Hitachi ZAXIS 120-3 class, ZAXIS 330-3 class, ZAXIS 180-3 class, ZAXIS 200-3 class, ZAXIS 270-3 class Operator's Manual

Page 1

Page 2

INTRODUCTION

Read this manual carefully to learn how to operate and

service your machine correctly. Failure to do so could

result in personal injury or machine damage.

This standard specification machine can be operated

under the following conditions without being modified.

Atmospheric Temperature: −20 °C to 40 °C (−4 °F to 104 °F)

Altitude: 0 m to 2000 m (0 ft to 6600 ft)

In case the machine is used under conditions other than

described above, consult your nearest Hitachi dealer.

This manual should be considered a permanent part of

your machine and should remain with the machine when

you sell it.

This machine is of metric design. Measurements in this

manual are metric. Use only metric hardware and tools as

specified.

Right-hand and left-hand sides are determined by facing in the direction of forward travel.

Write product identification numbers in the Machine

Numbers section. Accurately record all the numbers to

help in tracing the machine should it be stolen. Your

dealer also needs these numbers when you order parts. If

this manual is kept on the machine, also file the identification numbers in a secure place off the machine.

Use only diesel fuel with quality specified in JIS K-2204,

EN-590, ASTM D-975, GOST R52368 or GB252.

Failure to use diesel fuel with quality as specified above

may allow the engine to emit exhaust gas which cleanness can not conform to the requests in various relevant

regulations. In addition, serious damage to the engine

may result. Consult with your nearest Hitachi dealer for

detailed information.

Warranty is provided as a part of Hitachi’s support program for customers who operate and maintain their

equipment as described in this manual. The warranty is

explained on the warranty certificate which you should

have received from your dealer.

This warranty provides you the assurance that Hitachi will

back its products where defects appear within the warranty period. In some circumstances, Hitachi also provides

field improvements, often without charge to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to

change its performance beyond the original factory

specifications, the warranty will become void and field

improvements may be denied.

Setting fuel delivery above specifications or otherwise

overpowering machines will result in such action.

Only qualified, experienced operators officially licensed

(according to local law) should be allowed to operate

the machine. Moreover, only officially licensed personnel

should be allowed to inspect and service the machine.

PRIOR TO OPERATING THIS MACHINE, INCLUDING

SATELLITE COMMUNICATION SYSTEM, IN A COUNTRY

OTHER THAN A COUNTRY OF ITS INTENDED USE, IT

MAY BE NECESSARY TO MAKE MODIFICATIONS TO IT

SO THAT IT COMPLIES WITH THE LOCAL REGULATORY

STANDARDS (INCLUDING SAFETY STANDARDS) AND

LEGAL REQUIREMENTS OF THAT PARTICULAR COUNTRY. PLEASE DO NOT EXPORT OR OPERATE THIS MACHINE OUTSIDE OF THE COUNTRY OF ITS INTENDED

USE UNTIL SUCH COMPLIANCE HAS BEEN CONFIRMED.

PLEASE CONTACT HITACHI CONSTRUCTION MACHINERY CO., LTD. OR ANY OF OUR AUTHORIZED DISTRIBUTOR OR DEALER IF YOU HAVE ANY QUESTIONS CONCERNING COMPLIANCE.

©2008 Hitachi Construction Machinery Co., Ltd.

All rights reserved.

Hitachi machine models are classified into 5 classes and 1 model as shown in the

table below. When referring to the texts and/or illustrations indicated with the

applicable machine class names in this manual, check that the machine models

concerned are included using this table.

Class

ZX120-3 Class ZX110-3, 110M-3, 130-3, 130LCN-3

ZX180-3 Class ZX160LC-3, 180LC-3, 180LCN-3

ZX200-3 Class ZX210-3, 210LC-3, 210LCN-3, 240N-3

ZX270-3 Class ZX250LC-3, 250LCN-3, 280LC-3, 280LCN-3

ZX330-3 Class ZX350LC-3, 350LCN-3

Model

Std. Model ZX110-3, 110M-3, 130-3, 130LCN-3, 160LC-3, 180LC-3, 180LCN-3, 210-3, 210LC-3, 210LCN-3,

240N-3, 250LC-3, 250LCN-3, 280LC-3, 280LCN-3, 350LC-3, 350LCN-3

All information, illustrations and specifications in this manual are based on the latest product information available at the

time of publication. The right is reserved to make changes at any time without notice.

Page 3

Page 4

T

MACHINE NUMBERS

SAFETY

SAFETY SIGNS

COMPONENTS NAME

OPERATOR’S STATION

BREAK-IN

OPERATING THE ENGINE

DRIVING THE MACHINE

OPERATING THE MACHINE

TRANSPORTING

MAINTENANCE

HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

OPTIONAL ATTACHMENTS AND DEVICES

INDEX

INDEX

Page 5

Page 6

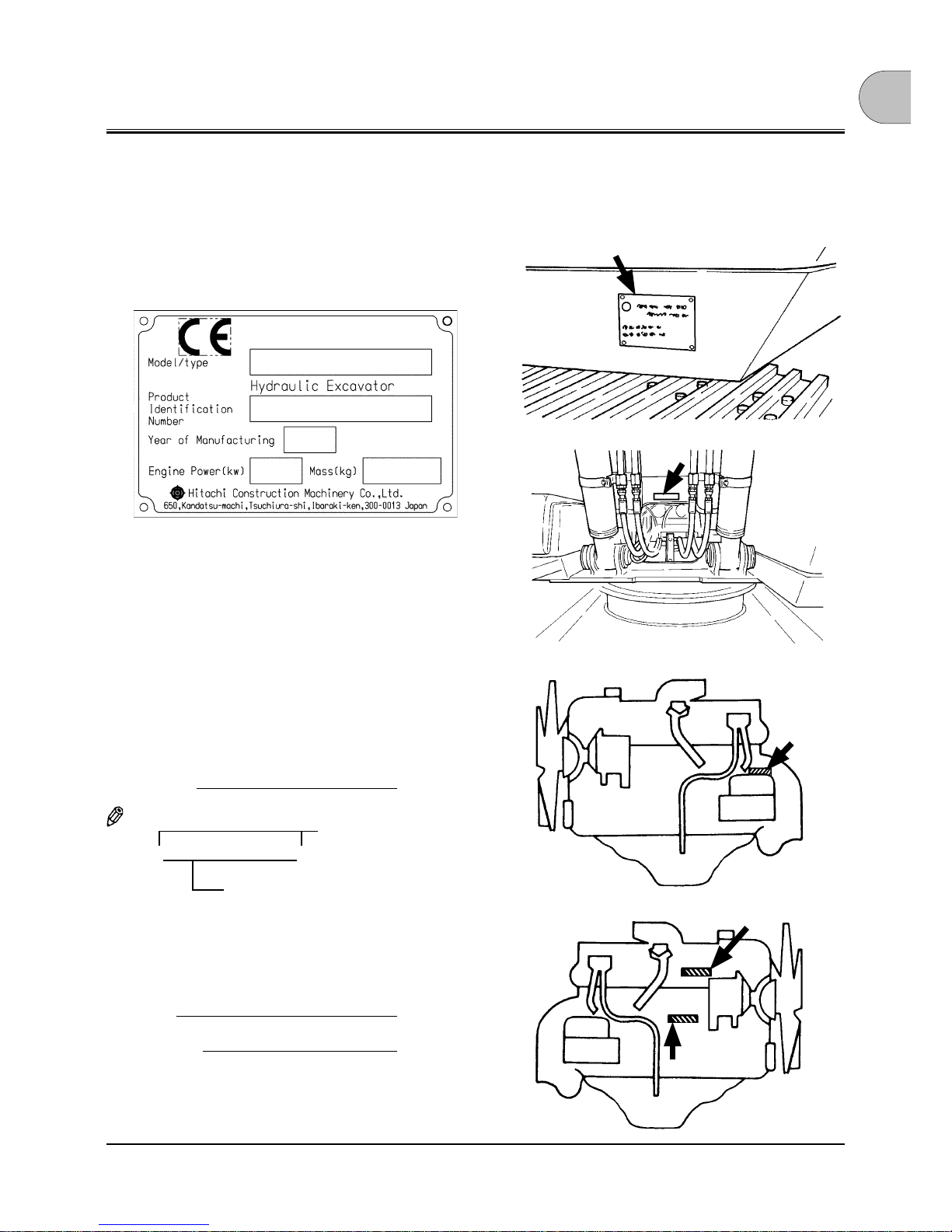

MACHINE NUMBERS

The manufacturing Nos. explained in this group is the individual number (serial No.) given to each machine and hydraulic

components. These numbers are requested when inquiring

any information on the machine and/or components. Fill these

serial Nos. in the blank spaces in this group to immediately

make them available upon request.

MACHINE

1. MODEL/TYPE

2. Product Identification Number

3. Year of Manufacturing

4. Operating mass (standard version)

5. Engine power in KW according to ISO9249

PRODUCT IDENTIFICATION NUMBER

PRODUCT

IDENTIFICATION

NUMBER:

NOTE:

*HCM1U100L00100001*

ENGINE

TYPE:

MFG. NO.:

M157-00-001

SS3097499

Marks to indicate the

start and end of the PIN

PRODUCT IDENTIFICATION

NUMBER (PIN)

(ZX330-3

class)

(ZX200-3,

270-3 class)

M178-00-002

M1U1-00-001

M157-12-008

(ZX120-3,

180-3 class)

Page 7

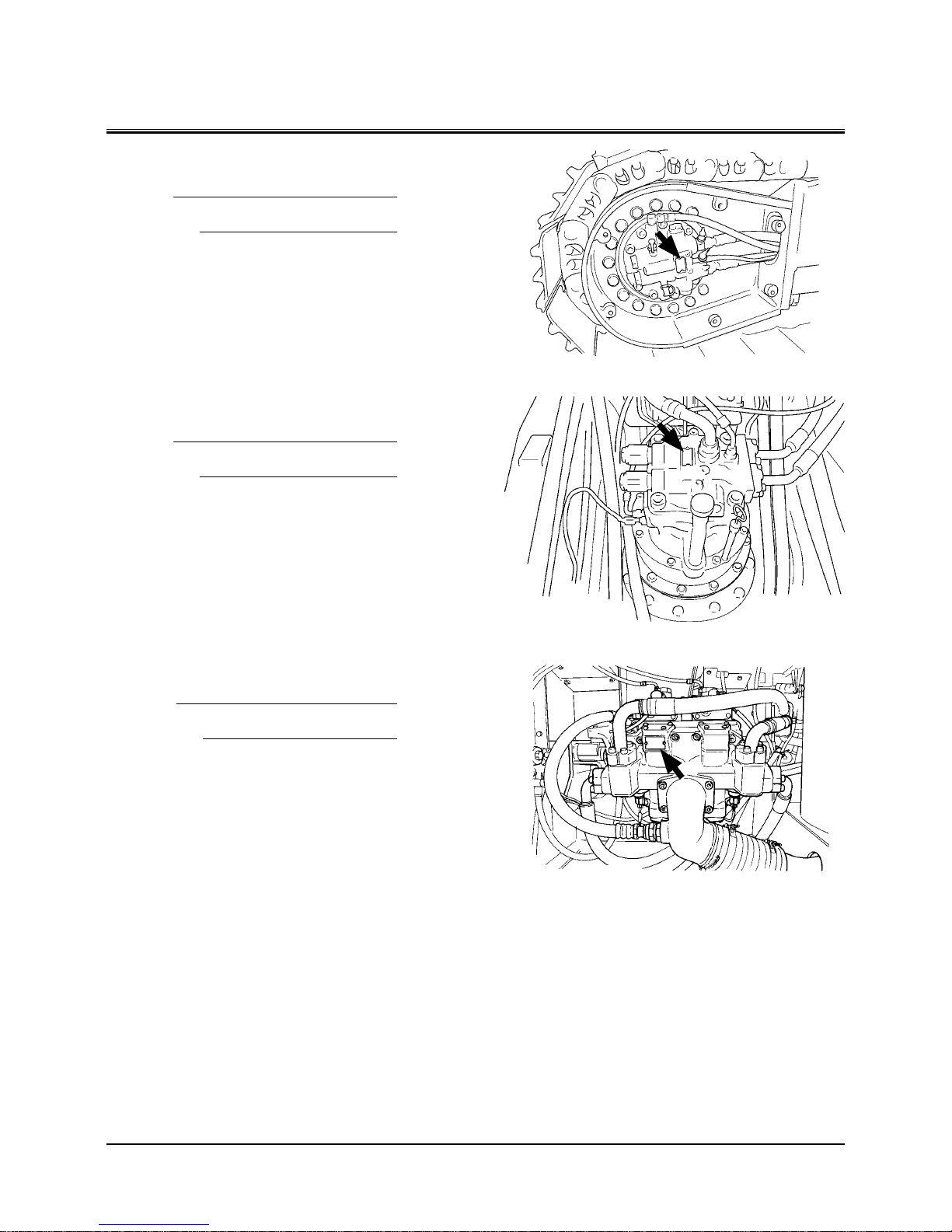

MACHINE NUMBERS

TRAVEL MOTOR

TYPE:

MFG. NO.:

SWING MOTOR

TYPE:

MFG. NO.:

HYDRAULIC PUMP

TYPE:

MFG. NO.:

M178-07-086

M178-07-047

M157-00-004

Page 8

CONTENTS

MACHINE NUMBERS

SAFETY

Recognize Safety Information ....................................................S-1

Understand Signal Words .............................................................S-1

Follow Safety Instructions ............................................................S-2

Prepare for Emergencies ...............................................................S-3

Wear Protective Clothing..............................................................S-3

Protect Against Noise ....................................................................S-3

Inspect Machine ..............................................................................S-4

General Precautions for Cab ........................................................S-4

Use Handholds and Steps ............................................................S-5

Adjust the Operator’s Seat ...........................................................S-5

Ensure Safety Before Rising from or

Leaving Operator’s Seat .........................................................S-5

Fasten Your Seat Belt ......................................................................S-6

Move and Operate Machine Safely ...........................................S-6

Handle Starting Aids Safely .........................................................S-6

Operate Only from Operator’s Seat ..........................................S-7

Jump Starting ...................................................................................S-7

Keep Riders Off Machine ..............................................................S-7

Precautions for Operations ..........................................................S-8

Investigate Job Site Beforehand ................................................S-9

Equipment of Head Guard, Rops, Fops ................................S-10

Provide Signals for Jobs Involving

Multiple Numbers of Machines ........................................S-10

Confirm Direction of Machine to Be Driven ........................ S-10

Drive Machine Safely ................................................................... S-11

Avoid Injury from Rollaway Accidents ..................................S-13

Avoid Injury from Back-over and Swing Accidents .......... S-14

Keep Person Clear from Working Area..................................S-15

Never Position Bucket Over Anyone ..................................... S-15

Avoid Undercutting .....................................................................S-15

Avoid Tipping ................................................................................. S-16

Never Undercut a High Bank ....................................................S-16

Dig with Caution ........................................................................... S-17

Operate with Caution .................................................................S-17

Avoid Power Lines ........................................................................S-18

Precautions for Lightning .......................................................... S-18

Object Handling ...........................................................................S-18

Protect Against Flying Debris ..................................................S-19

Park Machine Safely ..................................................................... S-19

Handle Fluids Safely−avoid Fires ............................................ S-19

Transport Safely ............................................................................ S-20

Practice Safe Maintenance ........................................................S-21

Warn Others of Service Work ...................................................S-22

Support Machine Properly ........................................................S-22

Stay Clear of Moving Parts ........................................................S-22

Prevent Parts from Flying .......................................................... S-23

Store Attachments Safely .......................................................... S-23

Prevent Burns ................................................................................. S-24

Replace Rubber Hoses Periodically ........................................ S-24

Avoid High-pressure Fluids ....................................................... S-25

Prevent Fires ................................................................................... S-26

Evacuating in Case of Fire ..........................................................S-27

Beware of Exhaust Fumes..........................................................S-27

Precautions for Welding and Grinding ................................. S-27

Avoid Heating Near Pressurized Fluid Lines ....................... S-28

Avoid Applying Heat to Lines Containing

Flammable Fluids ..................................................................S-28

Remove Paint Before Welding or Heating ...........................S-28

Beware of Asbestos Dust ........................................................... S-29

Prevent Battery Explosions ....................................................... S-29

Service Air Conditioning System Safely ...............................S-29

Handle Chemical Products Safely ........................................... S-30

Dispose of Waste Properly ......................................................... S-30

SAFETY SIGNS .............................................................................. S-31

COMPONENTS NAME ................................................................. 1-1

OPERATOR’S STATION

Cab Features ..................................................................................... 1-2

Multi Function Monitor ................................................................ 1-3

Outline ................................................................................................ 1-4

Menu Screen (23) ..................................................................... 1-7

Hour Meter ................................................................................. 1-8

Fuel Gauge ................................................................................. 1-8

Clock ............................................................................................. 1-8

Back Monitor Selector ............................................................ 1-8

Menu Key .................................................................................... 1-9

Optional Function Key ........................................................... 1-9

Return to Basic Screen Key .................................................. 1-9

Alarm Light ................................................................................ 1-9

Optional Function Display .................................................. 1-9

Coolant Temperature Gauge ............................................. 1-10

Operating Status Icon Display ..........................................1-10

Alarm Occurrence Screen ..........................................................1-15

Contents of Alarms ...................................................................... 1-17

Clock Setting .................................................................................. 1-19

Attachment Selection

(Only Machines Equipped with Optional Parts) .........1-20

Pump 2 Flow Rate Adjustment

(Only Machines Equipped with Optional Parts) .........1-24

Displaying Operating Conditions ...........................................1-25

Fuel Rate Display/No Display ................................................... 1-26

Back Monitor Settings ................................................................1-34

Maintenance Settings .................................................................1-36

Mail (Optional) ...............................................................................1-41

Language Settings ....................................................................... 1-43

Switch Panel ...................................................................................1-45

Engine Control Dial ...................................................................... 1-46

Auto-idle Switch ...........................................................................1-46

Power Mode Switch .................................................................... 1-47

Travel Mode Switch .....................................................................1-47

Work Light Switch ........................................................................ 1-48

Wiper/Washer Switch ..................................................................1-49

Switch Panel (Optional) .............................................................. 1-51

Key Switch .......................................................................................1-53

Power Boost Switch

(ZX180-3, 200-3, 270-3, 330-3 Class) .............................. 1-53

Page 9

CONTENTS

Horn Switch .................................................................................... 1-53

Cigar Lighter ................................................................................... 1-54

Cab Light .........................................................................................1-55

Installing Fire Extinguisher (Optional) .................................. 1-55

Pilot Control Shut-off Lever ...................................................... 1-56

Engine Stop Switch ...................................................................... 1-56

Fuse Box ...........................................................................................1-57

Auto Air Conditioner ...................................................................1-58

Cab Heater Operation .................................................................1-62

Cooling Operation .......................................................................1-62

Defroster Operation ....................................................................1-63

Tips for Optimal Air Conditioner Usage ............................... 1-64

Cab Heater (Optional) .................................................................1-65

Cab Heater Operation .................................................................1-66

Defroster Operation ....................................................................1-67

AM/FM Radio Operation ............................................................1-68

Digital Clock Setting Procedure ..............................................1-69

Cab Door Release Lever .............................................................1-70

Opening Upper Front Window ................................................1-70

Closing Upper Front Window ................................................... 1-71

Removing and Storing Lower Front Window ..................... 1-72

Opening Side Windows ..............................................................1-72

Opening/Closing Overhead Window .................................... 1-73

Emergency Exit .............................................................................1-74

Adjusting the Seat ....................................................................... 1-75

Seat with a Built-in Heater.........................................................1-76

Adjusting the Air-suspension Seat (Optional) ...................1-77

Seat with a Built-in Heater.........................................................1-78

Adjusting Console Height ......................................................... 1-79

Seat Belt ........................................................................................... 1-80

BREAK-IN

Observe Engine Operation Closely .......................................... 2-1

Every 8 Hours or Daily ................................................................... 2-1

After the First 50 Hours ................................................................ 2-1

After the First 100 Hours .............................................................. 2-1

OPERATING THE ENGINE

Inspect Machine Daily Before Starting ................................... 3-1

Before Starting Engine ................................................................. 3-2

Starting the Engine in Ordinary Temperature ...................... 3-3

Starting in Cold Weather.............................................................. 3-5

Check Instruments After Starting ............................................. 3-7

Using Booster Batteries ................................................................ 3-8

Stopping the Engine ...................................................................3-10

DRIVING THE MACHINE

Drive the Machine Carefully ....................................................... 4-1

Steering the Machine Using Pedals ......................................... 4-2

Steering the Machine Using Levers ......................................... 4-3

Travel Mode Switch ....................................................................... 4-4

Travel Alarm (Optional) ................................................................ 4-4

Operating on Soft Ground .......................................................... 4-5

Raise One Track Using Boom and Arm ................................... 4-5

Towing Machine a Short Distance ............................................ 4-6

Operating in Water or Mud ......................................................... 4-7

Parking the Machine on Slopes ................................................. 4-8

Parking the Machine ..................................................................... 4-8

OPERATING THE MACHINE

Control Lever (ISO Pattern) ......................................................... 5-1

Attachment Pedal (Hydraulic Breaker) (Optional) .............. 5-2

Attachment Pedal (Hydraulic Crusher) (Optional) .............. 5-3

Pilot Control Shut-off Lever ........................................................ 5-4

Engine Speed Control ................................................................... 5-6

Auto-idle ............................................................................................ 5-7

Work Mode ....................................................................................... 5-8

Work Mode Select .......................................................................... 5-9

Power Boost (ZX180-3, 200-3, 270-3, 330-3 Class)............5-10

Power Mode ................................................................................... 5-11

Operating Backhoe ......................................................................5-12

Grading Operation .......................................................................5-12

Face Shovel Operation................................................................5-13

Avoid Abusive Operation .......................................................... 5-13

Operating Tips ...............................................................................5-14

Select Correct Track Shoes ........................................................ 5-14

Hydraulic Breaker and Hydraulic Crusher ............................ 5-15

Pipings for Breaker and Crusher (Optional) ........................ 5-16

Secondary Relief Pressure Adjustment ................................5-18

Precautions for Breaker Operation ......................................... 5-20

Breaker Maintenance .................................................................. 5-23

Precautions for Crusher Operation ........................................ 5-24

Attachment ..................................................................................... 5-26

Attachment Connection Parts ................................................. 5-30

Precaution for Arm Roll-in/Bucket Roll-in

Combined Operation --- If Headguard-Integrated

Cab or Rainguard is Equipped ..........................................5-31

When Installing an Attachment Longer

Than Standard Bucket ..........................................................5-31

Shackle Hole Usage .....................................................................5-32

Overnight Storage Instructions ...............................................5-32

Emergency Boom Lowering Procedure

(Without hose-rupture safety valve) ..............................5-33

Object Handling --- If Equipped ..............................................5-35

TRANSPORTING

Transporting By Road ................................................................... 6-1

Loading/unloading on a Trailer ................................................. 6-1

Machine Lifting Procedure .......................................................... 6-5

MAINTENANCE

Correct Maintenance and Inspection Procedures .............. 7-1

Check the Hour Meter Regularly ............................................... 7-2

Use Correct Fuels and Lubricants ............................................. 7-2

Layout ................................................................................................. 7-3

Maintenance Guide Table ............................................................ 7-4

Prepare Machine for Maintenance ........................................... 7-6

Hood and Access Covers (ZX120-3, 180-3 Class) ................ 7-7

Hood and Access Covers (ZX200-3, 270-3, 330-3 Class) ... 7-8

Periodic Replacement of Parts ................................................... 7-9

Page 10

CONTENTS

Maintenance Guide ..................................................................... 7-10

A. Greasing ......................................................................................7-16

Front Joint Pins .......................................................................7-16

Swing Bearing ......................................................................... 7-18

Swing Internal Gear ..............................................................7-19

B. Engine ..........................................................................................7-20

Engine Oil Level ......................................................................7-20

Change Engine Oil ................................................................ 7-21

Replace Engine Oil Filter .....................................................7-21

C. Transmission .............................................................................. 7-23

Pump Transmission ............................................................... 7-23

Swing Reduction Gear ......................................................... 7-24

Travel Reduction Gear ..........................................................7-25

D. Hydraulic System ..................................................................... 7-27

Inspection and Maintenance of Hydraulic

Equipment...........................................................................7-27

Breaker Maintenance ...........................................................7-29

Check Hydraulic Oil Level ...................................................7-30

Change Hydraulic Oil ...........................................................7-31

Suction Filter Cleaning ........................................................7-31

Replace Hydraulic Oil Tank Filter ......................................7-34

Replace Pilot Oil Filter ..........................................................7-35

Replace Air Breather Element ...........................................7-36

Check Hoses and Lines ........................................................7-37

Service Recommendations for Hydraulic Fittings .....7-40

E. Fuel System ................................................................................7-42

Drain Fuel Tank Sump .........................................................7-44

Drain Fuel Filter ......................................................................7-45

Replace Fuel Main Filter Element ..................................... 7-49

Replace Fuel Pre-Filter Element ........................................ 7-50

Clean Fuel Solenoid Pump Strainer ................................7-51

Check Fuel Hoses ................................................................... 7-52

F. Air Cleaner ...................................................................................7-53

Clean Air Cleaner Outer Element .....................................7-53

Replace Air Cleaner Outer and Inner Elements ..........7-53

G. Cooling System ........................................................................ 7-55

Check Coolant Level .............................................................7-57

Check and Adjust Fan Belt Tension

(ZX120-3, 180-3 Class) .....................................................7-58

Check and Adjust Fan Belt Tension

(ZX200-3, ZX270-3, ZX330-3 Class) ............................. 7-59

Change Coolant .....................................................................7-60

Clean Radiator Interior.........................................................7-60

Clean Radiator, Oil Cooler Core

and Inter Cooler Outside ................................................ 7-61

Clean Oil Cooler, Radiator and Inter

Cooler Front Screen ......................................................... 7-61

Clean Air Conditioner Condenser .................................... 7-61

Clean Fuel Oil Cooler ........................................................... 7-61

Clean Air Conditioner Front Screen (Opt.) ....................7-61

H. Electrical System ......................................................................7-62

Batteries ....................................................................................7-62

Replace Batteries ...................................................................7-65

Replacing Fuses ......................................................................7-66

I. Miscellaneous ............................................................................7-68

Check Bucket Teeth ...............................................................7-68

Change Bucket .......................................................................7-72

Convert Bucket Connection Into Face Shovel .............7-73

Adjust Bucket Linkage .........................................................7-74

Remove Travel Levers ...........................................................7-75

Check and Replace Seat Belt Check ................................ 7-75

Check Windshield Washer Fluid Level ............................7-76

Check Track Sag ...................................................................... 7-77

Clean and Replace Air Conditioner Filter ...................... 7-79

Check Air Conditioner ..........................................................7-81

Clean Cab Floor ......................................................................7-82

Retighten Cylinder Head Bolt............................................ 7-83

Inspect and Adjust Valve Clearance ................................7-83

Measure Engine Compression Pressure ........................ 7-83

Check Starter and Alternator.............................................7-83

Check and Replace EGR Device ........................................7-83

Check Tightening Torque of Bolts and Nuts ................7-84

HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT

Hydraulic Circuit ............................................................................. 8-1

Electrical Circuit .............................................................................. 8-2

Electrical Diagram .......................................................................... 8-3

MAINTENANCE UNDER SPECIAL

ENVIRONMENTAL CONDITIONS

Maintenance Under Special Environmental

Conditions .................................................................................. 9-1

STORAGE

Storing the Machine ....................................................................10-1

Removing the Machine from Storage ................................... 10-2

TROUBLESHOOTING

Impossible to Start the Engine ................................................11-1

Engine ............................................................................................... 11-2

Electrical System ...........................................................................11-6

Mode Selection .............................................................................11-8

Control Levers ................................................................................ 11-9

Hydraulic System ..........................................................................11-9

SPECIFICATIONS

Specifications (ZX110-3, 110M-3) ...........................................12-1

Working Ranges (ZX110-3, 110M-3) ......................................12-2

Shoe Types and Applications

(ZX110-3) ..................................................................................12-3

(ZX110M-3) ..............................................................................12-4

Bucket Types and Applications (ZX110-3, 110M-3) .......... 12-5

Specifications (ZX130-3, 130LCN-3) .......................................12-6

Working Ranges (ZX130-3, 130LCN-3) .................................. 12-7

Shoe Types and Applications (ZX130-3)...............................12-8

Shoe Types and Applications (ZX130LCN-3) ...................... 12-9

Bucket Types and Applications (ZX130-3, 130LCN-3) ...12-10

Specifications (ZX160LC-3) .....................................................12-11

Working Ranges (ZX160LC-3) ................................................12-12

Shoe Types and Applications (ZX160LC-3) ........................12-14

Bucket Types and Applications (ZX160LC-3) ....................12-15

Page 11

CONTENTS

Specifications (ZX180LC-3, 180LCN-3) ................................12-16

Working Ranges (ZX180LC-3, 180LCN-3) ...........................12-17

Shoe Types and Applications

(ZX180LC-3, 180LCN-3) ......................................................12-19

Bucket Types and Applications

(ZX180LC-3, 180LCN-3) ......................................................12-20

Specifications (ZX210-3, 210LC-3) ........................................12-21

Working Ranges (ZX210-3, 210LC-3) ...................................12-22

Shoe Types and Applications (ZX210-3, 210LC-3) ..........12-23

Bucket Types and Applications (ZX210-3, 210LC-3) .......12-24

Specifications (ZX210LCN-3, 240N-3) .................................12-25

Working Ranges (ZX210LCN-3, 240N-3).............................12-26

Shoe Types and Applications

(ZX210LCN-3, 240N-3) .......................................................12-27

Bucket Types and Applications

(ZX210LCN-3, 240N-3) .......................................................12-28

Specifications (ZX250LC-3, 250LCN-3) ................................12-29

Working Ranges (ZX250LC-3, 250LCN-3) ...........................12-30

Shoe Types and Applications

(ZX250LC-3, 250LCN-3) ......................................................12-31

Bucket Types and Applications

(ZX250LC-3, 250LCN-3) ......................................................12-32

Specifications (ZX280LC-3, 280LCN-3) ................................12-33

Working Ranges (ZX280LC-3, 280LCN-3) ...........................12-34

Shoe Types and Applications

(ZX280LC-3, 280LCN-3) ......................................................12-35

Bucket Types and Applications

(ZX280LC-3, 280LCN-3) ......................................................12-36

Specifications (ZX350LC-3, 350LCN-3) ................................12-37

Working Ranges (ZX350LC-3, 350LCN-3) ...........................12-38

Shoe Types and Applications

(ZX350LC-3, 350LCN-3) ......................................................12-39

Bucket Types and Applications

(ZX350LC-3, 350LCN-3) ......................................................12-40

Sound Level Results (2000/14/EC) .......................................12-41

Vibration Level .............................................................................12-41

OPTIONAL ATTACHMENTS AND DEVICES

Using Pad Crawler Shoe .............................................................13-1

Traveling and Other Cautions ..................................................13-2

Transporting ................................................................................... 13-3

Precautions for Transporting Machines

with Pad Crawler Shoes .......................................................13-3

Long Arm Operation --- If Equipped ...................................... 13-6

Blade Lever .....................................................................................13-7

Precautions for Blade Operation .............................................13-7

Avoid Hitting Blade with Front-end Attachment..............13-8

Avoid Hitting Blade with Bucket .............................................13-8

Avoid Striking The Blade Into a Rock .....................................13-8

Blade Maintenance ...................................................................... 13-9

Specifications (ZX110-3 with Blade) ....................................13-10

Working Ranges (ZX110-3 with Blade) ...............................13-11

Shoe Types and Applications (ZX110-3 with Blade) ......13-12

Specifications (ZX130-3 with Blade) ....................................13-13

Working Ranges (ZX130-3 with Blade) ...............................13-14

Shoe Types and Applications (ZX130-3 with Blade) ......13-15

Offset Arm Front .........................................................................13-16

Offset Direction and Working Range ..................................13-17

Precautions for Operating with The Offset Function .....13-18

Maintenance ................................................................................13-19

Specifications (ZX110-3, 110M-3 Offset) ............................13-20

Working Ranges (ZX110-3, 110M-3 Offset) .......................13-21

Bucket Teeth (Transverse-type-pin-used Type) ...............13-22

2-piece Boom ...............................................................................13-23

Maintenance (2-piece Boom) .................................................13-24

Specifications

ZX130-3, 130LCN-3 (2-piece Boom) ..............................13-27

Working Ranges

ZX130-3, 130LCN-3 (2-piece Boom) ..............................13-28

Shoe Types and Applications

ZX130-3 (2-piece Boom) ...................................................13-29

ZX130LCN-3 (2-piece Boom) ...........................................13-30

Specifications

ZX210-3, 210LC-3 (2-piece Boom) .................................13-31

Working Ranges

ZX210-3, 210LC-3 (2-piece Boom) .................................13-32

Shoe Types and Applications

ZX210-3 (2-piece Boom) ...................................................13-33

ZX210LC-3 (2-piece Boom) ..............................................13-33

Specifications

ZX210LCN-3, 240N-3 (2-piece Boom) ...........................13-34

Working Ranges

ZX210LCN-3, 240N-3 (2-piece Boom) ...........................13-35

Shoe Types and Applications

ZX210LCN-3 (2-piece Boom) ...........................................13-36

ZX240N-3 (2-piece Boom) ................................................13-36

Specifications

ZX250LC-3, 250LCN-3 (2-piece Boom) .........................13-37

Working Ranges

ZX250LC-3, 250LCN-3 (2-piece Boom) .........................13-38

Shoe Types and Applications

ZX250LC-3 (2-piece Boom) ..............................................13-39

ZX250LCN-3 (2-piece Boom) ...........................................13-39

Specifications

ZX280LC-3, 280LCN-3 (2-piece Boom) .........................13-40

Working Ranges

ZX280LC-3, 280LCN-3 (2-piece Boom) .........................13-41

Shoe Types and Applications

ZX280LC-3 (2-piece Boom) ..............................................13-42

ZX280LCN-3 (2-piece Boom) ...........................................13-42

Specifications

ZX350LC-3, 350LCN-3 (2-piece Boom) .........................13-43

Working Ranges

ZX350LC-3, 350LCN-3 (2-piece Boom) .........................13-44

Shoe Types and Applications

ZX350LC-3 (2-piece Boom) ..............................................13-45

ZX350LCN-3 (2-piece Boom) ...........................................13-45

Lifting Hook ..................................................................................13-46

Lifting Capacities ........................................................................13-48

INDEX ...............................................................................................14-1

Page 12

SAFETY

S-1

SA-688

SA-1223

RECOGNIZE SAFETY INFORMATION

•

These are the SAFETY ALERT SYMBOLS.

• When you see these symbols on your machine or in this

manual, be alert to the potential for personal injury.

• Follow recommended precautions and safe operating

practices.

001-E01A-0001

UNDERSTAND SIGNAL WORDS

•

On machine safety signs, signal words designating the

degree or level of hazard - DANGER, WARNING, or CAUTION

- are used with the safety alert symbol.

•

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

•

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

•

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

•

DANGER or WARNING safety signs are located near spe-

cific hazards. General precautions are listed on CAUTION

safety signs.

• Some safety signs do not use any of the designated signal

words above after the safety alert symbol are occasionally

used on this machine.

•

To avoid confusing machine protection with personal safety

messages, a signal word IMPORTANT indicates a situation

which, if not avoided, could result in damage to the machine.

•

NOTE indicates an additional explanation for an element

of information.

002-E01A-1223

Page 13

SAFETY

S-2

FOLLOW SAFETY INSTRUCTIONS

•

Carefully read and follow all safety signs on the machine

and all safety messages in this manual.

•

Safety signs should be installed, maintained and replaced

when necessary.

• If a safety sign or this manual is damaged or missing,

order a replacement from your authorized dealer in the

same way you order other replacement parts (be sure to

state machine model and serial number when ordering).

•

Learn how to operate the machine and its controls correctly

and safely.

•

Allow only trained, qualified, authorized personnel to oper

-

ate the machine.

•

Keep your machine in proper working condition.

• Unauthorized modifications of the machine may impair

its function and/or safety and affect machine life.

• Do not modify any machine parts without authorization.

Failure to do so may deteriorate the part safety, function, and/or service life. In addition, personal accident,

machine trouble, and/or damage to material caused by

unauthorized modifications will void Hitachi Warranty

Policy.

• Do not use attachments and/or optional parts or equip

ment not authorized by Hitachi. Failure to do so may

deteriorate the safety, function, and/or service life of the

machine. In addition, personal accident, machine trouble,

and/or damage to material caused by using unauthorized

attachments and/or optional parts or equipment will void

Hitachi Warranty Policy.

•

The safety messages in this SAFETY chapter are intended to

illustrate basic safety procedures of machines. However it is

impossible for these safety messages to cover every hazardous situation you may encounter. If you have any questions,

you should first consult your supervisor and/or your authorized dealer before operating or performing maintenance

work on the machine.

003-E01B-0003

SA-003

Page 14

SAFETY

S-3

PREPARE FOR EMERGENCIES

•

Be prepared if a fire starts or if an accident occurs.

• Keep a first aid kit and fire extinguisher on hand.

• Thoroughly read and understand the label attached on

the fire extinguisher to use it properly.

• To ensure that a fire extinguisher can be always used

when necessary, check and service the fire extinguisher at

the recommended intervals as specified in the fire extinguisher manual.

• Establish emergency procedure guidelines to cope with

fires and accidents.

• Keep emergency numbers for doctors, ambulance service,

hospital, and fire department posted near your telephone.

004-E01A-0437

WEAR PROTECTIVE CLOTHING

•

Wear close fitting clothing and safety equipment appropri-

ate to the job.

You may need:

A hard hat

Safety shoes

Safety glasses, goggles, or face shield

Heavy gloves

Hearing protection

Reflective clothing

Wet weather gear

Respirator or filter mask.

Be sure to wear the correct equipment and clothing for the

job. Do not take any chances.

• Avoid wearing loose clothing, jewelry, or other items that

can catch on control levers or other parts of the machine.

•

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones while

operating the machine.

005-E01A-0438

PROTECT AGAINST NOISE

•

Prolonged exposure to loud noise can cause impairment or

loss of hearing.

• Wear a suitable hearing protective device such as ear

muffs or earplugs to protect against objectionable or

uncomfortably loud noises.

006-E01A-0434

SA-437

SA-434

SA-438

Page 15

SAFETY

S-4

INSPECT MACHINE

•

Inspect your machine carefully each day or shift by walking

around it before you start it to avoid personal injury.

• In the walk-around inspection be sure to cover all points

described in the “PRE-START INSPECTION” chapter in the

operator’s manual.

007-E01A-0435

GENERAL PRECAUTIONS FOR CAB

• Before entering the cab, thoroughly remove all dirt and/

or oil from the soles of your work boots. If any controls

such as a pedal is operated while with dirt and/or oil on

the soles of the operator’s work boots the operator’s foot

may slip off the pedal, possibly resulting in a personal accident.

• Do not leave parts and/or tools lying around the opera-

tor’s seat. Store them in their specified locations.

• Avoid storing transparent bottles in the cab. Do not at

tach any transparent type window decorations on the

windowpanes as they may focus sunlight, possibly starting a fire.

• Refrain from listening to the radio, or using music head

phones or mobile telephones in the cab while operating

the machine.

• Keep all flammable objects and/or explosives away from

the machine.

• After using the ashtray, always cover it to extinguish the

match and/or tobacco.

• Do not leave cigarette lighters in the cab. When the tem

-

perature in the cab increases, the lighter may explode.

524-E01A-0000

SA-435

Page 16

SAFETY

S-5

USE HANDHOLDS AND STEPS

•

Falling is one of the major causes of personal injury.

• When you get on and off the machine, always face the

machine and maintain a three-point contact with the

steps and handrails.

• Do not use any controls as hand-holds.

• Never jump on or off the machine. Never mount or dis

-

mount a moving machine.

• Be careful of slippery conditions on platforms, steps, and

handrails when leaving the machine.

008-E01A-0439

ADJUST THE OPERATOR'S SEAT

•

A poorly adjusted seat for either the operator or for the

work at hand may quickly fatigue the operator leading to

misoperations.

• The seat should be adjusted whenever changing the op

-

erator for the machine.

• The operator should be able to fully depress the pedals

and to correctly operate the control levers with his back

against the seat back.

• If not, move the seat forward or backward, and check

again.

• Adjust the rear view mirror position so that the best rear

visibility is obtained from the operator’s seat. If the mirror

is broken, immediately replace it with a new one.

009-E01A-0462

ENSURE SAFETY BEFORE RISING FROM OR LEAVING OPERATOR’S SEAT

•

Before rising from the operator’s seat to open/close either

side window or to adjust the seat position, be sure to first

lower the front attachment to the ground and then move

the pilot control shut-off lever to the LOCK position. Failure

to do so may allow the machine to unexpectedly move

when a body part unintentionally comes in contact with a

control lever, possibly resulting in serious personal injury or

death.

•

Before leaving the machine, be sure to first lower the front

attachment to the ground and then move the pilot control

shut-off lever to the LOCK position. Turn the key switch OFF

to stop the engine.

•

Before leaving the machine, close all windows, doors, and

access covers and lock them up.

SA-439

SA-378

Page 17

SAFETY

S-6

FASTEN YOUR SEAT BELT

•

If the machine should overturn, the operator may become

injured and/or thrown from the cab. Additionally the operator may be crushed by the overturning machine, resulting in

serious injury or death.

• Prior to operating the machine, thoroughly examine web

bing, buckle and attaching hardware. If any item is damaged or worn, replace the seat belt or component before

operating the machine.

• Be sure to remain seated with the seat belt securely

fastened at all times when the machine is in operation to

minimize the chance of injury from an accident.

• We recommend that the seat belt be replaced every three

years regardless of its apparent condition.

010-E01A-0237

MOVE AND OPERATE MACHINE SAFELY

•

Bystanders can be run over.

• Take extra care not to run over bystanders. Confirm the

location of bystanders before moving, swinging, or operating the machine.

• Always keep the travel alarm and horn in working condi

tion (if equipped). It warns people when the machine

starts to move.

• Use a signal person when moving, swinging, or operating

the machine in congested areas. Coordinate hand signals

before starting the machine.

• Use appropriate illumination. Check that all lights are op

erable before operating the machine. If any faulty illumination is present, immediately repair it.

011-E01A-0398

HANDLE STARTING AIDS SAFELY

Starting fluid:

•

Starting fluid is highly flammable.

• Keep all sparks and flame away when using it.

• Keep starting fluid well away from batteries and cables.

• Remove container from machine if engine does not need

starting fluid.

• To prevent accidental discharge when storing a pressur

ized container, keep the cap on the container, and store it

in a cool, well-protected location.

• Do not incinerate or puncture a starting fluid container.

036-E01A-0293-3

SA-237

SA-426

SA-293

Page 18

SAFETY

S-7

OPERATE ONLY FROM OPERATOR'S SEAT

•

Inappropriate engine starting procedures may cause the

machine to runaway, possibly resulting in serious injury or

death.

• Start the engine only when seated in the operator's seat.

• NEVER start the engine while standing on the track or on

ground.

• Do not start engine by shorting across starter terminals.

• Before starting the engine, confirm that all control levers

are in neutral.

• Before starting the engine, confirm the safety around the

machine and sound the horn to alert bystanders.

012-E01B-0431

JUMP STARTING

•

Battery gas can explode, resulting in serious injury.

• If the engine must be jump started, be sure to follow the

instructions shown in the “OPERATING THE ENGINE” chapter in the operator’s manual.

• The operator must be in the operator’s seat so that the

machine will be under control when the engine starts.

Jump starting is a two-person operation.

• Never use a frozen battery.

• Failure to follow correct jump starting procedures could

result in a battery explosion or a runaway machine.

S013-E01A-0032

KEEP RIDERS OFF MACHINE

•

Riders on machine are subject to injury such as being struck

by foreign objects and being thrown off the machine.

• Only the operator should be on the machine. Keep riders

off.

• Riders also obstruct the operator’s view, resulting in the

machine being operated in an unsafe manner.

014-E01B-0427

SA-444

SA-032

SA-379

Page 19

SAFETY

S-8

PRECAUTIONS FOR OPERATIONS

•

Investigate the work site before starting operations.

• Be sure to wear close fitting clothing and safety equip

ment appropriate for the job, such as a hard hat, etc.

when operating the machine.

• Clear all persons and obstacles from area of operation and

machine movement.

Always beware of the surroundings while operating.

When working in a small area surrounded by obstacles,

take care not to hit the upperstructure against obstacles.

• When loading onto trucks, bring the bucket over the truck

beds from the rear side. Take care not to swing the bucket

over the cab or over any person.

M178-05-007

Page 20

SAFETY

S-9

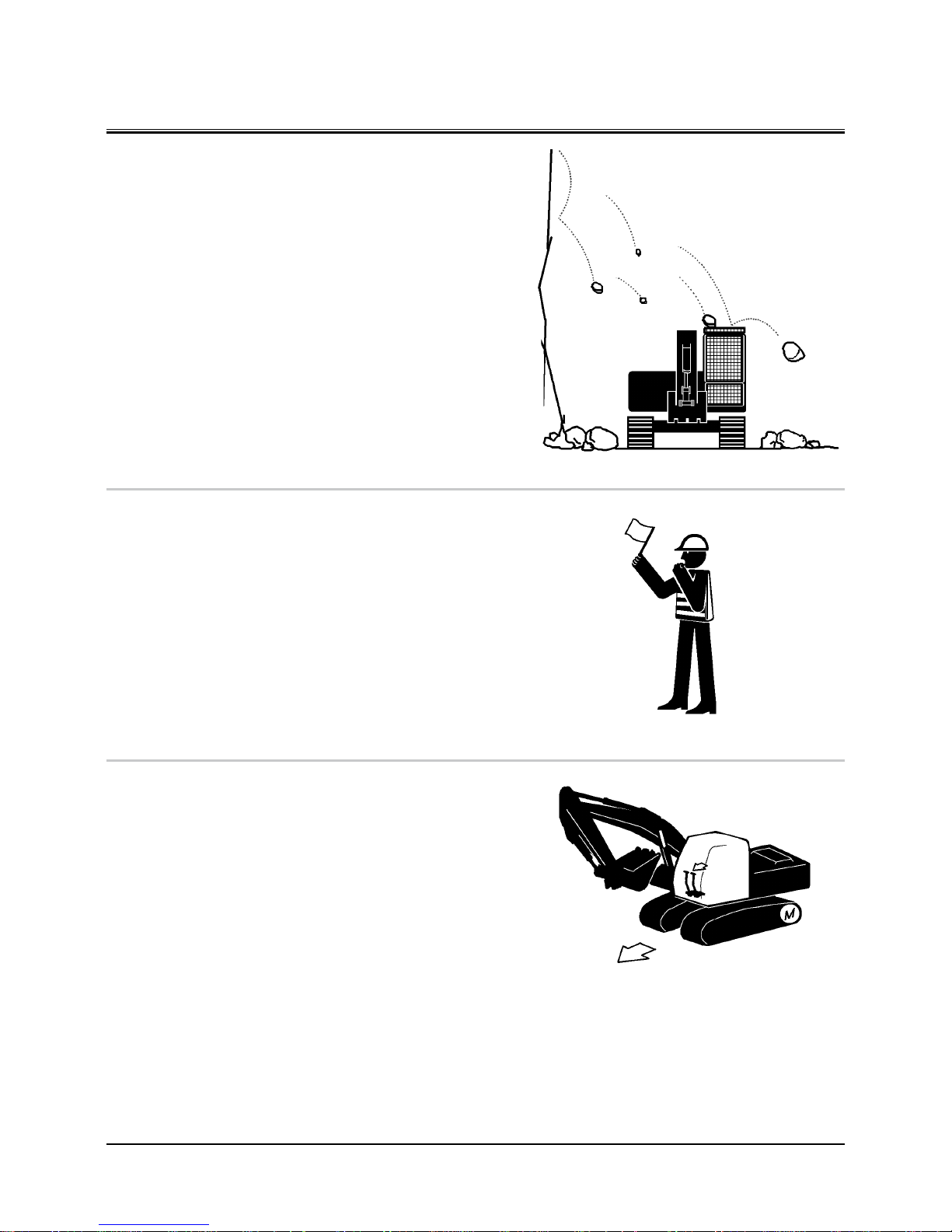

INVESTIGATE JOB SITE BEFOREHAND

•

When working at the edge of an excavation or on a road

shoulder, the machine could tip over, possibly resulting in

serious injury or death.

• Investigate the configuration and ground conditions of

the job site beforehand to prevent the machine from falling and to prevent the ground, stockpiles, or banks from

collapsing.

• Make a work plan. Use machines appropriate to the work

and job site.

• Reinforce ground, edges, and road shoulders as necessary.

Keep the machine well back from the edges of excavations and road shoulders.

• When working on an incline or on a road shoulder, em

-

ploy a signal person as required.

• Confirm that your machine is equipped a FOPS cab before

working in areas where the possibility of falling stones or

debris exist.

• When the footing is weak, reinforce the ground before

starting work.

• When working on frozen ground, be extremely alert. As

ambient temperatures rise, footing becomes loose and

slippery.

• Beware the possibility of fire when operating the machine

near flammable objects such as dry grass.

•

Make sure the worksite has sufficient strength to firmly sup-

port the machine.

When working close to an excavation or at road shoulders,

operate the machine with the tracks positioned perpendicular to the cliff face with travel motors at the rear, so that the

machine can more easily evacuate if the cliff face collapses.

•

If working on the bottom of a cliff or a high bank is required,

be sure to investigate the area first and confirm that no

danger of the cliff or bank collapsing exists. If any possibility

of cliff or bank collapsing exists, do not work on the area.

•

Soft ground may collapse when operating the machine on

it, possibly causing the machine to tip over. When working

on soft ground is required, be sure to reinforce the ground

first using large pieces of steel plates strong and firm

enough to easily support the machine.

•

Note that there is always a possibility of machine tipping

over when working on rough terrain or on slopes. Prevent

machine tipping over from occurring. When operating on

rough terrain or on slopes:

• Reduce the engine speed.

• Select slow travel speed mode.

• Operate the machine slowly and be cautious with ma

-

chine movements.

SA-380

M104-05-016

Page 21

SAFETY

S-10

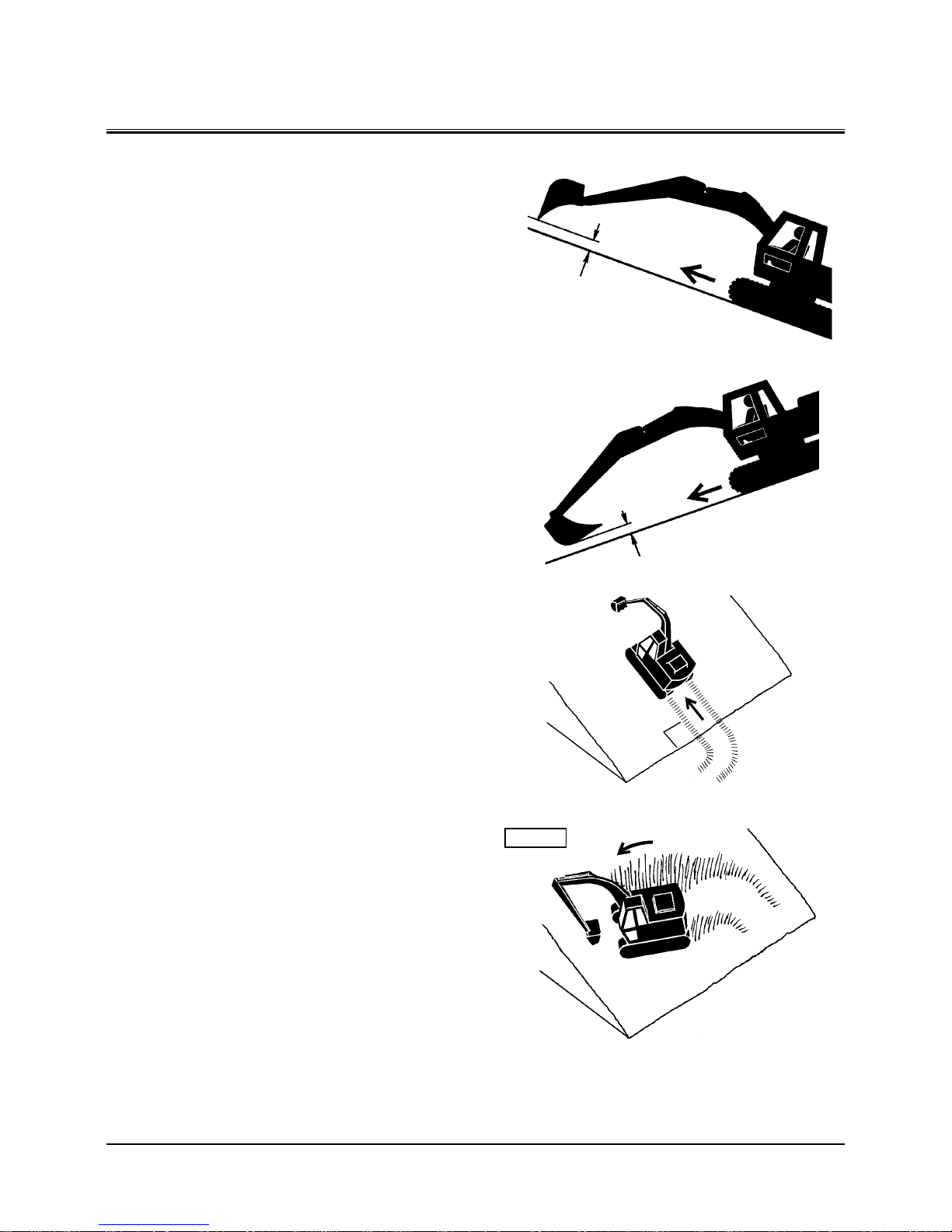

EQUIPMENT OF HEAD GUARD, ROPS, FOPS

In case the machine is operated in areas where the possibility

of falling stones or debris exist, equip a head guard, ROPS, or

FOPS according to the potential hazardous conditions. (The

standard cab for this machine corresponds to ROPS and FOPS.)

ROPS: Roll-Over Protective Structure

FOPS: Falling Object Protective Structure

PROVIDE SIGNALS FOR JOBS INVOLVING MULTIPLE NUMBERS OF MACHINES

•

For jobs involving multiple numbers of machines, provide

signals commonly known by all personnel involved. Also,

appoint a signal person to coordinate the job site. Make

sure that all personnel obey the signal person’s directions.

018-E01A-0481

CONFIRM DIRECTION OF MACHINE TO BE DRIVEN

•

Incorrect travel pedal/lever operation may result in serious

injury death.

• Before driving the machine, confirm the position of the

undercarriage in relation to the operator’s position. If the

travel motors are located in front of the cab, the machine

will move in reverse when travel pedals/levers are operated to the front.

017-E01A-0491

SA-490

SA-481

SA-491

Page 22

SAFETY

S-11

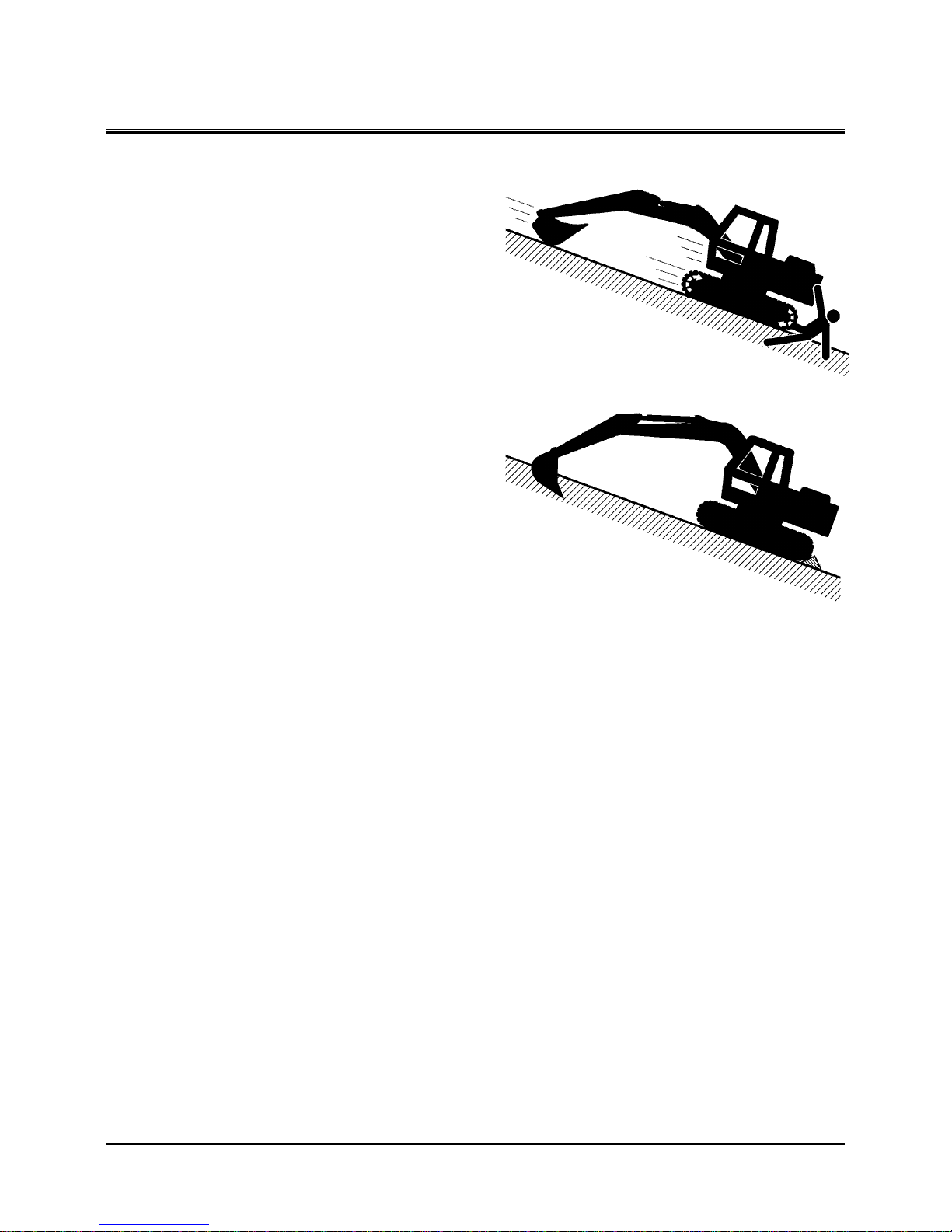

DRIVE MACHINE SAFELY

•

Before driving the machine, always confirm that the travel

levers/pedals direction corresponds to the direction you

wish to drive.

• Be sure to detour around any obstructions.

• Avoid traveling over obstructions. Soil, fragments of rocks,

and/or metal pieces may scatter around the machine. Do

not allow personnel to stay around the machine while

traveling.

•

Driving on a slope may cause the machine to slip or over-

turn, possibly resulting in serious injury or death.

• Never attempt to ascend or descend 35 degrees or steep

-

er slopes.

• Be sure to fasten the seat belt.

• When driving up or down a slope, keep the bucket fac

ing the direction of travel, approximately 0.5 to 1.0 m (A)

above the ground.

• If the machine starts to skid or becomes unstable, imme

-

diately lower the bucket to the ground and stop.

A

A

SA-657

SA-658

SA-441

SA-590

WRONG

Page 23

SAFETY

S-12

• Driving across the face of a slope or steering on a slope

may cause the machine to skid or turnover. If the direction must be changed, move the machine to level ground,

then, change the direction to ensure safe operation.

• Avoid swinging the upperstructure on slopes. Never at

tempt to swing the upperstructure downhill. The machine

may tip over. If swinging uphill is unavoidable, carefully

operate the upperstructure and boom at slow speed.

• If the engine stalls on a slope, immediately lower the

bucket to the ground. Return the control levers to neutral.

Then, restart the engine.

• Be sure to thoroughly warm up the machine before as

cending steep slopes. If hydraulic oil has not warmed up

sufficiently, sufficient performance may not be obtained.

• Use a signal person when moving, swinging or operating

the machine in congested areas. Coordinate hand signals

before starting the machine.

• Before moving machine, determine which way to move

travel pedals/levers for the direction you want to go.

When the travel motors are in the rear, pushing down on

the front of the travel pedals or pushing the levers forward moves the machine forward, towards the idlers.

An arrow-mark seal is stuck on the inside surface of the

side frame to indicate the machine front direction.

• Select a travel route that is as flat as possible. Steer the

machine as straight as possible, making small gradual

changes in direction.

• Before traveling on them, check the strengths of bridges

and road shoulders, and reinforce if necessary.

• Use wood plates in order not to damage the road surface.

Be careful of steering when operating on asphalt roads in

summer.

• When crossing train tracks, use wood plates in order not

to damage them.

• Do not make contact with electric wires or bridges.

• When crossing a river, measure the depth of the river

using the bucket, and cross slowly. Do not cross the river

when the depth of the river is deeper than the upper

edge of the upper roller.

• When traveling on rough terrain, reduce engine speed.

Select slow travel speed. Slower speed will reduce possible damage to the machine.

• Avoid operations that may damage the track and under

-

carriage components.

• During freezing weather, always clean snow and ice from

track shoes before loading and unloading machine, to

prevent the machine from slipping.

Travel Motor

Arrow -mark

M104-05-008

M178-03-001

SA-011

Page 24

SAFETY

S-13

AVOID INJURY FROM ROLLAWAY ACCIDENTS

•

Death or serious injury may result if you attempt to mount

or stop a moving machine.

To avoid rollaways:

• Select level ground when possible to park the machine.

• Do not park the machine on a grade.

• Lower the bucket and/or other work tools to the ground.

• Turn the auto-idle switch OFF and the power mode switch

E or P.

• Run the engine at slow idle speed without load for 5 min

-

utes to cool down the engine.

• Stop the engine and remove the key from the key switch.

• Pull the pilot control shut-off lever to LOCK position.

• Block both tracks and lower the bucket to the ground.

Thrust the bucket teeth into the ground if you must park

on a grade.

• Position the machine to prevent rolling.

• Park a reasonable distance from other machines.

020-E02A-0493

SA-392

SA-391

Page 25

SAFETY

S-14

AVOID INJURY FROM BACK-OVER AND SWING

ACCIDENTS

•

If any person is present near the machine when backing or

swinging the upperstructure, the machine may hit or run

over that person, resulting in serious injury or death.

To avoid back-over and swing accidents:

• Always look around BEFORE YOU BACK UP AND SWING

THE MACHINE. BE SURE THAT ALL BYSTANDERS ARE

CLEAR.

• Keep the travel alarm in working condition (if equipped).

ALWAYS BE ALERT FOR BYSTANDERS MOVING INTO THE

WORK AREA. USE THE HORN OR OTHER SIGNAL TO WARN

BYSTANDERS BEFORE MOVING MACHINE.

• USE A SIGNAL PERSON WHEN BACKING UP IF YOUR VIEW

IS OBSTRUCTED. ALWAYS KEEP THE SIGNAL PERSON IN

VIEW.

Use hand signals, which conform to your local regulations,

when work conditions require a signal person.

• No machine motions shall be made unless signals are

clearly understood by both signalman and operator.

• Learn the meanings of all flags, signs, and markings used

on the job and confirm who has the responsibility for

signaling.

• Keep windows, mirrors, and lights clean and in good con

-

dition.

• Dust, heavy rain, fog, etc., can reduce visibility. As visibility

decreases, reduce speed and use proper lighting.

• Read and understand all operating instructions in the

operator’s manual.

021-E01A-0494

SA-383

SA-384

Page 26

SAFETY

S-15

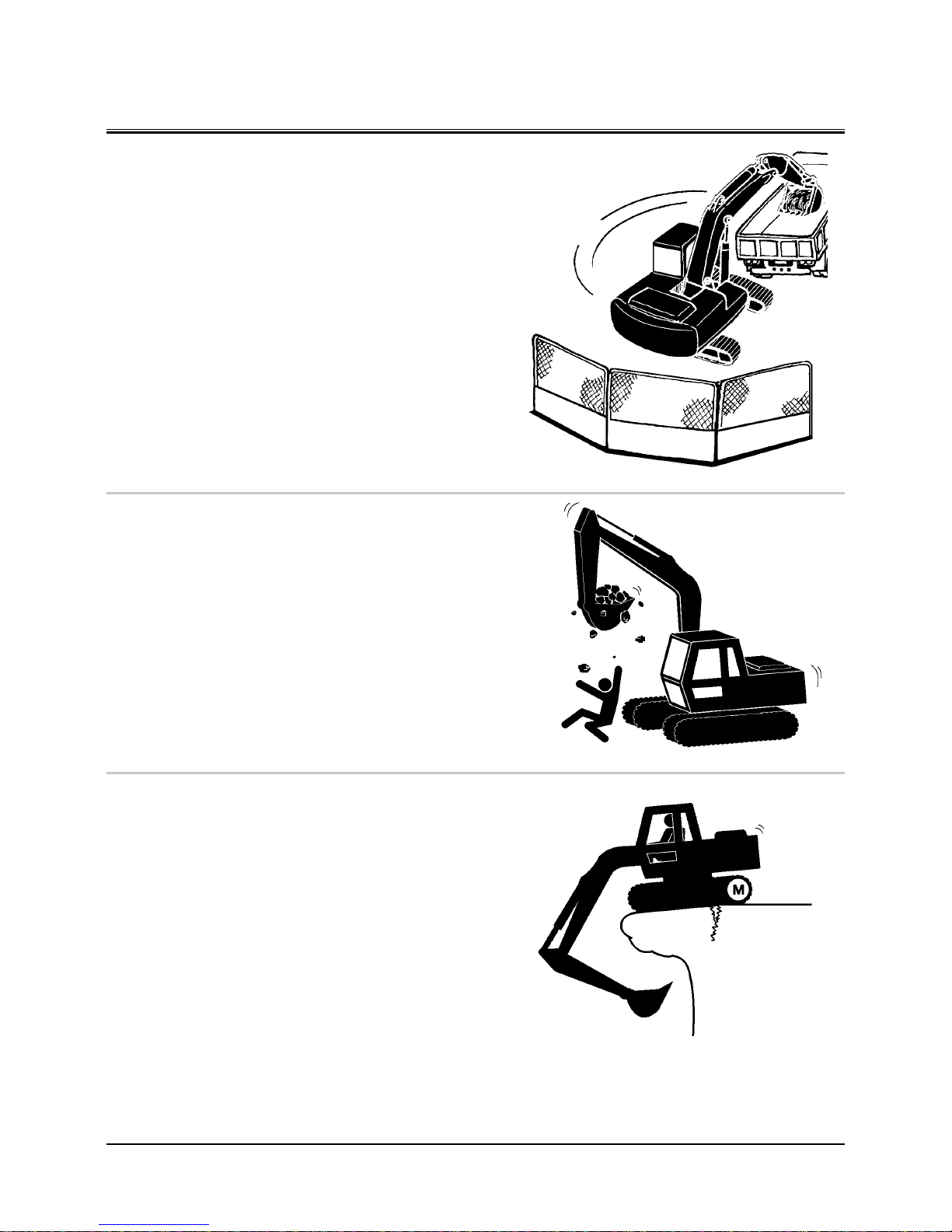

KEEP PERSON CLEAR FROM WORKING AREA

•

A person may be hit severely by the swinging front attach-

ment or counterweight and/or may be crushed against an

other object, resulting in serious injury or death.

• Keep all persons clear from the area of operation and

machine movement.

• Before operating the machine, set up barriers to the sides

and rear area of the bucket swing radius to prevent anyone from entering the work area.

022-E01A-0386

NEVER POSITION BUCKET OVER ANYONE

•

Never lift, move, or swing bucket above anyone or a truck

cab.

Serious injury or machine damage may result due to bucket

load spill or due to collision with the bucket.

023-E01A-0487

AVOID UNDERCUTTING

•

In order to retreat from the edge of an excavation if the

footing should collapse, always position the undercarriage

perpendicular to the edge of the excavation with the travel

motors at the rear.

• If the footing starts to collapse and if retreat is not pos

sible, do not panic. Often, the machine can be secured by

lowering the front attachment, in such cases.

024-E01A-0488

SA-386

SA-487

SA-488

Page 27

SAFETY

S-16

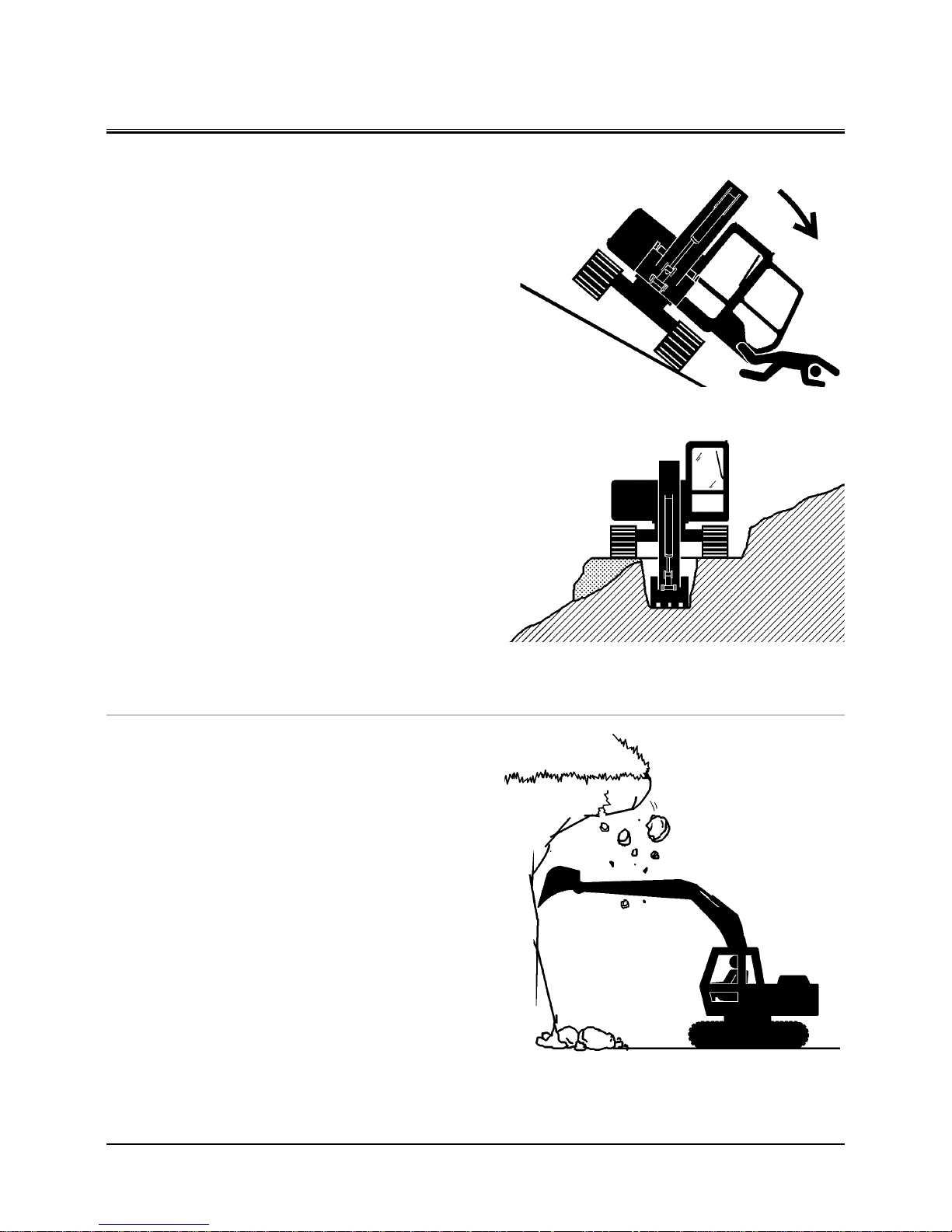

AVOID TIPPING

DO NOT ATTEMPT TO JUMP CLEAR OF TIPPING MACHINE---SERIOUS OR FATAL CRUSHING INJURIES WILL

RESULT

MACHINE WILL TIP OVER FASTER THAN YOU CAN JUMP

FREE

FASTEN YOUR SEAT BELT

•

The danger of tipping is always present when operating on

a grade, possibly resulting in serious injury or death.

To avoid tipping:

•

Be extra careful before operating on a grade.

• Prepare machine operating area flat.

• Keep the bucket low to the ground and close to the ma

-

chine.

• Reduce operating speeds to avoid tipping or slipping.

• Avoid changing direction when traveling on grades.

• NEVER attempt to travel across a grade steeper than 15

degrees if crossing the grade is unavoidable.

• Reduce swing speed as necessary when swinging loads.

•

Be careful when working on frozen ground.

• Temperature increases will cause the ground to become

soft and make ground travel unstable.

025-E03B-0463

NEVER UNDERCUT A HIGH BANK

•

The edges could collapse or a land slide could occur causing

serious injury or death.

026-E01A-0519

SA-012

SA-440

SA-489

Page 28

SAFETY

S-17

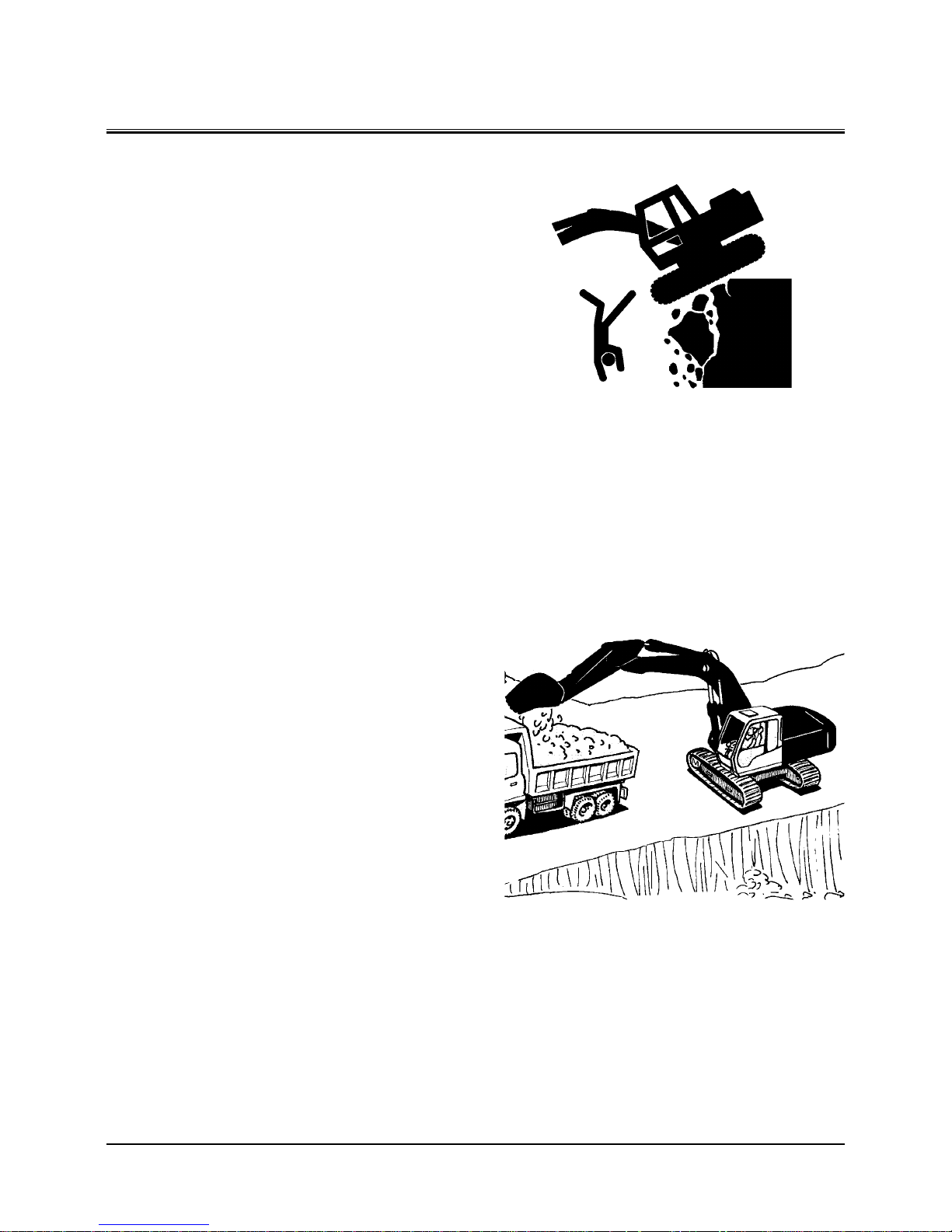

DIG WITH CAUTION

•

Accidental severing of underground cables or gas lines may

cause an explosion and/or fire, possibly resulting in serious

injury or death.

• Before digging check the location of cables, gas lines, and

water lines.

• Keep the minimum distance required, by law, from cables,

gas lines, and water lines.

• If a fiber optic cable should be accidentally severed, do

not look into the end. Doing so may result in serious eye

injury.

• Contact your local “diggers hot line” if available in your

area , and/or the utility companies directly.

Have them mark all underground utilities.

027-E01A-0382

OPERATE WITH CAUTION

•

If the front attachment or any other part of the machine hits

against an overhead obstacle, such as a bridge, both the

machine and the overhead obstacle will be damaged, and

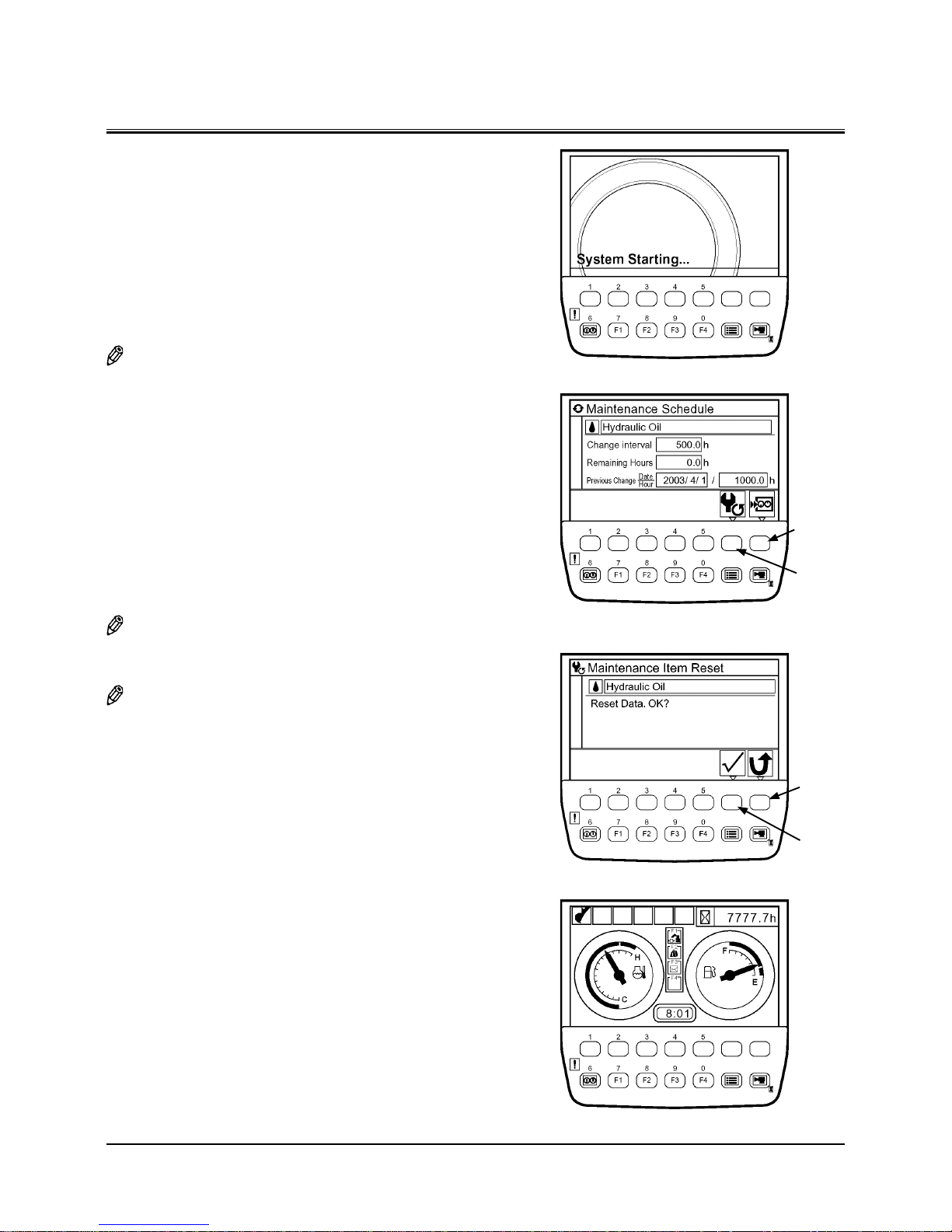

personal injury may result as well.

• Take care to avoid hitting overhead obstacles with the

boom or arm.

028-E01A-0389

SA-382

SA-389

Page 29

SAFETY

S-18

AVOID POWER LINES

•

Serious injury or death can result if the machine or front at-

tachments are not kept a safe distance from electric lines.

• When operating near an electric line, NEVER move any

part of the machine or load closer than 3 m plus twice the

line insulator length.

• Check and comply with any local regulations that may ap

-

ply.

• Wet ground will expand the area that could cause any

person on it to be affected by electric shock. Keep all

bystanders or co-workers away from the site.

029-E01A-0381

PRECAUTIONS FOR LIGHTNING

•

The machine is vulnerable to lightning strikes.

• In the event of an electrical storm, immediately stop op

eration, and lower the bucket to the ground. Evacuate to

a safe place far away from the machine.

• After the electrical storm has passed, check all of the

machine safety devices for any failure. If any failed safety

devices are found, operate the machine only after repairing them.

OBJECT HANDLING

•

If a lifted load should fall, any person nearby may be struck

by the falling load or may be crushed underneath it, resulting in serious injury or death.

• When using the machine for craning operations, be sure

to comply with all local regulations.

• Do not use damaged chains or frayed cables, sables,

slings, or ropes.

• Before craning, position the upperstructure with the travel

motors at the rear.

• Move the load slowly and carefully. Never move it sud

-

denly.

• Keep all persons well away from the load.

• Never move a load over a person’s head.

• Do not allow anyone to approach the load until it is safely

and securely situated on supporting blocks or on the

ground.

• Never attach a sling or chain to the bucket teeth. They

may come off, causing the load to fall.

032-E01A-0132

SA-381

SA-1088

SA-014

Page 30

SAFETY

S-19

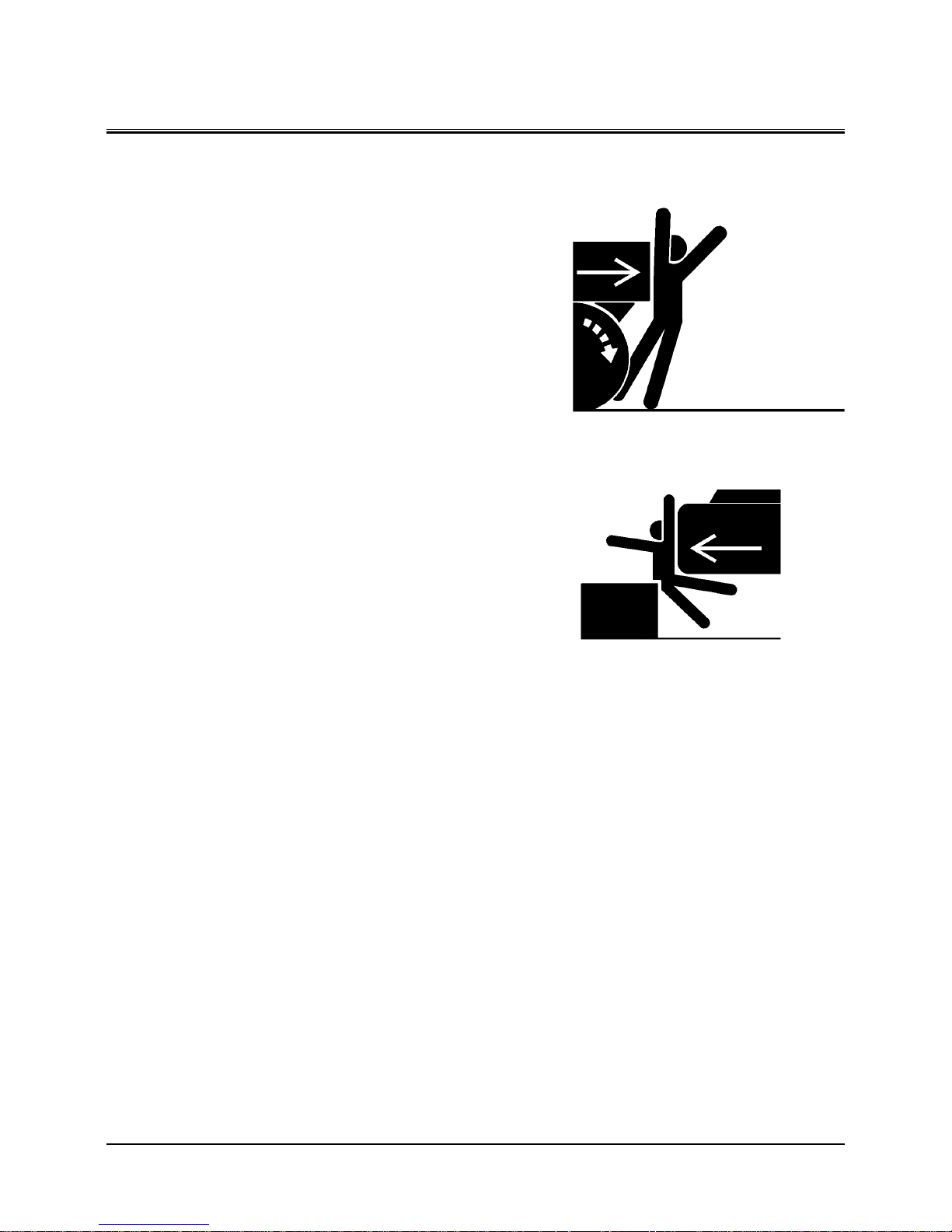

PROTECT AGAINST FLYING DEBRIS

•

If flying debris hit eyes or any other part of the body, serious

injury may result.

• Guard against injury from flying pieces of metal or debris;

wear goggles or safety glasses.

• Keep bystanders away from the working area before strik

-

ing any object.

031-E01A-0432

PARK MACHINE SAFELY

To avoid accidents:

• Park machine on a firm, level surface.

• Lower bucket to the ground.

• Turn auto-idle switch OFF and power mode switch E or P.

• Run engine at slow idle speed without load for 5 minutes.

• Turn key switch to OFF to stop engine.

• Remove the key from the key switch.

• Pull the pilot control shut-off lever to the LOCK position.

• Close windows, roof vent, and cab door.

• Lock all access doors and compartments.

HANDLE FLUIDS SAFELY−AVOID FIRES

•

Handle fuel with care; it is highly flammable. If fuel ignites,

an explosion and/or a fire may occur, possibly resulting in

serious injury or death.

• Do not refuel the machine while smoking or when near

open flame or sparks.

• Always stop the engine before refueling the machine.

• Fill the fuel tank outdoors.

•

All fuels, most lubricants, and some coolants are flammable.

• Store flammable fluids well away from fire hazards.

• Do not incinerate or puncture pressurized containers.

• Do not store oily rags; they can ignite and burn spontane

-

ously.

• Securely tighten the fuel and oil filler cap.

034-E01A-0496

SA-432

SA-390

SA-018

SA-019

Page 31

SAFETY

S-20

TRANSPORT SAFELY

•

Take care the machine may turn over when loading or un-

loading the machine onto or off of a truck or trailer.

• Observe the related regulations and rules for safe trans

-

portation.

• Select an appropriate truck or trailer for the machine to

be transported.

• Be sure to use a signal person.

• Always follow the following precautions for loading or

unloading:

1. Select solid and level ground.

2. Always use a ramp or deck strong enough to support the

machine weight.

3. Turn auto-idle switch OFF.

4. Always select the slow speed mode with the travel mode

switch.

5. Never load or unload the machine onto or off a truck or

trailer using the front attachment functions when driving

up or down the ramp.

6. Never steer the machine while on the ramp. If the travel

ing direction must be changed while the ramp, unload

the machine from the ramp, reposition the machine on

the ground, then try loading again.

7. The top end of the ramp where it meets the flatbed is a

sudden bump. Take care when traveling over it.

8. Place blocks in front of and behind the tires. Securely

hold the machine to the truck or trailer deck with wire

ropes.

Be sure to further follow the details described in the TRANSPORTING section.

035-E07A-0454

SA-395

Page 32

SAFETY

S-21

PRACTICE SAFE MAINTENANCE

To avoid accidents:

• Understand service procedures before starting work.

• Keep the work area clean and dry.

• Do not spray water or steam inside cab.

• Never lubricate or service the machine while it is moving.

• Keep hands, feet and clothing away from power-driven

parts.

Before servicing the machine:

1. Park the machine on a level surface.

2. Lower the bucket to the ground.

3. Turn the auto-idle switch off.

4. Run the engine at slow idle speed without load for 5 min

-

utes.

5. Turn the key switch to OFF to stop engine.

6. Relieve the pressure in the hydraulic system by moving

the control levers several times.

7. Remove the key from the skey witch.

8. Attach a “Do Not Operate” tag on the control lever.

9. Pull the pilot control shut-off lever to the LOCK position.

10. Allow the engine to cool.

• If a maintenance procedure must be performed with the

engine running, do not leave the machine unattended.

• If the machine must be raised, maintain a 90 to 110˚ angle

between the boom and arm. Securely support any machine elements that must be raised for service work.

• Inspect certain parts periodically and repair or replace as

necessary. Refer to the section discussing that part in the

“MAINTENANCE” chapter of this manual.

• Keep all parts in good condition and properly installed.

• Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

• When cleaning parts, always use nonflammable detergent

oil. Never use highly flammable oil such as fuel oil and

gasoline to clean parts or surfaces.

• Disconnect battery ground cable (−) before making

adjustments to electrical systems or before performing

welding on the machine.

500-E02C-0520

SA-028

SA-527

Page 33

SAFETY

S-22

• Sufficiently illuminate the work site. Use a maintenance

work light when working under or inside the machine.

• Always use a work light protected with a guard. In case

the light bulb is broken, spilled fuel, oil, antifreeze fluid,

or window washer fluid may catch fire.

WARN OTHERS OF SERVICE WORK

•

Unexpected machine movement can cause serious injury.

• Before performing any work on the machine, attach a “Do

Not Operate” tag on the control lever.

This tag is available from your authorized dealer.

501-E01A-0287

SUPPORT MACHINE PROPERLY

•

Never attempt to work on the machine without securing

the machine first.

• Always lower the attachment to the ground before you

work on the machine.

• If you must work on a lifted machine or attachment, se

curely support the machine or attachment. Do not support the machine on cinder blocks, hollow tires, or props

that may crumble under continuous load. Do not work

under a machine that is supported solely by a jack.

519-E01A-0527

STAY CLEAR OF MOVING PARTS

•

Entanglement in moving parts can cause serious injury.

• To prevent accidents, care should be taken to ensure that

hands, feet, clothing, jewelry and hair do not become

entangled when working around rotating parts.

502-E01A-0026

SA-037

SS2045102

SA-527

SA-026

Page 34

SAFETY

S-23

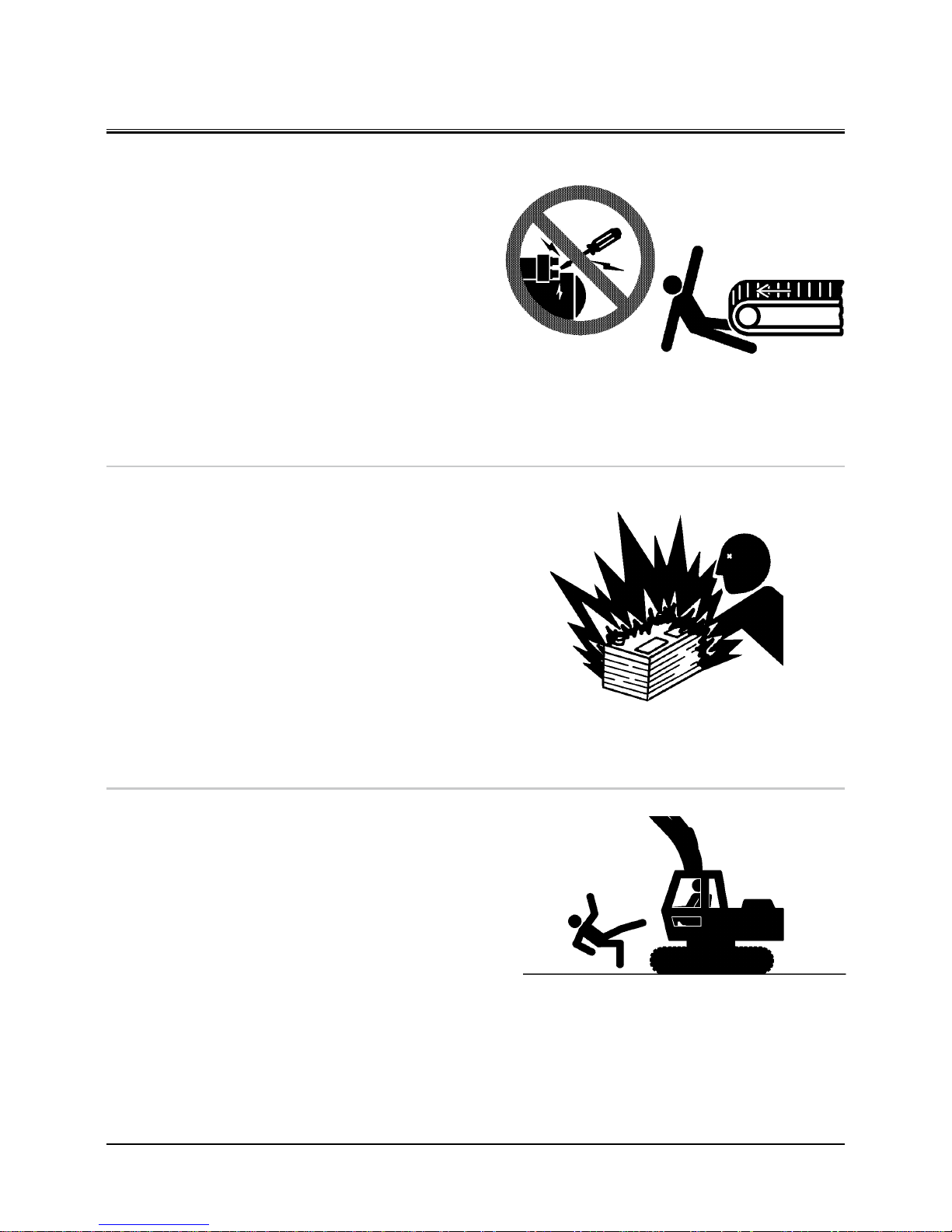

PREVENT PARTS FROM FLYING

•

Grease in the track adjuster is under high pressure.

Failure to follow the precautions below may result in serious

injury, blindness, or death.

• Do not attempt to remove GREASE FITTING or VALVE AS

-

SEMBLY.

• As pieces may fly off, be sure to keep body and face away

from valve.

• Never attempt to disassemble the track adjuster. Inad

vertent disassembling of the track adjuster may cause

the parts such as a spring to fly off, possibly resulting in

severe personal injury or death.

•

Travel reduction gears are under pressure.

• As pieces may fly off, be sure to keep body and face away

from AIR RELEASE PLUG to avoid injury.

• GEAR OIL is hot. Wait for GEAR OIL to cool, then gradually

loosen AIR RELEASE PLUG to release pressure.

503-E01B-0344

STORE ATTACHMENTS SAFELY

•

Stored attachments such as buckets, hydraulic hammers,

and blades can fall and cause serious injury or death.

• Securely store attachments and implements to prevent

falling. Keep children and bystanders away from storage

areas.

504-E01A-0034

SA-344

SA-034

Page 35

SAFETY

S-24

PREVENT BURNS

Hot spraying fluids:

•

After operation, engine coolant is hot and under pressure.