POWER TOOLS

TECHNICAL DATA

AND

SERVICE MANUAL

CORDLESS IMPACT DRIVER

WH 8DH

CORDLESS IMPACT WRENCH

WR 8DH

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LIST Nos. WH 8DH: F832

WR 8DH: F833

Jul. 1999

W

MODEL

WH 8DH

WH 8DH

WR 8DH

WR 8DH

REMARK:

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s)

is(are) used in the place of company name(s) and model name(s) of our

competitor(s). The symbol(s) utilized here is(are) as follows:

Symbol Utilized

Competitor

Company Name

Model Name

C MAKITA

6908DWA

WH 8DH

Page

CONTENTS

[ Business Section ]

1. PRODUCT NAME

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

2. MARKETING OBJECTIVE

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

3. APPLICA TIONS

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

4. SELLING POINTS

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

2

4-1. Selling Point Descriptions

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

4

5. SPECIFICATIONS

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

5

5-1. Specifications

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

5

5-2. Optional Accessories

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

6

6. COMPARISONS WITH SIMILAR PRODUCTS

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

10

6-1. Specification Comparisons (Cordless Impact Driver)

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

10

6-2. Specification Comparisons (Cordless Impact Wrench)

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

11

6-3. Tightening Torque

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

12

6-4 Tightening Speed

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

16

6-5. Number of Screws or Bolts Driven

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

17

7. PRECAUTIONS IN SALES PROMOTION

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

19

7-1. Safety Instructions

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

19

7-2. Tightening Torque Inspection Prior to Operation

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

21

7-3. Tightening Torque V ariation

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

21

7-4. Suggestions and precautions for the Efficient Use of the Charger

••••••••••••••••••••••••••••••••••••••••••••

23

8. OTHER PRECAUTIONS

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

24

[ Service section ]

9. REPAIR GUIDE

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

25

9-1. Precautions in Disassembly and Reassembly

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

25

9-2. Precautions in Disassembly and Reassembly of Battery Charger

•••••••••••••••••••••••••••••••••••••••••••••

30

11. STANDARD REPAIR TIME (UNIT) SCHEDULES

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

31

[ Appendix ]

Assembly Diagram for WH 8DH

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

32

Assembly Diagram for WR 8DH

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

35

--- 1 ---

1. PRODUCT NAME

Hitachi Cordless Impact Driver, Model WH 8DH

Hitachi Cordless Impact Wrench, Model WR 8DH

2. MARKETING OBJECTIVE

The current Hitachi cordless impact driver series has provided excellent on-the-job performance thanks to their

design that produces no recoil force in tightening screws and bolts and also no damage to the screw heads.

The current DC 12V cordless impact driver Model WH 12DH and the cordless impact wrench Model WR 12DH

are well-reputed because they have better tightening performance and longer service life than previous models,

thanks to a replaceable carbon brush motor. Now, the new cordless impact driver Model WH 8DH is brought out

to respond to users' requests for a replaceable carbon brush motor for a DC 9.6 V product. The new cordless

impact wrench Model WR 8DH is also brought out. The Model WR 8DH has higher tightening torque than the

previous Model WH 8D2 and its square drive dimension is 12.7 mm (1/2") for use of commercially-available 1/2"

sockets. The construction of the Model WR 8DH is the same as that of the Model WH 8DH except the anvil (K)

assembly and the hammer case.

3. APPLICA TIONS

•

Tightening/loosening of small screws, tapping screws, wood screws, bolts, nuts, etc.

•

Drilling into wood and various other materials (with use of optional accessory drill chuck adapter).

[Applicable Markets]

•

Wood-product assembly: Tightening/loosening of wood screws, lag bolts, etc.

•

Construction industry: Assembly of scaffolding, roofing, aluminum sashes, fencing, etc.; removal of plastic cones

from concrete forms, mounting/removal of form ties; drilling into the wood frames of concrete forms, etc.

•

Manufacturing industry: Assembly work for automobiles, rolling stock, shipbuilding, agricultural machinery and

tools, industrial machines, steel furniture, etc.

•

Utility industry: Assembly and installation of electric equipment, plumbing facilities, air conditioning (duct

assembly, etc.), sanitary fixtures and various other facilities.

•

Service industry: General repair work; installation of advertising signs, automobile repair, assembly of garages

and carports storage sheds, etc.

•

Various other assembly, construction or repair facilities.

--- 2 ---

4. SELLING POINTS

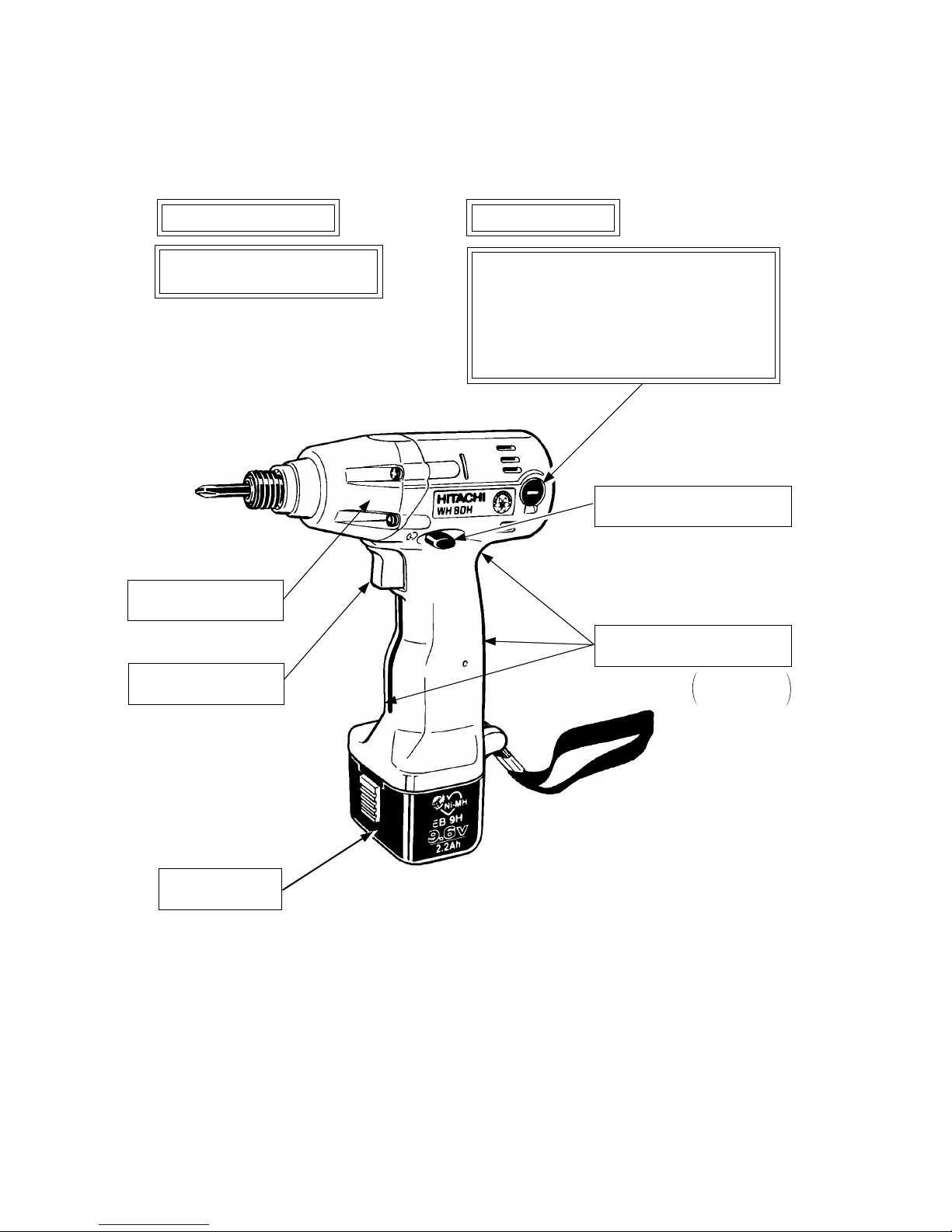

(1) Cordless Impact Driver: WH 8DH

Faster screw fastening

Higher fastening torque

88.2 N•m (900 kgf•cm, 65 ft-lbs)

Improved motor performance

•

Replaceable carbon brushes for longer

motor life

•

High-power fan-cooled DC magnet motor

•

Higher heat-resistance

•

The same torque and speed in both

forward and reverse modes

Longer service life

DC 9.6 V battery

EB 9B or EB 9H

Heavy-duty aluminum

hammer case

Variable speed switch

with electric brake

Easy-to-use forward/reverse

changeover pushing button

Ergonomically designed

handle for a comfortable grip

Grip inserts

front and rear

--- 3 ---

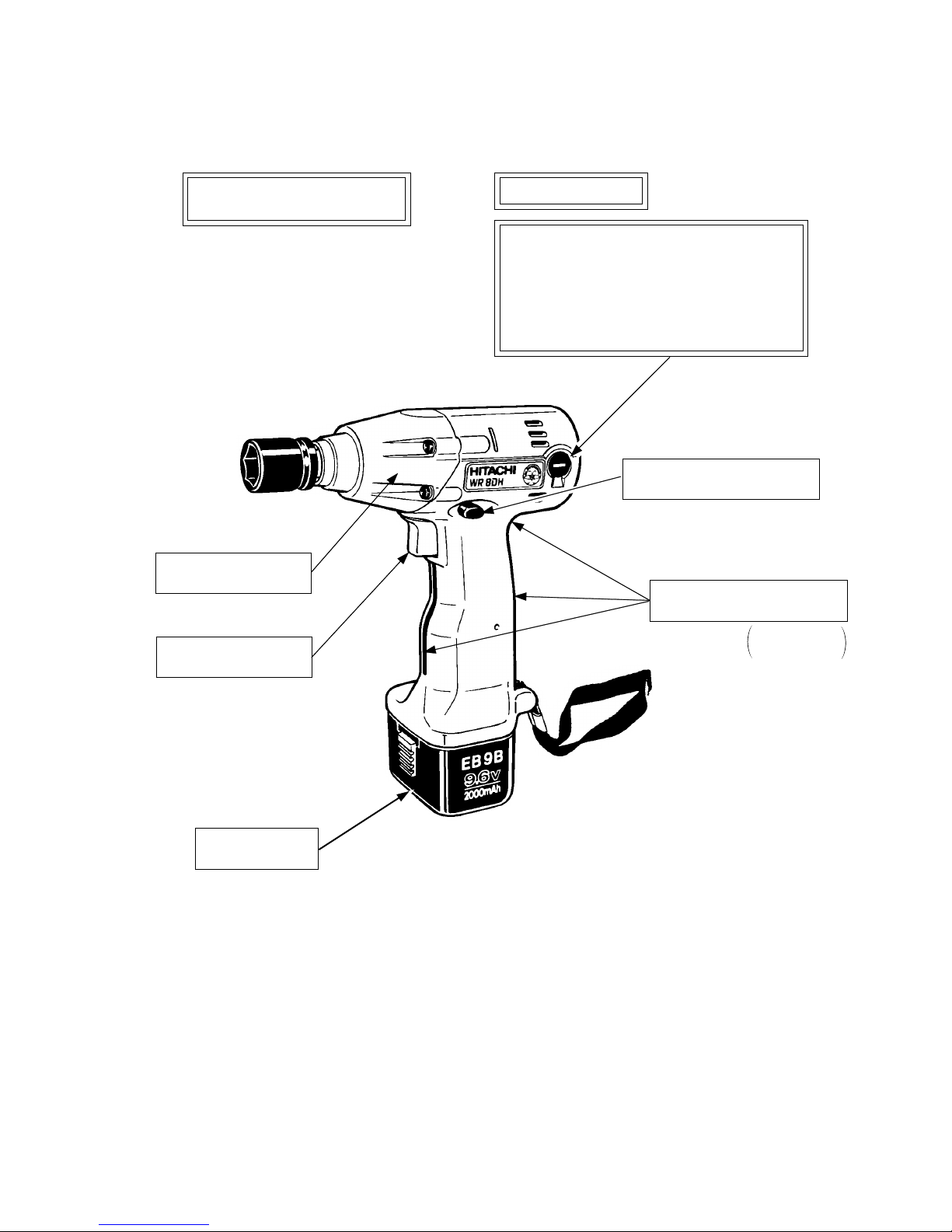

(2) Cordless Impact Wrench: WR 8DH

Higher fastening torque

98 N•m (1000 kgf•cm, 72 ft-lbs)

Improved motor performance

•

Replaceable carbon brushes for longer

motor life

•

High-power fan-cooled DC magnet motor

•

Higher heat-resistance

•

The same torque and speed in both

forward and reverse modes

Longer service life

DC 9.6 V battery

EB 9B or EB 9H

Heavy-duty aluminum

hammer case

Variable speed switch

with electric brake

Easy-to-use forward/reverse

changeover pushing button

Ergonomically designed

handle for a comfortable grip

[12.7 mm (1/2") Square drive]

Grip inserts

front and rear

--- 4 ---

4-1. Selling Point Descriptions

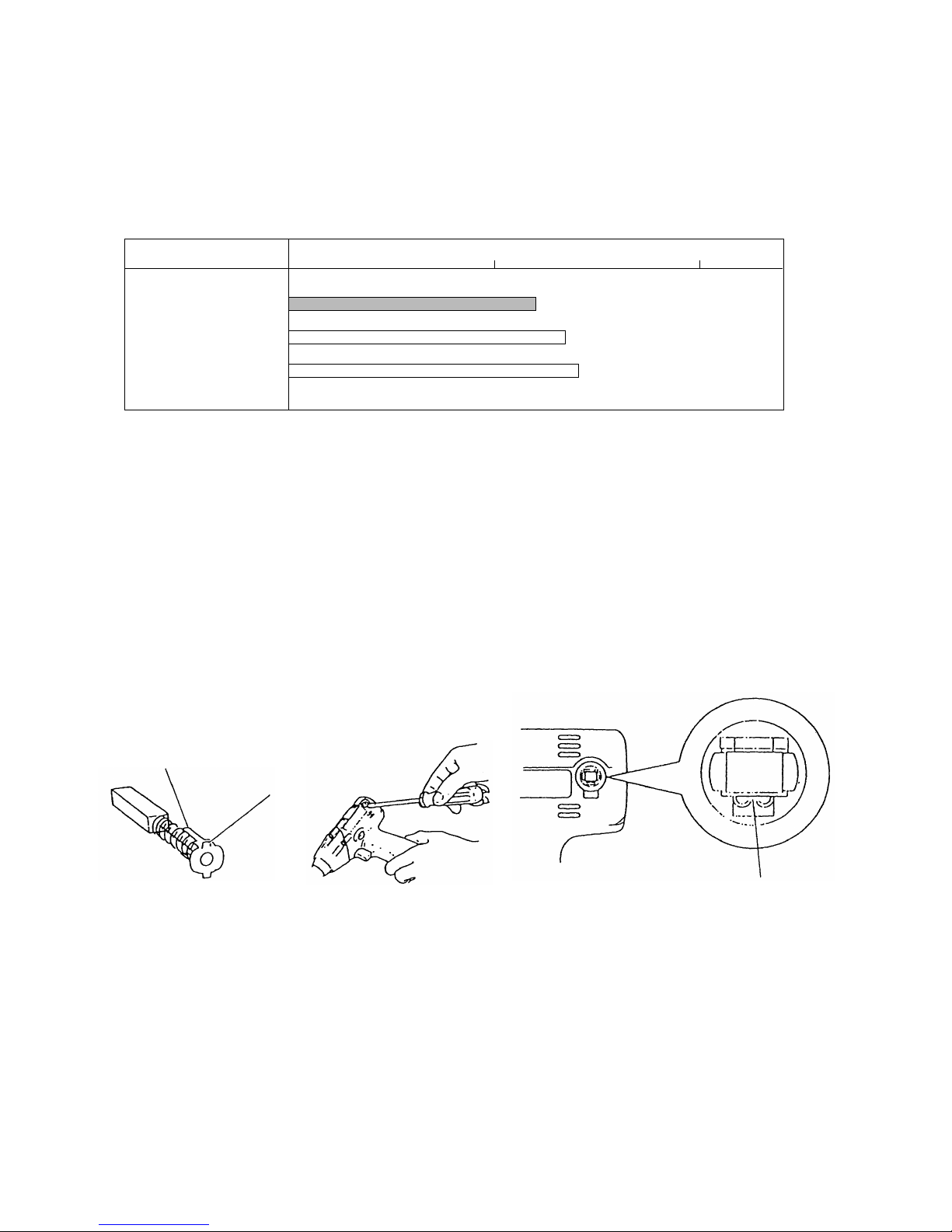

(1) Faster tightening speed

The Model WH 8DH provides faster driving speed than the previous model thanks to the high-power motor

and the higher moment of inertia of the hammer.

Tightening time comparison of the Model WH 8DH with the previous Model WH 8DA2 and maker C's model

are shown below. (Wood screw 4.2 mm dia. x 90 mm length, hemlock spruce)

HITACHI WH 8DH

HITACHI WH 8DA2

C

5.9 sec.

Model

510

sec.

6.5 sec.

6.8 sec.

(2) Improved motor performance

The Models WH 8DH and WR 8DH have high power thanks to the fan cooled DC magnet motor. They have

better heat-resistance because the built-in fan enhances cooling efficiency. Their motors have replaceable

carbon brushes, and the service life of the carbon brush has been extended by increasing its size by about 70

% (volume) compared to our previous model.

(3) Construction of replaceable carbon brushes

The carbon brush can be easily removed from the motor with a flat-blade screwdriver as shown in Fig. 2 and

can also be easily and securely mounted to the motor by hanging the claw of the carbon brush on the

connecting portion on the outside of the brush tube.

Claw of

carbon brush

Collar of

carbon brush

Connecting portion at the

outside of brush tube

Fig. 1 Fig. 2 Fig. 3

(4) Safe handle shape

Compared with the previous WH 8DA2, the housing of the Model WH 8DH produces no clearance caused by

vibration because front and rear grip inserts [part names: grip (R) and grip (F), made of rubber] are provided at

the juncture of the handle, and the housing is secured with two screws at the center of the handle to prevent

the operator's hand from being pinched. Furthermore, the rear portion of the housing is shaped upward so not

to interfere with the base of the operator's thumb.

--- 5 ---

5. SPECIFICATIONS

5-1. Specifications

Model

Cordless Impact Driver

WH 8DH

Capacity

Item

Cordless Impact Wrench

WR 8DH

Small screw M4 --- M8 (5/32" --- 5/16")*

1

Ordinary bolt M5 --- M12 (3/16" --- 15/32")

Ordinary bolt M6 --- M14 (1/4" --- 9/16")

High-strength bolt M6 --- M10 (1/4" --- 3/8")

Tightening torque

88.2 N•m (900 kgf•cm, 65 ft-lbs)*

2

98 N•m (1000 kgf•cm, 72 ft-lbs)

*

3

Tip condition

6.35 mm (1/4") Bit holder

12.7 mm (1/2") Square drive

Type of motor

Fan cooled DC magnet motor

Enclosure

Main body: Polyamide resin

••••••

Housing

Aluminum alloy die casting

••••••

Hammer case

Storage battery: ABS resign (black)

Charger: ABS resin (black)

Type of switch

Trigger switch with forward / reverse changeover pushing button (with brake and variable)

Handle configuration

T-type

No-load rotational speed

0 --- 2,200 /min

Impact rate

0 --- 2,900 /min

Main body

1.6 kg (3.5 lbs) (Includes battery)*

4

Battery

0.52 kg (1.1 lbs)

Overall length x height

176 mm (6-15/16") x 220 mm (8-21/32")

Center height

26 mm (1-1/64")

Battery (Type EB 9B)

Sealed cylindrical nickel-cadmium batteries

Nominal voltage: DC 9.6V

Nominal life: Charging/discharging approximately 1,000 cycles (in case of Model

UC 14YF2)

Nominal capacity: 2.0 Ah

180 mm (7-1/8") x 220 mm (8-21/32")

Battery (Type EB 9H)

Sealed cylindrical nickel-metal hydride batteries

Nominal voltage: DC 9.6V

Nominal life: Charging/discharging approximately 500 cycles (in case of Model

UC 14YF2)

Nominal capacity: 2.2 Ah

*1: In the case of tapping screws and wood screws, a minimum of M3 (1/8") is possible.

*

2

: This torque is based on tightening an M12 (15/32") bolt (strength grade: 12.9) for 3 seconds with a hexagonal socket.

*

3

: This torque is based on tightening an M12 (15/32") bolt (strength grade: 12.9) for 3 seconds with a hexagonal socket.

*

4

: Main body does not include accessory tools (hexagonal bit, etc.).

Charger (UC 14YF2)

Charger power source: single-phase AC, 50/60 Hz

Voltage: Depending on the order specification

Power input: 44 W

Charging system: Constant current charge with full wave phase control

Overcharge protection system: (1) Battery voltage detection ( 2V system)

(2) Battery surface temperature detection

(thermostat or thermistor)

(3) 120 minute timer

Output voltage: 7.2 V --- 14.4 V

Output current: 1.9 A

Charging time: Approx. 60 minutes (for B-type storage battery at 20 ˚C)

Approx. 70 minutes (for H-type storage battery at 20 ˚C)

Product weight: 1.3 kg

Operable ambient temperature range: 0 ˚C --- 40 ˚C

The maximum allowable temperature of the EB 9B type battery is 60 ˚C and the

EB 9H type battery is 45 ˚C.

Weight

--- 6 ---

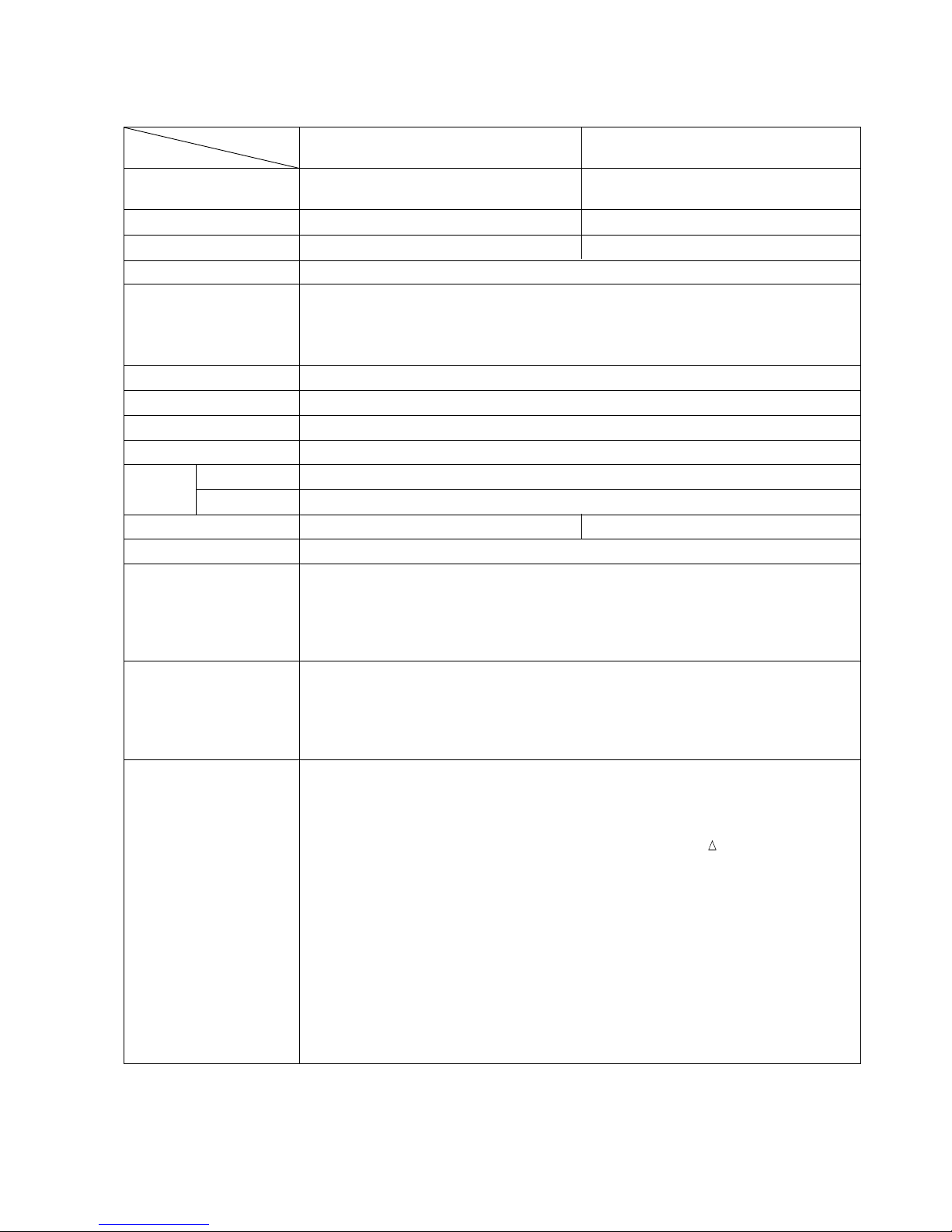

Prior to charging

During charging

Charging completed

Charging not

possible

High battery

temperature

Blinks

Lit

Blinks

Flickers

Lit

0.5 sec ON, 0.5 sec OFF

Stays ON constantly

0.5 sec ON, 0.5 sec OFF

0.1 sec ON, 0.1 sec OFF

Stays ON constantly

Pilot lamp indications (UC 14YF2)

Red pilot lamp

remains lit of flashes

Green pilot lamp is lit

Storage battery or charger

is faulty.

Charging not possible

because storage battery

temperature is too high.

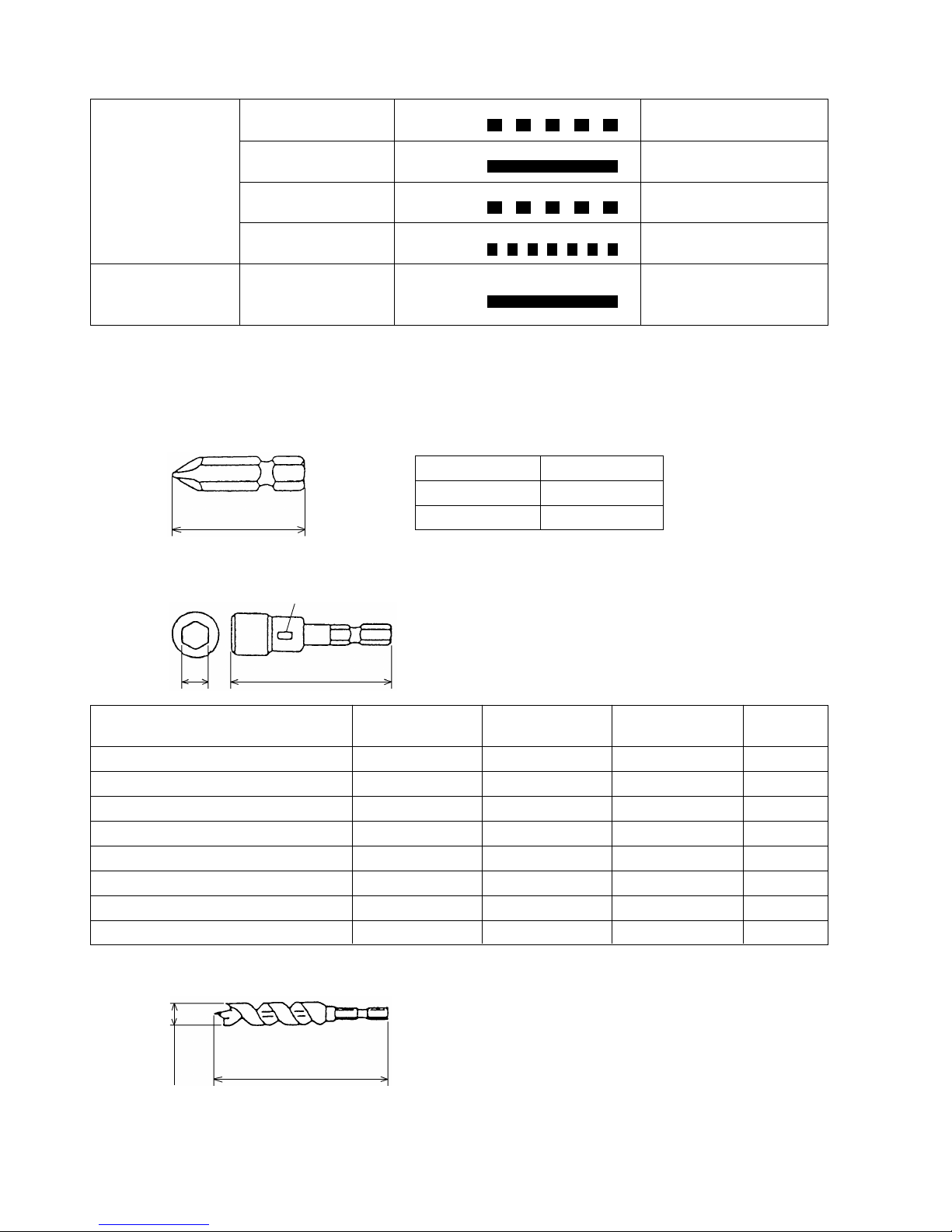

5-2. Optional Accessories

(1) Optional accessories for the Model WH 8DH

•

Plus driver bit

50 mm (2")

Bit No.

No. 2

No. 3

Code No.

992671

992672

•

Hexagon socket

L

B

Stamped figures

996177 8 (5/16")65 (2-9/16") 8

Stamped figures

5 mm Hexagon socket

Part Name

L

(mm)

B

(mm)

Code No.

98532910 (3/8")65 (2-9/16")106 mm Hexagon socket

99617812 (15/32")65 (2-9/16")125/16" Hexagon socket

99617913 (1/2")65 (2-9/16")138 mm Hexagon socket

99618014 (9/16")65 (2-9/16")1410 mm Hexagon socket (small type)

99618116 (5/8")65 (2-9/16")1610 mm Hexagon socket

99618217 (21/32")65 (2-9/16")1710 mm Hexagon socket

99619721 (53/64")166 (6-17/32")211/2" Hexagon long socket

•

Woodworking drill bit (Code No. 959183)

14 mm dia.

(35/64")

83 mm (3-17/64")

--- 7 ---

•

Drill chuck adaptor set (Code No. 996195)

The drill chuck adaptor set permits mounting of various types of locally-available drill bits for a variety of drilling

operations.

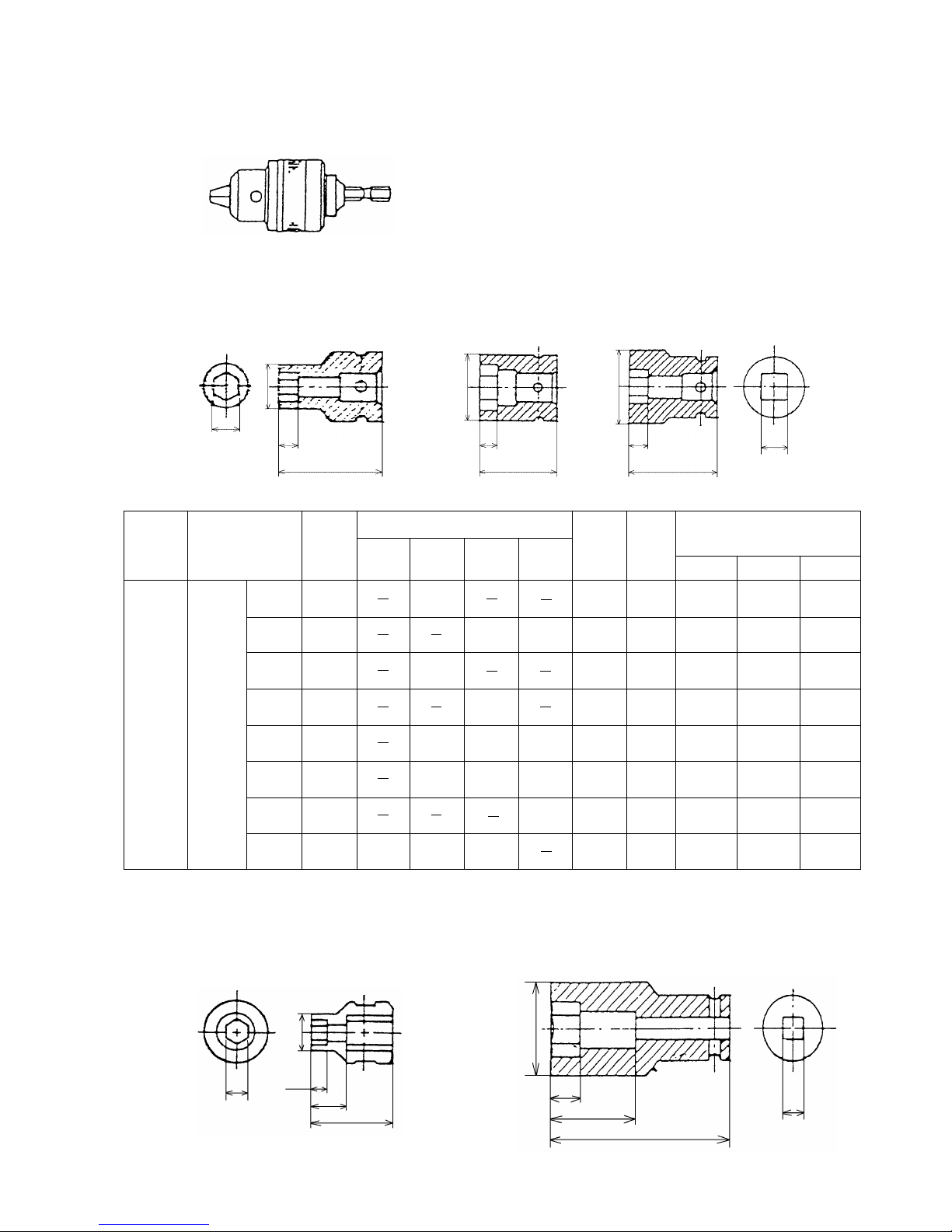

(2) Optional accessories for the Model WR 8DH

•

Each dimension and applicable bolt for each hexagon socket

Shape B

Shape C Shape D

H

D

1

L1

L

D

1

L1

L

D

1

L1

L

Sq

18

(23/32")

20

(25/32")

25

(1")

25

(1")

28

(1-3/32")

28

(1-3/32")

32

(1-1/4")

35

(1-3/8")

8

(5/16")

8

(5/16")

9

(11/32")

9

(11/32")

8

(5/16")

9

(11/32")

10

(3/8")

14

(9/16")

40

(1-9/16")

40

(1-9/16")

40

(1-9/16")

40

(1-9/16")

32

(1-1/4")

34

(1-11/32")

36

(1-13/32")

40

(1-9/16")

B

B

B

B

C

C

D

D

10

(3/8")

12

(15/32")

13

(1/2")

14

(9/16")

17

(21/32")

19

(23/32")

21

(53/64")

22

(7/8")

W 5/16"

W 3/8"

W 7/16"

W 1/2"

M 8

(5/16")

M 10

(3/8")

M 12

(15/32")

M 14

(9/16")

M 16

(5/8")

M 6

(1/4")

M 8

(5/16")

M 10

(3/8")

M 12

(15/32")

M 14

(9/16")

M 12

(15/32")

944291

873632

873539

873540

873536

873624

873626

873627

10 mm

12 mm

13 mm

14 mm

17 mm

19 mm

21 mm

22 mm

Hexagon

socket

12.7 mm

(1/2")

Square

drive

dimension

Sq

Part Name

Code No.

Nominal diameter of applicable bolts

Dihedral

width

H (mm)

Shape

Socket primary dimensions

(mm)

ISO

(high-strength)

ISO

(ordinary)

ISO

(small type)

Inch

screw L

L

1 D1

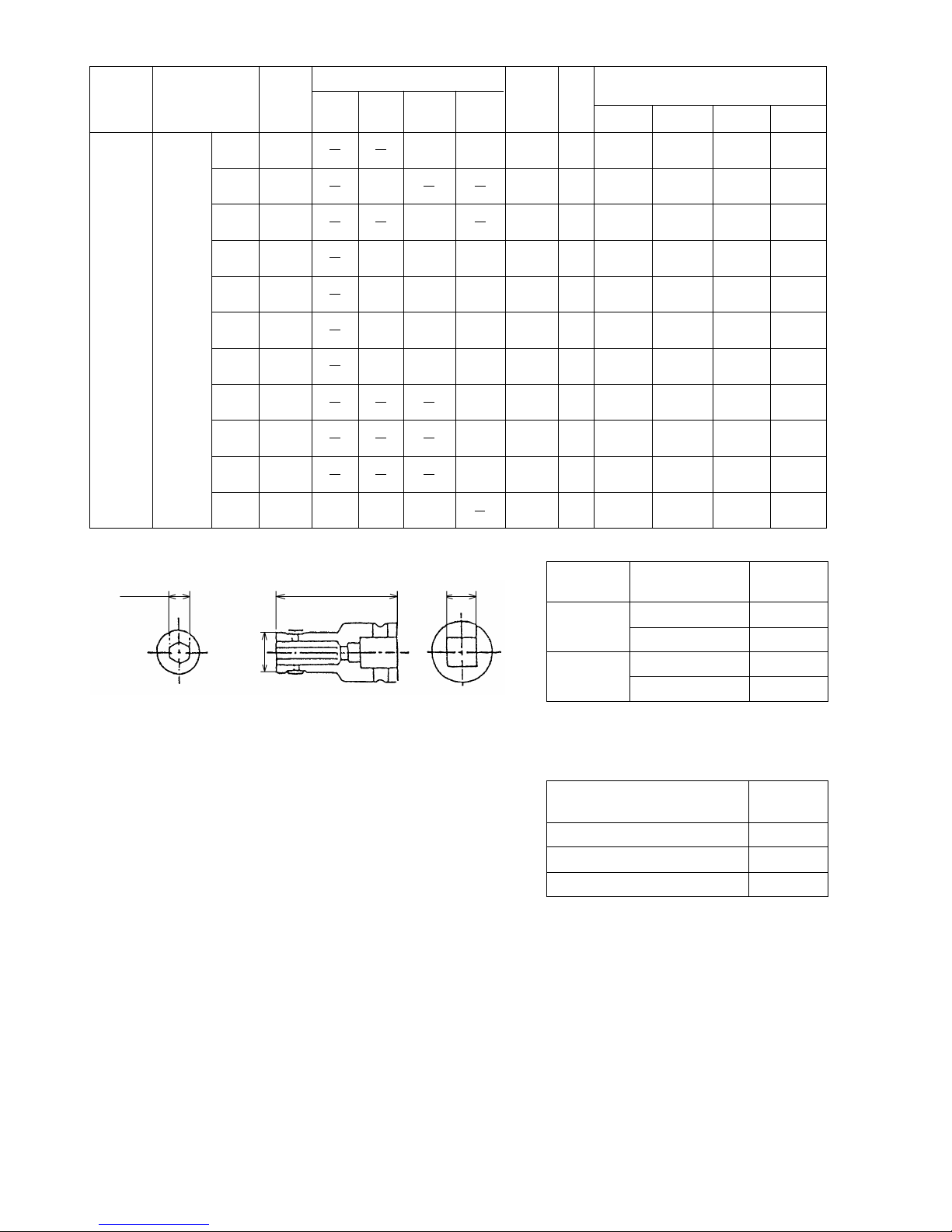

•

Each dimension and applicable bolt for each long socket

Shape B Shape D

H

D

1

(dia.)

L1

L

L1

L

Sq

L

2

D

1

(dia.)

L2

--- 8 ---

20

(25/32")

21.5

(53/64")

22

(7/8")

25

(1")

25

(1")

28

(1-3/32")

28

(1-3/32")

31

(1-7/32")

31

(1-7/32")

31

(1-7/32")

32.5

(1-9/32")

20

(25/32")

20

(25/32")

20

(25/32")

24

(15/16")

24

(15/16")

24

(15/16")

24

(15/16")

24

(15/16")

24

(15/16")

24

(15/16")

24

(15/16")

52

(2-3/64")

52

(2-3/64")

52

(2-3/64")

52

(2-3/64")

75

(2-15/16")

52

(2-3/64")

75

(2-15/16")

52

(2-3/64")

75

(2-15/16")

125

(2-15/16")

52

(2-3/64")

B

B

B

B

B

B

B

D

D

D

D

12

(15/32")

13

(1/2")

14

(9/16")

17

(21/32")

17

(21/32")

19

(23/32")

19

(23/32")

21

(53/64")

21

(53/64")

21

(53/64")

22

(7/8")

W 5/16"

W 3/8"

W 3/8"

W 7/16"

W 7/16"

W 1/2"

W 1/2"

W 1/2"

M 8

(5/16")

M 10

(3/8")

M 12

(15/32")

M 12

(15/32")

M 14

(9/16")

M 14

(9/16")

M 16

(5/8")

M 8

(5/16")

M 10

(3/8")

M 10

(3/8")

M 12

(15/32")

M 12

(15/32")

M 14

(9/16")

M 12

(15/32")

955138

955139

955140

955141

955149

955142

955150

955143

955151

991480

955144

12 mm

13 mm

14 mm

17 mm

17 mm

19 mm

19 mm

21 mm

21 mm

21 mm

22 mm

Long

socket

12.7 mm

(1/2")

Square

drive

dimension

Sq

Part Name

Code

No.

Nominal diameter of applicable bolts

Dihedral

width

H (mm)

Shape

Socket primary dimensions (mm)

ISO

(high-strength)

ISO

(ordinary)

ISO

(small type)

Inch

screw

L

L

1

D1

•

Bit adaptor (Code No. 991476)

6.35 mm (1/4")

45 mm (1-25/32")

13.5 mm dia.

(17/32")

12.7 mm (1/2")

34

(1-11/32")

34

(1-11/32")

34

(1-11/32")

34

(1-11/32")

57

(2-1/4")

34

(1-11/32")

57

(2-1/4")

34

(1-11/32")

57

(2-1/4")

107

(4-7/32")

34

(1-11/32")

L2

Part name

Overall length

(mm)

Code No.

Plus hd.

driver bit

No.2

Plus hds.

driver bit

No.3

45 (1-25/32") 955229

70 (2-3/4") 955654

45 (1-25/32") 955230

70 (2-3/4") 955655

•

Extension bar [Overall length 100 mm (3-15/16") ] (Code No. 873633)

•

Universal joint (Code No. 992610)

•

Socket ass'y for duct

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Dihedral width of

applicable bolts

Code No.

993658

13 (1/2") 992613

14 (9/16") 992615

12 (15/32")

•

EW-14R corner attachment (Code No. 9329-9001)

--- 9 ---

(3) Optional accessories for the Models WH 8DH and WR 8DH

•

Holster (Code No. 307824)

Use the holster to hold the unit during its operation.

Carefully read the warnings attached to the holster for safe use.

•

Hook (Code No. 308090)

Use the hook to hold the unit during its operation.

Carefully read the instructions that come with the hook to learn how to use it.

--- 10 ---

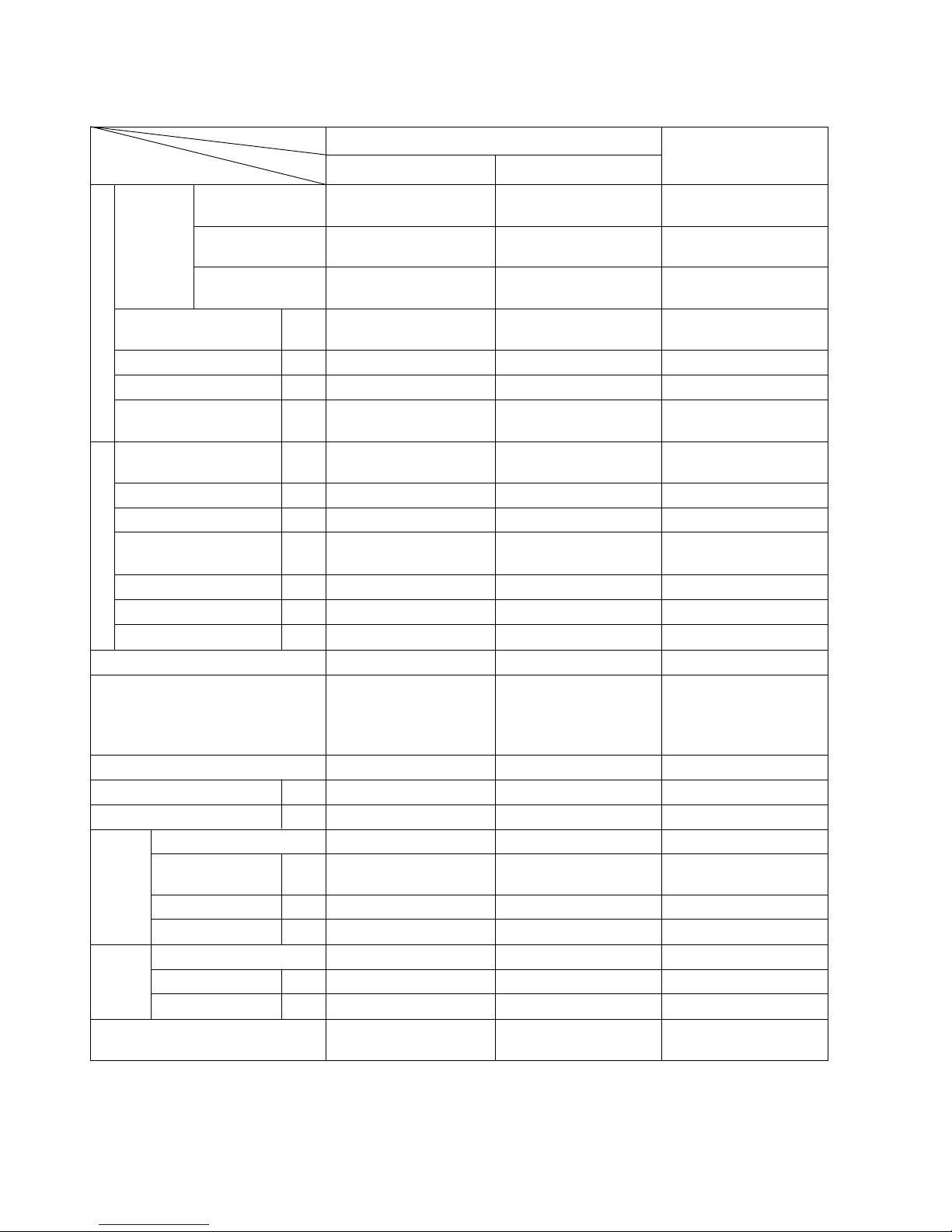

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. Specification Comparisons (Cordless Impact Driver)

M 4 --- M 8

(5/32" --- 5/16")

HITACHI

WH 8DH WH 8DA2

C

Maker

Model

Item

M 5 --- M 8

(3/16" --- 5/16")

M 4 --- M 8

(5/32" --- 5/16")

Catalog specifications

Capacity

Small screw

M 5 --- M 12

(3/16" --- 15/32")

M 5 --- M 12

(3/16" --- 15/32")

M 5 --- M 12

(3/16" --- 15/32")

Ordinary bolt

M 5 --- M 10

(3/16" --- 3/8")

M 5 --- M 10

(3/16" --- 3/8")

M 5 --- M 10

(3/16" --- 3/8")

High-strength bolt

88.2

(900 kgf•cm, 65 ft-lbs)*

2

78.4

(800 kgf•cm, 58 ft-lbs)*

3

78.4

(800 kgf•cm, 58 ft-lbs)*

3

Max. tightening torque N•m

0 --- 2,200

2,200 0 --- 2,200No-load rotation speed

/min

0 --- 2,900

2,800 0 --- 2,800Impact rate

/min

1.6 (3.5 lbs) 1.4 (3.1 lbs) 1.4 (3.1 lbs)Main body weight

kg

91.1

(930 kgf•cm, 67.3 ft-lbs)*

2

83.8

(850 kgf•cm, 61 ft-lbs)*

3

85.8

(875 kgf•cm, 63.3 ft-lbs)*

3

Max. tightening torque

N•m

Measured figures

0 --- 2,230

2,150 0 --- 2,470No-load rotation speed

/min

0 --- 2,790

2,700 0 --- 2,680Impact rate

/min

176 x 220

(6-15/16" x 8-21/32")

175 x 218

(6-7/8" x 8-19/32")

Overall length x height

mm

171 x 232

(6-47/64" x 9-9/64")

26 (1-1/64")

26 (1-1/64") 26 (1-1/64")Center height

mm

1.6 (3.5 lbs)

1.47 (3.2 lbs) 1.5 (3.3 lbs)Main body weight

kg

67

66 68

No-load sound pressure level

dB(A)

Driver chuck

Driver chuck Driver chuck

Tool tip mounting system

Trigger switch with

forward / reverse

changeover pushing

button with brake and

variable

Type of switch

Trigger switch with

forward / reverse

changeover pushing

button with brake

Variable speed switch with

forward/reverse

changeover lever

DC magnet

DC magnet DC magnet

Type of motor

9.6

9.6 9.6

Voltage

20

20 20

Current

EB 9B or EB 9H

EB 9 9122

Battery

V

A

Type

EB 9B: 2.0

EB 9H: 2.2

1.3 2.0

Nominal capacity

Ah

9.6

9.6 9.6

Nominal voltage

V

0 --- 40

5 --- 40 ------

Ambient temperature

˚C

UC 14YF2

UC 12Y DC1411

Model

44

51 ------

Power input capacity

VA

7.2 --- 14.4

2.4 --- 12 7.2 --- 14.4

Recharging voltage

V

•

Plastic tool case

•

Charger (UC 14YF2)

•

Plastic tool case

•

Charger (UC 12Y)

•

Plastic tool case

•

Charger (DC1411)

Standard accessories

Charger

*1: In the case of tapping screws and wood screws, a minimum of M3 (1/8") is possible.

*

2

: Max. tightening torque is based on tightening an M12 (5/32") bolt (strength grade: 12.9) for 3 seconds with a hexagon

socket.

*3: Max. tightening torque is based on tightening an M10 (3/8") bolt (strength grade: 12.9) for 3 seconds with a hexagon socket.

*

4

: Main body weight does not include accessory tools (hexagon bit, etc.).

*

1

*

4

*

2

*

4

--- 11 ---

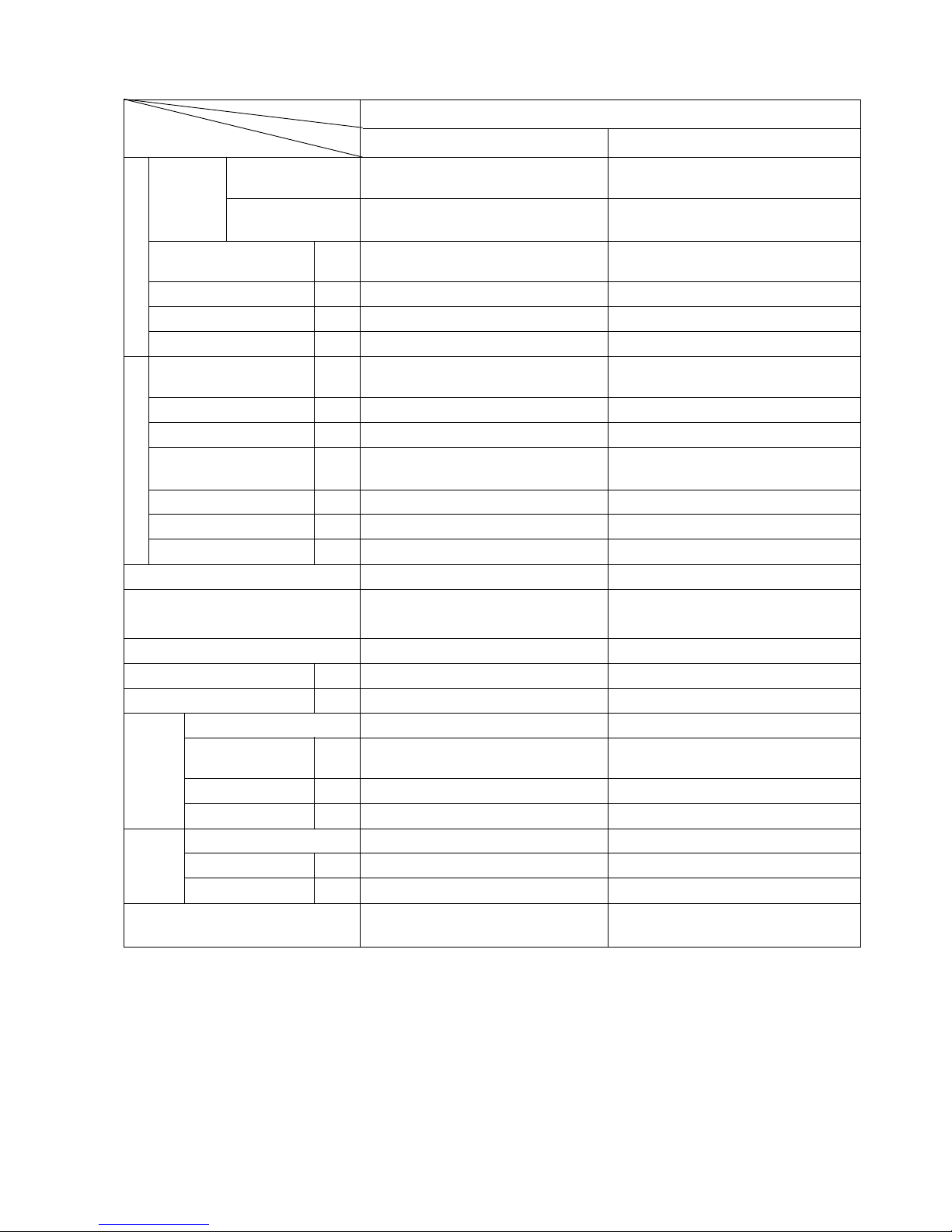

6-2. Specification Comparisons (Cordless Impact Wrench)

HITACHI

WR 8DH

Maker

Model

Item

Catalog specifications

Capacity

M 6 --- M 14

(1/4" --- 9/16")

Ordinary bolt

M 6 --- M 10

(1/4" --- 3/8")

High-strength bolt

98

(1,000 kgf•cm, 72 ft-lbs)

Max. tightening torque

N•m

0 --- 2,200

No-load rotation speed

/min

0 --- 2,900

Impact rate

/min

1.6 (3.5 lbs)

Main body weight

kg

100

(1,010 kgf•cm, 73.1 ft-lbs)

Max. tightening torque

N•m

Measured figures

0 --- 2,230

No-load rotation speed

/min

0 --- 2,790

Impact rate

/min

180 x 220

(7-1/8" x 8-21/32")

Overall length x height

mm

26 (1-1/64")

Center height

mm

1.6 (3.5 lbs)

Main body weight

kg

67

No-load sound pressure level

dB(A)

Pin/O-ring or plunger

Tool tip mounting system

Trigger switch with forward/reverse

changeover pushing button with

brake and variable

Type of switch

DC magnet

Type of motor

9.6

Voltage

20

Current

EB 9B or EB 9H

Battery

V

A

Type

EB 9B: 2.0

EB 9H: 2.2

Nominal capacity

Ah

9.6

Nominal voltage

V

0 --- 40

Ambient temperature

˚C

UC 14YF2

Model

44

Power input capacity

VA

7.2 --- 14.4

Recharging voltage

V

•

Plastic tool case

•

Charger (UC 14YF2)

Standard accessories

Charger

*1: Max. tightening torque is based on tightening an M12 (5/32") bolt (strength grade: 12.9) for 3 seconds with a hexagon

socket.

*2: Main body weight does not include accessory tools (hexagon bit, etc.).

*

1

*

2

*

1

*

2

WH 8D2

M 5 --- M 12

(3/16" --- 15/32")

M 5 --- M 10

(3/16" --- 3/8")

88.2

(900 kgf•cm, 65.1 ft-lbs)

2,200

2,800

1.4 (3.1 lbs)

93.1

(950 kgf•cm, 68.7 ft-lbs)

2,150

2,700

171 x 218

(6-23/32" x 8-19/32")

26 (1-1/64")

1.46 (3.2 lbs)

66

Pin/O-ring or plunger

Trigger switch with forward /

reverse changeover pushing button

with brake

DC magnet

9.6

20

EB 9

1.2

9.6

5 --- 40

UC 12Y

51

2.4 --- 12

•

Charger (UC 12Y)

--- 12 ---

6-3. Tightening Torque

6-3-1. Tightening Torque Characteristic Comparisons

The Model WH 8DH and WR 8DH provide greater tightening torque than the previous models thanks to the high

power motor and the higher moment of inertia of the hammer. The tightening torque does not drop even when

loosening bolts because the motor runs at the same torque and speed in both the forward and reverse directions.

Tightening torque comparisons of Models WH 8DH and WR 8DH with previous models are shown in Figs. 4-1 and

4-2. It should be noted that M12 (15/32") and M10 (3/8") strength grade 12.9 high-strength bolts were utilized in

the tests to ensure that the bolts were not stripped or distorted, even though such bolts are actually beyond the

recommended maximum capacity of these models. Accordingly, the data in the figures below are intended for

reference purposes only.

(1) Impact Driver

Fig. 4-1

Fig. 4-2

Test conditions

Bolt: M12 x 45 mm (15/32" x 1-3/4")

M10 x 30 (3/8" x 1-3/16")

(strength grade: 12.9)

Steel plate: Mild steel

M12 (15/32") Thickness = 25 mm (1")

M10 (3/8") Thickness = 10 mm (3/8")

Accessory tool: Hexagon socket ass'y

* An M10 x 30 high-strength bolts are tested unless

otherwise specified.

WH 8DH (M12 x 45)

WH 8DH*

WH 8DA2

200

(19.6 N

•

m,

14 ft-lbs)

0123

400

(39.2 N

•

m,

29 ft-lbs)

600

(58.8 N

•

m,

43 ft-lbs)

800

(78.4 N

•

m,

58 ft-lbs)

1000

(98 N

•

m,

72 ft-lbs)

(kgf•cm)

(sec.)

Tightening time

Tightening torque

C (forward)

[Tightening torque

in reverse rotation

is about 90 % of

that in forward

rotation.]

(2) Impact Wrench

WR 8DH

WH 8D2

200

(19.6 N

•

m,

14 ft-lbs)

0123

400

(39.2 N

•

m,

29 ft-lbs)

600

(58.8 N

•

m,

43 ft-lbs)

800

(78.4 N

•

m,

58 ft-lbs)

1000

(98 N

•

m,

72 ft-lbs)

(kgf•cm)

(sec.)

Tightening time

Tightening torque

Test conditions

Bolt: M12 x 45 mm (15/32" x 1-3/4")

(strength grade: 12.9)

Steel plate: Mild steel

M12 (15/32") Thickness = 25 mm (1")

Accessory tool: Hexagon socket ass'y

--- 13 ---

6-3-2. Screw Diameter and Appropriate Tightening Torque

Generally speaking, the appropriate tightening torque for a screw can be determined by the strength grade of the

screw and the material tightened. Tables 1 and 2, and Fig. 5 below list data relative to the strength grade of

various screws and the appropriate tightening torque. For further reference, appropriate tightening torque is

calculated with the following formula. Study and use this formula for accurate selection of tightening torque.

T=k•d•p

T: Appropriate tightening torque (kgf•cm)

k: Torque coefficient (0.17)

d: Nominal diameter for the screw (mm)

p: Recommended axial tightening force to be applied to the screw (kgf)

p=rated axial stress (kgf/cm2) x 0.8 x effective sectional area of the thread (mm2)

•

Strength grade and rated axial stress of threads

Strength grade

Rated axial stress (kgf/mm2)

Material

Heat treatment

4.8 6.8 8.8 12.9

29.1 43.7 58.2 95

Mild steel Alloy steel including Ni, Mn, Cr, etc.

None Processed-hard material

•

Diameter and effective sectional areas of threads

Kind of thread (x pitch)

Effective sectional area of

thread (mm2)

M5 x 0.8 mm

(3/16")

14.2

M6 x 1 mm

(1/4")

20.1

M8 x 1.25 mm

(5/16")

36.6

M10 x 1.5 mm

(3/18")

58.0

M12 x 1.75 mm

(15/32")

84.3

M14 x 2 mm

(9/16")

115

•

Thread diameter and appropriate tightening torque

Fig. 5

Strength grade 12.9

(high-strength bolt)

Strength grade 8.8

(high-strength bolt)

Strength grade 6.8

(ordinary bolt)

Strength grade 4.8

(ordinary bolt)

005

(3/16")6(1/4")

8

(5/16")

10

(3/8")

12

(15/32")

14

(9/16")

mm

200

(19.6 N•m, 14 ft-lbs)

400

(39.2 N

•

m, 29 ft-lbs)

600

(58.8 N

•

m, 43 ft-lbs)

800

(78.4 N•m, 58 ft-lbs)

1000

(98 N•m, 72 ft-lbs)

1200

(117.6 N

•

m, 86 ft-lbs)

(kgf•cm)

Thread diameter

Appropriate tightening torque

Table 1

Table 2

--- 14 ---

200

(19.6 N•m,14 ft-lbs)

0123

400

(39.2 N

•

m,29 ft-lbs)

600

(58.8 N

•

m,43 ft-lbs)

800

(78.4 N

•

m,58 ft-lbs)

1000

(98 N

•

m,72 ft-lbs)

(kgf•cm)

Tightening time

[steel plate thickness:

t=3/8" (10 mm)]

M8 x 30 mm

(5/16" x 1-3/6")

Tightening torque

High-strenge bolt

Ordinary bolt

200

(19.6 N•m,14 ft-lbs)

0123

400

(39.2 N

•

m,29 ft-lbs)

600

(58.8 N

•

m,43 ft-lbs)

800

(78.4 N

•

m,58 ft-lbs)

1000

(98 N

•

m,72 ft-lbs)

(kgf•cm)

Tightening time

[steel plate thickness:

t=3/8" (10 mm)]

M10 x 30 mm

(8/8" x 1-3/6")

Tightening torque

High-strenge bolt

Ordinary bolt

200

(19.6 N•m,14 ft-lbs)

0123

400

(39.2 N

•

m,29 ft-lbs)

600

(58.8 N

•

m,43 ft-lbs)

800

(78.4 N

•

m,58 ft-lbs)

1000

(98 N

•

m,72 ft-lbs)

1200

(117.6 N

•

m,86 ft-lbs)

(kgf•cm)

Tightening time

[steel plate thickness:

t=1" (25 mm)]

M12 x 45 mm

(15/32" x 1-3/4")

Tightening torque

High-strenge bolt

Ordinary bolt

(sec.)

(sec.)

(sec.)

6-3-3. Bolt Tightening Torque Characteristics

Figs. 6-1 and 6-2 show relationships between time and tightening torque for individual bolt types and sizes. While

the data are useful for handy reference, actual tightening torque will vary depending on tightening conditions and

other variables. For details, please refer to Para. 7-3, Tightening Torque Variation.

(Note)

•

The term "tightening time" indicates the impact time after the lower surface of the bolt has come in contact with

the material into which it is being tightened.

•

In the tightening conditions shown in Figs. 6-1 and 6-2, the screws are being tightened directly into a steel

plate; accordingly, the torque goes up very abruptly in comparison with ordinary bolt tightening conditions.

•

Model WH 8DH

Fig. 6-1

Bolt

Nut

Steel plate

thickness: t

* The following bolts were utilized:

Ordinary bolt; strength grade 4.8

High-strength bolt; strengh grade

12.9

Strength grade is read as follows:

4.8

Yield point or durable force:

(45,500 psi)

Tensile strength of the bolt:

(56,900 psi)

--- 15 ---

200

(19.6 N•m,14 ft-lbs)

0123

400

(39.2 N

•

m,29 ft-lbs)

600

(58.8 N•m,43 ft-lbs)

800

(78.4 N

•

m,58 ft-lbs)

1000

(98 N

•

m,72 ft-lbs)

1200

(117.6 N•m,86 ft-lbs)

(kgf•cm)

Tightening time

[steel plate thickness:

t=3/8" (10 mm)]

M8 x 30 mm

(5/16" x 1-3/6")

Tightening torque

High-strenge bolt

Ordinary bolt

200

(19.6 N•m,14 ft-lbs)

0123

400

(39.2 N

•

m,29 ft-lbs)

600

(58.8 N•m,43 ft-lbs)

800

(78.4 N

•

m,58 ft-lbs)

1000

(98 N

•

m,72 ft-lbs)

1200

(117.6 N•m,86 ft-lbs)

(kgf•cm)

Tightening time

[steel plate thickness:

t=1" (25 mm)]

M12 x 45 mm

(15/32" x 1-3/4")

Tightening torque

High-strenge bolt

Ordinary bolt

200

(19.6 N•m,14 ft-lbs)

0123

400

(39.2 N

•

m,29 ft-lbs)

600

(58.8 N•m,43 ft-lbs)

800

(78.4 N

•

m,58 ft-lbs)

1000

(98 N

•

m,72 ft-lbs)

1200

(117.6 N•m,86 ft-lbs)

(kgf•cm)

Tightening time

[steel plate thickness:

t=3/8" (10 mm)]

M10 x 30 mm

(8/8" x 1-3/6")

Tightening torque

High-strenge bolt

Ordinary bolt

(sec.)

(sec.)

(sec.)

•

Model WR 8DH

Fig. 6-2

--- 16 ---

6-4. Tightening Speed

Tightening speed comparisons of the Model WH 8DH with the previous Model WH 8DA2 and maker C's model

are shown below. The data shown below are intended for reference purposes only because actual tightening

speed will vary depending on the tightening conditions such as ambient temperature, charging capacity and

workpieces.

1 Tightening time (sec.) (Wood screw 4.2 mm dia. x 90 mm length, hemlock spruce)

HITACHI WH 8DH

HITACHI WH 8DA2

C

5.9 sec.

Model

510

sec.

6.5 sec.

6.8 sec.

HITACHI WH 8DH

HITACHI WH 8DA2

C

3.0 sec.

Model

1

sec.

3.3 sec.

3.5 sec.

2 3 4 5

HITACHI WH 8DH

HITACHI WH 8DA2

C

3.2 sec.

Model

1

sec.

3.5 sec.

3.8 sec.

2 3 4 5

HITACHI WH 8DH

HITACHI WH 8DA2

C

6.9 sec.

Model

510

sec.

8.5 sec.

8.7 sec.

2 Tightening time (sec.) (Wood screw 4.2 mm dia. x 75 mm length, soft wood)

3 Tightening time (sec.) (Wood screw 4.2 mm dia. x 90 mm length, soft wood)

4 Tightening time (sec.) (Wood screw 5.5 mm dia. x 120 mm length, soft wood)

--- 17 ---

5 Tightening time (sec.) (Teks screw 4 mm dia. x 13 mm length, SPCC 1.6 t )

6 Tightening time (sec.) (Wood screw 3.8 mm dia. x 20 mm length, lauan)

HITACHI WH 8DH

HITACHI WH 8DA2

C

2.5 sec.

Model

1

sec.

3.0 sec.

3.0 sec.

2 3 4 5

HITACHI WH 8DH

HITACHI WH 8DA2

C

1.2 sec.

Model

12

sec.

1.3 sec.

1.2 sec.

6-5. Number of Screws or Bolts Driven

6-5-1. Per-Charge Working Capacity Comparisons

Test data on the number of screws or bolts which can be driven per battery charge by the new models vs. the

previous models are shown in the tables below. Please note that the data below are intended for general

reference only as the number of screws which can be tightened per charge will vary slightly depending on screw

tightening conditions, screw sizes, ambient temperatures and the charging capacity of the battery.

(1) Number of screws or bolts driven (Cordless impact driver)

Battery

Tightening condition

Model

HITACHI

WH 8DH

HITACHI

WH 8DA2

C

EB 9B EB 9B

9122

(Corresponding EB 9B)

Wood screw 3.8 mm dia. x 20 mm

(soft wood)

430 460

450

Wood screw 4.0 mm dia. x 50 mm

(soft wood)

300 300

290

Wood screw 4.2 mm dia. x 75 mm

(soft wood)

220 220

210

Machine screw M8 x 16 mm

1,120 1,120

950

Teks screw 4.0 mm dia. x 13 mm

Mild steel plate t=1.6

170 170

160

--- 18 ---

6-5-2. Tightening Time and Number of Screws Driven Per Battery Charge

Fig. 7 Tightening time and number of

screws tightened

EB 9B

Tightening time

Number of screws tightened

0

100

200

300

400

500

600

700

800

(pcs.)

(sec.)

012345

Fig. 7 shows the relationship between the

tightening time and the number of screws which

can be tightened in a single battery charge in the

case of the EB 9B. (Tightening time is defined as

the period of time elapsed from the

commencement of the screw tightening operation

to the completion. As it can be seen, when the

tightening time is prolonged, the number of screws

which can be tightened per charge is decreased.)

Please note that the left data are intended for

general reference only, as the number of screws

which can be tightened per charge will vary slightly

depending on screw tightening conditions, screw

sizes, ambient temperatures and the charging

capacity of the battery.

(2) Ordinary bolt (Cordless impact wrench)

Battery

Tightening condition

Model

HITACHI

WR 8DH

HITACHI

WH 8D2

EB 9B

M8

ordinary bolt

880

0.4

Number of bolts

Time (sec.)

M10

ordinary bolt

430

0.8

Number of bolts

Time (sec.)

M12

ordinary bolt

220

1.5

Number of bolts

Time (sec.)

EB 9B

880

0.4

430

0.8

220

1.5

--- 19 ---

7. PRECAUTIONS IN SALES PROMOTION

7-1. Safety Instructions

In the interest of promoting the safest and most efficient use of these tools by all our customers, it is very

important that at the time of sale the salesperson carefully ensures that the buyer seriously recognizes the

importance of the contents of the Handling Instructions, and fully understands the meaning of the precautions

listed on the Caution Plate and Name Plate attached to each tool.

A. Handling Instructions

Salespersons must be thoroughly familiar with the contents of the Handling Instructions in order to give pertinent

advice to the customer. In particular, they must have a thorough understanding of the precautions in the use of

the cordless (battery charger type) electric power tools which are different from those of ordinary electric power

tools

(1) Before use, ensure that the unit is fully charged.

New units are not fully charged. Even if the units were fully charged at the factory, long periods without use,

such as during shipping, cause the storage battery to lose its charge. Customers must be instructed to fully

charge the unit prior to use.

(2) When charging storage batteries, use only the exclusive Model UC 14YF2 Charger provided with the tool.

Because of the designed rapid-charging feature (about one hour), use of other battery chargers is hazardous.

(3) Follow prescribed steps in using the charger.

First connect the EB 9B or EB 9H Storage Battery to the Model UC 14YF2 Charger, then plug the charger into

an AC outlet (ensuring that the voltage matches that indicated on the unit). If this order is reversed, the

charger may not function properly.

(4) Ensure the power source voltage is the same as that indicated on the Name Plate of the charger. Use of any

other power source (DC outlet, fuel powered generator, etc.) will cause the charger to overheat and burn out.

(5) Do not use any voltage increasing equipment (transformer, etc.) between the power source and the charger.

If the charger is used with voltage over and above that indicated on the unit, it will not function properly.

(6) Conduct battery charging at an ambient temperature range of 0 ˚C --- 40 ˚C (32 ˚F - -- 104 ˚F).

Special temperature sensitive devices are employed in the charger to permit rapid charging. Ensure that

customers are instructed to use the charger at the indicated ambient temperature range. At temperatures

under 0 ˚C (32 ˚F), the thermostat will not function properly, and the storage battery may be over-charged.

At temperatures over 40 ˚C (104 ˚F), the storage battery cannot be sufficiently charged. The optimum

temperature range is 20 ˚C --- 25 ˚C (68 ˚F --- 77 ˚F).

(7) The battery charger should not be used continuously.

At high ambient temperatures, if over three storage batteries are charged in succession, the temperature of

the coils on the transformer will rise and there is a chance that the temperature fuse inserted in the interior of

the transformer will inadvertently melt. After charging one battery, please charge the next battery after about a

fifteen-minute interval.

(8) The charger case is equipped with air vents to protect the internal electronic components from overheating.

Caution the customer not to allow foreign materials, such as metallic or flammable objects, to be dropped or

inserted into the air vents. This could cause electric shock, fire or other serious hazards.

--- 20 ---

CAUTION

•

Read thoroughly HANDLING INSTRUCTIONS

before use.

(9) Do not attempt to disassemble the storage battery or the charger.

Special devices, such as a thermostat, are built into the storage battery and charger to permit rapid charging.

Incorrect parts replacement and/or wiring will cause malfunctions which could result in fire or other hazards.

Instruct the customer to bring these units to an authorized service center in the event repair or replacement is

necessary.

(10) Disposal of the Type EB 9B or EB 9H Storage Battery

Ensure that all customers understand that Type EB 9B or EB 9H Storage Batteries should be turned into any

Hitachi power tool sales outlet or authorized service center when they are no longer capable of being

recharged or repaired. If thrown into a fire, the batteries may explode, or if discarded indiscriminately, leakage

of the cadmium compound contained in the battery may cause environmental pollution.

B. Caution Plates

(1) The following precautions are listed on the Name Plate attached to the main body of each tool.

For Europe

ACHTUNG

•

Lesen Sie die Bedienungsanleitung sorgfältig.

For Germany, Switzerland and Austria

TRES IMPORTANT

•

Lire avec attention la notice d'utilisation.

For France

Warning

•

To reduce the risk of injury, user must read and

understand Instruction Manual.

AVERTISSEMENT

•

Afin de réduire le risque de blessures, I'utilisateur doit lire

et bien comprendre le mode d'emploi.

For the U.S.A. (excludes French) or Canada

ATTENZIoNE

•

Leggere attentamente le istruzioni prima dell' uso.

For Itary

--- 21 ---

CAUTION

•

Read thoroughly HANDLING INSTRUCTIONS

before use.

•

Do not disassemble nor throw into fire.

(2) The following cautions are listed on the Name Plate attached to each Type EB 9B or EB 9H Storage Battery

For Europe

CAUTION

•

For safe operation, see Instruction Manual.

For the U.S.A.

CAUTION

•

For safe operation, see Instruction Manual.

•

Charge HITACHI rechargeable batteries Type EB 7, EB 9,

EB 12 and EB 14 series. Other types of batteries may burst

causing personal injury and damage.

•

Charge between 32 and 104 ˚F.

•

Indoor use only.

•

Replace defective cord immediately.

(3) The following caution is listed on the Name Plate attached to the Model UC 14YF2 Charger.

For the U.S.A.

7-2. Tightening Torque Inspection Prior to Operation

As described and shown in Para. 6-3-3, the output tightening torque of which the Models WH 8DH and

WR 8DH are capable in excess of the rated tightening torque of certain bolts and screws. Accordingly, if the

tightening time is prolonged for such bolts and screws, it could cause damage to their threads or, in the worst

case, cause them to be sheared off. (This phenomenon is common to all existing impact drivers.) Particularly

when tightening M6 (1/4") or smaller screws, tightening time must be kept extremely short: 0.5 seconds or less.

The customer should be advised to carry out several screw tightening operations and adjust the tightening time as

necessary by measuring the tightening torque with an appropriate torque wrench or driver before commencing

continuous operation

7-3. Tightening Torque Variation

The tightening torque of the cordless impact driver or wrench may vary slightly in accordance with the factors

described below. Salespersons are requested to advise the customer to confirm that appropriate tightening

torque is obtained by measuring the torque with an appropriate torque wrench or torque driver at the beginning of

the tightening operations, and as necessary during the tightening operations. In addition, the torque values

shown in Para. 6-3-2 above are useful as a handy reference, and may be utilized as tentative standards.

--- 22 ---

(1) Voltage of battery

Tightening torque is affected by the voltage output of the battery. For example, the relationship between

tightening torque and the number of M12 x 45 mm (15/32" x 1-3/4") high-strength bolts tightened is shown in

Fig. 8 below. As can be seen in the graph, tightening torque decreases as the number of bolts tightened

increases. This phenomenon is caused by the decline in voltage output of the battery due to the increasing

number of bolts tightened. In particular, the tightening torque decreases rapidly just before the battery is fully

discharged (range "a" in the graph). As this phenomenon is an inherent drawback in any cordless impact

driver, salespersons are requested to ensure that the customer is fully aware of and understands this

characteristic.

Model WR 8DH

Fig. 8

(2) Effects of low ambient temperatures

The tightening torque required may be reduced at low ambient temperatures or under the influence of grease

and different torque coefficients (dependent on manufacturing and finishing processes, and specified by bolt

manufacturers).

(3) Different bolt diameter

Differences in bolt diameter will cause variation of the required levels of tightening torque. Generally speaking,

tightening torque is higher for large bolts.

(4) Different materials being tightened

When a bolt is tightened into a soft material such as aluminum, plastic, wood, etc., the tightening torque is

considerably less than when the bolt is tightened into a hard material such as steel.

(5) Different tightening conditions

The tightening torque may vary in accordance with bolt torque coefficient (dependent on manufacturing

process, and specified by bolt manufactures), bolt grade and bolt length, even though the dimensions of the

bolts are the same. Tightening torque may also vary depending on the surface finishing state of tightening

materials (steel, aluminum, etc.), and materials to be tightened. In addition, if there is seal packing, clearance,

etc., between tightening materials, the tightening torque is decreased.

Fully charged

a

Battery voltage

Tightening torque

M12 x 45 mm (15/32" x 1-3/4") high-strength bolt (tightening time: 3 seconds)

400

(39.2 N•m, 29 ft-lbs)

800

(78.4 N•m, 58 ft-lbs)

1,200

(117.6 N•m, 86 ft-lbs)

0

2

4

6

8

10

20 40 60 80 100 120

Number of screws driven per charge (EB 9B battery)

Tightening torque

Battery voltage

(pcs.)

(kgf•cm)

(V)

--- 23 ---

(6) Wear and looseness of the socket

With extended use, the hexagonal portion of the socket which is fitted to the head of the bolt or drill bit, and/or

hexagonal portion of the driver chuck which is fitted onto the anvil in the main body will become worn and

loose. Wear and looseness will cause a proportionate loss of tightening torque.

In addition, use of an incorrect size socket (slightly larger than the bolt being tightened) will also result in

decreased torque.

(7) Bolt and nut rotate together

Tightening torque that can be achieved will be considerably decreased if the bolt and nut rotate together

during the tightening operation. The customer should be advised to carefully observe the operation and

ensure this does not occur.

7-4. Suggestions and precautions for the Efficient Use of the Charger

(1) Batteries may not be rechargeable immediately after use

If the Type EB 9B or EB 9H Storage Batteries are exposed to direct sunshine for an extended period, or if the

temperature of the batteries is 40 ˚C (104 ˚F) or higher immediately after they have been used in the tool, the

pilot lamp may not light up when the batteries are connected to the Model UC 14YF2 Charger. This is

because the built-in thermostat functions to stop the charging when the temperature of the storage batteries

reach 40 ˚C (104 ˚F) or more. In such a case, the customer should be advised to place the batteries in a

shaded area with a good airflow, and allow sufficient cooling before recharging.

This phenomenon is common to all existing batteries which employ temperature sensitive overcharge devices.

The cooling time required before charging can be accomplished varies from a few minutes to about 30

minutes, depending on the load, duration of use, and ambient temperatures.

--- 24 ---

8. OTHER PRECAUTIONS

(1) Check for cracks or other damage on the socket

Cracks or any other faults on the socket are very hazardous. In addition, cracks or other damage to

accessories will cause loss of tightening torque efficiency. Advise the customer to inspect accessories often,

and ensure there are no abnormalities.

(2) Socket dimensions

Without fail, utilize an appropriate socket which matches the bolt and/or nut dimensions. If the socket

dimensions are larger than the bolts or nuts, it will not only cause insufficient tightening torque, but could also

easily cause damage to the socket. Please refer to the tables in Para. 5-2 for appropriate socket dimensions.

(3) Hammering section lubrication

Grease (ATTOLUB MS No. 2) is utilized in the hammering section. Frequent or continuous use of the tool will

cause excessive temperature rise of the hammering section, resulting in depletion of the grease and

subsequent increased wear of components which will, in turn, cause loss of tightening efficiency. Accordingly,

it is necessary to periodically replenish the grease in the hammering section to ensure proper lubrication of

moving and sliding components.

(4) Vent holes in the handle

Do not stop up or cover the holes on either face of the handle. They are essential for ventilation.

--- 25 ---

9. REPAIR GUIDE

WARNING: Without fail, remove the Model EB 9B or EB 9H Battery from the main body before starting

repair or maintenance work. Because the tool is cordless, if the battery is left in and the

switch is activated inadvertently, the motor will start rotating unexpectedly, which could

cause serious injury.

9-1. Precautions in Disassembly and Reassembly

The [bold] and <bold> numbers correspond to the item numbers in the Parts List and the exploded assembly

diagram. ( [ ]: WH 8DH, < >: WR 8DH )

9-1-1. Disassembly

(1) Removal of the Hammer Case [6] <2> and the Inner Cover [21] <19>

Remove the four Tapping Screws D4 x 30 [5] <1> that connect the Hammer Case [6] <2> with the Housing

(A).(B) Set [28] <26>. Remove the Hammer Case [6] <2>, the Inner Cover [21] <19> and the Damper [22]

<20> together from the Housing (A).(B) Set [28] <26>.

(2) Removal of Housing (B)

Remove the seven Tapping Screws D4 x 20 [26] <24> from the main body to remove Housing (B).

(3) Remove the DC-Speed Control Switch [30] <28>, Fin Ass'y [32] <30>, Motor [23] [21], Grip (F) [33] <31> and

Grip (R) [37] <35> together. Remove the Pushing Button [31] <29> and the Strap [35] <33>.

(4) Disassembly of the switch ass'y

Remove the two Machine Screws M3 x 5 [29] <27> that secure the flag terminal and then disconnect the

internal wires (purple and black) of the Motor [23] <21> from the DC-Speed Control Switch [30] <28>.

Remove the S-Tight Screw D3.5 x 6 [36] <34> to remove the Fin Ass'y [32] <30> from the FET of the DCSpeed Control Switch .

(Note) Do not disconnect the three FET internal wires soldered to the DC-Speed Control Switch.

(5) Removal of the Guide Sleeve [4] (for WH 8DH only)

By following the procedure shown in Figs. 9-1 to 9-4, you can remove the Retaining Ring [1], Washer (D) [2],

Guide Spring [3] and Guide Sleeve [4] in this order. Be sure not to lose the Steel Ball D3.5 [7] in Anvil (B) [8].

--- 26 ---

Anvil (B) [8]

Retaining

Ring [1]

Washer (D) [2]

Guide Sleeve [4]

Gap of retaining ring

1

Fig. 9-1

Hold the body and adjust gap of the retaining ring to

groove of anvil (B), then insert a small flat-blade

screwdriver into the groove at an angle.

2

Fig. 9-2

Press down washer (D) with the screwdriver.

3

Fig. 9-3

Slide the screwdriver under one side of the gap of

the retaining ring.

4

Fig. 9-4

Slowly raise the retaining ring using the end face of

the guide sleeve as a fulcrum.

Then slowly raise the other side of the retaining ring with the screwdriver until it is free. The Guide Sleeve [4] can

not be removed. Avoid quickly raising the retaining ring or it may fly out forcefully.

The retaining ring can also be easily removed by widening the gap of the retaining ring with the jig for retaining

ring and slowly raising the retaining ring with a small flat-blade screwdriver.

(6) Disassembly of the hammer assembly

Hammer [10] <7>

Push down.

Spindle [15] <13>

Spring [12] <10>

Stopper [14] <12>

Washer (S) [13] <11>

J-297 Base for washer (S)

Fig. 10

Mount the hammer assembly onto the

J-297 base for washer (S). With a

hand press, push down the top of the

Spindle [15] <13> to compress the

Spring [12] <10>. In this position,

remove the Stopper [14] <12> with a

flat-blade screwdriver, then release

the hand press. (See Fig. 10.)

Small flat-blade

screwdriver

--- 27 ---

Remove the hammer assembly from the J-297 base for washer (S) and support the end surface of the Spindle

[15] <13>. With a hand press, push down either of the raised faces of the Hammer [10] <7> to compress the

Spring [12] <10>. In this position, extract the two Steel Balls D5.556 [9] <6> from the cam grooves of the

Spindle [15] <13> and the Hammer [10] <7> with a small flat-blade screwdriver or a similar tool. Then, slowly

release the hand press and lift the Hammer [10] <7> and Washer (S) [13] <11> together to extract them from

the Spindle [15] <13>. The Spring [12] <10> can then be removed.

Steel ball

guide groove

Spindle [15] <13>

Hammer [10] <7>

Raised faces

of hammer

Top of spindle cam

Steel Ball [9] <6>

Fig. 11

9-1-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

(1) Reassembly of Housing (A) assembly

(a) Be sure to follow the wiring diagram (Fig. 12-1) for proper wiring.

(b) When connecting the internal wires of the Motor [23] <21> to the DC-Speed Control Switch [30] <28>,

tightly fasten them with the Machine Screw M3 x 5 [29] <27> paying close attention to the direction of the

flag terminal (Fig. 12-2).

(c) Mount the Motor [23] <21> into Housing (A) so that the Brush Caps [25] <23> of the Motor [23] <21> and

the rib for preventing motor body from rotating fit in Housing (A).

(Note) Make sure that the internal wire (purple) is passed under the Motor so that it is not caught between

the Motor and Housing (A).

(d) Mount the DC-Speed Control Switch [30] <28> to Housing (A) so that the projection of the forwarding/

reversing lever at the top of the Switch is inserted into the U-shaped groove of the Pushing Button [31]

<29>. Secure the Fin Ass'y [32] <30> to the FET of the DC-Speed Control Switch [30] <28> with the S-

Tight Screw D3.5 x 6 [36] <34>.

(Note) Make sure that the three internal wires from the FET are passed above the DC-Speed Control

Switch [30] <28>.

(2) Reassembly of the Housing (A).(B) Set [28] <26>

Mount the Strap [35] <33>, Grip (F) [33] <31>, Grip (R) [37] <35> and Housing (B) to Housing (A), and secure

them with the seven Tapping Screws D4 x 20 [26] <24>.

--- 28 ---

Fig. 12-1

Fig. 12-2

Internal wire (purple)

Motor

Pinion

(Black)

(Purple)

Fin Ass'y [32] <30>

FET

S-Tight Screw D3.5 x 6

[36] <34>

Flag terminal

Machine screw M3 x 5

[29] <27>

DC-Speed Control Switch [30] <28>

Projection of forward/

reverse lever

Internal wire (black)

Schematic diagram viewed from A

--- 29 ---

(3) Reassembly of the hammer assembly

(a) Put Washer (S) [13] <11> onto the shaft of the Spindle [15] <13> and mount the Hammer [10] <7>

containing the twenty-five Steel Balls D3.5 [7] <8>, Washer (J) [11] <9> and the Spring [12] <10> to the

Spindle [15] <13>.

(b) Align the top of the cam groove on the Spindle [15] <13> with the steel ball guide groove on the Hammer

[10] <7> as illustrated in Fig. 11. Press down either of the raised faces of the Hammer [10] <7> with a

hand press to compress the Spring [12] <10> until the end surface of the Hammer contacts the flange of

the Spindle [15] <13>.

(c) Insert the two Steel Balls D5.556 [9] <6> into the steel ball guide groove. Check that the Steel Balls are

properly inserted in the cam groove. Then release the hand press.

(d) Mount the hammer assembly onto the J-297 base for washer (S). With a hand press, push down the top of

the Spindle [15] <13> to compress the Spring [12] <10>. On this condition, mount the Stopper [14] <12>

onto the spindle shaft and then release the hand press.

(e) Mount the Ring Gear [18] <16>, Ball Bearing [20] <18>, Inner Cover [21] <19> and Damper [22] <20> to

the above reassembly. Furthermore, mount the other mechanical parts and Anvil (B) [8] or Anvil (K) Ass'y

<4>, then the Hammer Case [6] <2>. When mounting Anvil (B) [8], use the J-296 anvil cap

(Fig. 13).

(Note) The oil seal may be turned inside out if the anvil cap is not used.

(4) Mounting the assembly from the Hammer Case [6] <2> to the Inner Cover [21] <19> to the housing assembly

Push the assembly from the Hammer Case [6] <2> to the Inner Cover [21] <19> into the housing assembly by

turning them clockwise and counterclockwise. Check that the Anvil can be easily turned. (If it cannot be

turned, check for correct mesh of the gears.) Secure the above assembly with the four Tapping Screws D4 x

30 [5] <1>.

(5) Reassembly of the Guide Sleeve [4] (for WH 8DH only)

Insert the Steel Ball D3.5 [7] into the hole of Anvil (B) [8]. Mount the Guide Sleeve [4], the Guide Spring [3]

and Washer (D) [2] in sequence. Mount the Retaining Ring [1] into the groove of Anvil (B) using the J-295 jigs

(A) and (B) for retaining ring as illustrated in Fig. 14.

J-296 anvil cap

Anvil (B) [8]

Push down.

Retaining

Ring [1]

Washer (D) [2]

J-295 jig (B) for retaining ring

J-295 jig (A) for retaining ring

Fig. 13 Fig. 14

--- 30 ---

(6) Check whether the direction of rotation of Anvil (B) [8] or Anvil (K) Ass'y <4> coincides with the directional

markings on the push-on side of the Pushing Button [31] <29>. When the Pushing Button [31] <29> is turned

to the (R) side, the direction of rotation of Anvil (B) [8] or Anvil (K) Ass'y <4> should be clockwise, as viewed

from behind.

(7) Lubrication

(a) ATTOLUB MS No. 2

•

Cam groove of the Spindle [15] <13>

•

Cam groove of the Hammer [10] <7>

•

Sliding section of the Hammer and the Spindle

•

8 mm Diameter hole of Anvil (B) [8] or Anvil (K) Ass'y [4]

•

Sliding section between Anvil (B) [8] or Anvil (K) Ass'y [4] and the metal

•

Two Steel Balls D5.556 [9] <6>

•

Pinion tooth flanks of the Motor [23] <21>

•

Tooth flanks of the Ring Gear [18] <16>

•

Twenty-five Steel Balls D3.5 [7] <8>

(b) HITACHI MOTOR GREASE No. 29 (for WH 8DH only)

•

Steel Ball D3.5 [7]

•

Sliding section of Anvil (B) [8] and the Guide Sleeve [4]

(8) Screw tightening torque

•

Tapping Screw (with sp. washer) D4 x 30

••••••••••••••••••••

20 5 kgf•cm (1.96 0.49 N•m, 1.44 0.36 ft-lbs)

•

Tapping Screw (with flange) D4 x 20

•••••••••••••••••••••••••••

20 5 kgf•cm (1.96 0.49 N•m, 1.44 0.36 ft-lbs)

•

S-Tight Screw D3.5 x 6

••••••••••••••••••••••••••••••••••••••••••••••

15 --- 20 kgf•cm (1.96 --- 2.61 N•m, 1.44 --- 1.92 ft-lbs)

•

Machine Screw M3 x 5

•••••••••••••••••••••••••••••••••••••••••••••••

3 --- 4 kgf•cm (0.294 --- 0.392 N•m, 0.22 --- 0.29 ft-lbs)

9-2. Precautions in Disassembly and Reassembly of Battery Charger

Refer to the Technical Data and Service Manual for precautions in disassembly and reassembly of the Model

UC 14YF2 Battery Charger.

--- 31 ---

11. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40 50 60 min.

Fixed

Variable

WH 8DH

Work Flow

Inner Cover

Motor

Switch

Hammer Case

Washer

Anvil

Ring Gear

Housing

General Assembly

WR 8DH

Steel Ball

Hammer Ass'y

Spring

Spindle

Idle Gear

Needle Roller

Ball Bearing

(6001C2)

Fixed Cost

Switch 0 min.

Others 20 min.

--- 32 ---

Assembly Diagram for WH 8DH

--- 33 ---

PARTS

WH 8DH

: ALTERNATIVE PARTS

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

1 315-984 RETAINING RING 1

2 315-983 WASHER (D) 1

3 315-982 GUIDE SPRING 1

4 315-981 GUIDE SLEEVE 1

5 307-851

TAPPING SCREW (W/SP. WASHER) D4X30(BLACK)

4

6 317-339 HAMMER CASE 1

7 315-980 STEEL BALL D3.5 26

8 317-338 ANVIL (B) 1

9 959-154 STEEL BALL D5.556 (10 PCS.) 2

10 316-780 HAMMER 1

11 315-978 WASHER (J) 1

12 316-781 SPRING 1

13 316-172 WASHER (S) 1

14 316-171 STOPPER 1

15 316-169 SPINDLE 1

16 316-313 IDLE GEAR 2

17 991-449 NEEDLE ROLLER 2

18 302-337 RING GEAR 1

19 991-455 WASHER (C) 1

20 600-1VV BALL BEARING 6001VVCMPS2L 1

21 316-167 INNER COVER 1

22 310-319 DAMPER 1

23 316-782 MOTOR 1

24 999-054 CARBON BRUSH 5X6X11.5 (1 PAIR) 2

25 316-180 BRUSH CAP 2

26 302-086

TAPPING SCREW (W/FLANGE) D4X20 (BLACK)

7

27 NAME PLATE 1

28 317-879 HOUSING (A).(B) SET (GREEN) 1 INCLUD.33,37

29 994-532 MACHINE SCREW (W/SP. WASHER) M3X5 2

30 316-783 DC-SPEED CONTROL SWITCH 1

31 316-166 PUSHING BUTTON 1

32 316-179 FIN ASS’Y 1 (INCLUD.36)

33 316-178 GRIP (F) 1

34 HITACHI LABEL 1

35 306-952 STRAP 1

36 311-131 S-TIGHT SCREW D3.5X6 1

37 316-177 GRIP (R) 1

* 38 310-377 BATTERY EB 9B (W/ENGLISH N.P.) 1

* 38 310-450 BATTERY EB 9B (W/ENGLISH N.P.) 1 FOR TPE,NZL,AUS,SIN

* 38 310-451 BATTERY EB 9B (W/ENGLISH N.P.) 1 FOR USA,CAN

* 38 316-662 BATTERY EB 9H (W/ENGLISH N.P.) 1

*

3

----

99

--- 34 ---

STANDARD ACCESSORIES

WH 8DH

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

: ALTERNATIVE PARTS

*

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

* 501 CHARGER(MODEL UC 14YF2) 1 DEPENDING ON ORDER SPEC.

502 306-306 CASE 1

* 601 316-662 BATTERY EB 9H (W/ENGLISH N.P.) 1 EXCEPT FOR TPE,NZL,AUS,SIN,USA

602 992-671 + DRIVER BIT (B) NO.2 50L 1

603 992-672 + DRIVER BIT (B) NO.3 50L 1

604 996-177 NON-MAGNETIC HEX. SOCKET 8MM 65L 1

605 985-329 NON-MAGNETIC HEX. SOCKET 10MM 65L 1

606 996-178 NON-MAGNETIC HEX. SOCKET 12MM 65L 1

607 996-179 NON-MAGNETIC HEX. SOCKET 13MM 65L 1

608 996-180 NON-MAGNETIC HEX. SOCKET 14MM 65L 1

609 996-181 NON-MAGNETIC HEX. SOCKET 16MM 65L 1

610 996-182 NON-MAGNETIC HEX. SOCKET 17MM 65L 1

611 996-185 NON-MAGNETIC HEX. SOCKET 15MM 65L 1

612 996-186 NON-MAGNETIC HEX. SOCKET 19MM 65L 1

613 996-197 HEX. SOCKET (LONG) 21MMX166L 1

614 996-195 DRILL CHUCK AND ADAPTER SET 1 INCLUD.615,616

615 930-119 CHUCK WRENCH 6.5G 1

616 307-543 CHUCK ADAPTER 1

617 307-824 HOLSTER 1

618 308-090 HOOK (FOR CORDLESS TOOLS) 1

619 309-922 GREASE FOR IMPACT DRIVER (500G) 1

3

----

99

Printed in Japan

(990330 N)

--- 35 ---

Assembly Diagram for WR 8DH

--- 36 ---

PARTS

WR 8DH

: ALTERNATIVE PARTS

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

1 307-851

TAPPING SCREW (W/SP. WASHER) D4X30(BLACK)

4

2 317-343 HAMMER CASE 1

* 3 985-209 PIN RETAINER 1

* 4 317-342 ANVIL (K) ASS’Y 1 INCLUD.3,5

* 4 316-181 ANVIL (J) 1 FOR TPE,SIN

* 5 985-208 PLUNGER 1

6 959-154 STEEL BALL D5.556 (10 PCS.) 2

7 316-780 HAMMER 1

8 315-980 STEEL BALL D3.5 25

9 315-978 WASHER (J) 1

10 316-781 SPRING 1

11 316-172 WASHER (S) 1

12 316-171 STOPPER 1

13 316-169 SPINDLE 1

14 316-313 IDLE GEAR 2

15 991-449 NEEDLE ROLLER 2

16 302-337 RING GEAR 1

17 991-455 WASHER (C) 1

18 600-1VV BALL BEARING 6001VVCMPS2L 1

19 316-167 INNER COVER 1

20 310-319 DAMPER 1

21 316-782 MOTOR 1

22 999-054 CARBON BRUSH 5X6X11.5 (1 PAIR) 2

23 316-180 BRUSH CAP 2

24 302-086

TAPPING SCREW (W/FLANGE) D4X20 (BLACK)

7

25 NAME PLATE 1

26 317-879 HOUSING (A).(B) SET (GREEN) 1 INCLUD.31,35

27 994-532 MACHINE SCREW (W/SP. WASHER) M3X5 2

28 316-783 DC-SPEED CONTROL SWITCH 1

29 316-166 PUSHING BUTTON 1

30 316-179 FIN ASS’Y 1 INCLUD.34

31 316-178 GRIP (F) 1

32 HITACHI LABEL 1

33 306-952 STRAP 1

34 311-131 S-TIGHT SCREW D3.5X6 1

35 316-177 GRIP (R) 1

* 36 310-377 BATTERY EB 9B (W/ENGLISH N.P.) 1

* 36 310-450 BATTERY EB 9B (W/ENGLISH N.P.) 1 FOR TPE,NZL,AUS,SIN

* 36 310-451 BATTERY EB 9B (W/ENGLISH N.P.) 1 FOR USA

* 36 316-662 BATTERY EB 9H (W/ENGLISH N.P.) 1

*

3

----

99

--- 37 ---

STANDARD ACCESSORIES

WR 8DH

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

: ALTERNATIVE PARTS

*

3

----

99

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

501 CHARGER (MODEL UC 14YF2) 1 DEPENDING ON ORDER SPEC.

502 306-306 CASE 1

* 601 316-662 BATTERY EB 9H (W/ENGLISH N.P.) 1 EXCEPT TPE,NZL,AUS,SIN,USA

602 CORNER ATTACHMENT (MODEL EW-14R) 1 INCLUD.603-618

603 955-300 HOUSING 1

604 955-301 METAL 3

605 955-302 SPINDLE 1

606 955-303 BEARING RACE 2

607 955-304 NEEDLE THRUST BEARING (NTA-1413) 2

608 955-305 COVER 1

609 955-306 NEEDLE BEARING (NTN BK1012) 1

610 948-227 RETAINING RING FOR D47 HOLE 1

611 955-307 PINION 1

612 955-308 SLEEVE 1

613 955-309 WASHER 1

614 955-310 SOCKET COVER 1

615 955-311 SOCKET 1

616 303-247 SEAL LOCK HEX. SOCKET HD. BOLT M5X25 6

617 873-537 SOCKET PIN 1

618 873-187 O-RING (J1SW1516) 1

619 991-481 FORM TIE SOCKET ASS’Y 11.3MMX95L 1 INCLUD.617,618

620 944-291 HEX. SOCKET ASS’Y 10MMX40L 1 INCLUD.617,618

621 873-632 HEX. SOCKET ASS’Y 12MMX40L 1 INCLUD.617,618

622 873-539 HEX. SOCKET ASS’Y 13MMX40L 1 INCLUD.617,618

623 873-540 HEX. SOCKET ASS’Y 14MMX40L 1 INCLUD.617,618

624 873-536 HEX. SOCKET ASS’Y 17MMX32L 1 INCLUD.617,618

625 873-624 HEX. SOCKET ASS’Y 19MMX34L 1 INCLUD.617,618

626 873-626 HEX. SOCKET ASS’Y 21MMX36L 1 INCLUD.617,618

627 873-627 HEX. SOCKET ASS’Y 22MMX40L 1 INCLUD.617,618

--- 38 ---

: ALTERNATIVE PARTS

*

WR 8DH

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

628 986-058 HEX. SOCKET FOR PLASTIC CONE 12MMX70L 1 INCLUD.617,618

629 955-138 HEX. SOCKET ASS’Y (LONG) 12MMX52L 1 INCLUD.617,618

630 955-139 HEX. SOCKET ASS’Y (LONG) 13MMX52L 1 INCLUD.617,618

631 955-140 HEX. SOCKET ASS’Y (LONG) 14MMX52L 1 INCLUD.617,618

632 955-141 HEX. SOCKET ASS’Y (LONG) 17MMX52L 1 INCLUD.617,618

633 955-149 HEX. SOCKET ASS’Y (LONG) 17MMX75L 1 INCLUD.617,618

634 955-142 HEX. SOCKET ASS’Y (LONG) 19MMX52L 1 INCLUD.617,618

635 955-150 HEX. SOCKET ASS’Y (LONG) 19MMX75L 1 INCLUD.617,618

636 955-143 HEX. SOCKET ASS’Y (LONG) 21MMX52L 1 INCLUD.617,618

637 955-151 HEX. SOCKET ASS’Y (LONG) 21MMX75L 1 INCLUD.617,618

638 991-480 HEX. SOCKET ASS’Y (LONG) 21MMX125L 1 INCLUD.617,618

639 955-144 HEX. SOCKET ASS’Y (LONG) 22MMX52L 1 INCLUD.617,618

640 873-633

EXTENSION BAR ASS’Y (SQUARE) 12.7MMX100L

1 INCLUD.617,618

641 992-610 UNIVERSAL JOINT ASS’Y 1 INCLUD.617,618,642

642 955-153 UNIVERSAL JOINT PIN 1

643 993-658 SOCKET ASS’Y FOR DUCT 12MMX95L 1 INCLUD.617,618,644

644 993-659 SOCKET FOR DUCT 12MMX52L 1

645 992-613 SOCKET ASS’Y FOR DUCT 13MMX95L 1 INCLUD.617,618,646

646 992-614 SOCKET FOR DUCT 13MMX52L 1

647 992-615 SOCKET ASS’Y FOR DUCT 14MMX95L 1 INCLUD.617,618,648

648 992-616 SOCKET FOR DUCT 14MMX52L 1

649 991-476 BIT ADAPTER ASS’Y 1 INCLUD.617,618

650 307-824 HOLSTER 1

651 308-090 HOOK (FOR CORDLESS TOOLS) 1

652 309-922 GREASE FOR IMPACT DRIVER (500G) 1

3

----

99

Printed in Japan

(990330 N)

OPTIONAL ACCESSORIES

Loading...

Loading...