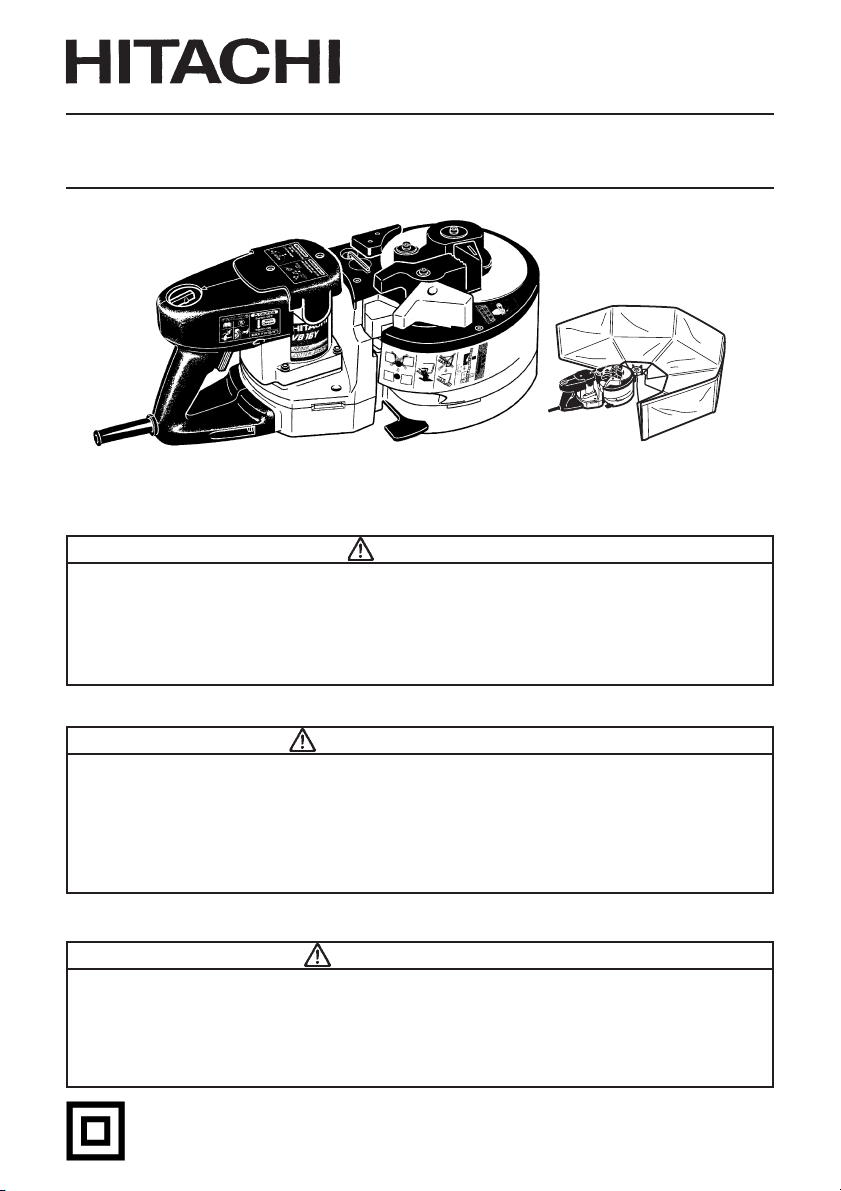

MODEL REBAR CUTTER/BENDER

MODÈLE

MODELO CORTADORA DOBLADORA DE VARILLA

VB 16Y

CISAILLE/CINTREUSE POUR BARRES BÉTON

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily

injury!

This manual contains important information about product safety. Please read

and understand this manual BEFORE operating the power tool. Please keep this

manual available for other users and owners before they use the power tool.

This manual should be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner

la mort ou de sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de

ce produit. Prière de lire et de comprendre ce mode d’emploi AVANT d’utiliser

l’outil motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs

et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi doit être

conservé dans un endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede

resultar en lesiones de gravedad o la muerte!

Este manual contiene información importante sobre la seguridad del producto.

Lea y comprenda este manual ANTES de utilizar la herramienta eléctrica. Guarde

este manual para que puedan leerlo otras personas antes de utilizar la herramienta

eléctrica. Este manual debe ser guardado en un lugar seguro.

DOUBLE INSULATION

DOUBLE ISOLATION

AISLAMIENTO DOBLE

English

IMPORTANT INFORMATION ..................... 3

MEANINGS OF SIGNAL WORDS............... 3

SAFETY ............................................................4

INPORTANT SAFETY INSTRUCTIONS

FOR USING POWER TOOLS ................. 4

SPECIFIC SAFETY RULES AND SYMBOLS ...

REPLACEMENT PARTS .............................. 7

USE PROPER EXTENSION CORD .............. 8

DOUBLE INSULATION FOR SAFER

OPERATION............................................ 9

FUNCTIONAL DESCRIPTION ....................... 10

NAME OF PARTS .......................................... 10

SPECIFICATIONS .......................................... 11

CONTENTS

Page

ASSEMBLY AND OPERATION ..................... 12

APPLICATIONS ......................................... 12

PRIOR TO OPERATION ............................. 12

PICTGRAPH ILLUSTRATION AND

EXPLANATION ..................................... 13

6

HOW TO USE (CUTTING) ......................... 15

SERVICE LIFE AND REPLACEMENT

OF THE CUTTER................................... 16

HOW TO USE (BENDING) ........................ 17

MAINTENANCE AND INSPECTION ............. 21

ACCESSORIES .............................................. 22

STANDARD ACCESSORIES ..................... 22

OPTIONAL ACCESSORIES ....................... 22

Page

Français

INFORMATIONS IMPORTANTES ............ 23

SIGNIFICATION DES MOTS

D’AVERTISSEMENT ............................. 23

SECURITE ......................................................24

CONSIGNES DE SÉCURIT´E RELATIVES

AUX OUTILS ÉLECTRIQUES ............... 24

REGLES DE SECURITE SPECIFIQUES ET SYMBOLES

PIECES DE RECHANGE ............................ 27

UTILISER LE CORDON DE RALLONGE APPROPRIÉ .

DOUBLE ISOLATION POUR UN

FONCTIONNEMENT PLUS SUR ......... 29

DESCRIPTION FONCTIONNELLE................. 30

NOM DES PARTIES................................... 30

SPECIFICATIONS ...................................... 31

Español

INFORMACIÓN IMPORTANTE .................44

SIGNIFICADO DE LAS PALABRAS DE

SEÑALIZACIÓN ....................................44

SEGURIDAD .................................................. 45

NORMAS DE SEGURIDAD PARA LAS

HERRAMIENTAS ELÉCTRICAS .............

NORMAS Y SÍMBOLOS ESPECÍFICOS DE SEGURIDAD

PIEZAS DE REEMPLAZO .......................... 48

UTILICE EL CABLE PROLONGADOR ADECUADO ........

AISLAMIENTO DOBLE PARA OFRECER

UNA OPERACIÓN MÁS SEGURA ....... 50

DESCRIPCIÓN FUNCTIONAL ....................... 51

NOMENCLATURA ..................................... 51

ESPECIFICACIONES .................................. 52

TABLE DES MATIERES

Page

.26

28

ÍNDICE

Página

45

... 47

49

ASSEMBLAGE ET FONCTIONNEMENT ...... 32

Page

APPLICATIONS ......................................... 32

AVANT L’UTILISATION ............................ 32

SCHÉMA ET EXPLICATION ...................... 33

UTILISATION (COUPE) ............................. 35

DURÉE DE SERVICE ET REMPLACEMENT

DU COUTEAU ......................................36

UTILISATION (CINTRAGE) ....................... 37

ENTRETIEN ET INSPECTION ....................... 42

ACCESSOIRES .............................................. 43

ACCESSOIRES STANDARD ..................... 43

ACCESSOIRES SUR OPTION ................... 43

Página

MONTAJE Y OPERACIÓN ............................ 53

APLICACIONES ......................................... 53

ANTES DE LA OPERACIÓN ...................... 53

ILUSTRACION PICTRORICA Y

EXPLICACION ....................................... 54

NOTAS SOBRE EL USO (CORTADORA) . 56

VIDA DE SERVICIO Y REEMPLAZO DE LA

CORTADORA ........................................57

NOTAS SOBRE EL USO (CURVADORA) . 58

MANTENIMIENTO E INSPECCIÓN .............. 63

ACCESORIOS ................................................ 64

ACCESORIOS ESTÁNDAR ....................... 64

ACCESORIOS OPCIONALES .................... 64

English

IMPORTANT INFORMATION

Read and understand all of the operating instructions, safety precautions and warnings in

the Instruction Manual before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the

failure to observe basic safety rules or precautions. An accident can often be avoided by

recognizing a potentially hazardous situation before it occurs, and by observing appropriate

safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and

in the sections which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by

WARNINGS on the power tool and in this Instruction Manual.

Never use this power tool in a manner that has not been specifically recommended by

HITACHI, unless you first confirm that the planned use will be safe for you and others.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situation which, if ignored, could result in

serious personal injury.

CAUTION indicates a hazardous situation which, if ignored, could result in moderate

personal injury, or could cause machine damage.

NOTE emphasizes essential information.

3

English

SAFETY

INPORTANT SAFETY INSTRUCTIONS FOR USING ALL POWER TOOLS

READ ALL OF THE WARNINGS AND OPERATING INSTRUCTIONS IN THIS MANUAL

BEFORE OPERATING OR MAINTAINING THIS TOOL:

WARNING: When using this electric tool, take all necessary precautions to minimize

the risk of electric shock or other personal injury.

In particular, always comply with the following safety rules:

1. ALWAYS KEEP GUARDS IN PLACE and in working order.

2. ALWAYS REMOVE ADJUSTING KEYS AND WRENCHES BEFORE STARTING TOOL.

Always confirm that all keys and adjusting wrenches have been removed from the tool

before it is turned on.

3.ALWAYS KEEP WORK AREA CLEAN. Avoid injuries by not cluttering the work areas and

work benches.

4. NEVER USE TOOL IN HAZARDOUS ENVIRONMENTS. Never use the power tool in damp

or wet places and never expose it to rain. Always keep the work area well lighted.

5. NEVER PERMIT CHILDREN OR OTHERS TO LOITER NEAR THE WORK AREA. Keep all

people (especially children) away from the work area. Always unplug unattended tools

and keep the work place tamper-proof by installing locks on the doors and on the master

switches. Always remove the lock-off button from the tool and store it in a secure place,

when the tool is not in use.

6. NEVER FORCE THE TOOL. It will do the job better and more safely if it is operated at the

rate for which it was designed.

7.ALWAYS USE THE RIGHT TOOLS. Never force a tool or an attachment to do a job for

which it was not designed.

8. ALWAYS WEAR PROPER APPAREL WHEN WORKING WITH THE TOOL. Never wear

loose clothing, gloves, neckties, rings, bracelets or other jewelry which may get caught

in the moving parts. Always wear non-slip footwear, preferably with steel toes. Wear

protective hair covering to contain long hair.

9. ALWAYS USE EYE PROTECTION WHEN WORKING WITH THE TOOL TO PREVENT EYE

INJURY. Ordinary eyeglasses do not provide adequate protection because the lenses are

not made of safety glass. Also, use a face mask for additional safety and wear a dust mask

if the cutting/bending operation produces dust.

10. ALWAYS SECURE THE WORKPIECE TO THE FENCE OR THE TABLE. Use clamps or a vise

to hold the workpiece in place. It is safer than using your hand and it frees both hands to

operate the tool.

11. NEVER OVERREACH. Always keep proper footing and balance when working with the

tool.

12. ALWAYS MAINTAIN TOOLS WITH CARE. Always keep tools sharp and clean for the best

and safest performance. Always follow instructions for lubricating the tool and for

changing accessories.receptacle.

4

English

13. ALWAYS DISCONNECT THE TOOL before servicing and before changing blades or other

accessories.

14. NEVER RISK UNINTENTIONAL STARTING WHEN PLUGGING IN THE TOOL. Always

confirm that the switch is in the OFF position before inserting the power plug into the

15. ALWAYS USE RECOMMENDED ACCESSORIES ONLY WHEN OPERATING THIS TOOL.

Consult this instruction manual for descriptions of recommended accessories. To avoid

personal injuries, use only recommended accessories in conjunction with this tool.

16. NEVER STAND ON THE TOOL. Prevent serious injury by not tipping the tool and by not

risking unintentional contact with the cutter.

17. ALWAYS CHECK FOR DAMAGED PARTS BEFORE USING THE TOOL. Always check the

guard and all other components for damage before using the tool to assure that they will

function properly. Check all moving parts for proper alignment, freedom from binding

and other conditions that might affect proper operation. Always repair or replace any

damaged guards or other damaged components before using the tool.

18. ALWAYS CONFIRM THE ROTATION DIRECTION OF THE BLADE BEFORE USING THE

TOOL. Always feed work into the tool against the moving direction of the cutter in order

to prevent possible injury.

19. NEVER LEAVE THE TOOL RUNNING WHILE UNATTENDED. TURN POWER OFF. Do not

leave tool until it comes to a complete stop. Always turn the power off when the tool is

not in use. Always unplug the power cord when the tool is not in use.

20. This tool was not designed to be used for mass-production applications and should not

be used in mass-production environments.

21. When servicing this tool, use only authorized replacement parts.

22. Apply 120 volts AC only to this tool. Applying the wrong voltage or applying DC power

can cause the POWER TOOL to operate improperly and cause serious personal injury or

damage to the tool.

23. POLARIZED PLUGS To reduce the risk of electric shock, this equipment has a polarized

plug (one blade is wider than the other). This plug will fit in a polarized outlet only one

way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper outlet. Do not change the plug in any way.

5

English

SPECIFIC SAFETY RULES AND SYMBOLS

WARNING: For Your Own Safety Read Instructon Manual Before Operating Tool.

Wear Eye Protection.

Risk of injury due to accidental starting.

Do not use in a home workshop or other work area where children may

be present.

1. Hold tools by insulated gripping surfaces when performing an operation where the tool

may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

2. Wear ear plugs when using the tool for extended periods. Prolonged exposure to high

intensity noise can cause hearing loss.

3. Never touch moving parts.

Never place your hands, fingers or other body parts near the tool’s moving parts.

4. Never use a power tool for applications other than those specified.

Never use a power tool for applications other than those specified in the Instruction

Manual.

5. Handle tool correctly.

Operate the tool according to the instructions provided herein. Do not drop or throw the

tool. Never allow the tool to be operated by children, individuals unfamiliar with its

operation or unauthorized personnel.

6. Keep all screws, bolts and covers tightly in place.

Keep all screws, bolts, and plates tightly mounted. Check their condition periodically.

7. Do not use power tools if the plastic housing or handle is cracked.

Cracks in the tool’s housing or handle can lead to electric shock. Such tools should not

be used until repaired.

8. Cutters and accessories must be securely mounted to the tool.

Prevent potential injuries to youself or others. Cutters, cutting implements and accessories

which have been mounted to the tool should be secure and tight.

9. Keep motor air vent clean.

The tool’s motor air vent must be kept clean so that air can freely flow at all times. Check

for dust build-up frequently.

10. Operate power tools at the rated voltage.

Operate the power tool at voltages specified on its nameplate.

If using the power tool at a higher voltage than the rated voltage, it will result in

abnormally fast motor revolution and may damage the unit and the motor may burn out.

11. Never use a tool which is defective or operating abnormally.

If the tool appears to be operating unusually, making strange noises, or otherwise

appears defective, stop using it immediately and arrange for repairs by a Hitachi

authorized service center.

12. Never leave tool running unattended. Turn power off.

Don’t leave tool until it comes to a complete stop.

13. Carefully handle power tools.

Should a power tool be dropped or struck against hard materials inadvertently, it may be

deformed, cracked, or damaged.

6

English

14. Do not wipe plastic parts with solvent.

Solvents such as gasoline, thinner benzine, carbon tetrachloride, and alcohol may

damage and crack plastic parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dry

thoroughly.

15. Definitions for symbols used on this tool

V ............. volts

Hz ........... hertz

A ............. amperes

no .......... no load speed

W ............ watt

............ Class II Construction

---/min .... revolutions per minute

REPLACEMENT PARTS

When servicing use only identical replacement parts.

Repairs should be conducted only by a Hitachi authorized service center.

7

English

USE PROPER EXTENSION CORD

Make sure your extension cord is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product will draw.

An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. Table shows the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the

heavier the cord.

MINIMUM GAGE FOR CORD SETS

Total Length of Cord in Feet (Meter)

0 – 25 26 – 50 51 – 100 101 – 150

(0 – 7.6) (7.9 – 15.2) (15.5 – 30.5) (30.8 – 45.7)

Ampere Rating AWG

More Not More

Than Than

0 – 618161614

6 – 10 18 16 14 12

10 – 12 16 16 14 12

12 – 16 14 12 Not Recommended

WARNING: Avoid electrical shock hazard. Never use this tool with a damaged or

frayed electrical cord or extension cord.

Inspect all electrical cords regularly. Never use in or near water or in any

environment where electric shock is possible.

8

English

DOUBLE INSULATION FOR SAFER OPERATION

To ensure safer operation of this power tool, HITACHI has adopted a double insulation

design. “Double insulation “ means that two physically separated insulation systems have

been used to insulate the electrically conductive materials connected to the power supply

from the outer frame handled by the operator. Therefore, either the symbol “ ” or the words

“Double insulation” appear on the power tool or on the nameplate.

Although this system has no external grounding, you must still follow the normal electrical

safety precautions given in this Instruction Manual, including not using the power tool in wet

environments.

To keep the double insulation system effective, follow these precautions:

䡬 Only HITACHI AUTHORIZED SERVICE CENTER should disassemble or assemble this

power tool, and only genuine HITACHI replacement parts should be installed.

䡬 Clean the exterior of the power tool only with a soft cloth moistened with soapy water,

and dry thoroughly.

Never use solvents, gasoline or thinners on plastic components; otherwise the plastic

may dissolve.

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO

OTHER USERS OF THIS TOOL!

9

English

FUNCTIONAL DESCRIPTION

NOTE:

The information contained in this Instruction Manual is designed to assist you in the safe

operation and maintenance of the power tool.

Some illustrations in this Instruction Manual may show details or attachments that differ

from those on your own power tool.

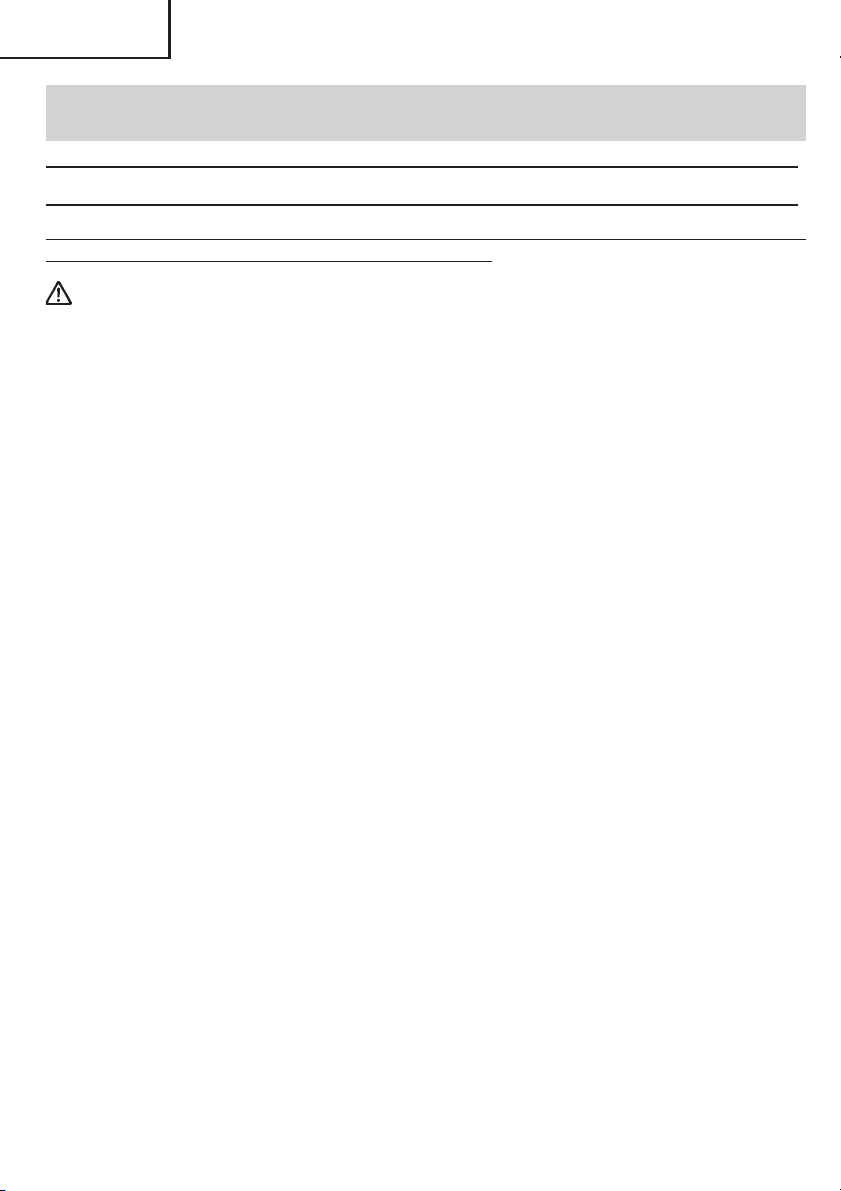

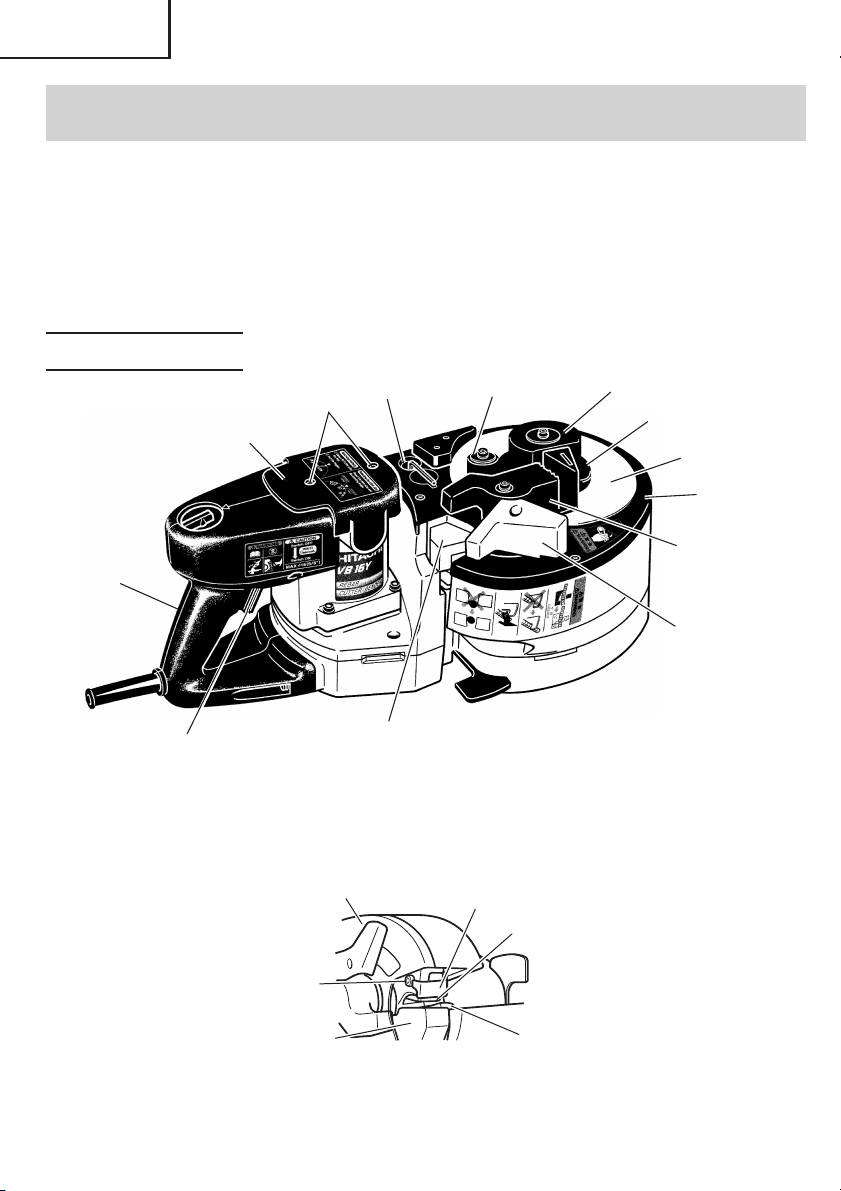

NAME OF PARTS

Center roller

Center plate

Turn table

Cam cover

Guide

Handle

Tail cover

Set screws

Allen key

Bending roller

Lever

Switch trigger

Cam cover

Hexagon socket bolt

Grip rubber

10

Grip rubber

Fig. 1

Cutter guard

Upper cutter

Lower cutter

Fig. 2

When installing the deflection When folding the deflection

guard guard

English

Guard

Arm

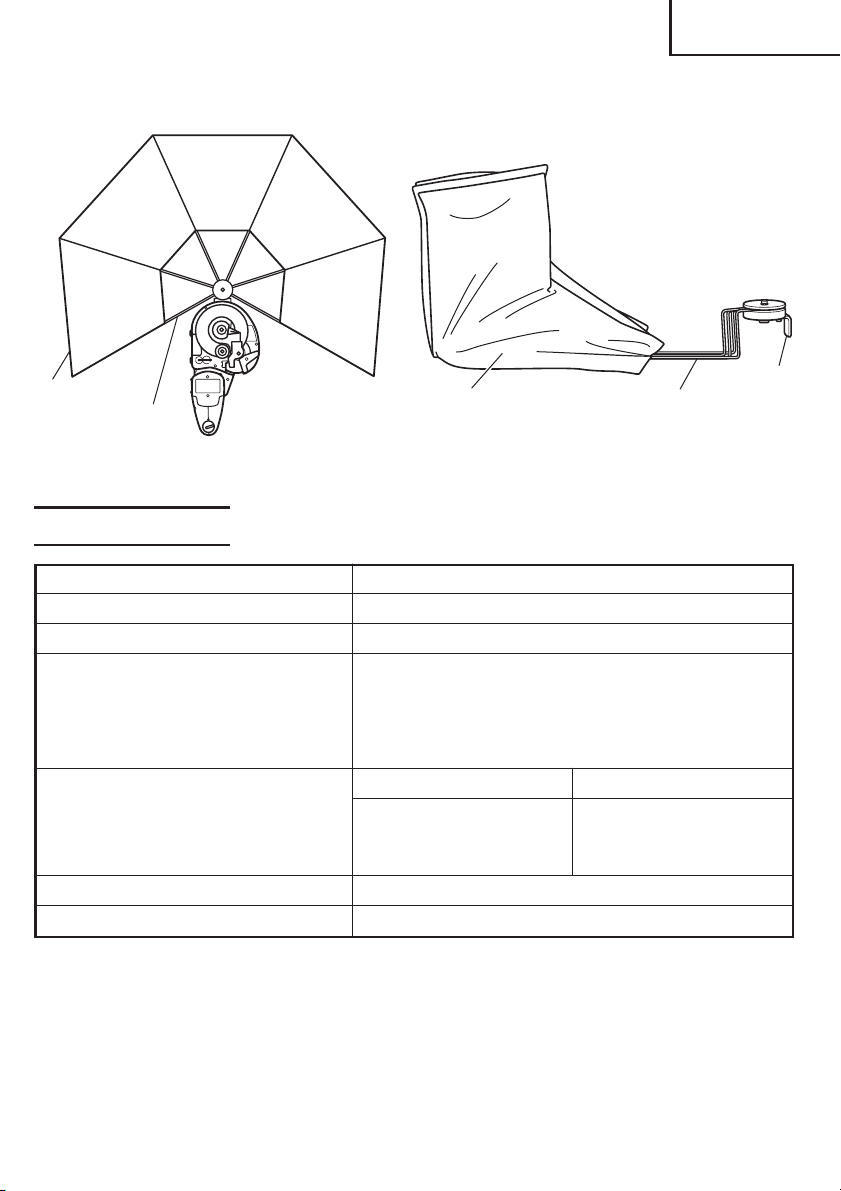

Fig. 3 Fig. 4

Guard

Arm

SPECIFICATIONS

Motor Single-Phase, Series Commutator Motor

Power Source Single-Phase, 120 V AC 60 Hz

Current 8 A

Capacities (1) Material: Concrete reinforcing bars only

(for ASTM)

GRADE 40, GRADE 60

(2) Bar Designation Size

#3, #4, #5 (3/8", 1/2", 5/8")

Cutting Bending

Number of piece(s) that

can be processed at one time

No-Load Speed 0 – 16/min.

Weight (without cord) 39.7 lbs (18.0 kg)

#3 (3/8")..... 2 pieces #3 (3/8") .... 3 pieces

#4 (1/2")..... 1 piece #4 (1/2") .... 2 pieces

#5 (5/8")..... 1 piece #5 (5/8") .... 1 piece

Base

11

English

ASSEMBLY AND OPERATION

APPLICATIONS

䡬 Cutting of rebar

䡬 Bending of rebar

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms to the power source requirements

specified on the product nameplate.

2. Power switch

Ensure that the switch is in the OFF position. If the plug is connected to a receptacle while

the switch is in the ON position, the power tool will start operating immediately and can

cause serious injury.

3. Extension cord

When the work area is far away from the power source, use an extension cord of sufficient

thickness and rated capacity. The extension cord should be kept as short as practicable.

WARNING: Damaged cord must be replaced or repaired.

4. Check the receptacle

If the receptacle only loosely accepts the plug, the receptacle must be repaired. Contact

a licensed electrician to make appropriate repairs.

If such a fautly receptacle is used, it may cause overheating, resulting in a serious hazard.

5. Confirming condition of the environment:

Confirm that the work site is placed under appropriate conditions conforming to

prescribed precautions.

6. For safety sake, use the provided Allen key to make absolutely sure that the hexagon

socket bolt is securely clamped. Use of the unit with the bolt in a loosely clamped

condition can result in damage to the unit and cutter as well as accidents.

7. Confirm that the cutter is in sharp condition.

Make certain that the cutter is in a sharp condition. Continued use of a worn out and

deformed cutter with dull edges results in damage to the unit and cutter as well as

accidents.

12

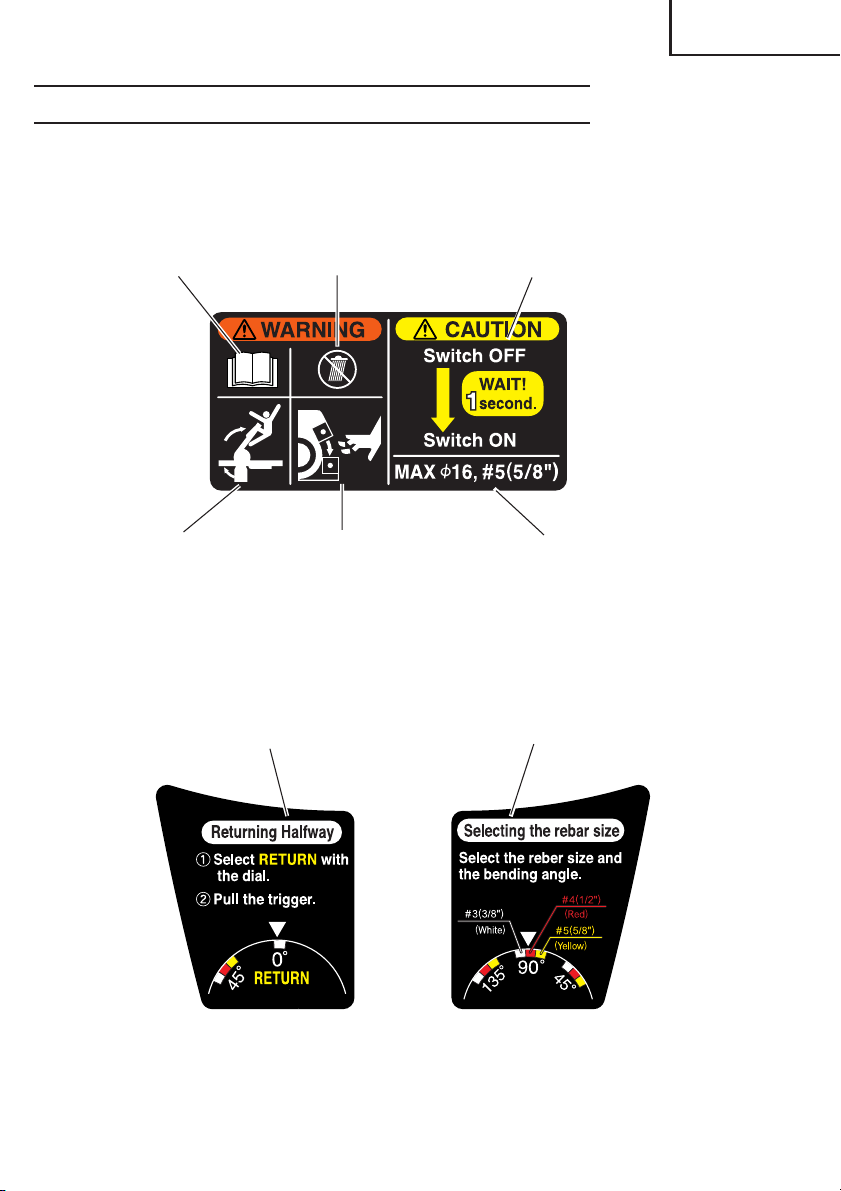

PICTGRAPH ILLUSTRATION AND EXPLANATION

If the switch is turned off and then

immediately turned on again, the

motor may not start. Wait for at least

Read handling

instructions before

use.

Do not this electric

power tools in wet

wether conditions.

one full second before attempting to

turn the motor on again after it has

been switched off.

English

Begin operation only after

ensuring that there are no

people within the turning

range of the material to

be bent.

(Returning Halfway)

1 Select RETURN with the dial.

2 Pull the triger.

Never bring your

hand close to the

cutter during

operation.

Avoid any work exceeding the

maximum capacities.

(Rebar diameter: #5 (5/8"))

(Selecting the rebar size)

Select the rebar size and

the bending angle.

13

English

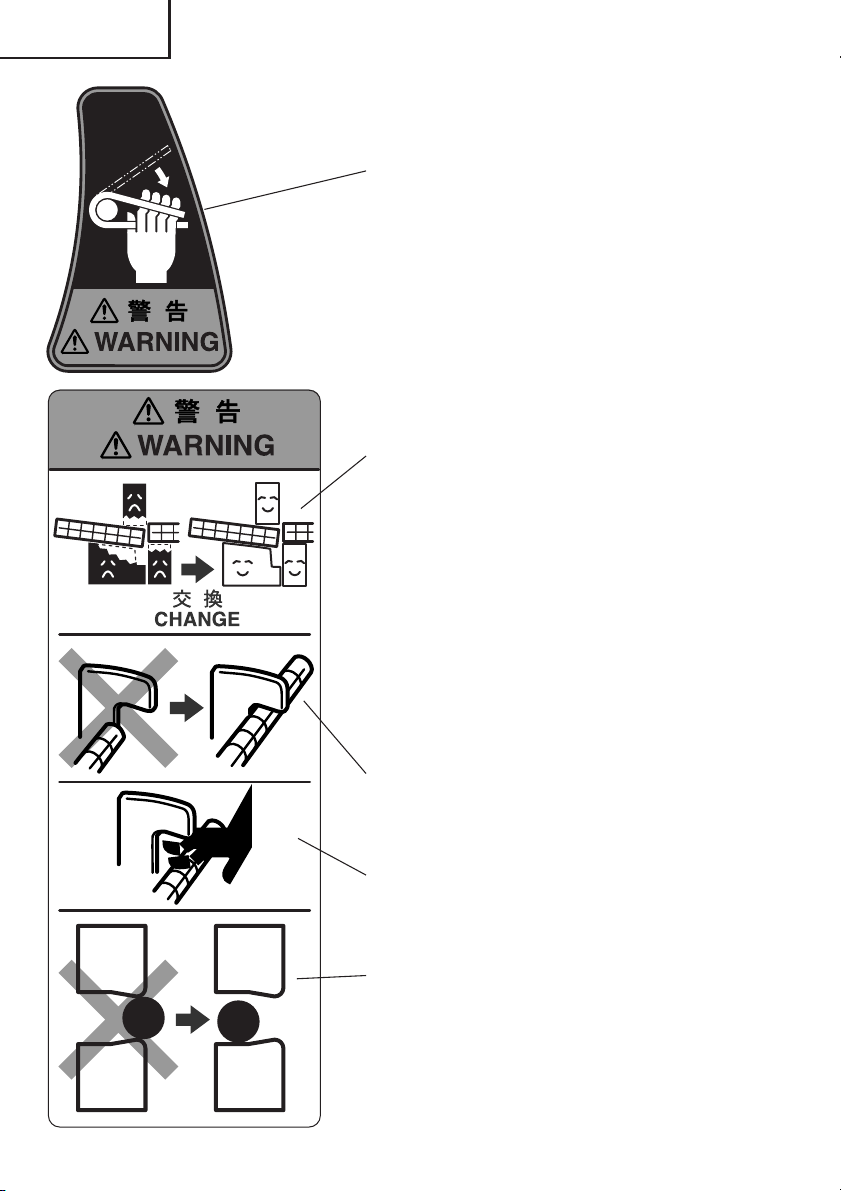

● If you bend the rebar with a large angle while placing

your hand onto it, there is a fear of getting your

hand caught in by the fold-back reaction of the rebar.

Never place your hand onto the position where the

rebar may fold back.

● The cutter blade can get worn out by repeated rebar

cutting. Continued use of a worn-out cutter can

result in the damage and the broken pieces flying

around. Replace it with a new cutter after no more

than 5,000 times of cutting.

● The machine is so designed that the upper cutter

and the grip rubber can support a rebar.

If the grip rubber gets worn out, there is a fear that

it cannot sufficiently hold the rebar and gets broken

down with its parts flying around, etc.

If the grip rubber cannot hold the rebar much longer,

replace it with a new grip rubber. Also replace the

worn grip rubber with new one when replacing the

cutter.

● During cutting work, securely hook the rebar to the

reaction stopper B. Furthermore, secure enough

length of a rebar to be hooked to the reaction

stopper B.

● Avoid bringing your hand near to the reaction

stopper B during operation. If you do so, you may

get your finger caught in or may run the hazard of

other injuries.

● Set the rebar in the center or the recess of the cutter

during cutting work. Any cutting work with the

rebar set on corners or ends of the cutter can result

in the pieces of broken rebar flying around or the

damage to the cutter and the machine.

14

English

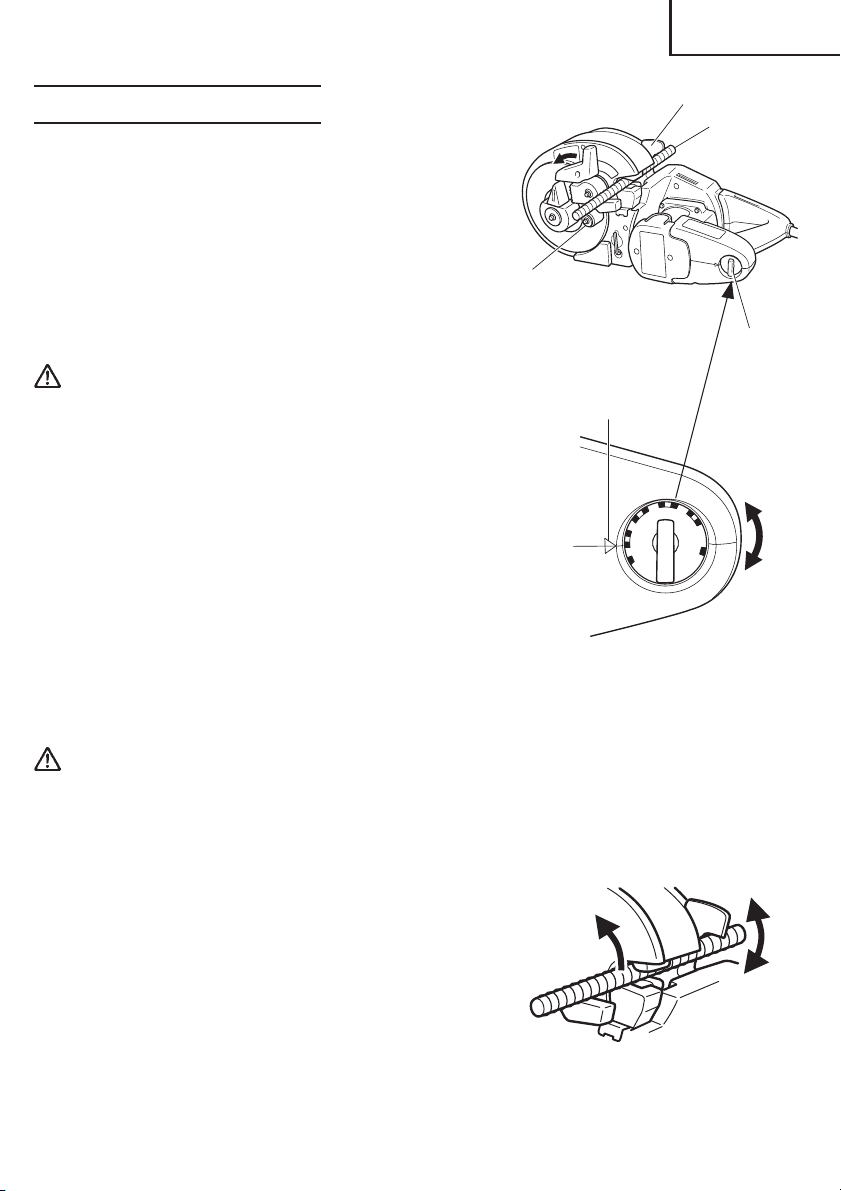

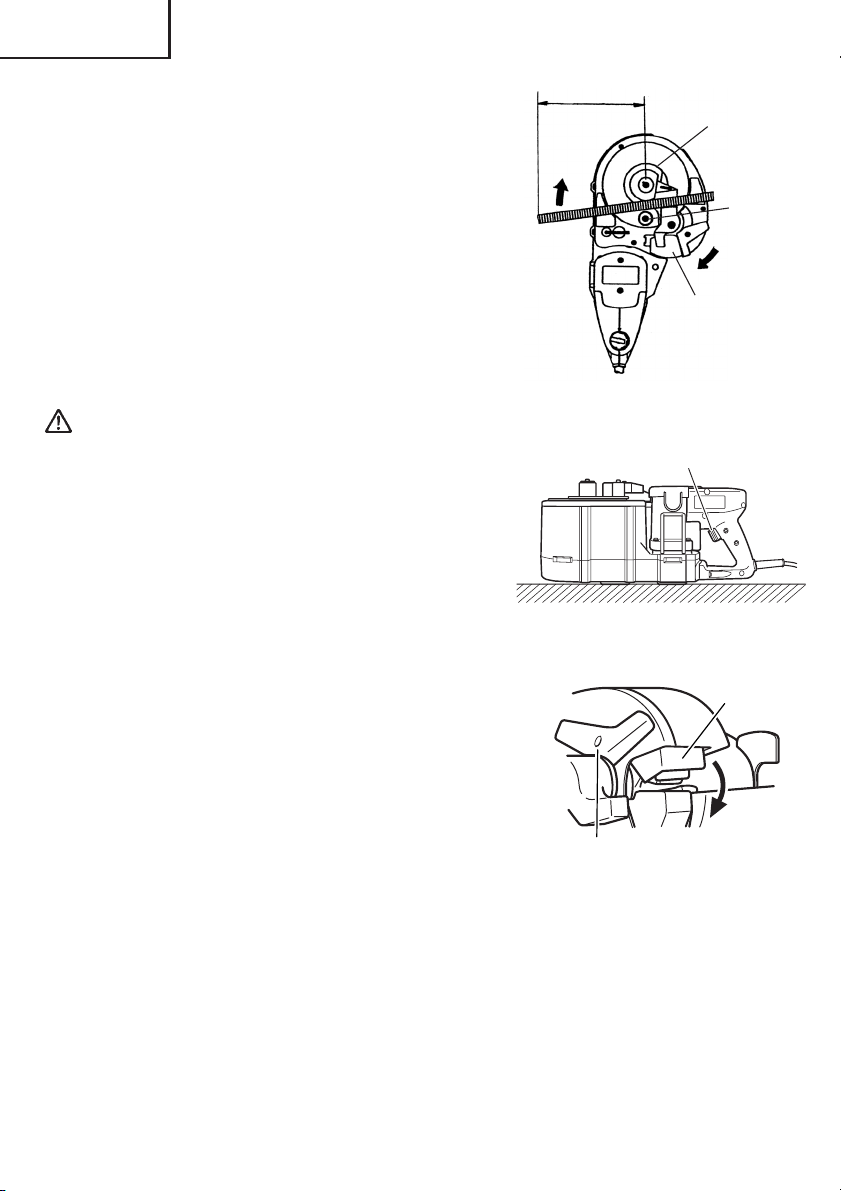

HOW TO USE (CUTTING)

Reaction stopper B

Rebar

1. Normal cutting (Fig. 5)

(1) Turn the lever in the direction of the arrow mark

and open the cover.

(2) Set the setting dial at the “cut” position. (Turn

the setting dial all the way clockwise.) (Fig. 6)

(3) Set the unit in the position shown in Fig. 5.

(4) Set the rebar to be cut on the lower cutter.

(5) When the rebar is set, make sure that the reaction

Bending

roller

stopper B is hooked to the rebar.

(6) Pull the switch trigger and cut the rebar.

Fig. 5

Setting

dial

WARNING:

䡬 While turning switches, never put your hand close

to the cutter, reaction stopper, or bending roller.

䡬 Bringing your hand close to these components can

result in serious injury.

䡬 Do not cut any rebar exceeding the maximum

capacities of the unit described in the specifications.

䡬 Never cut any hard materials such as PC(Precast

concrete) steel. Materials of this type are likely to

scatter into pieces and cause injuries.

䡬 The rebar you are cutting may have a hard spot in

it. Quality may vary within each rebar. Do not

attempt to cut NON-GRADE rebar.

䡬 Replace the worn grip rubber with new one when

replacing the cutter.

䡬 Note that the unit is not a hand held tool. Be absolutely sure to use the unit only after

placing it on stable spots such as floor, ground, etc.

Adjusting position

135˚

180˚

CUT

Fig. 6

90˚

45˚

RETURN

0˚

CAUTION:

Even after the cutting has been completed, continue pulling the switch trigger until the

motor starts to run in the reverse direction and the cutter starts to return. If the switch

trigger is released too early, the cutter will not return and the trigger will have to be

pulled again.

2. Removing the rebar during cutting operation.

(Fig. 7)

If the switch trigger is released in the middle of

cutting, the cutter can come to a stop at a halfway

position, jumming the rebar in the unit.

When this occurs, you can either pull the switch

trigger again and cut off the rebar, or you can free

the rebar by bringing the upper cutter back up to

the home position by carrying out the following

procedure. (Fig. 7)

Fig. 7

15

English

0˚

RETURN

CUT

45˚

90

˚

135˚

180

˚

䡬 Removing (Fig. 8)

Set the setting dial to the “RETURN” position as

shown in Fig. 8 and pull the switch trigger again.

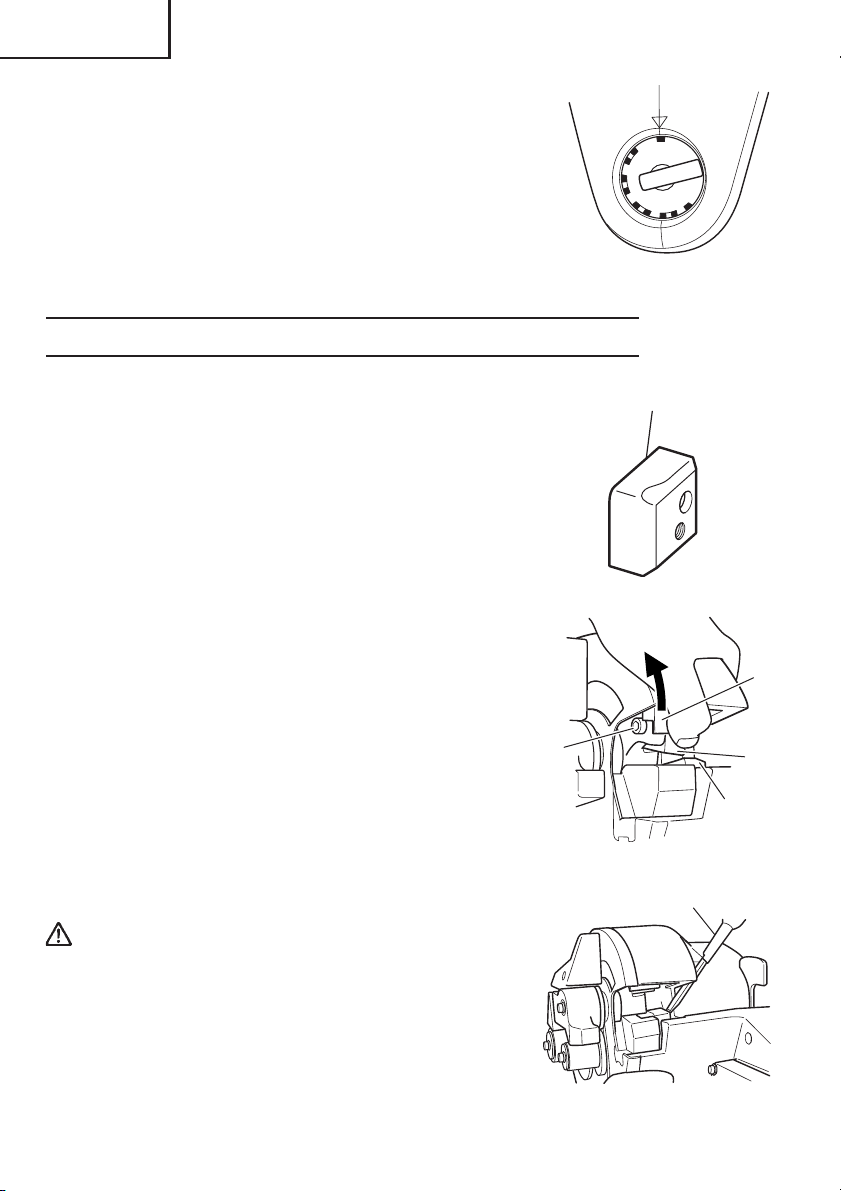

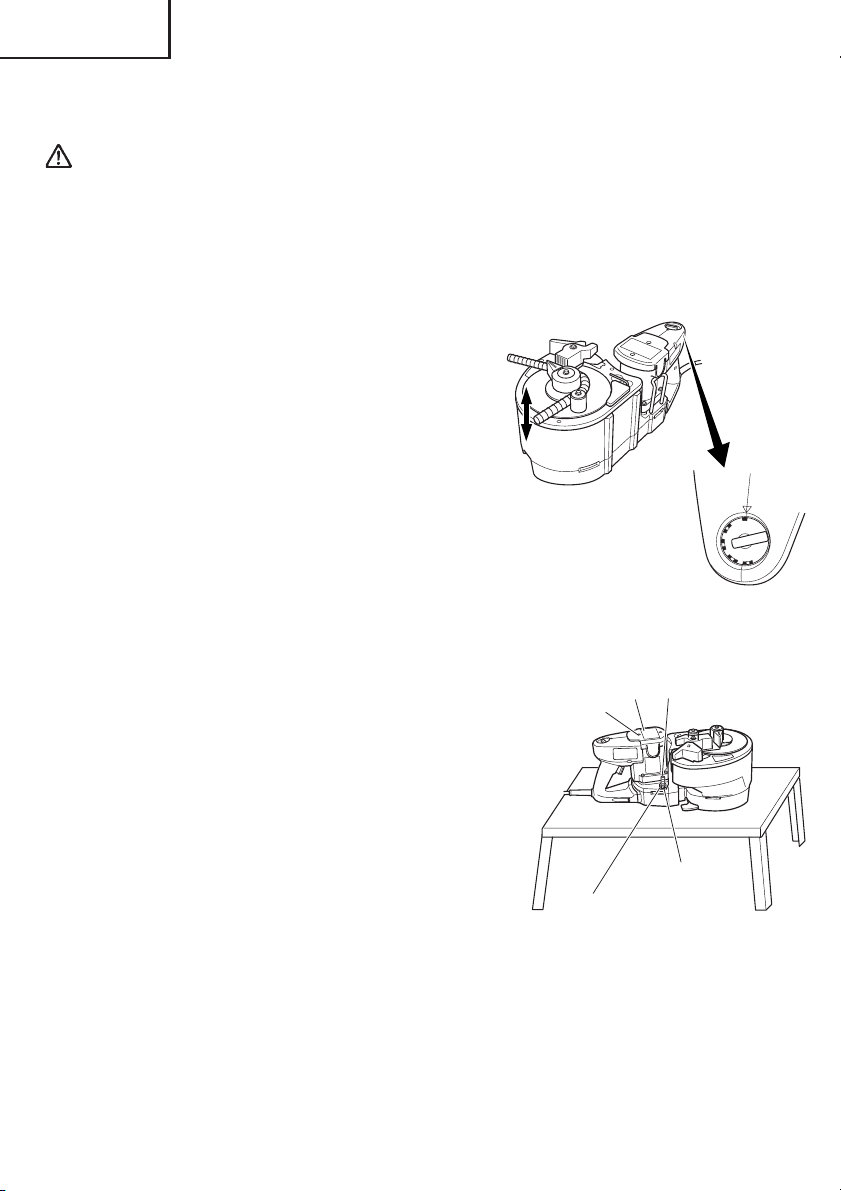

SERVICE LIFE AND REPLACEMENT OF THE CUTTER

Fig. 8

1. Service life of cutter (Fig. 9)

Repeated cutting of the rebar can result in the

"wear and tear", "deformation", "nicked edges",

etc. Using the cutter under such circumstances will

not only damage the machine but also there will be

a fear of the broken cutter fragments flying around.

Replace it with a new cutter after cutting no more

than 5,000 pieces of rebar.

2. Before removing the cutter

(1) Pull the switch lightly and let the upper cutter

move slowly. When the hexagon socket bolt

that fixes the upper cutter comes out of the cam

cover, turn the switch OFF and stop the motor.

(2) Unplug the power cord from the receptacle.

3. Removal

䡬 If you remove the hexagon socket bolt using the

provided Allen key, you can remove the cutter.

(Pushing the cutter guard up in the direction of

the arrow shown in Fig. 10, facilitates removal

of the upper cutter.)

䡬 Removal of the lower cutter can be easily made

if the lower cutter is wrenched with a Phillips

head screwdriver as shown in the following

diagram. (Fig. 11)

WARNING:

䡬 To prevent accidents, always be sure to turn the

switch OFF and unplug the power cord from the

receptacle.

䡬 If you remove the hexagon socket bolt using the

provided Allen key, you can remove the cutter.

(Pushing the cutter guard up in the direction of the

arrow shown in Fig. 10, facilitates removal of the

upper cutter.)

16

Hexagon

socket

bolt

Blade

Fig. 9

Cutter

guard

Upper

cutter

Lower

cutter

Fig. 10

Fig. 11

English

0˚

RETURN

CUT

45˚

90

˚

135˚

180˚

4. Mounting

(1) Get rid of dust around the cutter installing section and clean it up.

(2) Align the hole of a new cutter and the position of a pin, and insert into the installing

section.

(3) Also replace the hexagon socket bolt (packed along with the cutter) with a new one

simultaneously, completely tighten it using the attached Allen key, and then fix the

cutter.

CAUTION:

䡬 Install the cutter and accessories securely according to the instruction manual. If you fail

to install them properly, they may come off and cause an injury.

䡬 Be sure to unplug the power cord from the receptacle when the cutter is checked,

cleaned, and replaced. Failure to do so can result in a serious injury.

HOW TO USE (BENDING)

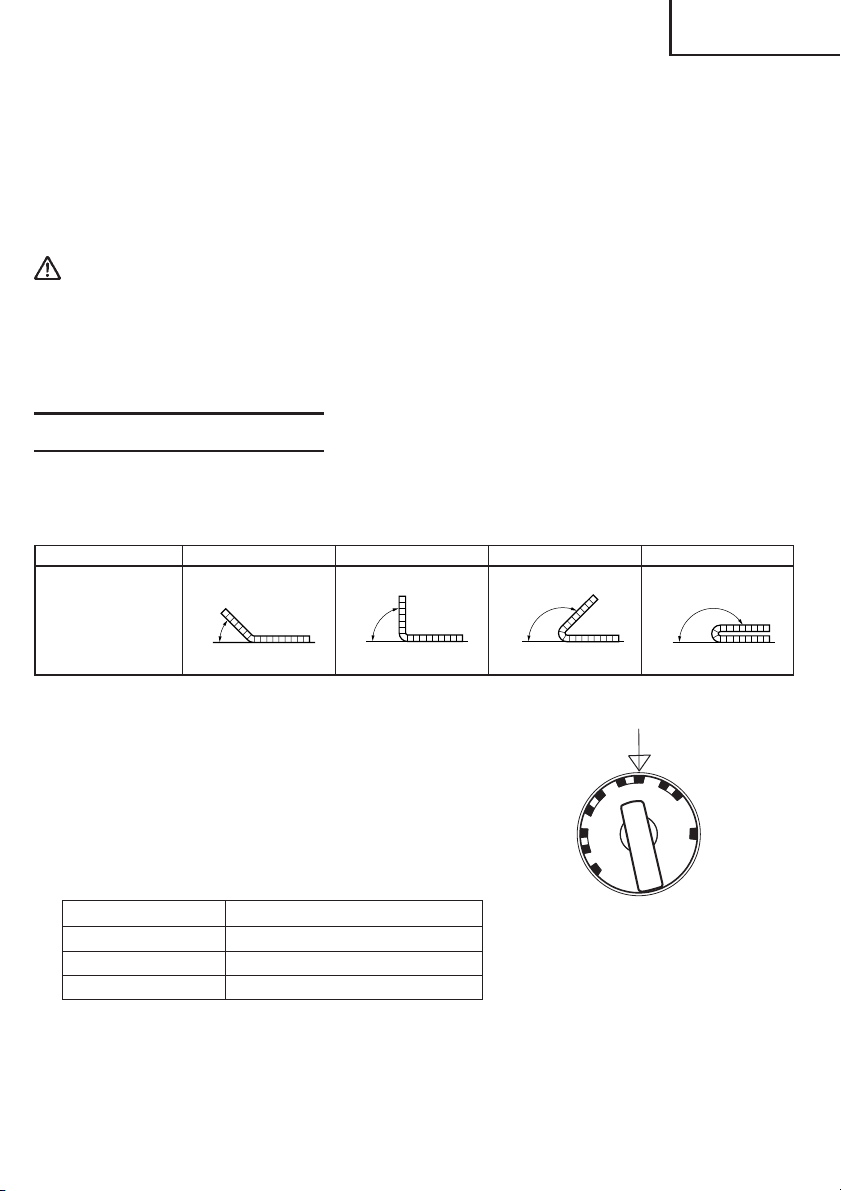

1. Setting bending angles by setting dial.

The bar can be bent according to the angles indicated on the setting dial, as shown in Fig.

12.

Dial indication 45° 90° 135° 180°

Condition of rebar

180°135°90°45°

Fig. 12

Adjusting position

In bending the rebar of #3(3/8"), #4(1/2"), and #5(5/

8") diameters, a difference takes place in the bending

angle even in the same dial position depending

upon the difference of rebar's thickness. Slightly

change a position of the setting dial depending

upon the rebar's diameter even with the same

bending angle as shown in Fig. 13.

Size of rebar Colors of indicated marks

Fig. 13

#3(3/8") White

#4(1/2") Red

#5(5/8") Yellow

NOTE

Even at the same dial setting position, the bending angle can sometimes differ if the diameter

or hardness of the rebar is different. Use the angle marks merely as a rough guideline.

17

English

2. Ordinary bending.

(1) Set the unit in the position with the turntable up

as shown in Fig. 14.

(2) Make sure that the cover is closed.

(3) Set the setting dial at the desired angle. (Fig. 13)

(4) Place the rebar on the center plate and set it

correctly as shown in Fig. 14.

(5) Pull the switch trigger and bent the rebar.

(6) Continue pulling the switch trigger untill the

motor makes reverse rotation and the bending

roller starts to return. (Once the bending roller

starts to return, it will automatically return all

the way to the home position even if the switch

trigger is released.)(Fig. 15)

Bending length

8" (200 mm) or

more

Fig. 14

Center plate

Bending

roller

Cover

WARNING:

䡬 Make absolutely sure that the cutter cover is closed

when you don’t carry out the cutting work. If the

cover is kept open, the cutter can jam on foreign

objects and cause serious accidents. (Fig. 16)

䡬 Never bring your hand close to the bending roller

during operation.

䡬 If you bend the rebar with a large angle while

placing your hand onto it, there is a fear of getting

your hand caught in by the fold-back reaction of

the rebar. Never place your hand onto the position

where the rebar may fold back.

䡬 Do not bend any rebar exceeding the maximum

capacities of the unit described in the specifications.

Never bend any hard materials such as PC(Precast

concrete) steel. Materials of this type are likely to

scatter into pieces and cause injuries.

䡬 The rebar you are bending may have a hard spot in

it. Quality may vary within each bar. Do not attempt

to bend NON-GRADE Rebar.

䡬 Never place your hand onto the bending side of the

rebar. If you do so, your hand may be caught in the

mechanical parts.

䡬 Install the deflection guard for operation with the bending length of a rebar 20" (inside

dimension of the deflection guard) or less to protect the persons around the rebar cutter/

bender in case rebar splinters into pieces and deflects during bending. (Fig. 20)

䡬 Remove the deflection guard when bending a rebar whose bending length and the fixed

length are more than 20" to prevent damage to the deflection guard.

䡬 Replace the deflection guard with new one if it is damaged. Damaged deflection guard

cannot protect the persons around the rebar cutter/bender in case a rebar splinters into

pieces and deflects during bending.

䡬 Note that the unit is not a hand-held tool. Be absolutely sure to use the unit only after

placing it on a stable spots such as floor, ground, etc.

18

Lever

Switch trigger

Fig. 15

Cover

Fig. 16

English

䡬 Begin operation only after marking sure that there

are no people within the turning range of the

material to be bent.

䡬 The minimum required bending length is 8" (200

mm).

If the bending length is not long enough, the rebar

can come off during bending operation, or it can

break into fragments and scatter dangerously.

(Fig. 14)

䡬 Be sure to set the rebar in the roller correctly. If it

protrudes from the roller, the rebar can come off

during bending operation and scatter into pieces.

䡬 Bend less than every 3 pieces of rebar with a #3(3/

8") diameter, less than every 2 pieces with a #4(1/

2") diameter, and every 1 piece with a #5(5/8")

diameter.

䡬 Remember that the cutter moves even during the

bending operation, thereby, close the cutter cover

without fail.

Fig. 17

Fig. 18

Slot for

base

insertion

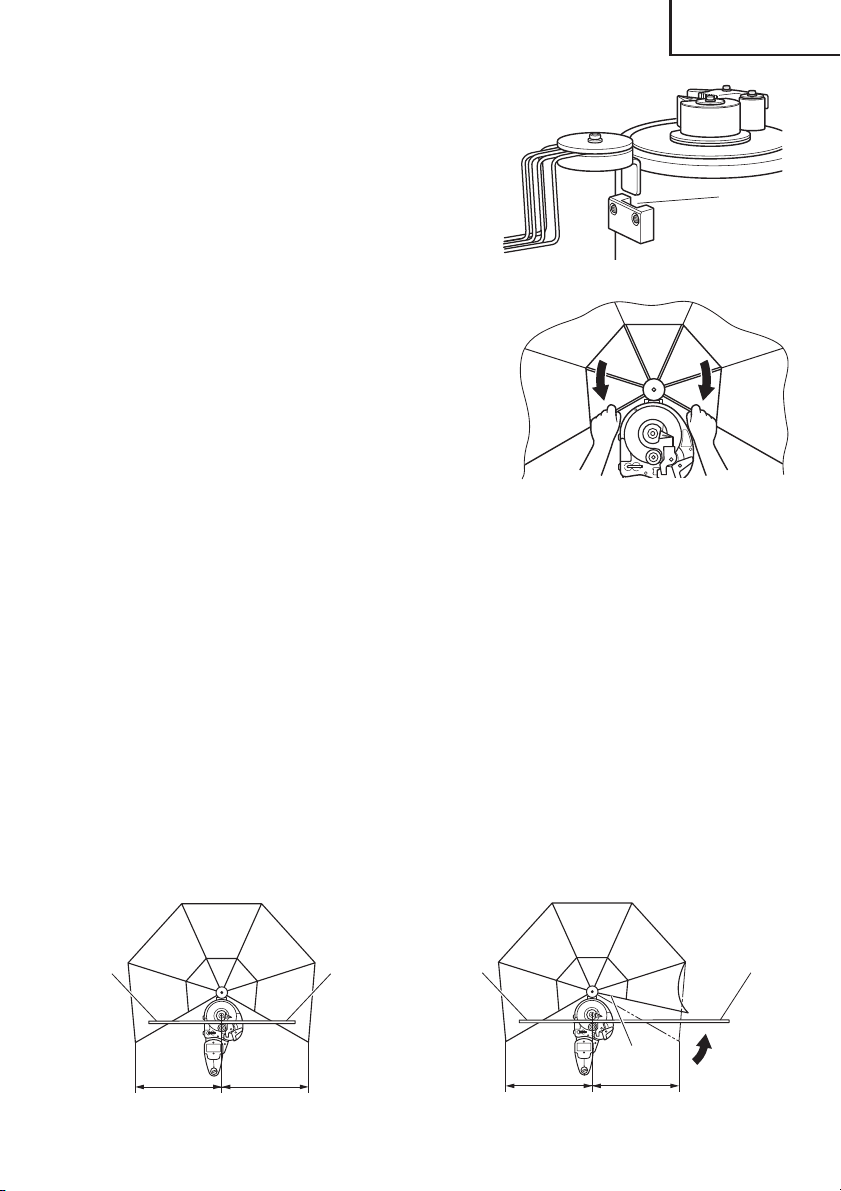

3. How to install deflection guard

The deflection guard is provided to protect the persons around the rebar cutter/bender

in case a rebar splinters into pieces and deflects during bending. Install the deflection

guard to the VB16Y for operation with the bending length of a rebar 20" (inside dimension

of the deflection guard) or less.

(1) Insert the base of the deflection guard into the slot of the rebar cutter/bender. (Fig. 17)

(2) Open the guard fully by pulling the arms as shown below until a click is heard. (Fig.

18)

4. How to remove deflection guard

䡬 Reverse the installation procedure to remove the deflection guard.

5. How to use deflection guard

(1) Be sure to install the deflection guard when bending a rebar whose bending length

and the fixed length are 20" (inside dimensin of deflection guard) or less (Fig. 19)

(2) Be sure to install the deflection guard when bending a rebar whose bending length

is 20" (inside dimensin of diflection guard) or less and the fixed length is more than

20". In this case, move the arm at the fixed end. (Fig. 20)

Bending

side

Fixed

end

20"

Fig. 19 Fig. 20

20"

Bending

side

20" 20"

Fixed

end

Arm

19

English

0°

45°

90°

135

°

180°

R

E

T

U

R

N

C

U

T

(3) Remove the deflection guard when bending a rebar whose bending length and the

fixed length are more than 20" (inside dimension of the deflection guard).

CAUTION:

䡬 Set a rebar on the rebar cutter/bender so that the bending length is equal to or shorter

than the fixed length.

6. Bending by eye measurement.

Since the unit uses a variable-speed switch, you can bend the rebar to your desired angle

by eye measurement in addition to the dial setting.

(1) Set the setting dial to a larger angle than you

desire.

(2) Pull the switch trigger lightly and bend the rebar

slowly.

(3) When the rebar is bent to the desired angle,

stop pulling the switch. If the bar is still small of

the desired angle, pull the switch again.

(4) Remove the rebar after bending has been

finished. Then, pull the switch once more and

return the bending roller to the home position.

(Continue pulling the switch until the bending

roller begins reverse rotation.)

7. Removing rebar during bending operation

Fig. 21

When bending out at a low speed in “bending by

eye measurement”, the rebar can sometimes get

caught in the bending roller due to its own flexure.

If this occurs, you can return the bending roller to

the home position by pulling the switch again after

setting the setting dial to the “return” position.

Set

screws

Tail

cover

Bolt

This is the same method used to remove the rebar

when it gets caught during cutting operation. (Fig.

21)

8. Using hole to fix unit in place.

A hole is provided at the center of the unit to fix and

stabilize it. This hole comes in quite handy when

used in the following manner. (Fig. 22)

䡬 For bending operation when the unit is fixed to

a work bench.

This hole will prove very convenient when the

unit is bolted to a suitable work bench.

(Bolt size M10, less than W3/8.)

Nut

Hole to fix

unit

Fig. 22

20

English

MAINTENANCE AND INSPECTION

WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle

during maintenance and inspection.

1. Inspecting the cutter

Continued use of a dull or damaged cutter will result in reduced cutting efficiency and

may cause overloading of the motor. Replace the cutter with a new one as soon as

excessive abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that they are properly tightened.

Should any of the screws be loosened, retighten them immediately.

WARNING: Using this Reber cutter/bender with loosened screws is extremely

dangerous.

3. Maintenance of the motor

The motor unit winding is the very “heart“ of the power tool. Exercise due care to ensure

the winding does noto become damaged and/or wet with oil or water.

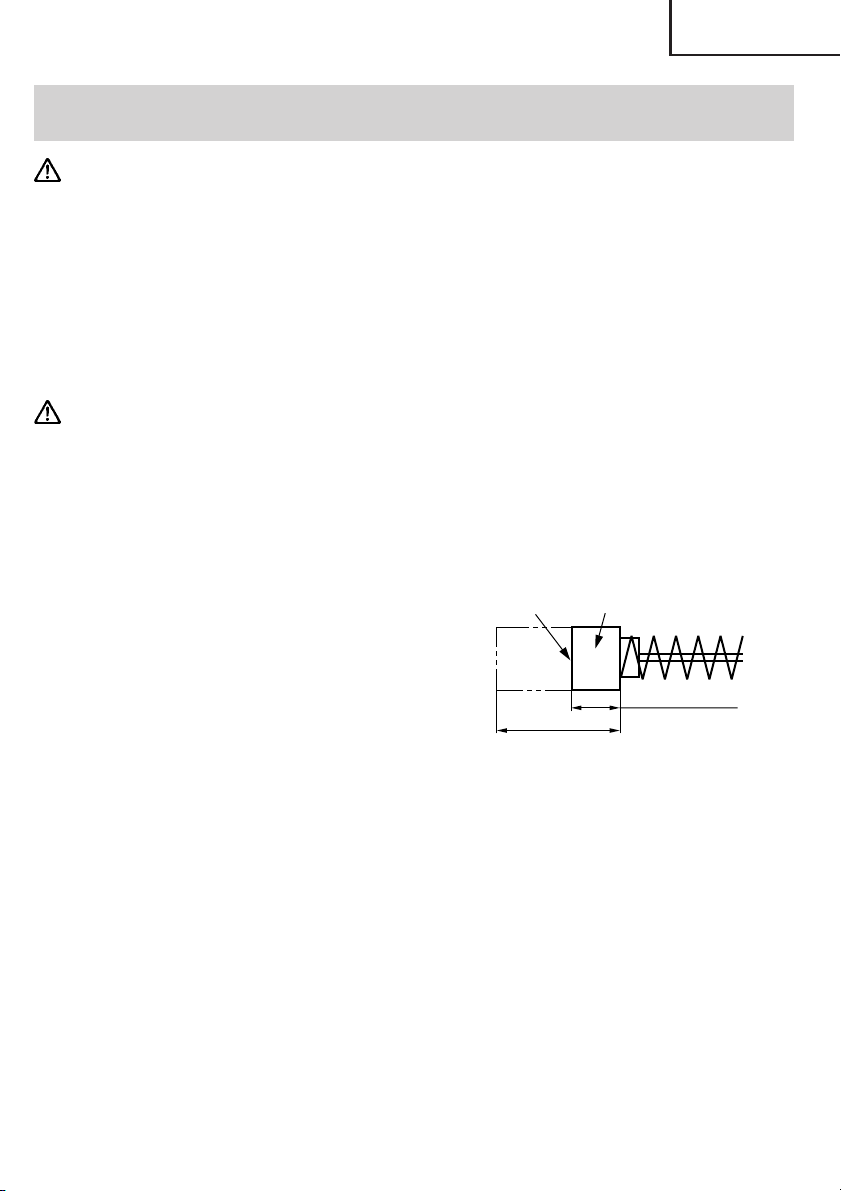

4. Inspecting the carbon brushes (Fig. 23)

The Motor employs carbon brushes which

are consumable parts. When they become

worn to or near the “wear limit”, it could

result in motor trouble. When an auto-stop

carbon brush is equipped, the motor will

stop automatically. At that time, replace

both carbon brushes with new ones which

have the same carbon brush Numbers shown

in the figure. In addition, always keep carbon

brushes clean and ensure that they slide

freely within the brush holders.

Wear limit

0.67” (17 mm)

No. of carbon

brush

43

0.24" (6 mm)

Fig. 23

NOTE: Use HITACHI carbon brush No. 43 indicated in Fig. 23.

5. Replacing carbon brushes

Loosen the set screws and remove the tail cover. Remove the brush caps and carbon

brushes. After replacing the carbon brushes, do not forget to tighten the brush caps

securely and to mount the tail cover with set screws.

6. Service and repairs

All quality power tools will eventually require servicing or replacement of parts because

of wear from normal use. To assure that only authorized replacement parts will be used,

all service and repairs must be performed by a HITACHI AUTHORIZED SERVICE CENTER,

ONLY.

21

English

ACCESSORIES

WARNING: Accessories for this power tool are mentioned in this Instruction Manual.

The use of any other attachment or accessory can be dangerous and

could cause injury or mechanical damage.

NOTE:

Accessories are subject to change without any obligation on the part of the HITACHI.

STANDARD ACCESSORIES

(1) Allen wrench (For M5 hexagon socket bolt) ....................................... 1 (attached to unit)

(2) One set of cutters .................................................................................. 1 (attached to unit)

(3) Deflection guard .................................................................................... 1

OPTIONAL ACCESSORIES.......sold separately

䡬 Cutter (Fig. 24)(Code No. 319706)

* One set containing two pieces

Fig. 24

NOTE:

Specifications are subject to change without any obligation on the part of the HITACHI.

22

Français

INFORMATIONS IMPORTANTES

Lire et comprendre toutes les instructions de fonctionnement, les précautions de sécurité et

les avertissements dans ce mode d’emploi avant d’utiliser ou d’entretenir cet outil motorisé.

La plupart des accidents causés lors de l’utilisation ou de l’entretien de l’outil motorisé

proviennent d’un non respect des règles ou précautions de base de sécurité. Un accident

peut la plupart du temps être évité si l’on reconnaît une situation de danger potentiel avant

qu’elle ne se produise, et en observant les procédures de sécurité appropriées.

Les précautions de base de sécurité sont mises en évidence dans la section “SECURITE” de

ce mode d’emploi et dans les sections qui contiennent les instructions de fonctionnement

et d’entretien.

Les dangers qui doivent être évités pour prévenir des blessures corporelles ou un

endommagement de la machine sont identifiés par AVERTISSEMENTS sur l’outil motorisé

et dans ce mode d’emploi.

Ne jamais utiliser cet outil motorisé d’une manière qui n’est pas spécifiquement recommandée

par HITACHI sans avoir d’abord vérifié que l’utilisation prévue est sans danger pour vous et

les autres.

SIGNIFICATION DES MOTS D’AVERTISSEMENT

AVERTISSEMENT indique des situations potentiellement dangereuses qui, si elles sont

ignorées, pourraient entraîner de sérieuses blessures personnelles.

PRECAUTION indique des situations dangereuses qui, si elles sont ignorées, pourrait

entraîner de légères blessures personnelles ou endommager la machine.

REMARQUE met en relief des informations essentielles.

23

Français

SECURITE

CONSIGNES DE SECURITE RELATIVES AUX OUTILS ELECTRIQUES.

LIRE TOUS LES AVERTISSEMENTS ET TOUTES LES INSTRUCTIONS D’UTILISATION DU

MANUEL AVANT DE METTRE L’OUTIL EN SERVICE OU DE L’ENTRETENIR :

AVERTISSEMENT: Lorsqu’on utilise l’outil électrique, prendre toutes les

précautions nécessaires pour éviter au maximum tout risque

de choc électrique ou autre blessure physique.

En particulier, toujours respecter les consignes de sécurité

suivantes :

1. TOUJOURS LAISSER LES PROTECTIONS EN PLACE ET LES MAINTENIR EN BON ORDRE

DE MARCHE.

2. TOUJOURS RETIRER LES CLAVETTES DE REGLAGE ET LES CLES AVANT DE METTRE

L’OUTIL EN MARCHE. Toujours vérifier que les clés et les clavettes de réglage sont bien

toutes retirées de l’outil avant de le mettre en marche.

3. TOUJOURS MAINTENIR L’AIRE DE TRAVAIL PROPRE. Pour éviter tout risque de

blessure, ne pas encombrer l’aire de travail ni l’établi.

4. NE JAMAIS UTILISER L’OUTIL DANS UN ENVIRONNEMENT DANGEREUX. Ne jamais

utiliser l’outil électrique dans un endroit humide ou mouillé, et ne jamais l’exposer à la

pluie. Toujours veiller à ce que l’aire de travail soit suffisamment éclairée.

5. NE JAMAIS LAISSER LES ENFANTS NI AUCUNE AUTRE PERSONNE APPROCHER DE

L’AIRE DE TRAVAIL. Interdire l’accès de l’aire de travail à tout le monde (en particulier aux

enfants). Toujours débrancher l’outil quand on s’en éloigne et veiller à ce que personne

ne puisse pénétrer dans l’aire de travail en mettant des verrous aux portes et aux

interrupteurs principaux. Toujours retirer le bouton de déverrouillage de l’outil et le

ranger en lieu sûr lorsqu’on ne s’en sert pas.

6. NE JAMAIS FORCER L’OUTIL. Il effectuera le travail le meilleur et avec la sécurité

maximale au régime pour lequel il a été conçu.

7. TOUJOURS UTILISER LES OUTILS APPROPRIES. Ne jamais utiliser un outil ou un

accessoire pour un travail pour lequel il n’est pas conçu.

8. PORTER DES VETEMENTS APPROPRIES PENDANT LE TRAVAIL. Ne jamais porter de

vêtements lâches ni de gants, cravate, bagues, bracelets ni aucun autre bijou. Ils

pourraient se coincer dans les pièces en rotation. Toujours porter des chaussures antidérapantes, en particulier avec des doigts de pied en acier. Porter un couvre-chef qui

recouvre les cheveux longs.

9. TOUJOURS PORTER DES LUNETTES DE PROTECTION PENDANT LE TRAVAIL POUR

EVITER TOUT RISQUE DE BLESSURE DES YEUX. Les lunettes ordinaires n’assurent pas

une protection suffisante parce que les verres ne sont pas faits en verre de sécurité. Par

ailleurs, porter un masque sur le visage pour accroître la sécurité, et un masque antipoussière si le travail doit dégager de la poussière.

10. TOUJOURS FIXER LA PIECE A LA GARDE OU A LA TABLE. Utiliser des dispositifs de

serrage ou un étau pour tenir la pièce. Cela sera plus sûr que de tenir la pièce à la main

et libérera les deux mains pour le travail.

24

Français

11. NE JAMAIS TROP SE PENCHER. Toujours garder une bonne assise et un bon équilibre

pendant le travail.

12. TOUJOURS ENTRETENIR LES OUTILS AVEC SOIN. Maintenir les outils aiguisés et

propres pour optimiser le travail et la sécurité. Toujours suivre les instructions de

graissage et de remplacement des accessoires.

13. TOUJOURS DEBRANCHER L’OUTIL avant un entretien et lors du remplacement des

lames ou de tout autre accessoire.

14. NE JAMAIS RISQUER UNE MISE EN MARCHE INOPINEE LORSQU’ON BRANCHE

L’OUTIL. Toujours vérifier que l’interrupteur est en position OFF avant de brancher la

fiche d’alimentation dans la prise secteur.

15. TOUJOURS UTILISER EXCLUSIVEMENT LES ACCESSOIRES RECOMMANDES POUR

L’OUTIL. Consulter le mode d’emploi pour la description des outils recommandés. Pour

éviter tout risque de blessure, utiliser exclusivement les accessoires recommandés pour

cet outil.

16. Ne jamais monter sur l’outil. Pour éviter tout risque de blessures graves, ne pas incliner

l’outil, et veiller à ne pas toucher le couteau par inadvertance.

17. TOUJOURS VERIFIER SI L’OUTIL A DES PIECES ENDOMMAGEES AVANT DE L’UTILISER.

Toujours vérifier si la protection et les autres composants sont endommagés avant

d’utiliser l’outil pour s’assurer qu’ils fonctionneront correctement. Vérifier si toutes les

pièces mobiles sont bien alignées, non voilées, ou toute autre condition qui pourrait

entraver leur bon fonctionnement. Toujours réparer ou remplacer les protections ou les

autres pièces endommagées avant d’utiliser l’outil.

18. TOUJOURS VERIFIER LE SENS DE ROTATION DE LA LAME AVANT D’UTILISER L’OUTIL.

Toujours avancer la pièce dans l’outil contre le sens de déplacement du couteau pour

éviter tout risque de blessure.

19. NE JAMAIS S’ELOIGNER DE L’OUTIL QUAND IL FONCTIONNE. LE METTRE HORS

TENSION. Ne pas s’éloigner de l’outil tant qu’il n’est pas complètement arrêté. Toujours

mettre l’outil hors tension quand on ne s’en sert pas. Toujours débrancher le cordon

d’alimentation quand on ne se sert pas de l’outil.

20. L’outil n’est pas conçu pour des applications de fabrication en série, et il ne devra donc

pas être utilisé dans un environnement de fabrication en série.

21. Pour les réparations, utiliser exclusivement des pièces de rechange agréées.

22. Alimenter l’outil exclusivement sur un courant alternatif de 120 volts. Une tension ou une

alimentation incorrectes pourraient provoquer un mauvais fonctionnement de l’OUTIL

ELECTRIQUE et provoquer des blessures physiques ou des dommages matériels graves.

23. FICHES POLARISEES Pour réduire tout risque de choc électrique, l’appareil possède une

fiche polarisée (l’une des lames est plus large que l’autre). Cette fiche ne rentrera dans

une prise polarisée que dans un sens. Si la fiche ne rentre pas dans la prise, l’inverser.

Si elle ne rentre toujours pas, faire installer une prise appropriée par un électricien

qualifié. Ne pas modifier la fiche de quelque façon que ce soit.

25

Français

REGLES DE SECURITE SPECIFIQUES ET SYMBOLES

AVERTISSEMENT: A des fins de sécurité, lire le mode d’emploi avant d’utiliser

l’outil.

Porter des lunettes de protection.

Risque de blessure en cas de démarrage accidentel.

Ne pas utiliser dans un atelier domestique ni dans aucune

autre aire de travail où des enfants risquent de se trouver

présents.

1. Tenir les outils par les surfaces de grippage lors de la réalisation d’opération où l’outil

de coupe risque d’entrer en contact avec des câbles cachés ou son propre cordon. Un

contact avec un fil “sous tension” mettra les parties métalliques de l’outil “sous tension”

et électrocutera l’utilisateur.

2. TOUJOURS porter des bouchons d’oreille lors de l’utilisation de l’outil pendant de

longues périodes. Une exposition prolongée à un son de forte intensité peut endommager

l’ouïe de l’utilisateur.

3. Ne jamais toucher les parties mobiles.

Ne jamais placer ses mains, ses doigts ou toute autre partie de son corps près des parties

mobiles de l’outil.

4. Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées.

Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées

dans le mode d’emploi.

5. Manipuler l’outil correctement

Utiliser l’outil de la façon indiquée dans ce mode d’emploi. Ne pas laisser tomber ou

lancer l’outil. Ne jamais permettre que l’outil soit utilisé par des enfants, des personnes

non familiarisées avec son fonctionnement ou un personnel non autorisé.

6. Maintenir toutes les vis, tous les boulons et les couvercles fermement en place.

Maintenir toutes les vis, tous les boulons et les couvercles fermement montés. Vérifier

leurs conditions périodiquement.

7. Ne pas utiliser les outils motorisés si le revêtement de plastique ou la poignée est fendu.

Des fentes dans le revêtement ou la poignée peuvent entraîner une électrocution. De tels

outils ne doivent pas être utilisés avant d’être réparé.

8. Les couteaux et les accessoires doivent être fermement montés sur l’outil.

Eviter les blessures potentielles personnelles et aux autres. Les couteaux, les instruments

de coupe et les accessoires qui ont été montés sur l’outil doivent être fixés et serrés

fermement.

9. Garder propres les évents d’air du moteur

Les évents d’air du moteur doivent être maintenus propres de façon que l’air puisse

circuler librement tout le temps. Vérifier les accumulations de poussière fréquemment.

10. Utiliser l’outil motorisé à la tension nominale.

Utiliser l’outil motorisé à la tension spécifiée sur sa plaque signalétique.

Si l’on utilise l’outil motorisé avec une tension supérieure à la tension nominale, il en

résultera une rotation anormalement trop rapide du moteur et cela risque d’endommager

l’outil et le moteur risque de griller.

26

Français

11. Ne jamais utiliser un outil défectueux ou qui fonctionne anormalement.

Si l’outil n’a pas l’air de fonctionner normalement, fait des bruits étranges ou sans cela

paraît défectueux, arrêter de l’utiliser immédiatement et le faire réparer par un centre de

service Hitachi autorisé.

12. Ne jamais laisser fonctionner l’outil sans surveillance. Le mettre hors tension.

Ne pas abandonner l’outil avant qu’il ne soit complètement arrêté.

13. Manipuler l’outil motorisé avec précaution.

Si un outil motorisé tombe ou frappe un matériau dur accidentellement, il risque d’être

déformé, fendu ou endommagé.

14. Ne pas essuyer les parties en plastique avec du solvant.

Les solvants comme l’essence, les diluants, la benzine, le tétrachlorure de carbone et

l’alcool peuvent endommager et fissurer les parties en plastique. Ne pas les essuyer avec

de tels solvants.

Essuyer les parties en plastique avec un chiffon doux légèrement imbibé d’une solution

d’eau savonneuse et sécher minutieusement.

15. Définitions pour les symboles utilisés sur cet outil

V ............. volts

Hz ........... hertz

A ............. ampères

no .......... vitesse sans charge

W ............ watt

............ Construction de classe II

---/min .... tours par minute

PIECES DE RECHANGE

Pour les réparations, utiliser exclusivement des pièces de rechange identiques.

Les réparations devront être effectuées exclusivement par un centre de service après-vente

Hitachi agréé.

27

Français

UTILISER LE CORDON DE RALLONGE APPROPRIÉ

Utiliser exclusivement un cordon de rallonge en bon état. Lorsqu’on utilise un cordon de

rallonge, veiller à ce qu’il soit suffisamment lourd pour supporter le courant dont l’appareil

aura besoin. Un cordon trop petit provoquera une chute de la tension de ligne, ce qui

entraînera une perte de puissance et une surchauffe. Le tableau indique le calibre à utiliser

en fonction de la longueur du cordon et de l’intensité nominale indiquée sur la plaque

signalétique. En cas de doute, utiliser un calibre supérieur. Plus le numéro du calibre est petit,

plus le cordon est lourd.

CALIBRE MINIMUM DES CORDONS

Longueur totale de cordon en pieds (mètres)

0 – 25 26 – 50 51 – 100 101 – 150

(0 – 7,6) (7,9 – 15,2) (15,5 – 30,5) (30,8 – 45,7)

Intensité nominale CALIBRE

Supérieure Non supérieure

àà

0 – 618161614

6 – 10 18 16 14 12

10 – 12 16 16 14 12

12 – 16 14 12 Non recommandé

AVERTISSEMENT: Eviter tout risque de choc électrique. Ne jamais utiliser l’outil

avec un cordon électrique ou un cordon de rallonge

endommagé ou dénudé.

Inspecter régulièrement les cordons électriques. Ne jamais

utiliser dans l’eau ou à proximité d’eau, ni dans un

environnement susceptible de provoquer un choc électrique.

28

Français

DOUBLE ISOLATION POUR UN FONCTIONNEMENT PLUS SUR

Pour assurer un fonctionnement plus sûr de cet outil motorisé, HITACHI a adopté une

conception à double insolation. “Double isolation” signifie que deux systèmes d’isolation

physiquement séparés ont été utilisés pour isoler les matériaux conducteurs d’électricité

connectés à l’outil motorisé à partir du cadre extérieur manipulé par l’utilisateur. C’est

pourquoi, le symbole “ ” ou les mots “Double insulation” (double isolation) apparaissent

sur l’outil motorisé ou sur la plaque signalétique.

Bien que ce système n’ait pas de mise à terre extérieure, il est quand même nécessaire de

suivre les précautions de sécurité électrique données dans ce mode d’emploi, y-compris de

ne pas utiliser l’outil motorisé dans un environnement humide.

Pour garder le système de double isolation effectif, suivre ces précautions:

䡬 Seuls les CENTRES DE SERVICE AUTORISES HITACHI peuvent démonter et remonter cet

outil motorisé et uniquement des pièces de rechange HITACHI garanties d’origine

doivent être utilisées.

䡬 Nettoyer l’extérieur de l’outil motorisé uniquement avec un chiffon doux légèrement

imbibé d’une solution savonneuse et essuyer minutieusement.

Ne jamais utiliser des solvants, de l’essence ou des diluants sur les parties en plastique;

sinon le plastique risquerait de se dissoudre.

CONSERVER CES INSTRUCTIONS

ET

LES METTRE A LA DISPOSITION

DES AUTRES UTILISATEURS

DE CET OUTIL!

29

Français

DESCRIPTION FONCTIONNELLE

REMARQUE:

Les informations contenues dans ce mode d’emploi sont conçues pour assister l’utilisateur

dans une utilisation sans danger et un entretien de l’outil motorisé.

Certaines illustrations dans ce mode d’emploi peuvent montrer des détails ou des

accessoires différents de ceux de l’outil motorisé utilisé.

NOM DES PARTIES

Vis de fixation

Couvercle arrière

Poignée

Gâchette

Carter de came

Rouleau de

Clé Allen

Caoutchouc de poignée

Fig. 1

Protection du couteau

cintrage

Couteau supérieur

Rouleau central

Plaque centrale

Table rotative

Carter de

came

Guide

Levier

Boulon à douille

hexagonale

Caoutchouc de poignée

30

Couteau inférieur

Fig. 2

Installation de la protection Repliage de la protection

anti-fièche anti-fièche

Français

Protection

Bras

Fig. 3 Fig. 4

Protection

Bras

SPECIFICATIONS

Moteur Moteur série monophasé à collecteur

Source d’alimentation Secteur, 120 V 60 Hz, monophasé

Courant 8 A

Capacités (1) Matériel: Barres de renfort de béton seulement)

(pour ASTM)

GRADE 40, GRADE 60

(2) Taille de désignation des barres

#3, #4, #5 (3/8", 1/2", 5/8")

Coupe Cintrage

Nombre de piéces qu’il est

possible de traiter à la fois

Vitesse sans charge 0 – 16/min.

Poids (sans cordon) 39,7 lbs (18,0 kg)

#3 (3/8") ..... 2 pièces #3 (3/8") ..... 3 pièces

#4 (1/2") ..... 1 pièce #4 (1/2") ..... 2 pièces

#5 (5/8") ..... 1 pièce #5 (5/8") ..... 1 pièce

Base

31

Français

ASSEMBLAGE ET FONCTIONNEMENT

APPLICATIONS

䡬 Coupe de barres béton

䡬 Cintrage de barres béton

AVANT L’UTILISATION

1. Source d’alimentation

S’assurer que la source d’alimentation qui doit être utilisée est conforme à la source

d’alimentation requise spécifiée sur la plaque signalétique du produit.

2. Interrupteur d’alimentation

S’assurer que l’interrupteur est sur la position OFF (arrêt). Si la fiche est connectée sur

une prise alors que l’interrupteur est sur la position ON (marche), l’outil motorisé

démarrera immédiatement risquant de causer de sérieuses blessures.

3. Cordon prolongateur

Quand la zone de travail est éloignée de la source d’alimentation, utiliser un cordon

prolongateur d’épaisseur et de capacité nominale suffisante. Le cordon prolongateur

doit être aussi court que possible.

AVERTISSEMENT: Tout cordon endommagé devra être remplacé ou réparé.

4. Vérifier la prise

Si la prise reçoit la fiche avec beaucoup de jeu, elle doit être réparée. Contacter un

électricien licencié pour réaliser les réparations nécessaires.

Si une telle prise défectueuse est utilisée, elle peut causer une surchauffe entraînant des

dangers sérieux.

5. Vérification des conditions d’environnement

Vérifier que l’état de l’aire de travail est conforme aux précautions.

6. A des fins de sécurité, utiliser la clé Allen fournie pour être absolument sûr que le boulon

à douille hexagonale est solidement vissé. Le fait d’utiliser l’outil avec un boulon lâche

risque d’endommager l’outil et de provoquer des accidents.

7. Vérifier que le couteau est bien affûté.

S’assurer que le couteau est bien affûté. Le fait de continuer à utiliser l’outil avec un

couteau émoussé et déformé risque d’endommager l’outil et le couteau et de provoquer

des accidents.

32

SCHÉMA ET EXPLICATION

Lire le mode

d’emploi avant

d’utiliser l’outil.

Ne pas utiliser cet outil

électrique par temps

humide.

Français

Si l’on coupe l’interrupteur puis

qu’on le rallume tout de suite après,

le moteur risque de ne pas démarrer.

Attendre au moins une bonne

seconde avant de remettre le moteur

en marche après l’avoir éteint.

Ne pas utiliser l’outil sans

s’être auparavant assuré

qu’il n’y a personne dans

le rayon de rotation du

matériau à cintrer.

(Retour à mi-course)

1 Sélectionner RETURN avec la bague.

2 Tirer sur la gâchette.

Ne jamais approcher

les mains du

couteau pendant le

fonctionnement.

Eviter tout travail dépassant les

capacités maximales.

(Barre béton de #5 (5/8") de

diamètre)

(Sélection de la taille de la barre béton)

Sélectionner la taille de la barre béton et

l’angle de cintrage.

33

Français

● Si l’on cintre la barre béton à un angle large en

plaçant la main dessus, l’on risque de se prendre la

main lors de la réaction de retour de la barre béton.

Ne jamais mettre la main à l’endroit où la barre

béton risque de se plier en retour.

● Le couteau peut s’user après des coupes répétées

de barres béton. Le fait de continuer à utiliser un

couteau émoussé risque d’entraîner des dommages

et de faire voler des éclats. Remplacer le couteau

par un neuf au bout de 5 000 coupes.

● L’outil est conçu de façon que le couteau

supérieur et le caoutchouc de la poignée puissent

supporter une barre béton.

Si le caoutchouc de la poignée s’use, il risque de

ne pas assurer une prise suffisante de la barre

béton et de se briser en faisant voler des éclats,

etc.

Si le caoutchouc de la poignée ne supportera

bientôt plus la barre béton, le remplacer par un

neuf. Remplacer également le caoutchouc de la

poignée usé par un neuf lors du remplacement

du couteau.

● Pendant la coupe, accrocher solidement la barre

béton à la butée de réaction B. De plus, accrocher

une longueur suffisante de barre béton à la butée

de réaction B.

● Ne pas approcher les mains de la butée de réaction

B pendant le fonctionnement. L’on risque de se

prendre les doigts ou de recevoir des blessures.

● Placer la barre béton au centre ou dans le

renfoncement du couteau pendant la coupe. Une

coupe avec la barre béton placée sur les coins ou à

l’extrémité du couteau risque de faire voler les

morceaux de la barre béton cassée ou

d’endommager le couteau et l’outil.

34

Français

UTILISATION (COUPE)

Butée de réaction B

Barre béton

1. Coupe normale (Fig. 5)

(1) Tourner le levier dans le sens de la flèche et

ouvrir le couvercle.

(2) Mettre la bague de réglage sur la position

“coupe”. (Tourner la bague de réglage à fond

dans le sens des aiguilles d’une montre.) (Fig. 6)

(3) Mettre l’outil dans la position indiquée à la Fig.

5.

(4) Placer la barre béton à couper sur le couteau

inférieur.

(5) Lorsque la barre béton est installée, s’assurer

que la butée de réaction B est accrochée sur la

barre béton.

(6) Tirer sur la gâchette et couper la barre béton.

Rouleau

de cintrage

Bague de

réglage

Fig. 5

Position de réglage

AVERTISSEMENT:

䡬 Lors de l’action des interrupteurs, ne jamais

approcher les mains du couteau, de la butée de

réaction ni du rouleau de cintrage.

䡬 L’on pourrait se blesser grièvement.

䡬 Eviter tout travail de coupe dépassant les capacités

maximales de l’outil données dans les

spécifications.

䡬 Ne jamais couper de matériaux durs, par exemple

du béton préfabriqué (PC) ou de l’acier. Ce genre de

matériaux risque de se fendre en éclats et de

provoquer des blessures.

䡬 La barre béton que l’on est en train de couper peur

avoir un point dur. La qualité peut varier dans

chaque barre béton.

䡬 Ne pas tenter de couper une barre béton NON-GRADE.

䡬 Remplacer également le caoutchouc de la poignée usé par un neuf lors du remplacement

du couteau.

䡬 Noter que l’outil n’est pas un outil qui se tient dans la main. Il faudra absolument le poser

à un endroit stable, par exemple le plancher, le sol, etc.

Fig. 6

135˚

180˚

CUT

90˚

45˚

RETURN

0˚

PRECAUTION:

Lorsque la coupe est terminée, continuer à tirer sur la gâchette jusqu’à ce que le moteur

commence à tourner en sens inverse et que le couteau commence à revenir. Si l’on

relâche la gâchette trop tôt, le couteau risque de ne pas revenir et il faudra à nouveau

tirer sur la gâchette.

2. Retrait de la barre béton pendant la coupe

(Fig. 7)

Si l’on relâche la gâchette au milieu de la coupe, le

couteau risque de s’arrêter à mi-chemin, et la barre

béton restera coincée dans l’outil.

Dans ce cas, on pourra soit tirer à nouveau sur la

gâchette et terminer la coupe de la barre béton, soit

libérer la barre béton en ramenant le couteau

supérieur à la position d’origine en procédant

comme suit. (Fig. 7)

Fig. 7

35

Français

0˚

RETURN

CUT

45˚

90

˚

135˚

180

˚

䡬 Retrait (Fig. 8)

Mettre la bague de réglage sur la position

“RETURN”, comme indiqué à la Fig. 8, et tirer à

nouveau sur la gâchette.

DURÉE DE SERVICE ET

REMPLACEMENT DU COUTEAU

1. Durée de service du couteau (Fig. 9)

Des coupes répétées finiront inévitablement par

user la lame du couteau et par déformer et fissurer

les tranchants, etc. Si l’on continue à utiliser le

couteau alors qu’il est abîmé de cette façon, non

seulement cela risque d’endommager l’outil, mais

des éclats de matériau risquent également de

s’éparpiller. Remplacer le couteau par un neuf au

bout de 5 000 coupes.

2. Avant de retirer le couteau

(1) Tirer légèrement sur l’interrupteur de façon que

le couteau supérieur se déplace lentement.

Lorsque le boulon à douille hexagonale qui fixe

le couteau supérieur sort du couvercle de came,

couper l’interrupteur et arrêter le moteur.

(2) Débrancher le cordon d’alimentation de la prise.

3. Retrait

䡬 Si l’on retire le boulon à douille hexagonale

avec une clé Allen, le couteau sortira. (Pousser

la protection du couteau vers le haut dans le

sens la flèche de la Fig. 10 pour faciliter le retrait

du couteau supérieur.)

䡬 Le retrait du couteau inférieur s’effectuera en

toute facilité en le serrant avec un tournevis à

tête Phillips, comme indiqué sur le schéma

suivant. (Fig. 11)

Boulon à

douille

hexagonale

Fig. 8

Lame

Fig. 9

Protection

du

couteau

Couteau

supérieur

Couteau

inférieur

Fig. 10

AVERTISSEMENT:

䡬 Pour éviter tout risque d’accident, toujours éteindre

l’interrupteur (OFF) et débrancher le cordon

d’alimentation de la prise secteur.

䡬 Si l’on retire le boulon à douille hexagonale à l’aide

de la clé Allen, on pourra retirer le couteau. (Pousser

la protection du couteau dans le sens de la flèche,

comme indiqué à la Fig. 10, pour faciliter le retrait

du couteau supérieur.)

36

Fig. 11

Français

0˚

RETURN

CUT

45˚

90

˚

135˚

180˚

4. Montage

(1) Retirer toute poussière qui s’est accumulée autour de la section d’installation du

couteau et nettoyer.

(2) Aligner l’orifice du nouveau couteau sur l’emplacement de la tige, et insérer dans la

section d’installation.

(3) Remplacer également le boulon à douille hexagonale (fourni avec le couteau) par un

neuf au même moment, le serrer à fond avec la clé Allen, puis fixer le couteau.

PRECAUTION :

䡬 Installer solidement le couteau et les accessoires, en suivant les instructions du mode

d’emploi. Si on ne les installe pas correctement, ils risquent de se détacher et de

provoquer des blessures.

䡬 Bien débrancher le cordon d’alimentation de la prise secteur lors de la vérification, du

nettoyage et du remplacement du couteau. Sinon, l’on risque de se blesser grièvement.

UTILISATION (CINTRAGE)

1. Réglage des angles de cintrage avec la bague de réglage

La barre béton pourra être cintrée aux angles indiqués sur la bague de réglage, comme

indiqué à la Fig. 12.

Indication de

la bague

Position de la

barre béton

45° 90° 135° 180°

180°135°90°45°

Fig. 12

Lors du cintrage de barres béton de #3 (3/8"), #4 (1/

Position de réglage

2") ou #5 (5/8") de diamètre, il y aura une différence

dans l’angle de cintrage même si la bague est à la

même position à cause de la différence d’épaisseur

des barres béton. Modifier légèrement la position

de la bague de réglage en fonction du diamètre de

la barre béton, même si l’angle de cintrage est le

même, comme indiqué à la Fig. 13.

Taille de barre béton Couleur des repères indiqués

#3(3/8") Blanc

Fig. 13

#4(1/2") Rouge

#5(5/8") Jaune

REMARQUE

Même si l’on place la bague sur la même position, l’angle de cintrage risque de différer

légèrement si le diamètre ou la dureté de la barre béton sont différents. Les repères d’angle

ne donnent qu’un indication approximative.

37

Français

2. Cintrage ordinaire

(1) Disposer l’outil par rapport à la table rotative

comme indiqué à la Fig. 14.

Longueur de

cintage

8" (200 mm) ou

plus

Plaque centrale

(2) Vérifier que le couvercle est bien fermé.

(3) Placer la bague de réglage à l’angle voulu (Fig.

13).

(4) Placer la barre béton sur la plaque centrale et la

Rouleau de

cintrage

disposer exactement comme indiqué sur la Fig.

14.

(5) Tirer sur la gâchette et cintrer la barre béton.

(6) Continuer à tirer sur la gâchette jusqu’à ce que

le moteur tourne en sens inverse et que le

Couvercle

rouleau de cintrage commence à revenir en

arrière. (Une fois que le rouleau de cintrage a

commencé à revenir en arrière, il reviendra

Fig. 14

automatiquement jusqu’à la position d’origine,

même si l’on relâche la gâchette.) (Fig.15)

Gâchette

AVERTISSEMENT:

䡬 Vérifier impérativement que le couvercle du

couteau est refermé lorsqu’on ne se sert pas de

l’outil pour un travail de coupe. Si le couvercle

reste ouvert, le couteau risque de se coincer dans

des corps étrangers et de provoquer des blessures

graves. (Fig. 16)

䡬 Ne jamais approcher les mains du rouleau de

cintrage pendant le fonctionnement.

䡬 Si l’on cintre la barre béton à un angle large en

plaçant la main dessus, l’on risque de se prendre la

main lors de la réaction de retour de la barre béton.

Ne jamais mettre la main à l’endroit où la barre

béton risque de se plier en retour.

䡬 Eviter tout travail de coupe dépassant les capacités

maximales de l’outil données dans les

spécifications. Ne jamais couper de matériaux durs,

par exemple du béton préfabriqué (PC) ou de

Levier

l’acier. Ce genre de matériaux risque de se fendre

en éclats et de provoquer des blessures.

䡬 La barre béton que l’on est en train de couper peut avoir un point dur. La qualité peut

varier dans chaque barre béton. Ne pas tenter de couper une barre béton NON-GRADE.

䡬 Ne jamais placer la main sur le côté de cintrage de la barre béton. L’on risquerait de se

prendre la main dans les pièces mécaniques.

䡬 Installer la protection anti-flèche avec des barres béton de 20" (dimension intérieure de

la protection anti-flèche) ou moins pour protéger les personnes autour de la cisailleuse/

cintreuse au cas où la barre béton se briserait en éclats et dévierait pendant le cintrage.

(Fig. 20)

Fig. 15

Couvercle

Fig. 16

38

Français

䡬 Retirer la protection anti-flèche pour le cintrage d’une barre béton dont la longueur de

cintrage et la longueur de fixation sont inférieures à 20" pour éviter d’endommager la

protection anti-flèche.

䡬 Remplacer la protection anti-flèche par une neuve si elle est endommagée. Une

protection anti-flèche endommagée ne peut pas protéger les personnes autour de la

cisailleuse/cintreuse au cas où la barre béton se briserait en éclats et dévierait pendant

le cintrage.

䡬 Noter que l’outil n’est pas un outil qui se tient dans la main. Il faudra absolument le poser

à un endroit stable, par exemple le plancher, le sol, etc.

䡬 Ne commencer à travailler qu’après s’être assuré qu’il n’y a personne dans le rayon de

rotation du matériau à cintrer.

䡬 La longueur de cintrage minimum requise est de 8" (200 mm).

Si la longueur de cintrage n’est pas suffisante, la barre béton peut se détacher pendant

l’opération de cintrage, ou elle peut se briser en éclats qui pourraient s’éparpiller et être

dangereux. (Fig. 14)

䡬 Bien installer la barre béton correctement dans le

rouleau. Si elle dépasse du rouleau, elle risque de

se détacher 2pendant le cintrage et de s’éparpiller

en éclats.

䡬 Cintrer moins de tous les 3 morceaux avec une

barre béton d’un diamètre de #3 (3/8"), moins de

tous les 2 morceaux avec une barre béton d’un

diamètre de #4 (1/2"), et moins de tous les morceaux

avec une barre béton d’un diamètre de #5 (5/8").

䡬 Bien savoir que le couteau continue à se déplacer

pendant l’opération de cintrage; il faudra donc

refermer le couvercle du couteau sans faute.

Fig. 17

Fente

d’insertion

de la base

3. Installation de la protection anti-flèche

La protection anti-flèche a pour but de protéger les

personnes autour de la cisailleuse/cintreuse au cas

où la barre béton se briserait en éclats et dévierait

pendant le cintrage. Installer la protection antiflèche sur la VB 16Y pour traiter des barres béton

d’une longueur de cintrage de 20" (dimension

intérieure de la protection anti-flèche) ou moins.

(1) Insérer la base de la protection anti-flèche dans la

fente de la cisailleuse/cintreuse. (Fig. 17)

(2) Ouvrir complètement la protection en déployant les bras comme indiqué ci-dessous,

jusqu’au déclic. (Fig. 18)

Fig. 18

4. Retrait de la protection anti-flèche

䡬 Procéder dans le sens inverse de l’installation.

5. Utilisation de la protection anti-flèche

(1) Bien installer la protection anti-flèche pour cintrer des barres béton d’une longueur

de cintrage et d’une longueur de fixation (dimension intérieure de la protection antiflèche) égales à 20" moins (Fig. 19)

39

Français

0°

45°

90°

135

°

180°

R

E

T

U

R

N

C

U

T

(2) Bien installer la protection anti-flèche pour cintrer des barres béton d’une longueur

de cintrage de 20" (dimension intérieure de la protection anti-flèche) ou moins et

d’une longueur de fixation supérieure à 20". Dans ce cas, amener le bras sur le côté

fixation, comme indiqué ci-dessous. (Fig. 20)

(3) Retirer la protection anti-flèche pour cintrer des barres béton d’une longueur de

cintrage et d’une longueur de fixation supérieures à 20" (dimension intérieure de la

protection anti-flèche).

Côté

cintrage

Extrémité

fixe

Côté

cintrage

Extrémité

fixe

Bras

20"

20"

20"

20"

Fig. 19 Fig. 20

PRECAUTION:

䡬 Placer la barre béton sur la cisailleuse/cintreuse de façon que la longueur de cintrage soit

égale ou inférieure à la longueur de fixation.

6. Cintrage par mesure visuelle.

L’outil utilisant un sélecteur de vitesse variable, il est possible de cintrer la barre béton

à l’angle voulu en mesurant l’angle visuellement en plus d’avec la bague de réglage.

(1) Mettre la bague de réglage à un angle plus grand que l’angle voulu.

(2) Tirer légèrement sur la gâchette et cintrer la barre béton lentement.

(3) Lorsque la barre béton est cintrée à l’angle voulu, cesser de tirer sur l’interrupteur. Si

la barre béton n’a pas encore atteint l’angle voulu, tirer à nouveau sur la gâchette.

(4) Lorsque le cintrage est terminé, retirer la barre béton. Puis, tirer une nouvelle fois sur

l’interrupteur et ramener le rouleau de cintrage à la position d’origine. (Continuer à

tirer sur l’interrupteur jusqu’à ce que le rouleau de cintrage commence à tourner en

sens arrière.)

7. Retrait de la barre béton pendant le cintrage

Lorsqu’on effectue le cintrage à vitesse lente,

notamment lors d’un “cintrage par mesure

visuelle”, il arrive que la barre béton se coince dans

le rouleau de cintrage sous l’effet de sa propre

flexion.

Dans ce cas, on pourra ramener le rouleau de

cintrage à la position d’origine en tirant à nouveau

sur l’interrupteur après avoir mis la bague de réglage

sur la position “retour”. Cette méthode est la même

que pour le retrait des barres béton qui se coincent

pendant la coupe. (Fig. 21)

40

Fig. 21

Français