Page 1

Hitachi Inverter

SJ300/L300P SERIES

SJ-LW

INSTRUCTION MANUAL

Thank you for purchase of “HITACHI INVERTER”. This manual

explains about treatment of “SJ-LW (LonWorks Option)”. By reading this

manual and an instruction manual of inverter use practically for

installation, maintenance, and inspection. After reading this manual,

keep it handy for future reference.

Make sure to reach this manual to the end user.

(LonWorks Option)

Table of Contents

Chapter1 Introduction 1

Chapter2 Installation method of printed board 5

Chapter3 Wiring, Connecting 6

Chapter4 Setting 7

Chapter5 LonWorks Communication Function 8

Chapter6 Control from LonWorks 17

Chapter7 Countermeasure for abnormality 21

Appendix1 Parameter Object Lists

Appendix2 Trip monitor data address

After reading this manual, keep it at handy for future reference.

23

32

NB623X

Page 2

SAFTY PRECAUTIONS

- Request Thank you for purchase of “SJ-LW (LonWorks Option)”.

This instruction manual explains about treatment and maintenance of “SJ-LW ”. Before using the product,

carefully read this manual with the instruction manual of inverter, and keeps it handy for quick reference of

operator and maintenance inspector. Before installing, operating, maintenance and inspection read this

manual carefully and follow the instructions exactly.

Always keep various kinds of specification mentioned in this manual and use exactly. And make sure to

prevent trouble by correct inspection and maintenance. Make sure to reach this manual to the end user.

- About treatment of this manual (1)Please consent that mentioned items of this manual may be change without permission.

(2)Keep this manual carefully not to lose because it can not be reissued

(3)All right reserved.

(4)Contents in this manual is written to make assurance doubly sure but, but please contact if you have

some doubts about spelling mistakes, omitted word etc.

(5)Please agree that there is no responsibility for effects resulted, in spite of contents above mentioned.

- About trademark (1) Echelon, Neuron, LON, LonTalk, LonWorks, 3120 are registered trademark of Echelon Corporation.

(LON: Local Operating Network)

(2) LonMaker, LonMark are trademark of Echelon Corporation.

- Reference

W hen Co nne ct ing S J- LW to LON netwo rk ,XI F f ile is n eces s ar y as ex ter na l in ter fac e file .

XIF file is possible to download from the web site below.

http://www.hitachi-ds.com

General information regarding LonWorks and how to get LonW orks specificatio ns , re fer to the web site belo w.

http://www.lonmark.org

Revision His tor y Table

No.

1. Initial release of Manual NB623X Sep. 2001 NB623X

Revision contents The date of issued Manual No.

Except this table, revised only spelling mistakes omitted words, and error writings without notice.

Page 3

SAFTY PRECAUTIONS

!

!

!

!

SAFTY PRECAUTIONS

Carefully read this manual and all of the warning labels attached to the inverter before installing, operating,

maintaining, inspecting, it. Safety precautions are classified into “Warning” and “Caution” in this manual.

:Indicates a potentially hazardous situation which, if not avoided, can result in serious

WARNING

injury or death.

CAUTION

:Indicates a potentially hazardous situation which, if not avoided, can result in minor to

moderate injury, or serous damage to the product

The situation described in may, if not avoided, lead to serious results. Important safety

measures are described in CAUTION (as well as WARNING) so be sure observe them.

Notes are described in this manual in “(Note)”. Carefully read the contents and follow them exactly.

CAUTION

CAUTION

In all the illustrations in this manual, covers and safely device are occasionally removed to describe the

details. When the product is operated, make sure that the covers and safety devices are placed as they

were specified originally and operate it according to the instruction manual.

Page 4

SAFTY PRECAUTIONS

!

!

WARNING

Wiring:

W iring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock, fire and/or damage of product.

Implement wiring after checking that the power supply is off.

Otherwise, there is a danger of electric shock and/or fire.

Operating:

Be sure not to touch the surface or the terminal of option board while energizing.

Otherwise, there is a danger of electric shock and/or fire.

Be sure not to remove the LonWorks option printed board while operating.

Otherwise, there is a danger of electric shock and/or fire.

Maintenance, Inspection and Part Replacement:

Wait at least 10 minutes after turning off the input power supply before performing maintenance and

inspection.

(Confirm the charge lamp on the inverter is off, checks direct current voltage between P-N terminals and

confirm it is less than 45V)

Otherwise, there is a danger of electric shock.

Make sure that only qualified persons will perform maintenance, inspection, and part replacement

(Before st ar tin g th e work , rem ov e me tall ic o bje cts fr om your per son (wr is twa tch , br ac ele t, etc .) .

Be sure to use tools protected with insulation.)

Otherwise, there is a danger of electric shock and/or injury.

Note:

Never modify the unit.

Otherwise, there is a da nger o f e lec tric sh ock and /o r inju r y.

CAUTION

Installation:

Be sure not to let the foreign matter enter such as wire clippings, spatter from welding, metal shaving,

dust etc.

Otherwise, there is a danger of fire.

Be sure to fix inverter to option printed board with an attached fixed screw.

Otherwise, there is a danger of connecting error.

Be sure to fasten the screws connecting signal wire in side of option printed board. Check for any

loosening of screw.

Otherwise, there is a danger of connecting error.

Wiring:

Be sure to fasten the screws not to loose.

Otherwise, there is a danger of connecting error.

Operation:

Check rotary direction, abnormal motor noise and vibrations during operating.

Otherwise, there is a da nger o f inju r y to pe rso nnel and/o r ma chi ne brea kage

Page 5

CHAPTER 1 INTRODUCTION

1.1 INSPECTION UPON UNPACKING

Make sure to treat the product carefully not to give shock and vibration while unpacking. Check that the

product is the one you ordered, no defect, and that there is no damage during transportation.

(Content s of pack i ng)

(1) SJ-LW (LonWorks option printed board):1 (also Install Manual atached)

(2) Instruction manual:1

(3) Screws fixed printed board (M3 times 8 mm):2

If you discover any problems, contact your sales agent immediately.

1.2 INQUIRY OF THE PRODUCT AND WARRANTY FOR THE PRODUCT

1.2.1 REQUIRE WHILE INQUIRING

If inquiry of breakage, question, damage etc. is needed, please tell the following information to the supplier

you ordered or the nearest Hitachi Distributor.

(1) Type(SJ-LW )

(2) Manuf ac tu rin g num b er (It em of lab e l, th at labe le d s urfac e of pr i nte d bo ard . SJ -LW XXX

(3) Date of purchasing

(4) Contents of inquiry

Damage parts and its condition etc.

・

Question parts and their contents etc.

・

In order to shorten impossible working time, standing spare unit is recommended.

)

1.2.2 WARRANTY OF THE PRODUCT

This product is guaranteed to last for one year after purchase. But, the next case is toll repair, even if within

warranty period.

(1) In case caused by operating mistake, and incorrect repair and modification.

(2) Trouble caused by reasons except the shipped product.

(3) In case of using in range over the value of specification.

(4) In case caused by natural calamity, disaster, and secondary disaster.

Warranty mentioned here means warranty for shipped product itself. Damage caused by trouble of shipped

product is not guaranteed.

[Replacement]

Any inspection and replacement after the expiration of warranty period (one-year) shall be charged to the

purchaser. And also any inspection and repair which are not covered in warranty mentioned above, even if it

is within warranty period, it shall be charged to the purchaser. If you require the replacement, please contact

your Hitachi distributor.

1

Page 6

CHAPTER 1 INTRODUCTION

1.3 Outline of product

SJ-LW is LonWorks communication board for SJ300/L300P series inverter.

SJ300/L300P series inverter can get to connect another devices via LonWorks when install SJ-LW.

SJ-LW is possible to connect for all models of SJ300/L300P series.

The SJ-LW option card communi cate s a ccording to t he L on Works P roto col Stan dard ANS I/EIA 709. 1- A -1999.

This means that it can communicate with all LonWorks nodes that comply with this standard, but it does not

necessarily mean that all services available in the LonWorks standard are supported. The “LonMark

Functional Profile: Variable Speed motor Drive” (doc no. 6010_11) is supported.

In a control system the option board will act as a node that can be read and written to, from any other

LonWorks node that has SNVT’s that corresponds to the one on SJ-LW.

(Note) RS485 communication function is disabled by installing SJ-LW to the inverter.

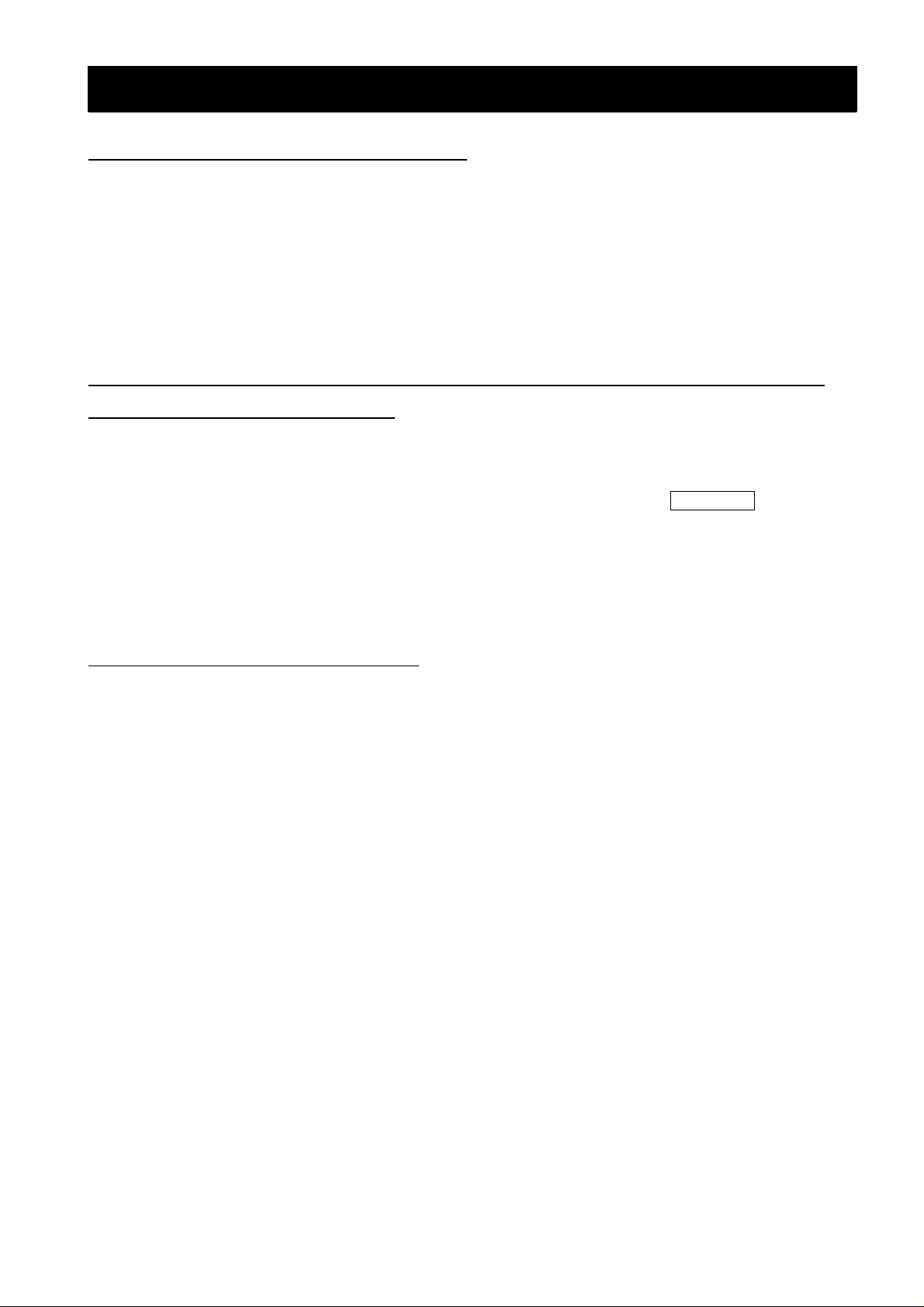

1.4 Appearance and Names of Parts

Figure 1-1 indicates the appearance of SJ-LW.

Connector for connection to SJ 300 /L300 P(Rea r o f unit)

Terminal S witch(S2 )

BUS

NO

FT

Service Pin (S1)

LonWorks contact (open type)

PhoenixContactCo.Ltd.(MC1.5/3‑ST‑3.81)etc

Serial Channel Status LE D (S ER IAL )

LonWorks Service LED (SERV)

Power/Status LED ( POWER)

Figure 1-1 Appearance of SJ-LW

2

Page 7

CHAPTER 1 INTRODUCTION

118KT1234510001

118KT1234510001118KT1234510001

118KT1234510001

0101

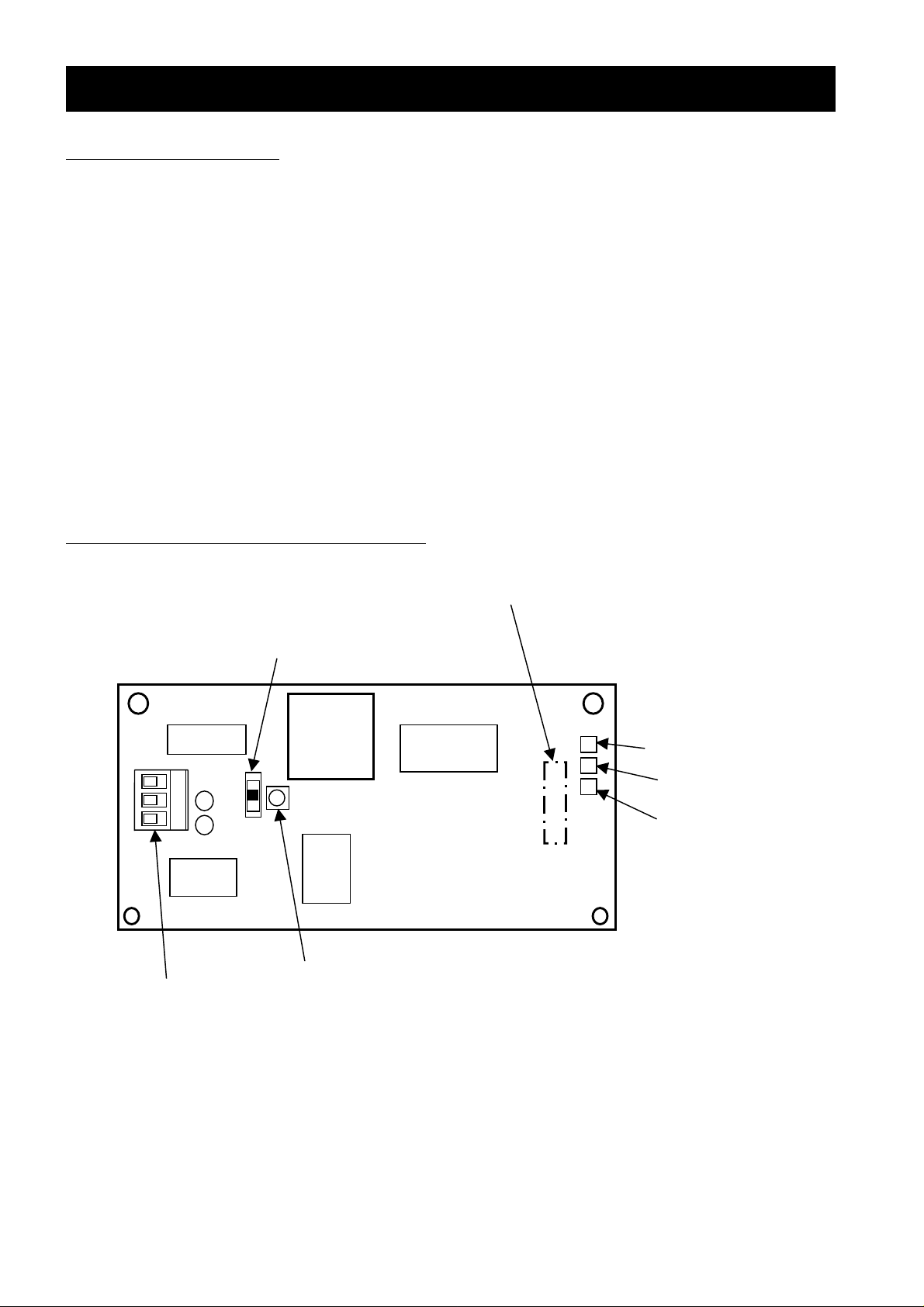

1.5 LonWorks Supported Version

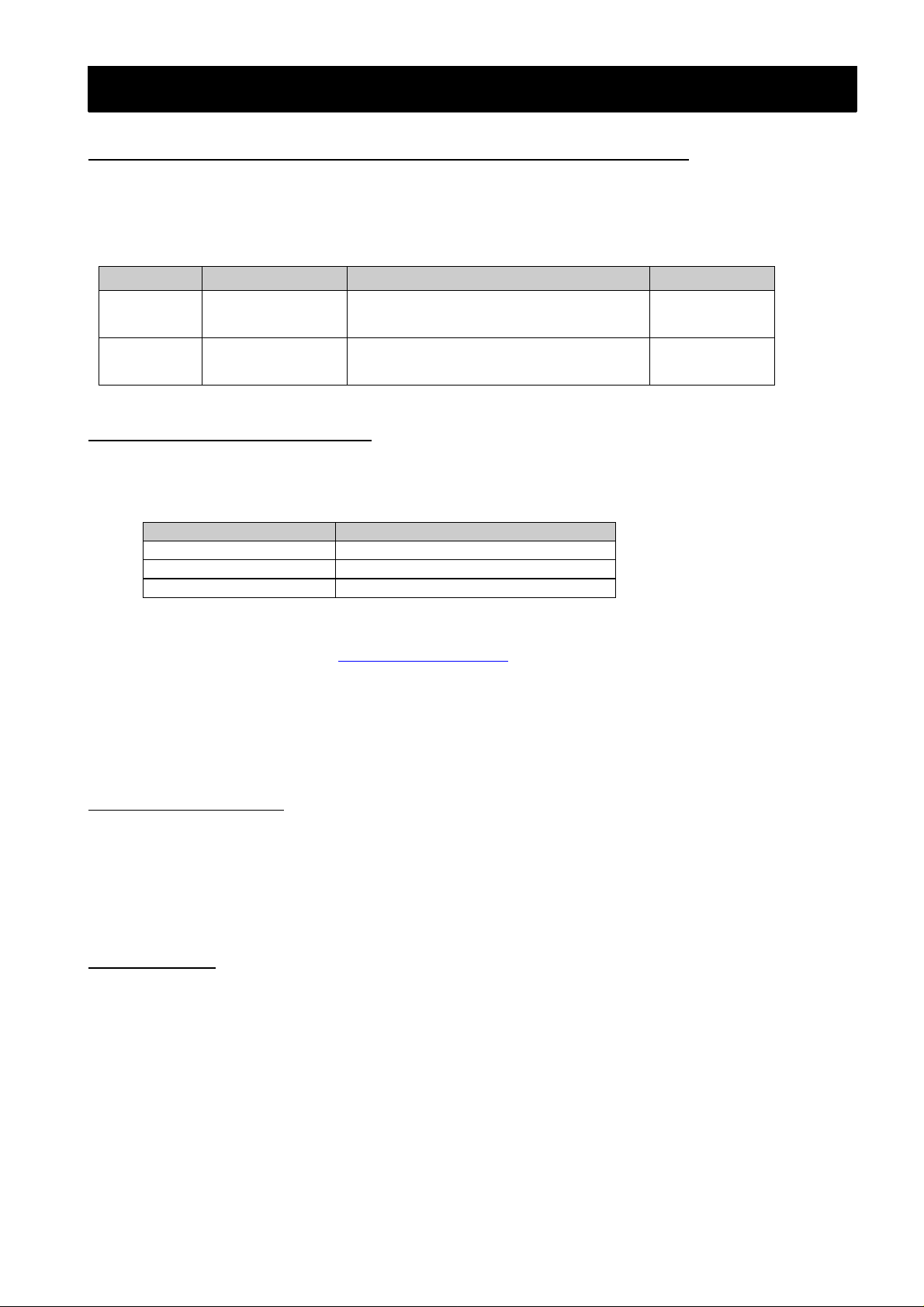

SJ-LW can use following Manufacturing number (MFG No) of SJ300/L300P series.

After Manufacturing number : XX8KXXXXXXXXXXXX(SJ300-0.4-55kW / L300P-11-75kW supported

XXEMXXXXXXXXXXXX(SJ300-75-132kW / L300P-90-132kW supported

)

)

(Note) Manufacturing number is written in specifications label on main body of SJ300/L300Pseries. Refer to

figure 1- 2, f igur e 1- 3.

(Figure 1-2 , 1- 3 ar e t he example of SJ 3 00 se r ies . L3 00P ser i es ar e th e s am e manne r as SJ 300 ser ies .)

Specifications label

Figure 1-2 Position of specifications label

Inverter model

Maximum applicable motor

Input ratings

Output ratings

Manufacturing numbe r

Figure 1- 3 Co nt ent s of spe cif i cat ion s l abe l

1.6 Technical features of Lonworks

Transmission Technique:

- Free topology (FTT-10A) twisted pair cable

- Transmission rate 78kbits/s

Max Bus length: Bus up to 2000 m

Max. node-to-node distance: 500m

Max amount of nodes: 32.385 nodes divided as 127 nodes/subnet, 255 subnets/domain.

Medium Ac c ess : Pr edi ct ive CS MA

Data types: Peer-to-peer communication

LonWorks communication ASIC: TMPN3120FE5 chip from Toshiba.

LonWorks transceiver: FTT10A from Echelon.

3

Page 8

CHAPTER 1 INTRODUCTION

1.7 Production specification

Bacicaly, the environmental specification of the SJ-LW is in accordance with SJ300/L300P series inverter.

Please refer the instruction manual of SJ300/L300P series.

But only application temperature of SJ-LW is different. Please note.

applicat i on temperature : 0 t o 50 deg re e

4

Page 9

CHAPTER 2 INSTALLATION METHOD OF PRINTED BOARD

p

g

p

(

)

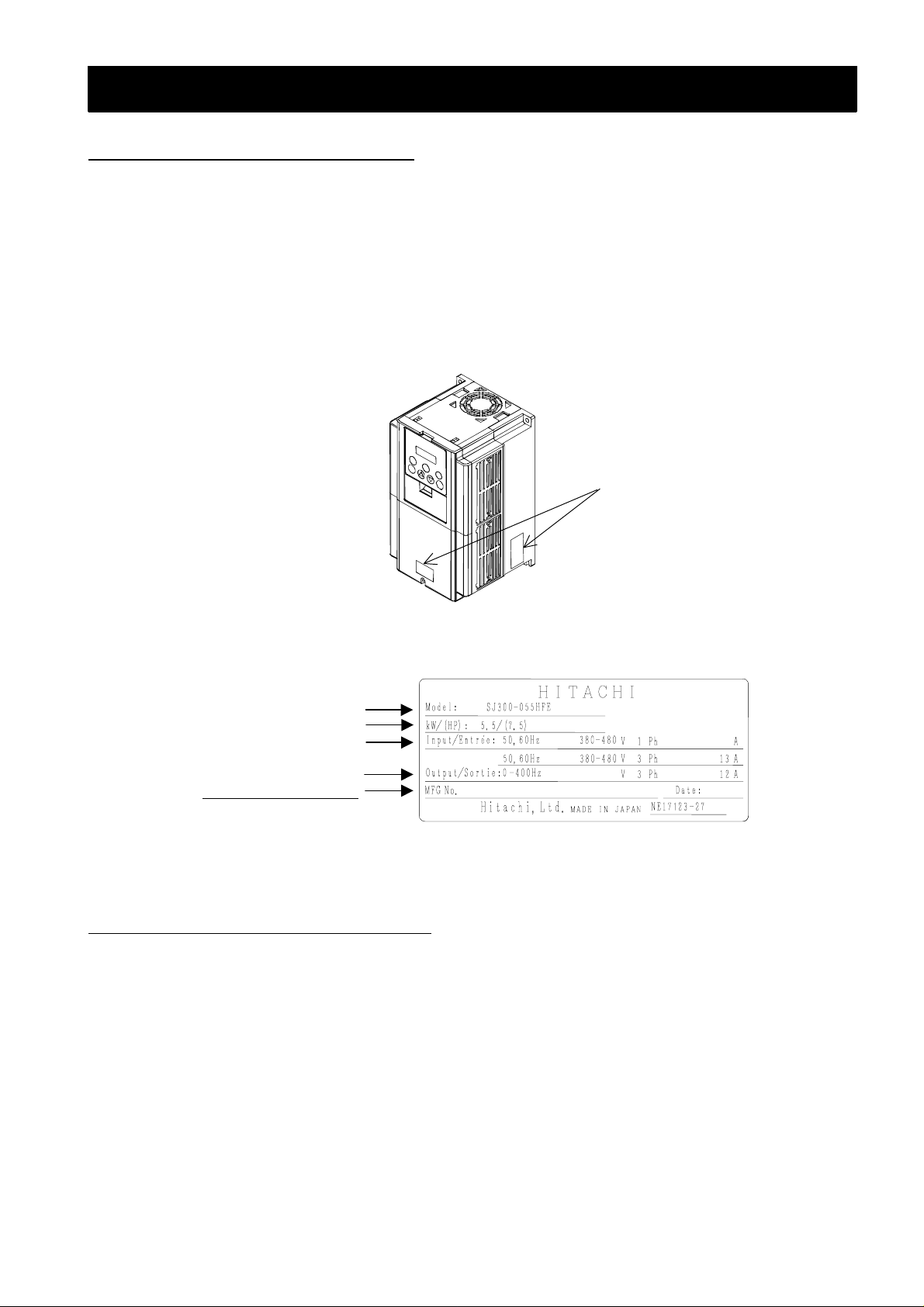

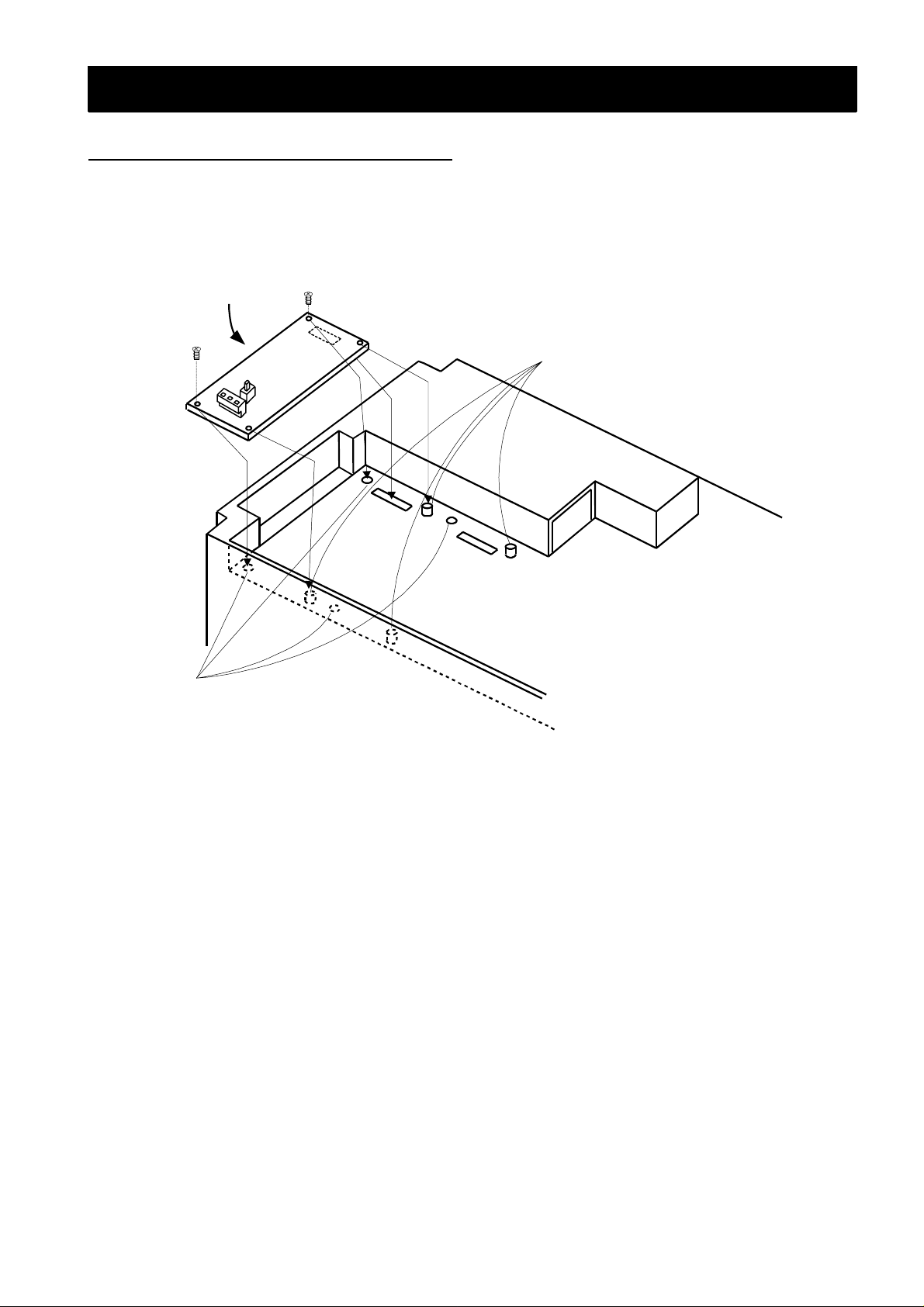

2.1 Mounting method of option board

Figure 2-1 describes how to mount the option board to the option port 1 or 2.

There are four holes on th e optio n boa rd, mat ch the t wo o f th em with t he screw holes on t he o ption po rt 1 or 2 .

and mount the other two holes with the guide posts which are located on the option port 1 and 2. To avoid

connection failure, secure the option board with screws after connection.

Option board

Guide posts for mountin

the option board.

Option port 1

Screw holes for secure o

M3 Screws

O

tion port 2

tion board.

Figure 2-1 In st al l ation o f opt io n bo a rd

5

Page 10

CHAPTER 3 WIREING,CONNECTING

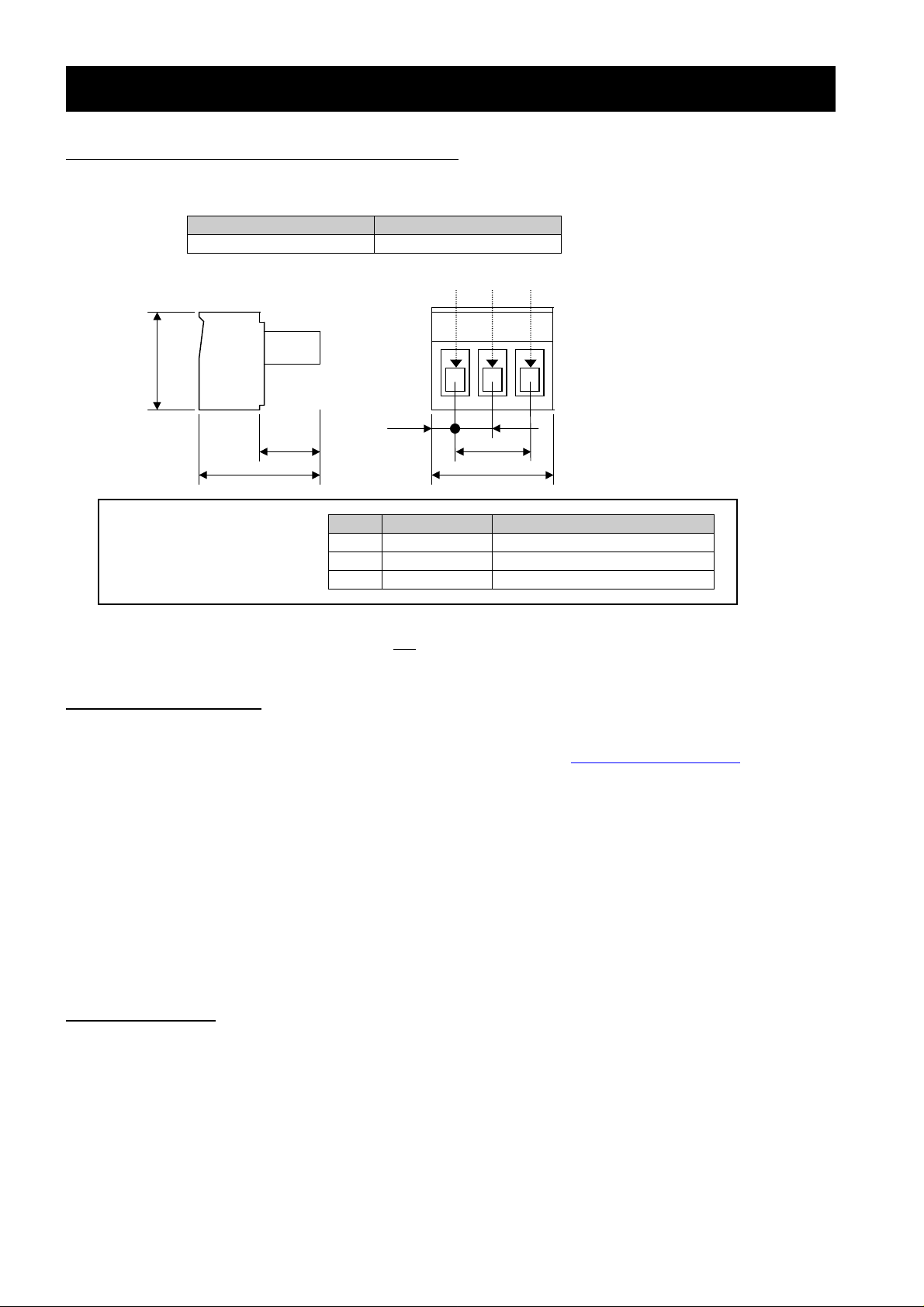

3.1 Connection for LonWorks connector

The SJ-LW connects t o the LonWorks net work wit h a 3- pin c onn ec tor. For the p in l a yout , ref er to Fi gu r e 3-1.

Cablesideconnector(attache dconnector)

Maker Type

Phoenix contact co, Ltd. MC 1.5/3-ST-3.81

Dimensio n

11.1

6.6

15.5

Wiring of LonWorks

Communication connector

Figure 3-1 Connector specification

NOTE : NET A and NET B connection is not polarity sensitive.

Pin No. 1 2 3

2.3

No. Signal mark Function

1 Shield Shield connection

2 NET A LonWorks NET A connection

3 NET B LonWorks NET B connection

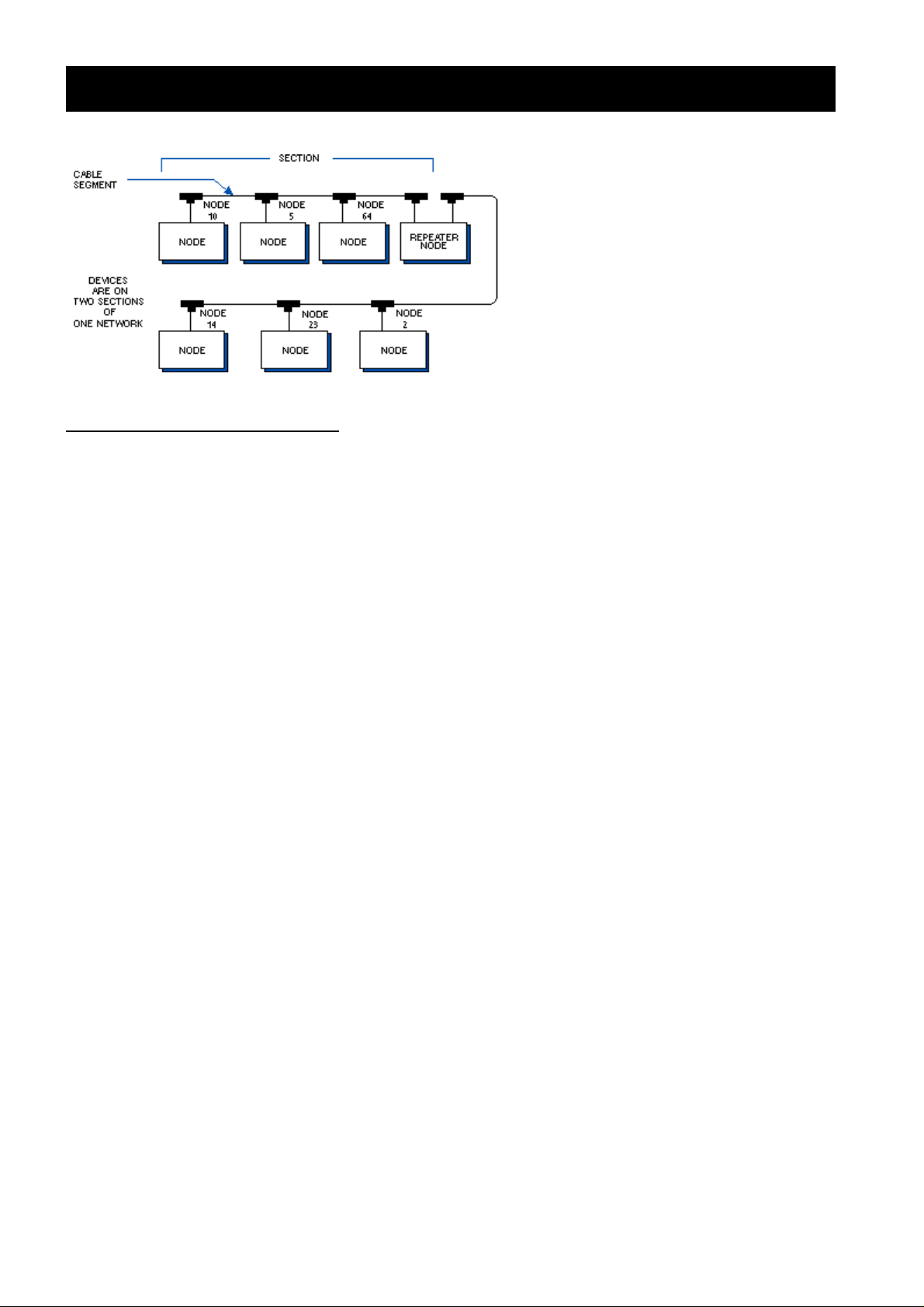

3.2 Network cabling

3.8

7.62

12.22

Dimensio n i n mm

For detailed information about recommended cables for a LonWorks network, please see the FTT-10A Free

Topology Transceiver User’s Guide (doc.id.078-0156-01F) available at http://www.echelon.com

Below are some recommended cables :

-Belden 85102, unshielded

-Belden 8471, unshielded

-Level IV 22AWG, unshielded

-JY (St) Y 2x2x0.8, shielded

-TIA568A Cat.5 24AW G

Note) To be able to communicate in a noisy environment, and to fulfil all EMC-requirements, it’s

important that a shielded cable is used, and that proper grounding is provided.

3.3 Wiring note

1.Installing the cable to Network connector must be done after checking the power supply off.

2.Wiring should not have bare cables exposed between connector contacts.

3.Network cables should be fixed without tension. Cables fixed under tension have potential of causing a

communication fault by to be removed a connector.

4.Ensure external emergency stop measures are taken to stop the inverter, in the event of a network fault.

(a) Remove the Power supply of the Inverter when the network master detects a communication fault.

(b) When the m aster d etects a com m unicat ion f ault, turn on the intellig ent input terminal which would be

allocated (FRS), (RS) and/or (EXT) function.

6

Page 11

CHAPTER 4 SETTING

4.1 Setting of controlling frequency and start/stop commands

The Hitachi SJ300/L300P inverters can be configured to take reference set-points and commands from

several different locations. Re fer to the ta ble below for info rmation of how t o configu re the inve rter so that the

Lonworks controls frequency and the commands.

Command Function Setting range Setting data

A001

A002

Frequency

setting selection

Operating mode

selection

00(Volume)/01(Terminal)/02(Operator)

03(Rs485)/04(Option1)/05(Option2)

01(Terminal)/02(Operator)/03(Rs485)

04(Option1)/05(Option2)

02(Operator)

01(Terminal)

4.2 Network termination (S2)

The SJ-LW option board provides internal termination of the LonWorks network. To enable/disable the

termination a switch (S2) is used. See Figure 1-1 for location of the switch. The following table explains the

possible switch-settings :

Switch-position Termination type

FT Free topology termination enabled

NO Termination disabled

BUS Bus topology termination enabled

For more information about termination, see the FTT-10A Free Topology Transceiver User’s Guide

(doc.id.078-0156-01F) available at http://www.echelon.com

Note) Risk of equipment damage exists. The SJ-LW contains ESD (Electrostatic Discharge) sensitive

parts that can be damaged if you do not follow ESD control procedures. Static control precautions

are required when handling the adapter.

4.3 Service pin (S1)

The SJ-LW option board provides one Service pushbutto n (S1 ), which i s used d uring the i nstalla tion pha se to

identify the node. See Figure 1-1 for location of the pushbutton.

The SJ-LW is installed in a LonWorks network using any standard LonWorks installation tool.

(i.e. “LonMaker for Windows” from Echelon).

4.4 Baudrate

The SJ-LW has a fixe d bau dr at e of 78k bps (F TT -10 A).

7

Page 12

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

5.1 Operating the drive via Lon Mark profile

A LonMark profile defines a functional profile for a node communicating with others. A LonMark profile

specifies which SNVT’s and SCPT’s to be used and also a semantic meaning about the information being

communicated.

When a prof ile is imp lemen ted in a nod e, it is call ed a Lo nMa rk Objec t. O ne node can have s evera l obj ects

implemented. The SJ300 LonWorks adapter has two objects, a node-object and a drive-object. The nodeobject is used to control the other objects in a node.

(1)NodeObject

(1)NodeObject

(1)NodeObject(1)NodeObject

NodeObject

(2)Drive Object

(2)DriveObject

(2)DriveObject(2)DriveObject

nviRequest

nv1

SNVTobjrequest

nv1

nv2

nv18

nv16

nv3

nv4

nv17

Mandatory

Network

Variables

VariableSpeedMotor

Drive:6010

Mandatory

nviDrvSpeedStpt

SNVTswitch

Variables

Optional

nviDrvSpeedScale

SNVTlevpercent

nviWriAdr

SNVTcount

nviWriValue

UNVTsj300

nviInvSetFreq

SNVTfreqhz

nviEmergOverride

SNVThvacemerg

nviRdAdr

SNVTcount

ManufacturerDefinedConfigurationProperties

Variables

ConfigurationProperties

ConfigurationProperties

ConfigurationPropertiesConfigurationProperties

nc17‑nciLocation(optional)

nc50‑nciMaxSpeed(mandatory)

nc53‑nciMinSpeed(mandatory)

nc48‑nciRcvHrtBt(optional)

nc49‑nciSndHrtBt(mandatory)

nc52‑nciMinOutTm(optional)

nc158‑nciNmlSpeed(mandatory)

nc159‑nciNmlFreq(mandatory)

nc160‑nciRampUpTm(mandatory)

nc161‑nciRampDownTm(mandatory)

nc162‑nciDrvSpeedScale (optional)

Manufacturer

Variables

nc1‑nciPwUpOutTm(optional)

Network

Network

Defined

Network

nv2

nv5

nv6

nv9

nv8

nv10

nv7

nv11

nv15

nv12

nv13

nv14

nvoDrvSpeed

SNVTlevpercent

nvoDrvCurnt

SNVTamp

nvoDrvVolt

SNVTvolt

nvoDrvPwr

SNVTpowerkilo

nvoDrvRunHours

SNVTtimehour

nvoDrvStatus

UNVTsj300

nvoFreqAct

SNVTfreqhz

nvoParam

UNVTSJ300

nvoEmergStatus

SNVThvacemerg

nvoDrvAlarm

SNVTswitch

nvoDrvWarning

SNVTswitch

nvoStatus

SNVTobjstatus

8

Page 13

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

5.2 Input Network Variables (nvi’s)

5.2.1 Node object request (SNVT_obj_request nv iOb jRequest)

This input is used to enable control commands and updates from network.

The valid iden tif ic at io n num b ers mus t be us ed. The v al id num bers ar e 0 and 1.

The status of the node is reported in nvoObjStatus, see chapter 5.3.1.

Value Identifier Function

0 RQ_NORMAL enable settings of nviDrvSpeedStpt and nviDrvSpeedScale

again, if they were disabled by RQ_DISABLED. Speed

settings need to be updated to start the inverter again if

disabled.

1 RQ_DISABLED disables settings of nviDrvSpeedStpt and

nviDrvSpeedScale. It also stops the inverter.

2 RQ_UPDATE_STATU S updates nvoObjStatus

5 RQ_REPORT_MASK reports supported requests in nvoObjStatus

7 RQ_ENABLE enable settings of nviDrvSpeedStpt and nviDrvSpeedScale

again, if they were disabled by RQ_DISABLED. Speed

settings need to be updated to start the inverter again if

disabled.

9 RQ_CLE AR _STATUS clears n voO bj Sta tus

10 RQ_CLEAR_ALARM resets a fault (trip) in the drive

13 RQ_MANUAL_CTRL can be used when the inverter only want to be monitored

from Lon Network, not controled. No message containing a

WRITE_DEMAND_CODE (0x02) in the FrameType f ield of

the Hitachi high-speed serial protocol will be communicated

to the inverter from the option card. All messages with other

FrameType codes will be sent to the inverter.

14 RQ_REMORT_CTRL allow WRITE_DEMAND_CODE(0x02)

messages to be communicated to the inverter.

If RQ_SELF_TEST, RQ_OVERRIDE, RQ_RMV_OVERRIDE, RQ_ALARM_NOTIFY_ENABLED,

RQ_ALARM_NOTIFY_DISABLED, RQ_PROGRAM or RQ_NUL is requested, the invalid_request bit will be

set in nvoObjStatus.

Which request of RQ_DISABLED, RQ_NORMAL or RQ_ENABLE is set last is remembered. This means that

nviObjRequest can first be set RQ_DISABLED and then e.g RQ_REPORT_MASK. Then it is still disabled

but reported masks will be shown in nvoObjStatus.

Which requ est of RQ_M ANUAL_CT RL or RQ_RE MOTE_CTRL is set last is remember ed. This m eans that

nviObjRequest can first be set RQ_MANUAL_CTRL and then e.g RQ_REPORT_MASK. Then it is still in

manual control but reported masks will be shown in nvoObjStatus.

With regard to RQ_MANUAL_CTRL and RQ_REMOTE_CTRL, please refer chapter 6.8.

5.2.2 Drive Speed Setpoint (SNVT_switch nviDrvSpeedStp t),

5.2.3 Inverter frequency sett in g (SNVT_f req_hz nviIn vSetFre q)

This input network variable provides a low-resolution speed setpoint.

When nv iD r v S p e ed S t pt.State i s set to ze ro the dr i v e is stopped using ramp 1 (Normal Stop).

Following two methods are used for setting frequency.

(1) nviInvSetFreq = 0x7FFF (D efault)

It is possible to set the request speed by using ratio of Nominal Frequency (Refer to chapter 5.4.6) or

Nominal Speed (Refer to chapter 5.4.5).

(2) nviInvSetFreq = 0 to 400,

I

t is possible to set 0 to 400Hz to nviInvSetFreq directly.

9

Page 14

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

NviInvSetFreq

0x7FFF

(Initial value)

0〜400Hz

Note: Requested speed will not be greate r then th e valu e de fined by n ciMaxSpeed (Refer to chapte r 5.4. 8) o r

less then t he v al ue d ef ined b y nci Min Sp eed ( R efer to c h apt er 5. 4. 7).

*1:nviDrvSpeedScale = 100, Direction: Forward

= -100, Direction: Reverse

= When a value in nviDrvSpeedScale is set any value except for 100 and –100, i t

Default value:

Default value is AUTO (state = 0xFF). T his value will be adapted at power-up. This network variable input

may use the Receive Heartbeat function depending on if Receive Heartbeat function is setup for use. The

actual value of drive speed does also depend on nviDrvSpeedScale.

NviDrvSpeedStpt

State Value

0xFF N/A N/A AUTO(Invalid)

0 N/A N/A

1 0 0% 0%

1

1 201 〜255 100.0% 100.0%

0xFF N/A N/A AUTO(Invalid)

0 N/A N/A

1 N/A N/A nviInvSetFreq *1

1〜200 0.5〜100.0 % nciNmlFreq*nviDrvSpeedSpt

becomes the stop command (Run: Deceleration stop, Stop: Maintain to stop).

Setting ratio Request speed

Stop st at e

*nviDrvSpeedScale

Stop st at e

Scaling: See chapter 6.1.4

5.2.4 Speed Setpoint Scaling (SNVT_lev_percent nviDrvSpeedScale)

This input network variable provides scaling for nviDrvSpdStpt. For example if nviDrvSpeedStpt value is

100% and nviDrvSpeedScale value is -150%, then actual speed setpoint value is -15 0% meaning reverse 1,5

times nominal speed. The requested speed will not be greater than the value defi ned by nciMaxSpeed or

less than t he v al ue d ef ined b y nci Min Sp eed.

Depending on Drive Speed Setpoint, behavior of Speed Setpoint Scaling will be changed. Followings are

explanation of behavior.

(1) nviInvSetFreq = 0x7FFF(Initial value)

It prescribes the scaling for Drive Speed Setpoint (Refer to chapter 5.2.2).

(2) nviInvSetFreq = 0 to 400

It sets direction of rotation.

nviDrvSpeedScale = 100, Direction: Forward

= -100, Direction: Reverse

= When a value in nviDrvSpeedScale is set any value except for 100 and –100, i t

becomes the stop command (Run: Deceleration stop, Stop: Maintain to stop).

Example (1): nviInvSetFreq = 0x7FFF

For example if nviDrvSpeedStpt value is 100% and nviDrvSpeedScale value is -150%, then actual speed

setpoint value is -150% meaning reverse 1,5 times nominal speed (Refer to chapter 5.3.6).

Also refer to 6.1.4.

10

Page 15

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

Example (2) : nviInvSetFreq = 0 to 400

When nviI n vSet Fr eq is at 60H z and nviDrvSpeedScale is 100%, the inverter is in forward run at 60Hz.

Valid Range: -163.84 to163.83%

Default Value: Is defined by nciDrvSpeedScale (Refer to 5.4.14).

Scaling: See chapter 6.1.4

5.2.5 Emergency Override (SNVT_hvac_emerg nviEmergOverride)

When EMER G_S HUTD OW N c omm and is inputted, the inverter executes the deceleration stop and also the

value in EMERG_SHUTDOWN is supported but the other values are not supported.

(Deceleration time is dependant on Ramp Down Time (Refer to chapter 5.4.10))

Value Definition Contents Support

0 EMERG_NORMAL

1 EMERG_PRESSURIZE

2 EMERG_DEPRESSURIZE

3EMERG_PURGE

4EMERG_SHUTDOWN

5EMERG_FIRE

0xFF EMERG_NUL

Noemergencymode

Emergencypressurize

Emergencydepressurize

Emergencypurgemode

Emergencyshutdown

−

Valuenotavailable

Yes

No

No

No

Yes

No

No

11

Page 16

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

5.3 Output Network Variables - nvo’s

5.3.1 Node Object Status (SNVT_obj_status nvoObjStatus)

This nvo reports node object status. It will be updated every time status change. See chap. 5.1.1 for different

requests.

Identifier Status

Invalid_request The node has been asked for an unsupported request.

Report_mask Report supported fields.

Comm_failure No contact with SJ300/L300P.

In_alarm The SJ300/L300P inverter is tripped.

Disabled NviObjRequest have received a RQ_DISABLED request. Settings of

nviSpeedScale and nviSpeedStpt is disabled.

Manual_control SJ300/L300P is not controlled from the option card.

See digital operator value at A001 (should be 02 to avoid manual control to be

set) and A002 (should be 01 to avoid manual control to be set). Manual_control

will be set if option-board isn’t in control over one parameter. O ption card can

still give or der wh er e it h as com m and .

It will be set if NviObjRequest have received a RQ_MANUAL_CTRL request.

Invalid ID If another identification number then 0 and 1 have been set in request by SNVT

nviObjRequest. The request will not be carried out.

5.3.2 Drive Status (UNVT_sj300 nvoDrvStatus)

This output network variable provides the status of the drive.

The first three bytes will be mapped directly from the information received at address 0xFFFF8E10 in the

SJ300/L300P. If tripped, the last byte will contain an error code read from where pointer of last trip

(0x08000363) points too.

data format :

Status A Status B Status C Status D

Status C : Lad mode

Status A: Inverter status 1

Value State

00 initial status

01 ---02 On stopping

03 On running

04 On FRS

05 On JG

06 On DB

07 On reading frequency

08 On retrying

09 On UV

10 On TRIP

11 On waiting reset

Value State

00 --01 Stop

02 Deceleration speed

03 Constant speed

04 Acceleration speed

05 Forward

06 Reverse

07 Reverse from forward

08 Forward from reverse

09 Forward start

10 Revers e start

Status B: Inverter status 2

Value State

00 On stopping

01 On running

02 On tripping

Status D: trip code (see chapter 6.3)

12

Page 17

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

5.3.3 Drive Current (SNVT_amp nvoDrvCurnt)

This outp ut net wor k var ia ble pro vi des th e dr ive out p ut cu rr en t in Am ps.

5.3.4 Drive Speed (SNVT_level_percent nvoDrvSpeed)

This output network variable provides the speed of the drive as a percentage of the nominal speed. Since

nominal speed and nominal frequncy are tightly connected to eachother, the out value is calculated on the

nominal (base) frequency and the running (out) frequency. This output network variable is used as a

heartbeat to monitor the health of the LonWorks communication interface. See chapter 5.3.1 about

heartbeats.

Scaling:

If value of present running is forward then run_dir will be1.

If value of present running is reverse then run_dir will be -1.

BASE_FREQ / ((raw data format)OUT_FREQ / 1000) * (run_dir) = nvoDrvSpeed

5.3.5 Drive Power (SNVT_power_kilo nvoDrvPwr)

This output network variable provides the drive power in kilowatts.

5.3.6 Drive voltage (SNVT_volt nvoDrvVolt)

This output network variable provides the drive voltage in volts.

5.3.7 Output Frequency (SNVT_fre q_hz n voFreqA ct)

Output frequency in Hz. Always positive, i.e. no information about direction of revolution (forward/reverse).

5.3.8 Operation Hour Counter (SNVT_time_hour nvoDrvRun Hours)

Total power on time in whole hours.

5.3.9 Parameter value out (SNVT_count_inc nvoParam)

Used as feedback variable for generic parameter requests. See nciRdAdr (chapter 5.3.13), nciWriAdr

(chapter 5.3.11) and nciWriValue (chapter 5.3.12).

5.3.10 Emergency Status (SNVT_hvac_emerg nvoEmergStatus)

It indicates emergency stop status. Emergency stop state (nvoEmergStatus) is indicated as

EMERG_ SHUT DOWN while em er g ency stop com m and (nvi Em er gO ver ri de) is EME R G_S HUT DOWN.

Value Definition Contents Support

0 EMERG_NORM AL No emer ge nc y mo de Ye s

1 EMERG_PRESSURIZE Emergency pressurize No

2 EMERG_DEPRESSURIZE Emergency depressurize No

3 EMERG_PURGE Emergency purge mode No

4 EMERG_SHUTDOWN Emergency shutdown Yes

5EMERG_FIRE

0xFF EMERG_NUL Value not available No

−

No

5.3.11 Drive Alarm (SNVT_switch nvoDrvAlarm)

5.3.12 Drive Warning (SNVT_switch nvoDrvWarning)

It is defined as Drive Alarm: when an inverter trip occurs, Drive Warning: when an inverter warning occurs,

and then output the warning state.

Trip Warning

Yes No 1 100(%) 0 0(%) Drive Alarm

No Yes 0 0(%) 1 100(%) Drive Warning

Yes Yes 1 100(%) 1 100(%) Drive Alarm and Warning

No No 0 0(%) 0 0(%) No warning

NvoDrvAlarm nvoDrvWarning

State value state value

13

Contents

Page 18

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

5.4 Configuration Properties - nc i’s

If an nci has a corresponding parameter in the inverter it will be written to with the value of the nci at some

occations, apart from when nci is update from network. These occations are when:

-Node is brought online

-Inverter is power-cycled

-Inverter is tripped and error is reset from LonWorks option card

-If there is a communication error between neuron chip and option board host processor

This means that if setting e.g. F002 (Ra mp up ti me) fro m the D.O. to e.g . 3 sec will be set to 3 sec until an y of

these things happen. To ensure that these parameters have the values intended, set them from the option

board.

5.4.1 Send Heartbeat (SNVT_time_sec nciSndHrtBt)

This input configuration network variable provides the maximum send time for the variable nvoDrvSpeed.

Default value = 0 (disabled).

5.4.2 Receive Heartbeat (SNVT_time_sec nciRcvHrtBt)

This configuration property is used to control the maximum time that elapses between updates of the input

network variable nviDrvSpe edStpt. If timeout occurs, the module will trip the inverter by setting

OPT1(2)_TRIP_N low.

The valid range is any value between 0.0 sec and 6,553.4 sec. Setting nciRcvHrtBt=0 disables the Receive

Heartbeat mechanism. Default value is 0.

5.4.3 Minimum Send Time (SNVT_time_sec nciMinOutTm)

This input configuration network variable control the minimum period of time that expires before the network

output variables can be resent. This is good for limiting use of bandwidth on the LonWorks channel.

The valid range is any value between 0.0 to 6,553.4 secs. Setting nciMinOutTm = 0 disables transmission

limiting.

Default va lu e = 0.

5.4.4 Location Label (SNVT_str_asc n ciLo cation)

This configuration property can optionally be used to provide more descriptive physical location information

than can be provided by the Neuron Chip’s 6-by te location string. The loca tion relates to the ob ject and not t o

the node.

Default va lu e = em pt y sp ac es.

5.4.5 Motor Nominal Speed (SNVT_rpm nciNmlSpeed)

This configuration property can be used for setting the base frequency (Range of setting: 30 to 400Hz or

equivalent frequency).

Base frequency(Hz)=the number of rotation(min

-1

)*the number of motor poles/120

Initial value is the value which is set at first base frequency: A003. If data is changed, it will be reflected to

A003.

Inverter parameter P049 is used for setting the number of motor poles.

14

Page 19

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

5.4.6 Nominal Frequency (SNVT_freq_hz nciNmlFreq)

This configuration property is used to provide the nominal frequency of the motor. This value is necessary to

determine the minimum and maximum frequency.

Default va lu e: 50 Hz

5.4.7 Minimum Speed (SNVT_lev_percent nciMinSpeed)

This configuration property is used to define the minimum speed of a motor. It’s value is entered as a

percent of nominal frequency, as defined by the Nominal frequency (nciNmlFreq) configuration value. Set

this parameter when drive is stopped for be st resul t, sin ce thi s i s a w rite pr ote cted p ara meter in SJ300/L300P

when drive is running. If parameter is set when running it will only be saved in optionboard and not in drive.

If the running ordered frequency is lower then nciMinSpeed, ordered frequency will not be highered.

NciMinSpeed will be in effect on the next frequency setting.

If nciNmlFreq = 50Hz and nciMinSpeed = 10%, the minimum frequency is 5Hz.

-163.84 ≤ minimum speed ≤ maximum speed ≤ 163.83

Default value: 0%

5.4.8 Maximum Speed (SNVT_lev_percent nciMaxSpeed)

This configuration property is used to define the maximum speed of a motor. It’s value is entered as a

percent of nominal speed, as defined by the Nominal Speed (nciNomSpeed) configuration value. Set this

parameter when drive is stopped for best result, since this is a write protected parameter in SJ300/L300P

when drive is running. If parameter is set when running it will only be saved in optionboard and not in drive.

If the running ordered frequency is higher then nciMaxSpeed, ordered frequency will not be lowered.

NciMaxSpeed will be in effect on the next frequency setting.

If nciNmlFreq = 50Hz and nciMaxSpeed = 125%, the maximum frequency is 65.5Hz.

The value of the maximum speed must be validated against the value of the minimum speed as follows:

-163.84 ≤ minimum speed ≤ maximum speed ≤ 163.83

Default value: 100%

5.4.9 Ramp Up Time (SNVT_time_sec nciRampUpTm)

This configuration property is used to set the ramp up time.

Default va lu e: 30 Sec

5.4.10 Ramp Down Time (SNVT_time_sec nciRampDownTm)

This configuration property can optionally be used to provide to set the ramp down This configuration

property is used to set the ramp up time.

Default va lu e: 30 Sec

5.4.11 Generic Parameter address setting, Write (SNVT_count nciWriAdr)

Chooses the parameter address (16 bits) to be w ri tten to t h e drive. Addre sses i n the 0 xFFFF**** area can not

be reached.

Valid range: See SJ300/L300P manual.

15

Page 20

CHAPTER 5 LONWORKS COMMUNICATION FUNCTION

5.4.12 Parameter value, Write (UNVT_sj300 nciWriValue)

This nci is used as a value input for the user selected parameter nciWriAdr. The SCPT uses the following

format:

struct{

unsigned long int lowWord; //Used for byte and word data

unsigned long int highWord; //Used for highWord when

transmitting 4 byte data

}UNVT_sj300

Scaling is defined in SJ300/L300P user’s manual.

5.4.13 Generic Parameter address setting, Read (SNVT_coun t nc iRdAdr)

Chooses the parameter address (16 bits) to be read from the drive. Addresses in the 0xFFFF**** area can

not be reached.

Default value: 0x0070

Valid range: See SJ300/L300P manual.

5.4.14 Speed setpoint scaling default value (SNVT_ lev_percent)

This parameter is used for setting its value to nviDrvSpeedScale (see chapter5.1.3) on every startup.

Default value : 0

Valid range : -163-163%

5.4.15 Power Up Out Time (SNVT_time_sec nciPwUpOutTm)

When the p ower is ON, the inv er te r a nd P C do not com m unic a te e ac h ot her d ur ing se tt ing tim e.

This setting is used for avoiding data collision, when the power is ON.

16

Page 21

CHAPTER 6 CONTROL FROM LONWORKS

6.1 Conditions for operating

This section will decsribe what conditions there are for performing some common actions and how the

combination of SNVTs and SCPTs will affect the operation of the SJ300/L300P inverter.

6.1.1 General

Communication and configuation of LonWorks optionboard and SJ300/L300P must be set up and function

properly. See manuals on both subjects.

Note: The SJ300/L300P parameter A001 must be set to 02 and A002 must be set to 01 if drive is to accept

frequency settings or/and start/stop commands from LonWorks optionboard.

6.1.2 Start

The inverter will output a frequency if nviDrvSpeedStpt.value is greater than zero, nviDrvSpeedStpt.state

isn’t zero and nviDrvSpeedScale isn’t zero. RQ_NORMAL or RQ_ENABLE has to be requested more

recently then RQ_DISABLED. RQ_REMOTE_CTRL has to be requested more recently then

RQ_MANUAL_CTRL. Node has to be online.

6.1.3 Stop

The inverter will stop and use the normal stop ramp if NviSpeedStpt.state is set to any value different from 1

or if node is brought offline. The inverter will aslo stop if RQ_DISABLED or RQ_MANUAL_CTRL is requested

in nviObjRequest or if saving to inverter EEPROM, using using 0xFFFF in nviWriteAdr.

6.1.4 Frequency setting

Followings describe two methods for setting frequency.

(1) nviInvSetFreq = 0x7FFF(Initial value)

It is possible to set request speed by using ratio of Nominal Frequency (Refer to chapter 5.4.6) or

Nominal Speed (Refer to chapter 5.4.5).

The formula below is calculation of frequency.

Frequency setting(Hz)=nviDrvSpeedStpt.value(%)×nviDrvSpeedScale(%)×nciNml Freq(Hz)

(2) nviInvSetFreq = 0 to 400,

It is possible to set 0 to 400Hz to nviInvSetFreq directly.

Example below indicates frequency setting.

(1) nviInvSetFreq = 0x7FFF(Initial value)

NviSpeedScale

0% 0% 1 0Hz Forwar d comman d

100% 0% 1 0Hz Forward command

0% 100% 1 0Hz Forward command

150% 100% 0 1.5*1.0* nciNmlFreq Stop command

150% 100% 1 1.5*1.0* nciNmlFreq Forward command

-75% 100% 1 -0.75*1.0* nciNmlFreq Reverse command

150% 50% 1 1.5*0.50* nciNmlFreq Forward command

NviSpeedStpt

value state

Frequency setting Operation command

17

Page 22

CHAPTER 6 CONTROL FROM LONWORKS

( 2) In cas e of nv iIn vS etFre q = 0 to 4 00

NviSetFreq NviSpeedScale

50Hz 100% N/A 0 nviInvSetFreq Stop command

30Hz 100% N/A 1 nviInvSetFreq Forward command

60Hz 100% N/A 1 nviInvSetFreq Forward command

50Hz

60Hz

30Hz 99% N/A 1 nviInvSetFreq Stop command

30Hz

−100%

−100%

−99%

NviSpeedStpt

value State

N/A 1 nviInvSetFreq Reverse comm and

N/A 1 nviInvSetFreq Reverse comm and

N/A 1 nviInvSetFreq Stop comm and

Frequency setting Operation command

6.1.5 Write value to an address

1. Change address in nciWriAdr.

2. Change value in nciWriValue.

It is the changing of value in nciWriValue that triggers writing to an address in SJ300/L300P. This means that

just changing address alone will not perform a writing sequence.

To be sure that SJ300/L300P has accepted the value written to it, read it back with setting nciRdAdr to the

same address as nciWriAdr. See SJ300/L300P manual or chapter 4 for a description of available adresses.

Only addresses in the 0x0800**** area can be reached.

This parameter is also used for saving values set from option board in SJ300/L300P EEPROM. See chapter

6.2 for more details.

Address wanted NciWriAdr NciWriValue Result

0x08000000 0x0000 0 “1st setting multispeed frequency 0” set

to zero

Other val id ad dr es s Last two b ytes of

valid address

Other val id ad dr es s Last two b ytes of

valid address

Access inhibited

area

Save to

SJ300/L300P

EEPROM

Last two bytes of

access inhibited

area

0xFFFF Any (but writing

Valid value Address written to with value

Unvalid value

Value

needed to

compleat

sequence).

Address written to with unvalid value.

SJ300/L300P take cares of unvalid

values.

Address written to with value.

SJ300/L300P take cares of access

inhibited addresses.

Saving values set from option board in

SJ300/L300P EEPROM.

18

Page 23

CHAPTER 6 CONTROL FROM LONWORKS

6.1.6 Read value from an address

The address set in nciRdAdr will be polled and result will be written to nvoParam as often as value on

address changes or the workload on the host application and nciMinOutTime allows.

If nciRdAdr is set to 0 x007 0 it will not load the ne twork wi th i n formati on not wan ted or need ed for th e momen t.

This is recommended to minimalize network load. Addresses in the 0xFFFF**** area can not be read.

0x08000070 is an area in SJ300/L300P where access is inhibited. There are other areas in SJ300/L300P

were access is inhibited but if such address is set it to nciRdAdr the option board will try to read it anyway.

See appendix 1 for a list of valid addresses.

Default value: 0x08000070 (Access Inhibited in SJ300/L300P)

Address wanted Nc i RdAdr NvoParam

0x08000070 0x0070 Zero or latest polled value , not updated

Other access inhibited area

Valid address Valid address Polled from SJ300, continuously updated

Other access inhibited

area

Polled from SJ300, continuously updated

6.1.7 Reset fault

If an error has occured SJ300/L300P will trip. By removing the reason for tripping and setting nviObjRequest

to RQ_CLEAR_ALARM it can be reset.

6.1.8 Prioritation between nciMinOutTm and nciSendHrtBt

The nciMinOutTm will have prioritation over nciSendHrtBt. This will mean that heartbeats will not be sent as

often as specified in nciSendHrtBt if nciMinOutTm has a longer time set.

6.2 Save data in SJ300/L300P EEPRO M

To store parameter values set from option board in SJ300/L300 between power-cycles they have to be saved

in SJ300/L300P EEPROM.

Setting nciWriAdr to 0xFFFF (65535 decimal) and writing any value to nciWriValue will save parameters to

SJ300/L300P EEPROM.

NOTE : The inverter will be stopped using the normal stop ramp before saving, so it’s recommended to send

the save command only when inverter already is stopped.

The values set from option board will now remain the same after a boot sequence of the inverter.

There is no need to use the saving to EEPROM function when parameters are set from the digital operator

since they always are saved between power-cycles.

6.3 Optionboard Error han dling

If there is no response from SJ300/L300P on the serial channel in three messages in a row communication is

believed to be down.

Communication with LON is considered down if heartbeats aren’t received within nciRcvHrtBt time.

This will make SJ300/L300P trip.

19

Page 24

CHAPTER 6 CONTROL FROM LONWORKS

6.4 How to switch to operation command and f req uenc y co mmand

Table below indicates how to switch to operation command and frequency command by using the commands

in nviObjRequest. (Refer to chapter 4.1, 5.2.1 and 5.3.1)

nviObjRequest Command setting data Control and frequency setting

RQ_REMOTE_

CTRL

RQ_MANUAL_

CTRL

A001 = 02(Operator)

A002 = 01(Terminal)

Any data for A001 and A002

except above.

A001 = 02(Operator)

A002 = 01(Terminal)

Any data for A001 and A002

except above.

Comply with LonWork s.

Comply with A001 and A002.

Command setting mentioned as left.

Comply with A001 and A002.

6.5 Internal SJ300/L300P error codes

The malfunction codes are coded as follows. See chapter 5.3.2. Those error codes will be found in

the fourth byte of nvoDrvStatus.

Fault code SJ300/L300P Fault description

0 No fault

1 Overcur re nt dri ve.

2 Overcurrent deceleration.

3 Overcurrent acceleration.

4 Overcurrent.

5 Overload protection.

6 Braking resistor overload protection.

7 Over-voltage protection.

8 EEPROM error.

9 Under-voltage.

10 Current detector error.

11 CPU error.

12 External trip.

13 USP error.

14 Ground fault protection.

15 Incoming over-voltage protection.

16 Temporary power loss protection.

21 Abnormal temperature.

23 Gate allay error.

24 Open-phase error.

30 IGBT error.

35 Therm is tor error.

36 Abnorm al br ake.

60-69 Option 1 error 0-9.

70-79 Option 2 error 0-9.

20

Page 25

CHAPTER 7 COUNTERMEASURE FOR ABNORMALITY

7.1 Trip display

When the in vert er is in a tripped state, the inverter displays an error code (See table below). The trip history

monitor (d081 to d086) also displays the same error code as the inverter.

Trip code

Inverter’s running condition of trip d etect ed

7.2 Protection function list

The table below describes an error code for protecting the inverter and the motor.

Error Display in the table below, X is 6 (Error for option slot 1) or 7 (Error for option slot 2).

No. Function

1Lonworks

communic a ti on err or

2 Inverter communication

error

With regard to the other errors except table above, refer to Inverter instruction manual chapter 4 Explanation

of funct i o n.

Error

Display

EX0 This error is displayed, when disconnection occured, while

the inverter is operating with Lonworks.

EX9 This error is displayed, when communication timeout occurs

between the inverter and the option board.

Action

7.3 Countermeasure for a trip state

The table below only corresponds to additional trip codes, with regard to the other countermeasures refer to

Inverter instruction manual chapter 4 Explanation of function.

Trip code Name of tri p Cause Conformation Countermeasure

EX0 L on w o r ks

Communication

error

EX9 Inverter

communication

error

Defective connector

for signal cable

causes connection

fail.

Terminating resistor

is not connected.

Wiring distance does

not much with

baudrate.

Option board is

removed.

Check the ar ea of

Connection.

Check the

Connection

Check the wir in g

Distance

Check as

Mentioned left

Improve the connection and then

reset the power supply.

Connect the terminating Resistor

and then reset the power supply

Adjust the setting to the matching

Baudrate

Adjust wiring distance

Mount the option board again

and then secure it with screws.

21

Page 26

CHAPTER 7 COUNTERMEASURE FOR ABNORMALITY

7.4 LED display and Counter measur e

Following states are indicated by three LED's.

LED Color Function Countermeasure

Green Power on and CPU running

Red flashing Flash or RAM error

Power/

Status

LonWorks

Service

Serial

channel

status

Red Hardware error(if flashing red

together with Serial Status

LED, Wink command has been

received) or during initializing

inverter data.

Unlit Neuron Chip is

Configured/Normal Run mode

Flash Green

1Hz

Green Neuron Chip is Applicationless,

Green Serial channel status OK.

Flash Red

1Hz

Red No serial communication. (If

Neuron Chip is Unconfigured

(No Netwo rk co nfi gur a tio n)

Unrecoverable fault

Serial communication error. Confirm cable length and connection fails

flashing red together with

Power/Status LED, Wink

command has been received)

Need to change the SJ-LW.

(Back to green after initializing data)

Confirm system setting and adjust

adequate.

Need to change the SJ-LW.

of connector. And then adjust adequate.

Confirm cable length and connection fails

of connector. And then adjust adequate.

−

−

−

−

22

Page 27

APPENDIX PARAMETER OBJECT LISTS

APPENDIX1 Parameter cross-reference list

Address Size

H'08000000 4 0〜400.00Hz *100 1st setting Multispeed frequency 0 A020

H'08000004 4

H'08000008 4

H'0800000C 4

H'08000010 4 0〜400.00Hz *100 Multispeed frequency 2 A022

H'08000014 4

H'08000018 4

H'0800001C 4

H'08000020 4 0〜400.00Hz *100 Multispeed frequency 6 A026

H'08000024 4

H'08000028 4

H'0800002C 4

H'08000030 4 0〜400.00Hz *100 Multispeed frequency 10 A030

H'08000034 4

H'08000038 4

H'0800003C 4

H'08000040 4 0〜400.00Hz *100 Multispeed frequency 14 A034

H'08000044 4

H'08000048 4

H'0800004C 4

H'08000050 4 0〜400.00Hz *100 1st Lower limiter frequency A062

H'08000054 4

H'08000058 4

H'0800005C 4

H'08000060 4 0.01〜3600.00s *100 3rd Acceleration time 1 No F302

H'08000064 4

H'08000068 4

H'0800006C 4

H'08000070 4 - - Access Inhibited No H'08000074 4

H'08000078 4

H'0800007C 4 0.01〜3600.00s *100 3rd Acceleration time 2 No A392

H'08000080 4

H'08000084 4

H'08000088 4

H'0800008C 4 0〜400.00Hz *100 Start frequency of “O” terminaly A011

H'08000090 4

H'08000094 4

H'08000098 4

H'0800009C 4 0〜400.00Hz *100 Start frequency of “OI” terminal 0 A101

H'080000A0 4

H'080000A4 8 - - Access Inhibited No -

H'080000AC 4 0〜400.00Hz *100 Jumping frequency 1 A063

H'080000B0 4

H'080000B4 4

H'080000B8 4

H'080000BC 4 0〜400.00Hz *100 1st Frequency of 2-stage acceleration A095

H'080000C0 4

H'080000C4 4

H'080000C8 4

H'080000CC 4 0〜400.00Hz *100 Frequency of frequency matching b007

H'080000D0 4

Setting

range

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0.01〜3600.00s

0〜400.00Hz

-400.00〜400.00Hz

-400.00〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

0.01〜3600.00s

magn. Contents L300P

*100 2nd setting Multispeed frequency 0 A220

*100 3rd setting Multispeed frequency 0 No A320

*100 Multispeed frequency 1 A021

*100 Multispeed frequency 3 A023

*100 Multispeed frequency 4 A024

*100 Multispeed frequency 5 A025

*100 Multispeed frequency 7 A027

*100 Multispeed frequency 8 A028

*100 Multispeed frequency 9 A029

*100 Multispeed frequency 11 A031

*100 Multispeed frequency 12 A032

*100 Multispeed frequency 13 A033

*100 Multispeed frequency 15 A035

*100 1st Upper limiter frequency A061

*100 2nd Upper limiter frequency A261

*100 2nd Lower limiter frequency A262

*100 1st Acceleration time 1 F002

*100 2nd Acceleration time 1 F202

*100 1st Deceleration time 1 F003

*100 2nd Deceleration time 1 F203

*100 3rd Deceleration time 1 No F303

*100 1st Acceleration time 2 A092

*100 2nd Acceleration time 2 A292

*100 1st Deceleration time 2 A093

*100 2nd Deceleration time 2 A293

*100 3rd Deceleration time 2 No A393

*100 End frequency of “O” terminalal A012

*100 Start frequency of “O2” terminal 0 A111

*100 End frequency of “O2” terminalal A112

*100 End frequency of “OI” terminalal A102

*100 Jumping frequency 2 A065

*100 Jumping frequency 3 A067

*100 Frequency of stopping acceleration A069

*100 2nd Frequency of 2-stage acceleration A295

*100 1st Frequency of 2-stage deceleration A096

*100 2nd Frequency of 2-stage deceleration A296

*100 Deceleration time of Non-stop No b053

operator

code

23

Page 28

APPENDIX PARAMETER OBJECT LISTS

Address Size

H'080000D4 4

H'080000D8 4 0〜400.00Hz *100 Arrival frequency at deceleration1 C043

H'080000DC 4

H'080000E0 4

H'080000E4 12 - - Access Inhibited No H'080000F0 2

H'080000F2 2

H'080000F4 2

H'080000F6 2 0〜9.99Hz *100 J0gging frequency A038

H'080000F8 2

H'080000FA 2

H'080000FC 2

H'080000FE 2 - - Access Inhibited No -

H'08000100 4

H'08000104 4

H'08000108 4 0〜65.530

H'0800010C 4

H'08000110 4

H'08000114 4

H'08000118 4 0〜655.35A *100 1st No load current Io of motor No H023

H'0800011C 4

H'08000120 4

H'08000124 4

H'08000128 4

H'0800012C 4

H'08000130 4 0〜65.530

H'08000134 4

H'08000138 4

H'0800013C 4

H'08000140 4

H'08000144 4

H'08000148 4

H'0800014C 4

H'08000150 2

H'08000152 2 0〜50.0% *10 2nd Break point of manual torque boost A243

H'08000154 2

H'08000156 2

H'08000158 2

H'0800015A 2

H'0800015C 2

H'0800015E 2

H'08000160 2

H'08000162 2 0〜60.0s *10 Time of stopping to accelerate A070

H'08000164 2

H'08000166 2

H'08000168 2

H'0800016A 2 0〜100.0 *10 Response time of Energy saving functio n A086

H'0800016C 2 - - Access Inhibited No H'0800016E 2

Setting

range

0〜400.00Hz

0〜400.00Hz

0〜400.00Hz

30〜400Hz

30〜400Hz

30〜400Hz

30〜400Hz

30〜400Hz

30〜400Hz

0〜65.530

0〜65.530

0〜65.530

0〜655.35mH

0〜655.35mH

0〜655.35A

0.001

9999.000kgm2

0.001

9999.000kgm2

0〜65.530

0〜65.530

0〜65.530

0〜655.35mH

0〜655.35mH

0〜655.35A

0〜655.35A

0.001

9999.000kgm2

0.001

9999.000kgm2

0〜50.0%

0〜50.0%

0〜60.00Hz

0〜60.0s

0〜60.0s

0〜10.00Hz

0〜10.00Hz

0〜10.00Hz

0〜3600.0s

0〜100.00

0.01〜99.99%

0.3〜100.0s

Ω

Ω

Ω

Ω

〜

〜

Ω

Ω

Ω

Ω

〜

〜

magn. Contents L300P

operation at Instantaneous power failure

*100 Arrival frequency at acceleration1 C042

*100 Arrival frequency at acceleration2 No C045

*100 Arrival frequency at deceleration2 No C046

*1 1st Base frequency A003

*1 2nd Base frequency A203

*1 3rd Base frequency No A303

*1 1st Maximum frequency A004

*1 2nd Maximum frequency A204

*1 3rd Maximum frequency No A304

*1000 1st Primary resistor R1 of motor No H020

*1000 2nd Primary resistor R1 of motor No H220

*1000 1st Secondary resistor R2 of motor No H021

*1000 2nd Secondary resistor R2 of motor No H221

*100 1st Inductance L of motor No H022

*100 2nd Inductance L of motor No H222

*100 2nd No load current Io of motor No H223

*100 1st Inertia J of motor No H024

*100 2nd Inertia J of motor No H224

*1000 1st Primary resistor R1 of motor (Auto) No H030

*1000 2nd Primary resistor R1 of motor (Auto) No H230

*1000 1st Secondary resistor R2 of motor (Auto) No H031

*1000 2nd Secondary resistor R2 of motor (Auto) No H231

*100 1st Inductance L of motor (Auto) No H032

*100 2nd Inductance L of motor (Auto) No H232

*100 1st No load current Io of motor (Auto) No H033

*100 2nd No load current Io of motor (Auto) No H233

*100 1st Inertia J of motor (Auto) No H034

*100 2nd Inertia J of motor (Auto) No H234

*10 1st Break point of manual torque boost A043

*10 3rd Break point of manual torque boost No A343

*100 Frequency of DC braking start A052

*10 Time of DC braking working A055

*10

*100 Width of jumping frequency 1 A064

*100 Width of jumping frequency 2 A066

*100 Width of jumping frequency 3 A068

*10 Integrate (I) gain of PID control A073

*100 Differential (D) gain of PID control A074

*100 Scale of PID control A075

*10 Waiting time of retry b003

Time of DC braking working for beginning of

inverter running

operator

code

A058

24

Page 29

APPENDIX PARAMETER OBJECT LISTS

Address Size

H'08000170 2

H'08000172 2

H'08000174 2 20.0〜120.0 *10 Level of 3rd Electronic thermal protection No b312

H'08000176 2

H'08000178 2

H'0800017A 2

H'0800017C 2 0〜1000.0A *10 Free electronic thermal current 2 b018

H'0800017E 2

H'08000180 2

H'08000182 2

H'08000184 2 0.0〜800.0V *10 Free V/F control voltage 1 b101

H'08000186 2

H'08000188 2

H'0800018A 2

H'0800018C 2 0.0〜800.0V *10 Free V/F control voltage 3 b105

H'0800018E 2

H'08000190 2

H'08000192 2

H'08000194 2 0.0〜800.0V *10 Free V/F control voltage 5 b109

H'08000196 2

H'08000198 2

H'0800019A 2

H'0800019C 2 0.0〜800.0V *10 Free V/F control voltage 7 b113

H'0800019E 2

H'080001A0 2

H'080001A2 2

H'080001A4 2

H'080001A6 2

H'080001A8 2

H'080001AA 2 0〜1000.0V *10

H'080001AC 2 0〜10.00Hz *100

H'080001AE 2

H'080001B0 2 0.1〜99.9 *10 Coefficient of converting frequency b086

H'080001B2 2

H'080001B4 2

H'080001B6 2

H'080001B8 2

H'080001BA 2

H'080001BC 2

H'080001BE 2 0.00〜5.00s *100

H'080001C0 2 0〜400.00Hz *100 Release frequency of external braking No b125

H'080001C2 2

H'080001C4 14 - - Access Inhibited No H'080001D2 2 0.001〜65.535 *1000 1st Speed response gain No H005

H'080001D4 2

H'080001D6 2

H'080001D8 2

H'080001DA 2 0〜255 *1 3rd Stability gain No H306

H'080001DC 2

Setting

range

20.0〜120.0

20.0〜120.0

0〜400Hz

0〜1000.0A

0〜400Hz

0〜400Hz

0〜1000.0A

0〜400Hz

0〜400Hz

0.0〜800.0V

0〜400Hz

0〜400Hz

0.0〜800.0V

0〜400Hz

0〜400Hz

0.0〜800.0V

0〜400Hz

50.0〜200.0

0.10〜30.00

50.0〜200.0

0.10〜30.00

0〜65535(*10hr)

0〜1000.0V

0.10〜9.99Hz

0〜100.0%

330〜380/660〜760

0〜9999ohm

0.00〜5.00s

0.00〜5.00s

0.00〜5.00s

0〜200.0(%)

0.001〜65.535

0〜255

0〜255

0〜1000.0(%)

magn. Contents L300P

*10 Level of 1st Electronic thermal protect ion b012

*10 Level of 2nd Electronic thermal protect ion b212

*1 Free electronic thermal frequency 1 b015

*10 Free electronic thermal current 1 b016

*1 Free electronic thermal frequency 2 b017

*1 Free electronic thermal frequency 3 b019

*10 Free electronic thermal current 3 b020

*1 Free V/F control frequency 1 b100

*1 Free V/F control frequency 2 b102

*10 Free V/F control voltage 2 b103

*1 Free V/F control frequency 3 b104

*1 Free V/F control frequency 4 b106

*10 Free V/F control voltage 4 b107

*1 Free V/F control frequency 5 b108

*1 Free V/F control frequency 6 b1 10

*10 Free V/F control voltage 6 b111

*1 Free V/F control frequency 7 b1 12

*10 Level of Overload restriction 1

*100 Constant value of Overload restriction 1 b023

*10 Level of Overload restriction 2

*100 Constant value of Overload restriction 2 b026

*1/10 Display time of warning b034

*10

*100 Minimum frequency b082

*10 Usage rate of BRD b090

*1 On level of BRD b096

*1 Level of Thermister error b099

*100

*100 Waiting time for acceleration at external braking No b122

*100 Waiting time for stop at external braking No b123

*10 Release current of external braking No b126

*1000 2nd Speed response gain No H205

*1 1st Stability gain H006

*1 2nd Stability gain H206

*10 1st Proportional gain of speed control No H050

Starting voltage of Nonstop operation

for Instantaneous power failure

Starting voltage of OV-LAD stop at Nonstop

operation for Instantaneous power failure

Frequency width of starting deceleration at

Nonstop operation for Instantaneous power failure

Waiting time for establishing external braking

condition

Waiting time for confirmation signal at external

braking

50.0

150.0

50.0

150.0

No b051

No b052

No b054

No b121

No b124

〜

〜

operator

code

b022

b025

25

Page 30

APPENDIX PARAMETER OBJECT LISTS

Address Size

H'080001DE 2

H'080001E0 2 0〜1000.0(%) *10 1st Integral gain of speed control (PI control) No H051

H'080001E2 2

H'080001E4 2

H'080001E6 2

H'080001E8 2 0〜100.0 *10 1st Limiter of 0Hz control No H060

H'080001EA 2

H'080001EC 2

H'080001EE 2

H'080001F0 2 0.01〜10.00 *100 P Proportion gain Change No H072

H'080001F2 2 - - Access Inhibited No -

H'080001F4 1

H'080001F5 4 - - Acces s I nhibi ted No -

H'080001F9 1 00〜07 code Selection of AMI function C029

H'080001FA 1

H'080001FB 1

H'080001FC 1 - - Access Inhibited No H'080001FD 1 00,01 code Selection of Debug mode method C091

H'080001FE 4 - - Access Inhibited No -

H'08000202 2

H'08000204 2

H'08000206 2

H'08000208 2 0〜100.00Hz *100 Level f detecting Zero speed No C063

H'0800020A 2 - - Access Inhibited No H'0800020C 2

H'0800020E 2 0〜1000ms *1 Waiting time of communication start C078

H'08000210 18 - - Access Inhibited No -

H'08000222 2 128〜65000pls *1 Pulse number of the encoder No P011

H'08000224 2

H'08000226 2

H'08000228 2

H'0800022A 2 0〜9.99s *100 Delay time of completion Orientation mode No P018

H'0800022C 2

H'0800022E 2

H'08000230 2

H'08000232 2 0〜100.00 *100 Loop gain of position control No P023

H'08000234 2

H'08000236 2

H'08000238 6 - - Access Inhibited No H'0800023E 1 00,01 code Selection of running direction for DIG-OPE F004

H'0800023F 1

H'08000240 1 01〜05 code Selection of running command destination A002

H'08000241 1 00,01 code Selection of AT function A005

H'08000242 1

H'08000243 1 0〜100% *1 Starting rate of O terminal A013

Setting

range

0〜1000.0(%)

0〜1000.0(%)

0.01〜10.00

0.01〜10.00

0〜100.0

0〜1000.0(%)

0〜1000.0(%)

0:周波数設定

1〜19:回転数設定

0:Norpm,1:2pole,

2:4pole,3:6pole,

4:8pole,5:10pole,

6:12pole,7:14pole,

8:16pole,9:18pole,

10:20pole,11:22pole,

12:24pole,13:26pole,

14:28pole,15:30pole,

16:32pole,17:34pole,

18:36pole,19:38pole

0〜255

0.0〜20.0mA

0〜200.0(%)

0〜200.0(%)

0〜100.0%

0〜100%

0〜4095

0〜120.00Hz

0〜10000pls

0〜9999

0〜9999

0〜655.35

0〜150.0

0〜120.00Hz

00〜05

00〜02

magn. Contents L300P

(PI control)

*10 2nd Proportional gain of speed control (PI control) No H250

*10 2nd Integral gain of speed control (PI control) No H251

*100 1st Proportional gain of speed control (P control) No H052

*100 2nd Proportional gain of speed control (P control) No H252

*10 2nd Limiter of 0Hz control No H260

*10 PI Proportion gain Change No H070

*10 PI Integral gain Change No H071

code Rpm change Pole select P049

*1 Adjustment of AMI output C087

*10 Adjustment of Offset of AMI output C088

*10 Level1 of overload restriction warning C041

*10 Level2 of overload restriction warning No C111

*10 Level over acceptable deviation of PID control C044

*1 Warning Level of electronic thermal protection C061

*1 Stop position at Orientation mode No P014

*100 Speed at Orientation mode No P015

*1 Defining Area of completion of Orientation mode No P017

*1 The numerator of electric gear No P020

*1 The denominator of electric gear No P021

*100 Feed forward gain of position control No P022

*10 Level of detecting over speed No P026

*100 Value of detecting over deviation No P027

code Selection of frequency command destination A001

code Selection of O2 terminal function A006

operator

code

26

Page 31

APPENDIX PARAMETER OBJECT LISTS

Address Size

H'08000244 1

H'08000245 1 00,01 code Selection of starting function of O terminal A015

H'08000246 1

H'08000247 1

H'08000248 1

H'08000249 1 0〜100% *1 Starting rate of OI terminal A103

H'0800024A 1

H'0800024B 1 00,01 code Selection of starting function of OI terminal A105

H'0800024C 3 - - Access Inhibited No H'0800024F 1 00,01 code Selection of Multispeed method A019

H'08000250 1 00〜05 code Selection of Jogging method A039

H'08000251 1 00,01 code Selection of 1st Torque boost Method A041

H'08000252 1 00,01 code Selection of 2nd Torque boost Method A241

H'08000253 1

H'08000254 1

H'08000255 1

H'08000256 1 00〜05 code Selection of 1st Control method 00〜02 A044

H'08000257 1

H'08000258 1 00,01 code Selection of 3rd Control method No A344

H'08000259 1 20〜100% *1 Gain of output voltage A045

H'0800025A 1 00,01 code Selection of DC braking method A051

H'0800025B 1

H'0800025C 1 0〜100 *1 Power of DC braking(end of running) A054

H'0800025D 1 00,01 code

H'0800025E 1

H'0800025F 1

H'08000260 1 00,01 code Selection of PID control presence A071

H'08000261 1

H'08000262 1 00,01 code

H'08000263 1

H'08000264 1

H'08000265 1

H'08000266 1 00,01 code Selection of 1st 2-stage accel/decel Method A094

H'08000267 1 00,01 code Selection of 2nd 2-stage accel/decel Method A294

H'08000268 1 00〜03 code Selection of acceleration pattern A097

H'08000269 1

H'0800026A 1

H'0800026B 1

H'0800026C 4 - - Access Inhibited No -

H'08000270 1

H'08000271 1

H'08000272 1

H'08000273 1 00,01 code

H'08000274 1 00,01 code Selection of fail phase function b006

H'08000275 1

H'08000276 1 00〜02 code

H'08000277 1 00〜02 code

H'08000278 1 - - Access Inhibited No -

H'08000279 1

Setting

range

0〜100%

1〜30times

-100〜100%

-100〜100%

0〜100%

0〜20.0%

0〜20.0%

0〜20.0%

00〜04

0〜5.0s

0〜100

0.5〜15.0kHz

0.2〜5.0

00〜02

200〜240/

380〜480

00〜02

00〜03

01〜10

01〜10

00〜03

0.3〜1.0s

00〜02

00〜02

00〜03

magn. Contents L300P

*1 End rate of O terminal A014

*1 Sampling number of fetching data from “O”na A016

*1 Starting rate of O2 terminal A113

*1 End rate of O2 terminal A114

*1 End rate of OI terminal A104

*10 Value of 1st Manual torque boost A042

*10 Value of 2nd Manual torque boost A242

*10 Value of 3rd Manual torque boost No A342

code Selection of 2nd Control method

*10 Delay time of DC braking start A053

Selection of edge/level action of

DC braking trigger

*1 Power of DC braking(start of running) A057

*10 Carrier frequency of DC braking

*10 Proportional(P) gain of PID control A072

Selection of feedback destination

for PID control

code Selection of AVR function A081

code Selection of Motor voltage A082

code Selection of operation mode 00,01 A085

code Selection of deceleration pattern A098

code Curve constant of acceleration A131

code Curve constant of deceleration A132

code Selection of retry method b001

*10 Acceptable time for Instantaneous power failure b002

code

code

code Selection of method of overload restriction1 b021

Selection of method(action)

at instantaneous power and under voltage

Retry number of instantaneous power and

under voltage

Selection of characteristic of

1st electronic thermal protection

Selection of characteristic of

2nd electronic thermal protection

Selection of characteristic of

3rd electronic thermal protection

00〜02

0.5

〜

12.0kHz

No b313

operator

code

A244

A056

A059

A076

b004

b005

b013

b213

27

Page 32

APPENDIX PARAMETER OBJECT LISTS

Address Size

H'0800027A 1

H'0800027B 1

H'0800027C 1

H'0800027D 3 - - Access Inhibited No -

H'08000280 1

H'08000281 1 0〜200% *1

H'08000282 1

H'08000283 1 0〜200% *1

H'08000284 1 0〜200% *1

H'08000285 1 00,01 code Selection of LAD stop by torque No b045

H'08000286 1

H'08000287 1 00,01 code Selection of preventive of reverse running No b046

H'08000288 1 00〜06 *1 Selection of method of reducing voltage start b036

H'08000289 1 - - Access Inhibited No H'0800028A 1 00,01 code

H'0800028B 1 0〜255 *1 Adjustment of AM(analog monitor) b080

H'0800028C 1

H'0800028D 1

H'0800028E 1

H'0800028F 1

H'08000290 1 00,01 code Selection of “STOP” key function b087

H'08000291 1 00,01 code Selection free run function b088

H'08000292 1 00,01 code Selection of action at stop b091

H'08000293 1 - - Access Inhibited No -

H'08000294 1 00,01 code Selection of action of cooling fan b092

H'08000295 1

H'08000296 1

H'08000297 1 00,01 code Selection of external braking function No b120

H'08000298 1 - - Access Inhibited No -

H'08000299 1

H'0800029A 1

H'0800029B 1

H'0800029C 1

H'0800029D 1

H'0800029E 1

H'0800029F 1

H'080002A0 1

H'080002A1 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002A2 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002A3 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002A4 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002A5 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002A6 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent No C016

Setting

range

00〜03

00〜03,10

00〜02

00〜04

0〜200%

00〜02

0〜255

0.5〜15.0kHz

00〜02

00〜02

00〜02

00〜02

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

01〜48,255

magn. Contents L300P

code Selection of method of overload restriction2 b024

code Selection of method of Software lock b031

code Selection of Display b037

code Selection of method of Torque limiter No b040

Level of torque limiter in forward and drive

(1st quadrant)

*1

code Selection of running direction limitation b035

*1 Adjustment of FM(digital monitor) b081

*10 Carrier frequency(PWM frequency

code Selection of Initialization b084

code Selection of initialized data b085

code Selection of BRD function b095

code Selection of Thermister function b098

code Selection of function in Intelligent input 1

code Selection of function in Intelligent input 2

code Selection of function in Intelligent input 3

code Selection of function in Intelligent input 4

code Selection of function in Intelligent input 5

code Selection of function in Intelligent input 6 No C006

code Selection of function in Intelligent input 7 No C007

code Selection of function in Intelligent input 8 No C008

Level of torque limiter in reverse and regenerative

(2nd quadrant)

Level of torque limiter in reverse and drive

(3rd quadrant)

Level of torque limiter in forward and regenerative

(4th quadrant)

Selection of Non stop operation at instantaneous

power failure

input 1

input 2

input 3

input 4

input 5

No b041

No b042

No b043

No b044

No b050

0.5

〜

12.0kHz

01〜39,

255

01〜39,

255

01〜39,

255

01〜39,

255

01〜39,

255

operator

code

b083

C001

C002

C003

C004

C005

C011

C012

C013

C014

C015

28

Page 33

APPENDIX PARAMETER OBJECT LISTS

Address Size

H'080002A7 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002A8 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002A9 1 00,01 code Selection of a(NO) or b(NC) contact in FW input C019

H'080002AA 1 00,01 code Selection of UP/DOWN function C101

H'080002AB 1 00,02 code Selection of RESET function C102

H'080002AC 1 00,01 code Selection of frequency matching function at

H'080002AD 1

H'080002AE 1

H'080002AF 1

H'080002B0 1

H'080002B1 1

H'080002B2 1

H'080002B3 1

H'080002B4 1

H'080002B5 1

H'080002B6 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002B7 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002B8 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002B9 1 00,01 code Selection of a(NO) or b(NC) contact in Intelligent

H'080002BA 1 00,01 code

H'080002BB 1 00,01 code

H'080002BC 1 00,01 code

H'080002BD 1 0〜200% *1

H'080002BE 1 0〜200% *1

H'080002BF 1 0〜200% *1

H'080002C0 1

H'080002C1 1 - - Access Inhibited No -

H'080002C2 1

H'080002C3 1 02〜05 code Selection of Data command C070

H'080002C4 1

H'080002C5 1

H'080002C6 1 7,8bits *1 Selection of bit length of data for RS485 C073

H'080002C7 1

H'080002C8 1 1,2bits *1 Selection of stop bit for RS485 C075

H'080002C9 2 - - Access Inhibited No H'080002CB 1

H'080002CC 1

H'080002CD 1 00〜02 code Selection of Motor constant for 2nd motor No H202

H'080002CE 1

H'080002CF 1

H'080002D0 1

H'080002D1 1 00〜03 code Selection of Motor poles for 2nd motor H204

H'080002D2 1 00,01 code Selection of Control Mode No P012

Setting

00〜26

00〜26

00〜26

00〜26

00〜26

00〜26

00〜07

00〜07

0〜10.0V

0〜200%

00〜02

02〜06

1〜32

00〜02

00〜02

00〜02

00〜21

00〜21

00〜03

range

magn. Contents L300P

input 6

No C017

input 7

No C018

input 8

RESET

code Selection of function

in Intelligent output 11

code Selection of function in Intelligent output 12

code Selection of function in Intelligent output 13 No C023

code Selection of function in Intelligent output 14 No C024

code Selection of function in Intelligent output 15 No C025

code Selection of function in Alarm relay output