Page 1

ZAXIS

-5G

series

HYDRAULIC EXCAVATOR

Model Code : ZX240

ZX250K

Engine Rated Power : 132 kW (177 HP)

Operating Weight : ZX240

ZX250H

ZX250K

Backhoe Bucket : ISO Heaped : 0.80 - 1.40 m

/ ZX240LC

-5G

/ ZX250LCK

-5G

: 23 400 kg / ZX240LC

-5G

: 24 800 kg / ZX250LCH

-5G

: 25 200 kg / ZX250LCK

-5G

/ ZX250H

-5G

-5G

-5G

3

/ ZX250LCH

: 24 000 kg

-5G

: 25 300 kg

-5G

: 25 800 kg

-5G

-5G

Page 2

2

3

A ZAXIS hallmark – industry-leading hydraulic technologies, and performance

no other can beat. New ZAXIS provides reliable solutions: impressive fuel

economy, swift front movements, and easy operation. You'll also find Hitachi

technological prowess and expertise, such as the optimized hydraulic

system and engine.

New ZAXIS features the key benefits of high quality, low fuel

consumption, and high durability, all of which serve to

ensure low running costs.

New ZAXIS, which is empowered by

comprehensive evolution, will realize

customers’ visions and dreams, and

pioneer your colorful future.

· 8% reduction in fuel consumption

· More fuel reduction in the ECO mode

· Swift front movements with HIOS III hydraulics

· Powerful lifting operation

· Boosted swing torque

· Enhanced power boost

· Prestige R&D and quality control

· Durable, reliable engine

· Rock-solid, durable front attachment

· Strengthened undercarriage

· Proven upperstructure

Pursuits of Performance and

Durability

Page 6-7

Hitachi Support Chain

Page 14-15

Various Versions

Page 16-17

More Production with Less Fuel

Page 4-5

Simplifi ed Maintenance

Page 10-11

Key Benefits for Low Running Costs

High

Quality

High

Durability

Low Fuel

Consumption

No Compromise on Operator

Comfort

Page 8-9

Reliable Solutions, with Various

Options

Page 12-13

· Comfortable operating environment

· Comfort-designed operator seat

· Robust cab

· New, easy-to-use multifunction monitor

· Dust-proof indoor net

· Grouped remote inspection points

· Attractive, robust body

· Low life cycle costs

· Varied jobs, varied options

· Recommended options

· Remote fleet management with Global e-Service

· Parts and service

· Heavy-duty version: H-series

· Demolition version: K-series

Note: The ph otos in thi s brochure show exc avators w ith opti onal eq uipme nts such as rear v iew cam era.

Page 3

4

5

More Production with

Less Fuel

8% Reduction in Fuel Consumption

New ZAXIS is a fuel-thrifty excavator that can reduce

fuel consumption by 8%*, compared to the conventional

ZX240-3/ZX240

system and engine control system, thereby reducing CO2

emissions.

*6%, compared to the Z X240/ ZX240

family, thanks to the HIOS III hydraulic

-3F

.

-3G

More Fuel Reduction in the ECO mode

The ECO mode, a new economical mode, can further cut

fuel consumption by 10% compared to the PWR mode,

without sacrificing digging speed by optimal matching of

operations.

Swift Front Movements with HIOS* III Hydraulics

Operating speed increases with less fuel consumption

thanks to the HIOS III hydraulic system, developed by

industry-leading hydraulic technologies and a wealth of

experience. Actuators work quickly by boom weight, without

needing a regenerative circuit and pressure oil.

*Human & Intellige nt Operation Syste m

Rapid Arm Roll-in

Arm roll-in speed increases by combined flow from arm and

boom cylinders through regenerative valves for productive

excavation.

Powerful Lifting Operation

The Auto Power Lift mode, which automatically surge lifting

force by 10% when needed, allows for powerful lifting of

buried concrete pipes or sheathing sheets.

Boosted Swing Torque

Allows for powerful wall cutting with the bucket, and smooth

swing operation on slope.

Enhanced Power Boost

The Power Boost mode allows the operator to surge 10%

more digging force for powerful excavation by pressing its

button on the control lever.

Fast Arm Speed During Boom Lowering

Arm speed increases by boom weight during boom lowering,

without needing pressure oil from a pump. That is, arm circuit

flow is increased for higher arm speed, allowing for quick

loading of a dump truck and positioning of the front.

Page 4

6

7

HN bushing

WC thermal spraying

Reinforced resin thrust plates

X-beam frame

Pursuits of Performance and

Durability

The boom top and foot are reinforced with

thickened high-tensile steel brackets, which

incorporate steel bushings to enhance

durability. Arm cylinder and boom cylinders

(rod extend ends) cushion shocks at stroke

ends to cut noise and extend service life.

Joint pins at the front attachment are tightly

fi t to reduce jolt and sound. The arm-bucket

joint is protected by WC thermal spraying

on its contact surfaces to reduce wear and

jolt. New-type HN bushings, utilized on joint

pins, retain grease inside for longer greasing

intervals. A reinforced resin thrust plate,

mounted on the bucket pin, helps reduce

wearing noise.

Rock-Solid, Durable Front Attachment

The X-beam frame is made monolithically

with fewer welds for higher rigidity and

durability.

Track adjusters absorb impacts to crawlers.

Front idlers and adjuster cylinders are

integrated to increase durability.

Idler brackets and travel motor brackets are

both thickened for added durability.

Strengthened Undercarriage

Th e uppers tructure f rame is rei nfo rced

with the proven D-section skirt to increase

rigidity against damage by obstacles.

The door catch is improved to shut the door

tightly, reducing door rattling.

Proven Upperstructure

Prestige R&D and Quality Control

Hitachi has earned praise for technological prowess and product performance around the world.

R&D Division has a track record – including excellent design,

stress analysis expertise using CAE system, and abundant

production data base. What’s more, a large-scale durability

test fi eld (427 hm2) allows for a series of stringent testing of

new machines.

Production Division strives to automatize production

processes, including robotic welding, machining, painting,

assembling and transferring.

Compu ter-A ided Engineer ing

Main pum p test ing area

Mid-si zed excav ator as sembl y line

Main frame weld ing line Simula tion te sting from

opera tor sea t

This engine has a track record showing

impressive durability at countless tough job

sites around the world.

The engine — associated with a rugged

design, a direct fuel injection system and

an elaborate governor — goes green, and

complies with EU Stage II and US EPA Tier

2 emissions regulations.

The cooling system well keeps the engine

cool. The engine cover has a wider air

suction area, and radiators are arranged

in parallel for effi cient cooling. This parallel

arrangement also facilitates their cleaning.

The ample-capacity intercooler and

turbocharger help yield a whopping 132 kW

(177 HP) output for higher production in

shorter job schedule.

Durable, Reliable Engine

Engine

Radiator

Oil Cooler

Intercooler

Parallel arr angement

Track adjuster

Boom foot

Page 5

8

9

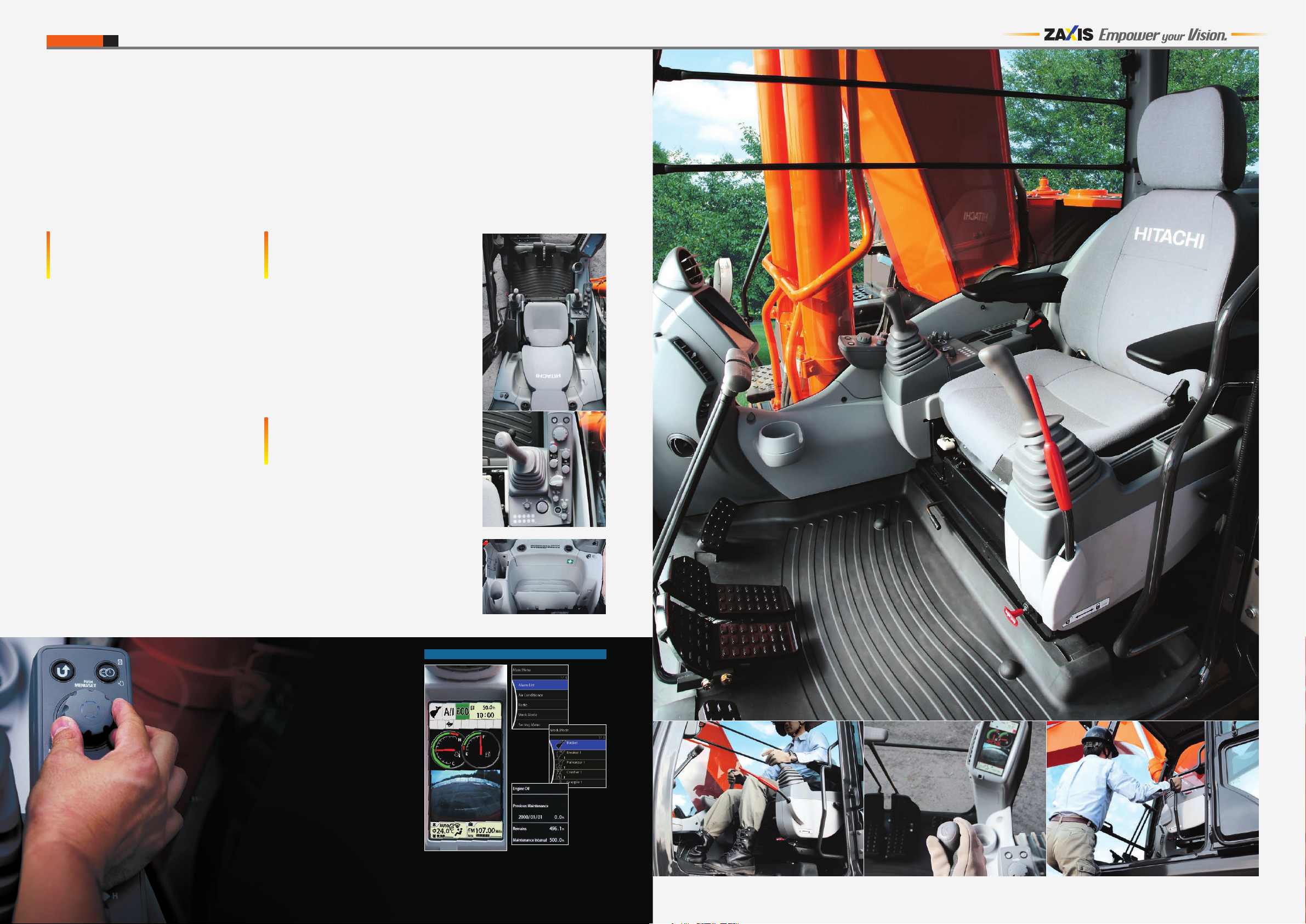

No Compromise on Operator

Comfort

Comfortable Operating Environment

You'll feel comfortable and confident, with

plenty of leg space and excellent visibility

when operating the cab. The new compact

console gives more leg space. The new

door pillar is shifted rearward by 70 mm

to widen an entry space for easy access.

A new LED room light, interlocked with the

door, turns on when the door opens. The

front window is easily removed and stored

overhead using slide rails. The overhead

window is openable for ventilation.

Ample air conditioner vents are located

strategically for uniform air circulation inside

the cab. The control panel and control

levers are arranged within easy reach of

the operator. AM/FM radio and AUX port

(optional) for a mobile music player are

available for a long work day with less

fatigue. All these designs focus on operator

comfort.

Comfort-Designed Operator Seat

The luxury cloth seat is fitted with a

headrest and arm rests for operator

comfort. The seat can be adjusted in

multiple ways, sliding and reclining, to suit

operator’s size and preferences. The seat

can slide rearward by 40 mm more for

added leg space. An air suspension with a

heat pad is optional.

Robust Cab

The robust cab, meeting the OPG (Top

Guard Level 1), protects the operator from

falling objects. The pilot control shut-off

lever is provided with a neutral engine start

system that permits engine starting only

when the pilot control shut-off lever is in

Lock position.

Control panel

New, Easy-to-Use Multifunction Monitor

The new multi-language, multifunction

monitoring system comprises a 7-inch highresolution color monitor and a multifunction

controller. The monitor allows the operator to

check varying operating variables: hydraulic oil

temperature, fuel level, work mode, full-auto air

conditioner, AM/FM radio, rear view monitor

camera (optional), maintenance support, and

attachment flow adjustment. Menu items can

be selected and adjusted by a multifunction

controller on the control panel. A new rear view

monitor camera always displays the view behind

the machine.

Large storage space

Menu Items

Main menu

Engine oil

Work mode

menu

Page 6

10

11

Simplified Maintenance

Dust-Proof Indoor Net

A dust-proof indoor net, provided at the

front of radiator, can be easily removed and

cleaned with compressed air. At the rear of

the radiator, air blowing can be done through

a one-touch open cover. The air condenser

is openable for easy cleaning at its rear.

Grouped Remote Inspection Points

Service points are concentrated inside left

and right covers that are readily accessible

from ground level for convenient servicing

and inspection, including water draining

from the fuel tank, replenishment of coolant,

and replacement of filters. The fuel tank is

anti-corrosion coated on its inside, and has

a large cleaning port at the bottom. These

wise designs effectively keep fuel clean, and

ease servicing. Handrails are provided at

convenient locations for easy riding on the

upperstructure. Plenty slip-resistant plates

are located for safe maintenance.

Attractive, Robust Body

Side frame tops of the undercarriage are

sloped to let muck slide away. Track adjuster

greasing ports are repositioned for easier

lubrication, and well protected from muck

packing.

Grouped rem ote filters and ins pection poin ts

Fuel tank water drai nage cock

Utility spa ce and radiators

Low Life Cycle Costs

Service intervals are long enough to slash

maintenance costs.

Lubricant Consumables

The photo shows an excavator with an optional front glass lower guard.

Engine Oil : 500 h

Engine Oil Filter : 500 h

Hydraulic Oil : 5 000 h

Hydraulic Oil Filter : 1 000 h

Fuel Filter : 500 h

Front : 500 h

Boom Foot : 500 h

Bucket : 500 h

Note: Periodic ins pecti on is req uired to c heck oi l conta minati on and li kes.

Page 7

12

13

Reliable Solutions, with

Various Options

Easy-to-Use Attachments

The operator can change over valves, adjust extra circuit

flow, and check settings from the multifunctional monitor

next to the operator seat. What’s more, 11 jobs, including

flow rate setting, can easily be selected by their identified

names.

Easy-to-Operate Breaker

When using a breaker that requires frequent change

of hydraulic oil and filters, an extra hour meter on the

multifunctional monitor displays operating hours of the

breaker, suggesting adequate replacement timing of oil and

filters. The Breaker Alarm (optional) displays an alert mark

on the monitor screen, and sounds when the breaker works

continuously over one minute.

Varied Jobs, Varied Options

Lower cab front guard is provided for protection against

debris during demolition and breaker operation.

High-performance filters and in-line filters are available at

tough job sites.

Recommended Options

Lower cab front guard Electric fuel refilling pump

Pre-Cleaner

Breaker se tting s

Breaker ho ur meter

Attachment basic piping

Additional cab roof front lights

Rear view camera

Page 8

14

15

Hitachi Support Chain

This on-line fl eet management system allows you to access

each on-site machine from a PC in your offi ce. You can get

its operating information and location to increase productivity

of the fl eet and reduce downtime. Operating data and log

are sent to a Hitachi server for processing, and then to

customer and dealers around the world. This system is

available 24 hours a day, all the year around.

Easy Access to On-Site Machines through the Internet

Functions

Global e-Service provides easy access to a machine on

site, conveying operating information and log, including

daily operating hours, fuel level, temperatures, pressures,

and likes.

Maintenance

Maintenance data and log are displayed on a easy-to-read

monitor screen, suggesting recommended maintenance for

effi cient fl eet management.

Main Features of Global e-Service

Hitachi Support Chain is a full customer support system offered after

buying a Hitachi machine.

Hitachi Global Online Network, a parts supply system, is

linked with Japan Parts Center, overseas depots and over

150 dealers abroad to deliver on-line parts information,

including in-stock parts, order receptions, shipments and

delivery period of over one million parts and components.

Genuine Hitachi Parts

Genuine Hitachi parts, meeting Hitachi stringent quality

standards, are guaranteed according to Hitachi warranty

standards. The use of genuine Hitachi parts, including

engine, fuel, hydraulic oil and fi lters, may slash running costs,

and extend machine life.

Ground Engaging Tools (GETs)

Hitachi provides an array of Hitachi Ground Engaging

Tools developed and built for a variety of applications.

Parts

Hitachi full customer support is available every area on the globe for full customer

satisfaction through Hitachi local dealers.

Using high-quality, well-maintained GETs will help you get

customers' trust.

Note: Some dealers do not handle Hitachi GETs.

Remanufactured Components

Hitachi components are remanufactured according to the

stringent remanufacturing standards at factories around the

world. They have high quality equivalent to new ones, and

backed up by Hitachi warranty system.

Note: Some dealers do not handle Hitachi Reman ufactured Components.

Antenna(GPRS) or Satellite

Machine

Information Center,

Hitachi Construction Machinery

Hitachi Construction Machinery

Group and Dealers

Internet

Operating Information

Information sharing

Quick access to information

on remote machines

Offering prompt and

adequate service

Customer

Extended Warranty — HELP

Hitachi Standard Warranty System is available on all new

Hitachi machines. In addition, Hitachi offers Hitachi Extended

Life Programs (HELPs) to suit customer expectations –

Service

protecting machines under tough operating conditions,

avoiding unexpected downtime, and reducing repair costs.

Note: Warranty conditions vary by equipm ent.

Diagnostic Tools — Maintenance Pro

Electronic control system needs quick on-site solutions, apart

from mechanical repairs. Hitachi’s Maintenance Pro can

diagnose machine failures in a short time by plugging a PC

into a failed machine.

Technical Training

On-site servicing matters despite locations to keep the

machine at peak performance and reduce downtime.

Technical Training Center (TTC), located in Japan, educates

and trains service technicians and service support personnel

coming from Hitachi dealers and factories on the globe

according to the international training programs.

Note: In Some Regions, Global e-Service Is Not Available by Local Regulations.

Operat ion

Mainten ance

Locati on

Page 9

16

17

Various Versions

The photos above show machine imag es at work, which include machines other than ZAX IS 240 series.

Heavy-Duty Version: H-Series

ZAXIS 250

Reinforced Front Attachment (H-Boom / H-Arm)

Thickened steel plates,

damage prevention

plates and square bars

Thickened steel plates

Reinforcement

*Reinf orced portions not

availa ble on st andard

ZA XIS 240 are sh own.

Reinforced

link B

H

Later al-ty pe

wear plat es

Lower cab front guard

Mechanial suspension seat

650 kg heavier

counterweight

Demolition Version: K-Series

ZAXIS 250

Reinforced Front Attachment

(K-Boom / K-Arm)

Thickened steel plates,

and damage prevention

plates

Attachment basic

piping

Reinforced link B for

demolition

K

Twin wipers

Breaker and crusher

piping

High-performance

full-flow filters with

restriction indicators

K-cab

(Cab with overhead window & guard)

Lower cab front guard

1 050 kg heavier

counterweight

1.00 m3 H-bucket

Thickened steel plates, additional

lateral-type wear plates, and

additional reinforcement plates at

cutting edges

Reinforced lower

flange

Reinforced idler bracket

600 mm reinforced triple

grouser shoes

6.0 mm reinforced

undercover

Reinforced side step

(bolted)

Reinforced track guards

(2 on each side)

Reinforced lower

flange

1.00 m3 reinforced bucket

9 mm reinforced track

undercover

600 mm reinforced triple

grouser shoes

6.0 mm reinforced

undercover

Reinforced side step (bolted)

Reinforced idler bracket

Notes : Photo shown mo del equ ipped with opti onal access ories for

breake r and cru sher. For mo re detai ls, cont act your deale r.

Page 10

18

19

SPECIFICATIONS

ENGINE

Model ........................ Isuzu CC-6BG1T

Type ..........................

Aspiration ..................

4-cycle water-cooled, direct injection

Turbocharged, intercooled

No. of cylinders ......... 6

Rated power

ISO 9249, net ........

SAE J1349, net .....

132 kW (177 HP) at 2 150 min-1 (rpm)

132 kW (177 HP) at 2 150 min-1 (rpm)

Maximum torque ....... 637 Nm (65 kgfm) at 1 800 min-1 (rpm)

Piston displacement .. 6.494 L

Bore and stroke ........ 105 mm x 125 mm

Batteries .................... 2 x 12 V / 88 Ah

HYDRAULIC SYSTEM

Hydraulic Pumps

Main pumps .............. 2 variable displacement axial piston pumps

Maximum oil flow .. 2 x 223 L/min

Pilot pump ................. 1 gear pump

Maximum oil flow .. 32.0 L/min

Hydraulic Motors

Travel ........................ 2 variable displacement axial piston motors

Swing ........................ 1 axial piston motor

Relief Valve Settings

Implement circuit ....... 34.3 MPa (350 kgf/cm2)

Swing circuit .............. 32.4 MPa (330 kgf/cm2)

Travel circuit .............. 34.8 MPa (355 kgf/cm2)

Pilot circuit ................ 3.9 MPa (40 kgf/cm2)

Power boost ............. 38.0 MPa (388 kgf/cm2)

Hydraulic Cylinders

Quantity Bore Rod diameter

Boom 2 125 mm 90 mm

Arm 1 140 mm 100 mm

Bucket 1 130 mm 90 mm

UPPERSTRUCTURE

Revolving Frame

D-section frame skirt for resistance to deformation.

Swing Device

Swash plate piston motor with planetary reduction gear is bathed in oil.

Swing circle is single-row. Swing parking brake is spring-set/hydraulicreleased disc type.

Swing speed ............. 11.0 min-1 (rpm)

Swing torque ............. 77.5 kNm (7 900 kgfm)

UNDERCARRIAGE

Tracks

Heat-treated connecting pins with dirt seals. Hydraulic (grease) track

adjusters with shock-absorbing recoil springs.

Numbers of Rollers and Shoes on Each Side

Upper rollers .............

Lower rollers ............. 8 : ZX240-5G/ZX250H-5G/ZX250K-

Track shoes .............. 47 : ZX240-5G/ZX250H-5G/ZX250K-

Track guard ............... 1 : ZX240-5G/ZX240LC-5G/ZX250K-

2

9 : ZX240LC-5G/ZX250LCH-5G/

5G

ZX250LCK-

5G

5G

51 : ZX240LC-5G/ZX250LCH-5G/ZX250LCK-

ZX250LCK-

5G

2 : ZX250H-5G/ZX250LCH-

5G

5G/

5G

Travel Device

Each track driven by 2-speed axial piston motor.

Parking brake is spring-set/hydraulic-released disc type.

Automatic transmission system: High-Low.

Travel speeds ............. High : 0 to 5.5 km/h

Low : 0 to 3.4 km/h

Maximum traction force

Gradeability ................ 70% (35 degree) continuous

.. 222 kN (22 600 kgf)

SERVICE REFILL CAPACITIES

Fuel tank ................................................................................... 510.0 L

Engine coolant ............................................................................. 26.0 L

Engine oil ..................................................................................... 25.0 L

Swing device ................................................................................. 9.1 L

Travel device (each side) ................................................................. 7.8 L

Hydraulic system ....................................................................... 280.0 L

Hydraulic oil tank ....................................................................... 156.0 L

WEIGHTS AND GROUND PRESSURE

Operating weight and Ground pressure

ZX240 -

Shoe type Shoe width Arm length kg kPa(kgf/cm2) kg kPa(kgf/cm2)

2.50 m 23 300 51 (0.52) 23 900 47 (0.48)

600 mm

700 mm

Triple

grouser

800 mm

900 mm

Reinforced

Triple

grouser

Trianglar

Flat 600 mm

Shoe type Shoe width Arm length kg kPa(kgf/cm2) kg kPa(kgf/cm2) kg kPa(kgf/cm2) kg kPa(kgf/cm2)

Reinforced

Triple

grouser

600 mm

760 mm

900 mm

600 mm 2.96 m 24 800 54 (0.55) 25 300 50 (0.51) 25 200 55 (0.56) 25 800 51 (0.52)

2.96 m 23 400 51 (0.52) 24 000 48 (0.49)

3.61 m 23 500 51 (0.52) 24 100 48 (0.49)

2.50 m 23 700 44 (0.45) 24 400 41 (0.42)

2.96 m 23 800 44 (0.45) 24 400 41 (0.42)

3.61 m 23 900 45 (0.46) 24 500 41 (0.42)

2.50 m 24 000 39 (0.40) 24 700 36 (0.37)

2.96 m 24 100 39 (0.40) 24 700 36 (0.37)

3.61 m 24 200 39 (0.40) 24 800 37 (0.38)

2.50 m 24 100 35 (0.36) 25 200 33 (0.34)

2.96 m 24 200 35 (0.36) 25 300 33 (0.34)

3.61 m 24 200 35 (0.36) 25 300 33 (0.34)

2.50 m — — — —

2.96 m — — — —

3.61 m — — — —

2.50 m 24 400 41 (0.42) 25 000 38 (0.39)

2.96 m 24 400 41 (0.42) 25 100 39 (0.40)

3.61 m 24 500 41 (0.42) 25 200 39 (0.40)

2.50 m 25 400 36 (0.37) 26 200 34 (0.35)

2.96 m 25 500 36 (0.37) 26 200 34 (0.35)

3.61 m 25 500 36 (0.37) 26 300 34 (0.35)

2.50 m 24 100 52 (0.53) 24 800 49 (0.50)

2.96 m 24 200 52 (0.53) 24 900 49 (0.50)

3.61 m 24 300 53 (0.54) 24 900 49 (0.50)

ZX250H-

*2

5G

*1

5G

ZX250LCH-

ZX240LC-

*2

5G

ZX250K-

*3

5G

*1 :Including 1.00 m3 (ISO heaped) bucket weight (850 kg) and counterweight (5 250kg).

*2 :Including 1.00 m3 (ISO heaped) H-bucket weight (990 kg) and counterweight (5 900kg).

*3 :Including 1.00 m3 (ISO heaped) reinforced bucket weight (970 kg) and counterweight (6 300kg).

*1

5G

ZX250LCK-

*3

5G

Operator's Cab

Independent spacious cab, 1 005 mm wide by 1 675 mm high,

conforming to ISO* Standards.

* International Organization for Standardization

Page 11

20

21

SPECIFICATIONS

WEIGHT: BASIC MACHINE and COMPONENTS

Basic Machine Weight and Overall width

Excluding front-end attachment, fuel, hydraulic oil,

coolant, etc., and including counter weight.

ZX240-

5G

Shoe width Weight Overall width

600 mm 17 800 kg 2 990 mm

700 mm 18 200 kg 3 090 mm

800 mm 18 400 kg 3 190 mm

900 mm 18 500 kg 3 290 mm

ZX250H-

5G

Shoe width Weight Overall width

600 mm 18 900 kg 2 990 mm

ZX250K-

5G

Shoe width Weight Overall width

600 mm 19 300 kg 2 990 mm

ZX240LC-

Shoe width Weight Overall width

600 mm 18 400 kg 3 190 mm

700 mm 18 800 kg 3 290 mm

800 mm 19 100 kg 3 390 mm

900 mm 19 600 kg 3 490 mm

ZX250LCH-

Shoe width Weight Overall width

600 mm 19 400 kg 3 190 mm

ZX250LCK-

Shoe width Weight Overall width

600 mm 19 900 kg 3 190 mm

Component weights

ZX240-5G / ZX240LC-

Counterweight 5 250 kg 5 900 kg 6 300 kg

Boom (with boom and arm cylinder) 2 660 kg 2 700 kg 2 660 kg

2.50 m arm (with bucket cylinder) 1 270 kg — —

2.96 m arm (with bucket cylinder) 1 320 kg 1 400 kg 1 340 kg

3.61 m arm (with bucket cylinder) 1 410 kg — —

1.00 m3 bucket 850 kg 975 kg 970 kg

5G

5G

5G

5G

ZX250H-5G / ZX250LCH-

5G

ZX250K-5G / ZX250LCK-

BACKHOE ATTACHMENTS

Boom and arms are of welded, box-section design. 6.00 m boom, and 2.50 m, 2.96 m and 3.61 m arms are available.

Bucket is of welded steel structure. Side clearance adjust mechanism provided on the bucket joint bracket.

Buckets

Capacity Width

ISO heaped

0.80 m

1.00 m

1.10 m

1.25 m

1.40 m

*1

0.92 m

*2

1.00 m

*2

1.10 m

*3

1.00 m

*4

1.00 m

*5

0.80 m

3

3

3

3

3

3

3

3

3

3

3

Without side

cutters

950 mm 1 080 mm 4 760 kg

1 130 mm 1 260 mm 5 850 kg

1 220 mm 1 350 mm 5 900 kg

1 360 mm 1 490 mm 5 945 kg —

1 500 mm 1 630 mm 5 1 020 kg — — — — — — — —

1 130 mm 1 180 mm 5 990 kg — — — —

1 130 mm 1 260 mm 5 970 kg

1 220 mm 1 350 mm 5 1 030 kg

1 140 mm 1 270 mm 5 975 kg

1 140 mm 1 270 mm 5 955 kg

1 000 mm — 3 1 220 kg — — — —

With side

cutters

No. Of

teeth

Weight

2.50 m

arm

ZX240-

2.96 m

arm

5G

3.61 m

arm

One-point ripper 1 680 kg — — — —

Center-pull type clamshell bucket: 0.60 m3 (CECE heaped), Width 940 mm

Shell-push type clamshell bucket: 0.60 m3 (CECE heaped), Width 870 mm

*1 Rock bucket

5G

*2 Reinforced bucket

*3 Heavy-duty bucket

*4 Heavy-duty level-pin-type bucket

*5 Ripper bucket

8 1 130 kg — —

7 960 kg — —

Suitable for materials with density of 2 000 kg/m3 or less

Suitable for materials with density of 1 600 kg/m3 or less

Suitable for materials with density of 1 100 kg/m3 or less

Heavy-duty service

Slope-finishing service

— Not applicable

Recommendation

ZX240LC-

2.50 m

2.96 m

arm

arm

5G

3.61 m

arm

ZX250H-

ZX250LCH-

2.96 m

H-arm

5G

5G

ZX250K-

ZX250LCK-

2.96 m

K-arm

5G

5G

BUCKET AND ARM DIGGING FORCES

Arm length 2.50 m 2.96 m 3.61 m

Bucket digging force* ISO

Bucket digging force* SAE : PCSA

Arm crowd force* ISO

Arm crowd force* SAE : PCSA

* At power boost

188 kN (19 200 kgf) 188 kN (19 200 kgf) 188 kN (19 200 kgf)

163 kN (16 600 kgf) 163 kN (16 600 kgf) 163 kN (16 600 kgf)

156 kN (15 900 kgf) 131 kN (13 300 kgf) 113 kN (11 500 kgf)

155 kN (15 800 kgf) 126 kN (12 900 kgf) 110 kN (11 200 kgf)

Page 12

22

23

SPECIFICATIONS

8

11

10

9

8

7

6

5

4

3

2

1

9

7

6

5

4

3

2

1

0

14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

WORKING RANGES

meter

E

C

D

D'

Ground Line

B

B'

F

Arm length 2.50 m 2.96 m 3.61 m

A Max. digging reach 9 880 10 290 10 910

A’ Max. digging reach (on ground)

B Max. digging depth

B’ Max. digging depth for 2.5 m level

C Max. cutting height

D Max. dumping height

D’ Min. dumping height

E Min. swing radius

F Max. vertical wall digging depth

Excluding track shoe lug

9 690 10 110 10 750

6 500 6 960 7 610

5 940 6 750 7 440

9 950 10 160 10 560

6 990 7 200 7 580

3 330 2 830 2 180

3 480 3 440 3 430

5 580 6 030 6 740

A'

A

2.5 m

meter

Unit: mm

DIMENSIONS

K

E

N

F’

F

L

G

I

H

J

ZX240-

5G

A Distance between tumblers 3 460 3 850 3 460 3 850 3 460 3 850

B Undercarriage length

* C Counterweight clearance

D Rear-end swing radius

D’ Rear-end length

E Overall width of upperstructure

F Overall height of cab

F’ Overall height of upperstructure

* G Min. ground clearance

H Track gauge

I Track shoe width

J Undercarriage width

K Overall width

* L Track height with triple grouser shoes

M Overall length

With 2.50 m arm

With 2.96 m arm

With 3.61 m arm

N Overall height of boom

With 2.50 m arm

With 2.96 m arm

With 3.61 m arm

4 260 4 640 4 260 4 640 4 260 4 640

1 080 1 080 1 080 1 080 1 080 1 080

3 140 3 140 3 140 3 140 3 140 3 140

3 140 3 140 3 140 3 140 3 140 3 140

2 870 2 870 2 870 2 870 2 870 2 870

3 010 3 010 3 010 3 010 3 140 3 140

3 080 3 080 3 080 3 080 3 140 3 140

460 460 460 460 460 460

2 390 2 590 2 390 2 590 2 390 2 590

G 600 G 600 G 600 G 600 G 600 G 600

2 990 3 190 2 990 3 190 2 990 3 190

2 990 3 190 2 990 3 190 2 990 3 190

920 920 920 920 920 920

10 470 10 470 — — — —

10 360 10 360 10 360 10 360 10 360 10 360

10 400 10 400 — — — —

3 370 3 370 — — — —

3 070 3 070 3 070 3 070 3 070 3 070

3 320 3 320 — — — —

ZX240LC-

5G

ZX250H-

* Excluding track shoe lug G: Triple grouser shoe

M

D/D'

C

A

B

5G

ZX250LCH-

5G

ZX250K-

5G

ZX250LCK-

Unit: mm

5G

Page 13

24

25

LIFTING CAPACITIES (Without Bucket)

A

B

C

ZX240-

5G

Conditions

Boom 6.00 m

Arm 2.50 m

Counterweight

5 250 kg

Shoe 600 mm

Boom 6.00 m

Arm 2.96 m

Counterweight

5 250 kg

Shoe 600 mm

Boom 6.00 m

Arm 3.61 m

Counterweight

5 250 kg

Shoe 600 mm

Rating ov er-front Rating ov er-side or 3 60 degrees Un it : kg

Load

point

height

m

6.0 *6 320 6 050 *6 240 4 460 7.20

4.5 *8 520 *8 520 *7 050 5 800 5 810 4 090 5 350 3 760 7.88

3.0 *10 880 8 220 7 950 5 470 5 660 3 950 4 890 3 410 8.24

1.5 11 830 7 650 7 620 5 180 5 500 3 800 4 740 3 280 8.31

(Ground)

0

-1.5 *9 550 *9 550 11 570 7 430 7 360 4 940 5 380 3 690 5 310 3 640 7.58

-3.0 *16 120 14 830 11 720 7 560 7 450 5 020 6 400 4 370 6.69

-4.5 *12 610 *12 610 *9 340 7 870 *7 840 6 380 5.23

-6.0

6.0 *5 780 *5 780 *4 930 4 220 *4 390 4 060 7.67

4.5 *7 730 *7 730 *6 570 5 890 5 860 4 230 *4 400 3 470 8.32

3.0 *10 110 8 420 *7 670 5 540 5 690 3 970 4 540 3 160 8.65

1.5 11 970 7 770 7 670 5 220 5 510 3 810 4 400 3 040 8.72

(Ground)

0

-1.5 *9 380 *9 380 11 520 7 380 7 330 4 910 5 330 3 633 4 850 3 330 8.03

-3.0 *10 880 *10 880 *15 560 14 620 11 610 7 460 7 370 4 940 5 700 3 900 7.20

-4.5 *14 240 *14 240 *10 330 7 710 *7 630 5 310 5.87

-6.0

7.5 *3 560 *3 560 7.43

6.0 *5 030 *5 030 *4 730 4 330 *3 420 *3 420 8.38

4.5 *5 860 *5 860 *5 480 4 200 *3 410 3 080 8.97

3.0 *8 950 8 700 *7 020 5 650 5 750 4 020 4 290 2 990 *3 530 2 830 9.28

1.5 *11 270 7 950 7 750 5 290 5 540 3 830 4 200 2 890 *3 770 2 730 9.35

(Ground)

0

-1.5 *5 260 *5 260 *8 610 *8 610 11 450 7 320 7 290 4 860 5 270 3 580 4 280 2 920 8.71

-3.0 *8 940 *8 940 *13 080 *13 080 11 470 7 330 7 260 4 840 5 280 3 580 4 880 3 330 7.95

-4.5 *13 560 *13 560 *16 110 14 680 *11 330 7 500 7 400 4 960 6 240 4 240 6.77

-6.0 *8 040 7 910 *7 240 7 050 4.88

1.5 3.0 4.5 6.0 7.5 9.0

11 580 7 440 7 420 5 000 5 390 3 700 4 850 3 340 8.10

11 610 7 460 7 430 5 000 5 380 3 680 4 490 3 090 8.52

*5 400 *5 400 11 660 7 490 7 450 5 010 5 370 3 670 4 120 2 820 4 010 2 750 9.16

Load radius m

At max. reach

meter

Notes: 1. Ratings are based on ISO 10567.

2. Lifting capacity does not exceed 75% of tipping load with the machine on firm,

level ground or 87% full hydraulic capacity.

3. The load point is the center-line of the bucket pivot mounting pin on the arm.

4. *Indicates load limited by hydraulic capacity.

5. 0 m = Ground.

For lifting capacities, subtract bucket and quick hitch weight from lifting capacities without bucket.

ZX250H-

Conditions

H-Boom 6.00 m

H-Arm 2.96 m

Counterweight

5 900 kg

Shoe 600 mm

ZX250LCH-

Conditions

H-Boom 6.00 m

H-Arm 2.96 m

Counterweight

5 900 kg

Shoe 600 mm

5G

5G

Load

point

height

m

6.0 *5 780 *5 780 *4 930 4 630 *4 390 *4 390 7.67

4.5 *7 730 *7 730 *6 560 6 420 *6 020 4 540 *4 400 3 830 8.32

3.0 *10 100 9 210 *7 670 6 080 6 190 4 380 *4 590 3 500 8.65

1.5 *12 140 8 550 8 350 5 750 6 010 4 210 4 810 3 380 8.72

(Ground)

0

-1.5 *9 380 *9 380 12 560 8 160 8 000 5 440 5 820 4 040 5 310 3 700 8.03

-3.0 *10 880 *10 880 *15 560 *15 560 *12 280 8 240 8 040 5 480 6 230 4 320 7.20

-4.5 *14 220 *14 220 *10 320 8 490 *7 620 5 860 5.87

-6.0

Load

point

height

m

6.0 *5 780 *5 780 *4 930 *4 930 *4 390 *4 390 7.67

4.5 *7 730 *7 730 *6 560 *6 560 *6 020 5 000 *4 400 4 220 8.32

3.0 *10 100 *10 100 *7 670 6 720 *6 540 4 830 *4 590 3 880 8.65

1.5 *12 140 9 580 *8 740 6 390 6 980 4 670 *4 960 3 750 8.72

(Ground)

0

-1.5 *9 380 *9 380 *13 100 9 180 9 420 6 070 6 780 4 490 6 170 4 110 8.03

-3.0 *10 880 *10 880 *15 560 *15 560 *12 280 9 260 *9 190 6 100 7 260 4 800 7.20

-4.5 *14 220 *14 220 *10 320 9 520 *7 620 6 520 5.87

-6.0

1.5 3.0 4.5 6.0 7.5 9.0

12 640 8 240 8 110 5 530 5 880 4 090 4 910 3 430 8.52

1.5 3.0 4.5 6.0 7.5 9.0

*13 100 9 260 *9 460 6 160 6 840 4 540 *5 610 3 810 8.52

Load radius m

Load radius m

A: Load radius

B: Load point height

C: Lifting capacity

Rating ov er-front Rating ov er-side or 3 60 degrees Un it : kg

At max. reach

meter

Rating ov er-front Rating ov er-side or 3 60 degrees Un it : kg

At max. reach

meter

ZX240LC-

Conditions

Boom 6.00 m

Arm 2.50 m

Counterweight

5 250 kg

Shoe 600 mm

Boom 6.00 m

Arm 2.96 m

Counterweight

5 250 kg

Shoe 600 mm

Boom 6.00 m

Arm 3.61 m

Counterweight

5 250 kg

Shoe 600 mm

5G

Rating ov er-front Rating ov er-side or 3 60 degrees Un it : kg

Load

point

height

m

6.0 *6 320 *6 320 *6 240 4 940 7.20

4.5 *8 520 *8 520 *7 050 6 430 *6 420 4 530 6 220 4 170 7.88

3.0 *10 880 9 220 *8 100 6 090 6 590 4 390 5 690 3 800 8.24

1.5 *12 670 8 640 8 990 5 790 6 430 4 240 5 520 3 660 8.31

(Ground)

0

-1.5 *9 550 *9 550 *12 950 8 410 8 720 5 550 6 300 4 130 6 210 4 070 7.58

-3.0 *16 120 *16 120 *11 840 8 540 8 810 5 630 7 520 4 890 6.69

-4.5 *12 610 *12 610 *9 340 8 860 *7 840 7 140 5.23

-6.0

6.0 *5 780 *5 780 *4 930 4 670 *4 390 *4 390 7.67

4.5 *7 730 *7 730 *6 570 6 510 *6 020 4 580 *4 400 3 850 8.32

3.0 *10 110 9 430 *7 670 6 160 *6 550 4 410 *4 590 3 520 8.65

1.5 *12 150 8 760 *8 750 5 830 6 440 4 250 *4 960 3 400 8.72

(Ground)

0

-1.5 *9 380 *9 380 *13 120 8 360 8 690 5 520 6 250 4 070 5 680 3 720 8.03

-3.0 *10 880 *10 880 *15 560 *15 560 *12 300 8 440 8 730 5 550 6 690 4 360 7.20

-4.5 *14 240 *14 240 *10 330 8 700 *7 630 5 940 5.87

-6.0

7.5 *3 560 *3 560 7.43

6.0 *5 030 *5 030 *4 730 *4 730 *3 420 *3 420 8.38

4.5 *5 860 *5 860 *5 480 4 650 *3 410 *3 410 8.97

3.0 *8 950 *8 950 *7 020 6 280 *6 080 4 460 *4 450 3 330 *3 530 3 160 9.28

1.5 *11 270 8 940 *8 220 5 900 6 470 4 270 4 890 3 240 *3 770 3 050 9.35

(Ground)

0

-1.5 *5 260 *5 260 *8 610 *8 610 *13 130 8 290 8 640 5 470 6 190 4 020 *4 890 3 280 8.71

-3.0 *8 940 *8 940 *13 080 *13 080 *12 720 8 300 8 620 5 450 6 200 4 020 5 730 3 730 7.95

-4.5 *13 560 *13 560 *16 110 *16 110 *11 330 8 480 *8 380 5 570 *7 070 4 750 6.77

-6.0 *8 040 *8 040 *7 240 *7 240 4.88

1.5 3.0 4.5 6.0 7.5 9.0

*13 250 8 420 8 780 5 600 6 320 4 140 5 670 3 730 8.10

*13 110 8 440 8 790 5 610 6 300 4 120 5 240 3 450 8.52

*5 400 *5 400 *12 690 8 480 8 810 5 620 6 290 4 110 4 810 3 160 *4 190 3 080 9.16

Load radius m

At max. reach

meter

ZX250K-

Conditions

K-Boom 6.00 m

K-Arm 2.96 m

Counterweight

6 300 kg

Shoe 600 mm

5G

ZX250LCK-

Conditions

K-Boom 6.00 m

K-Arm 2.96 m

Counterweight

6 300 kg

Shoe 600 mm

5G

Rating ov er-front Rating ov er-side or 3 60 degrees Un it : kg

Load

point

height

m

6.0 *5 780 *5 780 *4 930 4 820 *4 390 *4 390 7.67

4.5 *7 730 *7 730 *6 560 *6 560 *6 020 4 730 *4 400 4 000 8.32

3.0 *10 100 9 580 *7 670 6 330 6 420 4 570 *4 590 3 670 8.65

1.5 *12 140 8 930 8 660 6 010 6 240 4 400 *4 960 3 540 8.72

(Ground)

0

-1.5 *9 380 *9 380 13 040 8 540 8 320 5 700 6 060 4 230 5 520 3 880 8.03

-3.0 *10 880 *10 880 *15 560 *15 560 *12 280 8 620 8 350 5 730 6 470 4 520 7.20

-4.5 *14 220 *14 220 *10 320 8 860 *7 620 6 120 5.87

-6.0

Load

point

height

m

6.0 *5 780 *5 780 *4 930 *4 930 *4 390 *4 390 7.67

4.5 *7 730 *7 730 *6 560 *6 560 *6 020 5 200 *4 400 *4 400 8.32

3.0 *10 100 *10 100 *7 670 6 990 *6 540 5 040 *4 590 4 050 8.65

1.5 *12 140 9 980 *8 740 6 660 *7 100 4 870 *4 960 3 920 8.72

(Ground)

0

-1.5 *9 380 *9 380 *13 100 9 570 *9 670 6 340 7 040 4 690 6 400 4 290 8.03

-3.0 *10 880 *10 880 *15 560 *15 560 *12 280 9 660 *9 190 6 370 *7 320 5 010 7.20

-4.5 *14 220 *14 220 *10 320 9 910 *7 620 6 790 5.87

-6.0

1.5 3.0 4.5 6.0 7.5 9.0

*13 100 8 610 8 420 5 790 6 110 4 280 5 110 3 600 8.52

1.5 3.0 4.5 6.0 7.5 9.0

*13 100 9 650 *9 460 6 430 7 090 4 740 *5 610 3 990 8.52

Load radius m

Load radius m

At max. reach

Rating ov er-front Rating ov er-side or 3 60 degrees Un it : kg

At max. reach

meter

meter

Page 14

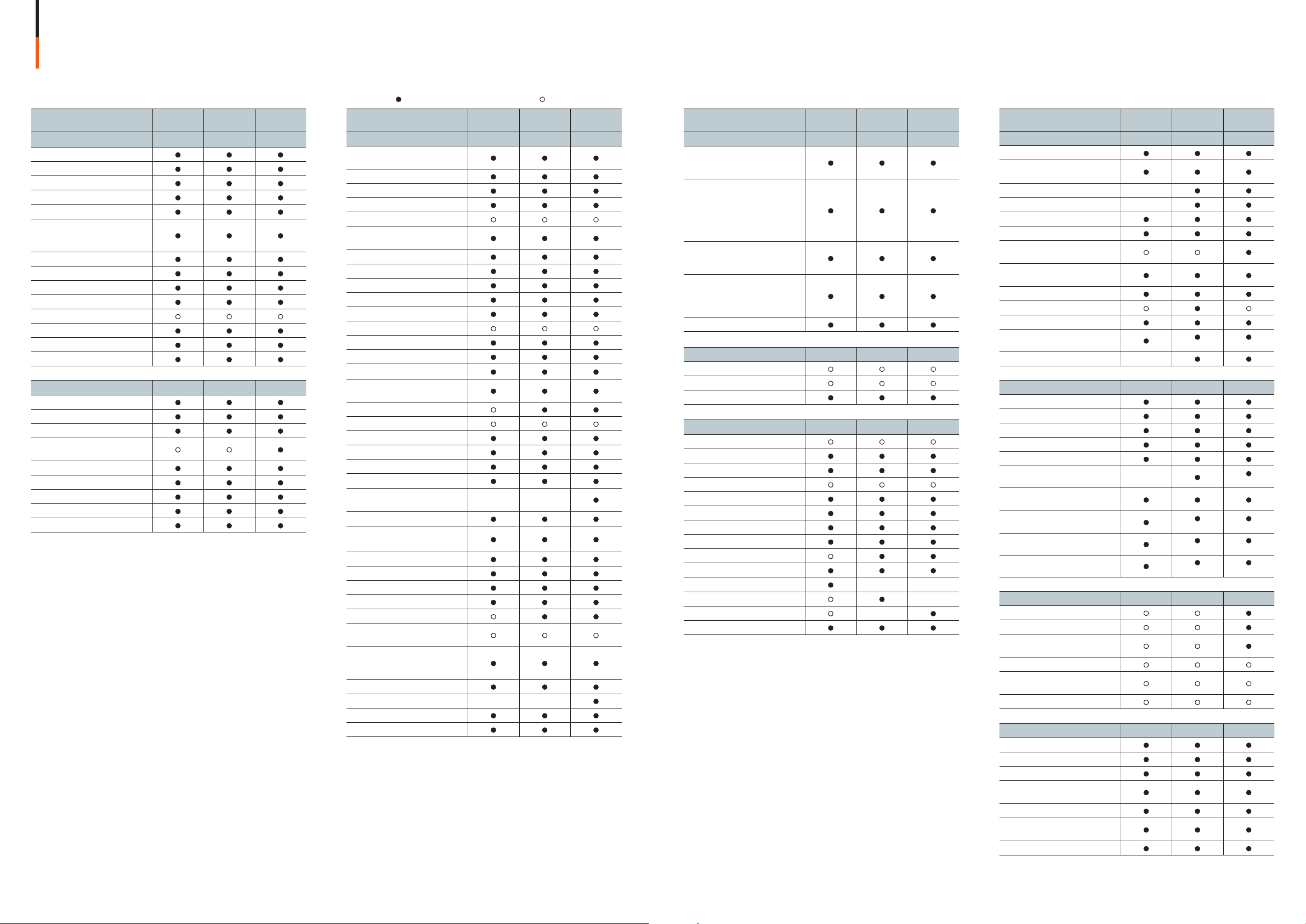

EQUIPMENT

26

27

ENGINE

Air cleaner double filters

Auto idle system

Cartridge-type engine oil filter

Cartridge-type fuel pre-filter

Cartridge-type fuel main filter

Dry-type air filter with evacuator

valve (with air filter restriction

indicator)

ECO/PWR mode control

Engine warm-up device

Fan guard

Water separator

Pre-cleaner

Dust-Proof indoor net

Radiator reserve tank

50 A alternator

HYDRAULIC SYSTEM

Auto power lift

Control valve with main relief valve

Full-flow filter

High mesh full flow filter

with restriction indicator

Pilot filter

Power boost

Suction filter

One extra port for control valve

Work mode selector

ZX240-

ZX240LC-

5G /

5G

ZX250H-

ZX250LCH-

5G /

5G

Standard and optional equipment may vary by country, so please consult your Hitachi dealer for details.

: Standard equipment : Optional equipment

ZX250K-

ZX250LCK-

5G /

5G

ZX240-

ZX240LC-

5G /

5G

ZX250H-

ZX250LCH-

5G /

5G

CAB

All-weather sound suppressed

steel cab

AM-FM radio with 2 speaker

Ashtray

Auto control air conditioner

AUX. terminal and storage

Cab (Center pillar reinforced

structure)

Drink holder

Drink holder with hot & cool

Electric double horn

Engine shut-off lever

Evacuation hammer

Fire extinguisher bracket

Floor mat

Footrest

Front window washer

Front windows on upper, lower

and left side can be opened

Lower cab front guard

Upper cab front guard

Glove compartment

Hot & cool box

Intermittent windshield wipers

Key cylinder light

K-cab. (Cab with overhead

window & guard)

LED room light with door courtesy

OPG top guard Level I (ISO10262)

compliant cab

Pilot control shut-off lever

Rear tray

Retractable seat belt

Rubber radio antenna

Seat : mechanical suspension seat

Seat : air suspension seat with

heater

Seat adjustment part : backrest,

armrest, height and angle, slide

forward / back

Short wrist control levers

Twin wiper

4 fluid-filled elastic mounts

24V cigarette lighter

— —

— —

ZX250K-

ZX250LCK-

5G /

ZX240-

5G

ZX240LC-

MONITOR SYSTEM

Alarm buzzers:

overheat, engine oil pressure,

overload

Alarms:

overheat, engine warning, engine

oil pressure, alternator, minimum

fuel level, hydraulic filter restriction,

air filter restriction, work mode,

overload, etc

Display of meters:

water temperature, hour, fuel rate,

clock

Other displays:

work mode, auto-idle, glow,

rearview monitor, operating

conditions, etc

32 languages selection

5G /

5G

ZX250H-

ZX250LCH-

5G /

5G

ZX250K-

ZX250LCK-

5G /

5G

UNDERCARRIAGE

Bolt-on sprocket

Reinforced track links with pin

seals

Reinforced lower flange

Reinforced idler bracket

Travel motor covers

Travel parking brake

9.0 mm reinforced track

undercover

Track guard (each side) and

hydraulic track adjuster

Upper and lower rollers

2 track guards

4 tie down hooks

ZX240-

ZX240LC-

—

—

600 mm triple grouser shoes

LIGHTS

Reinforced side step

—

ZX250H-

5G

ZX250LCH-

5G

Reinfo rced Reinfo rced

5G

5G

ZX250K-

ZX250LCK-

5G

5G

Additional cab roof front lights

Additional boom light with cover

2 working lights

FRONT ATTACHMENTS

Centralized lubrication system

Dirt seal on all bucket pins

UPPER STRUCTURE

Electric fuel refilling pump

Fuel level float

Hydraulic oil level gauge

Rear view camera

Rear view mirror (right & left side)

Swing parking brake

Tool box

Undercover

6.0 mm reinforced undercover

Utility space

5 250 kg counterweight

5 900 kg counterweight

6 300 kg counterweight

2 x 88 Ah batteries

— —

—

—

Flanged pin

HN bushing

Reinforced resin thrust plate

Reinfoced link B

WC (tungsten-carbide) thermal

spraying

1.00 m3 bucket (ISO heaped)

2.96 m arm

6.00 m boom

ATTACHMENTS

Attachment basic piping

Breaker and crusher piping

—

H-bucket

H-arm K-arm

H-boom K-boo m

for demolitio n

Reinfo rced bu cket

High mesh full flow fillter with

restriction indicator

Parts for breaker and crusher

2 pump combined flow for

attachment basic piping

Line filter

MISCELLANEOUS

Lockable fuel refilling cap

Lockable machine covers

Onboard information controller

Skid-resistant tapes, plates

and handrails

Standard tool kit

Travel direction mark on track

frame

Global e-Service

Page 15

Built on the foundation of superb technological capabilities,

Hitachi Construction Machinery is committed to providing leading-

edge solutions and services to contribute as a reliable partner to

the business of customers worldwide.

Hitachi Environmental Vision 2025

The Hitachi Group released the Environmental Vision 2025 to curb annual

carbon dioxide emissions. The Group is committed to global production

while reducing environmental impact in life cycles of all products, and

realizing a sustainable society by tackling three goals — prevention of

global warming, conservation of resources, and preservation of ecosystem.

Before using a machine with a satellite communication system, please make sure that

the satellite communication system complies with local regulations, safety standards

and legal requirements. If not so, please make modifications accordingly.

Reducing Environmental Impact by New ZAXIS

Hitachi makes a green way to cut carbon emissions for global warming

prevention according to LCA*. New ZA XIS utilizes lots of technological

advances, including the new ECO mode, and Isochronous Control. Hitachi

has long been committed to recycling of components, such as aluminum

parts in radiators and oil cooler. Resin parts are marked for recycling.

*Life Cycle Asse ssment – ISO 14040

These specifications are subject to change without notice.

Illustrations and photos show the standard models, and may or may not include optional equipment,

accessories, and all standard equipment with some differences in color and features.

Before use, read and understand the Operator’s Manual for proper operation.

Hitachi Construction Machinery Co., Ltd.

www.hitachi-c-m.com

KS-EN192Q

13.08 (KA/KA,MT3)

Loading...

Loading...