Page 1

Cordless Impact Driver/Wrench

Atornillador/Llave de impacto a batería

日立牌充電式衝擊起子機扳手機

WH 12DAF2 • WR 12DAF2

Handling instructions

Instrucciones de manejo

使用說明書

WH12DAF2 WR12DAF2

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

使用前務請詳加閱讀。

Page 2

1

2

3

4

1

3

7

1

2

4

6

1

5

2

1

6

E

8

7

〈UC18YG〉

8

〈UC14YFA〉

5

B

9

A

6

C

D

0

87

H

I

E

C

F

C

G

E

1

Page 3

5

109

4

J

3

11

13

J

2

(B)

(A)

1

12

L

K

14

3

M

O

J

J

N

15

P

Q

2

16

R

T

,

.

,.

J

R

S

S

Q

Page 4

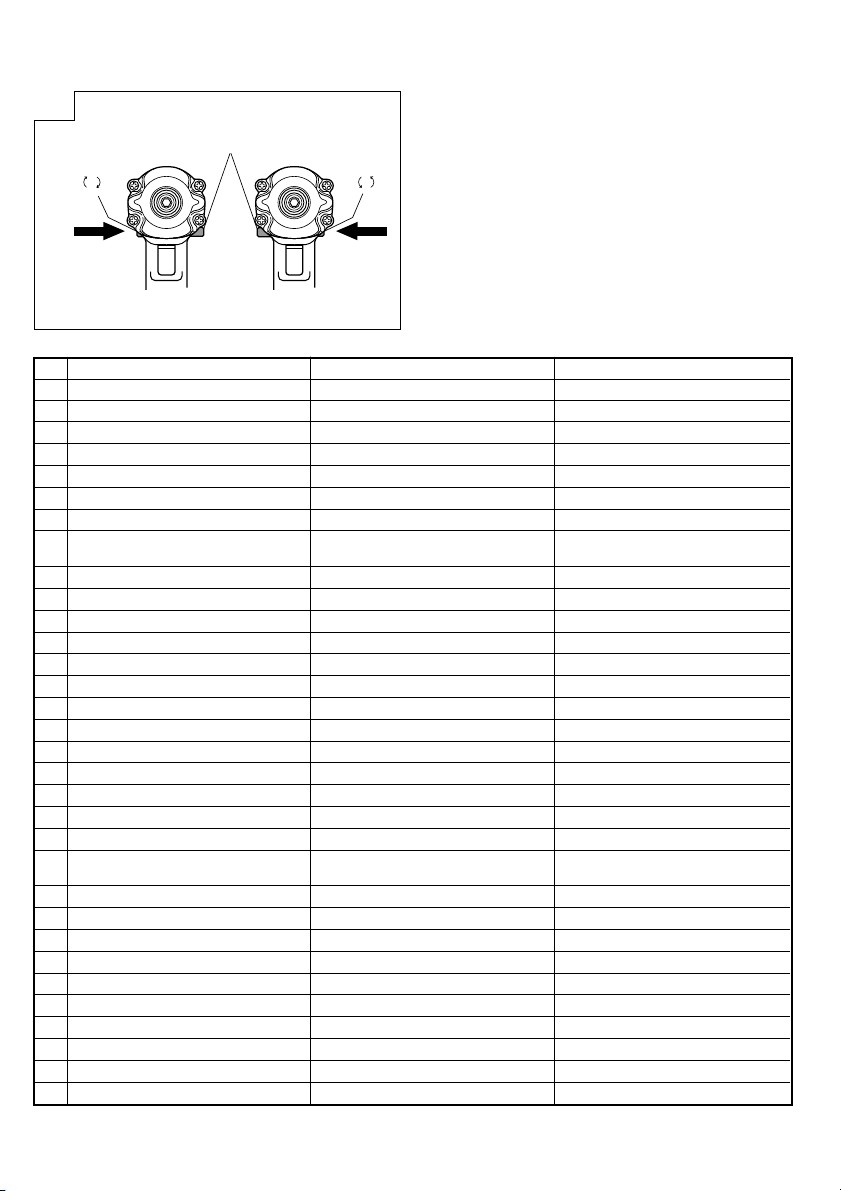

17

U

R

V V

1

12 V Rechargeable battery

2

Latch

3

Handle

4

Insert

5

Pull out

6

Insert

7

Pilot lamp

8

Hole for connecting the

rechargeable battery

9

Movement

0

Guide sleeve

A

Hexagonal hole in the anvil

B

Driver bit

C

Hexagonal socket

D

Groove

E

Anvil

F

Pin

G

Ring

H

Hole

I

Plunger

J

Hook

K

Spring

L

Larger diameter faces away

M

Switch

N

Phillips-head screwdriver

O

Screw

P

Arrow

Q

Hook cover

R

Indentation

S

Protuberance

T

AAAA batteries

U

Push button

V

Push

English Español 中國語

L

Batería recargable, 12 V

Enganche

Mango

Insertar

Sacar

Insertar

Lámpara piloto

Agujero para conectar la batería

recargable

Movimiento

Manguito guía

Orificio hexagonal en el yunque

Punta de destornillador

Recaptáculo hexanogal

Ranura

Yunque

Pasador

Anillo

Orificio

Embolo

Gancho

Resorte

El diámetro más grande queda en

dirección opuesta

Interruptor

Destornillador con cabeza Phillips

Tornillo

Flecha

Cubierta del gancho

Indentación

Saliente

Pilas AAAA

Pulsador

Presionar

12伏特充電式電池

插銷

把手

插入

拉出

插入

指示燈

充電式電池連接孔

移動

導筒

砧座的六角形孔

起子刀頭

六角形套筒

凹槽

砧座

銷子

O形環

孔

柱塞

掛鉤

彈簧

較大直徑向外

開關

十字螺絲起子

螺釘

箭頭

掛鉤蓋

缺口

凸起

AAAA電池

按鈕

按

3

Page 5

English

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using battery operated tools, basic

safety precautions should always be followed to reduce

the risk of fire, leaking batteries and personal injury,

including the following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

tools to rain. Do not use tools in damp or wet

locations. Keep work area well lit.

Do not use tools where there is risk to cause fire

or explosion.

3. Keep children away. Do not let visitors touch the

tool. All visitors should be kept away from work

area.

4. Store batteries or idle tools. When not in use,

tools and batteries should be stored separately in

a dry, high or locked up place, out of reach of

children.

Ensure that battery terminals cannot be shorted

by other metal parts such as screws nails etc.

5. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

6. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended.

7. Dress properly. Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protecting hair covering to contain long hair.

8. Use safety glasses. Also use face or dust mask

if the cutting operation is dusty.

9. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

10. Do not abuse the cord (if fitted). Never carry the

tool by the cord or yank it to disconnect it from

the socket. Keep the cord away from heat, oil and

sharp edges.

11. Secure work. Use clamps or a vice to hold the

work. It is safer than using your hand and it frees

both hands to operate the tool.

12. Do not overreach. Keep proper footing and balance

at all times.

13. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

facility. Keep handles dry, clean, and free from oil

and grease.

14. Disconnect tools. Where the designs permits,

disconnect the tool from its battery pack, when

not in use, before servicing, and when changing

accessories such as blades, bits and cutters.

15. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

16. Avoid unintentional starting. Do not carry the tool

with a finger on the switch.

17. Stay alert. Watch what you are doing. Use common

sense. Do not operate the tool when you are tired.

18. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, free running

of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service facility. Do not

use the tool if the switch does not turn it on and

off.

19. Warning

䡬 The use of any accessory or attachment, other

than those recommended in this handling instructions, may present a risk of personal injury.

䡬 Ensure that the battery pack is correct for the tool.

䡬 Ensure that the outside surface of battery pack or

tool is clean and dry before plugging into charger.

䡬 Ensure that batteries are charged using the correct

charger recommended by the manufacturer. Incorrect use may result in a risk of electric shock,

overheating or leakage of corrosive liquid from

the battery.

20. Have your tool repaired by a qualified person.

This tool is in accordance with the relevant safety

requirements. Repairs should only be carried out

by qualified persons using original spare parts,

otherwise this may result in considerable danger

to the user.

21. Disposal of battery

Ensure battery is disposed of safely as instructed

by the manufacturer.

22. If under abusive conditions, liquid is ejected from

the battery, avoid contact

If this accidentally occurs, frush with water. If

liquid contacts eyes additionally, seek medical

help.

PRECAUTIONS FOR CORDLESS IMPACT

DRIVER

1. This is portable tool for tightening and loosenig

screws. Use it only for these operation.

2. Use the earplugs if using for a long time.

3. One-hand operation is extremely dangerous; hold

the unit firmly with both hands when operating.

4. After installing the driver bit, pull lightly out the

bit to make sure that it does not come loose. If

the bit is not installed properly, it can come loose

during use, which can be dangerous.

5. Use the bit that matches the screw.

6. Tightening a screw with the impact driver at an

angle to that screw can damage the head of the

screw and the proper force will not be transmitted

to the screw. Tighten with this impact driver lined

up straight with the screw.

7. Always charge the battery at a temperature of 0

– 40°C.

A temperature of less than 0°C will result in over

charging which is dangerous. The battery cannot

be charged at a temperature greater than 40°C.

The most suitable temperature for charging is that

of 20 – 25°C.

8. Do not use the charger continuously.

When one charging is completed, leave the charger

for about 15 minutes before the next charging of

battery.

9. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

10. Never disassemble the rechargeable battery and

charger.

11. Never short-circuit the rechargeable battery.

Short-circuiting the battery will cause a great

electric current and overheat. It results in burn or

damage to the battery.

4

Page 6

English

12. Do not dispose of the battery in fire.

If the battery burnt, it may explode.

13. Do not insert object into the air ventilation slots

of the charger.

Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical

shock hazard or damaged charger.

14. Bring the battery to the shop from which it was

purchased as soon as the post-charging battery

life becomes too short for practical use. Do not

dispose of the exhausted battery.

15. Using an exhausted battery will damage the

charger.

PRECAUTIONS FOR CORDLESS IMPACT

WRENCH

1. This is a portable tool for tightening and loosening

bolts and nuts. Use it only for these operation.

2. Use the earplugs if using for a long time.

3. One-hand operation is extremely dangerous; hold

the unit firmly with both hands when operating.

4. Check that the socket is not cracked or broken.

Broken or cracked sockets are dangerous. Check

the socket before using it.

5. Secure the socket with the socket pin and the ring.

If the socket pin or ring securing the socket is damaged,

the socket may come off from the impact wrench,

which is quite dangerous. Do not use socket pins

or rings that are deformed, worn out, cracked, or in

any other way damaged. Always make sure to install

the socket pin and ring in the correct position.

6. Check the tightening torque.

The appropriate torque for tightening a bolt

depends on the material the bolt is made of, its

dimensions, grade, etc.

Also, the tightening torque generated by this impact

wrench depends on the materials and dimensions

of the bolt, how long the impact wrench is applied

for the way in which the socket is installed, etc.

Also the torque when the battery has just been

charged and when it is about to run out are slightly

different. Use a torque wrench to check that the

bolt has been tightened with the appropriate torque.

7. Stop the impact wrench before switching the

direction of rotation. Always release the switch

and wait for impact wrench to stop before

switching the direction of rotation.

8. Never touch the turning part.

Do not allow the turning socket section to get near

your hands or any other part of your body. You could

be cut or caught in the socket. Also, be careful not

to touch the socket after using continuously it for

a long time. It gets quite hot and could burn you.

9. Never let the impact wrench turn without a load

when using the universal joint.

If the socket turns without being connected to a load,

the universal joint causes the socket to turn wildly.

You could get hurt or the movement of the socket

could shake the impact wrench so much as to

make you drop it.

10. Always charge the battery at a temperature of 0

– 40°C.

A temperature of less than 0°C will result in over

charging which is dangerous. The battery cannot

be charged at a temperature greater than 40°C.

The most suitable temperature for charging is

that of 20 – 25°C.

11. Do not use the charger continuously.

When one charging is completed, leave the charger

for about 15 minutes before the next charging of

battery.

12. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

13. Never disassemble the rechargeable battery and

charger.

14. Never short-circuit the rechargeable battery.

Short-circuiting the battery will cause a great

electric current and overheat. It results in burn

or damage to the battery.

15. Do not dispose of the battery in fire.

If the battery burnt, it may explode.

16. Do not insert object into the air ventilation slots

of the charger.

Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical

shock hazard or damaged charger.

17. Bring the battery to the shop from which it was

purchased as soon as the post-charging battery

life becomes too short for practical use. Do not

dispose of the exhausted battery.

18. Using an exhausted battery will damage the

charger.

MODEL

WH12DAF2:with charger and case

WR12DAF2:with charger and case

SPECIFICATIONS

POWER TOOL

Model WH12DAF2 WR12DAF2

No-load speed 0 – 2500/min

Capacity M4 – M8 (Small screw) M6 – M14 (Ordinary bolt)

Tightening torque

Rechargeable battery EB1214S: Ni-Cd battery, 12 V (1.4 Ah 10 cells)

Weight 1.6 kg (EB1214S Installation)

5

M5 – M12 (Ordinary bolt) M6 – M10 (High tension bolt)

M5 – M10 (High tension bolt)

Maximum 110 N·m {1120 kgf·cm}

Tightening is M12 high tension bolt

(strength grade 12.9), when fully

charged at 20°C temp.

Tightening time: 3 sec.

EB1220BL: Ni-Cd battery, 12 V (2.0 Ah 10 cells)

EB1226HL: Ni-MH battery, 12 V (2.6 Ah 10 cells)

Maximum 130 N·m {1330 kgf·cm}

Tightening is M12 high tension bolt

(strength grade 12.9), when fully

charged at 20°C temp.

Tightening time: 3 sec.

Page 7

English

CHARGER

Model UC14YFA UC18YG

Charging time EB1214S: Approx. 30 min. (at 20°C) EB1214S: Approx. 30 min. (at 20°C)

EB1220BL: Approx. 50 min. (at 20°C) EB1220BL: Approx. 50 min. (at 20°C)

EB1226HL: Approx. 60 min. (at 20°C) ×

Charging voltage 7.2 – 14.4 V 7.2 – 18 V

Weight 0.6 kg 0.3 kg

“x” Indicates that the battery pack is not compatible with that specific charger.

NOTE: The charging time may vary according to the ambient temperature and power source voltage.

STANDARD ACCESSORIES

1. Charger (UC14YFA or UC18YG) ............................... 1

2. Plastic case ................................................................ 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES

(Sold separately)

1. Battery (EB1214S, EB1220BL, EB1226HL)

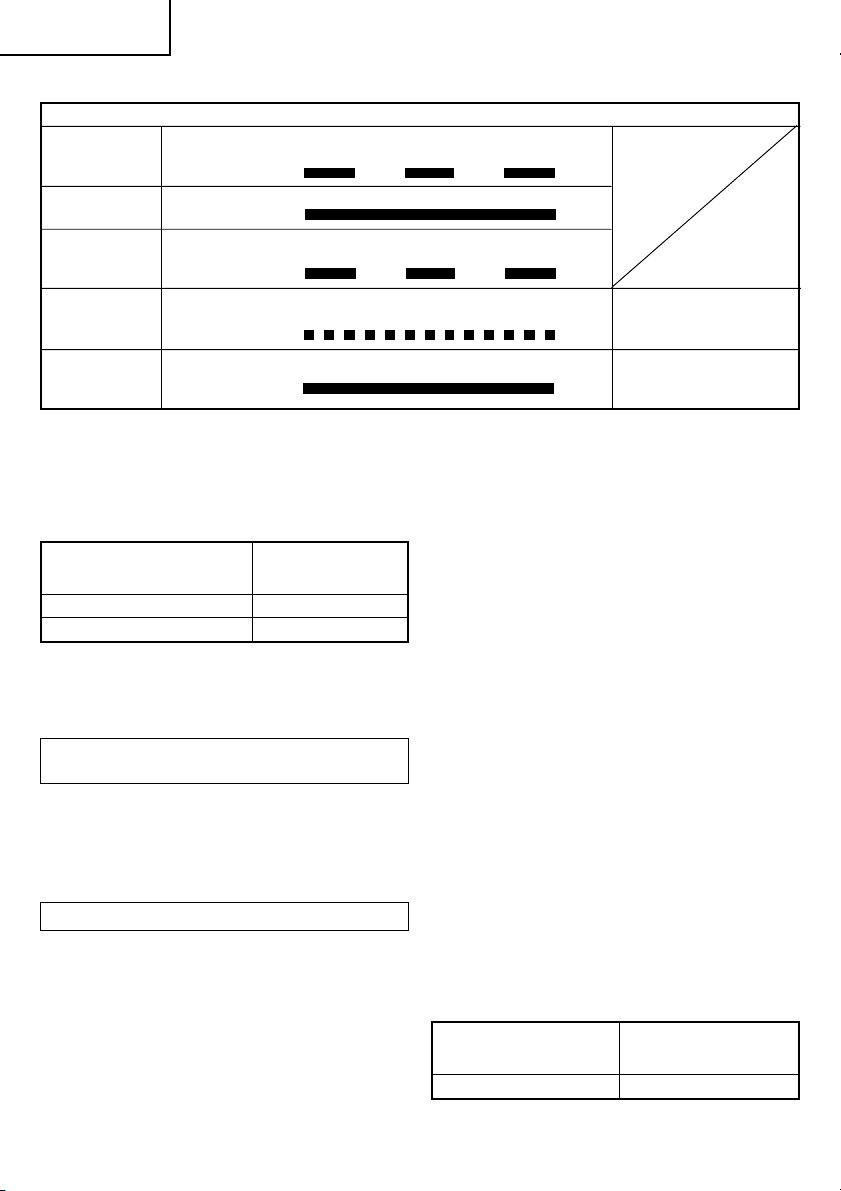

2. For WH12DAF2

There are two types of attachment sizes for the driver

bit and the socket. Please refer to the table below and

select the attachment size for the driver bit or socket

that is appropriate for your WH12DAF2.

Attachment size Purchase location

Type-L

Type-S

3. For WR12DAF2

The WR12DAF2 type is a 12.7 square driver

specification. Please select the socket with the

appropriate attachment size.

Optional accessories are subject to change without notice.

17mm

12mm

13mm

Republic of Korea,

Taiwan, Hong Kong,

People’s Republic of

China, Republic of

Singapore

9mm

Other than above

regions.

APPLICATION

〈WH12DAF2〉

䡬 Driving and removing of small screws, small bolts,

etc.

〈WR12DAF2〉

䡬 Tightening and loosening of all types of bolts and

nuts, used for securing structural items

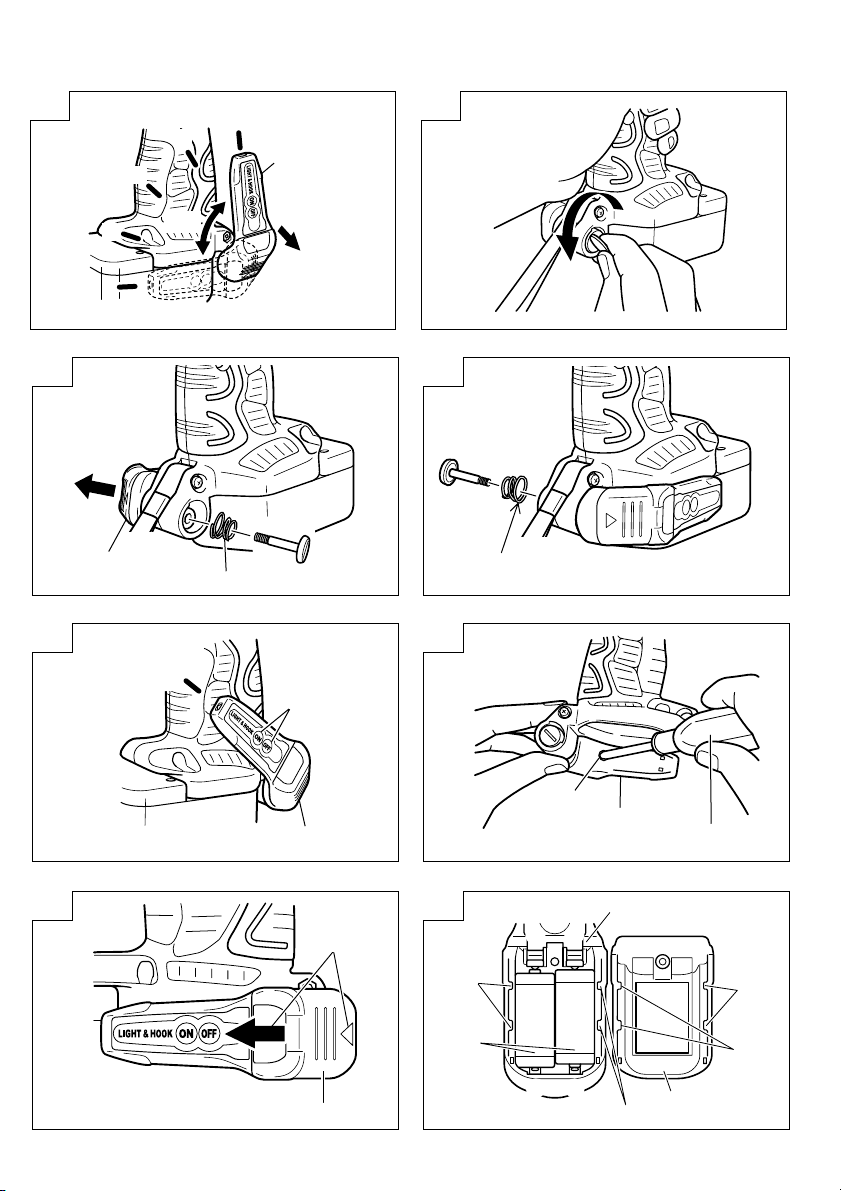

BATTERY REMOVAL/INSTALLATION

1. Battery removal

Hold the handle tightly and push the battery latch to

remove the battery. (See Fig. 1 and 2)

CAUTION:

Never short-circuit the battery.

2. Battery installation

Insert the battery while observing its polarities. (See

Fig. 2)

CHARGING

〈UC14YFA〉

Before using the power tool, charge the battery as follows.

1. Connect the charger’s power cord to a receptacle

When the power cord is connected, the charger’s

pilot lamp will blink in red. (At 1-second intervals.)

2. Insert the battery into the charger

Insert the battery firmly, in the direction shown in

Fig. 3, until it contacts the bottom of the charger

compartment.

CAUTION:

䡬 If the battery is inserted in the reverse direction, not

only recharging will become impossible, but it may

also cause problems in the charger such as deformed

recharging terminal.

3. Charging

When inserting a battery in the charger, charging will

commence and the pilot lamp will light up

continuously in red.

When the battery becomes fully recharged, the pilot

lamp will blink in red. (At 1-second intervals.) (See

Table 1)

(1) Pilot lamp indication

The indications of the pilot lamp will be as shown in

Table 1, according to the condition of the charger or

the rechargeable battery.

6

Page 8

English

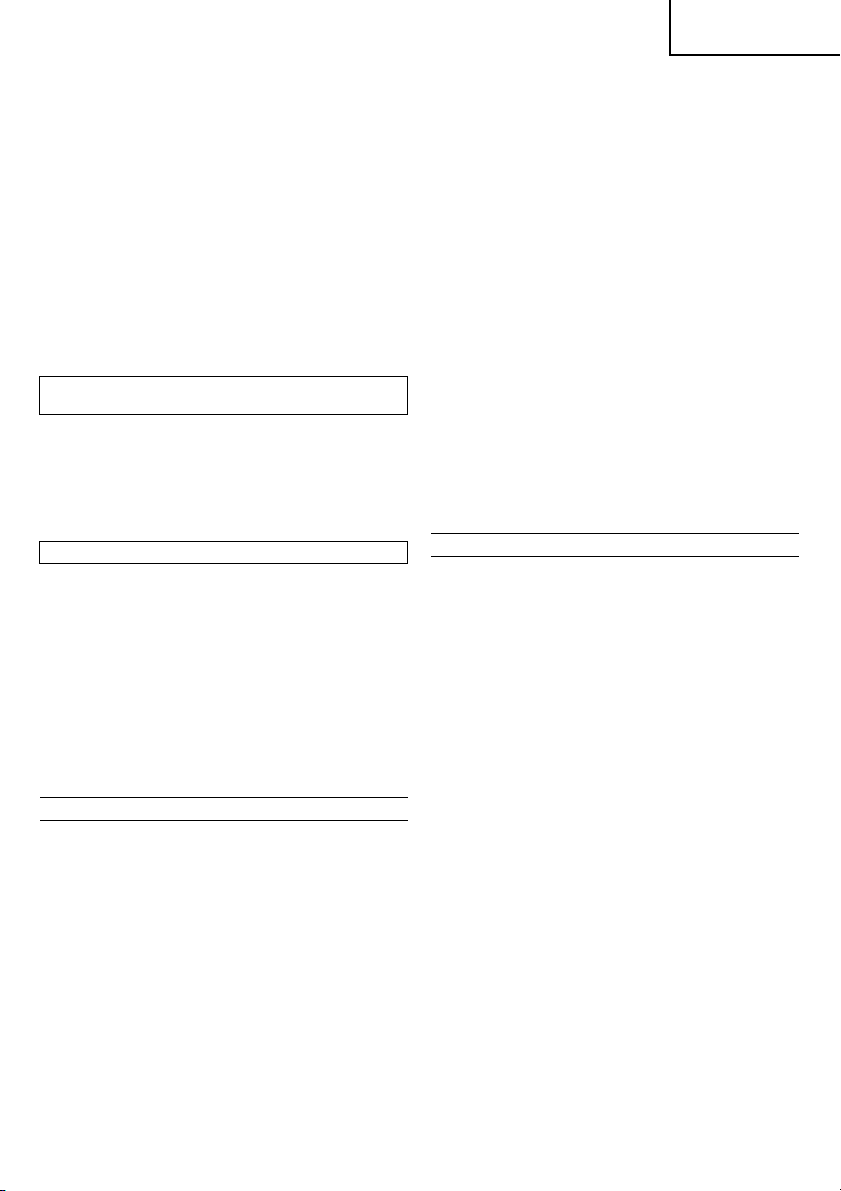

Table 1

Before

charging

While

charging

Charging

complete

Charging

impossible

Charging

impossible

Blinks

(RED)

Lights

(RED)

Blinks

(RED)

Flikers

(RED)

Lights

(GREEN)

Indications of the lamps

Lights for 0.5 seconds. Does not light for

0.5 seconds. (off for 0.5 seconds)

Lights continuously

Lights for 0.5 seconds. Does not light for

0.5 seconds. (off for 0.5 seconds)

Lights for 0.1 seconds. Does not light for

0.1 seconds. (off for 0.1 seconds)

Lights continuously

Malfunction in the battery

or the charger.

The battery temperature

is high, making

recharging impossible.

(2) Regarding the temperatures of the rechargeable battery

The temperatures for rechargeable batteries are as

shown in the table below, and batteries that have

become hot should be cooled for a while before

being recharged.

Table 2 Recharging ranges of batteries

Rechargeable batteries which the battery

EB1214S, EB1220BL –5°C – 60°C

EB1226HL 0°C – 45°C

4. Disconnect the charger’s power cord from the receptacle

5. Hold the charger firmly and pull out the battery

NOTE:

Be sure to pull out the battery from the charger after

use, and then keep it.

Regarding electric discharge in case of new

batteries, etc.

As the internal chemical substance of new batteries

and batteries that have not been used for an extended

period is not activated, the electric discharge might

be low when using them the first and second time.This is a temporary phenomenon, and normal time

required for recharging will be restored by recharging

the batteries 2 – 3 times.

How to make the batteries perform longer

(1) Recharge the batteries before they become completely

exhausted.

When you feel that the power of the tool becomes

weaker, stop using the tool and recharge its battery.

If you continue to use the tool and exhaust the electric

current, the battery may be damaged and its life will

become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after

use. If such a battery is recharged immediately after

use, its internal chemical substance will deteriorate,

and the battery life will be shortened. Leave the battery

and recharge it after it has cooled for a while.

7

Temperatures at

can be recharged

CAUTION:

䡬 If the battery is charged while it is heated because it

has been left for a long time in a location subject to

direct sunlight or because the battery has just been

used, the pilot lamp of the charger lights up green. In

such a case, first let the battery cool, then start

charging.

䡬 When the pilot lamp flikers in red quickly (at 0.2-

second intervals), check for and take out any foreign

objects in the charger’s battery installation hole. If

there are no foreign objects, it is probable that the

battery or charger is malfunctioning. Take it to your

Authorized Service Center.

䡬 Since the built-in micro computer takes about 3

seconds to confirm that the battery being charged

with UC14YFA is taken out, wait for a minimum of 3

seconds before reinserting it to continue charging. If

the battery is reinserted within 3 seconds, the battery

may not be properly charged.

〈

Before using the power tool, charge the battery as follows.

1. Connect the charger power cord to the receptacle

2. Insert the battery into the charger

䡬 Regarding the temperatures of the rechargeable

Table 3 Recharging ranges of batteries

䡬 The pilot lamp goes off to indicate that the battery is

〉

UC18YG

Connecting the power cord will turn on the charger.

Insert the battery firmly while observing its direction,

until it contacts the bottom of the charger (the pilot

lamp lights up) (See Fig. 4).

CAUTION

If the pilot lamp does not light up, pull out the

power cord from the receptacle and check the

battery mounting condition.

battery

The temperatures for rechargeable batteries are as

shown in Table 3.

Rechargeable batteries which the battery

EB1214S, EB1220BL 0°C – 45°C

fully charged.

Temperatures at

can be recharged

Page 9

English

The battery charging time becomes longer when a

temperature is low or the voltage of the power source

is too low.

When the pilot lamp does not go off even if more

than 120 minutes have elapsed after starting of the

charging, stop the charging and contact your HITACHI

AUTHORIZED SERVICE CENTER.

CAUTION

If the battery is heated due to direct sunlight, etc.,

just after operation, the charger pilot lamp may

not light up. At that time, cool the battery first,

then start charging.

3. Disconnect the charger’s power cord from the

receptacle

4. Hold the charger firmly and pull out the battery

NOTE

After charging, pull out batteries from the charger

first, and then keep the batteries properly.

Regarding electric discharge in case of new batteries,

etc.

As the internal chemical substance of new batteries

and batteries that have not been used for an extended

period is not activated, the electric discharge might

be low when using them the first and second time.

This is a temporary phenomenon, and normal time

required for recharging will be restored by recharging

the batteries 2 – 3 times.

How to make the batteries perform longer.

(1) Recharge the batteries before they become

completely exhausted.

When you feel that the power of the tool becomes

weaker, stop using the tool and recharge its battery.

If you continue to use the tool and exhaust the electric

current, the battery may be damaged and its life will

become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after

use. If such a battery is recharged immediately after

use, its internal chemical substance will deteriorate,

and the battery life will be shortened. Leave the

battery and recharge it after it has cooled for a while.

PRIOR TO OPERATION

1. Preparing and checking the work environment

Make sure that the work site meets all the conditions

laid forth in the precautions.

2. Checking the battery

Make sure that the battery is installed firmly. If it is at

all loose it could come off and cause an accident.

3. Installing the bit (WH12DAF2)

Always follow the following procedure to install driver

bit. (Fig. 5)

(1) Pull the guide sleeve away from front of the tool.

(2) Insert the bit into the hexagonal hole in the anvil.

(3) Release the guide sleeve and it returns to its original

position.

CAUTION:

If the guide sleeve does not return to its original

position, then the bit is not installed properly.

4. Selecting the socket matched to the bolt

(WR12DAF2)

Be sure to use a socket which is matched to the bolt

to be tightened. Using an improper socket will not

only result in insufficient tightening but also in

damage to the socket or nut.

A worn or deformed hex. or square-holed socket will

not give an adequate tightness for fitting to the nut or

anvil, consequently resulting in loss of tightening

torque.

Pay attention to wear of socket hole, and replace

before further wear has developed.

Finally, install the socket prescribed in Item 5. The

section on “Optional Accessories” details the

relationship between bolt sizes and sockets. Sockets

are named according to the dihedral width of the

hexagonal hole.

5. Installing a socket (WR12DAF2)

Select the socket to be used.

䢇 Pin, O-ring type (Fig. 6 and 7)

(1) Align the hole in the socket with the hole in the anvil

and insert the anvil into the socket.

(2) Insert the pin into the socket.

(3) Attach the ring to the groove on the socket.

䢇 Plunger type (Fig. 8)

Align the plunger located in the square part of the

anvil with the hole in the hex. socket. Then push the

plunger, and mount the hex. socket on the anvil.

Check that the plunger is fully engaged in the hole.

When removing the socket, reverse the sequence.

HOW TO USE

CAUTION:

䡬 When using the light equipped hook, pay sufficient

attention so that the main equipment does not fall. If

the tool falls, there is a risk of accident.

䡬 Do not attach the tip tool except phillips bit to the tool

main unit when carrying the tool main unit with the

light equipped hook suspended from a waist belt.

Injury may result if you carry the equipment

suspended from the waist belt with sharp tipped

components such as drill bit attached.

1. Using the light equipped hook

The light equipped hook can be installed on the right

or left side and the angle can be adjusted in 5 steps

between 0° and 80°.

(1) Operating the hook

(a) Pull out the hook toward you in the direction of

arrow (A) and turn in the direction of arrow (B).

(Fig. 9)

(b) The angle can be adjusted in 5 steps (0°, 20°, 40°,

60°, 80°).

Adjust the angle of the hook to the desired position

for use.

(2) Switching the hook position

CAUTION:

Incomplete installation of the hook may result in

bodily injury when used.

(a) Securely hold the main unit and remove the screw

using a slotted head screwdriver or a coin. (Fig.

10)

(b) Remove the hook and spring. (Fig. 11)

(c) Install the hook and spring on the other side and

securely fasten with screw. (Fig. 12)

NOTE:

Pay attention to the spring orientation. Install the

spring with larger diameter away from you. (Fig. 12)

8

Page 10

English

(3) Using as an auxiliary light

(a) Press the switch to turn off the light.

If forgotten, the light will turn off automatically

after 15 minutes.

(b) The direction of the light can be adjusted within

the range of hook positions 1 - 5. (Fig. 13)

䡬 Lighting time

AAAA manganese batteries: approx. 15 hrs.

CAUTION:

(4) Replacing the batteries

NOTE:

CAUTION:

䡬 Failure to observe the following can result in battery

䡬 Do not discard batteries together with normal trash

䡬 Store batteries out of the reach of children.

䡬 Use batteries correctly in accordance with the battery

2. Check the rotational direction

CAUTION:

3. Switch operation

䡬 When the trigger switch is depressed, the tool rotates.

䡬 The rotational speed can be controlled by varying the

4. Tightening and loosening screws (WH12DAF2)

9

AAAA alkali batteries: approx. 30 hrs.

Do not look directly into the light.

Such actions could result in eye injury.

(a) Loosen the hook screw with a phillips-head

screwdriver (No. 1). (Fig. 14)

Remove the hook cover by pushing in the direction

of the arrow. (Fig. 15)

(b) Remove the old batteries and insert the new

batteries. Align with the hook indications and

position the plus (+) and minus (–) terminals

correctly. (Fig. 16)

(c) Align the indentation in the hook main body with

the protuberance of the hook cover, press the

hook cover in the direction opposite to that of the

arrow shown in Fig. 15 and then tighten the screw.

Use commercially available AAAA batteries

(1.5 V).

Do not tighten the screw excessively. Such action

could strip the screw threads.

leakage, rust or malfunction.

Position the plus (+) and minus (–) terminals correctly.

Replace both batteries at the same time. Do not mix

old and new batteries.

Remove exhausted batteries from the hook

immediately.

and do not throw batteries into fire.

specifications and indications.

The bit rotates clockwise (viewed from the rear side)

by pushing the R-side of the push button.

The L-side of the push button is pushed to turn the bit

counterclockwise. (See Fig. 17) (The

are provided on the body.)

The push button cannot be switched while the impact

driver is turning. To switch the push button, stop the

impact driver, then set the push button.

When the trigger is released, the tool stops.

amount that the trigger switch is pulled. Speed is low

when the trigger switch is pulled slightly and increases

as the trigger switch is pulled more.

Install the bit that matches the screw, line up the bit

in the grooves of the head of the screw, then tighten

it.

Push the impact driver just enough to keep the bit

fitting the head of the screw.

and R marks

L

CAUTION:

Applying the impact driver for too long tightens the

screw too much and can break it.

Tightening a screw with the impact driver at an angle

to that screw can damage the head of the screw and

the proper force will not be transmitted to the screw.

Tighten with this impact driver lined up straight with

the screw.

5. Number of screws tightenings possible (WH12DAF2)

Please refer to the table below for the number of

screw tightened possible with one charge.

EB1214S

Screw used No. of tightenings

Wood screw ø4 × 50

(Soft wood)

Machine screw M8 × 16

These values may vary slightly, according to

surrounding temperature and battery characteristics.

6. Number of bolt tightened possible (WR12DAF2)

Please refer to the table below for the number of bolt

tightened possible with one charge.

EB1214S

Bolt used No. of tightenings

M12 × 45 High tension bolt

These values may vary slightly, according to

surrounding temperature and battery characteristics.

NOTE:

The use of the battery EB1226HL in a cold condition

(below 0 degree Centigrade) can sometimes result in

the weakened tightening torque and reduced amount

of work. This, however, is a temporary phenomenon,

and returns to normal when the battery warms up.

Approx. 190

Approx. 500

Approx. 87

OPERATIONAL CAUTIONS

1. Resting the unit after continuous work

After use for continuous bolt-tightening work, rest

the unit for 15 minutes or so when replacing the

battery. The temperature of the motor, switch, etc.,

will rise if the work is started again immediately after

battery replacement, eventually resulting in burnout.

NOTE:

Do not touch the hammer case, as it gets very hot

during continuous work.

2. Cautions on use of the speed control switch

This switch has a built-in, electronic circuit which

steplessly varies the rotation speed. Consequently,

when the switch trigger is pulled only slightly (low

speed rotation) and the motor is stopped while

continuously driving in screws, the components of

the electronic circuit parts may overheat and be

damaged.

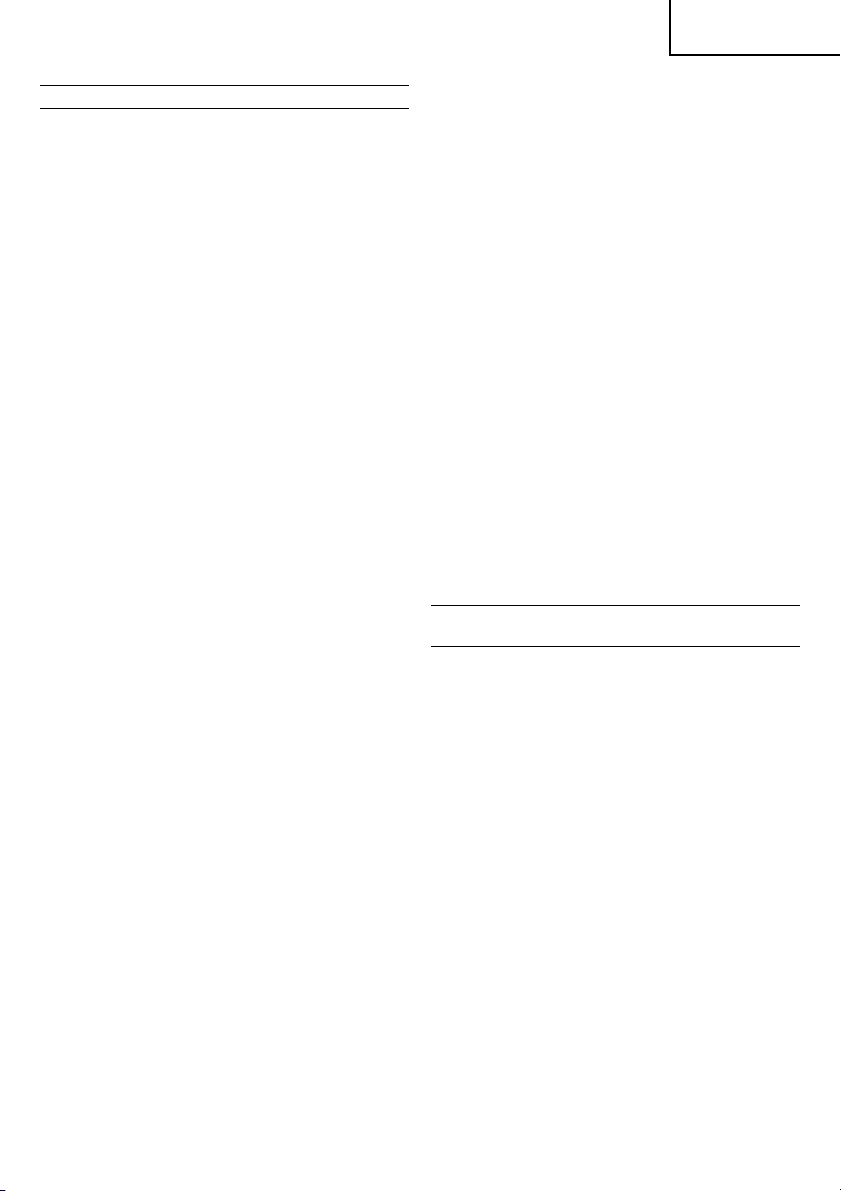

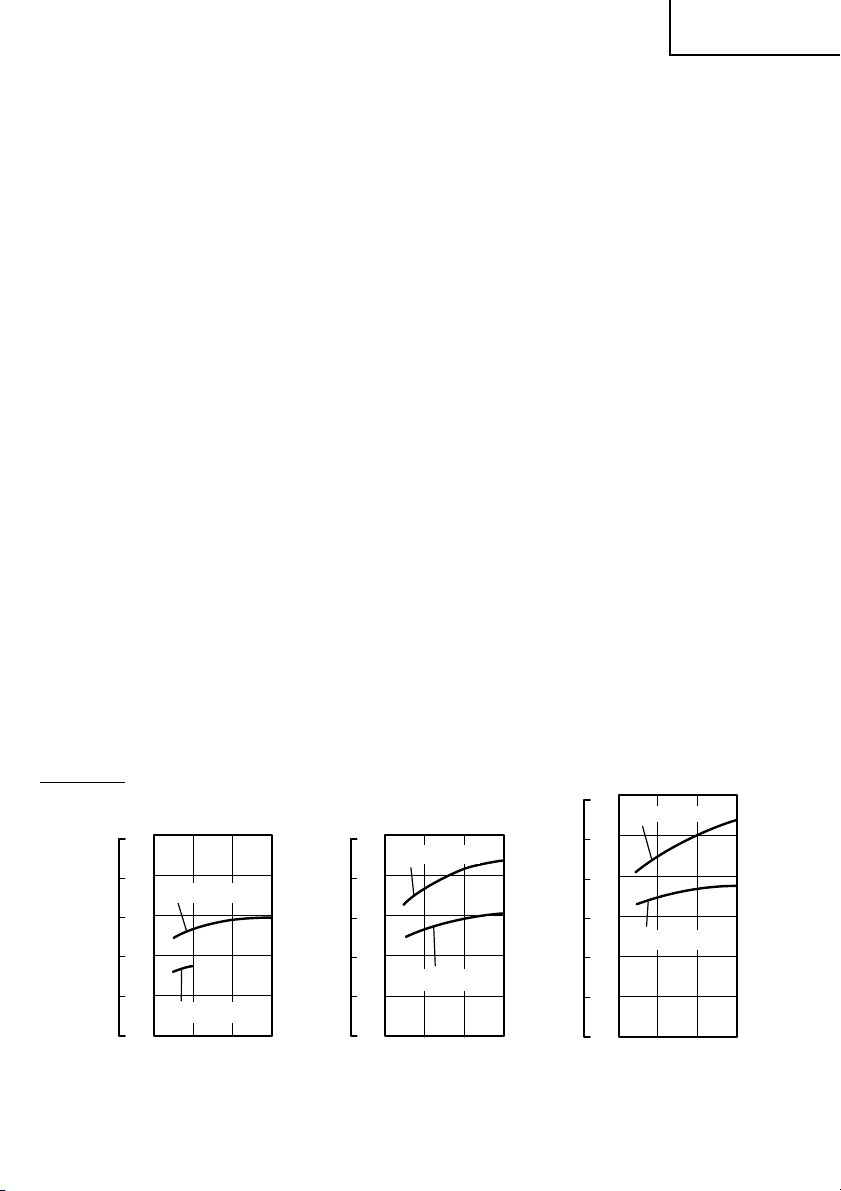

3. Tightening torque

Refer to Fig. 18 and Fig. 19 for the tightening torque

of bolts (according to size), under the conditions

shown in Fig. 20. Please use this example as a general

reference, as tightening torque will vary according to

tightening conditions.

Page 11

English

NOTE:

䡬 If a long striking time is used, screws will be strongly

tightened. This may cause the screw to break, or may

damage the tip of the bit.

䡬 If the unit is held at an angle to the screw being

tightened, the head of the screw may be damaged, or

the specified torque may not be transmitted to the

screw. Always keep the unit and the screw being

tightened in a straight line.

4. Use a tightening time suitable for the screw

The appropriate torque for a screw differs according

to the material and size of the screw, and the material

being screwed etc., so please use a tightening time

suitable for the screw. In particular, if a long tightening

time is used in the case of screws smaller than M8,

there is a danger of the screw breaking, so please

confirm the tightening time and the tightening torque

beforehand.

5. Work at a tightening torque suitable for the bolt

under impact

The optimum tightening torque for nuts or bolts differs

with material and size of the nuts or bolts. An

excessively large tightening torque for a small bolt

may stretch or break the bolt. The tightening torque

increases in proportion to the operaton time. Use the

correct operating time for the bolt.

6. Holding the tool

Hold the impact wrench firmly with both hands. In

this case hold the wrench in line with the bolt.

It is not necessary to push the wrench very hard.

Hold the wrench with a force just sufficient to

counteract the impact force.

7. Confirm the tightening torque

The following factors contribute to a reduction of the

tightening torque. So confirm the actual tightening

torque needed by screwing up some bolts before the

job with a hand torque wrench. Factors affecting the

tightening torque are as follows.

(1) Voltage

When the discharge margin is reached, voltage

decreases and tightening torque is lowered.

(2) Operating time

The tightening torque increases when the operating

time increases. But the tightening torque does not

increase above a certain value even if the tool is

driven for a long time. (See Fig. 18 and 19)

(3) Diameter of bolt

The tightening torque differs with the diameter of the

bolt as shown in Fig. 18 and 19. Generally a larger

diameter bolt requires larger tightening torque.

(4) Tightening conditions

The tightening torque differs according to the torque

ratio; class, and length of bolts even when bolts with

the same size threads are used. The tightening torque

also differs according to the condition of the surface

of workpiece through which the bolts are to be

tightened. When the bolt and nut turn together, torque

is greatly reduced.

(5) Using optional parts (WR12DAF2)

The tightening torque is reduced a little when an

extension bar, universal joint or a long socket is

used.

(6) Clearance of the socket (WR12DAF2)

A worn or deformed hex. or a square-holed socket

will not give an adequate tightness to the fitting

between the nut or anvil, consequently resulting in

loss of tightening torque.

Using an improper socket which does not match to

the bolt will result in an insufficient tightening torque.

(7) Tightening torque varies, depending on the battery’s

charge level. (WR12DAF2)

Fig. 21 show examples of the relationship between

tightening torque and the number of tightenings, for

WR12DAF2. As shown, tightening torque gradually

weakens with the increase in the number of

tightenings. In particular, as the torque decreases

very close to the complete discharge (“a” margin in

graph), the unit’s impact weakens, the number of

time impacts declines and tightening torque drops

off abruptly. If this occurs, check torque level, then

recharge the battery if necessary.

〈

WH12DAF2

•

cm

kgf

1000

800

600

400

Tightening torque

200

〉

•

N

m

100

80

High tension bolt

60

M8 × 30

kgf

•

cm

1000

800

600

•

N

m

M10 × 30

100

High tension bolt

80

60

kgf

•

cm

1200

1000

800

600

•

N

m

M12 × 45

120

High tension bolt

100

80

60

Ordinary bolt

40

40

20

Ordinary bolt

0

0

0123 0123 0123

Tightening time: sec.

(Steel plate thickness

t = 10 mm)

400

Tightening torque

200

0

Ordinary bolt

20

0

Tightening time: sec.

(Steel plate thickness

t = 10 mm)

40

400

Tightening torque

20

200

0

0

Tightening time: sec.

(Steel plate thickness

t = 25 mm)

Fig. 18

10

Page 12

English

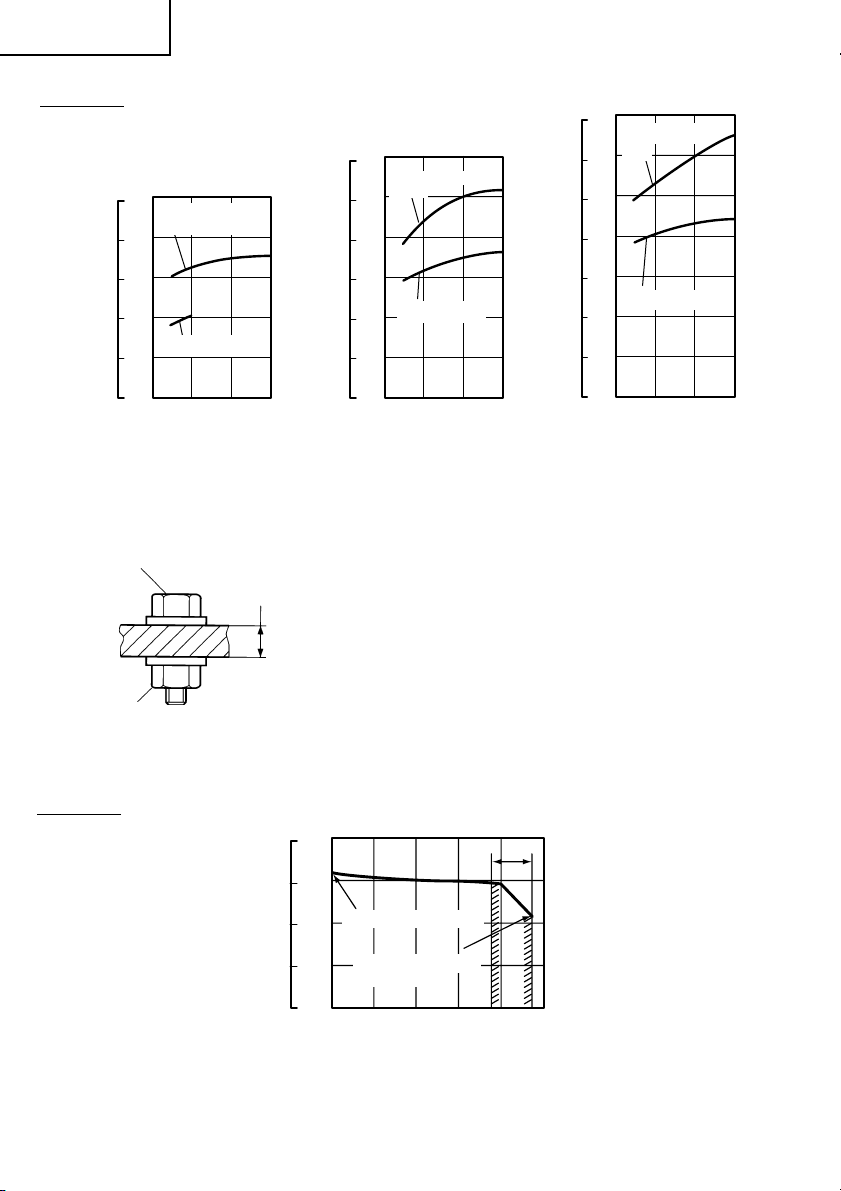

〈

WR12DAF2

•

cm

kgf

1000

800

600

400

200

Tightening torque

•

•

m

cm

kgf

〉

•

•

N

m

cm

kgf

1200

N•m

0

Tightening time: sec.

(Steel plate thickness

t = 10 mm)

M8 × 30

100

High tension

bolt

80

60

40

Ordinary bolt

20

0

012 3 0123 01 23

1000

800

600

400

Tightening torque

200

0

Tightening time: sec.

(Steel plate thickness

t = 10 mm)

120

High tension

bolt

100

80

60

40

20

0

M10 × 30

Ordinary bolt

N

140

1400

1200

1000

800

600

400

Tightening torque

200

120

100

0

High tension

bolt

80

60

Ordinary bolt

40

20

0

Tightening time: sec.

(Steel plate thickness

t = 25 mm)

M12 × 45

Fig. 19

〈WR12DAF2〉

Bolt

Nut

Steel plate thickness t

M12 × 45 High tension bolt

•

•

m

cm

kgf

N

160

1600

120

1200

When full recharged

80

800

40

400

Tightening torque

0

0

0 20 40 60 80 100

Number of tightenings (PCS)/charging

*The following bolt is used.

Ordinary bolt: Strength grade 4.8

High tension bolt: Strength grade 12.9

Fig. 20

(tighening time 3 sec)

When completely

discharged

Fig. 21

Explanation of strength grade:

4 — Yield point of bolt: 32 kgf/mm

2

8 — Pulling strength of bolt: 40 kgf/mm

a

)(

2

11

Page 13

MAINTENANCE AND INSPECTION

1. Inspecting the driver bit (WH12DAF2)

Using a broken bit or one with a worn out tip is

dangerous because the bit can slip. Replace it.

2. Inspecting the socket (WR12DAF2)

A worn or deformed hex. or a square-holed socket

will not give an adequate tightness to the fitting

between the nut or anvil, consequently resulting in

loss of tightening torque. Pay attention to wear of a

socket holes periodically, and replace with a new one

if needed.

3. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so may result in serious hazard.

4. Cleaning of the outside

When the impact driver is stained, wipe with a soft

dry cloth or a cloth moistened with soapy water. Do

not use chloric solvents, gasoline or paint thinner, as

they melt plastics.

5. Storage

Store the impact driver in a place in which the

temperature is less than 40°C, and out of reach of

children.

6. Service parts list

A : Item No.

B : Code No.

C : No. Used

D : Remarks

CAUTION:

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS:

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE:

Due to HITACHI’s continuing program of reserch and

development, the specifications herein are subject to

change without prior notice.

English

12

Page 14

Español

PRECAUCIONES GENERALES PARA

OPERACIÓN

¡ADVERTENCIA! Cuando utilice herramientas con pilas,

siga siempre las precauciones básicas relativas a la

seguridad para reducir el riesgo de incendio, la fuga de

las pilas y los daños personales, incluidos los siguientes.

Lea todas todas estas instrucciones antes de utilizar este

producto y guárdelas.

Para realiza roperaciones seguras:

1. Mantener el área de trabajo limpia, áreas y bancos

de trabajo desordenados son causa de daños

personales.

2. Tenga en cuenta el entorno de trabajo. No exponga

las herramientas a la lluvia. No utilice herramientas

en lugares húmedos o mojados. Mantenga el área

de trabajo bien iluminado.

No utilice las herramientas cuando haya riesgo de

incendio o explosión.

3. Mantenga a los niños alejados del área de trabajo.

No deje que otras personas toquen la herramienta.

Toda persona ajena al trabajo debe mantenerse

alejada del área de trabajo.

4. Guardar las pilas o herramientas que no se utilicen.

Cuando no se utilicen las herramientas y las pilas,

deben guardarse por separado en un lugar seco,

alto o con llave, fuera del alcance de los niños.

Asegúrese de que los terminales de las pilas no

pueden fundirse por otras piezas metálicas como

tornillos, clavos, etc.

5. No forzar las herramientas, éstas trabajarán más

y con mayor seguridad cuando cumplan con las

especificaciones para las cuales fueron diseñadas.

6. Utilice la herramienta adecuada. No fuerce

herramientas pequeñas o accesorios para hacer

el trabajo de herramientas de alta resistencia. No

utilice herramientas para fines para los que no

están diseñadas.

7. Vestir apropiadamente. No ponerse ropas que

queden flojas ni tampoco joyas. Estas podrian

quedar atrapadas en las partes móviles de las

herramientas. Cuando se trabaje en exteriores, se

recomienda el uso de guantes de goma y calzado

que no resbale. Utilice elementos de protección

para sujetar el cabello largo.

8. Utilice gafas de seguridad. Asimismo, utilice

mascarilla para el polvo o la cara si la operación

de cortado levanta mucho polvo.

9. Conecte un equipo colector de polvo.

Si existen dispositivos para la conexión de equipos

de extracción y recolección de polvo, cerciórese

de queéstos estén conectados adecuadamente, y

de utilizarlos en la forma correcta.

10. No abuse del cable (si viene incorporado). No

transporte la herramienta con el cable o tire de

él para desconectarla del enchufe. Mantenga el

cable alejado de las fuentes de calor, el aceite y

bordes afilados.

11. Asegurar la pieza de trabajo usando para ello

abrazaderas o un tornillo. Esto es más seguro que

usar las manos, ademas, ambas manos quedan

libres para operar la herramienta.

12. No extenderse excesivamente para efectuar un

trabajo. Mantener en todo momento un buen

balance y base de apoyo.

13. Mantenga las herramientas con cuidado. Mantenga

las herramientas de cortado afiladas y limpias

para un funcionamiento mejor y más seguro. Siga

las instrucciones de lubricación y cambio de

accesorios. Inspeccione los cables de la

herramienta periódicamente y si están dañados,

llévelos a un servicio autorizado para que los

repare. Mantenga los mangos secos, limpios y

libres de aceite y grasa.

13

14. Desconecte las herramientas

Cuando el diseño lo permita, extraiga el paquete

de pilas de la herramienta cuando no la esté

utilizando, antes de realizar su mantenimiento o

cuando cambie accesorios como cuchillas, brocas

y cortadoras.

15. Quitar las cuñas y las llaves de tuercas.

Acostumbrarse a comprobar si se han quitado las

cuñas y las llaves de tuercas antes de poner las

harramientas en funcionamiento.

16. Evite que la herramienta se ponga en marcha

inesperadamente. No transporte la herramienta

con un dedo en el interruptor.

17. Estar siempre alerta y poner atención a lo que

se está haciendo, usar el sentido común y no

operar con la herramienta cuando se esté cansado.

18. Comprobar las piezas dañadas. Antes de seguir

con el funcionamiento de las herramientas, las

piezas que estén dañadas deberán comprobarse

cuidadosamente para determinar si pueden

funcionar apropiadamente y cumplir con la función

para las que fueron diseñadas. Comprobar el

alineamiento y agarrotamiento de piezas móviles,

rotura de piezas, montura, y cualiquier otra

anomalia que pudiese afectar al rendimiento de

la herramienta. Cualquier pieza que estuviese

dañada deberá repararse apropiadamente o

cambiarse en un centro de reparaciones autorizado,

al menos que se indique, lo contrario en este

manual de instrucciones. Deje que un servicio

autorizado sustituya los interruptores defectuosos.

No utilice la herramienta si el interruptor no la

enciende o apaga.

19. Advertencia

䡬 La utilización de cualquier accesorio o aditivo no

recomendado en este manual de instrucciones

puede conducir al riesgo de lesiones.

䡬 Asegúrese de que el paquete de pilas es correcto

para la herramienta.

䡬 Asegúrese de que la superficie externa del paquete

de pilas y la herramienta están limpias y secas

antes de enchufar el cargador.

䡬 Asegúrese de que las pilas están cargadas

utilizando el cargador correcto recomendado por

el fabricante. Una utilización incorrecta puede

causar una descarga eléctrica, un recalentamiento

o una fuga de líquido corrosivo de las pilas.

20. La herramienta debe ser reparada por una persona

cualificada.

Esta herramienta cumple los requisitos relevantes

sobre seguridad. Las reparaciones sólo deben

realizarse por personas cualificadas que utilicen

piezas de repuesto originales. De lo contrario, el

usuario podría estar expuesto a importantes

riesgos.

21. Desecho de las pilas

Asegúrese de que las pilas se desechan de forma

segura tal y como indica el fabricante.

22. Si se utilizan bajo condiciones abusivas, saldrá

líquido de las pilas. Evite el contacto.

Si ocurre esto, aclare con agua. Si entra líquido

en contacto con los ojos, acuda a su médico.

PRECAUCIONES PARA EL ATORNILLADOR DE

IMPACTO A BATERÍA

1. Esta es una herramienta portátil para apretar y

aflojar tornillos. Empléela solamente para este fin.

2. Utilizar tapones en los oidos cuando se utilice la

herramienta durante un largo período de tiempo.

3. El empleo con una sola mano es extremadamente

peligroso; cuando utilice La unidad, sosténgala

firmemente con ambas manos.

Page 15

Español

4. Después de instalar la punta de destornillador, tire

ligeramente de la misma para asegurarse de que

no esté floja. Si no instala adecuadamente la

punta, es posible que ésta se afloje durante la

operación, lo que podría resultar peligroso.

5. Emplee la punta de destornillador adecuada al

tornillo.

6. El apretado angular de un tornillo con el

atornillador de impacto puede dañar la cabeza del

mismo, y es posible que a éste no se le transmita

la fuerza apropiada. Apriete con este atornillador

de impacto alineado con el tornillo.

7. Siempre cargar la batería a una temperatura de

0 – 40°C.

Una temperatura inferior a 0°C causa una

sobrecarga, lo que es peligroso. No puede cargarse

la batería a una temperatura mayor de 40°C.

La temperatura más apropiada para cargar es la

de 20 – 25°C.

8. No usar el cargador continuamente.

Cuando se completa la carga, dejar descansar el

cargador por 15 minutos antes de proseguir con

la carga siguiente.

9. No dejar que entre suciedad por el orificio de

conexión de la batería recargable.

10. Nunca desarmar la batería recargable ni el

cargador.

11. Nunca poner en cortocircuito la batería recargable.

Poner en cortocircuito a la batería produce una

corriente eléctrica enorme y el consecuente

recalentamiento, pudiendo quemar o deteriorar la

batería.

12. No tirar la batería al fuego.

Si se quema la batería puede explotar.

13. No insertar ningún objeto en las ranuras de

ventilación del cargador.

La penetración de objetos metálicos o inflamables

en dichas ranuras puede provocar electrochoques

o dañar el cargador.

14. Llevar la batería al sitio de compra original en el

caso de que la duración de la batería recargable

sea reducida al usarse. No tirar la batería

descargada.

15. El uso de una batería descargada dañará el

cargador.

PRECAUCIONES PARA LA LLAVE DE IMPACTO

A BATERÍA

1. Esta es una harramienta prtátil para apretar y

aflojar tornillos. Empléela solament para este fin.

2. Utilizar tapones en los oidos cuando se utilice la

herramienta durante un largo período de tiempo.

3. El empleo con una sola mano es extremadamente

peligroso; cuando utilice La unidad, sosténgala

firmemente con ambas manos.

4. Comprueba que el receptáculo no esté rajado ni

roto.

Los receptáculos rajados o rotos son peligrosos.

Compruébelos antes de emplearlos.

5. Sujete el receptáculo con el pasador y el anillo.

Si el pasador o el anillo de sujeción del receptáculo

está dañado, éste oye de salirse de la llave de

percusión, lo que puede resultar bastante peligroso.

No emplee pasadores ni anillos deformados,

gastados, rajados, ni con qualiquier otro daño.

Asegúrese siempre de instalar el apsador y el

anillo en la posición correcta.

6. Verifique el par de apriete. El par correcto para

apretar un perno dependerá del material dicho

perno, sus dimensiones, clase, etc.

Además, el par de apriete generado por esta llave

de percusión dependerá de los materiales y

dimensiones del perno, el tiempo que se aplique

la llava, la forma en la que se haya instalado el

receptáculo, etc.

Además, el par con la batería recién cargada y

con ella a punto de agatarse será ligeramente

diferente. Emplee una llave torsimétrica para

comprobar si el pernose ha apretado con el par

apropiado.

7. Antes de cambiar el sentodo de rotación para la

llave de percuión. Antes de cabiar el sentido de

rotación, suelte el interruptor y espere hasta que

la llave de percusión se pare.

8. No toque nunca las partes giratorias.

No permita que la sección del receptáculo entre

en contacto con sus manos ni con ninguna otra

parte del cuerpo. El receptáculo podría dañarle.

Además, tenga cuidado de no tocarlo después de

haberlo empleado continumente durante mucho

tiempo ya que estará caliente y podria porducirle

quemaduras.

9. No deje nunca que la llave de percusión gire sin

carge cuando emplee la junta cardáncica.

Si el receptáculo gira sin carge conectada, la junta

cardáncia hará que el receptáculo gire libremente,

en cuyo caso podría surfrir daños personales, o

las sacudidas del receptáculo podrían hacer que

la llave de percusión se cayese.

10. Siempre cargar la batería a una temperatura de

0 – 40°C.

Una temperatura inferior a 0°C causa una

sobrecarga, lo que es peligroso. No puede cargarse

la batería a una temperatura mayor de 40°C.

La temperatura más apropiada para cargar es la

de 20 – 25°C.

11. No usar el cargador continuamente.

Cuando se completa la carga, dejar descansar el

cargador por 15 minutos antes de proseguir con

la carga siguiente.

12. No dejar que entre suciedad por el orificio de

conexión de la batería recargable.

13. Nunca desarmar la batería recargable ni el

cargador.

14. Nunca poner en cortocircuito la batería recargable.

Poner en cortocircuito a la batería produce una

corriente eléctrica enorme y el consecuente

recalentamiento, pudiendo quemar o deteriorar la

batería.

15. No tirar la batería al fuego.

Si se quema la batería puede explotar.

16. No insertar ningún objeto en las ranuras de

ventilación del cargador.

La penetración de objetos metálicos o inflamables

en dichas ranuras puede provocar electrochoques

o dañar el cargador.

17. Llevar la batería al sitio de compra original en el

caso de que la duración de la batería recargable

sea reducida al usarse. No tirar la batería

descargada.

18. El uso de una batería descargada dañará el

cargador.

MODELO

WH12DAF2: con cargador y caja

WR12DAF2:con cargador y caja

14

Page 16

Español

ESPECIFICACIONES

HERRAMIENTA MOTORIZADA

Modelo WH12DAF2 WR12DAF2

Velocidad sin carga 0 – 2500/min

Capacidad M4 – M8 (Tornillo pequeño) M6 – M14 (Perno ordinario)

Torsión de apriete

Batería recargable EB1214S: Batería Ni-Cd, 12 V (1,4 Ah 10 elementos)

Peso 1,6 kg (Instalación de EB1214S)

CARGADOR

Modelo UC14YFA UC18YG

Tiempo de carga EB1214S: Aprox. 30 min. (a 20°C) EB1214S: Aprox. 30 min. (a 20°C)

Tensión de carga 7,2 – 14,4 V 7,2 – 18 V

Peso 0,6 kg 0,3 kg

“×” indica que el paquete de batería no es compatible con dicho cargador.

NOTA: El tiempo de carga puede variar de acuerdo con la temperatura ambiente y la tensión de la fuente de

alimentación.

M5 – M12 (Perno ordinario)

M5 – M10 (Pernos de gran resistencia a la tracción)

Máxima 110 N·m {1120 kgf·cm}

La torsión es de pernos M12 de gran

resistencia a la tracción (división de

dureza 12,9) con la batería

completamente cargada a 20°C de

temperatura.

Tiempo de torsión: 3 seg.

EB1220BL: Batería Ni-Cd, 12 V (2,0 Ah 10 elementos)

EB1226HL: Batería Ni-MH, 12 V (2,6 Ah 10 elementos)

EB1220BL: Aprox. 50 min. (a 20°C) EB1220BL: Aprox. 50 min. (a 20°C)

EB1226HL: Aprox. 60 min. (a 20°C) ×

ACCESORIOS ESTÁNDAR

1. Cargador (UC14YFA o UC18YG) ............................... 1

2. Caja de plástico .......................................................... 1

Los accesorios están sujetos a cambio sin previo aviso.

Tipo-L

ACCESORIOS OPCIONALES

(de venta por separado)

1. Batterie (EB1214S, EB1220BL, EB1226HL)

Tipo-S

M6 – M10 (Pernos de gran resistencia a la tracción)

Máxima 130 N·m {1330 kgf·cm}

La torsión es de M12 Pernos de gran

resistencia a la tracción (división de

dureza 12,9), con la batería

completamente cargada, a 20°C de

temperatura.

Tiempo de torsión: 3 seg.

Tamaño del accesorio Lugar de compra

17mm

12mm

13mm

República de Corea,

Taiwán, Hong Kong,

República Popular de

China, República de

Singapur

Otras regiones

9mm

diferentes a las

indicadas más

arriba.

2. Para WH12DAF2

Hay dos tipos de tamaños de accesorios para la

broca del atornillador y el receptáculo. Consulte la

tabla de abajo y seleccione el tamaño del accesorio

para la broca del atornillador o el receptáculo

adecuado para su WH12DAF2.

15

3. Para WR12DAF2

El WR12DAF2 es un atornillador cuadrado de 12,7.

Seleccione el receptáculo con el tamaño de accesorio

adecuado.

Los accesorios estándar están sujetos a cambio sin previo

aviso.

APLICACIÓN

〈WH12DAF2〉

䡬 Apretado y aflojado de tornillos pequeños, pernos

pequeños, etc.

Page 17

Español

〈WR12DAF2〉

䡬 Apretado y aflojado de cualquier tipo de pernos y

tuercas pasa aseguerar estructuras.

DESMONTAJE E INSTALACIÓN DE BATERÍA

1. Desmontaje de la batería

Sujetar firmemente el asidero y presionar el cierre de

la batería para desmontarla (Ver las Figs. 1 y 2).

PRECAUCIÓN:

No cortocircuitar nunca la batería.

2. Instalación de la batería

Insertar la batería observando sus polaridades (Ver

la Fig. 2).

CARGA

〈UC14YFA〉

Antes de utilizar la herramienta eléctrica, cargue la batería

de la siguiente manera.

1. Enchufe el cable de alimentación del cargador a un

tomacorriente de CA

Tabla 1

Indicaciones de la lámpara piloto

Antes de la

carga

Durante la

carga

Carga

completa

Parpadeo

(ROJA)

Iluminación

(ROJA)

Parpadeo

(ROJA)

Se encenderá durante 0,5 segundos.

No se encenderá durante 0,5 segundos.

(Apagada durante 0,5 segundos)

Iluminación permanente

Se encenderá durante 0,5 segundos.

No se encenderá durante 0,5 segundos.

(Apagada durante 0,5 segundos)

Cuando haya conectado el enchufe del cargador a

una toma de la red, la lámpara piloto se encendrá en

rojo. (A intervalos de 1 segundo.)

2. Inserte la batería en el cargador

Inserte firmemente la batería en la dirección mostrada

en la Fig.3, hasta que entre en contacto con el fondo

del compartimiento del cargador.

PRECAUCIÓN:

䡬 Si inserta la batería al revés, no sólo será imposible

cargarlas, sino que también se podrán producir

problemas en el cargador, como la deformación del

terminal de recarga.

3. Carga

Cuando inserte una batería en el cargador, la carga

comenzará la lá mpara piloto permanecerá

continuamente encendida en rojo.

Cuando la bateria se haya cargado completamente,

la lámpara piloto parpadeará en rojo. (A intervalos de

1 segundo.) (Vea las Tabla 1)

(1) Indicaciones de la lámpara piloto

Las indicaciones de la lámpara piloto mostradas en la

Tabla 1, se producirán de acuerdo con la condición

del cargador o de la batería.

Carga

imposible

Carga

imposible

(2) Temperatura de las baterías

La temperatura de las baterías se muestra en la tabla

siguiente, y las baterías que se hayan calentado

deberán dejarse enfriar durante cierto tiempo antes

de cargarlas.

Tabla 2 Márgenes de carga de las baterías

Batería que podrá cargarse

EB1214S, EB1220BL –5°C – 60°C

EB1226HL 0°C – 45°C

4. Desenchufe el cable de alimentación del cargador

del tomacorriente de CA

5. Sostenga el cargador firmemente y saque la batería

Parpadeo

(ROJA)

Iluminación

(VERDE)

Se encenderá durante 0,1 segundos.

No se encenderá durante 0,1 segundos.

(Apagada durante 0,1 segundos)

Illuminación permanente

Temperatura con la

la batería

Mal funcionamento de

la batería o del

cargador

La température de la

batería es alta, lo que

imposibilita la carga.

NOTA:

Asegúrese de extraer la batería del cargador después

del uso, y guárdela después.

Descarga eléctrica en caso de baterías nuevas, etc.

Como la substancia química interna de las baterías

nuevas o las que no se hayan utilizado durante mucho

tiempo no está activada, la descarga eléctrica puede

ser inferior cuando se utilicen por primera y segunda

vez. Este fenómeno es temporal, y el tiempo normal

requerido para la recarga se restablecerá recargando

las baterías 2 – 3 veces.

Forma de hacer que las baterías duren más

(1) Recargue las baterías antes de que se hayan agotado

completamente.

Si siente que la potencia de la herramienta eléctrica

se debilita, deje de utilizarla y recargue la batería. Si

continuase utilizando la herramienta hasta agotar la

16

Page 18

Español

capacidad de la batería, ésta podría dañarse y su

duración útil podría acortarse.

(2) Evite realizar la recarga a altas temperaturas.

Una batería se calentará inmediatamente después de

haberla utilizado. Si recargase tal batería

inmediatamente después de haberla utilizado, su

substancia química interna se deterioraría, y la

duración útil de la batería se acortaría. Deje la batería

y recárguela después de que se haya enfriado durante

cierto tiempo.

PRECAUCIÓN:

䡬 Si carga la batería mientras esté caliente por haber

estado mucho tiempo en un lugar sometido a la luz

solar directo, o por haber acabado de utilizarla, es

posible que la lampara piloto del cargador se encienda

en verde. En tales casos, deje primero que se enfríe

la batería e inicie luego la carga.

䡬 Cuando la lámpara piloto parpadee rápidamente en

rojo (a intervalos de 0,2 segundos), realice una

comprobación y extraiga los objetos extraños del

orificio de instalación de batería del cargador. Si no

hay ningún objeto extraño, es posible que la batería

o el cargador funcione mal: Llévelos a un agente de

servicio técnico autorizado.

䡬 Como el microcomputador incorporado tarda unos 3

segundos en confirmar que se extraído la batería

cargada con el UC14YFA, espere por lo menos 3

segundos antes de volverla a insertar para continuar

cargando. Si reinserta la batería antes de 3 segundos,

es posible que no se cargue adecuadamente.

〈UC18YG〉

Antes de utilizar la herramienta eléctrica, cargue la batería

de la siguiente manera.

1. Conectar el cable de alimentación del cargador a la

toma de CA

Al conectar el cable de alimentación se encenderá el

cargador.

2. Insertar la batería en el cargador

Inserte firmemente la batería prestando atención a la

orientación, hasta que entre en contacto con la parte

inferior del cargador (la lámpara piloto se ilumina)

(Véase Figs. 4).

PRECAUCIÓN

Si no se enciende la lámpara piloto, desenchufar

el cable de alimentación de la toma de la red

y verificar la condición de montaje de la batería.

䡬 Temperatura de las baterías

Las temperaturas de las pilas recargables se indican

en la Tabla 3.

Tabla 3 Márgenes de carga de las baterías

Baterías la que podrá

EB1214S, EB1220BL 0°C – 45°C

䡬 La lámpara piloto se apaga para indicar que la batería

está completamente cargada.

El tiempo de carga será más largo a temperatura

baja o si la tensión de la fuente de alimentación es

demasiado baja.

Cuando la lámpara piloto no se apague incluso

cuando hayan transcurrido más de 120 minutos

después de haberse iniciado la carga, pare ésta y

póngase en contacto con un CENTRO DE SERVICIO

AUTORIZADO POR HITACHI.

17

Temperatura con

cargarse la batería

PRECAUCIÓN

Si se calienta la batería debido a la luz directa

del sol etc, justo antes la operación, la lámpara

piloto del cargador puede que no se ilumine.

En este caso, enfriar primero la batería y a

continuación empezar a cargar.

3. Desenchufe el cable de alimentación del cargador

del tomacorriente de CA

4. Sostenga el cargador firmemente y saque la batería

NOTA

Después de la operación de carga, extraiga primero

las baterías del cargador y guárdelas adecuadamente.

Descarga eléctrica en caso de baterías nuevas, etc.

Como la substancia química interna de las baterías

nuevas o las que no se hayan utilizado durante mucho

tiempo no está activada, la descarga eléctrica puede

ser inferior cuando se utilicen por primera y segunda

vez. Este fenómeno es temporal, y el tiempo normal

requerido para la recarga se restablecerá recargando

las baterías 2 – 3 veces.

Forma de hacer que las baterías duren más.

(1) Recarque las baterías antes de que se hayan agotado

completamente.

Si siente que la potencia de la herramienta eléctrica

se debilita, deje de utilizarla y recargue su batería. Si

continuase utilizando la herramienta hasta agotar la

capacidad de la batería, ésta podría dañarse y su

duración útil podría acortarse.

(2) Evite realizar la recarga a altas temperaturas

Una batería se calentará inmediatamente después de

haberla utilizado. Si recargase tal batería

inmediatamente después de haberla utilizado, su

substancia química interna se deterioraría, y la

duración útil de la batería se acortaría. Deje la batería

y recárguela después de que se haya enfriado durante

cierto tiempo.

ANTES DE USAR LA HERRAMIENTA

1. Preparación y comprobación de las condiciones

ambientales de trabajo

Asegúrese de que el sitio de trabajo cumpla todas las

condiciones indicadas en las precauciones.

2. Comprobación de la batería

Asegúrese de que la batería esté firmemente

instalada. Si está floja, puede caerse y provocar

accidentes.

3. Instalación de la punta de destornillador (WH12DAF2)

Para instalar la punta de destornillador, realice

siempre el procedimiento siguiente. (Fig. 5)

(1) Tire del manguito guía alejándolo de la parte delantera

de la herramienta.

(2) Inserte la punta de destornillador en el orificio

hexagonal en el yunque.

(3) Suelte el manguito guía y devuélvalo a su posición

original.

PRECAUCIÓN:

Si el manguito guía no vuelve a su posición original,

significará que la punta de destornillador no está

correctamente instalada.

4. Selección del recepráculo que concuerde con el perno

(WR12DAF2)

Cerciorarse de utilizar un receptáculo que concuerde

con el perno a ser apretado. Si se utilizase un

Page 19

Español

receptáculo inadecuado, el apriete no será

satisfactorio y la cabeza el perno o la tuerca se

dañarán.

Un receptáculo, hexagonal o cuadrado, deformado

no quedará bien apretado en la tuerca o en el yunque

por lo que la tensión de apriete no será la adecuade.

Poner atención al desgaste de los agujeros del

receptáculo y cambiarlo antes de que el destaste sea

excesivo.

Finalmente, instale el receptáculo prescrito en el item

5. En la seción de “Accesorios opcionales” se ofrecen

los detalles sobre la relación entre el tamaño de los

pernos y los receptáculos. Los receptávculos se

denominan de acuerdo con la distancia entre las

superficies opuestas del orificio hexagona.

5. Instalacón de un receptáculo (WR12DAF2)

Seleccione el receptáculo que desee emplear.

䢇 Pasador, junta tórica (Figs. 6 y 7)

(1) Alinee el orificio del receptaáculo con el del yunque

en enserte éste en el primero.

(2) Inserte el pasador en el orificio del receptáculo.

(3) Fije el anillo a la ranura del receptáculo.

䢇 Tipo émbolo (Fig. 8)

Alinee el émbolo sitado en la parte cuadrada de la

boca con el orificio del cuo hexagonal. Después

empuje el émbolo y monte el cubo hexagonal en la

boca. Compruebe que el émbolo esté completamente

enganchada en el orificio. Para extraer el cubo invierta

la secuencia.

COMO SE USA

PRECAUCIÓN:

䡬 Cuando utilice el gancho equipado con luz, preste

atención para que la unidad no se caiga. La caída de

la herramienta implica el riesgo de accidentes.

䡬 Cuando lleve la unidad principal de la herramienta

provista de gancho equipado con luz colgada del

cinturón, evite fijar puntas de herramienta, a

excepción de una broca Phillips.

Sì llevara el equipo colgado del cinturón con una

broca de barrena u otros componentes de extremo

afilado fijado al mismo, se podrían producir lesiones.

1. Uso del gancho equipado con luz

El gancho equipado con luz puede instalarse en el

lateral derecho o izquierdo, y el ángulo puede

ajustarse en 5 pasos, entre 0° y 80°.

(1) Operación del gancho

(a) Extraiga el gancho hacia sí en la dirección de la

flecha (A) y gírelo en la dirección de la flecha (B).

(Fig. 9)

(b) El ángulo se puede ajustar en 5 pasos (0°, 20°,

40°, 60°, 80°).

Ajuste el ángulo del gancho en la posición

conveniente para el uso.

(2) Cambio de la posición del gancho

PRECAUCIÓN:

La instalación incompleta del gancho puede provocar

lesiones corporales durante el uso.

(a) Sujete firmemente la unidad principal y saque el

tornillo usando un destornillador de cabeza

ranurada o una moneda. (Fig. 10)

(b) Saque el gancho y el resorte. (Fig. 11)

(c) Instale el gancho y el resorte en el otro lateral y

asegure firmemente con el tornillo. (Fig. 12)

NOTA:

Preste atención a la orientación del resorte. El

diámetro más grande debe quedar opuesto a usted.

(Fig. 12)

(3) Empleo como luz auxiliar

(a) Presione el interruptor para apagar la luz.

Si se olvida de apagar la luz, la misma se apagará

automáticamente al cabo de 15 minutos.

(b) La dirección de la luz se puede ajustar dentro del

alcance de las posiciones 1 - 5 del gancho. (Fig.

13)

䡬 Tiempo de iluminación

Pilas de manganeso AAAA: aprox. 15 horas

PRECAUCIÓN:

(4) Sustitución de las pilas

NOTA:

PRECAUCIÓN:

䡬 La negligencia en la observación de las siguientes

䡬 No descarte las pilas junto con la basura normal y no

䡬 Guarde las pilas fuera del alcance de los niños.

䡬 Utilice las pilas correctamente, de acuerdo con las

2. Comprobación de la dirección de rotación

PRECAUCIÓN:

3. Operación de conmutación

䡬 Cuando apriete el disparador, la herramienta girará.

Pilas alcalinas AAAA: aprox. 30 horas

No mire directamente hacia la luz.

Tal acción podría dañar la vista.

(a) Afloje el tornillo de gancho con un destornillador

tipo Phillips (Núm.1) (Fig. 14)

Quite la tapa del gancho empujando en la dirección

de la flecha. (Fig. 15)

(b) Retire las pilas usadas e introduzca las pilas

nuevas. Alineélas con las indicaciones del gancho

y posicione correctamente los terminales positivo

(+) y negativo (–). (Fig. 16)

(c) Haga coincidir la muesca del cuerpo principal del

gancho con el saliente de la tapa del gancho,

presione la tapa en la dirección opuesta a la flecha

mostrada en la Fig. 15 y apriete el tornillo.

Utilice pilas AAAA (1,5 V) disponibles en los

establecimientos del ramo.

No apriete los tornillos excesivamente, pues se

podrían dañar las roscas de los tornillos.

precauciones puede provocar fugas de electrólito,

oxidación o fallos de funcionamiento.

Posicione correctamente los terminales positivo (+) y

negativo (–).

Siempre cambie ambas pilas a la vez. No mezcle

pilas nuevas con pilas usadas.

Las pilas agotadas deben ser retiradas

inmediatamente del gancho.

las arroje al fuego.

especificaciones e indicaciones provistas con las

mismas.

La broca gira hacia la derecha (vista desde atrás) al

oprimir el lado R (dcha.) del botón pulsador. El lado

L (izda.) del botón pulsador se utiliza para hacer que

la broca gire hacia la izquierda. (Vea la Fig. 17) (Las

L y

marcas

El botón pulsador no podrá accionarse mientras la

herramienta esté en funcionamiento. Para accionar

el botón pulsador, pare en primer lugar la

herramienta, y después presione el botón pulsador.

Al soltar el disparador, la herramienta se parará.

R están en el cuerpo.)

18

Page 20

Español

䡬 La velocidad de rotación podrá controlarse variando

la presión de apriete del disparador. La velocidad

será lenta cuando se apriete ligeramente el

disparador, y aumentará a medida que lo apriete

más.

4. Apretado y aflojado de pernos (WH12DAF2)

Instale la punta de destornillador adecuada al tornillo,

alinéela con las ranuras de la cabeza del mismo, y

después apriételo.

Empuje el atornillador de percusión lo

suficientemente como para que la punta de

destornillador encaje en la cabeza del tornillo.

PRECAUCIÓN:

Si aplica demasiado tiempo el atornillador de impacto

sobre el tornillo, éste se apretará demasiado y se

romperá.

Apriete los tornillos con el ángulo que no dañe sus

cabezas y de forma que se pueda aplicar la fuerza

apropiada.

Apriete con el atornillador de impacto alineado con

el tornillo.

5. Número posible de aprietes (WH12DAF2)

Con respecto al número de aprietes de tornillos con

una carga, consultar la tabla siguiente.

EB1214S

Tornillos utilizados N° de aprietes

Tornillo para madera ø4 × 50

(Madera blanda)

Tornillo para metales M8 × 16

Estos valores pueden variar ligeramente de acuerdo

con la temperatura ambiental y las características de

la batería.

6. Número posible de aprietes (WR12DAF2)

Con respecto al número de aprietes de tornillos con

una carga, consultar la tabla siguiente.

EB1214S

Perno utilizados N° de aprietes

Perno de alta tensión M12 × 45

Estos valores pueden variar ligeramente de acuerdo

con la temperatura ambiental y las características de

la batería.

NOTA:

La utilización de la batería EB1226HL en lugares fríos.

(menos de 0 grados centigrados) puede resultar a

veces en la reducción del par de apriete y el

rendimiento del trabajo. Sin embargo, éste es un

fenómeno temporal y, cuando la batería se caliente,

volverá a la normalidad.

Aprox. 190

Aprox. 500

Circa. 87

PRECAUCIONES OPERACIONALES

1. Reposo de la herramienta después de un

funcionamiento prolongado