Polisher

日立牌毛輪磨光機

SP 18VB

HANDLING INSTRUCTIONS

使用說明書

(Wool bonnet is an optional acccessory.)

(羊毛罩是選購附件-)

Read through carefully and understand these instructions before use.

使用前務請詳加閱讀-

1

1

2

4

1

2

3

4

5

3

6

7

4

5

9

8

=

1

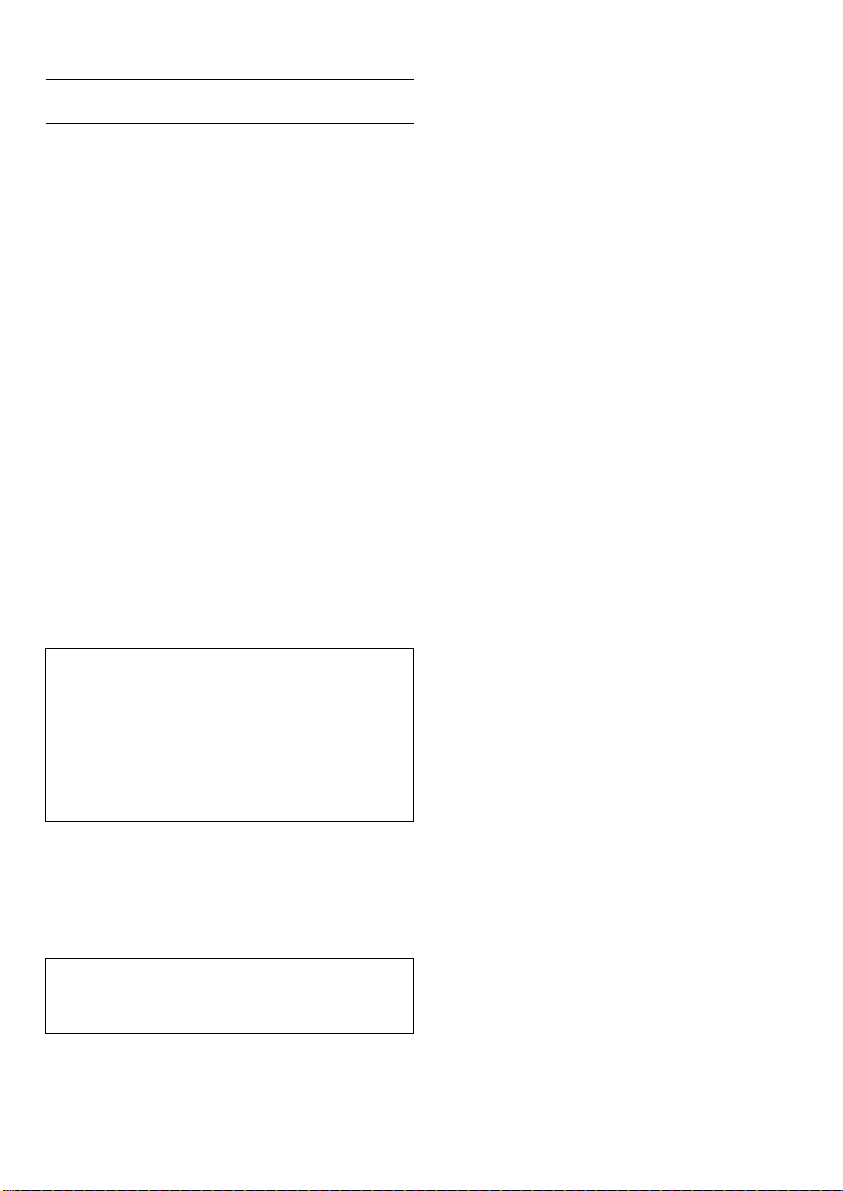

Wrench

2

Tighten

3

Washer nut

4

Wool bonnet (optional accessory)

5

Rubber pad

6

Spindle

7

Lock lever

8

Dial

9

Air cover

0

Wear limit

A

No. of carbon brush

17mm

73

6mm

A

2

GENERAL SAFETY RULES

WARNING!

Read all instructions

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below

refers to your mains operated (corded) power tool or

battery operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks which may ignite the

dust of fumes.

c) Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded)

power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

c) Avoid accidental starting. Ensure the switch is in the

off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning

the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

Use of these devices can reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power

tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn

it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions and in the manner

intended for the particular type of power tool, taking

into account the working conditions and the work to

be performed.

Use of the power tool for operations different from

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of

children and infirm persons.

3

PRECAUTIONS ON USING POLISHER

1. Do not leave the revolving polisher unattended

on the floor.

2. Always hold the body handle and side handle of

the polisher firmly.

Otherwise the counterforce produced may result

in inaccurate and even dangerous operation.

SPECIFICATIONS

Voltage 110V

Power Input* 1010W

No-Load Speed 600 – 2000/min.

Weight (only main body) 2.2 kg

*Be sure to check the nameplate on product as it is subject to change by areas.

Electronic Control

The grinder has an electronic speed control which

provides:

䡬 full speed at all times in the range up to rated load.

䡬 soft-start.

䡬 variable speed.

STANDARD ACCESSORIES

(1) Washer nut .................................................................. 1

(2) Rubber Pad ................................................................. 1

(3) Wrench ........................................................................ 1

(4) Side Handle ................................................................. 1

Standard accessories are subject to change without

notice.

APPLICATIONS

䡬 Polishing or shining painted metal surfaces, such as

those of automobiles, trains, elevators, refrigerators,

sewing machines, washing machines, metal

appliances, etc.

䡬 Polishing varnished surfaces of wooden furniture,

etc.

䡬 Shining synthetic resin or ebonite products.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

CAUTION

Do not operate on Direct Current power source.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, inviting serious

accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

CAUTION

Damaged cord must be replaced or repaired.

4. Fixing the side handle

Screw the side handle into the housing.

5. Confirm the lock lever

Confirm that the lock lever is disengaged by pushing

lock lever two or three times before switching the

power tool on (See Fig. 1)

6. Adjusting the number of revolution

The SP18VB model is equipped with an electronic

infinite-variable-speed drive and can change the

number of revolution according to a use.

If you turn and set the dial scale (Fig. 3) to 6, the

number of revolution increases, and if you turn and

set it to 1, the number of revolution decreases.

Before use, set the number of revolution using the

dial. In so doing, refer to the following table as

a rough guide.

Dial number Number of revolution / min

1 600

2 800

3 1150

4 1500

5 1850

6 2000

Note: Use caution not to turn the dial scale to any

7. Install the air cover on the air vent on the side where

value below 1 or above 6.

the side handle is attached to divert the cooling air

flow of the motor during operation as much as

possible. Hook tab of the air cover to the air vent and

push in the tab when installing. Use a screwdriver

etc. to pull as shown in Fig. 4 when removing.

4

MOUNTING AND DISMOUNTING THE WOOL

BONNET (Optional accessory) (Fig. 1)

CAUTION

Be sure to switch power OFF and disconnect the plug

from the receptacle to avoid serious trouble.

1. Mounting

(1) Attach the washer nut on the rubber pad.

(2) While pushing the lock lever with one hand, lock the

spindle by turning the rubber pad slowly with the

other hand.

Tighten the washer nut by using the supplied wrench.

(3) Cover the rubber pad with the wool bonnet. (optional

accessory)

Pull the string of the wool bonnet, (optional accessory)

let it contact the rubber pad, and tie the string up.

Then, tuck the knot and the remainder of the string

into the wool bonnet. (optional accessory) (See Fig.

2)

CAUTION

䡬 Improper fitting of the wool bonnet may cause

vibration.

䡬 Confirm that the lock lever is disengaged by pushing

lock lever two or three times before switching the

polisher on.

2. Dismounting

To remove the wool bonnet, follow the above

precedures in reverse.

PRACTICAL POLISHER APPLICATIONS

1. Curved surface as well as plain one is treated for

finishing. It is recommended to hold the polisher

without pushing on the material, and make the best

of the weight of the machine alone. As the excessive

pressure on the polishing surface will not only bring

unsatisfactory result but also apply overload on the

motor.

CAUTION

When using the tool at any value except the full

speed (Dial scale 6), the motor cannot be sufficiently

cooled due to the decreased number of revolution.

This could result in the risk of burning and damaging

the motor before an overload protective mechanism

starts to function.

Make sure that you use the tool by lightly applying

it to the surface of material when you use it at any

value except the full speed (Dial scale 6).

2. Depending on the finishing degree of the surface,

use the polishing compound or wax. In order to

attain the maximum polishing effect, first polish the

surface with the fine sand paper using the sander,

than polish it with the polishing compound using the

wool bonnet, and than finish with wax. Apply a small

quantity of the compound and wax to the surface,

and polish with the wool bonnet.

3. Don’t let the cord touch the wool bonnet during its

operation, for the rotating wool bonnet may catch

the cord and get caught it in.

4. Switching on the polisher

Pulling the trigger of switch and push the stopper, it

keeps the switched-on condition and it is convenient

for the continuous operation. When switched off, the

stopper can be disengaged by means of pulling the

trigger again.

5. Precaution after use

Do not lay the polisher down immediately after using

on a place where there are many shavings, much dirt

and dust until it has completely stopped revolving.

CAUTION

When the polisher is not in use, the power source

should be disconnected.

MAINTENANCE AND INSPECTION

1. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

2. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

3. Inspecting the carbon brushes (Fig. 5)

The Motor employs carbon brushes which are consumable parts. When they become worn to or near

the “wear limit”, it could result in motor trouble.

When an auto-stop carbon brush is equipped, the

motor will stop automatically. At that time, replace

both carbon brushes with new ones which have the

same carbon brush Number shown in the figure.

In addition, always keep carbon brushes clean and

ensure that they slide freely within the brush holders.

4. Replacing carbon brushes

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

5. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

Note

Due to HITACHI’s continuing program of research

and development, the specifications herein are subject to change without prior notice.

5

6

1

1

2

4

1

2

3

4

5

3

6

7

4

5

9

8

=

1

扳手

2

緊

3

墊片螺帽

4

羊毛罩(選購附件)

5

襐膠墊圈

6

主軸

7

鎖定桿

8

撥盤

9

空氣保護罩

0

磨損極限

A

碳刷號

17mm

73

6mm

A

2

一般安全規則

警告!

請通讀本說明書

若不遵守下列注意事項﹐可能會導致電擊﹑火災及/或

嚴重傷害下述警告中的術語「電動工具」﹐指插電 (有線) 電

動工具或電池 (無線) 電動工具-

請妥善保管本說明書

1) 工作場所

a) 工作場所應打掃乾淨﹐並保持充分的亮度-

雜亂無章及光線昏暗容易導致事故-

b) 請勿在易爆炸的環境中操作電動工具﹐ 如

存在易燃液體﹑氣體或粉塵的環境中-

電動工具產生的火花可能會點燃煙塵-

c) 操作電動工具時﹐孩童與旁觀者勿靠近工作

場所-

工作時分神可能會造成工具失控-

2) 電氣安全

a) 電動工具插頭必須與插座相配-

不得以任何形式改裝插頭不得對接地的電動工具使用任何轉接插頭原裝插頭及相配插座將會減少電擊的危險-

b) 應避免身體與大地或接地表面﹐如管道﹑散

熱器﹑爐灶﹑冰箱等的接觸-

若身體接觸大地或接地表面﹐ 更會增加電擊

的危險-

c) 電動工具不可任其風吹雨打﹐ 或置於潮濕

的環境中-

水進入電動工具也會增加電擊的危險-

d) 要小心使用電線-不要用電線提拉電動工

具﹐或拉扯電線來拆除工具的插頭-

電線應遠離熱源﹑油液﹐並避免接觸到銳利邊

緣或轉動部分電線損壞或攪纏在一起會增加電擊的危險-

e) 在室外操作電動工具時﹐請使用專用延伸

線-

使用專用延伸線可降低電擊的危險-

3) 人身安全

a) 保持高度警覺﹐充分掌握情況﹐以正常的判

斷力從事作業-

疲勞狀態或服藥﹑飲酒後﹐請勿使用電動工

具-

操作電動工具時﹐ 一時的疏忽都可能造成嚴

重的人身傷害-

b) 使用安全設備-始終配戴安全眼鏡-

在適用條件下﹐使用防塵面罩﹑防滑膠鞋﹑安

全帽或聽覺保護裝置等安全設備﹐ 都會減少

人身傷害-

c) 謹防誤開動-插接電源前﹐請先確認開關是

否已切斷-

搬移電動工具時指頭接觸開關﹐ 或接通開關

狀態下插上電源插座﹐都容易導致事故-

d) 開動前務必把調整用鍵和扳手類拆除下來-

扳手或鍵留在轉動部分上﹐ 可能會造成人身

傷害-

e) 要在力所能及的範圍內進行作業-作業時腳

步要站穩﹐身體姿勢要保持平衡-

這樣在意外情況下可以更好地控制工具-

f) 工作時衣服穿戴要合適-不要穿著過於寬鬆

的衣服或佩帶首飾-頭髮﹑衣角和手套等應遠

離轉動部分-

鬆散的衣角﹑ 首飾或長髮都可能會捲入轉動

部分-

g) 如果提供連接除塵和集塵的設備﹐ 請確認

是否已經連接好並且使用正常-

使用這些設備可降低粉塵引起的危險-

4) 電動工具的使用和維護

a) 不要使勁用力推壓-應正確使用電動工具-

正確使用才能讓工具按設計條件有效而安全地

工作-

b) 如果電動工具不能正常開關﹐切勿使用-

無法控制開關的電動工具非常危險﹐ 必須進

行修理-

c) 進行調整﹑更換附件或存放工具前﹐請拆除

電源插頭-

此類預防安全措施可減少誤開動工具的危險-

d) 閒置不用的工具﹐應存放在孩童夠不到的地

方;不熟悉電動工具或本說明書的人員﹐ 不

允許操作本工具-

未經培訓的人員使用電動工具非常危險-

e) 妥善維護工具-檢查轉動部分的對準﹑連

接﹐各零件有無異常﹐ 及其他足以給工作帶

來不良影響的情況-

如有損壞﹐必須修理後才能使用-

許多事故都是因工具維護不良引起的-

3

f) 保持工具鋒利﹑清潔-

正確維護工具﹐使其保持鋒利﹐作業順暢﹐便

於控制-

g) 請根據本說明書﹐ 按照特殊類型電動工具

的方式﹐使用本工具﹑附件及鑽頭﹐並考慮作

業條件及具體的作業情況-

電動工具用於規定外的作業﹐ 可能會導致危

險狀況-

5) 維修

a) 本電動工具的維修必須由專業人員使用純正

配件進行-

這樣才能確保電動工具的安全性-

注意事項:

不可讓孩童和體弱人士靠近工作場所應將不使用的工具存放在孩童和體弱人士伸手不及的

地方-

使用毛輪磨光機時的注意事項

1. 請勿將正在旋轉的毛輪磨光機放在無人看管的地

板上-

2. 使用毛輪磨光機時﹐應牢牢握住機體操作柄和側

柄-否則所產生的反作用力會將孔鑽歪-甚至會造

成危險-

規 格

電壓 110V

輸入功率* 1010W

額定輸出功率 400 W

無負荷速度 600 – 2000 轉/分

重量(僅限於本體) 2.2 kg

*當須改變地區時應檢查產品上的銘牌-

電子控制

砂輪具備電子速度控制﹐能夠提供以下速度選擇:

䡬 額定負荷範圍內任意時間全速-

䡬 平穩啟動-

䡬 變速-

作 業 之 前

1. 電源

確認所使用的電源與工具銘牌上標示的規格是否

相符-

標 準 附 件

(1) 墊片螺帽 ..........................................................1

(2) 橡膠墊圈 ..........................................................1

(3) 扳手 ................................................................. 1

(4) 側柄 ................................................................. 1

標準附件可能不預先通告而徑予更改-

用 途

䡬 汽車﹑火車﹑電梯﹑冰箱﹑縫紉機﹑洗衣機及其它

金屬裝置等的涂漆金屬表面的拋光和磨亮-

䡬 木製家具等的清漆表面的拋光-

䡬 合成樹脂﹑硬橡膠的磨亮-

注意︰

請勿在直流電源下操作-

2. 電源開關

確認電源開關是否切斷-若電源開關接通﹐則插頭

插入電源插座時電動工具將出其不意地立刻轉動﹐

從而招致嚴重事故-

3. 延伸線纜

若作業場所移到離開電源的地點﹐應使用容量足

夠﹐鎧裝合適的延伸線纜﹐並且要盡可能地短些-

注意︰

損壞和導線一定要更換或修理-

4. 固定側柄

把側柄旋進罩中-

4

5. 檢查鎖定桿

在打開電源開關之前按兩三下鎖定桿﹐檢查它是否

已被釋放(參照圖 1)-

6. 調整旋轉次數

SP18VB型號配備電子無限變速驅動器﹐可以根據

使用情況而改變旋轉次數如果旋轉撥盤刻度片(圖 3)並將其設定至6﹐則

旋轉次數增加;如果旋轉撥盤刻度片並將其設定至

1﹐則旋轉次數減小-使用之前﹐請使用撥盤設定

旋轉次數-相關操作﹐請大致參考下表-

撥盤數字 旋轉次數

1 600

2 800

3 1150

4 1500

5 1850

6 2000

注意︰

請勿將撥盤刻度片旋轉至1以下或6以上的任何值-

7. 將空氣護罩安裝到側面裝有手柄的通風口﹐從而在

運轉期間盡可能轉移電動機的冷風氣流-將空氣護

罩凸起掛到通風口﹐然後在安裝時將其推入-取出

時﹐請按照圖 4所示用螺絲刀等工具將其拉出-

羊毛罩的拆卸(選購附件)

(圖 1)

注意︰

確認開關已斷開並且從電源插座中拔去電源插頭以

避免嚴重事故-

1. 安裝

(1) 將底座螺母裝在椽膠墊圈上(2) 用一只手按鎖定桿﹐同時用另一只手慢慢轉動橡膠

墊圈鎖住主軸用附帶的扳手旋緊輪狀墊片螺帽-

(3) 將羊毛罩(選購附件)罩在海綿墊上-

拉出羊毛罩(選購附件)的線並將其同海綿墊連接

後將線扎緊將扎緊線後所剩下的線放入羊毛罩(選購附件)內

側收納-(圖 2)

注意︰

䡬 羊毛罩安裝得不妥當的話﹐可能會引起振動-

䡬 確認鎖定桿被解除鎖定;可在打開磨光機之前

通過撳兩三下鎖定桿進行檢查-

2. 拆卸

請按與上述相反的順序來拆卸羊毛罩-

實用毛輪磨光機的應用

1. 可進行彎曲表面和平面的拋光-請不要將毛輪磨光

機壓在物體表面上﹐而盡量利用毛輪磨光機本身的

重量-用力將毛輪磨光機壓在物體表面上的話﹐不

僅拋光效果不理想﹐而且會給馬達帶來不必要的負

載-

注意︰

在全速(撥盤刻度片6)以外的速度使用電動工具

時﹐由於旋轉次數減小致使電動機無法充分冷卻此時﹐超負荷保護機械裝置開始運作之前﹐可能會

有導致起火和損壞電動機的危險在全速(撥盤刻度片6)以外的速度使用電動工具

時﹐請務必通過將其輕輕放至物體表面的方式使用

電動工具-

2. 請根據所需的拋光狀態來選擇使用拋光用的化合物

和蠟-為了達到最佳的拋光效果﹐用砂紙機使用粒

度細的砂紙拋光後﹐使用羊毛罩並涂上拋光所用化

合物﹐最後進行打蠟將少量的化合物和蠟涂在要拋光的表面﹐然後再用

羊毛罩拋光-

3. 在操作期間﹐請勿使電線碰到羊毛罩﹐因為羊毛罩

會鉤住電線並將之捲進-

4. 接通毛輪磨光機的電源

扣動開關板機並推入停止銷﹐這樣開關便被保持在

開的狀態﹐便於連續操作-要想關掉開關時﹐請再

次扣動板機開關﹐這樣停止銷也會被斷開-

5. 使用須知

使用本工具之後﹐在砂盤沒有完全停止之前﹐請勿

將其立即放在有許多細層﹑髒物和灰塵的地方-

注意:

毛輪磨光機不用時﹐應將電源關掉-

5

維 護 和 檢 查

1. 檢查安裝螺釘

要經常檢查安裝螺釘是否緊固妥善-若發現螺釘鬆

了﹐應立即重新扭緊﹐否則會導致嚴重的事故-

2. 電動機的維護

電動機繞線是電動工具的心臟部-應仔細檢查有無

損傷﹐是否被油液或水沾濕-

3. 檢查碳刷(圖 5)

電動機裏的碳刷是一種消耗品-碳刷一旦使用到

“磨損極限”﹐電動機就會出現各種障礙;如果所

使用的碳刷是“自停式”﹐電動機將自動地停止轉

動-遇到上述情況﹐應立即換上與圖上代號一致的

新碳刷-此外﹐碳刷應經常保持乾淨狀態﹐以保證

能在刷握裏自由滑動-

4. 更換碳刷

用無頭螺絲刀卸下碳刷蓋﹐然後可以很容易地取下

碳刷-

5. 維修部件目錄

A:項目號碼

B:代碼號碼

C:所使用號碼

D:備註

注意:

日立電動工具的修理﹑維護和檢查必須由日立所認

可的維修中心進行當尋求修理或其他維護時﹐將本部件目錄與工具一

起提交給日立所認可的維修中心會對您有所幫助在操作和維護電動工具中﹐必須遵守各國的安全規

則和標准規定-

改進:

日立電動工具隨時都在進行改進以適應最新的技術進

步因此﹐有些部件(如﹐代碼號碼和/或設計)可能未

預先通知而進行改進-

注:

為求改進﹐本手冊所載規格可能不預先通告而徑予

更改-

6

ABCD

43 311-935 1

1 953-381 1

ABCD

44 984-750 2 D4 × 16

2 953-255 1

45 937-631 1

3 944-005 1

46 938-051 1 D10.1

4 325-485 1

47 323-974 1

48 938-477 2 M5 × 8

49 995-662 1

50 320-946 1

51 325-489 1

52 301-653 7 D4 × 20

5 620-1DD 1 6201DDCMPS2L

6939-542 1

7309-778 2 D5 × 55

8325-478 1 “9, 19”

9 608-VVM 2 608VVC2PS2L

10 325-479 1

53 325-490 1

54 ––––––––––– 1

501 325-491 1

11 317-906 1

12 325-476 1

13 600-0DD 1 6000DDCMPS2L

14 325-477 1

15 360-755C 1 110V

16 325-474 1

17 937-089 1

18 323-209 2 D5 × 35

19 937-033 2

20 325-480 1

21 325-483 1

22 992-509 2 D5 × 45

23 340-653C 1 110V “24”

24 930-703 2

25 315-877 1

26 325-475 1

27 325-482 1 “31, 48 – 50”

29 ––––––––––– 1

30 325-484 1

31 958-900 2

32 999-073 1

33 945-161 2

34 ––––––––––– 1

35 325-481 1

36 305-499 2 M3.5 × 6

37 980-063 1

38 311-741 1

39 959-141 2

40 305-409 1

41 999-043 1

42 980-063 1

7

8

Hitachi Koki Co., Ltd.

Code No. C99143831

Printed in Malaysia

601

Loading...

Loading...