Check the

items listed in 1 and 2 before plugging into the power

socket.

1. Check to make sure the switch is at the “OFF”

position (Fig. 5)

Plugging the washer into the power socket with the

switch set at “ON” will cause the washer to immediately

begin operating, which may result in unexpected injuries.

2. Check the power supply

Only use a rated voltage.

Do not use motor engines are direct current. Failure to

observe this will not only result in damage to the washer,

it is also very dangerous.

3. Check the power socket

If the power socket is loose or the plug is easily dislodged,

it needs to be repaired.

It is dangerous to use it in this condition. Consult with

your local electrical engineering outlet.

ATTACHING PARTS

Make sure all parts are correctly attached in the following

sequence in order to guarantee safe usage.

WARNING

Switch o the washer and disconnect it from the power

socket without fail to prevent unexpected accidents.

1. Attach the water feed connector to the water feed

inlet on the washer (Fig. 6)

Remove the cap on the washer’s water feed inlet and

fi rmly attach the water feed connector.

Loose connections may result in water leaks.

2. Pull the high-pressure hose from the hose reel

(Fig. 7)

Pull the entire length of the high-pressure hose from the

reel while steadying the reel to prevent it from toppling

over.

NOTE

Using the washer with part of the hose wrapped around

the reel may result in insu cient pressure or abnormal

vibrations.

3. Attach the high-pressure hose to the trigger gun.

(Fig. 8)

Grip the thick end of the high-pressure hose, insert it into

the connector on the trigger gun, and then rotate the ring

on the hose to fi x it in place.

NOTE

Moisten the O-ring with water to facilitate the connection

if it is di cult to insert the hose.

If the ring cannot be tightened, it means that the end of

the high-pressure hose has not been su cient inserted.

4. Attach the nozzle to the trigger gun.

<Attachment (Fig. 9)>

(1) Align the protrusion on the nozzle with the entry hole on

the trigger gun and press it into place.

NOTE

Remove all dirt, mud and other matter from the trigger

gun’s entry hole and the protrusion on the nozzle.

Moisten the O-ring with water to facilitate the connection

if it is di cult to insert the nozzle.

(2) Press down fi rmly on the nozzle and then rotate it in the

direction of the arrow until it stops (half rotation.)

(3) Check to make sure that the nozzle cannot be pulled out

once it has been attached.

<Detachment (Fig. 10)>

Press down fi rmly on the nozzle and then rotate it counter-

clockwise until it stops. The nozzle can be withdrawn at

that position.

18

Page 13

English

USING DIFFERENT NOZZLES

Variable nozzle (with pressure adjustor) (Fig. 11)

The variable nozzle (with pressure adjustor) can be used

to alternation between “Jet” and “Spray” and between

“High Pressure” and “Low Pressure”.

Rotate the end on the nozzle clockwise for “Jet”, and

counter-clockwise for “Spray”.

Also, rotate the pressure adjuster clockwise for “Low

Pressure”, and counter-clockwise for “High Pressure”.

• Jet washer

A water jet is discharged in a direct line to remove

stubborn mud and other dirt from agricultural machinery,

etc.

• Spray washer

The water is discharged in a wide fan for cleaning walls,

motorbikes and automobiles, etc.

The entire nozzle can be rotated by approximately 90

degrees to change the shape of the spray between

horizontal and vertical.

NOTE

The pressure adjuster will also be rotated when

alternating between “Jet” and “Spray”, so readjust this to

the required setting after making the adjustment.

Set the spray adjustment to “Jet” fi rst of all, and then

gradually move it to the “Spray” position while pulling the

trigger.

Note that there is a chance of the water being sprayed

horizontally over a wide area if this is rotated fully to the

“Spray” position.

Note that the nozzle may be damaged if it is forced to

move past the stop position when alternating between

“Jet” and “Spray”.

Turbo nozzle

The turbo nozzle rotates as it sprays high-pressure jets of

water for e cient washing.

NOTE

The turbo nozzle only discharges powerful jets of water

when set at the “Jet” mode.

Avoid using this on items that are easily broken or for

which coatings are easily peeled.

USING THE DETERGENT BOTTLE (Fig. 12)

Sprays water mixed with detergent.

Uses neutral detergents available on the open market.

WARNING

Do not use acidic or alkali detergents. Use only neutral

detergents available on the open market.

Using detergents other than neutral detergents or

chemical agents may result in accidents or malfunctions.

NOTE

Check to make sure that the water feed pipe is fi rmly

connected to the washer.

The detergent will not be mixed with the spray otherwise.

ï Remove the cap from the detergent bottle and pour the

detergent into it.

î Make sure the fi lter on the tip of the detergent bottle’s

water feed pipe is inserted into the liquid and then tighten

the cap fi rmly.

NOTE

Only the “Low Pressure” setting can be used for variable

nozzles (with pressure adjustors) when using the

detergent bottle.

The detergent will not be sprayed if the “High Pressure”

setting on variable nozzles (with pressure adjustors) or

turbo nozzles are used.

í Set the adjustor to “Low Pressure” when using variable

nozzles (with pressure adjustors.)

ì Water containing the detergent will be sprayed at low

pressure when the trigger on the trigger gun is pulled.

Cleaning the detergent bottle (Figs. 13 and 14)

ï Remove the detergent bottle’s water feed pipe from the

washer.

î Push the detergent bottle from the bottom and withdraw it

from the top.

í Wash the detergent bottle, water feed pipe and fi lter with

water from the faucet.

ì When reattaching the bottle, hold it as shown in Fig. 14,

and then push the protrusion on the bottom in as far as it

will go.

ë Insert the water feed pipe into the washer and tighten the

cap while making sure dust or dirt does not enter.

USING THE STRAINER HOSE SET (sold

separately)

The separately-sold strainer hose set is equipped with a

function that will automatically suck water from a water tank,

etc., when attached to the AW150.

The maximum height of suction (lifting range) is

approximately 0.5 m.

Attach this correctly in accordance with conditions.

Í«½¬·±² ¸»·¹¸¬ ©¸»² ¬¸» ¸»·¹¸¬ ±º ¬¸» ©¿¬»® º»»¼ ±«¬´»¬

·- ´±©»® ¬¸¿² ¬¸» ³¿¨·³«³ ¸»·¹¸¬ ±º ¬¸» -«½¬·±² ¸±-»æ

Ú®±³ ¬¸» ³¿¨·³«³ ¸»·¹¸¬ ±º ¬¸» -«½¬·±² ¸±-» ¬± ¬¸»

-«®º¿½» ±º ¬¸» ©¿¬»®ò

Ó¿¨·³«³ ¸»·¹¸¬ ±º

¬¸» -«½¬·±² ¸±-»

Water surface

Water

feed inlet

Í«½¬·±² ¸»·¹¸¬ ©¸»² ¬¸» ¸»·¹¸¬ ±º ¬¸» ©¿¬»® º»»¼

±«¬´»¬ ·- ¬¸» -¿³» ¿- ¬¸» ³¿¨·³«³ ¸»·¹¸¬ ±º ¬¸»

-«½¬·±² ¸±-»æ Ú®±³ ¬¸» ©¿¬»® º»»¼ ±«¬´»¬ ¬± ¬¸» -«®º¿½»

±º ¬¸» ©¿¬»®ò

É¿¬»® º»»¼ ·²´»¬

ø³¿¨·³«³ ¸»·¹¸¬ ±º

¬¸» -«½¬·±² ¸±-»÷

Water surface

19

Page 14

English

1. Attaching the strainer to the suction hose (Fig. 15)

(1) Pass the suction hose through the hose band supplied

and then gently moisten the inside of the suction hose

with water.

(2) Insert the strainer as far as it will go, and then fi rmly

tighten the hose band with a fl at-headed screwdriver.

2. Attaching the one-touch joint (black) to the suction

hose (Fig. 16)

Attach the one-touch joint (black) supplied as a standard

accessory to the suction hose.

3. Starting the suction hose water suction process

(Fig. 17)

Sink the strainer hose set into a container fi lled with

water.

Start o the suction process (introduce water to the

suction hose.)

NOTE

Do not use anything other than clean water (river or pond

water, muddy water containing sand granules.)

Failure to observe this may result in malfunctions.

Set the switch at “ON” without the nozzle attached.

Failure to observe this may result in dry operations,

leading to malfunctions.

4. Insert the one-touch joint into the water feed

connector (Fig. 18)

Withdraw the one-touch joint from the accumulated water

and insert it into the water feed connector on the washer

while making sure that the water inside the hose does not

escape.

5. Check to make sure the water is fl owing out

(Fig. 19)

(1) Connect the trigger gun from which the nozzle has been

removed to the high-pressure hose.

(2) Plug in the power socket and set the switch to “ON”.

(3) Pull the trigger gun’s trigger, and then set the switch to

“OFF” after checking that su cient water is fl owing out.

6. Attach the nozzle.

NOTE

Set the switch at “OFF” if water does not fl ow out within

two minutes.

Failure to observe this may result in malfunctions (dry

operations.)

7. Washing

Set the switch at “ON” and pull the trigger gun’s trigger to

commence washing.

8. Cleaning

Remove all dirt from the strainer’s grill, wash it with water

and store it after it has dried.

WASHING

WARNING

Do not switch the washer on while the trigger is being

pulled.

Failure to observe this may result in high-pressure water

being sprayed immediately, leading to unexpected

accidents.

Do not point the nozzle at people or animals.

Failure to observe this may result in injury.

CAUTION

Set the switch to “OFF” immediately if the hose becomes

detached from the faucet or washer, and if water is no

longer being fed to the washer.

Failure to observe this may result in immediate

malfunctions (dry operations.)

Set the switch to “OFF” without fail when temporarily

suspending operations.

Failure to observe this may result in the motor

automatically starting up.

Place your fi nger in the center of the trigger during

operations (Fig. 20)

Failure to observe this may result in injury from pinched

fi ngers.

Grip the gun and nozzle fi rmly with both hands.

The trigger gun may kick back when water is discharged.

NOTE

Do not use the water hose when it is wound onto the reel.

Failure to observe this may result in insu cient water

feed.

Commence initial washing approximately 2 to 3 meters

away from the targeted item, and then move gradually

closer while checking the level of cleaning until you reach

a distance in which soiling is e ectively washed away.

The pressure of the spray from the washer is

approximately 20-times greater than tap water. Highpressure water jets may therefore damage or peel the

coating from the items being washed.

There are cases when the water spray will appear

unstable owing to the fact that air that has built up in

the pump and hose is purged together with the water

immediately after use. In this event, allow the water to

fl ow out until it stabilizes.

Leave two or more seconds gap between pulling and

releasing the trigger.

Failure to observe this may result in the pressure switch

malfunctions.

Do not use the washer for more than thirty consecutive

minutes without giving it a break.

1. Open the faucet to its fullest.

Point the nozzle in a safe direction and then fully open the

faucet. Check to make sure no water is leaking from the

joints.

Release the trigger stopper with the washer switched o ,

pull the trigger on the trigger gun to discharge a small

amount of water from the nozzle with just the pressure

from the tap water. Check to make sure that no water is

leaking.

NOTE

Do not switch the washer on with the faucet turned o .

Failure to observe this may result in malfunctions.

2. Set the switch to the “ON” position (Fig. 21)

The motor will start operating when the washer is

switched on. The motor will automatically switch o once

su cient water pressure has built up inside the washer.

3. Pull the trigger (Fig. 22)

Hold the trigger gun fi rmly in both hands, point the nozzle

at the item to be washed, and then pull the trigger.

The high-pressure water jet will spray out.

Adjust the nozzle between “Jet” and “Spray” in

accordance with need.

Trigger stopper (Fig. 23)

The trigger gun is fi tted with a trigger stopper to prevent

the trigger from being pulled.

The trigger is locked and released by pressing the

stopper in the direction shown by the arrows.

NOTE

Lock the trigger with the trigger stopper during pauses

and after washing has been completed.

20

Page 15

English

ON COMPLETION OF USE

Once the targeted item has been washed, drain the residual

water from the washer and store it in a well-ventilated

location to dry.

There are cases in which water left in the hose may freeze

during the winter, so drain as much water as possible and

store it indoors.

WARNING

Make sure all residual water is drained from the washer,

the trigger gun and the hose, etc., after use.

Failure to observe this may result in freezing, leading to

malfunctions.

1. Draining water from the washer

(1) Stop the water supply.

(2) Set the switch to “ON” and pull the trigger on the trigger

gun to drain the water from the inside of the washer.

Continue this until water is no longer discharged

(approximately 30 to 60 seconds.)

(3) Press the trigger stopper on the trigger gun to lock it in

place.

2. Set the switch to “OFF”.

(1) Switch o the washer.

(2) Unplug the power cord from the mains socket.

NOTE

Leaving the washer switched on may result in dry

operations, leading to malfunctions.

3. Detach the trigger gun.

Follow the reverse procedure explained in “Attach the

high-pressure hose to the trigger gun” to detach the

trigger gun.

4. Rewind the high-pressure hose (Fig. 24)

Place the end of the high-pressure hose at a position

lower than the reel and then rewind it while draining out

all residual water.

5. Drain the water from the washer (Fig. 25)

(1) Tilt the washer to drain out the residual water.

(2) Wipe away all moisture with a dry cloth.

CAUTION

Water left in the washer may freeze in the winter, which

could result in damage to the pump.

SAFETY MECHANISMS

The washer is equipped with the following safety mechanisms

to ensure safe usage.

Power switch

This prevents the washer from being unintentionally

operated.

Trigger gun equipped with a lock

This prevents the trigger from being pulled, unintentionally

operating the washer.

Pressure switch

This prevents the pressure inside the washer from

exceeding permissible levels. Releasing the lever on the

trigger gun causes the valve operated by water pressure

to halt pump operations, which allows the pressure to be

released through the water feed. The pump is started

again when the lever is pulled.

Thermal protector

This protects the motor by halting operations when

abnormal heat is detected in the motor. It will start

operating again when the motor cools down.

MAINTENANCE AND INSPECTION

WARNING

Switch o the washer and disconnect the plug from the

power socket without fail when inspecting and cleaning it.

1. Inspecting the washer and hoses (Fig. 26)

Check to make sure that there is no damage, cracks or

malformations.

Make sure you clean the hole on the nozzle with the

nozzle cleaner pin supplied on a regular basis.

NOTE

Detach the trigger gun and clean the nozzle hole.

2. Inspecting the strainer (Fig. 27)

Wash all blockages out of the grid with water on a regular

basis.

NOTE

Withdraw the strainer from the water feed inlet with the

use of fl at radio pliers.

3. Clean the washer

Squeeze the excess moisture from a cloth soaked in

soap and water and wipe the washer.

Do not use gasoline, thinner, benzene, kerosene, etc.

Failure to observer this may result in malformations.

4. Check for loose screws.

Check for loose screws on a regular basis and tighten

any screws that are loose. Failure to observe this could

be dangerous.

5. Tidying up and storing the washer after use

(Fig. 28)

The accessories can be stored inside the washer as

shown in Fig. 28 when not in use and when being carried

around.

Avoid the following environments and store the washer

and accessories in a safe, dry location when not in use.

Do not store within the reach of children, or in locations

where children can use it.

Do not store in location where rain can reach it, such as in

front of the house, or in locations with high humidity.

Do not store in locations that are subject to drastic

changes in temperature or direct sunlight.

Do not store in locations containing volatile substances

that may ignite or explode.

6. Replacing supply cord

If the replacement of the supply cord is necessary, it has

to be done by a Hitachi Authorized Service Center to

avoid a safety hazard.

7. Service parts list

CAUTION

Repair, modifi cation and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized Service

Center.

This Parts List will be helpful if presented with the tool to

the Hitachi Authorized Service Center when requesting

repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modifi ed to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without prior

notice.

21

Page 16

English

TROUBLESHOOTING

Use the inspections in the table below if the tool does not operate normally. If this does not remedy the problem, consult your

dealer or the Hitachi Authorized Service Center.

Symptom Possible cause Remedy

The motor won’t operate

when the trigger is pulled.

The motor continues

operating when the

trigger is released.

Water is not being

discharged.

The water pressure won’t

rise.

The power plug is not plugged into the power

socket.

The switch is set at “OFF” Switch the washer on.

The extension cord is unplugged or severed

midway.

The thermal protector has been activated. Remedy the problem in accordance with the

The water volume or pressure from the faucet

is too low.

Water is leaking. Check the hose connections.

The water hose is not connected. Connect the water hose.

The water hose or high-pressure hose is

twisted.

The backfl ow valve on the one-touch joint is

not operating.

The trigger stopper is locked. Remedy the problem in accordance with the

The faucet it turned o . Open the faucet fully.

The nozzle is blocked. Clean the end of the nozzle with the nozzle

The strainer is blocked. Wash the strainer, which is incorporated into

The power plug is not plugged into the power

socket.

The switch is set at “OFF”. Switch the washer on.

The water volume or pressure from the faucet

is too low.

The nozzle is blocked. Clean the end of the nozzle with the nozzle

The electrical voltage is too low. Check to make sure that the thickness and

Water is leaking. Check the hose connections.

Plug the power cord into the power socket.

Replace the extension cord or check it with a

di erent electrical appliance.

details listed in “Safety Mechanisms” on

page 21.

Open the faucet fully.

Unravel any twists in the water hose and

high-pressure hose.

Check to make sure that the inner diameter

of the water hose is correct.

Check to make sure that the water hose is

not wound onto the reel.

Unravel the twists.

Check to make sure that the inner diameter of

the water hose is correct.

details listed in “Trigger Stopper” on page 20.

cleaner pin supplied.

the water feed inlet, in accordance with the

details listed in “Inspecting the Strainer” on

page 21.

Plug the power cord into the power socket.

Open the faucet fully.

Unravel any twists in the water hose and

high-pressure hose.

Check to make sure that the inner diameter

of the water hose is correct.

Check to make sure that the water hose is

not wound onto the reel.

cleaner pin supplied.

length of the extension cord is appropriate.

22

Page 17

GUARANTEE

We guarantee Hitachi Power Tools in accordance with

statutory/country specifi c regulation. This guarantee does

not cover defects or damage due to misuse, abuse, or normal

wear and tear. In case of complaint, please send the Power

Tool, undismantled, with the GUARANTEE CERTIFICATE

found at the end of this Handling instruction, to a Hitachi

Authorized Service Center.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

Information concerning airborne noise and vibration

The measured values were determined according to

EN60335 and declared in accordance with ISO 4871.

Measured A-weighted sound power level: 92 dB (A)

Measured A-weighted sound pressure level: 81 dB (A)

Uncertainty KpA: 3 dB (A).

Wear hearing protection.

Vibration total values (triax vector sum) determined

according to EN60335.

Vibration emission value a

Uncertainty K = 1.5 m/s

2

= 3.3 m/s

h

2

English

The declared vibration total value has been measured in

accordance with a standard test method and may be used

for comparing one tool with another.

It may also be used in a preliminary assessment of exposure.

WARNING

The vibration emission during actual use of the power

tool can di er from the declared total value depending on

the ways in which the tool is used.

Identify safety measures to protect the operator that

are based on an estimation of exposure in the actual

conditions of use (taking account of all parts of the

operating cycle such as the times when the tool is

switched o and when it is running idle in addition to the

trigger time).

23

Page 18

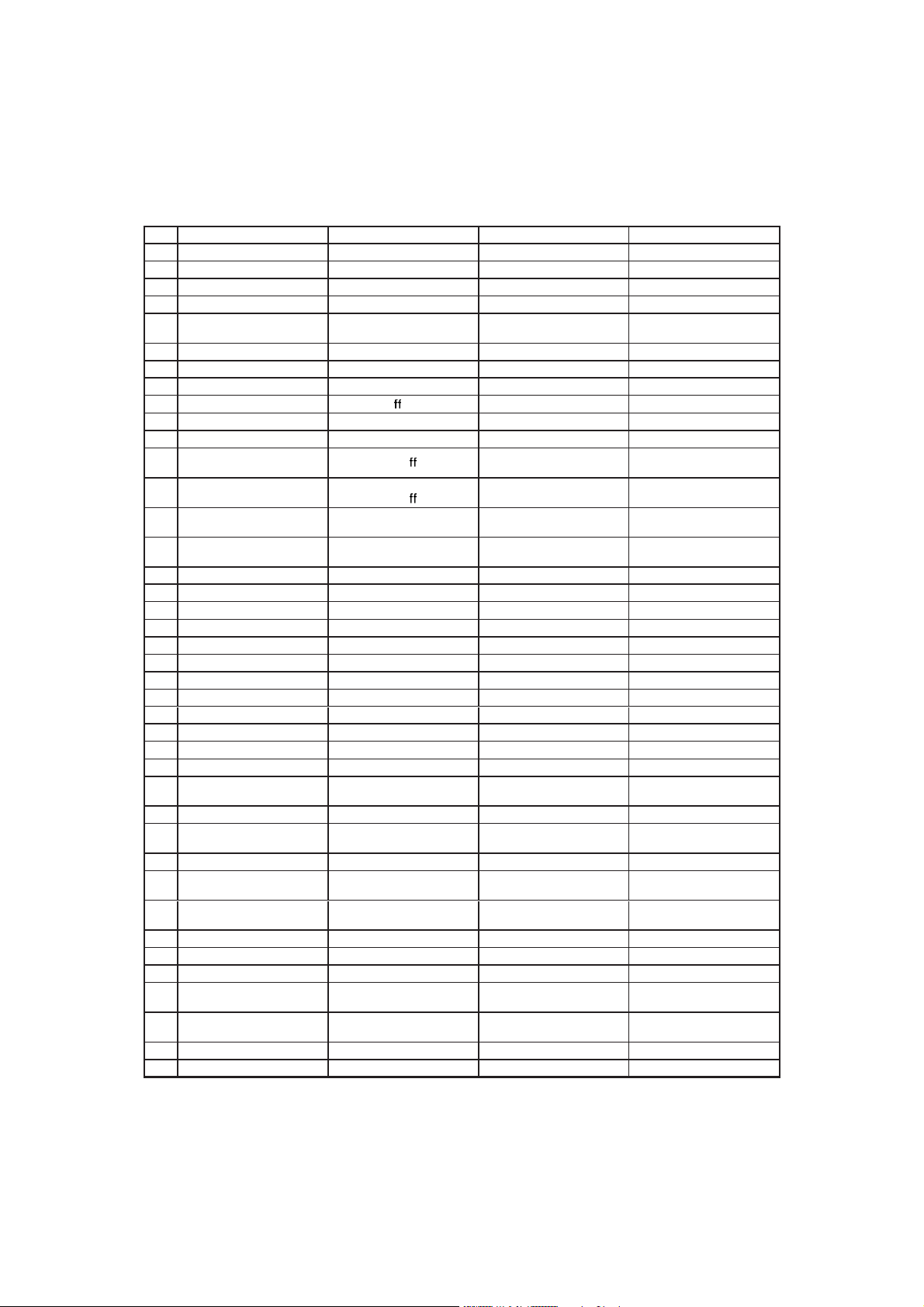

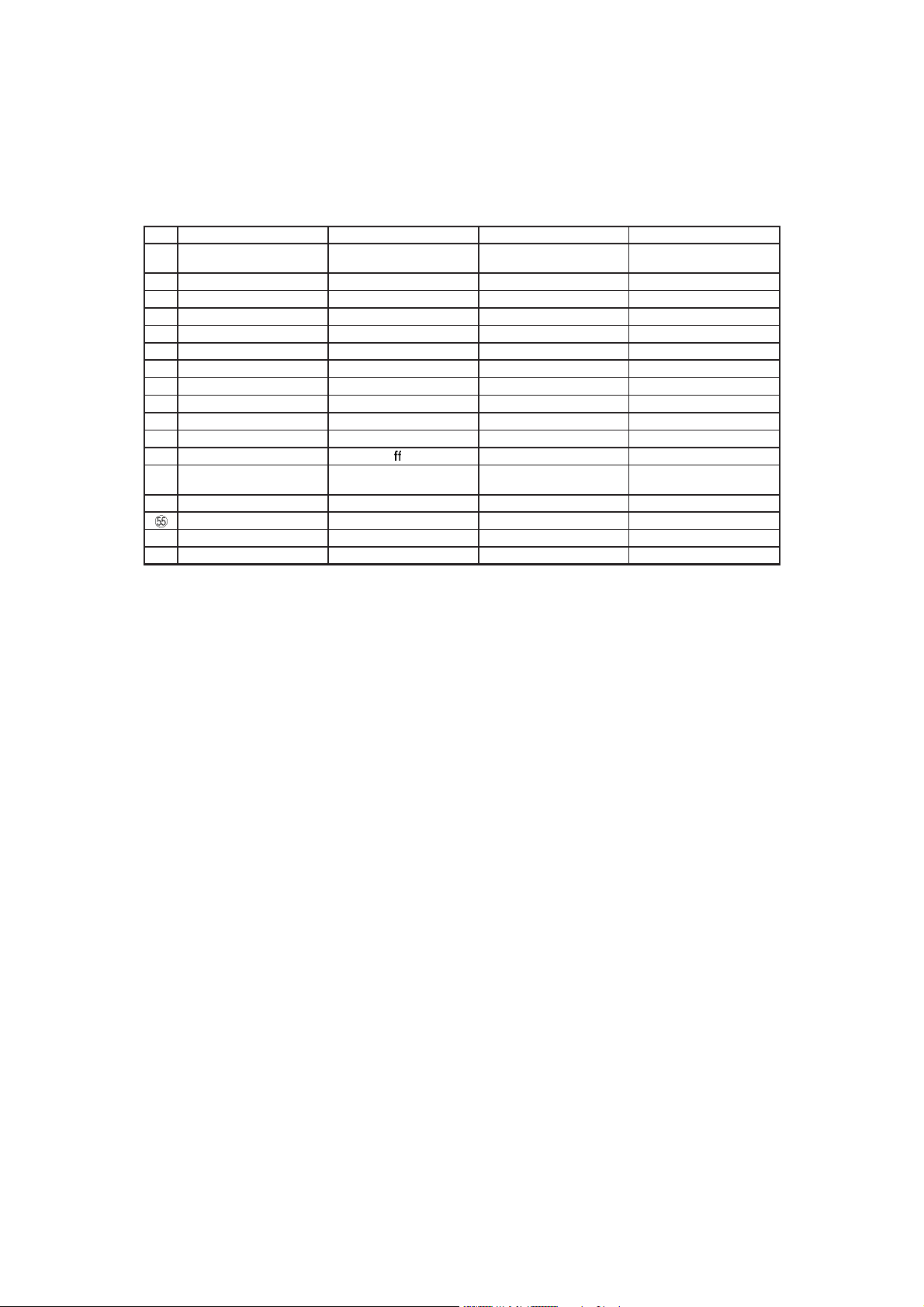

Part NameQ’TY

55BACK SW COVER1

56WIND BOARD1

57FERRITE CORE2

58PLATE1

59GUN SUPPORT1

61FERRITE CORE2

53MAIN SWITCH1

54CAPACITOR1

No.

Item

Part NameQ’TY

1PUMP ASS'Y (P8) (INCLUDE 6-8)1

2MOTOR 1

3MOTOR COVER 1

4BACK MOTOR FILTER 1

Item

No.

5CARBON BRUSH 2

62SCREW M5 × 18 2

60 1

6FRONT MOTOR FILTER 1

7SCREW 5.5 × 25 4

8PEACH SHAPED RING 1

9INLET FILTER (MESH) 1

10VALVE CAP 1

65CORD SET 1

66BACK HOUSING 1

67WHEEL SHAFT 1

68NAME PLATE 1

69WHEEL 2

70WHEEL COVER 2

63WHEEL GUARD (L) 1

64WHEEL GUARD (R) 1

11VALVE CORE 1

12SPRING 1

13MICRO SWITCH 1

14MOTOR WIND COVER (A)2

71WASHER 2

15SCREW 2.9 × 13 4

16FAN COVER 1

17SEAL PLATE 1

18HANDLE 1

19HOSE REEL COVER 1

1

VARIABLE NOZZLE (B)

(INCLUDE 505)

72EXTERNAL CIRCLIP 2

501NOZZLE CLEANER PIN 1

502INLET NUT 1

503TURBO NOZZLE (INCLUDE 505)1

504

21O-RING ( 4.8 × 1.8) 1

20CONNECTOR 1

22CONNECTION TUBE 1

23HOSE REEL 2

24HANDLE (HOSE REEL) 1

25HANDLE COVER (L) 1

1

HIGH-PRESSURE HOSE

(INCLUDE 507)

505O-RING 2

506GUN (A) 1

507O-RING 2

508

509ONE-TOUCH JOINT 1

26SCREW 4.8 × 20 20

31SCREW 4.8 × 16 6

27HANDLE COVER (R) 1

28GUN HOLDER 1

29U-PIN 2

30INNER HOSE 1

32HANDLE GRIP 1

33SCREW 4.8 × 25 4

34TUBE CONNECTOR 1

35CAUTION LABEL 1

36INNER TUBE 1

41TANK 1

37SPRAY TUBE 1

38TANK COVER 1

39SPRAY SPIGOT 1

40SPRAY PLUG 1

42FRONT CLAMP 1

47 1

43KNOB 1

44 1

45 1

46 1

51FRONT SW COVER 1

48BACK CLAMP1

49SCREW (C) 4 × 1413

50SEAL RING 1

52SW SHAFT 1

133

Page 19

English Polski

GUARANTEE CERTIFICATE

ï Model No.

î Serial No.

í Date of Purchase

ì Customer Name and Address

ë Dealer Name and Address

(Please stamp dealer name and address)

Deutsch

ï Model

î Numer seryjny

í Data zakupu

ì Nazwa klienta i adres

ë Nazwa dealera i adres

(Piecz punktu sprzeda y)

Magyar

GARANTIESCHEIN

ï Modell-Nr.

î Serien-Nr.

í Kaufdaturn

ì Name und Anschrift des Kunden

ë Name und Anschrift des Händlers

(Bitte mit Namen und Anschrift des Handlers

abstempeln)

Français Türkçe

ï Típusszám

î Sorozatszám

í A vásárlás dátuma

ì A Vásárló neve és címe

ë A Keresked neve és címe

(Kérjük ide elhelyezni a Keresked nevének és

címének pecsétjét)

CERTIFICAT DE GARANTIE

ï No. de modèle

î No de série

í Date d achat

ì Nom et adresse du client

ë Nom et adresse du revendeur

(Cachet portant le nom et l adresse du

ï Model No.

î Seri No.

í Satın Alma Tarihi

ì Mü teri Adı ve Adresi

ë Bayi Adı ve Adresi

(Lütfen bayi adını ve adresini ka e olarak basın)

revendeur)

Italiano

CERTIFICATO DI GARANZIA

ï Modello

î N° di serie

í Data di acquisto

ì Nome e indirizzo dell acquirente

ë Nome e indirizzo del rivenditore

(Si prega di apporre il timbro con questi dati)

Español

ï

î

í

ì '

ë '

( ,

CERTIFICADO DE GARANTÍA

ï Número de modelo

î Número de serie

í Fecha de adquisición

ì Nombre y dirección del cliente

ë Nombre y dirección del distribudor

(Se ruega poner el sello del distribudor con su

ï

î

í

ì

ë

( ,

nombre y dirección)

Português

CERTIFICADO DE GARANTIA

ï Número do modelo

î Número do série

í Data de compra

ì Nome e morada do cliente

ë Nome e morada do distribuidor

(Por favor, carímbe o nome e morada do

distribuidor)

GWARANCJA

GARANCIA BIZONYLAT

GARANT SERT F KASI

)

)

135

Page 20

English Polski

Object of declaration: Hitachi High Pressure Washer AW150

We declare under our sole responsibility that this product is in conformity with standards or

standardization documents EN60335-1, EN60335-2-79, EN55014-1, EN55014 -2, EN61000-3-2

and EN61000-3-3 in accordance with Directives 2004/108/EC a nd 2006/42/EC. This product

also conforms to RoHS Directive 2011/65/EU.

The European Standards Manager at Hitachi Koki Europe Ltd. is authorized to compile

the technical fi le.

This declaration is applicable to the product a xed CE marking.

EC DECLARATION OF CONFORMITY

Przedmiot deklaracji: Hitachi Myjka wysokoci nieniowa AW150

Oznaj

miamy z cakowit odpowiedzialno ci , e produkt ten jest zgodny ze standardami

lub standardowymi dokumentami EN60335-1, EN60335-2-79, EN55014-1, EN55014-2,

EN61000-3-2 i EN61000-3-3 w zgodzie z Zasadami 2004/108/EC i 2006/42/EC. Ten produkt

spe nia tak e wymagania Dyrektywy RoHS 2011/65/EU.

Mened er Standardów Europejskich w fi rmie Hitachi Koki Europ Ltd. Jest upowa niony

d

o kompilowania pliku technicznego.

To o wiadczenie odnosi si do za czonego produktu z oznaczeniami CE.

Deutsch Magyar

Gegenstand der Erklärung: Hitachi Hochdruckreiniger AW150

Wir erklären mit alleini ger Verantwor tung, dass diese s Produkt den Standards oder

EN60335-1, EN60335-2-79, EN55014-1, EN55014-2, EN61000-3-2 und EN61000-3-3 in

Übereinstimmung mit den Direktiven 2004/108/EG und 2006/42/ EG entspricht. Dieses

Produkt stimmt auch mit der RoHS-Richtlinie 2011/65/EU überein.

Der Manager für

Datei befugt.

Diese Erklärung gilt für Produkte, die die CE-Markierung tragen.

EG-KONFORMITÄTSERKLÄRUNG

europäische Standards bei der Hitachi Koki Europe Ltd. ist zum Verfassen der technischen

Standardisierungsdokumenten

Megfelel ségi nyilatkozat: Hitachi Magasnyomású mosó AW150

Teljes felel sségünk tudatában kijelentjük, hogy ez a termék megfelel az EN60335-1,

EN60335-2-79, EN55014-1, EN55014-2, EN61000-3-2, és EN61000-3-3 szabványoknak

illetve szabványosítási dokumentumoknak, az Európa Tanács 2004/108/EK és 2006/42/

EK Direktíváival összhangban. Ez a termék is megfelel a 2011/65/EU RoHS irányelvnek.

Az Hitachi Koki Europe Ltd. Európai Szabványkezel je fel van hatalmazva a

Jelen nyilatkozat a terméken feltüntetett CE jelzésre vonatkozik.

Français Türkçe

Objet de la déclaration: Hitachi Nettoyeur haute pression AW150

Nous déclarons sous notre seule et entière responsabilité que ce produit est conforme aux

normes ou doc uments de normalisation EN60335-1, EN60335-2-79, EN55014-1, EN55014-2,

EN61000-3-2 et EN61000-3-3 en accord avec les Directives 2004/108/CE et 2006/42/

CE. Ceproduit est aussi conforme à la Directive RoHS 2011/65/EU.

Le responsable des normes européennes d’Hitac hi Koki Europe Ltd. est autorisé à compiler

les données techniques.

Cette déclaration s’applique aux produits désignés CE.

DECLARATION DE CONFORMITE CE

Beyan konusu: Hitachi Basinçli yikama makinesi AW150

Bu ürünün, 2004/108/EC ve 2006/42/EC sayılı Direktifl erine uygun olarak, EN60335-1,

EN60335 -2-79, EN55014-1, EN55014-2, EN61000-3-2 ve EN61000-3-3 sayılı stand artlar a

ve standardizasyon belgelerine uygun olduåunu, tamamen kendi sorumluluåumuz altında

beyan ederiz. Bu ürün, ayrıca RoHS Yönergesi 2011/65/EU’ya uygundur.

Hitachi Koki Europe Ltd. Avrupa Standartlar Müdürü, teknik dosyayı hazırlama yetkisine sahiptir.

Bu beyan, üzerinde CE i areti bulunan ürünler için geçerlidir.

Italiano

Oggetto della dichiarazione: Hitachi Idropulitrice ad alta pressione AW150

Dichiariamo sotto nostra responsabilità che questo prodotto è conforme agli standard o ai

documenti sulla standardizzazione EN60335-1, EN60335-2-79, EN55014-1, EN55014-2,

EN61000-3-2 e EN61000-3-3 in conformità alle Direttive 2004/108/CE e 2006/42/CE. Il

prodotto è inoltre conforme alla direttiva RoHS 2011/65/EU.

Il Responsabile delle Norme Europee di Hitachi Koki Ltd. è autorizzato a compilare la

scheda tecnica.

Questa dichiarazione è applicabile ai prodotti cui sono applicati i marchi CE.

DICHIARAZIONE DI CONFORMITÀ CE

,

EN60335-1, EN60335-2-79, EN55014-1, EN55014-2, EN61000-3-2 EN61000-3-3

, .

Español Pycc

Objeto de declaración: Hitachi Arandela de alta presión AW150

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramo s bajo nuestra única responsabilidad que este producto está de acuerdo con las

normas o con los documentos de normalización EN60335-1, EN60335-2-79, EN55014-1,

EN55014-2, EN61000-3-2 y EN61000-3-3, según indican las Directrices 2004/108/CE y

2006/42/CE. Este producto satisface también los requisitos establecidos por la Directiva

2011/65/EU (RoHS).

El Jefe de Normas Europeas de Hitachi Koki Europe Ltd. está autorizado para recopilar

archivos técnicos.

Esta declaración se aplica a los productos con marcas de la CE.

,

EN55014-2, EN61000-3-2 EN61000-3-3 2004/108/ 2006/42/ .

.

Ltd. .

Português

Objeto de declaração: Hitachi Anilha de alta pressão AW150

Declaramos,

as normas ou documentos normativos EN60335-1, EN60335-2-79, EN55014-1, EN55014-2,

EN61000-3-2 e EN61000-3-3, em conformidade com as Directrizes 2004/108/CE e 2006/42/

CE. Este produto está também em conformidade com a Directiva RoHS 2011/65/EU.

O Gestor de Normas Europeias da Hitachi Koki Europe Ltd. está autorizado a compilar

o fi chei

Esta declaração se aplica aos produtos designados CE.

DECLARAÇÃO DE CONFORMIDADE CE

sob nossa única e inteira responsabilidade,que este produto está de a cordo com

ro técnico.

Hitachi Koki Europe Ltd.

Clonshaugh Business & Technology Park, Dublin 17, lreland

Representative o ce in Europe

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 Willich 1, F. R. Germany

Head o ce in Japan

Hitachi Koki Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

DEKLARACJA ZGODNO CI Z EC

EK MEGFELEL SÉGI NYILATKOZAT

m szak i fájl elkészítésé re.

AB UYGUNLUK BEYANI

: Hitachi M a AW150

2004/108/EC 2006/42/EC.

2011/65/EU.

Hitachi Koki Europe Ltd.

.

: Hitachi M a AW150

EN6033 5-1, EN60335-2-79, EN55014-1,

2011/65/EU

Hitachi Koki Europe

, .

30. 12. 2012

Mr. John de Loughry

European Standards and

Compliance Manager

30. 12. 2012

F. Tashimo

Vice-President & Director

212

Code No. C99205291

Printed in China

Loading...

Loading...