Page 1

Random Orbit Sander

SV 13YA • SV 13YB

Handling instructions

Note:

Before using this Electric Power Tool, carefully read through these

HANDLING INSTRUCTIONS to ensure efficient, safe operation. It is

recommended that these INSTRUCTIONS be kept readily available

as an important reference when using this power tool.

Page 2

SYMBOLS

When symbols are used on the machine, refer to the followings to understand the meaning.

..................................................................

V

.................................................................

A

................................................................

Hz

................................................................

W

...............................................................

kW

..................................................................

g

................................................................

kg

volts

amperes

hertz

watts

kilowatts

grams

kilograms

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases

or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded)

power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving

parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

3) Personal safety

4) Power tool use and care

.............................................................

min

..................................................................

s

........................................................................................

n

0

.../min or ...min

or d.c.

or a.c.

-1

Revolutions or reciprocations per minute

.......

..................................................

..............................................

..............................................................

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

minutes

seconds

no-load speed

direct current

Alternating current

class ll tool

protected supply.

Use of an RCD reduces the risk of electric shock.

a) Stay alert, watch what you are doing and use common

sense when operating a power tool.

Do not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch

or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning

the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

Use of dust collection can reduce dust related hazards.

a) Do not force the power tool. Use the correct power

tool for your application.

The correct power tool will do the job better and safer

at the rate for which it was designed.

1

Page 3

b) Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool's

operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed.

Use of the power tool for operations different from

those intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of children and

infirm persons.

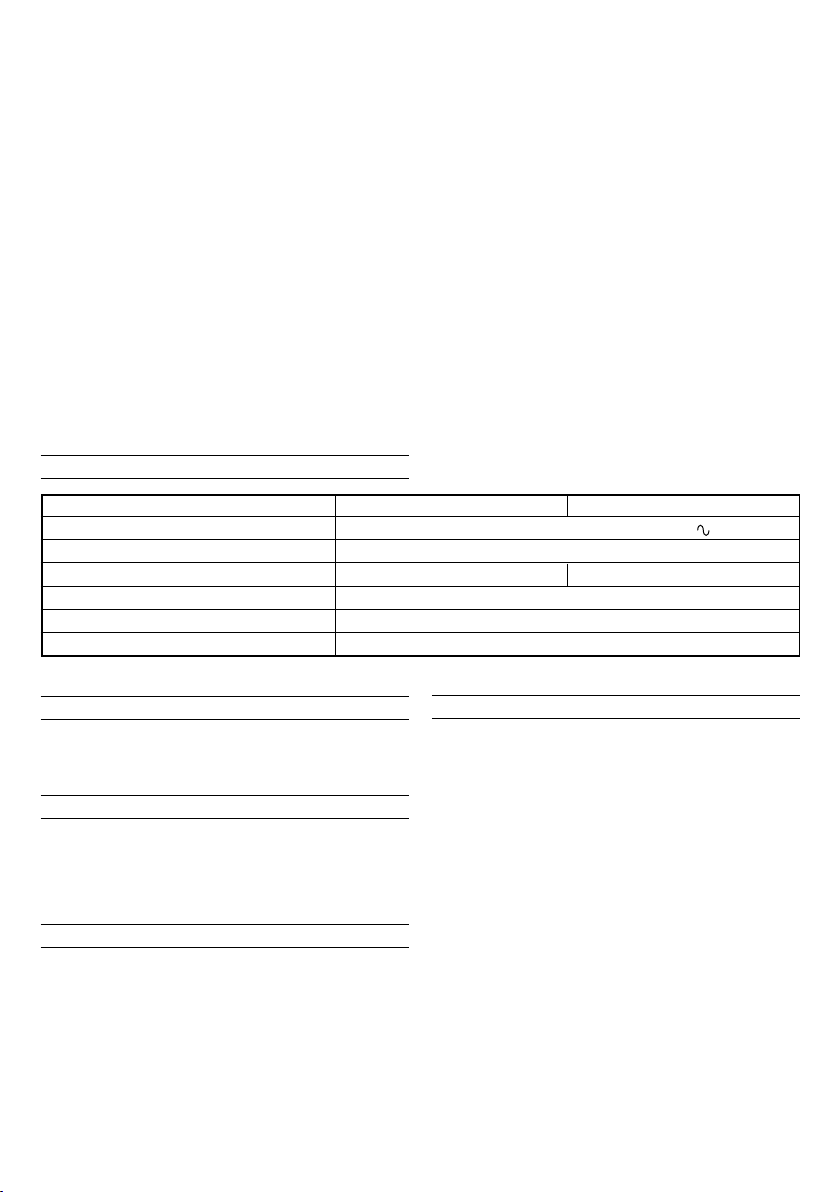

SPECIFICATIONS

Model SV13YA SV13YB

Voltage (by areas)* (110 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Power Input 230 W*

No-load speed 7000 – 12000 min

Sanding pad size (Outer diameter) 125 mm

Sanding paper size (Outer diameter) 125 mm

Weight (without cord) 1.4 kg

*Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

䡬 Sanding paper ............................................................ 1

䡬 Dust bag ...................................................................... 1

Standard accessories are subject to change without notice.

OPTIONAL ACCESSORIES (sold separately)

1. Sanding paper

Grain: AA40, AA60, AA80, AA120, AA180, AA240,

2. Polyester buff

Optional accessories are subject to change without notice.

AA320, AA400

PRIOR TO OPERATION

1. Power source

2. Power switch

3. Extension cord

APPLICATIONS

䡬 Roughing or finishing of woodwork and metal surfaces.

䡬 Preliminary sanding of woodwork and metal surfaces

before painting.

䡬 Paint removal.

䡬 Rust removal.

4. Installing the sanding paper

–1

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

Ensure that the power switch is in the OFF positon. If

the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will start

operating immediately, which could cause a serious

accident.

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

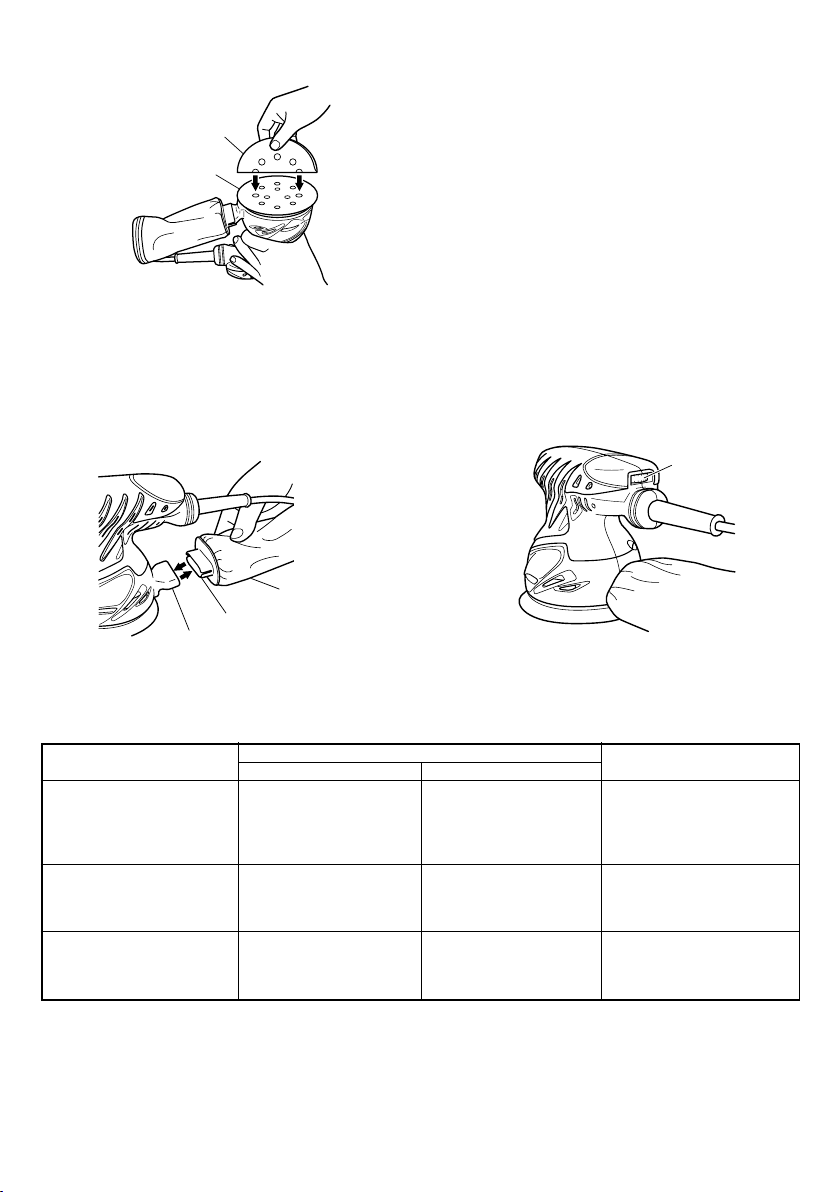

Since the attachment is a hook-and-loop type, the

sanding paper can be installed easily by just pressing it onto the pad. When installing the sanding

paper, in order to match it to the holes in the pad,

gently fold it along the axis of two holes as shown

in Fig. 1.

Next, use the holes along the fold as a guide to

match the sanding paper and the pad. Finally, press

the entire sanding paper uniformly onto the pad.

12000 min

–1

2

Page 4

Sanding paper

Pad

Fig. 1

5. Attaching and Removing the Dust Bag

(1) Attaching the Dust Bag

As shown in Fig. 2, hold the dust gate and push it in

the direction of Arrow A to attach it to the dust outlet.

(2) Removing the Dust Bag

As shown in Fig. 2, hold the dust gate and pull it in

the direction of Arrow B to remove it from the dust

outlet.

A

CAUTION

Prior to the sanding operation, make sure the material

of surface you are going to sand.

If the surface under sanding operation is expected to

generate harmful / toxic dusts such as lead painted

surface, make sure the dust bag or appropriate dust

extraction system is connected with dust outlet tightly.

Wear the dust mask additionally, if available.

Do not inhale or touch the harmful / toxic dusts

generated in sanding operation, the dust can

endanger the health of yourself and bystanders.

6. Adjustment of speed (SV13YA only)

The SV13YA is equipped with the electric control

circuit which enables non-step speed control. To

adjust the speed, turn the dial shown in Fig. 3.

When the dial is set to “1”, the sander operates

at the minimum speed (7000 min

set to “6”, the sander operates at the maximum

speed (12000 min–1). Adjust the speed according to

–1

). When the dial

the material to be cut and working efficiency.

Dial

B

Dust bag

Dust gate

Dust outlet

Fig. 3

Fig. 2

By adjusting the dial, match the speed to the material and type of work.

Material

Rough grinding Fine grinding

Grain

Paintwork:

Sanding 180 400 3 – 6

Repairs

(scratches, rust spots) 120 240 2 – 4

Stripping 40 80 2 – 4

Wood:

Softwood 60 – 80 240 3 – 6

Hardwood 60 180 3 – 5

Veneers 240 320 2 – 4

Metals:

Aluminium 80 240 2 – 4

Steel 60 240 3 – 6

Stainless steel 120 240 3 – 6

Note: Please use this table as a standard.

7. RCD

The use of a residual current device with a rated

residual current of 30 mA or less at all times is

recommended.

3

Dial scale

Page 5

PRACTICAL OPERATING PROCEDURES

CAUTION

Never apply water or grinding fluid when sanding.

This could result in electrical shock.

1. Switching the sander ON and OFF

The power can be turned on by setting the lever to

ON (1) and turned off by setting the lever to OFF (0).

CAUTION

Never turn the power switch ON when the sander is

contacting the surface to be sanded. This is necessary

to preclude damage to the material. The same applies

when switching the power OFF.

2. How to hold the random orbit sander

While gripping the housing, lightly press the sander

against the surface to be sanded so that the sanding

paper uniformly contacts the surface, as shown in

Fig. 4. DO NOT apply excessive pressure to the sander

while sanding. Excessive-pressure may cause

overload of the motor, reduced service life of the

sanding paper, and lowered sanding or polishing

efficiency.

3. How to move the random orbit sander

Move the sander by either moving it up and down

or by moving it in circles while gradually progressing in a sideways direction (Figs. 5 and 6).

Fig. 4

Fig. 5

4. After installing new sanding paper

Movement of the sander may tend to become

unsteady after new sanding paper has been installed,

because of the new, coarse grain of the paper. This

can be avoided by slightly tilting the sander forward

or backward during sanding or polishing. Sander

movement will become steady as the sanding paper

surface becomes properly abraded.

MOUNTING THE OPTIONAL ACCESSORIES

䡬 Mounting the polyester buff

Since the attachment is a hook-and-loop type as

with the sanding paper, the polyester buff can be

mounted by just pressing it onto the pad (Fig. 7).

Polyester buff

Fig. 7

MAINTENANCE AND INSPECTION

1. Empting and cleaning the Dust Bag

If the dust bag contains too much saw dust, dust

collection will be affected. Empty the dust bag when

it gets full.

Remove the dust bag, open the fastener, and dispose

of the contents.

2. Inspecting the sanding paper

Since use of worn-out sanding paper will degrade

efficiency and cause possible damage to the pad,

replace the sanding paper as soon a excessive

abrasion is noted.

3. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

4. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

5. Replacing supply cord

If the supply cord of Tool is damaged, the Tool must

be returned to Hitachi Authorized Service Center for

the cord to be replaced.

6. Servicing

Consult an authorized Service Agent in the event of

power tool failure.

Fig. 6

4

Page 6

7. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

5

Page 7

1 324-249 1

ABC D

SV13YA

2 301-653 7 D4 × 20

3 993-195 1

4 324-207 1

5 ––––––– 1

6 937-631 1

7 984-750 2 D4 × 16

8-1 324-245 1 110V

8-2 324-248 1 220V

8-3 324-244 1 230V

9 959-140 1

8-4 324-247 1 240V

10 938-307 1

11 311-948 1

12 ––––––– 1

13 324-206 1

14 ––––––– 1

15 953-327 1 D8.8

16 322-764 1

17 322-761 1

18 626-VVM 1 626VVC2PS2L

19 322-763 1

20 322-762 1

21 930-483 2

22 999-041 2

23-1 340-616C 1 110V

23-2 340-616E 1 220V-230V

23-3 340-616F 1 240V

24-1 360-696C 1 110V

24-2 360-696E 1 220V-230V

24-3 360-696F 1 240V

25 629-VVM 1 629VVC2PS2L

26 324-521 1

27 324-208 1

28 324-212 1

29 600-2DW 1 6002DDWCMPS2L

30 309-422 1

31 993-244 1 M4 × 12

32 324-210 1

33 324-211 1

34 324-209 1

35 307-109 3 M4 × 16

36 930-039 1

501 310-339 1

502 308-519 1 A-P120

503 324-613 1

6

Page 8

ABC D

SV13YB

7 937-631 1

8 930-039 1

6 984-750 2 D4 × 16

9 938-307 1

10 311-948 1

11 ––––––– 1

12 324-206 1

13 ––––––– 1

14 953-327 1 D8.8

15 322-764 1

16 322-761 1

17 626-VVM 1 626VVC2PS2L

18 322-763 1

19 322-762 1

20 930-483 2

21 999-041 2

22-1 340-618C 1 110V

22-2 340-618E 1 220V-230V

22-3 340-618F 1 240V

23-1 360-698C 1 110V

23-2 360-698E 1 220V-230V

23-3 360-698F 1 240V

24 629-VVM 1 629VVC2PS2L

25 324-521 1

26 324-208 1

27 324-212 1

28 600-2DW 1 6002DDWCMPS2L

29 309-422 1

30 993-244 1 M4 × 12

31 324-210 1

32 324-211 1

33 324-209 1

34 307-109 3 M4 × 16

501 310-339 1

502 308-519 1 A-P120

3 993-195 1

4 324-207 1

2 301-653 7 D4 × 20

5 ––––––– 1

1 324-214 1

7

Page 9

8910

Page 10

Page 11

Page 12

Hitachi Koki Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

Code No. C99138911 G

008

Printed in China

Loading...

Loading...