Page 1

p

SJ-MB Modbus/RTU

Communications Option Board

Instruction Manual

• SJ300 Series

• L300P Series

NOTE: REFER ALSO TO SJ300 or L300P SERIES INSTRUCTION MANUAL

Manual Number: HAL1052

Se

tember 2007

Hitachi America, Ltd.

After reading this manual,

keep it handy for future reference.

Page 2

NOTES:

Page 3

Table of Contents

Table of Contents

Table of Contents................................................................................................................... 3

Chapter 1 – General Description.......................................................................................... 5

Chapter 2 – Installation and Wiring...................................................................................... 9

Chapter 3 – Configuration................................................................................................... 13

Chapter 4 – Operation......................................................................................................... 15

Chapter 5 – Troubleshooting.............................................................................................. 17

Appendix – Parameter List ................................................................................................. 18

Index..................................................................................................................................... 33

Page 3 of 36

Page 4

NOTES:

Table of Contents

Page 4 of 36

Page 5

Chapter 1

Chapter 1 – General Description

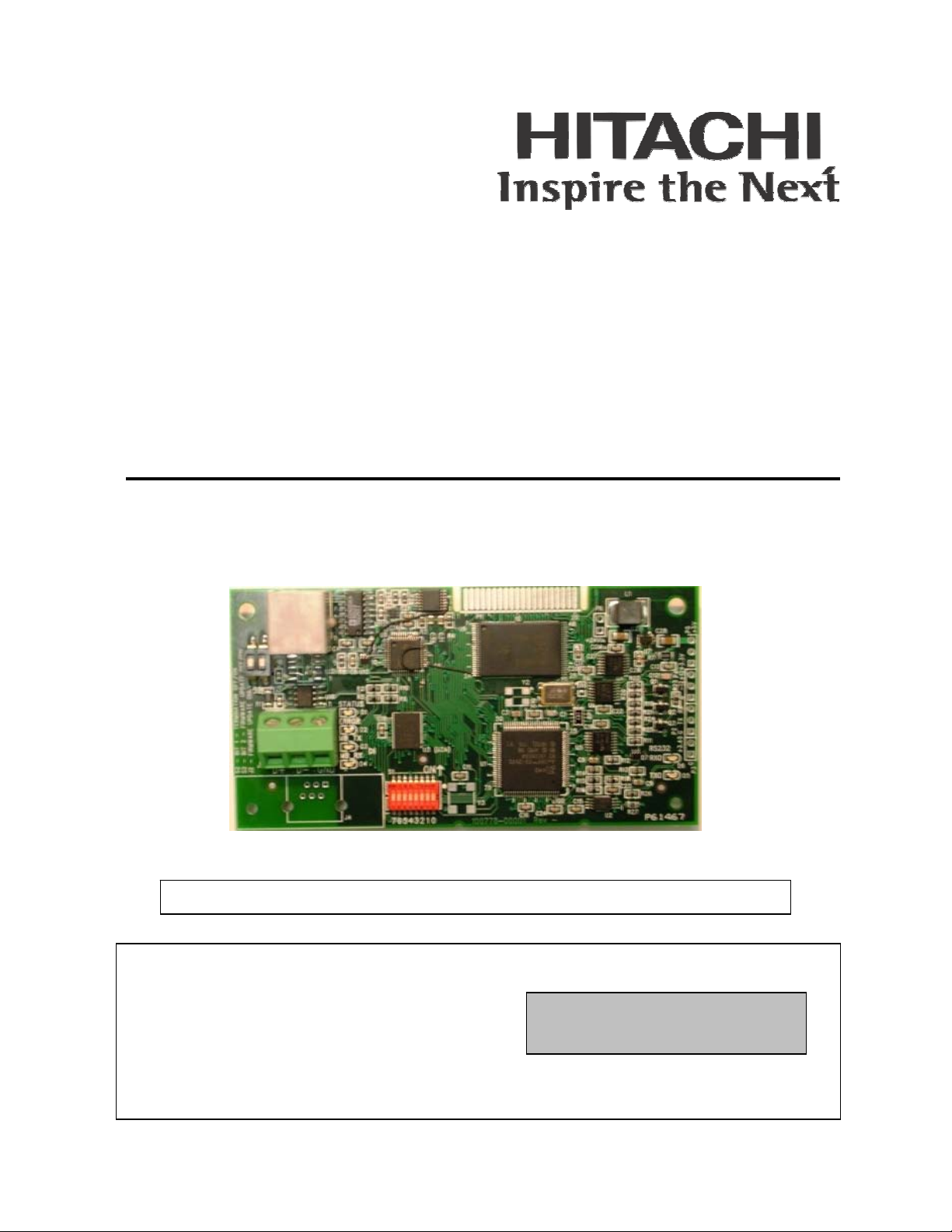

The SJ-MB option board is a Modbus/RTU communication interface for the Hitachi SJ300 and L300P series of

AC Variable Frequency Inverters. The board can be installed in either of the two available option slots in the

inverter.

The SJ-MB uses the open MODBUS/RTU communication protocol. It utilizes a serial RS485 physical interface

with a maximum 57600 Baud data rate. Even though the board uses the MODBUS/RTU protocol, this does not

mean that all MODBUS services and functions are supported. Detailed description of the available functionality

is provided in Chapter 4 of this manual. The board will act as a MODBUS/RTU slave that can be read from and

written to over a serial RS485 network from a MODBUS/RTU master device. It will not initiate communication

with other devices on the network. It will only respond to requests from a master device. The SJ-MB will allow

a user to control the operation of the inverter, monitor its operation, and modify parameters.

Before using this product, please read this manual and the relevant inverter manual, and be sure to follow all

safety precautions noted therein. After unpacking the SJ-MB board, carefully inspect it for any defect or

damage, and be sure all parts are present.

Carton Contents

(1) SJ-MB Modbus Communication Interface Board

(2) Screws to secure board to inverter case (M3 x 8mm)

(1) CD-ROM containing this manual (pdf)

WARRANTY

The warranty period under normal installation and handling conditions shall be eighteen (18) months

from the date of purchase, or twelve (12) months from the date of installation, whichever occurs first.

The warranty shall cover repair or replacement, at Hitachi’s sole discretion, of the SJ-MB Option board.

Service in the following cases, even within the warranty period, shall be to the customers account:

1. Malfunction or damage caused by misuse, modification or unauthorized repair.

2. Malfunction or damage caused by mishandling, dropping, etc., after delivery.

3. Malfunction or damage caused by fire, earthquake, flood, lightning, abnormal input voltage,

contamination, or other natural disasters.

If service is required for the product at your worksite, all expenses associated with field repair are the

purchaser’s responsibility. This warranty only covers service at Hitachi designated service facilities.

If making a warranty claims in reference to the above, please contact the distributor from whom you

purchased the SJ-MB, and provide the model number, purchase date, installation date, and description

of damage or missing components.

Page 5 of 36

Page 6

SAFETY PRECAUTIONS

HIGH VOLTAGE: This symbol indicates high voltage. It calls your attention to items or operations

that could be dangerous to you and other persons operating this equipment. Read the message and

follow the instructions carefully.

WARNING: Indicates a potentially hazardous situation that, if not avoided, can result in serious

injury or death.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, can result in minor to

moderate injury, or serious damage to the product. The situation described in the CAUTION may, if

not avoided, lead to serious results. Important safety measures are described in CAUTION (as well as

WARNING), so be sure to observe them.

HIGH VOLTAGE: Motor control equipment and electronic controllers are connected to hazardous

line voltages. When servicing drives and electronic controllers, there may be exposed components

with housings or protrusions at or above line potential. Extreme care should be taken to protect

against shock. Stand on an insulating pad and make it a habit to use only one hand when checking

components. Always work with another person in case an emergency occurs. Disconnect power

before checking controllers or performing maintenance. Be sure equipment is properly grounded.

Wear safety glasses whenever working on electronic controllers or rotating machinery.

WARNING: This equipment should be installed, adjusted, and serviced by qualified electrical

maintenance personnel familiar with the construction and operation of the equipment and the hazards

involved. Failure to observe this precaution could result in bodily injury.

WARNING: HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING POWER

BEFORE WORKING ON THIS CONTROL.

WARNING: Wait at least five (5) minutes after turning OFF the input power supply before

performing maintenance or an inspection. Otherwise, there is the danger of electric shock.

WARNING: Do not install or remove the SJ-MB Modbus option board while the inverter is

energized. Otherwise there is the danger of electric shock and/or injury due to unexpected inverter

operation.

WARNING: Never modify the unit. Otherwise, there is a danger of electric shock and/or injury.

CAUTION: Be sure to secure the SJ-MB option board with the supplied mounting screws. Make sure

all connections are made securely; otherwise there is danger of a loose connection and unpredictable

operation.

CAUTION: Alarm connection may contain hazardous live voltage even when inverter is

disconnected. When removing the front cover for maintenance or inspection, confirm that incoming

power for alarm connection is completely disconnected.

Chapter 1

Page 6 of 36

Page 7

Chapter 1

CAUTION: Be sure not to touch the surface or terminals of the SJ-MB Modbus option board while

the inverter is energized; otherwise there is the danger of electric shock.

CAUTION: The software lock modes described in the SJ300 inverter manual are NOT supported via

the SJ-MB option board. This means that network commands can bypass any software lock settings

configured via the inverter keypad. It is therefore incumbent on the user to make sure no safety

lockouts are violated through network commands.

CAUTION: When configuring parameters with the standard keypad, the inverter checks for and

inhibits invalid parameter combinations when the STR key is pressed. The SJ-MB bypasses this

check, so it is incumbent on the user to make sure invalid configuration parameters or combinations

are not sent through network commands. Otherwise undesirable inverter behavior may occur.

CAUTION: Certain parameter data ranges vary depending on model and capacity. The SJ-MB does

NOT check to make sure these data are within range. Thus it is incumbent on the user to make sure

data for these parameters is within range for the specific model and rating. These parameters are noted

in the parameter tables in the Appendix. Otherwise undesirable inverter behavior may occur.

INVERTER COMPATIBILITY

The inverter firmware revision number is embedded within the inverter Manufacturing Number, which can be

found on the product nameplate. The SJ-MB Modbus Interface option board is compatible only with SJ300 and

L300P series inverters with Revision Numbers HIGHER than those shown below.

XX

8KT XXXXX XXXXX – for SJ300-xxxXFU 0.4 kW (0.5 hp) to 55 kW (75 hp), or

L300P-xxxXFU or L300P-xxxXBRM 1.5 kW (2 hp) to 75 kW (100 hp)

EMT XXXXX XXXXX – for SJ300-xxxXFU 75kW (100 hp) to 150 kW (200 hp), or

XX

L300P-xxxXFU or L300P-xxxXBRM 90 kW

(125 hp) to 132 kW (175 hp)

Note: All inverters in the model number series L300P-xxxXFU2 are compatible with

the SJ-MB, regardless of revision number. All SJ300 and L300P models

manufactured in 2004 or later are compatible as well.

Page 7 of 36

Page 8

NOTES:

Chapter 1

Page 8 of 36

Page 9

(

)

Chapter 2

Chapter 2 – Installation and Wiring

Orientation to Product Features

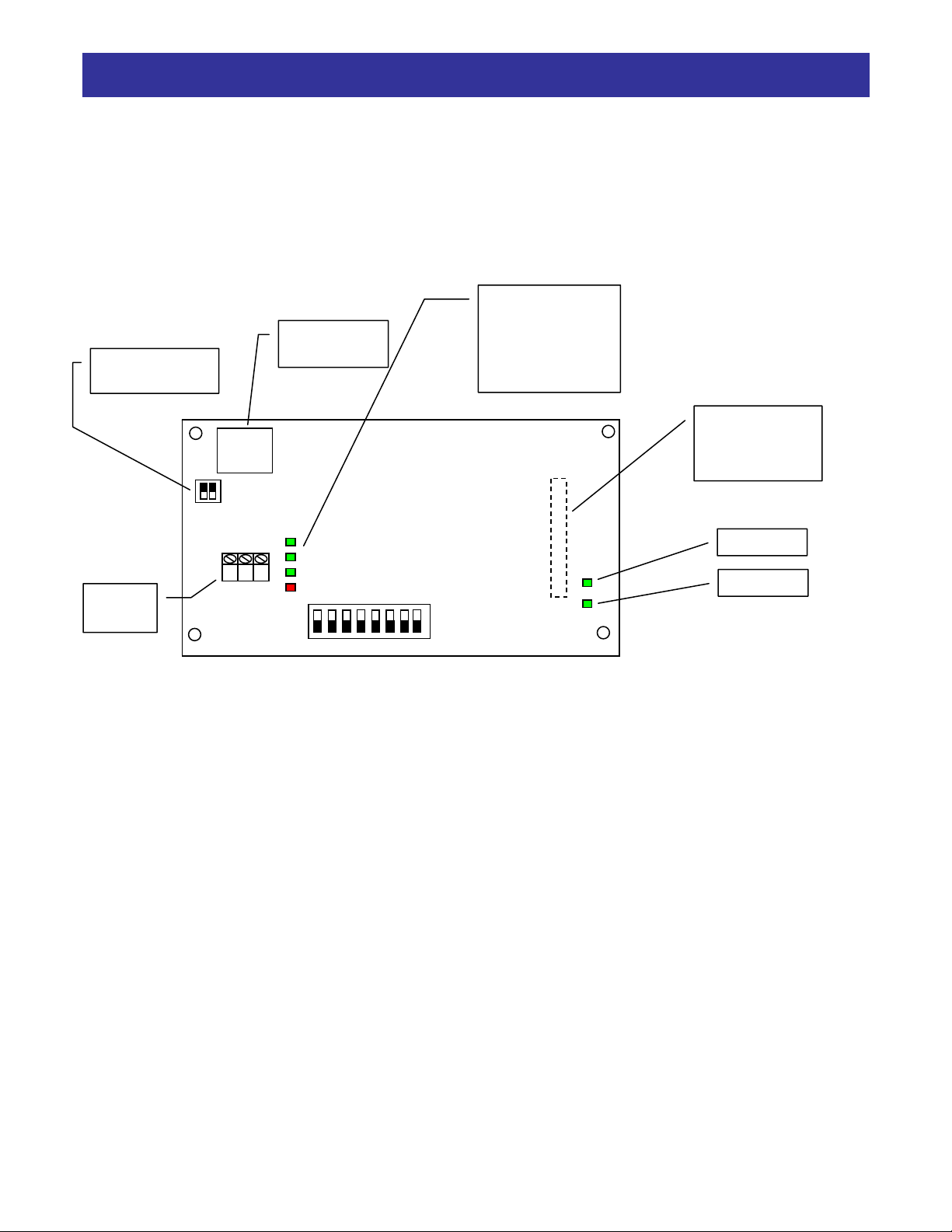

Figure 2-1 below shows the physical layout of the SJ-MB Modbus option board. In particular, note the location

of status LEDs and DIP-switches.

Left: Termination

Right: Config

Programming

Port

RJ1 1

Jack

Modbus

Port

D+ D- GND

7 6 5 4 3 2 1 0

ON

OFF

Figure 2-1

SJ-MB Layout

Installing the Option Board

Power down the inverter and wait at least five minutes before moving to the next step. Open and remove the

lower terminal cover. Confirm that the red CHARGE LED is extinguished and that the DC bus is fully

discharged before proceeding further, otherwise there is the danger of electric shock. Then remove keypad from

the inverter. You can now remove the upper front cover to expose the two option ports inside.

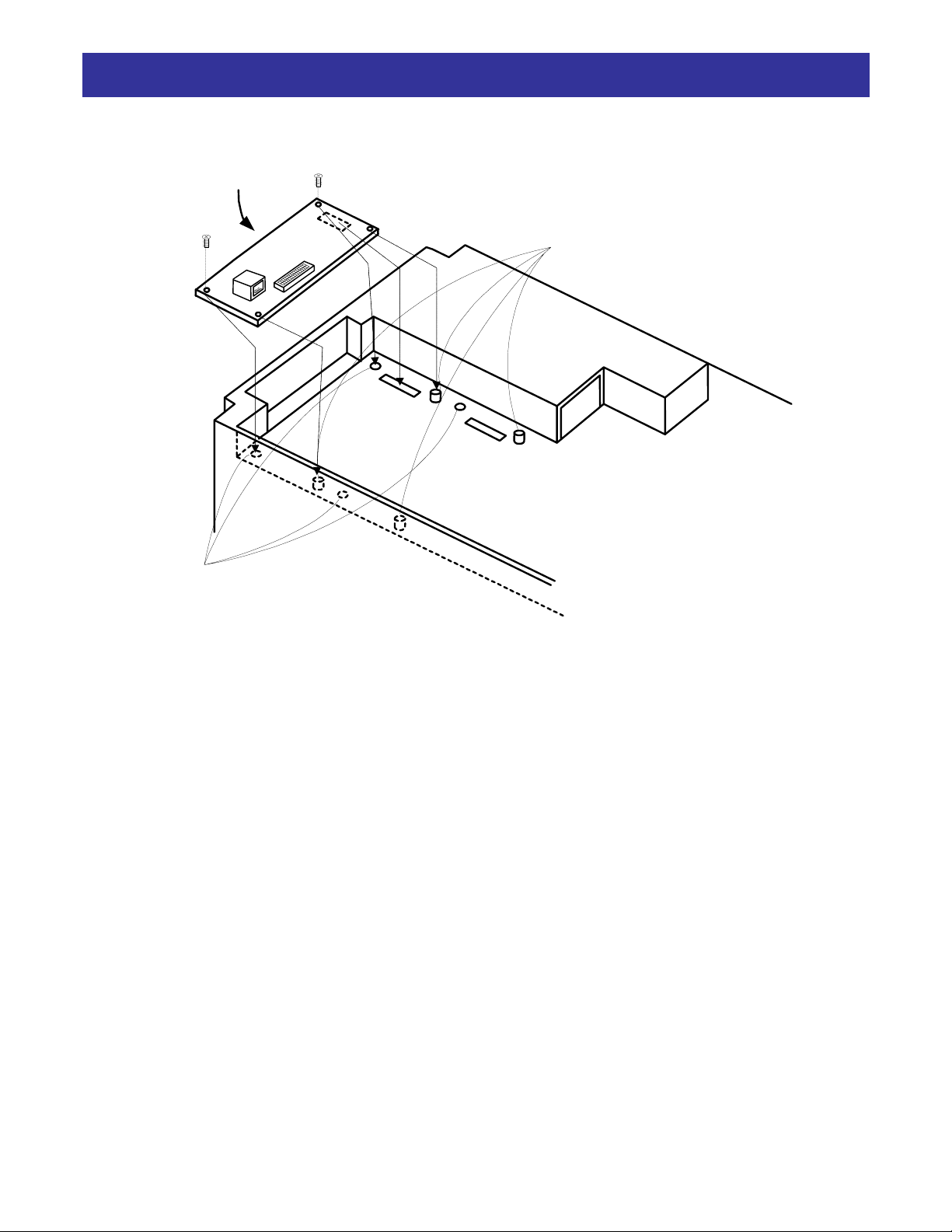

Figure 2-2 on the next page shows how to install the option board to option port 1 or 2 of the inverter. There are

four holes on the corners of the option board. Align the board with the port connector in the proper orientation

(to the left, when facing the inverter as show). Then align the top two holes with the two screw holes, and the

bottom two holes with the two guide posts. Insert the board fully into the connector. Secure the board with the

two M3 screws supplied.

STATUS LEDs

• STATUS

• ERROR

• TX

• RX

Connector to

connect to

SJ300 or L300P

rear of board

RXD LED

TXD LED

DIP Switches

Page 9 of 36

Page 10

Screw holes for securing the option board

Option board

Option port 1

(M3 screws x 2)

Chapter 2

Guide posts for

option board positioning

Option port 2

Figure 2-2

Installation of SJ-MB

Page 10 of 36

Page 11

Chapter 2

User Interface

The SJ-MB has six LEDs to convey module status and activity.

Four LEDs next to the Modbus port connector:

• STATUS (GREEN) – This LED will be ON whenever the SJ-MB is receiving proper power from the

inverter and the self diagnostics have shown the board to be functioning normally.

• ERROR (RED) – This LED will be ON if the SJ-MB has failed due to a hardware watchdog timeout, or

the Modbus communications has been absent for the software watchdog timeout period.

MB TX – This LED is ON when the SJ-MB is transmitting Modbus data over the network.

•

• MB RX – This LED is ON when the SJ-MB is receiving Modbus data over the network.

Two LEDs near the right edge of the board:

• TXD – This LED indicates communication from the SJ-MB to the inverter through the option port.

• RXD – This LED indicates communication to the SJ-MB from the inverter through the option port.

(These two LEDs may appear blinking or may appear steady ON due to the high blink rate.)

Page 11 of 36

Page 12

NOTES:

Chapter 2

Page 12 of 36

Page 13

Chapter 3

Chapter 3 – Configuration

Configuration of the SJ-MB Board

Ensure that the SJ-MB is properly installed as described in Chapter 2.

There are two DIP-switch banks on the SJ-MB board (see Figure 2-1). The eight-position bank is not used;

however ensure that all switches are in the OFF position.

On the two-position DIP-switch bank, the left switch (bit 1) of controls whether a termination resistor is

connected across the D+ and D- data terminals. This switch should be in the OFF position, unless this SJ-MB

board is the last device in the Modbus/RTU network. In this case, move this switch to the on position to provide

proper network termination resistance. The right switch SHOULD NOT be used. It is for factory use only, and

should be in the OFF position for normal operation.

Make sure that all wiring is secure in the inverter, and that the power connections are free and clear. Be sure to

separate power wiring from control wiring. If they have to cross, be sure that they cross at a right angle to

minimize the possibility of interference. Power up the inverter, and observe the LEDs on the SJ-MB board. The

STATUS LED should be illuminated, and the RX and TX LEDs should blink when Modbus data is being

passed. The red ERROR LED should NOT be illuminated. Also, the RXD and TXD LEDs should be blinking

(may appear as though ON continuously, due to high blink rate). See Chapter 4 for detailed description of LED

functions. If the LED conditions are not correct, proceed to Chapter 5 for Troubleshooting. If you power up the

inverter before powering up the PC, an error code may appear. After powering up the PC and properly

connecting the cable, you should be able to clear the error with the STOP/RESET key on the inverter keypad.

If the LEDs are correct, continue with the configuration.

Configuring Parameters that Control the SJ-MB

Using either the keypad, or the ProDrive Programming Software, you will need to configure the communication

settings for the SJ-MB board. Refer to the following table.

Function

Code

Name Description

Run

Mode

Edit

Lo Hi

–FE

(EU)

Defaults

–FU

(US)

–FR

(Jpn)

Setting for Modbus Control

via SJ-MB

C070

Data

Command

Method

Four options; select codes:

02 Digital Operator

03 RS485 port

04 Expansion board 1

05 Expansion board 2

8 8

02 02 02 02

Page 13 of 36

Page 14

C071

Comm.

Speed

Selection

Five options; select codes:

02 Test

03 2400 bps

04 4800 bps

05 9600 bps

06 19200 bps

8 9

Chapter 3

04 04 04 To Match Master Device

C072

C073

C074

C075

C078

Node

Allocation

Comm. Data

Length

Selection

Comm.

Parity

Selection

Comm. Stop

Bit Selection

Comm. W ait

Time

Set the desired address of the

inverter on the Modbus/RTU

network. Range is 1 to 32.

Two options, select codes:

07 7-bit data

08 8-bit data

Three options, select codes:

00 No parity

01 Even parity

02 Odd parity

Two options, select codes:

01 1 stop bit

02 2 stop bits

Time the board waits after

receiving a message before it

transmits data. Range is 0.0 to

1000 ms

8 9

8 9

8 9

8 9

8 9

1 1 1 As required

7 7 7 To Match Master Device

00 00 00 To Match Master Device

1 1 1 To Match Master Device

0.0 0.0 0.0 As required

Page 14 of 36

Page 15

Chapter 4

Chapter 4 – Operation

Setting Up the Inverter for Modbus Network Operation

Once the SJ-MB board has been properly configured and connected to a network as described in Chapter 3, it is

capable of reading data from and writing data to the inverter. However if it is desired to have either the RUN

command and/or the speed reference come from the Ethernet master, you must change two inverter parameters

as shown in the following table.

Run

Function

Code

A001

A002

Name Description

Six options; select codes:

00 Keypad potentiometer

Frequency

Source

Setting

Run

command

source setting

01Control terminal

02 Function F001 setting

03 RS485 serial command

04 Expansion board 1

05 Expansion board 2

Five options; select codes:

01 Input terminal [FW] or [RV]

(assignable)

02 Run key on keypad, or

digital operator

03 RS485 serial command

04 Start/Stop, expansion card #1

05 Start/Stop, expansion card #2

Mode

Edit

Lo Hi

8 8

8 8

Supported MODBUS Functions

The SJ-MB is implemented with the MODBUS/RTU communication protocol. It supports the following

MODBUS functions:

• 1 - MODBUS_READ_COILS (up to 32 at a time)

• 3 - MODBUS_READ_MULTIPLE_REGS (Up to 4 at a time)

• 5 - MODBUS_WRITE_COIL

• 6 - MODBUS_WRITE_SINGLE_REGISTER

• 8 - MODBUS_LOOPBACK_TEST

• 15 - MODBUS_FORCE_MULTIPLE_COILS (up to 32 at a time)

• 16 - MODBUS_WRITE_MULTIPLE_REGS (up to 4 at a time)

Additional MODBUS/RTU protocol details, including specifications, application information, implementation

guides, and other resources are available from the web site

www.modbus.org.

Defaults

–FE

(EU)

01 01 02 02

01 01 02 02

–FU

(US)

–FR

(Jpn)

Setting for Modbus Control

Page 15 of 36

Page 16

NOTES:

Chapter 4

Page 16 of 36

Page 17

Chapter 5

Chapter 5 – Troubleshooting

In general, the first step to troubleshooting should be to inspect the status LEDs on the SJ-MB board, in addition

to the inverter operator/keypad display. These will give valuable clues to the nature of the problem.

In addition, the inverter operator/keypad will provide diagnostic information for certain types of errors. Error

codes for the option boards will have the format of:

E6X.X for a board installed in option slot 1, or E7X.X for a board installed in option slot 2. The number

to the right of the decimal point indicates the drive status at the time of trip, as follows:

During

deceleration

EXX.0

At reset

EXX.1

At stop

EXX.2

At constant

EXX.3

EXX.6

The digit immediately to the left of the decimal point has the following meaning:

Code Trip Name Cause Check Remedy

EX0.X

speed

At starting

Modbus Communication

Error

EXX.4

EXX.7

Defective

connection

PC not powered up

or not connected to

inverter

Network

configuration error

During

acceleration

During DC

injection

braking

EXX.5

EXX.8

Connectors (plugs

& jacks), cable

That PC is powered

on and connected

Verify proper

Modbus setup of

SJ-MB and master

device

f0 Stop

During overload

restriction

Replace or repair;

press STOP/RESET

on inverter keypad

Press STOP/RESET

on inverter keypad

Reconfigure

incorrect settings.

EX9.X

Internal Communication

Error (between SJ-MB and

inverter)

Inverter Mismatch

(blinking display as

shown)

Option board ajar o

loose

Board lockup Check status LEDs

Board defective Check status LEDs Replace SJ-MB

Inverter firmware

version not

compatible with

SJ-MB option

board

Page 17 of 36

Verify board is

r

properly seated in

connector

Inverter

Manufacturing

Number for version

(see Page 7)

Remove and reseat

board

Press STOP/RESET

key on inverter or

cycle power

Replace Inverter

with later version

Page 18

NOTES:

Appendix

Page 18 of 36

Page 19

Appendix

Appendix – Parameter List

The following lists include the combined parameter sets of both the L300P series and SJ300 series of inverters.

Therefore, all parameters listed are not available on both series. Please refer to the instruction manual for the

inverter you have to determine the list of available parameters. Then you can find the parameter on these lists

and determine proper addressing for Modbus/RTU.

Coil List

Coil

No.

0001h Operation command R/W 1: Run, 0: Stop (valid when A002 = 02)

0002h Rotation direction command R/W 1: Reverse, 0 : Forward (valid when A002 = 02)

0003h External trip (EXT) R/W 1: Trip

0004h Trip reset (RS) R/W 1: Reset

0007h Intelligent input terminal [1] R/W 1: ON, 0: OFF (*1)

0008h Intelligent input terminal [2] R/W 1: ON, 0: OFF (*1)

0009h Intelligent input terminal [3] R/W 1: ON, 0: OFF (*1)

000Ah Intelligent input terminal [4] R/W 1: ON, 0: OFF (*1)

000Bh Intelligent input terminal [5] R/W 1: ON, 0: OFF (*1)

000Ch Intelligent input terminal [6] R/W 1: ON, 0: OFF (*1)

000Dh Intelligent input terminal [7] R/W 1: ON, 0: OFF (*1)

000Eh Intelligent input terminal [8] R/W 1: ON, 0: OFF (*1)

000Fh Operation status R 1: Run, 0: Stop (interlocked to "d003")

0010h Rotation direction R

0013h RUN (running) R 1: Tripped, 0: Normal

0014h FA1 (constant-speed reached) R 1: ON, 0: OFF

0015h FA2 (set frequency overreached) R 1: ON, 0: OFF

0016h

0017h OD (output deviation for PID control) R 1: ON, 0: OFF

0018h AL (alarm signal) R 1: ON, 0: OFF

0019h FA3 (set frequency reached) R 1: ON, 0: OFF

001Ah OTQ (over-torque) R 1: ON, 0: OFF

001Bh IP (instantaneous power failure) R 1: ON, 0: OFF

001Ch UV (under voltage) R 1: ON, 0: OFF

001Dh TRQ (torque limited) R 1: ON, 0: OFF

001Eh RNT (operation time over) R 1: ON, 0: OFF

001Fh ONT (plug-in time over) R 1: ON, 0: OFF

0020h THM (thermal alarm signal) R 1: ON, 0: OFF

0026h BRK (brake release) R 1: ON, 0: OFF

0027h BER (brake error) R 1: ON, 0: OFF

0028h ZS (0 Hz detection signal) R 1: ON, 0: OFF

0029h DSE (speed deviation maximum) R 1: ON, 0: OFF

002Ah POK (positioning completed) R 1: ON, 0: OFF

OL (overload notice advance signal

(1))

Item R/W Setting

1: Reverse rotation, 0: Forward rotation (interlocked to

"d003")

R 1: ON, 0: OFF

Page 19 of 36

Page 20

Appendix

002Bh FA4 (set frequency overreached 2) R 1: ON, 0: OFF

002Ch FA5 (set frequency reached 2) R 1: ON, 0: OFF

002Dh

0032h FBV (PID feedback comparison) R 1: ON, 0: OFF

0033h

0034h LOG1 (logical operation result 1) R 1: ON, 0: OFF

0035h LOG2 (logical operation result 2) R 1: ON, 0: OFF

0036h LOG3 (logical operation result 3) R 1: ON, 0: OFF

0037h LOG4 (logical operation result 4) R 1: ON, 0: OFF

0038h LOG5 (logical operation result 5) R 1: ON, 0: OFF

0039h LOG6 (logical operation result 6) R 1: ON, 0: OFF

003Ah WAC (capacitor life warning) R 1: ON, 0: OFF

003Bh WAF (cooling-fan speed drop) R 1: ON, 0: OFF

003Ch FR (starting contact signal) R 1: ON, 0: OFF

003Dh OHF (heat sink overheat warning) R 1: ON, 0: OFF

003Eh LOC (low-current indication signal) R 1: ON, 0: OFF

003Fh M01 (general output 1) R 1: ON, 0: OFF

0040h M02 (general output 2) R 1: ON, 0: OFF

0041h M03 (general output 3) R 1: ON, 0: OFF

0042h M04 (general output 4) R 1: ON, 0: OFF

0043h M05 (general output 5) R 1: ON, 0: OFF

0044h M06 (general output 6) R 1: ON, 0: OFF

0046h FWR (forward rotation) R 1: ON, 0: OFF

0047h RVR (reverse rotation) R 1: ON, 0: OFF

0048h MJA (major failure) R 1: ON, 0: OFF

0049h Data writing in progress R 1: Writing in progress, 0: Normal status

004Ah CRC error R 1: Error detected, 0: No error (*2)

004Bh Overrun R 1: Error detected, 0: No error (*2)

004Ch Framing error R 1: Error detected, 0: No error (*2)

004Dh Parity error R 1: Error detected, 0: No error (*2)

004Eh Sum check error R 1: Error detected, 0: No error (*2)

*1 Normally, this coil is turned on when the corresponding intelligent input terminal on the control circuit terminal

*2 Communication error data is retained until an error reset command is input (can be reset during inverter

OL2 (overload notice advance signal

(2))

NDc (communication line

disconnection)

block is turned on or the coil itself is set to on. In this regard, the operation of the intelligent input terminal has

priority over the operation of the coil. If disconnection of the communication line has disabled the master

system from turning off the coil, turn the corresponding intelligent input terminal on the control circuit block on

and off. This operation turns off the coil.

operation.)

R 1: ON, 0: OFF

R 1: ON, 0: OFF

Page 20 of 36

Page 21

Appendix

Register List

Dec Hex Description

1 0x1 Set frequency (Hz) / PID Setpoint (%) [MSW] F1

2 0x2 Set frequency (Hz) / PID Setpoint (%) [LSW] F1

3 0x3 Status of Inverter [BYTE 3] R1

4 0x4 Status of Inverter [BYTE 2] R1

5 0x5 Status of Inverter [BYTE 1] R1

17 0x11 Accumulated number of Trip(error) D80

18 0x12 Factor and Status of Trip1 [MSW] D81

19 0x13 Factor and Status of Trip1 [LSW] D81

20 0x14 Frequency of Trip1 [MSW]

21 0x15 Frequency of Trip1 [LSW]

22 0x16 Output current of Trip1

23 0x17 PN voltage (DC voltage) of Trip1

24 0x18 Accumulated time during running of Trip1 [MSW]

25 0x19 Accumulated time during running of Trip1 [LSW]

26 0x1A Accumulated time during power ON of Trip1 [MSW]

27 0x1B Accumulated time during power ON of Trip1 [LSW]

28 0x1C Factor and Status of Trip2 [MSW] D82

29 0x1D Factor and Status of Trip2 [LSW] D82

30 0x1E Frequency of Trip2 [MSW]

31 0x1F Frequency of Trip2 [LSW]

32 0x20 Output current of Trip2

33 0x21 PN voltage (DC voltage) of Trip2

34 0x22 Accumulated time during running of Trip2 [MSW]

35 0x23 Accumulated time during running of Trip2 [LSW]

36 0x24 Accumulated time during power ON of Trip2 [MSW]

37 0x25 Accumulated time during power ON of Trip2 [LSW]

38 0x26 Factor and Status of Trip3 [MSW] D83

39 0x27 Factor and Status of Trip3 [LSW] D83

40 0x28 Frequency of Trip3 [MSW]

41 0x29 Frequency of Trip3 [LSW]

42 0x2A Output current of Trip3

43 0x2B PN voltage (DC voltage) of Trip3

44 0x2C Accumulated time during running of Trip3 [MSW]

45 0x2D Accumulated time during running of Trip3 [LSW]

46 0x2E Accumulated time during power ON of Trip3 [MSW]

47 0x2F Accumulated time during power ON of Trip3 [LSW]

48 0x30 Factor and Status of Trip4 [MSW] D84

49 0x31 Factor and Status of Trip4 [LSW] D84

50 0x32 Frequency of Trip4 [MSW]

51 0x33 Frequency of Trip4 [LSW]

52 0x34 Output current of Trip4

53 0x35 PN voltage (DC voltage) of Trip4

54 0x36 Accumulated time during running of Trip4 [MSW]

55 0x37 Accumulated time during running of Trip4 [LSW]

56 0x38 Accumulated time during power ON of Trip4 [MSW]

Parameter

Inverter

Page 21 of 36

Page 22

Appendix

57 0x39 Accumulated time during power ON of Trip4 [LSW]

58 0x3A Factor and Status of Trip5 [MSW] D85

59 0x3B Factor and Status of Trip5 [LSW] D85

60 0x3C Frequency of Trip5 [MSW]

61 0x3D Frequency of Trip5 [LSW]

62 0x3E Output current of Trip5

63 0x3F PN voltage (DC voltage) of Trip5

64 0x40 Accumulated time during running of Trip5 [MSW]

65 0x41 Accumulated time during running of Trip5 [LSW]

66 0x42 Accumulated time during power ON of Trip5 [MSW]

67 0x43 Accumulated time during power ON of Trip5 [LSW]

68 0x44 Factor and Status of Trip6 [MSW] D86

69 0x45 Factor and Status of Trip6 [LSW] D86

70 0x46 Frequency of Trip6 [MSW]

71 0x47 Frequency of Trip6 [LSW]

72 0x48 Output current of Trip6

73 0x49 PN voltage (DC voltage) of Trip6

74 0x4A Accumulated time during running of Trip6 [MSW]

75 0x4B Accumulated time during running of Trip6 [LSW]

76 0x4C Accumulated time during power ON of Trip6 [MSW]

77 0x4D Accumulated time during power ON of Trip6 [LSW]

2304 0x900 Writing to EEPROM

4097 0x1001 Output frequency [MSW] D1

4098 0x1002 Output frequency [LSW] D1

4099 0x1003 Output current D2

4100 0x1004 Direction of p resent running D3

4101 0x1005 Feedback data of PID control [MSW] D4

4102 0x1006 Feedback data of PID control [LSW] D4

4103 0x1007 Status of Input terminal D5

4104 0x1008 Status of output terminal D6

4105 0x1009 Value of conversion of frequency [MSW] D7

4106 0x100A Value of conversion of frequency [LSW] D7

4112 0x1010 Output Torque D12

4113 0x1011 Output voltage D13

4114 0x1012 Input electric power D14

4117 0x1015 Accumulate d time during running [MSW] D16

4118 0x1016 Accumulate d time during running [LSW] D16

4119 0x1017 Accumulate d time during Power ON [MSW] D17

4120 0x1018 Accumulate d time during Power ON [LSW] D17

4134 0x1026 DC Voltage D102

4135 0x1027 On time of BRD running D103

4136 0x1028 Used rate of electroni cs thermal protection D104

4355 0x1103 1st Acceleration time 1 [MSW] F2

4356 0x1104 1st Acceleration time 1 [LSW] F2

4357 0x1105 1st Decel eration time 1 [MSW] F3

Page 22 of 36

Page 23

Appendix

4358 0x1106 1st Decel eration time 1 [LSW] F3

4359 0x1107 Selection of running direction for DIG-OPE F4

4609 0x1201 Selection of frequency com mand destination A1

4610 0x1202 Selection of running com mand destination A2

4611 0x1203 1st Base frequency A3

4612 0x1204 1st Maximum frequen cy A4

4613 0x1205 Selection of AT function A5

4614 0x1206 Selection of O2 terminal function A6

4619 0x120B Start frequen cy of .O. terminal [MSW] A11

4620 0x120C Start frequency of .O. terminal [LSW] A11

4621 0x120D End frequency of .O. terminal [MSW] A12

4622 0x120E End frequency of .O. terminal [LSW] A12

4623 0x120F Starting rate of O terminal A13

4624 0x1210 End rate of O terminal A14

4625 0x1211 Selection of starting function of O terminal A15

4626 0x1212 Sampling number of fetching data from .O. A16

4629 0x1215 Selection of Multispeed method A19

4630 0x1216 1st setting Multispeed frequency 0 [MSW] A20

4631 0x1217 1st setting Multispeed frequency 0 [LSW] A20

4632 0x1218 Multispeed frequency 1 [MSW] A21

4633 0x1219 Multispeed frequency 1 [LSW] A21

4634 0x121A Multispeed frequency 2 [MSW] A22

4635 0x121B Multispeed frequency 2 [LSW] A22

4636 0x121C Multispeed frequency 3 [MSW] A23

4637 0x121D Multispeed frequency 3 [LSW] A23

4638 0x121E Multispeed frequency 4 [MSW] A24

4639 0x121F Multispeed frequency 4 [LSW] A24

4640 0x1220 Multispeed frequency 5 [MSW] A25

4641 0x1221 Multispeed frequency 5 [LSW] A25

4642 0x1222 Multispeed frequency 6 [MSW] A26

4643 0x1223 Multispeed frequency 6 [LSW] A26

4644 0x1224 Multispeed frequency 7 [MSW] A27

4645 0x1225 Multispeed frequency 7 [LSW] A27

4646 0x1226 Multispeed frequency 8 [MSW] A28

4647 0x1227 Multispeed frequency 8 [LSW] A28

4648 0x1228 Multispeed frequency 9 [MSW] A29

4649 0x1229 Multispeed frequency 9 [LSW] A29

4650 0x122A Multispeed frequency 10 [MSW] A30

4651 0x122B Multispeed frequency 10 [LSW] A30

4652 0x122C Multispeed frequency 11 [MSW] A31

4653 0x122D Multispeed frequency 11 [LSW] A31

4654 0x122E Multispeed frequency 12 [MSW] A32

4655 0x122F Multispeed frequency 12 [LSW] A32

4656 0x1230 Multispeed frequency 13 [MSW] A33

4657 0x1231 Multispeed frequency 13 [LSW] A33

4658 0x1232 Multispeed frequency 14 [MSW] A34

4659 0x1233 Multispeed frequency 14 [LSW] A34

4660 0x1234 Multispeed frequency 15 [MSW] A35

Page 23 of 36

Page 24

Appendix

4661 0x1235 Multispeed frequency 15 [LSW] A35

4664 0x1238 Jogging frequency A38

4665 0x1239 Selection of Jogging method A39

4667 0x123B Selection of 1st Torque boost Method A41

4668 0x123C Value of 1st Manual torque boost A42

4669 0x123D 1st Break point of manual torque boost A43

4670 0x123E Selection of 1st Control method A44

4671 0x123F Gain of output voltage A45

4677 0x1245 Selection of DC braking method A51

4678 0x1246 Frequency of DC braking start A52

4679 0x1247 Delay time of DC braking start A53

4680 0x1248 Power of DC braking(end of running) A54

4681 0x1249 Time of DC braking working A55

4682 0x124A Selection of edge/level action of DC braking trigger A56

4683 0x124B Power of DC braking (start of running) A57

4684 0x124C Time of DC braking working for beginning of inverter running A58

4685 0x124D Carrier frequency of DC braking A59

4687 0x124F 1st Upper limiter frequency [MSW] A61

4688 0x1250 1st Upper limiter frequency [LSW] A61

4689 0x1251 1st Lower limiter frequency [MSW] A62

4690 0x1252 1st Lower limiter frequency [LSW] A62

4691 0x1253 Jumping frequency 1 [MSW] A63

4692 0x1254 Jumping frequency 1 [LSW] A63

4693 0x1255 Width of jumping frequency 1 A64

4694 0x1256 Jumping frequency 2 [MSW] A65

4695 0x1257 Jumping frequency 2 [LSW] A65

4696 0x1258 Width of jumping frequency 2 A66

4697 0x1259 Jumping frequency 3 [MSW] A67

4698 0x125A Jumping frequency 3 [LSW] A67

4699 0x125B Width of jumping frequency 3 A68

4700 0x125C Frequency of stopping acceleration [MSW] A69

4701 0x125D Frequency of stopping acceleration [LSW] A69

4702 0x125E Time of stopping to accelerate A70

4703 0x125F Selection of PID control presence A71

4704 0x1260 Proportional(P) gain of PID control A72

4705 0x1261 Integrate (I) gain of PID control A73

4706 0x1262 Differential (D) gain of PID control A74

4707 0x1263 Scale of PID control A75

4708 0x1264 Selection of feedback destination for PID control A76

4713 0x1269 Selection of AVR function A81

4714 0x126A Selection of Motor voltage A82

4717 0x126D Selection of operation mode A85

4718 0x126E Response time of Energy saving function A86

4724 0x1274 1st Acceleration time 2 [MSW] A92

Page 24 of 36

Page 25

Appendix

4725 0x1275 1st Acceleration time 2 [LSW] A92

4726 0x1276 1st Deceleration time 2 [MSW] A93

4727 0x1277 1st Deceleration time 2 [LSW] A93

4728 0x1278 Selection of 1st 2-stage accel/decel Method A94

4729 0x1279 1st Frequency of 2-stage acceleration [MSW] A95

4730 0x127A 1st Frequency of 2-stage acceleration [LSW] A95

4731 0x127B 1st Frequency of 2-stage deceleration [MSW] A96

4732 0x127C 1st Frequency of 2-stage deceleration [LSW] A96

4733 0x127D Selection of acceleration pattern A97

4734 0x127E Selection of deceleration pattern A98

4737 0x1281 Start frequency of .OI. terminal [MSW] A101

4738 0x1282 Start frequency of .OI. terminal [LSW] A101

4739 0x1283 End frequency of .OI. terminal [MSW] A102

4740 0x1284 End frequency of .OI. terminal [LSW] A102

4741 0x1285 Starting rate of OI terminal A103

4742 0x1286 End rate of OI terminal A104

4743 0x1287 Selection of starting function of OI terminal A105

4749 0x128D Start frequency of .O2. terminal [MSW] A111

4750 0x128E Start frequency of .O2. terminal [LSW] A111

4751 0x128F End frequency of .O2. terminal [MSW] A112

4752 0x1290 End frequency of .O2. terminal [LSW] A112

4753 0x1291 Starting rate of O2 terminal A113

4754 0x1292 End rate of O2 terminal A114

4773 0x12A5 Curve constant of acceleration A131

4774 0x12A6 Curve constant of deceleration A132

4865 0x1301 Selection of retry method B1

4866 0x1302 Acceptable time for Instantaneous power failure B2

4867 0x1303 Waiting time of retry B3

4868 0x1304 Selection of method(action) at instantaneous power and under voltage B4

4869 0x1305 Retry number of instantaneous power and under voltage B5

4870 0x1306 Selection of fail phase function B6

4871 0x1307 Frequency of frequency matching [MSW] B7

4872 0x1308 Frequency of frequency matching [LSW] B7

4877 0x130D Level of 1st Electronic thermal protection B12

4878 0x130E Selection of characteristic of 1st electronic thermal protection B13

4880 0x1310 Free electronic thermal frequency 1 B15

4881 0x1311 Free electronic thermal current 1 B16

4882 0x1312 Free electronic thermal frequency 2 B17

4883 0x1313 Free electronic thermal current 2 B18

4884 0x1314 Free electronic thermal frequency 3 B19

4885 0x1315 Free electronic thermal current 3 B20

4886 0x1316 Selection of method of overload restriction1 B21

4887 0x1317 Level of Overload restriction 1 B22

Page 25 of 36

Page 26

Appendix

4888 0x1318 Constant value of Overload restriction 1 B23

4889 0x1319 Selection of method of overload restriction 2 B24

4890 0x131A Level of Overload restriction 2 B25

4891 0x131B Constant value of Overload restriction 2 B26

4896 0x1320 Selection of method of Software lock B31

4899 0x1323 Display time of warning [MSW] B34

4900 0x1324 Display time of warning [LSW] B34

4901 0x1325 Selection of running direction limitation B35

4902 0x1326 Selection of method of reducing voltage start B36

4903 0x1327 Selection of Display B37

4906 0x132A Selection of method of Torque limiter B40

4907 0x132B Level of torque limiter in forward and drive (1st quadrant) B41

4908 0x132C Level of torque limiter in reverse and regenerative (2nd quadrant) B42

4909 0x132D Level of torque limiter in reverse and drive (3rd quadrant) B43

4910 0x132E Level of torque limiter in forward and regenerative (4th quadrant) B44

4911 0x132F Selection of LAD stop by torque B45

4912 0x1330 Selection of preventive of reverse running B46

4916 0x1334 Selection of Non stop operation at instantaneous power failure B50

4917 0x1335 Starting voltage of Nonstop operation for Instantaneous power failure B51

Starting voltage of OV-LAD stop at Nonstop operation for Instantaneous power

4918 0x1336

4919 0x1337

4920 0x1338

4921 0x1339

4949 0x1355 Minimum frequency B82

4950 0x1356 Carrier frequency(PWM frequency B83

4951 0x1357 Selection of Initialization B84

4952 0x1358 Selection of initialized data B85

4953 0x1359 Coefficient of converting frequency B86

4954 0x135A Selection of .STOP. key function B87

4955 0x135B Selection free run function B88

4957 0x135D Usage rate of BRD B90

4958 0x135E Selection of action at stop B91

4959 0x135F Selection of action of cooling fan B92

4962 0x1362 Selection of BRD function B95

4963 0x1363 On level of BRD B96

4965 0x1365 Selection of Thermister function B98

4966 0x1366 Level of Thermister error B99

4967 0x1367 Free V/F control frequency 1 B100

4968 0x1368 Free V/F control voltage 1 B101

4969 0x1369 Free V/F control frequency 2 B102

4970 0x136A Free V/F control voltage 2 B103

failure

Deceleration time of Non-stop operation at Instantaneous power failure

[MSW]

Deceleration time of Non-stop operation at Instantaneous power failure

[LSW]

Frequency width of starting deceleration at Nonstop operation for

Instantaneous power failure

B52

B53

B53

B54

Page 26 of 36

Page 27

Appendix

4971 0x136B Free V/F control frequency 3 B104

4972 0x136C Free V/F control voltage 3 B105

4973 0x136D Free V/F control frequency 4 B106

4974 0x136E Free V/F control voltage 4 B107

4975 0x136F Free V/F control frequency 5 B108

4976 0x1370 Free V/F control voltage 5 B109

4977 0x1371 Free V/F control frequency 6 B110

4978 0x1372 Free V/F control voltage 6 B111

4979 0x1373 Free V/F control frequency 7 B112

4980 0x1374 Free V/F control voltage 7 B113

4987 0x137B Selection of external braking function B120

4988 0x137C Waiting time for establishing external braking condition B121

4989 0x137D Waiting time for acceleration at external braking B122

4990 0x137E Waiting time for stop at external braking B123

4991 0x137F Waiting time for confirmation signal at external braking B124

4992 0x1380 Release frequency of external braking B125

4993 0x1381 Release current of external braking B126

5121 0x1401 Selection of function in Intelligent input 1 C1

5122 0x1402 Selection of function in Intelligent input 2 C2

5123 0x1403 Selection of function in Intelligent input 3 C3

5124 0x1404 Selection of function in Intelligent input 4 C4

5125 0x1405 Selection of function in Intelligent input 5 C5

5126 0x1406 Selection of function in Intelligent input 6 C6

5127 0x1407 Selection of function in Intelligent input 7 C7

5128 0x1408 Selection of function in Intelligent input 8 C8

5131 0x140B Selection of a(NO) or b(NC) contact in Intelligent input 1 C11

5132 0x140C Selection of a(NO) or b(NC) contact in Intelligent input 2 C12

5133 0x140D Selection of a(NO) or b(NC) contact in Intelligent input 3 C13

5134 0x140E Selection of a(NO) or b(NC) contact in Intelligent input 4 C14

5135 0x140F Selection of a(NO) or b(NC) contact in Intelligent input 5 C15

5136 0x1410 Selection of a(NO) or b(NC) contact in Intelligent input 6 C16

5137 0x1411 Selection of a(NO) or b(NC) contact in Intelligent input 7 C17

5138 0x1412 Selection of a(NO) or b(NC) contact in Intelligent input 8 C18

5139 0x1413 Selection of a(NO) or b(NC) contact in FW input C19

5141 0x1415 Selection of function in Intelligent output 11 C21

5142 0x1416 Selection of function in Intelligent output 12 C22

5143 0x1417 Selection of function in Intelligent output 13 C23

5144 0x1418 Selection of function in Intelligent output 14 C24

5145 0x1419 Selection of function in Intelligent output 15 C25

5146 0x141A Selection of function in Alarm relay output C26

5147 0x141B Selection of FM function C27

5148 0x141C Selection of AM function C28

5149 0x141D Selection of AMI function C29

5151 0x141F Selection of a(NO) or b(NC) contact in Intelligent output 11 C31

5152 0x1420 Selection of a(NO) or b(NC) contact in Intelligent output 12 C32

5153 0x1421 Selection of a(NO) or b(NC) contact in Intelligent output 13 C33

Page 27 of 36

Page 28

Appendix

5154 0x1422 Selection of a(NO) or b(NC) contact in Intelligent output 14 C34

5155 0x1423 Selection of a(NO) or b(NC) contact in Intelligent output 15 C35

5156 0x1424 Selection of a(NO) or b(NC) contact in Alarm relay output C36

5160 0x1428 Selection of output mode of overload warning signal C40

5161 0x1429 Level1 of overload restriction warning C41

5162 0x142A Arrival frequency at acceleration1 [MSW] C42

5163 0x142B Arrival frequency at acceleration1 [LSW] C42

5164 0x142C Arrival frequency at deceleration1 [MSW] C43

5165 0x142D Arrival frequency at deceleration1 [LSW] C43

5166 0x142E Level over acceptable deviation of PID control C44

5167 0x142F Arrival frequency at acceleration2 [MSW] C45

5168 0x1430 Arrival frequency at acceleration2 [LSW] C45

5169 0x1431 Arrival frequency at deceleration2 [MSW] C46

5170 0x1432 Arrival frequency at deceleration2 [LSW] C46

5179 0x143B Level of over torque in forward and drive (1st quadrant) C55

5180 0x143C Level of over torque in reverse and regenerative (2nd quadrant) C56

5181 0x143D Level of over torque in reverse and drive (3rd quadrant) C57

5182 0x143E Level of over torque in forward and regenerative (4th quadrant) C58

5185 0x1441 Warning Level of electronic thermal protection C61

5186 0x1442 Selection of Alarm code C62

5187 0x1443 Level f detecting Zero speed C63

5195 0x144B Selection of communication speed for RS485 C71

5196 0x144C Selection of Inverter address for RS 485 C72

5197 0x144D Selection of bit length of data for RS485 C73

5198 0x144E Selection of parity (odd or even) for RS485 C74

5199 0x144F Selection of stop bit for RS485 C75

5202 0x1452 Waiting time of communication start C78

5205 0x1455 Adjustment of .O. terminal C81

5206 0x1456 Adjustment of .OI. terminal C82

5207 0x1457 Adjustment of .O2. terminal C83

5209 0x1459 Adjusting value of Thermister C85

5215 0x145F Selection of Debug mode method C91

5225 0x1469 Selection of UP/DOWN function C101

5226 0x146A Selection of RESET function C102

5227 0x146B Selection of frequency matching function at RESET C103

5229 0x146D Adjustment of FM(digital monitor) B81

5230 0x146E Adjustment of AM(analog monitor) B80

5231 0x146F Adjustment of AMI output C87

5233 0x1471 Adjustment of offset of AM C86

5234 0x1472 Adjustment of Offset of AMI output C88

Page 28 of 36

Page 29

Appendix

5235 0x1473 Level2 of overload restriction warning C111

5245 0x147D Adjustment of Zero of .O. terminal C121

5246 0x147E Adjustment of Zero of .OI. terminal C122

5247 0x147F Adjustment of Zero of .O2. terminal C12 3

5377 0x1501 Selection of Auto-tuning presence H1

5378 0x1502 Selection of Motor constant for 1st motor H2

5379 0x1503 Selection of Motor capacity for 1st motor H3

5380 0x1504 Selection of Motor poles for 1st motor H4

5381 0x1505 1st Speed response gain [MSW] H5

5382 0x1506 1st Speed response gain [LSW] H5

5383 0x1507 1st Stability gain H6

5397 0x1515 1st Primary resistor R1 of motor [MSW] H20

5398 0x1516 1st Primary resistor R1 of motor [LSW] H20

5399 0x1517 1st Secondary resistor R2 of motor [MSW] H21

5400 0x1518 1st Secondary resistor R2 of motor [LSW] H21

5401 0x1519 1st Inductance L of motor [MSW] H22

5402 0x151A 1st Inductance L of motor [LSW] H22

5403 0x151B 1st No load current Io of motor [MSW] H23

5404 0x151C 1st No load current Io of motor [LSW] H23

5405 0x151D 1st Inertia J of motor [MSW] H24

5406 0x151E 1st Inertia J of motor [LSW] H24

5412 0x1524 1st Primary resistor R1 of motor (Auto) [MSW] H30

5413 0x1525 1st Primary resistor R1 of motor (Auto) [LSW] H30

5414 0x1526 1st Secondary resistor R2 of motor (Auto) [MSW] H31

5415 0x1527 1st Secondary resistor R2 of motor (Auto) [LSW] H31

5416 0x1528 1st Inductance L of motor (Auto) [MSW] H32

5417 0x1529 1st Inductance L of motor (Auto) [LSW] H32

5418 0x152A 1st No load current Io of motor (Auto) [MSW] H33

5419 0x152B 1st No load current Io of motor (Auto) [LSW] H33

5420 0x152C 1st Inertia J of motor (Auto) [MSW] H34

5421 0x152D 1st Inertia J of motor (Auto) [LSW] H34

5437 0x153D 1st Proportional gain of speed control(PI control) H50

5438 0x153E 1st Integral gain of speed control(PI control) H51

5439 0x153F 1st Proportional gain of speed control(P control) H52

5447 0x1547 1st Limiter of 0Hz control H60

5457 0x1551 PI Proportion gain Change H70

5458 0x1552 PI Integral gain Change H71

5459 0x1553 P Proportion gain Change H72

5633 0x1601 Selection of action at option1 error P1

5634 0x1602 Selection of action at option2 error P2

5643 0x160B Pulse number of the encoder P11

Page 29 of 36

Page 30

Appendix

5644 0x160C Selection of Control Mode P12

5645 0x160D Selection of method of Pulse lines input P13

5646 0x160E Stop position at Orientation mode P14

5647 0x160F Speed at Orientation mode P15

5648 0x1610 Set of Orientation direction P16

5649 0x1611 Defining Area of completion of Orientation mode P17

5650 0x1612 Delay time of completion Orientation mode P18

5651 0x1613 Selection of location of electric gear P19

5652 0x1614 The numerator of electric gear P20

5653 0x1615 The denominator of electric gear P21

5654 0x1616 Feed forward gain of position control P22

5655 0x1617 Loop gain of position control P23

5657 0x1619 Selection of Available of compensation of secondary resistor P25

5658 0x161A Level of detecting over speed P26

5659 0x161B Value of detecting over deviation P27

5663 0x161F Acc/Dec input mode selection P31

5664 0x1620 Stop position setting input mode selection P32

5678 0x162E Timer setting of communication timeout Whilst running (SJ-DN) P44

5679 0x162F Inverter action When communication error (SJ-DN) P45

5680 0x1630 Polled I/O OUTPUT Instance number (SJ-DN) P46

5681 0x1631 Polled I/O INPUT Instance number (SJ-DN) P47

5682 0x1632 Inverter action when Idle mode detected (SJ-DN) P48

5683 0x1633 Motor poles setting for revolutions per minute (SJ-DN) P49

8451 0x2103 2nd Acceleration time 1 [MSW] F202

8452 0x2104 2nd Acceleration time 1 [LSW] F202

8453 0x2105 2nd Deceleration time 1 [MSW] F203

8454 0x2106 2nd Deceleration time 1 [LSW] F203

8707 0x2203 2nd Base frequency A203

8708 0x2204 2nd Maximum frequency A204

8726 0x2216 2nd setting Multispeed frequency 0 [MSW] A220

8727 0x2217 2nd setting Multispeed frequency 0 [LSW] A220

8763 0x223B Selection of 2nd Torque boost Method A241

8764 0x223C Value of 2nd Manual torque boost A242

8765 0x223D 2nd Break point of manual torque boost A243

8766 0x223E Selection of 2nd Control method A244

8783 0x224F 2nd Upper limiter frequency [MSW] A261

8784 0x2250 2nd Upper limiter frequency [LSW] A261

8785 0x2251 2nd Lower limiter frequency [MSW] A262

8786 0x2252 2nd Lower limiter frequency [LSW] A262

Page 30 of 36

Page 31

Appendix

8815 0x226F 2nd Acceleration time 2 [MSW] A292

8816 0x2270 2nd Acceleration time 2 [LSW] A292

8817 0x2271 2nd Deceleration time 2 [MSW] A293

8818 0x2272 2nd Deceleration time 2 [LSW] A293

8819 0x2273 Selection of 2nd 2-stage accel/decel Method A294

8820 0x2274 2nd Frequency of 2-stage acceleration [MSW] A295

8821 0x2275 2nd Frequency of 2-stage acceleration [LSW] A295

8822 0x2276 2nd Frequency of 2-stage deceleration [MSW] A296

8823 0x2277 2nd Frequency of 2-stage deceleration [LSW] A296

8972 0x230C Level of 2nd Electronic thermal protection B212

8973 0x230D Selection of characteristic of 2nd electronic thermal protection B213

9474 0x2502 Selection of Motor constant for 2nd motor H202

9475 0x2503 Selection of Motor capacity for 2nd motor H203

9476 0x2504 Selection of Motor poles for 2nd motor H204

9477 0x2505 2nd Speed response gain [MSW] H205

9478 0x2506 2nd Speed response gain [LSW] H205

9479 0x2507 2nd Stability gain H206

9493 0x2515 2nd Primary resistor R1 of motor [MSW] H220

9494 0x2516 2nd Primary resistor R1 of motor [LSW] H220

9495 0x2517 2nd Secondary resistor R2 of motor [MSW] H221

9496 0x2518 2nd Secondary resistor R2 of motor [LSW] H221

9497 0x2519 2nd Inductance L of motor [MSW] H222

9498 0x251A 2nd Inductance L of motor [LSW] H222

9499 0x251B 2nd No load current Io of motor [MSW] H223

9500 0x251C 2nd No load current Io of motor [LSW] H223

9501 0x251D 2nd Inertia J of motor [MSW] H224

9502 0x251E 2nd Inertia J of motor [LSW] H224

9508 0x2524 2nd Primary resistor R1 of motor (Auto) [MSW] H230

9509 0x2525 2nd Primary resistor R1 of motor (Auto) [LSW] H230

9510 0x2526 2nd Secondary resistor R2 of motor (Auto) [MSW] H231

9511 0x2527 2nd Secondary resistor R2 of motor (Auto) [LSW] H231

9512 0x2528 2nd Inductance L of motor (Auto) [MSW] H232

9513 0x2529 2nd Inductance L of motor (Auto) [LSW] H232

9514 0x252A 2nd No load current Io of motor (Auto) [MSW] H233

9515 0x252B 2nd No load current Io of motor (Auto) [LSW] H233

9516 0x252C 2nd Inertia J of motor (Auto) [MSW] H234

9517 0x252D 2nd Inertia J of motor (Auto) [LSW] H234

9533 0x253D 2nd Proportional gain of speed control(PI control) H250

9534 0x253E 2nd Integral gain of speed control(PI control) H251

9535 0x253F 2nd Proportional gain of speed control(P control) H252

9543 0x2547 2nd Limiter of 0Hz control H260

12547 0x3103 3rd Acceleration time 1 [MSW] F302

12548 0x3104 3rd Acceleration time 1 [LSW] F302

12549 0x3105 3rd Deceleration time 1 [MSW] F303

Page 31 of 36

Page 32

Appendix

12550 0x3106 3rd Deceleration time 1 [LSW] F303

12803 0x3203 3rd Base frequency A303

12804 0x3204 3rd Maximum frequency A304

12822 0x3216 3rd setting Multispeed frequency 0 [MSW] A320

12823 0x3217 3rd setting Multispeed frequency 0 [LSW] A320

12860 0x323C Value of 3rd Manual torque boo st A342

12861 0x323D 3rd Break point of manual torque boost A343

12862 0x323E Selection of 3rd Control method A344

12909 0x326D 3rd Acceleration time 2 [MSW] A392

12910 0x326E 3rd Acceleration time 2 [LSW] A392

12911 0x326F 3rd Deceleration time 2 [MSW] A393

12912 0x3270 3rd Deceleration time 2 [LSW] A393

13068 0x330C Level of 3rd Electronic thermal protection B312

13069 0x330D Selection of characteristic of 3rd electronic thermal protection B313

13575 0x3507 3rd Stability gain H306

Page 32 of 36

Page 33

Index

Index

A

A - Standard Functions · 21

B

B - Fine-Tuning Functions · 24

C

C - Intelligent Terminal Functions · 27

Carton Contents · 5

Compatibility, Inverter · 7

Configuration · 13

D

D - Monitoring Functions · 19

DIP-switches · 9, 13

E

K

keypad, inverter · 17

L

layout, board · 9

LEDs · 9, 11, 13

M

MODBUS Functions, supported · 15

N

network operation · 15

O

O - Other Functions · 30

Operation · 15

error codes · 17

Error LED · 11

F

F - Main Profile Functions · 21

H

H - Motor Constants and Functions · 29

I

Installing · 9

Interface, User · 11

P

P - Expansion Card Functions · 31

parameter list · 19

parameters, inverter · 15

R

R - Reference Codes · 32

RXD LED · 11

S

Safety Precautions · 6

Status LED · 11

Page 33 of 36

Page 34

T

Index

W

Troubleshooting · 17

TXD LED · 11

Warranty · 5

Wiring · 9

Page 34 of 36

Page 35

NOTES:

Index

Page 35 of 36

Page 36

Hitachi America, Ltd.

Tarrytown, NY 10591

© 2007

www.hitachi.us/inverters

September 2007 HAL1052

Loading...

Loading...