Page 1

SERVICE MANUAL

PA No. 0239

UT42X902 / D8MW

UT42V702 / D8MW

NTSC

ATSC

ready monitor

D8MW

UT42X902 - P#: HL02561 (CLU-4981S)

Chassis

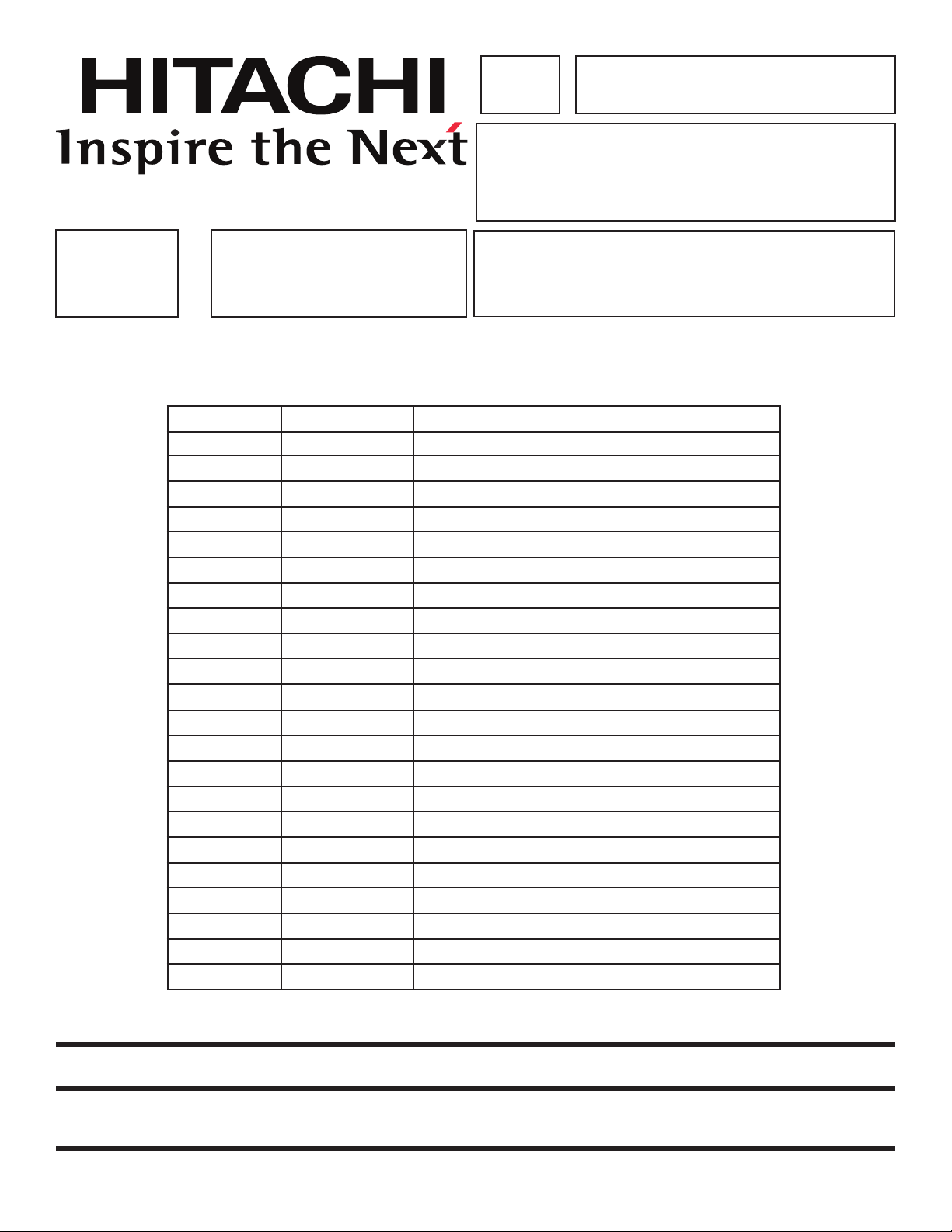

SERVICE MANUAL REVISION HISTORY INFORMATION

DATE REVISION # REASON

Oct. 03, 2008 SM00001 FIRST ISSUE OF MANUAL

UT42V702 - P#: HL02562 (CLU-4982S)

Remote controls:

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LCD DISPLAY PANEL

OCTOBER 2008 HIMEX MANUFACTURING DIVISION

Page 2

SERVICE MANUAL

NTSC

ATSC

ready monitor

D8MW

Chassis

PA No. 0239

UT42X902 / D8MW

UT42V702 / D8MW

Remote controls:

UT42X902 - P#: HL02561 (CLU-4981S)

UT42V702 - P#: HL02562 (CLU-4982S)

TO GO TO A CHAPTER, CLICK ON ITS HEADING BELOW

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PRODUCT SAFETY NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

AGENCY REGULATORY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ACKNOWLEDGEMENTS AND TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

BASIC SETUP & OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TROUBLESHOOTING FLOWCHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

CONNECTIONS DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

FINAL WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

FINAL ASSEMBLY GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

DC VOLTAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

CIRCUIT SCHEMATIC DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

MAIN PARTS VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

CAUTION:

These servicing instructions are for use by qualied service personnel only. To reduce the

risk of electric shock do not perform any servicing other than that contained in the operating

instructions unless you are qualied to do so. Before servicing this chassis, it is important that

the service technician read the “IMPORTANT SAFETY INSTRUCTIONS” in this service manual.

SAFETY NOTICE: USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special safety characteristics are identied by a ! on the schematics and on the

parts list in this service data and its suplements and bulletins. Before servicing the chassis, it is important

that the service technician read and follow the “Important Safety Instructions” in this service manual.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LCD DISPLAY PANEL

OCTOBER 2008 HIMEX MANUFACTURING DIVISION

Page 3

D8MW

SAFETY PRECAUTIONS

NOTICE: Comply with all cautions and safety-related notes

located on or inside the cover case and on the chassis or

LCD module.

WARNING: Since the chassis of this receiver is connected

to one side of the AC power supply during operation,

whenever the receiver is plugged in service should not

be attempted by anyone unfamiliar with the precautions

necessary when working on this type of receiver.

1. When service is required, an isolation transformer

should be inserted between power line and the receiver

before any service is performed on a “HOT” chassis

receiver.

2. When replacing a chassis in the receiver, all the

protective devices must be put back in place, such as

barriers, nonmetallic knobs, insulating cover-shields,

and isolation resistors, capacitors, etc.

3. When service is required, observe the original lead

dress (wiredress).

4. Always use manufacturer’s replacement components.

Critical components as indicated on the circuit diagram

should not be replaced by another manufacturer’s.

Furthermore, where a short circuit has occurred,

replace those components that indicate evidence of

over heating.

5. Before returning a serviced receiver to the customer,

the service technician must thoroughly test the unit to

be certain that it is completely safe to operate without

danger of electrical shock, and be sure that no protective

device built into the receiver by the manufacturer has

become defective, or inadvertently defeated during

servicing.

Therefore, the following checks should be performed

for the continued protection of the customer and service

technician.

Leakage Current Cold Check

With the AC plug removed from the 120V AC 60Hz source,

place a jumper across Line 1 and Line 2 of the three plug

prongs, do not connect with the third prong, which is

physical ground.

Using an insulation tester (DC500V), connect one of its

leads to the AC plug jumper and touch with the other lead

each exposed metal part (antennas, screwheads, metal

overlays, control shafts, etc.), particularly any exposed

metal part having a return path to the chassis should

have a resistor reading over 4MΩ. Any resistance value

below this range indicates an abnormality which requires

corrective action. An exposed metal part not having a

return path to the chassis will indicate an open circuit.

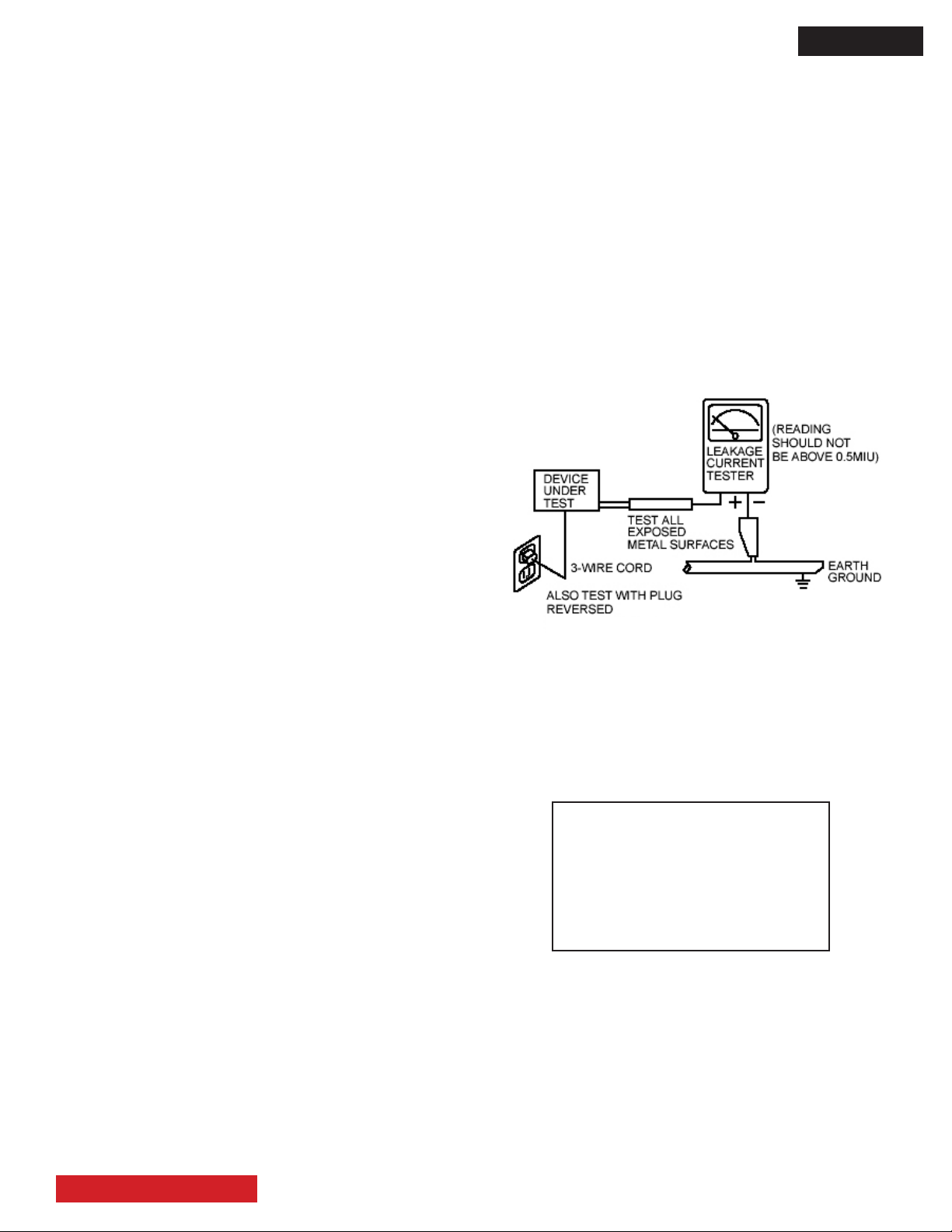

Leakage Current Hot Check

Plug the AC line cord directly into a 120V AC outlet. (Do

not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies

with the American National Standards Institute (ANSI)

C101.0 Leakage Current for Appliances. In the case of

the LCD monitor set the AC switch rst in the ON position and then in the OFF position, measure from across

Line 1 and Line 2 of the three plug prongs (do not connect with the third prong which is physical ground), to

all exposed metal parts of the instrument (antennas,

handle bracket, metal cabinet, screw heads, metallic

overlays, control shafts, etc.), especially any exposed

metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 MIU. Reverse

the instrument power cord plug in the outlet and repeat test.

AC LEAKAGE TEST

(USING ADAPTER AS

REQUIRED)

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE RECEIVER TO THE CUSTOMER.

NOTE:

Unplug the AC cord from the power

line before servicing the LCD TV

set.

The Main Power Switch does not

completely cut the AC power.

TABLE OF CONTENTS

2

Page 4

D8MW

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in HITACHI television

receivers have special safety-related characteristics.

These are often not evident from visual inspection nor can

the protection afforded by them necessarily be obtained

by using replacement components rated for higher

voltage, wattage, etc. Replacement parts which have

these special safety characteristics are identied in this

Service Manual.

Electrical components having such features are identied

with a ! mark in the schematics and parts list in this

Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

HITACHI recommended replacement component, shown

in the parts list in this Service Manual, may create shock,

re, X-radiation, or other hazards.

Product safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current HITACHI Service

Manual. A subscription to, or additional copies of HITACHI

Service Manuals may be obtained at a nominal charge

from HITACHI Sales Corporation.

UT42X902 and UT42V702 - LCD monitors

1. Follow the general caution recommendations from

“Safety precautions” section.

2. If necessary to replace Panel module, this work must

be started after the panel module and the AC/DC Power

supply becomes sufciently cool.

3. Special care must be taken with the display area to

avoid damaging its surface.

4. The Panel Module shall not be touched with bare hands

to protect its surface from stains.

5. It is recommended to use clean soft gloves during the

replacing work of the Panel module in order to protect, not

only the display area of the panel module but also the

serviceman.

6. Signal, power supply P.W.B.’s and LCD driving circuits

P.W.B.’s are assembled on the rear side of the LCD

module, take special care with this fragile circuitry.

They are not strong enough to withstand harsh outer

mechanical forces. Extreme bending of the exible

connectors must be avoided too.

SAFETY NOTICE

USE ISOLATION TRANSFORMER

WHEN SERVICING

POWER SOURCE

This LCD television is designed to operate on 120

Volts/60Hz, AC house current. Insert the power cord

into a 120 Volts/60Hz outlet.

NEVER CONNECT THE LCD TV TO OTHER THAN THE

SPECIFIED VOLTAGE OR TO DIRECT CURRENT AND

TO 50HZ. TO PREVENT ELECTRIC SHOCK, DO NOT

USE THE LCD TELEVISION’S (POLARIZED) PLUG

WITH AN EXTENSION CORD, RECEPTACLE, OR THE

OUTLETS UNLESS THE BLADES AND GROUND

TERMINAL CAN BE FULLY INSERTED TO PREVENT

BLADE EXPOSURE.

TABLE OF CONTENTS

3

Page 5

SERVICING PRECAUTIONS

D8MW

CAUTION: Before servicing instruments covered by this

service data and its supplements and addendum, read and

follow the information in previous pages number 2 and 3 of

this publication.

NOTE: If unforeseen circumstances create conict between

the following servicing precautions and any of the safety

precautions on the previous pages of this publication,

always follow the safety precautions. Remember: Safety

First.

General Servicing Guidelines

1. Always unplug the instrument AC power cord from the AC

power source before:

a. Removing or reinstalling any component, circuit board,

module, or any other instrument assembly.

b. Disconnecting or reconnecting any instrument electrical

plug or other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an explosion hazard.

2. Do not spray chemicals on or near this instrument or any

of its assemblies.

3. Unless specied otherwise in these service data, clean

electrical contacts by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

nonabrasive applicator: 10% (by volume) Acetone and 90%

(by volume) isopropyl alcohol (90%- 99% strength).

CAUTION: This is a ammable mixture. Unless specied

otherwise in these service data, lubrication of contacts is

not required.

4. Do not defeat any plug/socket of voltage interlocks with

which instruments covered by this service data might be

equipped.

5. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heatsinks

are correctly installed.

6. Always connect the test instrument ground lead to the

appropriate instrument chassis ground before connecting

the test instrument positive lead. Always remove the test

instrument ground lead last.

7. Use with this instrument only the test xtures specied in

this service data.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples

of typical ES devices are integrated circuits and some eld

effect transistors and semiconductor “chip” components.

The following techniques should be used to help reduce

the incidence of component damage caused by static

electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power

to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

desolder ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classied as “anti-static” can

generate electrical charges sufcient to damage ES

device.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufcient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparable conductive material.)

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety

precautions.

CAUTION: Do not connect the test xture ground strap

to any heatsink in this instrument.

TABLE OF CONTENTS

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted oor can generate

static electricity sufcient to damage an ES device.)

4

Page 6

D8MW

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range 600°F to 800°F.

2. Use an appropriate lead free solder (see page 8). Lead

solder can be used, but there is a possibility of failure due

to insufcient strength of the solder.

3. Keep the soldering iron tip clean and well-tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

small wire-bristle (0.5 inch or 1.25 cm) brush with a metal

handle. Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal temperature

(600°F to 800°F).

b. Heat the component lead until the solder melts.

Quickly draw away the melted solder with an antistatic,

suction-type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal temperature

(600°F to 800°F).

b. First, hold the soldering iron tip and solder strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and hold it

there only until the solder ows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil or components.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suctiontype

solder removal device (or with solder braid) before removing

the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to areas.)

“Small-signal” Discrete Transistor Removal/

Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a “U” shape the end of each of the three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to metal

contact, then solder each connection.

Power Output Transistor Devices Removal/

Replacements

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

4. Insert new transistor in circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Use soldering iron to pry the leads.

IC Removal/Replacement

Some Hitachi unitized chassis circuit boards have slotted

holes (oblong) through which the IC leads are inserted

and then bent at against the circuit foil. When holes are

the slotted type, the following technique should be used

to remove and replace the IC. When working with boards

using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

TABLE OF CONTENTS

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two “original leads”. If they are not shiny, reheat them

and, if necessary, apply additional solder.

5

Page 7

Fuses and Conventional Resistor Removal/

Replacement

1. Clip each fuse or resistor lead at top of circuit board

hollow stake.

2. Securely crimp leads of replacement component around

stake 1/8 inch from top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent components and

the circuit board, to prevent excessive component

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the

foil to the circuit board, causing the foil to separate

from, or “liftoff,” the board. The following guidelines and

procedures should be followed whenever this condition is

encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and

integrity of copper pattern in some circuit board areas

more critical than in others. The circuit foil in these areas is

designated as Critical Copper Pattern. Because Critical

Copper Pattern requires special soldering techniques to

ensure the maintenance of reliability and safety standards,

contact your Hitachi personnel.

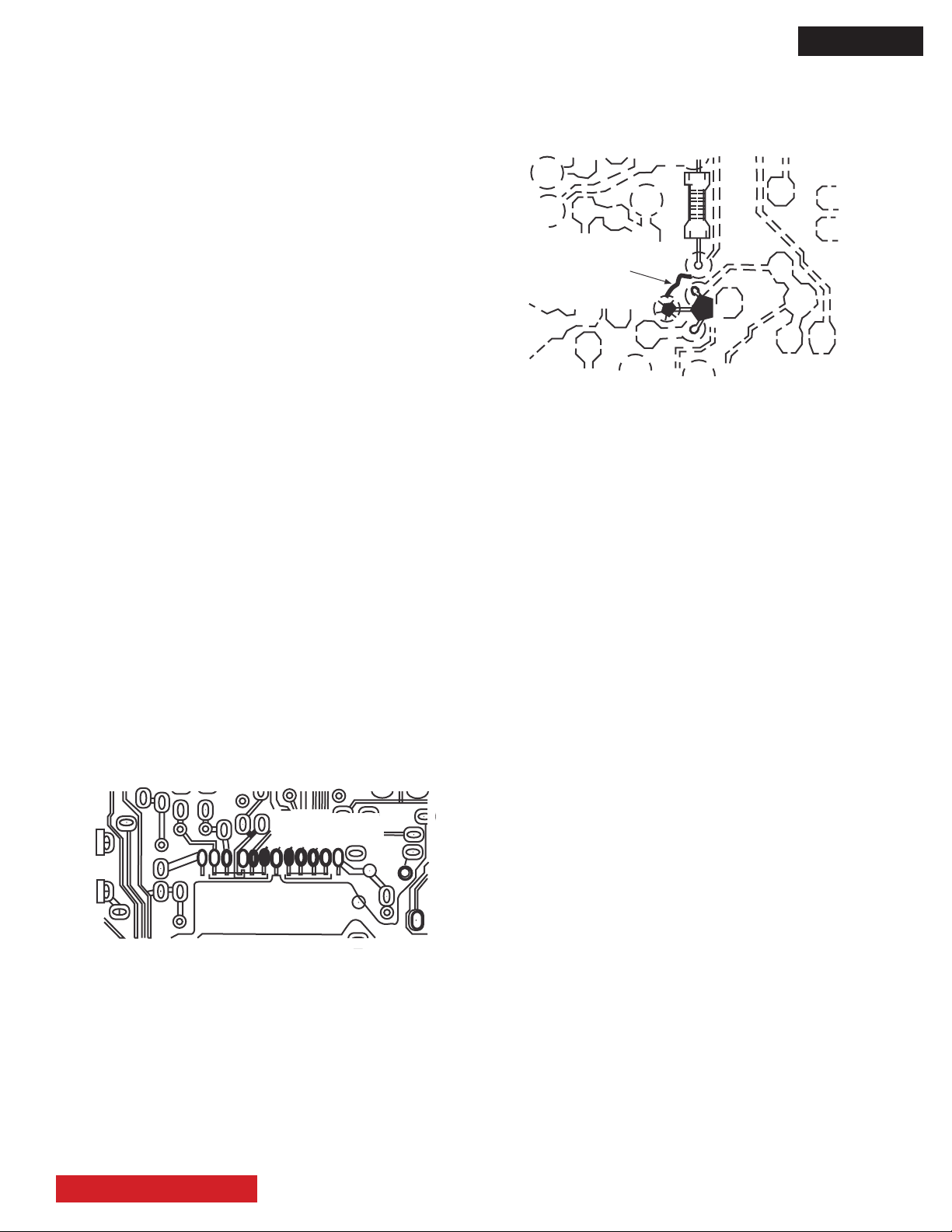

At IC Connections

To repair defective copper pattern at IC connections, use

the following procedure to install a jumper wire on the

copper pattern side of the circuit board. (Use this technique

only on IC connections.)

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

D8MW

At Other Connections

Use the following technique to repair defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the component

side of the circuit board.

DEFECTIVE

COPPER

REMOVED

Insulated jumper wire

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of

the pattern break and locate the nearest component directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the nearest

component on one side of the pattern break to the lead of

the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so

that it does not touch components or sharp edges.

BARE JUMPER

WIRE

CRIMP AND

SOLDER

Install jumper wire and solder.

3. Bend a small “U” in one end of a small-gauge jumper

wire and carefully crimp it around the IC pin. Solder the IC

connection.

4. Route the jumper wire along the path of the cut-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area, and clip off any excess jumper wire.

TABLE OF CONTENTS

6

Page 8

D8MW

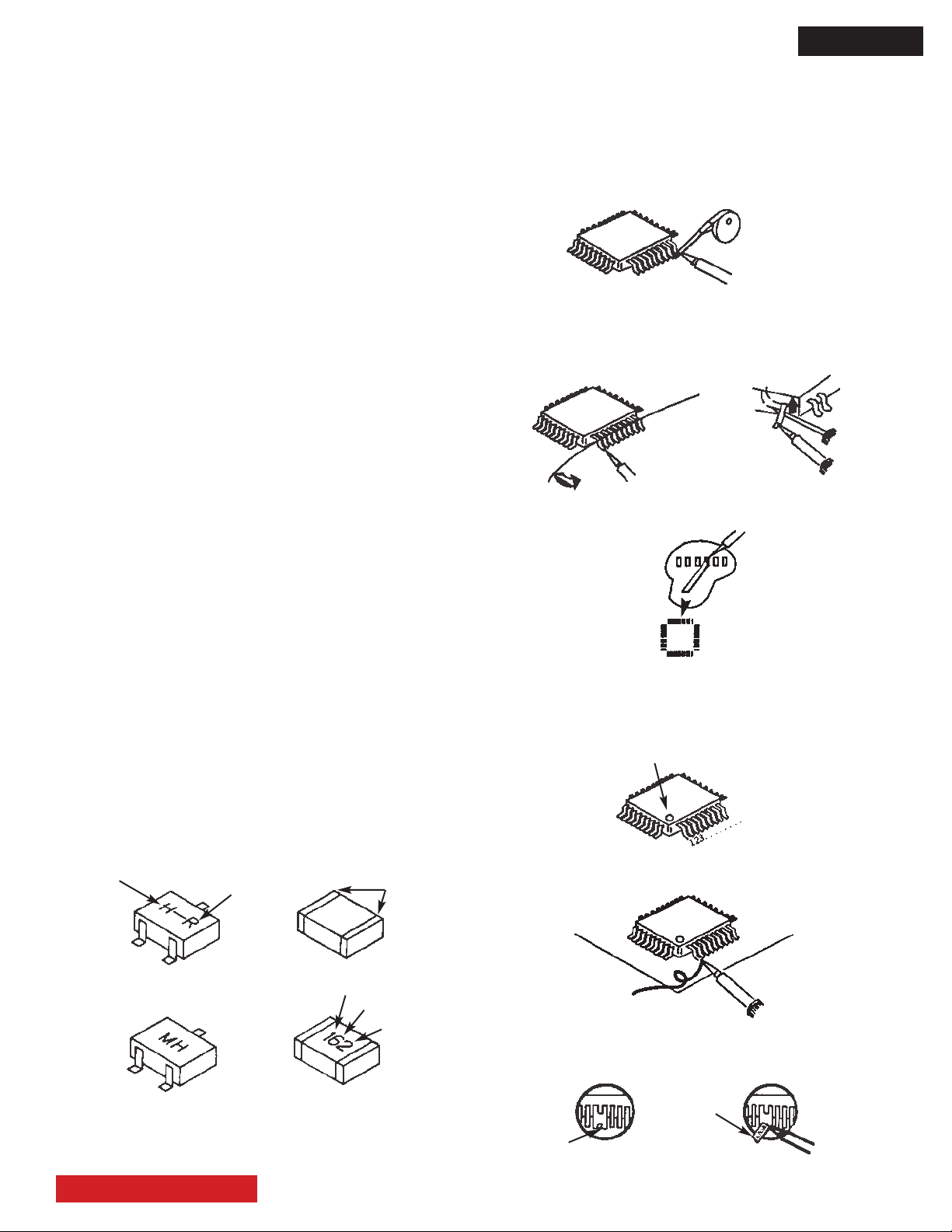

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical chips

due to critical foil track spacing. There are no holes in

the board to mount standard transistors or diodes. Some

chip capacitor or resistor board solder pads may have

holes through the board, however the hole diameter

limits standard resistor replacement to 1/8 watt. Standard

capacitors may also be limited for the same reason. It is

recommended that identical chip components be used.

Chip resistors have a three digit numerical resistance

code -1st and 2nd signicant digits and a multiplier.

Example: 162 = 1600 or 1.6KΩ resistor, 0 = 0Ω

(jumper).

Chip capacitors generally do not have the value indicated

on the capacitor. The color of the component indicates the

general range of the capacitance.

Chip transistors are identied by a two letter code. The

rst letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identication code as per the

code chart and are a dual diode pack with either common

anode or common cathode. Check the parts list for correct

diode number.

Component Removal

1. Use solder wick to remove solder from component

end caps or terminals.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal .

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt

iron until solder ows. Do not apply heat for more

than 3 seconds

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

• De-solder braids • Magnier

1. Remove the solder from all of the pins of a Flat-lC

by using a de-solder braid.

De-Solder

Braid

Soldering

Iron

2. Put the iron wire under the pins of the Flat-lC and pull

it in the direction indicated while heating the pins using a

soldering iron. A small awl can be used instead of the iron

wire.

Pull

Soldering

Iron

Iron

Wire

Awl

Soldering

Iron

3. Remove the solder from all of the pads of the Flat-lC by

using a de-solder braid.

Soldering

Iron

De-Solder

Braid

Flat-IC

4. Position the new Flat-lC in place (apply the pins of the

Flat-lC to the soldering pads where the pins need to be

soldered). Properly determine the positions of the soldering

pads and pins by correctly aligning the polarity symbol.

Polarity Symbol

TYPE

B

E

ANODES

MH DIODE

C

GRADE

TRANSISTOR

COMMON CATHODE

TABLE OF CONTENTS

Chip Components

SOLDER CAPS

1STDIGIT

RESISTOR

SOLDER

CAPS

CAPACITOR

2ND DIGIT

MULTIPLIER

= 1600 = 1.6K

5. Solder all pins to the soldering pads using a ne tipped

soldering iron.

Solder

Soldering

Iron

6. Check with a magnier for solder bridge between the pins

or for dry joint between pins and soldering pads. To remove

a solder bridge, use a de-solder braid as shown in the gure

below.

Bridge

Solder

De-Solder

Braid

Soldering

Iron

7

Page 9

Information for service about the lead-free solder introduction.

Hitachi introduced lead-free solder to conserve the “Earth Environment”.

Please refer to the following before servicing.

(1) Characteristic of lead-free solder

Melting point of lead free solder is 40-50°C higher than solder containing lead.

(2) Solder for service

Following composition is recommended.

“ Sn - 3.0Ag - 0.5Cu “ , or “ Sn - 0.7 Cu “

Lead solder can be used, but there is a possibility of failure due to insufcient strength of the solder.

Caution when using solder containing lead.

Please remove previous solder as much as possible from the soldering point.

When soldering, please perfectly melt the lead-free solder to mix well with the previous solder.

(3) Soldering iron for lead-free solder.

Melting point of lead-free solder is higher than solder containing lead.

Use of a soldering tool “with temperature control” and “with much thermal capacitance” is recommended.

(Recommended temperature control : 320°C - 450°C; [608°F - 842°F])

Recommended temperature

PWB with chip parts 320°C +/- 30°C (608°F +/- 86°F)

PWB without chip parts 380°C +/- 30°C (716°F +/- 86°F)

Chassis, metal, shield etc. 420°C +/- 30°C (788 °F +/- 86°F)

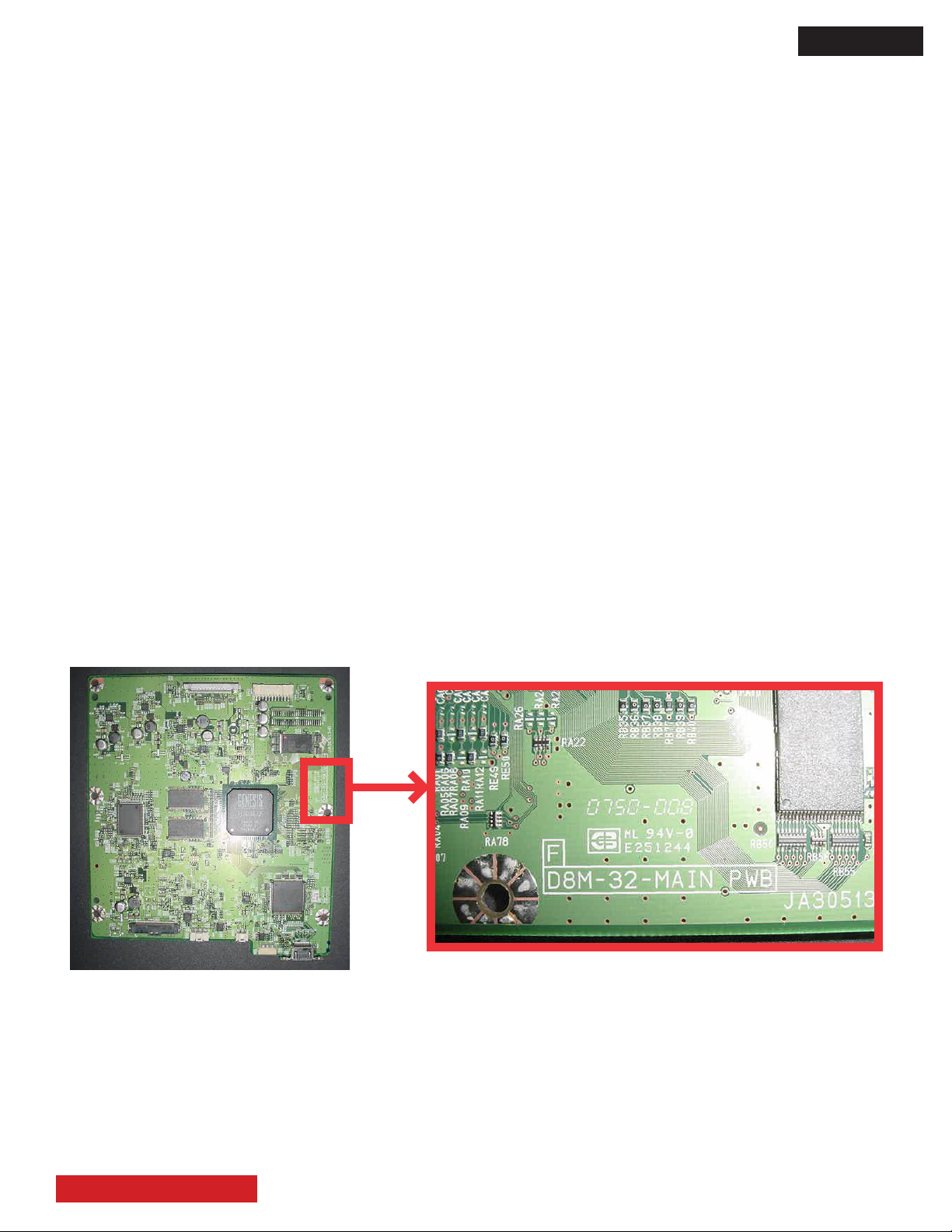

D8MW

(4) Identication of lead-free PWB

2004 models >> lead-free solder is introduced

2006 models >> lead-free solder applied

On lead-free PWB, “F” is added at the beginning of stamp on PWB.

TABLE OF CONTENTS

8

Page 10

AGENCY REGULATORY INFORMATION

Federal Communications Commission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

FCC Information

This device complies with part15 of the FCC Rules.Operation is subject to the following two conditions :

(1) This device may not cause harmful interference and (2) This device must accept any interference

received, including interference that may cause undesired operation.

D8MW

Modications

The FCC requires the user to be notied that any changes or modications made to this device that are not

expressly approved by Hitachi Home Electronics (America), Inc. may void the user’s authority to operate

the equipment.

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods to

maintain compliance with FCC Rules and Regulations.

Any cables that are supplied with the system must be replaced with identical cables in order to assure

compliance with FCC rules. Order Hitachi spares as replacement cables.

INDUSTRY CANADA AGENCY REGULATORY INFORMATION

This class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

ACKNOWLEDGMENTS

AND TRADEMARKS

HDMI, the HDMI logo and High-Denition Multimedia Interface are

trademarks or registered trademarks of HDMI Licensing LLC.

• VGA and XGA are trademarks of International Business Machines Corporation.

• VESA is a registered trademark of the Video Electronics Standard Association.

TABLE OF CONTENTS

9

Page 11

D8MW

19-

12/16

(502)

40-

13/16

(1036.2)

36-

3/4

(934)

19-

11/16

(500)

28-

11/16

(728)

26-

11/16

(678)

1-

15/16

(50)

16-

5/16

(413.7)

7-

7/8

(200)

20-

3/4

(526.8)

12-

3/16

(310)

1-

9/16

(39.9) Max5-

3/8

(136)

1-

3/8

(35.0) Min

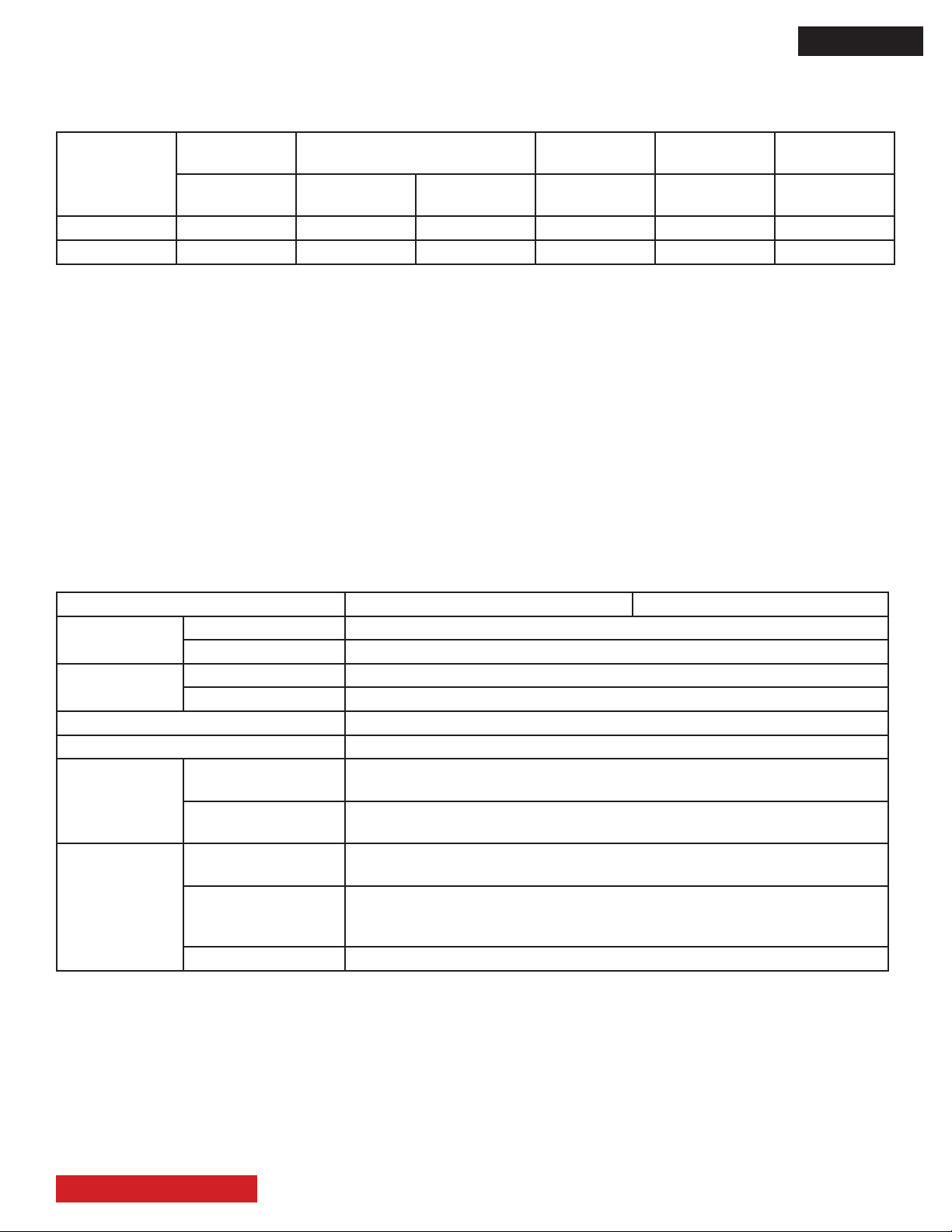

INTRODUCTION

This HITACHI Service Manual is intended for the qualied service personnel and it contains the necessary infor-

mation for troubleshooting the LCD television set in case of malfunction.

This service manual includes the information for the next models and chassis.

DIMENSIONS:

MODEL CHASSIS

UT42X902 D8MW

UT42V702 D8MW

Height: Excluding stand - 26 11/16”, Including stand - 28 11/16”.

Width: 40 13/16”.

Depth: Excluding stand - 1 9/16”, Including stand - 12 3/16”.

Weigth: Excluding stand - 18.0 kg; Including stand - 20.9 kg.

POWER RATINGS:

Indicated Value

No.

Model

Name

ChassisMax Rating

(W) (A)

1 UT42X902 243 2.3 D8MW

CIRCUIT PROTECTION:

2 UT42V702 243 2.3 D8MW

CAUTION: It is very important to replace the fuse with the same kind of fuse as original.

The fuse rating is indicated in the silk of the printed circuit board near the fuse location.

Example: Hitachi part number of the fuse is: FN00562.

High breaking capacity ceramic tube fuse (Time-Lag fuse)

This means the fuse rating is 6.3A, 250V.

TABLE OF CONTENTS

T6.3AH 250V

10

Page 12

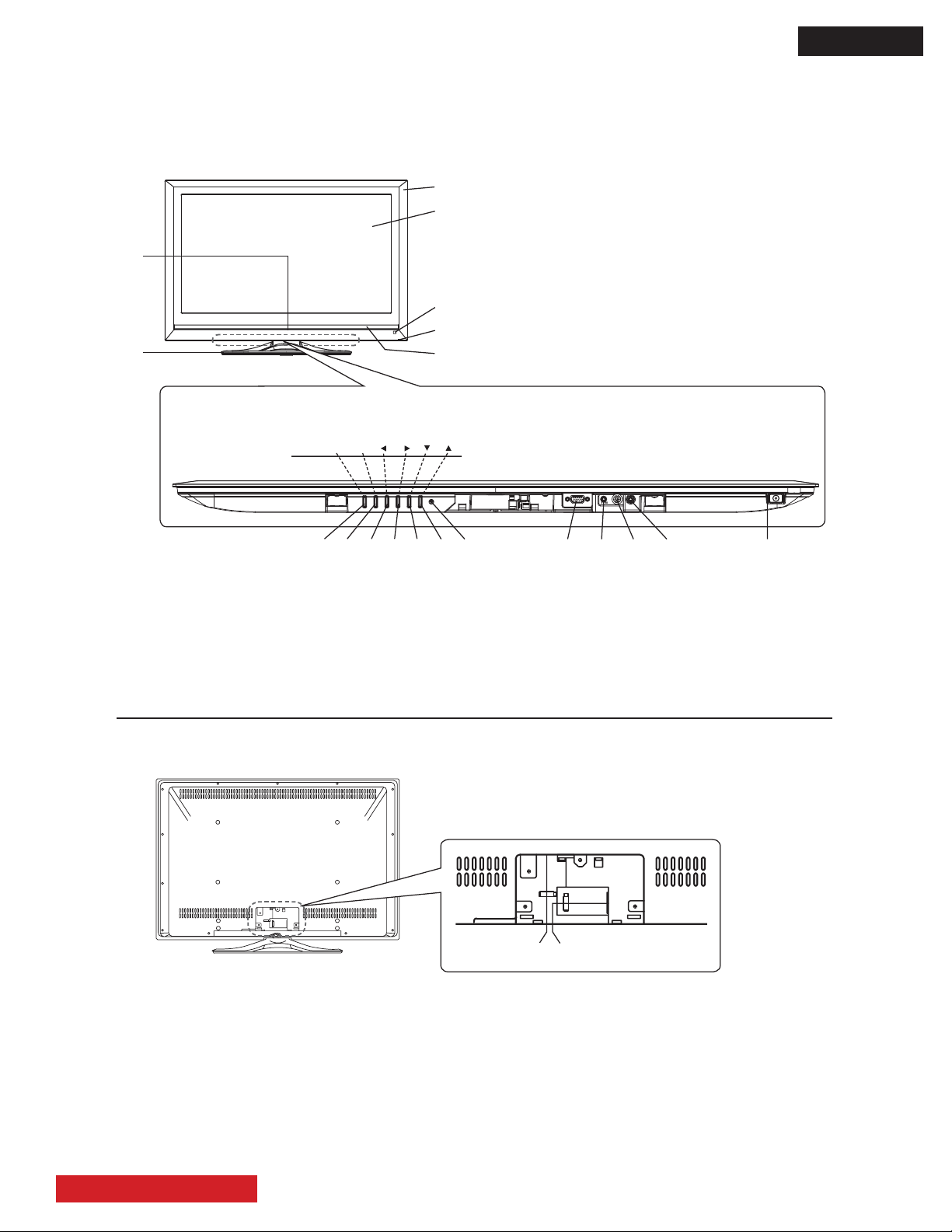

TERMINALS AND JACKS

D8MW

HDMI

MODEL

NAME

UT42X902 1 1 1 1 1 1

UT42V702 1 1 1 1 1 1

MAIN FEATURES

• Ultra-slim-line LCD monitor.

• Large-screen and high denition LCD.

• Enjoy high resolution display (1920 (H) x 1080 (V) pixels).

• Improved digital signal processor.

• High quality sound with deeper, richer tones and bass boost.

• Accepts a digital input device with HDMI terminal.

• Enjoy the image from your PC with a large, high-denition LCD screen.

• Easy-to-use On-screen Display system operated by remote control.

• Low power consumption with power saving feature.

SPECIFICATIONS

TERMINAL

HDMI

D-SUB 15 PIN

ANALOG

RGB

COMPOSITE

VIDEO

3.5 MINI

JACK

ANALOG

AUDIO

8 PIN

MINI-DIN

RS-232C

3.5 STEREO

MINI JACK

IR-

THROUGH

SPECIFICATION UT42X902 UT42V702

Panel

Ambient

conditions

Power supply AC120V, 60Hz

Audio output speaker 6W + 6W

HDMI input

RGB/Composite

input

* This analog audio input terminal can be used for PC (RGB) or HDMI-DVI.

Display dimensions Approx. 42 inches measured diagonal (36 3/4 (H) x 20 3/4 (V) in.

Resolution 1920 (H) x 1080 (V) pixels

Temperature Operating: 5ºC to 35ºC, Storage: 0ºC to 40ºC

Relative humidity Operating: 20% to 80%, Storage: 20% to 90% (non-condensing)

Input terminals

Input signals

Input terminals

Input signals

Sync signals H/V separate, TTL level [2KW]

HDMI: HDMI input terminal

Audio input terminal (Mini-pin)*

HDMI: VGA/60, 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50,

1080i/60, 1080p/50, /1080p/60, 1080p/24.

Analog RGB input terminal (D-sub 15 pin)

Audio input terminal (Mini-pin)*

0.7 Vp-p, analog RGB (Recommended Signal)

Composite video: NTSC3.58, NTSC4.43, PAL, SECAM, PAL60, PAL-M,

PAL-N.

TABLE OF CONTENTS

11

Page 13

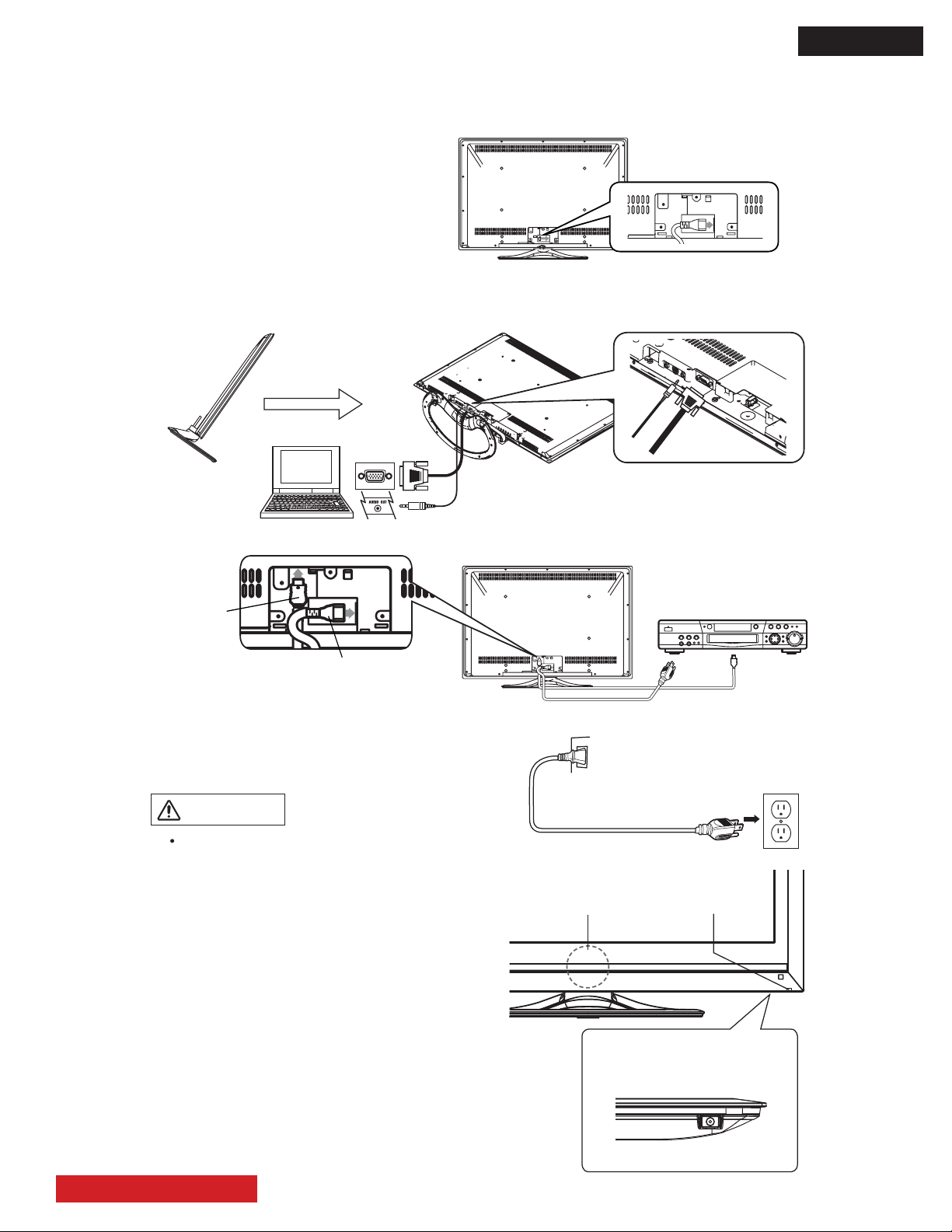

BASIC SETUP AND OPERATION

For more information on connecting and using the monitor, refer to the owner’s guide.

. Connect the power cord to the rear panel.

3 Connect to external equipment.

Example 1: Connecting to PC

To insert D-sub 15 pin, tilt the monitor forward and bring the terminals into view. Two people are required

to hold the monitor and insert D-sub 15 pin safely. Be careful not to damage the panel.

*D-sub 15 and Audio cables are not included.

Example 2: Connecting to DVD player

*

*

Audio Cable

D-Sub 15

Tilt Forward

HDMI Cable

Power Cord

HDMI Cable

Power On...

. Connect the plug into the wall socket after all other

connections are completed.

CAUTION

Ensure that both ends of the power cord are easily

accessible.

The Main Power Switch is factory set to On

(activated), therefore after you connect the plug into

the wall socket, the color of the indicating lamp must

turn Green and the Illumination Lamp turns Blue.The

image will display on screen.

Once the Main Power switch is on, you can turn On/

Off by pressing the Power (On/Off) button on the

remote control.

If no equipment is connected to the Monitor the color

of the indicating lamp turns to Orange, and the

Illumination Lamp turns off indicating Power Save

Mode.

AC

Wall

Socket

Monitor

Rear

Panel

Main Power Switch

(on the underside)

Front

Rear

Illumination Lamp

Indicating Lamp

D8MW

TABLE OF CONTENTS

12

Page 14

BASIC SETUP AND OPERATION

Front Panel

Rear Panel

.

Cabinet

3

Panel

$

Remote Control Receiver

/

Indicating Lamp

1

Speaker

4

Illumination Lamp

2

Desktop Stand

&

Ÿ button

'

ź button

)

Volume Up/Ź button

*

Volume Down/Ż button

+

Input Select/OK button

Menu/Exit button

.

Power Cord Socket

3

HDMI Input Terminal

Please refer to the owner’s guide for detailed information regarding the connections.

.

3

$

/

1

4

2

(

Main Power switch

,

Service use only

"

RS232C

0

PC (RGB)/DVI Analog Audio Input Terminal

#

PC Connection Terminal (D-sub 15 Pin)

%

Reset button.

(,"0#

')*&+

Control panel (located on the bottom)

MENU/EXIT VOLINPUT/OK

%

3 .

D8MW

TABLE OF CONTENTS

13

Page 15

ADJUSTMENTS

TO GO TO A SECTION, CLICK ON ITS HEADING BELOW.

TABLE OF CONTENTS OF ADJUSTMENTS

1. Adjustment procedure start-up

1.1 How to get to the service mode menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 Changing data and selecting adjustment codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2. Memory Initialize

2.1 EEPROM All Initialize operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 EEPROM renew procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Memory Initialize affected adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3. Video Adjustment

3.1 RGB amplitude adjustment (PC D-SUB input) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 NTSC Composite video adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4. Video Color Temperature adjustment

4.1 Video Color Temperature adjustment (Cool) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Video Color Temperature adjustment (Normal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Video Color Temperature adjustment (Warm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5. Another procedure to set to factory shipping conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Factory Shipping Conditions table 20

6. Software upgrade procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

D8MW

TABLE OF CONTENTS

14

Page 16

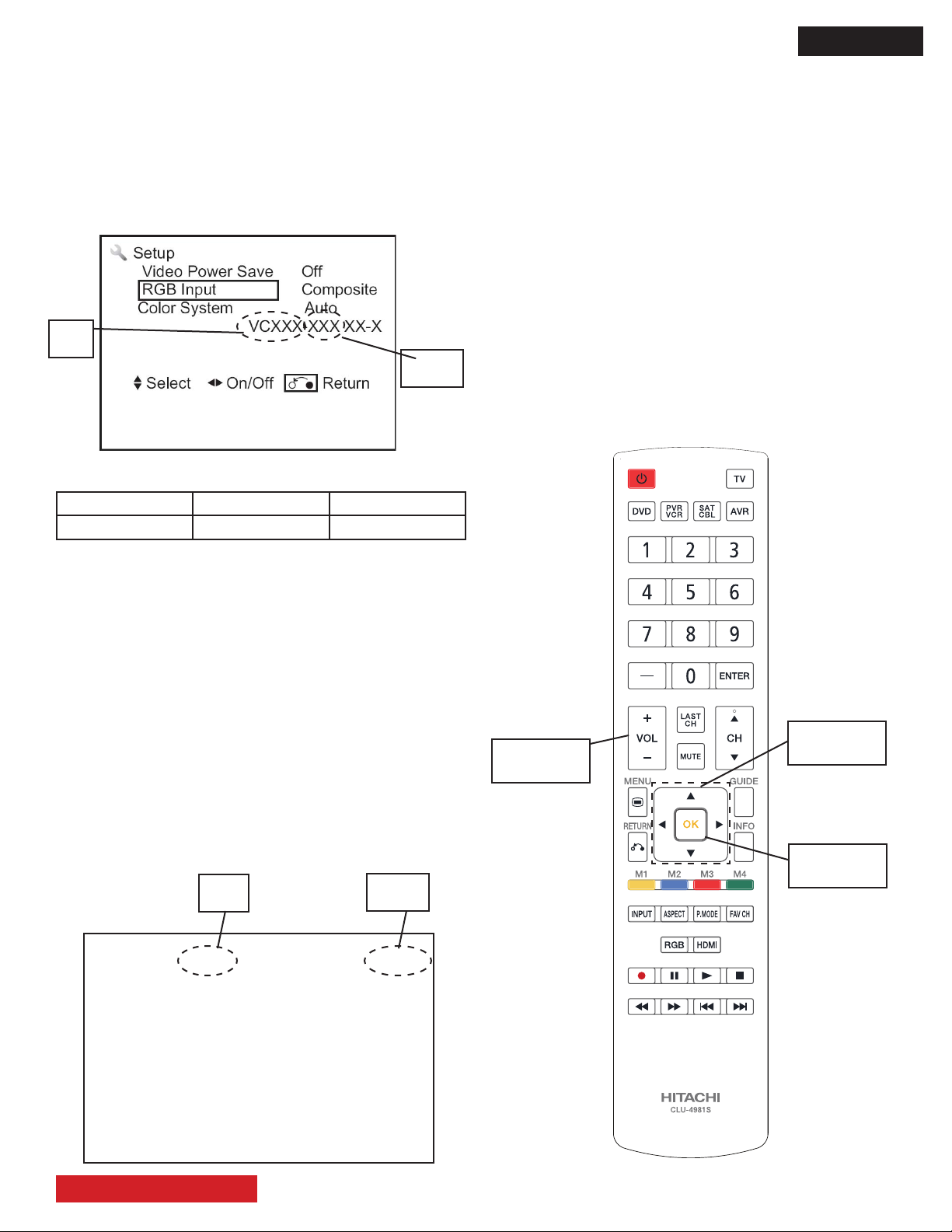

D8MW

1. ADJUSTMENT PROCEDURE START-UP

The UT42X902 and the UT42V702 LCD Monitors run through

a series of adjustments at the factory.

After servicing, these adjustments must be done again.

NOTE: - S/W version check -

The software version of the LCD monitor can be checked

under the SETUP OSD menu. The next image shows the

OSD where the version number is shown.

Main

S/W

Till this day, the latest software versions are:

Model Main S/W Sub S/W

All UT42” VS224 223

Sub

S/W

1.2 Changing data and selecting adjustment

codes.

When the UT monitor is in the Service Mode, use the remote

control cursor keys ◄, ►, ▲, ▼ to make the adjustments.

The bottom control panel in the UT monitor can also be used

for making the adjustments.

A. Use the Remote Control:

The ▲, ▼, keys are used for selecting the adjustment

item (in the same page).

The ◄, ► keys are used for changing the data values.

Use the VOL UP/DWN remote control button to scroll thru

the diferent Service Menu pages.

The “OK” button is equal to “Enter” key.

Next picture shows the R/C buttons mentioned in the previous explanation.

The software is subject to change, for the latest software call

1-800-HITACHI or log on to the Hitachi Service only web site

www.hitachiserviceusa.com.

1.1 How to get to the Service Mode Menu

The Service Mode Menu can be reached by following the

next sequence:

1. With TV in the off condition (with Main Power Off)

a) Press and hold Menu key of the bottom control panel,

while holding the menu key, press and release the master

power button.

b) Keep pressing the menu key until the Service Menu

appears on screen, release menu key.

2. To exit the Service Mode press [MENU] key of the remote

control or the UT monitor, the user menu OSD will appear.

The next picture shows the Service Mode OSD for the 42”

models(example).

Main

S/W

Sub

S/W

Service

NO. DATA VS224 42LW-A MU 146 Sub223

0: 208

1: 230

2: 237

3: 215

4: 224

5: 213

6: 223

7: 224

8: 187

9: 224

VOLUME

button

cursor

buttons

OK button

H: 33.6 V: 59.7 L: 562

TABLE OF CONTENTS

15

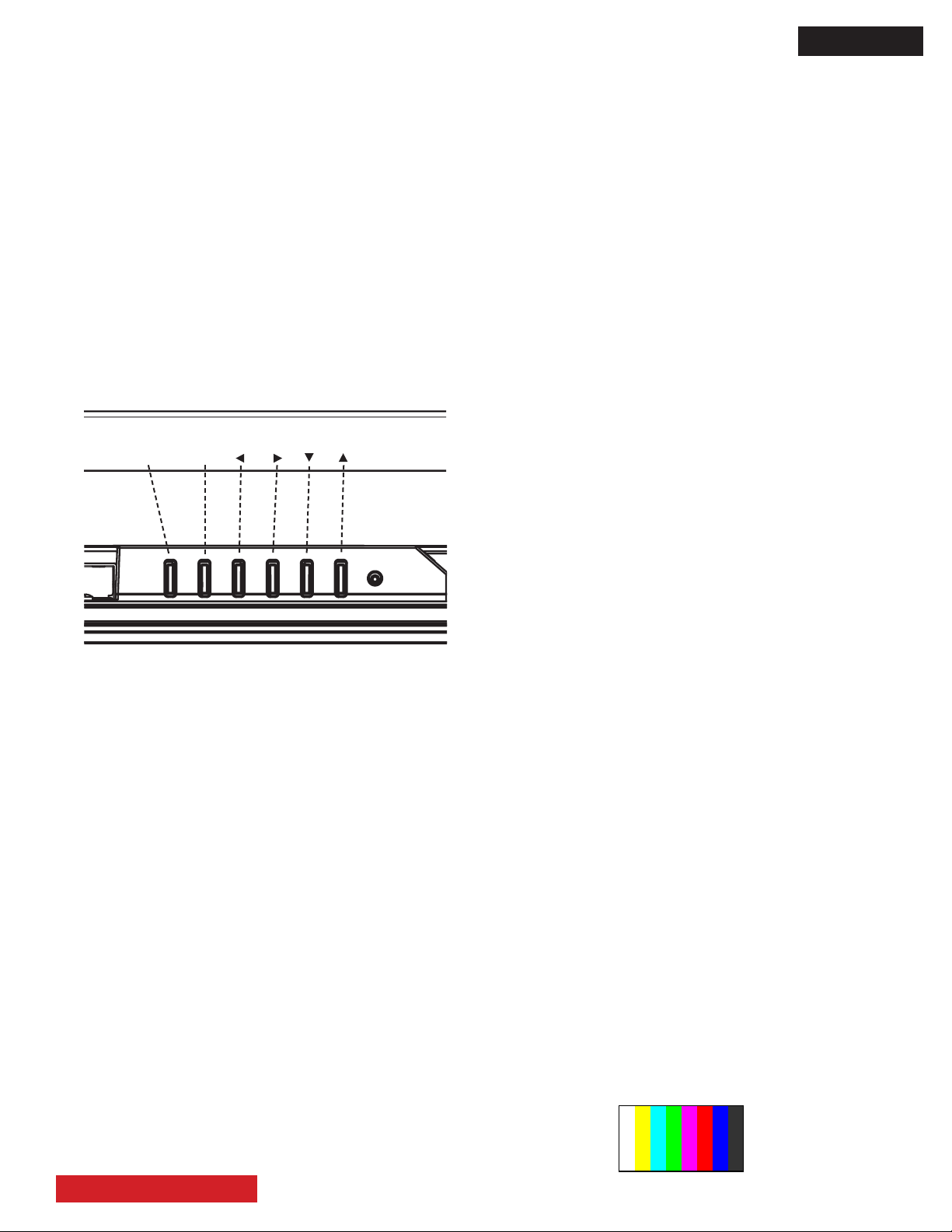

Page 17

D8MW

INPUT/OK

VOLMENU/EXIT

B. Use the Control Panel (located at the bottom):

Menu/Exit button is for calling the OSD menu or for exiting

such menu or any other OSD.

Input/Select button is for changing the displayed input or,

when some OSD is beeing displayed, to be able to select

the highlighted option.

◄ Vol - button is for reducing the audio volume or equiva-

lent to the Left cursor key when an adjustment value is

highlighted.

► Vol + button is for increasing the audio volume or

equivalent to the Right cursor key when an adjustment

value is highlighted.

▲ button is same as the R/C Up cursor button.

▼ button is same as the R/C Down cursor button.

The next gures show the labels of the bottom control panel

and a bottom view of the buttons.

2.2 EEPROM RENEW Procedure:

There are two methods.

FIRST METHOD.

(1) Enter Service Mode by the procedure in section 1.1.

(2) Change the data value of the adjustment item no. 659

from “0” to “1”.

(3) Push the OK button in the remote control. The picture will

disappear indicating that the initialization of the EEPROM is

started.

(4) About 2 seconds later, the initialization will nish and the

picture will appear again. Do not turn of the power until the

picture appears again.

(5) Set the adjustment item no. 630 to data value 6.

SECOND METHOD.

(1) Turn off the monitor by side panel power switch.

(2) Turn on the side panel power switch while keeping

pushed the up cursor key of the bottom control panel for

more than 5 seconds.

Conrm the settings are in factory shipping conditions (refer

to section 5.1 of this manual).

2.3 Memory initialize affected adjustments:

2. MEMORY INITIALIZE

The memory initialize operation is to clear the contents of

the data memory and to set all adjustment values to initial

default.

CAREFUL: The data that will be lost is shown in the section

no. “2.3 Memory initialize affected adjustments”.

2.1 EEPROM ALL INIT Procedure:

(1) Enter Service Mode by the procedure in section 1.1.

(2) Select adjustment item no. 657 and push the OK button

(the remote control must be set in normal TV mode).

The picture will disappear, and the initialization of the EE-

PROM will start.

The next table shows the adjustment items which are affected

by the Memory Initialize EEPROM ALL INIT operation and

EEPROM RENEW operation.

Adjustment ALL INIT RENEW

White balance Reset Not reset

Amplitude Reset Not reset

Item no. 657 Reset Not reset

3. VIDEO ADJUSTMENT

The next adjustments are related with the picture quality.

Special care must be put.

3.1 RGB amplitude adjustment (PC D-SUB input)

Adjustment preparations

(1) Turn on the UT monitor, allow a 20 minutes heat-run before beginning the adjustment.

(2) Input the PC VGA[60Hz] adjustment signal into the PC

D-SUB input terminal.

(3) The adjustment signal pattern is an 8 color bar. The black

should be at the pedestal level.

(3) About 2 seconds later, the initialization process will nish

and the picture will appear again. NOTE: Do not turn of the

(4) White level amplitude = 700 mV (100% of signal stan-

dard).

power until the picture appears again.

(4) Set the adjustment item no. 630 to data value 6.

TABLE OF CONTENTS

16

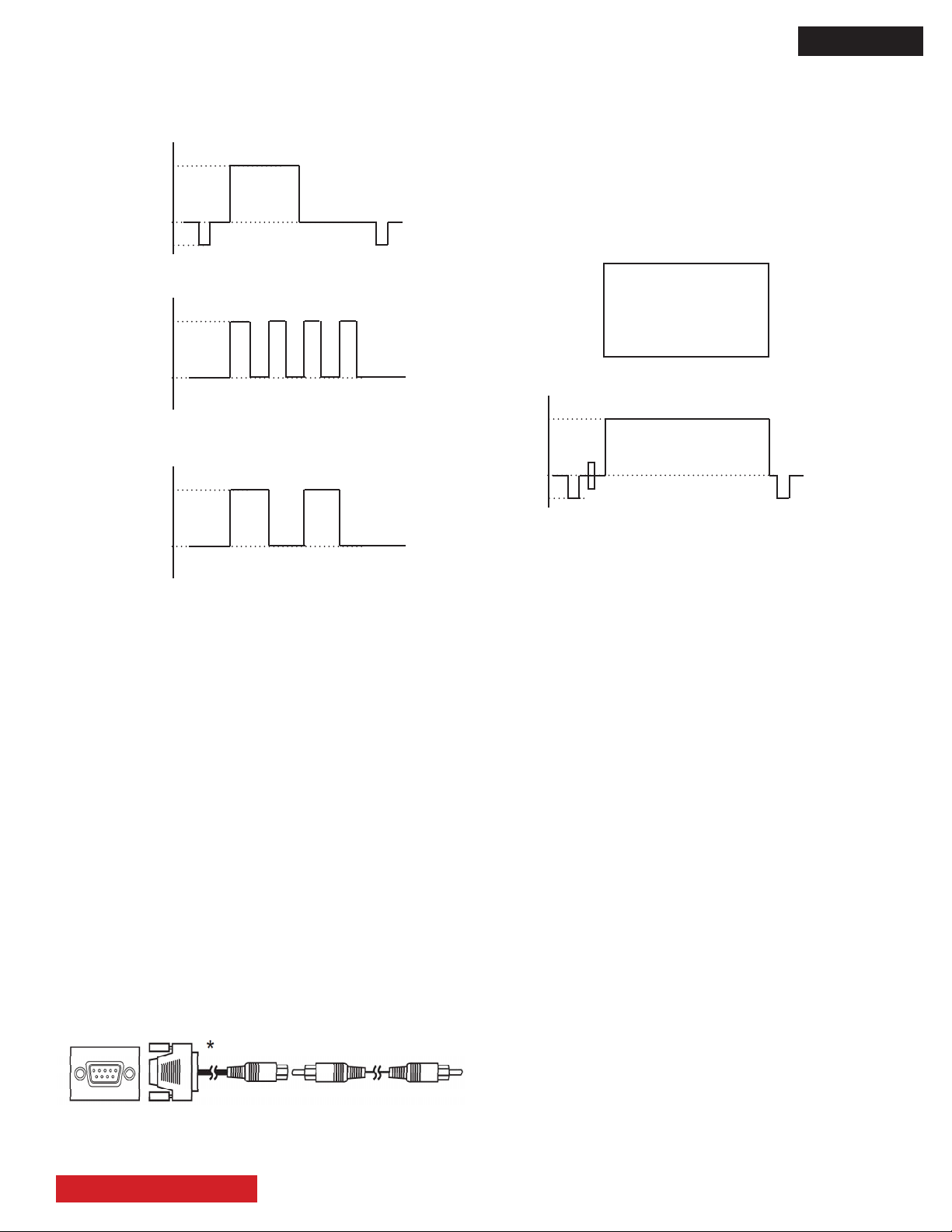

Page 18

D8MW

The next ghraphs show the waveform of the PC VGA[60Hz]

adjustment signal.

[mV]

700.0

Wh Ye Cy Gr Mg Re Bl Bk

G

0

-300.0

[mV]

700.0

Wh Ye Cy Gr Mg Re Bl Bk

B

0

[mV]

700.0

Wh Ye Cy Gr Mg Re Bl Bk

R

NOTE: Request this optional cable to Hitachi under the

next part numbers:

EW09192 - DSUB(LOW)-RCA CABLE 200MM

(4) The adjustment signal pattern is all white (The burst can

be disregarded).

(5) Set the amplitude of the adjustment signal [100% all

white] to 750.0 mV which is 105% (100% of the standard

signal is equal to 714.3 mV). The next graphics show the

white raster pattern and the waveform of the signal.

All white raster pattern.

[mV]

750.0

G

0

-300.0

White signal waveform.

0

Adjustment procedures

(1) Receive the PC adjustment signal.

(2) Select the adjustment item no. 658 of service adjustment

menu and push the OK button during 2 seconds or more.

The automatic adjustment will start.

(3) When the on screen display appears again, the automatic adjustment is nished.

3.2 NTSC Composite Video Adjustment

Adjustment Preparations

(1) Turn on the UT monitor and allow a 20 minutes heat-run

before starting the adjustment.

(2) Change the RGB input setting of the MENU’s second

page to “Composite”.

(3) Input the composite video adjustment signal into the

RGB D-SUB terminal. Consider the use of the next optional

cable.

EW09192

Adjustment Procedure

(1) Enter the Service Mode Menu by following the procedure

in section 1.1.

(2) Input the NTSC composite signal to the UT Monitor.

(3) Select the no. 658 adjustment item in the Service Mode

Menu and push the OK button for more than 2 seconds.

(4) The OSD will disappear for a brief moment. Once it appears again, the adjustment is nish.

(5) NOTE: Do not turn off the UT monitor until the OSD reappears.

4 VIDEO COLOR TEMPERATURE ADJUSTMENT.

The next adjustments are for setting the color coordinates or

color temperature of the picture.

4.1 Cool mode.

Adjustment preparations

(1) Adjustment signal: HDMI 1080i

Signal pattern: White raster.

Video level: 90%.

(2) Picture settings: Factory setting, check that the mode is

set as Factory shipping conditions.

Picture mode: Dynamic.

D-Sub 15 pin < ------- > RCA plug.

(3) The color analizer (CA-210) should be veried by a spectrum radiation brightness meter such as CS-1000 or stan-

The green color is connected.

TABLE OF CONTENTS

dard LCD.

17

Page 19

D8MW

(4) Set the aspect to full mode.

(5) Set the color analizer (CA-210) at the center of the pan-

el.

Adjustment procedures

(1) Enter the Service mode.

(2) Check that the adjustment items no. 0, no. 1 and no. 2

of the Service Mode menu have the next initial values. If the

initial values are different, set them as the following data.

No. 0 = 230

No. 1 = 230

No. 2 = 240

(3) Receive the white raster signal. Step down two (or only

one) of either of the R DRV_COOL, G DRV_COOL or B

DRV_COOL adjustment parameters and change to the

following values

(NOTE: At least one of the adjustment parameters should

remain in the initial data value).

4.2 Normal Mode.

Adjustment preparations

(1) Adjustment signal: HDMI 1080i

Signal pattern: White raster

Video level: 90%

(2) Picture settings: Factory setting. Check that the mode is

set as the factory shipping conditions.

Picture mode: Dynamic.

(3) The color analyzer (CA-210) should be veried by a

spectrum radiation brightness meter such as the CS-1000

or standard LCD.

(4) Set aspect to full mode.

(5) Set the color analyzer (CA-210) at the center of the pan-

el.

Adjustment procedures.

(1) Enter the Service mode by following the procedure in

section 1.1.

(2) Check that the initial data of the adjustment items no. 3,

4 and 5 are in the following values. If their initial values are

different, change them as shown.

Specication

Video Color Temperature (Cool)

x = 0.266 ± 0.005

y = 0.270 ± 0.005

14000K ± 0MPCD

REMARKS

(1) Color temperature should be adjusted under the condi-

tion in which the screen is the brightest, thus, the initial value

of the adjustment is set at its maximum.

This adjustment only decreases brightness.

(2) Beware, there is RESET in each picture mode.

(3) When the adjustment items no. 6, 7 or 8 are selected, the

color temperature of the picture changes to warm mode.

No. 3 = 224

No. 4 = 224

No. 5 = 224

(3) Receive the white raster signal. And decrease the value

of any two (or only one) of the R DRV_NORMAL, G DRV_

NORMAL or B DRV_NORMAL adjustment parameters in or-

der to get the X/Y coordinates to the following values.

Specication

Video Color Temperature (Normal)

x = 0.285 ± 0.005

y = 0.293 ± 0.005

9300K ± 0MPCD

REMARKS

(1) Color temperature should be adjusted under the condi-

tion in which the screen is the brightest, thus, the initial value

of adjustment is set at its maximum.

TABLE OF CONTENTS

(2) Beware there is RESET in each of the picture mode.

(3) When the adjustment items no. 6, 7 or 8 are selected, the

color temperature changes to warm mode.

18

Page 20

D8MW

4.3 Warm mode.

Adjustment preparations.

(1) Adjustment signal: HDMI 1080i

Signal pattern: White raster

Video level: 90%

(2) Picture settings: Factory shipping conditions.

Picture mode: Dynamic.

(3) The color analyzer (CA-210) should be veried by a

spectrum radiation brightness meter such as the CS-1000

or an LCD standard.

(4) Set the aspect to full mode.

(5) Set the color analyzer (CA-210) at the center of the pan-

el.

(6) Adjustment of color temperature cool mode and normal

mode should be nished.

Adjustment procedures.

(1) Enter the Service mode menu by following the procedure

in the section 1.1.

(2) Check that the initial data of the adjustment items no. 6,

7 and 8 are in the below shown values. If they are different,

change them to...

(4) Color temperature Warm synchronizes with the drive data

of the Normal mode color temperature. Therefore, when the

drive data of Normal color temperature is changed, the drive

data of the Warm color temperature is changed too.

5. Another procedure to set to Factory shipping

conditions

Adjustment procedures

(1) Turn off the power (Power indicator: Off)

(2) Push the ▲ key of the bottom control panel and turn on

the power of the UT monitor while keeping the up cursor key

pushed for more than 5 seconds.

(3) Verify the values of the factory shipping conditions according with the table in the next page.

(4) Set the adjustment item no. 630 to data value 6.

No. 6 = 224

No. 7 = 224

No. 8 = 224

(3) Receive the white raster signal. And decrease one or

two of the parameters R DRV_WARM, G DRV_WARM, or B

DRV_WARM in order to meet the X/Y coordinates with the

below values.

NOTE: At least one of the parameters should remain in the

initial value.

Specication

Video Color Temperature (Warm)

x = 0.313 ± 0.005

y = 0.329 ± 0.005

6500K ± 6.5MPCD

REMARKS

(1) Color temperature should be adjusted under the condi-

tion in which the screen is the brightest, thus, the initial value

of adjustment is set at its maximum.

(2) Beware there is RESET in each of picture mode.

(3) When the adjustment items no. 6, 7 or 8 are selected, the

color temperature of the picture changes to warm mode.

TABLE OF CONTENTS

19

Page 21

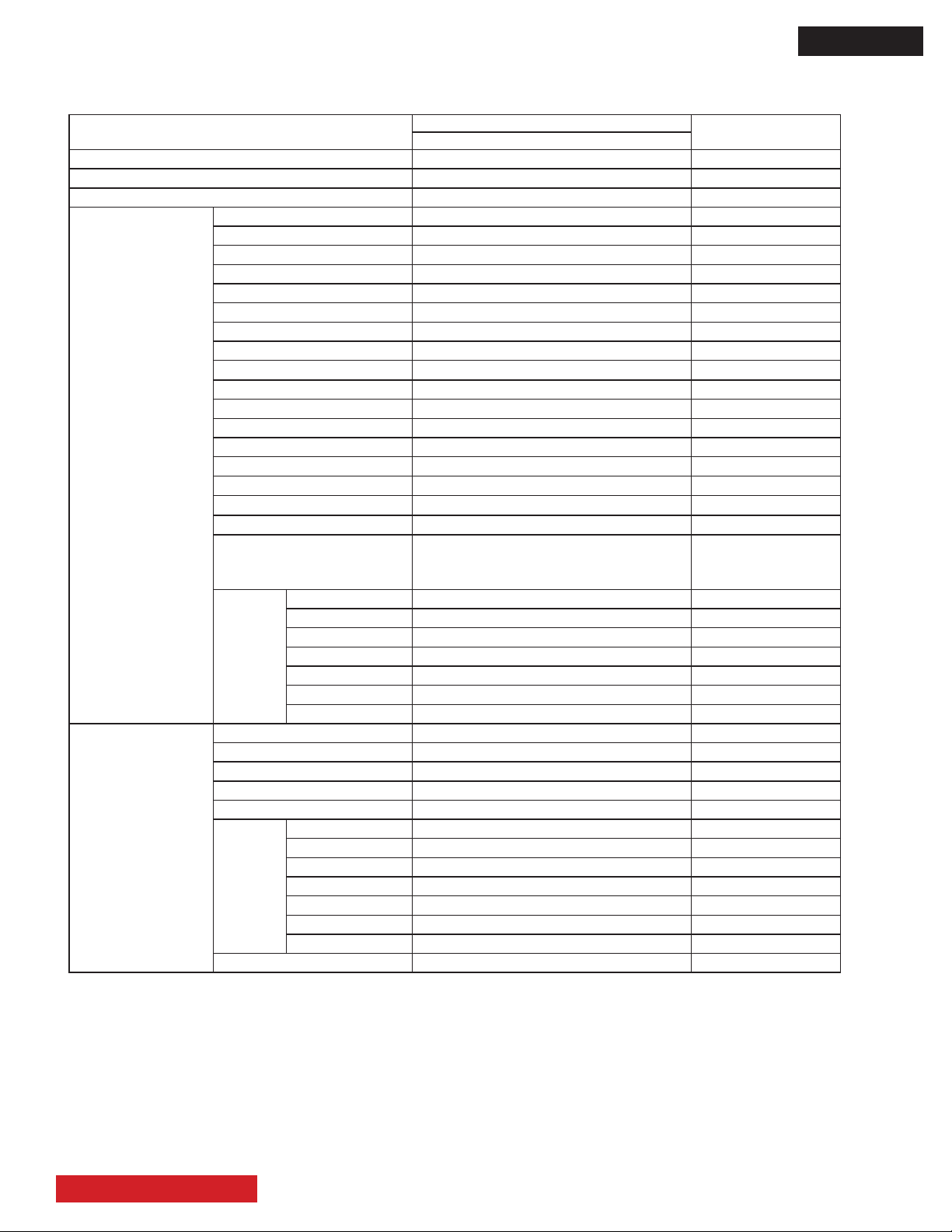

5.1 Factory shipping conditions:

D8MW

Item

Power Switch On (The switch is pushed condition.)

Volume 20

Mute Off

Picture Mode Dynamic

Contrast +31

Brightness 0

Color +3

Sharpness 0

Tint -1

Color Temperature Cool

Back Light +20

Deep Color Off

Contrast Mode Dynamic

3D Color Management On

Black Enhancement Middle

Picture

(HDMI/

Composite)

Picture

(RGB)

DNR Middle

MPEG NR Low

Cross Color NR Low

Game Mode Off

Film Mode Smooth2

3D Comb Filter Low

Amplitude Red 0

Color

Temp.

Adjus

Contrast +31

Brightness 0

Color 0

Tint 0

Color Temperature Normal

Amplitude Red 0

Color

Temp.

Adjust

Back Light +20

Green 0

Blue 0

Cut off Red 0

Green 0

Blue 0

Green 0

Blue 0

Cut off Red 0

Green 0

Blue 0

Initial data

42” UT monitor

Off

Off

Remarks

RGB

Input=Composite

only

TABLE OF CONTENTS

20

Page 22

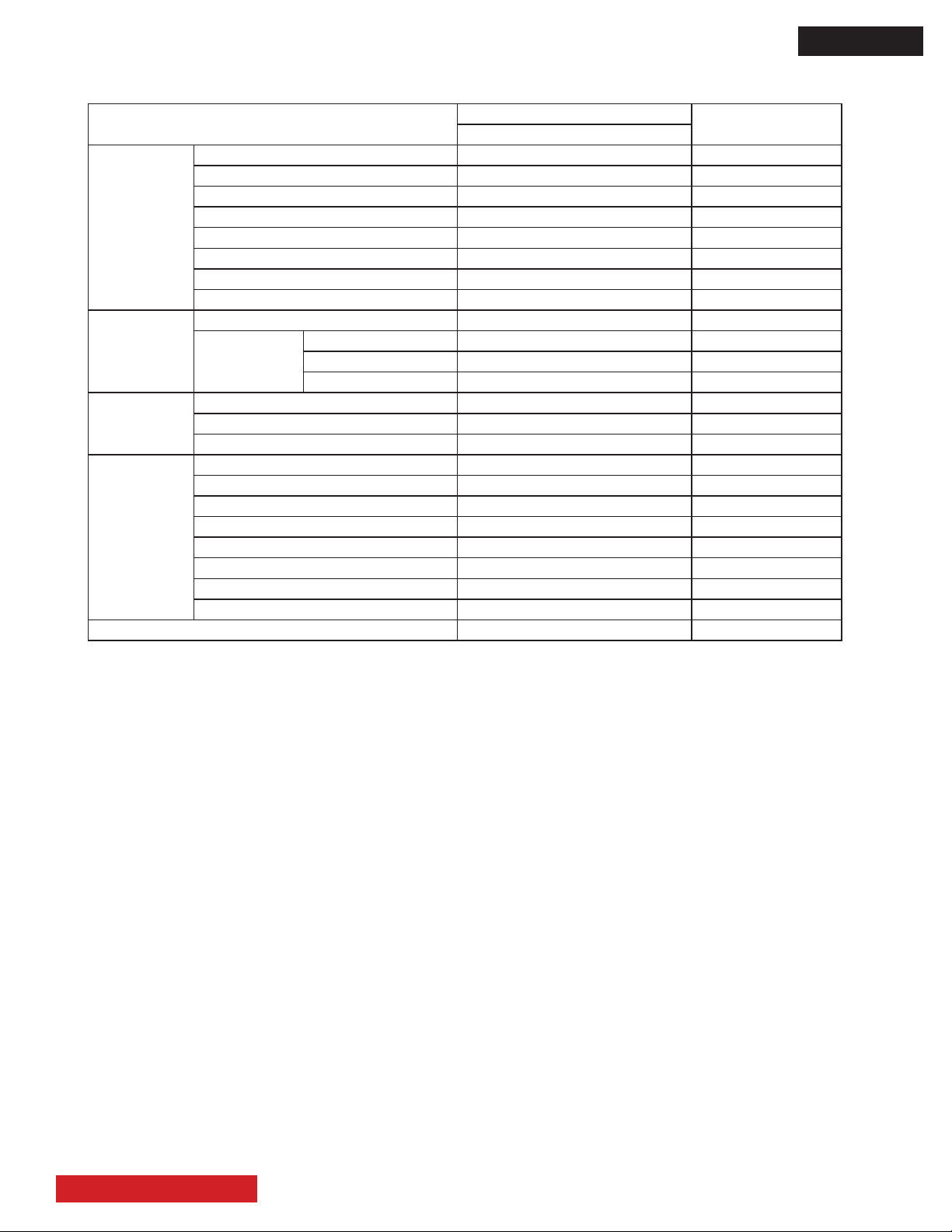

5.1 ... factory shipping conditions continued.

D8MW

Item

Audio Treble +6

Bass +2

Balance 0

Surround Off

Bass Boost On

Clear Voice Off

Perfect Volume Off

Speakers On

Function System ― Grayed out

HDMI Control Auto Input Change Off

System Standby None

AV Center Control Off

Setup

(HDMI)

Setup

(RGB)

Language English (US)

Video Power Save Off

RGB Input RGB Grayed out

Color System Auto Grayed out

Auto Adjust ―

Horizontal Position 0

Vertical Position 0

Horizontal Clock 0

Clock Phase 0

Frequency Display On

WXGA Mode Off

RGB Input RGB

Initial data

42” UT monitor

Remarks

TABLE OF CONTENTS

21

Page 23

Page Left Blank

Instruction in software renewal

After software version up, set the following lists for reference.

D8MW

TABLE OF CONTENTS

22

Page 24

Page Left Blank

D8MW

TABLE OF CONTENTS

23

Page 25

Page Left Blank

D8MW

TABLE OF CONTENTS

24

Page 26

Page Left Blank

D8MW

TABLE OF CONTENTS

25

Page 27

Page Left Blank

D8MW

TABLE OF CONTENTS

26

Page 28

Page Left Blank

D8MW

TABLE OF CONTENTS

27

Page 29

TROUBLESHOOTING FLOWCHARTS

How to get to Burn-in mode

This mode displays the test patterns of some single color raster in turn. These signals are from built-in generator of panel. So it can be presumed that maybe the panel has some trouble when the screen of Burn-in

mode is abnormal.

Using the remote control with the set turned on can activate the mode.

(1) Set the service adjustment mode.

(2) Change No.646 from “0” to “1”. After a few second, appear the burn-in picture.

(3) To escape from this mode, change No.646 from “1” to “0”.

At rst, please conrm whether you put a connector cable again, and a phenomenon comes out.

[no picture, no sound]

LED is not light.

Is the voltage of

pin 5 (+5.4V) of CNPS

(power supply unit)

normal?

It is trouble of Main PWB

or Power supply unit.

Please change.

No

It is trouble of Main PWB or

Terminal PWB.

Picture trouble Go to “A”

Sound trouble Go to “B”

Yes

D8MW

TABLE OF CONTENTS

28

Page 30

...TROUBLESHOOTING FLOWCHARTS (continued)...

Is the burn-in

mode normal?

LED is green lighting.

Are the voltage of

pin 1-5 of CNPP1and pin 1-5 of

CNPP2 (power supply unit) normal?

Normal voltage is +24V.

It is trouble of Power supply

unit.

Please change.

No

Go to # 1

Yes

It is trouble of Main PWB or

Terminal PWB.

Picture trouble Go to “A”

Sound trouble Go to “B”

No

Yes

After a few seconds, it becomes

a red lighting even if it turns on

power.

Main PWB -- Inverter PWB

PPO1(pin 10) -- CN2(pin 12)

PPO1(pin 11) -- CN2(pin 14)

Are these connected?

No

It is trouble of Power supply unit.

Please change.

Or please check ELCD2 connector

or EPS connector.

Yes

It is trouble of Main PWB or LCD

panel (include Inverter PWB)

Please change.

D8MW

TABLE OF CONTENTS

29

Page 31

...TROUBLESHOOTING FLOWCHARTS (continued)...

# 1

Dose the backlight

turn on?

No

Yes

Are the voltage of

pin 1-4 (+12V) of PDO1

(Main PWB) normal?

It is trouble of

Main PWB.

Please change.

No

Yes

It is trouble of LCD

panel module.

No

Is there voltage of

pin 9 of CNPS

(Power supplyunit) ?

It is trouble of Main PWB.

Please change.

Yes

It is trouble of Inverter PWB.

D8MW

TABLE OF CONTENTS

30

Page 32

...TROUBLESHOOTING FLOWCHARTS (continued)...

A : Picture Troubleshooting

No picture, no color or dark

Check the picture menu.

Are there problems?

No

Yes

No

It is trouble of IR/PW-SW PWB.

Please check EISP connector

No

Are there

signals(R,G,B,H,V) at

CE12-CE14,RE49 and

RE50 of Main PWB?

Adjust the picture

menu.

Are the voltage of

pin 7 and 9 (+5V) of PV01

(Main PWB) normal?

Yes

RGB input

HDMI input

Are there

signals(R(8bit),G(8bit),

B(8bit),H,V,DE,CLK) at

RH33,RH35,RH37 and

RH39 of Main PWB?

It is trouble of IA01

of Main PWB.

Please change.

Are there

signals(R,G,B,H,V) at

CE06-CE08 and

IW01(pin1, 13) of Main

PWB?

It is trouble of QE01-QE03

or IE01of Main PWB.

Please change.

Yes

Yes

No

Yes

It is trouble of EFFC connector,

Terminal PWB, or PW01 of

Main PWB.

No

Are there signals(TMDS)

at RH60-67 of Main PWB?

It is trouble of IH01

of Main PWB.

Please change.

No

Is there voltage at

pin 18 (+5V) of JH01 (Main

PWB) and is there

voltage(over +2.4V) at

pin19 of JH01?

It is trouble of IH02

of Main PWB.

Please change.

It is trouble of Q001, GH01

or DH03 of Main PWB.

Please change.

Yes

No

Yes

D8MW

TABLE OF CONTENTS

31

Page 33

...TROUBLESHOOTING FLOWCHARTS (nished).

B : Sound Troubleshooting

No sound, abnormal sound

Is there signal

No

Yes

Yes

No

Yes

Check the signal at the P301

of Terminal PWB

Change speaker.

Has it been

improved?

It is trouble of

the speaker.

Change EISP cable

Change Terminal PWB

Has it been

improved?

It is trouble of the

Terminal PWB

Change EFFC cable

Has it been

improved?

Yes

It is trouble of the

EFFC cable.

No

Change Main PWB

D8MW

TABLE OF CONTENTS

32

Page 34

㪈㪏㪅㪋㪊㪉㪤㪟㫑

㪉㪇㪇㪏㪅㪇㪊㪅㪇㪌

㪝㪩㪚㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉㩿㪰㪞㪫㪄㪇㪌㪈㪘㪀

㪝㪩㪚㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉㩿㪰㪞㪫㪄㪇㪌㪈㪘㪀㪝㪩㪚㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉㩿㪰㪞㪫㪄㪇㪌㪈㪘㪀

㪝㪩㪚㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉㩿㪰㪞㪫㪄㪇㪌㪈㪘㪀

㪩㪏㪘㪇㪊㪇㪉㪎㪙㪞

㪩㪏㪘㪇㪊㪇㪉㪎㪙㪞㪩㪏㪘㪇㪊㪇㪉㪎㪙㪞

㪩㪏㪘㪇㪊㪇㪉㪎㪙㪞

㪣㪭㪛㪪㩷㪉㪺㪿

㪠㪉㪪㩷㫀㫅

㪩㪜㪪㪜㪫㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷 㪝㪚㩷㪙㫌㫊

㪪㪬㪙㩷㪤㪧㪬

㪪㪬㪙㩷㪤㪧㪬㪪㪬㪙㩷㪤㪧㪬

㪪㪬㪙㩷㪤㪧㪬

㪤㪈㪍㪚㪆㪍㪋

㪤㪈㪍㪚㪆㪍㪋㪤㪈㪍㪚㪆㪍㪋

㪤㪈㪍㪚㪆㪍㪋

㪝㪚㪏㪶㪯㪩㪪㪫

㪫㫏㪃㩷㪩㫏㪃㩷㪚㪣㪢㪃㩷㪜㪥㪃㩷㪞㪶㪟㪙

㪞㪶㪯㪩㪪㪫

㪟㪆㪭㪶㪝㪩㪜㪨㪊

㪚㪜㪚

㪛㪛㪚

㪫㪤㪛㪪

㪚㪜㪚

㪉㫂㪹㫀㫋

㪜㪜㪧㪩㪦㪤

㪟㪛㪤㪠㩷㪩㫏

㪟㪛㪤㪠㩷㪩㫏㪟㪛㪤㪠㩷㪩㫏

㪟㪛㪤㪠㩷㪩㫏

㪪㫀㫃㪐㪈㪉㪌

㪪㫀㫃㪐㪈㪉㪌㪪㫀㫃㪐㪈㪉㪌

㪪㫀㫃㪐㪈㪉㪌

㪟㪛㪚㪧

㪫㪤㪛㪪

㪤㪘㪠㪥㩷㪪㪺㪸㫃㪼㫉㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉

㪤㪘㪠㪥㩷㪪㪺㪸㫃㪼㫉㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉㪤㪘㪠㪥㩷㪪㪺㪸㫃㪼㫉㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉

㪤㪘㪠㪥㩷㪪㪺㪸㫃㪼㫉㩷㪧㫉㫆㪺㪼㫊㫊㪼㫉

㪝㪣㪠㪏㪌㪊㪏

㪝㪣㪠㪏㪌㪊㪏㪝㪣㪠㪏㪌㪊㪏

㪝㪣㪠㪏㪌㪊㪏

㪠㪉㪚㩿㪪㪚㪣㪈㪆㪪㪛㪘㪈㪀

㪰㪆㪞㪃㩷㪚㪹㪆㪙㪃㩷㪚㫉㪆㪩

㪛㪜㪃㩷㪚㪣㪢

㪟㪆㪭㪶㪪㪰㪥㪚

㪟㪛㪩㫏㪤㪬㪫㪜

㪠㪉㪪㩿㪘㪭㪪㪶㪠㪥㪀

㪠㪉㪪㩿㪜㪯㪫㪶㪠㪥㪀

㪧㪚㪄㪩㪃㩷㪞㪃㩷㪙

㪧㪚㪄㪟㪛㪃㩷㪭㪛

㪭㪞㪘㪶㪪㪚㪣㪆㪪㪛㪘

㪠㪉㪚

㪰㪆㪞㪃㩷㪚㪹㪆㪙㪃㩷㪚㫉㪆㪩

㪛㪜㪃㩷㪚㪣㪢

㪟㪆㪭㩷㪪㪰㪥㪚

㪠㪥㪫

㪠㪉㪪

㪤㪚㪣㪢

㪛㪛㪩㪋㪇㪇㩷㪪㪛㪩㪘㪤

㪛㪛㪩㪋㪇㪇㩷㪪㪛㪩㪘㪤㪛㪛㪩㪋㪇㪇㩷㪪㪛㪩㪘㪤

㪛㪛㪩㪋㪇㪇㩷㪪㪛㪩㪘㪤

㪉㪌㪍㪤㪹㫀㫋㫏㪉

㪝㫃㪸㫊㪿㩷㪤㪼㫄㫆㫉㫐

㪝㫃㪸㫊㪿㩷㪤㪼㫄㫆㫉㫐㪝㫃㪸㫊㪿㩷㪤㪼㫄㫆㫉㫐

㪝㫃㪸㫊㪿㩷㪤㪼㫄㫆㫉㫐

㪈㪍㪤㪹㫀㫋

㪍㪋㫂㪹㫀㫋㩷㪜㪜㪧㪩㪦㪤

㪍㪋㫂㪹㫀㫋㩷㪜㪜㪧㪩㪦㪤㪍㪋㫂㪹㫀㫋㩷㪜㪜㪧㪩㪦㪤

㪍㪋㫂㪹㫀㫋㩷㪜㪜㪧㪩㪦㪤

㪣㪭㪛㪪㪶㪪㪜㪣

㪣㪭㪛㪪㪉㪺㪿

㪙㪣㪶㪦㪥

㪜㪭㪦㪣㪶㪈

㪙㪣㪶㪛㪜㪫

㪪㪺㪿㫄㫀㫋㫋㪄

㪪㪺㪿㫄㫀㫋㫋㪄㪪㪺㪿㫄㫀㫋㫋㪄

㪪㪺㪿㫄㫀㫋㫋㪄

㪫㪩㪞㪅

㪫㪩㪞㪅㪫㪩㪞㪅

㪫㪩㪞㪅

㪉㫂㪹㫀㫋

㪜㪜㪧㪩㪦㪤

㪝㪚㩷㪙㫌㫊

㪫㫏㪶㪧㪛㪮㪥

㪫㫏㪃㩷㪩㫏

㪉㪊㪉㪚㪶㪪㪮㪈

㪢㪜㪰

㪣㪜㪛

㪧㪮㪣㪜㪛

㪠㪩㫀㫅

㪧㪮㪩㪪㪮㪄㪥

㪧㪦㪮㪜㪩㪈

㪪㪚㪣㪢

㪩㪜㪪㪜㪫

㪠㪩㫆㫌㫋

㪠㪩㫆㪽㪽

㪪㪮

㪪㪮㪪㪮

㪪㪮

㪫㪚㪋㪇㪍㪍㪙㪝㪫

㪫㪚㪋㪇㪍㪍㪙㪝㪫㪫㪚㪋㪇㪍㪍㪙㪝㪫

㪫㪚㪋㪇㪍㪍㪙㪝㪫

㪫㫏㪃㩷㪩㫏

㪫㫏㪃㩷㪩㫏

㪚㪦㪥㪫

㪉㪊㪉㪚㩷㪛㫉㫀㫍㪼㫉

㪉㪊㪉㪚㩷㪛㫉㫀㫍㪼㫉㪉㪊㪉㪚㩷㪛㫉㫀㫍㪼㫉

㪉㪊㪉㪚㩷㪛㫉㫀㫍㪼㫉

㪤㪘㪯㪉㪇㪉㪠㪧㪮

㪤㪘㪯㪉㪇㪉㪠㪧㪮㪤㪘㪯㪉㪇㪉㪠㪧㪮

㪤㪘㪯㪉㪇㪉㪠㪧㪮

㪚㪫㪪㪃㩷㪩㪫㪪

㪫㫏㪃㩷㪩㫏

㪩㪪㪄㪉㪊㪉㪚

㪩㪪㪄㪉㪊㪉㪚㪩㪪㪄㪉㪊㪉㪚

㪩㪪㪄㪉㪊㪉㪚

㪤㫀㫅㫀㪛㪠㪥㩷㪐㫇㫀㫅

㪪㪮

㪪㪮㪪㪮

㪪㪮

㪪㪥㪎㪋㪣㪭㪚㪈㪞

㪪㪥㪎㪋㪣㪭㪚㪈㪞㪪㪥㪎㪋㪣㪭㪚㪈㪞

㪪㪥㪎㪋㪣㪭㪚㪈㪞

㪪㩿㪤㪚㪣㪢㪶㪪㪜㪣㪀

㪙㪈㩿㪟㪛㪤㪠㪀

㪙㪉㩿㪧㪚㪀

㪘㪛㪚

㪘㪛㪚㪘㪛㪚

㪘㪛㪚

㪧㪚㪤㪈㪏㪇㪏

㪧㪚㪤㪈㪏㪇㪏㪧㪚㪤㪈㪏㪇㪏

㪧㪚㪤㪈㪏㪇㪏

㪣㪃㩷㪩

㪤㪚㪣㪢

㪛㪪㪧

㪛㪪㪧㪛㪪㪧

㪛㪪㪧

㪥㪡㪬㪉㪍㪇㪋㪈

㪥㪡㪬㪉㪍㪇㪋㪈㪥㪡㪬㪉㪍㪇㪋㪈

㪥㪡㪬㪉㪍㪇㪋㪈

㪠㪉㪪

㪩㪜㪪㪜㪫

㪛㪄㪘㪤㪧

㪛㪄㪘㪤㪧㪛㪄㪘㪤㪧

㪛㪄㪘㪤㪧

㪫㪘㪪㪌㪎㪇㪍

㪫㪘㪪㪌㪎㪇㪍㪫㪘㪪㪌㪎㪇㪍

㪫㪘㪪㪌㪎㪇㪍

㪧㪛㪮㪥

㪩㪜㪪㪜㪫

㪠㪉㪪

㪤㪬㪫㪜

㪤㪚㪣㪢

㪤㫀㫅㪧㫀㫅㪡㪸㪺㫂

㪤㫀㫅㪧㫀㫅㪡㪸㪺㫂㪤㫀㫅㪧㫀㫅㪡㪸㪺㫂

㪤㫀㫅㪧㫀㫅㪡㪸㪺㫂

㪧㪚㩷㪘㫌㪻㫀㫆

㪘㫌㪻㫀㫆㩷㪪㪮㪆㪛㪼㫃㪸㫐

㪣㩷㫆㫌㫋

㪩㩷㫆㫌㫋

㪣㪧㪣㩷㪋㪉㪭㩷㪝㪟㪛㩿㪈㪉㪇㪀

㪣㪧㪣㩷㪋㪉㪭㩷㪝㪟㪛㩿㪈㪉㪇㪀㪣㪧㪣㩷㪋㪉㪭㩷㪝㪟㪛㩿㪈㪉㪇㪀

㪣㪧㪣㩷㪋㪉㪭㩷㪝㪟㪛㩿㪈㪉㪇㪀

㪂㪈㪉㪭

㪣㪭㪛㪪㪶㪪㪜㪣

㪣㪭㪛㪪

㪣㪭㪛㪪

㪣㪭㪛㪪

㪣㪭㪛㪪

㪉㪋㪭

㪙㪣㩷㪦㪥

㪙㪩㪫

㪙㪣㪶㪝㪘㪠㪣

㪚㪫㪪㪃㩷㪩㪫㪪

㪫㫏㪃㩷㪩㫏

㪠㪉㪪㩿㪛㪼㫃㪸㫐㩷㫆㫌㫋㪀

㪟㪧㪶㪛㪜㪫

㪟㪧㪶㪤㪬㪫㪜

㪫㫏㪃㩷㪩㫏㪃㩷㪚㪣㪢㪃㩷㪜㪥㪃㩷㪞㪶㪟㪙

㪩㪜㪪㪜㪫

㪘㪬㪛㪶㪩㪜㪪㪜㪫

㪘㪬㪛㪶㪤㪬㪫㪜

㪘㪬㪛㪶㪪㪜㪣

㪪㪚㪣㪉㪆㪪㪛㪘㪉

㪪㪚㪣㪉㪆㪪㪛㪘㪉

㪪㪚㪣㪈㪆㪪㪛㪘㪈

㪠㪉㪪

㪤㪚㪣㪢㩷㫆㫌㫋

㪢㪼㫐㪄㪙㪛

㪠㪩

㪧㫆㫎㪼㫉㩷㪬㫅㫀㫋

㪧㫆㫎㪼㫉㩷㪬㫅㫀㫋㪧㫆㫎㪼㫉㩷㪬㫅㫀㫋

㪧㫆㫎㪼㫉㩷㪬㫅㫀㫋

㪧㫆㫎㪼㫉㪈

㪉㪋㪭

㪪㪫㪙㪌㪭

㪧㫆㫎㪼㫉㩷㪦㪝㪝

㪙㪣㪶㪦㪥

㪙㪩㪫

㪙㪣㪶㪛㪜㪫

㪠㪉㪪

㪦㫌㫋

㪧㪮㪤㫋㫆㪛㪚

㪟㪧㩷㫆㫌㫋

㪟㪧㩷㫆㫌㫋㪟㪧㩷㫆㫌㫋

㪟㪧㩷㫆㫌㫋

㪤㫀㫅㫀㩷㪧㫀㫅㩷㪡㪸㪺㫂

㪪㪮

㪪㪮㪪㪮

㪪㪮

㪮㪛㪫

㪮㪛㪫㪮㪛㪫

㪮㪛㪫

㪩㪌㪈㪇㪍㪥㪉㪐㪈㪘

㪩㪌㪈㪇㪍㪥㪉㪐㪈㪘㪩㪌㪈㪇㪍㪥㪉㪐㪈㪘

㪩㪌㪈㪇㪍㪥㪉㪐㪈㪘

㪪㪚㪣㪢

㪩㪜㪪㪜㪫

㪩㪜㪪㪜㪫㩷㪪㪮

㪠㫅㫍㪼㫉㫋㪼㫉

㪤㪸㫀㫅㩷㪙㫆㪸㫉㪻

㪤㪸㫀㫅㩷㪙㫆㪸㫉㪻㪤㪸㫀㫅㩷㪙㫆㪸㫉㪻

㪤㪸㫀㫅㩷㪙㫆㪸㫉㪻

㪡㪘㪊㪇㪎㪈㪈㪆㪉

㪡㪘㪊㪇㪎㪈㪈㪆㪉㪡㪘㪊㪇㪎㪈㪈㪆㪉

㪡㪘㪊㪇㪎㪈㪈㪆㪉

㪫㪼㫉㫄㫀㫅㪸㫃㩷㪙㫆㪸㫉㪻

㪫㪼㫉㫄㫀㫅㪸㫃㩷㪙㫆㪸㫉㪻㪫㪼㫉㫄㫀㫅㪸㫃㩷㪙㫆㪸㫉㪻

㪫㪼㫉㫄㫀㫅㪸㫃㩷㪙㫆㪸㫉㪻

㪡㪘㪊㪇㪎㪉㪈㪆㪉

㪡㪘㪊㪇㪎㪉㪈㪆㪉㪡㪘㪊㪇㪎㪉㪈㪆㪉

㪡㪘㪊㪇㪎㪉㪈㪆㪉

㪩㪃㩷㪞㪃㩷㪙

㪟㪃㩷㪭

㪛㪛㪚

㪛㪄㫊㫌㪹

㪛㪄㫊㫌㪹㪛㪄㫊㫌㪹

㪛㪄㫊㫌㪹

㪈㪌㫇㫀㫅

㪈㪌㫇㫀㫅㪈㪌㫇㫀㫅

㪈㪌㫇㫀㫅

㪟㪛㪤㪠

㪟㪛㪤㪠㪟㪛㪤㪠

㪟㪛㪤㪠

㪩㪪㪉㪊㪉㪚

㪪㪚㪣㪉㪆㪪㪛㪘㪉

㪟㪧㩷㪘㪤㪧

㪟㪧㩷㪘㪤㪧㪟㪧㩷㪘㪤㪧

㪟㪧㩷㪘㪤㪧

㪥㪡㪮㪈㪈㪇㪐㪭

㪥㪡㪮㪈㪈㪇㪐㪭㪥㪡㪮㪈㪈㪇㪐㪭

㪥㪡㪮㪈㪈㪇㪐㪭

㪣㩷㫀㫅

㪩㩷㫀㫅

㪛㪘㪚

㪛㪘㪚㪛㪘㪚

㪛㪘㪚

㪮㪤㪏㪌㪉㪇

㪮㪤㪏㪌㪉㪇㪮㪤㪏㪌㪉㪇

㪮㪤㪏㪌㪉㪇

㪠㪉㪪

㪤㪬㪫㪜

㪩㪜㪪㪜㪫

㪤㪚㪣㪢

㪣㩷㫆㫌㫋

㪩㩷㫆㫌㫋

㪣㩷㫆㫌㫋

㪩㩷㫆㫌㫋

㪫㫏㩷㪃㪩㫏

㪧㪮㪄㪣㪜㪛

㪧㪮㪄㪪㪮

㪧㪮㩷㪚㫆㫅㫅㪼㪺㫋 㫆㫉

㪠㪩㪆㪧㪮

㪚㫆㫅

㪩㪃㪞㪃㪙㩷㪈㪺㪿

㪛㪜㪃㪚㪣㪢㪃㪟㪃㪭

㪩㪃㪞㪃㪙㪶㪈㪺㪿

㪠㪉㪪㩷㫆㫌㫋

㪛㪛㪩㪉

㪛㪛㪩㪉㪛㪛㪩㪉

㪛㪛㪩㪉

㪉㪌㪍㪤㪹㫀㫋㫏㪊

㪣㪭㪛㪪㩷㪫㫏

㪣㪭㪛㪪㩷㪫㫏㪣㪭㪛㪪㩷㪫㫏

㪣㪭㪛㪪㩷㪫㫏

㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊

㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊

㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊

㪩㪃㪞㪃㪙

㪛㪜㪃㪚㪣㪢㪃㪟㪃㪭

㪫㪯㪶㪧㪛㪮㪥

㪣㪭㪛㪪㩷㪈㪺㪿

㪣㪭㪛㪪㪶㪈㪺㪿

㪣㪭㪛㪪㩷㪈㪺㪿

㪣㪭㪛㪪㪶㪈㪺㪿

㪣㪭㪛㪪㩷㪚㫆㫅㫅㪼 㪺㫋㫆㫉㪉 㪣 㪭㪛㪪㩷㪚㫆㫅㫅㪼㪺 㫋㫆㫉㪈

㪉㪋㪭

㪣㪜㪛

㪣㪭㪛㪪㩷㪫㫏

㪣㪭㪛㪪㩷㪫㫏㪣㪭㪛㪪㩷㪫㫏

㪣㪭㪛㪪㩷㪫㫏

㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊

㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊

㪫㪟㪚㪍㪊㪣㪭㪛㪈㪇㪉㪊

㪛㪜㪃㪚㪣㪢㪃㪟㪃㪭

㪩㪃㪞㪃㪙

㪫㫏㪶㪧㪛㪮㪥

㪛㫆㫋㫋㪼㪻㩷㫃㫀㫅㪼㪑㩷㪥㫆㩷㫌㫊㪼㩷㫆㫉㩷㪥㫆㫋㩷㫄㫆㫌㫅㫋

㪣㪭㪛㪪㩷㪈㪺㪿

㪣㪭㪛㪪㪶㪈㪺㪿

BLOCK DIAGRAMS

42” UT Monitor.

D8MW

TABLE OF CONTENTS

33

Page 35

3

2

1

PSPK

PA-04H

1

2

3

4

PPU1

VH-03V-D(#2NC)

1

NC

3

PZ01

GH-03H

1

2

3

G1

G2

PM01

SH-10H

1

2

3

4

5

6

7

8

9

10

G1

G2

CNPP2

PH-12H

1

2

3

4

5

6

7

8

9

10

11

12

G1

G2

J001

1

L

2

N

3

FG

F.G

E902

F.G

P801

501568-04H

123

4

G1

G2

P602

501568-04H

123

4

G1

G2

P601

501568-06H

12345

6

G1

G2

PV02

501568-06H

1

2

3

4

5

6

G1

G2

CNPP1

PH-14H

1

2

3

4

5

6

7

8

9

10

11

12

13

14

G1

G2

PNPS

PA-11H

1234567891011

G1

G2

PP01

PA-11H

1234567891011

G1

G2

CNAC

1

2

3

PM02

SH-10H

1

2

3

4

5

6

7

8

9

10

G1

G2

PL02

FIR-4 1H

123456789

10111213141516171819202122232425262728293031323334353637383940

41

G1G2G3G4G5

G6

G7G8G9

G10

PL01

FIR-5 1H

123456789

101112131415161718

1920212223242526272829303132333435363738394041

G1

G2G3G4G5G6

G7G8G9

G10

424344454647484950

51

PW02

FH28- 50HL ow

12345678910111213141516171819202122232425262728293031323334353637383940414243444546474849

50

G1

G2

P102

FH28- 50HL ow

12345678910111213141516171819202122232425262728293031323334353637383940414243444546474849

50

G1

G2

PW01

50156 8-14 H

12345678910111213

14

G1

G2

P101

50156 8-14 H

12345678910111213

14

G1

G2

PV01

501568-10H

1

2

3

4

5

6

7

8

9

10

G1

G2

P701

501568-10H

1

2

3

4

5

6

7

8

9

10

G1

G2

CN1

PH-14H

1

2

3

4

5

6

7

8

9

10

11

12

13

14

G1

G2

CN2

PH-12H

1

2

3

4

5

6

7

8

9

10

11

12

G1

G2

Main P.W.B.

JA30711/2

POWER P.W.B.

Terminal P.W.B.

JA30721/2/3-A/B

Filter P.W.B.

Control P.W.B.

IR/PWR_SW

P.W.B.

Speaker

Lout-N

Lout-P

Rout-N

Rout-P

+24V

POWER 1

GND

STB5V

POWER OFF

GND

AC CL OCK

BRT

BL ON (ON /OFF )

+24V

+24V

AC CL OCK

BRT

BL ON (ON /OFF )

+24V

STB5V

POWER OFF

GND

GND

POWER 1

FANLOCK

FANVCC

GND(FAN)

(to FAN)

LVDS (to T-CON LCD UNIT) ECN1

SUBuCON I/F

AC

AC

AC

AC

+24V

+24V

+24V

+24V

+24V

GND

GND

GND

GND

GND

BRT

BL_ON(ON OFF)

EPS

EPU

ELS

(EJS)

AC cord

E001

AMP-IN 1P

ADKEY 1

USRRS T

ADKEY 2

GND

ADKEY 2

LED P.W.B.

ADKEY 1

USRRS T

GND

PWERL ED0

STB+5 V

ADKEY 1

USRRS T

ADKEY 2

GND

EKL

3.14.1

NC

DVR-03V-S

E002

EISP

BL_DE T

BL_DE T

STB+5V

ADKEY2

LEDB

ADKEY1

GND

USRRST

SUBuCON I/F

(EJS)

GND

SUB_RXD

S_BUSY

STB+3.3V

S_SCLK

SUB_TXD

S_CNVSS

S_RESET

GND

S_SCLK

SUB_TXD

S_CNVSS

S_RESET

GND

GND

SUB_RXD

S_BUSY

STB+3.3V

TD2-

GND

GND

GND

NC.

TA2-

TA1-

NC.(E XT_V BR)

TD2+

GND

NC.

TC1-

VDD

GND

TE1-

TE2-

TB1+

VDD

TCLK2 -

NC.

GND(L VDS)

TB2+

TC2+

TE1+

GND

TB1-

GND

TC2-

NC.

TCLK2 +

VDD

NC.

TE2+

TD1+

GND

NC.(D CR)

TD1-

GND

LVDSS EL

TC1+

GND

TCLK1 +

TCLK1 -

GND

TA1+

TB2-

NC.(V BR_o UT)

TA2+

GND(L VDS)

VDD

NC.

NC.

TA4-

NC.

GND

NC.

TCLK4 +

TCLK3 +

NC.

TCLK4 -

TD4-

GND

NC.

TC4-

NC.

GND

GND

TC3+

TE3+

TA3-

TE4+

TD3-

GND

GND

TD4+

TA3+

GND

TB4+

TE3-

TD3+

TE4-

TC4+

NC.

TB3-

TB4-

TB3+

TA4+

NC.

GND

TC3-

TCLK3 -

GND

PWRSW_N

LEDG

PWON+3.3V

GND

STB+5V

PoWER1_SW

LEDo

LEDR

PoWER1

iR_iN

LVDS (to T-CON LCD UNIT) ECN2

EMT1 EMT2

SPR

EIIV

Inverter

Master

Inverter

Slave

ELCD2

ELCD3

LCD Panel

SPL

EIP1

EIP1

CN5

CN6

CN3

CN4

+24V

+24V

+24V

+24V

+24V

GND

GND

GND

GND

GND

BRT

BL_ON(ON OFF)

NC

BL_DET

CONNECTIONS DIAGRAM

42” UT Monitor.

D8MW

TABLE OF CONTENTS

34

Page 36

'%0

'%0

'++8

'+2

'+52

'-.

'+2

'.%& '.%&

'.5

'/6

'/6

'25

'

27

D8MW UT42 Wiring Dress DWG

㪥㪜㪣㪪㩷

㪥㪪㪧㪢㪉 㪥㪪㪧㪢㩷

㪥㪠㪪㪈㩷

0

㶎㪈㩷³(36DQG³(/&'´PXVWSDVVRQ³(&1´DQG³(&1´㩷

㶎㪉㩷'RWKHVW\OLQJVRWKDWWKHELQGLQJWDSHRI³(/&'´DQG³(/&'´VKRXOGQRWWRXFKWKHPDLQIUDPH.㩷

㶎㪉

㶎㪊㩷'RWKHVW\OLQJVRWKDWWKHZLUHVKRXOGQRWWRXFKWKHPDLQ3:%VVKLHOGLQJFDVH㩷

㶎㪋㩷

7DNHORRVHQLQJRIWKH³(,63´ZLUHVRWKDWDORQJWKHJXLGHRI%H]HODVV¶\

'RWKHVW\OLQJVRWKDWWKHZLUHVKRXOGQRWWRXFKWKH

$&VZLWFK

㩷

㶎㪌㩷'RWKHVW\OLQJVRWKDWWKH(,63ZLUH

DORQJWKHJXLGHRI%H]HODVV¶\

㩷

㩷 1LWWRW DSH1R

: PP/ PP㩷

㩷 1LWWRW DSH1R

: PP/ PP㩷

㩷 '0:6 ,*1$/

6/'7 $3(㩷

㩷 '0:6,*1 $/

6/'7 $3(㩷

㩷 1LWWRW DSH1R

: PP/ PP㩷

㶎㪈

㶎㪊

㶎㪉

㶎㪌

㩷 1LWWRW DSH1R

: PP/ PP㩷

㶎㪌

㶎㪋㩷

㩷 1LWWRW DSH1R

: PP/ PP㩷

0'%0

㪜07

1LWWRWDSH1R

: PP/ PP

Wiring Diagram page 1/6

D8MW

TABLE OF CONTENTS

35

Page 37

䇼

Pre-operation䇽㩷

㪈

㩷 Set the ferrite core(NECN1) to ECN1.

NECN1 MAG K5BFP 40X2X12-K

(P#GX00821)

#WN03 Nitto tape No.5

W=20mm L=70mm

ECN1

Wiring Diagram page 2/6

D8MW

TABLE OF CONTENTS

36

Page 38

㪉㩷 Set the ferrite core(N001) to EMT2.

䇼

Pre-operation䇽㩷

㪥㪇㪇㪈㩷

㪜㪤㪫㪉㩷

㪓㪄㪄㩷 㪤㪸㫀㫅㩷 㪧㪮㪙㩷 㫊㫀㪻㪼㩷

㪫㪼㫉㫄㫀㫅㪸㫃㩷 㪧㪮㪙㩷 㫊㫀㪻㪼㩷 㪄㪄㪕

ޣ

surface

ޤ

Ferrite core is 1set by 2pcs.

㪌㫄㫄㫧㪈㫄㫄

㩷

#WN01 Nitto tape No.5

W=20mm L=70mm

㪓㪄㪄㪫㪼㫉㫄㫀㫅㪸㫃㩷 㪧㪮㪙㩷 㫊㫀㪻㪼㩷

㪤㪸㫀㫅㩷 㪧㪮㪙㩷 㫊㫀㪻㪼㪄㪄㪕㩷

ޣ

reverse

ޤ

ޣsideޤ

㪓㪄㪄㩷 㪤㪸㫀㫅㩷 㪧㪮㪙㩷 㫊㫀㪻㪼

㪫㪼㫉㫄㫀㫅㪸㫃㩷 㪧㪮㪙㩷 㫊㫀㪻㪼㩷 㪄㪄㪕㩷

Wiring Diagram page 3/6

D8MW

TABLE OF CONTENTS

37

Page 39

Paste to N001 Paste to near ECN1

㪊㩷 How to paste of #333 (D8MW SIGNAL SLD TAPE P#MD20801)㩷

ECN1

㪋㪅㩷 㩷 㪟㫆㫎㩷 㫋㫆㩷 㫊㫋㫐㫃㫀㫅㪾㩷 㵰㪜㪠㪪㪧㵱㩷 㫎㫀㫉㪼㩷 㫋㪿㪸㫋㩷 㪪㪧㪣㩷 㫊㫀㪻㪼㪅㩷

㩷 㩷 㩷 㩷

052-

#333 dose not touch the “NECN1” .

Separate 1mm or more.

#333

1mm or more

#333

Black tape

EISP wire

Guide of bezel

3mm or less

Speaker L

NECN1

#WN04 Nitto tape No.5

W=9mm L=30mm

N001

Wiring Diagram page 4/6

D8MW

TABLE OF CONTENTS

38

Page 40

Wiring Diagram page 5/6

㪌㩷 How to set the ferrite core(NELS) to ELS.㩷

㪜㪣㪪㩷

㪍㪇㫄㫄㫧㪌㫄㫄

㪍How to set the ferrite core(NSPK, NSPK2) to EISP.㩷

㪜㪠㪪㪧㩷

㪌㪇㫄㫄㫧㪌㫄㫄

㪉㪇㫄㫄㫧㪌㫄㫄

Main PWB side

LED PWB side

NELS MAG K5CRC12X15X7-MB2

(P# GX00738)

1 turn

SP R side

Main PWB side

Terminal PWB side

Binding tape

Binding tape

NSPK2 MAG K5CRC12X15X7-MB2

(P# GX00738)

1 turn

SP L side

NSPK MAG K5CRC12X15X7-MB2

(P# GX00738)

1 turn

D8MW

TABLE OF CONTENTS

39

Page 41

Wiring Diagram page 6/6

㪎㩷 Paste #327 so that ECN1, ECN2 should not float.

'%0

'

%0

#327

Nitto tape No.5

W=20mm L=100mm

㩷

㪏㩷 How to set the ferrite core NEPU㩷 to EPU.

20mm

25mm

78mm or more

NEPU MAGK5CRC16X28X9-M2G2

(P# GX00732)

Put on the core with fit.

ኒ⌕ߐߖࠆ

#NEPU SK-binder

(P#:3763751)

D8MW

TABLE OF CONTENTS

40

Page 42

Final assembly guide411/9

D8MW

TABLE OF CONTENTS

Page 43

Final assembly guide

2/9

D8MW

TABLE OF CONTENTS

42

Page 44

Final assembly guide

3/9

D8MW

TABLE OF CONTENTS

43

Page 45

Final assembly guide

4/9

D8MW

TABLE OF CONTENTS

44

Page 46

Final assembly guide

5/9

D8MW

TABLE OF CONTENTS

45

Page 47

Final assembly guide

6/9

D8MW

TABLE OF CONTENTS

46

Page 48

Final assembly guide

7/9

D8MW

TABLE OF CONTENTS

47

Page 49

Final assembly guide

8/9

D8MW

TABLE OF CONTENTS

48

Page 50

Final assembly guide

9/9

D8MW

TABLE OF CONTENTS

49

Page 51

WAVEFORMS

The number icons thru the circuit schematic are reference to the next waveforms.

The waveforms were taken with a color bar video signal and for the audio a 1Vp-p 1kHz audio signal was used.

PC video signal white icon numbers, example

HDMI video signal, black icon numbers, example: .

. PC signal, green color @ CE12 (page 62) . PC signal, blue color @ CE13 (page 62)

D8MW

. PC signal, red color @ CE14 (page 62) . PC signal, horizontal drive@ RE49 (page 62)

. PC signal, vertical drive @ RE50 (page 62) . PC signal, green color @ CE06 (page 62)

TABLE OF CONTENTS