Page 1

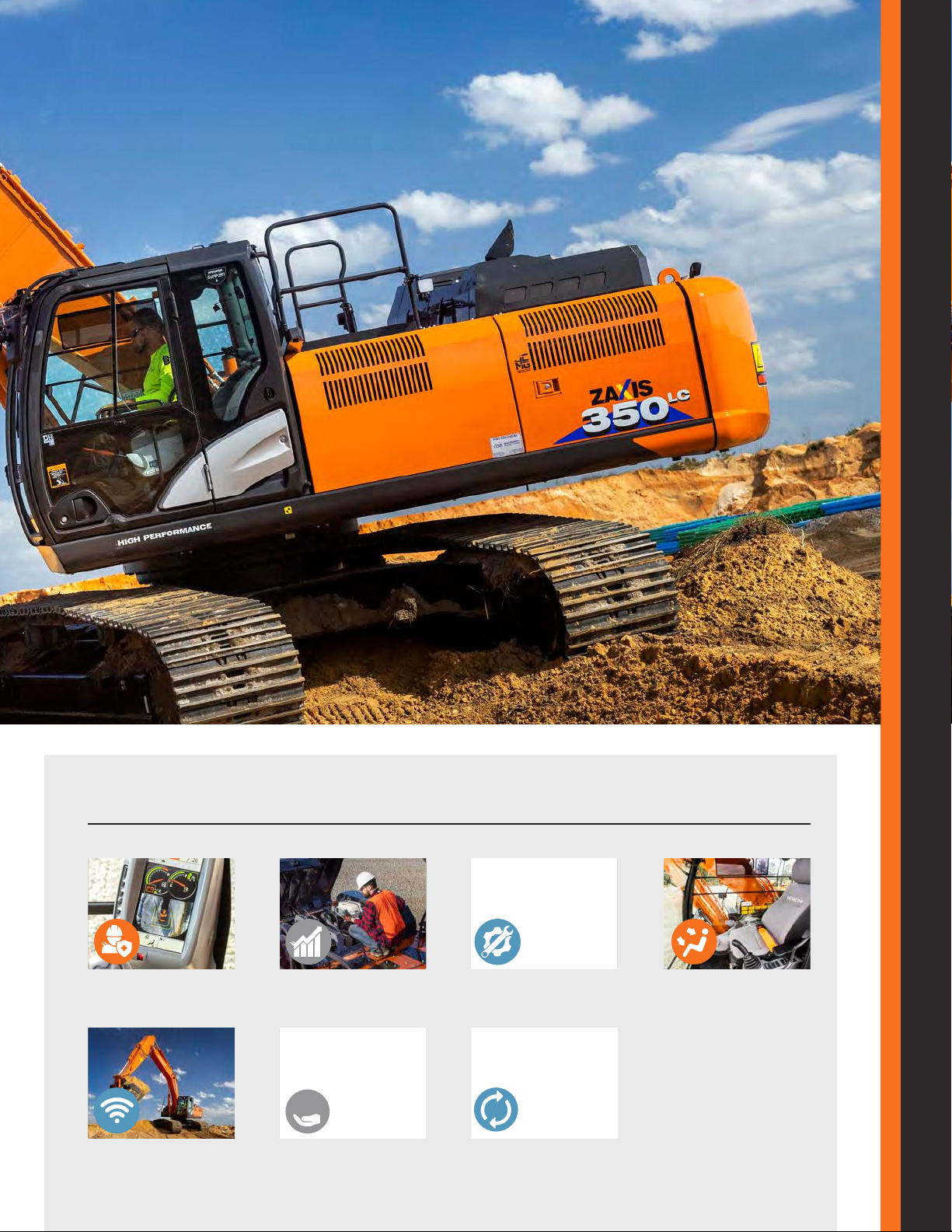

ZAXIS-6 series

ZX250LC-6

ZX300LC-6 HP ZX345USLC-6 HP ZX350LC-6 HP

ZX350LC-6

SPEC SUMMARY

ZX250LC-6 ZX300LC-6 ZX345USLC-6 ZX350LC-6

Operating 59,525 lb. 67,902 lb. 79,146 lb. 80,028 lb.

Weight

(27,000 kg) (30,800 kg) (35,900 kg) (36,300 kg))

Net Power

(ISO 9249)

177 hp (132 kW) 249.4 hp (186 kW) 249.4 hp (186 kW) 270.9 hp (202 kW)

@ 2,000 rpm @ 1,900 rpm @ 1,900 rpm @ 1,900 rpm

Hydraulic Excavator

Page 2

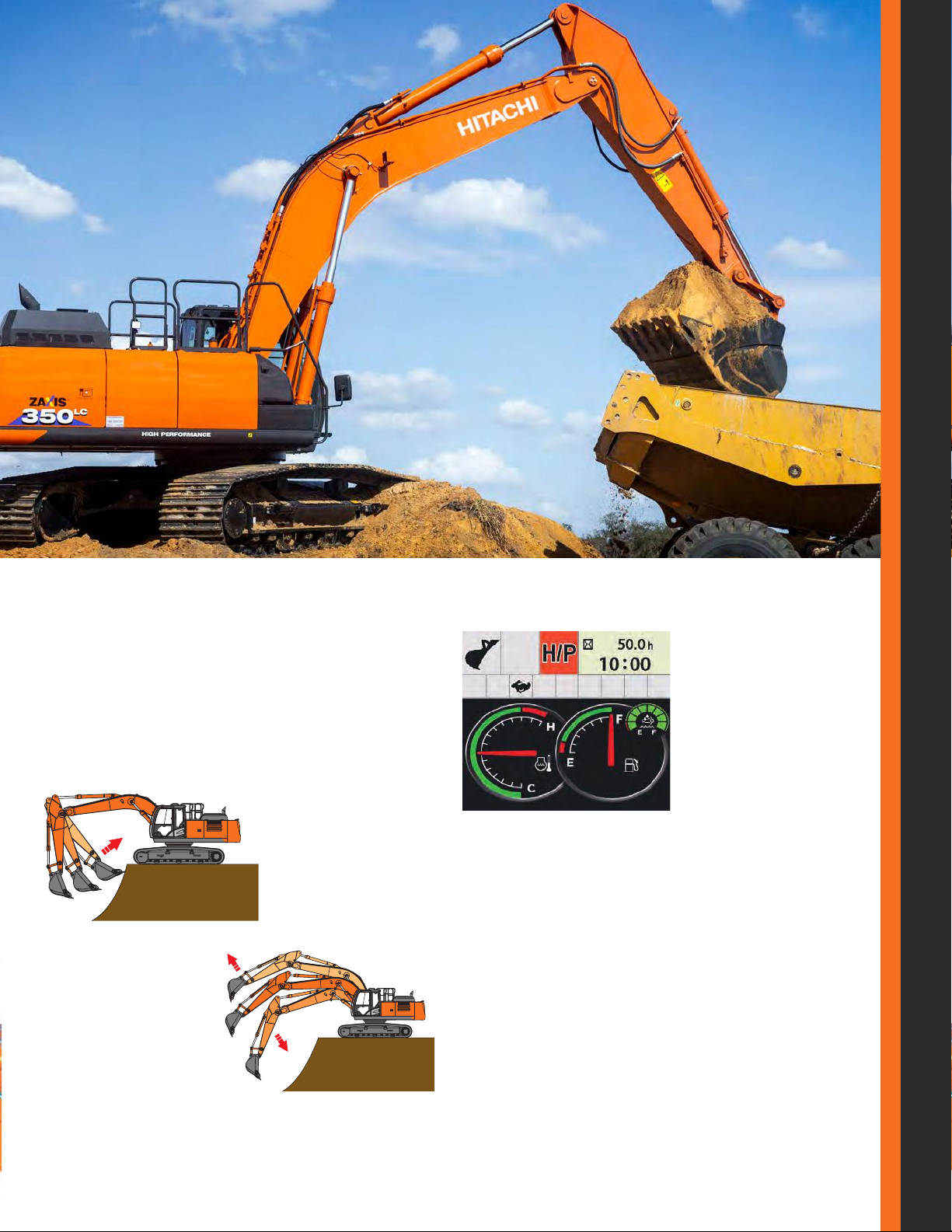

ENGINEERED FOR

ULTIMATE CONTROL

Whether you look at performance, efficiency, or cab comfort, Hitachi’s latest range of excavators was

designed around enhancing the operator experience and maximizing the fleet owner’s bottom line.

We’ve looked closely at the day-to-day challenges you face as the owner of a successful business and have

improved upon the comfort, efficiency and support we offer you over the life of your excavator.

By building the ZAXIS-6 series excavators around your needs, we have given you more control than ever of

your fleet on whatever job site you are on.

2

Page 3

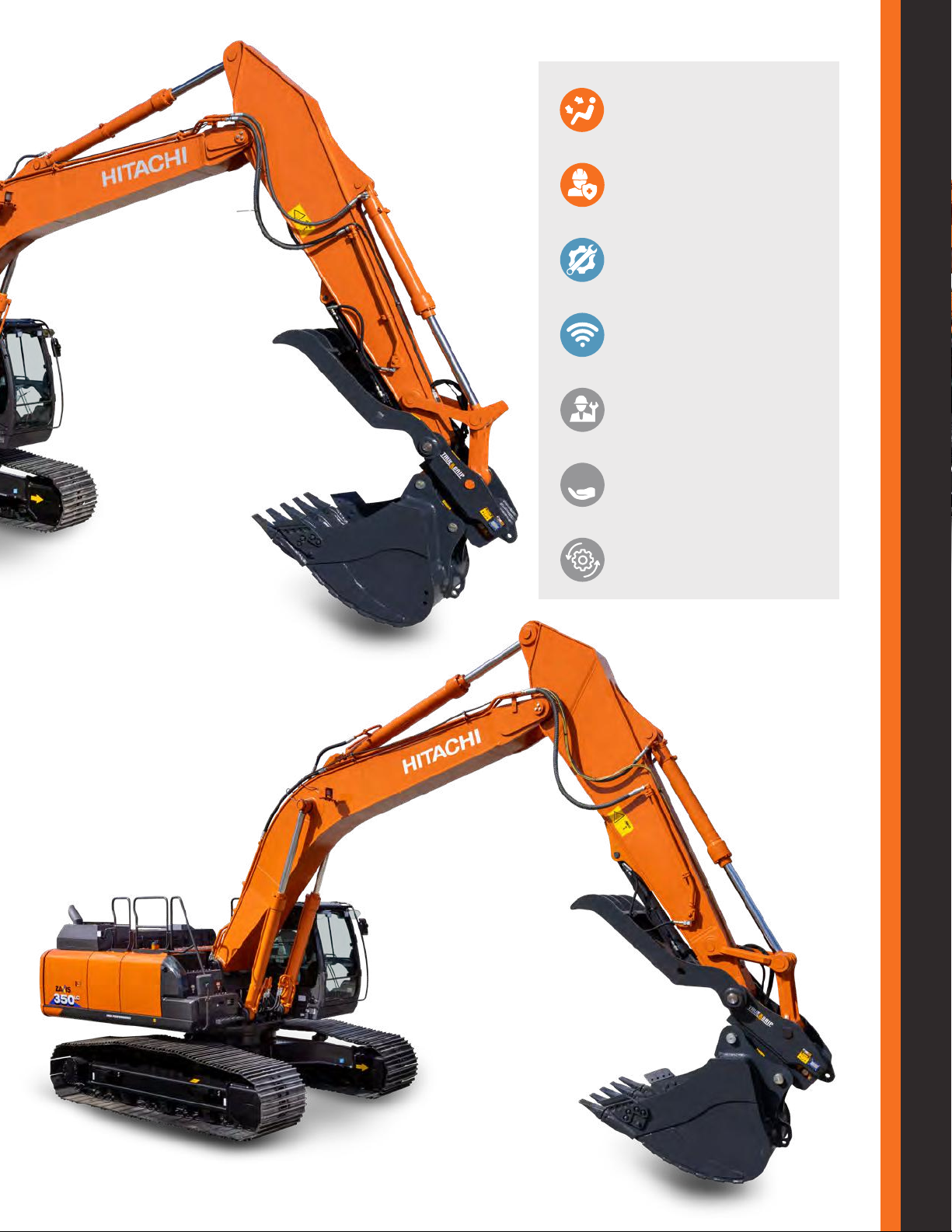

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

CONTENTS

6. Safely under control

8. Boost your uptime

$

10. Performance and fine

control

24 / 7

ZX350LC-6

13. More comfort features

14. Durability comes

standard

16. Reliability is the

backbone of your business

18. Get more from your excavator

3

Page 4

CONTROL YOU

CAN COUNT ON

The new ZAXIS-6 medium-sized excavators with three

working modes (ECO, Power, and High Power) puts you

firmly in control, to have your machine perform how

you need it to, when you need it to. Our excavators

are backed by Hitachi technological expertise and our

current 4-year, 4,000-hour STD warranty. We’ve got

this, and you’re in control.

4

Page 5

A large cab provides a more

comfortable working environment.

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

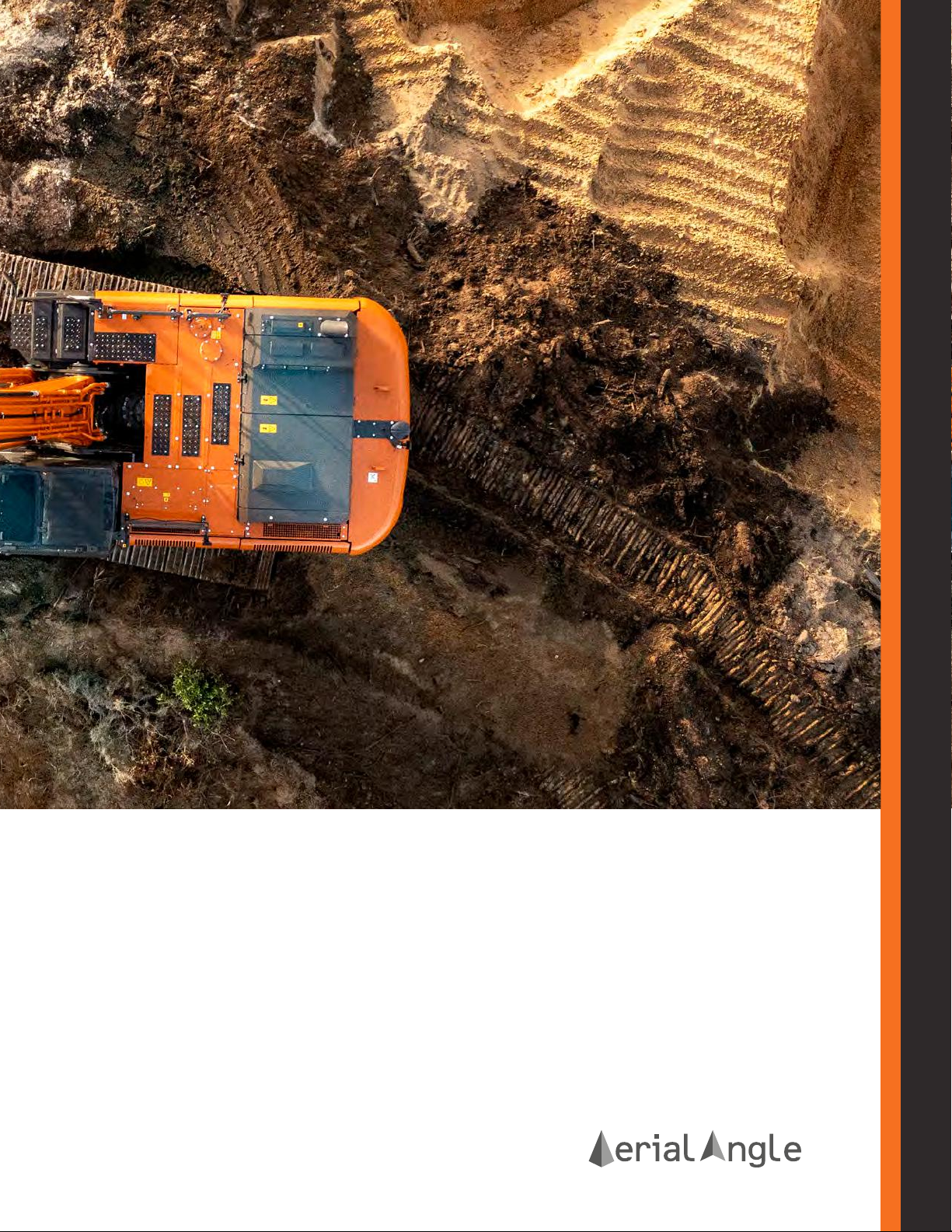

The Aerial Angle

and 7” LCD monitor takes visibility to

a new level.

ConSite OIL sensors monitor oil

quality proactively, easing your mind

so that you can focus on the work

that needs to be done.

The ConSite suite of apps track realtime performance metrics, making it

easy for you to manage your machines'

performance and productivity.

Improved access to components

makes maintenance quick and easy.

The improved TRIAS II hydraulic

system increases hydraulic efficiency

$

while reducing fuel consumption at

the same time.

The new powerful HP mode

improves productivity and reduces

cycle time.

®

camera system

5

Page 6

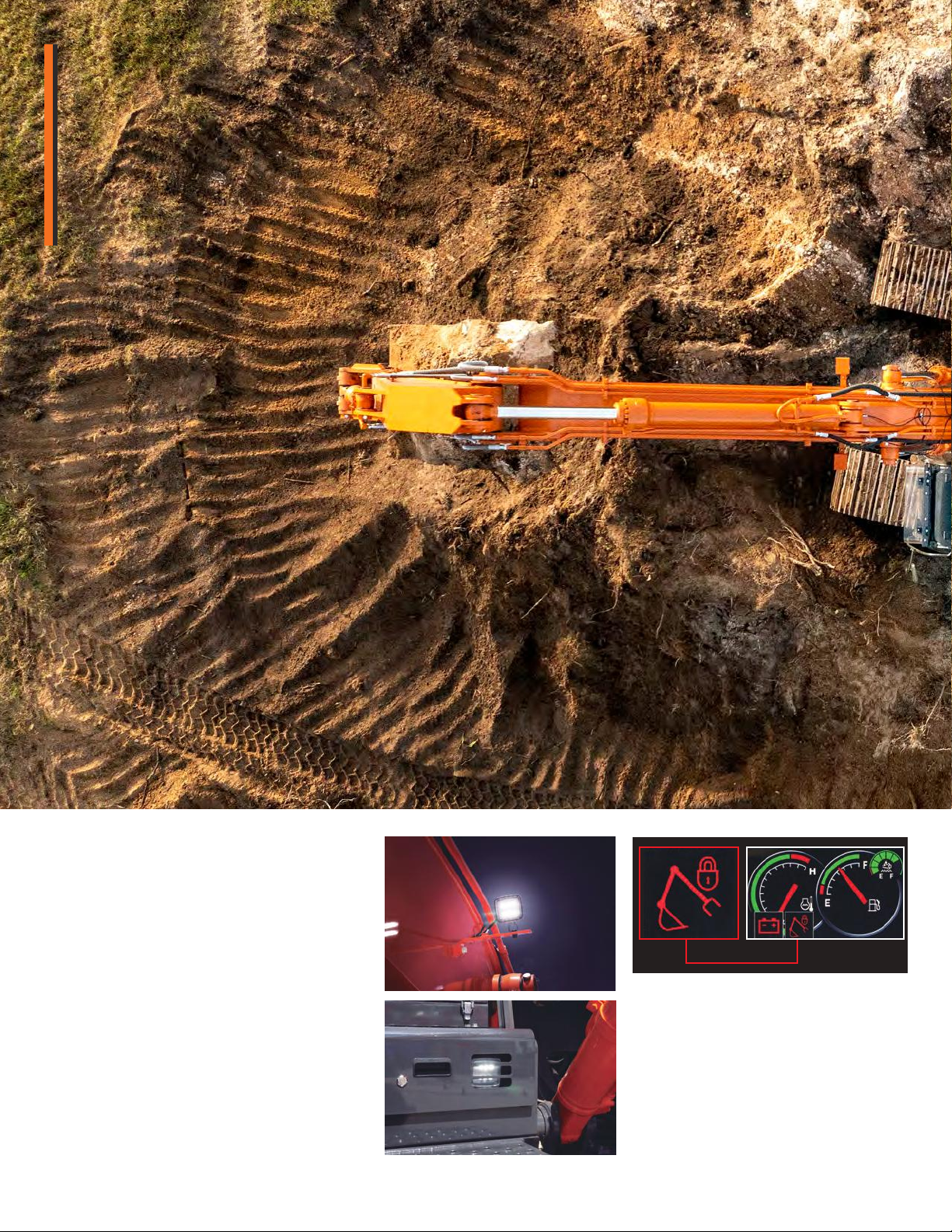

SAFELY UNDER

CONTROL

Safety is vital to everyone on the job site and for the

successful completion of any project. The Hitachi

ZAXIS-6 excavators give you a superior view of your

surroundings.

®

The Aerial Angle

exceptional 270-degree bird’s-eye view of the

surroundings. Three views of the machine’s

immediate environment can be selected, allowing

the operator to choose the view that best suits

the situation.

ZAXIS-6 excavators come standard with an

impressive array of LED work lights, lighting up your

job site at night like never before.

6

camera system allows an

LED working lights improve visibility in

challenging conditions.

Secure operation

Control-lever auto-lock helps prevent

unintentional movement of the front, swing,

travel, and attachment control functions.

When the control-lever auto-lock is engaged,

the icon will be illustrated on the monitor and

an alarm will sound.

The ZX250LC-6, ZX300LC-6, ZX345USLC-6,

and ZX350LC-6 ROPS cabs are pressurized to

help protect operators from dust and debris.

Page 7

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

Choose among different views to suit your jobsite and situation.

ZX350LC-6

Aerial Angle® Camera comes standard

The Aerial Angle® camera system offers

exceptional visibility of the job site. With a

push of the screen changeover button, an

operator can choose to view a combination

of all three cameras, providing a

270-degree view of the excavator; right and

rearview camera view; or left, right, and

rearview cameras separately depending on

what view best fits the work environment

and situation.

The excavator surrounding camera view

is a composite of the images from the

right, left, and rearview cameras, offering

a 270-degree birds-eye view of the

excavator’s immediate environment.

®

7

Page 8

BOOST YOUR

UPTIME

Ease of maintenance

The engine cover opens wide to reveal improved

access to the engine compartment and

components, making maintenance easier.

Conveniently located filters make daily inspections

and maintenance easier.

Grouped maintenance points with easy access.

Auto-Idle

Auto-Idle reduces engine speed when the machine

is not working for 4 seconds.

Auto-shutdown

Shuts down your excavator if left running between

1 to 30 minutes depending on the setting set within

the cab monitor.

ZX300LC-6

8

Page 9

Designed for durability

and easy maintenance,

ZAXIS-6 excavators

increase uptime and

reduce the total cost of

ownership.

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

ZX350LC-6

9

Page 10

PERFORMANCE

AND FINE

CONTROL

Machine representative of

global product. Options

may not be available

in all markets.

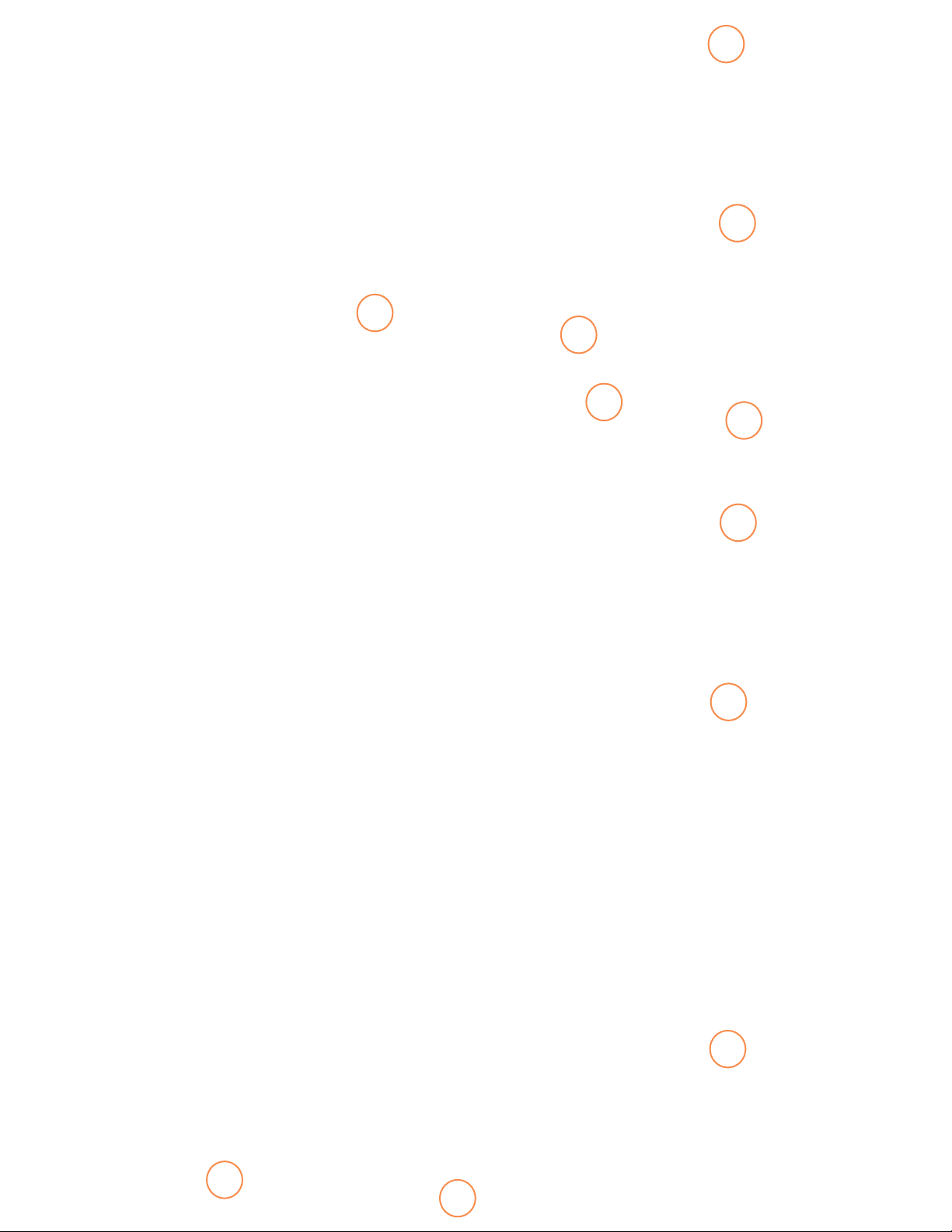

Trias II: Three hydraulic

pump power to the boom,

arm and bucket

The boom and

arm are more

responsive due to

direct oil flow to

each actuator

The pumps are controlled

electronically for improved

efficiency and lower fuel consumption

10

The SCR system injects urea

into exhaust gas (red) to reduce

NOx from emissions

Page 11

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

TRIAS II

The TRIAS II three-pump system ensures that the boom, arm,

and bucket are responsive and extremely hydraulically efficient,

which also results in better fuel efficiency.

Three solenoid valves ensure fine and sensitive front

attachment control.

Arm recirculation cancel system

The system increases arm roll-in speed in low-load conditions.

Boom recirculating system

By recirculating the

pressurized oil in

the bottom of the

boom cylinder when

lowering the boom, the

pressurized oil from the

pump can be efficiently

used by the arm,

increasing arm speed.

Boost system

During arm roll-in and

boom raise operations,

excessive pressurized

oil from the boom rod

flows to the arm cylinder

lower region, providing

responsive arm operation.

ZX350LC-6

H/P (High Power) mode

H/P mode increases

engine speed and pump

output torque when

additional speed and

power are needed during

operation.

Power boost

Power boost enhances

digging force up to 10%,

improving excavating and

lifting performance.

Machine performance

The ZX250LC-6, ZX300LC-6, ZX345USLC-6, and ZX350LC-6 are

equipped with two extra spools in the control valve, easing the

installation attachments that require higher oil demand.

11

Page 12

11

1

2

4

5

6

3

7

8

10

12

9

Page 13

MORE COMFORT

FEATURES

Enhanced comfort controls are at your fingertips

in the refined cab of ZAXIS-6 excavators, giving

you the power to perform with ease.

User-friendly monitor

A large 7-inch LCD monitor allows the operator to check

machine status at a glance in up to 32 languages.

Improved visibility

The optional front guard has been redesigned and improved,

providing the operator with an even better view of the job site.

A comfortable seat

A fully adjustable seat, spacious cab, ergonomic controls, and

advanced music system all contribute to the ultimate working

environment. The addition of an adjustable sun visor reduces

glare on those days when the sun is low in the sky.

Advanced audio system

The AM/FM radio is readily accessible

from the monitor, and an auxiliary

socket for devices such as MP3

players is linked to the sound system.

This choice of entertainment helps to

provide an enjoyable and productive

working environment.

Ease of use

A USB port in the cab enables operators

to charge smartphones and tablets

while they work for added convenience.

Cool, quiet cab

Features have been added to the cab

to make it quieter and to reduce dust

ingress.

ZX350LC-6

Comfortable cab space. ROPS certified CRESV cab.

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

ZX350LC-6

Air conditioning and audio are easily controlled via

1

the monitor.

Low-reflective color 7" LCD monitor is easy to view

2

and navigate.

USB power supply and smartphone holder helps you

3

stay connected.

4

Drink holder is easy to detach for cleaning.

5

Additional joystick controls for effortless operation.

6

Ergonomic design gives you convenient access to controls.

7

Multifunctional control panel makes operation easier.

Improved sound isolation makes this one of the

8

quietest cabs on the market.

User-friendly storage space keeps your workspace tidy

9

and clutter-free.

10

Coat hooks take care of your personal belongings.

11

Optimal pedal layout helps to reduce fatigue.

13

Page 14

DURABILITY

COMES

STANDARD

Enhanced fuel circuit

A high-performance water separator and

cold fuel resistance valve are integrated into

the pre-filter for added protection against

moisture. In addition, a large-capacity

electric fuel pump supplies an appropriate

amount of fuel to the engine for improved

performance.

14

Save fuel

Hydraulic loss is decreased by TRIAS II

technology. It reduces the hydraulic oil

returned to the tank due to the cooperative

control of the pump and valve. This helps to

lower fuel consumption by up to 19% in ECO

mode with the same productivity.

Engine protection

The combustion chamber is made from

stronger materials, and the revised shape

of the piston is designed to achieve cleaner

emissions. These features will further

enhance the reliability of the engine.

Page 15

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

Reinforced Undercarriage

New shape of the lower roller

The lower roller has been redesigned to

further help prevent mud ingress.

• Long-term durability

• Three track guards come standard for a

more durable undercarriage.

Integrated Idler and Adjuster

The front idler and adjuster cylinder

have been integrated in the new ZAXIS-6,

improving their durability.

Due to this integration, the bracket that

had supported the adjuster cylinder is

no longer required, resulting in less mud

buildup.

Reinforced idler bracket with slanted side frame

The side frame of the idler bracket is

slanted on both sides, which enlarges

the cross-sectional area of the external

surface of the idler bracket.

Reinforced undercarriage and increased crossbeam size and strength increase durability.

The design of the idler bracket has

been improved to make it easier to

remove mud.

ZX350LC-6

15

Page 16

RELIABILITY IS

THE BACKBONE OF

YOUR BUSINESS

Easy maintenance

The engine cover can be conveniently

opened fully from the platform. This

provides easy access to the engine

compartment and other components for

routine maintenance.

• Dust screen prevents plugging, providing

increased reliability.

Greater flexibility

Thumb mode is included on the ZX250LC-6,

ZX300LC-6, ZX345USLC-6, and ZX350LC-6.

This and 10 other modes can be registered

on the monitor for easy fitting of

attachments to increase versatility.

Long-lasting visibility

Eight standard LED lights enhance visibility

for the operator, particularly at night. LED

lights use less power, output more light,

and last longer than halogen lights.

Quickly and easily select between multiple

application modes.

ZX350LC-6

Filters within easy reach take just minutes to maintain.

16

Page 17

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

ZX350LC-6

17

Page 18

GET MORE FROM

YOUR EXCAVATOR

The new high-performance features set the ZX300LC-6, ZX345USLC-6, and ZX350LC-6 HP apart.

Lower emissions

The after-treatment device consists of

a diesel oxidation catalyst (DOC), urea

mixing pipe, SCR system, and silencer.

This advanced technology helps to reduce

emissions and noise levels.

Engine aftertreatment device

Consisting of a DOC, a urea water mixing pipe,

a SCR catalyst, and a silencer.

Urea SCR system without DPF reduces NOx

Tier 4 Final is currently achieved by using a

combination of urea SCR (Selective Catalytic

Reduction) and DOC (Diesel Oxidation

Catalyst). The DOC is basically maintenancefree. The amount of urea water is roughly

2% to 3% of the total fuel amount. Easy

maintenance without a DPF.

Checking DEF

fluid level through

Multi-function

monitor.

Easy-access DEF tank

Reliable Isuzu engine

Isuzu engines provide the reliability of

5+ years on-site experience in the North

American market.

ConSite OIL

ConSite OIL monitors the oil condition to

help ease your mind so that you can focus

on the work at hand.

• The oil-monitoring sensor attached to the

engine and hydraulic equipment monitors

the oil status of each operating machine.

Remote monitoring

Global e-Service allows for remote

monitoring of your fleet, providing useful

excavator data to enhance productivity and

minimize downtime. Improve performance

and maximize the efficiency of your

excavator using the Global e-Service online

management tool available 24/7 online.

18

Page 19

ZX250LC-6 | ZX300LC-6 | ZX345USLC-6 | ZX350LC-6

ZX300LC-6

ZX345USLC-6

19

Page 20

ZX250LC-6 SPECIFICATIONS

ENGINE

Model ............................ Isuzu 4HK1

Type .............................. 4-cycle water-cooled, common rail direct injection

Aspiration ......................

Aftertreatment ............... DOC and SCR system

No. of cylinders ............. 4

Rated power

ISO 14396: 2002 Gross 188 hp (140 kW) at 2,000 rpm

ISO 9249: 2007 Net ..... 177 hp (132 kW) at 2,000 rpm

Maximum torque ........... 499 lbf-ft (676 Nm) at 1,800 rpm

Piston displacement ...... 317 cu. in. (5.19L)

Bore and stroke ............ 4.5" x 4.7" (115 mm x 125 mm)

Batteries ........................ 2 x 12 V/126 Ah

Variable geometry turbocharged, intercooled,

cooled EGR

HYDRAULIC SYSTEM

Hydraulic Pumps

Main pumps .................. 3 variable displacement axial piston pumps

Maximum oil flow ........ 1 x 52.8 gal/m (1 x 200 L/min)

Pilot pump .................... 2 x 59.2 gal/m (2 x 224 L/min)

Maximum oil flow ........ 1 gear pump

Maximum oil flow 9.4 gal/m (35.5 L/min)

Hydraulic Motors

Travel ............................ 2 variable displacement axial piston motors

Swing ............................ 1 axial piston motor

Relief Valve Settings

Implement circuit ........... 4,975 psi (34.3MPa)

Swing circuit .................. 4,830 psi (32.4MPa)

Travel circuit .................. 4,975 psi (34.3MPa)

Pilot circuit .................... 566 psi (3.9MPa)

Power boost ................. 5,511 psi (38.0MPa)

Hydraulic Cylinders

Quantity Bore Rod diameter

Boom 2 4.9" (125) 3.5" (90)

Arm 1 5.5" (140) 3.9" (100)

Bucket 1 5.1" (130) 3.5" (90)

Unit: in (mm)

UPPERSTRUCTURE

Revolving Frame

D-section frame for resistance to deformation.

Swing Device

Axial piston motor with planetary reduction gear is bathed in oil.

Swing circle is single-row. Swing parking brake is spring-set/hydraulic-released

disc type.

Swing speed .................

Swing torque .................

11.0 rpm

57,161 lbf-ft (77.5 kNm)

UNDERCARRIAGE

Tracks

Tractor-type undercarriage. Welded track frame using selected materials.

Side frame welded to track frame. Lubricated track rollers, idlers, and

sprockets with floating seals.

Track shoes with triple grousers made of induction-hardened rolled alloy.

Heat-treated connecting pins with dirt seals. Hydraulic (grease) track

adjusters with shock-absorbing recoil springs.

Numbers of Rollers and Shoes on Each Side

Upper rollers ........... 2

Lower rollers ........... 9

Track shoes ............. 51

Track guards ........... 3

Travel Device

Each track driven by 2-speed axial piston motor.

Parking brake is spring-set/hydraulic-released disc type.

Automatic transmission system: High-Low.

Travel speeds ...........

Maximum traction

force ........................

Gradeability .............. 70% (35 degree) continuous

High: 0 to 3.4 mph (0 to 5.5 km/h)

Low: 0 to 2.2 mph (0 to 3.4 km/h)

49,908 lbf (222 kN)

ENVIRONMENT

Engine Emissions ......................... EPA Final Tier 4 / EU Stage IV

SOUND LEVEL

Sound level in cab according

to ISO 6396: 2008 .......................

External sound level according

to ISO 6395: 2008 and

EU Directive 2000/14/EC .............

*At PWR mode

*LpA 67 dB(A)

*LwA 102 dB(A)

SERVICE REFILL CAPACITIES

Fuel tank ............................................. 135 (510)

Engine coolant .................................... 9 (34)

Engine oil ........................................... 7 (26)

Swing device ....................................... 2.4 (9.1)

Travel device (each side) ...................... 2.1 (7.8)

Hydraulic system ................................. 77 (290)

Hydraulic oil tank ................................. 41 (156)

®

DEF/AdBlue

tank ............................... 18 (70)

Unit: gal (L)

20

Page 21

WEIGHTS AND GROUND PRESSURE

Operating Weight and Ground Pressure

Shoe type

Triple grouser shoes 32" (800) 59,525 (27,000) 5.8 (40)

* Including 1.31 yd3 (1.0 m3) (ISO 7451: 2007 heaped) bucket Weight 1,878 lb (852 kg) and counterweight 13,669 lb (6,200 kg).

Shoe width

Unit: in (mm)

Operating weight

Unit: lb (kg)

Ground pressure

Unit: psi (kPa)

BASIC MACHINE WEIGHT AND COMPONENTS WEIGHT

Basic Machine Weight and Overall Width

Excluding front end attachment, fuel, hydraulic oil and coolant, etc. Including counterweight.

ZX250LC-6

Shoe type

Triple grouser shoes 32" (800) 47,619 (21,600) 11' 1" (3,390)

Shoe width

Unit: in (mm)

Weight

Unit: lb (kg)

Overall width

Unit: ft-in (mm)

Components Weight

Counterweight 13,669 (6,200)

Boom (with arm cylinder and boom cylinder) 5,979 (2,712)

Arm 11' 10" (3.61 m) (with bucket cylinder) 3,188 (1,446)

3

Bucket ISO 7451: 2007 1.31 yd

. (1.0 m3) 1,878 (852)

BUCKET AND ARM DIGGING FORCE

Arm length 11' 10" (3.61 m)

Arm crowd force* (ISO 6015: 2006) 25,628 (114)

Bucket digging force* (ISO 6015: 2006) 42,264 (188)

* At power boost

Unit: lb (kg)

Unit: lbf (kN)

21

Page 22

ZX250LC-6 SPECIFICATIONS

DIMENSIONS

K

E

NF

M

D/D'

G

L

I

H

J

Distance between tumblers 12' 4" (3,840)

A

Undercarriage length 15' 3" (4,640)

B

Counterweight clearance 3' 5" (1,050)

C*

Rear-end swing radius 10' 4" (3,140)

D

Rear-end length 10' 4" (3,140)

D'

Overall width of upperstructure 9' 5" (2,870)

E

Overall height of cab 9' 11" (3,010)

F

Min. ground clearance 1' 6" (460)

G*

Track gauge 8' 6" (2,590)

H

Track shoe width 32" (800)

I

Undercarriage width 11' 1" (3,390)

J

Overall width 11' 1" (3,390)

K

Track height with triple grouser shoes 3' (920)

L*

Overall length with arm 11' 10 " (3.61 m) 34' 2" (10,400)

M

Overall height of boom with arm 11' 10 " (3.61 m) 10' 11" (3,320)

N

C

A

B

Unit: ft-in (mm)

ZX250LC-6

* Excluding track shoe lug

22

Page 23

WORKING RANGES

ft (m)

40' (12)

35' (10.5)

30' (9.0)

25' (7.5)

20' (6.0)

15' (4.5)

10' (3.0)

5' (1.5)

ZX250LC-6

E

C

D

0' (0)

5' (1.5)

10' (3.0)

B B'

F

15' (4.5)

20' (6.0)

25' (7.5)

8' (2.44 m)

30' (9.0)

A'

20'

(6.0)

A

15'

10'

5'

(4.5)

(3.0)

(1.5)

0'

(0)

(m)

ZX250LC-6

35' (10.5)

55'

40'

35'

30'

(13.5)

(12)

(10.5)

(9.0)

25'

(7.5)

Arm length 11' 10" (3.61 m)

Max. digging reach 35' 10" (10,910)

A

Max. digging reach (on ground) 35' 3" (10,750)

A'

Max. digging depth 25' (7,610)

B

Max. digging depth for 8' (2.44 m) level 24' 5" (7,440)

B'

Max. cutting height 34' 8" (10,560)

C

Max. dumping height 24' 10" (7,580)

D

Min. swing radius 11' 3" (3,430)

E

Max. vertical wall digging depth 22' 1" (6,740)

F

Ground Line

11' 10" (3.61 m)

ft

Unit: ft-in (mm)

Excluding track shoe lug

23

Page 24

ZX250LC-6 SPECIFICATIONS

ZX250LC-6 MACHINE CAPACITIES

Boldface type indicates hydraulically limited capacity; lightface type indicates stability

limited capacities, in lb (kg). All machine capacities are based on ISO 10567 (with power

boost). Ratings at bucket lift hook; Machine equipped with standard counterweight and

standard gauge; and situated on firm, uniform supporting surface. Total load includes

weight of cables, hook, etc. Figures do not exceed 87 percent of hydraulic capacities or

75 percent of weight needed to tip machine.

ZX250LC-6

Conditions

Boom 19' 8" H

(6.0 m H)

Arm 11' 10"

(3.61 m)

Bucket 1,878 lb

(852 kg)

Counterweight

13,669 lb (6,200 kg)

Triple grouser shoes

32" (800 mm)

Load point

height

ft (m)

25' (7.5 m)

20' (6.0 m)

15' (4.5 m)

10' (3.0 m)

5' (1.5 m)

0 (Ground)

-5' (-1.5 m)

-10' (-3.0 m)

-15' (-4.5 m)

-20' (-6.0 m)

5' (1.5 m) 10' (3.0 m) 15' (4.5 m) 20' (6.0 m) 25' (7.5 m) 30' (9.0 m)

10,090

(4,570)

18,380

(8,330)

28,920

(13,110)

10,090

(4,570)

18,380

(8,330)

28,920

(13,110)

28,720

(13,020)

10,680

(4,84 0)

17,850

(8,090)

28,040

(12,710)

32,950

(14,940)

28,720

(13,020)

10,680

(4,84 0)

17,850

(8,090)

28,040

(12,710)

32,950

(14,940)

A

B

C

Rating over-front Rating over-side or 360 degrees Unit: lb (kg)

Load radius

17,560

(7,960)

22,580

10240

25,73 0

(11, 6 70 )

26,710

(12 ,110)

25,800

(11, 70 0)

22,660

(10,270)

17,560

(7,960)

21,710

(9,840)

20,670

(9,370)

20,260

(9,180)

20,290

(9,200)

20,690

(9,380)

9,330

(4,230)

11,030

(5,000)

13,500

(6,120)

16,090

(7,290)

18,090

(8,200)

19,050

(8,640)

18,670

(8,460)

16,190

(7,340)

9,330

(4,230)

11,030

(5,000)

13,500

(6,120)

10,140

(4,590)

9,720

(4,400)

9,380

(4,250)

9,180

(4,160)

9,210

(4,170)

8,410

(3,810)

10,240

(4,640)

11,530

(5,220)

12,930

(5,860)

14,080

(6,380)

14,520

(6,580)

13,950

(6,320)

A: Load radius

B: Load point height

C: Machine capacity

8,410

(3,810)

10,240

(4,640)

10,140

(4,590)

9,720

(4,400)

9,380

(4,250)

9,180

(4,160)

9,210

(4,170)

7,130

(3,230)

8,430

(3,820)

7,710

(3,490)

7,130

(3,230)

7,100

(3,220)

6,940

(3,140)

24

Page 25

ZX250LC-6

ZX250LC-6 EQUIPMENT

ENGINE

Aftertreatment device

Air cleaner double filters

Alternator 50 A

Auto idle system

Auto shut-down control

Cartridge-type engine oil filter

Cartridge-type fuel main filter

Cold fuel resistence valve

ConSite OIL (sensor)*

DEF/AdBlue® tank inlet strainer and

extension filler

DEF/AdBlue® tank

Dry-type air filter with evacuator valve

(with air filter restriction indicator)

Dust-proof indoor net

ECO/PWR/HP mode control

Electrical fuel feed pump

Engine oil drain coupler

Expansion tank

Fan guard

Fuel cooler

Fuel pre-filter with water separator

Isolation-mounted engine

Radiator, oil cooler and intercooler

HYDRAULIC SYSTEM

Auto power lift

ConSite OIL (sensor)*

Control valve with main relief valve

High mesh full flow filter

Pilot filter

Power boost

Suction filter

Swing dampener valve

Two extra ports for control valve

Variable relief valve for crusher

Work mode selector

* Engine oil and hydraulic oil monitoring sensor.

ZX250 LC-6

ZX250 LC-6

CAB

All-weather sound suppressed steel cab

AM-FM radio

Ashtray

Auto control air conditioner

AUX function lever (Attachment)

AUX terminal and storage

Cigarette lighter 24 V

CRES V (Center pillar reinforced

structure) cab

Drink holder with hot & cool function

Electric double horn

Engine shut-off switch

Equipped with reinforced, tinted

(green color) glass windows

Evacuation hammer

Floor mat

Footrest

Front window washer

Glove compartment

Hot and cool box

Intermittent windshield wipers

Key cylinder light

Lever auto locking function

Motion alarm with cancel switch (conforms

to SAE J994: 2014)

OPG top guard Level I (ISO 10262: 1998)

compliant cab

Pilot control shut-off lever

Power outlet 12 V

Rain guard (without OPG front guard)

Retractable seat belt 3 in.

ROPS (ISO 12117-2: 2008 ) compliant cab

Rubber radio antenna

Seat: air suspension seat with heater

Seat adjustment part: backrest, armrest,

height and angle, slide forward/back

Short wrist control levers

Sun visor (multi-use front or side and

rear window)

Transparent roof with slide curtain

USB power supply

Windows on front, upper, lower and left side

can be opened

2 speakers

4 fluid-filled elastic mounts

ZX250 LC-6

: Standard equipment : Optional equipment

MONITOR SYSTEM

Alarms: overheat, engine warning, engine

oil pressure, alternator, minimum fuel level,

hydraulic filter restriction, air filter restriction,

work mode, SCR system trouble, etc.

Alarm buzzers: overheat, engine oil

pressure, SCR system trouble, etc.

Display of meters: water temperature, hour,

fuel rate, clock, DEF/AdBlue® rate, etc.

Other displays: work mode, auto-idle, glow,

rearview monitor, operating conditions, etc.

32-language selection

LIGHTS

Additional boom LED light with cover

Additional cab roof front LED lights

LED lights for camera (side and rear

view camera)

2 working LED lights

UPPERSTRUCTURE

AERIAL ANGLE® (270-degree view

camera system)

Batteries 2 x 126 Ah

Battery disconnect switch

Body top handrail

Counterweight 13,669 lbs. (6,200 kg)

Fuel level float

Hydraulic oil level gauge

Lockable fuel refilling cap

Lockable machine covers

Platform handrail

Rearview mirror (right and left)

Skid-resistant plates and handrails

Swing parking brake

Undercover

Utility space

ZX250 LC-6

ZX250 LC-6

ZX250 LC-6

25

Page 26

ZX250LC-6 EQUIPMENT

-6

UNDERCARRIAGE

Bolt-on sprocket

Reinforced track links with pin seals

Shoe: 32" (800 mm) triple grouser

Travel direction mark on track frame

Travel motor covers

Travel parking brake

Upper and lower rollers

3 track guards (each side) and hydraulic

track adjuster

4 tie down brackets

FRONT ATTACHMENTS

Arm 11' 10" (3.61 m)

Boom 19' 8" H (6.0 m H)

Casted bucket link A

Centralized lubrication system

Dirt seal on all bucket pins

Flanged pin

HN bushing

Reinforced bucket link B

Reinforced resin thrust plate

WC (tungsten-carbide) thermal spraying

ZX250 LC

ZX250 LC

-6

: Standard equipment : Optional equipment

ATTACHMENTS

Attachment basic piping

Breaker and crusher piping

MISCELLANEOUS

ConSite

Global e-Service

Onboard information controller

Standard tool kit

ZX250 LC-6

ZX250 LC-6

Standard and optional equipment may vary by country, so please consult your

Hitachi dealer for details.

Net engine power is with standard equipment including air cleaner, exhaust system,

alternator and cooling fan, at test conditions specified per ISO 9249: 2007. No

derating is required up to 6,600 ft. (2,000 m) altitude.

26

Specifications and design subject to change without notice. Wherever applicable,

specifications are in accordance with SAE standards. Except where otherwise noted,

these specifications are based on units with 11' 10" (3.61 m) Arms; 44" (1,130 mm),

1,878 lb (852kg) buckets; 13,669 lb (6,200 kg) counterweights; full fuel tanks; 165 lb

(75 kg) operators; and a ZX250LC-6 unit with 32" (800 mm) triple grouser shoes.

Page 27

NOTES

ZX250LC-6

27

Page 28

ZX300LC-6 SPECIFICATIONS

ENGINE

Model ............................ Isuzu 6HK1

Type .............................. 4-cycle water-cooled, common rail direct injection

Aspiration ......................

Aftertreatment ............... DOC and SCR system

No. of cylinders ............. 6

Rated power

ISO 14396: 2002 Gross 264 hp (197 kW) at 1,900 rpm

ISO 9249: 2007 Net ..... 249 hp (186 kW) at 1,900 rpm

Maximum torque ........... 774 lbf-ft (1,050 Nm) at 1,500 rpm

Piston displacement ...... 475 cu. in. (7.79L)

Bore and stroke ............ 4.5" x 4.7" (115 mm x 125 mm)

Batteries ........................ 2 x 12 V/135 Ah

Variable geometry turbocharged, intercooled,

cooled EGR

HYDRAULIC SYSTEM

Hydraulic Pumps

Main pumps .................. 3 variable displacement axial piston pumps

Maximum oil flow ........

Pilot pump .................... 1 gear pump

Maximum oil flow ........ 9.6 gal/m (36.4 L/min)

1 x 46.4 gal/m (1 x 211 L/min)

2 x 62.3 gal/m (2 x 236 L/min)

Hydraulic Motors

Travel ............................ 2 variable displacement axial piston motors

Swing ............................ 1 axial piston motor

Relief Valve Settings

Implement circuit ........... 4,975 psi (34.3 MPa)

Swing circuit .................. 4,830 psi (32.4 MPa)

Travel circuit .................. 4,975 psi (34.3 MPa)

Pilot circuit .................... 566 psi (3.9 MPa)

Power boost ................. 5,511 psi (38.0 MPa)

Hydraulic Cylinders

Quantity Bore Rod diameter

Boom 2 5.3" (135) 3.7" (95)

Arm 1 5.9" (150) 4.1" (105)

Bucket 1 5.3" (135) 3.5" (90)

Unit: in (mm)

UPPERSTRUCTURE

Revolving Frame

D-section frame for resistance to deformation.

Swing Device

Axial piston motor with planetary reduction gear is bathed in oil.

Swing circle is single-row. Swing parking brake is spring-set/hydraulic-released

disc type.

Swing speed .................

Swing torque .................

10.3 rpm

66,749 lbf-ft (90.5 kNm)

UNDERCARRIAGE

Tracks

Tractor-type undercarriage. Welded track frame using selected materials.

Side frame welded to track frame. Lubricated track rollers, idlers, and sprockets

with floating seals.

Track shoes with triple grousers made of induction-hardened rolled alloy.

Heat-treated connecting pins with dirt seals. Hydraulic (grease) track adjusters

with shock-absorbing recoil springs.

Numbers of Rollers and Shoes on Each Side

Upper rollers ........... 2

Lower rollers ........... 8

Track shoes ............. 48

Track guards ........... 3

Travel Device

Each track driven by 2-speed axial piston motor.

Parking brake is spring-set/hydraulic-released disc type.

Automatic transmission system: High-Low.

Travel speeds ...........

Maximum traction

force ........................

Gradeability .............. 70% (35 degree) continuous

High: 0 to 3.2 mph (0 to 5.2 km/h)

Low: 0 to 1.9 mph (0 to 3.1 km/h)

55,303 lbf (246 kN)

ENVIRONMENT

Engine Emissions ......................... EPA Final Tier 4 / EU Stage IV

SOUND LEVEL

Sound level in cab according

to ISO 6396: 2008 .......................

External sound level according

to ISO 6395: 2008 and

EU Directive 2000/14/EC .............

*At PWR mode

*LpA 69 dB(A)

*LwA 105 dB(A)

SERVICE REFILL CAPACITIES

Unit: gal (L)

Fuel tank ............................................. 135 (510)

Engine coolant .................................... 13 (48)

Engine oil ........................................... 13 (48)

Swing device ....................................... 3.2 (12)

Travel device (each side) ...................... 2.5 (9.4)

Hydraulic system ................................. 77 (290)

Hydraulic oil tank ................................. 41 (156)

®

DEF/AdBlue

tank ............................... 18 (70)

28

Page 29

WEIGHTS AND GROUND PRESSURE

Operating Weight and Ground Pressure

Shoe type

Triple grouser shoes 32" (800) 67,902 (30,800) 6.2 (43)

* Including 1.63 yd3 (1.25 m3) (ISO 7451: 2007 heaped) bucket weight 2,110 lb (957 kg) and counterweight 12,346 lb (5,600 kg).

Shoe width

Unit: in (mm)

Operating weight

Unit: lb (kg)

Ground pressure

Unit: psi (kPa)

BASIC MACHINE WEIGHT AND COMPONENTS WEIGHT

Basic Machine Weight and Overall Width

Excluding front end attachment, fuel, hydraulic oil and coolant, etc. Including counterweight.

ZX300LC-6

Shoe type

Triple grouser shoes 32" (800) 54,013 (24,500) 11' 1" (3,390)

Shoe width

Unit: in (mm)

Weight

Unit: lb (kg)

Overall width

Unit: ft-in (mm)

Components Weight

Counterweight 12,346 (5,600)

Boom (with arm cylinder and boom cylinder) 6,482 (2,940)

Arm (with bucket cylinder) 12' 4" (3.76 m) 3,457 (1,568)

3

Bucket (ISO 7451: 2007) 1.0 yd

(0.8 m3) 2,110 (957)

BUCKET AND ARM DIGGING FORCE

Arm length 12' 4" (3.76 m)

Arm crowd force* (ISO 6015: 2006) 28,551 (127)

Bucket digging force* (ISO 6015: 2006) 45,411 (202)

* At power boost

Unit: lb (kg)

Unit: lbf (kN)

29

Page 30

ZX300LC-6 SPECIFICATIONS

DIMENSIONS

K

E

NF

M

D/D'

L

I

H

J

Distance between tumblers 13' 3" (4,050)

A

Undercarriage length 16' 2" (4,940)

B

Counterweight clearance 3' 8" (1,130)

C*

Rear-end swing radius 10' 6" (3,210)

D

Rear-end length 10' 8" (3,250)

D'

Overall width of upperstructure 9' 10" (2,990)

E

Overall height of cab 10' 3" (3,120)

F

Min. ground clearance 1' 8" (500)

G*

Track gauge 8' 6" (2,590)

H

Track shoe width 32" (800)

I

Undercarriage width 11' 1" (3,390)

J

Overall width 11' 1" (3,390)

K

Track height with triple grouser shoes 3' 6" (1,070)

L*

Overall length with arm 12' 4" (3.76 m) 35' 2" (10,710)

M

Overall height of boom with arm 12' 4" (3.76 m) 10' 1" (3,380)

N

C

A

B

Unit: ft-in (mm)

ZX300LC-6

* Excluding track shoe lug

30

Page 31

WORKING RANGES

ft (m)

40' (12)

35' (10.5)

30' (9.0)

25' (7.5)

20' (6.0)

15' (4.5)

ZX300LC-6

E

C

10' (3.0)

5' (1.5)

0' (0)

5' (1.5)

10' (3.0)

15' (4.5)

20' (6.0)

25' (7.5)

30' (9.0)

35' (10.5)

B

55'

(13.5)

B'

D

Ground Line

F

8' (2.44 m)

12' 4" (3.76 m)

A'

A

40'

(12)

35'

(10.5)

30'

(9.0)

25'

(7.5)

20'

(6.0)

15'

(4.5)

10'

(3.0)

5'

(1.5)

ft

0'

(m)

(0)

Arm length 12' 4" (3.76 m)

Max. digging reach 37' (11,270)

A

Max. digging reach (on ground) 36' 5" (11,090)

A'

Max. digging depth 25' 10" (7,870)

B

Max. digging depth for 8' (2.44 m) level 25' 4" (7,710)

B'

Max. cutting height 34' 4" (10,470)

C

Max. dumping height 24' 9" (7,540)

D

Min. swing radius 12' 9" (3,890)

E

Max. vertical wall digging depth 23' 2" (7,050)

F

Excluding track shoe lug

Unit: ft-in (mm)

ZX300LC-6

31

Page 32

ZX300LC-6 SPECIFICATIONS

ZX300LC-6 MACHINE CAPACITIES

Boldface type indicates hydraulically limited capacity; lightface type indicates

stabilitylimited capacities, in lb (kg). All machine capacities are based on ISO 10567

(with power boost). Ratings at bucket lift hook; Machine equipped with standard

counterweight and standard gauge; and situated on firm, uniform supporting surface.

Total load includes weight of cables, hook, etc. Figures do not exceed 87 percent of

hydraulic capacities or 75 percent of weight needed to tip machine.

ZX300LC-6

Conditions

Boom 20' 4"

(6.2 m)

Arm 12' 4"

(3.76 m)

Bucket 2,110 lb

(957 kg)

Counterweight

12,346 lb

(5,600 kg)

Triple grouser shoes

32" (800 mm)

Load point

height

ft (m)

25'

(7.5 m)

20'

(6.0 m)

15'

(4.5 m)

10'

(3.0 m)

5'

(1.5 m)

0 (Ground)

-5'

(-1.5 m)

-10'

(-3.0 m)

-15'

(-4.5 m)

-20'

(-6.0 m)

5' (1.5 m) 10' (3.0 m) 15' (4.5 m) 20' (6.0 m) 25' (7.5 m) 30' (9.0 m)

12,570

(5,700)

21,130

(9,580)

31,600

(14,330)

12,570

(5,700)

21,130

(9,580)

31,600

(14,330)

31,2 30

(14 ,16 0)

12,930

(5,860)

20,570

(9,330)

30,940

(14, 03 0)

41,000

(18,5 90)

31,2 30

(14 ,16 0)

12,930

(5,860)

20,570

(9,330)

30,940

(14, 03 0)

41,000

(18,5 90)

A

B

C

Rating over-front Rating over-side or 360 degrees Unit: lb (kg)

Load radius

11,800

(5,350)

22,650

(10,270)

24 ,12 0

(10,940)

32,330

(14, 66 0)

33,340

(15 ,12 0)

32 ,160

(14, 58 0)

28, 470

(12, 910)

20 ,14 0

(9 ,13 0 )

22,650

(10,270)

28,720

(13,020)

22,990

(10,420)

22,550

(10,220)

22,570

(10,230)

22,970

(10,410)

20,140

(9,130)

14,060

(6,370)

17,210

(7,800)

20,390

(9,240)

22,780

(10,330)

23,890

(10,830)

23,440

(10,630)

20,720

(9,390)

14,060

(6,370)

16,380

(7,420)

15,460

(7,010)

14,770

(6,690)

14,400

(6,530)

14,340

(6,500)

14,610

(6,620)

12,890

(5,840)

14,540

(6,590)

16,310

(7,390)

17,580

(7,970)

17,320

(7,850)

17,310

(7,850)

A: Load radius

B: Load point height

C: Machine capacity

11,800

(5,350)

11,790

(5,340)

11,320

(5,130)

10,830

(4,910)

10,430

(4,730)

10,200

(4,620)

10,190

(4,620)

8,450

(3,830)

11,460

(5,190)

13,320

(6,040)

13,100

(5,940)

8,380

(3,800)

8,170

(3,700)

7,930

(3,590)

7,730

(3,500)

32

Page 33

ZX300LC-6

ZX300LC-6 EQUIPMENT

ENGINE

Aftertreatment device

Air cleaner double filters

Alternator 50 A

Auto idle system

Auto shut-down control

Cartridge-type engine oil filter

Cartridge-type fuel main filter

Cold fuel resistence valve

ConSite OIL (sensor)*

DEF/AdBlue® tank inlet strainer and

extension filler

DEF/AdBlue® tank

Dry-type air filter with evacuator valve

(with air filter restriction indicator)

Dust-proof indoor net

ECO/PWR/HP mode control

Electrical fuel feed pump

Engine oil drain coupler

Expansion tank

Fan guard

Fuel cooler

Fuel pre-filter with water separator

Isolation-mounted engine

Radiator, oil cooler and intercooler

HYDRAULIC SYSTEM

Auto power lift

ConSite OIL (sensor)*

Control valve with main relief valve

High mesh full flow filter

Pilot filter

Power boost

Suction filter

Swing dampener valve

Two extra ports for control valve

Variable relief valve for crusher

Work mode selector

* Engine oil and hydraulic oil monitoring sensor.

ZX300 LC-6

ZX300 LC-6

CAB

All-weather sound suppressed steel cab

AM-FM radio

Ashtray

Auto control air conditioner

AUX function lever (Attachment)

AUX terminal and storage

Cigarette lighter 24 V

CRES V (Center pillar reinforced

structure) cab

Drink holder with hot & cool function

Electric double horn

Engine shut-off switch

Equipped with reinforced, tinted

(green color) glass windows

Evacuation hammer

Floor mat

Footrest

Front window washer

Glove compartment

Hot and cool box

Intermittent windshield wipers

Key cylinder light

Lever auto locking function

Motion alarm with cancel switch

(conforms to SAE J994: 2014)

OPG top guard Level I (ISO 10262: 1998)

compliant cab

Pilot control shut-off lever

Power outlet 12 V

Rain guard (without OPG front guard)

Retractable seat belt 3 in.

ROPS (ISO 12117-2: 2008 ) compliant cab

Rubber radio antenna

Seat: air suspension seat with heater

Seat adjustment part: backrest, armrest,

height and angle, slide forward/back

Short wrist control levers

Sun visor (multi-use front or side and

rear window)

Transparent roof with slide curtain

USB power supply

Windows on front, upper, lower and left side

can be opened

2 speakers

4 fluid-filled elastic mounts

ZX300 LC-6

: Standard equipment : Optional equipment

MONITOR SYSTEM

Alarms: overheat, engine warning, engine

oil pressure, alternator, minimum fuel level,

hydraulic filter restriction, air filter restriction,

work mode, SCR system trouble, etc.

Alarm buzzers: overheat, engine oil

pressure, SCR system trouble, etc.

Display of meters: water temperature, hour,

fuel rate, clock, DEF/AdBlue® rate, etc.

Other displays:work mode, auto-idle, glow,

rearview monitor, operating conditions, etc.

32-language selection

LIGHTS

Additional boom LED light with cover

Additional cab roof front LED lights

LED lights for camera (side and rear

view camera)

2 working LED lights

UPPERSTRUCTURE

AERIAL ANGLE® (270-degree view

camera system)

Batteries 2 x 135 Ah

Battery disconnect switch

Body top handrail

Counterweight 12,346 lbs. (5,600 kg)

Fuel level float

Hydraulic oil level gauge

Lockable fuel refilling cap

Lockable machine covers

Lockable tool box

Platform handrail

Rear view mirror (right and left)

Skid-resistant plates and handrails

Swing parking brake

Undercover

Utility space

ZX300 LC-6

ZX300 LC-6

ZX300 LC-6

33

Page 34

ZX300LC-6 EQUIPMENT

: Standard equipment : Optional equipment

UNDERCARRIAGE

Bolt-on sprocket

Reinforced track links with pin seals

Shoe: 32" (800 mm) triple grouser

Travel direction mark on track frame

Travel motor covers

Travel parking brake

Upper and lower rollers

3 track guards (each side) and hydraulic

track adjuster

4 tie down brackets

FRONT ATTACHMENTS

Arm 12' 4" (3.76 m)

Boom 20' 4" (6.2 m)

Casted bucket link A

Centralized lubrication system

Dirt seal on all bucket pins

Flanged pin

HN bushing

Reinforced bucket link B

Reinforced resin thrust plate

WC (tungsten-carbide) thermal spraying

ZX300 LC-6

ZX300 LC-6

ATTACHMENTS

Attachment basic piping

Breaker and crusher piping

MISCELLANEOUS

ConSite

Global e-Service

Onboard information controller

Standard tool kit

ZX300 LC-6

ZX300 LC-6

Standard and optional equipment may vary by country, so please consult your

Hitachi dealer for details.

Net engine power is with standard equipment including air cleaner, exhaust system,

alternator and cooling fan, at test conditions specified per ISO 9249: 2007. No

derating is required up to 6,600 ft. (2,000 m) altitude.

34

Specifications and design subject to change without notice. Wherever applicable,

specifications are in accordance with SAE standards. Except where otherwise noted,

these specifications are based on units with 12' 4" (3.76 m) Arms; 54" (1,360 mm),

2,110 lb (957 kg) buckets; 12,346 lb (5,600 kg) counterweights; full fuel tanks; 165

lb (75 kg) operators; and a ZX300LC-6 unit with 32" (800 mm) triple grouser shoes.

Page 35

NOTES

ZX300LC-6

35

Page 36

ZX345USLC-6 SPECIFICATIONS

ENGINE

Model ............................ Isuzu 6HK1

Type .............................. 4-cycle water-cooled, common rail direct injection

Aspiration ......................

Aftertreatment ............... DOC and SCR system

No. of cylinders ............. 6

Rated power

ISO 14396: 2002 Gross 264 hp (197 kW) at 1,900 rpm

ISO 9249: 2007 Net ..... 249 hp (186 kW) at 1,900 rpm

Maximum torque ........... 774 lbf-ft (1,050 Nm) at 1,500 rpm

Piston displacement ...... 475 cu. in. (7.79 L)

Bore and stroke ............ 4.5" x 4.7" (115 mm x 125 mm)

Batteries ........................ 2 x 12 V/135 Ah

Variable geometry turbocharged, intercooled,

cooled EGR

HYDRAULIC SYSTEM

Hydraulic Pumps

Main pumps .................. 3 variable displacement axial piston pumps

Maximum oil flow ........ 1 x 46.4 gal/m (1 x 211 L/min)

Pilot pump .................... 2 x 62.3 gal/m (2 x 236 L/min)

Maximum oil flow ........ 1 gear pump

Maximum oil flow 9.6 gal/m (36.4 L/min)

Hydraulic Motors

Travel ............................ 2 variable displacement axial piston motors

Swing ............................ 1 axial piston motor

Relief Valve Settings

Implement circuit ........... 4,975 psi (34.3MPa)

Swing circuit .................. 4,830 psi (32.4MPa)

Travel circuit .................. 4,975 psi (34.3MPa)

Pilot circuit .................... 566 psi (3.9MPa)

Power boost ................. 5,511 psi (38.0MPa)

UNDERCARRIAGE

Tracks

Tractor-type undercarriage. Welded track frame using selected materials.

Side frame welded to track frame. Lubricated track rollers, idlers, and

sprockets with floating seals.

Track shoes with triple grousers made of induction-hardened rolled alloy.

Heat-treated connecting pins with dirt seals. Hydraulic (grease) track

adjusters with shock-absorbing recoil springs.

Numbers of Rollers and Shoes on Each Side

Upper rollers ........... 2

Lower rollers ........... 8

Track shoes ............. 48

Track guards ........... 3

Travel Device

Each track driven by 2-speed axial piston motor.

Parking brake is spring-set/hydraulic-released disc type.

Automatic transmission system: High-Low.

Travel speeds ...........

Maximum traction

force ........................

Gradeability .............. 70% (35 degree) continuous

High: 0 to 2.5 mph (0 to 4.1 km/h)

Low: 0 to 1.6 mph (0 to 2.6 km/h)

66,993 lbf (298 kN)

ENVIRONMENT

Engine Emissions ......................... EPA Final Tier 4 / EU Stage IV

Hydraulic Cylinders

Quantity Bore Rod diameter

Boom 2 5.3" (135) 3.9" (100)

Arm 1 5.9" (150) 4.1" (105)

Bucket 1 5.3" (135) 3.5" (90)

Unit: in (mm)

UPPERSTRUCTURE

Revolving Frame

D-section frame for resistance to deformation.

Swing Device

Axial piston motor with planetary reduction gear is bathed in oil.

Swing circle is single-row. Swing parking brake is spring-set/hydraulic-released

disc type.

Swing speed .................

Swing torque .................

36

10.5 rpm

66,749 lbf-ft (90.5 kNm)

SERVICE REFILL CAPACITIES

Fuel tank ............................................. 100 (380)

Engine coolant .................................... 10.8 (41)

Engine oil ........................................... 13 (48)

Swing device ....................................... 3.2 (12)

Travel device (each side) ...................... 2.9 (11)

Hydraulic system ................................. 87 (330)

Hydraulic oil tank ................................. 42 (160)

®

DEF/AdBlue

tank ............................... 4.2 (16)

Unit: gal (L)

Page 37

WEIGHTS AND GROUND PRESSURE

Operating Weight and Ground Pressure

Shoe type Shoe width in (mm) Operating Weight lb (kg) Ground Pressure psi (kPa)

Triple grouser shoes 32" (800) 79,146 (35,900) 7.3 (50)

* Including 1.63 yd3 (1.25 m3) (ISO 7451: 2007 heaped) bucket Weight 2,110 lb (957 kg) and counterweight 12,346 lb (8,680 kg).

BASIC MACHINE WEIGHT AND COMPONENTS WEIGHT

Basic Machine Weight and Overall Width

Excluding front end attachment, fuel, hydraulic oil and coolant, etc. Including counterweight.

Shoe type Shoe width in (mm) Weight lb (kg) Overall width ft-in (mm)

Triple grouser shoes 32" (800) 64,661 (29,330) 11' 1" (3,390)

ZX345USLC-6

Components Weight

Counterweight 19,136 (8,680)

Boom (with arm cylinder and boom cylinder) 6,614 (3,000)

Arm 12' 4" (3.76 m) (with bucket cylinder) 3,448 (1,564)

3

Bucket ISO 7451: 2007 1.63 yd

(1.25 m3) 2,110 (957)

BUCKET AND ARM DIGGING FORCE

Arm length 12' 4" (3.76 m)

Arm crowd force* (ISO 6015: 2006) 28,551 (127)

Bucket digging force* (ISO 6015: 2006) 45,411 (202)

* At power boost

Unit: lb (kg)

Unit: lbf (kN)

37

Page 38

ZX345USLC-6 SPECIFICATIONS

DIMENSIONS

K

E

NF

M

D/D'

G

L

I

H

J

Distance between tumblers 13' 3" (4,050)

A

Undercarriage length 16' 2" (4,940)

B

Counterweight clearance 3' 10" (1,160)

C*

Rear-end swing radius 11' 3" (3,420)

D

Rear-end length 11' 3" (3,420)

D'

Overall width of upperstructure 10' (3,050)

E

Overall height of cab 10' 7" (3,230)

F

Min. ground clearance 1' 8" (500)

G*

Track gauge 8' 6" (2,590)

H

Track shoe width 32" (800)

I

Undercarriage width 11' 1" (3,390)

J

Overall width 11' 1" (3,390)

K

Track height with triple grouser shoes 3' 6" (1,070)

L*

Overall length with arm 12' 4 " (3.76 m) 32' 10" (10,020)

M

Overall height of boom with arm 12' 4 " (3.76 m) 11' 3" (3,420)

N

* Excluding track shoe lug

C

A

B

Unit: ft-in (mm)

ZX345USLC-6

38

Page 39

WORKING RANGES

ft (m)

45' (13.5)

40' (12)

35' (10.5)

30' (9.0)

25' (7.5)

20' (6.0)

ZX345USLC-6

E

C

15' (4.5)

10' (3.0)

5' (1.5)

0' (0)

5' (1.5)

10' (3.0)

15' (4.5)

20' (6.0)

25' (7.5)

30' (9.0)

35' (10.5)

60'

(15)

B B'

D

55'

(13.5)

Ground Line

F

8' (2.44 m)

12' 4" (3.76 m)

A'

A

40'

35'

30'

25'

20'

15'

10'

5'

0'

(12)

(10.5)

(9.0)

(7.5)

(6.0)

(4.5)

(3.0)

(1.5)

ft

(0)

(m)

ZX345USLC-6

Arm length 12' 4" (3.76 m)

Max. digging reach 37' 7" (11,460)

A

Max. digging reach (on ground) 36' 10" (11,220)

A'

Max. digging depth 26' 10" (8,180)

B

Max. digging depth for 8' (2.44 m) level 24' 4" (7,410)

B'

Max. cutting height 38' 4" (11,690)

C

Max. dumping height 28' 5" (8,670)

D

Min. swing radius 11' 3" (3,430)

E

Max. vertical wall digging depth 22' (6,710)

F

Excluding track shoe lug

Unit: ft-in (mm)

39

Page 40

ZX345USLC-6 SPECIFICATIONS

ZX345USLC-6 MACHINE CAPACITIES

Boldface type indicates hydraulically limited capacity; lightface type indicates stability

limited capacities, in lb (kg). All machine capacities are based on ISO 10567 (with power

boost). Ratings at bucket lift hook; Machine equipped with standard counterweight and

standard gauge; and situated on firm, uniform supporting surface. Total load includes

weight of cables, hook, etc.

Figures do not exceed 87 percent of hydraulic capacities or 75 percent of weight

needed to tip machine.

ZX345USLC-6

Conditions

Boom 20' 4"

(6.2 m)

Arm 12' 4"

(3.76 m)

Bucket 2,110 lb

(957 kg)

Counterweight

19,136 lb (8,680 kg)

Triple grouser shoes

32" (800 mm)

Load point

height

ft (m)

25'

(7.5 m)

20'

(6.0 m)

15'

(4.5 m)

10'

(3.0 m)

5'

(1.5 m)

0 (Ground)

-5'

(-1.5 m)

-10'

(-3.0 m)

-15' (-4.5

m)

-20'

(-6.0 m)

5' (1.5 m) 10' (3.0 m) 15' (4.5 m) 20' (6.0 m) 25' (7.5 m) 30' (9.0 m)

14,090

(6,390)

22,660

(10,270)

14,090

(6,390)

22,660

(10,270)

12,730

(5,770)

21,030

(9,530)

31,8 30

(14,430)

37, 8 70

(17,170 )

12,730

(5,770)

21,030

(9,530)

31,8 30

(14,430)

37, 8 70

(17,170 )

A

B

C

Rating over-front Rating over-side or 360 degrees Unit: lb (kg)

Load radius

10,340

(4,690)

20,990

(9,520)

29,640

(13,4 40 )

35,380

(16,040)

37, 610

(17, 0 5 0 )

36,880

(16,720)

33,640

(15,250)

27, 240

(12, 35 0)

20,990

(9,520)

25,330

(11,480)

23,490

(10,650)

22,550

(10,220)

22,550

(10,220)

22,380

(10,150)

22,880

(10,370)

13,640

(6,180)

18,130

(8,220)

21,630

(9,810)

24,730

(11,210)

26,420

(11,980)

26,070

(11,820)

24,740

(11,220)

19,800

(8,980)

13,640

(6,180)

17,090

(7,750)

16,080

(7,290)

15,150

(6,870)

14,500

(6,570)

14,200

(6,440)

14,200

(6,440)

14,550

(6,590)

12,790

(5,800)

15,750

(7,140)

17,670

(8,010)

18,900

(8,570)

18,460

(8,370)

18,240

(8,270)

18,280

(8,290)

A: Load radius

B: Load point height

C: Machine capacity

10,340

(4,690)

12,100

(5,480)

11,690

(5,300)

11,170

(5,060)

10,660

(4,830)

10,270

(4,650)

10,070

(4,560)

10,110

(4,580)

10,580

(4,790)

13,330

(6,040)

14,060

(6,370)

13,840

(6,270)

8,360

(3,790)

8,100

(3,670)

7,840

(3,550)

7,640

(3,460)

40

Page 41

ZX345USLC-6

ZX345USLC-6 EQUIPMENT

ENGINE

Aftertreatment device

Air cleaner double filters

Alternator 50 A

Auto idle system

Auto shut-down control

Cartridge-type engine oil filter

Cartridge-type fuel main filter

Cold fuel resistence valve

ConSite OIL (sensor)*

DEF/AdBlue® tank inlet strainer and

extension filler

DEF/AdBlue® tank

Dry-type air filter with evacuator valve

(with air filter restriction indicator)

Dust-proof indoor net

ECO/PWR/HP mode control

Electrical fuel feed pump

Engine oil drain coupler

Expansion tank

Fan guard

Fuel cooler

Fuel pre-filter with water separator

Isolation-mounted engine

Radiator, oil cooler and intercooler

HYDRAULIC SYSTEM

Auto power lift

ConSite OIL (sensor)*

Control valve with main relief valve

High mesh full flow filter

Pilot filter

Power boost

Suction filter

Swing dampener valve

Two extra ports for control valve

Variable relief valve for crusher

Work mode selector

* Engine oil and hydraulic oil monitoring sensor.

ZX345USLC-6

ZX345USLC-6

CAB

All-weather sound suppressed steel cab

AM-FM radio

Ashtray

Auto control air conditioner

AUX function lever (Attachment)

AUX terminal and storage

Cigarette lighter 24 V

CRES V (Center pillar reinforced

structure) cab

Drink holder with hot & cool function

Electric double horn

Engine shut-off switch

Equipped with reinforced, tinted

(green color) glass windows

Evacuation hammer

Floor mat

Footrest

Front window washer

Glove compartment

Hot and cool box

Intermittent windshield wipers

Key cylinder light

Lever auto locking function

Motion alarm with cancel switch (conforms

to SAE J994: 2014)

OPG top guard Level I (ISO 10262: 1998)

compliant cab

Pilot control shut-off lever

Power outlet 12 V

Rain guard (without OPG front guard)

Retractable seat belt 3 in.

ROPS (ISO 12117-2: 2008 ) compliant cab

Rubber radio antenna

Seat: air suspension seat with heater

Seat adjustment part: backrest, armrest,

height and angle, slide forward/back

Short wrist control levers

Sun visor (multi-use front or side and

rear window)

Transparent roof with slide curtain

USB power supply

Windows on front, upper, lower and left side

can be opened

2 speakers

4 fluid-filled elastic mounts

ZX345USLC-6

: Standard equipment : Optional equipment

MONITOR SYSTEM

Alarms: overheat, engine warning, engine

oil pressure, alternator, minimum fuel level,

hydraulic filter restriction, air filter restriction,

work mode, SCR system trouble, etc.

Alarm buzzers: overheat, engine oil

pressure, SCR system trouble, etc.

Display of meters: water temperature, hour,

fuel rate, clock, DEF/AdBlue® rate, etc.

Other displays: work mode, auto-idle, glow,

rearview monitor, operating conditions, etc.

32-language selection

LIGHTS

Additional boom LED light with cover

Additional cab roof front LED lights

LED lights for camera (side and rear

view camera)

2 working LED lights

UPPERSTRUCTURE

AERIAL ANGLE® (270-degree view

camera system)

Batteries 2 x 126 Ah

Battery disconnect switch

Body top handrail

Counterweight 19,136 lbs.

(8,680 kg)

Fuel level float

Hydraulic oil level gauge

Lockable fuel refilling cap

Lockable machine covers

Lockable tool box

Platform handrail

Rear view mirror (right and left)

Skid-resistant plates and handrails

Swing parking brake

Undercover

Utility space

ZX345USLC-6

ZX345USLC-6

ZX345USLC-6

41

Page 42

ZX345USLC-6 EQUIPMENT

: Standard equipment : Optional equipment

UNDERCARRIAGE

Bolt-on sprocket

Reinforced track links with

pin seals

Shoe: 32" (800 mm) triple grouser

Travel direction mark on track frame

Travel motor covers

Travel parking brake

Upper and lower rollers

3 track guards (each side) and hydraulic

track adjuster

4 tie down brackets

FRONT ATTACHMENTS

Arm 12' 4" (3.76 m)

Boom 20' 4" (6.2 m)

Casted bucket link A

Centralized lubrication system

Dirt seal on all bucket pins

Flanged pin

HN bushing

Reinforced bucket link B

Reinforced resin thrust plate

WC (tungsten-carbide) thermal spraying

ZX345USLC-6

ZX345USLC-6

ATTACHMENTS

Attachment basic piping

Breaker and crusher piping

MISCELLANEOUS

ConSite

Global e-Service

Onboard information controller

Standard tool kit

ZX345USLC-6

ZX345USLC-6

Standard and optional equipment may vary by country, so please consult your

Hitachi dealer for details.

Net engine power is with standard equipment including air cleaner, exhaust system,

alternator and cooling fan, at test conditions specified per ISO 9249: 2007. No

derating is required up to 6,600 ft. (2,000 m) altitude.

42

Specifications and design subject to change without notice. Wherever applicable,

specifications are in accordance with SAE standards. Except where otherwise noted,

these specifications are based on units with 12' 4" (3.76 m) Arms; 54" (1,360 mm),

2,110 lb (957 kg) buckets; 19,136 lb (8,680 kg) counterweights; full fuel tanks; 165 lb

(75 kg) operators; and a ZX345USLC-6 unit with 32" (800 mm) triple grouser shoes.

Page 43

NOTES

ZX345USLC-6

43

Page 44

ZX350LC-6 SPECIFICATIONS

ENGINE

Model ............................ Isuzu 6HK1

Type .............................. 4-cycle water-cooled, common rail direct injection

Aspiration ......................

Aftertreatment ............... DOC and SCR system

No. of cylinders ............. 6

Rated power

ISO 14396: 2002 Gross 282 hp (210 kW) at 1,900 rpm

ISO 9249: 2007 Net ..... 271 hp (202 kW) at 1,900 rpm

Maximum torque ........... 796 lbf-ft (1,080 Nm) at 1,500 rpm

Piston displacement ...... 475 cu. in. (7.79 L)

Bore and stroke ............ 4.5" x 4.7" (115 mm x 125 mm)

Batteries ........................ 2 x 12 V/135 Ah

Variable geometry turbocharged, intercooled,

cooled EGR

HYDRAULIC SYSTEM

Hydraulic Pumps

Main pumps .................. 3 variable displacement axial piston pumps

Maximum oil flow ........ 1 x 68.7 gal/m (1 x 260 L/min)

Pilot pump .................... 2 x 76.1 gal/m (2 x 288 L/min)

Maximum oil flow ........ 1 gear pump

Maximum oil flow 9.6 gal/m (36.4 L/min)

Hydraulic Motors

Travel ............................ 2 variable displacement axial piston motors

Swing ............................ 1 axial piston motor

Relief Valve Settings

Implement circuit ........... 4,975 psi (34.3MPa)

Swing circuit .................. 4,685 psi (32.3MPa)

Travel circuit .................. 4,975 psi (34.3MPa)

Pilot circuit .................... 566 psi (3.9MPa)

Power boost ................. 5,511 psi (38.0MPa)

Hydraulic Cylinders

Quantity Bore Rod diameter

Boom 2 5.7" (145) 3.9" (100)

Arm 1 6.7" (170) 4.5" (115)

Bucket 1 5.5" (140) 3.7" (95)

Unit: in (mm)

UPPERSTRUCTURE

Revolving Frame

D-section frame for resistance to deformation.

Swing Device

Axial piston motor with planetary reduction gear is bathed in oil.

Swing circle is single-row. Swing parking brake is spring-set/hydraulic-released

disc type.

Swing speed .................

Swing torque .................

9.7 rpm

88,500 lbf-ft (120 kNm)

UNDERCARRIAGE

Tracks

Tractor-type undercarriage. Welded track frame using selected materials.

Side frame welded to track frame. Lubricated track rollers, idlers, and

sprockets with floating seals.

Track shoes with triple grousers made of induction-hardened rolled alloy.

Heat-treated connecting pins with dirt seals. Hydraulic (grease) track

adjusters with shock-absorbing recoil springs.

Numbers of Rollers and Shoes on Each Side

Upper rollers ........... 2

Lower rollers ........... 8

Track shoes ............. 48

Track guards ........... 3

Travel Device

Each track driven by 2-speed axial piston motor.

Parking brake is spring-set/hydraulic-released disc type.

Automatic transmission system: High-Low.

Travel speeds ...........

Maximum traction

force ........................

Gradeability .............. 70% (35 degree) continuous

High: 0 to 3.1 mph (0 to 5.0 km/h)

Low: 0 to 2.0 mph (0 to 3.2 km/h)

66,993 lbf (298 kN)

ENVIRONMENT

Engine Emissions ......................... EPA Final Tier 4 / EU Stage IV

SOUND LEVEL

Sound level in cab according

to ISO 6396: 2008 .......................

External sound level according

to ISO 6395: 2008 and

EU Directive 2000/14/EC .............

*At PWR mode

LpA 69 dB(A)

*LwA 105 dB(A)

SERVICE REFILL CAPACITIES

Fuel tank ............................................. 166 (630)

Engine coolant .................................... 12 (45)

Engine oil ........................................... 13 (48)

Swing device ....................................... 4.1 (15.7)

Travel device (each side) ...................... 2.9 (11)

Hydraulic system ................................. 90 (340)

Hydraulic oil tank ................................. 48 (180)

®

DEF/AdBlue

tank ............................... 18 (70)

Unit: gal (L)

44

Page 45

WEIGHTS AND GROUND PRESSURE

Operating Weight and Ground Pressure

Shoe type Shoe width in (mm) Operating Weight lb (kg) Ground Pressure psi (kPa)

Triple grouser shoes 32" (800) 80,028 (36,300) 7.4 (51)

* Including 1.8 yd3 (1.4 m3) (ISO 7451: 2007 heaped) bucket Weight 2,579 lb(1,170 kg) and counterweight 16,755 lb (7,600 kg).

BASIC MACHINE WEIGHT AND COMPONENTS WEIGHT

Basic Machine Weight and Overall Width

Excluding front end attachment, fuel, hydraulic oil and coolant, etc. Including counterweight.

Shoe type Shoe width in (mm) Weight lb (kg) Overall width ft-in (mm)

Triple grouser shoes 32" (800) 61,509 (27,900) 11' 1" (3,390)

ZX350LC-6

Components Weight

Counterweight 16,755 (7,600)

Boom (with arm cylinder and boom cylinder) 8,708 (3,950)

Arm 13' 1" (4.0 m) (with bucket cylinder) 4,932 (2,237)

3

Bucket ISO 7451: 2007 1.8 yd

(1.4 m3) 2,579 (1,170)

BUCKET AND ARM DIGGING FORCE

Arm length 13' 1" (4.0 m)

Arm crowd force* (ISO 6015: 2006) 35,745 (159)

Bucket digging force* (ISO 6015: 2006) 55,303 (246)

* At power boost

Unit: lb (kg)

Unit: lbf (kN)

45

Page 46

ZX350LC-6 SPECIFICATIONS

DIMENSIONS

NF

M

D/D'

G

I

H

L

A

B

J

Distance between tumblers 13' 3" (4,050)

A

Undercarriage length 16' 2" (4,940)

B

Counterweight clearance 4' (1,160)

C*

Rear-end swing radius 11' 10" (3,600)

D

Rear-end length 11' 9" (3,590)

D'

Overall width of upperstructure 9' 10" (2,990)

E

Overall height of cab 10' 4" (3,150)

F

Min. ground clearance 1' 8" (500)

G*

Track gauge 8' 6" (2,590)

H

Track shoe width 32" (800)

I

Undercarriage width 11' 1" (3,390)

J

Overall width 11' 1" (3,390)

K

Track height with triple grouser shoes 3' 6" (1,070)

L*

Overall length with arm 13' 1" (4.0 m) 37' 1" (11,310)

M

Overall height of boom with arm 13' 1 " (4.0 m) 11' 10" (3,600)

N

C

Unit: ft-in (mm)

ZX350LC-6

* Excluding track shoe lug

46

Page 47

WORKING RANGES

ft (m)

ZX350LC-6

40' (12)

35' (10.5)

30' (9.0)

25' (7.5)

20' (6.0)

15' (4.5)

10' (3.0)

5' (1.5)

0' (0)

5' (1.5)

10' (3.0)

15' (4.5)

C

D

B B'

E

Ground Line

F

13' 1" (4.0 m)

20' (6.0)

25' (7.5)

8' (2.44 m)

30' (9.0)

A'

25'

20'

(6.0)

A

15'

10'

(3.0)

5'

(1.5)

ZX350LC-6

(4.5)

35' (10.5)

60'

55'

40'

35'

(15)

(13.5)

(12)

(10.5)

30'

(9.0)

(7.5)

Arm length 13' 1" (4.0 m)

Max. digging reach 38' 11" (11,860)

A

Max. digging reach (on ground) 38' 3" (11,670)

A'

Max. digging depth 26' 10" (8,180)

B

Max. digging depth for 8' (2.44 m) level 26' 5" (8,040)

B'

Max. cutting height 35' 3" (10,750)

C

Max. dumping height 25' (7,630)

D

Min. swing radius 14' 8" (4,470)

E

Max. vertical wall digging depth 23' 10" (7,270)

F

0'

ft

(0)

(m)

Unit: ft-in (mm)

Excluding track shoe lug

47

Page 48

ZX350LC-6 SPECIFICATIONS

ZX350LC-6 MACHINE CAPACITIES

Boldface type indicates hydraulically limited capacity; lightface type indicates stability

limited capacities, in lb (kg). All machine capacities are based on ISO 10567 (with power

boost). Ratings at bucket lift hook; Machine equipped with standard counterweight and

standard gauge; and situated on firm, uniform supporting surface. Total load includes

weight of cables, hook, etc. Figures do not exceed 87 percent of hydraulic capacities or

75 percent of weight needed to tip machine.

ZX350LC-6

Conditions

Boom 21' H

(6.4 m H)

Arm 13' 1"

(4.0 m)

Bucket 2,806 lb

(1,273 kg)

Counterweight

16,755 lb

(7,600 kg)

Triple grouser shoes

32" (800mm)

Load point

height

ft (m)

25'

(7.5 m)

20'

(6.0 m)

15'

(4.5 m)

10'

(3.0 m)

5'

(1.5 m)

0 (Ground)

-5'

(-1.5 m)

-10'

(-3.0 m)

-15'

(-4.5 m)

-20'

(-6.0m)

5' (1.5 m) 10' (3.0 m) 15' (4.5 m) 20' (6.0 m) 25' (7.5 m) 30' (9.0 m)

15,550

(7,050)

25,920

(11,750)

38,450

(17,440)

15,550

(7,050)

25,920

(11,750)

38,450

(17,440)

15,8 00

(7,1 6 0)

25,080

(11, 3 70 )

37, 420

(16,970)

48, 510

(22,000)

33,570

(15,220 )

15,8 00

(7,1 6 0)

25,080

(11, 3 70 )

37, 420

(16,970)

48, 510

(22,000)

33,570

(15,220 )

A

B

C

Rating over-front Rating over-side or 360 degrees Unit: lb (kg)

Load radius

14,430

(6,540)

14,950

(6,780)

16,490

(7,470)

30,080

(13,640)

37,040

(16,8 00)

40,770

(18,4 90)

41,3 40

(18,750 )

39,260

(17, 8 0 0)

34, 210

(15,510)

24 ,15 0

(10,95 0)

30,080

(13,640)

29,100

(13,190)

27,610

(12,520)

27,030

(12,260)

27,050

(12,260)

27,560

(12,500)

24,150

(10,950)

22,430

(10,170)

26,160

(11,860)

28,750

(13,040)

29,650

(13,440)

28,760

(13,040)

25,170

(11,410)

19,920

(9,030)

18,640

(8,450)

17,700

(8,020)

17,980

(8,150)

17,090

(7,750)

17,400

(7,890)

18,570

(8,420)

20,650

(9,360)

20,970

(9,510)

20,600

(9,340)

20,550

(9,320)

17,730

(8,040)

A: Load radius

B: Load point height

C: Machine capacity

14,430

(6,540)

14,950

(6,780)

14,410

(6,530)

13,710

(6,210)

13,010

(5,900)

12,450

(5,640)

12,120

(5,490)

12,070

(5,470)

12,450

(5,640)

10,880

(4,930)

15,340

(6,950)

16,310

(7,390)

15,900

(7,210)

15,570

(7,060)

15,410

(6,980)

10,400

(4,710)

10,200

(4,620)

9,850

(4,460)

9,470

(4,290)

9,160

(4,150)

9,020

(4,090)

48

Page 49

ZX350LC-6

ZX350LC-6 EQUIPMENT

ENGINE

Aftertreatment device

Air cleaner double filters

Alternator 50 A

Auto idle system

Auto shut-down control

Cartridge-type engine oil filter

Cartridge-type fuel main filter

Cold fuel resistence valve

ConSite OIL (sensor)*

DEF/AdBlue® tank inlet strainer and

extension filler

DEF/AdBlue® tank

Dry-type air filter with evacuator valve

(with air filter restriction indicator)

Dust-proof indoor net

ECO/PWR/HP mode control

Electrical fuel feed pump

Engine oil drain coupler

Expansion tank

Fan guard

Fuel cooler

Fuel pre-filter with water separator

Isolation-mounted engine

Radiator, oil cooler and intercooler

HYDRAULIC SYSTEM

Auto power lift

ConSite OIL (sensor)*

Control valve with main relief valve

High mesh full flow filter

Pilot filter

Power boost

Suction filter

Swing dampener valve