Page 1

Page

Hitachi Displays, Ltd.

COSMETIC SPECIFICATIONS

10

13-1/3 - 3/3

3284STD - 2345 - 2

PRECAUTION

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

3284STD - 2345 - 2

DESIGNATION OF LOT MARK

8711-1/1

10-1/2 - 2/2

DIMENSIONAL OUTLINE

12-1/3 - 3/3

9

9-1/3 - 3/3

INTERFACE TIMING

6

8-1/6 - 6/6

7-1/1

6-1/1

5-1/2 - 2/2

4-1/1

3-1/1

2-1/1

1-1/1

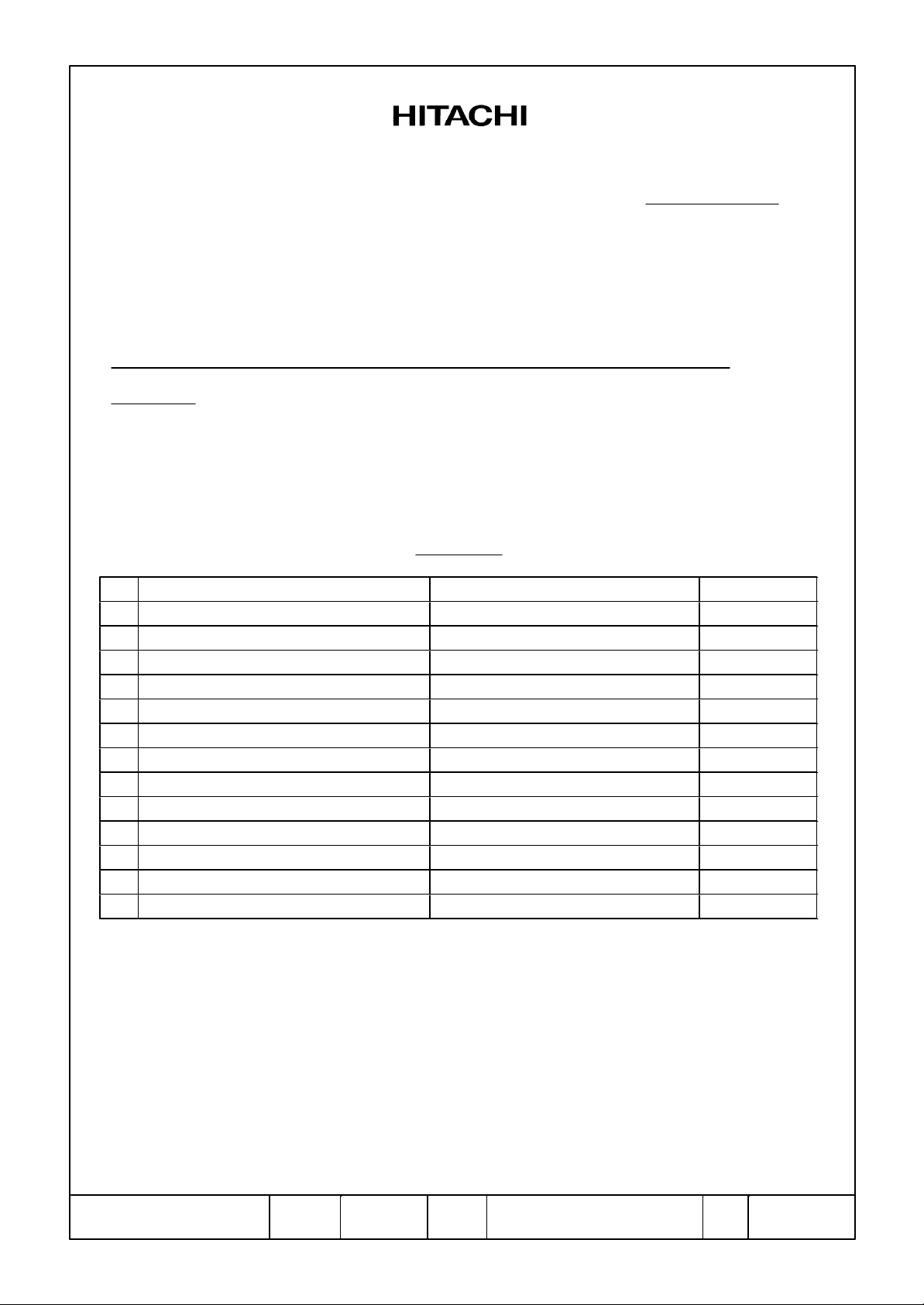

INTERFACE PIN ASSIGNMENT

BLOCK DIAGRAM

ELECTRICAL CHARACTERISTICS

OPTICAL CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS

DESCRIPTION

RECORD OF REVISION

COVER

54321---Page

Sheet No.

Item

No.

Module

The information described in this technical specification is tentative and it is possible to be changed without prior notice.

Date : Dec. 6, 2004

Technical Sheets of 32 inch diagonal WXGA Super-TFT

Product Name : TFTMD80160CBC

CONTENTS

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

1-1/1

Page 2

Page

Dec. 6,2004

2/2

Change of front view and back view

Change of

Back light unit

7 - 1/1

Dec. 6,2004

Summary

Page

Sheet No.

Date

RECORD OF REVISION

The upper section : Before revision

The lower section : After revision

3284STD - 2343 - 1

3284STD - 2343 - 2

3284STD - 2343 - 1

3284STD - 2343 - 2

10 - 1/2 -

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

2-1/1

Page 3

Page

DESCRIPTION

Note : Inverter for back light unit is built in this module.

The following specifications are applied to the following Super-TFT module.

Product Name : TFTMD80160CBC

General Specifications

Effective Display Area : (H)697.6845×(V)392.256 (mm)

Number of Pixels : (H)1,366×(V)768 (pixels)

Pixel Pitch : (H)0.51075×(V)0.51075 (mm)

Color Pixel Arrangement : R+G+B Vertical Stripe

Display Mode : Transmissive Mode

Normally Black Mode

Top Polarizer Type : Anti-Glare

Number of Colors : 16,777,216 (colors)

Viewing Angle Range : Super Wide Version

(Horizontal & Vertical : 170°, CR≧10)

Input Signal : 1-channel LVDS (LVDS:Low Voltage Differential Signaling)

Back Light : 16 pcs. of CCFL

External Dimensions : (H)780.0×(V)450.0×(t)50.5 (mm)

Weight : 8,500g typ.

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

3-1/1

Page 4

Page

1. ABSOLUTE MAXIMUM RATINGS

Note

DD

V

V

1)

ESD0

V

2),3)

2),4)

Note

1),5)

1)

Vibration

3)

4)

Not Acceptable

2

2

Not Acceptable

Note 1) Temperature and Humidity should be applied to the glass surface of a Super-TFT module,

Note

Note

Vin

VVV

1.1 Environmental Absolute Maximum Ratings

Operating

ITEM

Temperature

Humidity

Shock

Corrosive Gas

Illumination at

LCD Surface

not to the system installed with a module.

The temperature at the center of rear surface should be less than 70℃ on the condition of operating.

The brightness of a CCFL tends to drop at low temperature. Besides, the life-time becomes shorter

at low temperature.

2) Ta ≦40 ℃‥‥‥Relative humidity should be less than 85%RH max. Dew is prohibited.

Ta> 40 ℃‥‥‥Relative humidity should be lower than the moisture of the 85%RH at 40℃.

Min. Max. Min. Max.

0 -20

2)

-

-

- -

50 60

4.9(0.5G) 14.7 (1.5G)

29.4(3G) 294 (30G)

50,000 50,000

Storage

2)

-

-

Unit

℃

%RH

m/s

m/s

-

lx

3) Frequency of the vibration is between 15Hz and 100Hz. (Remove the resonance point )

4) Pulse width of the shock is 10 ms.

All mounting holes should be fixed. (Side mounting hole (4 locations), Top mounting hole

(4 locations), Rear mounting hole (4 locations)).

5) Long operation under low temperature may cause some portion of display area to be reddish for

several minutes after turning on the product.

However, it does not affect the characteristics and reliability of the product.

1.2 Electrical Absolute Maximum Ratings

(1)Super-TFT Module

ITEM SYMBOL Min. Max. Unit

Power Supply Voltage

Input Voltage for logic

Electrostatic Durability

1)It is applied to pixel data signal and clock signal.

2)Discharge Coefficient:200pF-250Ω, Environmental :25℃-70%RH

3)It is applied to I/F connector pins.

4)It is applied to the surface of a metallic bezel and a LCD panel.

V

VI

V

VESD1

0

-0.3 3.6

13.2

±100

±8 kV

Vss = 0 V

(2) Back-light Inverter

ITEM

Input Voltage

ON/OFF Control Input Voltage

Brightness Control Input Voltage

Hitachi Displays, Ltd. Dec.6,2004

Date

SYMBOL

ON/OFF

BRT

Sheet

No.

Min. Max.

0

0

0

3284STD - 2345 - 2

32

5.5

5.5

Vss = 0 V

Unit

4-1/1

Page 5

Page

CONDITION

NOTE

CR

2)

Time

ton

3)

Bwh

1)

Δχ

1)

5)

Buni

4)

=255]

=255]

3)

2

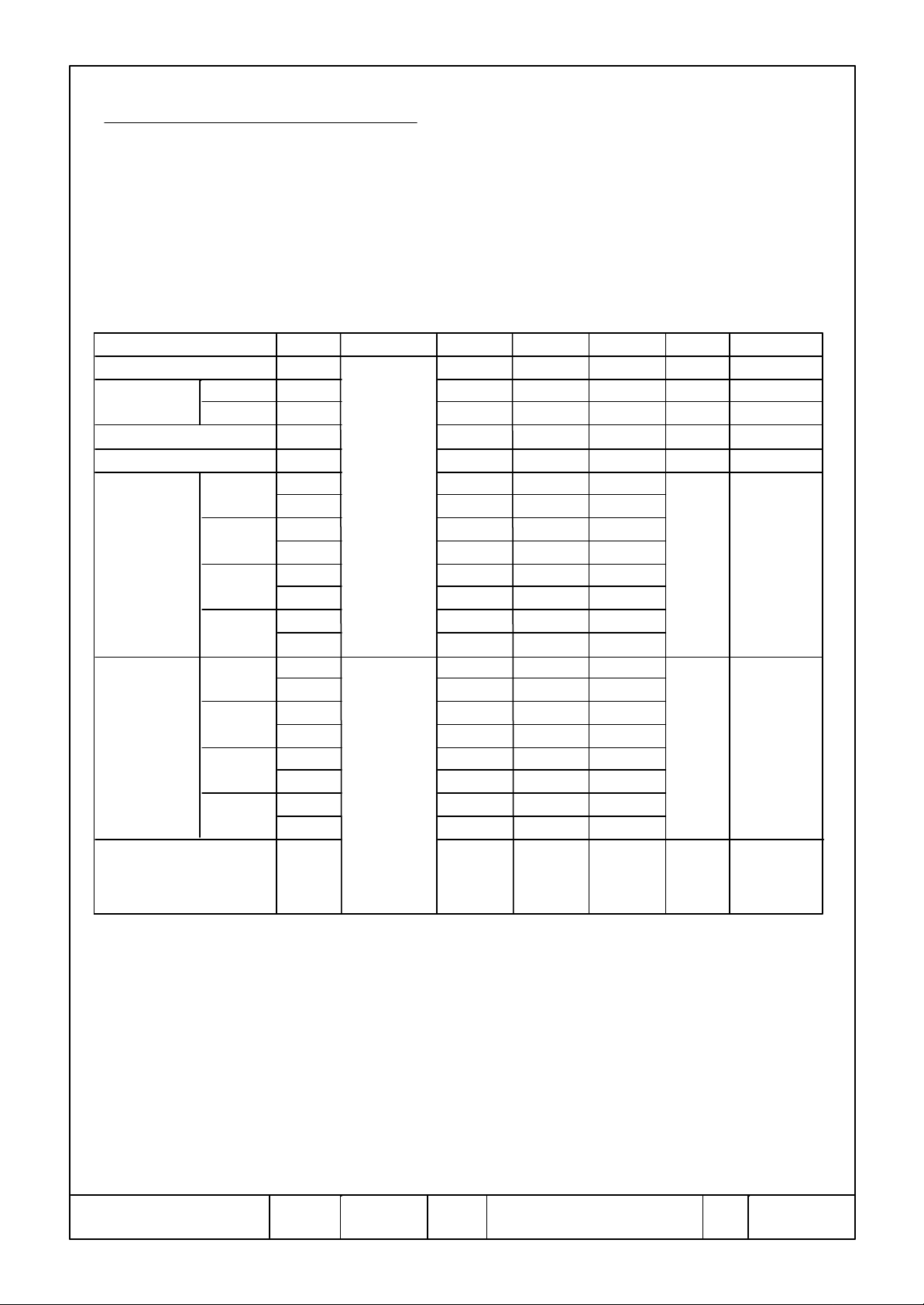

2. OPTICAL CHARACTERISTICS

The following optical characteristics are measured under stable conditions. It takes about 30 minutes

to reach stable conditions. The measuring point is the center of display area unless otherwise noted.

The optical characteristics should be measured in a dark room or equivalent state.

Measuring equipment:Pritchard 1980A, or equivalent

Temperature =25℃、VDD=12.0V、f V=60Hz、BRT:High(Duty:100%)

ITEM

Contrast Ratio

Response

Brightness of white

Brightness uniformity

Color

Chromaticity

(CIE)

Variation of

Color Position

(CIE)

Rise

Fall

Red

Green

Blue

White

Red

Green

Blue

White

SYMBOL

toff

χ

y

χ

y

χ

y

χ

y

Δχ

Δy

Δχ

Δy

Δy

Δχ

Δy

θ=0°

θ=+50°

φ=0 °,90°

180°,270°

Min.

400

-

- ms

350

0.61

0.29

0.26

0.58

0.12

0.04

0.251

0.258

-

-

-

-

-

-

-

-

Typ.

800

10

9

500 - cd/m

-

0.64

0.32

0.29

0.61

0.15

0.07

0.281

0.288

-

-

-

-

-

-

-

-

Max. UNIT

-

20

20

30-

0.67

0.35

0.32

0.64

0.18

0.10

0.311

0.318

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

-

ms

%

-

-

[Gray scale

[Gray scale

Contrast Ratio at 85° CR85 °

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

- -10

3284STD - 2345 - 2 5-1/2

-

-

Page 6

Page

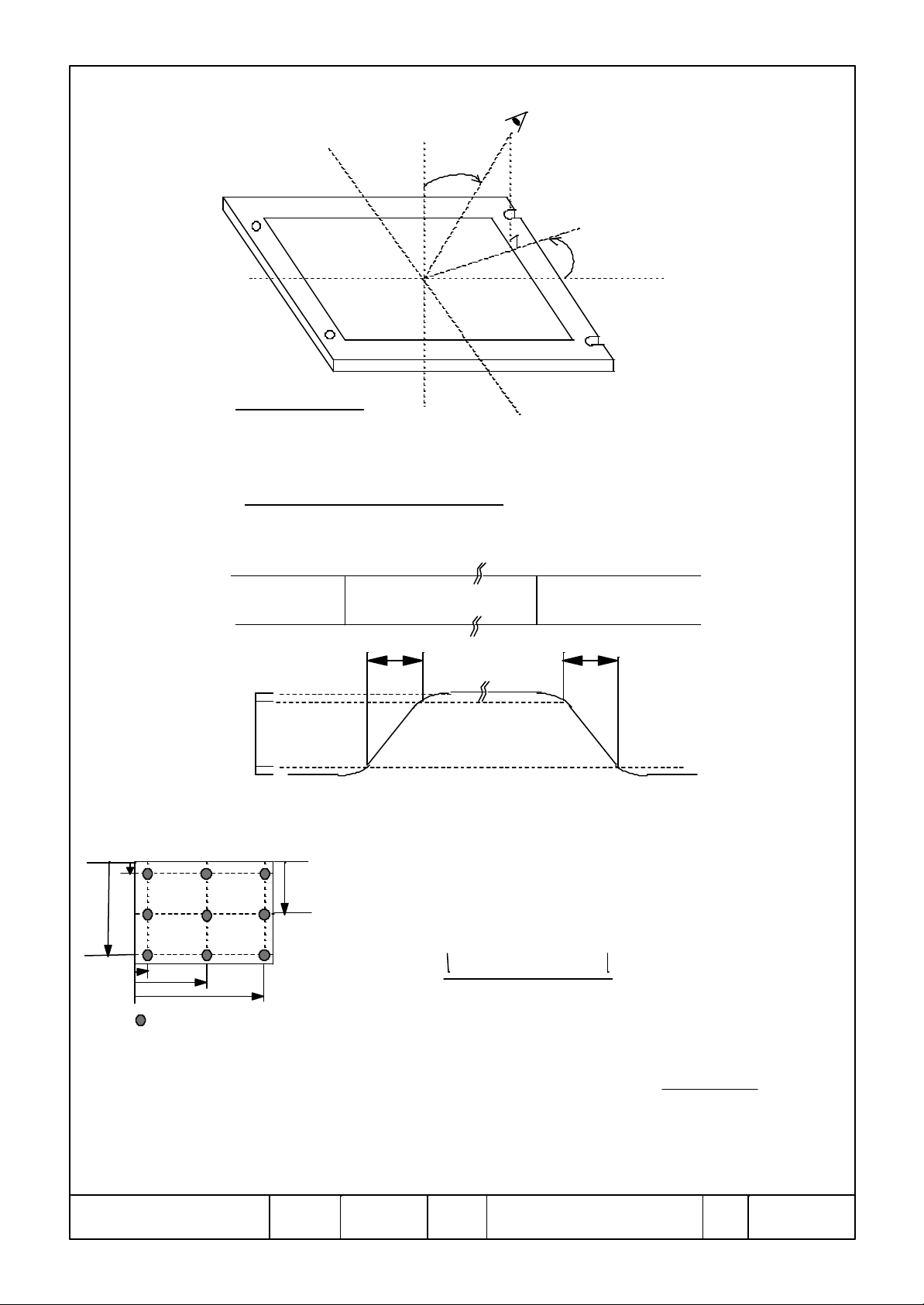

Note 1) Definition of Viewing Angle

φ=90°

01090

100%ton

toff

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

10%

50%

90%

10%

50%

90%

measuring points

k=1

9

φ=180°

(12 o'clock)

X'

Y

(9 o'clock )

Super-TFT Module

2) Definition of Contrast Ratio (CR)

(Luminance at displaying WHITE)

CR=

(Luminance at displaying BLACK)

3) Definition of Response Time

θ=0°

Z

θ

eye

φ

Y'Z'

φ=270°

(6 o'clock )

φ=0°

X(3 o'clock )

Displaying

Data Signal

BLACK

WHITE

BLACK

Optical

Response

( Luminance)

4) Definition of Brightness Uniformity

Display pattern is white (255 level) . The brightness

uniformity is defined as the following equation. Brightness at each

point is measured, and average, maximum and minimum

brightness is calculated.

Bmax or Bmin - Bave

Buni=

×100

Bave

:

where, Bmax = Maximum brightness

Bmin = Minimum brightness

Σ (B(k))

Bave= Average brightness =

9

5)Variation of color position on CIE is defined as difference between colors at θ=0°and

atθ=50°& φ=0°,90°,180 °,270°.

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

5-2/2

Page 7

Page

Note

V

V

A

1),2)

V

DDR

V

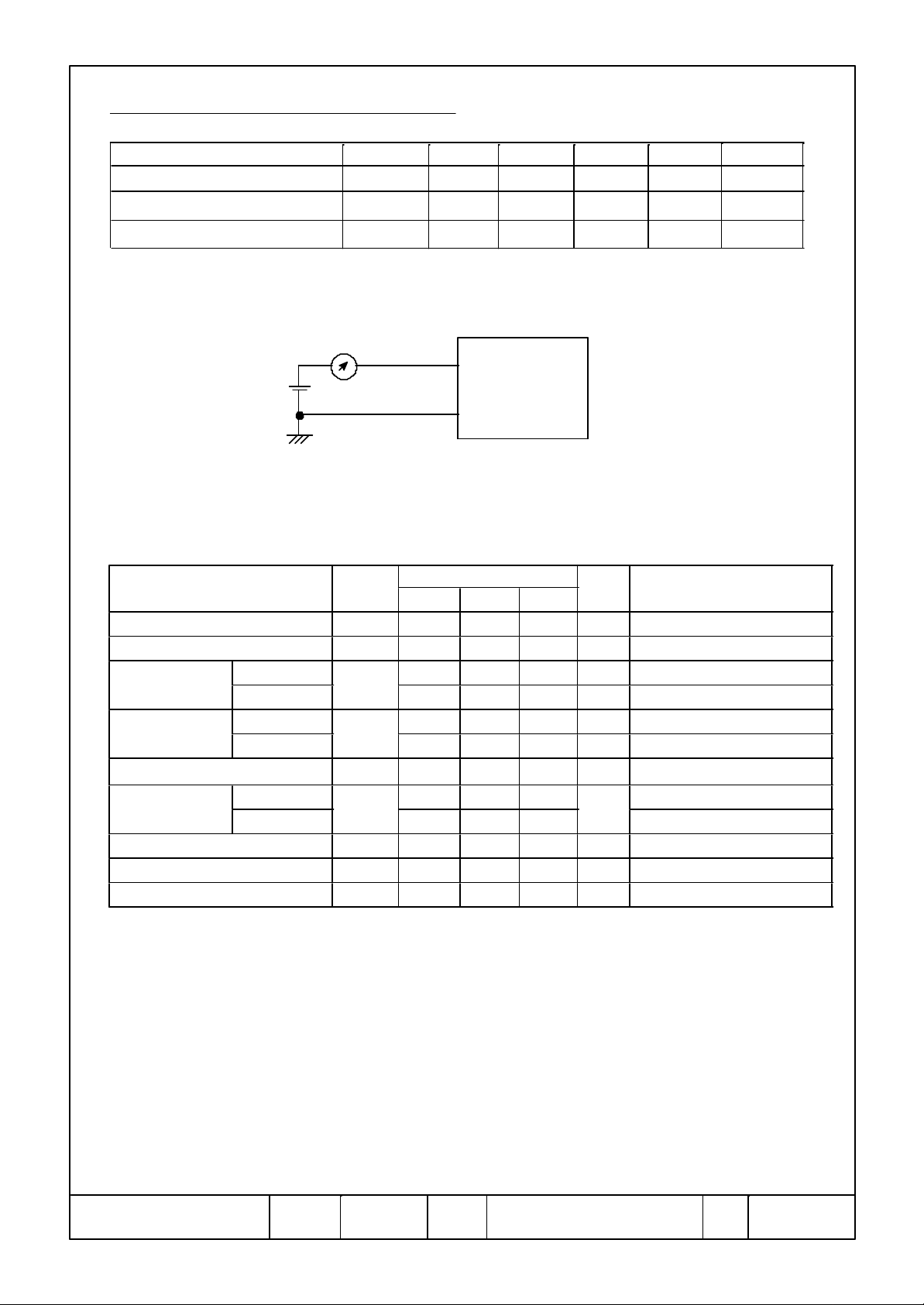

3. ELECTRICAL CHARACTERISTICS

DDVSS

Note 1) DC current at fv=60.0Hz,

kHz605550f

Output Frequency

BRT=3.3V

BRT=0V

%--

100-20-On-Duty

Max.Brightness

Min.Brightness

PWM Duty

at Max Brightness. Vin=Min

Max

BRT

Starting Voltage

BRT=3.3V

Ta=25

Vrms

Ta=0℃--1600VsV

3.0-3.3--V0

Max.Brightness

Min.Brightness

Input Voltage

VV0.805.5

2.2--

OFF

ON

Input Voltage

mArms

4.5

5.5

5.0ILOutput Current

6.5AVrms-(1200)

-VLLamp Voltage

4.5-IinV26.4

24.0

21.6

Vin

Input Current

Input Voltage

Notes

Unit

Symbol

ITEM

3.1 TFT-LCD Module Ta=25℃,Vss=0V

ITEM

Power Supply Voltage

Power Supply Current

Ripple Voltage of Power Supply

DC Ampere Meter

2) Current fuse is built in a module. Current capacity of power supply for VDD

should be larger than 4A, so that the fuse can be opened at the trouble of power supply.

3.2 Back Light

SYMBOL

DD 11.4 12.0

IDD

Min.

-

-

fCLK=85MHz, VDD=12.0V and Display pattern is white.

Super-TFT Module

V

Typ. Max.

12.6

0.5 0.8

-

0.15

Unit

ON/OFF Control

Brightness Control

VALUE

MaxTypMin

〜

ON/OFF

℃

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

6-1/1

Page 8

Page

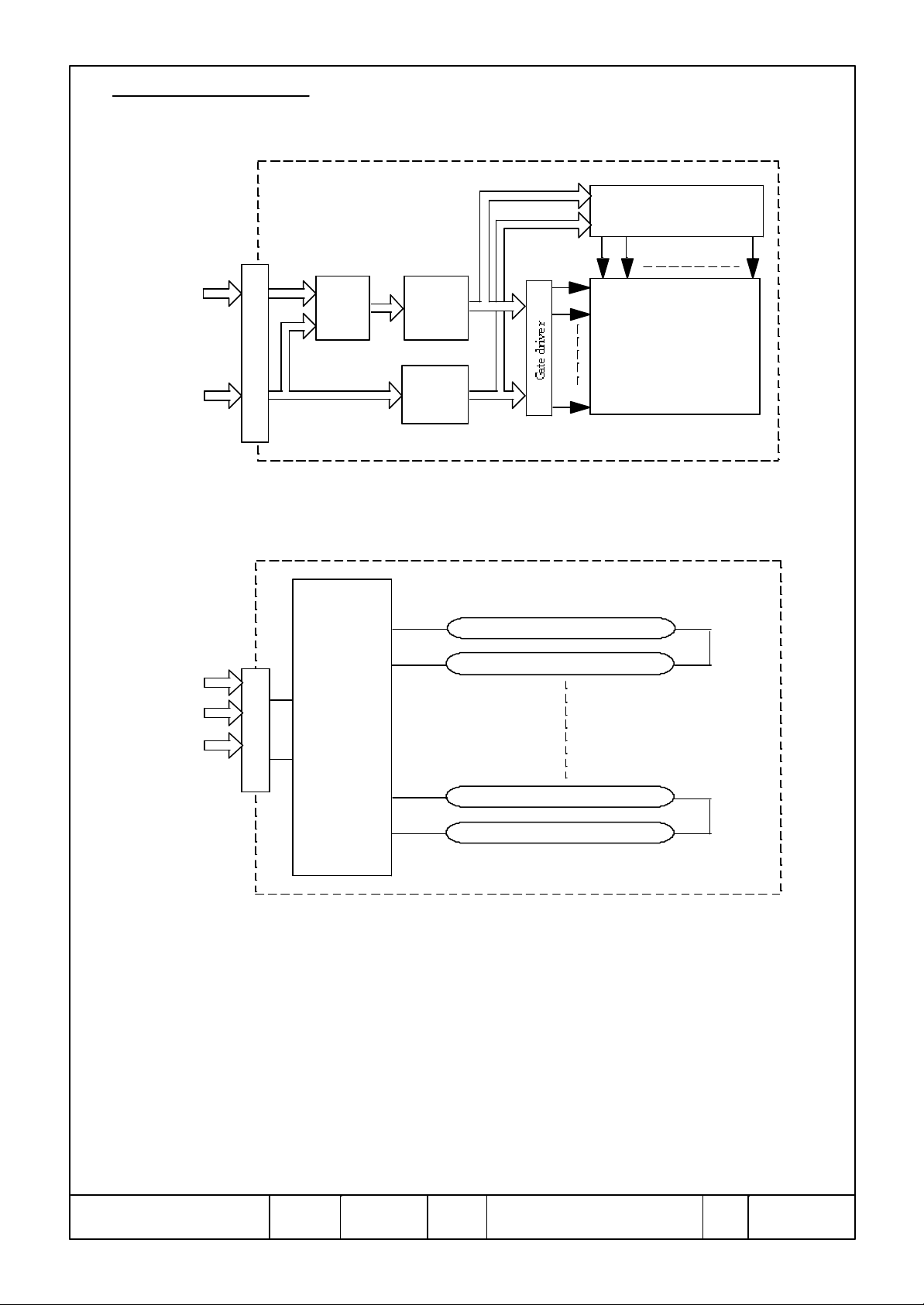

4. BLOCK DIAGRAM

D1D2D4098

G1G2G768

Receiver

Drain Driver

Converter

CN1

Brightness Control

HV

LV

(1) Super-TFT Module

LVDS

Display data.

Timing signal.

LVDS

Timing

Super TFT-LCD

DC power supply

(2) Back light unit

DC power supply

ON/OFF Control

CN2

Back light

Inverter

DC/DC

Converter

HV LV

HV LV

Lamp 16

Lamp 15

Lamp 2

HV LV

Lamp 1

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

7-1/1

Page 9

Page

5. INTERFACE PIN ASSIGNMENT

3

VDD

5

VSS

GND(0V)

2)6VSS7VSS

9

VSS10VSS

12

Rx0-

Pixel Data

3)13Rx0+14VSS

GND(0V)

2)

16

Rx1+17VSS

GND(0V)

2)

19

Rx2+20VSS

GND(0V)

2)21CLK-

Pixel Clock

3)

23

VSS

GND(0V)

2)24Rx3-

Pixel Data

3)

26

VSS

GND(0V)

2)27NC28NC

30

VSS

Notes

5. 1 TFT-LCD MODULE

CN1 : JAE FI-X30SSL-HF

(Matching connector : JAE FI-X30C2L or equivalent)

Pin No. Symbol Description Note

1 VDD Power Supply (typ.+12V) 1)

2 VDD

4 VDD

8 VSS

11 VSS

15 Rx1- Pixel Data 3)

18 Rx2- Pixel Data 3)

22 CLK+

25 Rx3+

29 VSS GND(0V) 2)

1) All VDD pins shall be connected to +12.0V(Typ.).

2) All VSS pins shall be grounded. Metal bezel is internally connected to VSS.

3) Rx n+ and Rx n- (n=1,2,3) should be wired by twist-pairs or side-by-side FPC patterns, respectively.

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2 8-1/6

Page 10

Page

5. 2 BACK-LIGHT UNIT

4)3)High:Lamp ON, Low:Lamp OFF

High:Max.Brightness, Low:Min. Brightness

2)2)1)

GND(0V)

Note

Description

GND(0V)

VSS

VSS

VSS

VSS10987

VIN

VIN

VIN

VIN5432

VSS

BRT

ON/OFF

NC

VSS141312116 Power supply(Typ. 24.0V)

VIN1SYMBOL

Pin No.

Notes

CN2 :JST S14B-PH-SM3-TB

(Matching connector : JST PHR-14 or equivalent)

1) All VIN pins shall be connected to +24.0V(Typ.).

2) All VSS pins shall be grounded. Metal bezel is internally connected to VSS.

3) High level:2.2〜5.5V, Low level:0〜0.8V

4) High level:3.0〜3.3V, Low level:0V

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

8-2/6

Page 11

Page

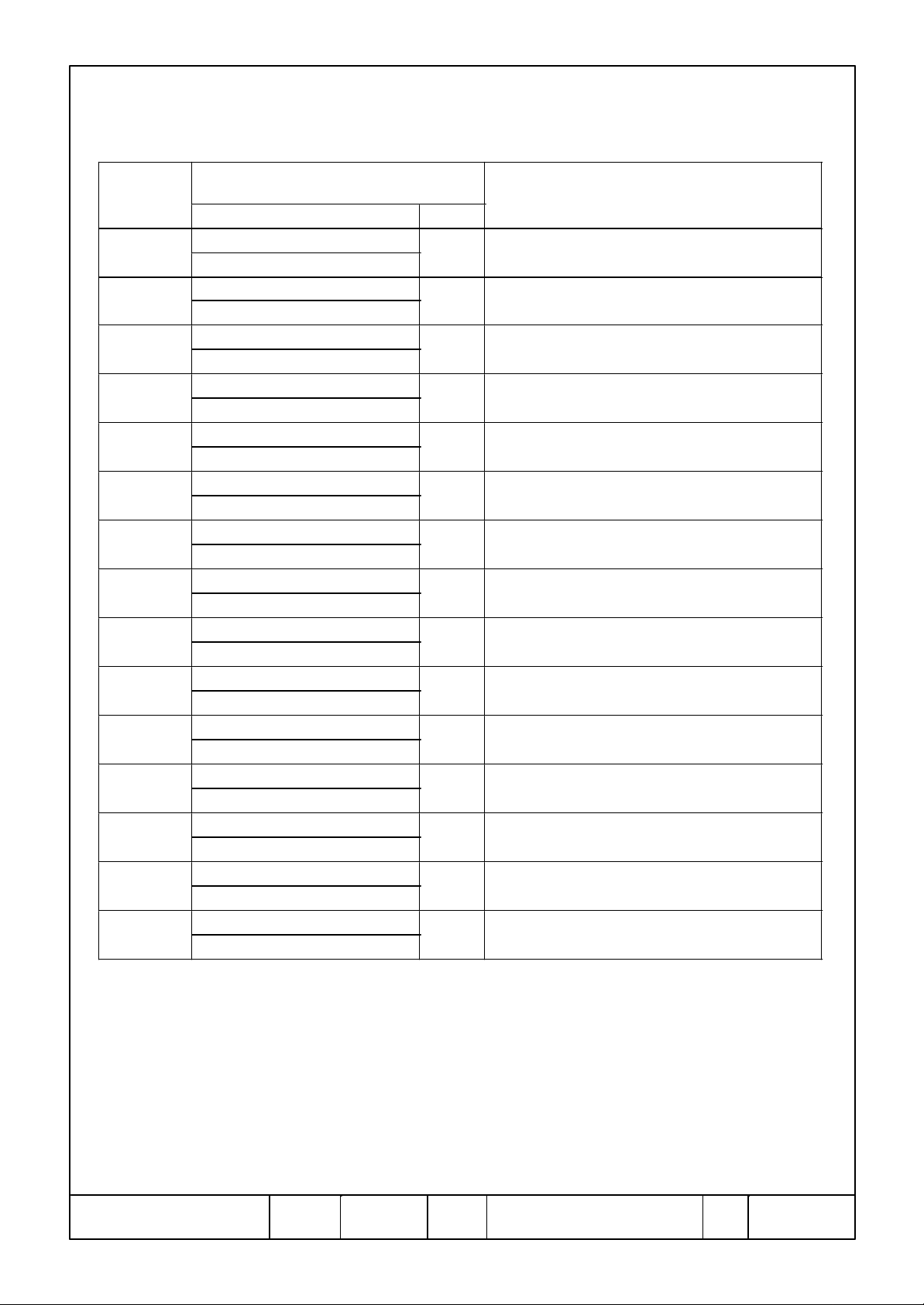

BLOCK DIAGRAM OF INTERFACE

LVDS

Transmitter

LVDS

Receiver

(LVDF83A)

R0-R7

TxIN

CN1

( THC63LVDF84B)

G0‐G7

B0‐B7

Hsync

DCLK

PLL

Notes

differentially.

R

xOUT

TFT-LCD ModuleSideTV setSide

G0-G7

B0-B7

Hsync

Vsync

DTMG

Host

Graphics

Controller

PLL

THC63LVDM83A

R0〜R7 :Pixel R Data

G0〜G7 :Pixel G Data

B0〜B7 :Pixel B Data

HSYNC :Horizontal synchronization signal

VSYNC :Vertical synchronization signal

DTMG :Display timing signal

Rx0+

Rx0‑

Rx1+

Rx1‑

Rx2+

Rx2‑

Rx3+

Rx3‑

CLK+

CLK‑

100 Ω

100 Ω

100 Ω

100 Ω

100 Ω

THC63LVDF84A

R0‐R7

Vsync

DTMG

Timing

Converter

1) The system must have the transmitter to drive the module.

2) LVDS cable impedance shall be 50 ohms per signal line or about 100 ohms per twist-pair line when it is used

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

8-3/6

Page 12

Page

LVDS INTERFACE

Notes

1) RSVD(reserved) pins on the transmitter shall be "H" or "L".

TRANSMITTER

TRANSMITTER

INTERFACE CONNECTOR

RECEIVER

RECEIVER

TFT

SIGNAL

THC63LVDM83A

THC63LVDM83A

THC63LVDF84A

THC63LVDF84A

CONTROL

PIN

INPUT

PC

TFT-LCD

PIN

OUTPUT

INPUT

R251Tx IN0

27

Rx OUT0

R2R352

Tx IN1

29

Rx OUT1

R3

R454Tx IN2

TA OUT0+

Rx 0+30Rx OUT2

R4

R555Tx IN3

32

Rx OUT3

R5R656

Tx IN4

33

Rx OUT4

R6

R73Tx IN6

TA OUT0-

Rx 0-35Rx OUT6

R7

G24Tx IN7

37

Rx OUT7

G2G36

Tx IN8

38

Rx OUT8

G3

G47Tx IN9

39

Rx OUT9

G4

G511Tx IN12

TA OUT1+

Rx 1+43Rx OUT12

G5G612

Tx IN13

45

Rx OUT13

G6

G714Tx IN14

46

Rx OUT14

G7

B215Tx IN15

TA OUT1-

Rx 1-47Rx OUT15

B2

24bitB319

Tx IN18

51

Rx OUT18

B3

B420Tx IN19

53

Rx OUT19

B4

B522Tx IN20

54

Rx OUT20

B5B623

Tx IN21

TA OUT2+

Rx 2+55Rx OUT21

B6

B724Tx IN22

1

Rx OUT22

B7

HSYNC

27

Tx IN24

3

Rx OUT24

HSYNC

VSYNC

28

Tx IN25

TA OUT2-

Rx 2-5Rx OUT25

VSYNC

DTMG

30

Tx IN26

6

Rx OUT26

DTMG

R050Tx IN27

7

Rx OUT27

R0R12

Tx IN5

34

Rx OUT5

R1

G08Tx IN10

TA OUT3+

Rx 3+41Rx OUT10

G0

G110Tx IN11

42

Rx OUT11

G1

B016Tx IN16

49

Rx OUT16

B0

B118Tx IN17

TA OUT3-

Rx 3-50Rx OUT17

B1

RSVD 1)

25

Tx IN23

2

Rx OUT23

not connect

DCLK

31

TxCLK IN

TxCLK OUT+

RxCLK IN+

26

RxCLK OUT

DCLK

TxCLK OUT-

RxCLK IN-

R0〜R7 :Pixel R Data (7;MSB, 0;LSB)

G0〜G7 :Pixel G Data (7;MSB, 0;LSB)

B0〜B7 :Pixel B Data (7;MSB, 0;LSB)

HSYNC :Horizontal synchronization signal

VSYNC :Vertical synchronization signal

DTMG :Display timing signal

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

8-4/6

Page 13

Page

CORRESPONDENCE BETWEEN INPUT DATA AND DISPLAY IMAGE

B0〜B7

:B data

Display data of adjacent one pixel is latched during one cycle of DCLK.

(1,1)

pixel : R0〜R7 :R data

G0〜G7 :G data

R G B

1,1 1,2 1,3 1,1366

2,1 2,2 2,3 2,1366

3,1 3,2 3,3 3,1366

DCLK

R0〜R7

G0〜G7

B0〜B7

DTMG

768,1 768,2 768,3

INVALID

1,1 1,2 1,1365 1,1366 2,1 2,2

768,1366

INVALID

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

8-5/6

Page 14

Page

RELATIONSHIP BETWEEN DISPLAY COLORS AND INPUT SIGNALS

RedData

RedData

GreenData

GreenData

BlueData

BlueData

Notes

Input R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

Color

Black 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red(255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Green(255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Basic Blue(255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

Color Cyan 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Magenta 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

Yellow 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

White 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Black 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red(1) 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red(2) 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red : : : : : : : : : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : : : : : : : : :

Red(254) 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red(255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Black 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Green(1) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

Green(2) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0

Green : : : : : : : : : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : : : : : : : : :

Green(254) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0

Green(255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Black 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Blue(1) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

Blue(2) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0

Blue : : : : : : : : : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : : : : : : : : :

Blue(254) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0

Blue(255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

MSB LSB MSB LSB MSB LSB

1) Definition of gray scale:

Color(n)・・・・Number in parenthesis indicates gray scale level. Larger n corresponds to brighter level.

2) Data: 1:High, 0:Low

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

8-6/6

Page 15

Page

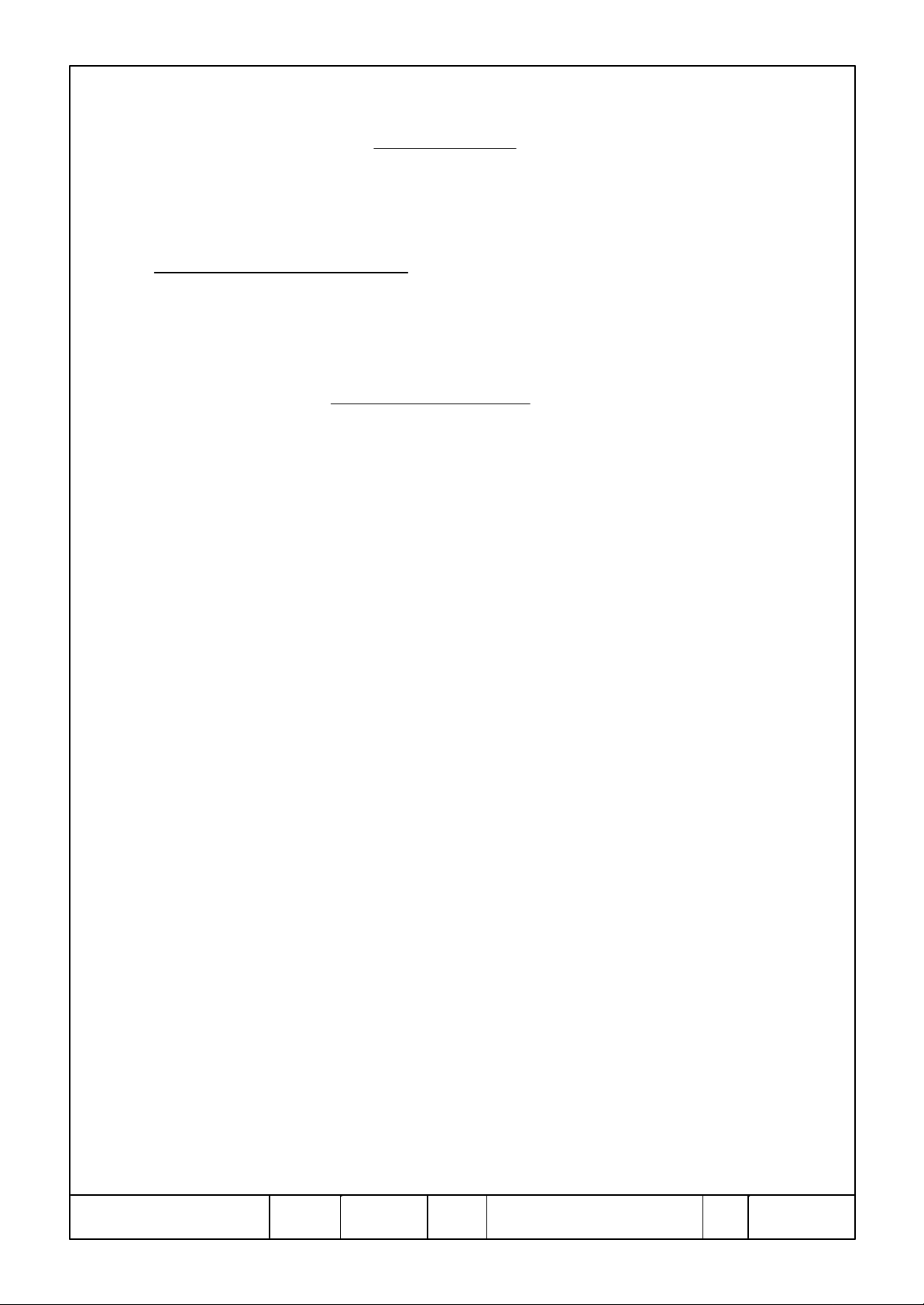

6. INTERFACE TIMING

Notes

R0〜7,G0〜7,B0〜7

TCIP

TWH

THP

THBP

THFP

TWV

TVP

TVBP

TVFP

TWD

6.1 TIMING CHART

TCIL

DCLK

HSYNC

VSYNC

HSYNC

DTMG

VSYNC

TSV

0.8V

THV

DTMG

TSTC

1.5V

THTC

1.5V

DCLK

VSYNC,HSYNC,DTMG,

1.5V

1) Reference level for each timing signal is 1.5V unless it is stated on the chart , high level voltage(VIH) and

low level voltage(VIL) are defined as follows:

VIH≧2.0V VIL ≦0.8V

The above definition conforms to the specifications of LVDS transmitter

( THC63LVDM83A / by THine Microsystems, Inc.).

2) The timing of DCLK to other signals conforms to the specifications of LVDS transmitter.

3) HSYNC, VSYNC timing is specified in negative polarity.

4) HSYNC pulse is needed while data is invalid (blanking period).

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

9-1/3

Page 16

Page

6.2 INTERFACE TIMING SPECIFICATIONS

項目

DCLK

Frequency

fCLK

788587

MHz

D=TCIL/TCIP

Set up Time

TSV0--TCIP

Width-Active

TWV

1-120

THP

Horizontal Front Porch

THFP

0--

TCIP

Vertical Back Porch

TVBP

2-1)

THP

Vertical Front porch

TVFP

2-1)

THP

COMMON

Set up Time

TSTC

5-2)ns2)

Hold Time

THTC

3-2)

ns

項目

DCLK

Frequency

fCLK

687887

MHz

D=TCIL/TCIP

VSYNC

Set up Time

TSV0--TCIP

Width-Active

TWV

1-120

THP

DTMG

Horizontal Front Porch

THFP

0--

TCIP

Vertical Back Porch

TVBP

2--

THP

Vertical Front porch

TVFP

2--

THP

COMMON

Set up Time

TSTC

5-2)ns2)

Hold Time

THTC

3-2)

ns

(1) I/F TIMING (60Hz)

Item Symbol Min. Typ. Max. Unit Note

Duty D 0.35 0.5 0.65 -

HSYNC Frequency fH 46.3 46.4 46.8 kHz 3)

Period THP 1410 1833 1992 TCIP

Width-Active TWH 8 - 240 TCIP

VSYNC Frequency fV 58 60 62 Hz to HSYNC

Hold Time THV 8 - - TCIP

Period TVP 772 773 780 THP

DTMG Horizontal Back porch THBP 16 - - TCIP 1)

Width-Active TWD 1366 1366 1366 TCIP

(2) I/F TIMING (50Hz)

Item Symbol Min. Typ. Max. Unit Note

Duty D 0.35 0.5 0.65 Frequency fH 40 43 46 kHz 3)

HSYNC Period THP 1410 1814 1992 TCIP

Width-Active TWH 8 - 240 TCIP

Frequency fV 48 50 52 Hz to HSYNC

Hold Time THV 8 - - TCIP

Period TVP 772 860 1080 THP

Horizontal Back porch THBP 16 - - TCIP 1)

Width-Active TWD 1366 1366 1366 TCIP

In addition to the above, these timing should conforms to the followings.

1) TVBP+TVFP≧4 THP

2) TSTC and THTC conforms to the specifications of LVDS transmitter.

It is preferable to check the specifications of LVDS transmitter in your system.

3) Frequency of power supply for a CFL may cause the interference with HSYNC frequency and cause beat or flicker on the display.

Therefore, HSYNC frequency shall be as different as possible from lamp frequency in order to avoid the interference.

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

9-2/3

Page 17

Page

6.3 TIMING BETWEEN INTERFACE SIGNALS AND POWER SUPPLY

1V

10

V

TPRTDF

TINTDRV

alid

0V12V1V10V

T

BF

0V21.6V0

V

TBR

0V0V0ms Min.

0ms Min.

0ms Min.

0ms Min.

Power Supply

VDD

Interface Signal

VI

Back-light

21.6V

Vin

Back-light

ON/OFF

Back-light

BRT

Note

1)Timing of power supply voltage and input signals should be used under the following specifications.

0ms ≦ TPR ≦ 10ms

10ms ≦ TDR ≦ 50ms

0ms ≦ TDF ≦ 50ms

TIN ≧ 1s

200ms ≦ TBR

TBF ≦ 100ms

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

9- 3/3

Page 18

Dec.6,2004

3284STD-2345-2

10-1/2

Page 19

3284STD-2345-2

Dec.6,2004

10-2/2

Page 20

Page

8. DESIGNATION OF LOT MARK

Notes

CAUTIONHIGHVOLTAGE

8.1 LOT MARK

Production management sign

Week 3)

Month 2)

Year 1)

5 digits for production number

(00001〜99999)

Special mark 4)

1)

2004

2005

2006

2007

Year Mark

4

5

6

7

2)

Month

1

2

3

4

5

6

Mark

01

02

03

04

05

06

Month Mark

7

8

9

10

11

12

07

08

09

10

11

12

3)

Week(Day) Mark

1〜7

8〜14

15〜21

22〜28

29〜31

4) It is the mark that was opened up by production person to take

correspondence with production number.

8.2 Location of lot mark

Lot mark is printed on a label. The label is on the metallic bezel as shown in 7. External Dimensional.

The style of character will be changed without notice.

1

2

3

4

5

Lot mark

Hitachi Displays, Ltd. Dec.6,2004

HITACHI

高電圧 注意

TFTMD80160CBC

4041H00001

MADEIN JAPAN .

本ディスプレイユニット内の蛍光管には水銀が含まれております。液晶ディスプレイの廃棄

に当たっては地方自治体の条例または規則に従って廃棄して下さい。

COLDCATHODEFLUORESCENT LAMPIN COLOR LCD CONTAINSMERCURY.

PLEASEFOLLOWLOCALORDINANCESORREGULATIONSFORITSDISPOSAL.

*TFTMD80160CBC04041H00001A*

R000000F 05400001

Date

Sheet

No.

3284STD - 2345 - 2

11-1/1

Page 21

Page

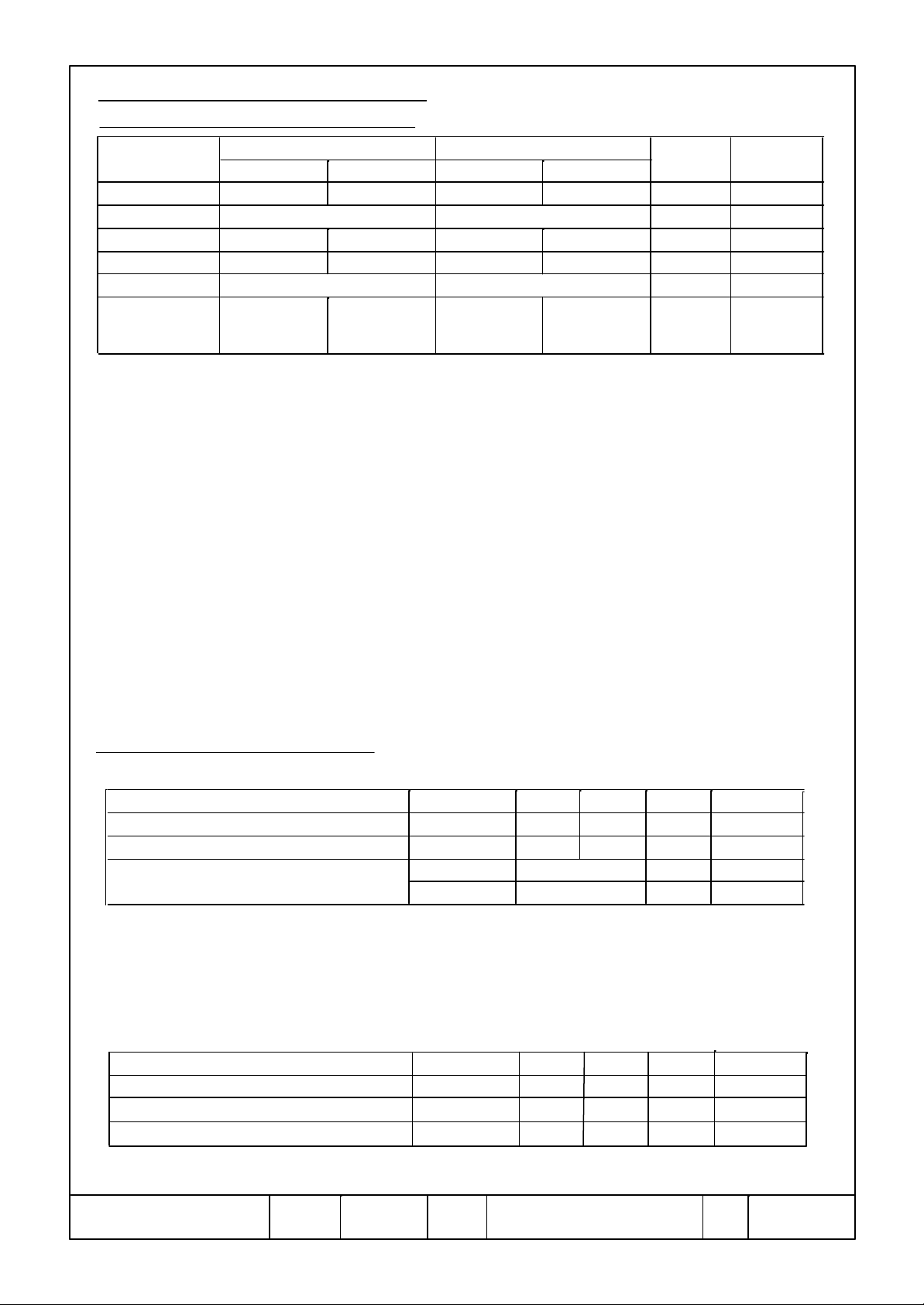

9. COSMETIC SPECIFICATIONS

c) Back-light : when non-operating inspection, back-light should be off .

TFT-LCD Module

about 500mm

A-zone

B

-zoneC-zone

9.1 Condition for cosmetic inspection

(1) Viewing zone

a) The figure shows the correspondence

between eyes (of inspector) and

TFT-LCD module.

θ≦45゜: when non-operating inspection

θ≦5゜ : when operating inspection

b) Inspection should be executed only from

front side and only A-zone.

Cosmetic of B-zone and C-zone are ignore.

(refer to 9.2 Definition of zone)

(2) Environmental

a) Temperature : 25 degrees

b) Ambient light : about 700 lx and non-directive when operating inspection.

: about 1000 lx and non-directive when non-operating inspection.

9.2 Definition of zone

Inspection view

θ θ

・A-zone : Display area (pixel area)

・B-zone : Area between A-zone and C-zone

・C-zone : Metallic bezel area

Light

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

12-1/3

Page 22

Page

9.3 COSMETIC SPECIFICATIONS

No.

1-dot

1),2)

2-dots

3-dots

1),2),5)

4-dots

0

Density

3

pcs/φ20mm1),2),6)

7

1),2)151),3),4)

3

1),3),5)

041),3),6)

15

1),3)211)

W<=0.08

L : Ignore

W<=0.25

2.0<L<=4.0

8

W : width(mm)

L>4.0

07)L : length(mm)

L<=2.0

160W>0.25

Dot shape

D<=1.0

87)

D : ave. dia.(mm)

D>1.0

06W<=0.15

1008)W<=0.3

L>207D<=0.6

D<=1.0

108)

D>1.0

0

Note

pcs

Units

pcs

pcs

pcs

pcs

Units

Total

2-dots

3-dots

4-dots

Total

Total

pcs/φ20mmIgnore

pcs

pcs

pcs

pcs

(See dot shape)

Ignore

Scratch on polarizer

Line shape

W : width(mm)

L : length(mm)

L : Ignore

Ignore

Scratch on polarizer

Dot shape

D : ave. dia.(mm)

Ignore

1160W>0.5

When displaying conditions are not stable (ex. at turn on or off), the following specifications

are not applied.

Operating

inspection

ITEM

1

Max. acceptable number

A-zone

2

Unit

Sparkle

mode

Dot defect

1-dot

Black

mode

Density

2

3

4

Stain inclusion

Line defect

Uneven brightness

Serious one is

not allowed.

5

Line shape

Stain inclusion

D<=0.5

L<=20

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

12-2/3

Page 23

Page

Note 1) Dot defect : defect area > 1/2 dot

No.

D<=1.0

10

09Wrinkles on polarizer

-

-

ITEM

A-zone

Note

in polarizer

Ignore

pcs

not allowed.

D<=0.5

Max. acceptable number

Unit

non-operating

inspection

8

Bubbles, peeling

D : ave. dia.(mm)

D>1.0

Serious one is

2) Sparkle mode : brightness of dot is more than 30% at black. (visible to eye)

3) Black mode : brightness of dot is less than 70% at white. (visible to eye)

4) 1 dot : defect dot is isolated, not attached to other defect dot.

5) N dots : N defect dots are consecutive. (N means the number of defects dots)

6) Density : number of defect dots inside 20mm φ.

7) Those stains which can be wiped out easily are acceptable.

8) Polarizer area inside of B-zone is not applied.

9) No major (serious) defects when viewed in gray scale mode.

8)

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

12-3/3

Page 24

Page

9. PRECAUTION

cover case

above precaution(5)

Please pay attention to the followings when a Super-TFT module with a back-light unit is used,

handled and mounted.

9.1 Precaution to handling and mounting

(1) Applying strong force to a part of the module may cause partial deformation of frame or mold,

and cause damage to the display.

(2) The module should gently and firmly be held by both hands. Never hold by just one hand in order

to avoid any internal damage. Never drop or hit the module.

(3) The module should be installed with mounting holes at each corner of a module.

(4) Uneven force such as twisted stress should not be applied to a module when a module is mounted

on the cover case. The cover case must have sufficient strength so that external force can not be

transmitted directly to a module.

(5) It is recommended to leave a space between a module and a holding board of a module so that

partial force is not applied to a module.

B-zone

Cover case

Effective display area

Edge of

Super-TFT module

Polarizer

Fig.1 Cross sectional view of a monitor set

(6) The edge of a cover case should be located inside more than 1mm from the edge of a module front

frame.

(7) A transparent protective plate should be added on the display area of a module in order to protect

a polarizer and Super-TFT cell. The transparent protective plate should have sufficient strength

so that the plate can not touch a module by external force.

(8) Materials included acetic acid and choline should not be used for a cover case as well as other parts

and boards near a mod ule. Acetic acid attacks a polarizer. Choline attacks electric circuits due to

electro-chemical reaction.

(9) The polarizer on a TFT cell should carefully be handled due to its softness, and should not be touched,

pushed or rubbed with glass, tweezers or anything harder than HB pencil lead. The surface of

a polarizer should not be touched and rubbed with bare hand, greasy clothes or dusty clothes.

(10) The surface of a polarizer should be gently wiped with absorbent cotton, chamois or other soft

materials slightly contained petroleum benzene when the surface becomes dirty. Normal-hexane

as cleaning chemicals is recommended in order to clean adhesives whic h fix front/rear polarizers

on a Super-TFT cell. Other cleaning chemicals such as acetone, toluen and alcohol should not be

used to clean adhesives because they cause chemical damage to a polarizer.

(11) Saliva or water drops should be immediately wiped off. Otherwise, the portion of a polarizer may

be deformed and its color may be faded.

(12) The module should not be opened or modified. It may cause not to operate properly.

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

13-1/3

Page 25

Page

(13) Metallic bezel of a module should not be handled with bare hand or dirty gloves. Otherwise,

color of a metallic frame may become dirty during its storage. It is recommended to use clean

soft gloves and clean finger stalls when a module is handled at incoming inspection process and

production (assembly) process.

(14) Lamp(CCFL) cables should not be pulled and held.

9.2 Precaution to operation

(1) The ambient temperature near the operated module should be satisfied with the absolute maximum

ratings. Unless it meets the specifications, sufficient cooling system should be adopted to system.

(2) The spike noise causes the mis-operation of a module. The level of spike noise should be as follows:

-200mV<=over- and under- shoot of VDD<= +200mV

VDD including over- and under- shoot should be satisfied with the absolute maximum ratings.

(3) Optical response time, luminance and chromaticity depend on the temperature of a Super-TFT

module. Response time and saturation time of CCFL luminance become longer at lower temperature

operation.

(4) Sudden temperature change may cause dew on and/or in the a module. Dew males damage to a

polarizer and/or electrical contacting portion. Dew causes fading of displayed quality.

(5) Fixed patterns displayed on a module for a long time may cause after-image. It will be recovered

soon.

(6) A module has high frequency circuits. Sufficient suppression to electromagnetic interference should

be done by system manufacturers. Grounding and shielding methods may be effective to minimize

the interference.

(7) Noise may be heard when a back-light is operated. If necessary, sufficient suppression should be

done by system manufacturers.

(8) The module should not be connected or removed while a main system works.

(9) Inserting or pulling I/F connectors causes any trouble when power supply and signal dates are

on-state.I/F connectors should be inserted and pulled after power supply and signal dates are

turned off.

9.3 Electrostatic discharge control

(1) Since a module consists of a Super-TFT cell and electronic circuits with CMOS-ICs, which are

very weak to electrostatic discharge, persons who are handling a module should be grounded

through adequate methods such as a list band. I/F connector pins should not be touched directly

with bare hands.

(2) Protection film for a polarizer on a module should be slowly peeled off so that the electrostatic

charge can be minimized.

9.4 Precaution to strong light exposure

(1) A module should not be exposed under strong light. Otherwise, characteristics of a polarizer and

color filter in a module may be degraded.

9.5 Precaution to storage

When modules for replacement are stored for a long time, following precautions should be taken care of:

(1) Modules should be stored in a dark place. It is prohibited to apply sunlight or fluorescent light

during storage. Modules should be stored at 0 to 35 °C at normal humidity (60%RH or less).

(2) The surface of polarizers should not come in contact with any other object. It is recommended that

modules should be stored in the Hitachi's shipping box.

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2 13-2/3

Page 26

Page

9.6 Precaution to handling protection film

(1) The protection film for polarizers should be pealed off slowly and carefully by persons who are

electrically grounded with adequate methods such as a list band. Besides, ionized air should be blown

over during peeling action. Dusts on a polarizer should be blown off by an ionized nitrogen gun and

so on.

(2) The protection film should be peeling off without rubbing it to the polarizer. Because, if the film is

rubbed together with the polarizer, since the film is attached to the polarizer with a small amount

of adhesive, the adhesive may remain on a polarizer.

(3) The module with protection film should be stored on the conditions explained in 9.5 (1). However,

in case that the storage time is too long, adhesive may remain on a polarizer even after a protection

film is peeled off. Besides, in case that a module is stored at higher temperature and/or higher

humidity, adhesive may remain on a polarizer. The remained adhesive may cause non-uniformity

of display image.

(4) The adhesive can be removed easily with Normal-Hexane. The remained adhesive or its vestige on

the polarizer should be wiped off with absorbent cotton or other soft materials such as chamois

slightly contained Normal-Hexane.

9.7 Safety

(1) Since a Super-TFT cell and lamps are made of glass, handling to the broken module should be taken

care sufficiently in order not to be injured. Hands touched liquid crystal from a broken cell should be

washed sufficiently.

(2) The module should not be taken apart during operation so that back-light drives by high voltage.

9.8 Environmental protection

(1) The Super-TFT module contains cold cathode fluorescent lamps. Please follow local ordinance or

regulations for its disposal.

(2) Flexible circuits board and printed circuits board used in a module contain small amount of lead.

Please follow local ordinance or regulations for its disposal.

9.9 Use restrictions and limitations

(1) This product is not authorized for use in life support devices or systems, military applications or

other applications which pose a significant risk of personal injury.

(2) In no event shall Hitachi, Ltd., be liable for any incidental, indirect or consequential damages in

connection with the installation or use of this product, even if informed of the possibility thereof

in advance. These limitations apply to all causes of action in the aggregate, including without

limitation breach of contact, breach of warranty, negligence, strict liability, misrepresentation and

other torts.

9.10 Others

(1) Electrical components which may not affect electrical performance are subjective to change without

notice because of their availability.

Hitachi Displays, Ltd. Dec.6,2004

Date

Sheet

No.

3284STD - 2345 - 2

13-3/3

Loading...

Loading...