Page 1

)

Hitachi Inverter

SJ300/L300P SERIES

(Profibus‑DPOption

Profibus‑DPOption)

SJ-PB(T

INSTRUCTION MANUAL

Thank you for purchase of “HITACHI INVERTER”. This manual

explains about treatment of “SJ-PB(T) (Profibus-DP Option)”. By

reading this manual and an instruction manual of inverter use practically

for installation, maintenance, and inspection. After reading this manual,

keep it handy for future reference.

Make sure to reach this manual to the end user.

Profibus‑DPOptionProfibus‑DPOption

Table of Contents

Chapter1 INTRODUCTION 1

Chapter2 INSTALLATION 5

Chapter3 WIRING, CONNECTING 6

Chapter4 SETTING 8

Chapter5 OPERATING 10

Chapter6 COUNTERMASURE FOR ABNORMALIT 21

Appendix PARAMETER CROSS-REFERENCE LIST 22

After reading this manual, keep it at handy for future reference.

NB622BX

Page 2

- Request -

Thank you for purchase of “SJ-PB(T) (Profibus-DP Option)”.

This instruction manual explains about treatment and maintenance of “SJ-PB(T)”. Before using the product,

carefully read this manual with the instruction manual of inverter, and keeps it handy for quick reference of

operator and maintenance inspector. Before installing, operating, maintenance and inspection read this

manual carefully and follow the instructions exactly.

Always keep various kinds of specification mentioned in this manual and use exactly. And make sure to

prevent trouble by correct inspection and maintenance. Make sure to reach this manual to the end user.

- About treatment of this manual -

(1)Please consent that mentioned items of this manual may be change without permission.

(2)Keep this manual carefully not to lose because it can not be reissued

(3)All right reserved.

(4)Contents in this manual is written to make assurance doubly sure but, but please contact if you have

some doubts about spelling mistakes, omitted word etc.

(5)Please agree that there is no responsibility for effects resulted, in spite of contents above mentioned.

- About trademark -

(1)Profibus is registered trademark of Profibus Nutzerorganisation.

Revision History Table

No.

1. Initial release of Manual NB622X May. 2001 NB622X

2. Looking at again details. Oct. 2001 NB622AX

3. Adding mention of SJ-PBT. Looking at again details. June. 2002 NB622BX

Except this table, revised only spelling mistakes omitted words, and error writings without notice.

Revision contents The date of issued Manual No.

Page 3

SAFETY PRECAUTIONS

!

!

!

!

SAFTY PRECAUTIONS

Carefully read this manual and all of the warning labels attached to the inverter before installing, operating,

maintaining, inspecting, it. Safety precautions are classified into “Warning” and “Caution” in this manual.

:Indicates a potentially hazardous situation which, if not avoided, can result in serious

WARNING

injury or death.

CAUTION

:Indicates a potentially hazardous situation which, if not avoided, can result in minor to

moderate injury, or serous damage to the product

The situation described in may, if not avoided, lead to serious results. Important safety

measures are described in CAUTION (as well as WARNING) so be sure observe them.

Notes are described in this manual in “(Note)”. Carefully read the contents and follow them exactly.

CAUTION

CAUTION

In all the illustrations in this manual, covers and safely device are occasionally removed to describe the

details. When the product is operated, make sure that the covers and safety devices are placed as they

were specified originally and operate it according to the instruction manual.

Page 4

SAFETY PRECAUTIONS

!

!

WARNING

Wiring:

Wiring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock, fire and/or damage of product.

Implement wiring after checking that the power supply is off.

Otherwise, there is a danger of electric shock and/or fire.

Operating:

Be sure not to touch the surface or the terminal of option board while energizing.

Otherwise, there is a danger of electric shock and/or fire.

Be sure not to remove the Profibus option printed board while operating.

Otherwise, there is a danger of electric shock and/or fire.

Maintenance, Inspection and Part Replacement:

Wait at least 10 minutes after turning off the input power supply before performing maintenance and

inspection.

(Confirm the charge lamp on the inverter is off, checks direct current voltage between P-N terminals and

confirm it is less than 45V)

Otherwise, there is a danger of electric shock.

Make sure that only qualified persons will perform maintenance, inspection, and part replacement

(Before starting the work, remove metallic objects from your person (wristwatch, bracelet, etc.).

Be sure to use tools protected with insulation.)

Otherwise, there is a danger of electric shock and/or injury.

Note:

Never modify the unit.

Otherwise, there is a danger of electric shock and/or injury.

CAUTION

Installation:

Be sure not to let the foreign matter enter such as wire clippings, spatter from welding, metal shaving,

dust etc.

Otherwise, there is a danger of fire.

Be sure to fix inverter to option printed board with an attached fixed screw.

Otherwise, there is a danger of connecting error.

Be sure to fasten the screws connecting signal wire in side of option printed board. Check for any

loosening of screw.

Otherwise, there is a danger of connecting error.

Wiring:

Be sure to fasten the screws not to loose.

Otherwise, there is a danger of connecting error.

Operation:

Check rotary direction, abnormal motor noise and vibrations during operating.

Otherwise, there is a danger of injury to personnel and/or machine breakage

Page 5

CHAPTER 1 INTRODUCTION

1.1 INSPECTION UPON UNPACKING

Make sure to treat the product carefully not to give shock and vibration while unpacking. Check that the product is

the one you ordered, no defect, and that there is no damage during transportation.

(Contents of packing)

(1) SJ-PB(T)(Profibus-DP option printed board):1 (Regarding SJ-PBT, also Install network connector)

(2) Instruction manual:1

(3) Screws fixed printed board (M3 times 8 mm):2

If you discover any problems, contact your sales agent immediately.

1.2 INQUIRY OF THE PRODUCT AND WARRANTY FOR THE PRODUCT

1.2.1 REQUIRE WHILE INQUIRING

If inquiry of breakage, question, damage etc. is needed, please tell the following information to the supplier you

ordered or the nearest Hitachi Distributor.

(1) Type(SJ-PB(T))

(2) Manufacturing number (Item of label, that labeled surface of PCB. X&&&&&&

Or ########

(3) Date of purchasing

(4) Contents of inquiry

・Damage parts and its condition etc.

・Question parts and their contents etc.

In order to shorten impossible working time, standing spare unit is recommended.

#:8 figures serial number.)

&:6 figures number.

1.2.2 WARRANTY OF THE PRODUCT

This product is guaranteed to last for one year after purchase. But, the next case is toll repair, even if within

warranty period.

(1) In case caused by operating mistake, and incorrect repair and modification.

(2) Trouble caused by reasons except the shipped product.

(3) In case of using in range over the value of specification.

(4) In case caused by natural calamity, disaster, and secondary disaster.

Warranty mentioned here means warranty for shipped product itself. Damage caused by trouble of shipped

product is not guaranteed.

[Toll repair]

Any explanation and repair after the warranty period (one-year) shall be charged to the purchaser. And also any

explanation and repair out of warranty mentioned above, even within warranty period, shall be charged to the

purchaser. If you require the toll repair, please contact your Hitachi distributor.

1

Page 6

CHAPTER 1 INTRODUCTION

(

)

)

1.3 Outline of product

SJ-PB(T) is Profibus-DP communication board for SJ300/L300P series inverter.

SJ300/L300P series inverter can get to connect another devices via Profibus-DP when install SJ-PB(T).

SJ-PB(T) is possible to use for all models of SJ300/L300P series.

The SJ-PB(T) option board communicates according to the Profibus Protocol Standard DIN 19245 part 1 & 3.

This means that it can communicate with all masters that comply with this standard, but it does not necessarily

mean that all services available in the Profibus standard are supported. The “Profibus Profile for Variable Speed

Drives” (order no. 3.072), also known as Profidrive, is a subset of Profibus which only supports the services

relevant to speed control applications.

In a control system the option board will act as a slave that can be read and written to, from a Profibus-DP master.

It will not initiate communication to other nodes, it will only respond to incoming telegrams.

(Note) RS485 communication function is disabled by installing SJ-PB(T) to the inverter.

Difference between SJ-PB and SJ-PBT is only connector for networking. Others are no difference.

1.4 Appearance and Names of Parts

Figure 1-1 indicates the appearance of SJ-PB(T).

Connector for connection to SJ300/L300P(Rear of unit)

Left rotary switch for setting Node Address (one to nine) (note)

Right rotary switch for setting Node Address (a times ten factor) (note)

5

0

5

0

Fieldbus On/Off

Fieldbus diagnosis (D13

D14

note: please see chapter 4.1.1 Node Address

Profibus contact (open type)

Serial channel status (D12)

Figure 1-1 Appearance of SJ-PB(T)

2

Page 7

CHAPTER 1 INTRODUCTION

118KT1234510001

118KT1234510001118KT1234510001

118KT1234510001

0101

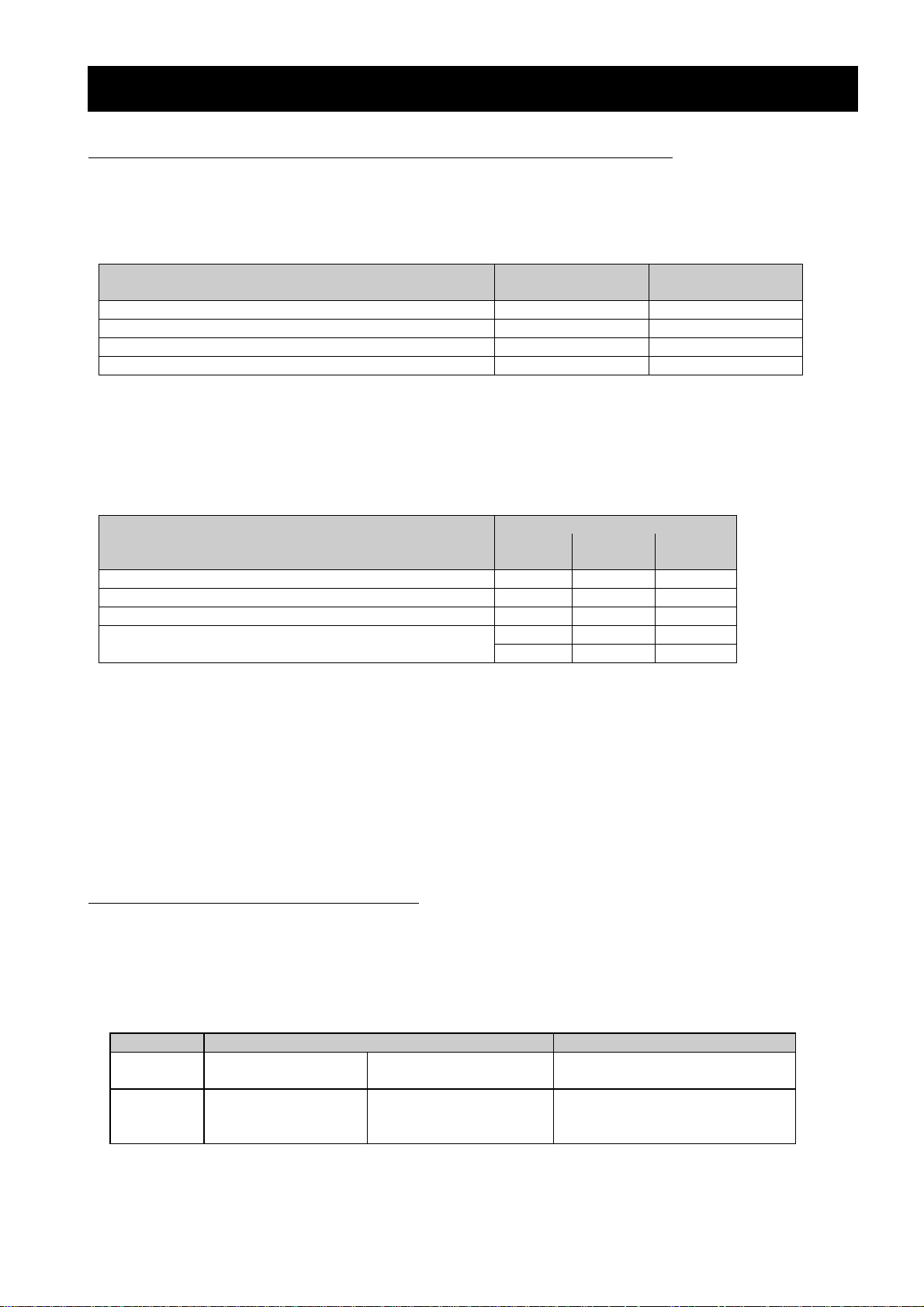

1.5 Profibus-DP Supported Version

SJ-PB(T) can use following Manufacturing number (MFG No) of SJ300/L300P series.

After Manufacturing number : XX8KXXXXXXXXXXXX(SJ300-0.4-55kW / L300P-11-75kW supported)

XXEMXXXXXXXXXXXX(SJ300-75-132kW / L300P-90-132kW supported)

(Note) Manufacturing number is written in specifications label on main body of SJ300/L300Pseries. Refer to

figure 1-2, figure 1-3.

(Figure1-2, 1-3 are the example of SJ300 series. L300P series are the same manner as SJ300 series.)

Specifications label

Figure 1-2 Position of specifications label

Invertermodel

Maximumapplicablemotor

Inputratings

Outputratings

Manufacturing

Manufacturingnumber

ManufacturingManufacturing

number

numbernumber

Figure 1-3 Contents of specifications label

1.6 Technical features of Profibus-DP

• Physical media: EIA RS 485 twisted pair cable or fiber optic.

• Baud rate: 9.6 kbaud up to 12Mbaud.

• Maximum number of nodes: 126

• Maximum number of I/O: 244 bytes/slave.

• Bus topology: Master-Slave communication. The figure below gives an overview of a Profibus-DP network.

• Cyclic user data transfer between DP-Master and DP-Slaves.

• Watch-Dog Timer at the DP-Slaves

• Connecting or disconnecting stations without affecting other stations.

• Powerful diagnosis mechanisms, 3 hierarchical levels of the diagnosis messages.

• Synchronization of inputs and/or outputs.

• All messages are transmitted with Hamming Distance HD=4.

3

Page 8

CHAPTER 1 INTRODUCTION

Figure 1-4 Bus cycle time of a Profibus-DP Mono Master system (2 bytes I/O data/slave)

1.7 Production specification

Bacicaly, the environmental specification of the SJ-PB(T) is in accordance with SJ300/L300P series inverter.

Please refer the instruction manual of SJ300/L300P series.

But only application temperature of SJ-PB(T) is different. Please note.

application temperature : 0 to 50 degree

4

Page 9

CHAPTER 2 INSTALLATION

2.1 Mounting method of option board

Figure 2-1 describes how to mount the option board to the option port 1 or 2.

There are four holes on the option board, match the two of them with the screw holes on the option port 1 or 2.

and mount the other two holes with the guide posts which are located on the option port 1 and 2. To avoid

connection failure, secure the option board with screws after connection.

Option board

Guide posts for mounting the

option board.

Option port 1

Screw holes for secure option board.

(M3 Screws)

Figure 2-1 Installation of option board

Option port 2

5

Page 10

CHAPTER 3 WIRING, CONNECTING

3.1 Physical interface

Isolation: The bus is galvanically separated from the other electronics with an on board DC/DC converter. Bus

signals (A-line and B-line) are isolated via photo couplers.

Profibus-DP communication ASIC: VPC3 chip from ProfiChip.

Bus connection: The SJ-PB connects to the Profibus network with a 9-pin female DSUB connector. For the pin

layout, refer to Table 3-1.

Table 3-1 Pin Layout of SJ-PB

Pin Name Function

Housing Shield Connected to PE

1 Not Connected 2 Not Connected 3 B-Line Positive RxD/TxD according to RS 485 specification

4 RTS Request To Send (note)

5 GND BUS Isolated GND from RS 485 side (note)

6 +5V BUS Isolated +5V from RS 485 side (note)

7 Not Connected 8 A-Line Negative RxD/TxD according to RS 485 specification

9 Not Connected -

(note) +5V BUS and GND BUS are used for bus termination. Some devices, like optical transceivers (RS485 to

fibre optics) might require external power supply from these pins. RTS is used in some equipment to determine

the direction of transmission. In standard applications only A-Line, B-Line and Shield are used.

The SJ-PBT connects to the Profibus network with a 6-poles 2pieces connector. For the pin layout, refer to

Table 3-2.

Table 3-2 Pin Layout of SJ-PBT

Pin Name Function

1 B-Line(in) Positive RxD/TxD according to RS 485 specification

2 A-Line(in) Negative RxD/TxD according to RS 485 specification

3 Shield Connected to PE

4 B-Line(out) Positive RxD/TxD according to RS 485 specification

5 A-Line(out) Negative RxD/TxD according to RS 485 specification

6 Shield Connected to PE

3.2 Profibus connectors

On the SJ-PB, any standard Profibus connector can be used. Depending on baudrate, IP-classing and physical

size of connector there are several different manufacturers and models, the prizing may also vary. For more

information it is recommended to contact the manufacturer, e.g., Siemens or Erni.

SJ-PBT: In this case, the network connector is attached with SJ-PBT option board.

6

Page 11

CHAPTER 3 WIRING, CONNECTING

3.3 Wiring note

1.Installing / removing the cable or connector must be done after checking the power supply off.

2.Wiring should not have bare cables exposed between connector contacts.

3.Network cables should be fixed without tension. Cables fixed under tension have potential of causing a

communication fault by to be removed a connector.

4.A terminating resistor is not built-in the unit. Please provide it.

5.Ensure external emergency stop measures are taken to stop the inverter, in the event of a network fault.

(a) Remove the Power supply of the Inverter when the network master detects a communication fault.

(b) When the master detects a communication fault, turn on the intelligent input terminal which would be

allocated (FRS), (RS) and/or (EXT) function.

6.Basic components for construction of Profibus-DP application are shown bellow.

Refer to the master’s description manuals when Profibus-DP Network system comes into operation.

Personal Computer

with Configuration

RS-232

PROFIBUS-DP

Master

Software

Profibus DP

Slave node #1

(SJ300/L300P)

DP

Profibus DP

Slave node #n

Profibus DP

Slave node #2

(SJ300/L300P)

7

Page 12

CHAPTER 4 SETTING

4.1 Profibus Configuration

Follow the procedure below to set Baud rate in Profibus-DP and Node Address, reset the power supply after

changing the setting (setting will be reflected after resetting power supply). Initial Node Address: 0, Initial Baud

rate: According to master’s setting.

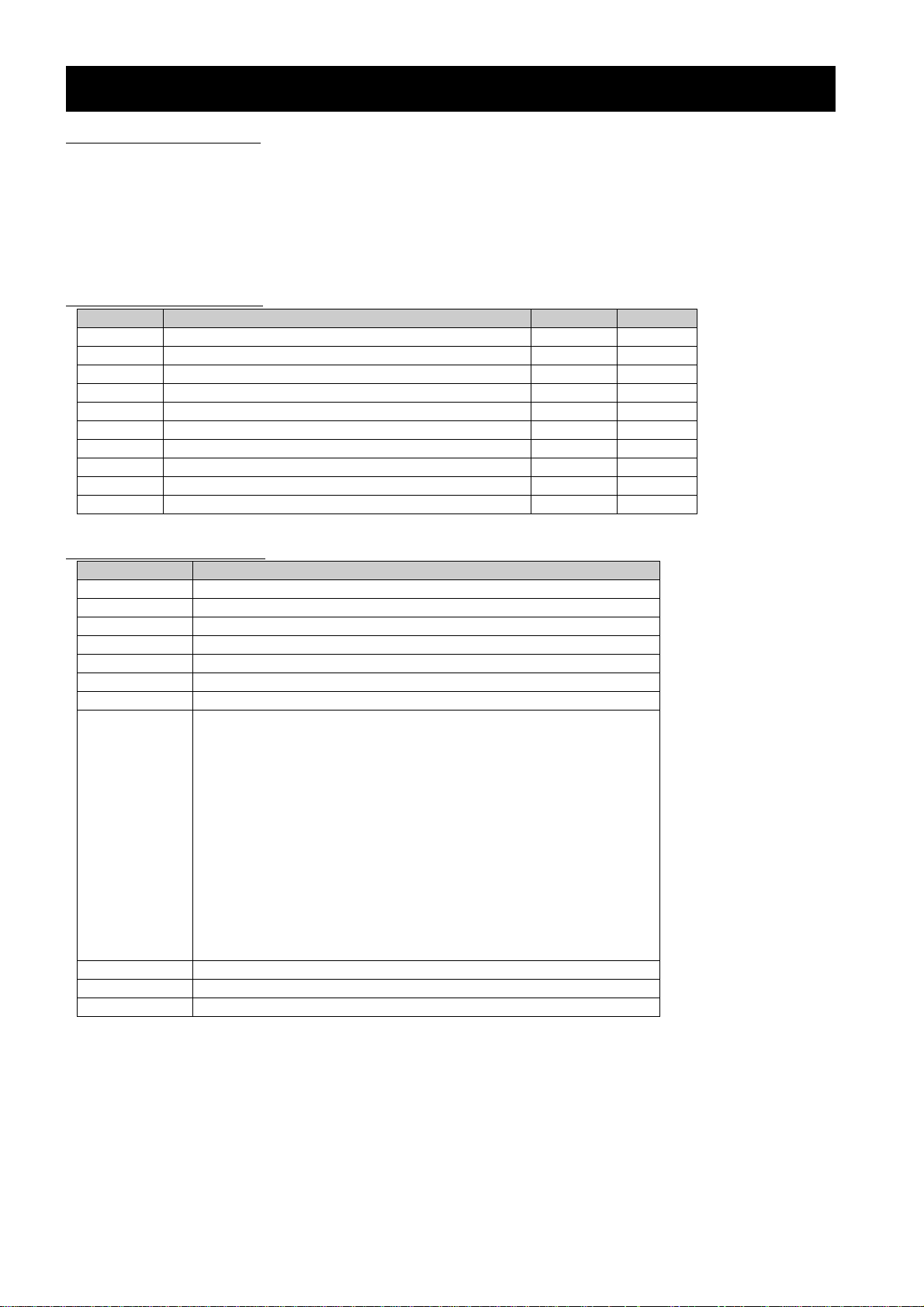

4.1.1 Node Address

Before power-on the SJ300/L300P the node address has to be set. This is done with the two rotary

switches(Figure 1-1) on the SJ-PB(T); this enables address settings from 0-99 in decimal format. The right rotary

switch at the top of the option board represents a times ten factor. The rotary switch at the left represents one to

nine. For example, if address 27 shall be set: Set the right rotary switch to two and the left rotary switch to seven.

Address = (Right Switch Setting x 10) + (Left Switch Setting x 1)

(Note) The node address cannot be changed during operation; the module needs to be re-powered in order for

the change to have effect.

4.1.2 Baudrate

The baudrate on a Profibus-DP network is set during configuration of the master and only one baudrate is

possible in a Profibus-DP installation. The SJ-PB(T) has an auto baudrate detection function and the user does

not have to configure the baudrate on the module. Refer to 4-1 for the baudrates supported.

Table 4-1 Supported baudrates

Baudrates supported by SJ-PB(T)

9.6 kbit/s

19.2 kbit/s

45.45 kbit/s

93.75 kbit/s

187.5 kbit/s

500 kbit/s

1.5 Mbit/s

3 Mbit/s

6 Mbit/s

12 Mbit/s

4.1.3 PPO-type selection

The SJ-PB(T) supports PPO-type 1-5. (Refer to chapter 5.1 for PPO description)

The PPO type is configured from the master. The SJ-PB(T) senses the configuration and configures itself

accordingly. The amount of input/output data transferred on the Profibus network depends on the selected PPO

type. Amount of data transferred in the data-exchange telegram is ranging from 4 bytes input/output (PPO3) to

28 bytes input/output (PPO5).

8

Page 13

CHAPTER 4 SETTING

4.2 Setting of controlling frequency and start/stop commands

The SJ300/L300P inverters can be configured to take reference set-points and commands from several different

locations. Refer to the table below for information of how to configure the inverter so that the fieldbus controls

frequency and the commands.

Control Frequency Setting

Selection - A001

SJ-PB(T) controls frequency and commands 2 1

SJ-PB(T) controls frequency only 2 Not equal to 1.

SJ-PB(T) controls commands only Not equal to 2. 1

SJ-PB(T) has no control. Not equal to 2. Not equal to 1.

However, since the SJ-PB(T) module uses the “Terminal” to give commands and “Operator” to give references to

the inverter certain steps must be taken in order to be able to control the inverter manually (not from fieldbus).

Study the table below to see how the control word bits shall be set to accomplish control from fieldbus and from

the user.

Control word bit settingsControlling the inverter with

A001 = 2 (Operator),

A002 = 1 (Terminal). 10 12 13

SJ-PB(T) controls frequency and commands 1 0 0

SJ-PB(T) controls frequency only* 1 1 0

SJ-PB(T) controls commands only 1 0 1

SJ-PB(T) has no control.

from the “Terminal” input when a SJ-PB(T) is present in the option slot. In order to do this, bit ten in the Control

Word shall be set to zero. That is, by setting A001=2, A002=1, and control word bit 10=0 it is possible to control

the inverter with the terminal while giving frequency reference from the fieldbus.

11 1

0- -

Operation Setting

Selection - A002

*Please note that when frequency reference is controlled from the fieldbus and commands from another location

(such as “Terminal”) the direction of the motor must be controlled from the command source (Reverse/Forward

command). In this case changing the sign of reference value cannot control the direction of the motor.

4.3 Action at communication error

In case of occurring transmission errors (communication cut-off with the master), the following actions can be

selected.

Depending on what option slot the option module is connected to, P001 (Option 1) or P002 (Option 2) is

changed.

P001/P002 Action at error detection Remarks

0 Inverter will trip. Option trip E6x or E7x. Fault can be reset either from

fieldbus or from keypad.

Continue operation

1

according to the last

received command.

--

9

Page 14

CHAPTER5 OPERATING

This section describes how to control the inverter via control word/status word and how to access the inverters

parameters.

5.1 PPO- description

The structure of the user data is designated as parameter process data objects (PPO) in the Profidrive profile.

The profile defines five PPO types, where SJ-PB supports all these PPO types.

There are PPO’s with a parameter area (PKW) and a process data area (PZD). There is also PPO’s that consist

exclusively of process data (PZD).

1. PPO1 consists of the PKW area and 2 words PZD.

2. PPO2 consists of the PKW area and 6 words PZD.

3. PPO3 consists only of 2 words PZD.

4. PPO4 consists only of 6 words PZD.

5. PPO5 consists of the PKW area and 10 words PZD.

The user can configure what shall be transferred in PZD3-10 (shaded grey below), for more instructions of how to

do this configuration see chapter 5.3.3, 5.4.2, 5.4.3 and Appendix.

PKW PZD

PKE IND PWE PZD1

STW

ZSW

Word 123456

PPO1

Word 12345678910

PPO2

Word 5 6

PPO3

Word 5678910

PPO4

Word 1234567891011121314

PZD2

HSW

HIW

PZD3 PZD4 PZD5 PZD6 PZD7 PZD8 PZD9 PZD10

PPO5

PKW -- Parameter ID/value.

PZD -- Process data, cyclically transferred.

PKE -- Parameter ID (1

IND -- Sub-index (3

PWE -- Parameter value (5

STW -- Control word.

ZSW -- Status word.

HSW -- Main reference.

HIW -- Main actual value.

st

and 2nd octet).

rd

octet), 4th octet is reserved.

th

to 8th octet, 32-bits).

10

Page 15

CHAPTER5 OPERATING

5.2 PKW-part

The parameter part (PKW) is fixed to 4 words and can be used for reading and/or updating the parameters in the

inverter one by one. Requests and responses is a handshake procedure and cannot be batched, meaning that if

the master sends out a read/write request, it has to wait for the response, before it sends a new request.

The PKW is further divided into three parts; PKE- Parameter ID (2 bytes), IND – Sub-index (2 bytes) and PWE-

Parameter value (4 bytes).

PKW

PKE IND PWE

PKW: Parameter ID/value.

PKE: Parameter ID.

IND: Sub-index (3

PWE: Parameter value (4 bytes).

rd

byte, 4th byte is reserved).

PZD

PZD1

STW

ZSW

PZD2

HSW

HIW

PCD3 PCD4 PCD5 PCD6 PCD7 PCD8 PCD9 PCD10

PKE handling:

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

AK SPM

PNU

Figure 5-1 PCA word

AK: Request/response characteristics (Range 0-15)

SPM: Toggle bit for Spontaneous Messages, not used by SJ-PB(T).

PNU: Parameter number. Range 1- 418 for Hitachi specific parameters and 900-999 for Profidrive specific parameters.

Please refer to chapter 3.5 for which Profidrive specific parameters that are supported.

11

Page 16

CHAPTER5 OPERATING

Request/Response handling

The AK portion of the PKE word defines the request/response that may be issued.

Since parameter length of the SJ300/L300P inverter may vary, parameter values are always transferred so that

the least significant byte is placed in octet 8.

If the Request/Response contains array elements, the high byte (byte 3) of the IND word will carry the array sub

index, low byte (byte 4) is reserved for future use.

AK content (master -> slave)

Request Function Ackn (+) Ackn (-)

0 No request 0 1 Request parameter value 1 7

2 Change parameter value (word) 1 7/8

3 Change parameter value (long word) 2 7/8

4 Request description element (note) 3 7

5 Change description element (note) 3 7

6 Request parameter value (array) 4 7

7 Change parameter value (array word) 4 7/8

8 Change parameter value (array long word) (note) 5 7/8

9 Request number of array elements 6 7

AK content (Slave -> master)

Response ID Function

0 No response

1 Transfer parameter value (word)

2 Transfer parameter value (long word)

3 Transfer description element (note)

4 Transfer parameter value (array word)

5 Transfer parameter value (array long word) (note)

6 Request number of array elements

7 Request rejected, followed by fault code (in PWE part).

0 = Non-admissible parameter number

1 = Parameter value cannot be changed

2 = Upper or lower limit exceeded

3 = Erroneous sub-index

4 = No array

5 = Incorrect data type

7 = Descriptive element cannot be changed

9 = Descriptive data not available

11 = No parameter change rights

17 = Task cannot be executed due to operating status

102= Task cannot be executed due to communication error.

106 = Illegal Task, Task ID not allowed.

18 = Other

8 No parameter change rights by PKW interface

9 Parameter data signal (word) (note)

10 Parameter data signal (double word) (note)

If the inverter rejects a request from the master, the AK word in the PPO-read will indicate this by assuming value

7 or 8. The describing fault number will be found in the PWE part.

(note) Not supported by the SJ-PB(T) option board.

12

Page 17

CHAPTER5 OPERATING

5.3 PZD-part

In this chapter the process data part (PZD) of a PPO is discussed.

The PZD part consists of a fixed part (PZD1-2, all PPO’s) and a parameterable part (PZD 3-10, shaded grey

above, PPO 2, 4 and 5).

In the fixed part, control word and speed reference are transferred to the inverter while status word and actual

output frequency are transferred from the inverter.

In the parameterable part, PZD word 3-10, the user can configure what parameters that should be transferred

to/from the inverter every bus-cycle (see chapter 5.3.3 and Appendix).

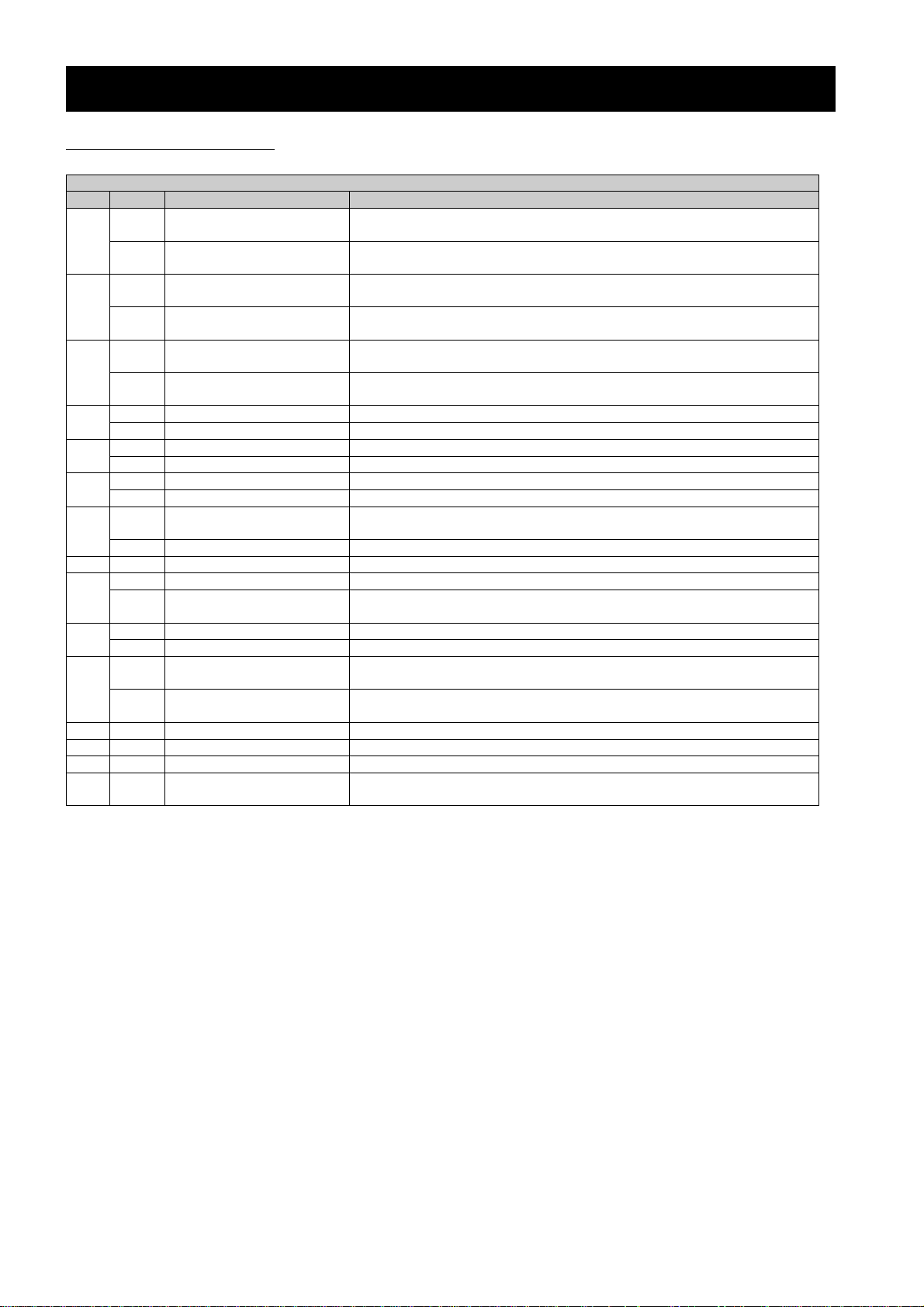

5.3.1 Control- / status word (STW/ZSW)

This section describes how to operate the inverter with the control-/status word. With the control word the

Profidrive state-machine (Figure 5-2) is controlled, the status word is reflecting the state of the inverter.

Profidrive Control Word (STW):

The control word is used to send control commands to the inverter (PLC->Inverter).

Bit Value Meaning Remark

1 On1 Inverter can be started if all other start conditions are fulfilled.0

0 OFF1 Normal stop; uses deceleration time specified in “1

1 ON2 Inverter can be started if all other start conditions are fulfilled.1

0 OFF2

1 ON3 Inverter can be started if all other start conditions are fulfilled.2

0 OFF 3 Quick stop that uses deceleration time specified in “2nd deceleration time”

1 Operation enabled Inverter can be started if all other start conditions are fulfilled.3

0 Operation disabled

1 Condition for operation Inverter can be started if all other start conditions are fulfilled.4

0 Ramp generator disabled Output frequency is set to zero. Inverter remains in the running state.

1 Ramp generator enabled Inverter can be started if all other start conditions are fulfilled.5

0 Stop ramp generator Actual output frequency is frozen. A change to frequency set-point has no

1 Enable set-point Inverter can be started if all other start conditions are fulfilled,

6

0 Inhibit set-point Normal stop that uses deceleration time specified in “1

1 Acknowledge Fault is acknowledged on positive edge, i.e. bit 7=0 then 1

7

0 No function

1 Inching 1 ON Inverter accelerates to inching set-point 1.

8

0 Inching 1 OFF

9 Not used

1 Data valid The control word and frequency set-point (from Profibus) are activated.

10

0 Data invalid The control word and frequency set-point (from Profibus) are not valid.

1 REV Inverter will operate in reverse motion.

11

0 FWD Inverter will operate in forward motion.

1 Commands invalid The fieldbus module will not write any commands to the inverter. This makes it

12

0 Commands valid The fieldbus module can write commands to the inverter (if A002 is set to

1 Reference invalid The fieldbus module will not write any reference to the inverter.13

0 Reference valid The fieldbus module can write reference to the inverter (if A001 is set to

14,

15

Not used

Inverter coast to stop. Returns to Switch-on inhibit state.

(F203).

Inverter coast to stop (Enter Inhibit operation state).

effect.

using “1

(Enter Switch-on inhibited state).

Profidrive must be in “Enable operation” state.

Parameter “Jogging frequency” specifies the jogging set-point (A038).

Inverter brakes as fast as possible and goes into the “Enable operation” state.

Please refer to chapter 2.2.4.

Please refer to chapter 2.2.4.

Please note that a negative reference and reverse selected will result in inverter

running forward.

possible to operate motor via the terminal input (if A002 is set to “Terminal”).

“Terminal”).

“Operator”).

Control word

st

Acceleration time” (F002).

st

Deceleration time” (F003).

st

deceleration time”.

13

Page 18

CHAPTER5 OPERATING

Profidrive Status Word (ZSW):

The status word indicates the status of the inverter (Inverter -> PLC).

Status word

Bit Valu e Meaning Remark

1 Ready to switch-on

0

0 Not ready to switch-on Control word bit 0, 1 or 2 (OFF1, OFF2, OFF3) is set to 0, or the inverter

1 Ready for operation

1

0 Not ready for operation Control word bit 0, 1 or 2 (OFF1, OFF2, OFF3) is set to 0, or the inverter

1 Operation enabled

2

0 Operation inhibited Control word bit 0, 1, 2 or 3 (OFF1, OFF2, OFF3, Operation disabled) is

1 Fault Inverter is faulted.3

0 No fault Inverter is not faulted.

1 ON2 Control word bit1=1.4

0 OFF2

1 ON3 Control word bit2=1.5

0 OFF 3

1 Start enable Control word bit1 or 2 (OFF2, OFF3) is set to 0 or fault has been

6

0 No switch-on inhibit

7 Not used

1 Frequency equal set-point Actual output frequency does equal frequency set-point.8

0 Frequency not equal set-

point

1 Bus control Run command or frequency setting is valid via Profibus.9

0 Local control Run command and frequency setting are invalid via Profibus.

1 Frequency within range Actual output frequency is above or equal to the limit specified by “Arrival

10

0 Frequency out of range Actual output frequency is below the limit specified by by “Arrival

11 Not used 12 - Mirror of bit 12 in the control word.

13 - Mirror of bit 13 in the control word.

14,15- Not used -

Control word bit 0=0 and bits 1, 2, 10 are set to 1 (Ready to switch-on

state).

is tripped.

Control word bit 0, 1 and 2 are set to 1. Inverter is not faulted (Ready

state).

is faulted.

Control word bit 0, 1, 2 and 3 are set to 1. Inverter is not faulted (Enable

operation state).

set to 0, or the inverter is faulted.

OFF2 command active. Control word bit1=0 (OFF2 active state).

OFF3 command active. Control word bit2=0 (OFF3 active state).

acknowledged (Switch-on inhibit state).

Control word bit 0=0 and bit10=1 (Not ready to switch-on state).

Actual output frequency does not equal frequency set-point

(i.e. motor accelerating/decelerating).

frequency at acceleration/deceleration 1” (C042/C043).

frequency at acceleration/deceleration 1” (C042/C043).

14

Page 19

CHAPTER5 OPERATING

START

Voltage

switched-off,

SW=0

SW: bit 0=1

SW: bit 1=0

Voltage on

CW: bit 3=0

bit 10=1

bit 4=1

bit 5=1

CW: bit 4=0

CW: bit 0=0

bit 10=1

A

Inhibit operation

active

Operation

inhibit

Ready A B C D

OFF1 Active

Stage 1

OFF1 Active

Stage 2

CBD

CBD

n(f)=0, I=0

Switch-on inhibit

Not ready for

switch-on

Ready for

switch-on

Ready

Enable operation

A

CW: bit 5=0

CW: bit 6=0

CW: bit 0=0

bit 10=1

CW: bit 0=0

bit 1=1

bit 2=1

bit 10=1

CW: bit 0=1

bit 10=1

CW: bit 3=1

bit 10=1

CW: bit 4=1

bit 10=1

bit 10=1

bit 10=1

CD

D

SW: bit0=0

bit1=0

bit2=0

bit 6=1

SW: bit 0=0

bit 2=0

bit 6=0

SW: bit 0=1

bit 4=1

bit 5=1

SW: bit 1=1

SW: bit 2=1

Load contactor open

RFG enabled

output

RFG Acc

enabled

Ready to

switch-on

Ready to

switch-on

CW: bit 5=1

bit 10=1

Ready A B C D

OFF3 Active

Ready A B C D

Fault

B

CW: bit 2=0

bit 10=1

n(f)=0, I=0

Fault

CW: bit 7=1

SW: bit 5=0

SW: bit 3=1

Drive running

Jogging active

Jogging-pause

monitoring

Ready to

switch-on

CW: bit 8=1

bit4=0

bit5=0

bit6=0

bit 10=1

CW: bit 8=0 or

bit 10=1

Ready A B C D

OFF2 Active

Jog setpoint

to speed

controller

CW: bit 1=0

bit 10=1

SW: bit 4=0

CW: bit 8=1

bit4=0

bit5=0

bit6=0

bit 10=1

n(f)=0, I=0

D

Operating status

CW: bit 6=1

bit 10=1

Outputing

frequency

(bit 10=1)

Figure 5-2 Profidrive state diagram

5.3.2 Frequency set-point/ Actual frequency

The data format is “Standardized value”, where 0 hex = 0 % and 4000 hex is 100% of Maximum frequency

specified in parameter A004.

Standardized value

A linear value.

0%=0 (0h), 100% is 2

Data type N2

Range -200%…200%-2

Resolution 2

Length 2 bytes

Notation: 2’s complement notation.

MSB is 1

Sign bit = 0 = positive number

Sign bit = 1 = negative number

Bit 8 7 6 5 4 3 2 1

Byte 1 SIGN 2

Byte 2 2

14

(4000h)

-14

-14

= 0.0061%

st

bit after sign bit in 1st byte.

0

-1

-7

2

-8

2

-9

2

-2

-3

-4

2

2

2

-10

2

2

-11

-12

2

-5

2

-13

2

-6

2

-14

2

15

Page 20

CHAPTER5 OPERATING

5.3.3 PZD word 3-10

In PZD word 3-10 the user can determine which inverter parameters that should be transferred to/from the

inverter every bus-cycle.

With some of the PPO types (PPO2, 4, 5) it is possible to read and write parameters cyclically. Parameter write

values are placed in the PZD’s 3-10 transferred from the master to the inverter. Parameter read values are

placed in the PZD’s 3-10 transferred from the inverter to the master. However, the meaning of the data

transferred in PZD3-10 must be defined in some way so that it can be determined what parameters that shall be

written, and also so that the data transferred from the inverter can be connected with the correct parameter.

Parameter 915 and 916 are used to determine what parameters that shall be written (915) and read (916)

cyclically (parameter number as specified below, for examples of how to assign these refer to chapter 5.4.2 and

5.4.3).

Assignment of PZD write word 3-10 (PLC -> Inverter) with parameter 915:

915, sub-index 1 = Parameter number for parameter transferred in PZD3

915, sub-index 2 = Parameter number for parameter transferred in PZD4

915, sub-index 3 = Parameter number for parameter transferred in PZD5

915, sub-index 4 = Parameter number for parameter transferred in PZD6

915, sub-index 5 = Parameter number for parameter transferred in PZD7

915, sub-index 6 = Parameter number for parameter transferred in PZD8

915, sub-index 7 = Parameter number for parameter transferred in PZD9

915, sub-index 8 = Parameter number for parameter transferred in PZD10

Assignment of PZD read word 3-10 (Inverter ->PLC) with parameter 916:

916, sub-index 1 = Parameter number for parameter transferred in PZD3

916, sub-index 2 = Parameter number for parameter transferred in PZD4

916, sub-index 3 = Parameter number for parameter transferred in PZD5

916, sub-index 4 = Parameter number for parameter transferred in PZD6

916, sub-index 5 = Parameter number for parameter transferred in PZD7

916, sub-index 6 = Parameter number for parameter transferred in PZD8

916, sub-index 7 = Parameter number for parameter transferred in PZD9

916, sub-index 8 = Parameter number for parameter transferred in PZD10

Please Note:

1. PZD words 3-6 are enabled if PPO 2 or 4 is selected. PZD words 3-10 are enabled with PPO5.

2. Parameter numbers are within the range 1-418. See chapter 5 for an index of the inverter parameter numbers.

If a parameter number is set to 0, the actual PZD word will be ignored.

3. Only parameters that are of size two bytes or less can be assigned as PZD objects.

16

Page 21

CHAPTER5 OPERATING

5.4 Parameter Examples

5.4.1 Writing a four byte parameter

In this first example, PPO1 is used to set parameter F002 (1st Acceleration time 1) to 4.00 seconds. Also, a Start

command and a frequency set-point (50%) is given.

Please note: When reading/writing parameters via the Profidrive profile the cross-reference list must be used,

see chapter 5. For example, parameter F002 (1

Profibus

.

PKW PZD

st

Acceleration time 1) have parameter number 23 (17h) on

Word

Request:

PLC->Inverter

Response:

Inverter->PLC

1

PKE

30 17 00 00 00 00 01 90

20 17 00 00 00 00 01 90

2

IND

3

PWE

4

PWE

5

STW

ZSW

04 06

04 7F*

03 31

03 37

6

HSW

HIW

20 00

20 00

In the request message the first two bytes are used for parameter identification. The first digit (2) denotes the

function “Change parameter value (long word)” (refer to chapter 3.2). The second digit along with the second

byte (0 and 17) indicates parameter number 23. Bytes 7 and 8 (01 90 = DEC 400) is the parameter value (400

meaning 4.00 seconds). The last four bytes are the Control Word and Frequency set-point. Control Word value

04 06 -> 04 7F* starts the motor, while 20 00 (refer to 5.3.2) signifies 50 % of the maximum frequency specified in

parameter A004.

In the response message, the first digit (2) indicates the function “Transfer parameter value (long word)”. Value

(01 90 in bytes 7 and 8) and parameter number (x0 17) are mirrored from the request. The last four bytes are

Status Word and Actual frequency (%).

5.4.2 Writing a two byte array parameter

In this second example, we are configuring PZD3 to contain the value of parameter A038, “Jogging frequency” in

the responses from the inverter to the master (PLC). PPO2 is used. On Profibus parameter A038 corresponds

to parameter number 61 (3Dh). This is configured with parameter number 916 (394h), “Assignment of PZD read

word” (see also chapter 5.3. and 5.5).

Word 1

Request:

PLC->Inverter

Response:

Inverter->PLC

PKW PZD

2

PKE

73 94 01 00 00 00 00 3D

43 94 01 00 00 00 00 3D

IND

3

PWE

4

PWE

STW

ZSW

04 06

04 7F

03 31

03 37

17

5

6

HSW

HIW

20 00 00 00 00 00 00 00 00 00

20 00 01 F4 00 00 00 00 00 00

7

PZD38PZD49PZD510PZD6

Page 22

CHAPTER5 OPERATING

In the request message the first two bytes are used for parameter identification. The first digit (7) denotes the

function “Change parameter value (array word)” (refer to chapter 3.2). The second digit along with the second

byte (3 and 93) indicates parameter number 916. Byte 3 (01) denotes sub-index in the array parameter, in this

case “01” means the first index in the array. Bytes 7 and 8 (00 3D = 61dec) contains the parameter number that

shall be mapped. This means that in the PZD3 place the read value of parameter A038 (Profibus parameter

number 61dec) shall be transferred from the inverter to the master every bus-cycle.

In the response message, the first digit (4) indicates the function “Transfer parameter value (array word)”. Sub-

index (01 00), value (00 3D in bytes 7 and 8) and parameter number (x3 94) are mirrored from the request. In the

PZD3 field (word 7) the value (01 F4 = 500dec, 5.00 Hz) of “Jogging frequency” is transferred.

5.4.3 Writing a two byte array parameter #2

In this third example, we are configuring PZD3 to contain the value of parameter A004, “1st Maximum frequency”

in the request from the master to the inverter. PPO2 is used. On Profibus parameter A004 corresponds to

parameter number 62 (3Eh). This is configured with parameter number 915 (393h), “Assignment of PZD write

word” (see also chapter 5.3.3 and 5.5).

PKW PZD

Word 1

PKE

2

IND

3

PWE

4

PWE

5

STW

ZSW

6

HSW

HIW

7

PZD38PZD49PZD510PZD6

Request:

PLC->Inverter

Response:

Inverter->PLC

73 93 01 00 00 00 00 3E 04 7F 20 00 00 4B 00 00 00 00 00 00

43 93 01 00 00 00 00 3E 03 37 20 00 01 F4 00 00 00 00 00 00

In the request message the first two bytes are used for parameter identification. The first digit (7) denotes the

function “Change parameter value (array word)” (refer to chapter 3.2). The second digit along with the second

byte (3 and 93) indicates parameter number 915. Byte 3 (01) denotes sub-index in the array parameter, in this

case “01” means the first index in the array. Bytes 7 and 8 (00 3E = 62dec) contains the parameter number that

shall be mapped. In the PZD3 field (word 7) the value (00 4B = 75, 75 Hz) of “1

st

Maximum frequency” is

transferred. That is, parameter A004 will be written with the value 75.

In the response message, the first digit (4) indicates the function “Transfer parameter value (array word)”. Sub-

index (01 00), value (00 3E in bytes 7 and 8) and parameter number (x3 93) are mirrored from the request. As

can be seen in word 7 (PZD3) 01 F4h is transferred from the inverter to the master, that is the mapping from the

example above (5.4.2) is still present.

*To start the inverter the Profibus state machine must be shifted in a correct way. This may be done in two steps.

First the control word should be set to 04 06 (Enter

Ready to switch-on state

) and then to 04 7F (Enter Operating

state). Refer to the state diagram in Figure 5-2.

18

Page 23

CHAPTER5 OPERATING

5.5 Profidrive specific parameters

The table below shows which Profidrive specific parameters that are supported by the SJ-PB(T).

Table 5-1 Profidrive parameters

PNU Parameter Number Description Range

915

Assignment of PZD write word

3-10

916

Assignment of PZD read word

3-10

918

Profibus-DP slave address

927

Parameter edit rights

928

Control rights (process data).

947

Indexed Fault memory

963

PROFIBUS-DP baud rate

964

Device identification

965

Profile version

967

Control Word

968

Status Word

971

Transfer into non-volatile

memory

Refer to chapter 5.3.3 and 5.4.3 for how to assign PZD

words. Use the parameter cross-reference list in

chapter 5.

Please note: Parameters will be lost when turning

power off unless parameter 971 has been written with

“0->1”.

Refer to chapter 5.3.3 and 5.4.2 for how to assign PZD

words. Use the parameter cross-reference list in

chapter 5.

Please note:

power off unless parameter 971 has been written with

“0->1”.

Returns address switch setting. 1-99 R

1 – PKW interface enabled. Parameters can be

read/written.

0 – PKW interface disabled, only parameter 927 can

be read/written.

1 – Option board will send control word, reference and

will update PZD3-10.

0 – PZD not enabled.

Fault. Codes as described in table 5-2 below.

Sub-index 1 = Not acknowledged fault.

Sub-index 9 = Latest acknowledged fault.

Sub-index 17 = 2

Sub-index 25 = 3

Sub-index 33 = 4

Sub-index 41 = 5

Sub-index 49 = 6th latest acknowledged fault.

the baudrate of the Profibus-DP network

0: 12 Mbit/s 1: 6 Mbit/s 2: 3 Mbit/s 3: 1.5 Mbit/s

4: 500 kbit/s 5: 187.5 kbit/s 6: 93.75 kbit/s

7: 45.45 kbit/s 8: 19.2 kbit/s 9: 9.6 kbit/s

Bit 15 represents the type of inverter, 0 – SJxxx, 1 –

LxxxP. Rest of the word represents the model number.

SJ300 - 0x012C

L300P - 0x812C

Returns the Profidrive profile version used in the SJ-PB

implementation

Shows the latest received control word in hex format

Refer to chapter 5.3.1 for detailed information about

the control word.

Shows the latest status word in hex format

Refer to chapter 5.3.1 for detailed information about

the status word.

Please note that it will take approximately 10s for this

process to finish (inverter must be stopped).

0 – No function.

1 – Will save inverter parameters to non-volatile

memory and the Profile specific parameters to FLASH.

Parameters will be lost when turning

nd

latest acknowledged fault.

rd

latest acknowledged fault.

th

latest acknowledged fault.

th

latest acknowledged fault.

Parameter range:

1 – 418.

Sub-index range:

1 – 8.

Parameter range:

1 – 418.

Sub-index range:

1 – 8.

0, 1 R/W

0, 1 R/W

-R

0-9 R

012Ch, 812Ch R

2R

Bit 0-15 R

Bit 0-15 R

0, 1 W

R/W

R/W

19

Page 24

CHAPTER5 OPERATING

The malfunction codes are coded as follows.

Table5- 2 Malfunction codes

Fault code SJ300/L300P

parameter 947

0 No fault

1 Overcurrent inverter.

2 Overcurrent deceleration.

3 Overcurrent acceleration.

4 Overcurrent.

5 Overload protection.

6 Braking resistor overload protection.

7 Over-voltage protection.

8 EEPROM error.

9 Under-voltage.

10 Current detector error.

11 CPU error.

12 External trip.

13 USP error.

14 Ground fault protection.

15 Incoming over-voltage protection.

16 Temporary power loss protection.

21 Abnormal temperature.

23 Gate allay error.

24 Open-phase error.

30 IGBT error.

35 Thermistor error.

36 Abnormal brake.

60-69 Option 1 error 0-9.

70-79 Option 2 error 0-9.

Fault description

20

Page 25

CHAPTER 6 COUNTERMEASURE FOR ABNORMALY

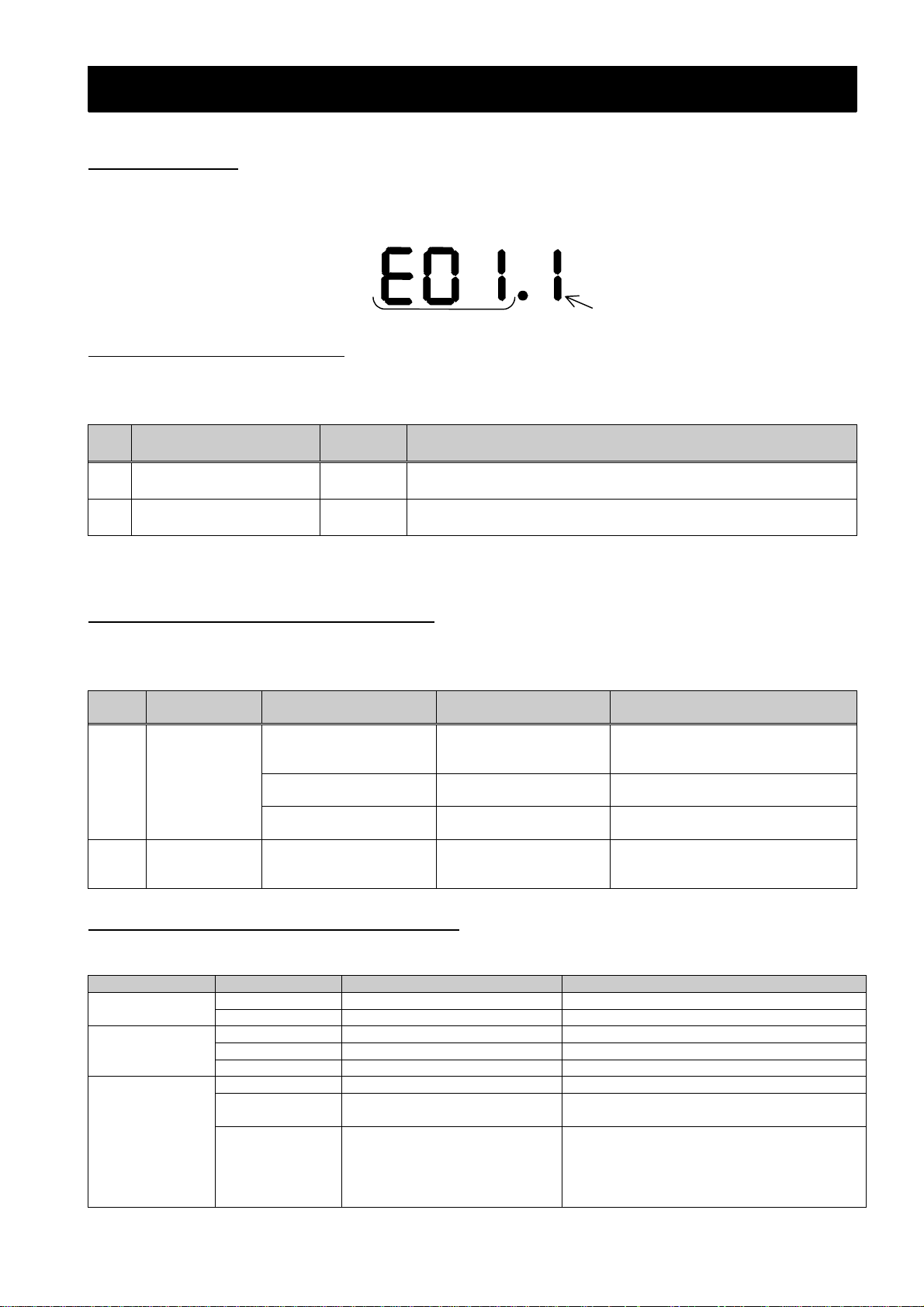

6.1 Trip display

When the inverter is in a tripped state, the inverter displays an error code (See table below). The trip history

monitor (d081 to d086) also displays the same error code as the inverter.

Trip code

Inverter’s running condition of trip detected

6.2 Protection function list

The table below describes an error code for protecting the inverter and the motor.

Error Display in the table below, X is 6 (Error for option slot 1) or 7 (Error for option slot 2).

No. Function Error

Action

Display

1 Profibus communication

error

2 Inverter communication

error

EX0 This error is displayed, when disconnection occurred, while

the inverter is operating with Profibus.

EX9 This error is displayed, when communication timeout occurs

between the inverter and the option board.

With regard to the other errors except table above, refer to Inverter instruction manual chapter 4 Explanation

of function.

6.3 Countermeasure for a trip state

The table below only corresponds to additional trip codes, with regard to the other countermeasures refer to

Inverter instruction manual chapter 4 Explanation of function.

Trip

code

EX0 Profibus

EX9 Inverter

Name of trip Cause Conformation Countermeasure

Communication

error

communication

error

Defective connector for

signal cable causes

connection fail.

Terminating resistor is

not connected.

Wiring distance does not

much with baudrate.

Option board is

removed.

Check the area of

connection.

Check the Connection Connect the terminating Resistor

Check the

wiring distance

Check as mentioned left Mount the option board again and

Improve the connection and then

reset the power supply.

and then reset the power supply

Adjust the setting to the matching

Baudrate or adjust wiring distance

then secure it with screws.

6.4 LED display and Countermeasure

Following states are indicated by three LED's.

LED Color Function Countermeasure

Fieldbus

On/Off

Fieldbus

diagnosis

Serial channel

status

Green Fieldbus is on-line. Red Fieldbus is off-line. Confirm connection fails of connector.

Flash Red 1Hz Configuration error. Confirm setting data and send correct data.

Flash Red 2Hz User configuration data error. Confirm system setting and adjust adequate.

Flash Red 4Hz VPC3+ initialization failed. Need to change the SJ-PB.

Green Serial channel status OK. Flash Red 1Hz Serial communication error. Confirm cable length and connection fails of

Red No serial communication.

(Or during initializing inverter

data. In this case, after

initializing, LED color returns to

green )

connector. And then adjust adequate.

Confirm cable length and connection fails of

connector. And then adjust adequate.

21

Page 26

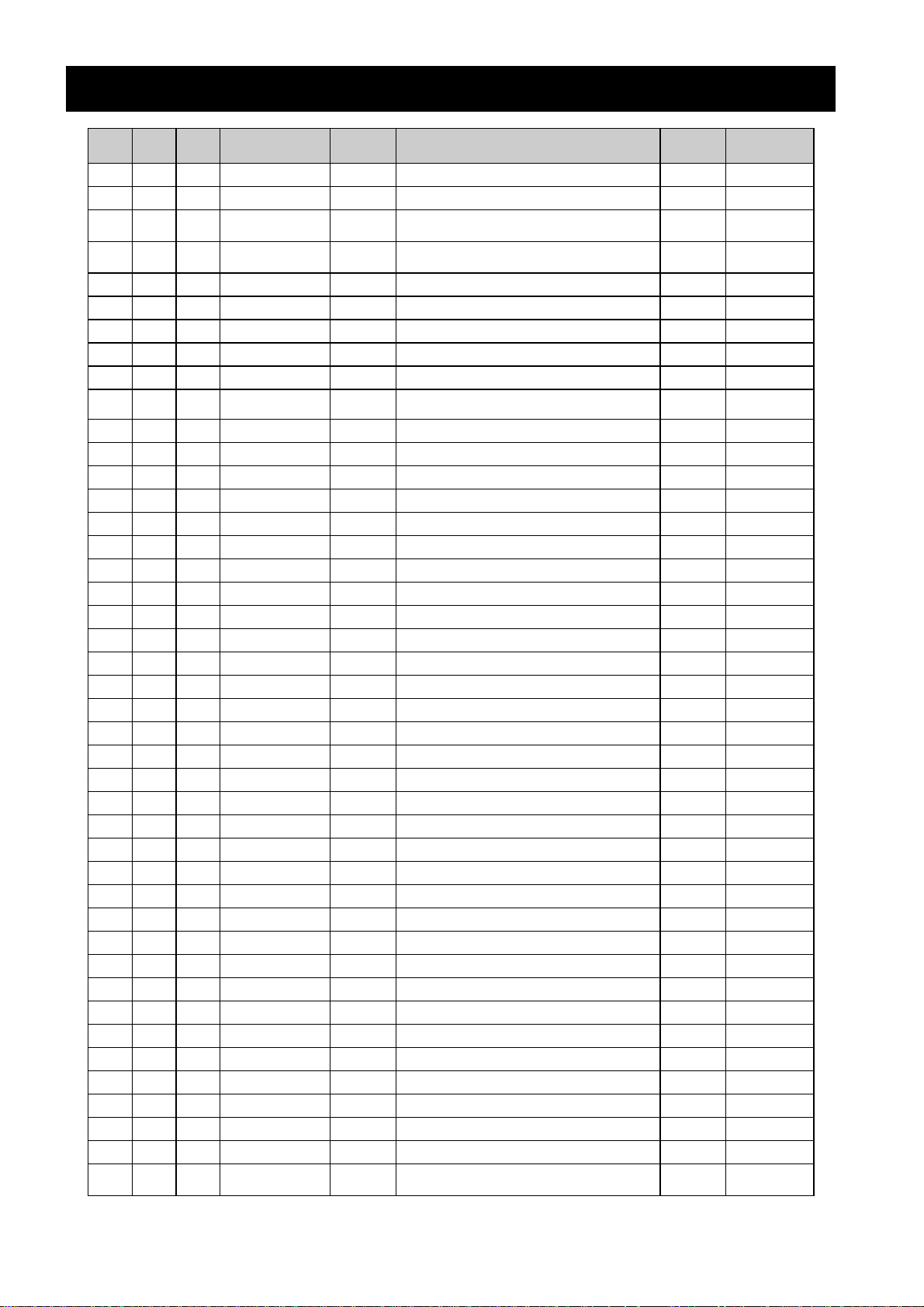

APPENDIX PARAMETER CROSS-REFERENCE LIST

Parameter cross-reference list

To be able to read/write parameters via Profibus it is necessary to use a cross-reference list to convert from

Profibus parameters to actual parameter values in the inverter.

Example, if parameter “1st Acceleration time 1” shall be read then parameter number 23 shall be used (if the

keypad is used F002 is used).

The L300P inverter supports a slightly different parameter map; the “L300P” field reflects this. “No” means

that the L300P inverter does not support the parameter, a figure means that the parameter is supported, but

with this maximum value instead.

Code No. Size Range Magn. Contents L300P

A020

A220 2 4

A320 3 4

A021 4 4

A022 5 4

A023 6 4

A024 7 4

A025 8 4

A026 9 4

A027 10 4

A028 11 4

A029 12 4

A030 13 4

A031 14 4

A032 15 4

A033 16 4

A034 17 4

A035 18 4

A061 19 4

A261 20 4

A062 21 4

A262 22 4

F002 23 4

F202 24 4

F302 25 4

F003 26 4

F203 27 4

F303 28 4

A092 30 4

A292 31 4

A392 32 4

A093 33 4

A293 34 4

A393 35 4

14

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

*100 1st setting Multispeed frequency 0 R/W

*100 2nd setting Multispeed frequency 0 R/W

*100 3rd setting Multispeed frequency 0 No R/W

*100 Multispeed frequency 1 R/W

*100 Multispeed frequency 2 R/W

*100 Multispeed frequency 3 R/W

*100 Multispeed frequency 4 R/W

*100 Multispeed frequency 5 R/W

*100 Multispeed frequency 6 R/W

*100 Multispeed frequency 7 R/W

*100 Multispeed frequency 8 R/W

*100 Multispeed frequency 9 R/W

*100 Multispeed frequency 10 R/W

*100 Multispeed frequency 11 R/W

*100 Multispeed frequency 12 R/W

*100 Multispeed frequency 13 R/W

*100 Multispeed frequency 14 R/W

*100 Multispeed frequency 15 R/W

*100 1st Upper limiter frequency R/WOS

*100 2nd Upper limiter frequency R/WOS

*100 1st Lower limiter frequency R/WOS

*100 2nd Lower limiter frequency R/WOS

*100 1st Acceleration time 1 R/W

*100 2nd Acceleration time 1 R/W

*100 3rd Acceleration time 1 No R/W

*100 1st Deceleration time 1 R/W

*100 2nd Deceleration time 1 R/W

*100 3rd Deceleration time 1 No R/W

*100 1st Acceleration time 2 R/W

*100 2nd Acceleration time 2 R/W

*100 3rd Acceleration time 2 No R/W

*100 1st Deceleration time 2 R/W

*100 2nd Deceleration time 2 R/W

*100 3rd Deceleration time 2 No R/WOS

Read/

Write

22

Page 27

APPENDIX PARAMETER CROSS-REFERENCE LIST

Code No. Size Range Magn. Contents L300P

A011 36 4

A012 37 4

A111 38 4

A112 39 4

A101 40 4

A102 41 4

A063 43 4

A065 44 4

A067 45 4

A069 46 4

A095 47 4

A295 48 4

A096 49 4

A296 50 4

b007 51 4

b053 52 4

C042 53 4

C043 54 4

C045 55 4

C046 56 4

A003 58 2

A203 59 2

A303 60 2

A038 61 2

A004 62 2

A204 63 2

A304 64 2

H020 66 4

H220 67 4

H021 68 4

H221 69 4

H022 70 4

H222 71 4

H023 72 4

H223 73 4

H024 74 4

H224 75 4

H030 76 4

H230 77 4

H031 78 4

H231 79 4

H032 80 4

H232 81 4

0〜400.00Hz

0〜400.00Hz

-400.00〜

400.00Hz

-400.00〜

400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0.01〜3600.00s

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

30〜400Hz

30〜400Hz

30〜400Hz

0〜9.99Hz

30〜400Hz

30〜400Hz

30〜400Hz

0〜65.530Ω

0〜65.530Ω

0〜65.530Ω

0〜65.530Ω

0〜655.35mH

0〜655.35mH

0〜655.35A

0〜655.35A

0.001〜

9999.000kgm2

0.001〜

9999.000kgm2

0〜65.5350Ω

0〜65.530Ω

0〜65.530Ω

0〜65.530Ω

0〜655.35mH

0〜655.35mH

*100 O Start frequency set R/W OS

*100 O End frequency set R/WOS

*100 O2 Start frequency set R/WOS

*100 O2 End frequency set R/WOS

*100 OI Start frequency set R/WOS

*100 OI End frequency set R/WOS

*100 Jumping frequency 1 R/WOS

*100 Jumping frequency 2 R/WOS

*100 Jumping frequency 3 R/WOS

*100 Frequency of stopping acceleration R/WOS

*100 1st Frequency of 2-stage acceleration R/WOS

*100 2nd Frequency of 2-stage acceleration R/WOS

*100 1st Frequency of 2-stage deceleration R/WOS

*100 2nd Frequency of 2-stage deceleration R/WOS

*100 Frequency of frequency matching R/WOS

*100

*100 Arrival frequency at acceleration1 R/WOS

*100 Arrival frequency at deceleration1 R/WOS

*100 Arrival frequency at acceleration2 No R/WOS

*100 Arrival frequency at deceleration2 No R/WOS

*1 1st Base frequency R/WOS

*1 2nd Base frequency R/WOS

*1 3rd Base frequency No R/WOS

*100 Jogging frequency R/W

*1 1st Maximum frequency R/WOS

*1 2nd Maximum frequency R/WOS

*1 3rd Maximum frequency No R/WOS

*1000 1st Primary resistor R1 of motor No R/WOS

*1000 2nd Primary resistor R1 of motor No R/WOS

*1000 1st Secondary resistor R2 of motor No R/WOS

*1000 2nd Secondary resistor R2 of motor No R/WOS

*100 1st Inductance L of motor No R/WOS

*100 2nd Inductance L of motor No R/WOS

*100 1st No load current Io of motor No R/WOS

*100 2nd No load current Io of motor No R/WOS

*100 1st Inertia J of motor No R/WOS

*100 2nd Inertia J of motor No R/WOS

*1000 1st Primary resistor R1 of motor (Auto) No R/WOS

*1000 2nd Primary resistor R1 of motor (Auto) No R/WOS

*1000 1st Secondary resistor R2 of motor (Auto) No R/WOS

*1000 2nd Secondary resistor R2 of motor (Auto) No R/WOS

*100 1st Inductance L of motor (Auto) No R/WOS

*100 2nd Inductance L of motor (Auto) No R/WOS

Deceleration time of Non-stop operation

at Instantaneous power failure

No R/WOS

Read/

Write

23

Page 28

APPENDIX PARAMETER CROSS-REFERENCE LIST

Code No. Size Range Magn. Contents L300P

H033 82 4

H233 83 4

H034 84 4

H234 85 4

A043 86 2

A243 87 2

A343 88 2

A052 89 2

A055 90 2

A058 91 2

A064 92 2

A066 93 2

A068 94 2

A070 95 2

A073 96 2

A074 97 2

A075 98 2

A086 99 2

b003 101 2

b012 102 2

b212 103 2

b312 104 2

b015 105 2

b016 106 2

b017 107 2

b018 108 2

b019 109 2

b020 110 2

b100 111 2

b101 112 2

b102 113 2

b103 114 2

b104 115 2

b105 116 2

b106 117 2

b107 118 2

b108 119 2

b109 120 2

b110 121 2

b111 122 2

b112 123 2

b113 124 2

b022 125 2

0〜655.35A

0〜655.35A

0.001〜

9999.000kgm2

0.001〜

9999.000kgm2

0〜50.0%

0〜50.0%

0〜50.0%

0〜60.00Hz

0〜60.0s

0〜60.0s

0〜10.00Hz

0〜10.00Hz

0〜10.00Hz

0〜60.0s

0〜3600.0s

0〜100.00

0.01〜99.99%

0〜100.0

0.3〜100.0s

20.0〜120.0

20.0〜120.0

20.0〜120.0

0〜400Hz

0〜1000.0A

0〜400Hz

0〜1000.0A

0〜400Hz

0〜1000.0A

0〜400Hz

0.0〜800.0V

0〜400Hz

0.0〜800.0V

0〜400Hz

0.0〜800.0V

0〜400Hz

0.0〜800.0V

0〜400Hz

0.0〜800.0V

0〜400Hz

0.0〜800.0V

0〜400Hz

0.0〜800.0V

50.0〜200.0

*100 1st No load current Io of motor (Auto) No R/WOS

*100 2nd No load current Io of motor (Auto) No R/WOS

*100 1st Inertia J of motor (Auto) No R/W OS

*100 2nd Inertia J of motor (Auto) No R/WOS

*10 1st Break point of manual torque boost R/W

*10 2nd Break point of manual torque boost R/W

*10 3rd Break point of manual torque boost No R/W

*100 Frequency of DC braking start R/WOS

*10 Time of DC braking working R/W OS

*10

*100 Width of jumping frequency 1 R/WOS

*100 Width of jumping frequency 2 R/WOS

*100 Width of jumping frequency 3 R/WOS

*10 Time of stopping to accelerate R/WOS

*10 Integrate (I) gain of PID control R/W

*100 Differential (D) gain of PID control R/W

*100 Scale of PID control R/WOS

*10 Response time of Energy saving function R/W

*10 Waiting time of retry R/WOS

*10 Level of 1st Electronic thermal protection R/WOS

*10 Level of 2nd Electronic thermal protection R/WOS

*10 Level of 3rd Electronic thermal protection No R/WOS

*1 Free electronic thermal frequency 1 R/WOS

*10 Free electronic thermal current 1 R/WOS

*1 Free electronic thermal frequency 2 R/WOS

*10 Free electronic thermal current 2 R/WOS

*1 Free electronic thermal frequency 3 R/WOS

*10 Free electronic thermal current 3 R/WOS

*1 Free V/F control frequency 1 R/WOS

*10 Free V/F control voltage 1 R/WOS

*1 Free V/F control frequency 2 R/WOS

*10 Free V/F control voltage 2 R/WOS

*1 Free V/F control frequency 3 R/WOS

*10 Free V/F control voltage 3 R/WOS

*1 Free V/F control frequency 4 R/WOS

*10 Free V/F control voltage 4 R/WOS

*1 Free V/F control frequency 5 R/WOS

*10 Free V/F control voltage 5 R/WOS

*1 Free V/F control frequency 6 R/WOS

*10 Free V/F control voltage 6 R/WOS

*1 Free V/F control frequency 7 R/WOS

*10 Free V/F control voltage 7 R/WOS

*10 Level of Overload restriction 1

Time of DC braking working

for beginning of inverter running

50.0〜

150.0

Read/

Write

R/WOS

R/WOS

24

Page 29

APPENDIX PARAMETER CROSS-REFERENCE LIST

Code No. Size Range Magn. Contents L300P

b023 126 2

b025 127 2

b026 128 2

b034 129 2

b051 130 2

b052 131 2

b054 132 2

b082 133 2

b086 134 2

b090 135 2

b096 136 2

b099 137 2

b121 138 2

b122 139 2

b123 140 2

b124 141 2

b125 142 2

b126 143 2

H005 145 2

H205 146 2

H006 147 2

H206 148 2

H306 149 2

H050 150 2

0.10〜30.00

50.0〜200.0

0.10〜30.00

0〜65535(*10hr)

0〜1000.0V

0〜1000.0V

0〜10.00Hz

0.10〜9.99Hz

0.1〜99.9

0〜100.0%

330〜380/

660〜760

0〜9999ƒ

0〜5.00‚“

0.00〜5.00s

0.00〜5.00s

0.00〜5.00s

0〜400.00Hz

0〜200.0(%)

0.001〜65.535

0.001〜65.535

0〜255

0〜255

0〜255

0〜1000.0(%)

*100 Constant value of Overload restriction 1 R/WOS

*10 Level of Overload restriction 2

*100 Constant value of Overload restriction 2 R/WOS

*1/10 Display time of warning R/WOS

*10

*10

*100

*100 Minimum frequency R/WOS

*10 Coefficient of converting frequency R/W

*10 Usage rate of BRD R/WOS

*1 On level of BRD R/WOS

*1 Level of Thermister error R/WOS

*100

*100

*100 Waiting time for stop at external braking No R/WOS

*100

*100 Release frequency of external braking No R/WOS

*10 Release current of external braking No R/WOS

*1000 1st Speed response gain No R/W

*1000 2nd Speed response gain No R/W

*1 1st Stability gain R/W

*1 2nd Stability gain R/W

*1 3rd Stability gain No R/W

*10

Starting voltage of Nonstop

operation for Instantaneous power failure

Starting voltage of OV-LAD

stop at Nonstop operation

for Instantaneous power failure

Frequency width of starting deceleration

at Nonstop operation for Instantaneous

power failure

Waiting time for establishing

external braking condition

Waiting time for acceleration

at external braking

Waiting time for confirmation

signal at external braking

1st Proportional gain of speed control

(PI control)

50.0〜

150.0

No R/WOS

No R/WOS

No R/WOS

No R/WOS

No R/WOS

No R/WOS

No R/W

Read/

Write

R/WOS

H250 151 2

H051 152 2

H251 153 2

H052 154 2

H252 155 2

H060 156 2

H260 157 2

H070 158 2

H071 159 2

H072 160 2

C029 162 1

C087 163 1

0〜1000.0(%)

0〜1000.0(%)

0〜1000.0(%)

0.01〜10.00

0.01〜10.00

0〜100.0

0〜100.0

0〜1000.0(%)

0〜1000.0(%)

0.01〜10.00

00〜07

0〜255

*10

*10

*10

*100

*100

*10 1st Limiter of 0Hz control No R/W

*10 2nd Limiter of 0Hz control No R/W

*10 PI Proportion gain Change No R/W

*10 PI Integral gain Change No R/W

*100 P Proportion gain Change No R/W

code Selection of AMI function R/WOS

*1 Adjustment of AMI output R/W

2nd Proportional gain of speed control

(PI control)

1st Integral gain of speed control

(PI control)

2nd Integral gain of speed control

(PI control)

1st Proportional gain of speed control

(P control)

2nd Proportional gain of speed control

(P control)

No R/W

No R/W

No R/W

No R/W

No R/W

25

Page 30

APPENDIX PARAMETER CROSS-REFERENCE LIST

Code No. Size Range Magn. Contents L300P

C088 164 1

C091 166 1 00,01 code Selection of Debug mode method R/W

C041 168 2

C111 169 2

C044 170 2

C063 171 2

C061 173 2

C078 174 2

P011 176 2

P014 177 2

P015 178 2

P017 179 2

P018 180 2

P020 181 2

P021 182 2

P022 183 2

P023 184 2

P026 185 2

P027 186 2

F004 188 1 00,01 code

A001 189 1

A002 190 1

A005 191 1 00,01 code Selection of AT function R/WOS

A006 192 1

A013 193 1

A014 194 1

A015 195 1 00,01 code Selection of starting function of O terminal R/WOS

A016 196 1

A113 197 1

A114 198 1

A103 199 1

A104 200 1

A105 201 1 00,01 code Selection of starting function of OI terminal R/WOS

A019 203 1 00,01 code Selection of Multispeed method R/WOS

A039 204 1

A041 205 1 00,01 code Selection of 1st Torque boost Method R/WOS

A241 206 1 00,01 code Selection of 2nd Torque boost Method R/WOS

A042 207 1

A242 208 1

A342 209 1

A044 210 1

A244 211 1

A344 212 1 00,01 code Selection of 3rd Control method No R/WOS

0.0〜20.0mA

0〜200.0(%)

0〜200.0(%)

0〜100.0%

0〜100.00Hz

0〜100%

0〜1000ms

128〜65000pls

0〜4095

0〜120.00Hz

0〜10000pls

0〜9.99s

0〜9999

0〜9999

0〜655.35

0〜100.00

0〜150.0

0〜120.00Hz

00〜05

01〜05

00〜02

0〜100%

0〜100%

1〜30times

-100〜100%

-100〜100%

0〜100%

0〜100%

00〜05

0〜20.0%

0〜20.0%

0〜20.0%

00〜05

00〜04

*10 Adjustment of Offset of AMI output R/W

*10 Level1 of overload restriction warning R/WOS

*10 Level2 of overload restriction warning No R/WOS

*10

*100 Level f detecting Zero speed No R/WOS

*1

*1 Waiting time of communication start R/WOS

*1 Pulse number of the encoder No R/WOS

*1 Stop position at Orientation mode No R/WOS

*100 Speed at Orientation mode No R/WOS

*1

*100

*1 The numerator of electric gear No R/WOS

*1 The denominator of electric gear No R/WOS

*100 Feed forward gain of position control No R/WOS

*100 Loop gain of position control No R/WOS

*10 Level of detecting over speed No R/WOS

*100 Value of detecting over deviation No R/WOS

code Selection of frequency command destination R/WOS

code Selection of running command destination R/WOS

code Selection of O2 terminal function R/WOS

*1 Starting rate of O terminal R/WOS

*1 End rate of O terminal R/WOS

*1 Analog Sampling R/WOS

*1 Starting rate of O2 terminal R/WOS

*1 End rate of O2 terminal R/WOS

*1 Starting rate of OI terminal R/WOS

*1 End rate of OI terminal R/WOS

code Selection of Jogging method R/WOS

*10 Value of 1st Manual torque boost R/W

*10 Value of 2nd Manual torque boost R/W

*10 Value of 3rd Manual torque boost No R/W

code Selection of 1st Control method

code Selection of 2nd Control method

Level over acceptable deviation of

PID control

Warning Level of

electronic thermal protection

Defining Area of completion of

Orientation mode

Delay time of completion

Orientation mode

Selection of running direction

for DIG-OPE

No R/WOS

No R/WOS

00〜02

00〜02

Read/

Write

R/WOS

R/WOS

R/WOS

R/WOS

R/WOS

26

Page 31

APPENDIX PARAMETER CROSS-REFERENCE LIST

Code No. Size Range Magn. Contents L300P

A045 213 1

A051 214 1 00,01 code Selection of DC braking method R/WOS

A053 215 1

A054 216 1

A056 217 1 00,01 code

A057 218 1

A059 219 1

A071 220 1 00,01 code Selection of PID control presence R/WOS

A072 221 1

A076 222 1 00,01 code

A081 223 1

A082 224 1

A085 225 1

A094 226 1 00,01 code Selection of 1st 2-stage accel/decel Method R/WOS

A294 227 1 00,01 code Selection of 2nd 2-stage accel/decel Method R/WOS

A097 228 1

A098 229 1

A131 230 1

A132 231 1

b001 233 1

b002 234 1

20〜100%

0〜5.0s

0〜100

0〜100

0.5〜15.0kHz

0.2〜5.0

00〜02

0〜10

00〜02

00〜03

00〜03

01〜10

01〜10

00〜03

0.3〜1.0s

*1 Gain of output voltage R/W

*10 Delay time of DC braking start R/WOS

*1 Power of DC braking(end of running) R/WOS

Selection of edge/level action of

DC braking trigger

*1 Power of DC braking(start of running) R/WOS

*10 Carrier frequency of DC braking

*10 Proportional(P) gain of PID control R/W

Selection of feedback destination for

code Selection of AVR function R/WOS

code Selection of Motor voltage R/WOS

code Selection of operation mode 00,01 R/WOS

code Selection of acceleration pattern R/WOS

code Selection of deceleration pattern R/WOS

code Curve constant of acceleration R/WOS

code Curve constant of deceleration R/WOS

code Selection of retry method R/WOS

*10

Instantaneous power failure

PID control

Acceptable time for

0.5〜12.0

Read/

Write

R/WOS

R/WOS

R/WOS

R/WOS

b004 235 1

b005 236 1 00,01 code

b006 237 1 00,01 code Selection of fail phase function R/WOS

b013 238 1

b213 239 1

b313 240 1

b021 242 1

b024 243 1

b031 244 1

b037 245 1

b040 247 1

b041 248 1

b042 249 1

b043 250 1

00〜02

00〜02

00〜02

00〜02

00〜03

00〜03

00〜03,10

00〜02

00〜04

0〜200%

0〜200%

0〜200%

code

code

code

code

code Selection of method of overload restriction1 R/WOS

code Selection of method of overload restriction2 R/WOS

code Selection of method of Software lock R/WOS

code Selection of Display R/WOS

code Selection of method of Torque limiter No R/WOS

Selection of method(action) at instantaneous

*1

*1

*1

power andunder voltage

Retry number of instantaneous power

and under voltage

Selection of characteristic of

1st electronic thermal protection

Selection of characteristic of

2nd electronic thermal protection

Selection of characteristic of

3rd electronic thermal protection

Level of torque limiter in forward

and drive (1st quadrant)

Level of torque limiter in reverse

and regenerative (2nd quadrant)

Level of torque limiter in reverse

and drive (3rd quadrant)

R/WOS

R/WOS

R/WOS

R/WOS

No R/WOS

No R/WOS

No R/WOS

No R/WOS

b044 251 1

0〜200%

*1

Level of torque limiter in forward

and regenerative (4th quadrant)

No R/WOS

27

Page 32

APPENDIX PARAMETER CROSS-REFERENCE LIST

Code No. Size Range Magn. Contents L300P

b045 252 1 00,01 code Selection of LAD stop by torque No R/WOS

b035 253 1

b046 254 1 00,01 code Selection of preventive of reverse running No R/WOS

b036 255 1

b050 257 1 00,01 code

b080 258 1

b081 259 1

b083 260 1

b084 261 1

b085 262 1

b087 263 1 00,01 code Selection of STOP key function R/WOS

b088 264 1 00,01 code Selection free run function R/WOS

b091 265 1 00,01 code Selection of action at stop R/W OS

b092 267 1 00,01 code Selection of action of cooling fan R/WOS

b095 268 1

b098 269 1

b120 270 1 00,01 code Selection of external braking function No R/WOS

C001 272 1

C002 273 1

C003 274 1

C004 275 1

C005 276 1

C006 277 1

C007 278 1

C008 279 1

C011 280 1 00,01 code

C012 281 1 00,01 code

00〜02

00〜06

0〜255

0〜255

0.5〜15.0kHz

00〜02

00〜02

00〜02

00〜02

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

code Selection of running direction limitation R/WOS

*1 Selection of method of educing voltage start R/WOS

Selection of Non stop operation

at instantaneous power failure

*1 Adjustment of AM(analog monitor) R/W

*1 Adjustment of FM(digital monitor) R/W

*10 Carrier frequency(PWM frequency

code Selection of Initialization R/WOS

code Selection of initialized data R/WOS

code Selection of BRD function R/W OS

code Selection of Thermister function R/WOS

code Selection of function in Intelligent input 1

code Selection of function in Intelligent input 2

code Selection of function in Intelligent input 3

code Selection of function in Intelligent input 4

code Selection of function in Intelligent input 5

code Selection of function in Intelligent input 6 No R/WOS

code Selection of function in Intelligent input 7 No R/WOS

code Selection of function in Intelligent input 8 No R/WOS

Selection of a(NO) or b(NC) contact

in Intelligent input 1

Selection of a(NO) or b(NC) contact

in Intelligent input 2

No R/WOS

0.5〜12.0

01〜39

01〜39

01〜39

01〜39

01〜39

Read/

Write

R/WOS

R/WOS

R/WOS

R/WOS

R/WOS

R/WOS

R/WOS

R/WOS

C013 282 1 00,01 code

C014 283 1 00,01 code

C015 284 1 00,01 code

C016 285 1 00,01 code

C017 286 1 00,01 code

C018 287 1 00,01 code

C019 288 1 00,01 code

C101 289 1 00,01 code Selection of UP/DOWN function R/WOS

C102 290 1

C103 291 1 00,01 code

00〜02

code Selection of RESET function R/WOS

Selection of a(NO) or b(NC) contact

in Intelligent input 3

Selection of a(NO) or b(NC) contact

in Intelligent input 4

Selection of a(NO) or b(NC) contact

in Intelligent input 5

Selection of a(NO) or b(NC) contact

in Intelligent input 6

Selection of a(NO) or b(NC) contact

in Intelligent input 7

Selection of a(NO) or b(NC) contact

in Intelligent input 8

Selection of a(NO) or b(NC) contact in

FW input

Selection of frequency matching function

at RESET

R/WOS

R/WOS

R/WOS

No R/WOS

No R/WOS

No R/WOS

R/WOS

R/WOS

28

Page 33

APPENDIX PARAMETER CROSS-REFERENCE LIST

Code No. Size Range Magn. Contents L300P

C021 292 1

C022 293 1

C023 294 1

C024 295 1

C025 296 1

C026 297 1

C027 298 1

C028 299 1

C086 300 1

C031 301 1 00,01 code

C032 302 1 00,01 code

C033 303 1 00,01 code

C034 304 1 00,01 code

C035 305 1 00,01 code

00〜26

00〜26

00〜26

00〜26

00〜26

00〜26

00〜07

00〜07

0〜10.0V

code Selection of function in Intelligent output 11

code Selection of function in Intelligent output 12

code Selection of function in Intelligent output 13 No R/WOS

code Selection of function in Intelligent output 14 No R/WOS

code Selection of function in Intelligent output 15 No R/WOS

code Selection of function in Alarm relay output

code Selection of FM function R/WOS

code Selection of AM function R/WOS

*10 Adjustment of offset of AM R/W

Selection of a(NO) or b(NC) contact

in Intelligent output 11