Page 1

FOR HITACHI INVERTER

SJ-FB (Feed-Back Board)

INSTRUCTION

HITACHI

NB616XB

Thank you for purchasing the SJ-FB (HITACHI FEED-BACK BOARD).

This manual explains the operation of the feed-back board for use with

Page 2

SAFETY

To get best performance with SJ-FB (Feedback Board), read this manual, the SJ300

Instruction Manual, and all of the warning labels attached to the inverter carefully before

installation and operation, and follow the instructions exactly. Keep this manual handy

for your quick reference.

Definitions and Symbols

A safety instruction (message) is given with a hazard alert symbol and a signal

word -

WARNING or CAUTION. Each signal word has the following meaning

throughout this manual.

This symbol means hazardous high voltage. It used to call your

attention to items or operations that could be dangerous to

your and/or other persons operating this equipment.

Read these messages and follow these instructions carefully.

WARNIN

G

CAUTION

NOTE

HAZARDOUS HIGH VOLTAGE

Motor control equipment and electronic controllers are connected to hazardous

line voltages. When servicing drives and electronic controllers, there might be

exposed components with cases or protrusions at or above line potential. Extreme

This is the "Safety Alert Symbol. " This symbol is used to call

your attention to items or operations that could be dangerous

to your and/or other persons operating this equipment. Read

the messages and follow these instructions carefully.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, can result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, can result in minor to moderate injury, or serious

damage of product.

The mat t ers des c ribed u nd er may, i f not av o ided,

lead to serious results depending on the situation. Important

matters are described

in CAUTION ( as well as WARNING ), so be sure to observe

them.

CAUTION

NOTE

Notes indicate an area or subject of special merit, emphasizing

either the product's capabilities or common errors in operation

or maintenance.

Page 3

care should be taken to protect against shock. Stand on an insulating pad and

make it a habit to use only one hand when checking components. Always work with

another person in case an emergency occurs. Disconnect power before checking

controllers or performing maintenance. Be sure the equipment is properly

grounded. Wear safety glasses whenever working on electronic controllers or

rotating electrical equipment.

Page 4

Revision History Table

No

.

Initial Release of Manual NB616X

1

Revision A, by P. Curtis/Hitachi America, Ltd.

A

Revision B, by P. Curtis/Hitachi America, Ltd.

B

Revision Contents

The Date

of Issue

Feb. 2000

August 2000

August 2001

Operation

Manual No.

NB616X

NB616XA

NB616XB

Page 5

WARNING

Only qualified personnel should carry out wiring work.

Otherwise, there is a danger of electric shock and/or fire.

Implement wiring after checking that the power supply is off.

Otherwise, there is a danger of electric shock and/or injury.

Be sure not to touch inside the inverter case and terminals of the option board while

the inverter is energized.

Otherwise, there is a danger of electric shock and/or injury.

Be sure not to remove the encoder line and feedback board during operation.

Otherwise, there is a danger of electric shock and/or fire.

Do not perform maintenance or inspection until 10 minutes or more after turning off the

input power supply.

Otherwise, there is a danger of electric shock

Make sure that only qualified persons will perform maintenance, inspection and part

replacement. Before starting work, remove metallic objects from your person. Be sure

to use tools protected with insulation

Otherwise, there is a danger of electric shock and/or injury.

Never modify the unit.

Otherwise, there is a danger of electric shock and/or injury.

Be sure to implement wiring after installing the inverter body.

Otherwise, there is a danger of electric shock and/or injury.

Page 6

CAUTION

Do not allow materials such as cutting waste, welding sputter, wire fragments, solder

balls, dust etc. to come into contact with the unit.

There is a fire risk.

Inverter main body and option board must be mounted securely.

There is a risk of intermittent connection due to vibration.

Tighten the screws of the encoder line on the option board so that there is no loose

connection.

There is a risk of intermittent connection due to vibration.

Confirm that the power supply rating of the encoder is the same as the option card (DC

5V).

Otherwise, there is the danger of damage, injury and/or fire.

Make sure that the direction of the motor is correct.

There is a danger of injury or machine damage.

Make sure there is no abnormal noise or vibration during operation.

There is a danger of injury or machine damage.

Page 7

CONTENTS

Contents PAGE

Chapter 1 GENERAL DESCRIPTIONS 7

1.1 Inspection upon unpacking 7

1.2 Inquiries and Warranty 7

1.2.1 Inquiries 7

1.2.2 Warranty 7

Chapter 2 OUTLINE OF SJ-FB 8

Chapter 3 INSTALLATION 9

Chapter 4 WIRING AND CONNECTION 10

4.1 Terminal Assignments of the SJ-FB Board 10

4.2 Function Explanation of the Terminals 11

4.3 Terminal Connections 12

Chapter 5 SETTINGS 14

5.1 Setting the DIP switches 14

5.2 Initial Settings 14

5.3 Inverter Configuration Parameters for the SJ-FB board 15

5.4 Setting Flowchart for the DIP Switches 18

Chapter 6 OPERATION 19

Chapter 7 FUNCTIONS 21

7.1 Orientation function 21

7.1.1 Function outline 21

7.1.2 Data setting 23

7.2 Speed control (ASR) 24

7.3 Position control (APR) (Electronic gear function) 24

7.3.1 Function outline 24

7.3.2 Control mode setting 24

7.3.3 Data setting 25

7.3.4 Pulse train mode selection 28

7.4 Speed control (P/PI) switching function 29

7.5 Compensation of secondary resistor function …. 30

Chapter 8 PROTECTION FUNCTION 31

8.1 Action selection in case of option error 31

8.2 Causes and countermeasures of Option Board Errors 31

8.3 Warning display 31

Chapter 9 SPECIFICATIONS 32

Page 8

Chapter 1 GENERAL DESCRIPTIONS

1.1 Inspection upon unpacking

Handle with care. Please verify the contents of the package check for any damage

that may have occurred during transportation.

(Package contents)

1. SJ-FB (Feed back board) 1

2. Instruction manual 1

3. Board mounting screws (M3×8mm) 2

Please contact your supplier or Hitachi Distributor immediately if anything is

missing or broken.

1.2 Inquiries and Warranty

1.2.1 Inquiries

If you have any questions regarding damage of the unit, unknown parts, or

general inquiries please contact your supplier or the local Hitachi Distributor

with the following information.

(1) Inverter Model

(2) Production Number (MFG. NO)

(3) Date of Purchase

(4) Reason for Calling

Damaged part and its condition etc.

Unknown parts and their contents etc.

1.2.2 Warranty

The warranty period of the board is shown below.

1 year after normal installation, or 2 years from date of manufacture.

However within the warranty period, the warranty will be void if the fault is due

to:

(1) Incorrect use as outlined in this manual, or attempted repair by

unauthorized personnel.

(2) Any damage to the board, other than from transportation (which should

be reported immediately).

(3) Operating the unit beyond the limits of the specifications.

(4) Act of God (Natural Disasters: Earthquakes, Lightning, etc)

The warranty covers the board only, any damage caused to third party equipment

by malfunction of the board is not covered by the warranty. Any examination or

repair after the warranty period (one year) is not covered. Within the warranty

period, any inspection and repair which shows the fault was caused by any of the

items mentioned above, the inspection and repair costs are not covered. If you

have any questions regarding the warranty please contact either your supplier or

8

Page 9

the local Hitachi Distributor.

Chapter 1 GENERAL DESCRIPTIONS

9

Page 10

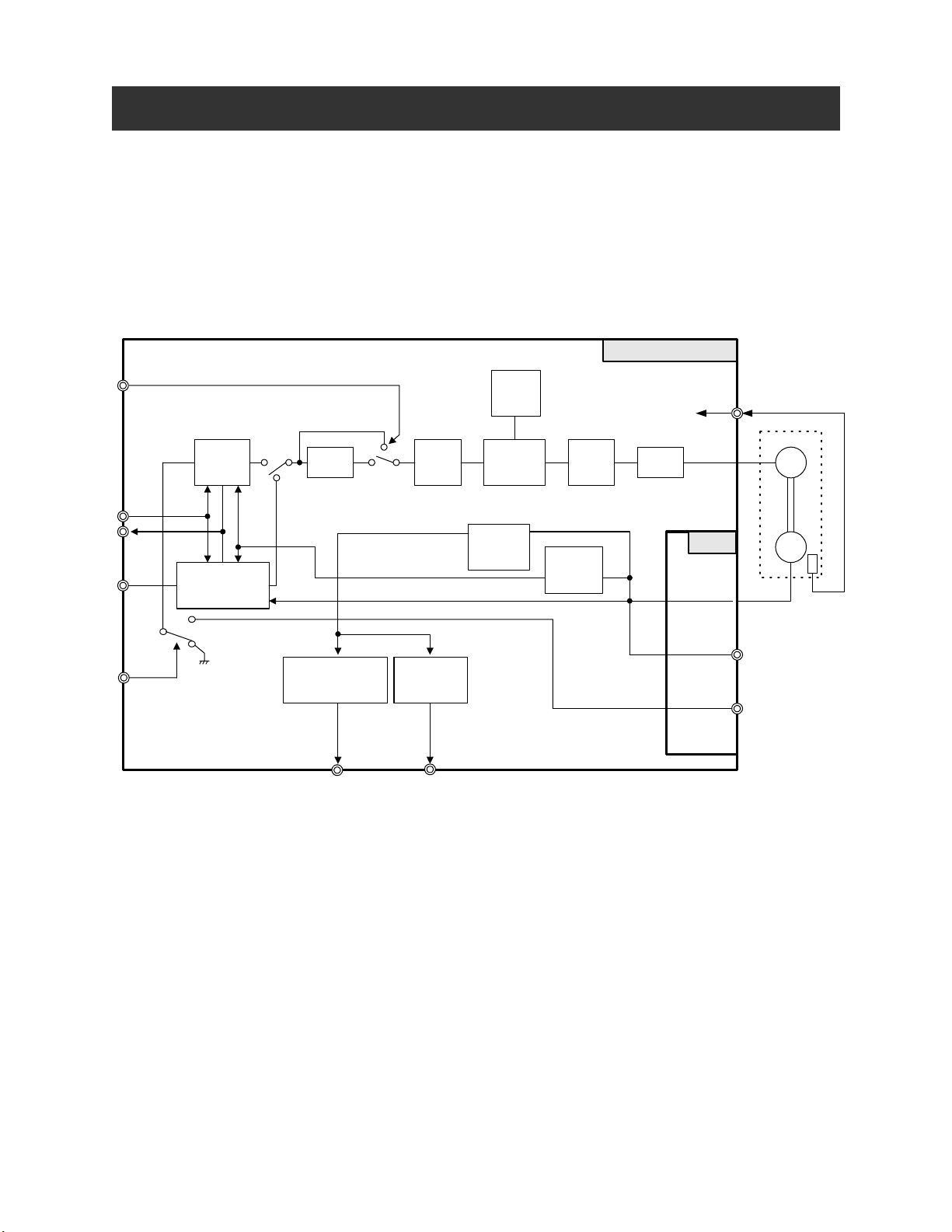

Chapter 2 OUTLINE OF SJ-FB

This manual describes the option board SJ-FB for the SJ300 series inverter.

This SJ-FB board, installed in an SJ300 inverter, detects the rotation speed of a motor by

accepting pulses from a shaft-mounted motor encoder, achieving highly accurate speed

regulation.

This SJ-FB board can also be used to control motor stop position by inputting 90 degree

out-of-phase (quadrature) pulses, as well as for synchronized operation between multiple

inverters (master/slave or electronic gear), orientation function, and external torque limit input

Inverter main body

LAC

Inside

setting

TH

PCLR

POK

ORT

STAT

function.

Position

control

Orientation

control

LAD

Speed deviation

excessive signal

DSE ZS

Speed

control

Zero speed

detection

Torque

limiter

Turn

several

detection

Current

control

Position

detection

Figure 2-1

Function Block Diagram

PWM M

SJ-FB

EAP,EAN

EBP,EBN

EZP,EZN

EP5,EG5

AP,AN

BP,BN

SAP,SAN

SBP,SBN

EC

10

Page 11

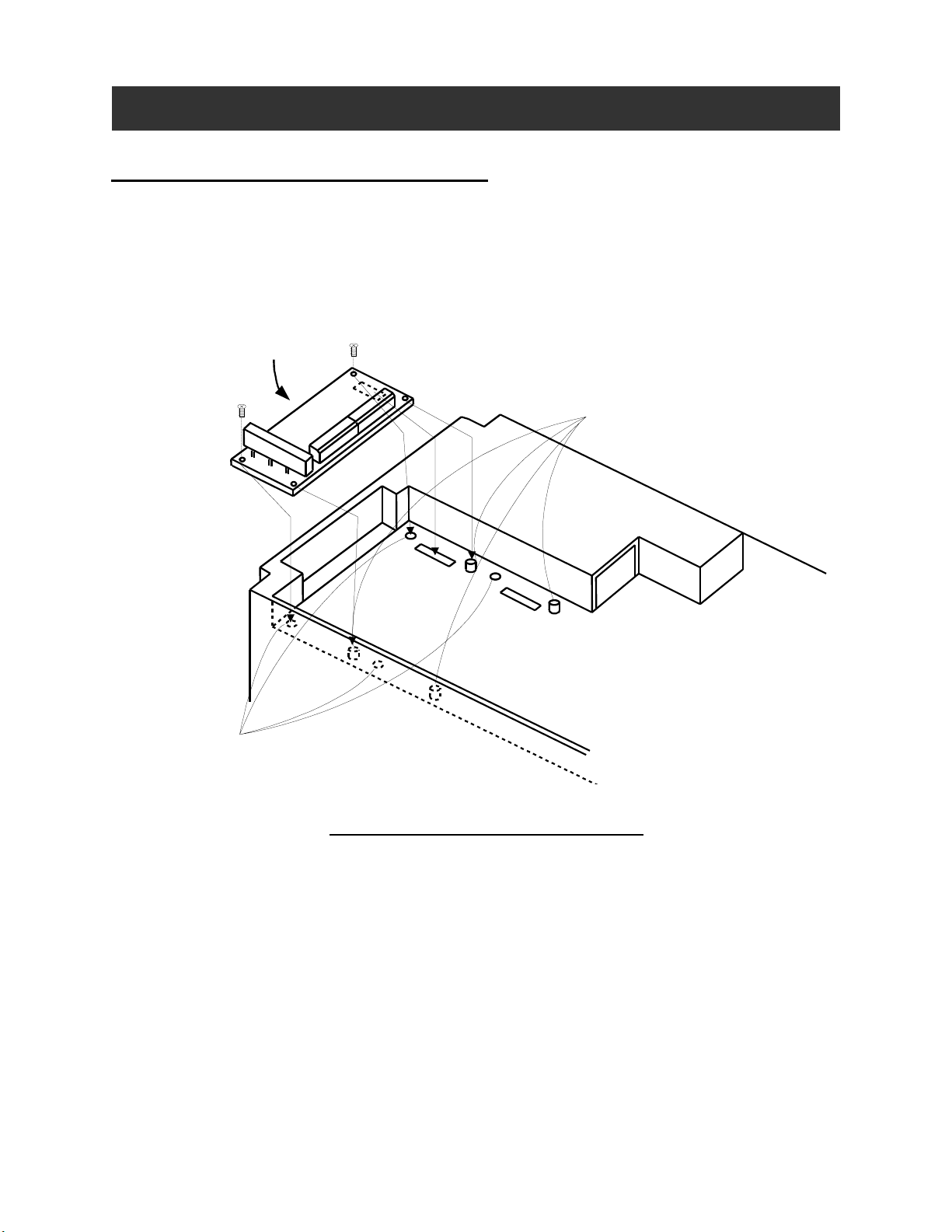

Chapter 3 INSTALLATION

How to Mount the SJ-FB Board

Align the holes at the four corners of the SJ-FB board to the guide posts for positioning, in option

port 1 or 2 of the inverter. Then gently push the option board into position, making sure the board

is fully seated in its connector. Install two screws to secure the board to the inverter body as

shown below.

Option board

Guide posts for

option board positioning

Option port 1

Screw hole for securing the option board

(M3 screw)

Figure 3-1 Option Board Installation

Option port 2

11

Page 12

Chapter 4 WIRING AND CONNECTION

4.1 Terminal Assignments of the SJ-FB Board

Outlook of SJ-FB

Dip switch SWENC

TM1 TM2

TM1 terminal assignment

EP5 EG5 EAP EAN EBP EBN EZP EZN

Figure 4-1 Terminal assignments

Dip switch SWR

Connector for Main body

connection

TM2 terminal assignment

SAP SAN SBP SBN AP AN BP BN

12

Page 13

p

Chapter 4 WIRING AND CONNECTION

4.2 Function Explanation of the Terminals

Terminal Code Function

Pulse train position

command inputs

Encoder signal

inputs

Input terminals

Pulse train position

command input

permissive signal

(Note 1)

Orientation signal:

(Note 1)

LAD cancel signal:

(Note 1)

Position deviation

clear signal:

(Note 1)

Encoder signal

output

Power supply for

encoder

Positioning

completion signal

(Note 2)

Output terminals

Speed deviation

excessive signal

(Note 2)

Zero speed signal

(note 2)

Pulse train position command input (see page 16)

• Mode 0 : 90 degree phase difference pulse

SAP

SAN

SBP

SBN

EAP

EAN

EBP

EBN

EZP

EZN

STAT

ORT

LAC

PCLR

AP

AN

BP

BN

EP5 DC +5V power supply EG5 150mA max

POK

DSE

ZS

(quadrature)

• Mode 1 : Forward/Reverse signal; pulse train

• Mode 2 : Forward pulse/Reverse pulse

Built-in 150 ohm termination resistance can be

turned ON or OFF with DIP switch SWR.

Mode is selected via the pulse mode selection

parameter (P013)

A, B, Z: rotary encoder signal input

Position control with pulse train input

is valid when STAT is Turned ON.

(Note 3)

Turn ON for orientation operation.

(Note 3)

Turn ON to cancel LAD.

(Note 3)

Turn ON to clear position deviation

counter. (Note 3)

Retransmits the input encoder signal (ratio 1:1).

Used for position control or

orientation.

Output ON when the position comes

within the specified range (P017).

(Note 3)

Output ON when the real rotation

speed deviation from command speed

exceeds (P027). (Note 3)

Output when the real rotation speed

becomes zero speed detection level

(C063). (Note 3)

Common

terminal

CM1

CM2

(Note 1): Valid when LAC is assigned to an intelligent input terminal of the inverter (SJ300).

(Note 2): Valid when POK is assigned to an intelligent output terminal of the main body (SJ300).

(Note 3): Refer to the configuration setting procedure for the inverter in the SJ300 Instruction Manual

electrical

specifications

DC 5V receiver in

(based on RS-422

standard)

Photo coupler input

(Compatible with the

DC5V line driver

type rotary encoder)

Photo coupler input

(Configure to an

inverter intelligent

input terminal.)

DC5V line driver

output (based on

RS-422 standard)

Open collector

outputs

(Configure to an

inverter intelligent

output terminal)

ut

13

Page 14

APA

Chapter 4 WIRING AND CONNECTION

Figure 4-2 Terminal wiring

Configure to an

intelligent input term. 1-8

Input

terminal

Output

terminal

Inverter main body control

FW

RV

LAC LAD cancellation signal

PCLR Position deviation Clear signal

ORT Orientation signal

STATPulse train input permisive signal

CM1

POK Positioning completion signal

ZS Zero speed signal

DSE Speed deviation excessive signal

H

O

L

Configure to an

intelligent output term. 1-5

SJ-FB

(Feed-back board)

EP5

EG5

EAP

EAN

EBP

TM1

EBN

EZP

EZN

SAP

SAN

SBP

TM2

SBN

BP

BN

Encoder signal

M

EC

Motor with

encoder

Pulse train pos.

command

N

Encoder

signal output

4.3 Terminal Connections

(Note 1) : Please refer to the SJ300 Instruction Manual for information about wiring the logic

terminals.

(Note 2) : Use a shielded, twisted pair cable for the signal cables, and cut the shielded covering as

shown in the diagram below. Make sure that the length of the signal cable is no more

than 20 meters. If the length exceeds 20 meters, use a VX application control device

RCD-E (remote control device) or CVD-E (signal isolation) to avoid malfunction

caused by EMC noise or voltage drop. Also, the signal wire for the encoder should be

shielded twisted pair line of 28 AWG (0.75mm2) or more, and the distance should also

be less than 20m. If more than 20m, use a 5V line driver relay amplifier.

Insulation

DO NOT GROUND

THIS END

Connect to common terminal

14

Page 15

Chapter 4 WIRING AND CONNECTION

(Note 3) : Be sure to separate the power wiring from the control circuit wiring. If they have to be

crossed, be sure that they cross at a right angle.

Power cables

Right angle

Control signals (STAT, ORT, LAC, PCLR, SAP, SAN, SBP, SBN,

EAP, EAN, EBP, EBN, POK, DSE, ZS, AP, AN, BP, BN, L, EP5,

EG5, CM1, CM2, P24, PLC etc.)

Separate 10cm or more.

R, S, T, U, V, W, P, PD,

RB, N, R0, T0 etc.

Input/Output signal lines

(Note 4) : Take care not to short circuit between the EP5 and EG5 terminals. There is a danger of

malfunction.

(Note 5) : Isolate common signal for inverter analog signals (L terminal of the logic card of

SJ300) from common terminal of the SJ-FB.

(Note 6) : Be sure to connect the encoder signal lines properly so that the relationship among their

phases is as shown below during rotation of the motor (Standard EG5).

EAP

EAN

EBP

EBN

EZP

EZN

15

Page 16

5.1 Setting the DIP Switches

Chapter 5 SETTING

Layout of SJ-FB

SWENC

SWR

TM1 TM2

Figure 5-1 Switch arrangement figure

5.2 Switch Initial Settings

Setting

item

SWENC

SWR

(Note) : Default setting for all the switches is OFF.

Switch

No.

1

2

1

2

ON

OFF

Detection of disconnected A or B signal (EAP-EAN or

EBP-EBN) is valid.

Detection of disconnected A or B signal (EAP-EAN or

EBP-EBN) is invalid.

ON Detection of disconnected Z signal (EZP-EZN) is valid.

OFF Detection of disconnected Z signal (EZP-EZN) is invalid.

ON

Termination resistance is provided between SAP and SAN

(150 ohms).

OFF No terminal resistance is provided between SAP and SAN.

ON

Termination resistance is provided between SBP and SBN

(150 ohms).

OFF No terminal resistance is provided between SBP and SBN.

How to Set Switches

SWENC and SWR

[ON/OFF]

O

F

F

Slide to the (OFF) marked side

of the switch to turn it off and the

opposite side to turn it on.

Contents

1

2

16

Page 17

Chapter 5 SETTING

5.3 Inverter Configuration Parameters for the SJ-FB Board

Code Function name Setting range Initial data

A044 1st control method

H001

H002

H003

H004

H005

H006 1st stabilized factor 0. - 255. 100.

H020 1st motor R1 setting

H021 1st motor R2 setting

H022 1st motor L setting 0.00 - 99.99 / 100.0 - 655.35(mH)

H023 1st motor I0 setting 0.00 - 99.99 / 100.0 - 655.35(A)

H024 1st motor J setting

H030

H031

H032

H033

Auto-tuning mode

selection

1st motor constant

selection

1st motor capacity

selection

1st motor pole

selection

1st motor speed

response setting

1st motor R1 setting

(Auto-tuning data)

1st motor R2 setting

(Auto-tuning data)

1st motor L setting

(Auto-tuning data)

1st motor I0setting

(Auto-tuning data)

00(VC) / 01(VP1.7power) / 02(Free V/f Setting)

/ 03(SLV) / 04(0Hz area SLV) / 05(V2)

00(NOR : Invalid) / 01(NRT : not rotate)/ 02(AUT :

rotate)

00(Hitachi standard motor constant)/

01(Auto-tuning data)/

02(Auto tuning data with online auto-tuning)

0.20 - 75.0(kW)

2/4/6/8 (Poles) 4 - -

0.001 - 9.999 / 10.00 - 65.53 1.590

0.000 - 9.999 / 10.00 - 65.53(Ω)

0.000 - 9.999 / 10.00 - 65.53(Ω)

0.000 - 9.999 / 10.00 - 99.99 /

100.0 - 9999.(kgm2)

0.000 - 9.999 / 10.00 - 65.53(Ω)

0.000 - 9.999 / 10.00 - 65.53(Ω)

0.00 - 99.99 / 100.0 - 655.35(mH)

0.00 - 99.99 / 100.0 - 655.35(A)

00 - -

00 - -

00 - -

Setting on

forwarding

depends on

the motor

capacity

depends on

the motor

capacity

depends on

the motor

capacity

depends on

the motor

capacity

depends on

the motor

capacity

depends on

the motor

capacity

depends on

the motor

capacity

depends on

the motor

capacity

depends on

the motor

capacity

Setting

on run

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

Change

mode on

run

17

Page 18

Chapter 5 SETTING

Code Function name Setting range Initial data

H034

H050

H051

H052

H070

st

The 1

motor J setting

(Auto-tuning data)

st

1

PI control proportional gain

setting

st

1

PI control integral gain

setting

st

1

P control proportional gain

setting

PI control proportional gain

switching

0.000 - 9.999 / 10.00 - 99.99 / 100.0 - 9999.( kgm

0.00 - 99.99 / 100.0 - 999.9 / 1000.(%) 100.0

0.00 - 99.99 / 100.0 - 999.9 / 1000. (%) 100.0

0.00 - 10.00 1.00

0.00 - 99.99 / 100.0 - 999.9 / 1000.(%) 100.0

2

)

depends on

the motor

capacity

H071 PI control integral gain setting 0.00 - 99.99 / 100.0 - 999.9 / 1000.(%) 100.0

H072

P001

P002

P control proportional gain

setting

Option 1 operation selection

on error

Option 2 operation selection

on error

0.00 - 10.00 1.00

00(TRP) / 01(RUN) 00 -

00(TRP) / 01(RUN) 00 -

Setting

on run

- -

P011 Encoder pulse setting 128. - 9999. / 1000 - 6500 (10000 - 65000)(Pulse) 1024. - P012 Control mode selection 00(ASR Mode) / 01(APR Mode) 00 - -

P013

P014

P015

P016

P017

P018

P019

P020

P021

P022

P023

P025

P026

P027

Pulse train input mode

selection

Stop position setting for

orientation

Frequency setting for

orientation

Direction setting for

orientation

Completion range setting for

orientation

Completion delay time setting

for orientation

Position selection for

electronic gear

Numerator of ratio setting for

electronic gear

Denominator of ratio setting

for electronic gear

Feed forward gain setting for

position control

Loop gain setting for position

control

The 2 next resistance revision

presence selection

Over speed abnormal

detection level

Speed error over detection

level

00(Mode 0) / 01(Mode 1) / 02(Mode 2) 00 - -

0. - 4095. 0. -

0.00 - 99.99 / 100.0 - 120.0(Hz) 5.00 -

00(Forward) / 01(Reverse) 00 - -

0. – 9999. / 1000(Pulse) 5 -

0.00 - 9.99(s) (Note3) 0.00 -

00(Position feed back side)/ 01(Position command

side)

00 -

0. - 9999. 1. -

0. - 9999. 1. -

0.00 - 99.99 / 100.0 - 655.3 0.00 -

0.00 - 99.99 / 100.0 0.50 -

00(Disable) / 01(Enable) 00 -

0.00 - 99.99 / 100.0 - 150.0(%) (Note 2)

(Note 3)

135.0 -

0.00 - 99.99 / 100.0 - 120.0(Hz) (Note 2) 7.50 -

Change

mode on

run

18

Page 19

r

r

Chapter 5 SETTING

(Note 1) : Please refer to the instruction manual of the inverter main body as to the setting procedure.

(Note 2): When the over speed abnormal detection level (P026), the speed error over detection level

(P027) are set 0, the Abnormal detection data processing will be invalid.

(Note 3): Regarding the SJ-FB setting, there are some warning about what type of main body

combines with the SJ-FB which is written following list.

Main body of SJ300 Production No (MFG No) (Note 4)

No. Item

1 Completion

delay time

setting for

orientation

(P018)

2 Over speed

abnormal

detection

level

Range of setting: 0.00 - 9.99 (X10(sec))

(Example) In order to operate the completion

delay time setting for orientation for 1(sec). Set

P018 setting which is written below.

P018=1(sec)/10(sec) =0.10

Range of setting: 0.0 - 150.0 (X100)

(Example) In order to operate the over speed

detection level at 66Hz while maximum

frequency is 60Hz. Set P026 setting which is

written below.

P026=66Hz / 60Hz=1.1

9 8 XXXXXXXXXXXX

9 9 XXXXXXXXXXXX

9 O XXXXXXXXXXXX

9 J XXXXXXXXXXXX

9 K XXXXXXXXXXXX

0 1 XXXXXXXXXXXX

others

Range of setting: 0.00 - 9.99 (X1(sec))

( Example) In order to operate the completion

delay time setting for orientation for 1(sec). Set

P018 setting which is written below.

P018=1(sec) / 1(sec)=1.00

Range of setting: 0.0 - 150.0 (X1%)

(Example) In order to operate the over speed

detection level at 66Hz, while maximum

frequency is 60Hz. Set P026 setting which is

written below.

P026=66Hz / 60HzX100=110.0

(Note 4) The SJ300 Production number (MFG No) is printed on the main body of the SJ300

specifications label. Refer to figure 5-2(1), figure 5-2(2).

Specifications label

Figure 5-2(1) location of specification labels

Inverter model

Maximum applicable moto

Input ratings

Output ratings

Production numbe

Figure 5-2 (2) Contents of specification label

19

Page 20

5.4 Setting Flowchart for the DIP Switches

Detect a wire break of the

Use the pulse train position

Connect parallel motors to the pulse

train position command input?

Turn SWR1, 2 on only 1 unit that is

the most distant from a master

inverter in a plural motor.

START

Detect a wire break of

A, B phase signal?

YES

Set SWENC1

switch ON.

Z phase signal?

YES

Set SWENC2

switch ON.

command input?

YES

YES

END

NO

NO

NO

NO

Set SWR1,2

Figure 5-3 Switch setting flowchart

Chapter 5 SETTING

Set SWENC1

switch OFF.

Set SWENC2

switch OFF.

switch ON.

20

Page 21

Chapter 6 OPERATION

Refer to [Chapter 3 OPERATION] in the instruction manual for the SJ300 inverter before

operating with this board. When the operation command is given from the terminal side of the

inverter main body, operate with the following procedure.

<Procedure>

1. Turn ON the POWER switch of the inverter.

2. Set the control method (A044) in [05].

3. Set the necessary items according to the instruction manual "Chapter 4 FUNCTION

EXPLANATION" of the inverter main body.

4. For speed control, operation is started when operation command of the inverter main

body is turned on.

5. For position control, turn on the STAT terminal of SJ-FB and operation command of the

inverter main body first of all. Next input the pulse train position command to

SAP-SAN and SBP-SBN. Then the motor turns only the pulse that you input.

Confirm the following while trial operation.

The motor accelerates normally.

The motor rotates in the correct direction.

Neither abnormal vibration nor noise is recognized in the motor.

If the motor doesn’t accelerate normally or the inverter trips with overload, check the encoder for

phase order. The normal phase order is that the waveform of phase A advances by 90° than that of

phase B when the motor rotates forward.

(Note 1) : The monitor signal may not be output from FM terminal of inverter main body under

vector control with sensor (A044=05). Please confirm the monitor output in this case.

(Note 2) : Please do not do the free run action by "RS terminal" of inverter main body. When you

do this action, over current trip, or power element destruction may occur. Please use

"FRS" the terminal when performing free run action.

(Note 3) : If the torque limit setting (b041-b044) is enlarged, over current trip would occur at the

time of the motor added burden. In this case, please adjust the torque limit setting

value.

(Note 4) : The motor constant data of the SJ300 series is the data at the time of base frequency

50Hz in the J1 motor made in Hitachi. . Please put in the value that did it to motor

constant I0 (H023) 0.7 times, in the case that you use it with base frequency 60Hz in

the J1 motor.

(Note 5) : Please do the auto tuning, in the case that you do not understand the motor constant.

21

Page 22

Chapter 6 OPERATION

(Note 6) : If satisfactory performance can not be obtained, adjust the motor constants for the

particular symptoms observed according to following table:

Inverter

Status

At starting

deceleratio

n

During

torque limit

At low

frequency

operation

Symptom Observed Adjustment Guidelines

Shock occurs at

starting

Instability of motor

rotation

Insufficient torque

during torque limit

at low speed

Irregular rotation

Set “Motor constant J” higher gradually, up to

1.2 times the initially preset (default) value.

Set the speed response lower. H005 At

Set “Motor constant J” smaller than the

initially preset value.

Set overload restriction level lower than the

torque limit level(s).

Set “Motor constant J” higher than the initial

preset (default) value.

Parameter(s)

to Adjust

H024/H034

H024/H034

b022

b041-b044

H024/H034

22

Page 23

Chapter 7 FUNCTIONS

7.1 Orientation function

This board is provided with the orientation function used to

position the motor at a certain point during operation. This

function can be used for replacing a component of the main axis

of the subject machine tool for example.

7.1.1 Function outline

The orientation function maintains position which has decided

with the position control after speed control operation. The action

is shown in Figure 7-1.

A044: 1st Control Method

P014: Orientation Stop Position

P015: Orientation Speed setting

P016: Orientation Direction setting

P017: Completion range setting

P018: Completion delay time

P023: Position loop gain

C001-C008: Intelligent input terminal

C021-C025: Intelligent output terminal

Relation

1. In the speed control operation period, inverter drives at constant speed with the orientation

speed setting (P015). (Orientation mode becomes valid when turning RUN command ON

under ORT is being ON.)

2. After arriving to the orientation speed setting(P015), the first coming the Z pulse is detected

after that the control mode moves to the position control.

3. Inverter controls the motor to stop at a certain stop position which is set to (P014) during

position control operation period.

Operation command

(FW/RV)

ORT terminal

Acceleration rate

follow acceleration

time setting F002

Rotation Speed

of Motor

Z pulse

POK signal output

(Positioning completion)

Output motor

Speed control Position control

(Note 1) Rotation speed of the motor is zero but inverter is outputting to the motor.

Don't touch the motor power line. Otherwise, there is a danger of electric shock and/or injury.

(Note 2) In case of reoperating when the operation command is set terminal.

Set the command operation(FW,REV)again.

(1)

Completion delay time setting (P018)

(2)

Deceleration time doesn't follow

deceleration time setting F003.

(3)

If the loop back gain (P023) is

big, deceleration time is short

In the case of exceeding

the required stop position

(4)

(5)

Output zero

servo

(Note 1)

Figure 7 - 1(1) Orientation and timing

23

Page 24

g

p

Chapter 7 FUNCTIONS

4. Inverter maintains the position after the completion, and outputs the ‘position control

completion (POK) signal’ after the set value of ‘delay time setting (P018). (Inverter drives

the motor reverse and return to the required stop position in the case it exceeds the required

stop position.)

5. When the ORT terminal is turned off, the inverter stops operation and the orientation mode is

cleared.

(Note3) In case of using Z pulse, use 5V line driver type output for EZP-EZN input.

(Note 4): Action timing of when only the operation command is OFF during the orientation.

If only the operation command is OFF, the motor will stop (1). After that if the ORT

terminal is OFF(2), POK signal output will be OFF (3).

(While ORT terminal is ON. Due to the orientation mode is running , even though

only the operation command is OFF , the POK signal output (4) keep ON within

the completion range.

Operationcomman

(1)

d

ORT terminal

Rotation Speed

of Motor

ulse

Z

POK signal output

(Positioning

completion)

Output motor

(Action timing of when only the operation command is OFF during the orientation.)

(4)

Position control

Figure 7 - 1(2) Orientation and timing

(2)

(3)

Completion delay time

settin

Output Zero

servo

(Note 5)

Don't touch the motor power line. Otherwise there is a danger of electric shock

Rotation speed of motor is zero but inverter is outputting to the motor.

/Injury

.

24

Page 25

m

Chapter 7 FUNCTIONS

7.1.2 Data setting

Data setting related to speed control

Setting item Function code Setting Range, Setting Contents

Orientation speed setting (Note 1) P015

Orientation direction setting (Note 2) P016 0:Forward / 1:Reverse

(Note 1) : In order to stop the motor for setting position. (Motor takes 2 rotation to stop setting

position)Don’t set high frequency to the orientation speed setting. Otherwise it will be

over-voltage protection trip.

(Note 2) : Turn direction of the motor while orientation is done based on the setting of P016.

Data setting related to position control

Setting item

0.00∼99.99 / 100.0∼120.0 (Hz)

Function

code

Setting range, setting contents

Orientation stop position(Note 3) P014

Completion range setting P017

Completion delay time (Note 4) P018

Position loop gain(Note 5) P023

0∼9999. / 1000 (10,000) (pulses)

(Setting four times fairly of the encoder pulses)

0.00∼99.99 / 100.0 (rad/s)

0. ∼4095.

0.00∼9.99

(Note 3) : The orientation stop position is to be set as 4096 of division (0∼4095) per 1 turn toward

forward from the original point. (It is 4096 division irrespective of the pulse number

of the encoder.) The original point is where the pulse has input to EZP-EZN.

Stoppage goal position is like shown in Figure 7-2 irrespective of the turn direction.

(Note 4) : It depends on what type of main body combines with the SJ-FB, the setting value

conversion is different. Please refer to the (Note 3) of the “5.3 Items regarding the

feed back board of the inverter main body“.

(Note 5) : To improve the positioning accuracy. Increase position loop gain (G).

When the motor is unstable. Decrease position loop gain.

Z pulse Position

(Reference point)

0

Motor Shaft viewed fro

the load side

1024

3072

Figure 7-2 Concept of Orientation setting Position

25

Page 26

Chapter 7 FUNCTIONS

Data setting of the input-output terminal

Input-output terminal Terminal assignment Contents

Input

ORT terminal (ORT)

Output

Positioning

completion signal

(POK)

Set up 45 to one of

them of C001∼C008

Set up 23 to one of

them of C021∼C025

ON : Orientation mode

Output when it comes to the positioning

completion range.

7.2 Speed control (ASR)

When the control mode selection (P012) is set to 00, operation mode

becomes a speed control operation mode (ASR mode).

Please drive after setting up the frequency, operation command and

each motor constant .

7.3 Position control (APR)

(Electronic gear function)

When the control mode selection (P012) is set to 01, operation

mode becomes a speed control operation mode (APR mode).

7.3.1 Function outline

This function generates the frequency based on the position

command pulse which comes from the pulse train input from the

terminal and position feed back pulse which is detected by the motor

encoder, and performs the position control operation. It can be used

as synchronous operation of main and sub motor. Also the turn

ratio of main and sub motor can be changed by setting up the

electronic gear ratio (N/D). (Electronic gear function)

7.3.2 Control mode setting

Inverter at the main motor (master inverter) can be set both as a

speed control and position control. Please set up the inverter at the

sub motor side (slave inverter) to a position control mode.

A044: 1

P012: Control mode selection

A001: Frequency command selection

A002: Operation command selection

F001: Frequency setting

F002: Acceleration time

F003: Deceleration time

F004: Operation direction selection

H002/H202-H052/H252:

A044: 1

P012: Control mode selection

A002: Operation command selection

P017: Completion range setting

P018: Completion delay time

P019: Electronic gear position selection

P020: Electronic gear ratio numerator

P021: Electronic gear ratio denominator

P022: Feed forward gain

P023: Position loop gain

C001-C008: Intelligent input terminal

C021-C025: Intelligent output terminal

H002/H202-H052/H252:

Motor constant relation data

Relation

st

Control method

Motor constant relation data

Relation

st

Control method

26

Page 27

Chapter 7 FUNCTIONS

Master Inverter Slave Inverter

AP,BP

AN,BN

EG5

EAP,EBP

EAN,EBN

Main Motor

M

EC

SAP,SBP

SAN,SBN

EG5

EAP,EBP

EAN,EBN

Sub Motor

M

EC

Figure 7-3 Wiring for Synchronized Operation

(Note) : Please connect EG5 of the main and sub inverter together to avoid

malfunction caused by EMC noise.

7.3.3 Data setting

Data setting related to position control

Setting item Function code Setting range, setting contents

Feed-forward gain

(Note 1)

Position loop gain (Note 2) P023

Electronic gear position

selection (Note 3)

Numerator of the electronic

gear ratio (Note 3)

Denominator of the electronic

gear ratio (Note 3)

Completion range setting P017

Completion delay time P018

(Note 1) : We promote the adjustment from P022=2.00 at the time of the feed forward gain

adjustment .To make the position deviation of the main and sub motor small, then

increase feed forward gain. When the motor is unstable, then decrease feed forward

gain

(Note 2) :We promote the adjustment from P023=2.00 at the time of the position loop gain

adjustment. To get good accuracy of the position control then increase posotion loop

gain, then to get much power to maintain the positioning then increase posotion loop

gain. Motor is unstable due to too big position loop gain, then decrease position loop

gain.

P022

P019

P020

P021

0.00∼99.99 / 100.0∼655.3

0.00∼9.99 / 100.0 (rad/s)

00: to the feed back side (FB)

01: to the position command side (REF)

1∼9999

1∼9999

0∼9999. / 1000 (10,000) (pulse)

0.00∼9.99 (s)

27

Page 28

Chapter 7 FUNCTIONS

(Note 3) : N/D must be given as the ranges of 1/50 ≤ (N/D) ≤ 20.

(N: Electronic gear ratio numerator, D: Electronic gear ratio denominator)

(Note 4) : It depends on what type of main body combines with the SJ-FB, the setting

value conversion is different. Please refer to the (Note 3) of the “5.3 Items

regarding the feed back board of the inverter main body“.

Data setting of input-output terminals

Input-output terminal With terminal assignment Contents

The pulse train position

command input

permission signal.

Input

(STAT)

Set ‘48’ to one of

C001∼C008

Pulse train position command

input is valid while ON.

Positioning completion

Output

signal.(POK)

Set ‘23’ to one of

C021∼C025

Output when it entered into the

positioning completion range

Set ‘48’ (the pulse train position command input permission signal (STAT)) to one of

C001∼C008. Pulse train position command input is valid only in the case that the STAT terminal

is turned ON. In the case that the STAT terminal is OFF or unestablished, pulse train position

command input is invalid.

Below the example of the proportion of the slave side turn number to the master side turn number

by the setting of P019~P021 is shown. (Yet, the encoder pulse number of the master side and

slave side are same and be in the case of 1024 pulses. )

Position selection for electronic gear (P019)

Numerator of ration setting for electronic gear

(P020)

Denominator of ratio setting for electronic gear

(P021)

Slave side turn number to the master side turn

number

01

(REF)

1024 2048 1024 2048

2048 1024 2048 1024

1/2 2 2 1/2

01

(REF)

00 (FB) 00 (FB)

28

Page 29

[Setting example]

Main Motor : Encoder pulse 1024 pulses

Sub Motor : Encoder pulse 3000 pulses

(Main motor rotation speed) : (sub motor rotation speed) = 2 : 1

Set the following for slave inverter in this case.

Electronic gear setting position (P019) : RET (command pulse side)

Electronic gear numerator (P020) : 3000

Electronic gear ratio denominator (P021) : 1024*2=2048

Figure 7-4 Control block diagram of the electron gear function (1)

Figure 7-5 Control block diagram of the electron gear function (2)

FFWG

Feed forward gain

Chapter 7 FUNCTIONS

REF

REF

+

-

N

D

FB

Electron gear establishment position selection = FB

N

D

Electron gear establishment position selection = REF

+

-

FB

G

Position loop gain

FFWG

Feed forward gain

G

Position loop gain

+

+

+

ASR

+

ASR

29

Page 30

Chapter 7 FUNCTIONS

7.3.4 Pulse train mode selection

The following 3 ways of pulse line input can be selected by the setting of P013.

1) 90° phase difference pulse train (Mode 0)

SAP

SAN

(Pulse train input)

SBP

SBN

(Pulse train input)

Detected

pulse number

Forward

Reverse

2) Forward/Reverse command + pulse train (mode 1)

SAP

SAN

(Pulse train input)

Time

SBP

SBN

(Forward/reverse command)

Detected

pulse number

Forward

3) Forward pulse train + Reversion pulse train (mode 2)

SAP

SAN

(Forward pulse train input)

SBP

SBN

(Reverse pulse train input)

Detected

pulse number

Reverse

Time

Forward Reverse

30

Time

Page 31

Chapter 7 FUNCTIONS

7.4 Speed control (P/PI) switching function

Speed control mode is normally controlled by

proportional-integration compensation (Pi), which keeps the

A044: 1st Control Method

P052: 1

st

Proportional gain

deviation between the actual speed and speed command

becomes 0. Further, you can also achieve a propotional control

function, which can be used as drooping operation (i.e. one load

with several inverters) with this option card.

Set P/PI switching function to one of the intelligent input terminal 1∼8 by the operator to achieve

this function. (Input ‘43’ in one of C001∼C008.) When this is turned on, control mode becomes

proportion control (P).

Please set proportional gain(Kpp ; a value used to decide the speed change rate) to H052 by a

digital operator. The relationship between the Kpp value and the speed change rate is shown

below.

10

=)RateChangeSpeed(

(%)

)ValueSetKpp(

Relationship between Kpp Value and Speed Change Rate

Torque

PI controlP control

100 %

(A)

0 Rotation Speed

Figure 7-6 Torque characteristic (P/PI)

()

=)RateChangeSpeed(

ATorqueRatedatErrorSpeed

frequencybasespeedsSynchronou

Relationship between Speed Change Rate and Rated Rotation Speed

31

Page 32

Chapter 7 FUNCTIONS

7.5 Compensation of secondary resistor function

(Temperature revision)

Please use this function, if you want to do the temperature revision

to restrain the speed fluctuation by the temperature change of the

motor. (Please use the thermistor of the characteristic like type B

that shows it below. (This thermistor is the characteristic of

PE-41E made of a Shibaura electronics co.,Ltd.))

Relation

P025: Compensation of secondary

resistor selection

b098: Thermistor selection

b099: Thermistor error level

C085: Thermistor adjustment

1. Please wire the thermistor that is built to the motor to the inverter.

(Wiring between TH and CM1 of the terminal unit board of the main body)

2. Please set up it as follows.

P025………01(valid) b098……… 02(NTC)

b099……….(This code is thermistor error level setting. Set the resistance value

of temperature for trip according to thermistor methods.)

C085……….(Use this as gain adjustment.)

Figure 7-7 Resistor vs. Temperature Curves

(Note):Please wire it once again after the thermistor error occurrence level is changed, after you

remove the wiring of the thermistor once, if the thermistor error occurred.

32

Page 33

Chapter 8 PROTECTION FUNCTION

8.1 Action selection in case of option error

To ignore or make inverter trip can be selected in case of option error.

Item Function code Data Contents

Action selection in

case of option error

P001 / P002

00 TRP: Inverter trips and outputs alarm signal.

01

RUN: Inverter ignores the option error and

continues the operation.

(Note) : Inverter trips anyway in case of encoder line break error (E60, E70), SJ-FB abnormal

connection (E69,E79) occurs, although action selection is set to 01 (RUN). Please refer to

"Chapter 5.2 FEED-BACK BOARD INITIAL SETTINGS".

8.2 Causes and Countermeasures for Option Board Errors

When any of the following alarms occurs, the inverter displays the alarm cause and stops.

Display Item Contents Processing

Detect the line break or disconnection of the

encoder line.

E60

(E70)

(Note 1)

E61

(E71)

(Note 1)

E62

(E72)

(Note 1)

E69

(E79)

(Note 1)

Encoder line

break

Over speed

Positioning

error

connection

error

Detect when there is an encoder failure.

Detect when the specification of the encoder is

not line driver output type.

Detect when there is no Z pulse.

Detect when the motor rotation speed exceeds

(maximum frequency (note 2))× (over speed

error detection level (P026).

(Note 3),(Note 4)

Detect when the deviation of the current

position and command value becomes more

than 1,000,000 pulses during position

controlling.

Detect abnormal connection between the

inverter main body and SJ-FB.

(Note 1): Data in parentheses ( ) applies when the option card is connected to option slot 2.

(Note 2): Frequency upper limit value (A061/A261) is reflected when it is set.

(Note 3): It depends on what type of main body combines with the SJ-FB, the setting value

conversion is different.

Please refer to the (Note 3) of the “5.3 Items regarding the feed back board of the

inverter main body“.

(Note 4): When the over speed error occurred . There is a possibility the over speed error occur

again. Even though the trip is cleared during the motor free run. In this case stop the

motor, then clear the trip please.

Check the encoder signal line and

connection.

Replace it to a suitable one.

Turn SWENC-2 OFF on the option

board.

Adjust the Kp and J constants

related to the speed control system

to reduce overshoot.

Increase the position loop gain.

Decrease the numbers of the pulse

train input per second.

Check the connection between the

inverter main body and SJ-FB.

8.3 Warning display (Feed back option relation)

(Refer to the operation manual of the main body about the warning other than the following,)

The 009 is displayed in the case that it became orientation speed setting (P015) > the highest

33

Page 34

Chapter 8 PROTECTION FUNCTION

frequency setting (A004). Please confirm the case, orientation speed setting (P015) and highest

frequency setting (A004).

34

Page 35

Chapter 8 PROTECTION FUNCTION

Product specification

Item Specification

Encoder

Speed

control

Position

control

Orientat

ion

Protection function

feed-back:

Speed control

system:

Position

command:

Electronic gear:

Stop position:

Speed:

(Note 1): The main body setting or external input is selectable.

SJ-DG (digital input option board) is required in case of external input.

(Note 2): It depends on what type of main body combines with the SJ-FB, the

setting value conversion is different.

Please refer to the (Note 3) of the “5.3 Items regarding the feed back

board of the inverter main body“.

• Standard encoder pulse number 1024 pulse/r

• Max. input pulse 100k pulse/s

• Proportional-Integral (PI) / Proportional (P) control

• Three kinds of pulse train input selectable by main

body setting.

Mode 0 : 90° phase difference pulse

Mode 1 : Forward/Reverse signal pulse

Mode 2 : Forward pulse/Reverse pulse

• Max. input pulse 100k pulse/s

• Pulse ratio A/B (A, B: 1~ 9999 selectable)

• Setting range 1/50 ≤ A/B ≤ 20

• 4096 division against 1 rotation of the motor shaft

(Note 1)

• Orientation speed and turn direction selectable

• Encoder cable line break protection

• Over speed protection (over speed error detection

level (P026)) (Note 2)

• Positioning error

• Connection abnormal of SJ-FB

HITACHI

35

HAL-PC0411

Loading...

Loading...