Hitachi UT32MH70E, UT32MH70U, UT37MX70E, UT37MX70U, UT42MX70E Service manual

...

SM0430

UT32MH70E

UT32MH70U

UT37MX70E

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

UT37MX70U

UT42MX70E

UT42MX70U

Data contained within this Service

manual is subject to alteration for

improvement.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

Contents

1. Features -----------------------------------------------3

2. Specifi cations ----------------------------------------- 3

3. Servicing ----------------------------------------------- 5

4. Controls ------------------------------------------------ 6

5. Adjustment -------------------------------------------- 8

6. Troubleshooting ------------------------------------ 18

7. Wiring diagrams ----------------------------------- 23

8. Block diagrams ------------------------------------- 37

9. Connector diagram ------------------------------- 43

10.Schematic diagrams ------------------------------ 44

11.PCB Layout diagrams -------------------------- 105

12.Disassembly diagrams ------------------------ 111

13.Replacement Parts list ------------------------- 121

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LCD Monitor

April 2008

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

CAUTION FOR SAFETY

Please read this page before repairing the monitor.

This page explains the following items for keeping the safety of the set and preventing accidents

during repair.

Symbols Used:

Warning

Caution

This symbol means "CAUTION"

This symbol means "POSSIBLITY of

ELECTRIC SHOCK"

This symbol means "possiblity of death or heavy damage"

This symbol means "possiblity of damage or breakage"

Follow instructions.

Special attention parts are indicated on the

cabinet, chassis and parts by label.

Please follow the notes in [Safety Instructions]

in the User’s Manual.

Prevent electric shock.

Take care during working because the

monitor has high voltage parts and power

supply parts.

Possibility of death if these parts are

touched by mistake.

Disconnect power plug during overhaul,

reassembly or parts change.

Death or injury by electric shock may

occur if live parts are touched.

Use recommended components.

Components and perts with special

characteristics for safety or reliability are

indicated in partslists and circuits diagrams

by the "!" mark.

Electric shock or fire amy occur if nonrecommended parts/component are used.

This symbol means "MUST"

This symbol means "DO NOT"

WARNING

Keep the same style of wiring..

Monitor uses insulating tubes or tapes

for safety and some components are

kept at a distance from PCB surfaces

for safety.

Internal leads are kept from hot- or high voltage

parts by clampers or styling. Return wiring to

original condition after repair to prevent electric

shock or fire.

Perform safety check after finished.

Every part (removed screws, components

and wiring) should be returned to its

original condition.

Check around the repair position for

damage and measure the insulation

impedance by using a meg-ohm meter.

Confirm that the value of impedance

is more than 4M ohm.

Electric shock or fire may occur if the

value is less than 4M ohm.

1

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

Cleaning and Maintenance

Please make sure to unplug the power lead before cleaning the unit.

ʄ

Cleaning the LCD panel of the unit.

Wipe the panel with a lint-free and dry cloth in order to prevent damage to the panel surface.

Do not use a chemical cloth or cleaners. Depending on the ingredients, these may cause discolouration and damage to the panel

surface.

Do not wipe with a rough cloth or rub hard. This may damage the panel surface.

With greasy dirt such as fingerprints, wipe the panel surface with a lint-free cloth moistened with a diluted neutral detergent

solution (dilute 1 part of detergent to 100 parts of water) and then wipe with a soft and dry cloth.

Do not use a spray cleaner.This could cause a malfunction.

ʄ

Cleaning the cabinet of the unit.

The following may cause cracking, deformation and peeling of paint.

Do not wipe the cabinet with benzene, thinners and other chemical products.

Do not spray volatile solutions such as insecticide over the cabinet.

Do not leave the cabinet in prolonged contact with plastic or rubber materials.

Do not use a chemical cloth, cleaner or wax. Depending on the ingredients, these may cause cracking and deformation.

Use a lint-free cloth (e.g. cloth for cleaning glasses) to clean the cabinet and control panel of the unit. In case of the excessive dirt,

wipe with a soft cloth moistened with a diluted neutral detergent solution and then wipe with a soft and dry cloth.

Never use the following detergents. They could cause cracking, discolouration and scratching.

Acidic/alkaline detergents, alcoholic detergents, abrasive cleaners, soap powder, OA cleaner, car wax, glass cleaner, etc.

Information for users applicable in European Union countries

This symbol on the product or on its packaging means that your electrical and electronic

equipment should be disposed at the end of life separately from your household waste.

There are separate collection systems for recycling in EU. For more information, please contact the local authority or the dealer where you purchased the product.

2

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

1. Features

• Ultra-slim-line LCD monitor.

• Large-screen and high-definition LCD.

• Enjoy high resolution display.

(32-inch model: 1366 (H) x 768 (V) pixels, 37-inch model: 1920 (H) x 1080 (V) pixels)

• Improved digital signal processor.

• High quality sound with deeper, richer and dynamic bass tones.

• Accepts a digital input device with HDMI terminal.

• Enjoy the image from your PC with a large, high-definition LCD screen.

• Easy-to-use On-screen Display system operated by remote control.

• Low power consumption with power saving feature.

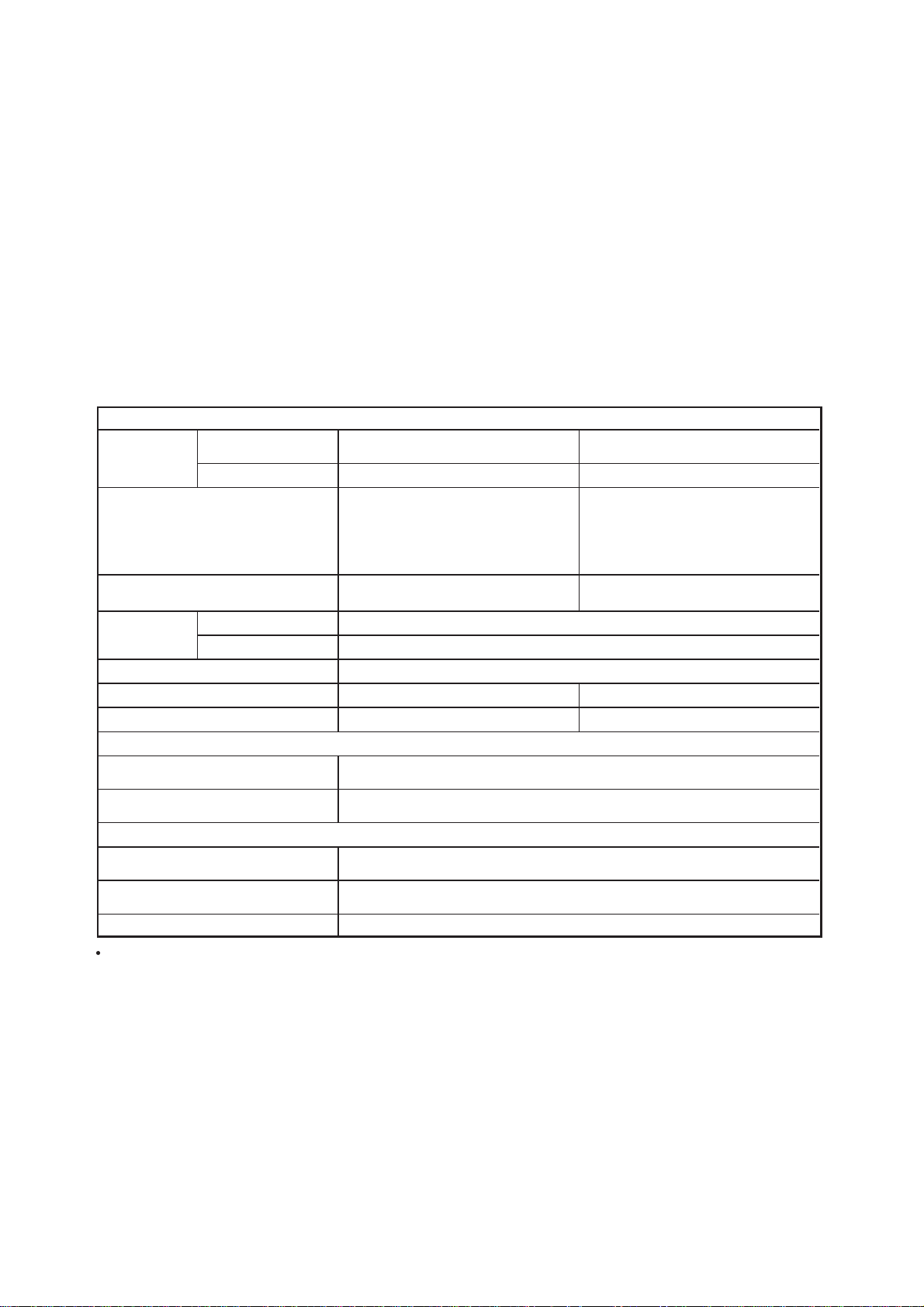

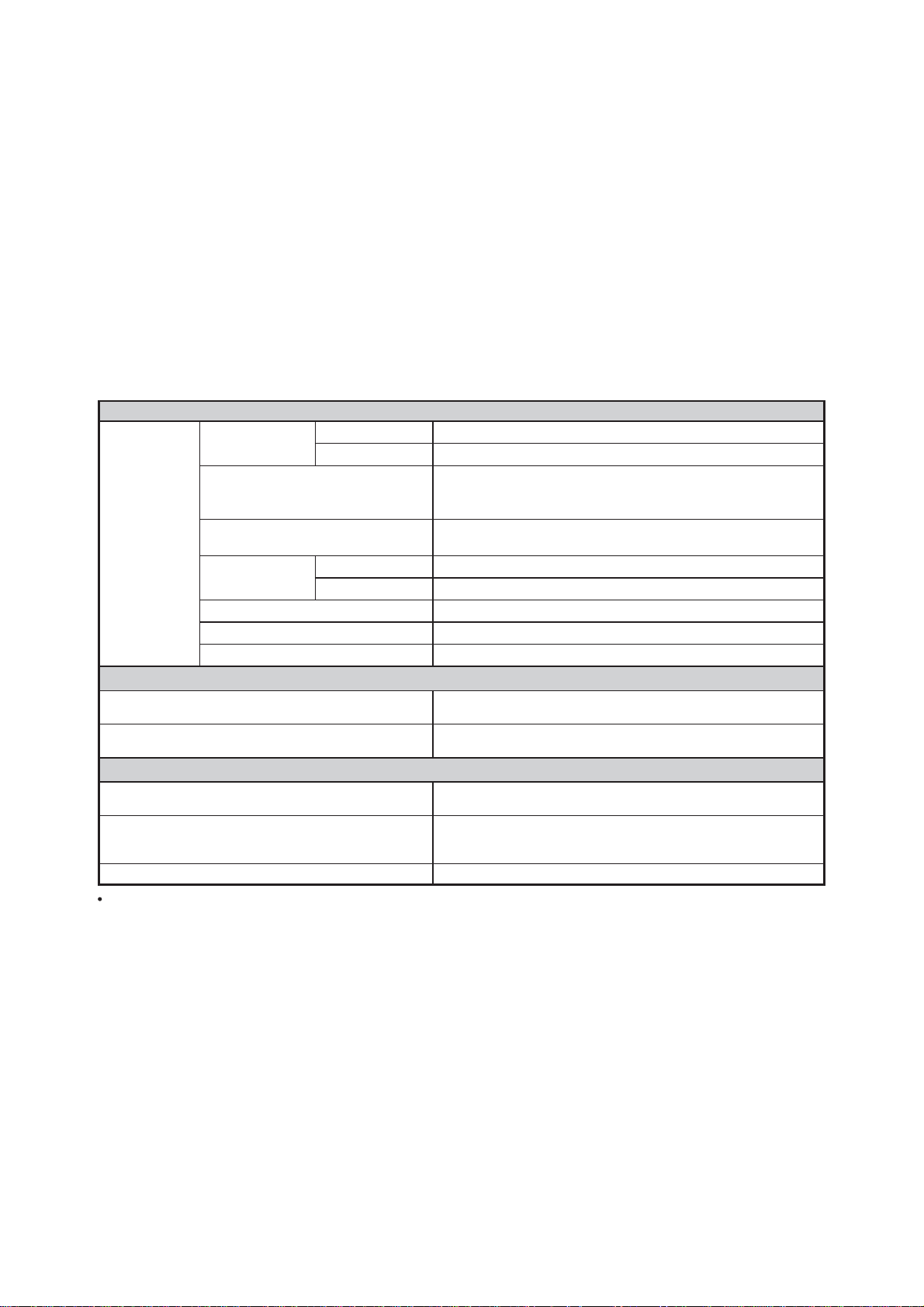

2. Specifications [For 32- & 37-inch versions ONLY]

SPECIFICATION

Approx. 32 inches

(698 (H) x 392 (V) mm, diagonal 801mm)

Including Stand:

814 (W) x 587 (H) x 249 (D) mm

excluding Stand:

814 (W) x 538 (H) x 39* (D) mm

* thinnest part: 35mm

Including Stand: 13.5 kg

Excluding Stand: 10.9 kg

AC220 - 240V, 50Hz

Panel

Net dimensions

Net weight

Ambient

conditions

Power supply

Display dimensions

Temperature Operating: 5°C to 35°C, Storage: 0°C to 40°C

Relative humidity Operating: 20% to 80%, Storage: 20% to 90% (non-condensing)

Power consumption/ at standby

(HDMI input)

Input terminals

Input signals

(RGB/Composite input)

Input terminals

Input signals

yS ȍ]

HDMI : HDMI input terminal

Audio input terminal (Mini-pin)*

HDMI: VGA/60, 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50, 1080i/60,

1080p/50, 1080p/60, 1080p/24

Analogue RGB input terminal (D-sub 15 pin)

Audio input terminal (Mini-pin)*

0.7 Vp-p, analogue RGB (Recommended Signal)

Composite video: PAL, SECAM, NTSC3.58, NTSC4.43, PAL60, PAL-M, PAL-N

K2[levelLTT,etarapesV/Hslangiscn

Approx. 37 inches

(820 (H) x 461 (V) mm, diagonal 941mm)

Including Stand:

936 (W) x 657 (H) x 310 (D) mm

excluding Stand:

936 (W) x 607 (H) x 39* (D) mm

* thinnest part: 35mm

Including Stand: 17.4 kg

Excluding Stand: 14.6 kg

W8.0</W171W8.0</W231

W6+W6rekaepSW6+W6rekaepStuptuooiduA

slexip)V(0801x)H(0291slexip)V(867x)H(6631noituloseR

The unit takes at least 30 minutes to attain the status of optimal picture quality.

* This Analogue Audio Input terminal can be used for PC (RGB) or HDMI-DVI.

3

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

2. Specifications [For 42-inch versions ONLY]

SPECIFICATION

Panel

Net dimension

UT42-MX700A

(HDMI input)

Input terminals

Input signals

(RGB/Composite input)

Input terminals

Input signals

Sync signals H/V separate, TTL level [2K]

The unit takes at least 30 minutes to attain the status of optimal picture quality.

* This analog audio input terminal can be used for PC (RGB) or HDMI-DVI.

Net Weight

Ambient conditions

Power supply AC110-240V, 50/60Hz

Power consumption/ at stand by 244W/<0.8W

Audio output speaker 6W + 6W

Display dimensions Approx. 42 inches (930 (H) x523 (V) mm, diagonal 1067mm)

Resolution 1920 (H) x 1080 (V) pixels

including Stand: 1036 (W) x 728 (H) x 310 (D) mm

excluding Stand: 1036 (W) x 678 (H) x 39*(D) mm

*thinnest part: 35mm

including Stand: 20.9kg

excluding Stand: 18.0kg

Temperature Operating: 5°C to 35°C, Storage: 0°C to 40°C

Relative humidity Operating: 20% to 80%, Storage: 20% to 90% (non-condensing)

HDMI : HDMI input terminal

Audio input terminal (Mini-pin)*

HDMI: VGA/60, 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50,

1080i/60, 1080p/50, 1080p/60, 1080p/24

Analog RGB input terminal (D-sub 15 pin)

Audio input terminal (Mini-pin)*

0.7 Vp-p, analog RGB (Recommended Signal)

Composite video: PAL, SECAM, NTSC3.58, NTSC4.43, PAL60, PAL-M,

PAL-N

4

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

3. Servicing

Lead free solder

All PCB assemblies in this unit use lead free solder.

This product uses lead free solder (unleaded) to help preserve the environment. Read these

instructions before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead

free solder can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F."

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity) and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

5

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

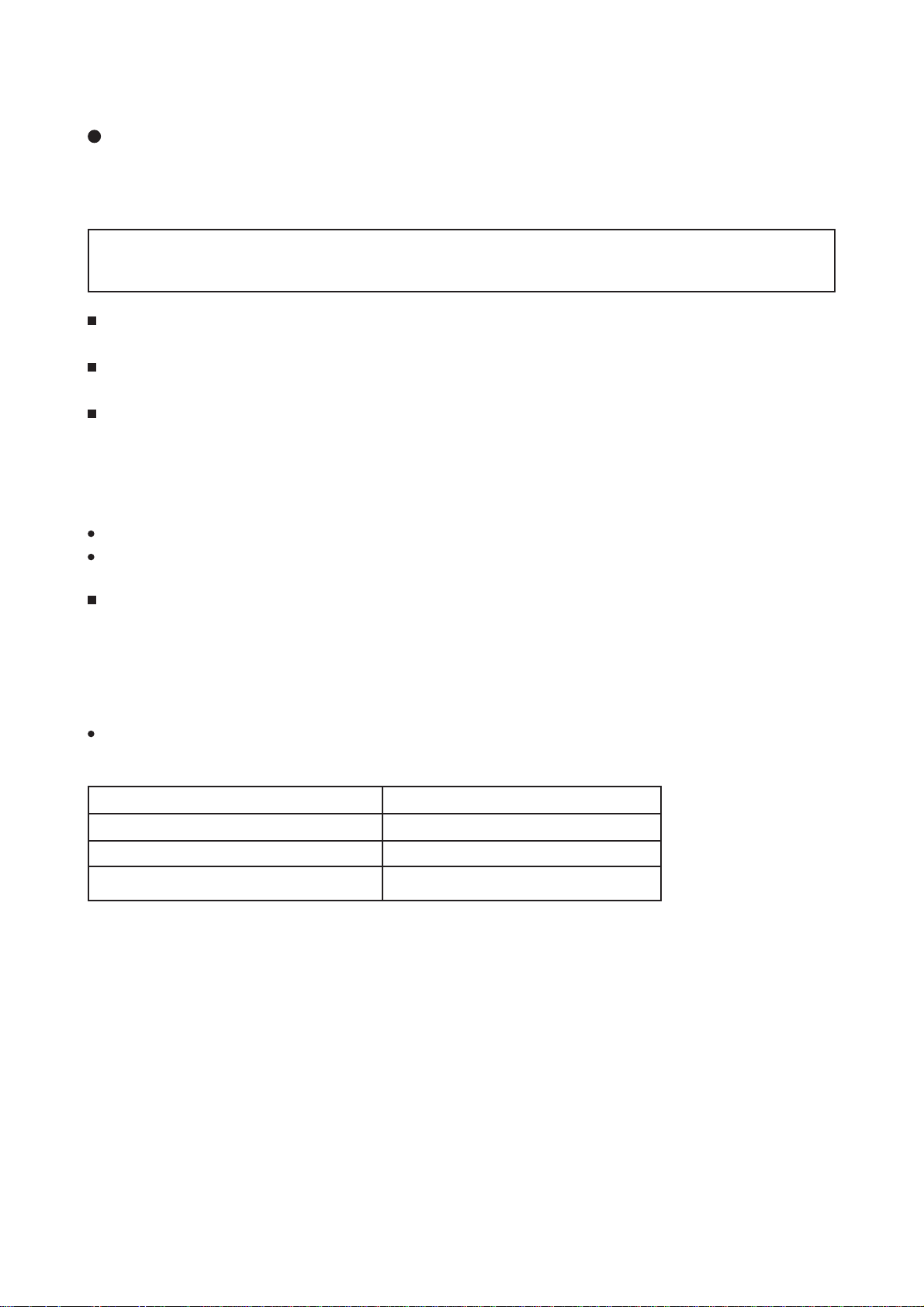

4. Controls

[Main unit]

Front Panel

6

7

Control panel (on the underside)

Cabinet

1

2

3

4

5

1

2

Panel

3

Remote Control Receiver

Indicating Lamp

4

Speaker

5

Illumination Lamp

6

Tabletop Stand

7

19

(

Power switch

8

Control Terminal*

9

Service use only

10

11

PC (RGB)/DVI Analogue Audio Input Terminal

12

PC Connection Terminal (D-sub 15 Pin)

13

Reset button

18

17

15

16

)(

OK

(Ż)(Ź)

)

14

(ź)(Ÿ)

13

11

10

9

12

Ÿ button

14

ź button

15

16

Volume Up/Ź button

17

Volume Down/Ż button

18

Input Select/OK button

19

Menu/Return button

8

* The Control Terminal allows linked operation with a Hitachi Media Box which equips a control terminal with the

logo.

Rear Panel

Power Cord Socket

1

HDMI Input Terminal

2

2

1

6

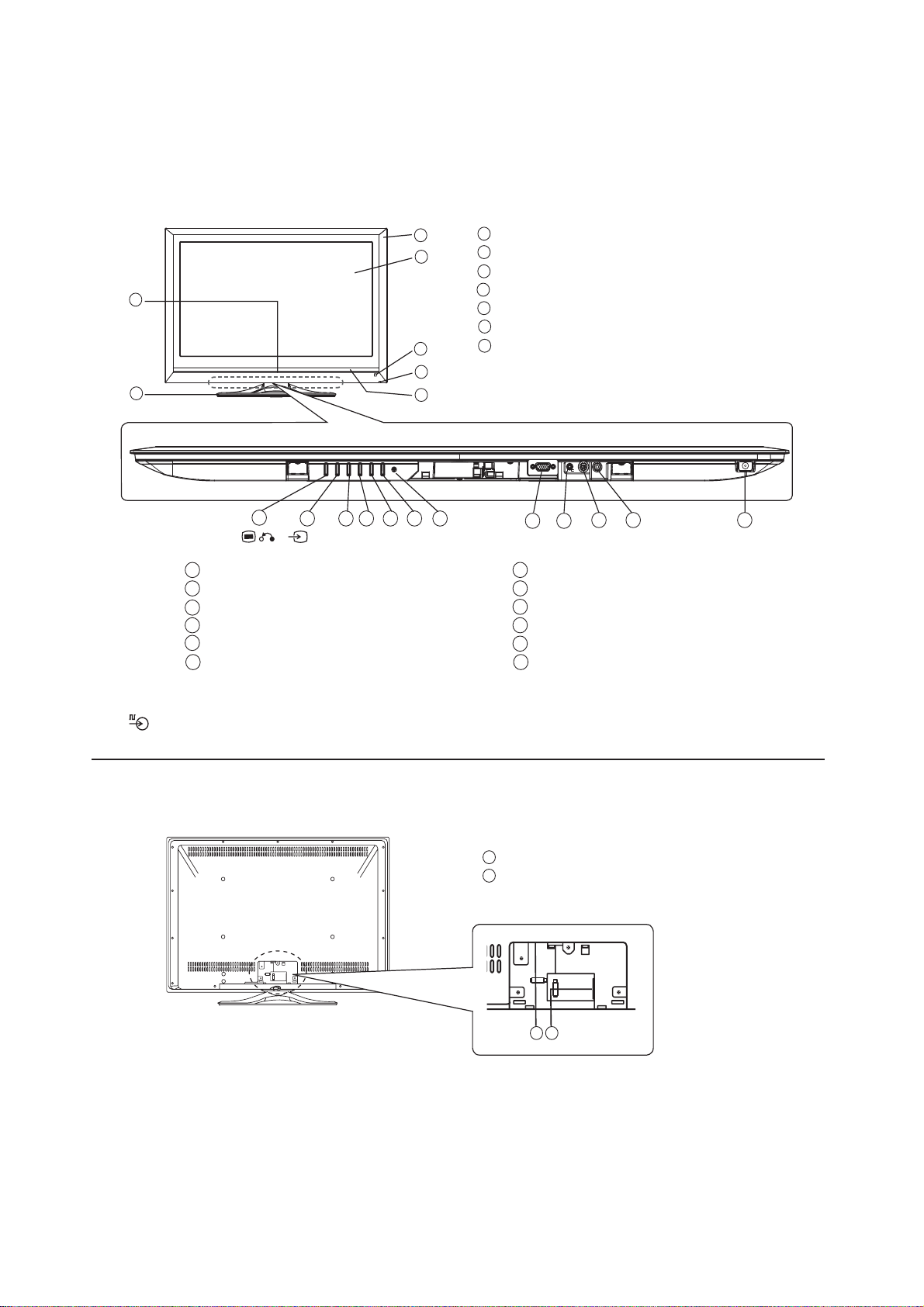

[Remote control]

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

Power On/Off

Press this button to switch

monitor On or Off standby.

Power Off

Press this button to switch

monitor Off standby.

RGB Input Select

Press this button to select

RGB (/Composite) input.

Menu

Cursor

OK

Input Select

Press this button to change

input mode.

HDMI RGB (/Composite)

Auto Adjust

Press this button to adjust the

picture automatically in RGB

mode.

Power On

Press this button to switch

monitor On.

Volume Up/Down

Mute

HDMI Input Select

Press this button to select

HDMI input.

Recall

Press this button to show the

input signal status.

Return

Press this button to return to

the previous menu.

Picture Mode

Picture mode can be changed

each time pressed in the

following sequence.

Dynamic Natural

Cinema

Size

Press this button to change

picture size.

7

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

5. Adjustment

Setting service adjustment mode

There are two methods as follows:

Method 1) Push the power switch with the “Menu/Return” button on the main unit pushed.

Keep pushing the “Menu/Return” button until the service screen is displayed.

Method 2) Keep pushing “Return” for about 3 seconds while pressing “Menu” and “Recall” of remote controller

at the same time.

The service screen appears.

Ending the service adjustment mode

1) Push the “Power switch” or “Menu” button on the main unit.

2) Push the “Power” or “Menu” button on the remote controller.

Operation (use the remote controller)

“ “ “ “ key ------ Selection of adjustment item (1 line)

“ “ “ “ key ------ Data adjustment

“OK” key ------ Enter

“Mute” key ------- reset the default value

5.1 Colour temperature adjustment

Average data has already been written in the Main Board for service parts.

You may not adjust it if there is no necessity.

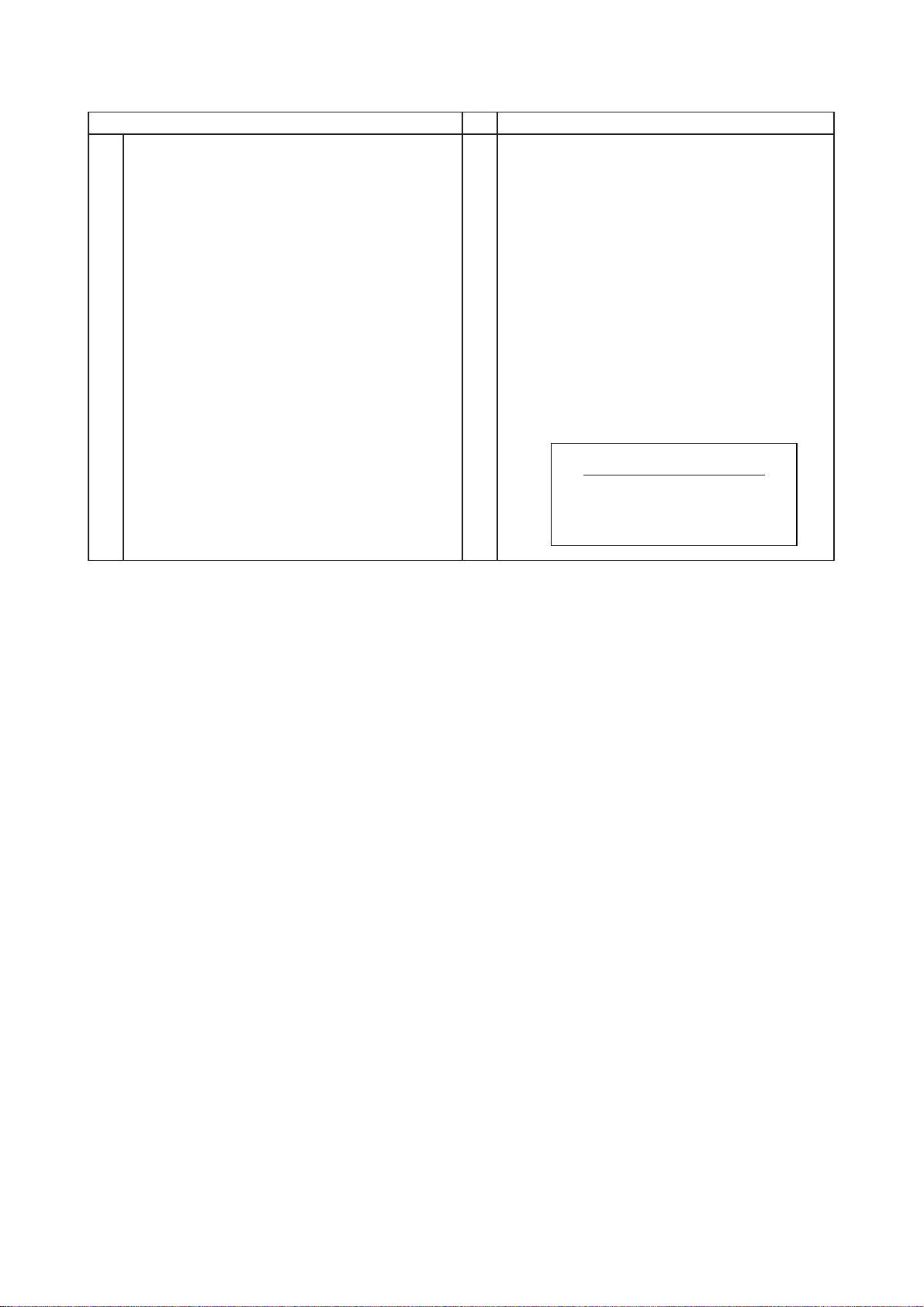

5.1.1 Colour temperature adjustment of “Cool” mode

Adjustment Preparations Adjustment Procedures

(1)

Adjustment signal: HDMI 1080i

Signal pattern: White raster

Video level: 90%

(2)

Picture settings: Factory setting, Check that the

mode is set as Factory Adjustment mode.

Picture mode: Dynamic

(3)

The colour analyzer (CA-210) should be proof

read by a spectrum radiation brightness meter

such as CS-1000 or standard LCD.

(4)

Set aspect to Full mode.

(5)

Set the colour analyzer (CA-210) at the centre

of the panel.

Set Factory Adjustment mode.

(1)

Check that the initial data of adjustment No.000,

(2)

No.001 and No.002 of service adjustment menu

is the following value. If the initial data is

different, set it to the following data.

Adjustment No.000=230

No.001=230

No.002=240

Receive a white raster signal. Step down either

(3)

R DRV_COOL (No.000), G DR V_COOL (No.001)

or B DRV_COOL (No.002) of the two (Or, one)

values and adjust to the following value.

(Note)

At least one of the data should be initial data.

Specification

Video colour temperature (Cool)

x㧩0.266 r0.005

y㧩0.270 r0.005

14000K r0MPCD

[Remarks]

(1) Colour temperature should be adjusted under the condition in which the screen is the brightest, thus the initial value

of adjustment is set at maximum. This adjustment only decreases brightness.

(2) Beware there is RESET in each of Picture mode.

(3) When adjustment number 000, 001 or 002 is selected, the colour temperature changes cool mode.

8

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

5.1.2 Colour temperature adjustment of “Normal” mode

Adjustment Preparations Adjustment Procedures

(1) Same as “Cool mode” adjustment.

(1) Set Factory Adjustment mode.

(2)

(3)

Check that the initial data of adjustment No.003,

No.004 and No.005 of the service adjustment

menu is the following value. If the initial data is

different, set it to the following data.

Adjustment No.003=224

No.004=224

No.005=224

Receive a white raster signal. Step down either

R DRV_NORMAL (No.003), G DR V_NORMAL

(No.004) or B DRV_NORMAL (No.005) of the two

(Or, one) values and adjust to the following value.

(Note)

[Remarks]

(1) Colour temperature should be adjusted under the condition in which the screen is the brightest, thus the initial value

of adjustment is set at maximum. This adjustment only decreases brightness.

(2) Beware there is RESET in each of Picture mode.

(3) When adjustment number 003, 004 or 005 is selected, the colour temperature changes normal mode.

At least one of the data should be initial data.

Specification

Video colour temperature (Normal)

x㧩0.285r0.005

y㧩0.293r0.005

9300Kr0MPCD

9

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

5.1.3 Colour temperature adjustment of “Warm” mode

Adjustment Preparations Adjustment Procedures

(1) Ssame as “Cool mode” adjustment.

Adjustment of colour temperature “Cool mode”

should be completed first.

(1)

(2)

(3)

Set Factory Adjustment mode.

Check that the initial data of adjustment No.006,

No.007 and No.008 of the service adjustment

menu is the following value. If the initial data is

different, set it to the following data.

Adjustment No.006=224

No.007=224

No.008=224

Receive a white raster signal. Step down either

R DRV_WARM (No.006), G DR V_WARM

(No.007) or B DRV_WARM (No.008) of the two

(Or, one) values and adjust to the following value.

(Note)

[Remarks]

(1) Colour temperature should be adjusted under the condition in which the screen is the brightest, thus the initial value

of adjustment is set at maximum. This adjustment only decreases brightness.

(2) Beware there is RESET in each of Picture mode.

(3) When adjustment number 006, 007 or 008 is selected, the colour temperature changes warm mode.

(4) Colour temperature Warm synchronises with the drive data of Normal colour temperature.

Therefore, when the drive data of Normal colour temperature is changed, the drive data of the Warm colour temperature

changes, too.

At least one of the data should be initial data.

Video colour temperature (Warm)

specification

x㧩0.314r0.005

y㧩0.323r0.005

6500Kr0MPCD

10

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

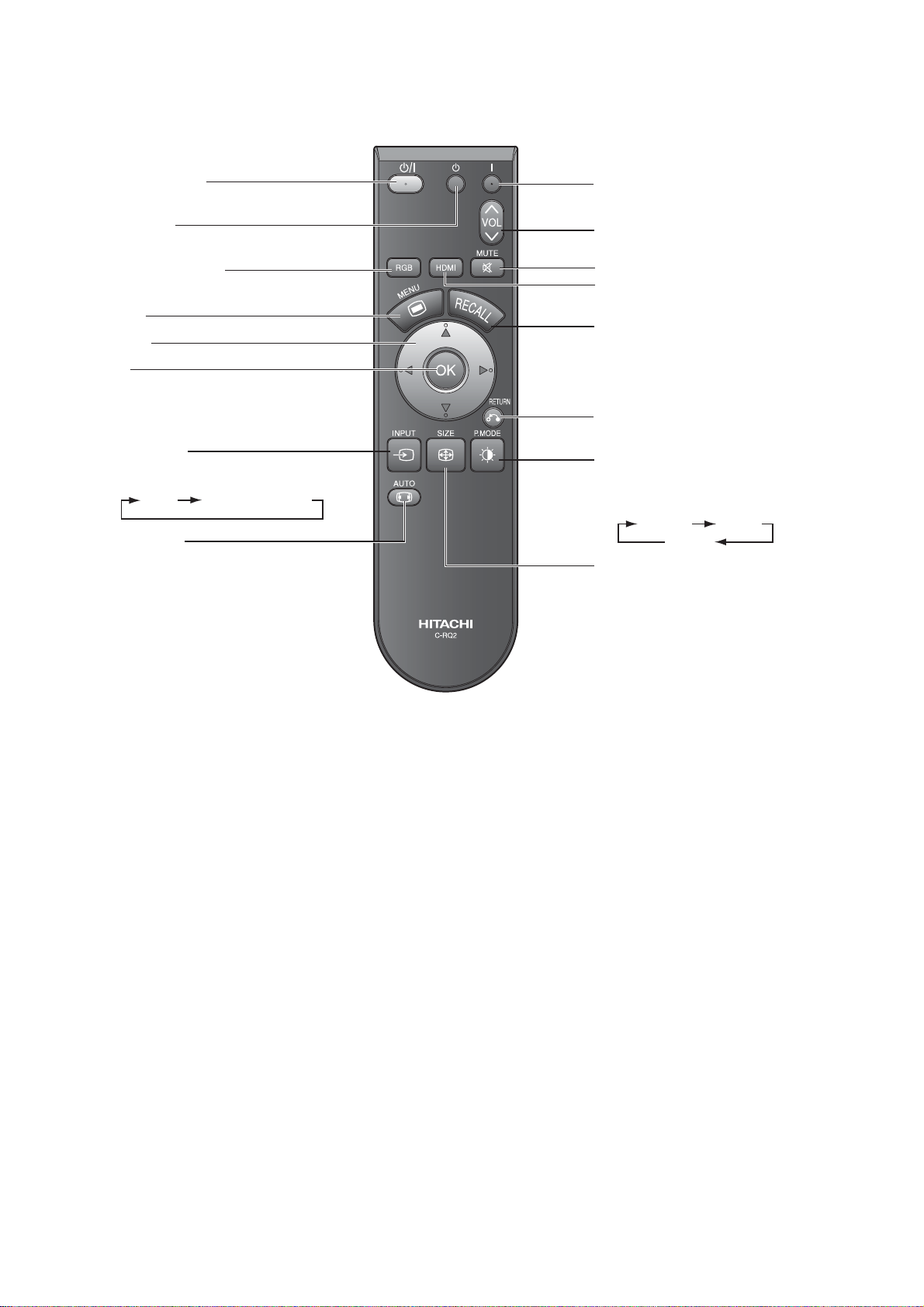

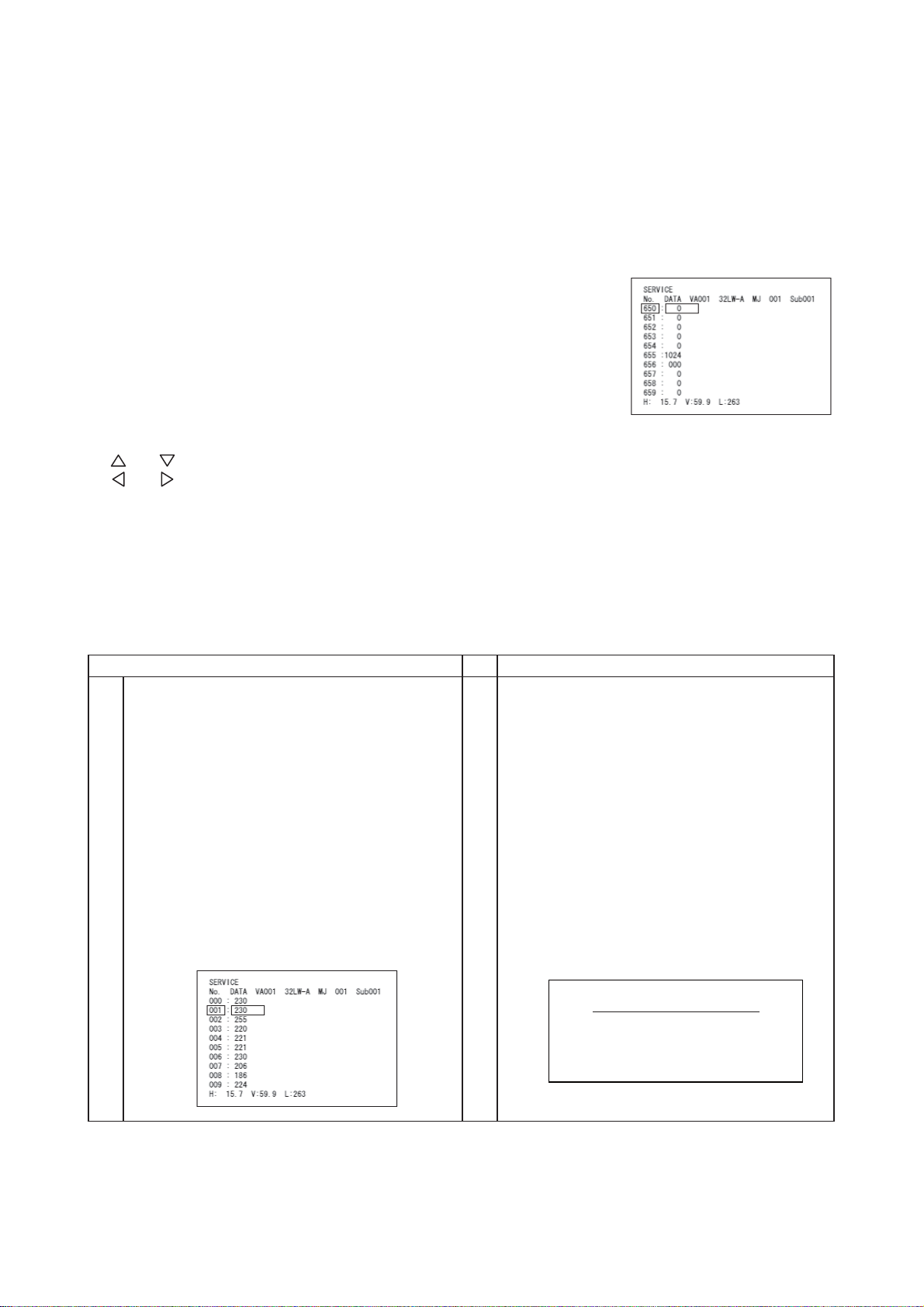

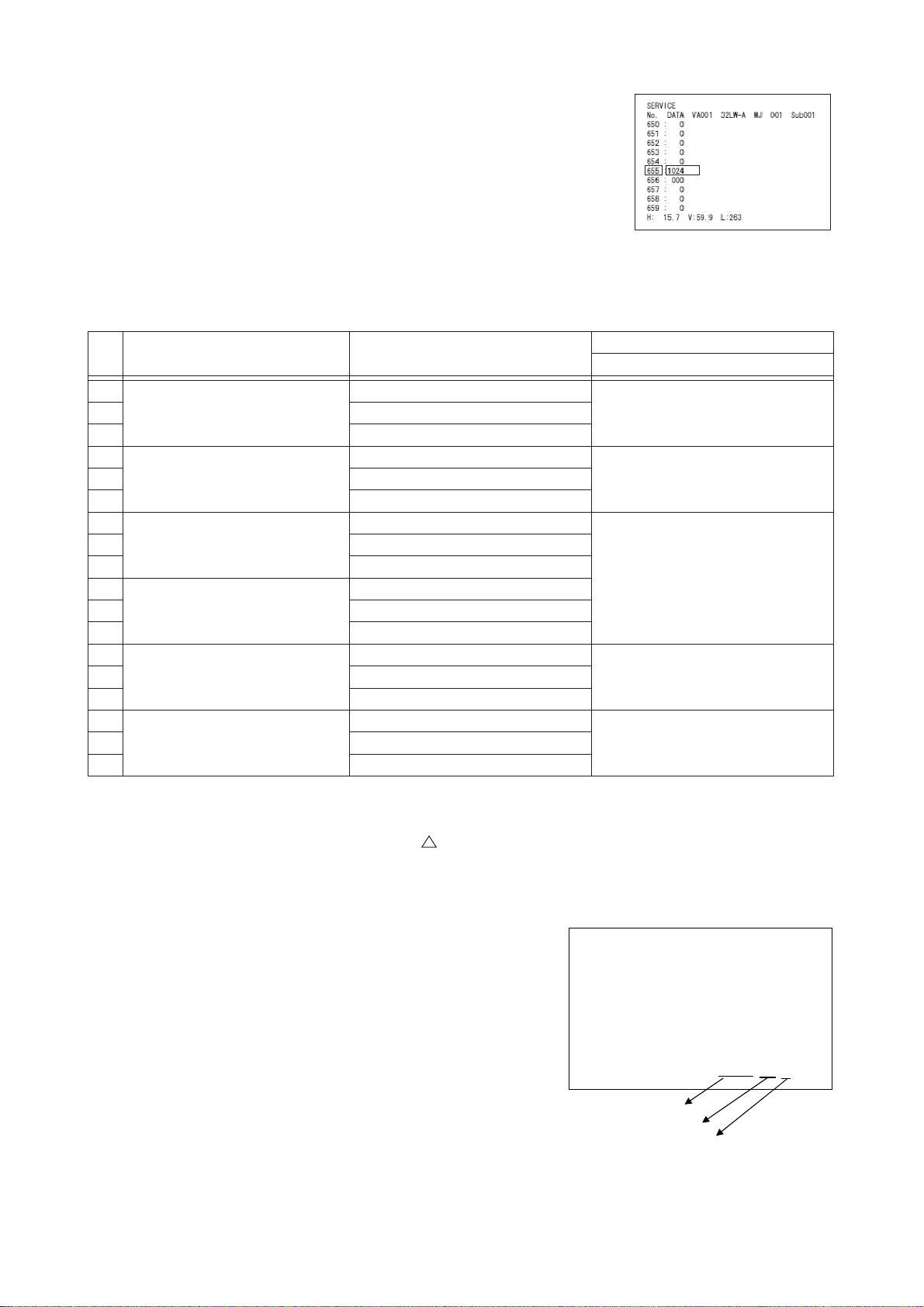

5.2 Special function

5.2.1 Accumulation time for Panel (hours)

The value of No.655 shows accumulated time (hours).

Reset when the value of No.654 is changed to “1” and “OK” button pushed.

5.2.2 Renew

(1) Change No.659 of the service adjustment menu from “0” to “1” and push

the “OK” button.

The picture will disappear and the initialisation will start.

(2) About 2 seconds later, the initialisation will finish and the picture will appear again.

Do not turn of the power until the picture appears again.

(3) Set adjustment item No.630 to the data in the following table for each model.

No. Destination

1

Japan

3 UT42-BX700J

4

USA

6 UT42X902

7

8 UT37MX70U

9 UT42MX70U

10

11 UT37MX70E

12 UT42MX70E

13

15 UT42-MX700A

16

18 UT42-MX708C

Europe (UK)

Europe

(Continent)

Asia

China

Model

Name

UT32-BH700J

UT32X802

UT32MH70U

UT32MH70E

UT32-MH700A

UT32-MH08C

Adjustment number

630: Custom Setting

42 UT37-BX700J

65 UT37X902

7

014 UT37-MX700A

317 UT37-MX08C

5.2.3 Factory Reset

(1) Turn off power. (Power indicator: Red)

(2) Turn on power while keeping pushed the “ “ button for 5 seconds or more.

5.3 Checking the software version

The software version is displayed on Setup (HDMI/Composite) menu.

Setup

Video Power Save Off

RGBInput Composite

Color System Auto

Select On/Off Return

VM200-20000-1

Main software ver.

Sub software ver.

Destination no.

Europe 07

Asia 00

China 03

USA 06

Japan 04

11

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

Instruction in software renewal

After software version up, set the following lists for reference.

Main Software Update

In this section, it explains the method of updating Main software.

This procedure should be processed only when it is necessary to update Main software.

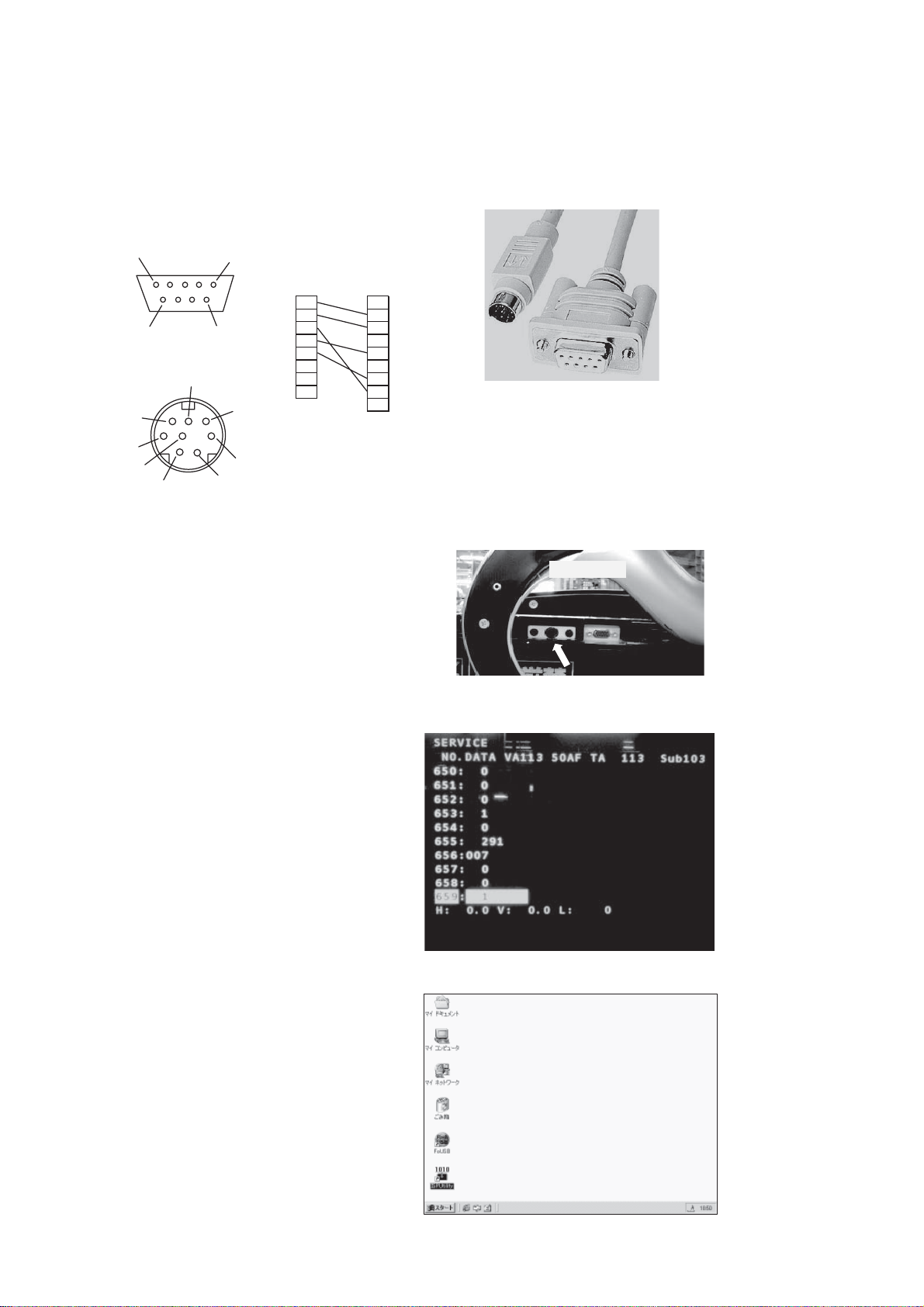

1) Prepare Dsub9pin-MiniDin8pin cable.

5

9

D sub 9pin

6

3

4

1

Mini Din 8pin

1

Mini Din 8pinD sub 9pin

1

2

6

7

8

5

2

37

4

5

64

7

82

9

8

6

5

3

1

2) Connect MiniDin8pin plug to Service terminal.

bottom view

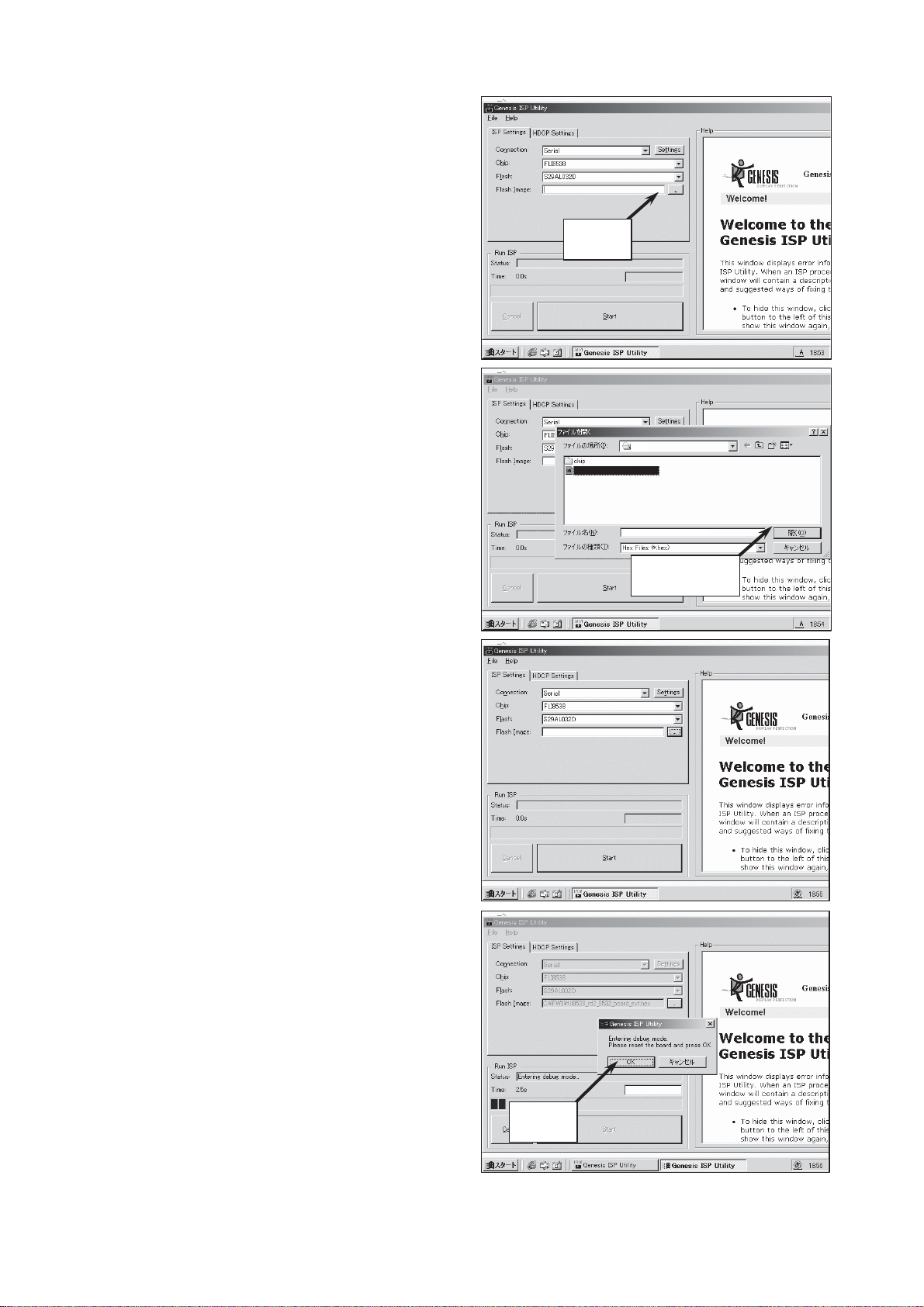

3) Press hold [Menu], [Recall] and [Return]

button on the remote controller until

appear the adjustment mode menu.

Select RS232C SW.

• Focus on No.653(RS232C SW).

• Press Right key (0 -> 1)

• Press “OK”.

4) Double click "ISP Utility" icon.

Double Click

12

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

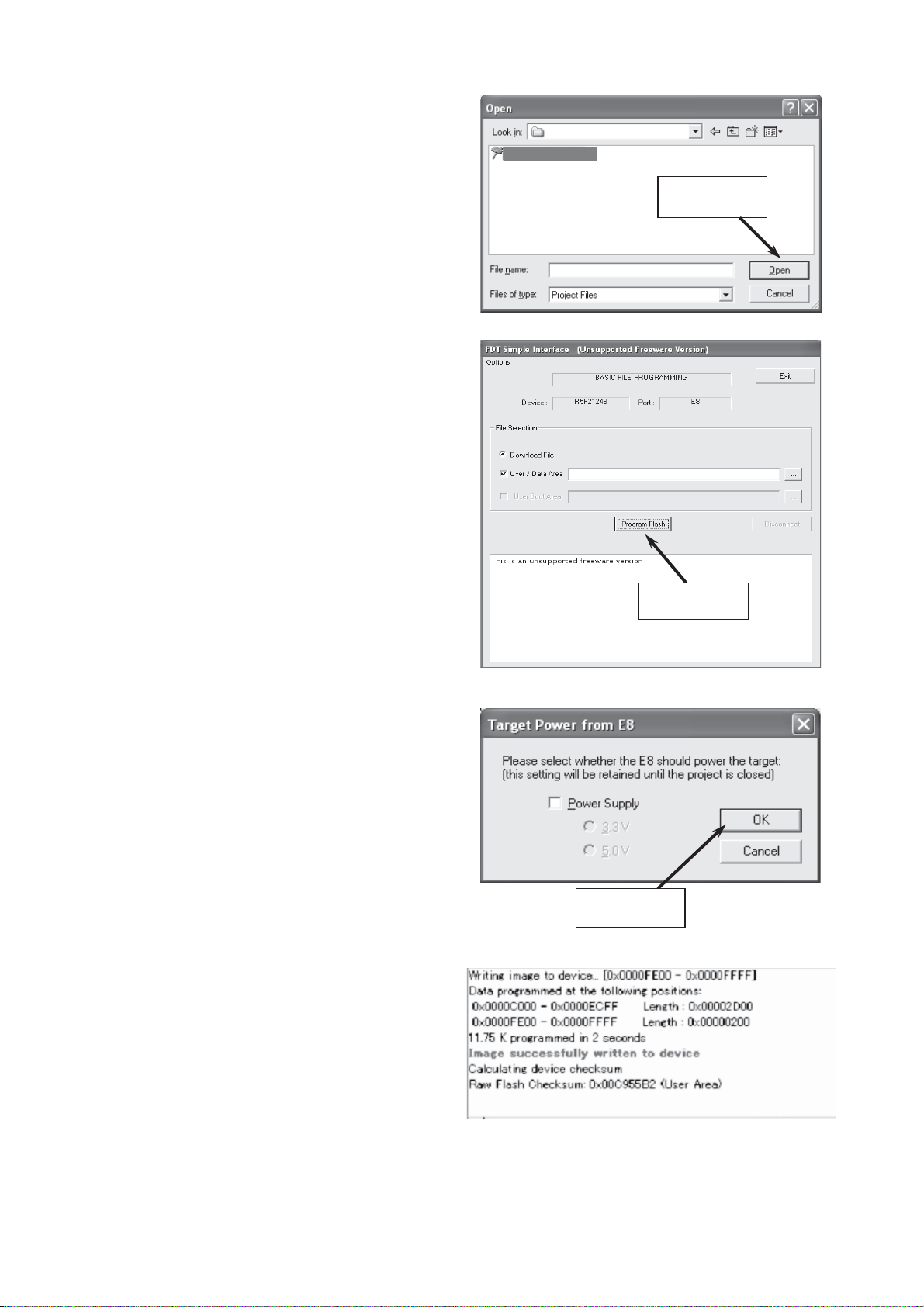

5) Select

Connection : Serial,

Chip : FLI8538,

Flash : S29AL032D,

and click Flash Image select button.

6) Select the new software

ex) ("D8M_VM200.hex")

Click

and click "Open".

7) Click "Start".

Then execute Erase, Program and

Verify.

D8M

D8M_VM200.hex

D8M_VM200.hex

Click Open

C:¥D8M_VM200.hex

8) Click "OK".

Click

13

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

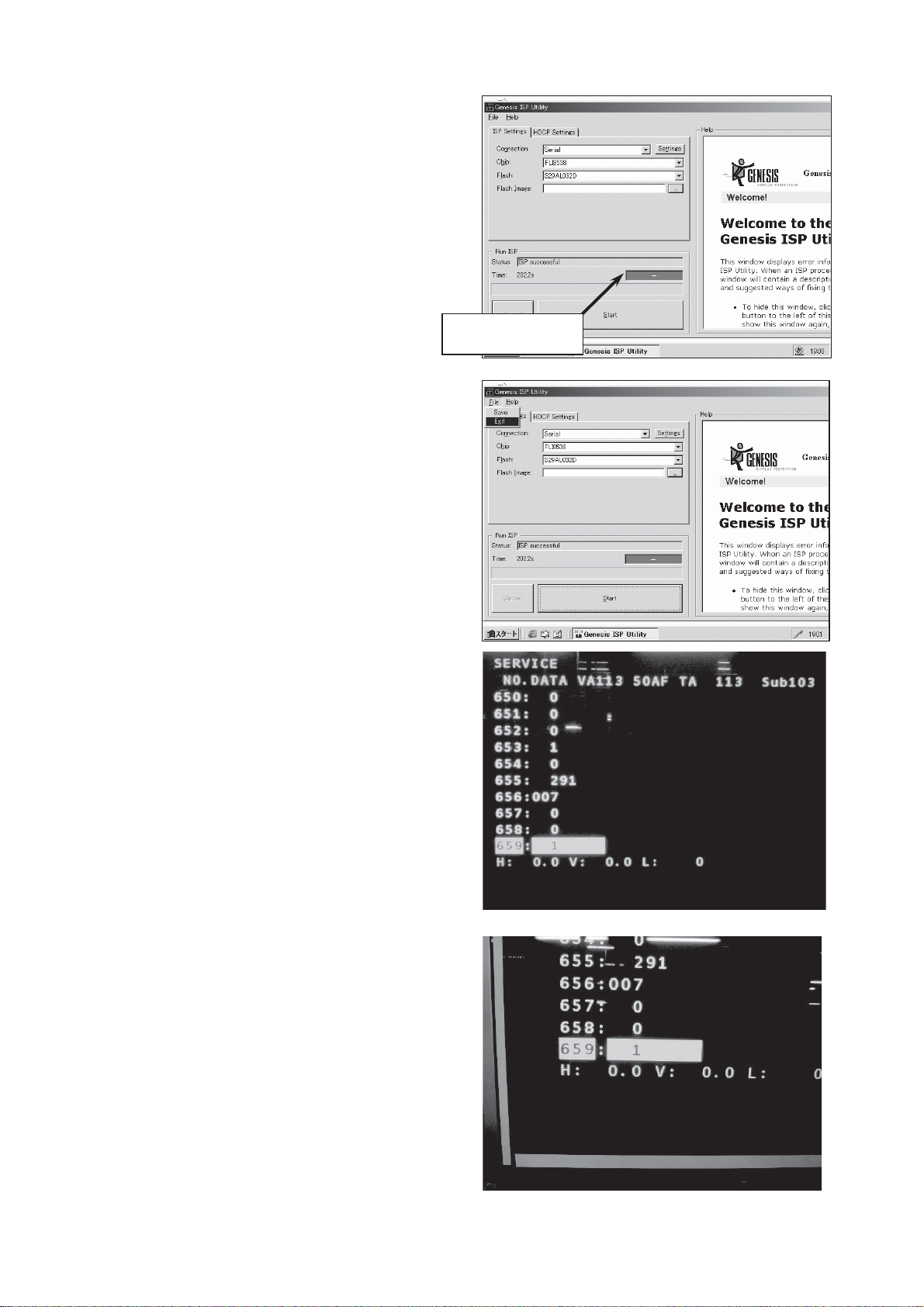

9) Wait about 200 seconds until

"ISP successful" appears.

(And appear Green display.)

10) Exit ISP Utility.

11) Turn off the TV set. (Unplug AC lead.)

12) Turn on the TV set again. (Connect AC lead.)

C:¥D8M_VM200.hex

Green display

C:¥D8M_VM200.hex

13) Press hold [Menu], [Recall] and [Return]

button on the remote controller until

the adjustment mode menu appears.

14) Focus on No.659 (EEPROM RENEW

operation) .

15) Press Right key (0 -> 1),

16) Press “OK”.

14

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

17) Wait until short blanking.

Then the value of No.659 will be changed to “0”.

(Finish EEPROM RENEW operation)

Both numbers should be same

18) Press VOLUME UP/DOWN and the cursor UP/DWON button.

• Focus on No.630 (Custom tuning). 0: ASIA, 3:CHINA, 4:JAPAN, 6:N-AMERICA, 7:EUROPE.

• Press LEFT/Right key and select an appropriate value.

• Press “OK”.

• Press “MENU” key and exit the adjustment mode.

19) Press hold [Menu], [Recall] and [Auto] button on the remote controller

for more than 5 seconds. (Start FACTORY RESET)

20) Turn off the TV set and remove MiniDin9pin connector.

15

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

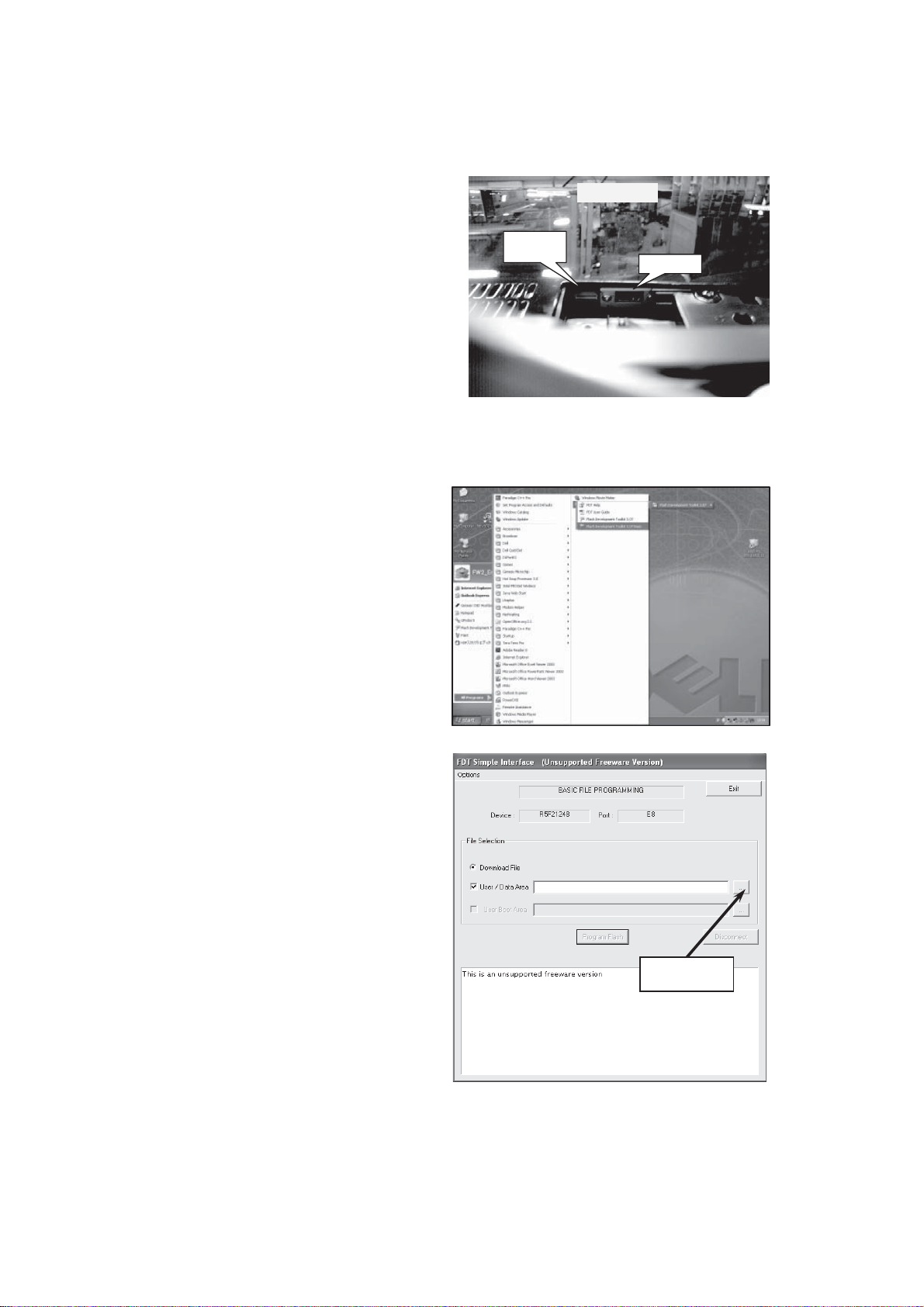

Sub Software Update

In this section, the method of updating Sub software is explained.

This procedure should be used only when it is necessary to update Sub software.

1) Turn off the TV set power.

2) Connect E8 or E8a and PC with USB

connection cable.

3) Connect the E8 or E8a to connector

PM02:ZH-10pin.

4) Start “Flash Development Toolkit 4.00 Basic”.

(Start > All Program > Renesas > Flash Development Toolkit 4.00 > Flash Development Toolkit 4.00 Basic)

㪧㪤㪇㪉

㪺㫆㫅㫅㪼㪺㫋㫆㫉

Rear view

㪟㪛㪤㪠

5) Select a download file. (ex. D8M_SUB_V200.mot)

Click

16

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

6) Turn On the TV set.

7) Click “Program Flash”.

D8M_Sub_ROM

D8M_SUB_V200.mot

Click

D8M_SUB_V200.mot

C:¥D8M_Sub_ROM¥D8M_SUB_V200.mot

Click

8) Click “OK” without selecting “Power Supply”. (start update)

Click

9) Wait until the message “Image successfully written to device” appears. (Finish Upadate)

(If necessary, verify the Flash Checksum.)

10) Click “Exit”.

11) Turn Off the TV set.

12) Remove the E8 or E8a from the connector PM02.

13) Turn On the TV set.

17

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

6. Troubleshooting

Burn-in mode

This mode displays the test patterns of single colour rasters in turn. These signals are from the built-in generator of the panel. It can be presumed that the panel has a fault when the screen of Burn-in mode is abnormal.

To activate the mode, use the remote control with the set turned on.

(1) Set the service adjustment mode.

(2) Change No.646 from “0” to “1”. After a few second, the burn-in picture appears.

(3) To escape this mode, change No.646 from “1” to “0”.

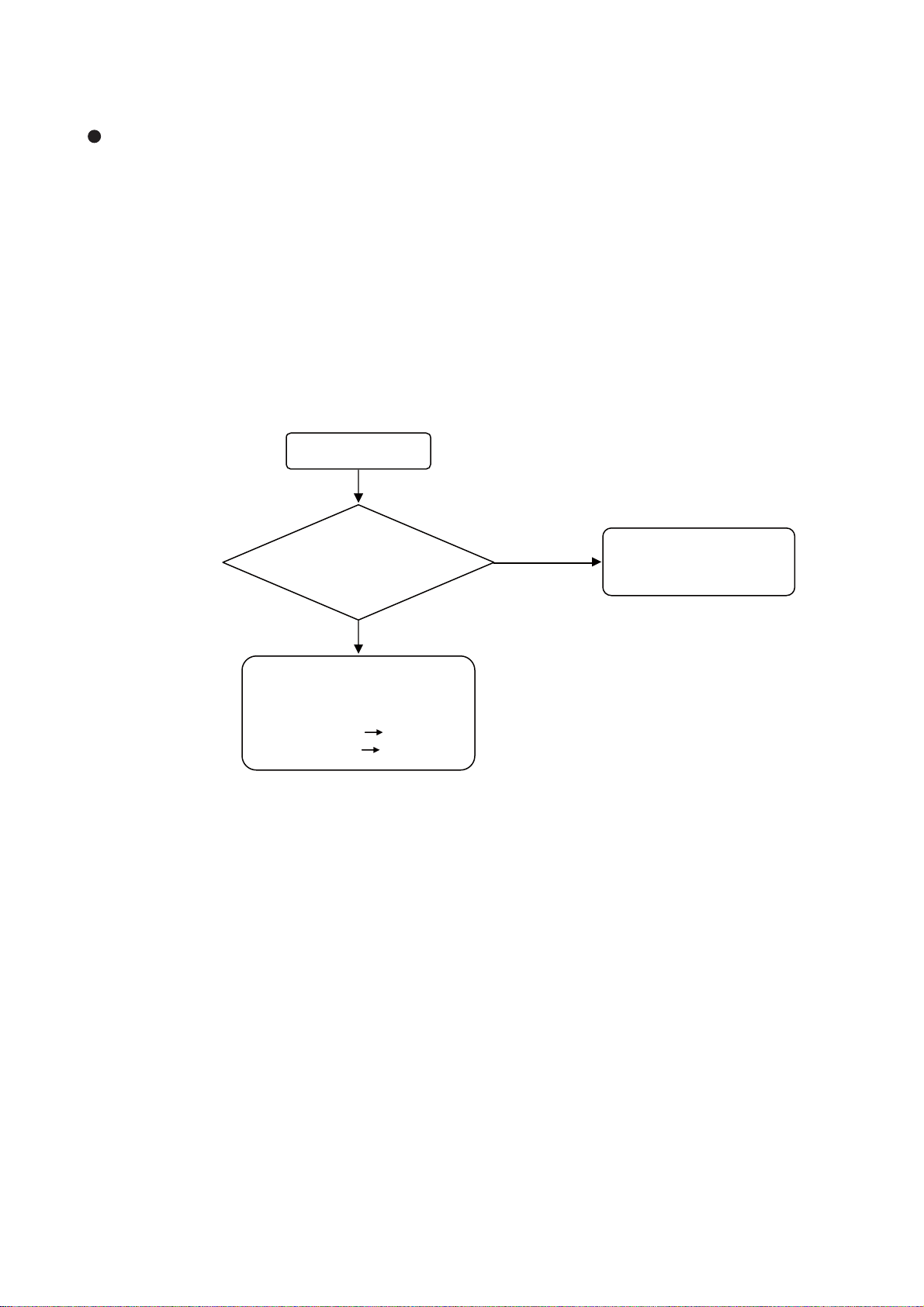

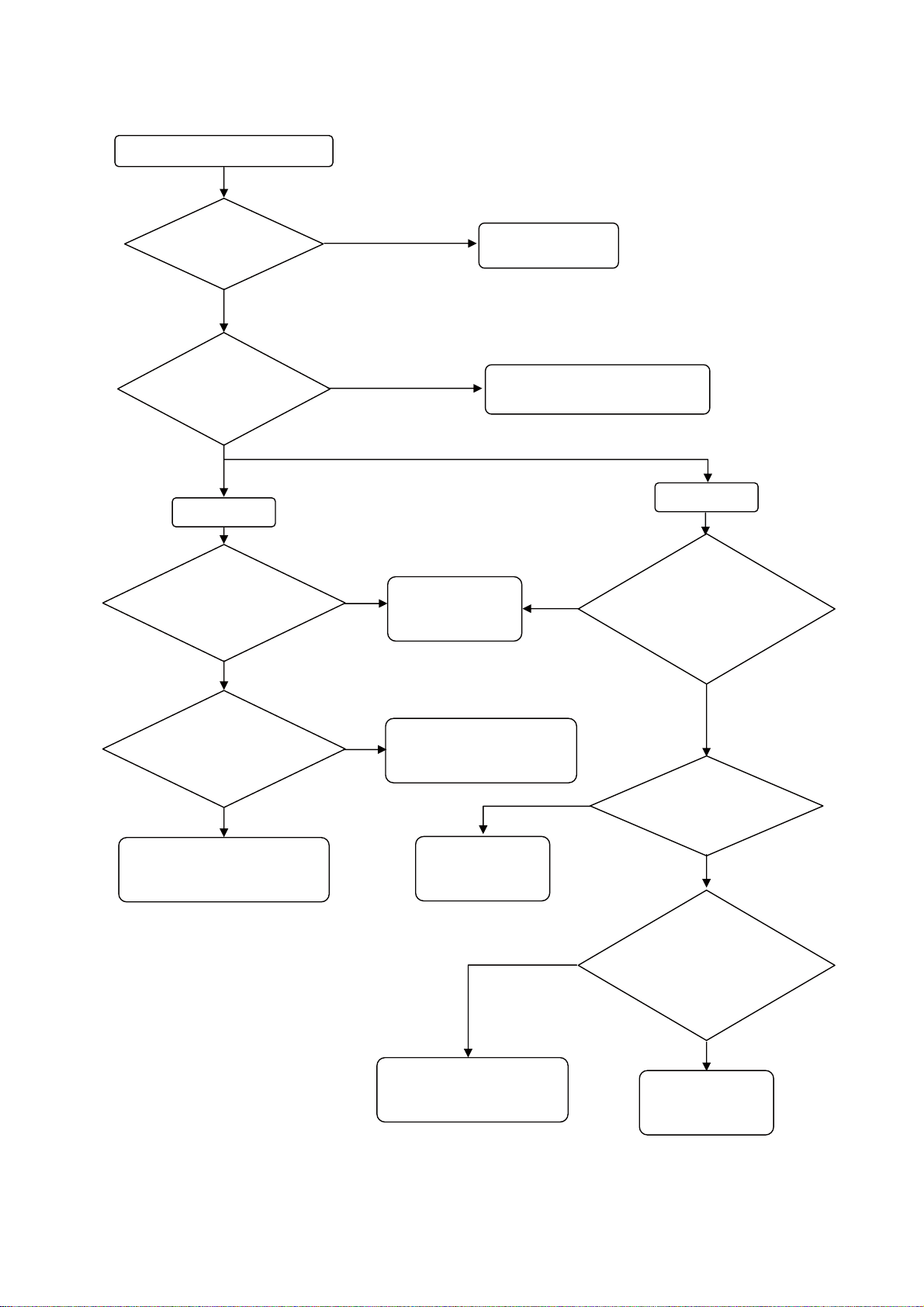

[no picture, no sound]

ԘLED does not light.

Is the voltage of

pin 5 (+5.4V) of CNPS

(power supply unit)

normal?

Yes

Main Board or Terminal

Board fault.

Picture fault Go to “A”

Sound fault Go to “B”

No

Main Board or Power

Supply Unit fault.

Please change.

18

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

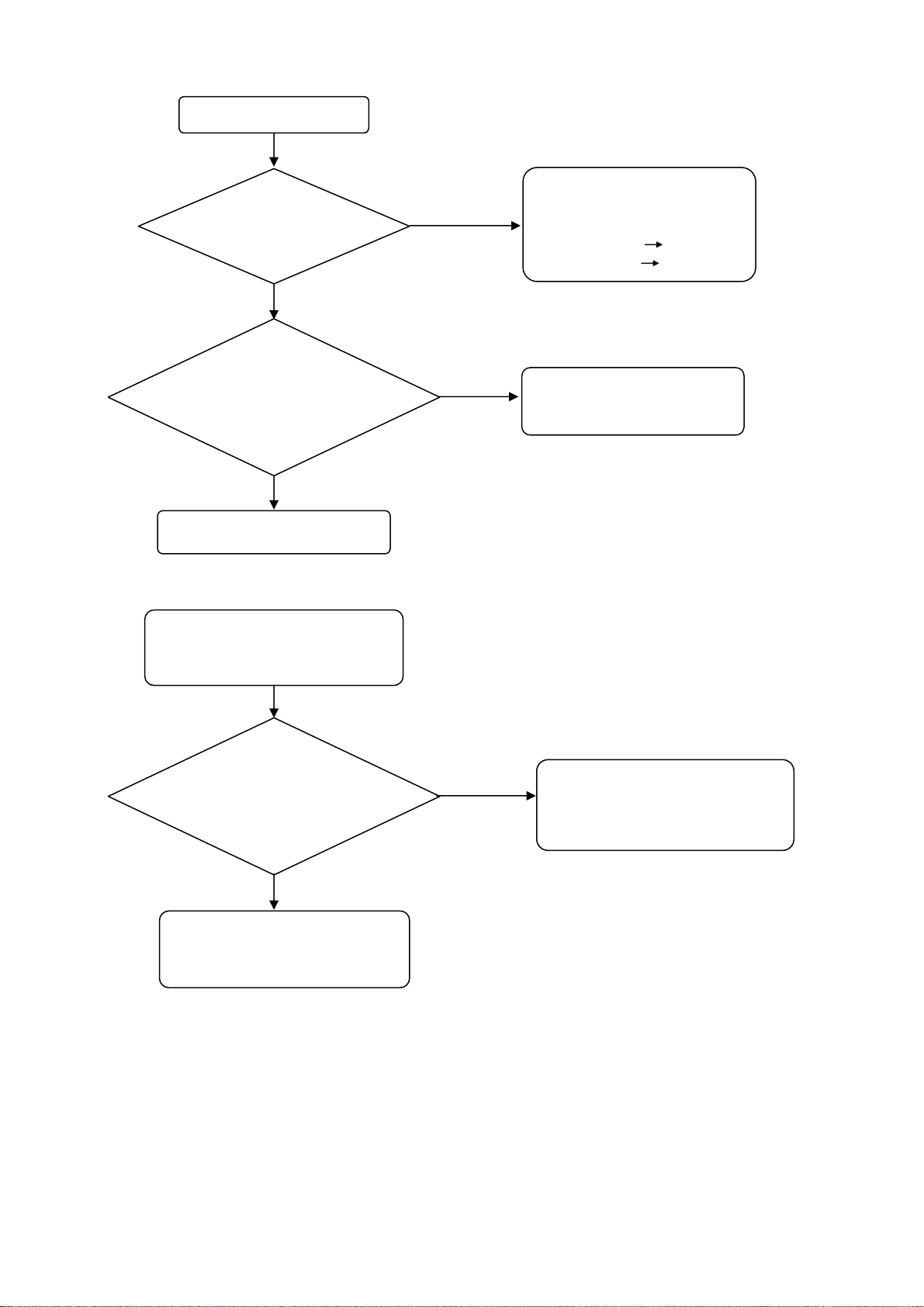

ԙLED lights Green.

Is the burn-in

mode normal?

No

Are the voltages of

pins 1-5 of CNPP1 and pins 1-5 of

CNPP2 (power supply unit) normal?

Normal voltage is +24V.

Yes

Yes

No

Main Board or Terminal

Board fault.

Picture fault Go to “A”

Sound fault Go to “B”

Power Supply Unit fault.

Please change.

Go to # 1

ԚAfter a few seconds, lights

Red even if power is turned on.

Main PCB -- Inverter PCB

PPO1(pin 10) -- CN2(pin 12)

PPO1(pin 11) -- CN2(pin 14)

Are these connected?

Yes

Main Board or LCD Panel

(including Inverter Board) fault.

Please change.

No

Power Supply Unit fault.

Please change.

Or please check ELCD2 connector

or EPS connector.

19

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

# 1

Does the backlight

turn on?

No

Is there a voltage

at pin 9 of CNPS

(Power supply unit)?

Yes

Inverter Board fault.

Yes

No

Are the voltages of

pin 1-4 (+12V) of PDO1

(Main PCB) normal?

Yes

LCD Panel Module

fault.

Main Board fault.

Please change.

No

Main Board

fault.

Please change.

20

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

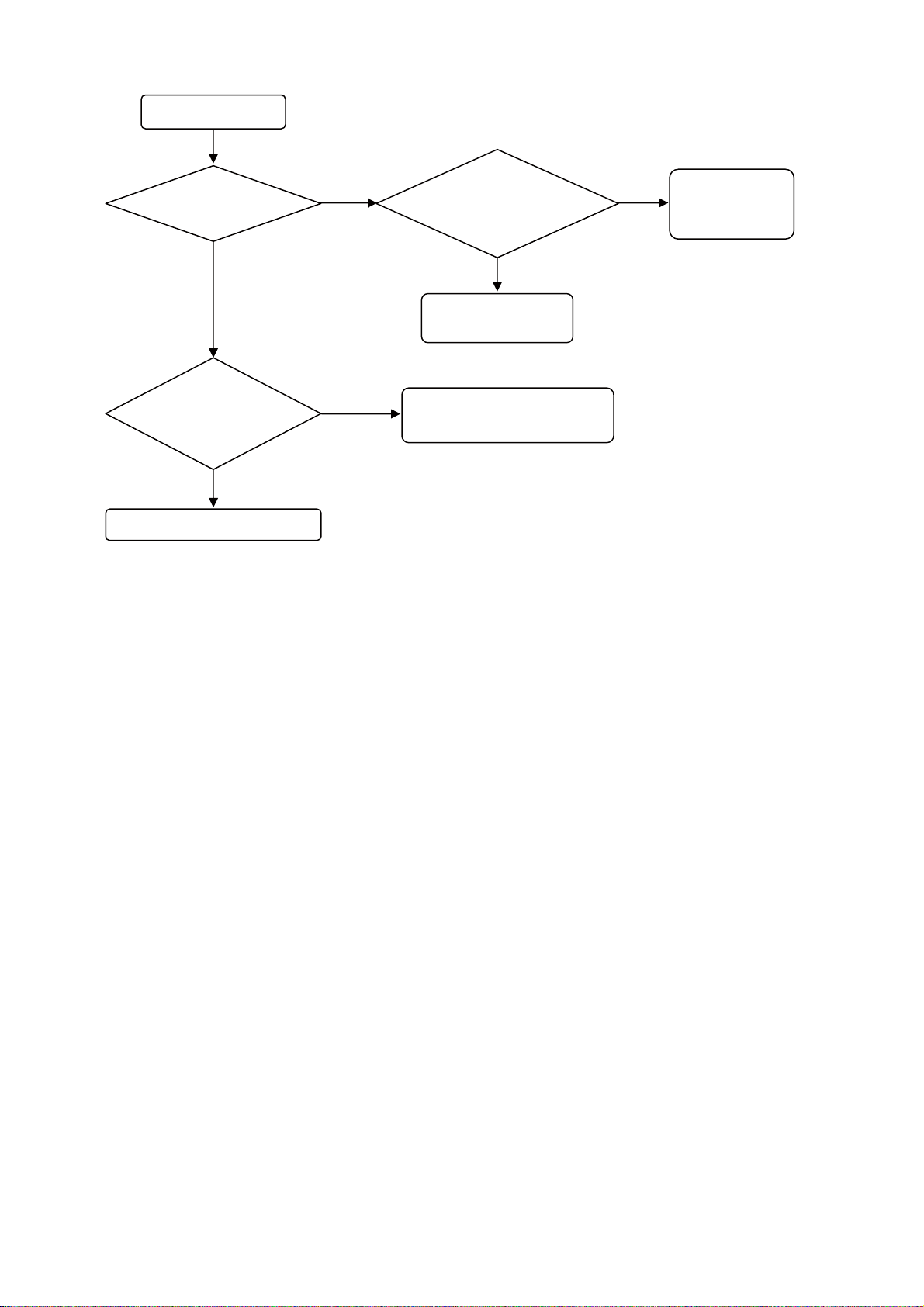

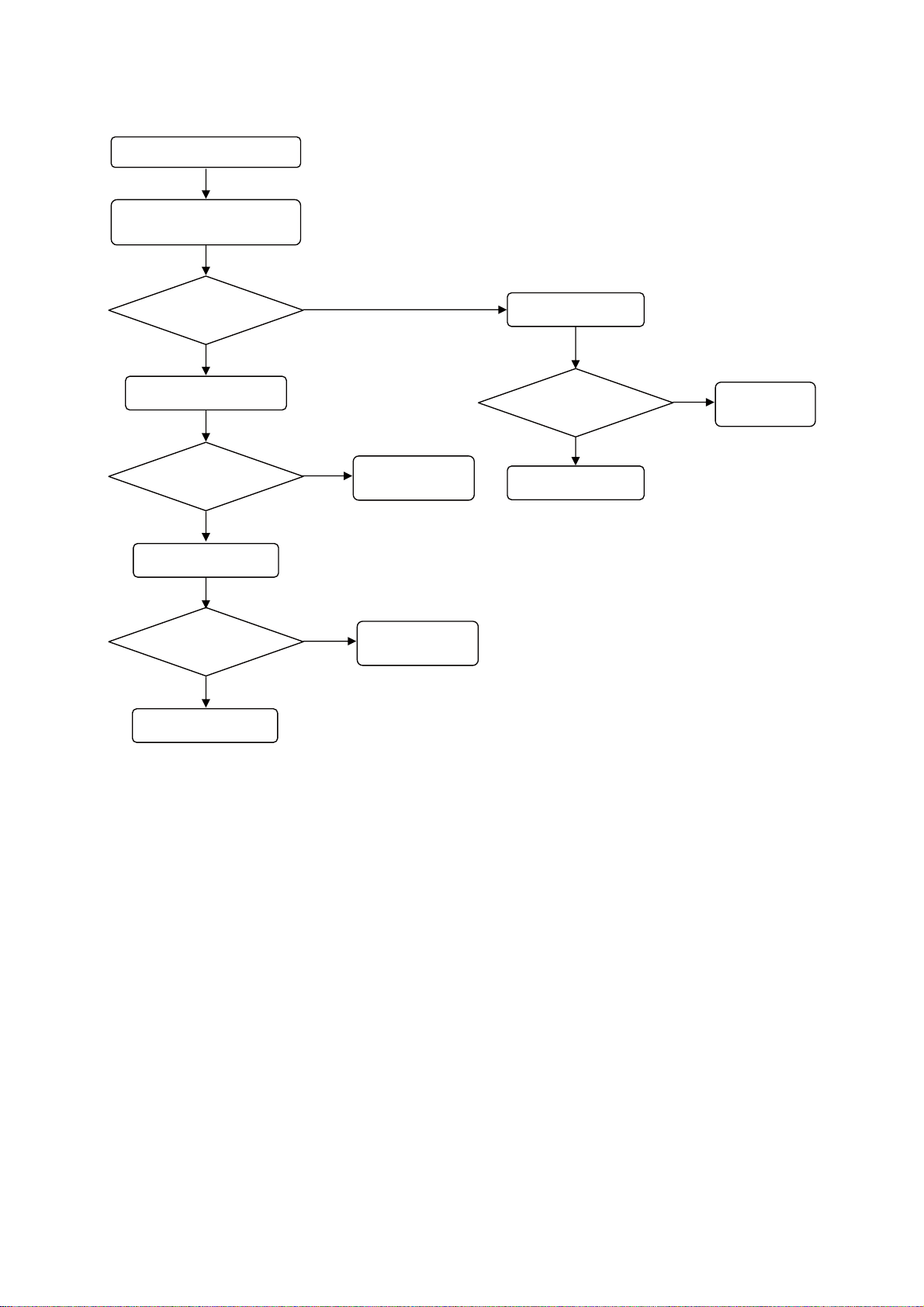

A : Picture Troubleshooting

No picture, no colour or dark

Check the picture menu.

Are there problems?

No

Are the voltages of

pin 7 and 9 (+5V) of PV01

(Main PCB) normal?

Yes

RGB Input

Are there

signals (R,G,B,H,V) at

CE12-CE14,RE49 and

RE50 on Main PCB?

No

Yes

No

Yes

IA01 fault

on Main Board.

Please change.

Adjust the picture

menu.

IR/PW-SW Board fault.

Please check EISP connector

Yes

signals(R(8bit),G(8bit),

B(8bit),H,V,DE,CLK) at

RH33,RH35,RH37 and

RH39 on Main PCB?

HDMI Input

Are there

Are there

signals(R,G,B,H,V) at

CE06-CE08 and

IW01(pin1, 13) on Main

PCB?

No

EFFC Connector on Terminal

Board or PW01 on Main Board

fault.

Yes

QE01-QE03 or IE01 fault

on Main Board.

Please change.

IH01 fault on the

Main Board.

Please change.

Q001, GH01 or DH034

fault on Main Board.

Please change.

No

No

No

Are there signals(TMDS)

at RH60-67 on Main PCB?

Yes

Is there voltage at

pin 18 (+5V) of JH01 (Main

PCB) and is there

voltage(over +2.4V) at

pin19 of JH01?

Yes

IH02 fault

on Main Board.

Please change.

21

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

B : Sound Troubleshooting

No sound, abnormal sound

Check the signal at the P301

on Terminal Board.

Is there signal

Change Terminal PCB

Has it been

improved?

No

Change EFFC cable

Has it

improved?

No

Change Main Board

Yes

Yes

Yes

Terminal Board

fault.

EFFC Cable

fault.

Change speaker.

Has it been

improved?

No

Change EISP cable

Yes

Speaker

fault.

22

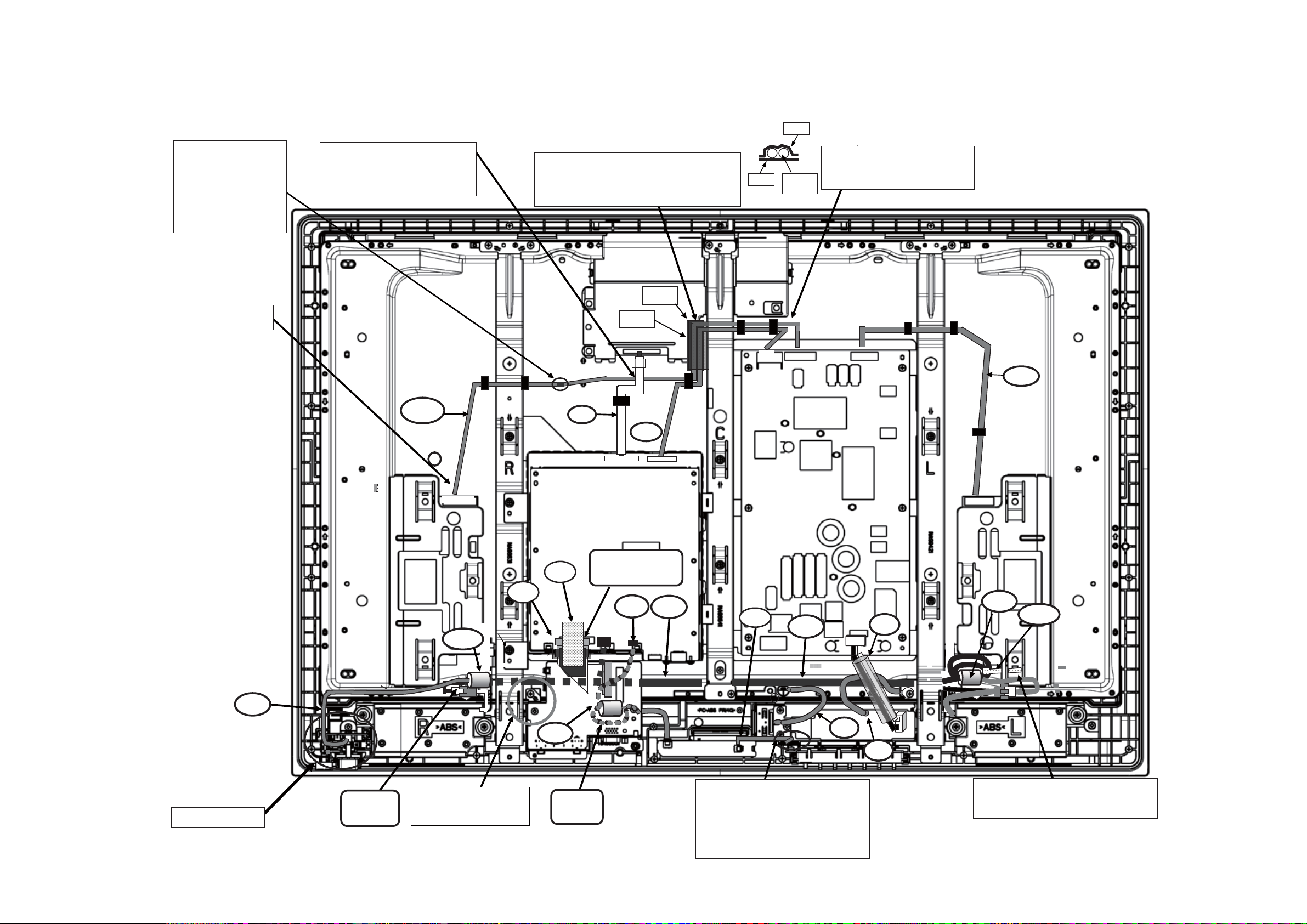

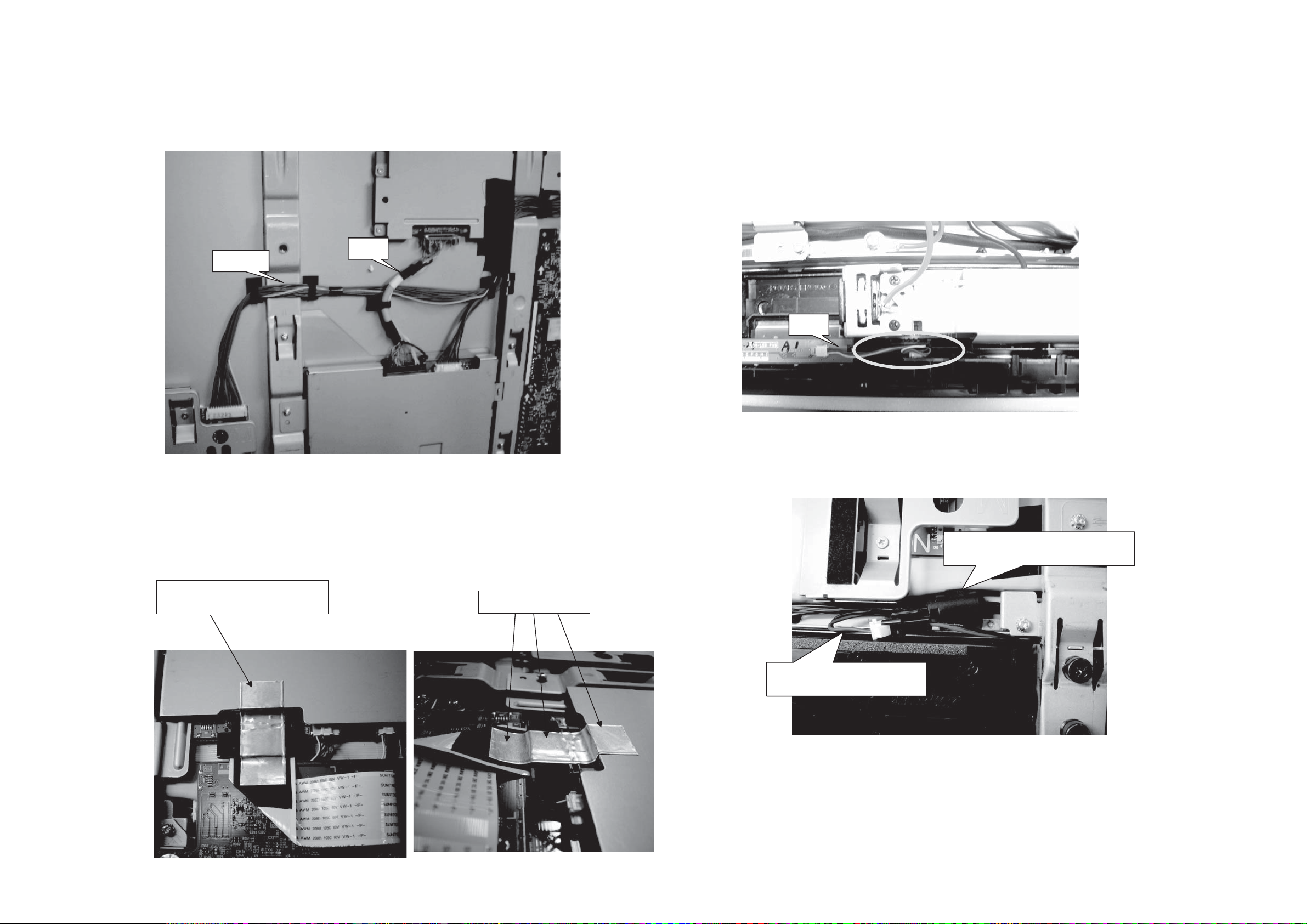

7. Wiring diagram

UT32-MH70U/E Wiring diagram-1

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

#266

Do the styling so

that the binding tape

of “ELCD3” does

not pass the upper

the frame. (Prevent it

from touching with the

back-cover.)

Insert securely.

1) Insert the white tape side of

"ECN" in the T-com board.

2) “ECN" must pass on “ELCD3”.

*Refer to photo 1 (page80)

'.%&

1) Stick the tape(#246 Nitto tape p#944545W)

to the shielding case of the T-CON board.

2) Put “EPS" and “ELCD3” on the tape(#246).

3) Stick the tape(#266 Nitto tape) on that.

'%0

'25

#264

ELCD3

EPS

Do the styling so that the wire

does not pass the upper part of

the shielding case.

'.%&

'+52

IR/POW SW board

RKP

Detail-1(page79)

Photo2(page80)

'((%

'.5

'+52

'-.

'+52

'27

052-

052-

052-

'

'

Fix with SK binder(#NSPK) so that the

wire of “EISP" does not touch the filter

board. *Refer to photo5 (page81)

Photo 4

(page80)

Please do not damage the

cable when exchanging

the Terminal board.

0'.5

Detail-2

(page79)

The wire of “EKL" must pass between

the KEY_SW board and the case and

allow loosening.

(It is to prevent the electric wire being

pinched when tightening up a screw.)

*Refer to photo3(page80)

23

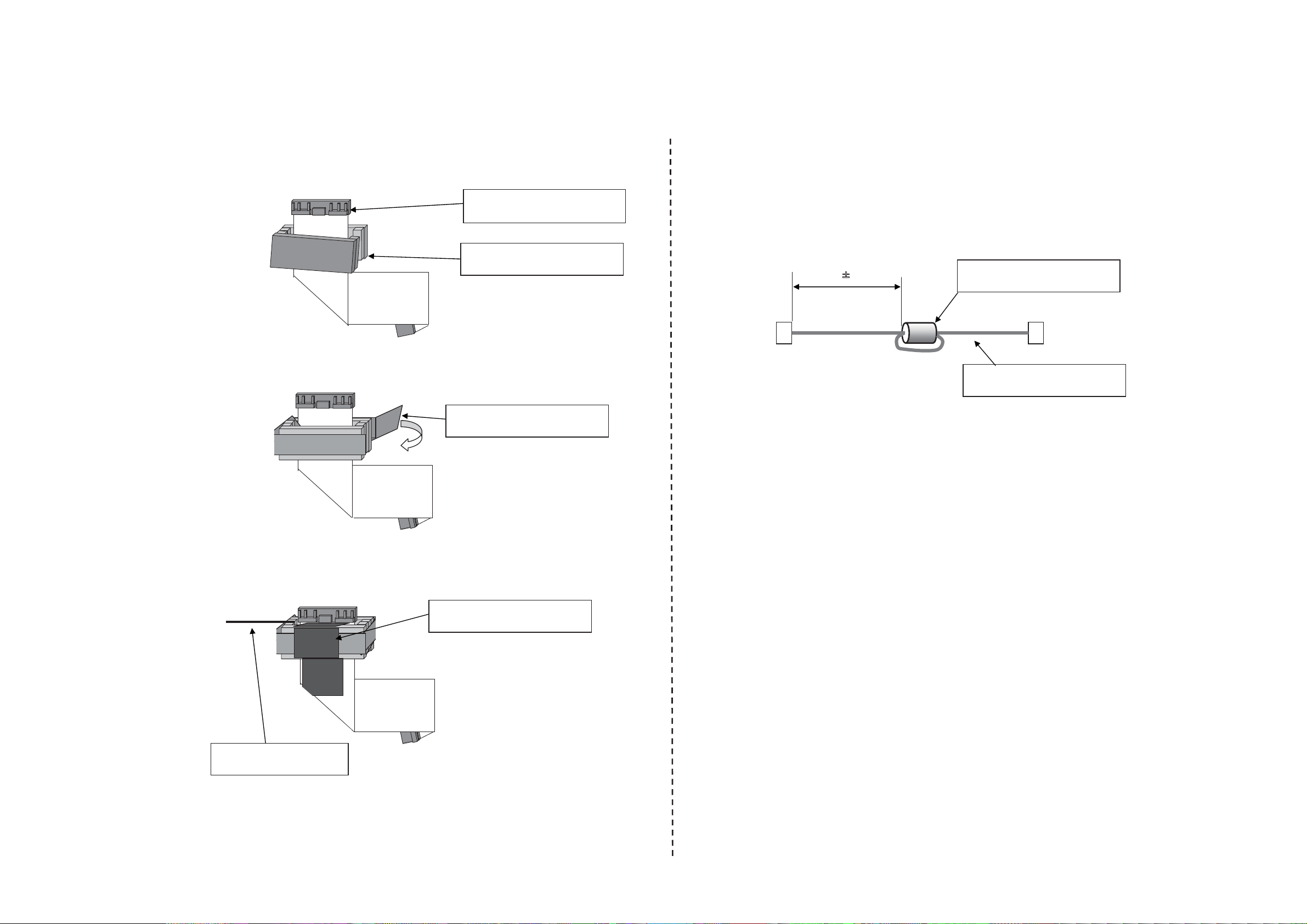

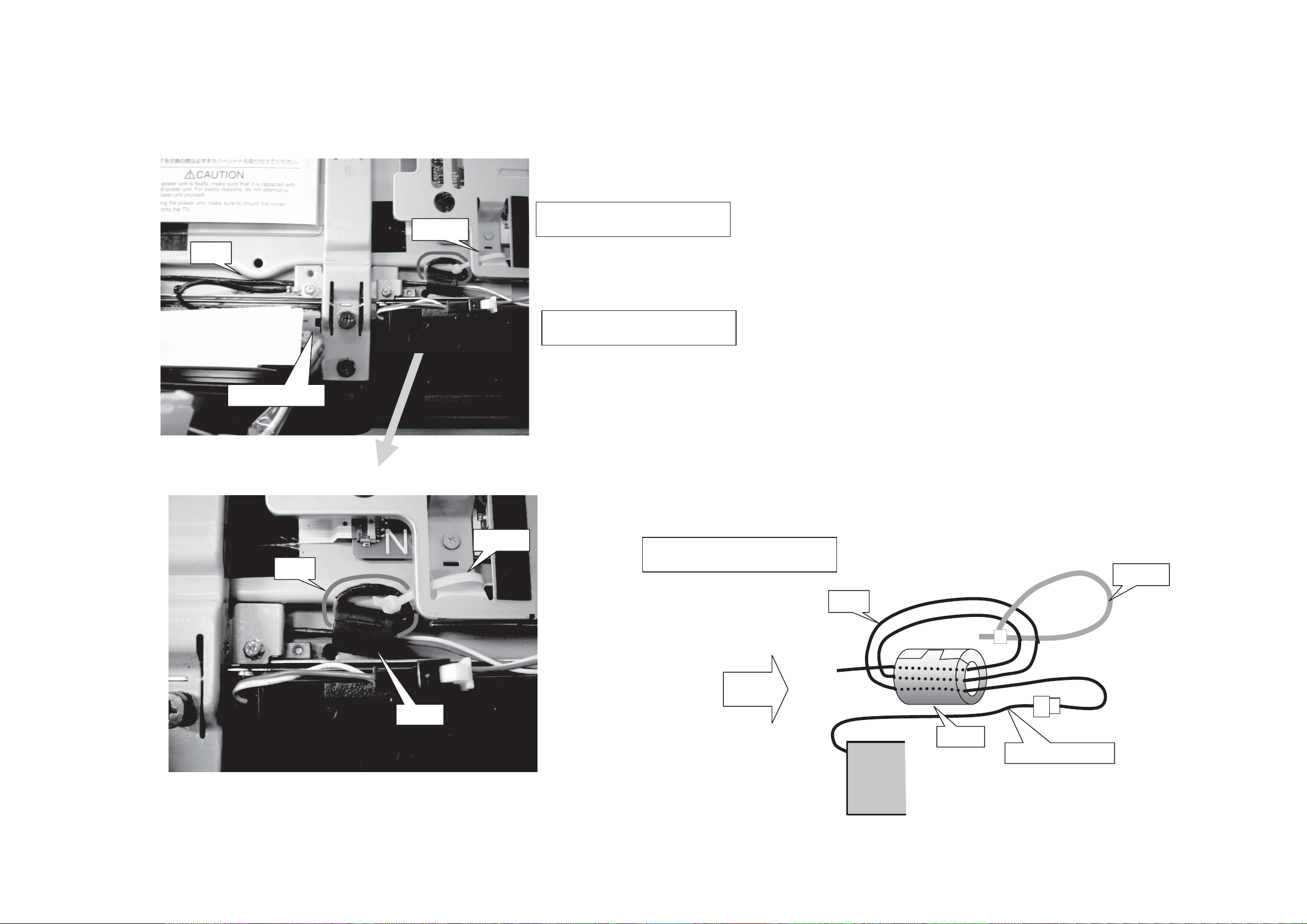

UT32-MH70U/E Wiring diagram-2

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

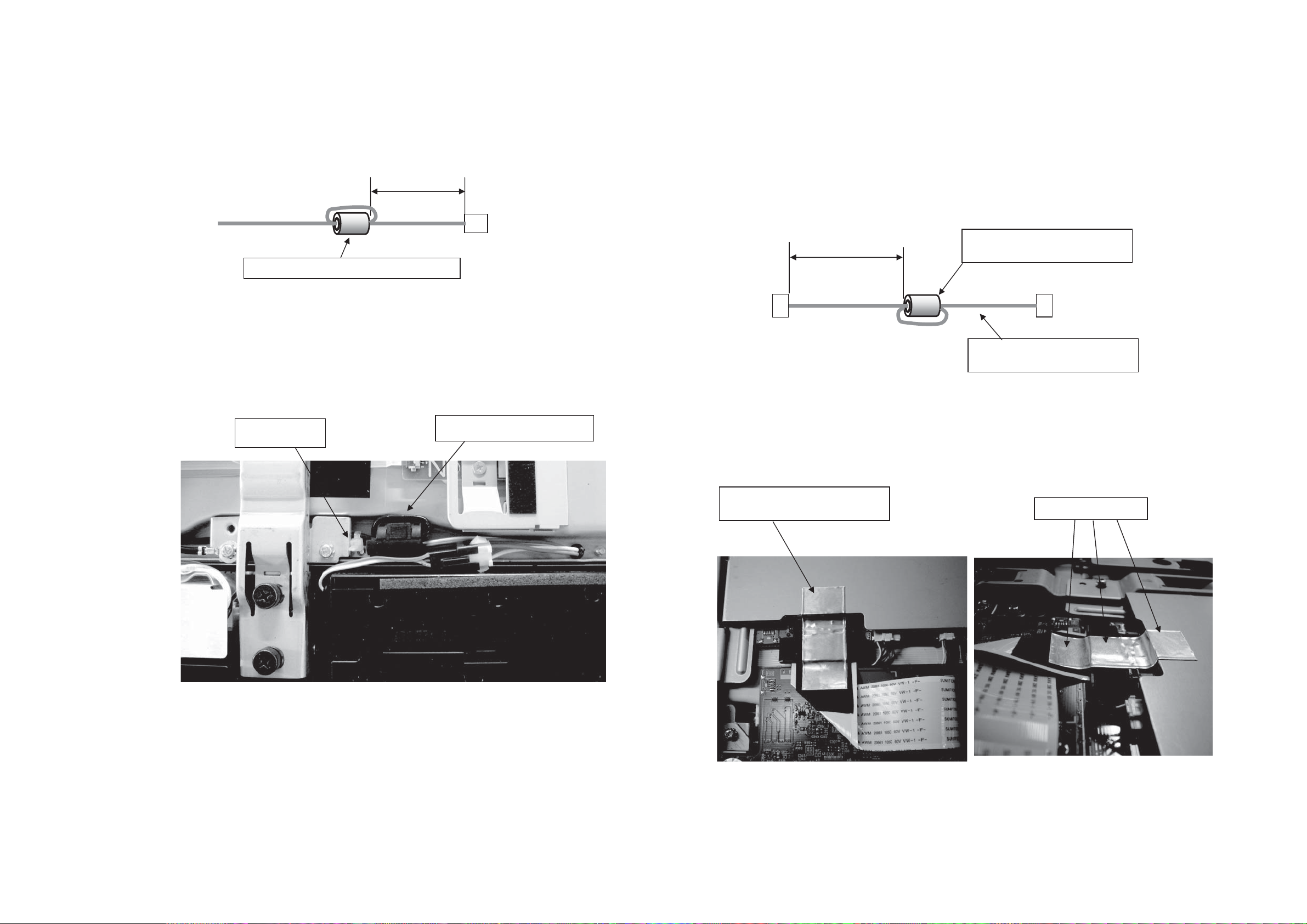

[ Detail-1 Pre-operation ] [ Detail-2 Pre-operation ]

(1) Set the ferrite core (N001) in EFFC.

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

EFFC PRW50FC0R5-131-20861

(p #: EK01902)

N001 MAG-FSRC400120RTF10T

(p #: GX00771)

(1) Set the ferrite core (NELS) in ELS. 1turn.

Pass the terminal board under.

60mmr

Main board side

(2) Wrap the tape(#WN01) around the ferrite core(N001).

#WN01 Nitto tape No.5 W=9mm

(P#9449507W) L=100mm

5mm

NELS MAG K5CRC12X15X7-MB2

(p㧏㧦GX00738)

ELS CO-06C-C1R0-201-LOCK

(p㧏㧦EF24946)

(3) Fix the ferrite core(N001) with the tape(#WN02).

Set the ferrite core(N001) in the

connector edge side.

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

57/+ 57/+ 57/+

#WN02 Nitto tape No.5 W=25mm

(P#9449538W) L=35mm

24

UT32-MH70U/E Wiring diagram-3

(1) “ECN" must pass on “ELCD3”.

ELCD3

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

(3) The electric wire of “EKL" must be pushed between the KEY_SW board and the case,

and allow loosening.

ECN

EKL

(2) How to stick aluminum tape

#360 D8MW SIGNAL SLD TAPE

(p# : MD20801)

(4) Set the ferrite core (NSPK2) in EISP.

NSPK2 MAG K5CRC12X15X7-MB2

(p#:GX00738)

Paste fit without space.

EISP CO-10C-C***-871-ASS

(p#:EF28881)

25

UT32-MH70U/E Wiring diagram-4

K

K

(5) Set the ferrite core (NSPK) in EISP.

EISP

#NSPK

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

#NSPK SK-binder

(p# : 3763751)

Filter Assembly

EISP

NSP

#NSPK

NSPK MAG K5CRC12X15X7-MB2

(p# : GX00738)

#NSPK SK-binder

(p# : 3763751)

EISP

Double wrap the EISP cable in the core (NSPK).

#NSPK

NSP

NSPK

Speaker cable

Speaker assembly

26

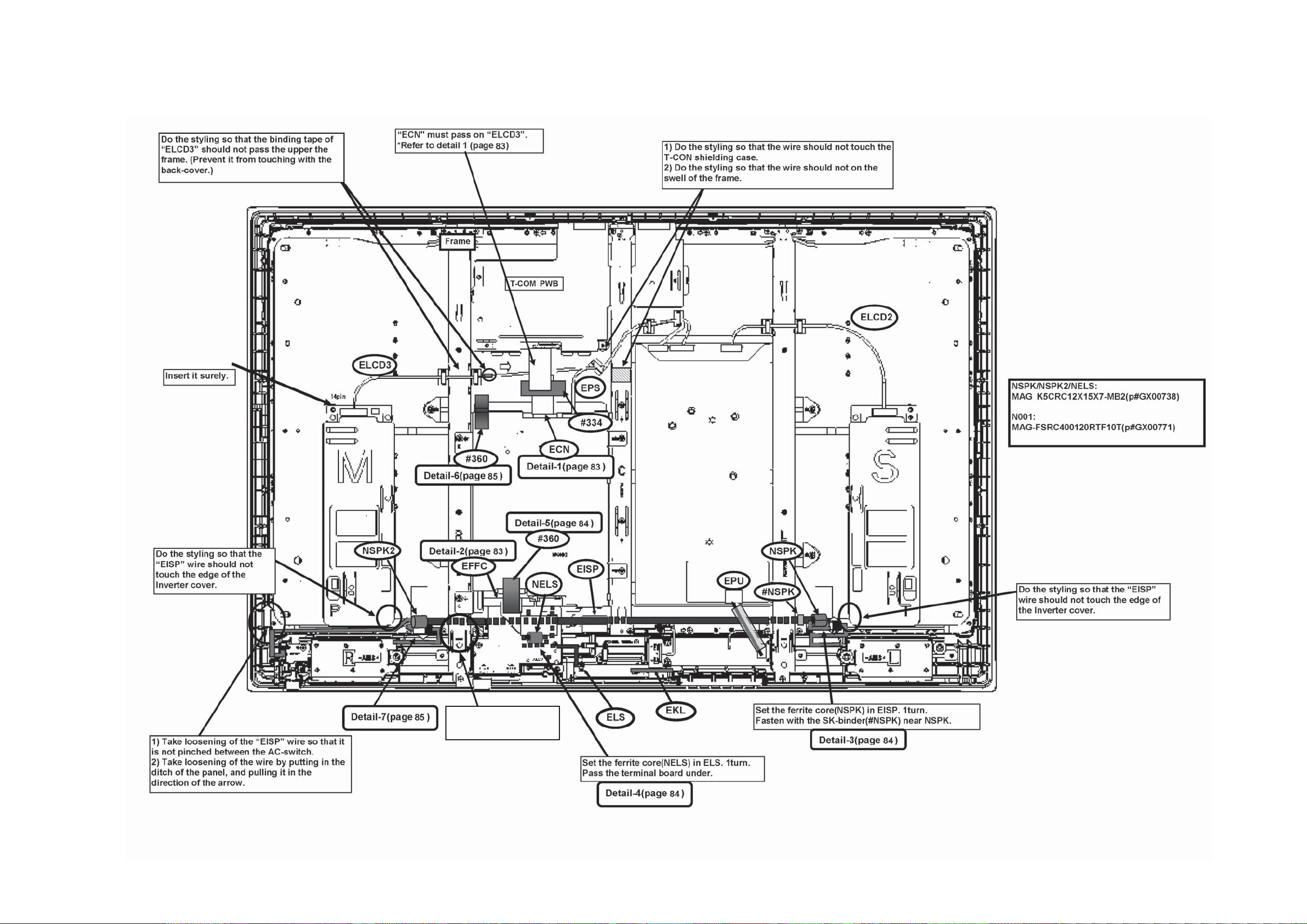

UT37-MX70U/E Wiring diagram-1

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

Please do not damage the

cable when you exchange

the terminal PWB.

27

UT37-MX70U/E Wiring diagram-2

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

[Detail-1 and Pre-operation] [Detail-2 and Pre-operation]

(1) Paste the Nitto tape(#ECN) on the backside of ECN(p#EF29004). (1) Set the ferrite core(N001) in EFFC.

#ECN

Nitto tape No.5 W25 L=105mm

(p#9449538W).

(2) Fold as shown in the figure below.

60mmr3mm

(2) Wrap the tape(#WN01) around the ferrite core(N001).

74 #9/ 89 9:( 7

T-CON PCB

side

74 #9/ 89 9:( 7

74 #9/ 89 9:(

74 #9/ 89 9:(

90mmr2mm

#9/

#9/

#9/

4 #9/

45mmr3mm

Main PCB

side

EFFC PRW50FC0R5-131-20861

(p#:EK01902)

N001 MAG-FSRC400120RTF10T

(p#:GX00771)

#WN01 Nitto tape NO.5 W9 100m

(p#:9449507W)

(3) Connect to the T-CON PCB. (3) Fix the ferrite core(N001) with the tape(#WN02).

#334

Nitto tape No.5 W25 L=60mm

(p#9449538W).

Paste the tape to the Main PCB side.

Float the T-CON side.

Set the ferrite core(N001) in the

connector edge side.

#WN02 Nitto tape No.5 W25

(P#9449538W) L=35mm

28

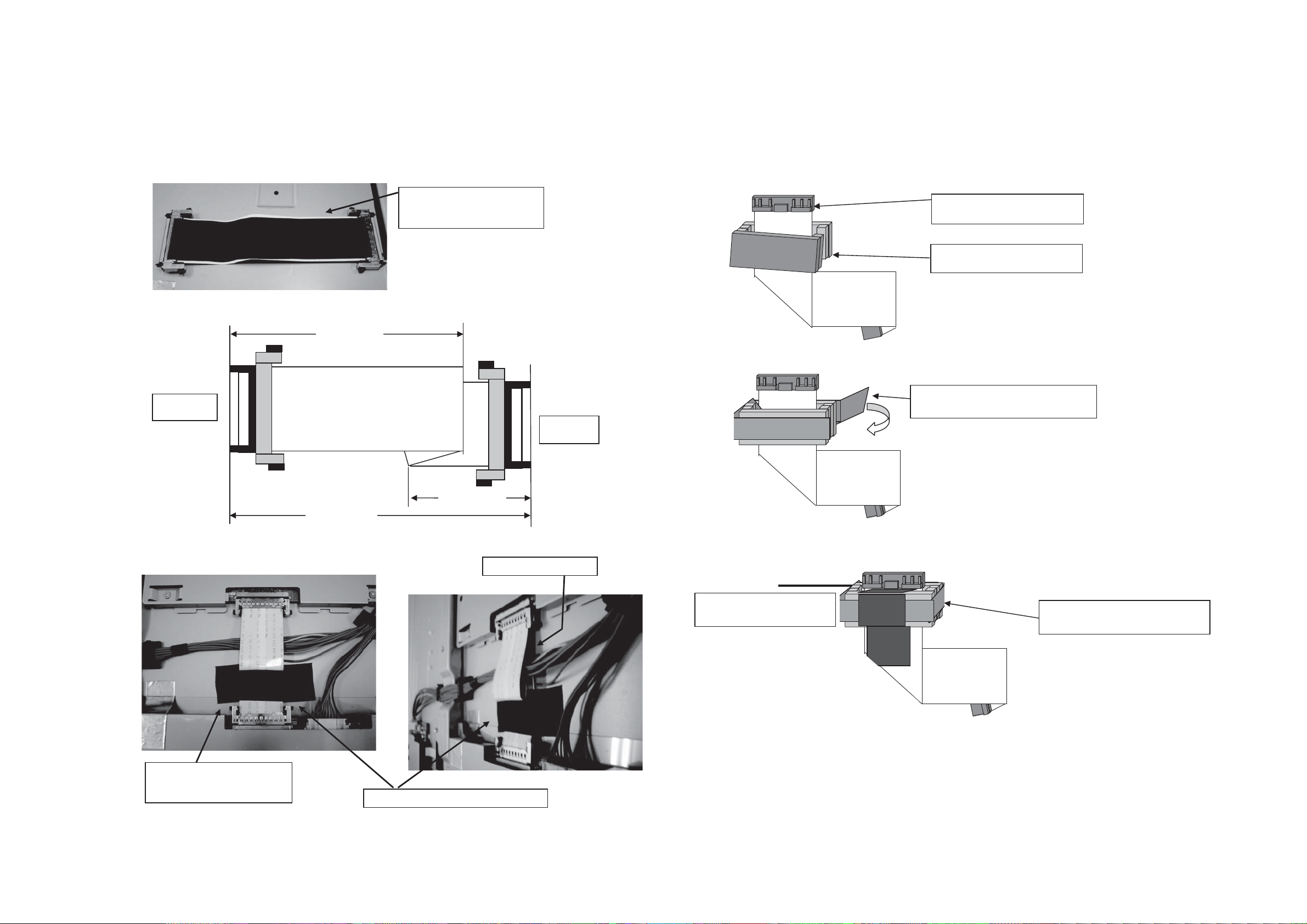

UT32-MH70U/E / UT37-MX70U/E / UT42-MX70U/E (D8MW)

UT37-MX70U/E Wiring diagram-3

[Detail-3 and Pre-operation] [Detail-4 and Pre-operation]

(1) Set the ferrite core (NSPK) in EISP. 1turn.

50mm±5mm

EISP

NSPK: MAG K5CRC12X15X7-MB2 (p#GX00738)

(2) Fasten with the SK-binder(#NSPK) near NSPK.

#NSPK SK-binder

(p#:3763751)

NSPK MAG K5CRC12X15X7-MB2

(p#GX00738)

(1) Set the ferrite core(NELS) in ELS. 1turn.

Pass the terminal board under.

60mm±5mm

Main board side

[Detail-5]

NELS MAG K5CRC12X15X7-MB2

(p#:GX00738)

ELS CO-06C-C1R0-201-LOCK

(p#:EF24946)

#360 D8MW SIGNAL SLD TAPE

(p#:MD20801)

Paste fit without space.

29

Loading...

Loading...