Page 1

-3

• ZX16

-3

• ZX18

PART NO.

EM1NC-EN3-1

-3

• ZX27

-3

HYDRAULIC EXCAVATOR OPERATOR’S MANUAL

Operator's Manual

14

16

-3

-3

URL:http://www.hitachi-c-m.com

PRINTED IN THE NETHERLANDS (ACI) 2009, 12

EM1NC-EN3-1ZX14

18

27

-3

-3

Hydraulic Excavator

Serial No.

ZX14-3 001001 and up

ZX16-3 003001 and up

ZX18-3 005001 and up

ZX27-3 007001 and up

Page 2

INTRODUCTION

Read this manual carefully to learn how to operate and

service your machine correctly. Failure to do so could

result in personal injury or equipment damage.

This standard specification machine can be operated

under the following conditions without being modified.

Atmospheric Temperature: −20°C to 40°C (−4°F to 104°F)

Altitude: 0 m to 1500 m (0 ft to 4900 ft)

In case the machine is used under conditions other than

described above, consult your authorized dealer.

This manual should be considered a permanent part of

your machine and should remain with the machine when

you sell it.

This machine is of metric design. Measurements in this

manual are metric. Use only metric hardware and tools as

specified.

• SI Units (International System of Units) are used in this

manual.

For reference MKS system units and English units are

also indicated in parentheses after the SI units.

Example : 24.5 MPa (250 kgf/cm², 3560 psi)

Right-hand and left-hand sides are determined by

facing in the direction of forward travel.

Write product identification numbers in the Machine

Numbers section. Accurately record all the numbers

to help in tracing the machine should it be stolen.

Your dealer also needs these numbers when you order

parts. If this manual is kept on the machine, also file the

identification numbers in a secure place off the machine.

Warranty is provided as a part of Hitachi’s support

program for customers who operate and maintain their

equipment as described in this manual. The warranty is

explained on the warranty certificate which you should

have received from your dealer.

This warranty provides you the assurance that Hitachi

will back its products where defects appear within the

warranty period. In some circumstances, Hitachi also

provides field improvements, often without charge to the

customer, even if the product is out of warranty.

Should the equipment be abused, or modified to

change its performance beyond the original factory

specifications, the warranty will become void and field

improvements may be denied.

Setting fuel delivery above specifications or otherwise

overpowering machines will result in such action.

Only qualified, experienced operators officially licensed

(according to local law) should be allowed to operate

the machine. Moreover, only officially licensed personnel

should be allowed to inspect and service the machine.

Prior to operating this machine in a country other than

a country of its intended use, it may be necessary to

make modifications to it so that it complies with the local

regulatory standards (including safety standards) and

legal requirements of that particular country. Please do

not export or operate this machine outside of the country

of its intended use until such compliance has been

confirmed.

Please contact Hitachi Construction Machinery Co., Ltd. or

any of our authorized distributor or dealer if you have any

questions concerning compliance.

All information, illustrations and specifications in this manual are based on the latest product information available at the

time of publication. The right is reserved to make changes at any time without notice.

©2009 Hitachi Construction Machinery Co., Ltd.

All rights reserved.

Page 3

INDEX

MACHINE NUMBERS

SAFETY

SAFETY SIGNS

COMPONENTS NAME

OPERATOR’S STATION

BREAK-IN

OPERATING ENGINE

DRIVING MACHINE

OPERATING MACHINE

TRANSPORTING

MAINTENANCE

CONSUMABLE PARTS LIST

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

EM1NC-EN3-1

TROUBLESHOOTING

SPECIFICATIONS

OPTIONAL ATTACHMENT AND DEVICE

INDEX

Page 4

Page 5

CONTENTS

MACHINE NUMBERS ........................................................................1

SAFETY ...............................................................................................S-1

Recognize Safety Information ....................................................S-1

Understand Signal Words .............................................................S-1

Follow Safety Instructions ............................................................S-2

Prepare for Emergencies ...............................................................S-2

Wear Protective Clothing..............................................................S-3

Protect Against Noise ....................................................................S-3

Inspect Machine ..............................................................................S-3

Tidy Up Inside Operator’s Space ................................................S-4

Use Handrails and Steps ...............................................................S-4

Never Ride Attachment .................................................................S-4

Adjust Operator’s Seat ...................................................................S-5

Ensure Safety Before Rising from or

Leaving Operator’s Seat ...........................................................S-5

Fasten Your Seat Belt ......................................................................S-5

Move and Operate Machine Safely ...........................................S-6

Operate Only from Operator’s Seat ..........................................S-7

Jump Starting ...................................................................................S-7

Keep Riders Off Machine ..............................................................S-7

Precautions for Operations ..........................................................S-8

Investigate Job Site Beforehand ................................................S-9

Equipment of OPG ....................................................................... S-10

Provide Signals for Jobs Involving

Multiple Machines ..................................................................S-10

Confirm Direction of Machine to be Driven .......................S-10

Drive Machine Safely ................................................................... S-11

Avoid Injury from Rollaway Accidents ..................................S-13

Avoid Injury from Back-over and Swing Accidents ..........S-14

Keep Personnel Clear from Working Area ...........................S-15

Never Position Bucket Over Anyone .....................................S-15

Avoid Undercutting .....................................................................S-15

Avoid Tipping ................................................................................. S-16

Never Undercut a High Bank ....................................................S-16

Dig with Caution ...........................................................................S-17

Operate with Caution ................................................................. S-17

Avoid Power Lines ........................................................................ S-17

Precautions for Lightning .......................................................... S-18

Do Not Use for Craning Operations .......................................S-18

Protect Against Flying Debris ..................................................S-18

Park Machine Safely ..................................................................... S-19

Handle Fluids Safely−Avoid Fires............................................S-19

Safety Transporting .....................................................................S-20

Practice Safe Maintenance ........................................................S-21

Warn Others of Service Work ................................................... S-22

Support Machine Properly ........................................................ S-22

Stay Clear of Moving Parts ........................................................S-23

Prevent Parts from Flying ..........................................................S-23

Store Attachments Safely .......................................................... S-24

Prevent Burns ................................................................................. S-24

Replace Rubber Hoses Periodically ........................................ S-25

Avoid High-pressure Fluids ....................................................... S-25

Prevent Fires ................................................................................... S-26

Evacuating in Case of Fire .......................................................... S-27

Beware of Exhaust Fumes..........................................................S-28

Beware of Asbestos and Silicon Dust and

Other Contamination ............................................................S-28

Precautions for Welding and Grinding .................................S-29

Avoid Heating Near Pressurized Fluid Lines .......................S-29

Avoid Applying Heat to Lines Containing

Flammable Fluids .................................................................... S-29

Remove Paint Before Welding or Heating ........................... S-30

Prevent Battery Explosions ....................................................... S-30

Handle Chemical Products Safely ........................................... S-31

Dispose of Waste Properly ......................................................... S-31

SAFETY SIGNS ............................................................................ S-33

COMPONENTS NAME ................................................................1-1

OPERATOR’S STATION ...............................................................1-3

Pedals, Levers and Monitor Panel ..............................................1-3

Switch Panel .................................................................................1-4

Key Switch ....................................................................................1-5

Monitor Panel ...................................................................................1-6

Alternator Indicator ...................................................................1-6

Fuel Level Indicator ...................................................................1-6

Preheat Indicator ........................................................................1-6

Overheat Indicator ....................................................................1-6

Engine Oil Pressure Indicator.................................................1-7

Hour Meter ...................................................................................1-7

Fuel Gauge (ZX14-3, 16-3, 18-3) ...........................................1-7

Fuel Gauge (ZX27-3) .................................................................1-7

Coolant Temperature Gauge (ZX27-3) ...............................1-7

Coolant Temperature Indicator .............................................1-7

Cab Heater Operation (Cab Equipped Machines) ...............1-8

Heater Operation .......................................................................1-8

Blower Operation .......................................................................1-8

Defroster Operation ..................................................................1-8

Radio (ZX14-3, 16-3, 18-3 Cab Equipped Machines) ..........1-9

AM/FM Radio Operation (Cab Equipped Machine, When

Genuine Radio is Installed) .................................................. 1-10

Part Name and Function ......................................................1-10

Radio Operation ......................................................................1-11

Tuning Procedure ...................................................................1-11

Station Presetting Procedure ..............................................1-12

Deletion of Preset Memory .................................................1-12

Clock Setting Procedure .......................................................1-12

Opening/Closing Cab Front Window (ZX14-3, 16-3, 18-3

Cab Equipped Machines) ..................................................... 1-13

Opening/Closing Cab Front Window (ZX27-3) ..................1-14

Emergency Exit (ZX14-3, 16-3, 18-3 Cab Equipped

Machines) ..................................................................................1-15

Emergency Exit (ZX27-3) ...........................................................1-16

Adjusting Operator’s Seat .........................................................1-17

Seat Fore-Aft Adjustment ....................................................1-17

Tool and Operator’s Manual Box ............................................. 1-18

Seat Belt ........................................................................................... 1-19

Cab Light (Cab Equipped Machines) .....................................1-20

Cab Door Release Lever

(ZX14-3, 16-3, 18-3 Cab Equipped Machines) ..............1-21

Cab Door Release Button (ZX27-3) ........................................1-21

Page 6

CONTENTS

BREAK-IN .........................................................................................2-1

Breaking in New Machine ............................................................2-1

OPERATING ENGINE ...................................................................3-1

Before Starting Engine ..................................................................3-1

Starting Engine ................................................................................3-2

Check Machine After Starting Engine ......................................3-5

Using Booster Battery ....................................................................3-6

Stopping Engine ..............................................................................3-7

DRIVING MACHINE .....................................................................4-1

Travel Levers .....................................................................................4-1

Travel Mode Switch (ZX16-3, 18-3, 27-3).................................4-3

Traveling on Soft Ground .............................................................4-4

Raise One Track Using Boom and Arm ....................................4-4

Towing Machine ..............................................................................4-5

Driving in Water or on Soft Ground ..........................................4-6

Parking and Stopping on Slopes ...............................................4-7

Parking on Slopes ............................................................................4-7

OPERATING MACHINE ...............................................................5-1

Control Lever (ISO Excavator Pattern) ......................................5-1

Boom-Swing Pedal ..........................................................................5-2

Auxiliary Pedal ..................................................................................5-3

Blade Lever ........................................................................................5-4

Precautions for Blade Operation ................................................5-5

Blade and Track Width

Control Lever Operation (ZX18-3) ........................................5-6

Extending / Retracting Blade Width

(ZX18-3) .........................................................................................5-7

Pilot Control Shut-Off Lever ........................................................5-8

Warming Up Operation .............................................................. 5-10

Warming Up in Cold Weather ..................................................5-10

Operating Backhoe ...................................................................... 5-11

Grading Operation .......................................................................5-12

Avoid Driving Bucket Teeth into Ground ............................. 5-12

Avoid Abusive Operation ..........................................................5-12

Avoid Striking with Bucket ........................................................ 5-13

Avoid Excavation Using Upperstructure and/or

Boom Swing Power ................................................................5-13

Use Correct Track Shoe ...............................................................5-13

Avoid Other Than Specified Machine Operations ............5-14

Precautions for Using Bucket Hook .......................................5-15

Boom Cylinder May Hit Blade ..................................................5-15

Avoid Hitting Blade with Bucket .............................................5-16

Avoid Colliding Blade Against Rocks ..................................... 5-16

Avoid Colliding Boom Cylinder with Track ......................... 5-16

Using Rubber Crawler .................................................................5-17

Pipings for Breaker and Crusher ..............................................5-19

Precautions for Breaker Operation ......................................... 5-20

Precautions for Crusher Operation ........................................ 5-23

Precautions for After Operating Machine............................5-24

Emergency Boom Lowering Procedure ...............................5-25

TRANSPORTING ...........................................................................6-1

Transporting by Road ....................................................................6-1

Trailer Loading/Unloading ...........................................................6-1

Loading ...............................................................................................6-2

Securing Machine to Trailer for Transportation ....................6-3

Unloading ..........................................................................................6-4

Lifting Machine with Crane .........................................................6-5

MAINTENANCE .............................................................................7-1

Procedures .........................................................................................7-1

Prepare Machine for Inspection/Maintenance .....................7-2

Opening/Closing Engine Access Covers .................................7-3

Opening/Closing Tank Covers (ZX27-3) ..................................7-4

Opening/Closing Right Side Covers (ZX27-3) .......................7-5

Daily Inspection ...............................................................................7-6

Periodic Replacement of Parts ....................................................7-8

Maintenance Guide ........................................................................7-9

Brand Names of Recommended

Oil and Lubricants ................................................................... 7-12

A. Greasing ......................................................................................7-15

Front Joint Pins (Incl. Swing Post Joint Pins) .................7-15

Bucket and Link Pins .............................................................. 7-18

Blade Pins (ZX27-3).................................................................7-18

Swing Bearing .........................................................................7-19

Swing Internal Gear ...............................................................7-20

Control Lever Universal Joint ..............................................7-20

B. Engine .......................................................................................... 7-21

Engine Oil .................................................................................7-21

Change Engine Oil / Replace Engine Oil Filter .............7-22

C. Transmission ..............................................................................7-24

Travel Reduction Gear ...........................................................7-24

D. Hydraulic System ..................................................................... 7-27

Check Hydraulic Oil Level ...................................................7-28

Drain Hydraulic Oil Tank Sump ..........................................7-29

Change Hydraulic Oil ............................................................7-30

Clean Suction Filter ................................................................7-33

Replace Full Flow Filter ........................................................7-34

Replace Pilot Filter ................................................................. 7-35

Check Hoses and Lines .........................................................7-37

E. Fuel System ................................................................................ 7-44

Check Water Separator .........................................................7-45

Drain Fuel Tank Sump ...........................................................7-46

Replace Fuel Filter ...................................................................7-47

Check Fuel Hoses ....................................................................7-48

F. Air Cleaner ................................................................................... 7-49

Clean Air Cleaner Element ................................................... 7-49

Replace Air Cleaner Element...............................................7-49

G. Cooling System ........................................................................ 7-51

Check Coolant Level .............................................................7-53

Check and Adjust Fan Belt Tension ...................................7-53

Change Coolant ....................................................................... 7-56

Clean Radiator ..........................................................................7-58

Clean Air Conditioner Condenser ..................................... 7-58

H. Electrical System ......................................................................7-59

Battery .........................................................................................7-59

Replacing Fuses ....................................................................... 7-63

I. Miscellaneous ............................................................................. 7-64

Check Bucket Teeth for Looseness and/or Wear ......... 7-64

Replace Bucket.........................................................................7-66

Adjust Track Sag (Rubber Crawler) and Check for

Damage ................................................................................7-67

Page 7

CONTENTS

Replace Rubber Track ............................................................7-69

Check Track Sag (Steel Crawler) (Optional)

(ZX27-3 Only) ...................................................................... 7-71

Check and Replace Seat Belt ............................................... 7-74

Clean Cab Floor (Cab Equipped Machines) ................... 7-75

Check Injection Nozzle .........................................................7-76

Adjust Valve Clearance ..........................................................7-76

Measure Engine Compression Pressure..........................7-76

Check Starter and Alternator .............................................. 7-76

Check Radiator Cap ................................................................ 7-76

Check Crankcase Breather ................................................... 7-76

Check Tightening Torque of Bolts and Nuts ..................7-77

CONSUMABLE PARTS LIST ......................................................8-1

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL

CONDITIONS ..................................................................................9-1

STORAGE ...................................................................................... 10-1

Storing Machine............................................................................10-1

Removing Machine from Storage ..........................................10-2

TROUBLESHOOTING ...............................................................11-1

Impossible to Start Engine ........................................................ 11-1

Engine ............................................................................................... 11-2

Electrical System ........................................................................... 11-5

Mode Selection .............................................................................11-6

Control Levers ................................................................................ 11-7

Hydraulic System ..........................................................................11-7

SPECIFICATIONS .......................................................................12-1

Specifications ZX14-3 ................................................................

Working Ranges ZX14-3 ........................................................... 12-2

Bucket Types and Applications ZX14-3 ...............................12-3

Specifications ZX16-3 ................................................................ 12-4

Working Ranges ZX16-3 ........................................................... 12-5

Bucket Types and Applications ZX16-3 ..............................12-6

Specifications ZX18-3 ................................................................ 12-7

Working Ranges ZX18-3 ........................................................... 12-8

Bucket Types and Applications ZX18-3 ...............................12-9

Specifications ZX27-3 ..............................................................12-10

Working Ranges ZX27-3 .........................................................12-11

Bucket Types and Applications ZX27-3 .............................12-12

Noise Level Results (2000/14/CE, art. VI) ............................12-13

Vibration Level .............................................................................12-13

Special Specification .................................................................12-14

OPTIONAL ATTACHMENT AND DEVICE ..........................13-1

Ignition Block System (Optional) ............................................ 13-1

INDEX ............................................................................................. 14-1

12-1

Page 8

CONTENTS

MEMO

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

Page 9

MACHINE NUMBERS

The manufacturing Nos. explained in this group is the

individual number (serial No.) given to each machine and

hydraulic components. These numbers are requested when

inquiring any information on the machine and/or components.

Fill these serial Nos. in the blank spaces in this group to

immediately make them available upon request.

Machine

MODEL/TYPE:________________

PRODUCT IDENTIFICATION NUMBER:

___________________________

Product Identification Number

PRODUCT IDENTIFICATION NUMBER:

___________________________

NOTE:

f

*HCM1NC00X00001001*

Marks to indicate the start

and end of the PIN

ZX14-3, 16-3, 18-3

ZX27-3

M1NC-00-001

M1N7-00-001

PRODUCT IDENTIFICATION

NUMBER (PIN)

ZX14-3, 16-3, 18-3

ZX27-3

M1NC-00-002

M1N7-00-002

1

Page 10

Engine

TYPE:

MFG. NO.:

MACHINE NUMBERS

Travel Motor

TYPE:

MFG. NO.:

ZX14-3, 16-3, 18-3

ZX27-3

M1NC-00-003

M1NC-00-015

Swing Motor

TYPE:

MFG. NO.:

M1NC-00-004

M1NC-00-005

2

Page 11

Hydraulic Pump

TYPE:

MFG. NO.:

MACHINE NUMBERS

ZX14-3, 16-3, 18-3

ZX27-3

M1NC-00-006

M1NC-00-016

3

Page 12

MACHINE NUMBERS

MEMO

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

..................................................................................................................................................................................................

4

Page 13

SAFETY

Recognize Safety Information

• These are the SAFETY ALERT SYMBOLS.

• When you see these symbols on your machine or in this

manual, be alert to the potential for personal injury.

• Follow recommended precautions and safe operating

practices.

Understand Signal Words

• On machine safety signs, signal words designating the

degree or level of hazard - DANGER, WARNING, or CAUTION

- are used with the safety alert symbol.

• DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

• WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

• CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

• DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs.

• Some safety signs do not use any of the designated signal

words above after the safety alert symbol are occasionally

used on this machine.

SA-688

• To avoid confusing machine protection with personal

safety messages, a signal word IMPORTANT indicates a

situation which, if not avoided, could result in damage to

the machine.

• fNOTE indicates an additional explanation for an element

of information.

SA-1223

S-1

Page 14

SAFETY

Follow Safety Instructions

• Carefully read and follow all safety signs on the machine as

well as all safety messages in this manual.

• Safety signs must be installed, maintained and replaced if

damaged.

• If a safety sign or this manual is damaged or missing,

order a replacement from your authorized dealer in the

same way you order other replacement parts (be sure to

state machine model and serial number when ordering).

• Allow only properly trained, qualified, authorized personnel

to operate the machine.

• Learn how to correctly operate and service the machine.

• Keep your machine in proper working condition.

• Always operate the machine within the specification.

• Unauthorized modifications of the machine may impair

the functions and/or safety and affect machine life and

the warranty will become void.

• The safety messages in this SAFETY chapter are intended

to illustrate basic safety procedures of machines. However

it is impossible for these safety messages to cover every

possible hazardous situation you may encounter. If you

have any questions concerning safety, you should first

consult your supervisor and/or your authorized dealer

before operating or performing maintenance work on the

machine.

SA-003

Prepare for Emergencies

• Be prepared if a fire starts or if an accident occurs.

• Keep a first aid kit and fire extinguisher on hand.

• Thoroughly read and understand the label attached on

the fire extinguisher to use it properly.

• To ensure that a fire extinguisher can be always used

when necessary, check and service the fire extinguisher

at the recommended intervals as specified in the fire

extinguisher manual.

• Establish emergency procedure guidelines to cope with

fires and accidents.

• Keep emergency numbers for doctors, ambulance

service, hospital, and fire department posted near your

telephone.

SA-437

S-2

Page 15

SAFETY

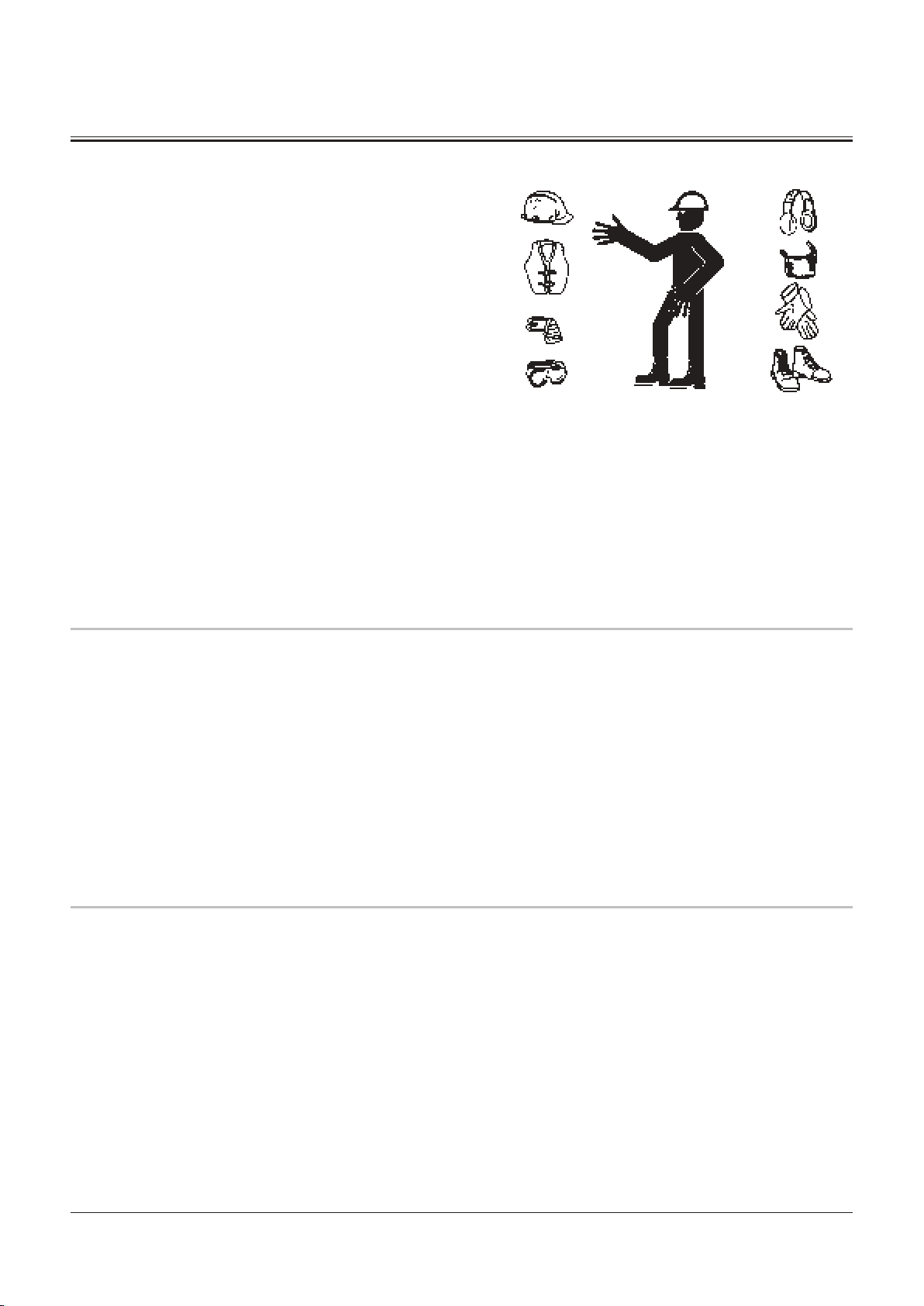

Wear Protective Clothing

• Wear close fitting clothing and safety equipment

appropriate to the job.

You may need:

A hard hat

Safety shoes

Safety glasses, goggles, or face shield

Heavy gloves

Hearing protection

Reflective clothing

Wet weather gear

Respirator or filter mask.

Be sure to wear the correct equipment and clothing for the

job. Do not take any chances.

• Avoid wearing loose clothing, jewelry, or other items that

can catch on control levers or other parts of the machine.

• Operating equipment safely requires the full attention of

the operator.

• Do not wear radio or music headphones while operating

the machine.

SA-438

Protect Against Noise

• Prolonged exposure to loud noise can cause impairment or

loss of hearing.

• Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortably loud noises.

Inspect Machine

• If any abnormality is found, be sure to repair it immediately

before operating the machine.

• In the walk-around inspection, be sure to cover all points

described in the “Before Starting Engine” section in the

operator’s manual.

SA-434

S-3

SA-435

Page 16

SAFETY

Tidy Up Inside Operator’s Space

• Always keep inside the operator’s space clean by observing

instructions below, to prevent any personal accidents from

occurring.

• Remove mud and/or oily material from the shoe soles

before entering the operator’s space. If pedals are

operated without removing mud or oily matter, the foot

may slip off the pedal, possibly creating a hazardous

situation.

• Do not leave parts and/or tools around the operator’s

seat.

• Avoid storing transparent bottles in the cab. Do not

attach any transparent type window decorations on

the windowpanes as they may focus sunlight, possibly

starting a fire.

• Do not wear radio or music headphones and do not use a

cell phone while traveling or operating the machine.

• Never allow hazardous materials such as combustible

and/or explosive material in the operator’s space.

• Do not leave cigarette lighters in the cab. If the

temperature in the cab increases, the lighter may

explode.

Use Handrails and Steps

• Falling is one of the major causes of personal injury.

• When you get on and off the machine, always use the

crawler instead of the step for safety. Also get on and off

from the position of the crawler that can secure your feet

space enough.

• When you get on and off the machine, always face the

machine.

• Maintain a three-point contact with the steps and

handrails.

• Do not use any controls as handholds.

• Never jump on or off the machine. Never mount or

dismount a moving machine.

• In case adhered slippery material such as oil, grease,

or mud is present on steps, handrails, or platforms,

thoroughly remove such material.

Never Ride Attachment

• Never allow anyone to ride attachments or the load. This is

an extremely dangerous practice.

SA-439

S-4

Page 17

SAFETY

Adjust Operator’s Seat

• A poorly adjusted seat for either the operator or the

work at hand may quickly fatigue the operator leading to

misoperation of the machine.

• The seat should be adjusted whenever the operator for

the machine changes.

• The operator should be able to fully depress the pedals

and to correctly operate the control levers with his back

firmly against the seat back.

• If not, readjust the seat forward or backward, and check

again.

Ensure Safety Before Rising from or Leaving

Operator’s Seat

• Before rising from the operator’s seat to open/close either

side window or to adjust the seat position, be sure to first

lower the front attachment to the ground and then move

the pilot control shut-off lever to the LOCK position. Failure

to do so may allow the machine to unexpectedly move

when a body part unintentionally comes into contact with a

control lever, possibly resulting in serious personal injury or

death.

• Before leaving the machine, be sure to first lower the

front attachment to the ground and then move the pilot

control shut-off lever to the LOCK position. Turn the key

switch OFF to stop the engine.

• Before leaving the machine, close all windows, doors, and

access covers and lock them up.

SA-378

Fasten Your Seat Belt

• If the machine should overturn, the operator may become

injured and/or thrown from the cab. Additionally the

operator may be crushed by the overturning machine,

resulting in serious injury or death.

• Be sure to remain seated with the seat belt securely

fastened whenever operating the machine.

• Prior to operating the machine, thoroughly examine

webbing, buckle and attaching hardware. If any item is

damaged or worn, replace the seat belt or component

before operating the machine. Replace the seat belt at

least once every 3 years regardless of appearance.

S-5

SA-237

Page 18

SAFETY

Move and Operate Machine Safely

• Always be aware that there is a potential danger around the

machine while operating the machine.

• Take extra care not to run over bystanders. Confirm the

location of bystanders before moving, swinging, or

operating the machine.

• Always keep the travel alarm and horn in working

condition (if equipped).

• Before starting to move or operate the machine, sound

the travel alarm and horn to alert bystanders.

• Use a signal person when moving, swinging, or operating

the machine in congested areas. Locate the signal person

so that the operator can always witness the signal person.

• Coordinate the meanings of all safety signs, hand signals

and marks before starting the machine. Appoint a person

who is responsible to make a signal and/or guidance.

• Never allow any persons or obstacles to enter the

machine operation areas.

• Use appropriate illumination. Check that all lights are

operable before operating the machine. If any faulty

illumination is present, immediately repair it.

SA-1291

S-6

Page 19

SAFETY

Operate Only from Operator’s Seat

• Inappropriate engine starting procedures may cause the

machine to runaway, possibly resulting in serious injury or

death.

• Start the engine only when seated in the operator’s seat.

• NEVER start the engine while standing on the tracks or on

ground.

• Do not start engine by shorting across starter terminals.

A hazardous situation may be created and/or possible

damage to the machine may result.

• Before starting the engine, confirm that all control levers

are in neutral.

Jump Starting

• Failure to follow correct jump starting procedures could

result in a battery explosion or a runaway machine.

• If the engine must be jump started, be sure to follow the

instructions shown in the “OPERATING ENGINE” chapter.

• The operator must be seated in the operator’s seat so

that the machine will be under control when the engine

starts. Jump starting is a two-person operation.

• Never use a frozen battery.

• Failure to follow correct jump starting procedures could

result in a battery explosion or a runaway machine.

SA-444

Keep Riders Off Machine

• Riders on machine are subject to injury such as being struck

by foreign objects and being thrown off the machine.

• Riders also obstruct the operator’s view, resulting in the

machine being operated in an unsafe manner.

• Only the operator is allowed on the machine. Keep riders

off.

SA-032

SA-1292

S-7

Page 20

Precautions for Operations

WARNING: Thoroughly make certain safety at the

d

work site before starting operations. Especially

always observe the following points.

• Be sure to install the overhead cab guard before

operating the machine in areas where the

possibility of falling stones or debris exists.

• If operation on soft ground is required, sufficiently

reinforce the ground beforehand.

• Be sure to wear close fitting clothing and required safety

items, such as a helmet, when operating the machine.

• Keep all bystanders and unnecessary objects out of and

away from the machine working areas. Always beware of

the surroundings while operating the machine. Take care

not to allow the rear part of the upperstructure to come

into contact with objects when swinging the machine in

a small area.

• When loading a dump truck, bring the bucket from the

rear side of the dump truck to avoid moving the bucket

over the dump truck cab or over any co-workers.

SAFETY

M586-12-012

S-8

Page 21

SAFETY

Investigate Job Site Beforehand

• When working at the edge of an excavation or on a road

shoulder, the machine could tip over due to collapse of the

ground, possibly resulting in serious injury or death.

• Investigate the configuration and ground conditions of

the job site beforehand to prevent the machine from

falling and to prevent the ground, stockpiles, or banks

from collapsing.

• Make a work plan. Use machines appropriate to the work

and job site.

• Reinforce ground, edges, and road shoulders as

necessary. Keep the machine well back from the edges of

excavations and road shoulders.

• When working on an incline or on a road shoulder,

employ a signal person as required.

• Never allow bystanders to enter the working area such as

swing radius or traveling range.

• When the footing is weak, reinforce the ground before

starting work.

• When working on frozen ground, be extremely alert. As

ambient temperatures rise, footing may become loose

and slippery.

• When operating the machine near open flame, sparks,

and/or dead grass, a fire may easily break out. Use special

care not to cause a fire.

• Make sure the work site ground has sufficient strength to

firmly support the machine. When working close to an

excavation or on road shoulders, operate the machine

with the tracks positioned perpendicular to the cliff face

with travel motors at the rear and with the blade at the

front, so that the machine can more easily evacuate if the

cliff face collapses.

• If working at the bottom of a cliff or on a high bank is

required, be sure to investigate the area first and confirm

that no danger of the cliff or bank collapsing exists. If any

possibility of cliff or bank collapsing exists, do not work in

that area.

• Soft ground may collapse when operating the machine

on it, possibly causing the machine to tip over. When

working on soft ground is required, be sure to reinforce

the ground first using large pieces of steel plates strong

enough and firm to easily support the machine.

• Note that there is always a possibility of machine tipping

over when working on rough terrain or on slopes. Prevent

machine tipping over from occurring. Operate the

machine slowly to ensure safe operation.

SA-1293

M586-05-021

S-9

Page 22

Equipment of OPG

• In case the machine is operated in areas where the

possibility of falling stones or debris exists, equip genuine

Hitachi OPG guard. Contact your nearest Hitachi dealer for

installation method of the OPG guard. Depending on the

specifications applied to your machine, modification of the

machine to meet ROPS standards will be possible.

• To maintain unimpaired operator protection and

manufacture's protective structure.

• Damaged ROPS, OPG guard must be replaced, not

repaired or revised.

• Any alternation to the ROPS or OPG guard must be

approved by the manufacturer.

ROPS : Roll Over Protective Structure

OPG : Operator Protective Guard

Provide Signals for Jobs Involving Multiple

Machines

SAFETY

• In case more than one machine is operated in the same

job site, accidental collision between machines may cause

serious injury or death.

• For jobs involving multiple machines, provide signals

commonly known by all personnel involved. Also, appoint

a signal person to coordinate the job site. Make sure that all

personnel obey the signal person’s directions.

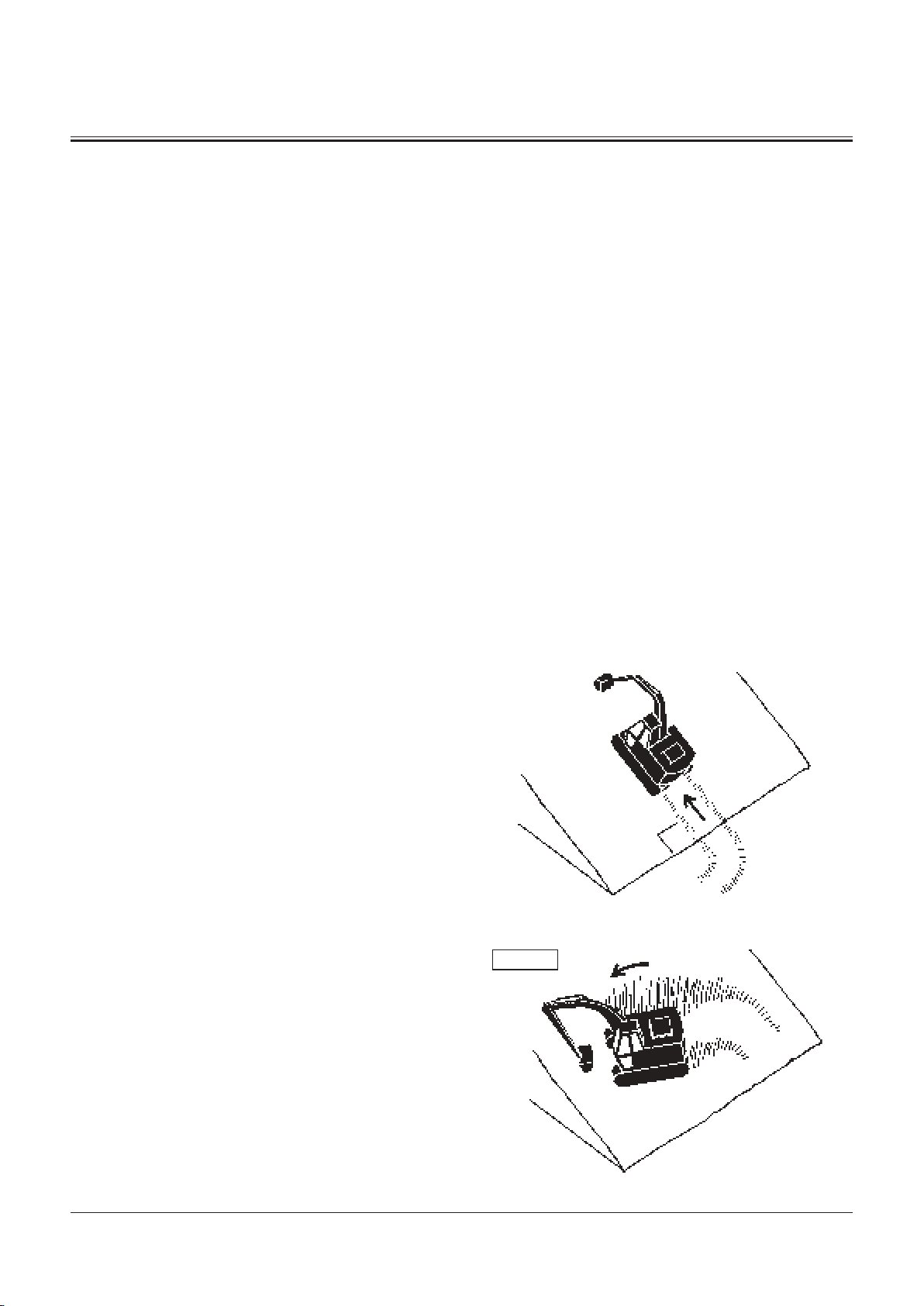

Confirm Direction of Machine to be Driven

• Incorrect travel pedal/lever operation may result in serious

injury death.

• Before driving the machine, confirm the position of the

undercarriage in relation to the operator’s position.

• If the travel motors are located towards the front of the

cab, the machine will move in the reverse direction when

travel pedals/levers are operated.

SA-481

SA-1294

S-10

Page 23

SAFETY

Drive Machine Safely

• Use a signal person when traveling the machine along road

shoulders or in congested areas.

• Driving the machine in the incorrect direction may result in

serious injury or death and/or severe damage to property.

• Before driving the machine, always confirm that the travel

pedals/levers direction corresponds to the direction you

wish to drive.

• Be sure to detour around any obstructions.

• Avoid traveling over obstructions. Soil, fragments of rocks,

and/or metal pieces may scatter around the machine. Do

not allow personnel to stay around the machine while

traveling.

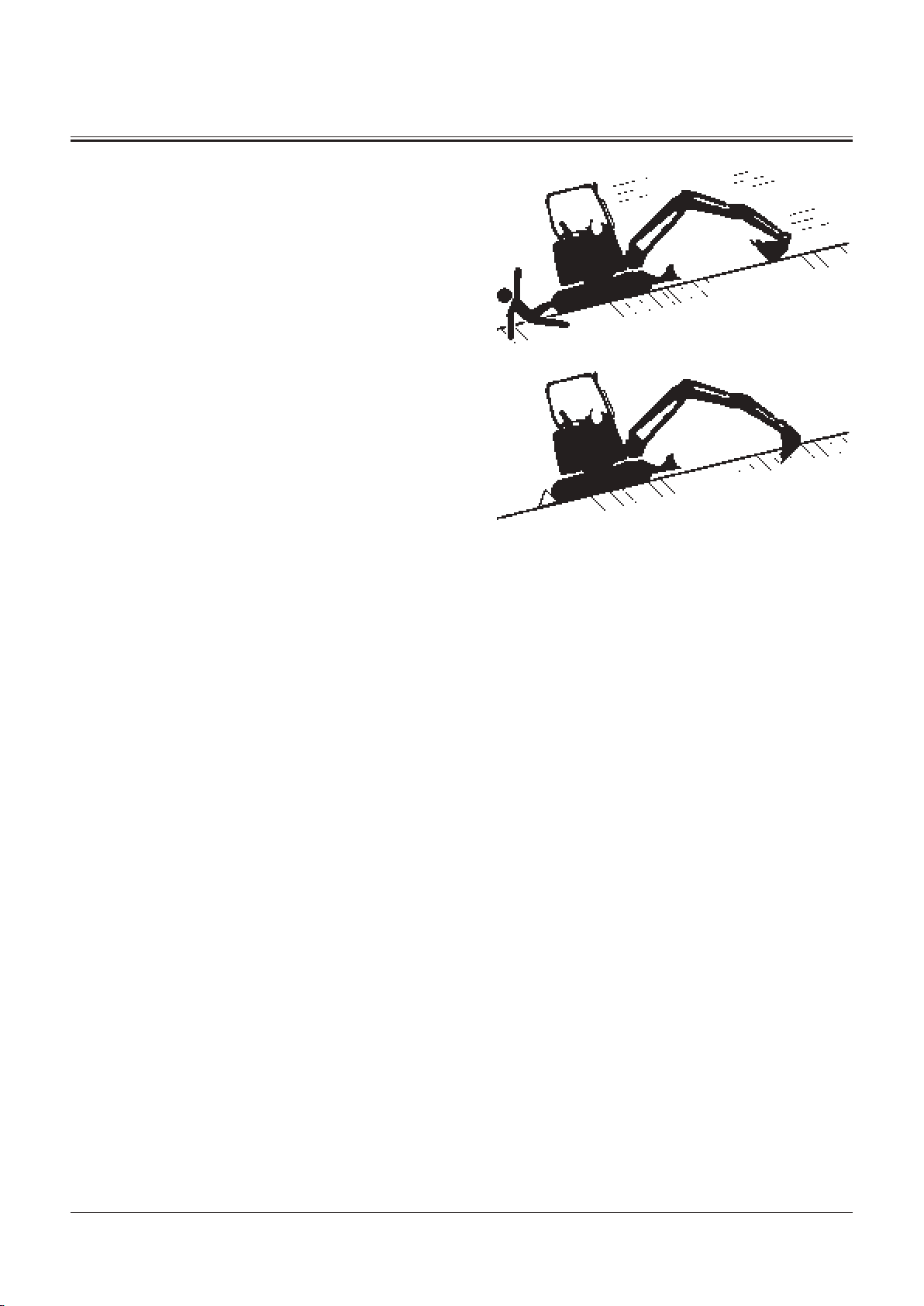

• Driving on a slope may cause the machine to slip or

overturn, possibly resulting in serious injury or death.

• Never attempt to ascend or descend (B) degrees or

steeper slopes.

B : ZX14-3, 16-3, 18-3 : 25˚

ZX27-3 : 30˚

• Be sure to fasten the seat belt.

• When driving up or down a slope, keep the bucket facing

the direction of travel, approximately 200 to 300 mm (8 to

12 in) (A) above the ground.

• If machine starts to skid or becomes unstable,

immediately lower the bucket to the ground and stop.

• Driving across the face of a slope or steering on a

slope may cause the machine to skid or turnover. If

the direction must be changed, move the machine to

level ground, then, change the direction to ensure safe

operation.

• Avoid swinging the upperstructure on slopes. Never

attempt to swing the upperstructure downhill. The

machine may tip over. If swinging uphill is unavoidable,

carefully operate the upperstructure and boom at slow

speed.

• If the engine stalls on a slope, immediately lower the

bucket to the ground. Return the control levers to neutral.

Then, restart the engine.

• Be sure to thoroughly warm up the machine before

ascending steep slopes. If hydraulic oil has not warmed

up sufficiently, sufficient performance may not be

obtained.

A

SA-1295

A

SA-1296

SA-441

WRONG

S-11

SA-590

Page 24

SAFETY

• Traveling down a slope in the fast mode requires a longer

time to stop the machine.

When traveling down a slope, place engine control lever

(1) in the TURTLE position.

• Use a signal person when moving, swinging or operating

the machine in congested areas. Coordinate hand signals

before starting the machine.

• Before moving machine, determine which way to move

travel pedals/levers for the direction you want to go.

When the travel motors are in the rear, pushing down

on the front of the travel pedals or pushing the levers

forward moves the machine forward, towards the idlers.

• Select a travel route that is as flat as possible. Steer the

machine as straight as possible, making small gradual

changes in direction.

• Before traveling on them, check the strengths of bridges

and road shoulders, and reinforce if necessary.

• Do not make contact with electric wires or bridges.

• When crossing a river, measure the depth of the river

using the bucket, and cross slowly. Do not cross the river

when the depth of the river is deeper than the upper

edge of the upper roller.

• When traveling on rough terrain, reduce engine speed.

Select slow travel speed. Slower speed will reduce

possible damage to the machine.

• Avoid operations that may damage the track and

undercarriage components.

• During freezing weather, always clean snow and ice from

track shoes before driving the machine on snowy and/or

frozen roads, or loading and unloading the machine for

transportation, to prevent the machine from slipping.

1

M1NC-00-007

Travel Motor

M104-05-008

S-12

SA-673

M586-05-002

Page 25

SAFETY

Avoid Injury from Rollaway Accidents

• Death or serious injury may result if you attempt to mount

or try to bodily stop a moving machine.

• Park the machine in compliance with the safe parking

procedures described on page S-19 to prevent the machine

from running away.

• Block both tracks and lower the bucket to the ground,

thrust the bucket teeth into the ground if you must park

on a grade.

• Park at a reasonable distance from other machines.

SA-1297

S-13

Page 26

SAFETY

Avoid Injury from Back-over and Swing

Accidents

• If any person is present near the machine when backing or

swinging the upperstructure, the machine may hit or run

over that person, resulting in serious injury or death.

To avoid back-over and swing accidents:

• Always look around BEFORE YOU BACK UP AND SWING

THE MACHINE. BE SURE THAT ALL BYSTANDERS ARE

CLEAR.

• Keep the travel alarm in working condition (if equipped).

ALWAYS BE ALERT FOR BYSTANDERS MOVING INTO THE

WORK AREA. USE THE HORN OR OTHER SIGNAL TO WARN

BYSTANDERS BEFORE MOVING MACHINE.

• USE A SIGNAL PERSON WHEN BACKING UP IF YOUR VIEW

IS OBSTRUCTED. ALWAYS KEEP THE SIGNAL PERSON IN

VIEW.

Use hand signals, which conform to your local regulations,

when work conditions require a signal person.

• No machine motions shall be made unless signals are

clearly understood by both signalman and operator.

• Learn the meanings of all flags, signs, and markings used

on the job and confirm who has the responsibility for

signaling.

• Keep windows, mirrors, and lights clean and in good

condition.

• Dust, heavy rain, fog, etc., can reduce visibility. As visibility

decreases, reduce speed and use proper lighting.

• Read and understand all operating instructions in the

operator’s manual.

SA-383

SA-384

S-14

Page 27

SAFETY

Keep Personnel Clear from Working Area

• If a person is present near the operating machine, the

person may come into contact with the swinging front

attachment or counterweight and/or may be crushed

against an other object, resulting in serious injury or death.

• Before operating the machine, set up barriers to the

sides and rear area of the bucket swing radius to prevent

anyone from entering the work area.

• Make sure that no personnel other than the signal person

or no obstacles are present in the working area before

operating the machine.

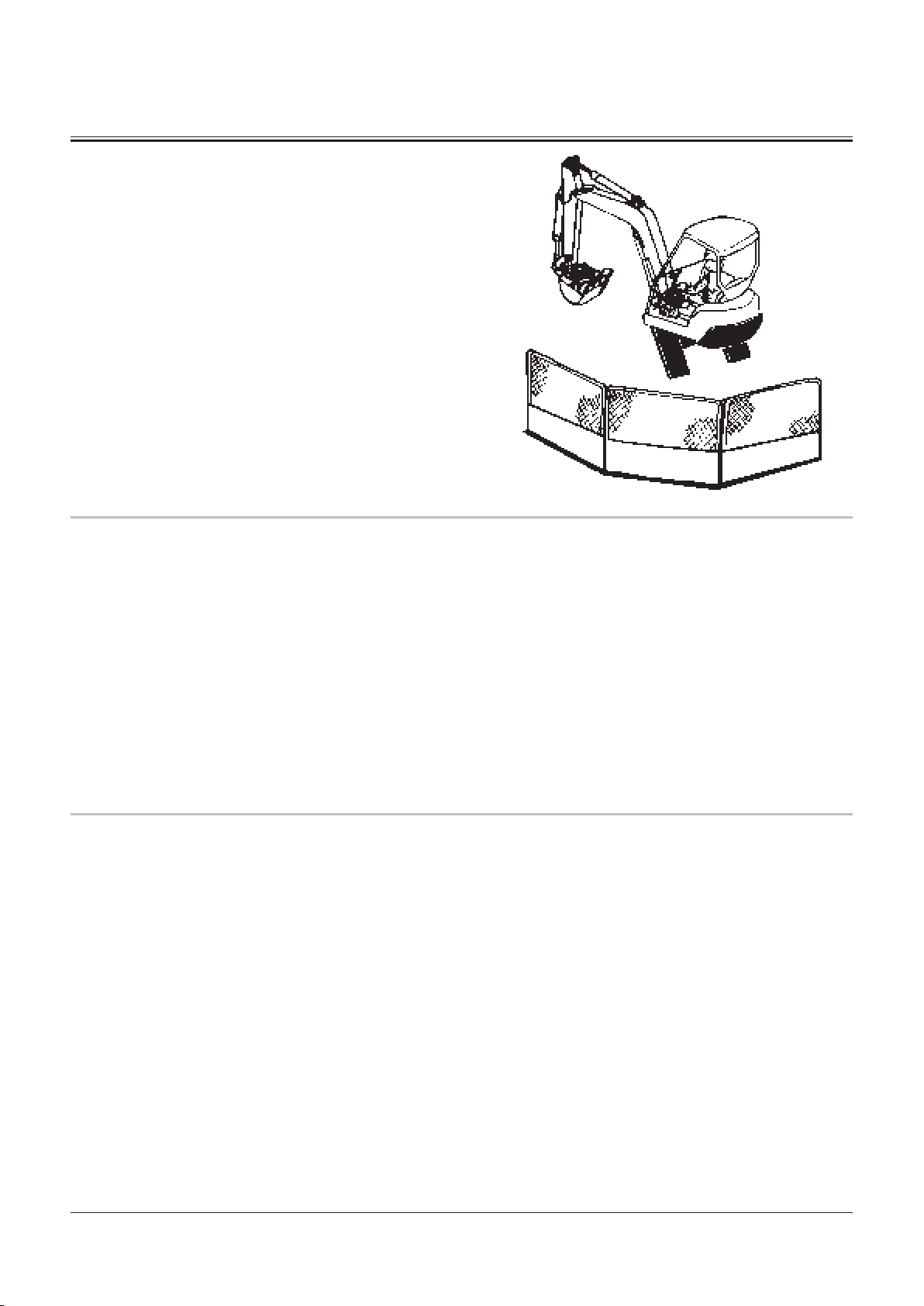

Never Position Bucket Over Anyone

• Never lift, move, or swing bucket above anyone or a truck

cab.

Serious injury or machine damage may result due to bucket

load spill or due to collision with the bucket.

• Never allow the bucket to pass over anyone to avoid

personal injury or death.

SA-667

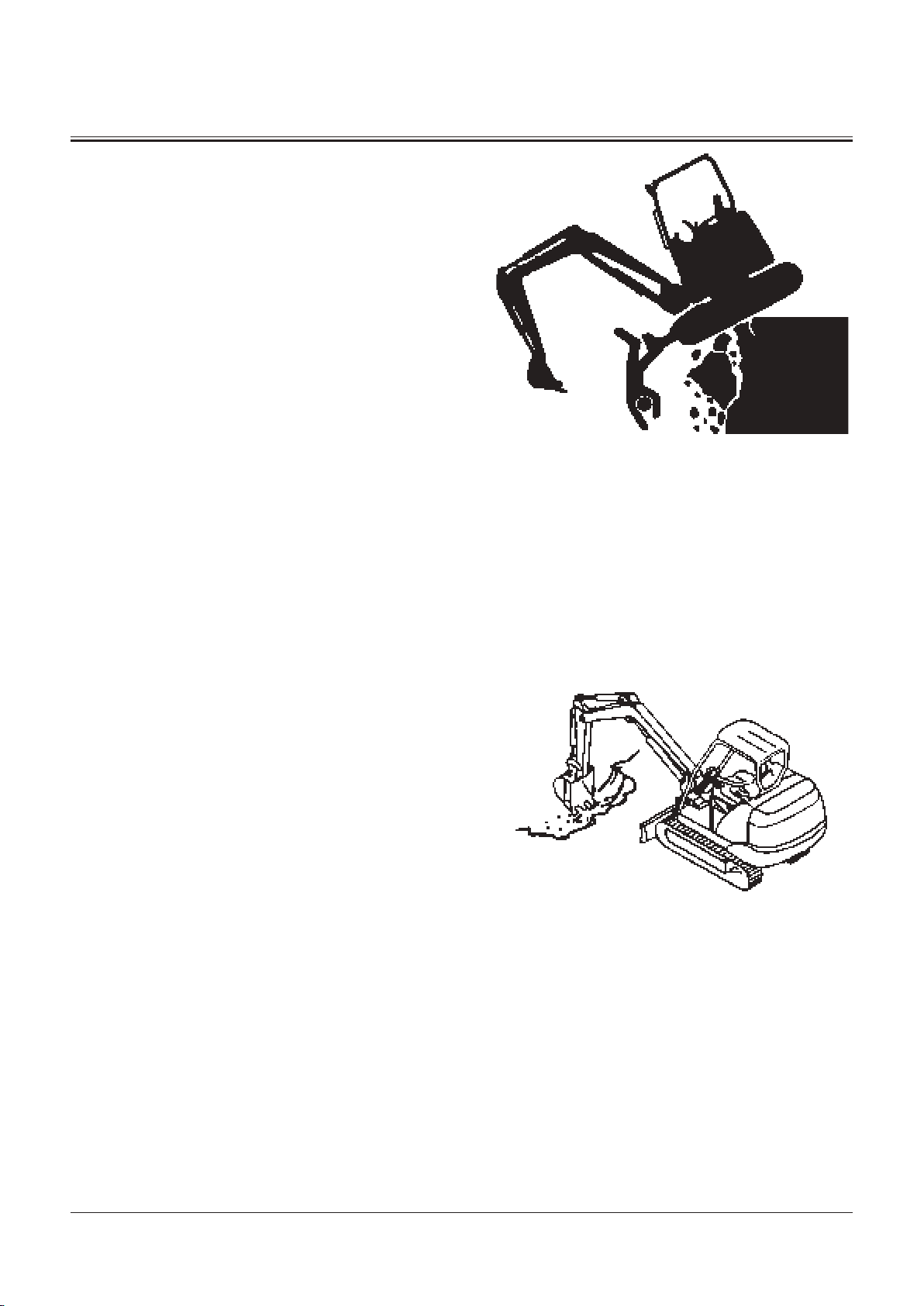

Avoid Undercutting

• In order to retreat from the edge of an excavation if the

footing should collapse, always position the undercarriage

perpendicular to the edge of the excavation with the travel

motors at the rear.

• If the footing starts to collapse and if retreat is not

possible, do not raise the front attachment in a panic.

Lowering the front attachment may be safer in most

cases.

SA-668

SA-1300

S-15

Page 28

SAFETY

Avoid Tipping

• The danger of tipping is always present when operating on

a grade, possibly resulting in serious injury or death.

To avoid tipping:

• Be extra careful before operating on a grade.

• Prepare machine operating area flat.

• Keep the bucket low to the ground and close to the

machine.

• Reduce operating speeds to avoid tipping or slipping.

• Avoid changing direction when traveling on grades.

• NEVER attempt to travel across a grade steeper than 15

degrees if crossing the grade is unavoidable.

• Reduce swing speed as necessary when swinging loads.

• Be careful when working on frozen ground.

• Temperature increases will cause the ground to become

soft and make ground travel unstable.

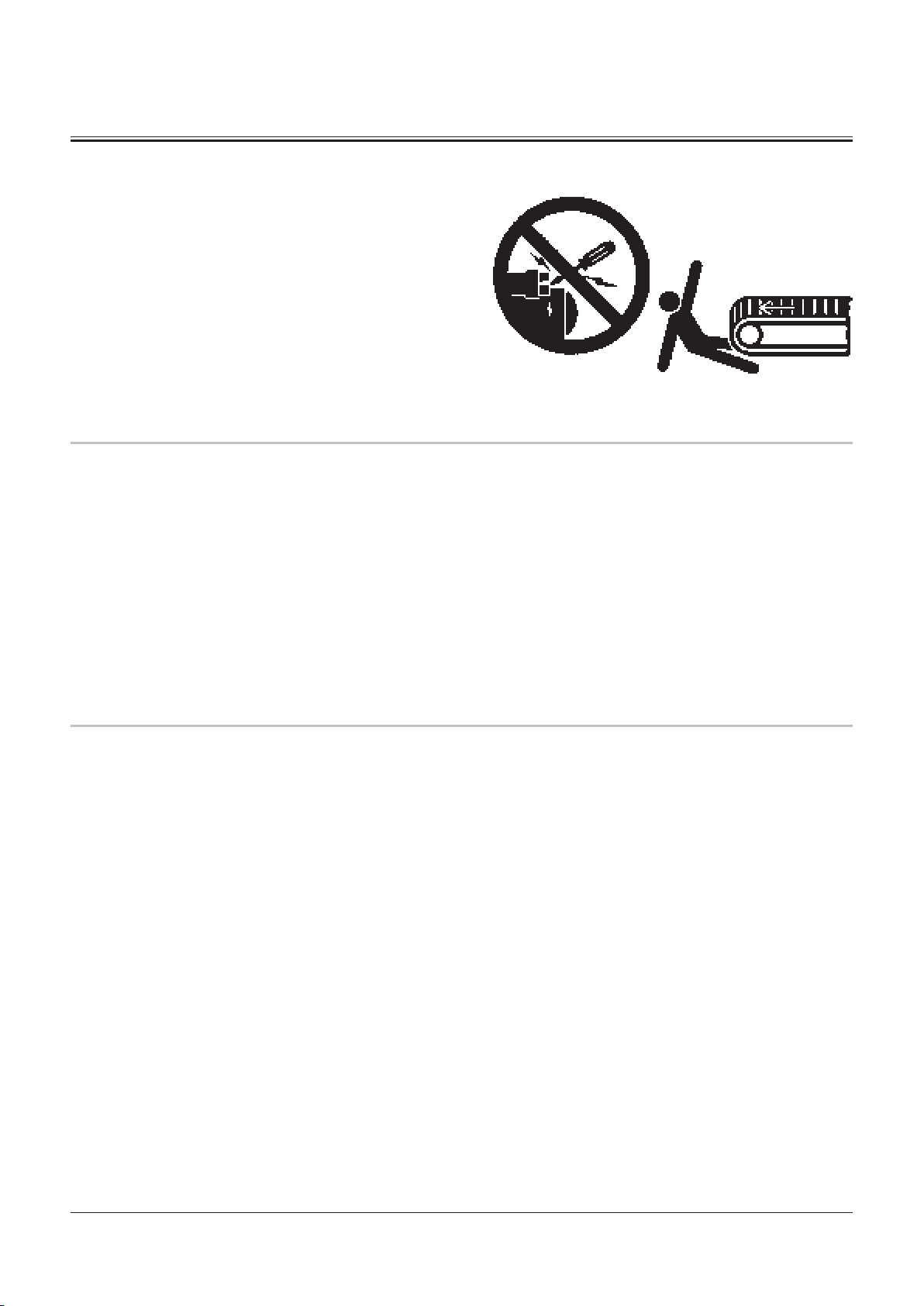

Never Undercut a High Bank

• The edges could collapse or a land slide could occur causing

serious injury or death.

SA-1301

SA-1302

S-16

Page 29

SAFETY

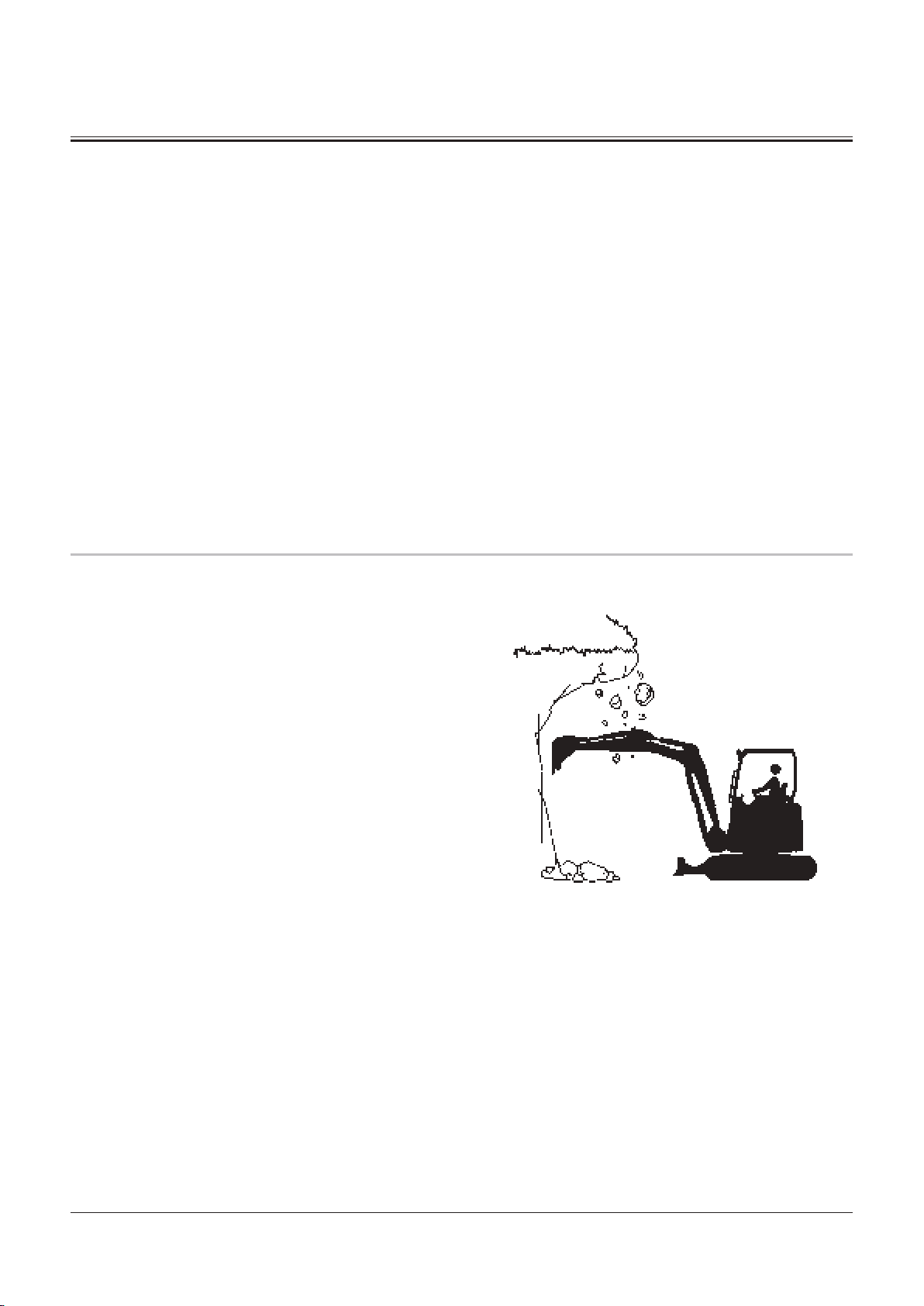

Dig with Caution

• Accidental severing of underground cables or gas lines may

cause an explosion and/or fire, possibly resulting in serious

injury or death.

• Before digging check the location of cables, gas lines, and

water lines.

• Keep the minimum distance required, by law, from cables,

gas lines, and water lines.

• If a fiber optic cable should be accidentally severed, do

not look into the end. Doing so may result in serious eye

injury.

• Contact your local “diggers hot line” if available in your

area, and/or the utility companies directly.

Have them mark all underground utilities.

Operate with Caution

• If the front attachment or any other part of the machine hits

against an overhead obstacle, such as a bridge, both the

machine and the overhead obstacle will be damaged, and

personal injury may result as well.

• Take care to avoid hitting overhead obstacles with the

boom or arm.

SA-672

Avoid Power Lines

• Serious injury or death can result if the machine or front

attachments are not kept a safe distance from electric lines.

• When operating near an electric line, NEVER move any

part of the machine or load closer than 3 m (10 ft) plus

twice the line insulator length.

• Check and comply with any local regulations that may

apply.

• Wet ground will expand the area that could cause any

person on it to be affected by electric shock. Keep all

bystanders or co-workers away from the site.

SA-673

SA-1305

S-17

Page 30

SAFETY

Precautions for Lightning

• The machine is vulnerable to lightning strikes.

• In the event of an electrical storm, immediately stop

operation, and lower the bucket to the ground. Evacuate

to a safe place far away from the machine.

• After the electrical storm has passed, check all of the

machine safety devices for any failure. If any failed

safety devices are found, operate the machine only after

repairing them.

Do Not Use for Craning Operations

• NEVER use the machine for craning operations. If the

machine is used for craning operations, the machine may

tip over and/or lifted load may fall, possibly resulting in

serious injury or death.

• This machine has been exclusively designed to engage in

excavation and loading works.

• This machine is not equipped with any of the necessary

safety devices that could allow the machine to be used for

craning operation.

SA-1805

Protect Against Flying Debris

• If flying debris such as soil, rock fragments or metal pieces

hit eyes or any other part of the body, serious injury may

result.

• Guard against such injuries when working in a job site

where possibility of flying pieces of metal or debris exist,

or when removing or installing pins using a hammer;

wear goggles or safety glasses.

• Keep bystanders away from the working area before

striking any object.

S-18

SA-014

SA-432

Page 31

SAFETY

Park Machine Safely

• Unless the machine is correctly parked, any hazardous

situations such as running away of the machine or damage

by vandalism may result, causing the machine to operate

unsafely when the engine is restarted. Follow instructions

described below when parking the machine.

• Park the machine on solid level surface to prevent the

machine from running away.

• Lower the bucket and/or blade to the ground.

• Pull the lock lever to the LOCK position.

• Run the engine at slow idle speed without load for 5

minutes.

• Turn key switch to OFF to stop engine. Remove the key

from the key switch.

• Before leaving the machine, close all windows, roof vent,

and cab door. Lock all access doors and compartments.

Handle Fluids Safely−Avoid Fires

• Handle fuel with care; it is highly flammable. If fuel ignites,

an explosion and/or a fire may occur, possibly resulting in

serious injury or death.

• Do not refuel the machine while smoking or when near

open flame or sparks.

• Always stop the engine before refueling the machine.

• Fill the fuel tank outdoors.

SA-1306

• All fuels, most lubricants, and some coolants are flammable.

• Store flammable fluids well away from fire hazards.

• Do not incinerate or puncture pressurized containers.

• Do not store oily rags; they can ignite and burn

spontaneously.

SA-018

SA-019

S-19

Page 32

SAFETY

Safety Transporting

• The danger of tipping is present when loading/unloading

the machine onto/from a truck or trailer bed.

• Be sure to observe local regulations when transporting

the machine on public roads.

• Provide an appropriate truck or trailer for transporting the

machine.

• Be sure to have a signal person.

• Take the following precautions when loading/unloading

the machine.

1. Select firm level ground.

2. Be sure to use a loading dock or ramp strong enough to

support the machine weight.

3. Ramps must be sufficient in width, length, and strength.

Be sure that the incline of the ramp is less than 15

degrees.

4. Loading docks must be sufficient in width and strength

to support the machine and have a gradient of less than

15 degrees.

5. Slowly drive the machine.

SA-1307

6. Avoid steering while driving up or down the ramp as it

is extremely dangerous. If steering is unavoidable, first

move back to the ground or flatbed, change traveling

direction, and begin to drive again.

7. The top end of the ramp where it meets the flatbed is a

sudden bump. Take care when traveling over it.

8. Wedge the front and rear of the tracks. Securely fasten

the machine to the trailer bed with chain or cables.

9. Do not operate any levers besides the travel levers when

driving up or down the ramp.

10. Prevent possible injury from machine tipping while the

upperstructure is rotating.

11. Keep the arm tucked under and rotate the

upperstructure slowly for best stability.

Refer to “transporting” chapter in this manual for details.

S-20

Page 33

SAFETY

Practice Safe Maintenance

• Inspection/maintenance work may produce hazardous

situations by contacting and/or accessing a part of body

to a moving, high pressure, and/or high temperature part

of the machine. To avoid serious personal injury or death,

follow the instructions described below.

• Thoroughly coordinate the working procedures to be

taken hereafter with the co-workers before beginning

work such as inspecting/servicing the machine, or

replacing the attachment .

• Safely park the machine in accordance with the

instructions for “Park Machine Safely.”

• Keep the work area clean and orderly.

• Attach a “DO NOT OPERATE” tag in an easy-to-see location

such as on a door or a control lever.

• If moisture permeates into the electrical system,

malfunction and/or erroneous movement of the machine

may result. Do not clean sensors, cable connectors, and

the cab inside using water and/or steam.

• Wait to begin to work until the engine and hydraulic oil

temperatures have cooled down to the safety range.

• In case inspection/maintenance must be performed with

the engine running, be sure to appoint an overseer.

• Never lubricate or service the machine while moving it.

• Repair the cracked windowpane before servicing the

machine. Failure to do so may cause personal injury.

• When raising the machine above the ground using the

front attachment function, maintain the angle between

the boom and the arm in the range of 90 to 110°. Never

allow anyone to enter under the machine raised with the

front attachment function.

• In case working under the machine raised above the

ground is unavoidably required, securely hold the

machine with stays or blocks strong enough to support

the machine weight.

• Never work under the raised bucket.

• Keep all parts in good condition and properly installed.

• Always use the specified tools correctly.

• Always use a clean tool.

• Fix any damage found immediately. Replace worn or

broken parts.

• Remove any buildup of grease, oil, or debris.

• When cleaning parts, use a non-combustible cleaning

solvent. Never use an inflammable fluid such as diesel

fuel, or gasoline.

SA-028

90 to 110°

M1M7-04-006

SA-527

S-21

Page 34

SAFETY