MODELS SV 8SA/SV 12SF

1. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

Please pay particular attention to the following items during disassembly and reassembly.

Since the SV 8SA and the SV 12SF are of the same structure, explanation is given only on the Model SV 8SA.

[Bold]

The

numbers in the description correspond to the item numbers in the parts exploded diagram of the

SV 8SA and the numbers in

1-1. Disassembly

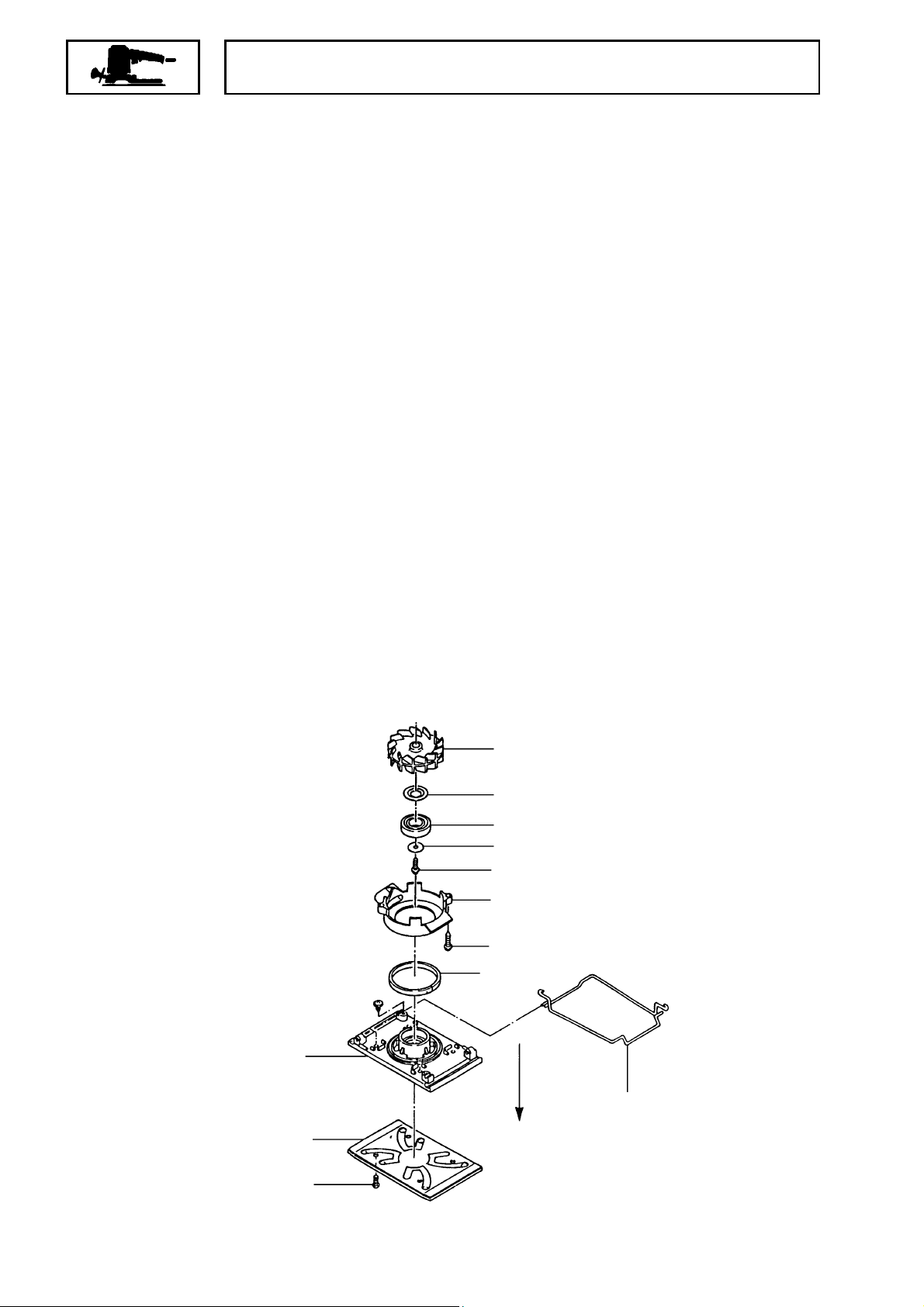

1-1-1. Remove the Felt Pad or the Pad [19] <19>

Remove the Felt Pad or the Pad

1-1-2. Remove the Base [18] <18>

Remove the Base

[18] <18>

Base

1-1-3. Remove the Fan Guide [34] <34>

Remove the Fan Guide

1-1-4. Remove the Thrust Washer [32] < 32> , t he Ball Bearing 6001 DDUCM [31] <31> , the Dust

Washer [30] <30> and the Balancer Fan [29] <29>

Remove the Thrust Washer

[30] <30>

and the Balancer Fan

[18] <18>

in the arrow-indicated direction.

<Bold>

together with the Paper Clips

[34] <34>

[32] <32>

to those in the parts exploded diagram of the SV 12SF.

[19] <19>

removing the two D4 x 20 Tapping Screws

[29] <29>

by removing the four M4 x 10 Machine Screws

, the Ball Bearing 6001 DDUCM

by removing the M4 x 12 Machine Screw

[37] <37>

and the Felt

[35] <35>

[31] <31>

[20] <20>

[36] <36>

, the Dust Washer

[33] <33>

by pulling out the

.

.

.

[18] <18>

[19] <19>

[20] <20>

[29] <29>

[30] <30>

[31] <31>

[32] <32>

[33] <33>

[34] <34>

[35] <35>

[36] <36>

Pull out

[37] <37>

Fig. 3

−

−#

1

1-1-5. Remove the Housing (B) [3] <3> and the Legs [16] <16>

After removing the Base

along the perforations with a cutter. Then remove the four Tapping Screws with D4 Flanges

<4>

securing the Housing (A)

Legs

[16] <16>

can be removed by pulling them out of the Housing (A)

[18] <18>

[12] <12>

and the Balancer Fan

and the Housing (B)

[29] <29>

[3] <3>

as indicated above, cut the Grip Tape

together, and the latter can be removed. The

[12] <12>

or the Housing (B)

1-1-6. Disassembly of the A rmature [28] <28>, the Stators [25] <25> and O t her Parts

(1) Remove the two Carbon Brushes

(A)

[12] <12>

.

[15] <15>

(2) Loosen the positive (+) terminal screw of the Slide Switch

and remove the lead wires of the Noise Suppressor

lead wires of the Stator

[25] <25>

.

(3) Loosen the negative (-) terminal screw of the Pillar Terminal

screwdriver and remove the lead wires of the Cord

[25] <25>

, and the parts inside the Housing can then be removed.

(4) With a bearing puller, pull of the two Ball Bearings 608 VVC2

Armature

[28] <28>

.

by lifting the Brush Holders

with a Phillips screwdriver

[5] <5>

[22] <22>

(excl. the U.S.A.) and Cord

[21] <21>

[10] <10>

and the lead wires of the Stator

[24] <24>

[14] <14>

off the Housing

with a flat-blade

press-fitted on both ends of the

[2] <2>

[10] <10>

[4]

[3] <3>

and the

.

1-2. Reassembly

Proceed as follows, paying particular attention to the it ems below.

1-2-1. Assembly of the Armature [28] <28> and the Stators [25] <25>

(1) With a hand press, press the two Ball Bearings 608VVC2

[24] <24>

until they hit against the stepped

portion of the Armature Shaft.

(2) Place the Stators

and make sure that the Armature

<12>

[25] <25>

and the Armature

[28] <28>

[28] <28>

in sequence within the Housing (A)

can turn freely.

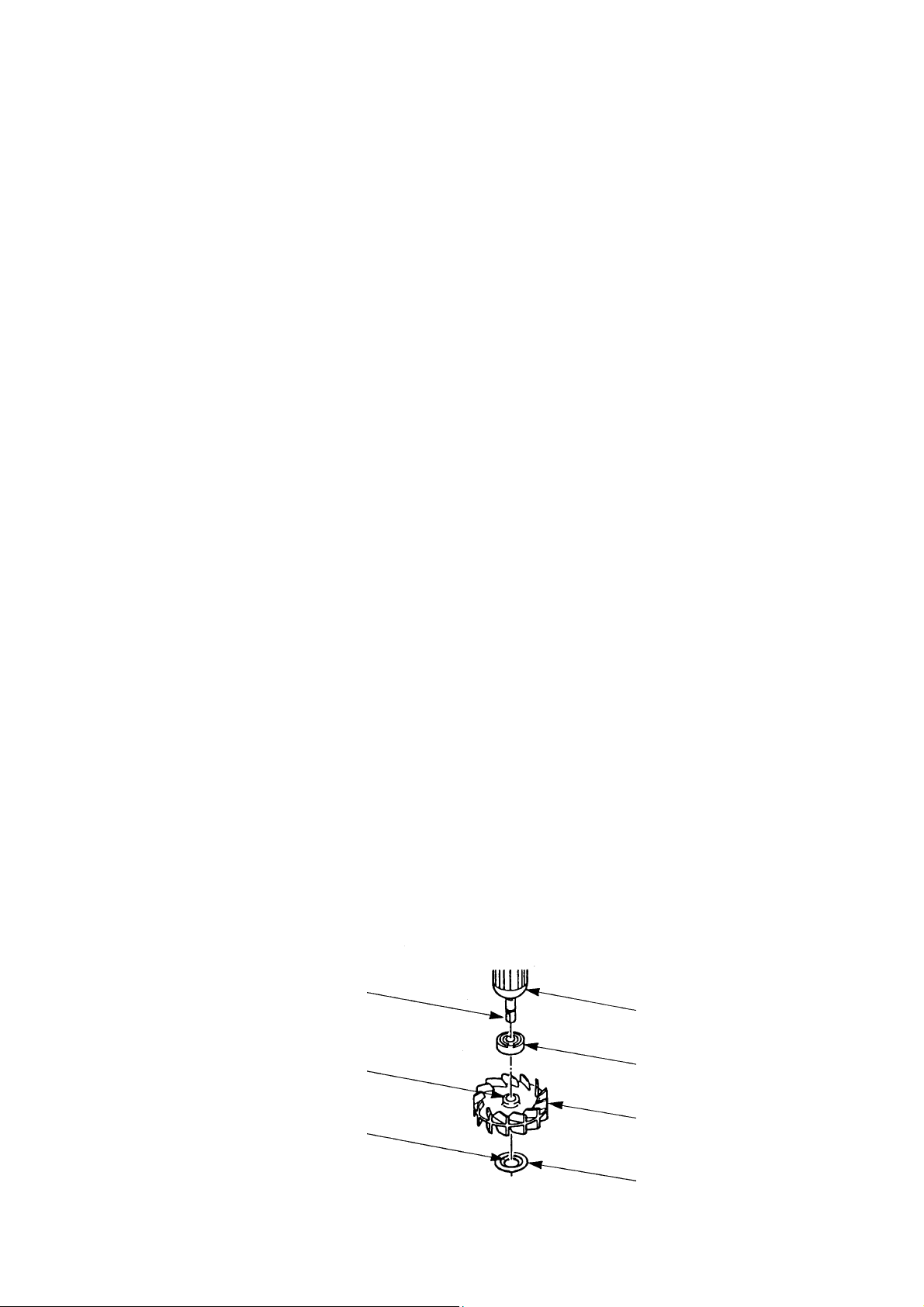

1-2-2. Installing the Balancer Fan [29] <29> and the Dust Washer [30] <30>

When inserting the Balancer Fan

[29] <29>

observe the proper direction of the Dust Washer

into the Armature Shaft, bring their flat faces into alignment. Also

[30] <30>

. (See Fig.4.)

Armature Shaft flat portion

Bring this flat face into alignment

with that of the Armature Shaft.

[12]

[28] <28>

[24] <24>

Install this with the recessed side

facing the Balancer Fan

[29] <29>

[29] <29>

.

[30] <30>

Fig.4

−#2 −

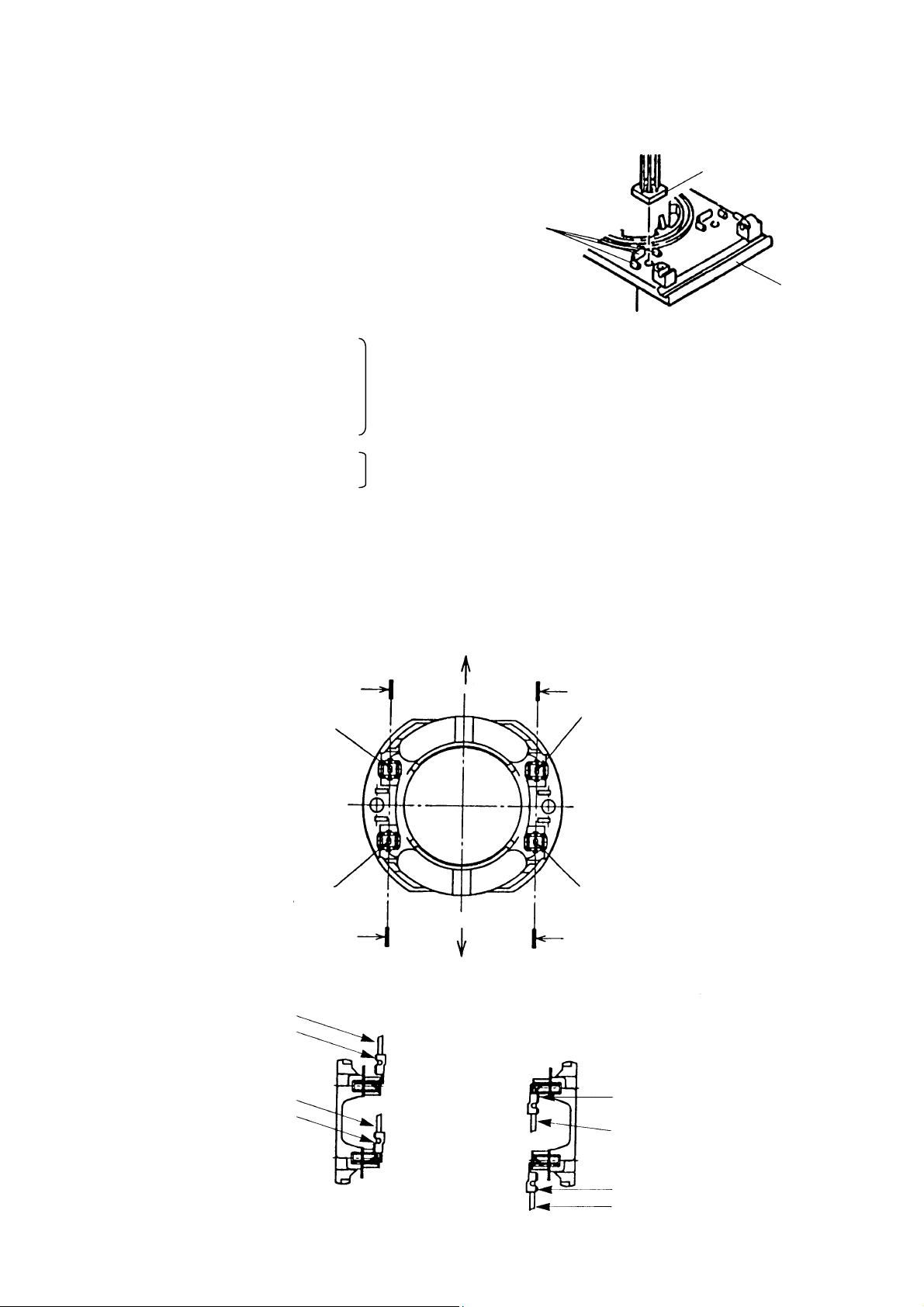

1-2-3. Installing the Base [18] <18>

Install the Legs

fitted within the Ribs. (See Fig.5.)

1-3. Screw Tightening Torque

D4 x 10 Tapping Screws with Flange

D4 x 16 Tapping Screws with Flange

D4 x 20 Tapping Screws with Flange

D4 x 20 Tapping Screws

M4 x 10 Machine Screws

M4 x 12 Machine Screw

Pillar Terminals with terminal screws......... 0.39 ± 0.1 N

Slide Switch with terminal screws .............. 0.39 ± 0.1 N

1-4. Wiring and Connecting Diagrams

[16] <16>

so that their lower parts are

1.96 ± 0.49 N

1.8 ± 0.4 N

Rib

⋅⋅⋅⋅

m (20 ± 5 kgf-cm)

⋅⋅⋅⋅

m (18 ± 4 kgf-cm)

⋅⋅⋅⋅

m (4 ± 1 kgf-cm)

⋅⋅⋅⋅

m (4 ± 1 kgf-cm)

Lower part

[18] <18>

Fig. 5

Perform the wiring as follows.

With the internal wire pointed at A, insert

the Tab Terminal (blue)

With the internal wire pointed at A, insert

the Internal Wire (brown)

Tab Terminal

Press the Tab Terminal

deeply into position.

[7] <7>

Fig. 6 Internal Wires Assembl y Positions (View from Commutator Side)

[7] <7>

.

[6] <6>

.

A

A-A

a

BA

With the internal wire pointed

at B, insert the Internal Wire

(blue)

[26] <26>

With the internal wire pointed

at B, insert the Tab Terminal

(brown)

[27] <27>

.

.

b

B

B-B

Internal Wire

Press the Tab Terminal

deeply into position.

[6] <6>

Fig. 7 Inserting Direction of I nt er nal Wires

−#3 −

Press the Tab Terminal

deeply into position.

Internal Wire

Press the Tab Terminal

deeply into position.

Tab Terminal

[26] <26>

[27] <27>

Wiring Diagram with Noise Suppressor

With Noise Suppressor

Cord

Noise Suppressor

[5] <5>

Tab Terminal (blue)

Pillar Terminal

[21] <21>

[10] <10>

[7] <7>

Brush Holders

Internal Wire

(brown)

[6] <6>

[14] <14>

Carbon Brushes

[15] <15>

Install with the terminal screw facing up.

Slide Switch

Internal Wire

(blue)

[26] <26>

Tab Terminal

(brown)

[22] <22>

[27] <27>

Without Noise Suppressor (for the U.S.A.)

Cord

[10] <10>

Tab Terminal (blue)

Pillar Terminal

[7] <7>

[21] <21>

Fig. 8

Internal Wire

(brown)

[6] <6>

Brush Holders

Carbon Brushes

[14] <14>

[15] <15>

Install with the terminal screw facing up.

Slide Switch

[22] <22>

Internal Wire (blue)

[26] <26>

Tab Terminal (brown)

[27] <27>

Fig. 9

−#4 −

Fit the lnternal Wire (brown)

[6] <6>

in this gap.

Fit the lnternal Wires (brown) (black) of the

Cord in this groove so that they do not

contact the Housing’s conductive part.

Internal Wire (black) of

Noise Suppressor

[5] <5>

Internal Wires (blue) (white)

of the Cord

Fit the Internal Wires (blue) (white)

of the Cord in this groove so that

they do not contact the Housing’s

air vents.

Fit the Internal Wires of the Noise

Suppressor

[5] <5> so

that they do

not contact the Housing’s air vents.

Fit the Internal Wire

of the Tab Terminal

(brown)

[27] <27>

Internal Wire (black)

of Noise Suppressor

[5] <5>

Internal Wires

(brown) (black)

of the Cord

(Cord, Noise Suppressor, Internal Wires, Tab Terminals)

Connecting Wiring Diagram

With Noise Suppressor

Internal Wire

(brown)

[6] <6>

Internal Wire (blue)

[26] <26>

Fig. 10 Wiring Diagram of the Internal Wires

Slide Switch

Tab Terminal (brown)

[27] <27>

12

Noise Suppressor

(excl. the U.S.A.)

[22] <22>

Brown

[5] <5>

Blue

Cord

Tab Terminal (blue)

Fig. 11

−#5 −

Pillar Terminal

[7] <7>

[21] <21>

Without Noise Suppressor (for the U.S.A.)

Tab Terminal (brown)

Internal Wire

(brown)

[6] <6>

Internal Wire (blue)

[26] <26>

[27] <27>

Tab Terminal (blue)

[7] <7>

Fig. 12

Slide Switch

12

Pillar Terminal

[22] <22>

Black

Cord

White

[21] <21>

1-5. Insulation Tests

On completion of disassembly and repair, measure the insulation resistance and conduct a dielectric

strength test.

Insulation Resistance: 7 MΩ or more with DC 500 V megohm tester

Dielectric:Strength: AC 4,000 V/1 min.

with no abnormalities 220 V - 240 V

(and for 110 V U.K. products)

AC 2,500 V/1 min.

with no abnormalities 110 V - 127 V

1-6. No-Load Current Value

After no-load operation for 30 minutes, the current value should be as follows.

Voltage 110 V 115 V 120 V 127 V 220 V 230 V 240 V

Current (A) Max. 1.15 A 1.10 A 1.05 A 0.99 A 0.57 A 0.55 A 0.53 A

−#6 −

2. STANDARD REPAIR TIME (UNIT) SCHEDULES

Variable

Model 10 20 30 40 50 60

Fixed

General

Assembly

Fixed Cost

Grip Tape

Felt Pad

Base

Paper Clip

Work Flow

Grip Tape

Felt Pad

Base

Paper Clip

0 min.

Fan Guide

Thrust Washer

Ball Bearing

(6001DDUCM)

Dust Washer

Balancer Fan

Slide Switch

Cord

Stator

Armature

Ball Bearing

(608VVC2)

x 2 pcs.

SV 8SA

SV 12SF

Cord 10 min.

Others

20 min.

Housing (A)

Housing (B)

Leg x 2 pcs.

Brush Holder

x 2 pcs.

CB x 2 pcs.

−#7 −

Loading...

Loading...