Page 1

. By reading this

1

Chapter2 Installation method of printed board 4

Chapter3 Wiring, Connecting 5

Chapter4 Setting 7

Chapter5 Operation 9

Chapter7 Countermeasure for abnormality 21

SJ-DN

Hitachi Inverter

After reading this manual, keep it at handy for future reference.

SJ300/L300P SERIES

(DeviceNet Option)

INSTRUCTION MANUAL

Thank you for purchase of “HITACHI INVERTER”. This manual

explains about treatment of “SJ-DN (DeviceNet Option)”

manual and an instruction manual of inverter use practically for

installation, maintenance, and inspection. After reading this manual,

keep it handy for future reference.

Make sure to reach this manual to the end user.

Table of Contents

Chapter1 Introduction

Chapter6 DeviceNet Communication Function 11

Appendix Parameter Object Lists 23

NB618X

Page 2

- Request Thank you for purchase of “SJ-DN (DeviceNet Option)”.

This instruction manual explains about treatment and maintenance of “SJ-DN”. Before using the product,

carefully read this manual with the instruction manual of inverter, and keeps it handy for quick reference of

operator and maintenance inspector. Before installing, operating, maintenance and inspection read this

manual carefully and follow the instructions exactly.

Always keep various kinds of specification mentioned in this manual and use exactly. And make sure to

prevent trouble by correct inspection and maintenance. Make sure to reach this manual to the end user.

- About treatment of this manual (1)Please consent that mentioned items of this manual may be change without permission.

(2)Keep this manual carefully not to lose because it can not be reissued

(3)All right reserved.

(4)Contents in this manual is written to make assurance doubly sure but, but please contact if you have

some doubts about spelling mistakes, omitted word etc.

(5)Please agree that there is no responsibility for effects resulted, in spite of contents above mentioned.

- About trademark (1)DeviceNet is trademark of Open DeviceNet Vendor Association, Inc.

Revision History Table

No. Revision contents The date of issued Manual No.

1. Initial release of Manual NB618X Jan. 2001 NB618X

Except this table, revised only spelling mistakes omitted words, and error writings without notice.

Page 3

SAFETY PRECAUTIONS

CAUTION

SAFTY PRECAUTIONS

Carefully read this manual and all of the warning labels attached to the inverter before installing, operating,

maintaining, inspecting, it. Safety precautions are classified into “Warning” and “Caution ” in this manual.

:Indicates a potentially hazardous situation which, if not avoided, can result in serious

WARNING

!

injury or death.

:Indicates a potentially hazardous situation which, if not avoided, can result in minor to

CAUTION

!

moderate injury, or serous damage to the product

The situation described in may, if not avoided, lead to serious results. Important safety

measures are described in CAUTION (as well as WARNING) so be sure observe them.

Notes are described in this manual in “(Note)”. Carefully read the contents and follow them exactly.

In all the illustrations in this manual, covers and safely device are occasionally removed to describe the

details. When the product is operated, make sure that the covers and safety devices are placed as they

were specified originally and operate it according to the instruction manual.

!

CAUTION

!

Page 4

SAFETY PRECAUTIONS

WARNING

!

Wiring:

Wiring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock, fire and/or damage of product.

Implement wiring after checking that the power supply is off.

Otherwise, there is a danger of electric shock and/or fire.

Operating:

Be sure not to touch the surface or the terminal of option board while energizing.

Otherwise, there is a danger of electric shock and/or fire.

Be sure not to remove the DeviceNet option printed board while operating.

Otherwise, there is a danger of electric shock and/or fire.

Maintenance, Inspection and Part Replacement:

Wait at least 10 minutes after turning off the input power supply before performing maintenance and

inspection.

(Confirm the charge lamp on the inverter is off, checks direct current voltage between P-N terminals and

confirm it is less than 45V)

Otherwise, there is a danger of electric shock.

Make sure that only qualified persons will perform maintenance, inspection, and part replacement

(Before starting the work, remove metallic objects from your person (wristwatch, bracelet, etc.).

Be sure to use tools protected with insulation.)

Otherwise, there is a danger of electric shock and/or injury.

Note:

Never modify the unit.

Otherwise, there is a danger of electric shock and/or injury.

CAUTION

!

Installation:

Be sure not to let the foreign matter enter such as wire clippings, spatter from welding, metal shaving,

dust etc.

Otherwise, there is a danger of fire.

Be sure to fix inverter to option printed board with an attached fixed screw.

Otherwise, there is a danger of connecting error.

Be sure to fasten the screws connecting signal wire in side of option printed board. Check for any

loosening of screw.

Otherwise, there is a danger of connecting error.

Wiring:

Be sure to fasten the screws not to loose.

Otherwise, there is a danger of connecting error.

Operation:

Check rotary direction, abnormal motor noise and vibrations during operating.

Otherwise, there is a danger of injury to personnel and/or machine breakage

Page 5

CHAPTER 1 INTRODUCTION

1.1 INSPECTION UPON UNPACKING

Make sure to treat the product carefully not to give shock and vibration while unpacking. Check that the

product is the one you ordered, no defect, and that there is no damage during transportation.

(Contents of packing)

(1) SJ-DN(DeviceNet option printed board):1

(2) Instruction manual:1

(3) DeviceNet connector:1

(4) Screws fixed printed board (M3 times 8 mm):2

If you discover any problems, contact your sales agent immediately.

1.2 INQUIRY OF THE PRODUCT AND WARRANTY FOR THE PRODUCT

1.2.1 REQUIRE WHILE INQUIRING

If inquiry of breakage, question, damage etc. is needed, please tell the following information to the supplier

you ordered or the nearest Hitachi Distributor.

(1) Type(SJ-DN)

(2) Manufacturing number (Item of label, that labeled surface of printed board. SJ-DN XXX )

(3) Date of purchasing

(4) Contents of inquiry

・Damage parts and its condition etc.

・Question parts and their contents etc.

In order to shorten impossible working time, standing spare unit is recommended.

1.2.2 WARRANTY OF THE PRODUCT

This product is guaranteed to last for one year after purchase. But, the next case is toll repair, even if within

warranty period.

(1) In case caused by operating mistake, and incorrect repair and modification.

(2) Trouble caused by reasons except the shipped product.

(3) In case of using in range over the value of specification.

(4) In case caused by natural calamity, disaster, and secondary disaster.

Warranty mentioned here means warranty for shipped product itself. Damage caused by trouble of shipped

product is not guaranteed.

[Toll repair]

Any explanation and repair after the warranty period (one-year) shall be charged to the purchaser. And also

any explanation and repair out of warranty mentioned above, even within warranty period, shall be charged

to the purchaser. If you require the toll repair, please contact your Hitachi distributor.

1

Page 6

CHAPTER 1 INTRODUCTION

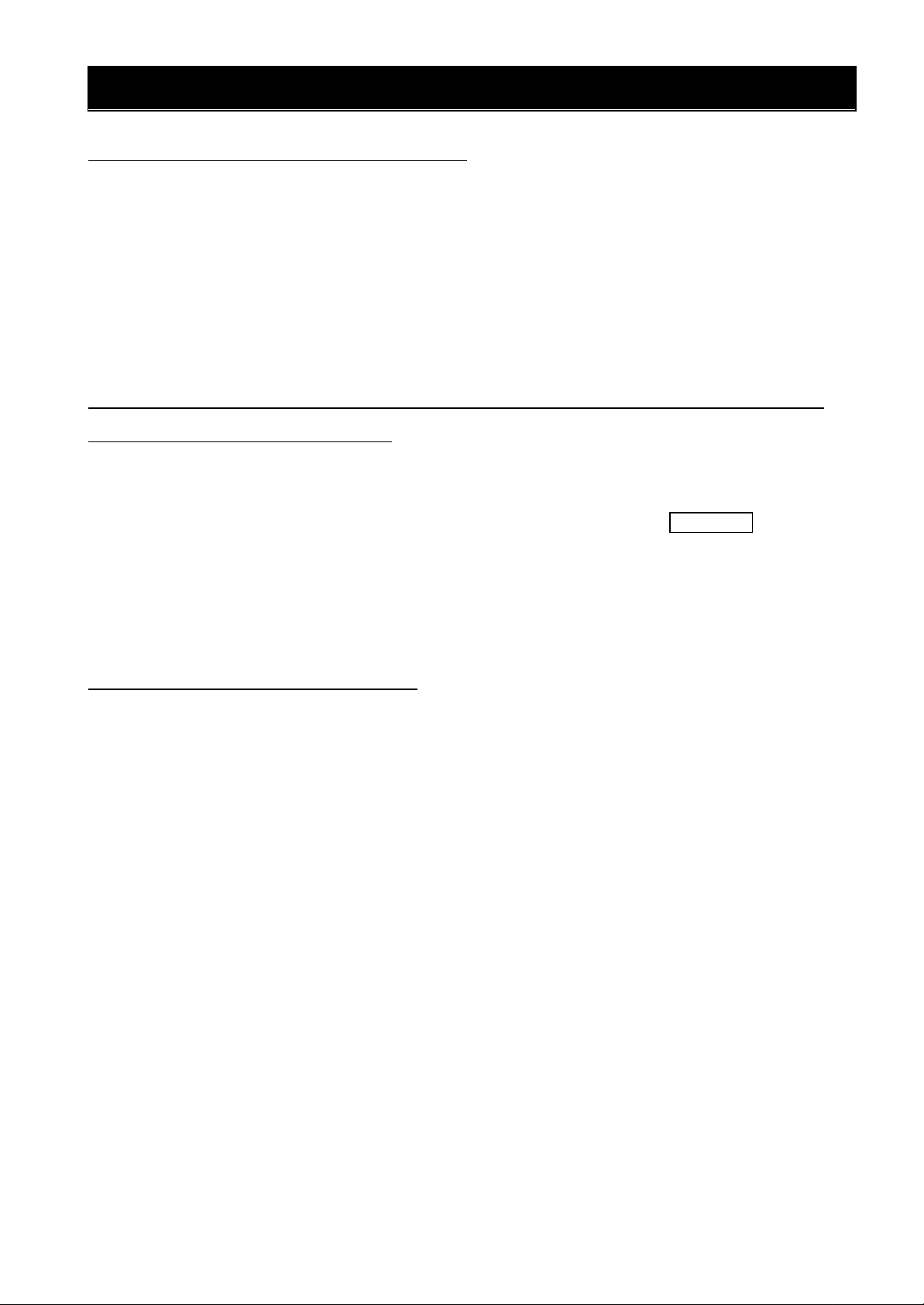

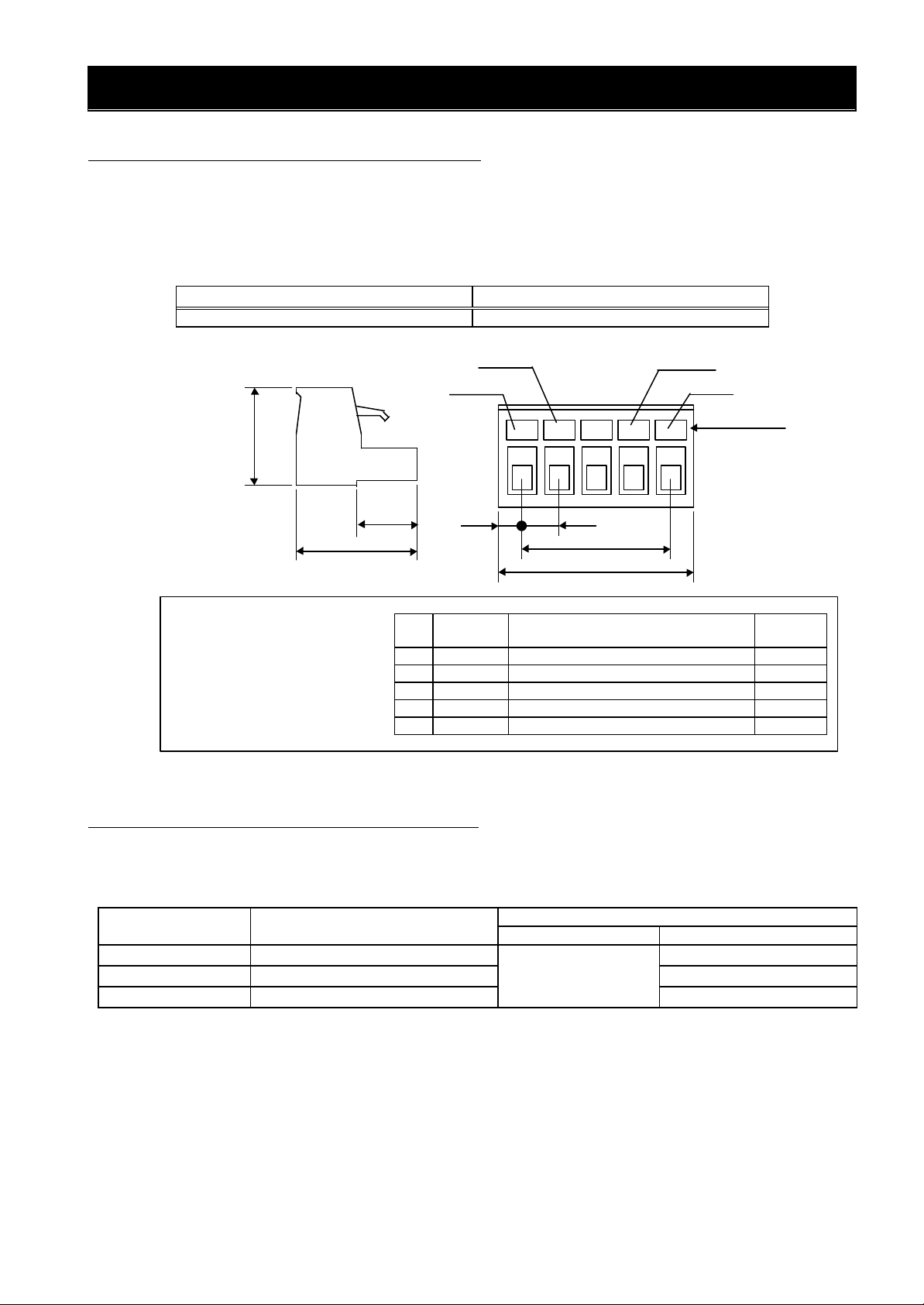

Connector for connecting to SJ300/L300P (Rear of unit)

Phoenix Contact Co, Ltd. (MSTB2.5/5-ST-5.08AU) etc

Module status LED (MOD)

DIP SW (SW) for setting MAC ID and Baud rate

1.3 Outline of product

SJ-DN is DeviceNet communication board for SJ300/L300P series inverter.

SJ-DN conforms to open field Network DeviceNet and it activates as slave function (Group 2 only server).

SJ-DN is also conforms ODVA’s certification.

(SJ-DN has been tested by ODVA's authorized Independent Test Lab and found to comply with ODVA

Conformance Test Software Version A-13.)

The following functions are available via DeviceNet communication function by installing SJ-DN to

SJ300/L300P series.

Polled Input/Output message connection

This command can exchange the master’s I/O data for the slave (Inverter) ’s I/O data.

Output data (from master to SJ-DN):

Run/Stop, reference frequency, Acceleration time, Deceleration time, Fault reset etc.

Input data (from SJ-DN to master):

Inverter status, output frequency, output current, trip history etc.

Explicit message connection

This function can reads and writes (configuration) the inverter’s parameter data, when it is necessary.

SJ-DN can use inverter below:

SJ300-004LF to 550LF, 007HF to 550HF, L300P-110LFR to 750LFR, 110HFR to 750HFR

(Note) RS485 communication function is disabled by installing SJ-DN to the inverter.

1.4 Appearance and Names of Parts

Figure 1-1 indicates the appearance of SJ-DN.

DeviceNet connector (open type)

Figure 1-1 Appearance of SJ-DN

Network status LED (NET)

2

Page 7

CHAPTER 1 INTRODUCTION

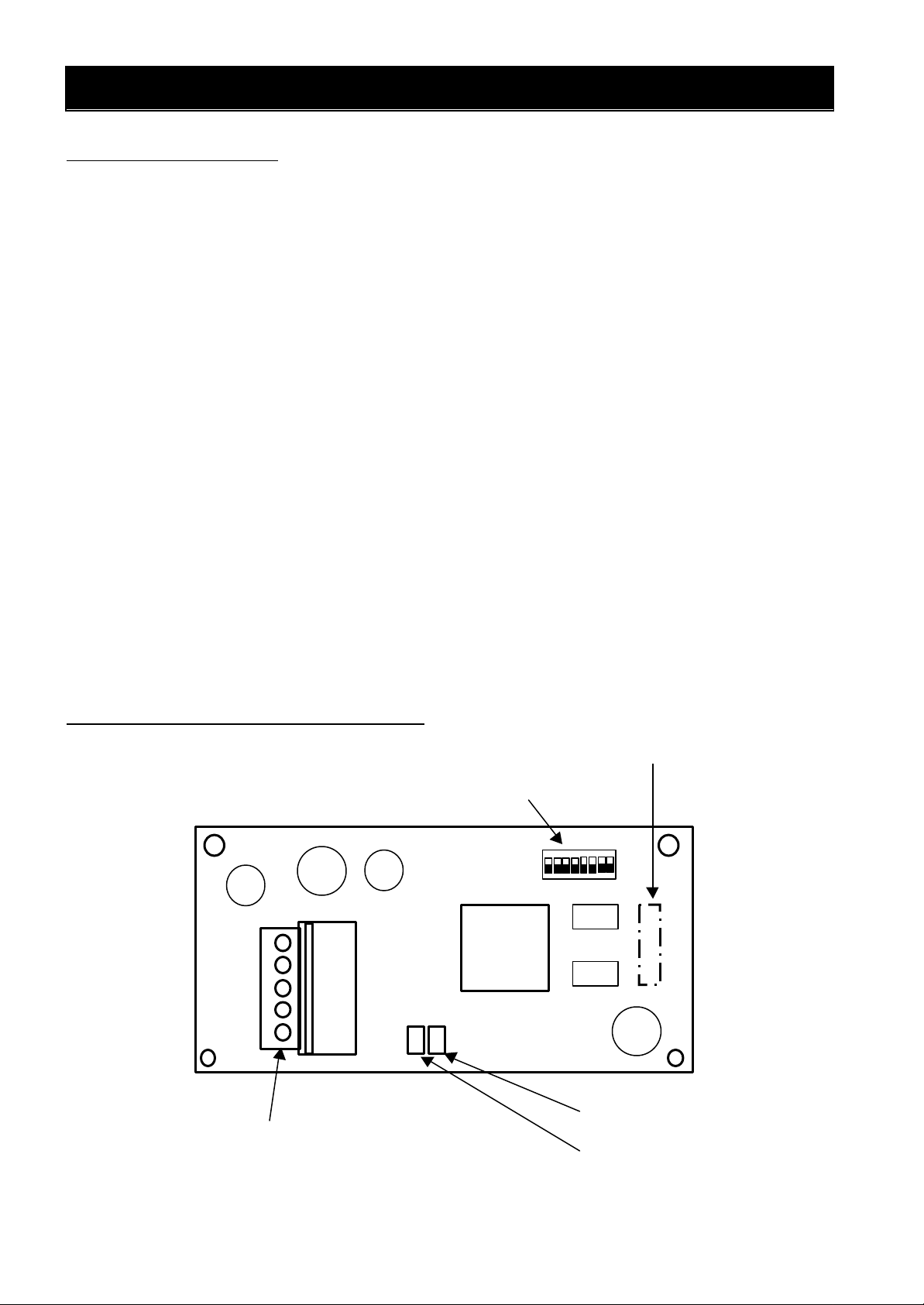

Specifications label

Inverter model

1.5 DeviceNet Support Version

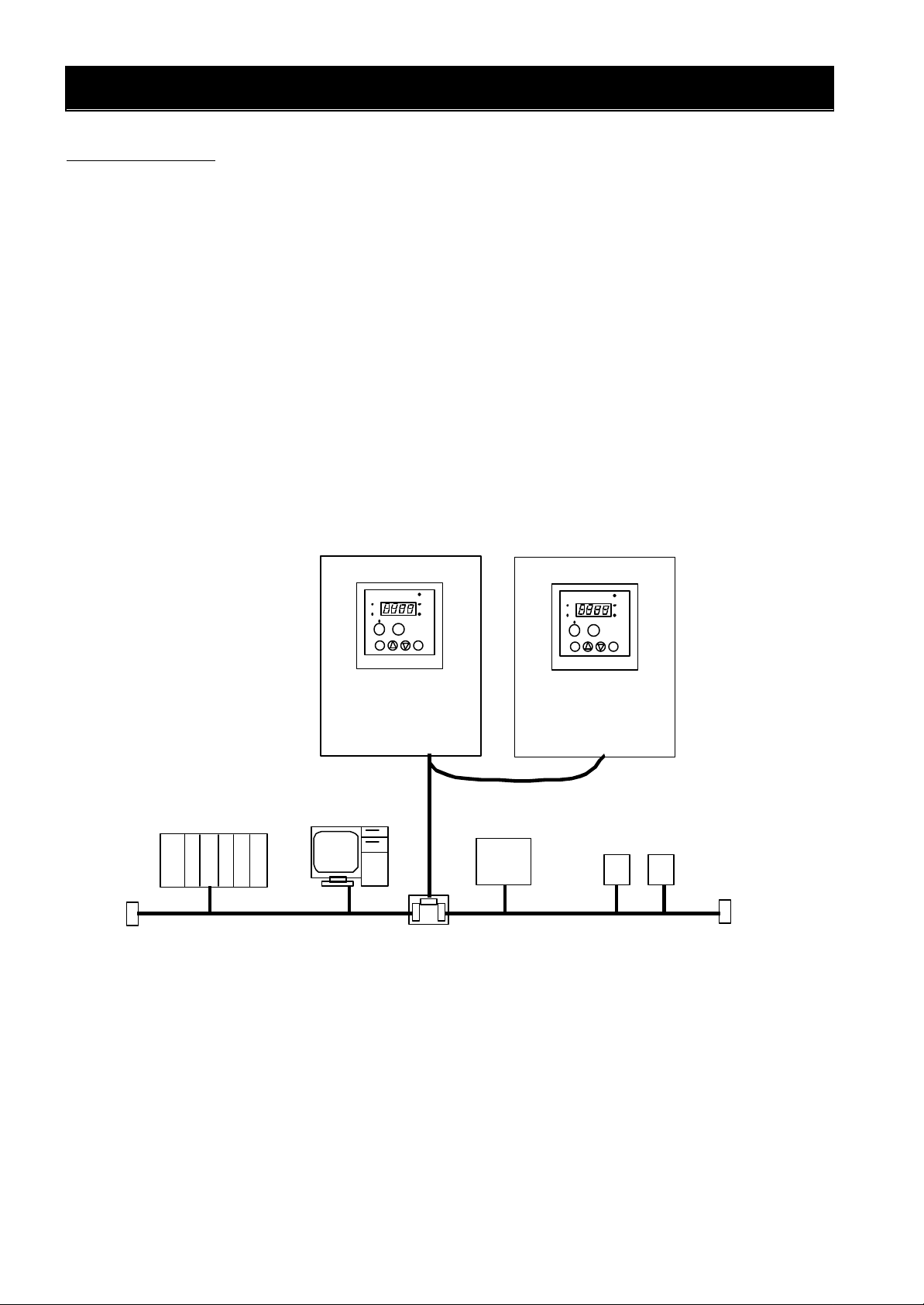

SJ-DN can use following Production number(MFG No) of SJ300/L300P series.

After MFG No. : XX8KXXXXXXXXXXXX

(Note) Production number (MFG No) is written in specifications label on main body of

SJ300/L300Pseries. Refer to figure 1-2, figure 1-3.

(Figure1-2,1-3 are the example of SJ300 series. L300P series are the same manner as

SJ300 series.)

Figure 1-2 Position of specifi cations label

Maximum applicable

Output ratings

Production number

motor

Input ratings

Figure 1-3 Contents of specifications label

3

Page 8

CHAPTER 2 INSTALLATION METHOD OF PRINTED BOARD

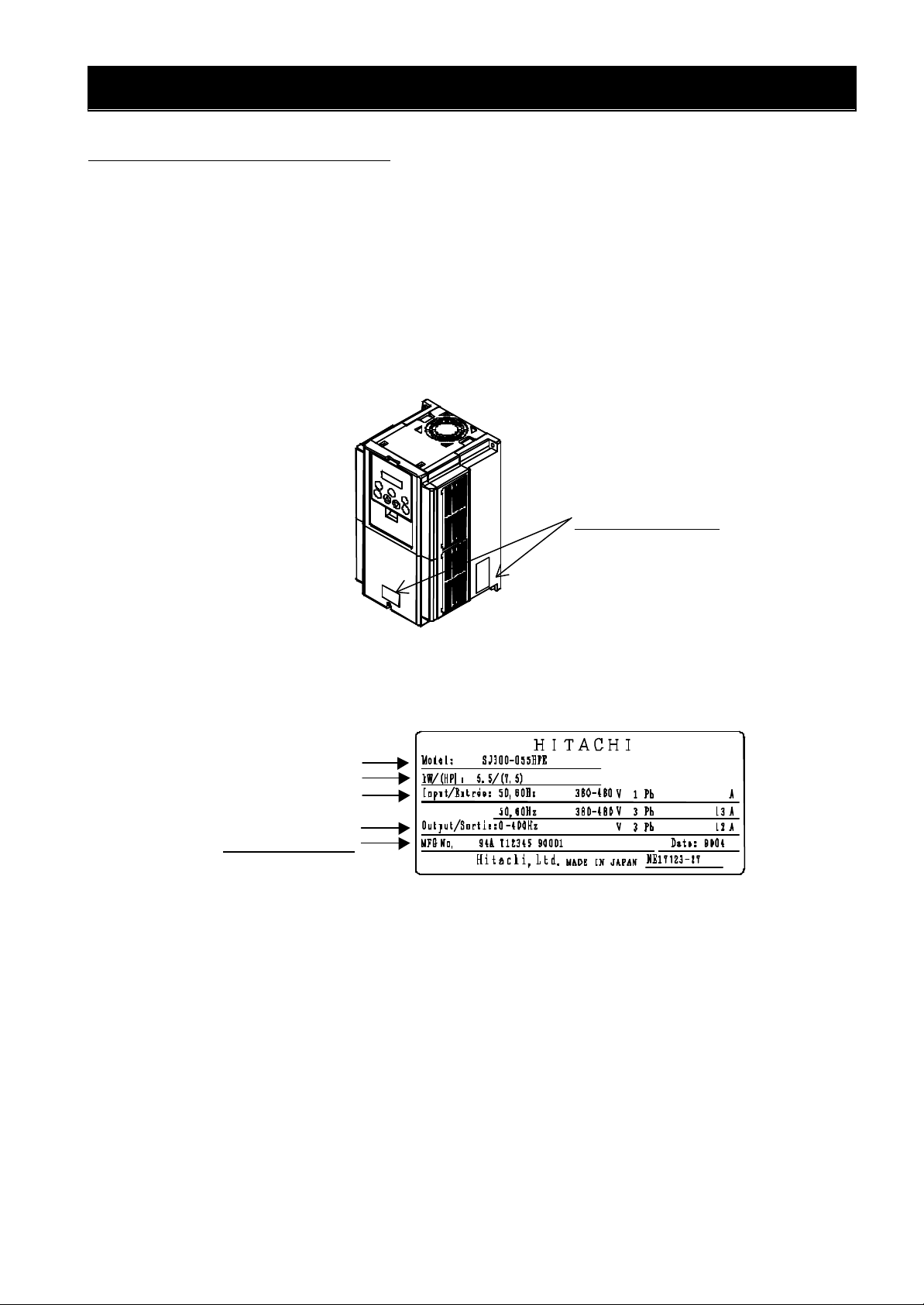

2.1 Mounting method of option board

Figure 2-1 describes how to mount the option board to the option port 1 or 2.

There are four holes on the option board, match the two of them with the screw holes on the option port 1 or 2.

and mount the other two holes with the guide posts which are located on the option port 1 and 2. To avoid

connection failure, secure the option board with screws after connection.

Option board

Guide posts for mounting the

option board.

Option port 1

Screw holes for secure option board.

(M3 Screws)

Figure 2-1 Installation of option board

Option port 2

4

Page 9

CHAPTER 3 WIRING, CONNECTING

Wiring of DeviceNet

No.

CAN_H

3.1 Connection for DeviceNet connector

SJ-DN has a Pluggable open connector (Male contacts), and a Network connector (Female contacts)

attached. The inverter and attach connector have a seal which is color coordinated to correspond to the

DeviceNet cable. Ensure the cable and contact are wired in the same color cable.

Cable side connector (attached connector)

Maker

Phoenix contact co, Ltd. MSTB 2.5/5ST-5.08 AU

Type

Dimension

15

18.2

Communication connector

Figure 3-1 Connector specification

Blue

Black

8.3

1 V- - (Minus) side of power supply Black

2 CAN_L Communication data (Low) Blue

3 Shield Shield Bare

4

5 V+ + (Plus) side of power supply Red

2.54

Signal

mark

5.0

20.32

25.4

Type of signal

Communication data (High) White

White

Red

Color label

Dimension in mm

Cable

color

3.2 Communication cable for DeviceNet

Use the connector which conforms to DeviceNet specification or five conductor cable and also make sure

that cable, connector and Network distance conform to DeviceNet specification.

Baud rate(kbps)

Maximum Trunk line length(m)

(Or Maximum system length(m)) Maximum length(m) Maximum total length(m)

Drop line

125 500 156

250 250 78

6

500 100

5

39

Page 10

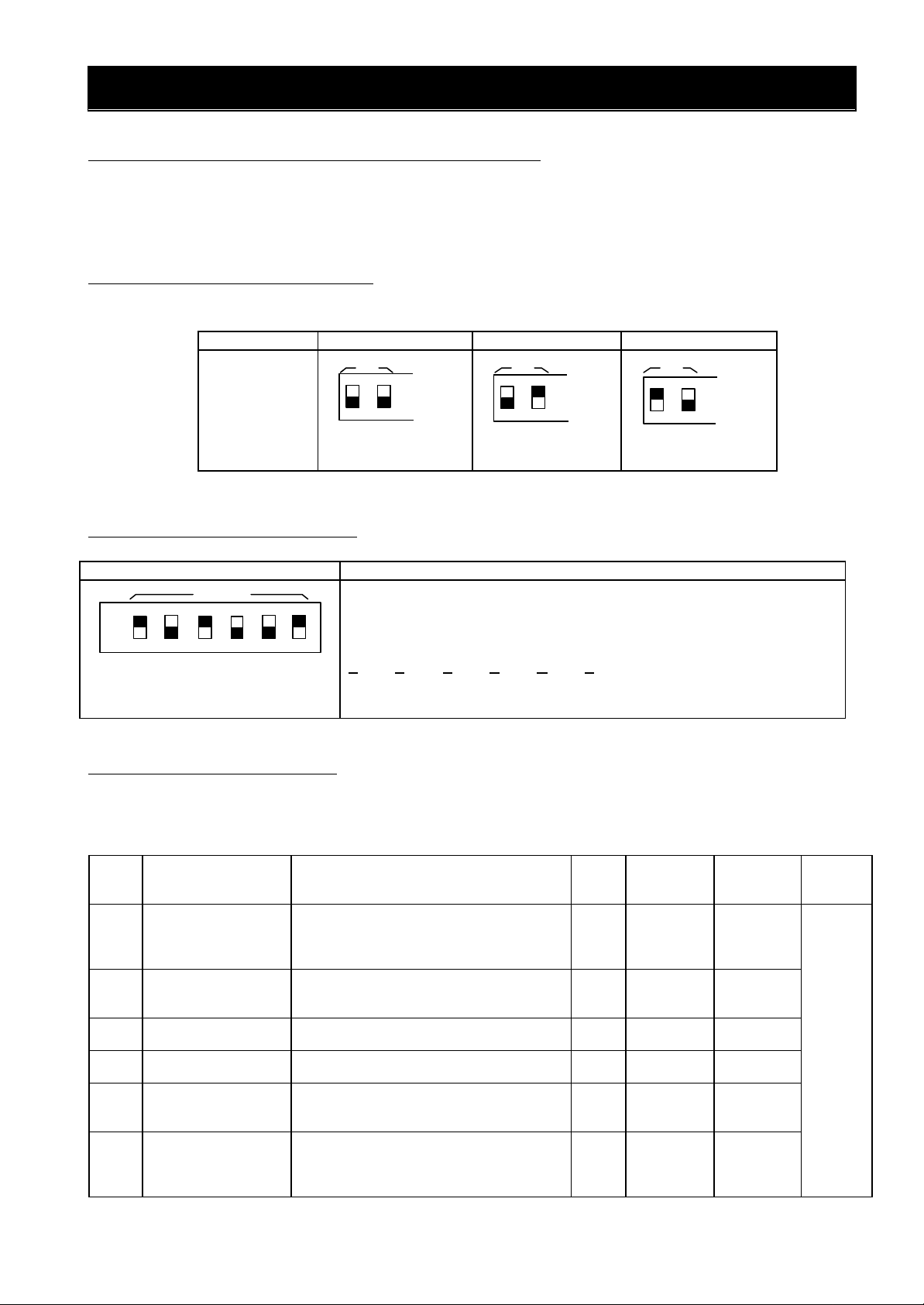

CHAPTER 3 WIRING, CONNECTING

HITACHI

Terminating

Terminating

Power

Drop

HITACHI

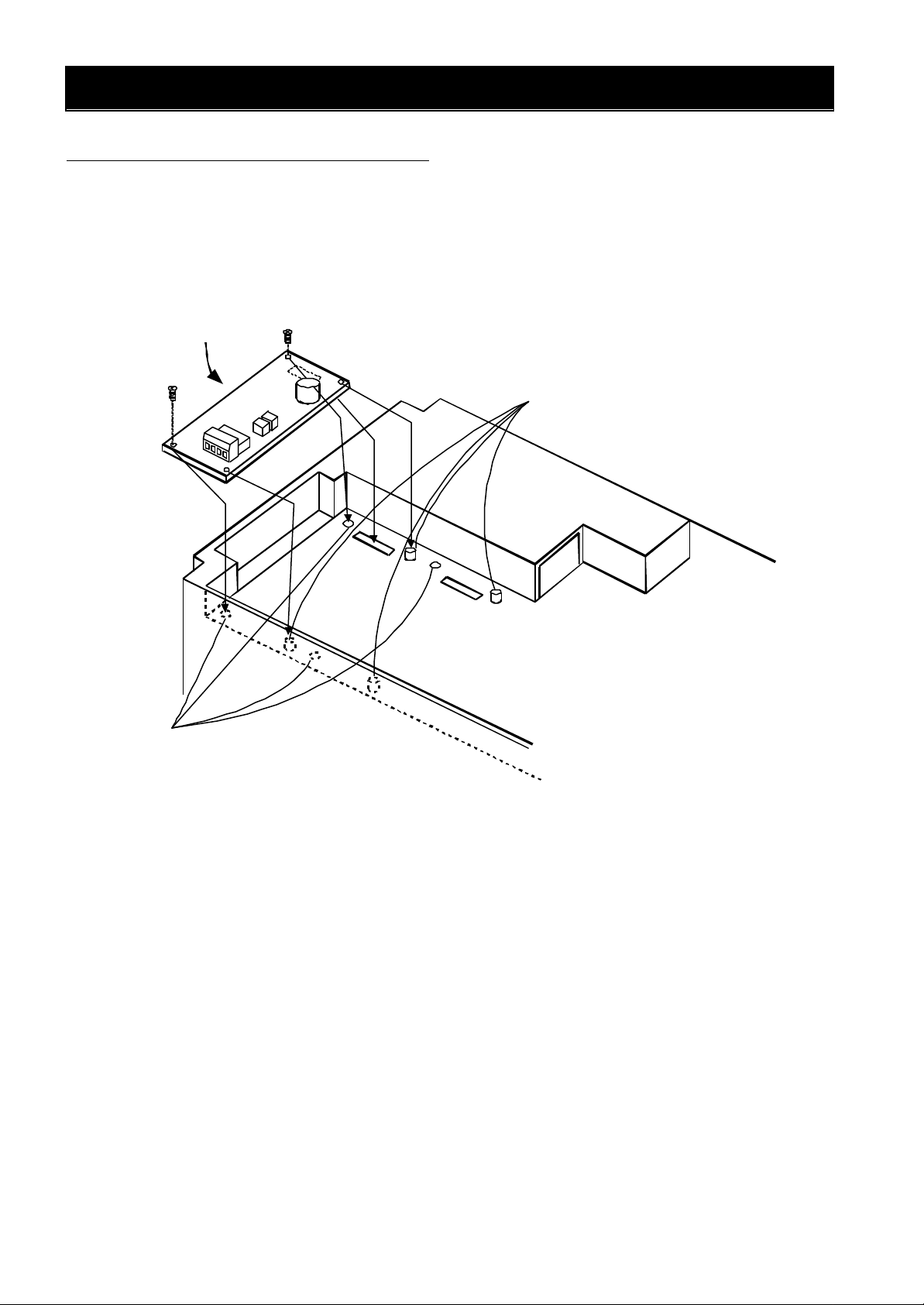

3.3 Wiring note

1.Installing / removing the cable or connector must be done after checking the power supply off.

2.Wiring should not have bare cables exposed between connector contacts.

3.Network cables should be fixed without tension. Cables fixed under tension have potential of causing a

communication fault by to be removed a connector.

4.Provide a communication power source (DC24V).

5.A terminating resistor is not built-in the unit. Please provide it.

6.Ensure external emergency stop measures are taken to stop the inverter, in the event of a network fault.

(a) Remove the Power supply of the Inverter when the network master detects a communication fault.

(b) When the master detects a communication fault, turn on the intelligent input terminal which would be

allocated (FRS), (RS) and/or (EXT) function.

(c) Setting command P045 to except “02”.

In this setting, the inverter is tripped, deceleration or free run stop when it detects a communication

fault itself. (Factory initialization of command P045 is trip after deceleration stop (code: 01).)

See “4.2 Setting of the Inverter” and “4.3 Explanation of additional parameters” about explanation of

P045 (Inverter action when communication error).

7.Basic components for construction of DeviceNet application are shown bellow.

Refer to the master ’s description manuals when DeviceNet Network system comes into operation.

DeviceNet Master UNIT

resistor(121Ω)

(PLC)

Trunk line

SJ300/L300P

Configurater (PC)

line

Multi port Tap

SJ300/L300P

Multiple Node branching drop line.

DC24V

Supply

Other slave units

Trunk line

resistor

(121Ω)

Figure 3-2 Example of components for construction of DeviceNet application

6

Page 11

CHAPTER 4 SETTING

Inverter action When

Polled I/O OUTPUT

except 0:setting and monitoring by [min-1]

↓

DR1

DR

↑

DR1

DR

↓

DR1

DRO

DR

0

MAC ID

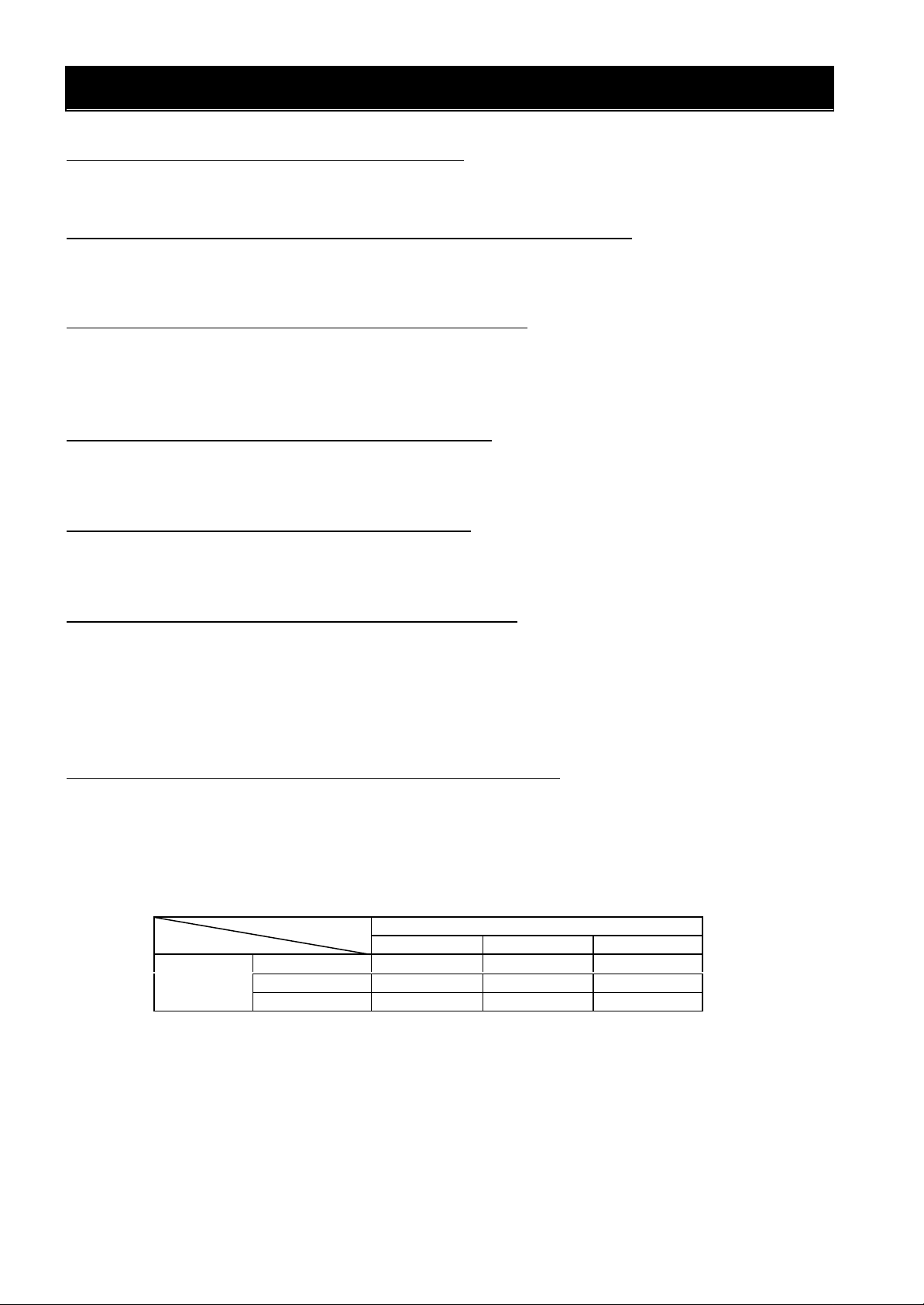

4.1 Setting methods of Baud rate and MAC ID

Follow the procedure below to set Baud rate in DeviceNet and MAC ID, reset the power supply after

changing the setting (setting will be reflected after resetting power supply.). Initial Baud rate: 125kbps, Initial

MAC ID: 0.

4.1.1 Setting method of Baud rate

The table below is the setting method of Baud rate (Front view of the option board.).

(↑,↓ indicate direction for switch of Dip switch )

Baud rate 125kbps 250kbps 500kbps

Dip switch

Setting

↓

DRO

ON

↓

OFF

DRO

ON

OFF

ON

↑

OFF

(Note) Do not switch on DR1 and DR0 at the same time.

4.1.2 Setting method of MAC ID

The table below is the setting method of MAC ID (Front view of the option board).

MAC ID Dip switch setting

Figure left describes the direction of Dip switches. See below.

1

NA32 NA16 NA8 NA4 NA2 NA1

Bottom: 0 Upper: 1

Bit increases from right to left switches.

Therefore, figure left becomes formula below.

1・2 +0・2 +1・2 +0・2 +0・2 +1・2 =29(Hex)=41(dec)

NA32 NA16 NA8 NA4 NA2 NA1

4

5

3 2

1

0

4.2 Setting of the Inverter

Following table describes setting items which relate SJ300 / L300P series Inverters with SJ-DN.

To set appropriate settings refer to inverter instruction manual “chapter 3 Operation”, “chapter 4 Explanation

of function” and this manual.

Code Function Range of data

P044

P045

P046

P047

P048

P049

Timer setting of

communication

timeout Whilst

running

communication

error.

Instance number

Polled I/O INPUT

Instance number

Inverter action when

Idle mode detected.

Motor poles setting

for revolutions per

minute

0.00 to 99.99(sec)

setting resolution 10nsec

Case of set to 0.00, this func. Is disable.

00(trip)/01(trip after deceleration stop)

/02(ignore)/03(free run)

/04(deceleration stop)

20,21,100 21 impossible impossible

70,71,101 71

00(trip)/01(trip after deceleration stop)

/02(ignore)/03(free run)

/04(deceleration stop)

0 to 38

Only even number is possible to set.

set to 0:setting and monitoring by [Hz ]

Initial

data

1.00 impossible impossible

Setting on

run

01 impossible impossible

impossible impossible

01 impossible impossible

0 impossible impossible

Change

mode on

run

Setting

Set data

when it

is need.

7

Page 12

CHAPTER 4 SETTING

4.3 Explanation of additional parameters

Following information provide explanation of additional parameters which are necessary to use SJ-DN.

4.3.1 P044 (Timer setting of communication timeout whilst running)

Set the allowable time that is an interval of polled I/O from DeviceNet master when the inverter is running.

When the timeout occurs, the inverter ’s behavior is as set in command P045.

4.3.2 P045 (Inverter action when communication error)

This command decides what action occurs when a communication fault is detected on the network or P044

timeout occurs at the inverter while controlled from DeviceNet.

When set to 0.00, this function is disable.

4.3.3 P046 (Polled I/O OUTPUT Instance number)

This command is instance number of assembly object Polled I/O output. Set the parameter to comply with

table below. (Combination table for P046, P047).

4.3.4 P047 (Polled I/O INPUT Instance number)

This command is instance number of assembly object Polled I/O input. Set the parameter to comply with

table below. (Combination table for P046, P047).

4.3.5 P048 (Inverter action when Idle mode detected)

This command decides what action occurs when on Idle mode is detected on the network. Inverter can start

to operate after behavior below.

At the time of set to 00, 01:After Idle mode released and fault reset, inputs stop command and run command.

At the time of set to 02 :After Idle mode released.

At the time of set to 03, 04:After Idle mode released, inputs stop command and run command.

4.3.6 P049 (Motor poles setting for revolutions per minute)

Set the Motor poles for AC Drive device profile.

0 to 38 (even number value only)

Set to 0 when frequency setting (Hz).

Set to 2 to 38 when revolution speed setting (min-1).

(Combination table for P046 and P047)

P047

70 71 101

20 ○ − −

21 − ○ −P046

100 − − ○

○:combine.

−:Do not combine.

(Note) Do not combine P046 with P047 except for combination table above, otherwise data may not be set

correctly or may not be displayed correctly.

8

Page 13

CHAPTER 5 OPERATION

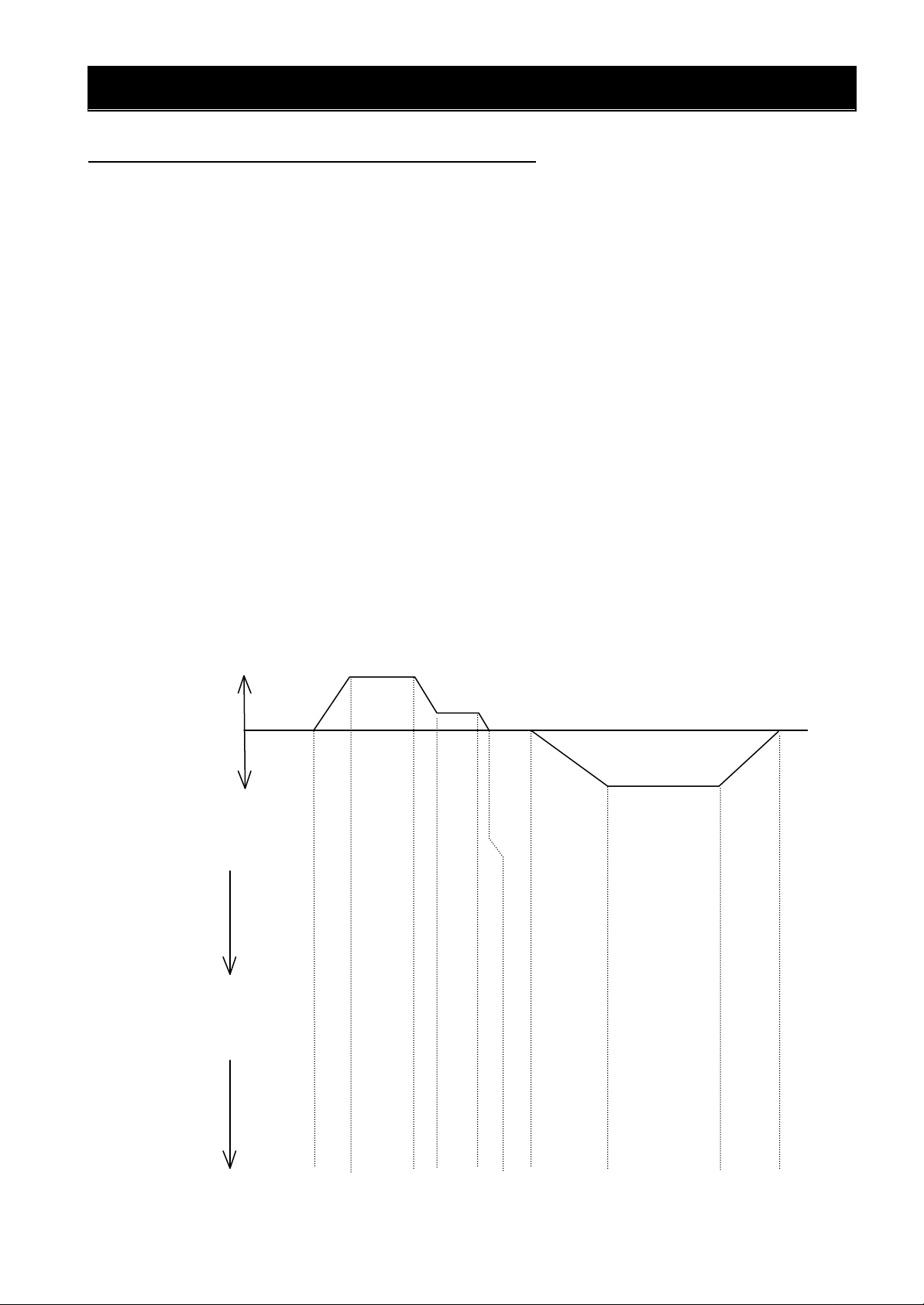

OUT

Reverse

Forward

5.1 Operate with Frequency command〔Hz〕

Following information indicate the explanation of the inverter control data at P046: 100 and P047: 101.

See Chapter 6 about explanation of Polled I/O message.

Explanation on each data frame

[Output data frame]

(1) Stop command. Set frequency: 50Hz (1388hex), Acceleration: 10sec.(0064hex) and Deceleration: 10sec.

(0064hex). Both Frequency source and Run command source set from DeviceNet.

(2) Forward running command.

(3) Change frequency setting: 10Hz(03E8hex).

(4) Stop command

(5) Reverse running command. Set Frequency: 50Hz(1388hex), Acceleration: 20sec.(00C8hex) and

Deceleration: 20sec.(00C8hex).

(6) Stop command

[Input data frame]

(7) Stop condition

(8) While the inverter is in the forward run condition and accelerating, “XX” represents frequency and current.

(9) Constant speed condition. Frequency arrives at 50Hz.

(10) Deceleration condition.

(11) Constant speed condition. Frequency arrives at 10Hz.

(12) Deceleration condition.

(13) Stop condition.

(14) The inverter is in the reverse run condition and accelerating.

(15) Constant speed condition. Frequency arrives at 50Hz.

(16) Deceleration condition.

(17) Stop condition.

ACC,DEC=10sec.

50Hz

running

running

0Byte

7Byte

IN

0Byte

7Byte

60

00

88

13

64

00

64

00

00

00

00

00

00

00

00

C0

10Hz

61

00

88

13

64

00

64

00

(8)(7)

11

01

01

01

88

xx

13

xx

xx

xx

xx

xx

00

00

C0

C0

61

00

E8

03

64

00

64

00

01

01

xx

xx

xx

xx

00

C0

11

01

E8

03

xx

xx

00

C0

60

00

E8

03

64

00

64

00

01

01

xx

xx

xx

xx

00

C0

ACC,DEC=20sec.

62

00

88

13

C8

00

C8

00

02

00

01

00

xx

00

xx

00

xx

00

xx

00

00

00

C0

C0

12

01

88

13

xx

xx

00

C0

50Hz

(6)(5)(4)(3)(2)(1)

60

00

88

13

C8

00

C8

00

02

01

xx

xx

xx

xx

00

C0

(17)(16)(15)(14)(13)(12)(11)(10)(9)

00

00

00

00

00

00

00

C0

9

Page 14

CHAPTER 5 OPERATION

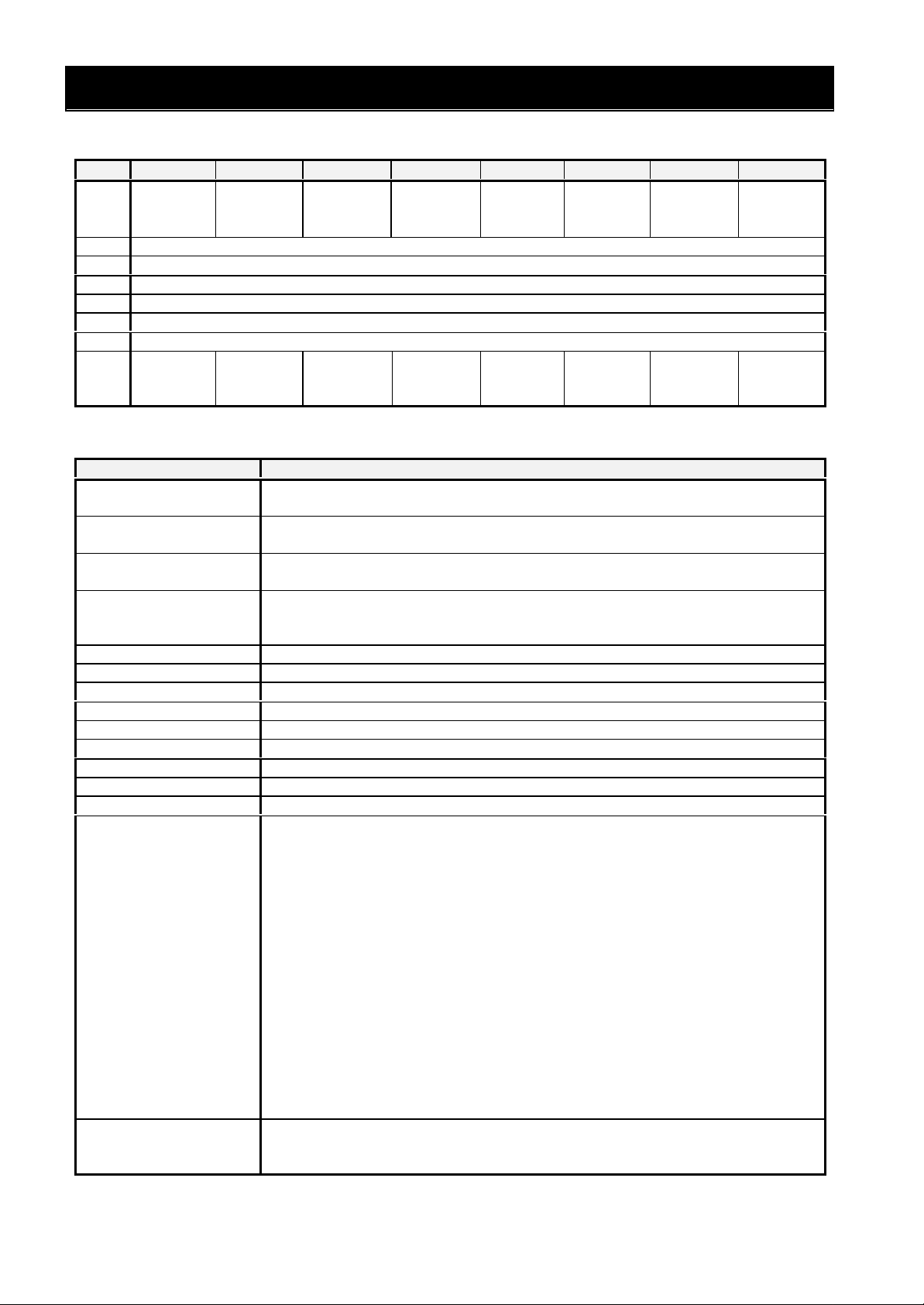

min

Reverse

Forward

5.2 Operate with Rotational speed command〔min-1〕

Following information indicate the example of the inverter control data at P046: 21, P047: 71 and P049: 4.

See Chapter 6 about explanation of Polled I/O message.

Explanation on each data frame.

[Output frame]

(1) Stop command. Set rotational speed:1800min-1(0708hex). Acceleration / Deceleration command are

dependant on the inverter setting. Both rotational speed and run command set from DeviceNet.

(2) Forward running command.

(3) Change rotational speed command: 600min-1 (0258hex).

(4) Stop command.

(5) Reverse running command. Set rotational speed:1800min-1 (0708hex).

(6) Stop command.

[Input frame]

(7) Stop condition

(8) While the inverter is forward run condition and accelerating, “XX” represents rotational speed.

(9) Constant speed condition. Revolutions arrive at 1800min-1.

(10) Deceleration condition.

(11) Constant speed run condition. Revolutions arrive at 600min-1.

(12) Deceleration condition.

(13) Stop condition.

(14) The inverter is in the reverse run condition and accelerating.

(15) Constant speed condition. Revolutions arrive at 1800min-1.

(16) Deceleration condition.

(17) Stop condition.

1800

-1

running

running

0Byte

3Byte

0Byte

3Byte

OUT

IN

60

00

08

07

70

03

00

00

61

00

08

07

(8)(7) (17)(16)(15)(14)(13)(12)(11)(10)(9)

F4

74

04

04

08

xx

07

xx

61

00

58

02

74

05

xx

xx

600min

F4

04

58

02

60

00

58

02

74

05

xx

xx

10

-1

-1

(6)(5)(4)(3)(2)(1)

60

00

08

07

78

05

xx

xx

70

03

00

00

70

03

00

00

62

00

08

07

78

04

xx

xx

1800min

F8

04

08

07

Page 15

CHAPTER 6 DEVICENET COMMUNICATION FUNCTION

6.1 Feature of DeviceNet communication function

SJ-DN conforms to open field Network DeviceNet and it activates as slave function (Group 2 only server).

There are two ways to communicate with the master, one is polled I/O message communication and the other

one is explicit message communication. Also SJ-DN corresponds to the AC Drive profile.

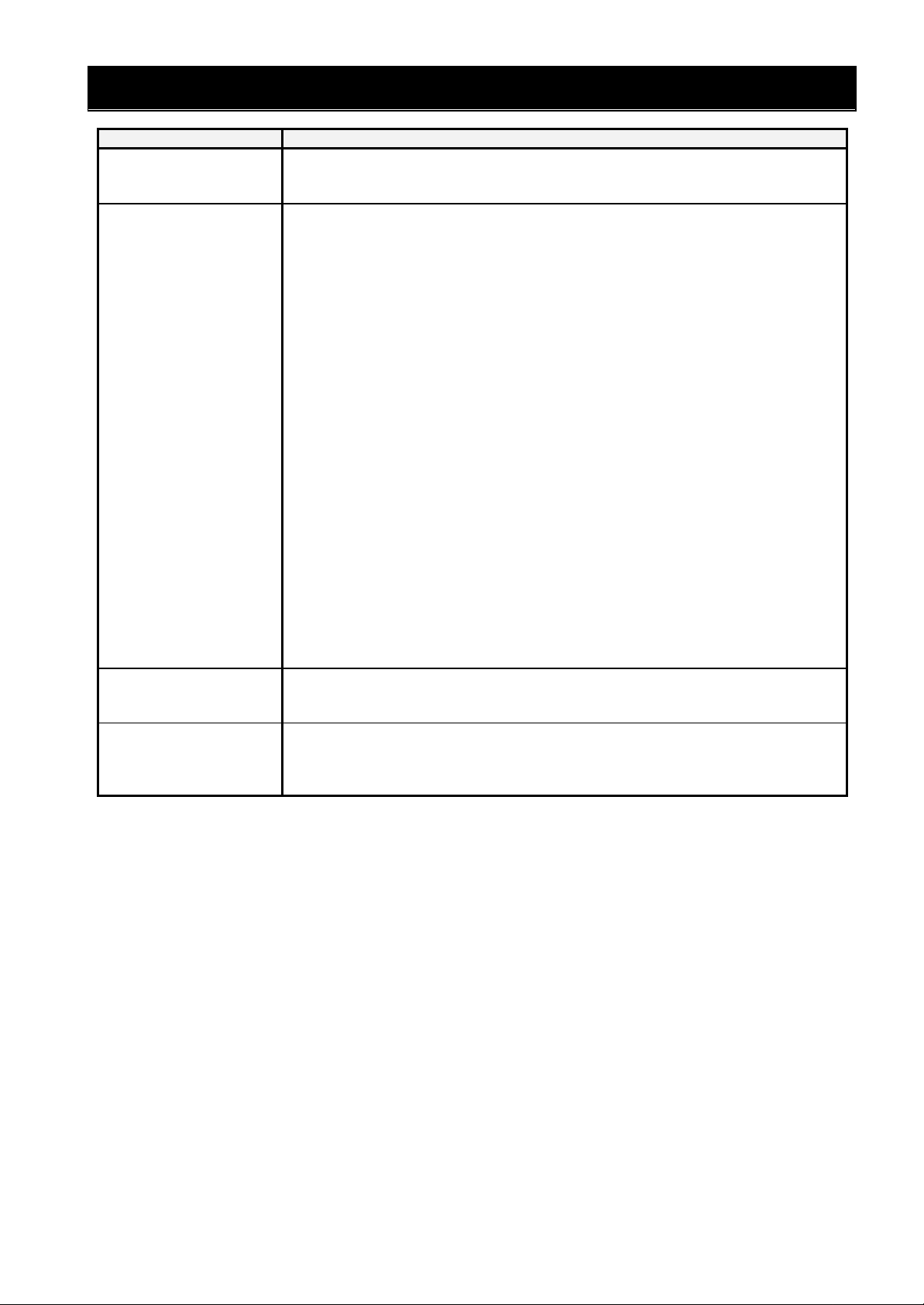

6.2 Basic DeviceNet specification

The table below describes basic DeviceNet specification of this product.

Items Specification

Protocol

Supportcommunicationspeed 125kbps(500m)/250kbps(250m)/500kbps(100m)

Maximumnumberofconnection

Node

Support connection

Datalength

Type of device

Device profile AC Drive

DeviceNet Volume I -Release2.0

DeviceNet Volume II-Release2.0

64 Nodes (Maximum number of Node for slaves are 63 Nodes)

Explicit Message

Polled Input/Output Message

Explicit Message (Each of Data has different length which are

dependant on data.)

Polled Input/Output Message 4Bytes / 8 Bytes

Group2 Only Server

(Predefined Master/Slave Connection Set)

List of object for mounting is shown below.

Name of objects Class ID Instance ID Contents

Identity 01

Message Router 02

DeviceNet 03

Connection 05

Motor Data 40

Control Supervisor 41

AC/DC Drive 42

Inverter parameter

100〜109 1,2,3

1

1

1

20,21,100

70,71,101

1,2

1

1

1

Information for distinguishing Device type, Serial

number and Vender ID etc.

This Router gives Explicit message to appropriate

object.

It controls Physical connection for DeviceNet

It controls Pol led I/O Output Message.Assembly 04

It controls Pol led I/O Input Message.

It controls Connection.

It controls the motor connected to the inverter.

It controls control information of the inverter.

It controls operational information of the inverter.

It controls inverter parameter.

See Appendix about details of Inverter parameter.

11

Page 16

CHAPTER6 DEVICENET COMMUNICATION FUNCTION

6.3 Details of Polled I/O communication

6.3.1 Basic I/O instance

This I/O instance is standard I/O instance, which is defined by AC drive profile in DeviceNet.

Master to SJ-DN: Instance20 (P046: 20)

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 - - - - 1 -

2 Speed Reference (Low Byte)

3 Speed Reference (High Byte)

Data Contents

Run Fwd The inverter is running forward. 0:Stop 1:Run

Fault Reset

Speed Reference

When the bit is set to “1”, the trip states can be cancelled

0:- 1:Fault reset

It indicates speed command of the inverter.

[P049:Except for 0]

Rotational speed setting: Speed Reference(min-1) / 2 SS: Speed scale

Range of setting:0〜24000(min-1) (Resolution: 1min-1) Magnification: 1 time

e.g.) When the order of speed setting is 1800 min-1, (Speed scale:0)

Speed Reference=1800/2 =1800=0708(Hex)

[P049:0]

Operational frequency setting (Resolution: 0.01Hz ).

Range of setting:0.00 to 400.00(Hz) Magnification: 100 time

O

Fault

Reset

- Run Fwd

SS

SJ-DN to Master: Instance70 (P047 : 70)

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 - - - - 1 -

2 Speed Actual (Low Byte)

3 Speed Actual (High Byte)

Data Contents

Faulted

Running 1

Speed Actual

It indicates the inverter is in a fault detecting state.

0:Normal 1:During detecting fault state

It indicates inverter’s running state.

0:Stop/During Reverse run 1:During Forward Run

It indicates inverter speed.

[P049:Except for 0]

Rotational speed monitor: Speed Actual(min-1) / 2 SS: Speed scale

Range of monitor:0〜24000(min-1) (Resolution: 1min-1) Magnification: 1 time

e.g.) When Speed Actual is 03E8(Hex) (Speed scale:0)

Speed Actual=03E8(Hex)/2 =1000/2 =1000(min-1)

[P049:0]

Current frequency display (Resolution: 0.01Hz ).

Range of monitor:0.00 to 400.00(Hz) Magnification: 100 time

O

Running

1

O

- Faulted

SS

12

Page 17

CHAPTER 6 DEVICENET COMMUNICATION FUNCTION

6.3.2 Expansive I/O Instance

This I/O instance is standard I/O instance, which is defined by AC drive profile in DeviceNet.

Master to SJ-DN: Instance21 (P046 : 21)

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 - NetRef NetCtrl - 1 -

2 Speed Reference (Low Byte)

3 Speed Reference (High Byte)

Data Contents

Run Fwd The inverter is running forward. 0:Stop 1:Run forward

Run Rev The inverter is running reverse. 0:Stop 1:Run reverse

Fault Reset

NetCtrl

NetRef

Speed Reference

When the Bit is set to “1”, the trip states can be cancelled.

0:- 1:Fault reset

It indicates method of operation command.

0:Method of operation command, which is selected at operation command

selection(A002).

1:Method of Operation command from DeviceNet is valid.

It indicates method of frequency command.

0:Method of frequency command, which is selected at frequency command

selection(A001).

1:Method of frequency command from DeviceNet is valid.

It indicates speed command of the inverter.

[P049:Except for 0]

Rotational speed setting: Speed Reference(min-1) / 2 SS: Speed scale

Range of setting:0〜24000(min-1) (Resolution: 1 min-1) Magnification: 1 time

e.g.) When the order of speed setting is 1800 min-1, (Speed scale:0)

Speed Reference=1800/2 =1800=0708(Hex)

[P049:0]

Operational frequency setting (Resolution: 0.01Hz).

Range of setting:0.00 to 400.00(Hz) Magnification: 100 time

O

Fault

Reset

Run Rev Run Fwd

SS

(Note) When set both Run Fwd and Run Rev to 1, the inverter executes the command, which is inputted first.

13

Page 18

CHAPTER6 DEVICENET COMMUNICATION FUNCTION

SJ-DN to Master: Instance71 (P047 : 71)

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0

1 Drive Status

2 Speed Actual (Low Byte)

3 Speed Actual (High Byte)

Faulted

Warning

Running1(Fwd)

Running2(Rev)

Ready

Ctrl From Net

Ref From Net

At Reference

Drive Status

Speed Actual

At

Reference

Data Contents

Ref From

Net

It indicates the inverter is in a fault detecting state.

0:Normal 1:During detecting fault state

It indicates the inverter is in a warning detecting state.

0:Normal

1:During detecting warning (When there is contradiction on the inverter setting.).

It indicates inverter’s running condition.

0:Stop / During reverse run 1:During forward run

It indicates inverter’s running condition.

0:Stop / During forward run 1:During reverse run

It indicates the inverter ready for drive.

0:Except Drive status: 3,4,5.

1:Complete ready to drive (Drive Status: 3,4,5).

It indicates selection state for inputting the inverter operational command

0:Operation command selection(A002) is valid to set.

1:Operation command from DeviceNet is valid.

It indicates selection state for inputting the inverter frequency command.

0:Frequency command selection(A001) is valid to set.

1:Frequency command from DeviceNet is valid.

It indicates arrival frequency detecting state for the inverter.

0:During stop / During accelerate or decelerate

1:Arrival frequency

It indicates inverter status.

1:Startup (Only R0-T0 power supply is ON)

2:Not Ready (Just after turn on power supply)

3:Ready (Able to activate the inverter )

4:Enabled (Inverter is running by run command)

5:Stopping (Inverter is decelerating by stop command)

6:Fault Stop (Inverter is decelerating because trip is detected)

7:Faulted (Trip condition)

It shows inverter speed.

[P49:Except for 0]

Rotational speed monitor: Speed Actual(min-1) / 2 SS: Speed scale

Range of monitor:0〜24000(min-1) (Resolution: 1min-1) Magnification: 1 time

e.g.) When Speed Actual is 03E8(Hex) (Speed scale:0)

Speed Actual=03E8(Hex)/2 =1000/2 =1000(min-1)

[P049:0]

Current frequency display (Resolution: 0.01Hz ).

Range of monitor:0.00 to 400.00(Hz) Magnification: 100 time

Ctrl From

Net

Ready

Running2

(Rev)

O O

Running1

(Fwd)

SS

Warning Faulted

14

Page 19

CHAPTER 6 DEVICENET COMMUNICATION FUNCTION

6.3.3 Hitachi inverter I/O Instance

This I/O instance is able to control the operation control, which is necessary to Hitachi inverters.

Master to SJ-DN: Instance100 (P046: 100

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 − NetRef NetCtrl −

1 −

2 Speed Reference (Low Byte)

3 Speed Reference (High Byte)

4 Acceleration time (Low Byte)

5 Acceleration time (High Byte)

6 Deceleration time (Low Byte)

7 Deceleration time (High Byte)

Data Contents

Run Fwd The inverter is running forward run. 0:Stop 1:Run forward

Run Rev The inverter is running reverse run. 0:Stop 1:Run reverse

When the Bit is set to “1”, the trip states can be cancelled.

Fault Reset

Free run stop

NetCtrl

NetRef

Speed Reference

Acceleration time /

Deceleration time

(Note) When set both Run Fwd and Run Rev to 1, the inverter executes as stop command.

0:- 1:Fault reset

Case of the inverter is not in trip condition, when the Bit is set to “1”, the inverter

will stop the motor.

When the Bit is set to “1”, the inverter stops output and the motor enters the free

run mode.

0:- 1:Free run stop

It indicates setting for method of operational command.

0:Method of operation command, which is selected at operation command

selection (A002).

1:Method of Operation command from DeviceNet is valid.

It indicates setting for method of frequency command.

0:Method of Frequency command, which is selected at frequency command

selection(A001) and setting at Acc / Dec time(F002, F003).

1:Method of frequency and Acc / Dec time command from DeviceNet is valid.

It indicates setting for output frequency of the inverter.

Range of setting:0.00 to 400.00(Hz), Resolution: 0.01(Hz), Magnification:100

times, Transmit data:0 to 9C4O(Hex)

It indicates setting for Acc/Dec time of the inverter.

Range of setting:0.1 to 3600.0(sec), Resolution:0.1(sec), Magnification:10 times

Transmit data:1 to 8CA0(Hex)

If Acceleration / Deceleration time has not been set by DeviceNet, the inverter will

use the settings in command F002 / F003.

)

Free run

stop

Fault

Reset

Run Rev Run Fwd

15

Page 20

CHAPTER6 DEVICENET COMMUNICATION FUNCTION

SJ-DN to Master: Instance101 (P047: 101)

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Input

Terminal

0

3 State

1 Drive Status

2 Speed Actual (Low Byte)

3 Speed Actual (High Byte)

4 Output current (Low Byte)

5 Output current (High Byte)

6 Trip cause

Ref From

7

Running1(Fwd)

Running2(Rev)

Faulted

At Reference

Input Terminal 1 State 0: (opened) 1: Input terminal 1 and common are closed.

Input Terminal 2 State 0: (opened) 1: Input terminal 2 and common are closed.

Input Terminal 3 State 0: (opened) 1: Input terminal 3 and common are closed.

Input Terminal 4 State 0: (opened) 1: Input terminal 4 and common are closed.

Input Terminal 5 State 0: (opened) 1: Input terminal 5 and common are closed.

Input Terminal 6 State 0: (opened) 1: Input terminal 6 and common are closed.

Input Terminal 7 State 0: (opened) 1: Input terminal 7 and common are closed.

Input Terminal 8 State 0: (opened) 1: Input terminal 8 and common are closed.

Forward Terminal State 0: (opened) 1: Forward terminal (FW) and common are closed.

Drive Status

Speed Actual

Net

Data Contents

Input

Terminal

2 State

Ctrl From

Net

It indicates inverter’s running condition.

0:Stop / During reverse run 1:During forward run

It indicates inverter’s running condition.

0:Stop / During forward run 1:During reverse run

It indicates the inverter is in a fault detecting state.

0:Normal 1:During detecting fault state

It indicates arrival frequency detecting state for the inverter.

0:During stop / During accelerate or decelerate

1:Arrival frequency

It indicates the inverter condition.

00:The inverter is stopping.

01:The inverter is running.

02:The inverter is in jogging mode.

03:The inverter’s output is stopped and the motor is free running (coasting).

04:The inverter is executing DC braking.

This includes the DC braking wait time.

05:The inverter is trying to restart with frequency matching.

Command b001 is set to ”3”.

06:Stop output at instantaneous power failure.

07:The inverter is trying to restart with frequency matching.

Command b001 is set to “2”.

08:The inverter is waiting before it runs on motor again to restart with

frequency matching (by setting b001, b088, C103).

This waiting time is as setting value command b003.

10:The inverter is in a trip condition.

11:The inverter is in under-voltage condition.

It indicates the inverter’s output frequency monitor.

Monitor range:0.00 to 400.00(Hz), Resolution: 0.01(Hz), Magnification:100

times, Receiving data:0 to 9C4O(Hex)

Input

Terminal

1 State

Forward

Terminal

state

At

Reference

Input

Terminal

8 State

− Faulted

Input

Terminal

7 State

Terminal

Input

6 State

Running2

(Rev)

Input

Terminal

5 State

Running1

(Fwd)

Input

Terminal

4 State

16

Page 21

Data Contents

Output current

Trip cause

Ctrl From Net

Ref From Net

CHAPTER 6 DEVICENET COMMUNICATION FUNCTION

It indicates the inverter’s output current monitor.

Monitor range:0 to 6553.5A, Magnification:10 times, Receiving data:0 to

FFFF(Hex)

Following codes are latest trip history.

00:No trip

01:Over current protection (at constant speed)

02:Over current protection (at deceleration)

03:Over current protection (at acceleration)

04:Over current protection (at the other)

05:Over load protection

06:Dynamic break resistor protection

07:Over voltage protection

08:EEPROM error

09:Under voltage

10:CT error

11:CPU error

12:External trip

13:USP error

14:Ground fault protection

15:Input over voltage protection

16:Instantaneous power failure protection

21:Abnormal temperature

23:Gate array error

24:Phase-failure

30:IGBT error

35:Thermistor error

36:Abnormal break

60 to 69:Option error 1

70 to 79:Option error 2

It indicates selection state for inputting the inverter operational command

0:Operation command selection(A002) is valid to set.

1:Operation command from DeviceNet is valid.

It indicates selection state for inputting the inverter frequency command.

0:Frequency command selection(A001), Aceeleration time setting (F002) and

Deceration time setting (F003) are valid to set.

1:Frequency command from DeviceNet is valid.

17

Page 22

CHAPTER6 DEVICENET COMMUNICATION FUNCTION

Communication

ID

Type of data

ID

Type of data

6.4 Detail of DeviceNet profile

6.4.1 Overall Specification

General

Device data

Physical Network power consumption 50mA

Conformance Type of connector Open connector

Data Isolated physical layer Yes

Data

6.4.2 Identity Object (ID=1 Hex)

Instance0 Not supported ― ― ― ―

Instance1 Vender ID 1 Get UINT 74 AC Drive

Support service (Common service)

Get_Attribute_Single H’0E

Reset H’05 00:Reset

NOP H’17

DeviceNet specification Volume I -Release2.0

Vender name Hitachi, Ltd. Vender ID=74

DeviceNet profile name Slave AC Drive Profile No=2

Product Catalog NO.

Product revision 1.1

Operation power source DC11V to 24V

Support LED Module status, Network status

Setting of MAC ID Set at Dip SW.

Default MAC ID 0

Communication Baud rate setting Set at Dip SW.

Communication Baud rate supported 125kbps/250kbps/500kbps

Device Network behavior Group 2 only server

UCMM support No

Support connection Explicit Message

Fragmented Explicit messaging Supported Yes

Attribute ID Access rule Type of data Initial data

Device Type 2 Get UINT 2

Product Code 3 Get UINT 0703(Hex)

Revision Major 4 Get USINT 1

Minor USINT 1

Status 5 Get WORD 0

Serial Number 6 Get UDINT Factory initial

Product Name 7 Get STRING “SJ-DN”

Service Service code Note

01:User initialize with History clear

Volume II-Release2.0

− −

Polled Input/Output Message

6.4.3 DeviceNet Object (ID=3 Hex)

Attribute

Instance0 Revision 1 Get UINT 2

Instance1 MAC ID 1 Get/Set USITT Set at Dip SW.

Baud Rate 2 Get/Set USINT Set at Dip SW.

BOI 3 Get BOOL 0

BusOff Counter 4 Get/Set USINT 0

Allocation Information Choice Byte 5 Get BYTE Masters MAC ID

Supported service

Service name Code Remarks

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

Allocate_M/S_Connection_Set H’4B

Release_M/S_Connection_Set H’4C

Access rule

USINT -

6.4.4 Assembly Object (ID=4 Hex)

Attribute

Instance0 Not supported - - - Instance20 DATA 3 Get/Set 4 Bytes Instance21 DATA 3 Get/Set 4 Bytes Instance70 DATA 3 Get 4 Bytes Instance71 DATA 3 Get 4 Bytes Instance100 DATA 3 Get/Set 8 Bytes Instance101 DATA 3 Get 8 Bytes -

Access rule

18

Initial data

Initial data

Page 23

ID

13

14

15

16

16

Supported service

Service name Code Remarks

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

CHAPTER 6 DEVICENET COMMUNICATION FUNCTION

6.4.5 Connection Object (ID=5 Hex)

Attribute

Instance0 Not supported - - - Instance1 state 1 Get USINT -

instance_type 2 Get USINT 00

transportClass_triger 3 Get BYTE H’83

prod_conn_id 4 Get UINT coms_conn_id 5 Get UINT initial_comm_characteristice 6 Get BYTE H’21

prod_conn_size 7 Get UINT H’24

coms_conn_size 8 Get UINT H’24

expected_packet_rate 9 Get/Set UINT H’09C4

watchdog_timeout_action 12 Get USINT 1

prod_conn_path_length

prod_conn_path

coms_conn_path_length

coms_conn_path

Instance2 state 1 Get USINT -

instance_type 2 Get USINT 01

transportClass_triger 3 Get BYTE H’82

prod_conn_id 4 Get UINT coms_conn_id 5 Get UINT initial_comm_characteristice 6 Get BYTE 01

prod_conn_size 7 Get/Set UINT H’08

coms_conn_size 8 Get UINT H’08

expected_packet_rate 9 Get/Set UINT 0

watchdog_timeout_action 12 Get USINT 0

prod_conn_path_length 13 Get UINT 3

prod_conn_path 14 Get UINT order H’623635

coms_conn_path_length 15 Get UINT 3

coms_conn_path

Access rule Data type Initial data

Get UINT 0

Get UINT order Get UINT 0

Get UINT order -

Get UINT order H’623634

Supported service

Reset H’05

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

Service name Code Remarks

6.4.6 Motor Date Object (ID=28 Hex)

Attribute ID Access rule Data type Initial data

Instance0 Revision 1 Get WORD 0001

Instance1 MotorType 3 Get BYTE 07

Supported service

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

RatedCurrent 6 Get/Set WORD b012 setting

RatedVoltage 7 Get/Set WORD A082 setting

PoleCount 12 Get/Set WORD P049 setting

Service name Code Remarks

19

Page 24

CHAPTER6 DEVICENET COMMUNICATION FUNCTION

10

11

12

13

15

16

17

18

6.4.7 Control Supervisor Object (ID=29 Hex)

Attribute ID Access rule Data type Initial data

Instance0 Revision 1 Get WORD 0001

Instance1 Run1 3 Get/Set BYTE 00

Run2 4 Get/Set BYTE 00

NetCtrl 5 Get/Set BYTE 00

State 6 Get BYTE 01

Running1 7 Get BYTE 00

Running2 8 Get BYTE 00

Ready 9 Get BYTE 00

Faulted

Warning

FaultRst

FaultCode

CtrlFromNet

DNFaultMode

ForceFautl/Trip

ForceStatus

Get BYTE 00

Get BYTE 00

Get/Set BYTE 00

Get WORD 0000

Get BYTE 00

Get BYTE 02

Get/Set BYTE 00

Get BYTE 00

Supported service

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

Service name Code Remarks

6.4.8 AC/DC Drive Object (ID=2A Hex)

Attribute ID Access rule Data type Initial data

Instance0 Revision 1 Get WORD 0001

Instance1 AtReference 3 Get BYTE 00

NetRef 4 Get/Set BYTE 00

NetCtrl 5 Get BYTE 00

DriveMode 6 Get BYTE 01

SpeedActual 7 Get WORD 0001

SpeedRef 8 Get/Set WORD F001 setting

CurrentActual 9 Get WORD 0000

CurrentLimit 10 Get/Set WORD 0000

TorqueActual 11 Get WORD 0000

PowerActual 15 Get WORD 0000

InputVoltage 16 Get WORD 0000

OutputVoltage 17 Get WORD 0000

AccelTime 18 Get/Set WORD F002 setting

DecelTime 19 Get/Set WORD F003 setting

LowSpdLimit 20 Get/Set WORD A062 setting

HightSpdLimit 21 Get/Set WORD A004 setting

SpeedScale 22 Get/Set BYTE 0

CurrentScale 23 Get/Set BYTE 0

TorqueScale 24 Get/Set BYTE 0

PowerScale 26 Get/Set BYTE 0

VoltageScale 27 Get/Set BYTE 0

TimeScale 28 Get/Set BYTE 0

RefFromNet 29 Get BYTE 00

Supported service

Servicxe name Code Remaraks

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

20

Page 25

CHAPTER 7 COUNTERMEASURE FOR ABNORMALITY

29Hex, Instance: 1 and Attribute:

Trip code

7.1 Trip display

When the inverter is in a tripped state, the inverter displays an error code (See table below). The trip history

monitor (d081 to d086) also displays the same error code as the inverter.

Inverter’s running condition of trip detected

7.2 Protection function list

The table below describes an error code for protecting the inverter and the motor.

Error Display in the table below, X is 6 (Error for option slot 1) or 7 (Error for option slot 2).

No. Function Error

Display

1 DeviceNet

EX0 This error is displayed, disconnection occurs when BusOff or

communication error

2 Duplicate MACID EX1 This error indicates that component have the same MADID,

3 External trip EX2 This error is displayed, when Fault / Trip is set to 1 toward

4 Inverter communication

EX9 This error is displayed, when communication timeout occurs

error

With regard to the other errors except table above, refer to Inverter instruction manual chapter 4 Explanation

of function.

Action

timeout is occurred, while the inverter is operating with

DeviceNet. (Trip is caused by P045 and P048 setting)

which exist on the same network.

control supervisor object data: Instance 1, Attribute 17.

between the inverter and the option board.

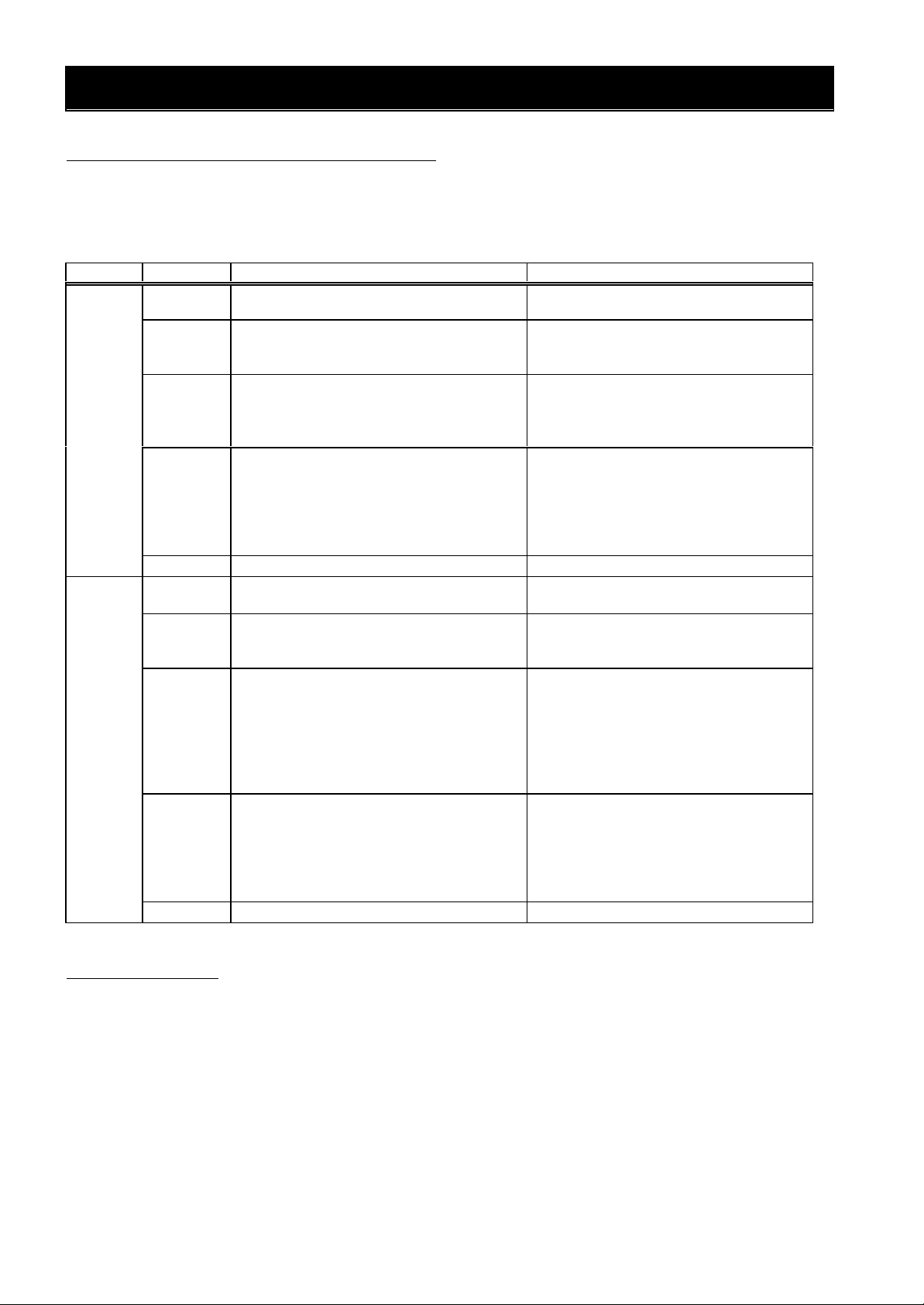

7.3 Countermeasure for a trip state

The table below only corresponds to additional trip codes, with regard to the other countermeasures refer to

Inverter instruction manual chapter 4 Explanation of function.

Trip

code

EX0 DeviceNet

EX1 Duplicate

EX2 External

EX9 Inverter

Name of trip Cause Conformation Countermeasure

Communication

error

MACID

Trip

communication

error

Baud rate is different. Check Baud

rate

Wiring distance does not

match with Baud rate

Defective connector for

signal cable causes

connection fail.

Terminating resistor is

not connected.

Network power supply is

not connected. Network

power supply is out of

regulation.

Exceeding maximum

Node.

Components have the

same MACID, which are

connected on the same

network.

Class : 29Hex

Instance: 1

Attribute: 17

Option board is

removed.

Check the wiring

distance

Check the area of

connection.

Check the

Connection

Check the

Network power

Supply voltage

(DC11 to 24V)

Check the Node. Remove unnecessary components

Check the all MACID

and also check the

component which has

the same MACID

Check as mentioned left. Set Fault/ trip to 0 toward class:

Check as mentioned left Mount the option board again and

Install correct Baud rate and then

reset the power supply.

Adjust the setting to the matching

Baud rate.

Adjust Wiring distance.

Improve the connection and then

reset the power supply.

Connect the terminating

Resistor and then reset the power

supply

Connect Network power supply and

then reset the power supply.

and adjust Node to 64 (Maximum)

or under, then reset the power

supply.

Set MACID and then reset the

power supply.

17.

then secure it with screws.

21

Page 26

CHAPTER 7 COUNTERMEASURE FOR ABNORMALITY

possible to restore. Mostly this state

7.4 LED display and Countermeasure

Following states are indicated by module LED and Network LED.

MOD (Module status) LED: It indicates Inverter condition.

NET (Network status) LED: It indicates Network condition.

LED Color Explanation Countermeasure

MOD Green lamp

is ON

Green lamp

goes ON

and OFF

Red lamp

is ON

Red lamp

goes ON

and OFF.

OFF Power off

NET Green lamp

is ON

Green lamp

goes ON

and OFF

Red lamp

is ON

Red lamp

goes ON

and OFF.

OFF Power off / DeviceNet offline

The inverter is in normal condition

The inverter is in standby condition.

An abnormality occurred which is

impossible to restore.

But except status below.

User initializing with b084 set to 01, 02.

An abnormality occurred which is

occurs, when the inverter is in trip

conditi on.

But except status below.

User initializing with b084 set to 01, 02.

Online state and Connection are

established.

Online state and Connection are not

established.

Network abnormality

(Duplicate MACID, Detect BusOff etc.)

Timeout communication Check the followings

Need to fix the inverter.

Refer to inverter instruction manual.

Check the followings

Duplicate MACID.

Communication speed.

Cable disconnection.

Connection’s fail for connector.

Connection for terminating resistor.

Length of cable

Communication speed.

Cable disconnection.

Connection’s fail for connector.

Connection for terminating resistor.

Length of cable.

−

−

−

−

−

−

7.5 Other notes

When SJ-DN is installed and the Inverter ’s setting is below, the inverter will be reset to fault status when it

occur trip while driving from DeviceNet command.

Case of the inverter drive again, set run command again after release run command.

Operating mode select(A002) setting: 02(Remort)

22

Page 27

APPENDIX PARAMETER OBJECT LISTS

mand

Bit6 : Dig input 7 Bit5 : Dig input 6

Bit4 : Dig input 5 Bit3 : Dig input 4

Bit2 : Dig input 3 Bit1 : Dig input 2

110

d007

111

d012

112

d013

121

d080

123

d081

124

d081

125

d081

126

d081

127

d081

130

d082

131

d082

132

d082

133

d082

135

d083

136

d083

141

d084

142

d084

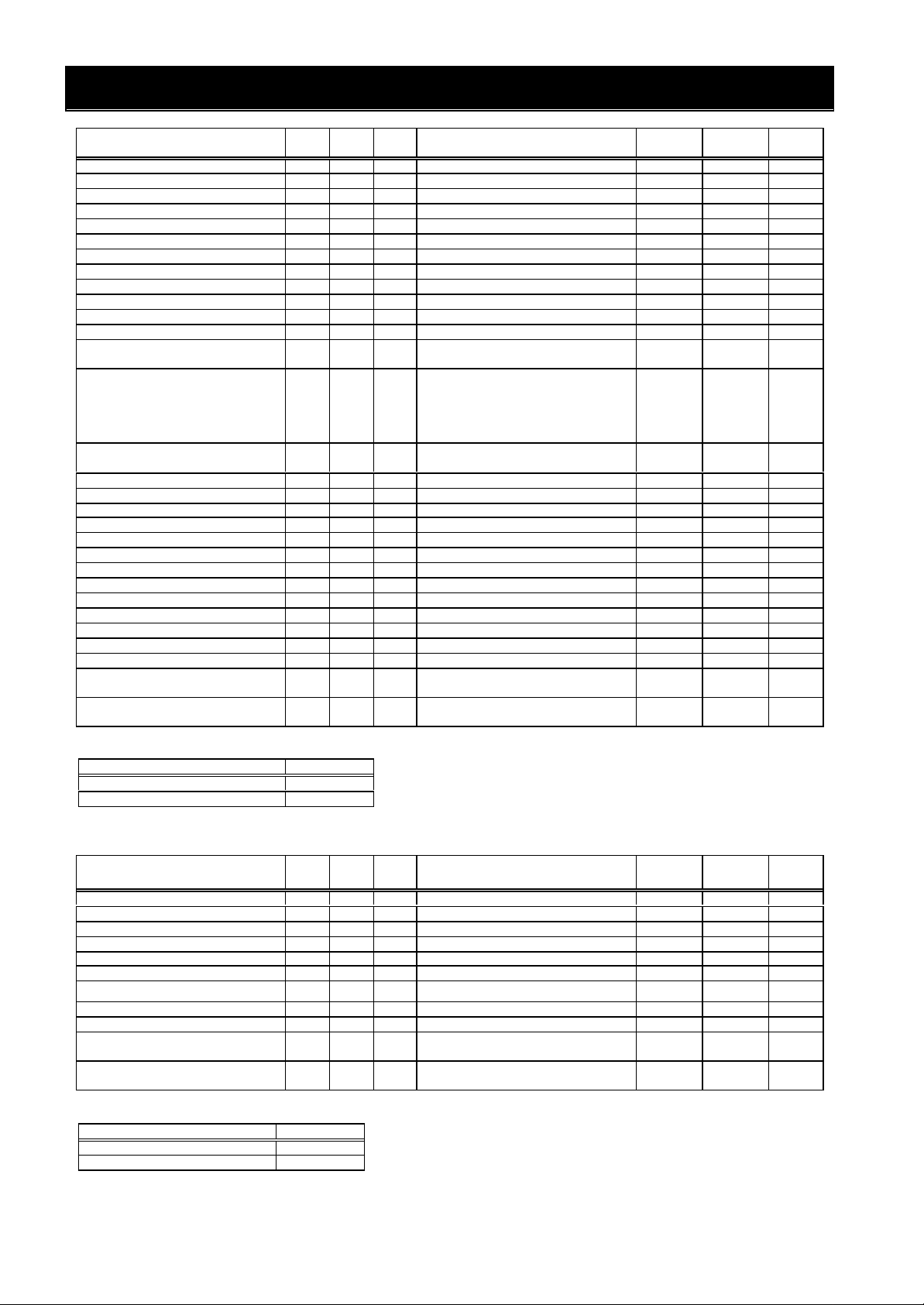

(1) Inverter Data monitor/Basic Data Setting object. Class ID=100

Function Inst Attr Size Monitoring/Setting Range

Inverter Mode (Param16) 1 100 1 00(SJ300)/01(L300P)/02(SJH300) 1 Get -

Rated Power (Param14) 1 101 1

Rated Voltage (Param15) 1 102 1

Output Frequency (Param1) 1 104 4 0.00 to 400.00(Hz) 100 Get d001

Output Current (Param2) 1 105 2 0.0 to 999.9(A) 10 Get d002

Direction (Param3) 1 106 1

PID Feedback (Param4) 1 107 4 0.00 to 999.00(%) 100 Get d004

00(0.20)/02(0.40)/04(0.75)/

06(1.50)/07(2.20)/09(3.70)/

11(5.50)/12(7.50)/13(11.0)/

14(15.0)/15(18.5)/16(22.0)/

17(30.0)/18(37.0)/19(45.0)/

20(55.0)/21(75.0)

00(200V Class)/01(400V Class)/

02(600V Class)

01(Forward)/00(Stopped)/

02(Reverse)

Bit8 : Forward Bit7 : Dig input 8

Magnifi-

cation

1 Get -

1 Get -

1 Get d003

Access

rule

Com-

Dig In Status (Param5) 1 108 2

Dig Out Status (Param6) 1 109 2

Freq-conversion (Param7) 1

Torque (Param8) 1

Output Voltage (Param9) 1

Input Elect- Pow (Param10) 1 113 2 0.0 to 999.9(kW) 10 Get d014

Elapsed Run time (Param11) 1 115 4 0 to 999999(hr) 1 Get d016

Power ON time (Param12) 1 116 4 0 to 999999(hr) 1 Get d017

DC Voltage (Param13) 1 118 2 0.0 to 999.9(V) 10 Get -

Trip Count (Param17) 1

Trip 1 Cause (Param18) 1 122 4

Trip 1 frequency (Param19) 1

Trip 1 Current (Param20) 1

Trip 1 DC Voltage (Param21) 1

Trip 1 RUN time (Param22) 1

Trip 1 P-ON time (Param23) 1

Trip 2 Cause (Param24) 1 128 4

Trip 2 frequency (Param25) 1 129 4 0.00 to 400.00(Hz) 100 Get d082

Trip 2 Current (Param26) 1

Trip 2 DC Voltage (Param27) 1

Trip 2 RUN time (Param28) 1

Trip 2 P-ON time (Param29) 1

Trip 3 Cause (Param30) 1 134 4

Trip 3 frequency (Param31) 1

Trip 3 Current (Param32) 1

Trip 3 DC Voltage (Param33) 1 137 2 0.0 to 600.0(V) 10 Get d083

Trip 3 RUN time (Param34) 2 138 4 0 to 999999(hr) 1 Get d083

Trip 3 P-ON time (Param35) 1 139 4 0 to 999999(hr) 1 Get d083

Trip 4 Cause (Param36) 2 140 4

Trip 4 frequency (Param37) 1

Trip 4 Current (Param38) 1

4 0.00 to 3996.00 100 Get

2 -300 to +300(%) 1 Get

2 0.0 to 600.0(V) 10 Get

2 0 to 65530 1 Get

4 0.00 to 400.00(Hz) 100 Get

2 0.0 to 999.9(A) 10 Get

2 0.0 to 600.0(V) 10 Get

4 0 to 999999(hr) 1 Get

4 0 to 999999(hr) 1 Get

2 0.0 to 999.9(A) 10 Get

2 0.0 to 600.0(V) 10 Get

4 0 to 999999(hr) 1 Get

4 0 to 999999(hr) 1 Get

4 0.00 to 400.00(Hz) 100 Get

2 0.0 to 999.9(A) 10 Get

4 0.00 to 400.00(Hz) 100 Get

2 0.0 to 999.9(A) 10 Get

Bit0 : Dig input 1

Close: 1, Open : 0

Bit5 : Alarm

Bit4 : Dig output 15

Bit3 : Dig output 14

Bit2 : Dig output 13

Bit1 : Dig output 12

Bit0 : Dig output 11

Close: 1, Open : 0

E01.X to E79.X (E??:Trip cause,

X:running condition)

See 6.3.3 Hitachi inverter I/O

Instance(Instance 101)

E01.X to E79.X (E??:Trip cause,

X:running condition)

See 6.3.3 Hitachi inverter I/O

Instance(Instance 101)

E01.X to E79.X (E??:Trip cause,

X:running condition)

See 6.3.3 Hitachi inverter I/O

Instance(Instance 101)

E01.X to E79.X (E??:Trip cause,

X:running condition)

See 6.3.3 Hitachi inverter I/O

Instance(Instance 101)

1 Get d005

1 Get d006

1 Get d081

1 Get d082

1 Get d083

1 Get d084

23

Page 28

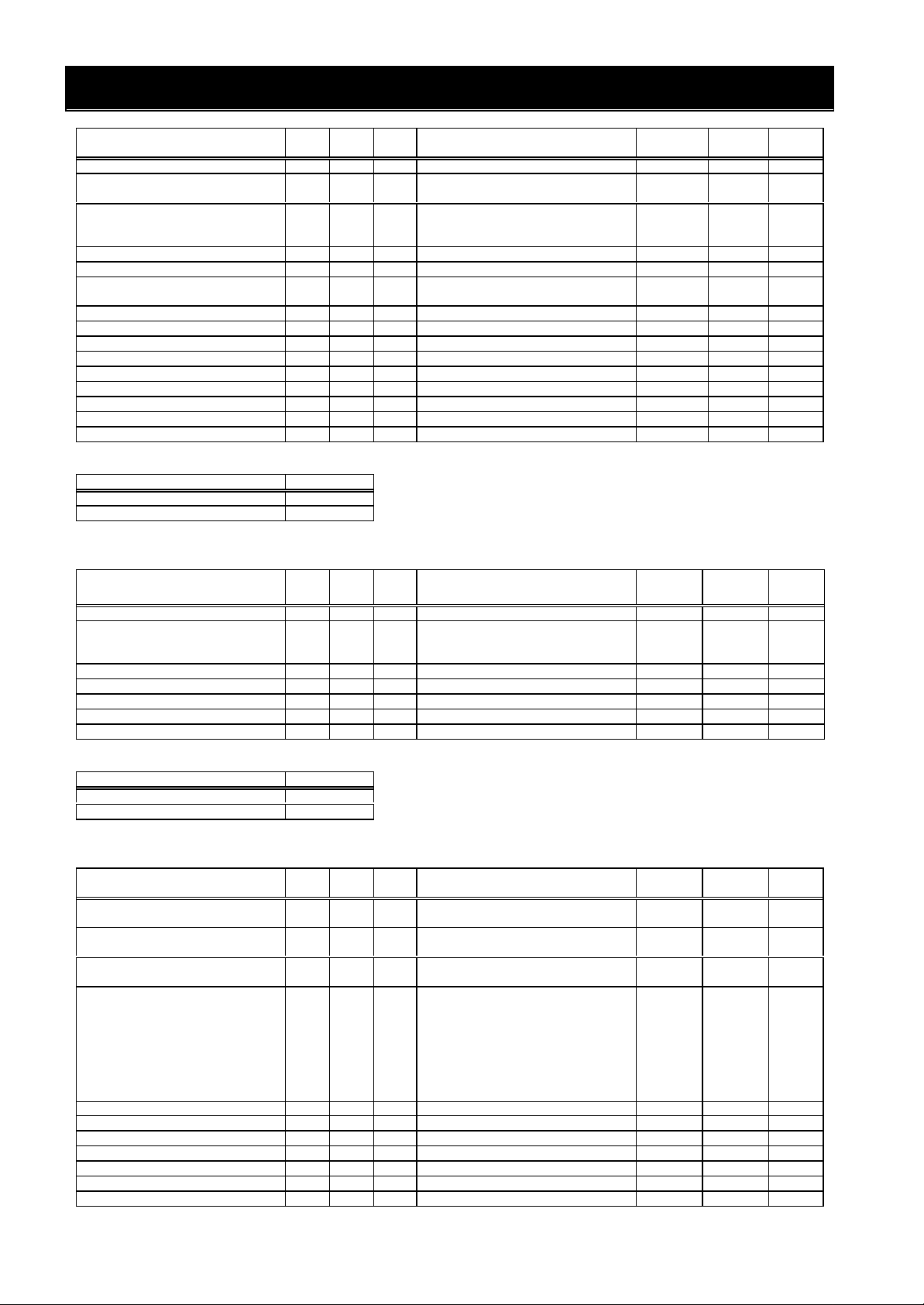

APPENDIX PARAMETER OBJECT LISTS

Magnifi-

Access

Com-

mand

147

d085

148

d085

149

d085

150

d085

151

d085

155

d086

156

d086

157

d086

159

Get/Set

F001

160

Get/Set

F002

161

Get/Set

F303

162

Get/Set

F004

Magnifi-

Access

Com-

mand

103

Get/Set

A003

2nd Base Frequency (Param334)

103

Get/Set

A203

3rd Base Frequency (Param371)

103

Get/Set

A303

104

Get/Set

A004

104

Get/Set

A204

3rd Max Frequency (Param370)

104

Get/Set

A304

Function Inst Attr Size Monitoring/Setting Range

Trip 4 DC Voltage (Param39) 1 143 2 0.0 to 600.0(V) 10 Get d084

Trip 4 RUN time (Param40) 1 144 4 0 to 999999(hr) 1 Get d084

Trip 4 P-ON time (Param41) 1 145 4 0 to 999999(hr) 1 Get d084

Trip 5 Cause (Param42) 1 146 4

Trip 5 frequency (Param43) 1

Trip 5 Current (Param44) 1

Trip 5 DC Voltage (Param45) 1

Trip 5 RUN time (Param46) 1

Trip 5 P-ON time (Param47) 1

Trip 6 Cause (Param48) 1 152 4

Trip 6 frequency (Param49) 1 153 4 0.00 to 400.00(Hz) 100 Get d086

Trip 6 Current (Param50) 1 154 2 0.0 to 999.9(A) 10 Get d086

Trip 6 DC Voltage (Param51) 1

Trip 6 RUN time (Param52) 1

Trip 6 P-ON time 6(Param53) 1

Warning Monitor (Param54) 1 158 1

Frequency Setting (Param60) 1

Accel Time 1 (Param61) 1

2nd Accel Time 1 (Param337) 2 160 4 0.01 to 3600.00(s) 100 Get/Set F202

3rd Accel Time 1 (Param372) 3 160 4 0.01 to 3600.00(s) 100 Get/Set F302

Decel Time 1(Param62) 1 161 4 0.01 to 3600.00(s) 100 Get/Set F003

2nd Decel Time 1(Param338) 2 161 4 0.01 to 3600.00(s) 100 Get/Set F203

3rd Decel Time 1 (Param373) 3

Direction Setting (Param63) 1

E01.X to E79.X (E??:Trip cause,

X:running condition)

See 6.3.3 Hitachi inverter I/O

Instance(Instance 101)

4 0.00 to 400.00(Hz) 100 Get

2 0.0 to 999.9(A) 10 Get

2 0.0 to 600.0(V) 10 Get

4 0 to 999999(hr) 1 Get

4 0 to 999999(hr) 1 Get

E01.X to E79.X (E??:Trip cause,

X:running condition)

See 6.3.3 Hitachi inverter I/O

Instance(Instance 101)

2 0.0 to 600.0(V) 10 Get

4 0 to 999999(hr) 1 Get

4 0 to 999999(hr) 1 Get

00(No Warning)

01(W001) 02(W002) 03(W004)

04(W005) 05(W006) 06(W009)

07(W201) 08(W202) 09(W204)

10(W205) 11(W206) 12(W209)

13(W304) 14(W305) 15(W306)

16(W309) 17(W012) 18(W015)

19(W016) 20(W019) 21(W212)

22(W215) 23(W216) 24(W219)

25(W021) 26(W025) 27(W026)

28(W029) 29(W221) 30(W225)

31(W226) 32(W229) 33(W031)

34(W231) 35(W032) 36(W232)

37(W035) 38(W235) 39(W335)

40(W036) 41(W037) 42(W085)

43(W285) 44(W385) 45(W086)

46(W091) 47(W291) 48(W092)

49(W292) 50(W095) 51(W295)

52(W395) 53(W096) 54(W110)

55(W120)

4 0.00 to 400.00(Hz) 100

4 0.01 to 3600.00(s) 100

4 0.01 to 3600.00(s) 100

1 00(Forward)/01(Reverse) 1

cation

1 Get d085

1 Get d086

1 Get d090

rule

Support service

Service name Code

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

(2) Extend Group A object Class ID=101

Function Inst Attr Size Monitoring/Setting Range

Freq-Setting Sel (Param64) 1 101 1

Operating Mode Sel (Param65) 1 102 1

Base Frequency (Param56) 1

Max Frequency (Param55) 1

2ndMaxFrequency (Param333) 2

cation

00(Volume)/01(Terminal)/

02(Operator)/03(RS485)/

04(Option1)/05(Option2)

01(Terminal)/02(Operator)/

03(RS485)/04(Option1)/

2

3

3

2 30 to 400(Hz) 1

2 30 to 400(Hz) 1

2 30 to 400(Hz) 1

2 30 to 400(Hz) 1

2 30 to 400(Hz) 1

2 30 to 400(Hz) 1

05(Option2)

1 Get/Set A001

1 Get/Set A002

rule

24

Page 29

APPENDIX PARAMETER OBJECT LISTS

Magnifi-

Access

Com-

111

Get/Set

A011

112

Get/Set

A012

113

Get/Set

A013

120

Get/Set

A020

120

Get/Set

A220

120

Get/Set

A320

121

Get/Set

A021

122

Get/Set

A022

123

Get/Set

A023

124

Get/Set

A024

125

Get/Set

A025

126

Get/Set

A026

127

Get/Set

A027

128

Get/Set

A028

133

Get/Set

A033

134

Get/Set

A034

135

Get/Set

A035

138

Get/Set

A038

141

Get/Set

A041

141

Get/Set

A241

142

Get/Set

A042

143

Get/Set

A343

145

Get/Set

A045

151

Get/Set

A051

152

Get/Set

A052

153

Get/Set

A053

154

Get/Set

A054

159

Get/Set

A059

161

Get/Set

A061

2ndUpperFRQLimit (Param336)

161

Get/Set

A261

162

Get/Set

A062

2ndLowerFRQLimit (Param335)

162

Get/Set

A262

163

Get/Set

A063

164

Get/Set

A064

Function Inst Attr Size Monitoring/Setting Range

AT Function Sel (Param66) 1 105 1 00(O/OI)/01(O/O2) 1 Get/Set A005

O2 Function Sel (Param67) 1 106 1

O Start Freq Set (Param68) 1

O End Freq Set (Param69) 1

O Start Rate (Param70) 1

O End Rate (Param71) 1 114 1 0 to 100(%) 1 Get/Set A014

O Start Mode Sel (Param72) 1 115 1 00(Set frequency)/01(0Hz) 1 Get/Set A015

Analog Sampling (Param73) 1 116 1 1 to 30 1 Get/Set A016

Multi-Speed Mode (Param74) 1 119 1 00(Binary)/01(Bit) 1 Get/Set A019

Multi-Speed 0 (Param75) 1

2nd Multi-Speed0 (Param339) 2

3rd Multi-Speed0 (Param374) 3

Multi-Speed 1 (Param76) 1

Multi-Speed 2 (Param77) 1

Multi-Speed 3 (Param78) 1

Multi-Speed 4 (Param79) 1

Multi-Speed 5 (Param80) 1

Multi-Speed 6 (Param81) 1

Multi-Speed 7 (Param82) 1

Multi-Speed 8 (Param83) 1

Multi-Speed 9 (Param84) 1 129 4 0.00 to 400.00(Hz) 100 Get/Set A029

Multi-Speed 10 (Param85) 1 130 4 0.00 to 400.00(Hz) 100 Get/Set A030

Multi-Speed 11 (Param86) 1 131 4 0.00 to 400.00(Hz) 100 Get/Set A031

Multi-Speed 12 (Param87) 1 132 4 0.00 to 400.00(Hz) 100 Get/Set A032

Multi-Speed 13 (Param88) 1

Multi-Speed 14 (Param89) 1

Multi-Speed 15 (Param90) 1

JoggingFrequency (Param91) 1

Jog StopMode Sel (Param92) 1 139 1

Torque Boost Sel (Param93) 1

2ndTrq-Boost Sel (Param340) 2

TorqueBoostValue (Param94) 1

2ndTrqBoostValue (Param341) 2 142 1 0.0 to 20.0(%) 10 Get/Set A242

3rdTrqBoostValue (Param375) 3 142 1 0.0 to 20.0(%) 10 Get/Set A342

TorqueBoostPoint (Param95) 1 143 2 0.0 to 50.0(%) 10 Get/Set A043

2ndTrqBoostPoint (Param342) 2 143 2 0.0 to 50.0(%) 10 Get/Set A243

3rdTrqBoostPoint (Param376) 3

Control Select (Param96) 1 144 1

2ndControlSelect (Param343) 2 144 1

3rdControlSelect (Param377) 3 144 1

Out-Voltage Gain (Param97) 1

DC Brake Enable (Param98) 1

DC Br Start Freq (Param99) 1

DC Br Wait Time (Param100) 1

DC Brake Power (Param101) 1

DC Brake Time (Param102) 1 155 2 0.0 to 60.0(s) 10 Get/Set A055

DC Brake ModeSel (Param103) 1 156 1 00(Edge)/01(Level) 1 Get/Set A056

DCBrPowerAtStart (Param104) 1 157 1 0 to 70(%) 1 Get/Set A057

DCBrTime AtStart (Param105) 1 158 2 0.0 to 60.0(s) 10 Get/Set A058

DCBr CarrierFreq (Param106) 1

Upper Freq Limit (Param59) 1

2

Lower Freq Limit (Param58) 1

2

Jump Frequency 1 (Param107) 1

Jump Freq Width 1 (Param108) 1

00(Invalid)/01(O/OI-no reverse)/

02(O/OI-reverse)

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

1 0 to 100(%) 1

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

2 0.00 to 9.99(Hz) 100

00(Free run)/01(Deceleration)/

02(DC Braking)/03(R-Free run)/

04(R-Deceleration)/

05(R-DC Braking)

1 00(Manual)/01(Automatic) 1

1 00(Manual)/01(Automatic) 1

1 0.0 to 20.0(%) 10

2 0.0 to 50.0(%) 10

00(Constant torque)/

01(Reduced torque)/

02(Free setting V/f)/

03(SLV contorol)/

04(0Hz-SLV control)/

05(Sensorring vector control)

00(Constant torque)/

01(Reduced torque)/

02(Free setting V/f)/

03(SLV contorol)/

04(0Hz-SLV control)

00(Constant torque)/

01(Reduced torque)/

02(Free setting V/f)

1 20 to 100 1

1 00(invalid)/01(Valid) 1

2 0.00 to 60.00(Hz) 100

1 0.0 to 5.0(s) 10

1 0 to 100(%) 1

1 0.5 to 15.0(kHz) 10

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

2 0.00 to 10.00(Hz) 100

cation

1 Get/Set A006

1 Get/Set A039

1 Get/Set A044

1 Get/Set A244

1 Get/Set A344

rule

mand

25

Page 30

APPENDIX PARAMETER OBJECT LISTS

Magnifi-

Access

Com-

mand

168

Get/Set

A068

169

Get/Set

A069

170

Get/Set

A070

171

Get/Set

A071

172

Get/Set

A072

173

Get/Set

A073

174

Get/Set

A074

175

Get/Set

A075

176

Get/Set

A076

EnergySavingResp (Param124)

186

Get/Set

A086

192

Get/Set

A092

192

Get/Set

A292

194

Get/Set

A094

194

Get/Set

A294

195

Get/Set

A095

195

Get/Set

A295

196

Get/Set

A096

196

Get/Set

A296

02(U Curve)/03(Reverse U Curve)

102

Get/Set

A102

103

Get/Set

A103

104

Get/Set

A104

105

Get/Set

A105

113

Get/Set

A113

114

Get/Set

A114

Function Inst Attr Size Monitoring/Setting Range

Jump Frequency 2 (Param109) 1 165 4 0.00 to 400.00(Hz) 100 Get/Set A065

Jump Freq Width 2 (Param110) 1 166 2 0.00 to 10.00(Hz) 100 Get/Set A066

Jump Frequency 3 (Param111) 1 167 4 0.00 to 400.00(Hz) 100 Get/Set A067

Jump Freq Width 3 (Param112) 1

Accel Stop Freq (Param113) 1

Accel Stop Time (Param114) 1

PID Enable (Param115) 1

PID-P Gain (Param116) 1

PID-I Gain (Param117) 1

PID-D Gain (Param118) 1

PID Scale (Param119) 1

PID Feedback Sel (Param120) 1

AVR Selection (Param121) 1 181 1

MotorVoltage Sel (Param122) 1 182 1

OperationModeSel (Param123) 1 185 1

1

Accel Time 2 (Param125) 1

2nd Accel Time 2 (Param344) 2

3rd Accel Time 2 (Param378) 3 192 4 0.01 to 3600.00(s) 100 Get/Set A392

Decel Time 2 (Param126) 1 193 4 0.01 to 3600.00(s) 100 Get/Set A093

2nd Decel Time 2 (Param345) 2 193 4 0.01 to 3600.00(s) 100 Get/Set A293

3rd Decel Time 2 (Param379) 3 193 4 0.01 to 3600.00(s) 100 Get/Set A393

Accel/Decel2 Sel (Param127) 1

2nd Acc/Dec2 Sel (Param346) 2

Accel2 StartFreq (Param128) 1

2ndAcc2StartFreq (Param347) 2

Decel2 StartFreq (Param129) 1

2ndDec2StartFreq (Param348) 2

AccelPattern Sel (Param130) 1 197 1

DecelPattern Sel (Param131) 1 198 1

2 0.00 to 10.00(Hz) 100

4 0.00 to 400.00(Hz) 100

2 0.0 to 60.0(s) 10

1 00(Invalid)/01(Valid) 1

1 0.2 to 5 1

2 0.0 to 3600.0(s) 10

2 0.00 to 100.00(s) 100

2 0.01 to 99.99(%) 100

1 00(OI)/01(O) 1

00(ON)/01(OFF)/

02(OFF on decel)

00(200)/01(215)/02(220)/03(230)/

04(240)/05(380)/06(400)/07(415)/

08(440)/09(460)/10(480)/11(575)/

12(600)

00(Normal)/01(Energy saving)/

02(Fuzzy)

2 0.0 to 100.0(s) 10

4 0.01 to 3600.00(s) 100

4 0.01 to 3600.00(s) 100

1 00(Terminal)/01(Frequency) 1

1 00(Terminal)/01(Frequency) 1

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

4 0.00 to 400.00(Hz) 100

00(Straight line)/01(S Curve)/

00(Straight line)/01(S Curve)/

02(U Curve)/03(Reverse U Curve)

cation

1 Get/Set A081

1 Get/Set A082

1 Get/Set A085

1 Get/Set A097

1 Get/Set A098

rule

Support service

Service name Code

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

(2) Extend Group A object Class ID=102

Function Inst Attr Size Monitoring/Setting Range

OI StartFreq Set (Param132) 1 101 4 0.00 to 400.00(Hz) 100 Get/Set A101

OI End Freq Set (Param133) 1

OI Start Rate (Param134) 1

OI End Rate (Param135) 1

OI StartMode Sel (Param136) 1

O2 StartFreq Set (Param137) 1 111 4 -400.00 to 400.00(Hz) 100 Get/Set A111

O2 End Freq Set (Param138) 1 112 4 -400.00 to 400.00(Hz) 100 Get/Set A112

O2 Start Rate (Param139) 1

O2 End Rate (Param140) 1

AccCurveSwelling (Param141) 1 131 1

DecCurveSwelling (Param142) 1 132 1

4 0.00 to 400.00(Hz) 100

1 0 to 100(%) 1

1 0 to 100(%) 1

1 00(Set Frequency)/01(0Hz) 1

1 -100 to 100(%) 1

1 -100 to 100(%) 1

01(small swelling) to

10(large swelling)

01(small swelling) to

10(large swelling)

Magnifi-

cation

1 Get/Set A131

1 Get/Set A132

Access

rule

Support service

Service name Code

Get_Attribute_Single H’0E

Set_Attribute_Single H’10

Com-

mand

26

Page 31

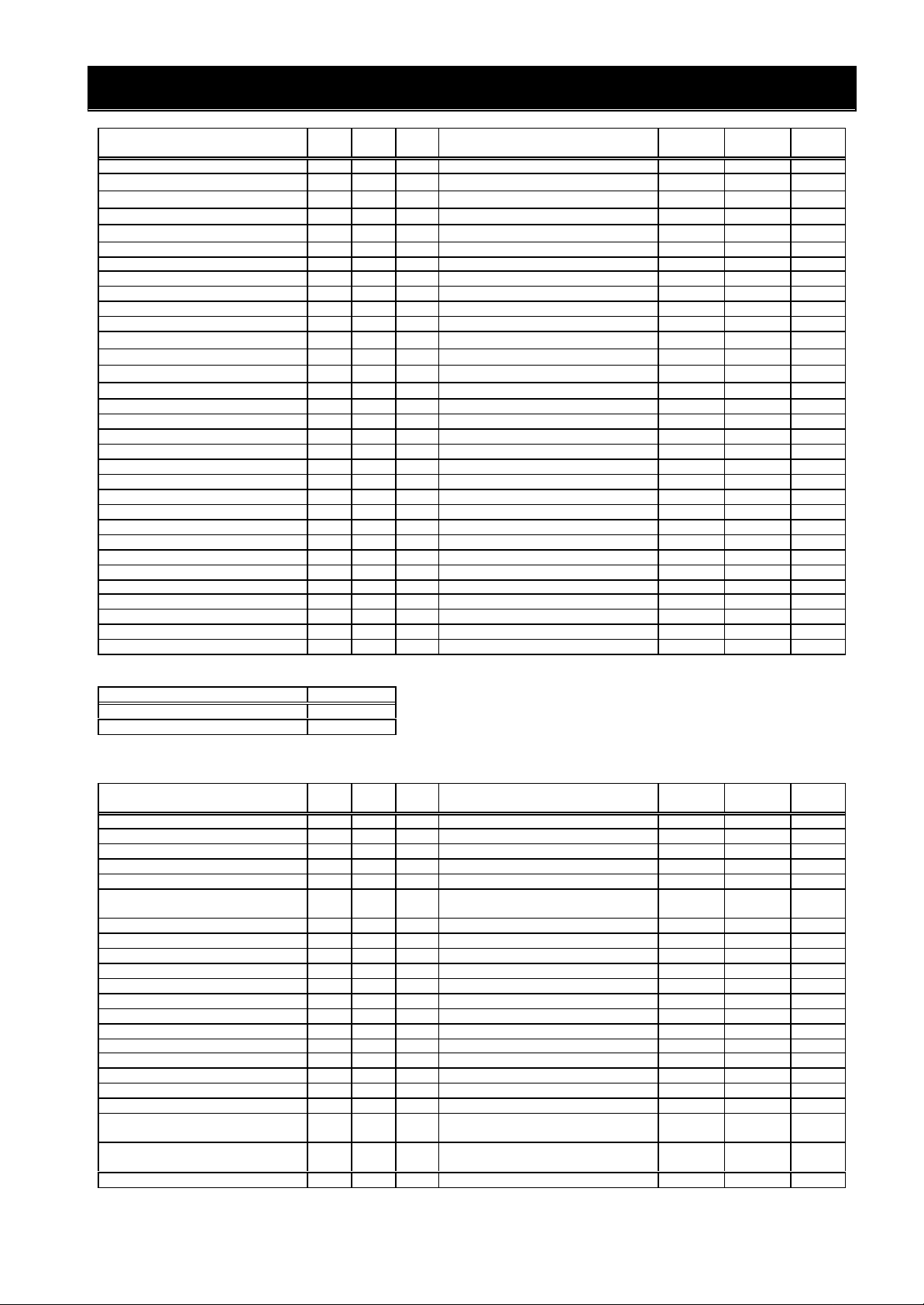

(3) Extend Group B object Class ID=103

Magnifi-

Access

mand

102

Get/Set

b002

103

Get/Set

b003

105

Get/Set

b005

106

Get/Set

b006

107

Get/Set

b007

112

Get/Set

b012

112

Get/Set

b212

112

Get/Set

b312

115

Get/Set

b015

116

Get/Set

b016

117

Get/Set

b017

118

Get/Set

b018

119

Get/Set

b019

120

Get/Set

b020

122

Get/Set

b022

123

Get/Set

b023

00(Inactive)/01(Inactive at dec 1)/

126

Get/Set

b026

134

Get/Set

b034

01(Forward only)/02(Reverse only)

ReducedV TimeSel (Param166)

136

Get/Set

b036

141

Get/Set

b041

142

Get/Set

b042

143

Get/Set

b043

144

Get/Set

b044

Torq LADSTOP Sel (Param173)

145

Get/Set

b045

IPNonStopDecTime (Param178)

153

Get/Set

b053

154

Get/Set

b054

180

Get/Set

b080

181

Get/Set

b081

182

Get/Set

b082

183

Get/Set

b083

185

Get/Set

b085

Function Inst Attr Size Monitoring/Setting Range

Restart Mode Sel (Param143) 1 101 1

Allowable UVTime (Param144) 1

Restart WaitTime (Param145) 1

IP/UVTrip AtStop (Param146) 1 104 1

IP/UVRestartTime(Param147) 1

Open-phaseSelect (Param148) 1

FreqSet To Match (Param149) 1

E-Thermal Level (Param150) 1

2nd E- ThermalLvl (Param349) 2

3rd E-ThermalLvl (Param380) 3

E- ThermalCharSel (Param151) 1 113 1

2ndEThermCharSel (Param350) 2 113 1

3rdEThermCharSel (Param381) 3 113 1

E-Thermal Freq 1 (Param152) 1

E-Thermal Cur 1 (Param153) 1

E-Thermal Freq 2 (Param154) 1

E-Thermal Cur 2 (Param155) 1

E-Thermal Freq 3 (Param156) 1

E-Thermal Cur 3 (Param157) 1

OL Limit Enable (Param158) 1 121 1

OL Limit Level (Param159) 1

OL Limit Const (Param160) 1

APPENDIX PARAMETER OBJECT LISTS

cation

00(Trip)/01(0Hz Start)/

02(Synchronize)/

03(Sync& Stop& Trip)

1 0.3 to 1.0(s) 10

2 0.3 to 100.0(s) 10

00(Invalid)/01(Valid)/

02(Invalid on stop)

1 00(16 times)/01(Free) 1

1 00(Invalid)/01(Valid) 1

4 0.00 to 400.00(Hz) 100

2 20 to 120(%)(constant current) 1

2 20 to 120(%)(constant current) 1

2 20 to 120(%)(constant current) 1

00(Reduced torque)/

01(Constant torque)/

02(Free setting)

00(Reduced torque)/

01(Constant torque)/

02(Free setting)

00(Reduced torque)/

01(Constant torque)/

02(Free setting)

2 0 to 400(Hz) 1

2 0.0 to 999.9(A) 10

2 0 to 400(Hz) 1

2 0.0 to 999.9(A) 10

2 0 to 400(Hz) 1

2 0.0 to 999.9(A) 10

00(Inactive)/01(Inactive at dec 1)/

02(Active at const 1)/

03(Inactive at dec 2)

2 50 to 200(%) (constant current) 1

2 0.1 to 30.00 100

1 Get/Set b001

1 Get/Set b004

1 Get/Set b013

1 Get/Set b213

1 Get/Set b313

1 Get/Set b021

rule

Com

OL Limit Enable2 (Param161) 1 124 1

OL Limit Level 2 (Param162) 1 125 2 50 to 200(%) (constant current) 1 Get/Set b025

OL Limit Const 2 (Param163) 1

SoftLock ModeSel (Param383) 1 131 1

Run/P-ONTime Lvl (Param164) 1

FW/RV Restrict (Param165) 1 135 1

1

Display Select (Param167) 1 137 1

TorqueLimit Mode (Param168) 1 140 1

TorqueLimit Lvl1 (Param169) 1

TorqueLimit Lvl2 (Param170) 1

TorqueLimit Lvl3 (Param171) 1

TorqueLimit Lvl4 (Param172) 1

1

RV-RunPreventSel (Param174) 1 146 1 00(Invalid)/01(Valid) 1 Get/Set b046

IPNonStopModeSel (Param175) 1 150 1 00(Invalid)/01(Valid) 1 Get/Set b050

IPNonStopStart-V (Param176) 1 151 2 0.0 to 999.9(V) 10 Get/Set b051

IP OV-LADSTOPLvl (Param177) 1 152 2 0.0 to 999.9(V) 10 Get/Set b052

1

IP StartDec-Freq (Param179) 1

AM Adjustment (Param180) 1

FM Adjustment (Param181) 1

Start Frequency (Param57) 1

CarrierFrequency (Param182) 1

Initialize Mode (Param183) 1 184 1

Initial Data Sel (Param184) 1

2 0.1 to 30.00 100

2 0 to 65535(hr) 1

1 00 to 06 1

1 0 to 200(%) 1

1 0 to 200(%) 1

1 0 to 200(%) 1

1 0 to 200(%) 1

1 00(Invalid)/01(Valid) 1

4 0.01 to 3600.00(s) 100

2 0.00 to 10.00(Hz) 100

1 0 to 255 1

1 0 to 255 1

2 0.1 to 9.99(Hz) 100

1 0.5 to 15.0(kHz) 10

1 00(Japan)/01( Europe)/02(USA) 1

02(Active at const 1)/

03(Inactive at dec 2)

00(SFT - All param)/

01(SFT - Only freq)/

02(All param)/03(Only freq)/

10(Change mode on run)

00(FW/RV Enable)/

00(All Display )/

01(Each Func Display)/

02(User setting)

00(4 Quadrant mode)/

01(Terminal)/02(Analog input)/

03(Option1)/04(Option2)

00(Trip history)/01(Data)/

02(Trip history & Data)

1 Get/Set b024

1 Get/Set b031

1 Get/Set b035

1 Get/Set b037

1 Get/Set b040

1 Get/Set b084

27

Page 32

APPENDIX PARAMETER OBJECT LISTS

Magnifi-

Access

mand

190

Get/Set

b090

191

Get/Set

b091

00(Invalid)/01(Invalid during stop)/

196

Get/Set

b096

104

Get/Set

105

Get/Set

106

Get/Set

107

Get/Set

108

Get/Set

109

Get/Set

110