Page 1

ZW310

-7

WHEEL LOADER TECHNICAL MANUAL

PART NO.

TONFQ50-EN-00

Technical Manual

Operational Principle

OPERATIONAL PRINCIPLE

URL:http://www.hitachi-c-m.com

ZW310

Wheel Loader

-7

PRINTED IN JAPAN (K) 2022, 02

TONFQ50-EN-00

Service Manual consists of the following separate Part No.

Technical Manual (Operational Principle) : Vol. No.TONFQ50-EN-00

Technical Manual (Troubleshooting) : Vol. No.TTNFQ50-EN-00

Workshop Manual : Vol. No.WNFQ50-EN-00

Page 2

Hitachi Construction Machinery Co., Ltd.

COPYRIGHT(C)2022

Tokyo, Japan

All rights reserved

Page 3

INTRODUCTION

To The Reader

This manual is written for an experienced technician to provide technical information needed to maintain and repair this

machine.

The machine specication and description according to destination may be explained on this manual.

● Be sure to thoroughly read this manual for correct product information and service procedures.

● If you have any questions or comments, at if you found any errors regarding the contents of this manual, please

contact using “Service Manual Revision Request Form” at the end of this manual. (Note: Do not tear o the form. Copy

this form for usage.)

• Hitachi Construction Machinery Co., Ltd.

• E-mail: HCM-TIC-GES@hitachi-kenki.com

All information, illustrations and specications in this manual are based on the latest product information available at the

time of publication. The right is reserved to make changes at any time without notice.

Additional References

Please refer to the other materials (operator’s manual, parts catalog, engine technical material and Hitachi training

material etc.) in addition to this manual.

Manual Composition

This manual consists the Technical Manual, the Workshop Manual and the Engine Manual.

● Information included in the Technical Manual: Technical information needed for redelivery and delivery

• Operation and activation of all devices and systems, operational performance tests, and troubleshooting

procedures.

● Information included in the Workshop Manual: Technical information needed for maintenance and repair of the

machine

• Tools and devices needed for maintenance and repair, maintenance standards, and removal / installation and

assemble / disassemble procedures

● Information included in the Engine Manual: Technical information needed for redelivery and delivery and

maintenance and repair of the machine

• Operation and activation of all devices and systems, troubleshooting and assemble / disassemble procedures

Page Number

Each page has a number, located on the center lower part of the page. Each number contains the following information:

● Technical Manual: T 1-3-5

T Technical Manual

1 Section Number

3 Group Number

5 Consecutive Page Number for Each Group

● Workshop Manual: W 1-3-2-5

W Workshop Manual

1 Section Number

3 Group Number

2 Sub Group Number

5 Consecutive Page Number for Each Group

TONFQ50-EN-00(28/02/2022)

IN-1

Page 4

INTRODUCTION

Trademark

AdBlue® is a registered trademark of the Verband der Automobilindustrie e.V. (VDA).

Safety Alert Symbol and Headline Notations

In this manual, the following safety alert symbol and signal words are used to alert the reader to the potential for personal

injury of machine damage.

WARNING

This is the safety alert symbol. When you see this symbol, be alert to the potential for personal injury. Never fail to

follow the safety instructions prescribed along with the safety alert symbol. The safety alert symbol is also used to

draw attention to component/part weights. To avoid injury and damage, be sure to use appropriate lifting

techniques and equipment when lifting heavy parts.

CAUTION

Indicates potentially hazardous situation which could, if not avoided, result in personal injury or death. This is also

provided before the indication of mass to draw attention to safety during handling of the machine.

IMPORTANT

Indicates a situation which, if not conformed to the instructions, could result in damage to the machine. This header is

given to matters that are important in terms of operation and management.

NOTE

Indicates supplementary technical information or know-how.

Units Used

SI Units (International System of Units) are used in this manual.

A table for conversion from SI units to other system units is shown below for reference purposes.

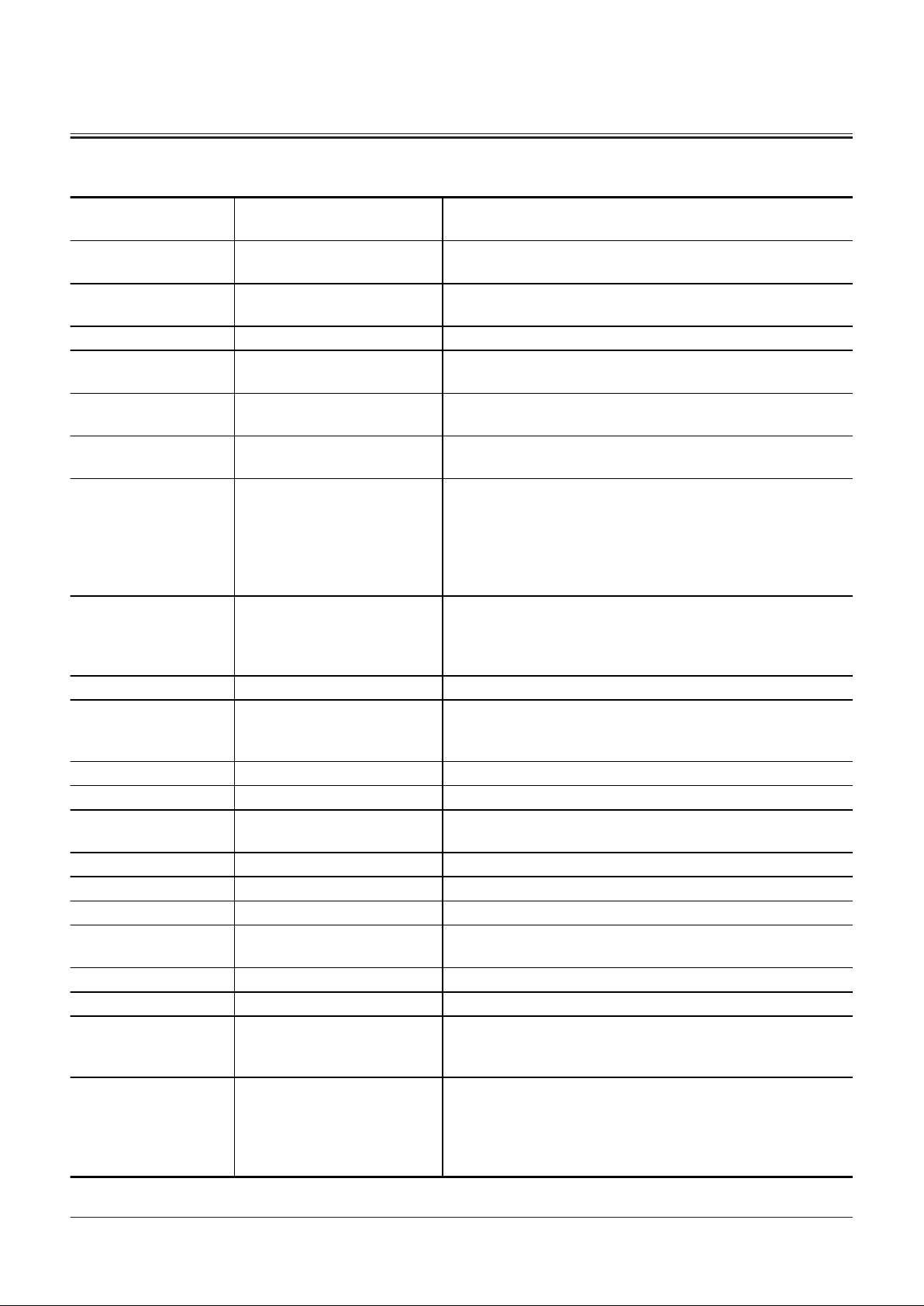

Quantity To Convert From Into Multiply By

Length mm in 0.03937

mm ft 0.003281

Volume L US gal 0.2642

L US qt 1.057

3

m

Weight kg lb 2.205

Force N kgf 0.10197

N lbf 0.2248

Torque N·m kgf·m 0.10197

Pressure MPa

MPa psi 145.0

Power kW PS 1.360

kW HP 1.341

Temperature °C °F °C×1.8+32

3

yd

kgf/cm

1.308

2

10.197

TONFQ50-EN-00(28/02/2022)

IN-2

Page 5

INTRODUCTION

Quantity To Convert From Into Multiply By

Velocity km/h mph 0.6214

-1

min

Flow rate L/min US gpm 0.2642

mL/rev cc/rev 1.0

rpm 1.0

TONFQ50-EN-00(28/02/2022)

IN-3

Page 6

MEMO

INTRODUCTION

TONFQ50-EN-00(28/02/2022)

IN-4

Page 7

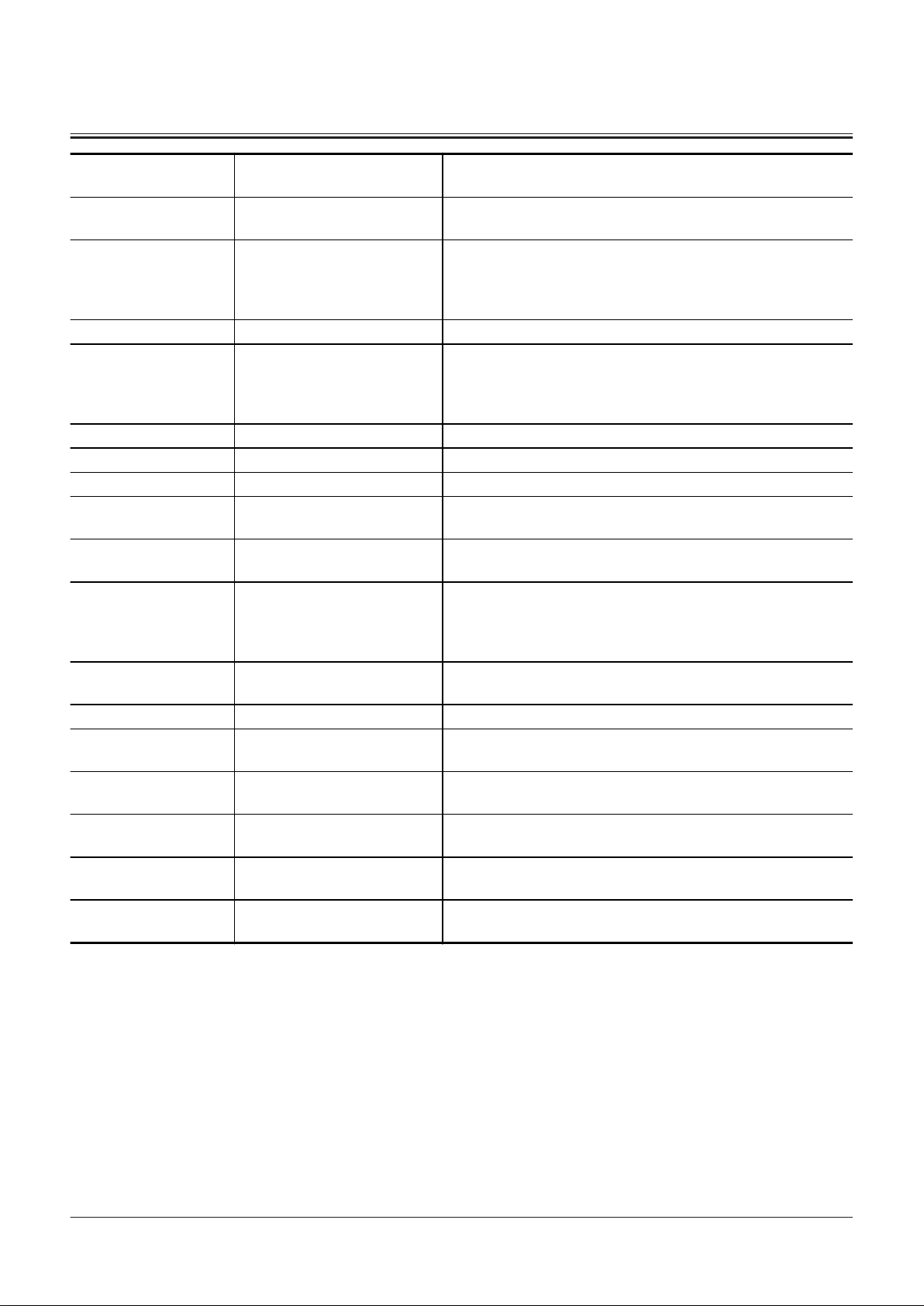

Symbol and Abbreviation

SYMBOL AND ABBREVIATION

Symbol and Abbrevia

tion

TO Technical manual (Operational

principle)

TT Technical manual (Trouble

shooting)

T/M Technical manual Technical manual.

W, W/M Workshop manual Workshop manual (Removal and Installation, Disassembly and

MC Main Controller Main controller. MC controls the engine, pump, and valve ac

ECM Engine Control Module Engine controller. ECM controls fuel injection amount accord

VGS Variable Geometry System con

troller

GSM Global System for Mobile com

munications controller

GPS Global Positioning System Global positioning system.

CAN Controller Area Network CAN communication. CAN is a serial communications protocol

A/C Air Conditioner Air conditioner.

OP, OPT Option Optional component.

MPDr. Maintenance Pro Dr. MPDr. is software that troubleshooting, monitoring, and ad

A/I Auto-Idle Auto-idle.

WU Warming-Up Warming-up.

Li Low (Slow) Idle Minimum Rotation Engine Speed.

ATT Attachment Attachment. Attachment is optional parts such as breaker,

HI, Hi High Travel fast position.

LO, Lo Low Travel slow position.

DPF Diesel Particulate Filter DPF is a lter which removes particulate matter (PM) including

DPD Diesel Particulate Diuser DPD is an exhaust emission control system, a type of DPF,

Part Name Explanation

Technical manual (Operational Principle).

Technical manual (Troubleshooting).

Assembly).

cording to the machine operating condition.

ing to the machine operating condition.

Variable turbo controller. VGS is an exhaust turbo charged sys

tem to supercharge the exhaust energy while running the en

gine at slow idle speed. VGS optimizes the turbine rotation, im

proves the performance at slow-speed torque and the acceler

ation, reduces fuel consumption, and reduces particulate mat

ter (PM) by adjusting the nozzle opening of turbine housing.

Communication controller. GSM is a type of wireless communi

cation system, is used in more than on 100 countries around

Europe and Asia, and becomes the factual global standards of

the mobile telephone.

internationally-standardized by ISO (International Organiza

tion for Standardization).

justment.

crusher, and pulverizer in this manual.

the toxic substance of exhaust gas of the diesel engine. Ex

haust particulate removal equipment.

which cleans up particulate matter (PM) of diesel engine ex

haust gas. DPD is a ceramic lter which traps and lters PM of

exhaust gas. DPD burns up accumulated PM when PM increa

ses and regenerates the lter.

TONFQ50-EN-00(28/02/2022)

SY-1

Page 8

SYMBOL AND ABBREVIATION

Symbol and Abbrevia

tion

DOC Diesel Oxidation Catalyst Oxidation catalyst for the diesel engine. Diesel oxidation cata

CSF Catalyzed Soot Filter Filter. The lter traps, burns, and remove particulate matter

PM Particulate Matter Particulate matter.

EGR Exhaust Gas Recirculation The EGR control re-circulates a part of exhaust gas in the in

ML Moment Limiter ML crane.

HRV Hose Rupture Valve Hose rupture valve.

LLC Long Life Coolant Long life coolant.

SCR Selective Catalytic Reduction The urea SCR system injects diesel exhaust uid to nitrogen

DCU Dosing Control Unit Urea SCR system controller. DCU controls the DEF injection

S/M Supply Module DEF supply module. The DEF supply module pumps diesel ex

D/M Dosing Module Dosing module. The dosing module (D/M) injects DEF into the

NOx Nitrogen Oxide Nitrogen oxide.

DEF Diesel Exhaust Fluid DEF. The DEF concentration is 32.5%, which is specied in

TPD Torque Proportioning Dieren

tial

LSD Limited Slip Dierential Limited Slip Dierential. The Limited Slip Dierential prevents

TBAP Temperature Barometric At

mospheric Pressure

JSS Joystick Steering System Joystick steering system. Operating the joystick steering lever

Part Name Explanation

lyst oxidizes unburnt fuel and raises exhaust temperature.

(PM) by using high-temperature-exhaust gas with diesel oxida

tion catalyst. Catalyst is applied onto the lter. This advances

PM burning.

take manifold and combines it with intake-air. Therefore, com

bustion temperature is lowered, and generation of nitrogen

oxides (NOx) is controlled.

oxide (NOx) exhausted from the engine and puries NOx.

amount according to the machine operating condition.

haust uid to the dosing module (D/M). Then, it returns diesel

exhaust uid in the DEF circuit when the key switch is turned

OFF.

exhaust piping according to the signal from DCU.

ISO22241.

Torque proportioning dierential. The torque proportioning

dierential prevents the tires from slipping.

the tires from slipping.

Atmospheric pressure, intake-air temperature, and intake-air

pressure.

controls the steering operation of the vehicle.

TONFQ50-EN-00(28/02/2022)

SY-2

Page 9

CONTRASTING LIST OF PART NAME

Contrasting List of Part Name between Technical Manual and Parts Catalog

Part name in technical manual Part name in parts catalog Part No.

Bucket Angle Sensor SENSOR;ANGLE YA00051742

Lift Arm Angle Sensor SENSOR;ANGLE YA00051742

TBAP Sensor SENSOR YL00009955

Hydraulic Oil Level Sensor SWITCH;LEVEL 4259787

Hydraulic Oil Temperature Sensor SENSOR 4697482

Fuel Level Sensor FLOAT 3582860580

Water Separator Sensor FILTER;FUEL YA00060028

Transmission Intermediate Shaft Speed Sensor SENSOR;REVOLUTION YB00004091

Torque Converter Output Shaft Speed Sensor SENSOR;REVOLUTION YB00004091

Torque Converter Input Shaft Speed Sensor SENSOR;REVOLUTION YB00004091

Vehicle Speed Sensor SENSOR;REVOLUTION YB00004091

Transmission Oil Temperature Sensor SENSOR;THERMO 3582960140

Service Brake Secondary Pressure Sensor SENSOR;PRESSURE YA00057050

Axle oil Temperature Sensor SENSOR;THERMO 3113925

Accelerator Pedal Sensor PEDAL;ACCELERATOR YA00003929

Brake Pedal Position Sensor SENSOR;ANGLE YA00050561

Fan Circuit Pressure Sensor SENSOR;PRESSURE 4436271

Pump Delivery Pressure Sensor SENSOR;PRESSURE 4436271

Primary Pilot Pressure Sensor SENSOR;PRESSURE YA00057050

Parking Brake Pressure Sensor SENSOR;PRES. 4436536

Service Brake Primary Pressure Sensor SENSOR;PRESSURE 4436271

Emergency Steering Pump Delivery Pressure Sen

sor

Position Sensor SENSOR;INERTIA YK00000145

Frost Sensor SENSOR;THERMO XB00001052

Re-circulated Air Temperature Sensor SENSOR;THERMO XB00001061

Solar Radiation Sensor SENSOR 4405814

Refrigerant Pressure Sensor HOSE;COOLER 4312426110

Ambient Temperature Sensor SENSOR 4405815

Lift Arm Bottom Pressure Sensor SENSOR;PRESSURE 4436271

Lift Arm Rod Pressure Sensor SENSOR;PRESSURE 4436271

Object Detection Sensor SENSOR YA00055127

DEF Quality Sensor TANK;UREA YA00070108

DEF Tank Level Sensor TANK;UREA YA00070108

DEF Tank Temperature Sensor TANK;UREA YA00070108

Steering LS Pressure Sensor SENSOR;PRESSURE YA00057050

SENSOR;PRESSURE 4436271

TONFQ50-EN-00(28/02/2022)

CO-1

Page 10

MEMO

CONTRASTING LIST OF PART NAME

TONFQ50-EN-00(28/02/2022)

CO-2

Page 11

SECTION AND GROUP

CONTENTS

TECHNICAL MANUAL

( O p e r a t i o n a l

P r i n c i p l e )

SECTION 1 GENERAL

Group 1 Specications

Group 2 Component Layout

Group 3 Component Specications

SECTION 2 SYSTEM

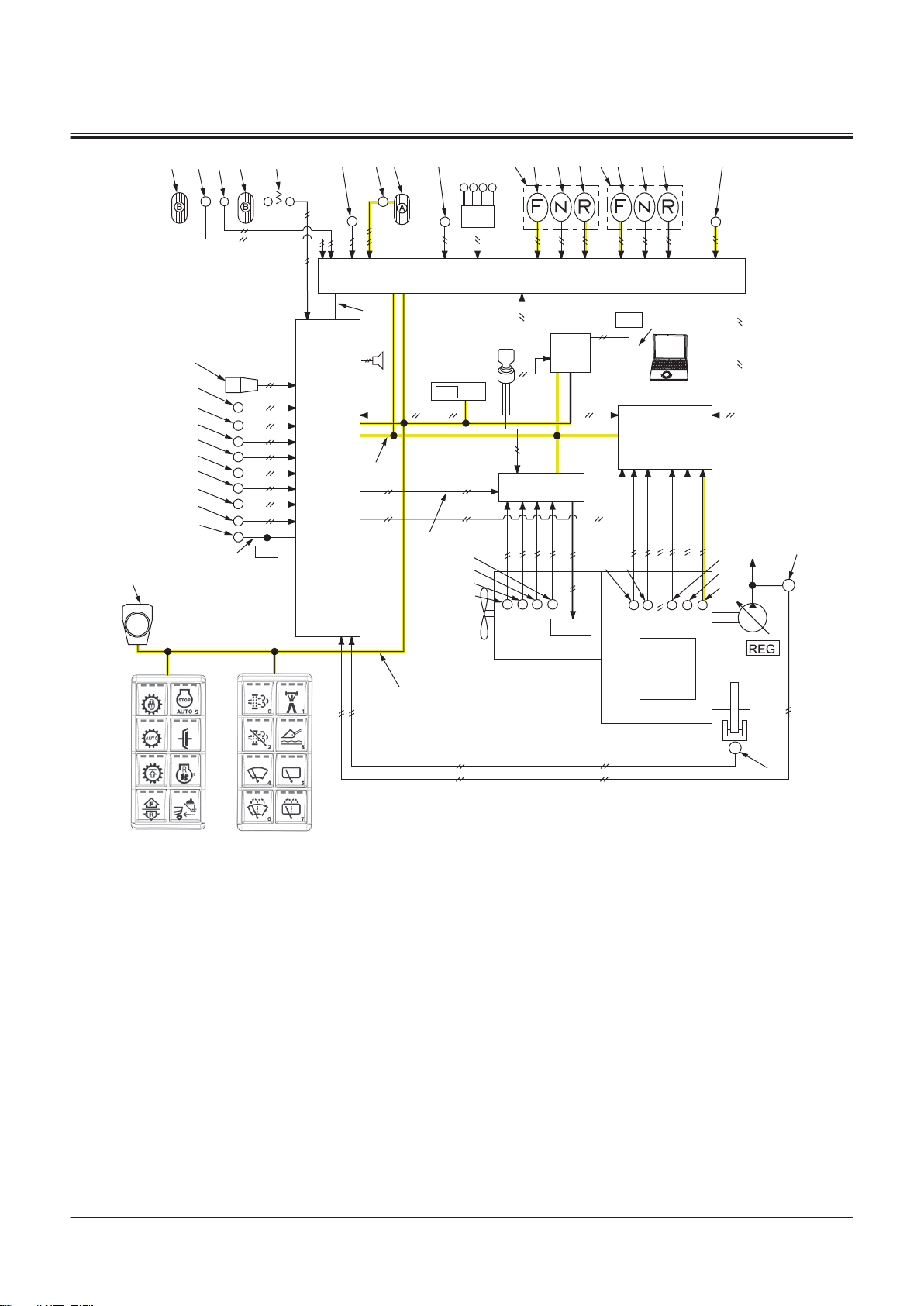

Group 1 Controller

Group 2 Control System

Group 3 Engine System

Group 4 Hydraulic System

Group 5 Electrical System

SECTION 3 COMPONENT OPERATION

Group 1 Pump Device

Group 2 Control Valve

Group 3 Cooling Fan System

Group 4 Steering Pilot Valve

Group 5 Steering Valve

Group 6 Charging Circuit

Group 7 Drive Unit

Group 8 Axle

Group 9 Brake Valve

Group 10 DEF Supply System

Group 11 Others

Page 12

MEMO

TONFQ50-EN-00(28/02/2022)

Page 13

SECTION 1

GENERAL

CONTENTS

Specications............................................T1-1-1

Specications ........................................................................ T1-1-1

Component Layout...................................T1-2-1

Main Component (Overview)..........................................T1-2-1

Main Component................................................................. T1-2-2

Electrical System (Overview) ...........................................T1-2-3

Air Cleaner and Radiator Assembly............................... T1-2-3

Radiator Assembly............................................................... T1-2-4

Battery Box............................................................................. T1-2-4

Hydraulic Oil Tank................................................................ T1-2-5

Fuel Tank .................................................................................T1-2-6

Drive Unit................................................................................ T1-2-7

Front Axle................................................................................T1-2-7

Cab ............................................................................................ T1-2-8

Front Console........................................................................T1-2-9

Panel Switch.........................................................................T1-2-10

Right Console......................................................................T1-2-11

Operator's Seat and Joystick Steering System........T1-2-12

Rear Console........................................................................T1-2-13

Control Unit .........................................................................T1-2-14

Column Monitor.................................................................T1-2-15

Engine....................................................................................T1-2-16

Aftertreatment Device.....................................................T1-2-17

Fan Valve...............................................................................T1-2-17

Pump Device .......................................................................T1-2-18

Control Valve .......................................................................T1-2-19

Brake Valve...........................................................................T1-2-20

Brake Charge Valve/Combination Valve....................T1-2-20

Steering Valve .....................................................................T1-2-21

Ride Control Valve.............................................................T1-2-22

2-Spool Solenoid Valve Unit ..........................................T1-2-22

Emergency Steering Pump Unit...................................T1-2-23

DEF Tank................................................................................T1-2-23

DEF Supply Module...........................................................T1-2-24

Joystick Steering Hydraulic Component...................T1-2-24

Joystick Steering Valve.....................................................T1-2-25

Joystick Steering Solenoid Valve Unit........................T1-2-25

Steering Pilot Valve...........................................................T1-2-26

Component Specications.......................T1-3-1

Specications of Engine.................................................... T1-3-1

Specications of Engine Accessories............................T1-3-5

Specications of Hydraulic Component...................... T1-3-6

Electrical Component......................................................... T1-3-8

TONFQ50-EN-00(28/02/2022)

Page 14

MEMO

TONFQ50-EN-00(28/02/2022)

Page 15

SECTION 2

SYSTEM

CONTENTS

Controller ..................................................T2-1-1

Outline of Controller........................................................... T2-1-1

CAN Circuit............................................................................. T2-1-1

Control System..........................................T2-2-1

Outline of Control System ................................................T2-2-1

Engine Control (ECM)......................................................... T2-2-1

Engine Control System Layout........................................T2-2-2

Engine Protection Control................................................T2-2-3

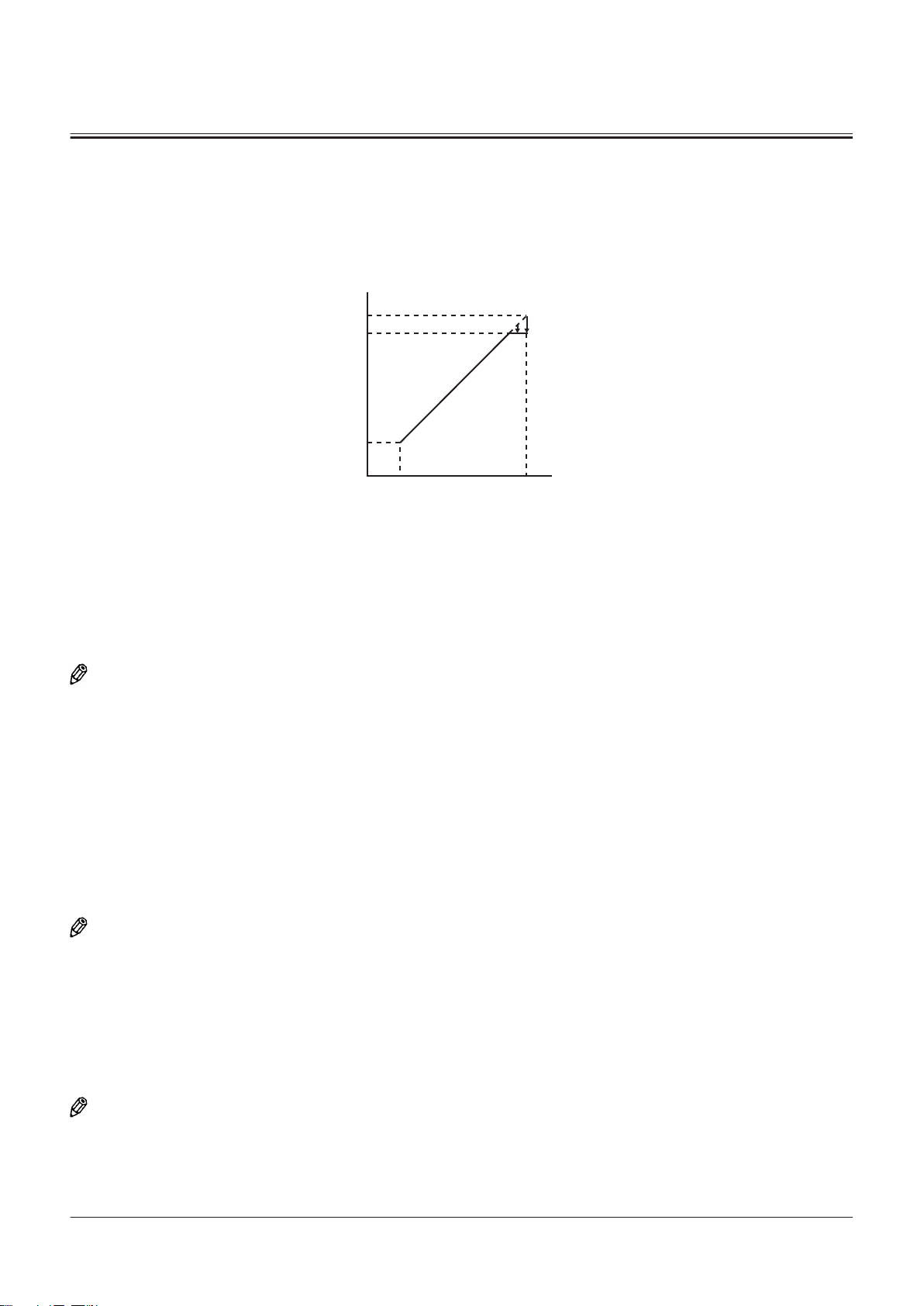

Accelerator Pedal Control................................................. T2-2-5

Auto Warming-Up Control ...............................................T2-2-7

Engine Torque Idle Speed-Up Control .........................T2-2-9

Forward/Reverse Selection Speed Limit Control

While Traveling..............................................................T2-2-11

Engine Speed Limit Control without Load...............T2-2-14

Matching Control While Digging.................................T2-2-16

Speed Limit Control with Power Mode OFF.............T2-2-19

Auto Power Up Speed Control......................................T2-2-21

Overheat Prevention Speed Limit Control ...............T2-2-24

Aftertreatment Device Manual Regeneration

Control..............................................................................T2-2-26

Engine Over Speed Limit Control ................................T2-2-28

Engine Max. Speed Limit Control at Stroke End

Stall and Front Relief ...................................................T2-2-30

Engine Torque Limit Control During Acceleration..

.............................................................................................T2-2-32

Pump Control......................................................................T2-2-34

Pump Control System Layout........................................T2-2-35

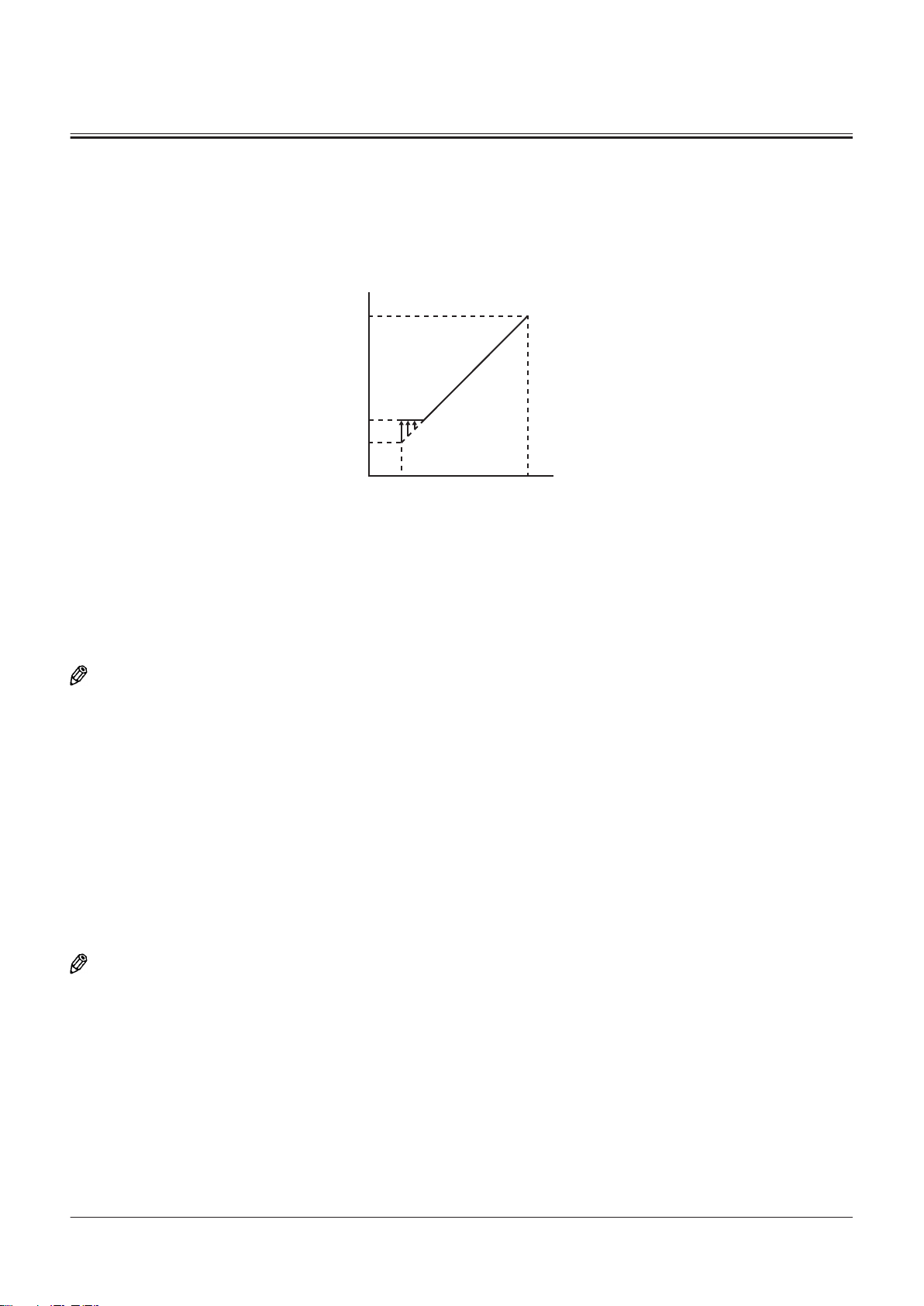

Base Torque Control..........................................................T2-2-36

Torque Decrease Control While Digging...................T2-2-37

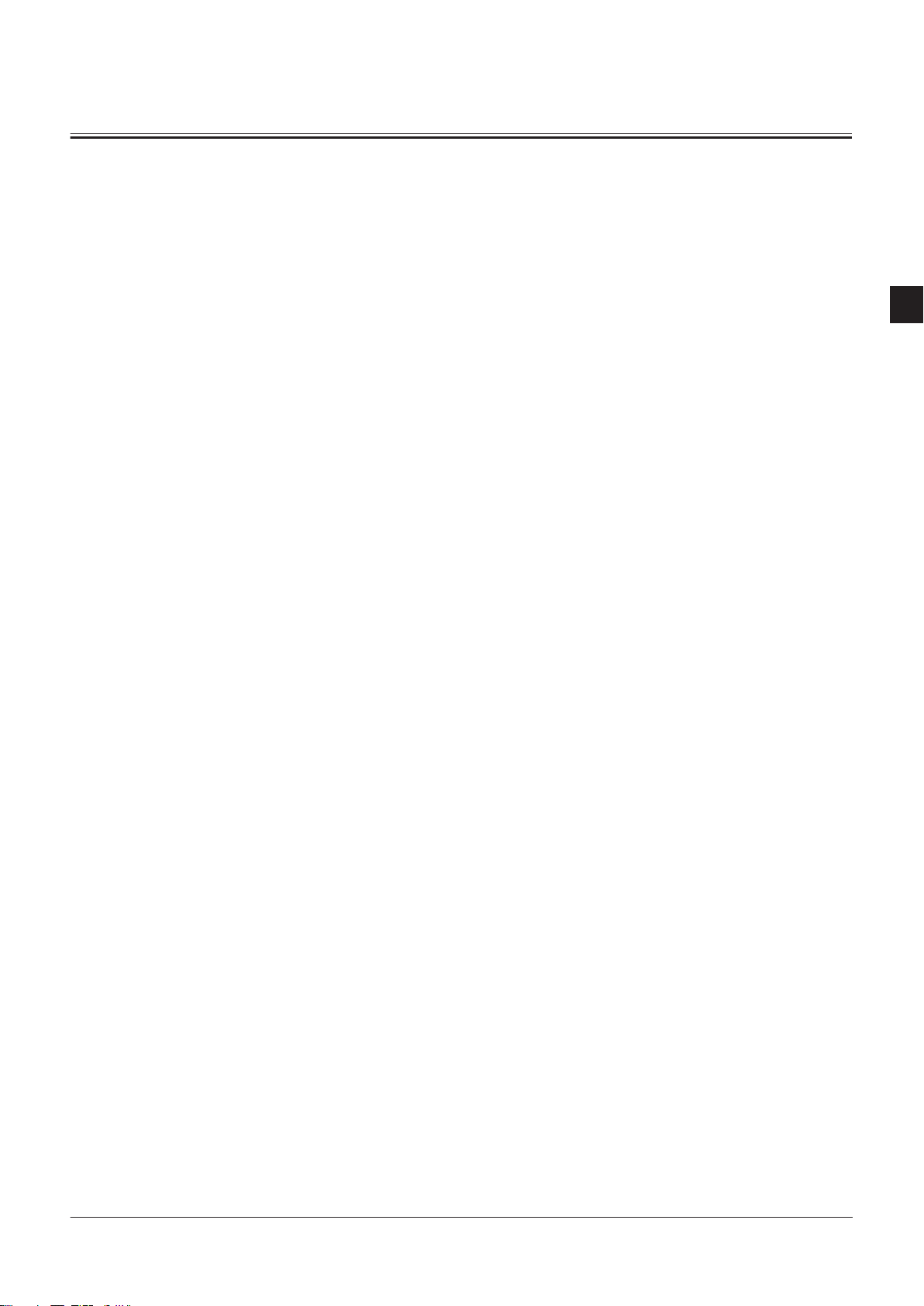

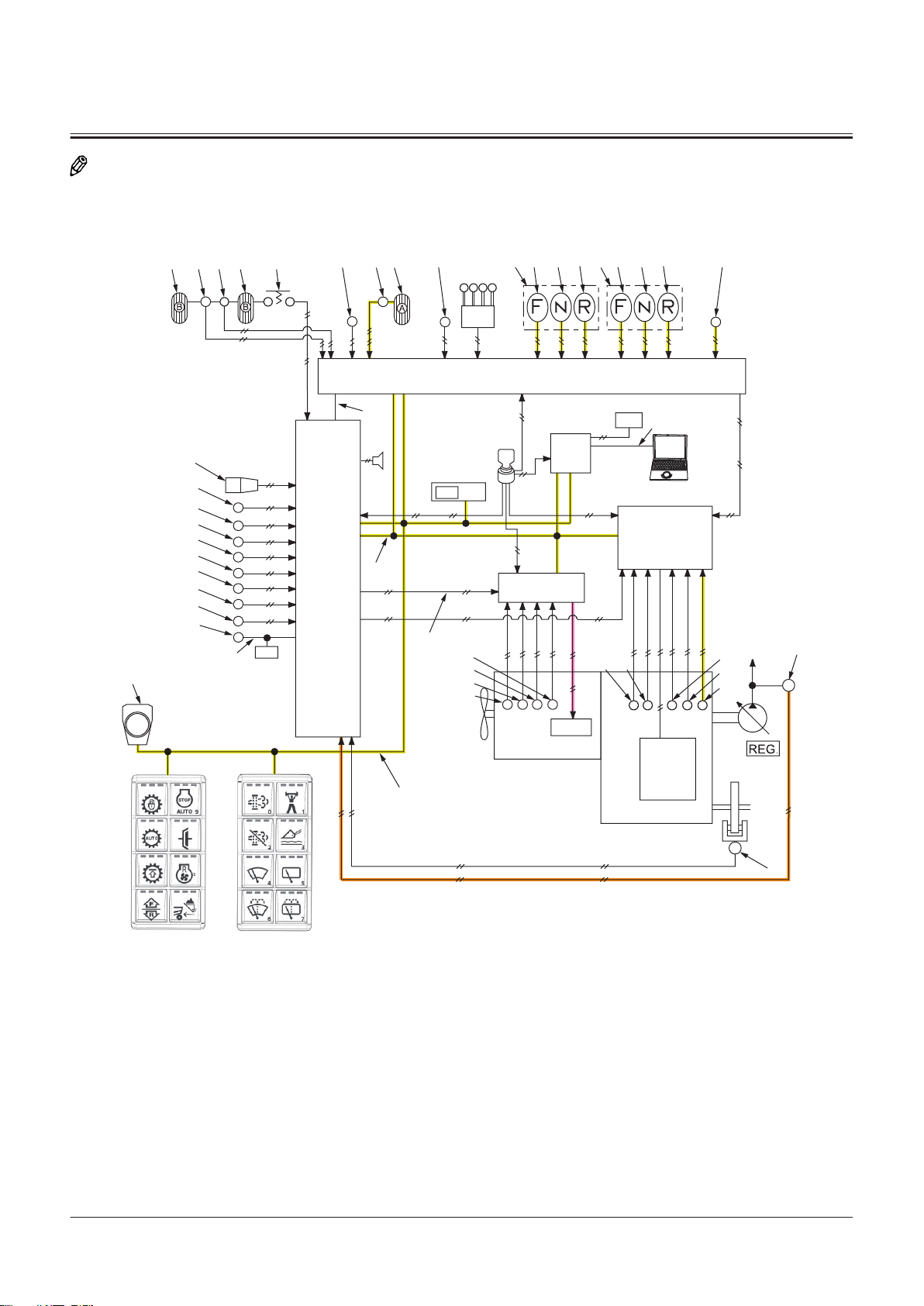

Transmission Control (TCU)............................................T2-2-39

Transmission Control System Layout..........................T2-2-40

Neutral Control...................................................................T2-2-41

Forward/Reverse Lever Priority Control.....................T2-2-43

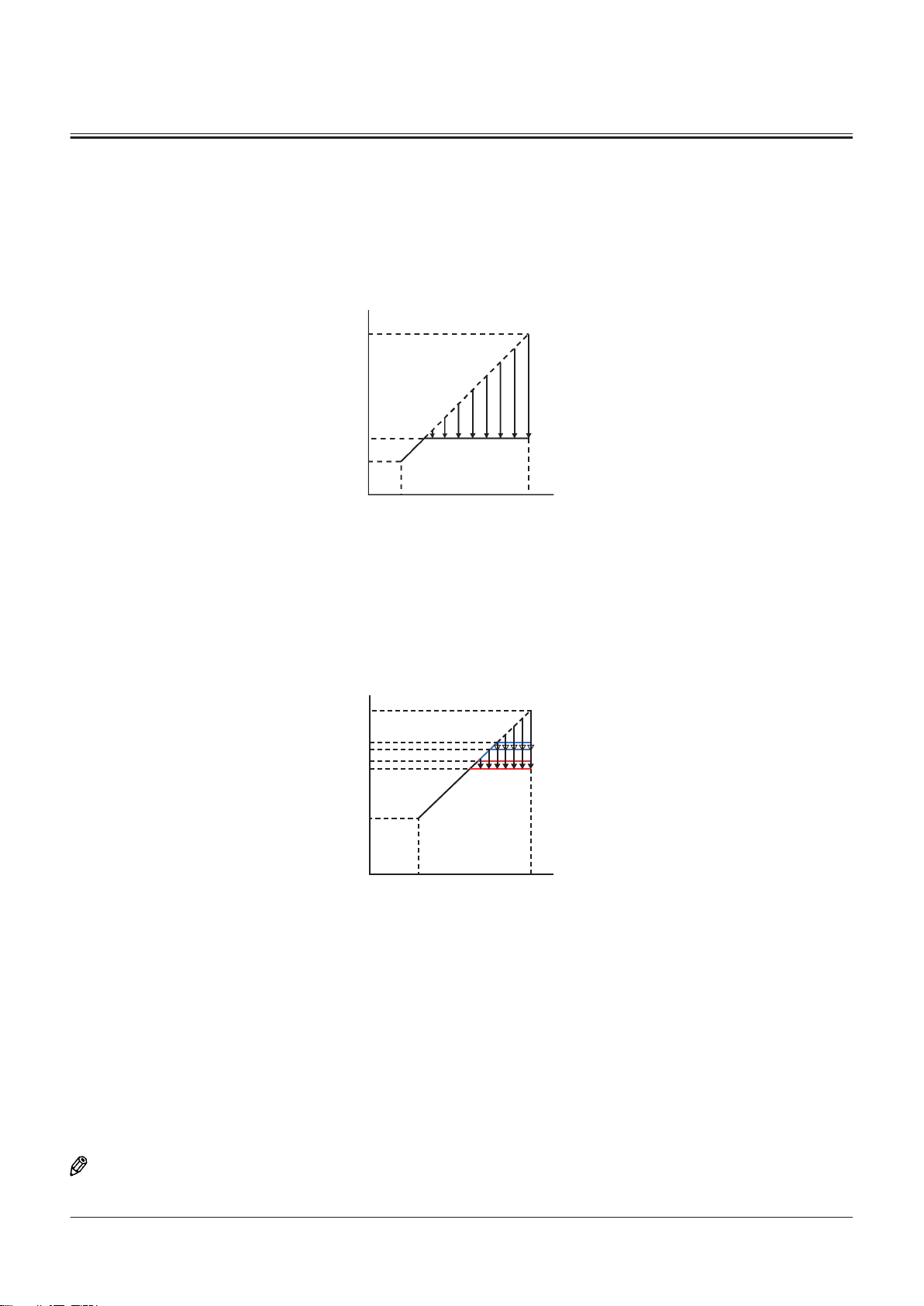

Manual Speed Shift Control...........................................T2-2-45

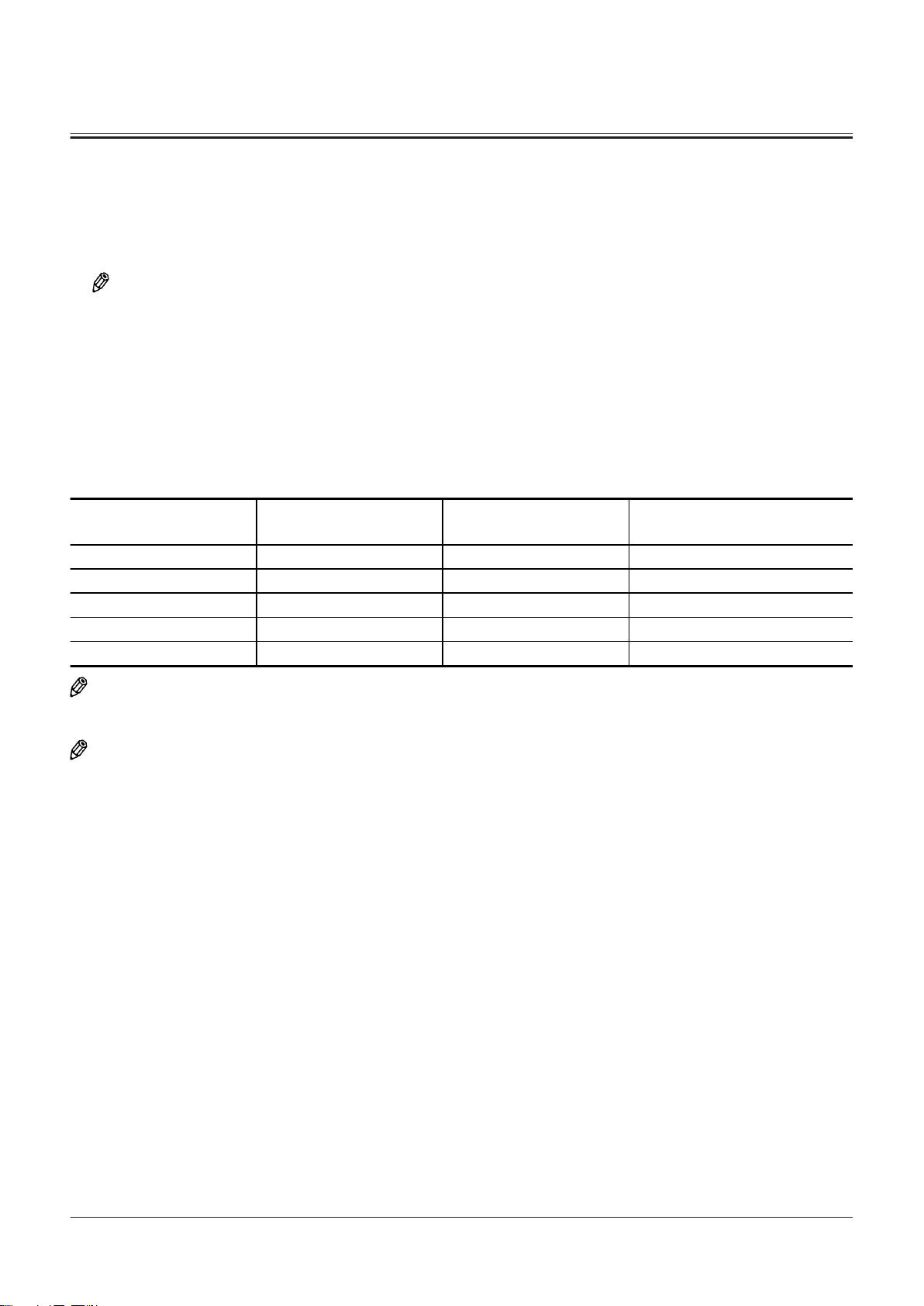

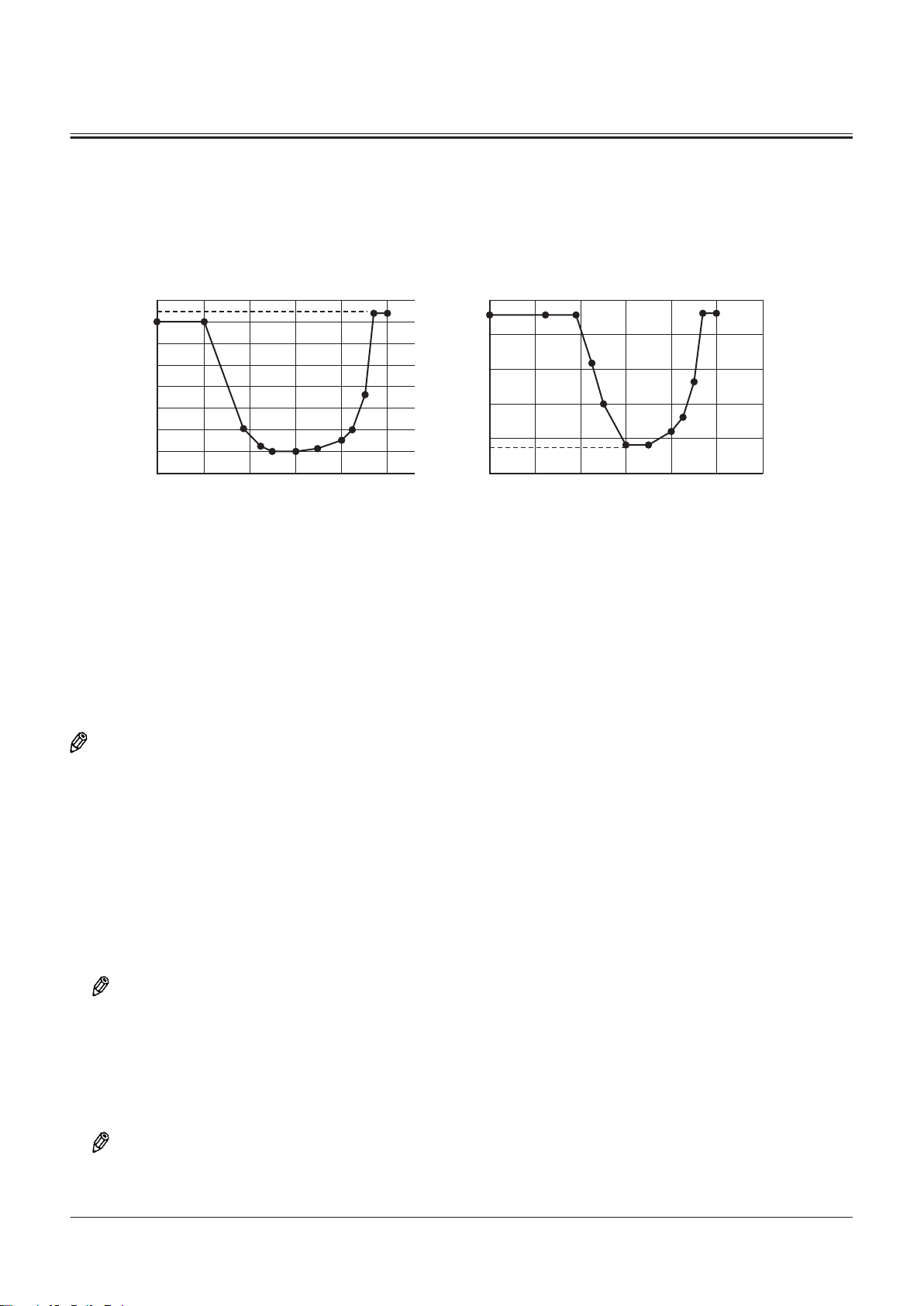

Automatic Speed Shift Control.....................................T2-2-47

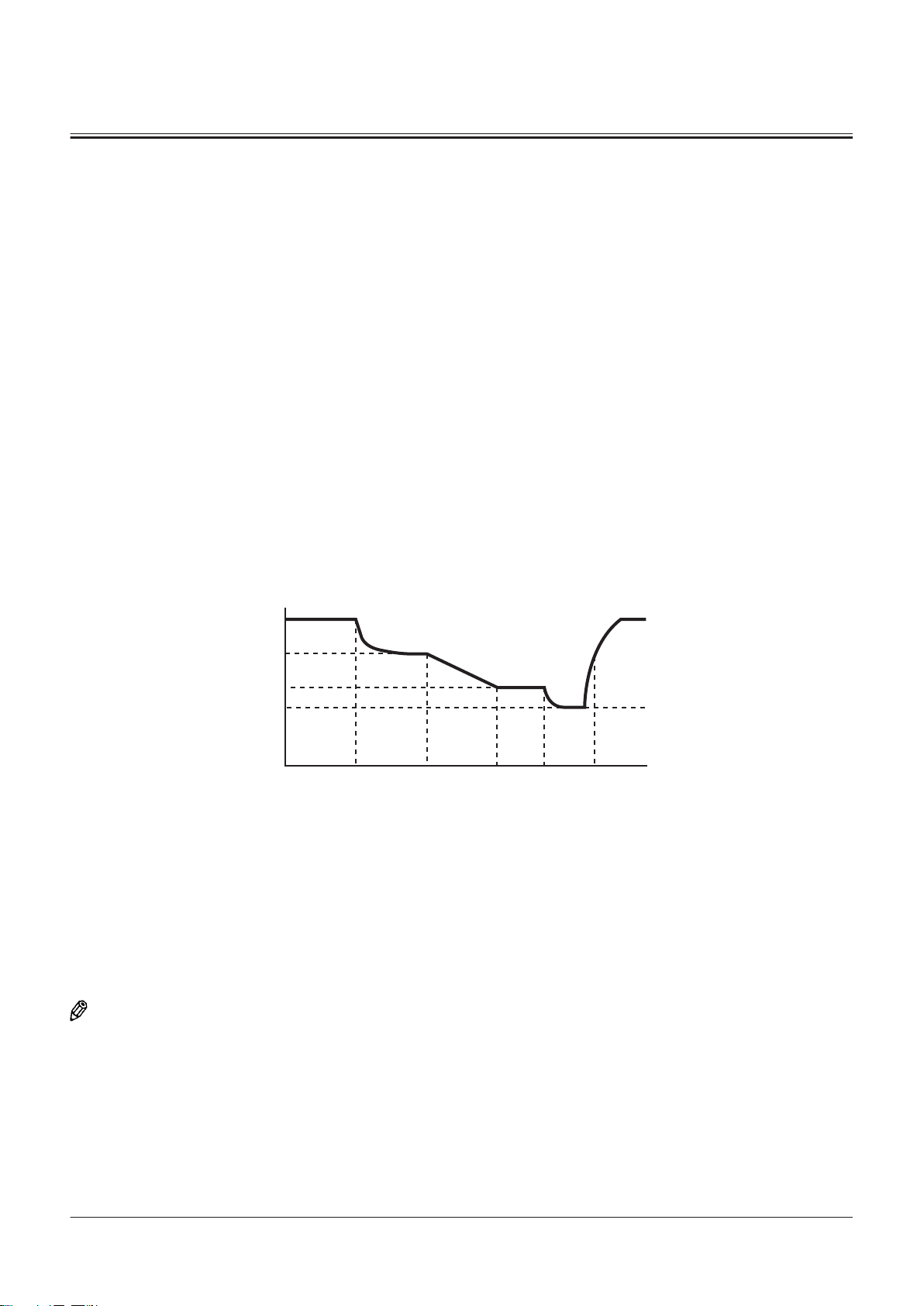

Downshift Control.............................................................T2-2-50

Rise Run Shift Prohibit Control......................................T2-2-52

Clutch Cuto Control........................................................T2-2-54

Shift Holding Control........................................................T2-2-56

Lock Up Control..................................................................T2-2-58

Fan Control, Valve Control ..............................................T2-2-60

Fan Control, Valve Control System Layout................T2-2-61

Fan Speed Control .............................................................T2-2-62

Fan Reverse Rotation Control........................................T2-2-63

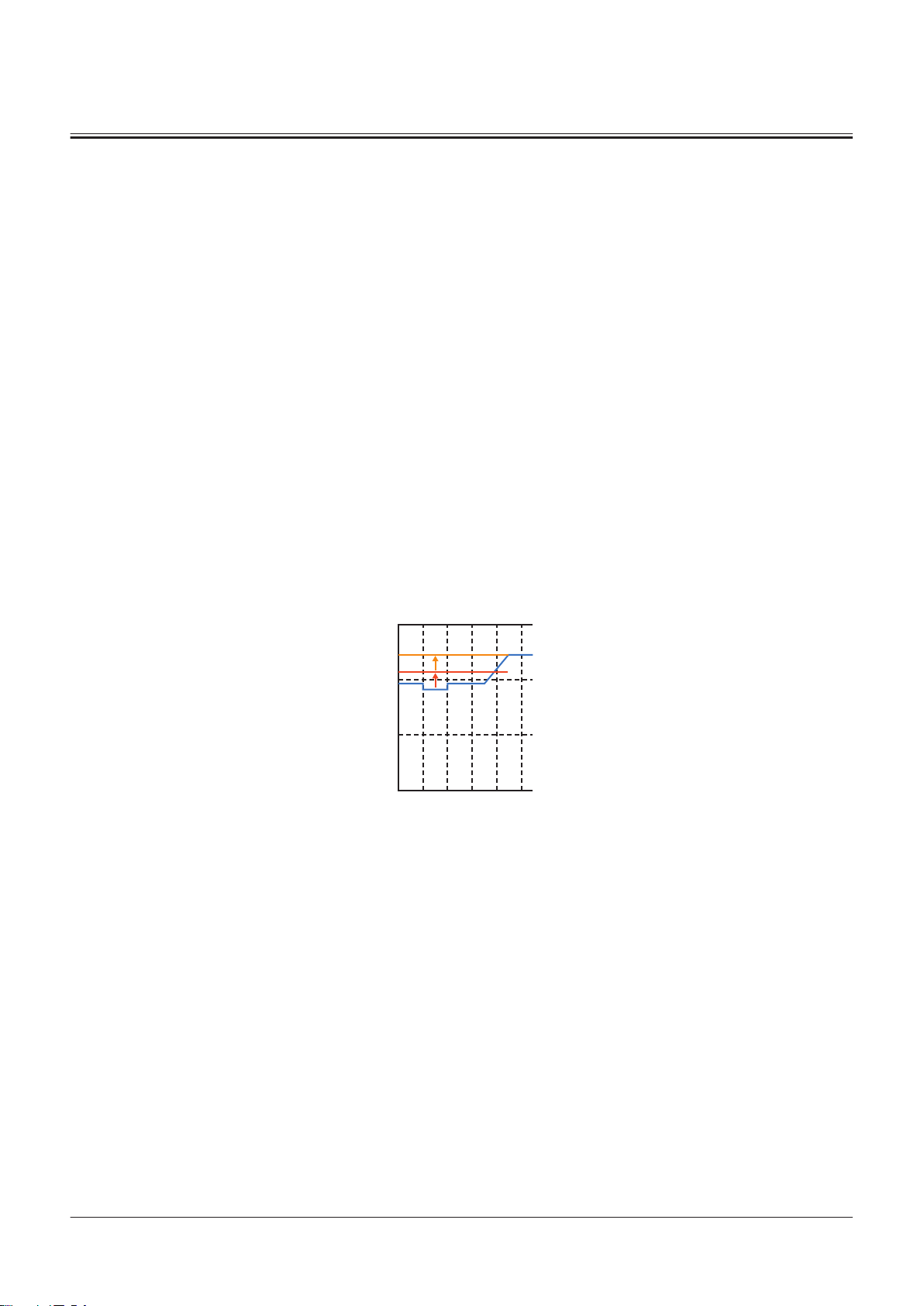

Fan Speed Control During Transmission Learning.

.............................................................................................T2-2-66

Front Attachment Operation Circuit Selection

Control..............................................................................T2-2-67

Ride Control.........................................................................T2-2-69

Control by Electrical and Hydraulic Combined

Circuit................................................................................T2-2-71

Bucket Auto Leveler Control..........................................T2-2-72

Lift Arm Float Control.......................................................T2-2-73

Front Loader Device Control..........................................T2-2-75

Outline of Front Attachment Operation Control.....

.............................................................................................T2-2-75

Process of Front Attachment Operation Control.....

.............................................................................................T2-2-76

Front Attachment Failure Detection ...........................T2-2-78

Detent Control....................................................................T2-2-80

3rd/4th Lever Control.......................................................T2-2-82

Control Lever Lock Control.............................................T2-2-83

Other Controls ....................................................................T2-2-85

Transmission Alarm Control...........................................T2-2-85

Parking Brake Operation Indicator Control..............T2-2-86

Brake Oil Low Pressure Indicator Control..................T2-2-87

Low Steering Oil Pressure Indicator Control............T2-2-88

Overrun Alarm Control ....................................................T2-2-89

Lift Arm Auto Leveler Height Kickout Control.........T2-2-91

Lift Arm Auto Leveler Lower Kickout Control..........T2-2-92

Quick Power Mode Control............................................T2-2-94

Auto Shut-Down Control................................................T2-2-95

Emergency Steering Control .........................................T2-2-98

Coolant Level Switch Control .....................................T2-2-100

Payload Checker Control.............................................. T2-2-100

Object Detection Sensor Control.............................. T2-2-101

Process of Object Detection Sensor Control......... T2-2-102

Notication Processing (Leveling)............................ T2-2-103

Scooping Flag ..................................................................T2-2-104

User Interface ................................................................... T2-2-104

Aerial Angle Control.......................................................T2-2-106

JSS Control System......................................................... T2-2-109

Joystick Steering Lever Control ................................. T2-2-109

Forward/Reverse Switch Control (JSS).................... T2-2-111

Alarm Control (JSS)......................................................... T2-2-114

Engine System ..........................................T2-3-1

Outline of ECM System ......................................................T2-3-1

Fuel Injection Control......................................................... T2-3-1

Fuel Injection Amount Control....................................... T2-3-2

TONFQ50-EN-00(28/02/2022)

Page 16

Fuel Injection Timing Control.......................................... T2-3-3

Fuel Injection Rate Control............................................... T2-3-5

Fuel Injection Pressure Control....................................... T2-3-7

Fuel Injection Amount Correction Control................. T2-3-8

Preheating Control.............................................................. T2-3-9

Alarm Control......................................................................T2-3-10

Urea SCR System................................................................T2-3-11

DEF Injection Control .......................................................T2-3-11

Start-Up Control.................................................................T2-3-12

DEF Defrosting Control....................................................T2-3-13

DEF Thermal Control ........................................................T2-3-14

After-Run Control...............................................................T2-3-15

Engine Output Restriction Control (INDUCEMENT)

.............................................................................................T2-3-16

Insucient DEF Level.......................................................T2-3-17

Malfunction of Urea SCR System..................................T2-3-18

Outline of Aftertreatment Device................................T2-3-19

Operation of Aftertreatment Device...........................T2-3-20

Aftertreatment Device Regeneration Control.........T2-3-21

Hydraulic System......................................T2-4-1

Outline of Hydraulic System ............................................ T2-4-1

Pilot Circuit of Hydraulic System.................................... T2-4-1

Charging Circuit ...................................................................T2-4-3

Charging Circuit (Outline)................................................. T2-4-3

Charging Circuit (When service brake is not

stepped)............................................................................. T2-4-4

Charging Circuit (When service brake is stepped)..

............................................................................................... T2-4-6

Service Brake Circuit ...........................................................T2-4-7

Service Brake Circuit (When brake is applied)........... T2-4-7

Service Brake Circuit (When brake is released) .........T2-4-8

Parking Brake Circuit...........................................................T2-4-8

Parking Brake Circuit (Outline)........................................ T2-4-9

Parking Brake Circuit (When parking brake is

applied).............................................................................. T2-4-9

Parking Brake Circuit (When parking brake is

released) ..........................................................................T2-4-10

Lift Arm/Bucket Operation Control Circuit...............T2-4-11

Lift Arm/Bucket Operation Control Circuit

(Outline)...........................................................................T2-4-11

Fan Circuit.............................................................................T2-4-12

Fan Reverse Rotation Control Circuit..........................T2-4-13

Fan Speed Control Circuit...............................................T2-4-14

Fan Circuit (Prevention of Cavitation).........................T2-4-15

Ride Control Circuit...........................................................T2-4-16

Main Circuit of Hydraulic System.................................T2-4-17

Main Circuit of Hydraulic System (Outline) ..............T2-4-18

Steering Priority Circuit....................................................T2-4-19

Steering Priority Circuit (When not Operated)........T2-4-19

Steering Priority Circuit (When Operated)................T2-4-20

Steering Operation Control Circuit..............................T2-4-22

Steering Operation Control Circuit (Outline)...........T2-4-22

Steering Operation Control Circuit (Steering

Operation).......................................................................T2-4-23

Steering Operation Control Circuit (Steering Stop

Operation).......................................................................T2-4-25

Front Attachment Control Circuit ................................T2-4-26

Neutral Circuit.....................................................................T2-4-27

Flow Rate Control Circuit................................................T2-4-28

Relief Circuit.........................................................................T2-4-29

Single Operation Circuit..................................................T2-4-30

Combined Operation Circuit (Combined

Operation of Lift Arm Raise and Bucket Dump).

.............................................................................................T2-4-31

Combined Operation Circuit (Combined

Operation of Steering and Lift Arm Raise) ..........T2-4-33

Pump Control Circuit........................................................T2-4-35

Parallel Circuit Flow Rate Control.................................T2-4-37

Emergency Steering Circuit ...........................................T2-4-38

Outline of JSS Hydraulic System...................................T2-4-40

Pilot Circuit of JSS Hydraulic System...........................T2-4-41

Joystick Steering Operation Control Circuit.............T2-4-41

Joystick Steering Operation (When Operating

Steering Wheel).............................................................T2-4-43

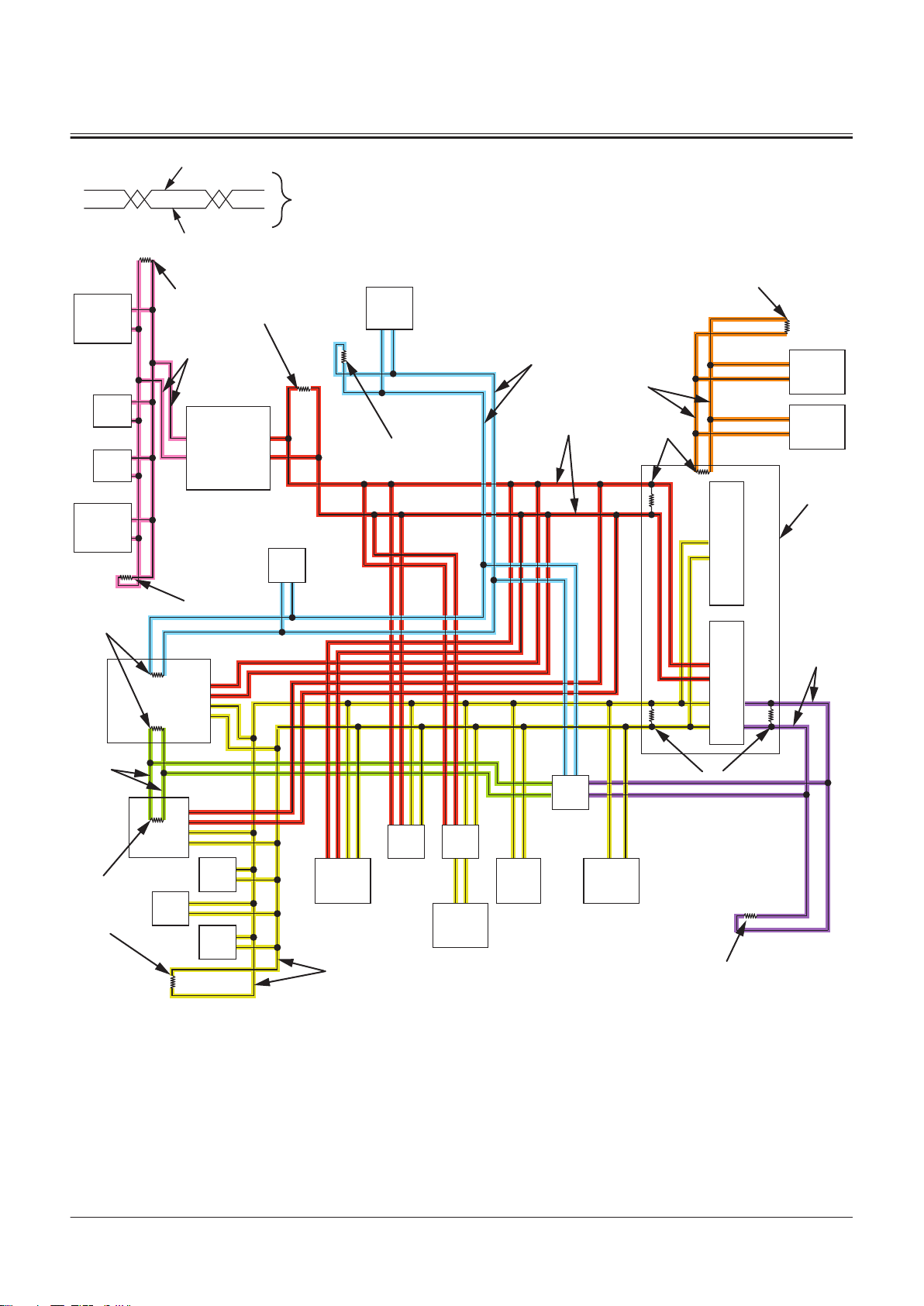

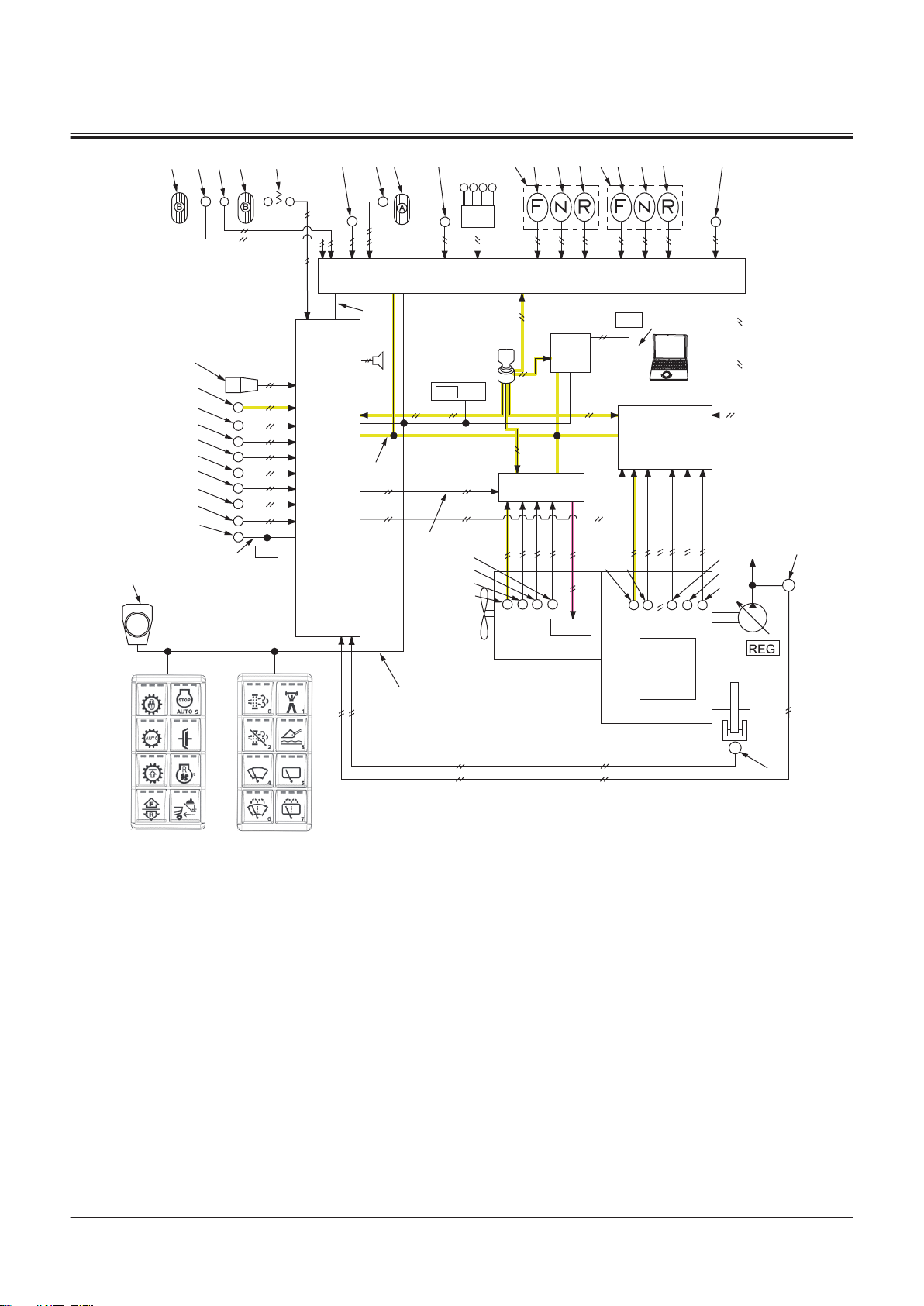

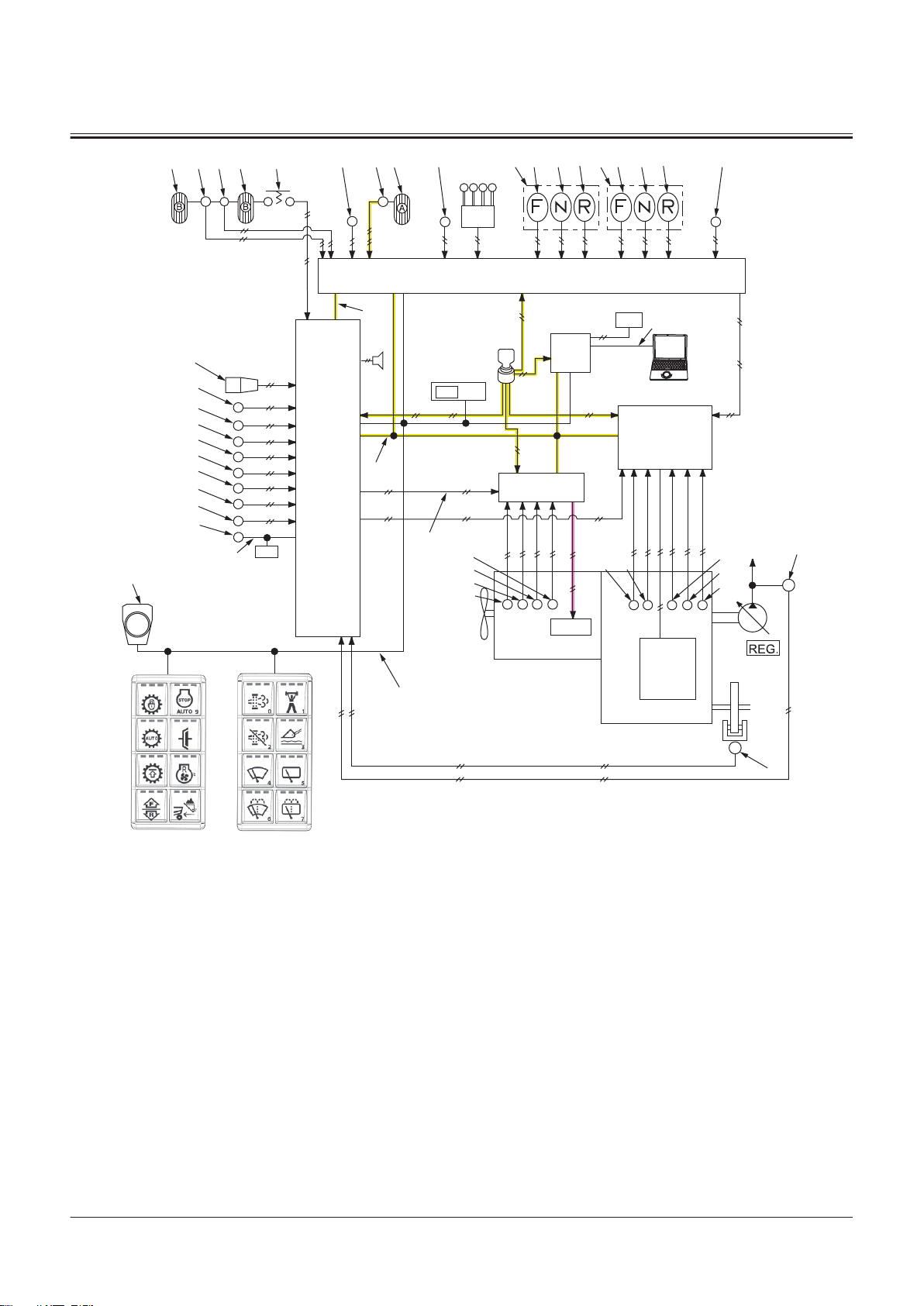

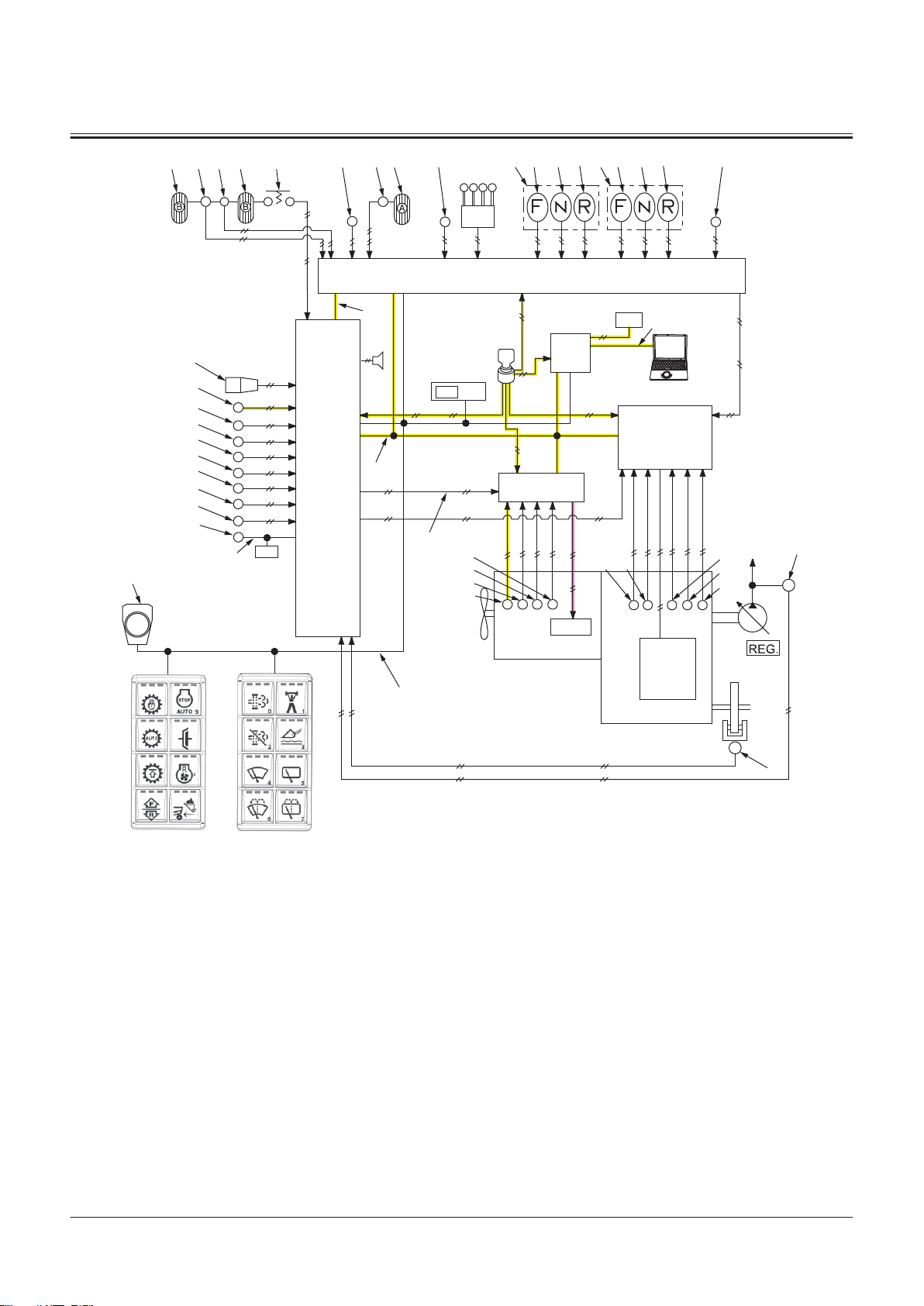

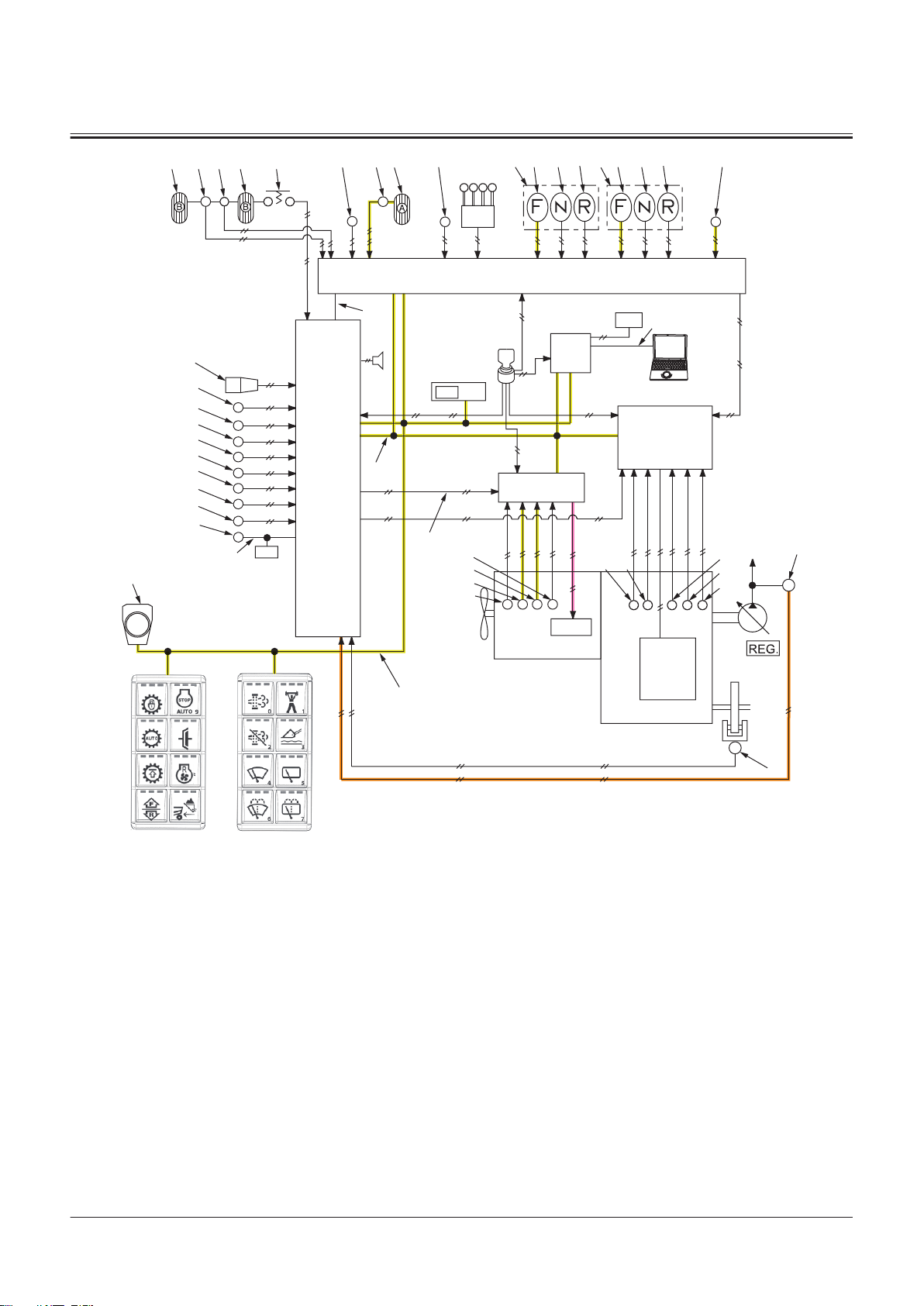

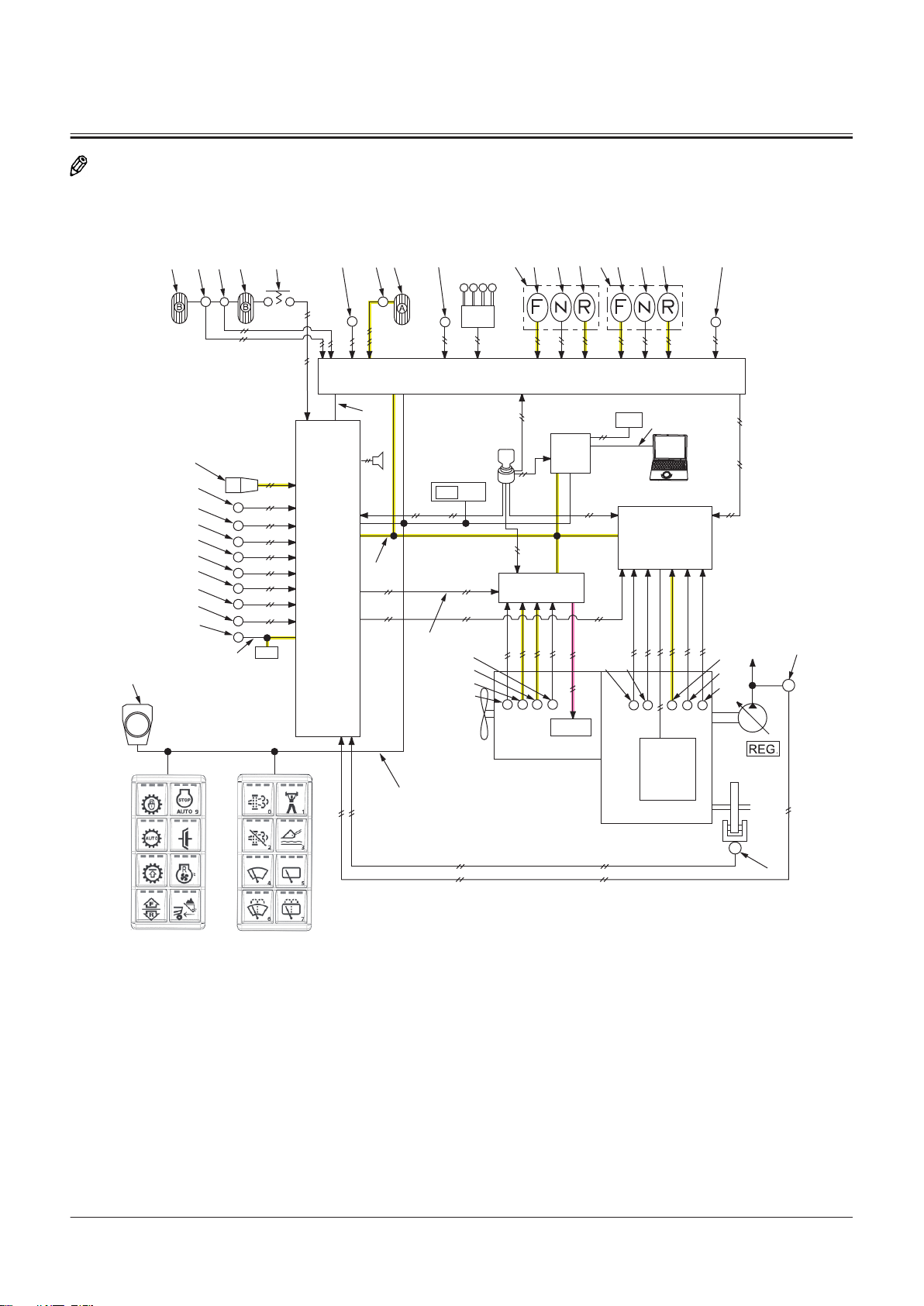

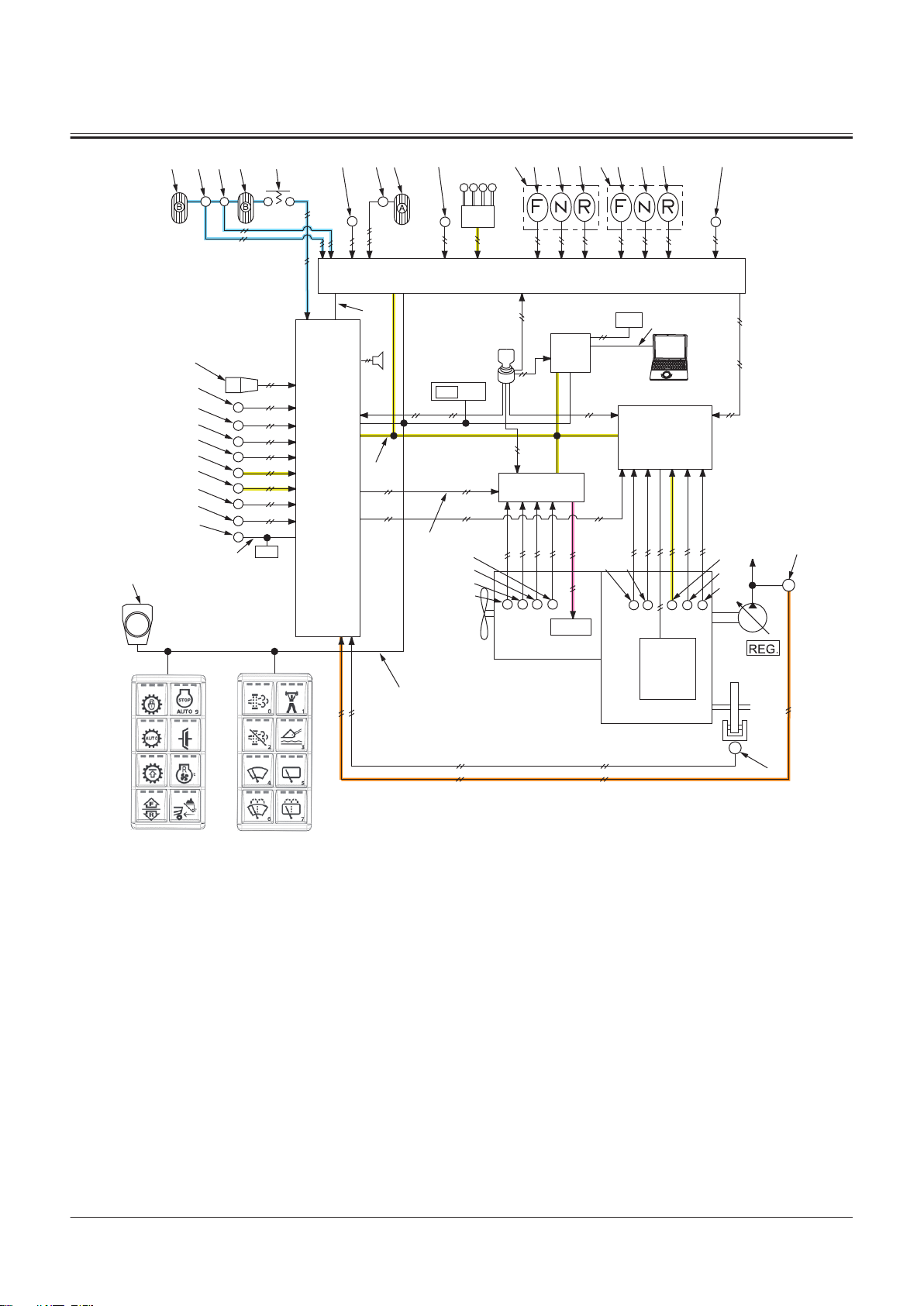

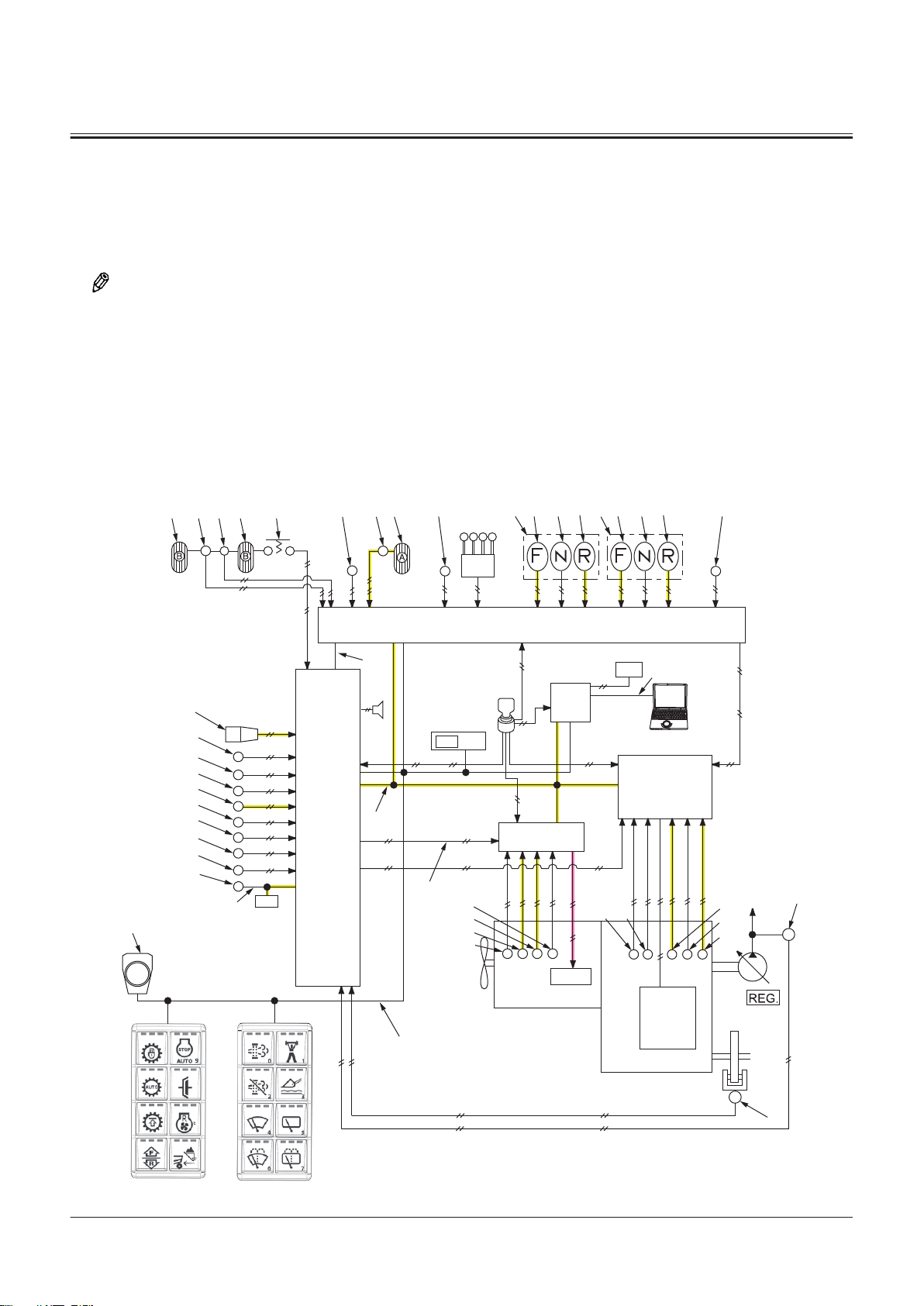

Electrical System.......................................T2-5-1

Outline of Electrical System .............................................T2-5-1

Main Circuit of Electrical System.................................... T2-5-1

Electric Power Circuit (Key Switch: OFF)......................T2-5-1

CAN Circuit............................................................................. T2-5-3

Accessory Related Circuits (Key Switch: ACC)............ T2-5-6

Starting Circuit (Key Switch: START)..............................T2-5-7

Charging Circuit (Key Switch: ON) ................................. T2-5-8

Surge Voltage Prevention Circuit................................... T2-5-9

Control Lever Lock Circuit (Key Switch: ON).............T2-5-10

Auto Shut-down Circuit...................................................T2-5-12

Engine Stop Circuit............................................................T2-5-14

Air Conditioner Circuit .....................................................T2-5-15

Column Box Circuit............................................................T2-5-16

Headlight Circuit (Clearance Light, License Light,

Tail Light Circuit (Light Switch: Clearance Light

Position))..........................................................................T2-5-16

Headlight Circuit (Dimmer Switch: Low Beam

Position)...........................................................................T2-5-18

High Beam Circuit..............................................................T2-5-20

Hazard Light Circuit (Key Switch: OFF).......................T2-5-21

Turn Signal Light Circuit..................................................T2-5-23

Horn Circuit (Key Switch: OFF) ......................................T2-5-24

Back Buzzer Circuit............................................................T2-5-24

Brake Light Circuit .............................................................T2-5-25

Parking Brake Circuit (Parking Brake: Released

(Parking Switch: Release Position))........................T2-5-26

Parking Brake Circuit (Parking Brake: Applied

(Parking Switch: Apply Position).............................T2-5-27

Accessory Circuit of Electrical System........................T2-5-28

Work Light Circuit..............................................................T2-5-28

Front Wiper Circuit ............................................................T2-5-29

Rear Wiper Circuit..............................................................T2-5-31

Washer Circuit.....................................................................T2-5-32

Cab Light Circuit.................................................................T2-5-33

TONFQ50-EN-00(28/02/2022)

Page 17

SECTION 3

COMPONENT OPERATION

CONTENTS

Pump Device .............................................T3-1-1

Outline of Pump Device ....................................................T3-1-1

Outline of Main Pump........................................................ T3-1-1

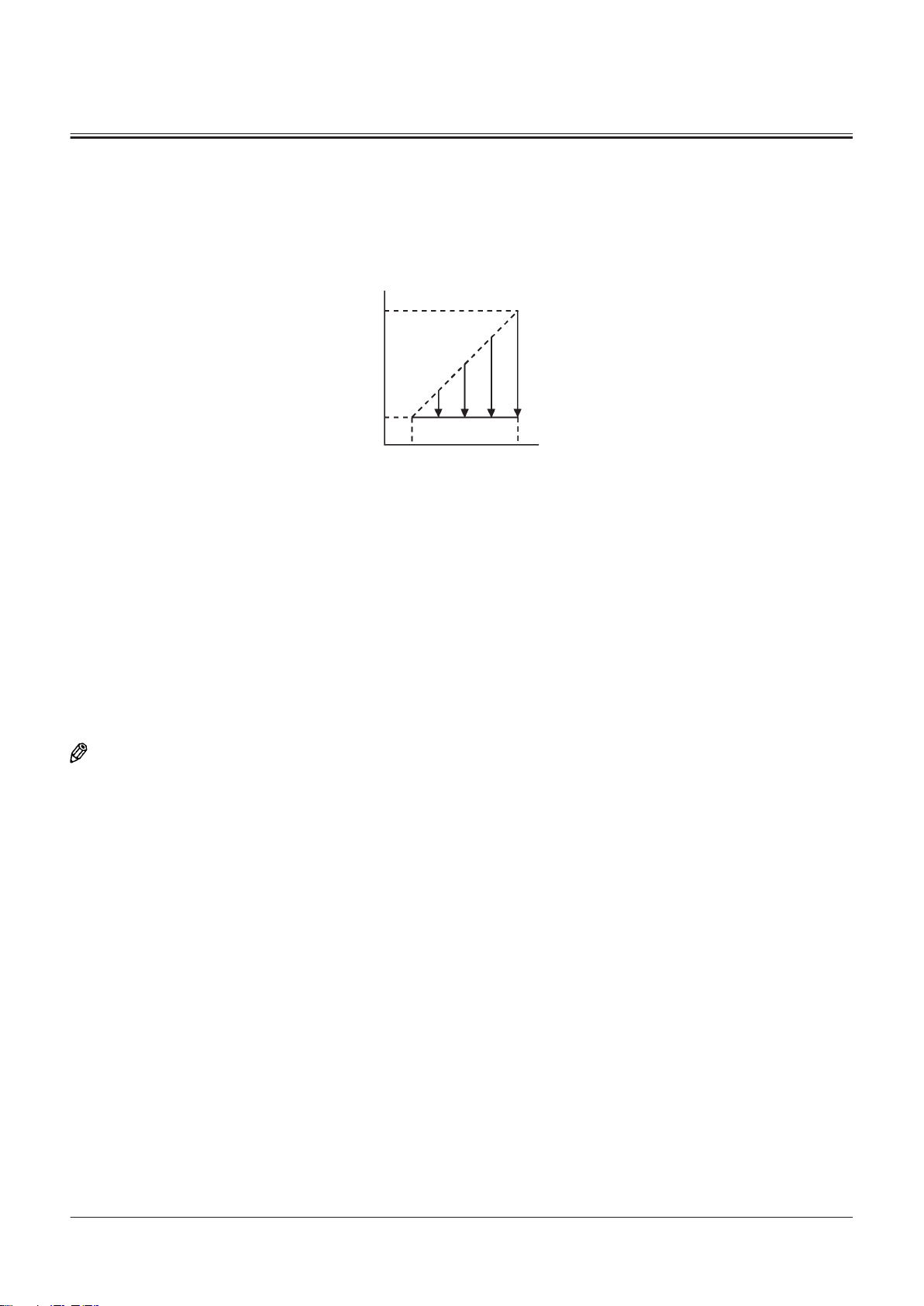

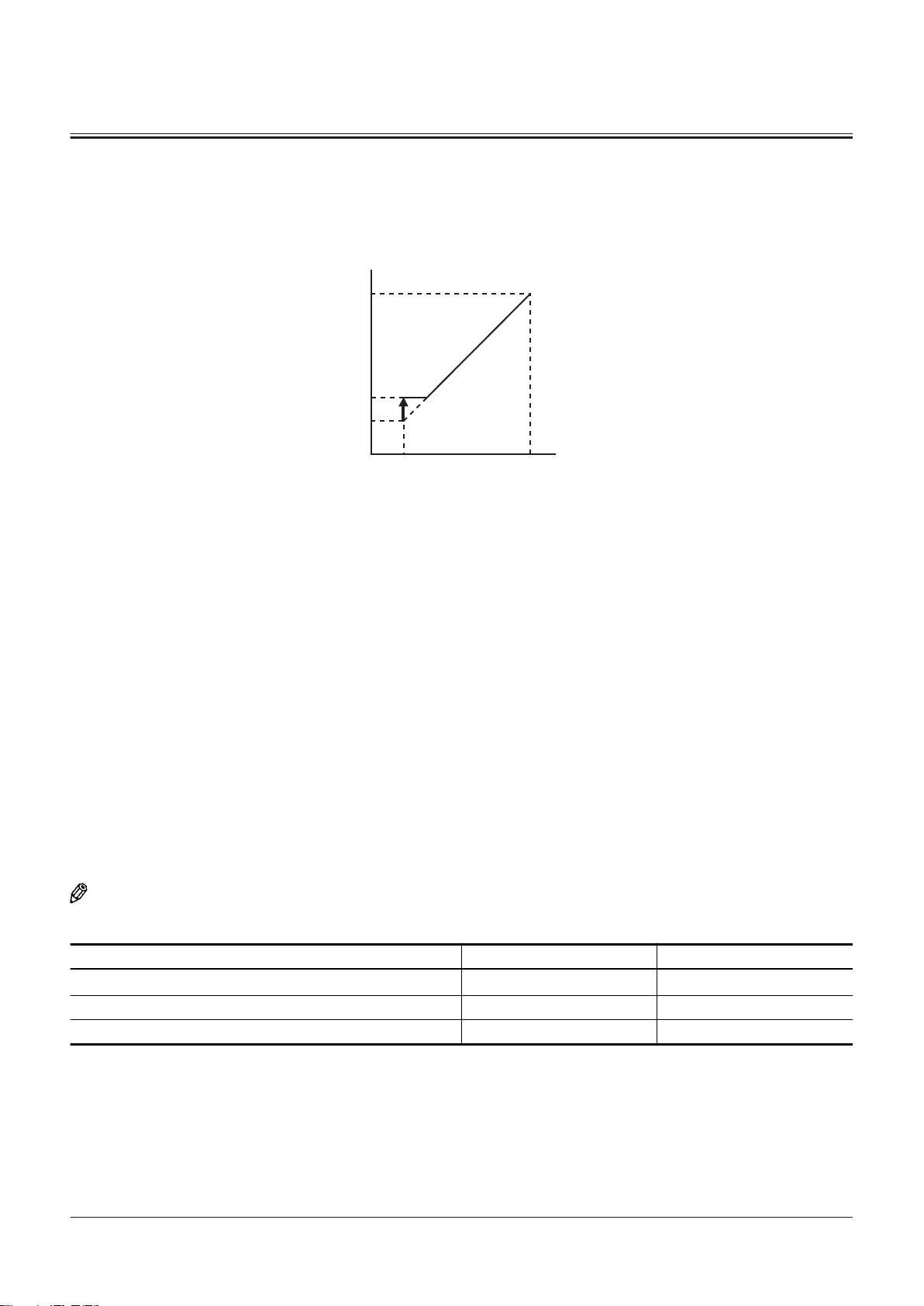

Increasing and Decreasing of Main Pump Delivery

Flow Rate...........................................................................T3-1-2

Outline of Regulator ...........................................................T3-1-5

Regulator Control Function..............................................T3-1-6

Control by Pump Control Pressure................................ T3-1-6

Maximum Torque Control................................................. T3-1-9

Control by Pilot Pressure from Torque Control

Solenoid Valve...............................................................T3-1-11

Outline of Pilot Pump.......................................................T3-1-13

Outline of Pump Delivery Pressure Sensor...............T3-1-13

Control Valve.............................................T3-2-1

Outline of Control Valve.................................................... T3-2-1

Components in Control Valve .........................................T3-2-2

Main Circuit of Control Valve.........................................T3-2-10

Pilot Operation Control Circuit of Control Valve.....T3-2-12

External Pilot Pressure Circuit of Control Valve.......T3-2-13

Outline of Main Relief Valve...........................................T3-2-16

Relief Operation of Main Relief Valve .........................T3-2-16

Outline of Overload Relief Valve (With Make-Up

Function) .........................................................................T3-2-17

Relief Operation of Overload Relief Valve.................T3-2-17

Make-Up Operation of Overload Relief Valve..........T3-2-18

Outline of Bleed-O Compensator .............................T3-2-19

Operation of Bleed-O Compensator........................T3-2-19

Operation of Bucket Spool (Bucket Tilt) ....................T3-2-22

Operation of Bucket Spool (Bucket Dump)..............T3-2-24

Operation of Lift Arm Spool (Lift Arm Raise) ...........T3-2-26

Operation of Lift Arm Spool (Lift Arm Lower)..........T3-2-28

Operation of Lift Arm Spool (Lift Arm Float)............T3-2-30

Outline of Pump Flow Rate Control Valve.................T3-2-32

Operation (When the Control Lever is in Neutral)

of Pump Flow Rate Control Valve ...........................T3-2-32

Operation (When the Control Lever is Operated)

of Pump Flow Rate Control Valve ...........................T3-2-34

Outline of Solenoid Valve (Built-in Control Valve) ..

.............................................................................................T3-2-36

Outline of Lift Arm Flow Rate Control Valve.............T3-2-36

Operation (When In Neutral) of Lift Arm Flow Rate

Control Valve..................................................................T3-2-36

Operation (When the Flow Rate Control) of Lift

Arm Flow Rate Control Valve....................................T3-2-38

Outline of Ride Control Selector Solenoid Valve....T3-2-40

Operation of Ride Control Selector Solenoid Valve

.............................................................................................T3-2-40

Cooling Fan System ..................................T3-3-1

Outline of Fan Motor .......................................................... T3-3-1

Outline of Fan Valve............................................................ T3-3-1

Operation of Fan Valve (Normal Rotation).................. T3-3-2

Operation of Fan Valve (Reverse Rotation)................. T3-3-4

Operation of Fan Valve (With Fan Speed

Controlled)........................................................................ T3-3-6

Make-Up Operation of Fan Valve...................................T3-3-8

Steering Pilot Valve ..................................T3-4-1

Outline of Steering Pilot Valve........................................ T3-4-1

Structure of Steering Pilot Valve.....................................T3-4-1

Operation of Steering Pilot Valve...................................T3-4-3

Operation of Steering Pilot Valve (Left Steering) ....

............................................................................................... T3-4-4

Operation of Steering Pilot Valve (Right Steering) .

............................................................................................... T3-4-6

Operation of Steering Pilot Valve (Neutral) ................ T3-4-6

Steering Valve ...........................................T3-5-1

Outline of Steering Valve.................................................. T3-5-1

Structure of Steering Valve...............................................T3-5-1

Operation of Steering Valve............................................. T3-5-4

Outline of Meter-in Compensator .................................T3-5-7

Operation of Meter-in Compensator............................ T3-5-7

Outline of Steering Main Relief Valve........................... T3-5-8

Relief Operation of Steering Main Relief Valve .........T3-5-9

Outline of Steering Overload Relief Valve.................T3-5-10

Relief Operation of Steering Overload Relief Valve

.............................................................................................T3-5-11

Make-Up Operation of Steering Overload Relief

Valve..................................................................................T3-5-12

Charging Circuit........................................T3-6-1

Outline of Charging Circuit ..............................................T3-6-1

Operation of Brake Charge Valve (Between

Pressure Charging Start and Pressure Charging

Finish) .................................................................................T3-6-1

Operation of Brake Charge Valve (After Pressure

Charging Finish).............................................................. T3-6-3

Structure of Combination Valve..................................... T3-6-6

Operation of Reducing Valve...........................................T3-6-7

TONFQ50-EN-00(28/02/2022)

Page 18

Specications of Primary Pilot Pressure Sensor........ T3-6-8

Outline of Lift Arm Flow Rate Control Solenoid

Valve..................................................................................T3-6-10

Outline of Proportional Solenoid Valve.....................T3-6-11

Operation of Proportional Solenoid Valve (When

in Neutral) .......................................................................T3-6-11

Operation of Proportional Solenoid Valve (When

Excited).............................................................................T3-6-12

Outline of Service Brake Accumulator .......................T3-6-13

Drive Unit ..................................................T3-7-1

Outline of Drive Unit........................................................... T3-7-1

Structure of Drive Unit....................................................... T3-7-2

Operation of Torque Converter ......................................T3-7-6

Outline of Transmission..................................................... T3-7-8

Operation of Transmission (Forward First Speed)...

.............................................................................................T3-7-10

Operation of Transmission (Forward Second

Speed) ..............................................................................T3-7-13

Operation of Transmission (Forward Third Speed).

.............................................................................................T3-7-16

Operation of Transmission (Forward Fourth

Speed) ..............................................................................T3-7-19

Operation of Transmission (Reverse First Speed)....

.............................................................................................T3-7-22

Operation of Transmission Control Valve..................T3-7-25

Outline of Transmission Regulator Valve ..................T3-7-29

Operation of Transmission Regulator Valve .............T3-7-31

Outline of Transmission Oil Filter Relief Valve.........T3-7-35

Operation of Transmission Oil Filter Relief Valve.....

.............................................................................................T3-7-36

Outline of Torque Converter Check Valve.................T3-7-37

Operation of Torque Converter Check Valve ...........T3-7-37

Outline of Parking Brake .................................................T3-7-39

Operation of Parking Brake............................................T3-7-40

Parking Brake Manual Release ......................................T3-7-42

Drive Unit Circuit................................................................T3-7-43

Axle............................................................T3-8-1

Outline of Axle ...................................................................... T3-8-1

Structure of Dierential Gear ..........................................T3-8-1

Purpose of Dierential Gear.............................................T3-8-2

Basic Operational Principle of Dierential Gear .......T3-8-3

Operation of Dierential Gear......................................... T3-8-3

Outline of Torque Proportioning Dierential (TPD)

............................................................................................... T3-8-4

Operation of Torque Proportioning Dierential

(TPD) ................................................................................... T3-8-5

Outline of Limited Slip Dierential (LSD).................... T3-8-6

Operation of Limited Slip Dierential (LSD)............... T3-8-7

Outline of Service Brake ....................................................T3-8-7

Operation of Service Brake (When Brake Is

Applied) .............................................................................T3-8-7

Operation of Service Brake (When Brake Is

Released) ...........................................................................T3-8-8

Outline of Final Drive/Axle Shaft.................................... T3-8-9

Brake Valve

Outline of Brake Valve........................................................ T3-9-1

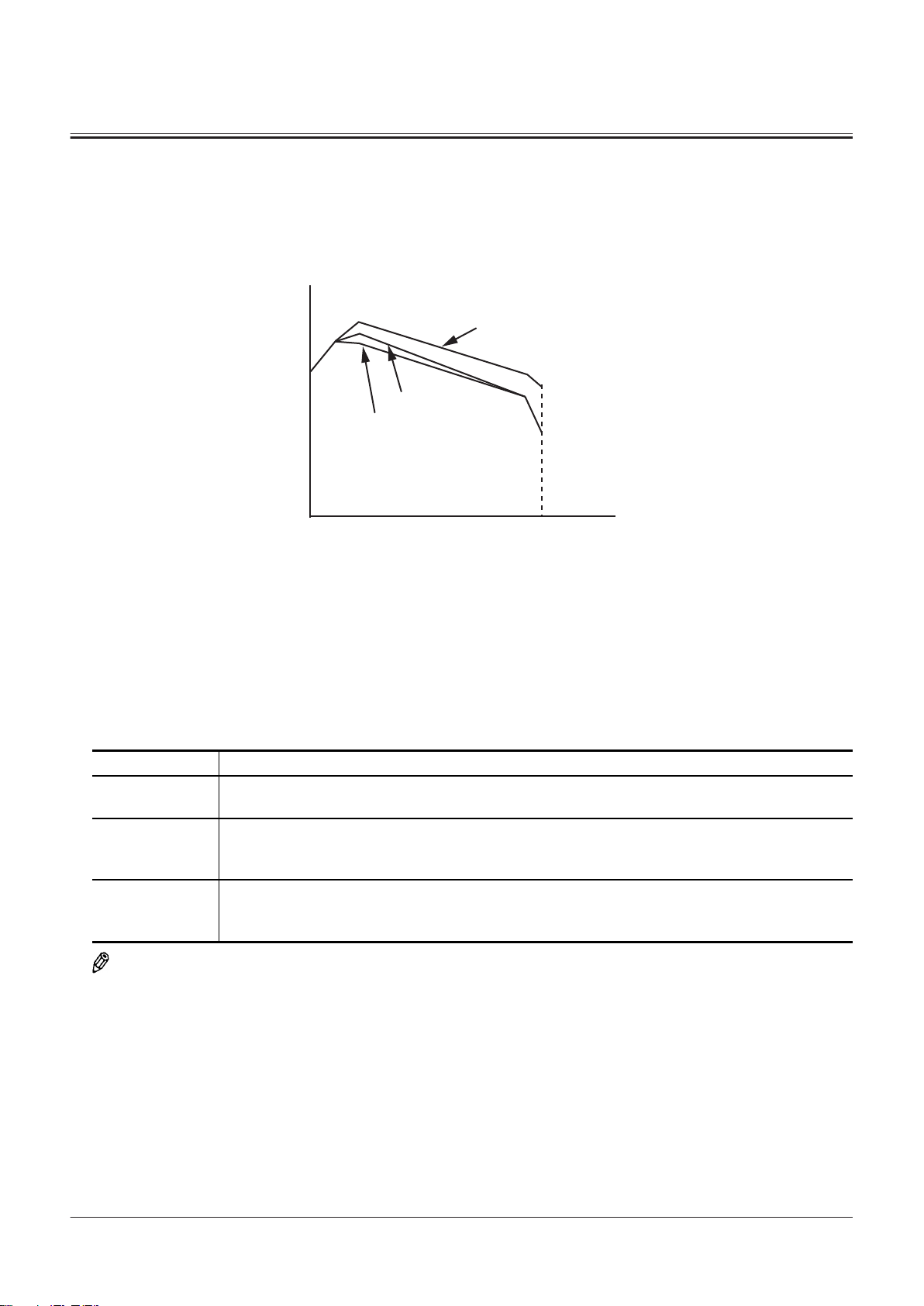

Operation of Brake Valve (When Brake Pedal Is In

Neutral) (Output Curve: A to B) ................................. T3-9-1

Operation of Brake Valve (During Metering or

Decompressing) (Output Curve: B-C) .....................T3-9-3

Operation of Brake Valve (Full Stroke) (Output

Curve: C to D)................................................................... T3-9-5

................................................T3-9-1

DEF Supply System.................................T3-10-1

Outline of DEF Supply System ......................................T3-10-1

Outline of DEF Tank...........................................................T3-10-1

Outline of DEF Hose..........................................................T3-10-2

Outline of DEF Sensor Unit.............................................T3-10-2

Outline of DEF Sensor Head Unit .................................T3-10-2

Functions of DEF Sensor Unit Parts.............................T3-10-3

Outline of DEF Supply Module .....................................T3-10-4

Outline of Coolant Line....................................................T3-10-5

Others......................................................T3-11-1

Outline of Propeller Shaft ...............................................T3-11-1

Outline of 2-Spool Solenoid Valve Unit.....................T3-11-2

Outline of Steering Accumulator.................................T3-11-2

Outline of Ride Control Valve........................................T3-11-3

Operation of Ride Control Valve (Control for Ride

Control: When Not Operating) ................................T3-11-4

Operation of Ride Control Valve (Control for Ride

Control: When Operating).........................................T3-11-5

Outline of Ride Control Accumulator.........................T3-11-6

Outline of Check Valve.....................................................T3-11-7

Operation of Stop Valve..................................................T3-11-7

Outline of Pilot Filter.........................................................T3-11-8

Outline of Emergency Steering Pump Unit..............T3-11-9

Outline of Joystick Steering Valve................................T3-11-9

Operation of Joystick Steering Valve (Right Turn) ..

.......................................................................................... T3-11-11

Operation of Joystick Steering Valve (Left Turn) .T3-11-11

TONFQ50-EN-00(28/02/2022)

Page 19

SECTION 1

GENERAL

CONTENTS

Specications............................................T1-1-1

Specications ........................................................................ T1-1-1

Component Layout...................................T1-2-1

Main Component (Overview)..........................................T1-2-1

Main Component................................................................. T1-2-2

Electrical System (Overview) ...........................................T1-2-3

Air Cleaner and Radiator Assembly............................... T1-2-3

Radiator Assembly............................................................... T1-2-4

Battery Box............................................................................. T1-2-4

Hydraulic Oil Tank................................................................ T1-2-5

Fuel Tank .................................................................................T1-2-6

Drive Unit................................................................................ T1-2-7

Front Axle................................................................................T1-2-7

Cab ............................................................................................ T1-2-8

Front Console........................................................................T1-2-9

Panel Switch.........................................................................T1-2-10

Right Console......................................................................T1-2-11

Operator's Seat and Joystick Steering System........T1-2-12

Rear Console........................................................................T1-2-13

Control Unit .........................................................................T1-2-14

Column Monitor.................................................................T1-2-15

Engine....................................................................................T1-2-16

Aftertreatment Device.....................................................T1-2-17

Fan Valve...............................................................................T1-2-17

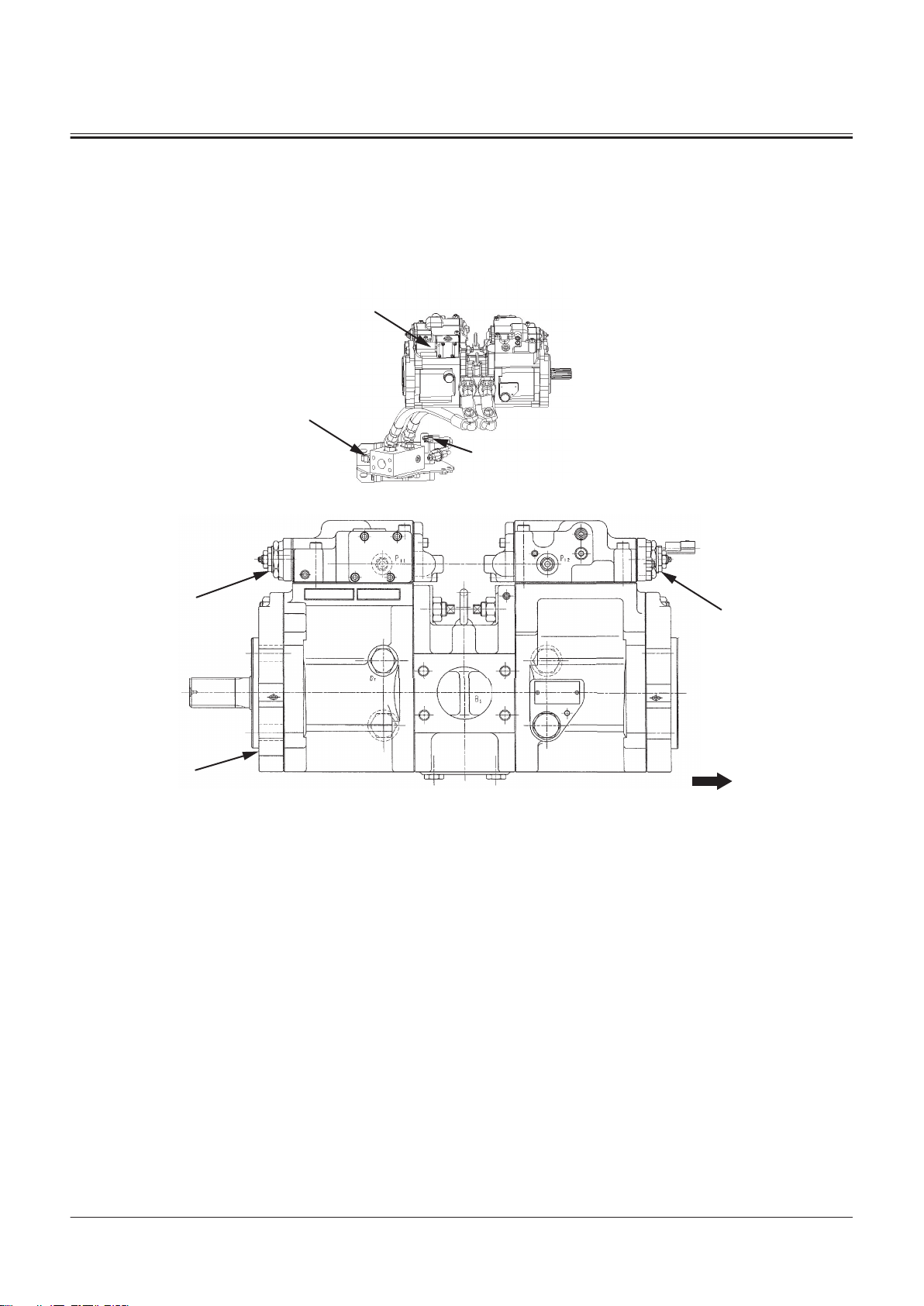

Pump Device .......................................................................T1-2-18

Control Valve .......................................................................T1-2-19

Brake Valve...........................................................................T1-2-20

Brake Charge Valve/Combination Valve....................T1-2-20

Steering Valve .....................................................................T1-2-21

Ride Control Valve.............................................................T1-2-22

2-Spool Solenoid Valve Unit ..........................................T1-2-22

Emergency Steering Pump Unit...................................T1-2-23

DEF Tank................................................................................T1-2-23

DEF Supply Module...........................................................T1-2-24

Joystick Steering Hydraulic Component...................T1-2-24

Joystick Steering Valve.....................................................T1-2-25

Joystick Steering Solenoid Valve Unit........................T1-2-25

Steering Pilot Valve...........................................................T1-2-26

Component Specications.......................T1-3-1

Specications of Engine.................................................... T1-3-1

Specications of Engine Accessories............................T1-3-5

Specications of Hydraulic Component...................... T1-3-6

Electrical Component......................................................... T1-3-8

TONFQ50-EN-00(28/02/2022)

Page 20

MEMO

TONFQ50-EN-00(28/02/2022)

Page 21

R1

B

R2

E

G

H

I

F

D

A

C

SECTION 1 GENERAL

Group 1 Specifications

Specications

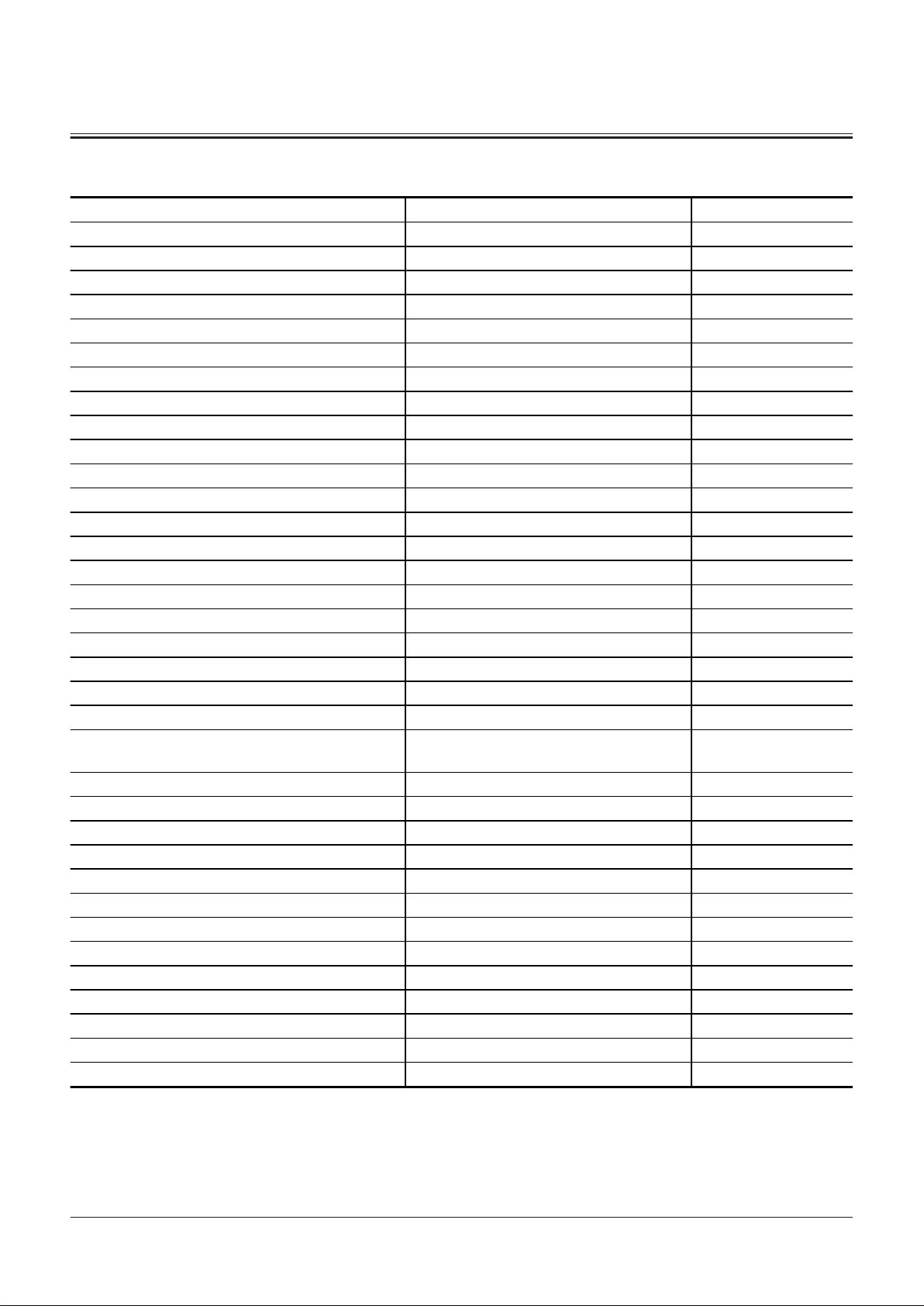

Model - ZW310-7

Bucket Capacity: heaped

Operating Weight kg 24390

Tipping Load (Full turn) kg 16040

Engine - Cummins L9

A: Overall Length mm 9025

B: Overall Width (Bucket) mm 2980

C: Overall Height mm 3530

D: Wheel Base mm 3540

E: Tread (front and rear tires) mm 2230

F: Ground Clearance mm 505

G: Bucket Hinge Height mm 4425

H: Dumping Clearance (45 °) mm 3090

I: Dumping Reach (45 °) mm 1305

R1: Minimum Rotation Radius mm 6420

R2: Minimum Rotation Radius mm 7455

Travel Speed Forward/Reverse (at Power mode) km/h 35.7/35.7(35.9/35.9)"

Transmission Speeds (F/R) - 4/4

Articulation Angle (Left/Right) deg ( ° ) 37

Tire Size - 26.5R25

m

3

4.3

TNFQ-01-01-001-1 ja

NOTE

These specications are subject to change without notice.

TONFQ50-EN-00(28/02/2022)

T1-1-1

Page 22

MEMO

SECTION 1 GENERAL

Group 1 Specifications

TONFQ50-EN-00(28/02/2022)

T1-1-2

Page 23

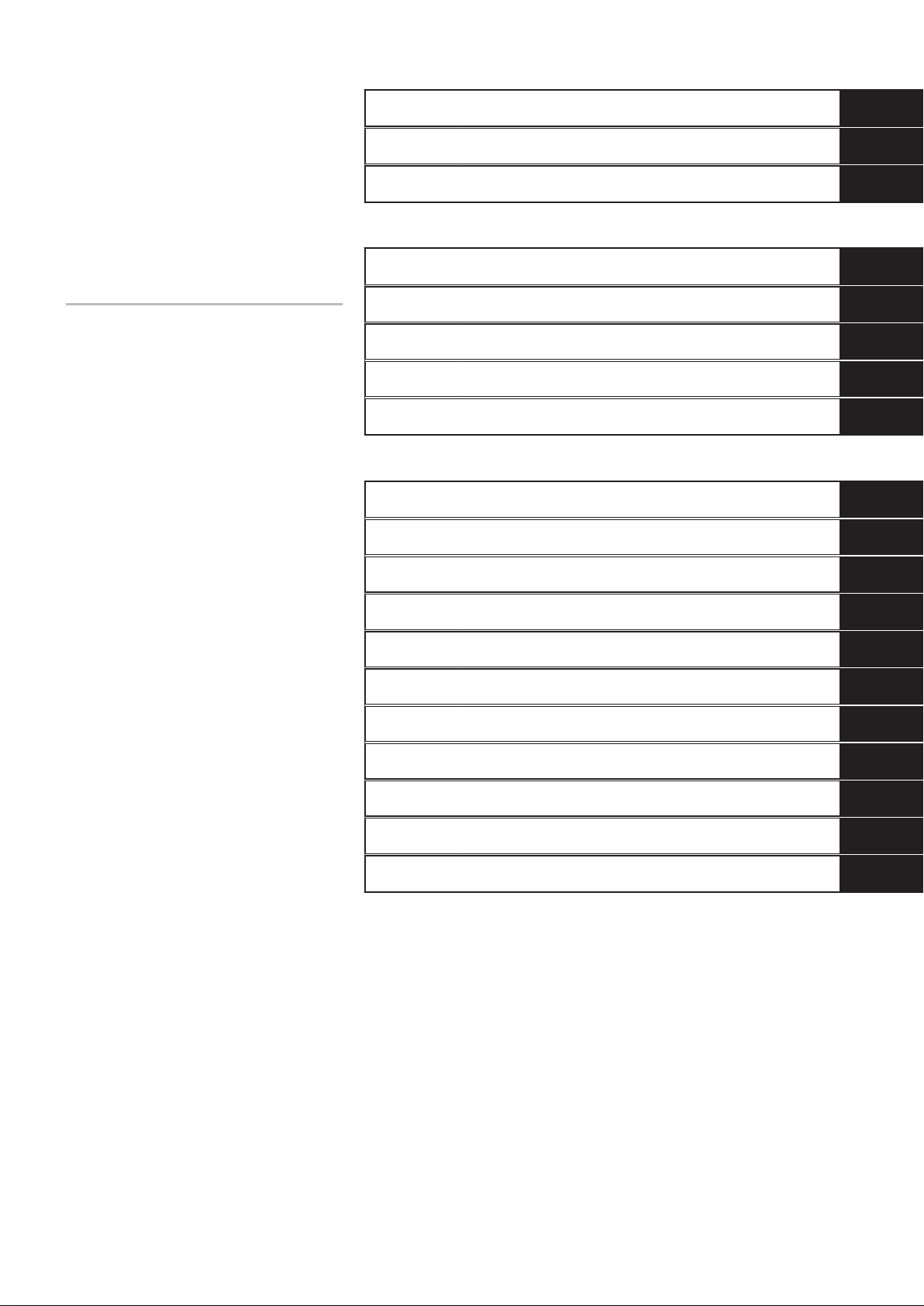

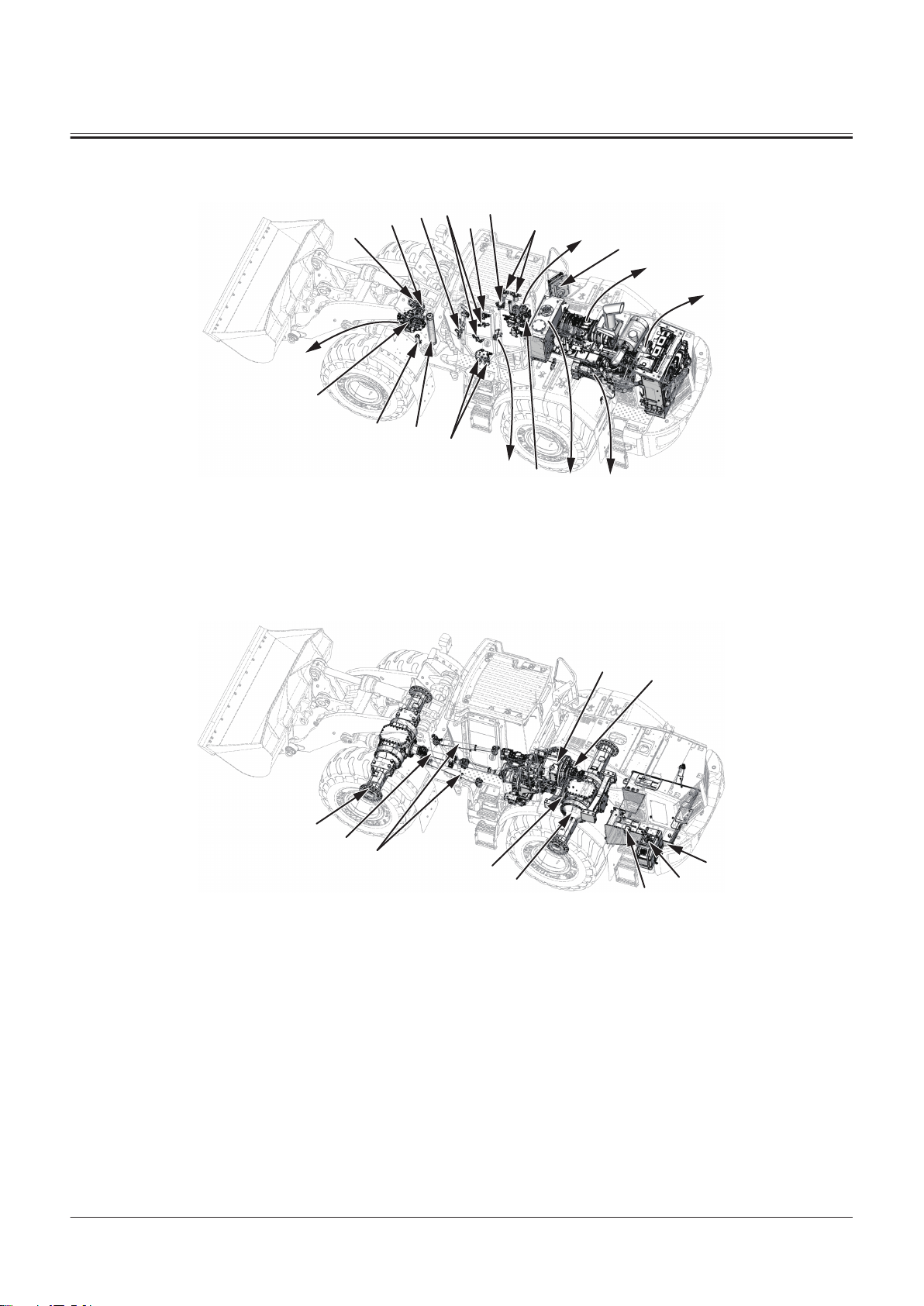

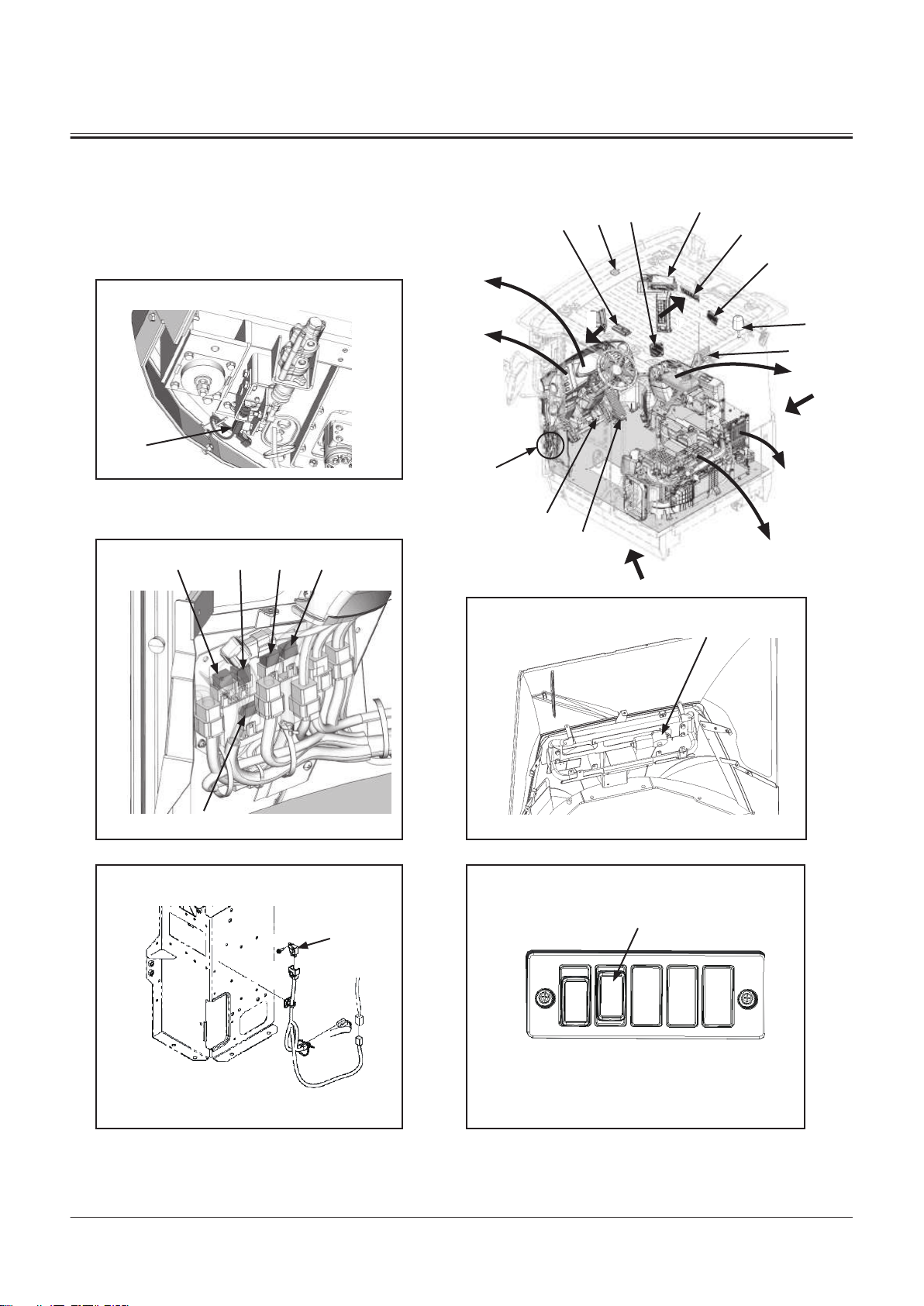

Main Component (Overview)

1

2

3

4

1

9

14

10

11

5

6

7

17

8

13

12

15

16

18

SECTION 1 GENERAL

Group 2 Component Layout

1- Bucket

2- Bucket Link

3- Bell Crank

4- Bucket Cylinder

12- Work Light (Rear)

13- Pre-Cleaner

TNFQ-05-04-019-1 ja

5- Front Combination Light

(Headlight/Turn Signal Light/

Clearance Light/Hazard Light)

6- Horn

7- Work Light (Cab Front)

8- Refer to "Cab"T1-2-8.

9- DEF Tank Box

10- Lift Arm Cylinder

11- Lift Arm

14- Refer to "Battery

Box"T1-2-4.

17- Additional Work Light (Cab

Front)

15- Rear Combination Light (Turn

Signal Light/ Hazard Light/

Tail Light/ Brake Light)

16- Additional Work Light (Cab

Rear)

18- Object Detection Sensor

TNFQ-05-04-020-1 ja

TONFQ50-EN-00(28/02/2022)

T1-2-1

Page 24

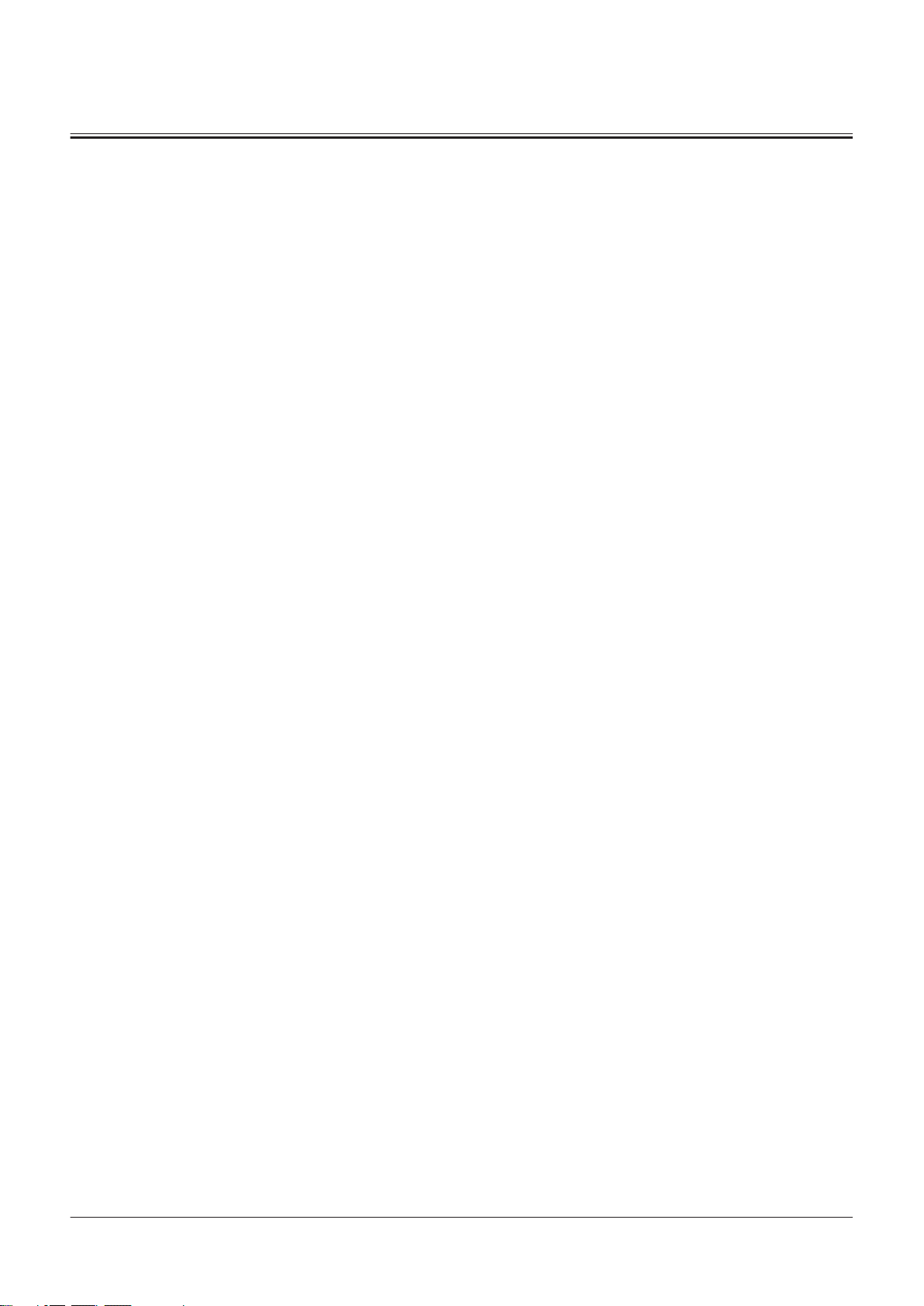

Main Component

11

33

8

41

44

45

36

3

16

20

39

18

42

40

1

37

2

35

32

38

17

30

29

28

24

26

25

31

21

22

1- Refer to "Air Cleaner and Radi

ator Assembly"T1-2-3.

2- Refer to "Aftertreatment De

vice"T1-2-17.

3- Refer to "Hydraulic Oil

Tank"T1-2-5.

8- Steering Accumulator

SECTION 1 GENERAL

Group 2 Component Layout

11- Refer to "Control

Valve"T1-2-19.

16- Refer to "Engine"T1-2-16.

18- Joystick Steering Valve

20- Stop Valve

32- Steering Valve

33- 2-Spool Solenoid Valve Unit

35- Ride Control Valve

36- Refer to"Joystick Steering Sol

enoid Valve Unit"T1-2-25.

37- Axle Oil Cooler

38- Brake Valve

39- Reducing Valve

TNFQ-05-04-021-1 ja

40- Refer to "Brake Charge Valve/

Combination Valve"T1-2-20.

41- Ride Control Accumulator

42- Axle Oil Filter

44- Transmission Oil Filter

45- Joystick Steering Accumulator

17- Refer to "Front Axle"T1-2-7.

22- Refer to "Drive Unit"T1-2-7.

24- Refer to "Fuel Tank"T1-2-6.

TONFQ50-EN-00(28/02/2022)

25- DEF Supply Module

26- DEF Tank

28- Rear Axle

29- Rear Propeller Shaft

30- Front Propeller Shaft

31- Steering Cylinder

T1-2-2

TNFQ-05-04-022-1 ja

Page 25

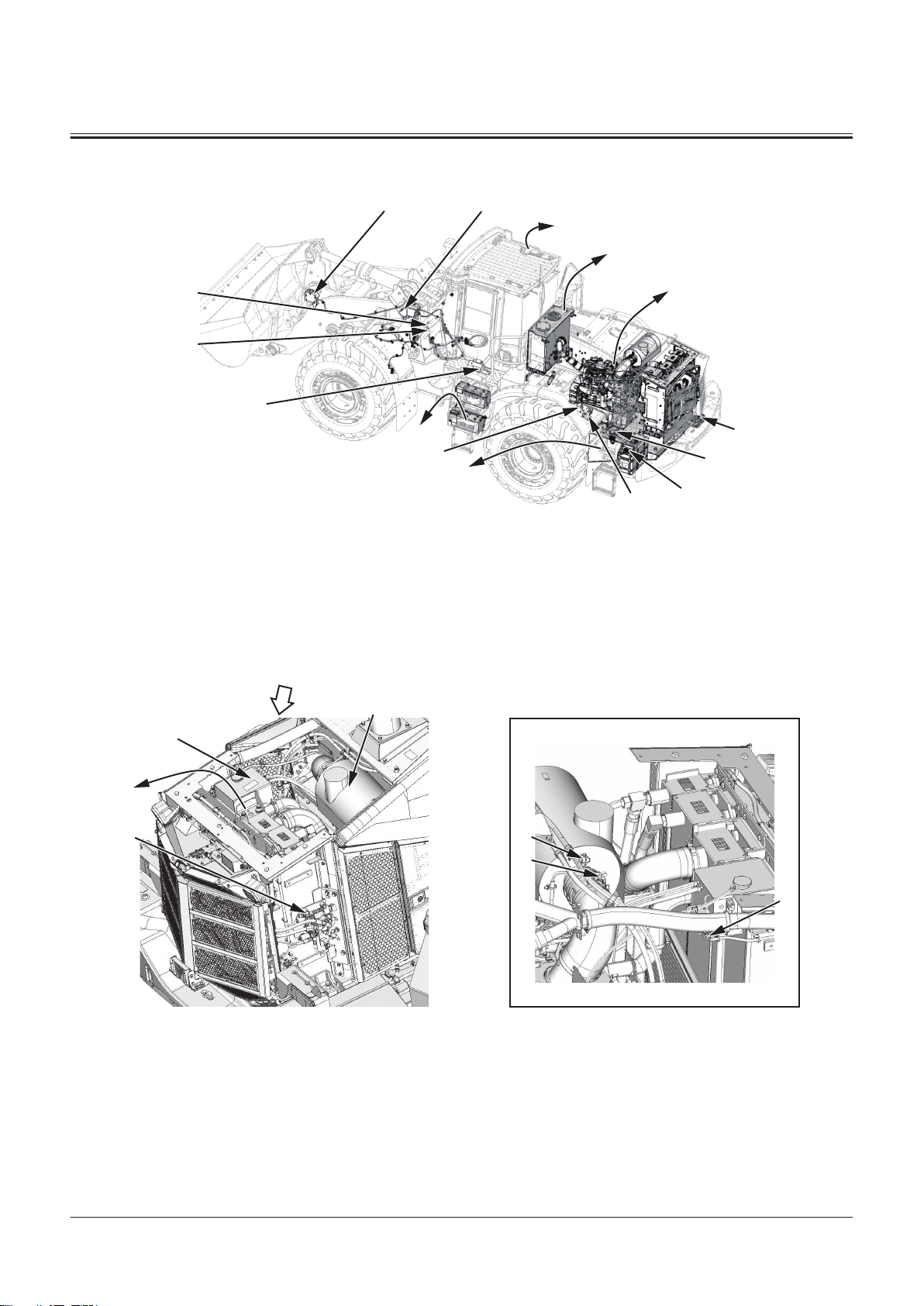

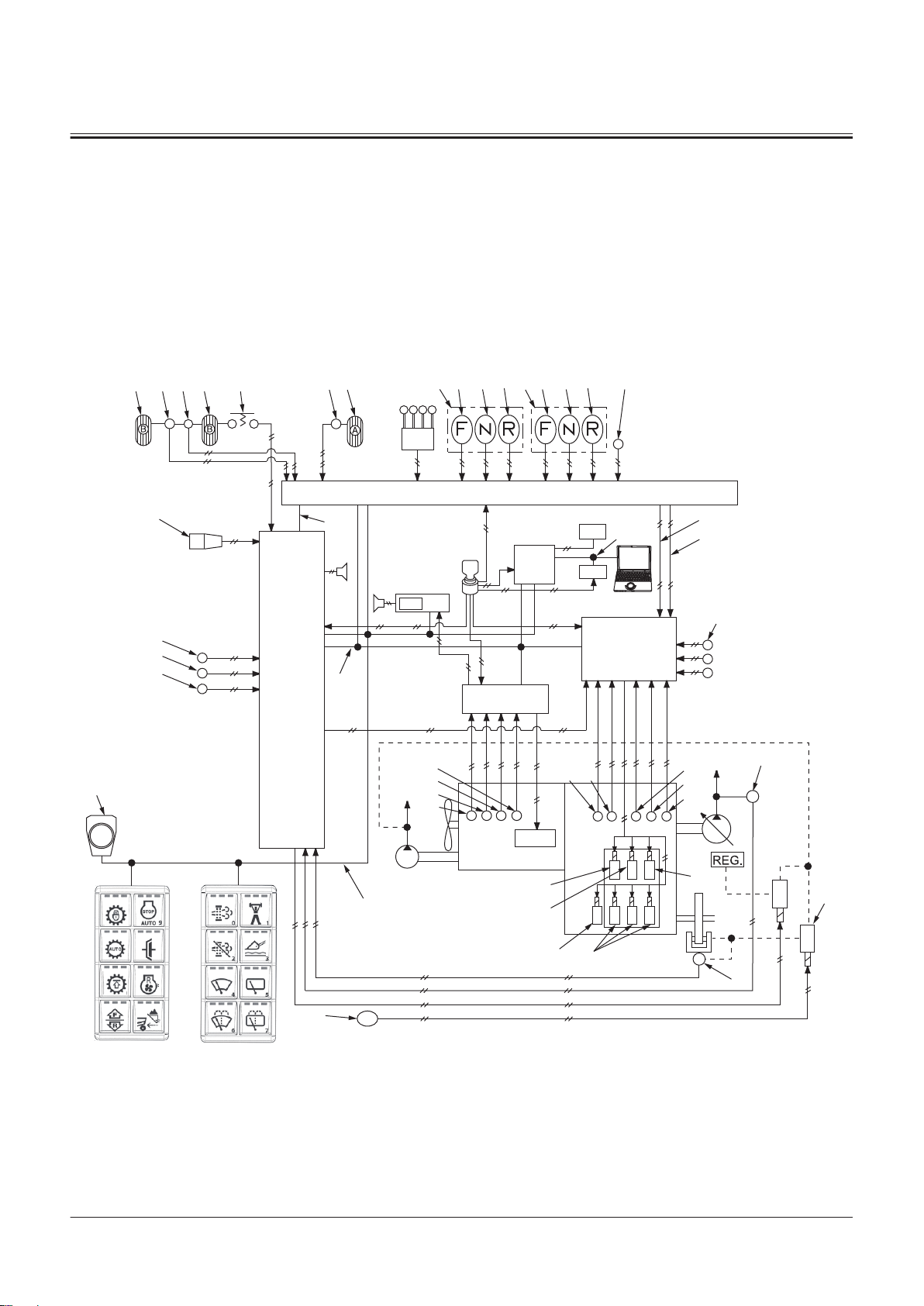

Electrical System (Overview)

46

9

10

8

14

13

12

11

2

3

5

4

1

6

7

A

6

5

7

1

4

2

3

A

1- Refer to "Engine"T1-2-16.

2- Refer to "Hydraulic Oil

Tank"T1-2-5.

3- Refer to "Cab"T1-2-8.

4- Bucket Angle Sensor

5- Lift Arm Angle Sensor

6- Refer to "Battery

7- Refer to "Fuel Tank"T1-2-6.

8- Refer to "DEF Tank"T1-2-23.

SECTION 1 GENERAL

Group 2 Component Layout

9- Back Buzzer

10- Refer to "DEF Supply Mod

Box"T1-2-4.

11- Lift Arm Rod Pressure Sensor

ule"T1-2-24.

TNFQ-05-04-023-1 ja

12- Lift Arm Bottom Pressure Sen

sor

13- Intake-Air Heater Relay

14- Starter Relay 1

46- Refer to "Emergency Steering

Pump Unit"T1-2-23.

Air Cleaner and Radiator Assembly

1- Air Cleaner

2- Refer to "Radiator Assem

bly"T1-2-4.

3- Refer to "Fan Valve"T1-2-17.

4- Expansion Tank

5- TBAP Sensor

6- AIR CLEANER RESTRICTION

SWITCH

7- Coolant Level Switch

TNFQ-05-04-005-1 ja

TONFQ50-EN-00(28/02/2022)

T1-2-3

Page 26

Radiator Assembly

A

1

6

2

3

5

4

A

a

A

10

11

8

9

7

6

5

1

2

3

A

4

SECTION 1 GENERAL

Group 2 Component Layout

TNFQ-05-04-001-1 ja

a- Machine Front Side

1- Expansion Tank

2- Radiator

3- Oil cooler

4- Intercooler

5- Torque Converter Cooler

6- Fan Motor

Battery Box

1- Battery Box

2- Battery

3- Battery Disconnect Switch

4- Battery Disconnect Switch In

5- Battery Relay

dicator Light

6- Fusible Link (30 A)

7- Fusible Link (70 A)

8- Fusible Link (120 A)

9- Fusible Link (120 A)

10- Fusible Link (30 A)

11- Fusible Link (140 A)

TNFQ-05-04-006-1 ja

TONFQ50-EN-00(28/02/2022)

T1-2-4

Page 27

Hydraulic Oil Tank

A

4

2

5

6

3

a

A

1

SECTION 1 GENERAL

Group 2 Component Layout

TNFQ-05-04-007-1 ja

a- Machine Front Side

1- Hydraulic Oil Tank

2- Hydraulic Oil Level Sensor

3- Washer Tank 4- Hydraulic Oil Temperature

Sensor

5- Rear Washer Motor

6- Front Washer Motor

TONFQ50-EN-00(28/02/2022)

T1-2-5

Page 28

Fuel Tank

A

B

4

5

2

3

6

1

B

a

A

SECTION 1 GENERAL

Group 2 Component Layout

TNFQ-05-04-002-1 ja

a- Machine Front Side

1- Fuel Tank

2- Fuel Level Sensor

3- Fuel Pump

4- Fuel Pre-Filter

5- Water Separator Sensor

6- Fuel Main Filter

TONFQ50-EN-00(28/02/2022)

T1-2-6

Page 29

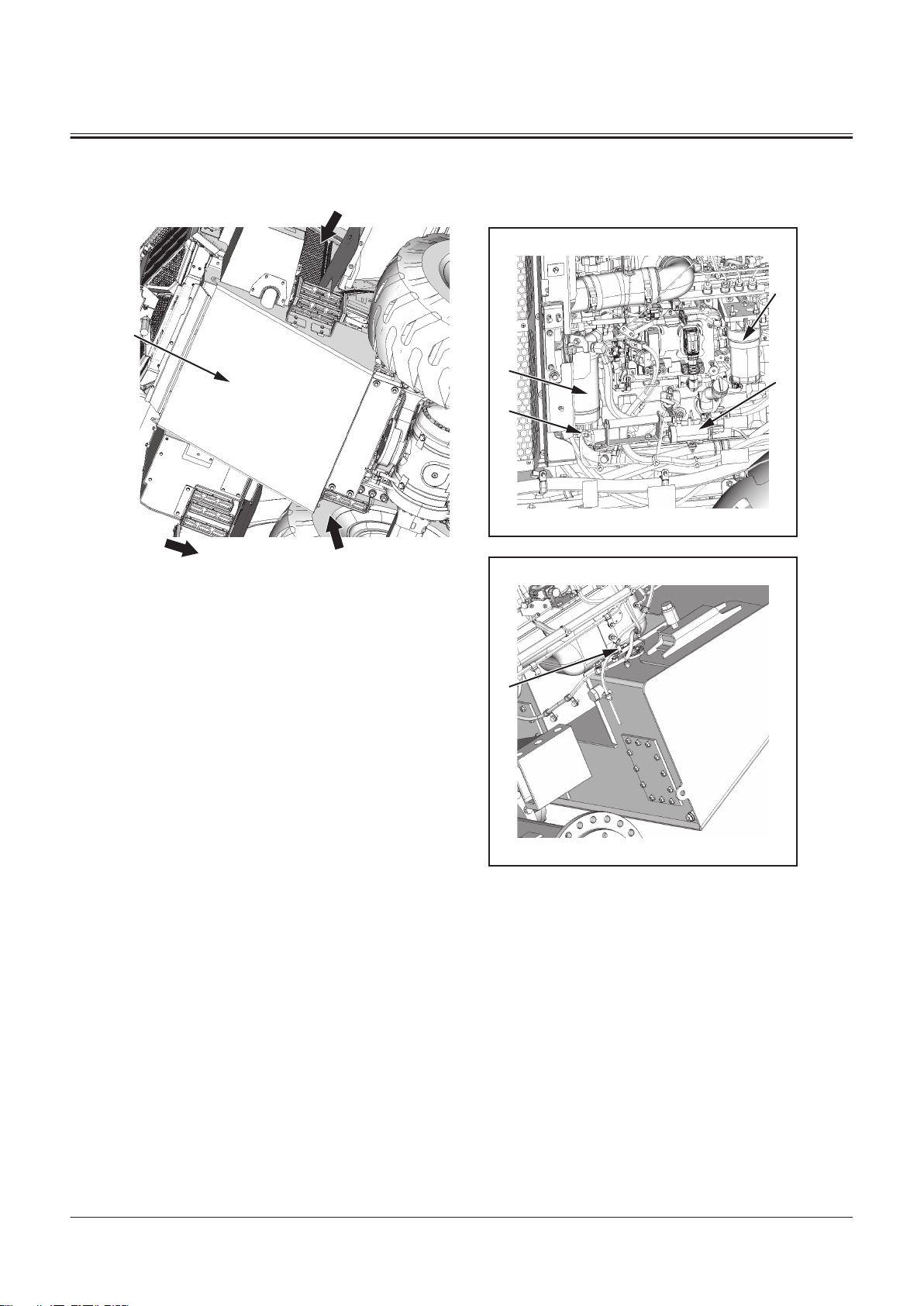

Drive Unit

A

6

2

9

20

8

11

10

4

22

3

A

a

18

21

1

7

23

24

5

19

12

13

14

15

16

17

1

2

SECTION 1 GENERAL

Group 2 Component Layout

a- Machine Front Side

1- Torque Converter

2- Torque Converter Charging

Pump

3- Drive Shaft In Main Pump

4- Parking Brake

5- Strainer

6- Air Breather

7- Transmission Control Valve

8- Torque Converter Output

Shaft Speed Sensor

Front Axle

TNFQ-05-04-025-1 ja

9- Torque Converter Input Shaft

Speed Sensor

10- Vehicle Speed Sensor

11- Transmission Intermediate

Shaft Speed Sensor

12- Forward Clutch Solenoid

Valve

13- Reverse Clutch Solenoid Valve

14- First Speed Clutch Solenoid

Valve

15- Second Speed Clutch Sole

noid Valve

16- Third Speed Clutch Solenoid

Valve

17- Fourth Speed Clutch Solenoid

Valve

18- Lock Up Clutch Solenoid

Valve

19- Parking Brake Pressure Sensor

20- Transmission Oil Temperature

Sensor

21- Flange (For Main Propeller

Shaft)

22- Flange (For Front Propeller

Shaft)

23- Flange (For Rear Propeller

Shaft)

24- Drain Port

1- Service Brake Secondary Pres

sure Sensor

TONFQ50-EN-00(28/02/2022)

2- Axle Oil Temperature Sensor

T1-2-7

TNEE-01-02-018-1 ja

Page 30

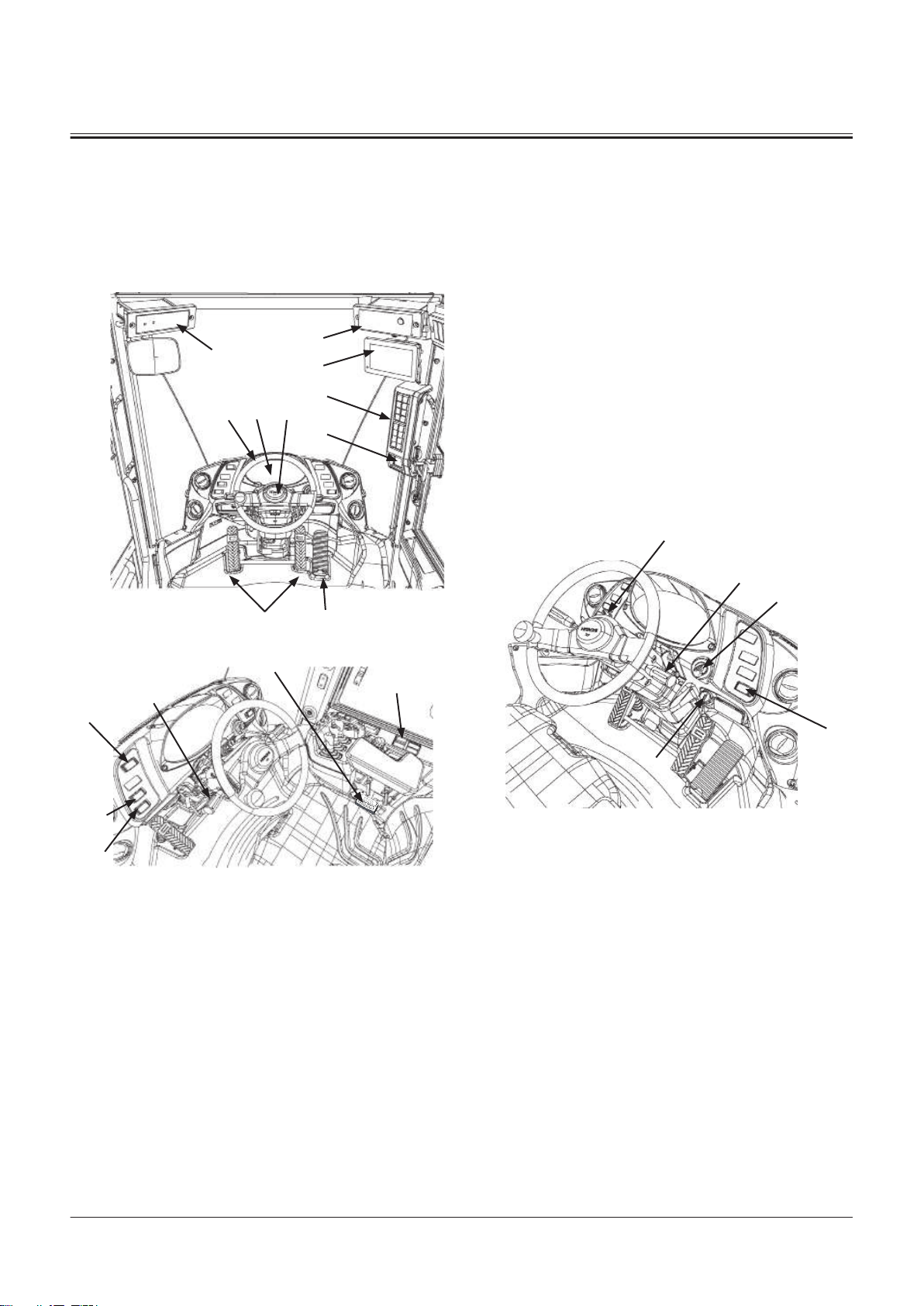

Cab

A

B

D

E F

13141011

12

16

15

9

18

b

E

D

e

c

3

8

2

1

1

B

A

a

e

7

6

4

17

5

F

SECTION 1 GENERAL

Group 2 Component Layout

a- (Refer to "Front Console"T1-2-9.) c- (Refer to "Rear Console"T1-2-13.)

b- (Refer to "Right Console"T1-2-11.) e- (Refer to "Control Unit"T1-2-14.)

TONFQ50-EN-00(28/02/2022)

TNUD-01-02-105-1 ja

T1-2-8

Page 31

7

8

2 3 4

5

6

17

13

20

9

21

12

10

1

18

22

15

14

16

19

SECTION 1 GENERAL

Group 2 Component Layout

1- Speaker

2- Satellite Communication An

tenna

3- Upper Switch Panel

4- Rear Wiper Motor

Front Console

5- Radio

6- Accelerator Pedal Sensor

7- Brake Pedal Position Sensor

8- Cab Light

9- Brake Pedal Switch

10- Front Wiper Relay 2

11- Front Wiper Relay 1

12- Auto Shut-Down Relay

13- Key Switch ON Cut Relay

14- ACC Cut Relay

15- Front Wiper Motor

16- Mirror Heater Relay

17- Beacon Light

18- Beacon Light Switch

1- Neutral Lever Lock for For

ward/Reverse Lever

2- Steering Wheel

3- Refer to"Column Moni

tor"T1-2-15.

4- Horn Switch

5- Radio

6- Sub Monitor

7- Panel Switch

8- Rear View Mirror Angle Ad

justment Switch

9- 24 V Power Supply Socket

10- Emergency Steering Check

Switch

12- Accelerator Pedal

13- Brake Pedal

14- Hazard Switch

15- Work Light Switch

16- Parking Switch

17- Air Conditioner Control Panel

18- USB Power Source

TNUD-01-02-106-1 ja

19- Forward/Reverse Lever, Shift

Switch

20- Turn Signal Lever, Light

Switch, Dimmer Switch

21- Key Switch

22- Seat Belt Switch

TONFQ50-EN-00(28/02/2022)

T1-2-9

Page 32

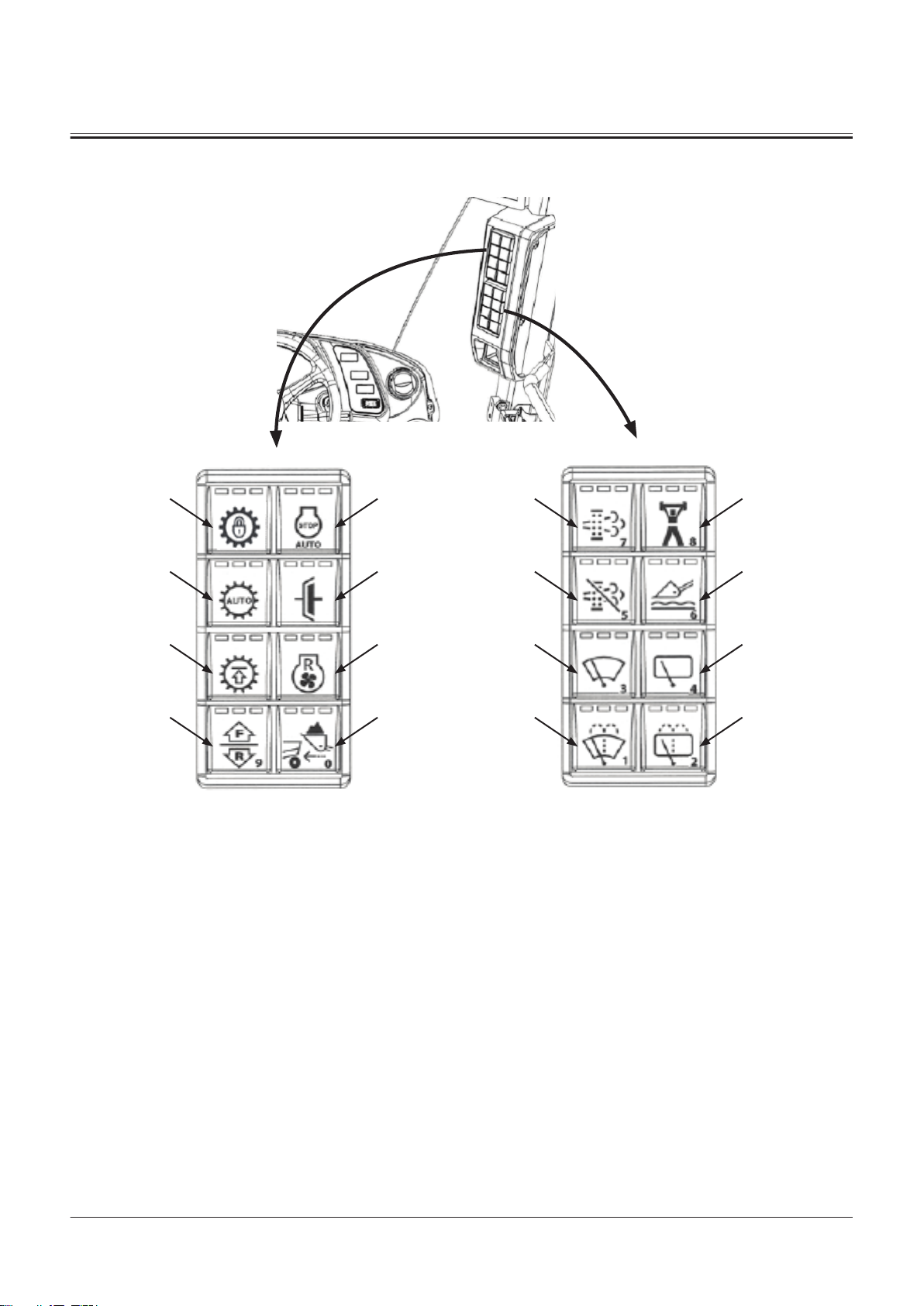

Panel Switch

8 161

6 143 11

7 152 10

9

5 134 12

SECTION 1 GENERAL

Group 2 Component Layout

1- Auto Shut-Down Switch

2- Clutch Cut Position Switch

3- Fan Reverse Rotation Switch

4- Dump Approach Mode Selec

tor Switch

5- Forward/Reverse Selector

Switch

6- Gear Restriction Switch

7- Travel Mode Switch

8- Lock Up Switch

9- Power Mode Switch

10- Ride Control Switch

11- Rear Wiper Switch

12- Rear Washer Switch

13- Front Washer Switch

TONFQ50-EN-00(28/02/2022)

T1-2-10

TNFQ-05-04-024-1 ja

14- Front Wiper Switch

15- Regeneration Inhibit Switch

16- Manual Regeneration Switch

Page 33

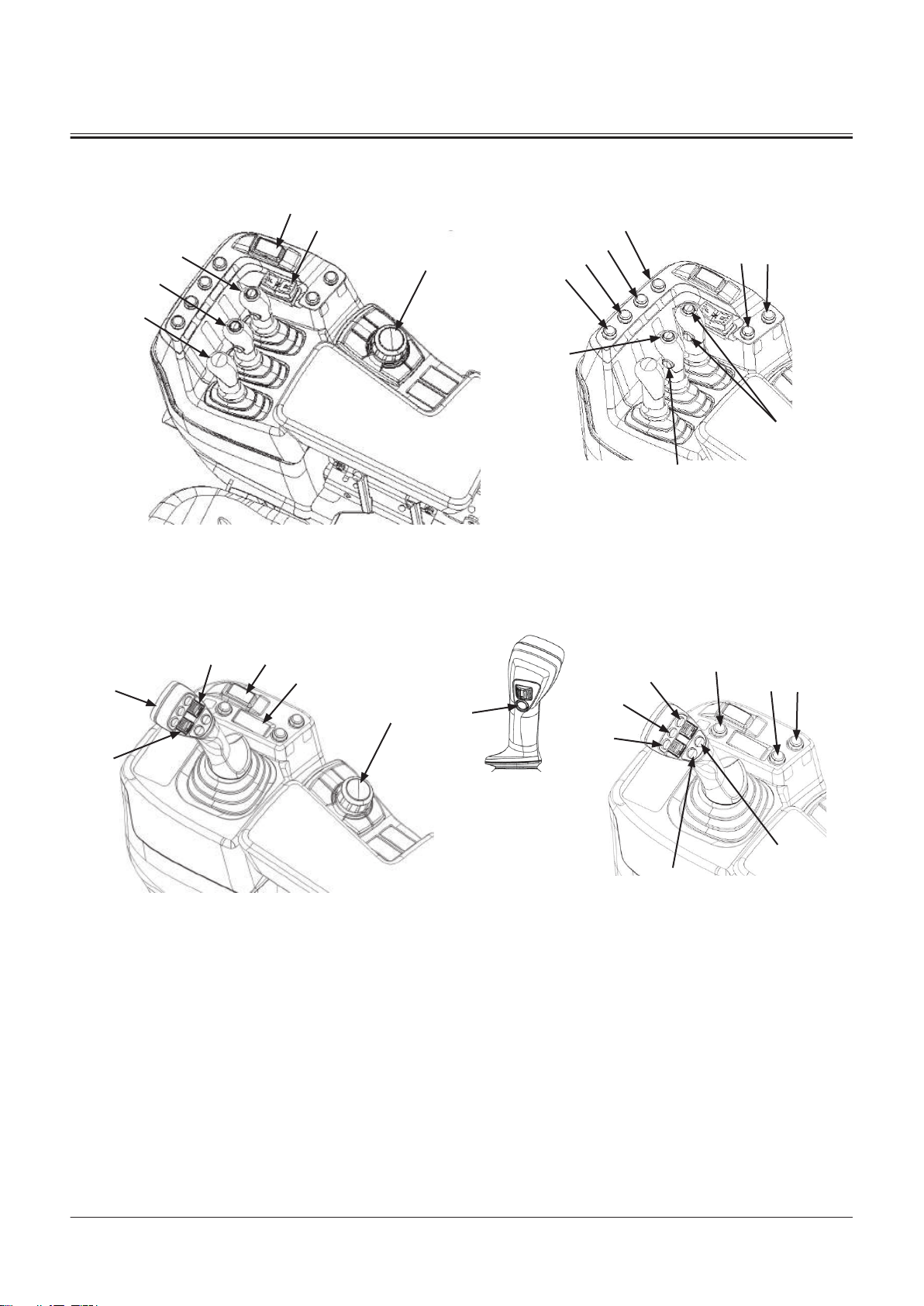

Right Console

12

11

10

9

6

5

4

3

2

1

17

16

15

14 13

6

8

4

19

18

5

9

10

11

12

15

16

14 13

17

SECTION 1 GENERAL

Group 2 Component Layout

Fingertip Control Lever Type

TNUD-01-02-108-2 ja

1- Auxiliary 1 Control Lever

2- Bucket Control Lever

3- Lift Arm Control Lever

4- Control Lever Lock Switch

5- Forward/Reverse Switch

6- Rotary Device

9- Load cancel Switch

10- Tip O Selector Switch

11- Track Clear Switch

12- Add Load Switch

13- Hold Switch

14- Mist Switch

15- Downshift Switch

16- Quick Power Switch

17- Horn Switch

Multi-Function Joystick Lever Type

TNUD-01-02-109-2 ja

4- Control Lever Lock Switch

5- Forward/Reverse Switch

6- Rotary Device

9- Load cancel Switch

10- Tip O Selector Switch

11- Track Clear Switch

12- Add Load Switch

13- Hold Switch

14- Mist Switch

15- Downshift Switch

16- Quick Power Switch

17- Horn Switch

18- Multi Function Joystick Lever

19- Auxiliary 1 Control Switch (For

Third Spool)

TONFQ50-EN-00(28/02/2022)

T1-2-11

Page 34

3

A

1

2

54

8

7

9

A

SECTION 1 GENERAL

Group 2 Component Layout

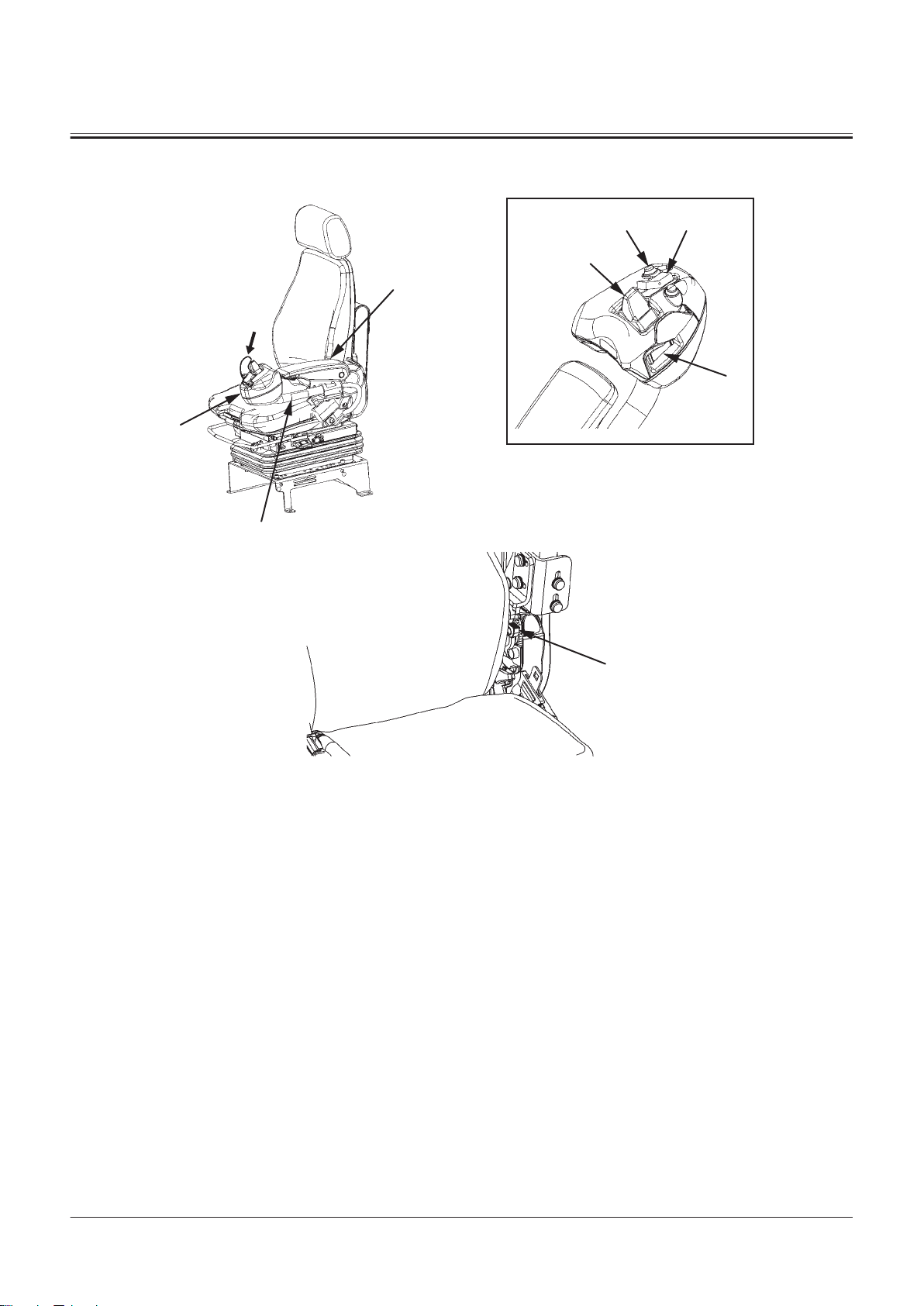

Operator's Seat and Joystick Steering System

1- Switch Box

2- Left Console Pipe

3- Left Armrest

4- Downshift Switch

5- Forward/Reverse Switch (JSS)

7- Joystick Steering Selector

8- Joystick Steering Lever

Switch

9- Left Console Lock Release

Lever

TNUD-01-02-110-2 ja

TONFQ50-EN-00(28/02/2022)

T1-2-12

Page 35

Rear Console

A

B

E

8

9

10

1

2 3 4 5

32

33

40

35

31

a

39

39

38

37

36

7

6

1211

27

17

26

16

2221

13

28

18

23

14

29

19

24

15

30

20

25

B

A

E

31

37

41

SECTION 1 GENERAL

Group 2 Component Layout

TONFQ50-EN-00(28/02/2022)

TNUD-01-02-111-2 ja

T1-2-13

Page 36

a- Machine Front Side

A

D

B

4

68

5

7

3

2

b

a

a

1

A

D

B

SECTION 1 GENERAL

Group 2 Component Layout

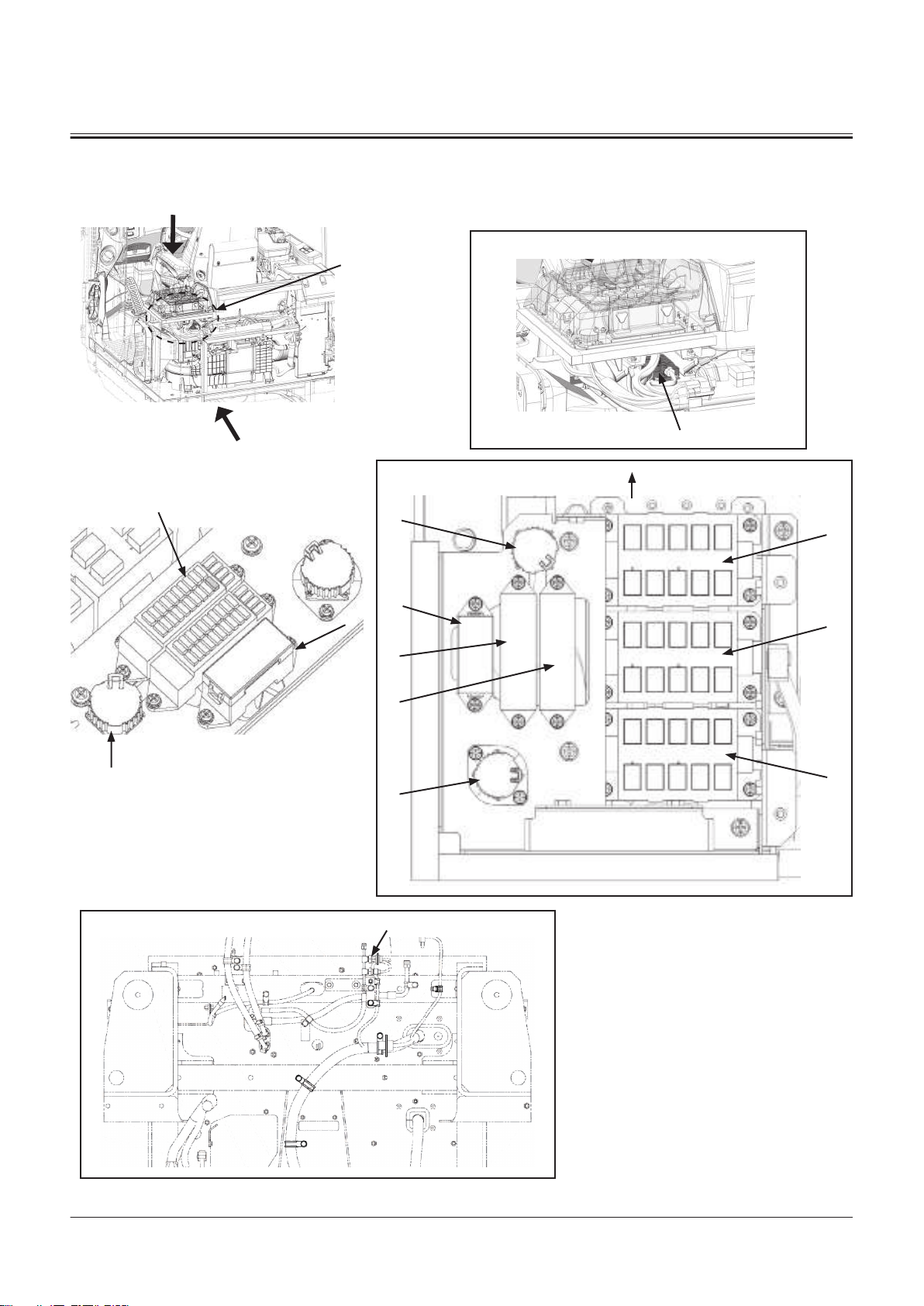

1- Back Buzzer Relay (A-R5)

2- Not Used

3- High Beam Relay (A-R3)

4- Headlight Relay (Right) (A-R2)

5- Headlight Relay (Left) (A-R1)

6- Starter Cut Relay (A-R10)

7- Horn Relay (A-R9)

8- Turn Signal Light Relay (Right)

(A-R8)

9- Work Light Relay (Rear) (A-R7)

10- Work Light Relay (Front) (A-

R6)

Control Unit

11- Load Dump Relay (B-R5)

12- Brake Light Relay (B-R4)

13- PLCU Relay (B-R3)

14- Parking Brake Relay 2 (B-R2)

15- Parking Brake Relay 1 (B-R1)

16- Rear Washer Relay (B-R10)

17- Rear Wiper Relay (B-R9)

18- Front Washer Relay (B-R8)

19- Turn Signal Light Relay (Left)

(B-R7)

20- Neutral Relay (B-R6)

21- DEF Heater Relay 3 (C-R5)

22- DEF Heater Relay 2 (C-R4)

23- DEF Heater Relay 1 (C-R3)

24- SCR Sensor Relay (C-R2)

25- DEF Supply Module Relay (C-

R1)

26- Additional Work Light Relay

(Cab Front) (C-R10)

27- Additional Work Light Relay

(Cab Rear) (C-R9)

28- Not Used

29- Not Used

30- Beacon Light Relay (C-R6)

31- MPDr. Connector

32- Relay Box A

33- Relay Box B

35- Relay Box C

36- Engine Diagnostic Connector

37- Fuse Box A

38- Fuse Box B

39- Fuse Box C

40- Position Sensor

41- Pressure Sensor (Refrigerant

Pressure)

a- Machine Front Side b- Main Monitor

TONFQ50-EN-00(28/02/2022)

T1-2-14

TNUD-01-02-112-1 ja

Page 37

1

32

33

34

35

36

37 38

2 3 4

5

6

7

8

9

10

11

12

13

14

15

24252627 1923 394041 1822 1721 20 16

31

29

30

28

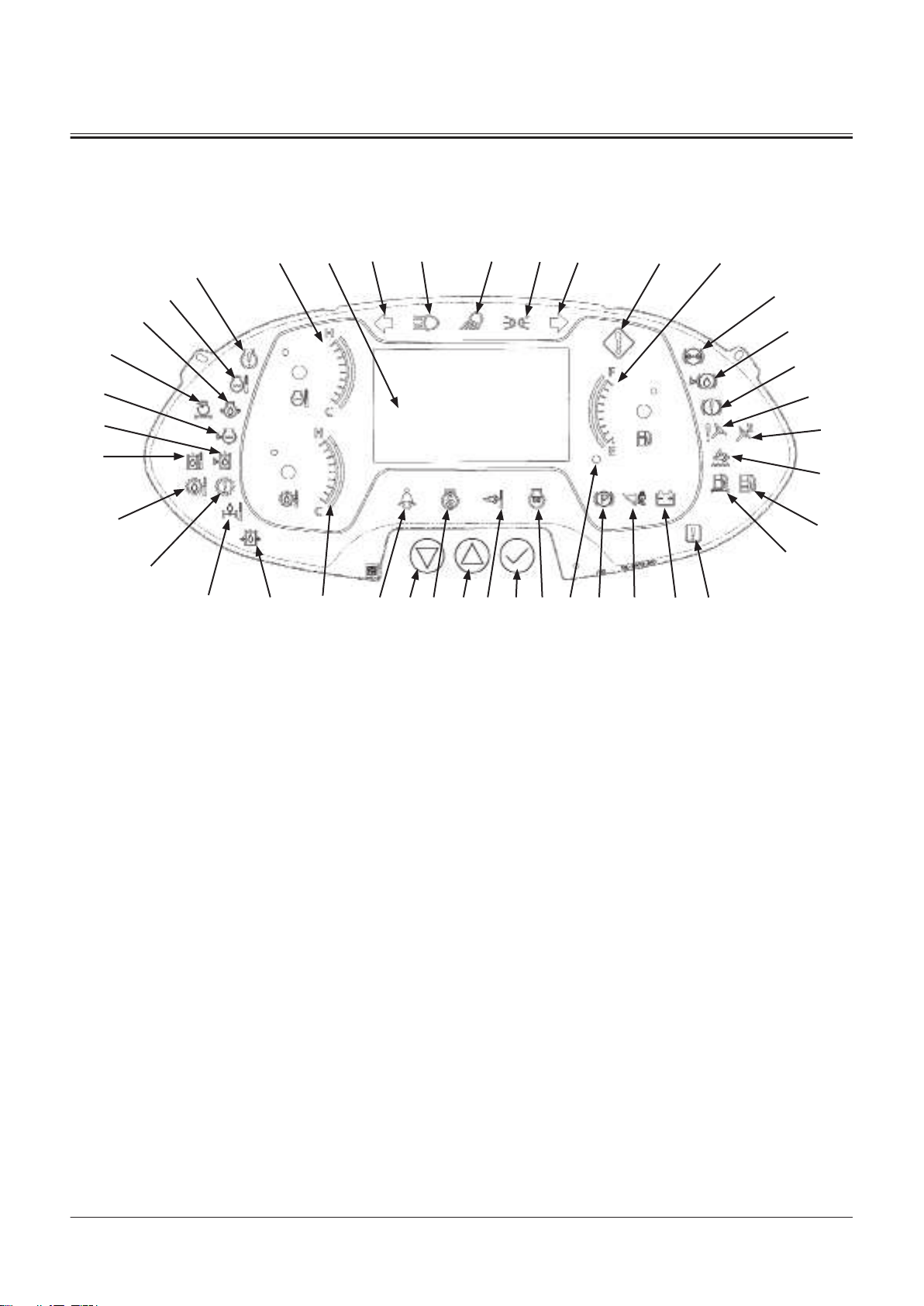

SECTION 1 GENERAL

Group 2 Component Layout

1- Air Conditioner Controller

2- Monitor Controller

Column Monitor

3- TCU

4- MC

5- PLCU

6- Aerial Angle Controller

7- GSM/GPS

8- Flasher Relay

1- Left Turn Signal Light Indica

tor

2- High Beam Indicator

3- Work Light Indicator

4- Clearance Light Indicator

5- Right Turn Signal Light Indica

tor

6- Service Indicator

7- Fuel Gauge

8- Brake Oil Pressure Indicator

9- Brake Oil Level Indicator

10- Not Used

11- Steering Oil Pressure Indicator

12- Emergency Steering Indicator

13- Urea Alarm

14- Water Separator Indicator

15- Fuel Filter Restriction Indica

tor

16- Communication System Error

Indicator

17- Discharge Warning Indicator

18- Control Lever Lock Indicator

19- Parking Brake Indicator

20- Fuel Level Indicator

21- Preheat Indicator

22- Aftertreatment Device Indica

tor

23- Fan Reverse Rotation Indica

tor

24- Seat belt Indicator

25- Transmission Oil Temperature

Gauge

26- Main Pump Oil Pressure Indi

cator

27- Axle Oil Temperature Indica

tor

28- Transmission Warning Indica

tor

29- Transmission Oil Temperature

Indicator

TNUD-01-02-113-1 ja

30- Hydraulic Oil Temperature In

dicator

31- Hydraulic Oil Level Indicator

32- Coolant Level Indicator

33- Air Filter Restriction Indicator

34- Engine Oil Pressure Indicator

35- Overheat Indicator

36- Engine Trouble Indicator

37- Coolant Temperature Gauge

38- Main Monitor

39- Select/Conrm Button

40- Up Button

41- Down Button

TONFQ50-EN-00(28/02/2022)

T1-2-15

Page 38

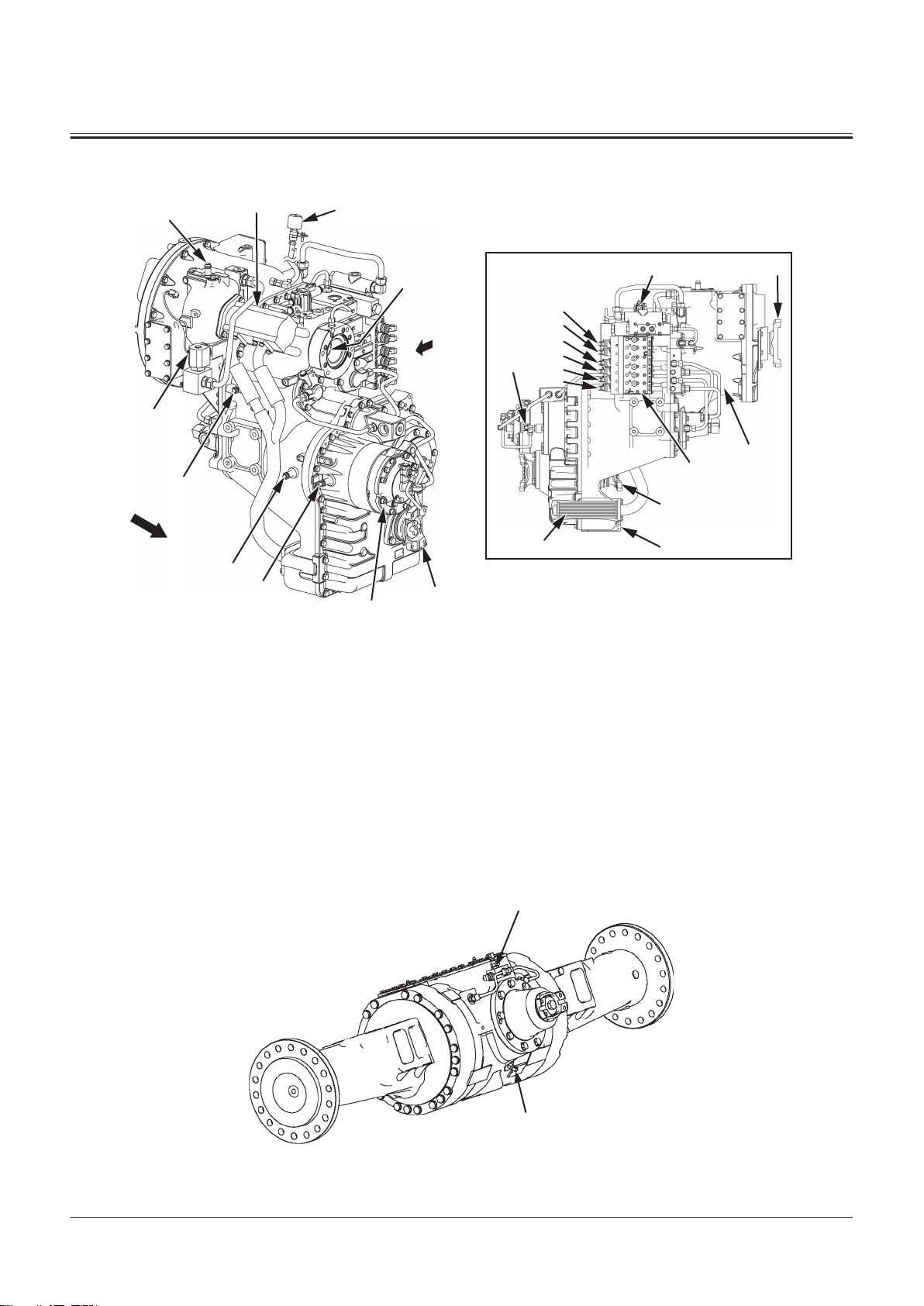

Engine

1

2

3

9

11

12

14

13

10

15

8

7

6

5

4

SECTION 1 GENERAL

Group 2 Component Layout

1- Crankcase Pressure Sensor

2- Supply Pump

3- Cam Angle Sensor

4- Boost Pressure/Temperature

Sensor

5- Common Rail Pressure Sensor

6- Fuel Main Filter

7- Crank Speed Sensor

8- Oil Pressure Switch

9- ECM

10- Exhaust Pressure Sensor

11- Alternator

12- Coolant Temperature Sensor

13- Starter

14- Engine Oil Filter

TNFQ-05-04-033-1 ja

15- Vibration Damper

TONFQ50-EN-00(28/02/2022)

T1-2-16

Page 39

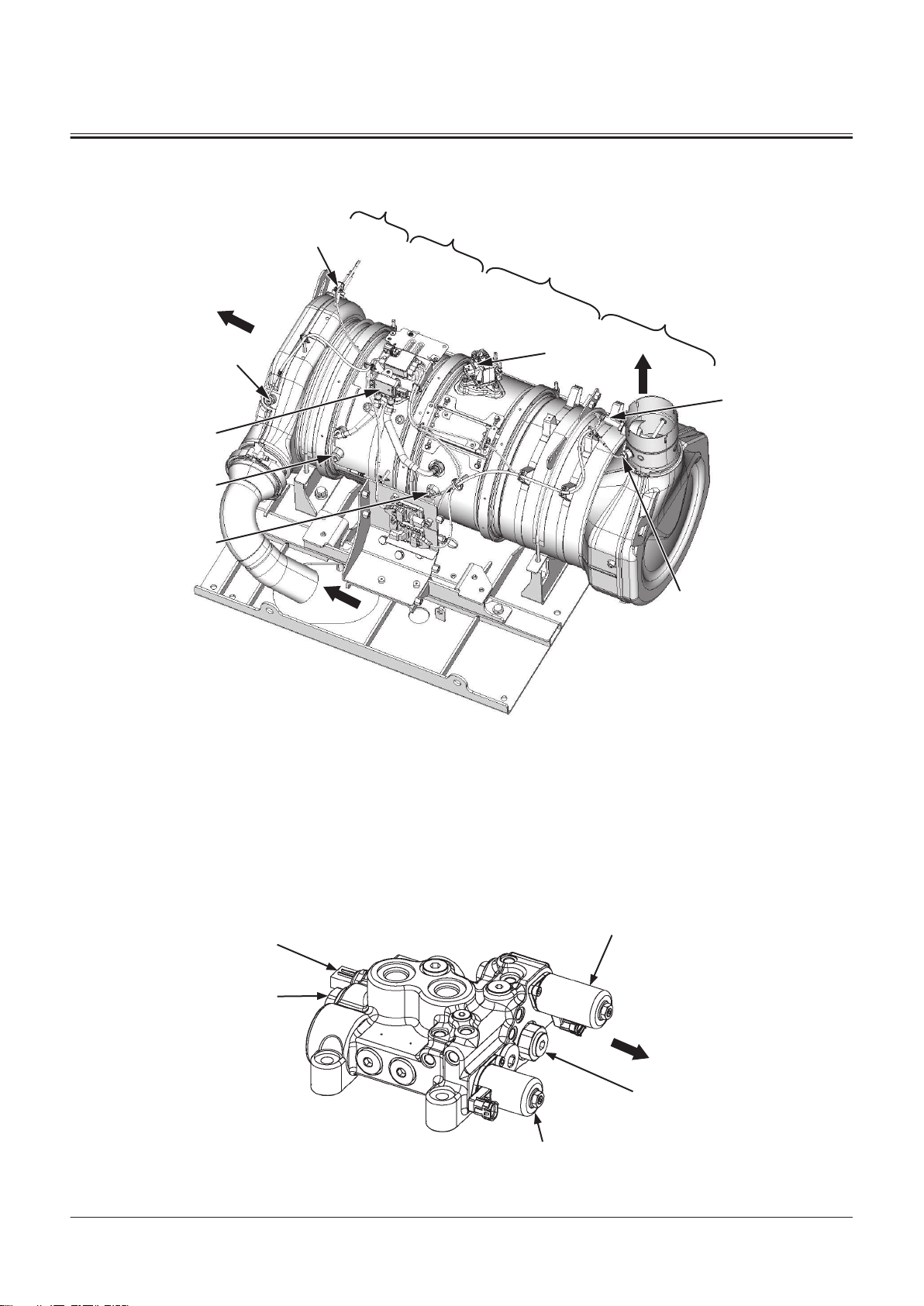

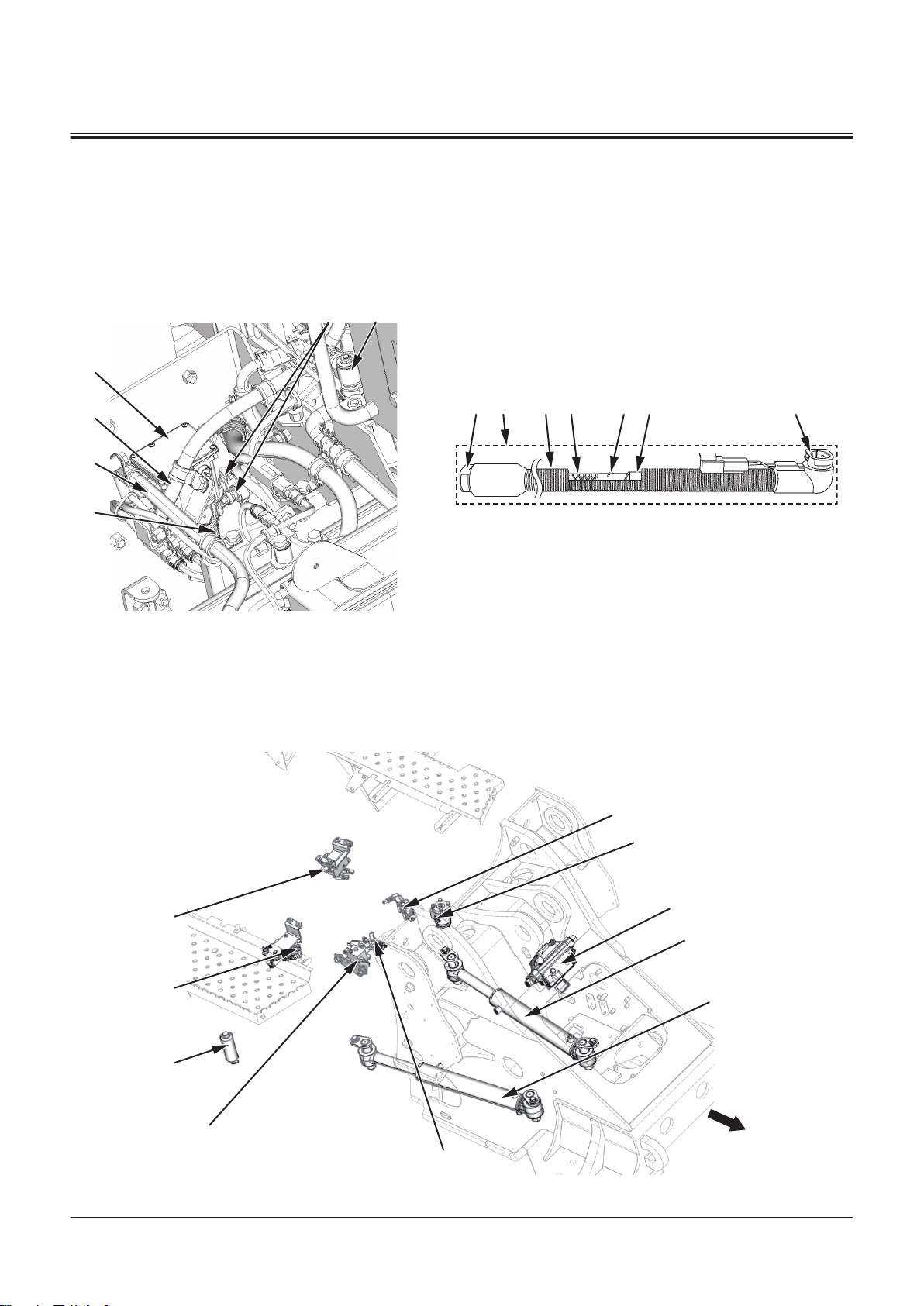

Aftertreatment Device

1

9

10

11

12

8

6

7

5

2

4

3

a

5

4

a

1

3

2

SECTION 1 GENERAL

Group 2 Component Layout

TNFQ-05-04-010-1 ja

a- Machine Front Side

1- Upstream NOx Sensor

2- Dosing Module

3- Downstream NOx Sensor

4- SCR Outlet Exhaust Tempera

Fan Valve

ture Sensor

5- SCR Inlet Exhaust Tempera

ture Sensor

6- Dierential Pressure Sensor

7- DOC Outlet Exhaust Tempera

ture Sensor

8- DOC Inlet Exhaust Tempera

ture Sensor

9- DOC (Diesel Oxidation Cata

lyst)

10- Filter (CSF)

11- Mixer Module

12- SCR Catalyst

TNEE-01-02-031-2 ja

TONFQ50-EN-00(28/02/2022)

T1-2-17

Page 40

a- Machine Front Side

7

10

9

2

1

8

a

SECTION 1 GENERAL

Group 2 Component Layout

1- Fan Speed Control Solenoid

Valve

Pump Device

2- Fan Reverse Rotation Control

Solenoid Valve

3- Fan Control Valve

4- Fan Reverse Rotation Spool

5- Fan Circuit Pressure Sensor

TNFQ-05-04-026-1 ja

a- Machine Front Side

1- Main Pump

2- Regulator 1

TONFQ50-EN-00(28/02/2022)

7- Torque Control Solenoid Valve

8- Regulator 2

9- Steering Pressure Switch 10- Pump Delivery Pressure Sen

sor

T1-2-18

Page 41

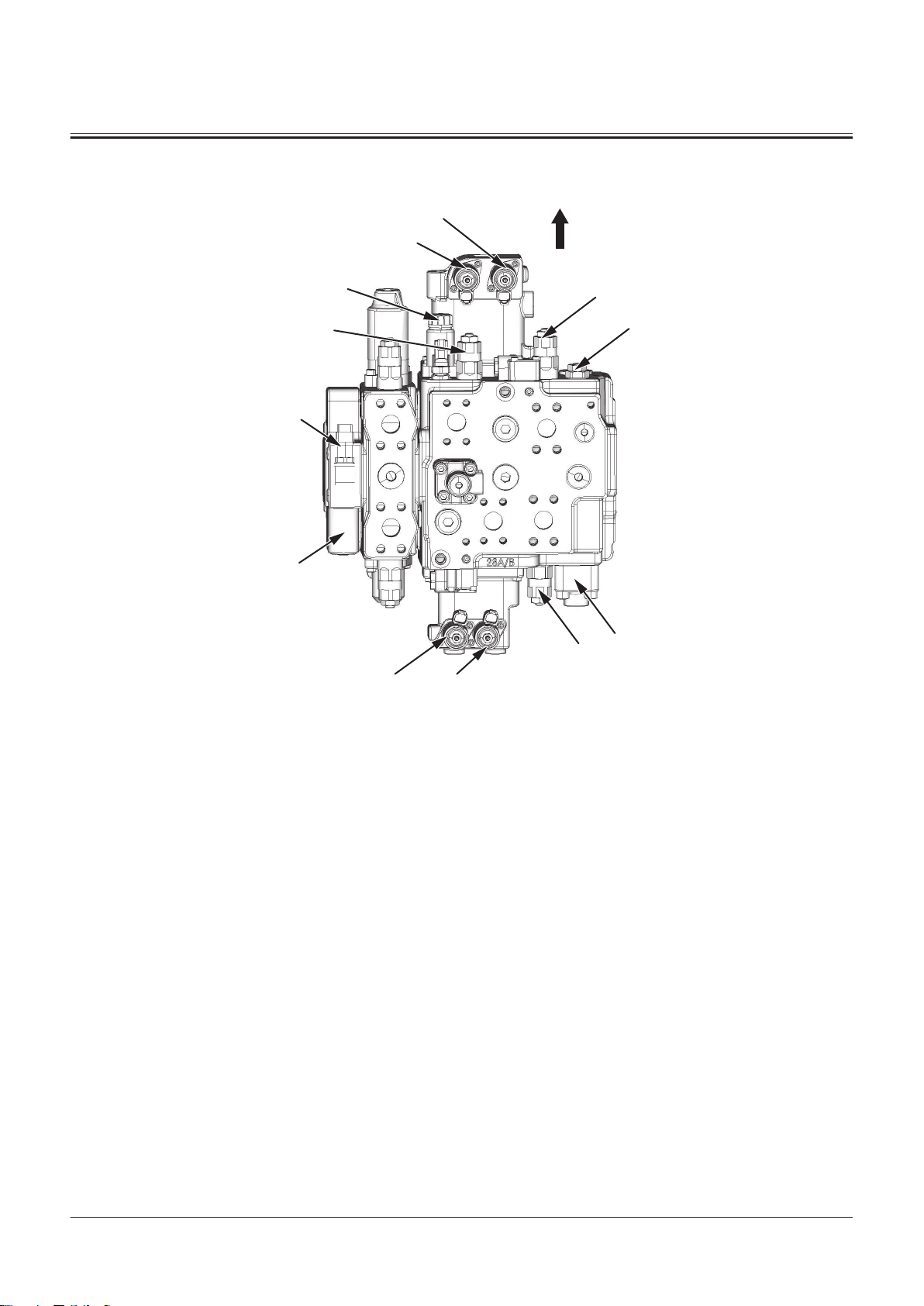

Control Valve

3

1

a

6

2

11

7

12

10

4

5

9

8

SECTION 1 GENERAL

Group 2 Component Layout

a- Machine Front Side

1- Main Relief Valve

2- Overload Relief Valve (Bucket:

Rod Side)

3- Overload Relief Valve (Bucket:

Bottom Side)

12 Negative Control Pressure

Sensor

4- Overload Relief Valve (Lift

Arm: Rod Side)

5- Ride Control Selector Sole

noid Valve

6- Bleed O Compensator

TNFQ-05-04-013-1 ja

7- Pump Flow Rate Control Valve

8- Bucket Dump Solenoid Valve

9- Lift Arm Raise Solenoid Valve

10- Bucket Tilt Solenoid Valve

11- Lift Arm Lower Solenoid Valve

TONFQ50-EN-00(28/02/2022)

T1-2-19

Page 42

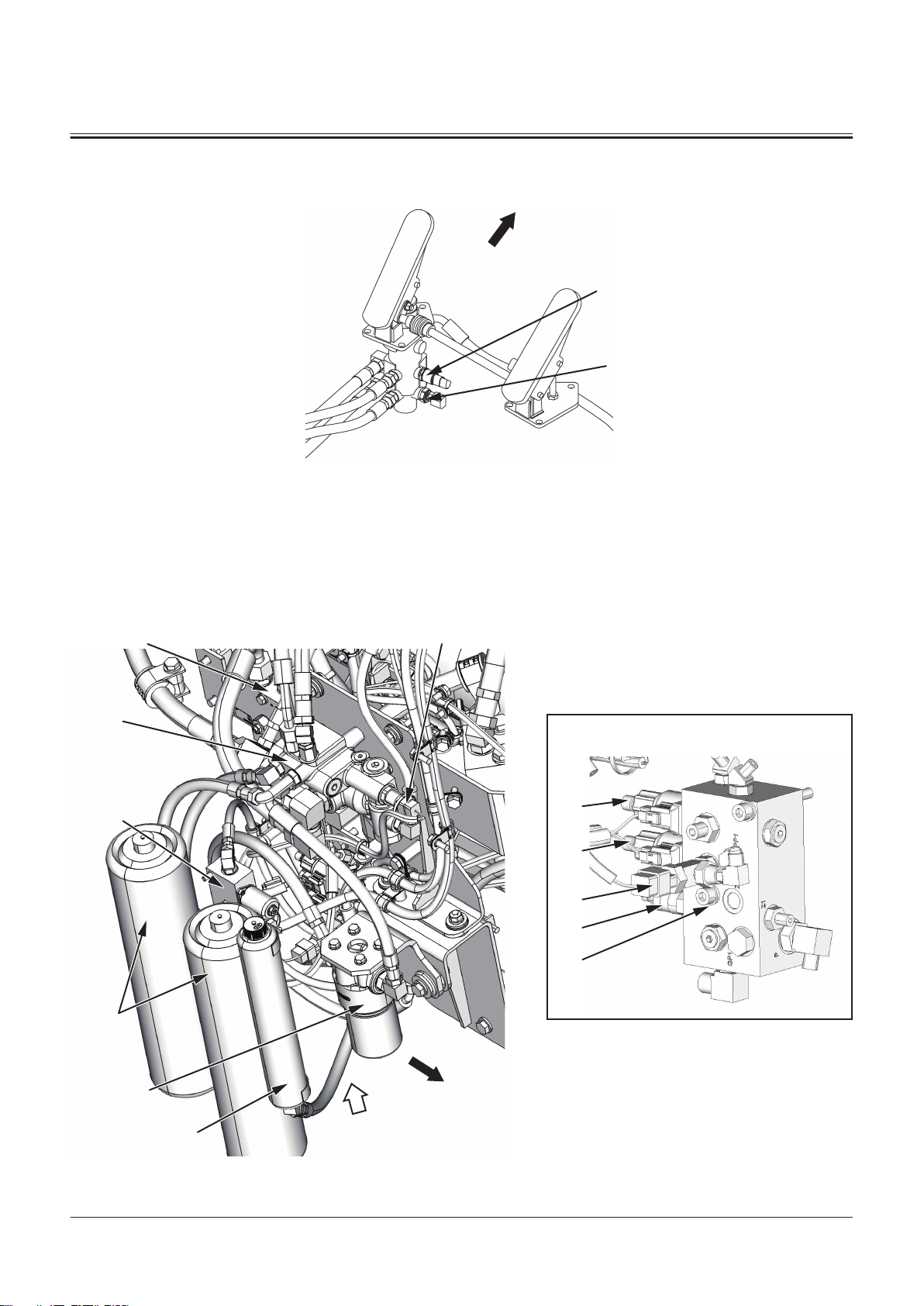

Brake Valve

2

1

a

A

a

A

11

1

2

3

4

12

10

6

7

8

9

5

a- Machine Front Side

SECTION 1 GENERAL

Group 2 Component Layout

TNFQ-05-04-029-1 ja

1- Brake Oil Pressure Switch 2- Service Brake Secondary Pres

sure Sensor

Brake Charge Valve/Combination Valve

TONFQ50-EN-00(28/02/2022)

T1-2-20

TNFQ-05-04-017-1 ja

Page 43

a- Machine Front Side

1

2

3

2

a

SECTION 1 GENERAL

Group 2 Component Layout

1- Brake Charge Valve

2- Service Brake Primary Pres

sure Sensor

3- Lift Arm Flow Rate Control

Solenoid Valve

Steering Valve

4- Service Brake Accumulator

5- Combination Valve

6- Parking Brake Solenoid Valve

7- Control Lever Lock Solenoid

Valve

8- Primary Pilot Pressure Sensor

9- Reducing Valve

10- Parking Brake Accumulator

11- Flow Combiner Control Valve

12- Pilot Filter

TNFQ-05-04-016-1 ja

a- Machine Front Side

1- Steering Main Relief Valve 2- Steering Overload Relief Valve 3- Emergency Steering Pump

Delivery Pressure Sensor

TONFQ50-EN-00(28/02/2022)

T1-2-21

Page 44

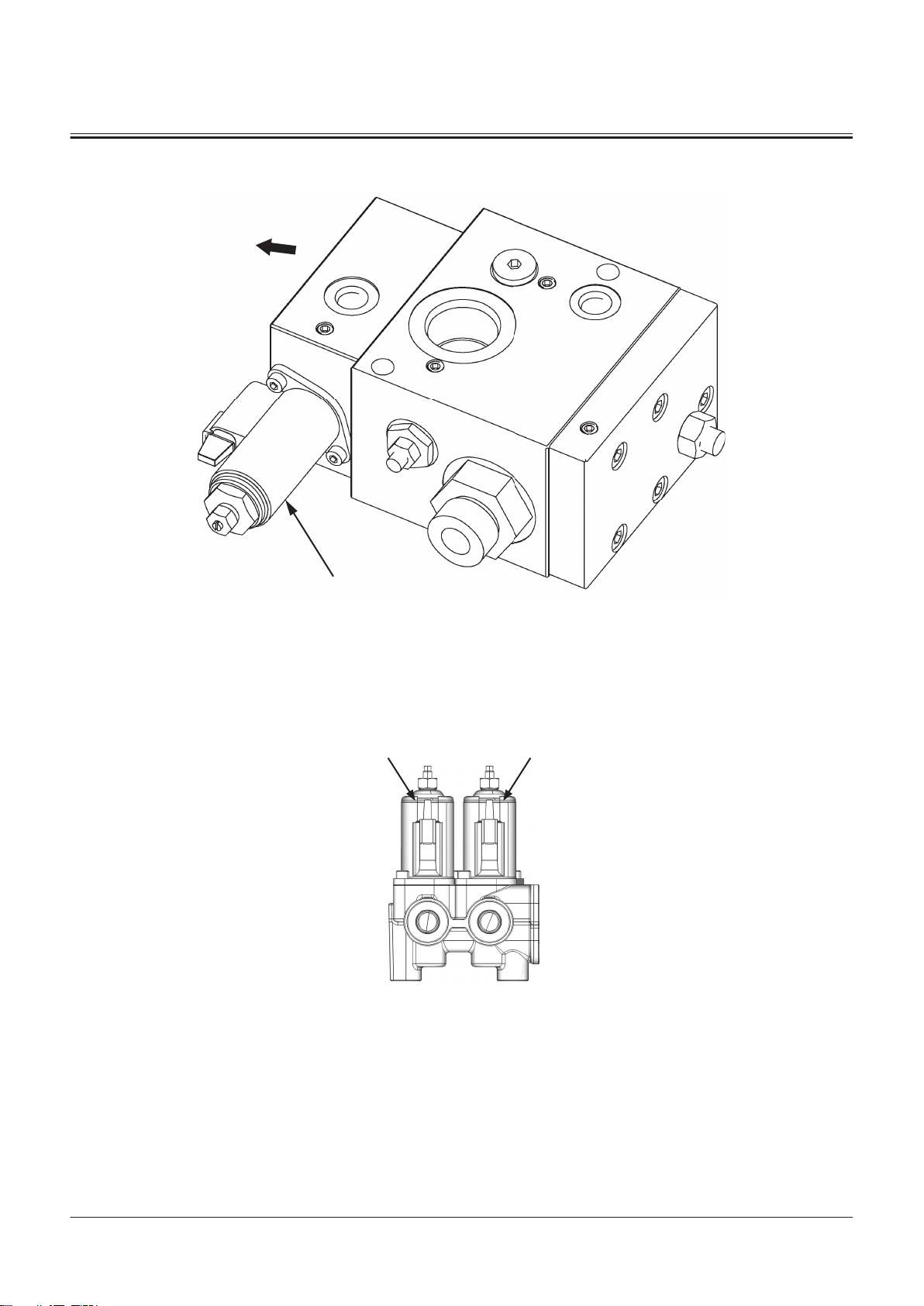

Ride Control Valve

1

a

A2 A1

SECTION 1 GENERAL

Group 2 Component Layout

a- Machine Front Side

1- Ride Control Solenoid Valve

2-Spool Solenoid Valve Unit

A2- Auxiliary 1 Solenoid Valve A1- Auxiliary 2 Solenoid Valve

TNFQ-05-04-028-1 ja

TNUD-01-02-020-2 ja

TONFQ50-EN-00(28/02/2022)

T1-2-22

Page 45

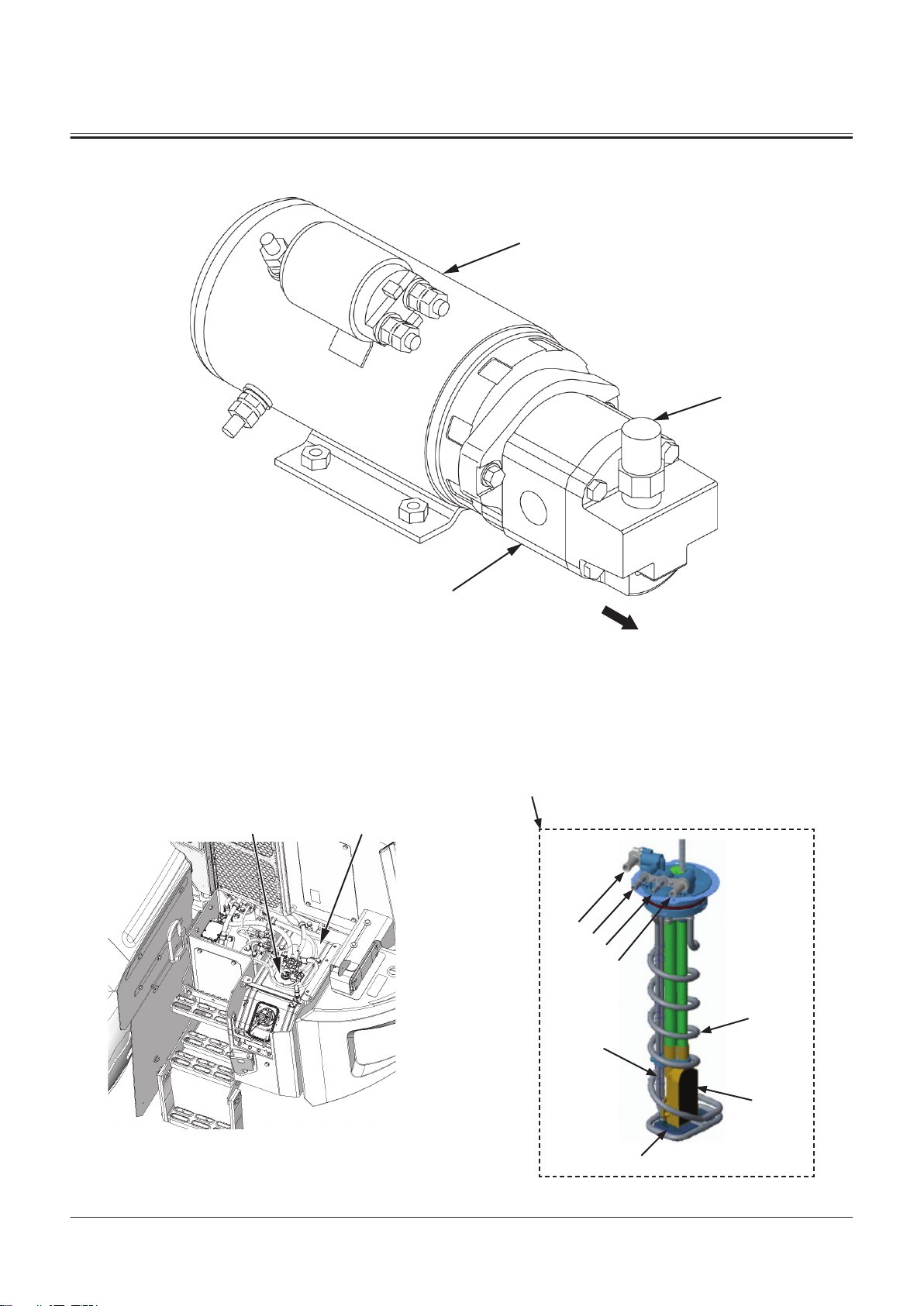

Emergency Steering Pump Unit

1

3

2

a

2

1

6

7

8

9

10

1

3

4

5

SECTION 1 GENERAL

Group 2 Component Layout

a- Machine Front Side

1- Relief Valve 2- Emergency Steering Pump 3- Emergency Steering Motor

DEF Tank

TNFQ-05-04-027-1 ja

TONFQ50-EN-00(28/02/2022)

T1-2-23

TNFQ-05-04-003-1 ja

Page 46

11 5, 6 7 8 9 10 11

1

6

5

42

3

10

7

3

4

6

5

2

1

9

8

a

SECTION 1 GENERAL

Group 2 Component Layout

1- DEF Sensor Unit

2- DEF Tank

3- Coolant Heater Tube

4- DEF Tank Level/DEF Tank

Temperature/DEF Quality

Sensor

DEF Supply Module

5- DEF Suction Filter

6- DEF Suction Tube

7- Coolant Port (To DEF Supply

Module)

8- DEF Port (From Dosing Mod

ule)

9- DEF Port (To DEF Supply Mod

ule)

10- Coolant Port (From Coolant

Control Valve)

TNFQ-05-04-004-1 ja

1- DEF Supply Module

2- DEF Hose

3- DEF Supply Module Main Fil

ter

4- Coolant Control Valve

5- DEF Hose

6- DEF Hose

7- Corrugate Tube

8- DEF Tube

9- Heating Wire

10- Thermoplastic Cover

11- Quick Connector

Joystick Steering Hydraulic Component

TONFQ50-EN-00(28/02/2022)

T1-2-24

TNFQ-05-04-018-1 ja

Page 47

1

3

4

A

5

B

SECTION 1 GENERAL

Group 2 Component Layout

1- Refer to "Steering

Valve"T1-2-21.

2- Refer to "Steering Pilot

Valve"T1-2-26.

3- Refer to "Joystick Steering

Valve"T1-2-25.*)

4- Refer to "Joystick Steering Sol

enoid Valve Unit"T1-2-25.*)

5- Stop Valve (Left)

6- Stop Valve (Right)

7- Joystick Steering Accumulator

8- Steering Cylinder (Right)

9- Steering Cylinder (Left)

10- Reducing Valve

NOTE

*

The component is an optional hydraulic component included with the joystick steering specication.

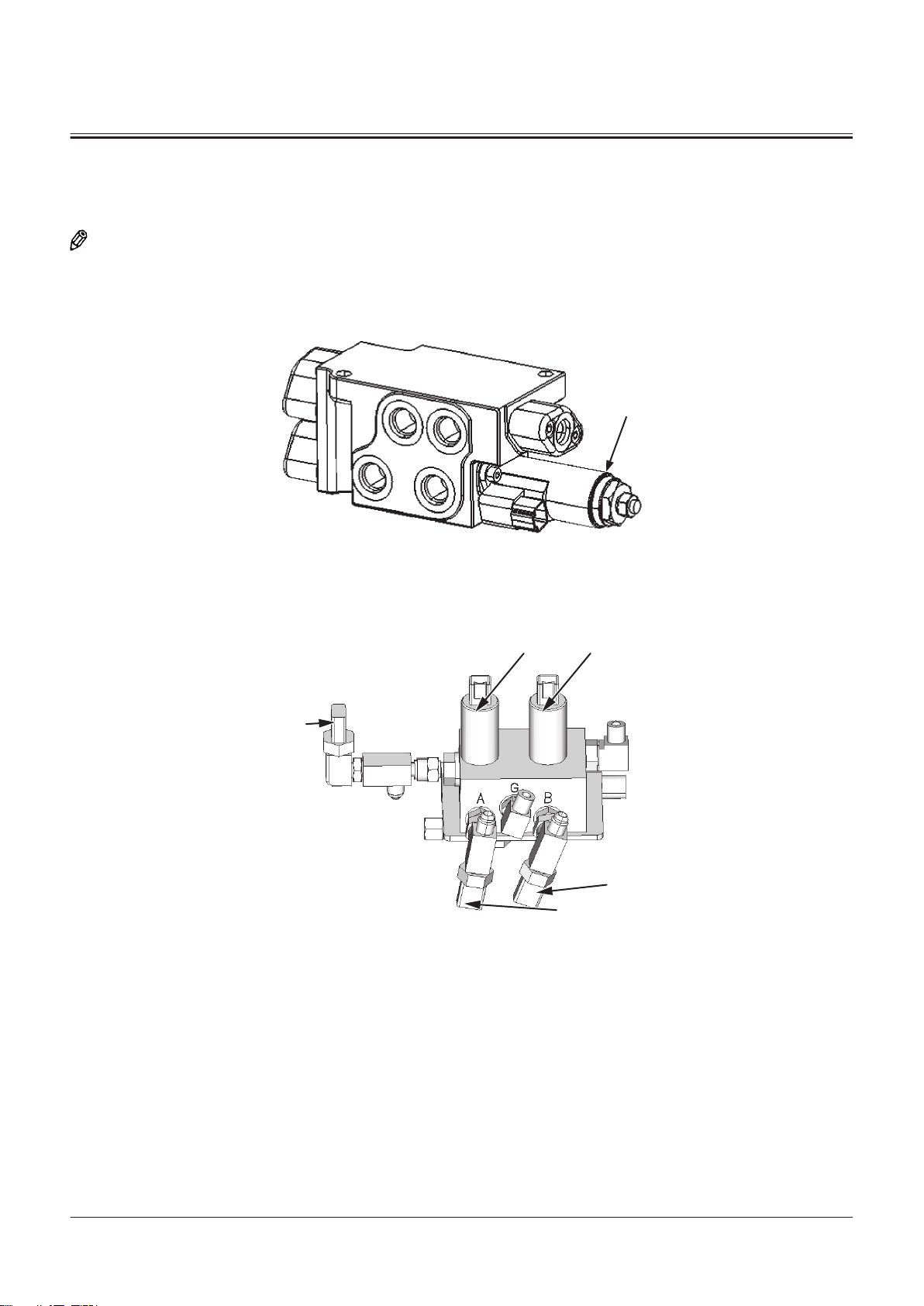

Joystick Steering Valve

1- Cuto Solenoid Valve

Joystick Steering Solenoid Valve Unit

TNUD-01-02-117-1 ja

TNFQ-05-04-031-1 ja

A- Right Steering Solenoid Valve B- Left Steering Solenoid Valve

3- Pilot Pressure Sensor for

Steering (Left)

TONFQ50-EN-00(28/02/2022)

4- Pilot Pressure Sensor for

Steering (Right)

5- Steering Source Pressure Sen

sor

T1-2-25

Page 48

Steering Pilot Valve

1

1- Steering LS Pressure Sensor

SECTION 1 GENERAL

Group 2 Component Layout

TNFQ-05-04-032-1 ja

TONFQ50-EN-00(28/02/2022)

T1-2-26

Page 49

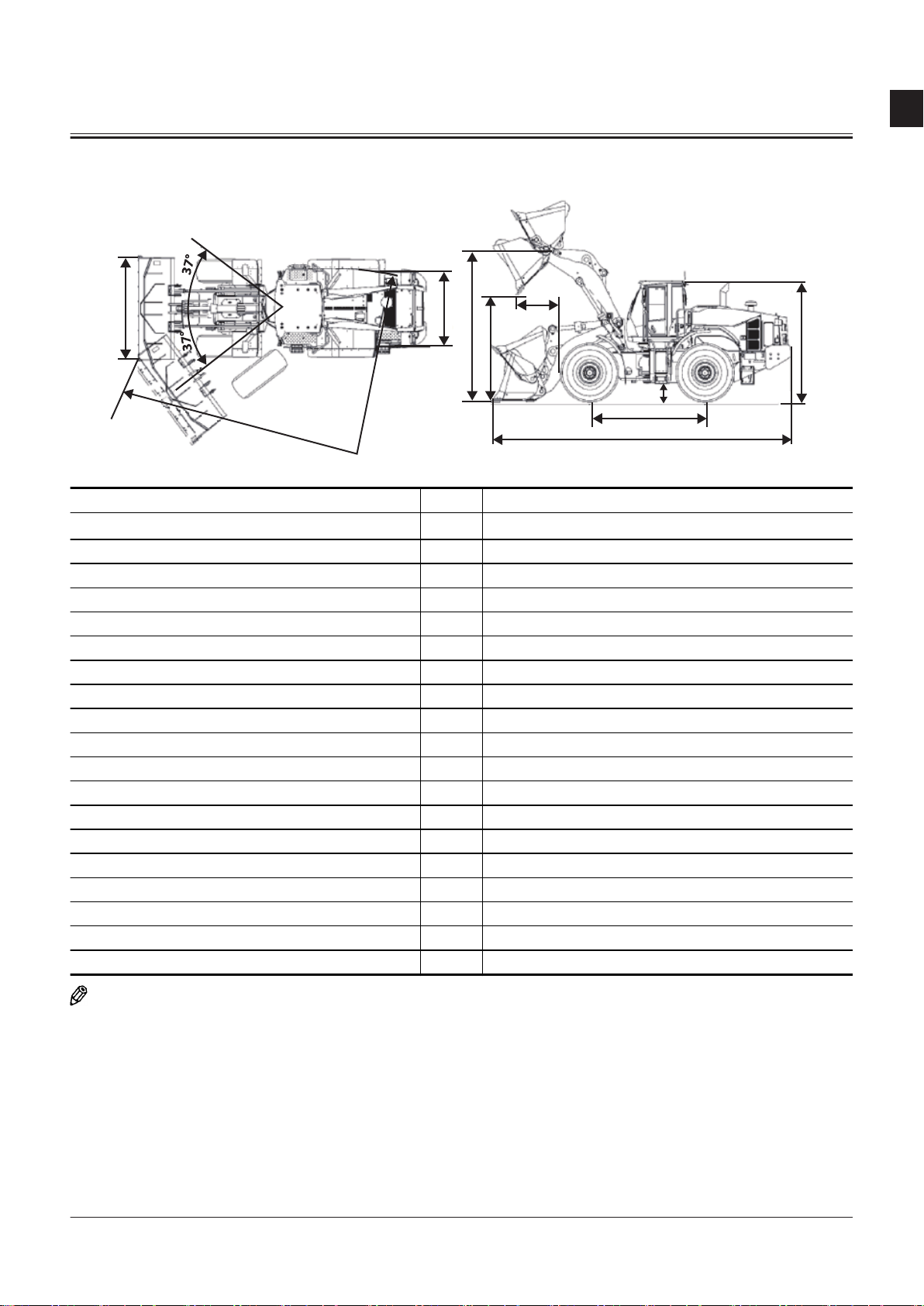

SECTION 1 GENERAL

Group 3 Component Specifications

Specications of Engine

Manufacturer Cummins Inc.

Model L9

Type Diesel, 4-Cycle, 6-Cylinder, Vertical Type, Water-cooled, Direct Injection Type, w/ Super

charger, Intake Air Cooling Type

Cyl. No.- Bore × Stroke 6-114 mm × 145 mm

Total Displacement

Rated Output (gross)

Dry Weight 753 kg

Firing Order 1-5-3-6-2-4

Rotating Direction Counterclockwise Viewed From Flywheel Side

Dimensions: Overall Length ×

Overall Width × Overall Height

8900 cm

213 kW/2000 min

1130 × 931 × 1108 mm

3

-1

TONFQ50-EN-00(28/02/2022)

T1-3-1

Page 50

SECTION 1 GENERAL

Group 3 Component Specifications

Cooling System Cooling Fan Dia. 850 mm, 6 Hybrid Blades

Thermostat Cracking Temperature at Atmospheric Pressure: 82 °C

Full Open: 94 °C

Water Pump Centrifugal Type

Lubrication System Type of Lubrication Pump Trochoid Type

Oil Filter Strata Pore (Plastic ber)/Spin-on Type

Oil Cooler Water Cooled Type

Starting System Electrical Motor Electromagnetic Pinion Shift Reduction Type

Voltage/Output 24 V/7.8 kW

Preheat System Type Grid Air Heater (24 V/100 A)

Engine Stop System Type Fuel Shut-O (Electronic Control)

Alternator Type AC Type

Voltage/Output 24 V/95 A

Supercharging System Type Exhaust-Turbocharger Type, Forced Lubrication

Fuel System Type Common Rail Type, HPCR Type

Governor Electronic All Speed Control

Injection Nozzle Electrical Multi-Hole Injector

Fuel Filter Nanonet (Plastic ber)/Spin-on Type

TONFQ50-EN-00(28/02/2022)

T1-3-2

Page 51

SECTION 1 GENERAL

Group 3 Component Specifications

IMPORTANT

This table shows design specications, which are not servicing standards.

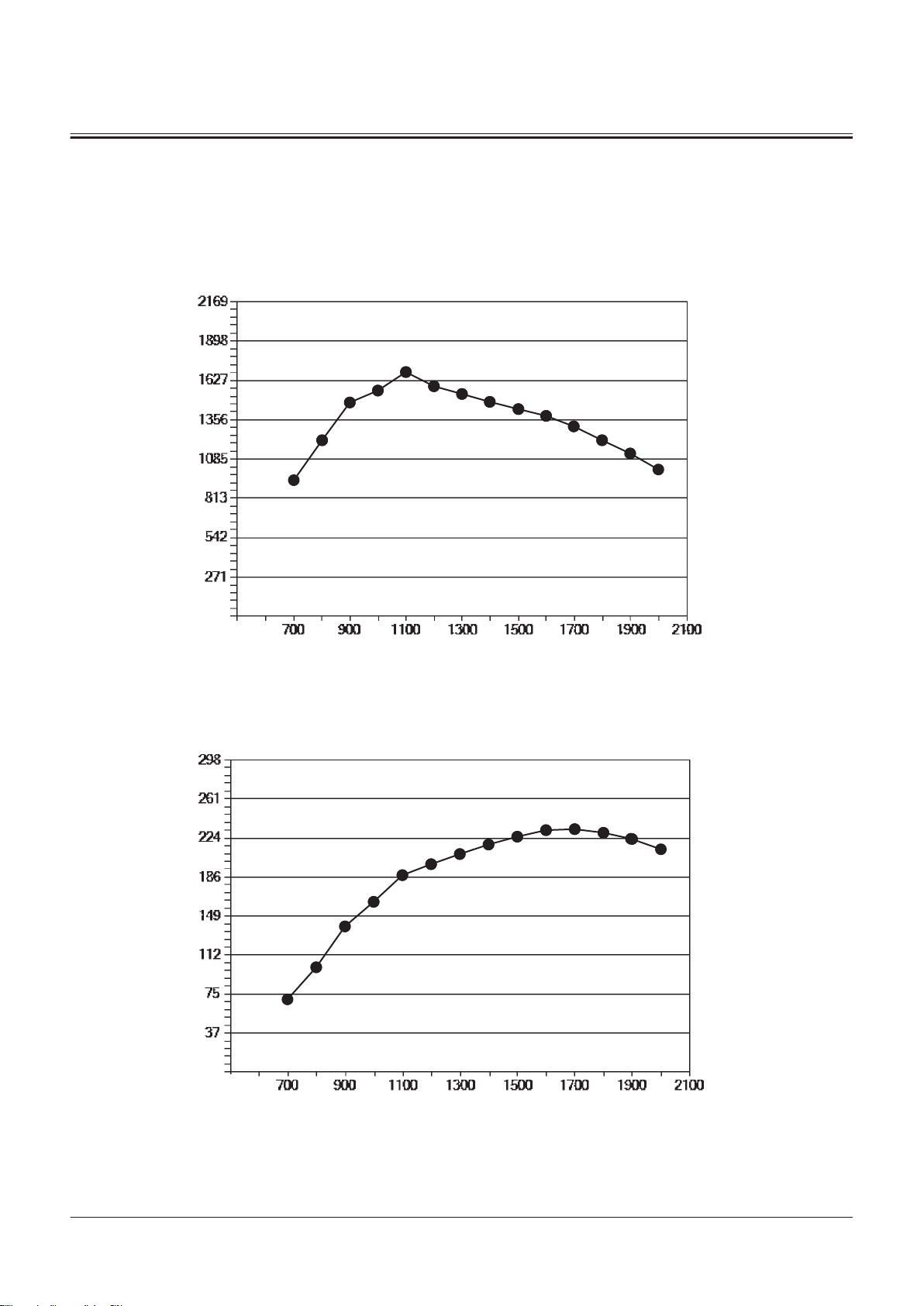

Performance (New Parts) Fuel Consumption Rate

Maximum Output Torque