Hitachi SJ700D-022L, SJ700D-004L, SJ700D-022H, SJ700D-037L, SJ700D-037H Quick Reference Manual

...

SJ700D-3 SERIES

Read through this Quick Reference Guide, and keep it handy for future reference.

HITACHI INVERTER

Quick Reference Guide

NT2311X

Introduction

No.

Revision content

Date of issue

Manual code

1

First edition

April, 2014

NT2311X

Introduction

Thank you for purchasing Hitachi SJ700D-3 Series Inverter. This Quick Reference Guide describes the contents of

planning the installation, installing, commissioning, using and servicing the Hitachi SJ700D-3 Series Inverter.

Please read this document and the instruction manual before operation to perfectly understand proper handling and

safety precautions for the product to ensure safety and proper usage. Before attempting installation, operation and

maintenance work, you should understand the knowledge of equipment, information of safety, caution and how to

use and service the inverter. You should also use the inverter by observing specifications described this guide and

prevent risks by performing maintenance.

This guide is “Quick Reference Guide”. Refer to "SJ700D-3 series Instruction Manual" on CD bundled with the

inverter for more information. If you use the inverter with optional products, also you should read the manuals for

those products. Note that this guide, the instruction manual and the manual for each optional product to be used

should be delivered to the end user of the inverter.

Handling of this Quick Reference Guide and bundled CD (the Instruction Manual)

- The contents of the guide and the CD are subject to change without prior notice.

- Even if you lose the guide and the CD, it will not be resupplied, so please keep it carefully.

- No part of the guide and the CD may be reproduced in any form without the publisher’s permission.

- If you find any incorrect description, missing description or have a question concerning the contents of these

manuals, please contact the publisher.

Revision History

- The current edition of this Quick Reference Guide also includes some corrections of simple misprints, missing

letters, misdescriptions and certain added explanations other than those listed in the above Revision History table.

Safety Instructions

CAUTION

- Many of the drawings in the Quick Reference Guide show the inverter with covers and/or parts blocking your view as

removed. Do not operate the inverter in the status shown in those drawings. If you have removed the covers and/or parts, be

sure to reinstall them in their original positions before starting operation, and follow all instructions in this Instruction

Manual when operating the inverter.

CAUTION

- Install the inverter on a non-flammable surface, e.g., metal. Otherwise, you run the risk of fire.

- Do not place flammable materials near the installed inverter. Otherwise, you run the risk of fire.

- When carrying the inverter, do not hold its top cover. Otherwise, you run the risk of injury by dropping the inverter.

- Prevent foreign matter (e.g., cut pieces of wire, sputtering welding materials, iron chips, wire, and dust) from entering the

inverter. Otherwise, you run the risk of fire.

- Install the inverter on a structure able to bear the weight specified in this Instruction Manual. Otherwise, you run the risk of

injury due to the inverter falling.

- Install the inverter on a vertical wall that is free of vibrations. Otherwise, you run the risk of injury due to the inverter falling.

- Do not install and operate the inverter if it is damaged or its parts are missing. Otherwise, you run the risk of injury.

- Install the inverter in a well-ventilated indoor site not exposed to direct sunlight. Avoid places where the inverter is exposed

to high temperature, high humidity, condensation, dust, explosive gases, corrosive gases, flammable gases, grinding fluid

mist, or salt water. Otherwise, you run the risk of fire.

- The inverter is precision equipment. Do not allow it to fall or be subject to high impacts, step on it, or place a heavy load on

it. Doing so may cause the inverter to fail.

WARNING

- Be sure to ground the inverter. Otherwise, you run the risk of electric shock or fire.

- Commit wiring work to a qualified electrician. Otherwise, you run the risk of electric shock or fire.

- Before wiring, make sure that the power supply is off. Otherwise, you run the risk of electric shock or fire.

- Perform wiring only after installing the inverter. Otherwise, you run the risk of electric shock or injury.

- Do not remove rubber bushings from the wiring section. Otherwise, the edges of the wiring cover may damage the wire,

resulting in a short circuit or ground fault.

CAUTION

- Make sure that the voltage of AC power supply matches the rated voltage of your inverter. Otherwise, you run the risk of

injury or fire.

- Do not input single-phase power into the inverter. Otherwise, you run the risk of fire.

- Do not connect AC power supply to any of the output terminals (U, V, and W). Otherwise, you run the risk of injury or fire.

- Do not connect a resistor directly to any of the DC terminals (PD, P, and N). Otherwise, you run the risk of fire.

- Connect an earth-leakage breaker to the power input circuit. Otherwise, you run the risk of fire.

- Use only the power cables, earth-leakage breaker, and magnetic contactors that have the specified capacity (ratings).

Otherwise, you run the risk of fire.

- Do not use the magnetic contactor installed on the primary and secondary sides of the inverter to stop its operation.

- Tighten each screw to the specified torque. No screws must be left loose. Otherwise, you run the risk of fire.

- Before operating, slide switch SW1 in the inverter, be sure to turn off the power supply. Otherwise, you run the risk of

electric shock and injury.

- Since the inverter supports two modes of cooling-fan operation, the inverter power is not always off, even when the cooling

fan is stopped. Therefore, be sure to confirm that the power supply is off before wiring. Otherwise, you run the risk of electric

shock and injury.

CAUTION

CAUTION

WARNING

Safety Instructions

Be sure to read this Quick Reference Guide and appended documents thoroughly before installing, operating,

maintaining, or inspecting the inverter. In this Quick Reference Guide, safety instructions are classified into two

levels, namely WARNING and CAUTION.

: Indicates that incorrect handling may cause hazardous situations, which may result in serious

personal injury or death.

: Indicates that incorrect handling may cause hazardous situations, which may result in

moderate or slight personal injury or physical damage alone.

Note that even a level situation may lead to a serious consequence according to circumstances.

Be sure to follow every safety instruction, which contains important safety information. Also focus on and observe

the items and instructions described under "Notes" in the text.

1. Installation

2. Wiring

i

Safety Instructions

WARNING

- While power is supplied to the inverter, do not touch any terminal or internal part of the inverter, check signals, or connect or

disconnect any wire or connector. Otherwise, you run the risk of electric shock or fire.

- Be sure to close the terminal block cover before turning on the inverter power. Do not open the terminal block cover while

power is being supplied to the inverter or voltage remains inside. Otherwise, you run the risk of electric shock.

- Do not operate switches with wet hands. Otherwise, you run the risk of electric shock.

- While power is supplied to the inverter, do not touch the terminal of the inverter, even if it has stopped. Otherwise, you run

the risk of injury or fire.

- If the retry mode has been selected, the inverter will restart suddenly after a break in the tripping status. Stay away from the

machine controlled by the inverter when the inverter is under such circumstances. (Design the machine so that human safety

can be ensured, even when the inverter restarts suddenly.) Otherwise, you run the risk of injury.

- Do not select the retry mode for controlling an elevating or traveling device because output free-running status occurs in retry

mode. Otherwise, you run the risk of injury or damage to the machine controlled by the inverter.

- If an operation command has been input to the inverter before a short-term power failure, the inverter may restart operation

after the power recovery. If such a restart may put persons in danger, design a control circuit that disables the inverter from

restarting after power recovery. Otherwise, you run the risk of injury.

- The [STOP] key is effective only when its function is enabled by setting. Prepare an emergency stop switch separately.

Otherwise, you run the risk of injury.

- If an operation command has been input to the inverter before the inverter enters alarm status, the inverter will restart

suddenly when the alarm status is reset. Before resetting the alarm status, make sure that no operation command has been

input.

- While power is supplied to the inverter, do not touch any internal part of the inverter or insert a bar in it. Otherwise, you run

the risk of electric shock or fire.

CAUTION

- Do not touch the heat sink, which heats up during the inverter operation. Otherwise, you run the risk of burn injury.

- The inverter allows you to easily control the speed of motor or machine operations. Before operating the inverter, confirm

the capacity and ratings of the motor or machine controlled by the inverter. Otherwise, you run the risk of injury.

- Install an external brake system if needed. Otherwise, you run the risk of injury.

- When using the inverter to operate a standard motor at a frequency of over 60 Hz, check the allowable motor speeds with

the manufacturers of the motor and the machine to be driven and obtain their consent before starting inverter operation.

Otherwise, you run the risk of damage to the motor and machine.

- During inverter operation, check the motor for the direction of rotation, abnormal sound, and vibrations. Otherwise, you run

the risk of damage to the machine driven by the motor.

WARNING

- Before inspecting the inverter, be sure to turn off the power supply and wait for 10 minutes or more. Otherwise, you run the

risk of electric shock. (Before inspection, confirm that the Charge lamp on the inverter is off and the DC voltage between

terminals P and N is 45 V or less.)

- Commit only a designated person to maintenance, inspection, and the replacement of parts. (Be sure to remove wristwatches

and metal accessories, e.g., bracelets, before maintenance and inspection work and to use insulated tools for the work.)

Otherwise, you run the risk of electric shock and injury.

WARNING

- Never modify the inverter. Otherwise, you run the risk of electric shock and injury.

CAUTION

- Do not discard the inverter with household waste. Contact an industrial waste management company in your area who can

treat industrial waste without polluting the environment.

3. Operation

4. Maintenance, inspection, and parts replacement

5. Others

ii

Safety Instructions

WARNING: This equipment must be installed, adjusted, and maintained by qualified engineers who have

expert knowledge of electric work, inverter operation, and the hazardous circumstances that

can occur. Otherwise, personal injury may result.

Caution for EMC (Electromagnetic Compatibility) (0.4kW-150kW)

The SJ700D series inverter conforms to the requirements of Electromagnetic Compatibility (EMC) Directive

(2004/108/EC). However, when using the inverter in Europe, you must comply with the following specifications and

requirements to meet the EMC Directive and other standards in Europe:

1. Power supply requirements

a. Voltage fluctuation must be -15% to +10% or less.

b. Voltage imbalance must be ±3% or less.

c. Frequency variation must be ±4% or less.

d. Total harmonic distortion (THD) of voltage must be ±10% or less.

2. Installation requirement

a. The integrated filter in the SJ700D series inverter must be enabled. (See chapter 2 Installation andWiring)

* When using the specific external filter for the SJ700D series inverter, please refer to the instruction

described in the dedicated guide book for the filter.

3. Wiring requirements

a. A shielded wire (screened cable) must be used for motor wiring, and the length of the cable must be

according to the following table (Table 1).

b. The carrier frequency must be set according to the following table to meet an EMC requirement (Table 1).

c. The main circuit wiring must be separated from the control circuit wiring.

4. Environmental requirements (to be met when a filter is used)

a. Ambient temperature must be within the range -10°C to +50°C.

b. Relative humidity must be within the range 20% to 90% (non-condensing).

c. Vibrations must be 5.9 m/s2 (0.6 G) (10 to 55 Hz) or less. (0.4 to 22kW)

2.94 m/s2 (0.3 G) (10 to 55Hz) or less. (30 to 150kW)

d. The inverter must be installed indoors (not exposed to corrosive gases and dust) at an altitude of 1,000 m

or less.

iii

Safety Instructions

model

cat.

cable

length(m)

carrier

frequency(kHz)

model

cat.

cable

length(m)

carrier

frequency(kHz)

SJ700D-004L

C3 5 2.5

SJ700D-007L

C3 5 2.5

SJ700D-007H

C3 5 2.5

SJ700D-015L

C3 5 2.5

SJ700D-015H

C3 5 2.5

SJ700D-022L

C3 5 2.5

SJ700D-022H

C3 5 2.5

SJ700D-037L

C3 5 2.5

SJ700D-037H

SJ700D-040H

C3 5 2.5

SJ700D-055L

C3 1 1

SJ700D-055H

C3 1 2.5

SJ700D-075L

C3 1 1

SJ700D-075H

C3 1 2.5

SJ700D-110L

C3 1 1

SJ700D-110H

C3 1 2.5

SJ700D-150L

C3 1 1

SJ700D-150H

C3 1 2.5

SJ700D-185L

C3 1 1

SJ700D-185H

C3 1 2.5

SJ700D-220L

C3 5 2.5

SJ700D-220H

C3 1 2.5

SJ700D-300L

C3 5 2.5

SJ700D-300H

C3 1 2.5

SJ700D-370L

C3 5 2.5

SJ700D-370H

C3 1 2.5

SJ700D-450L

C3 5 2.5

SJ700D-450H

C3 5 2.5

SJ700D-550L

C3 5 2.5

SJ700D-550H

C3 5 2.5

SJ700D-750H

C3

10

2.5

SJ700D-900H

C3

10

2.5

SJ700D-1100H

C3

10

2.5

SJ700D-1320H

C3

10

2.5

SJ700D-1500H

C3

10

2.5

Table 1

iv

Safety Instructions

Model No.

Required Torque (N.m)

Wire Range (AWG)

SJ700D-004L

1.8

14(Stranded only)

SJ700D-007L

1.8

14(Stranded only)

SJ700D-015L

1.8

14(Stranded only)

SJ700D-022L

1.8

14(Stranded only)

SJ700D-037L

1.8

10(Stranded only)

SJ700D-050L

3.0

8

SJ700D-055L

4.0

8

SJ700D-075L

4.0

6

SJ700D-110L

4.0

6-4

SJ700D-150L

4.9

2

SJ700D-185L

4.9

1

SJ700D-220L

8.8

1 or 1/0

SJ700D-300L

8.8

2/0 or Parallel of 1/0

SJ700D-370L

20.0

4/0 (Prepared wire only) or Parallel of 1/0

SJ700D-450L

20.0

4/0 (Prepared wire only) or Parallel of 1/0

SJ700D-550L

19.6

350 kcmil

(Prepared wire only) or Parallel of 2/0 (Prepared wire only)

Cautions for UL and cUL (0.4kW-150kW)

(Standard to comply with: UL508C, CSA C22.2 No14-5)

Warning Markings

GENERAL:

These devices are open type and/or Enclosed Type 1 (when employing accessory Type 1 Chassis Kit) AC Inverters

with three phase input and three phase output. They are intended to be used in an enclosure. They are used to

provide both an adjustable voltage and adjustable frequency to the ac motor. The inverter automatically maintains

the required volts-Hz ration allowing the capability through the motor speed range.

(1) “Use 60/75C CU wire only” or equivalent.

For models SJ700D series except for models SJ700D-055H, SJ700D-075H, SJ700D-110H.

(2) “Use 75C CU wire only” or equivalent.

For models SJ700D series except for SJ700D-075H, SJ700D-110H, SJ700D-055H.

(3) “Suitable for use on a circuit capable of delivering not more than 100,000rms symmetrical amperes,

240V maximum”. For models with suffix L.

(4) “Suitable for use on a circuit capable of delivering not more than 100,000 rms symmetrical amperes,

480V maximum”. For models with suffix H.

(5) “Install device in pollution degree 2 environment”

(6) “Maximum Surrounding Air Temperature 45 or 50C”

(7) “CAUTION - Risk of Electric Shock - Capacitor discharge time is at least 10 min.”

(8) ”Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection must be provided in accordance with the NEC and any additional local codes”

(9) “Solid State motor overload protection reacts with max. 120% of FLA”.

(10) Tightening torque and wire range for field wiring terminals are in the table below:

v

Safety Instructions

Model No.

Fuse Size (Maximum A)

Circuit Breaker (A)

Type

Rating Type

SJ700D-004L

J

30 A

SJ700D-004L

J

SJ700D-007L

J

30 A

SJ700D-007L

J

SJ700D-015L

J

30 A

SJ700D-015L

J

SJ700D-022L

J

30 A

SJ700D-022L

J

SJ700D-037L

J

30 A

SJ700D-037L

J

SJ700D-050L

J

30 A

SJ700D-050L

J

SJ700D-055L

J

100 A

SJ700D-055L

J

SJ700D-075L

J

100 A

SJ700D-075L

J

SJ700D-110L

J

100 A

SJ700D-110L

J

SJ700D-150L

J

125 A

SJ700D-150L

J

SJ700D-185L

J

125 A

SJ700D-185L

J

SJ700D-220L

J

125 A

SJ700D-220L

J

SJ700D-300L

J

225 A

SJ700D-300L

J

SJ700D-370L

J

225 A

SJ700D-370L

J

SJ700D-450L

J

250 A

SJ700D-450L

J

SJ700D-550L

J

300 A

SJ700D-550L

J

Model No.

Required Torque (N.m)

Wire Range (AWG)

SJ700D-007H

1.8

14(Stranded only)

SJ700D-015H

1.8

14(Stranded only)

SJ700D-022H

1.8

14(Stranded only)

SJ700D-037H

1.8

14(Stranded only)

SJ700D-040H

1.8

14(Stranded only)

SJ700D-055H

4.0

12

SJ700D-075H

4.0

10

SJ700D-110H

4.0

8

SJ700D-150H

4.9

6

SJ700D-185H

4.9

6

SJ700D-220H

4.9

6 or 4

SJ700D-300H

4.9

3

SJ700D-370H

20.0

1

SJ700D-450H

20.0

1

SJ700D-550H

20.0

2/0

SJ700D-750H

20.0

Parallel of 1/0

SJ700D-900H

20.0

Parallel of 1/0

SJ700D-1100H

35.0

Parallel of 3/0

SJ700D-1320H

35.0

Parallel of 3/0

SJ700D-1500H

35.0

Parallel of 3/0

(11) Distribution fuse / circuit breaker size marking is included in the manual to indicate that the unit shall be

connected with a listed inverse time circuit breaker, rated 600 V with the current ratings as shown in the

table below:

vi

Safety Instructions

Model No.

Fuse Size (Maximum A)

Circuit Breaker (A)

Type

Rating

Type

SJ700D-007H

J

20 A

SJ700D-007H

J

SJ700D-015H

J

20 A

SJ700D-015H

J

SJ700D-022H

J

20 A

SJ700D-022H

J

SJ700D-037H

J

20 A

SJ700D-037H

J

SJ700D-040H

J

20 A

SJ700D-040H

J

SJ700D-055H

J

40 A

SJ700D-055H

J

SJ700D-075H

J

40 A

SJ700D-075H

J

SJ700D-110H

J

40 A

SJ700D-110H

J

SJ700D-150H

J

75 A

SJ700D-150H

J

SJ700D-185H

J

75 A

SJ700D-185H

J

SJ700D-220H

J

75 A

SJ700D-220H

J

SJ700D-300H

J

100 A

SJ700D-300H

J

SJ700D-370H

J

100 A

SJ700D-370H

J

SJ700D-450H

J

150 A

SJ700D-450H

J

SJ700D-550H

J

150 A

SJ700D-550H

J

SJ700D-750H

J

225 A

SJ700D-750H

J

SJ700D-900H

J

225 A

SJ700D-900H

J

SJ700D-1100H

J

300 A

SJ700D-1100H

J

SJ700D-1320H

J

350 A

SJ700D-1320H

J

Note) Please select an appropriate fuse or an appropriate circuit breaker for a system.

(12) “Field wiring connection must be made by a UL Listed and CN closed-loop terminal connector sized for the

wire gauge involved. Connector must be fixed using the crimp tool specified by the connector

manufacturer.”

(13) “Motor over temperature protection is not provided by the drive.”

DANGER! RISQUE DE BLESSURE OU DE CHOC ELECTRIQUE

- Lire attentivement le manuel avant l’installation et suivre les instructions

- Avant d’intervenir dans le variateur, couper le circuit de puissance et attendre 10 minutes avant d’ouvrir le capot

vii

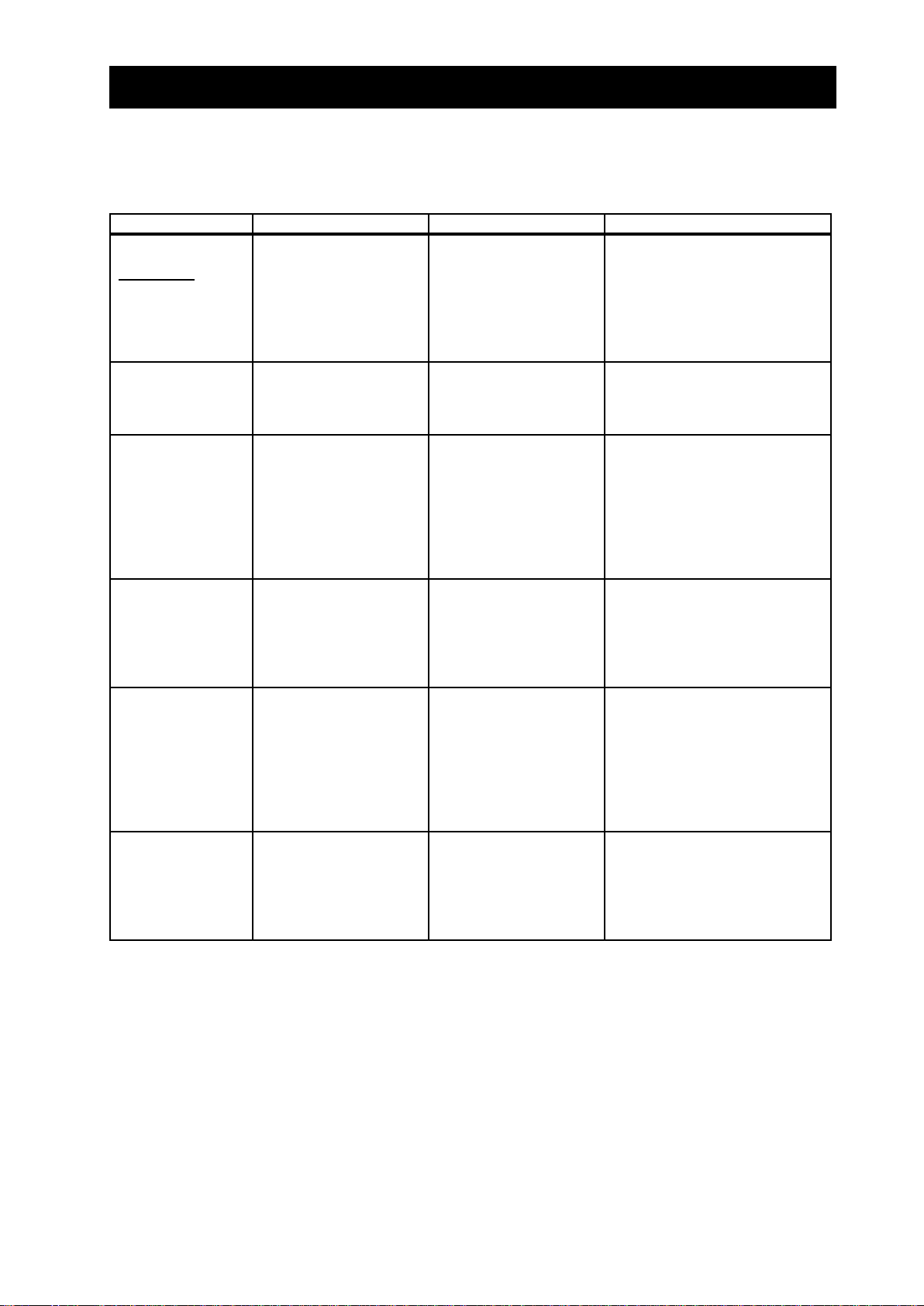

SJ700-2 to SJ700D-3

Subject

SJ700-2

SJ700D-3

Point!

Dual rating

Constant torque/

Variable torque

N/A

Selectable

If the inverter drives the light

load application (e.g. fan pump

application), you can choose

the one size smaller capacity

inverter than the motor capacity,

which allows you to reduce the

total cost of your system.

Easy sequence

(EzSQ) – Drive

program function

Process with 1 task.

Supporting 5 tasks

processing with

improved user

friendliness.

The inverter processes 5 tasks at

the same time, which allows you

to realize 5 times faster EzSQ

processing in maximum.

Optional LCD

Operator

WOP operator

(2-line LCD)

Full compatibility with

WOP operator

(5-line LCD and

multi-language)

WOP, the optional LCD

Operator, provides several user

friendliness;

− Multi data monitoring

− Parameter configuration as

monitoring data

− Parameter / Program copy

− Multi-language display

RS-485 serial

communications

19.2kbps (maximum)

115.2kbps (maximum),

and so on.

Approx. 6 times faster

communication in comparison

with the former model are

supported. In addition, some

communication commands are

newly supported.

Initialization

After setting b084

(initialization selection),

press some keys.

In addition to the

conventional method,

executing initialization

by a parameter is

possible.

(Select b084 and

b180=01 : enable the

initializing)

You can initialize easily only by

setting the parameter and no

special procedure is required

Phase loss

protection

Phase loss input

protection

Phase loss input

protection

Phase loss output

protection

Protection function expands to

not only input side but output

side, which provides more

reliable protection against the

phase loss.

The Hitachi SJ700D-3 series succeed the SJ700-2 series with the additional and enhanced features.

The table below is a belief summary of the major improved features.

Contents

Start-up Commissioning the drive

S.1 Quick installation and commissioning flowchart ................................................................................... S - 2

S.2 Instructing in using the panel.................................................................................................................. S - 3

S.3 Example of I/O connections ................................................................................................................... S - 4

S.4 Basic Parameter Setting to Drive Motor ................................................................................................. S - 8

S.4.1 Setting Frequency command source and Run command source .............................................. S - 8

S.4.2 Frequency command source selection ..................................................................................... S - 9

S.4.3 Run command source selection ............................................................................................... S - 11

S.5 Selecting the control mode ..................................................................................................................... S - 13

Chapter 1 Overview

1.1 Inspection of the Purchased Product ············································································· 1 - 2

1.1.1 Inspecting the product·················································································· 1 - 2

1.1.2 Quick Reference Guide and Instruction Manual···················································· 1 - 2

1.2 Method of Inquiry and Product Warranty ······································································· 1 - 3

1.2.1 Method of inquiry ······················································································ 1 - 3

1.2.2 Product warranty ························································································ 1 - 3

1.2.3 Warranty Terms ························································································· 1 - 3

1.3 Exterior Views and Names of Parts ·············································································· 1 - 4

Chapter 2 Installation and Wiring

2.1 Installation ·········································································································· 2 - 2

2.1.1 Precautions for installation ············································································ 2 - 3

2.1.2 Backing plate ································ ···························································· 2 - 5

2.2 Wiring ··············································································································· 2 - 6

2.2.1 Terminal connection diagram and explanation of terminals and switch settings ··············· 2 - 7

2.2.2 Wiring of the main circuit ············································································· 2 - 10

2.2.3 Wiring of the control circuit ··········································································· 2 - 19

2.2.4 Wiring of the digital operator ········································································· 2 - 20

Chapter 3 Operation

3.1 Operating Methods ································································································· 3 - 2

3.2 How to operate the Digital Operator (OPE-SBK) ····························································· 3 - 4

3.2.1 Names and functions of components ······························································· 3 - 4

3.2.2 Code display system and key operations ···························································· 3 - 5

Chapter 4 List of Data Settings

4.1 Precautions for Data Setting ······················································································ 4 - 2

4.2 Monitoring Mode ·································································································· 4 - 2

4.3 Function Mode ····································································································· 4 - 3

4.4 Extended Function Mode ························································································· 4 - 4

Chapter 5 Error Codes

5.1 Error Codes and Troubleshooting ················································································ 5 - 2

5.1.1 Error codes ······························································································ 5 - 2

5.1.2 Trip conditions monitoring ············································································ 5 - 4

5.2 Warning Codes ····································································································· 5 - 5

Chapter 6 Specifications

6.1 Specifications ······································································································· 6 - 2

6.2 External dimensions ······························································································· 6 - 5

Contents

(Memo)

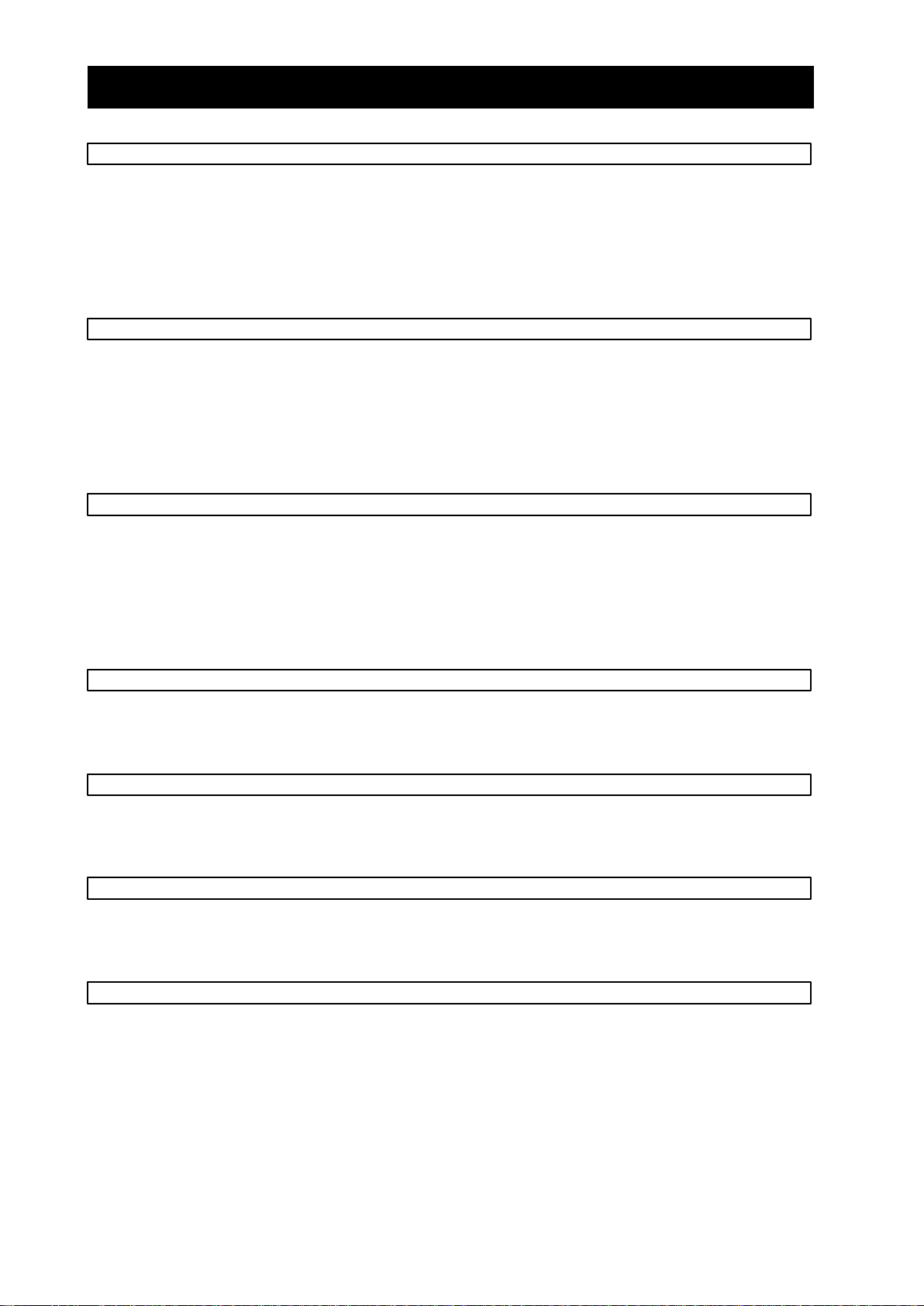

Start-up Commissioning the drive

This chapter contains quick installation and commissioning flowchart to drive the motor.

S.1 Quick installation and commissioning flowchart ............. S - 2

S.2 Instructing in using the panel ........................................... S - 3

S.3 Example of I/O connections ............................................. S - 4

S.4 Basic Parameter Setting to Drive Motor .......................... S - 8

S.5 Selecting the control mode ............................................... S - 13

Start-up Commissioning the drive

Start to confirm

Product inspection

Refer to chapter 1.

Installing

Wiring

Selecting the suitable control mode

End of Confirmation and start to drive

ON

Motor

Speed

Time

RUN

Frequency

command

Motor

speed

Refer to section 2.1.

・Installing

Initial settings of

SJ700D-****FF3

Initial settings of

3

Example 1

Example 2

Example 3

Example 4

Frequency

command

Data setting

(Operator)

External analog signal

(Voltage)

Data setting

(Multi-speed)

External analog signal

(Voltage and Current)

Drive

command

Push key

(Operator)

Push key

(Operator)

External signal

Before setting parameters,

see section S.2.

For basic settings to drive

the motor, see section S.4.

Example of basic setup

the motor, see section S.3.

Setting of control mode

see section S.5

Refer to section 2.2.

・Wiring

What are the desired sources

RUN command?

Setting of commands

S.1 Quick installation and commissioning flowchart

command

(IO connection) to drive

for giving frequency and

SJ700D-****FEF

External signal

S - 2

Start-up Commissioning the drive

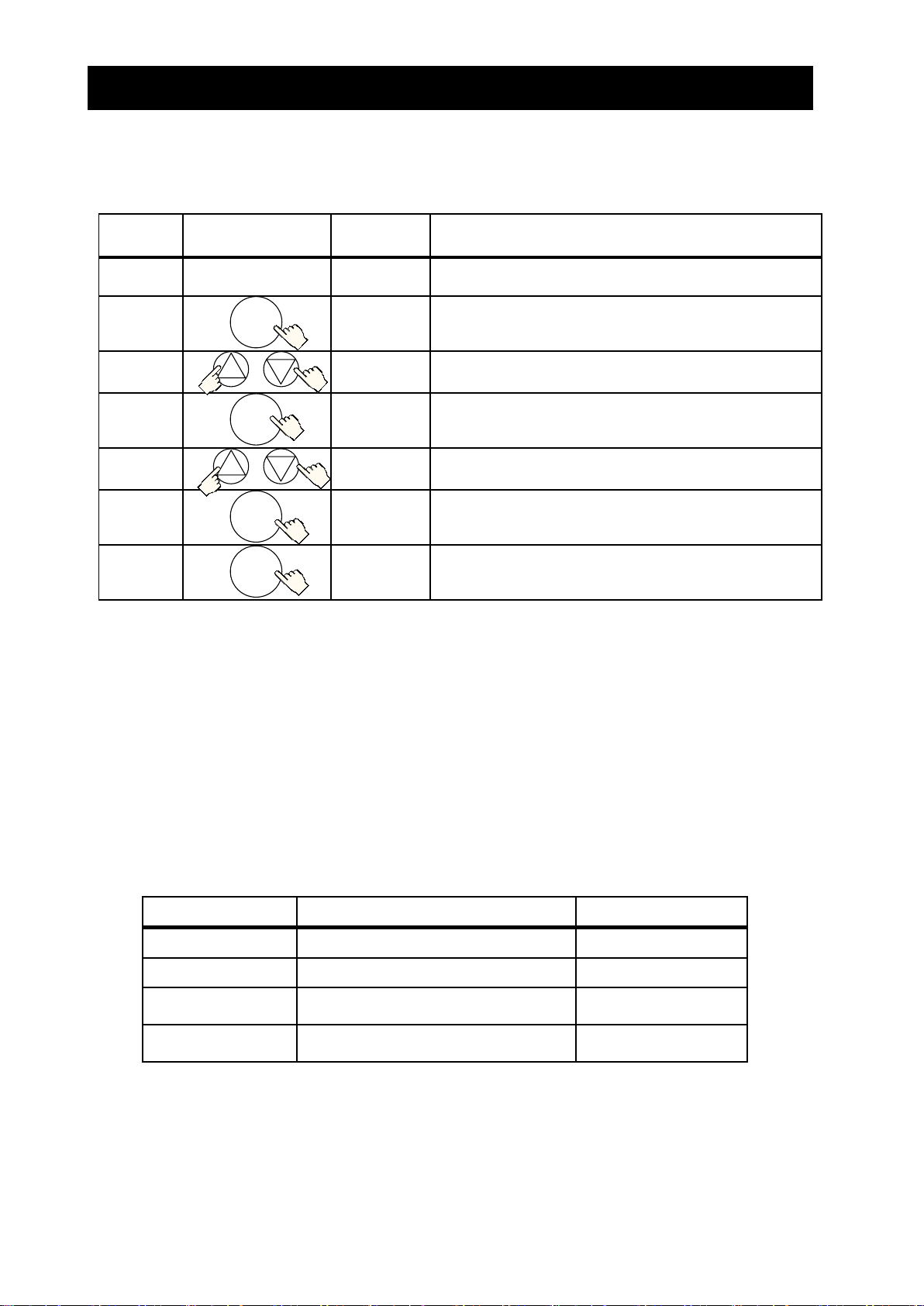

Key

Operation

Display(Example)

Use examples (*** is a three digit number)

d001 ←→ 0.00

(Frequency monitor)

In case d*** or F*** display on the panel, indication changes

between parameters and data with pushing FUNC key.

A--- → A044

↑ ↓

A044 ← 00

(Control mode)

In case A***, B***, C***, H***, P*** or U*** display on the

panel, indication changes among A--- (head of group), A044

(parameter) and 00 (data) with pushing FUNC key.

00 → A044

(Control mode)

When the panel indication displays 00 (data), the inverter saves the

displayed value as the new setting with pushing the STR key, and

panel indication changes to the A044 (parameter). The saved data

are held even if the power supply to the inverter is turned off.

d001→d002→…

→F004→A---→…

Panel Indication scrolls up through d***, F*** and the heads of

group (for example A---, B---, C---, H---, P--- and U---).

1.00→1.01→…

A011→A012→…

The value increases if panel indication displays parameters or data.

Holding the key down changes the value faster.

A---→F004→…→

d002→d001→…

Panel indication scrolls down through d***, F*** and the heads of

group (for example A---, B---, C---, H---, P--- and U---).

1.01→1.00→…

A012→A011→…

The value decreases if panel indication displays parameters or data.

Holding the key down changes the value faster.

Simultaneously

A044→’A’044

Pushing simultaneously enables to change each digit directly.

Operating of

the blinking digit is as follows.

0.00→’0’.00

FUNC

STR

1

2

2

1

A

ALARM

POWER

%

RUN

PRG

V

Hz

STR

FUNC

RUN

STOP/

RESET

kW

STR

FUNC

1

2

Left

Right/Save

Increasing

Decreasing

S.2 Instructing in using the panel

This section describes how to use the operator to

change the settings.

For more information, refer to the SJ700D-3 manual or

section 3.2 : How to operate the Digital Operator.

Indication of using the control panel Standard Operator (OPE-SBK)

*) In some cases parameters and data are discontinuous.

(For more information, refer to SJ700D-3 manual.)

S - 3

Start-up Commissioning the drive

Parameter

Details

Setting data

A001

Digital Operator

A002

Digital Operator

F001

Output frequency setting

.Note)

ELB

R/L1

S/L2

T/L3 R T

R0

T0

P

PD N RB

U

V

W

M

3-phase induction motor

RUN

STOP/

RESET

S.3 Example of I/O connections

Example 1: Frequency command source Setting data in F001 (Digital Operator)

Run command source RUN/STOP key (Digital Operator)

*) SJ700D-****FF3 (Initial settings)

(1) I/O connections

(2) Operation

Frequency: By using the digital operator, set the frequency command into parameter F001.

Run/Stop: Push the key and on the digital operator to run and stop.

*) Refer to section S.4.2 for changing the frequency command source and section S.4.3 for changing the run

command source.

(3) Parameter settings

Note) Initial settings are 0.00Hz. You need to set the appropriate data.

S - 4

Start-up Commissioning the drive

Parameter

Details

Setting data

A001

Control circuit terminal block

A002

Digital Operator

H O L

Potentiometer

R/L1

S/L2

T/L3

R T R0

T0

P

PD N RB

ELB

U

V

W

M

3-phase induction motor

RUN

STOP/

RESET

Example 2: :Frequency command source External potentiometer (Control terminal)

Run command source RUN/STOP key (Control panel)

(1) I/O connections

(2) Operation

Frequency: Set the frequency command via a potentiometer connected to H/O/L terminal.

Run/Stop: Push the key and to run and stop.

*) Refer to section S.4.2 for changing the frequency command source and section S.4.3 for changing the run

command source.

(3) Parameter settings

S - 5

Start-up Commissioning the drive

Parameter

Details

Setting data

A001

Digital Operator

A002

Control circuit terminal block

A020

Multi speed 1 and 2 are not active.

.Note)

A021

Multi speed 1is active and

multi speed 2 is not active.

.Note)

A022

Multi speed 1is not active and

multi speed 2 is active.

.Note)

FW

8:RV

CM1

Forward

7:CF1

6:CF2

P24

PLC

Reverse

Multi-speed1

Multi-speed2

CM1

P24

PLC

Sink logic

Source logic

R/L1

S/L2

T/L3

R

T

R0

T0

P

PD N RB

ELB

U

V

W

M

3-phase induction motor

Example 3: Frequency command source Setting data in F001 (Control panel) + multi speed select

Run command source External signal (Control terminal)

(1) I/O connections

*) In case of SJ700D-****FUF3, you need to set C006=03 and C016=00.

*) You need to set multi speed frequency command into parameters (from A020 to A022).

*) Refer to section S.4.2 for changing the frequency command source and section S.4.3 for changing the run

command source.

(2) Operation

Frequency: By using the multi speed terminals, set the frequency command.

Run/Stop: Using the forward / reverse terminal to run and stop.

(3) Parameter settings

Note) Initial settings are 0.00Hz. You need to set the appropriate data.

S - 6

Start-up Commissioning the drive

Parameter

Details

Setting data

A001

Control circuit terminal block

A002

Control circuit terminal block

FW

8:RV

CM1

Forward

2:AT

P24

PLC

Reverse

Analog select

CM1

P24

PLC

Sink logic

Source logic

R/L1

S/L2

T/L3 R T

R0

T0

P

PD N RB

OI O L

Voltage source

(0V to 10V)

Current source

(4mA to 20mA)

ELB

U

V

W

(+)

(-)

(+)

(-)

M

3-phase induction motor

Example 4: Frequency command source External analog voltage source and current source (Control terminal)

Run command source External signal (Control terminal)

*) SJ700D-****FEF3/FUF3 (Initial settings)

(1) I/O connections

*) Refer to S.4.2 for changing the frequency command source and S.4.3 for changing the run

command source.

(2) Operation

Frequency: Using the voltage source and current source to set the frequency command with analog

select terminal (AT terminal: OFF: Voltage command / ON: Current command).

* AT terminal is used to switch the analog input O and OI to which the inverter refers as the

frequency command. (e.g. When AT terminal is OFF, the inverter outputs the frequency

according to the voltage input given to the O terminal)

Run/Stop: Using the forward / reverse terminal to run and stop.

(3) Parameter settings

S - 7

Start-up Commissioning the drive

Parameter

Detail

Data range

Initial settings

****FF3

****FEF3

****FUF3

A001

Frequency source

00(keypad potentiometer)

01(control circuit terminal block)

02(operator)

03(RS485)

04(option 1)

05(option 2)

06(pulse-string input)

07(easy sequence)

10(operation function result)

02

01

A002

Run command source

01(control circuit terminal block)

02(operator)

03(RS485)

04(option 1)

05(option 2)

02

01

S.4 Basic Parameter Setting to Drive Motor

S.4.1 Setting Frequency command source and Run command source

This section describes how to drive the motor with SJ700D briefly.

The frequency and run command are necessary to drive the motor with the inverter.

In many cases, these sources are set as below;

Setting the frequency : (A) Data settings (Digital operator)

(B) Via external analog signals (Control terminal)

Run and stop : (A) RUN / STOP key (Digital operator)

(B) Via external signal (Control terminal)

The frequency command and Run command sources can be changed by the parameter A001 (Frequency command

source) and A002 (Run command source) respectively.

In addition to the basic setting mentioned above, there are several options for A001 and A002 setting.

*) This chapter explains 01(control circuit terminal block) and 02(operator) mainly.

S - 8

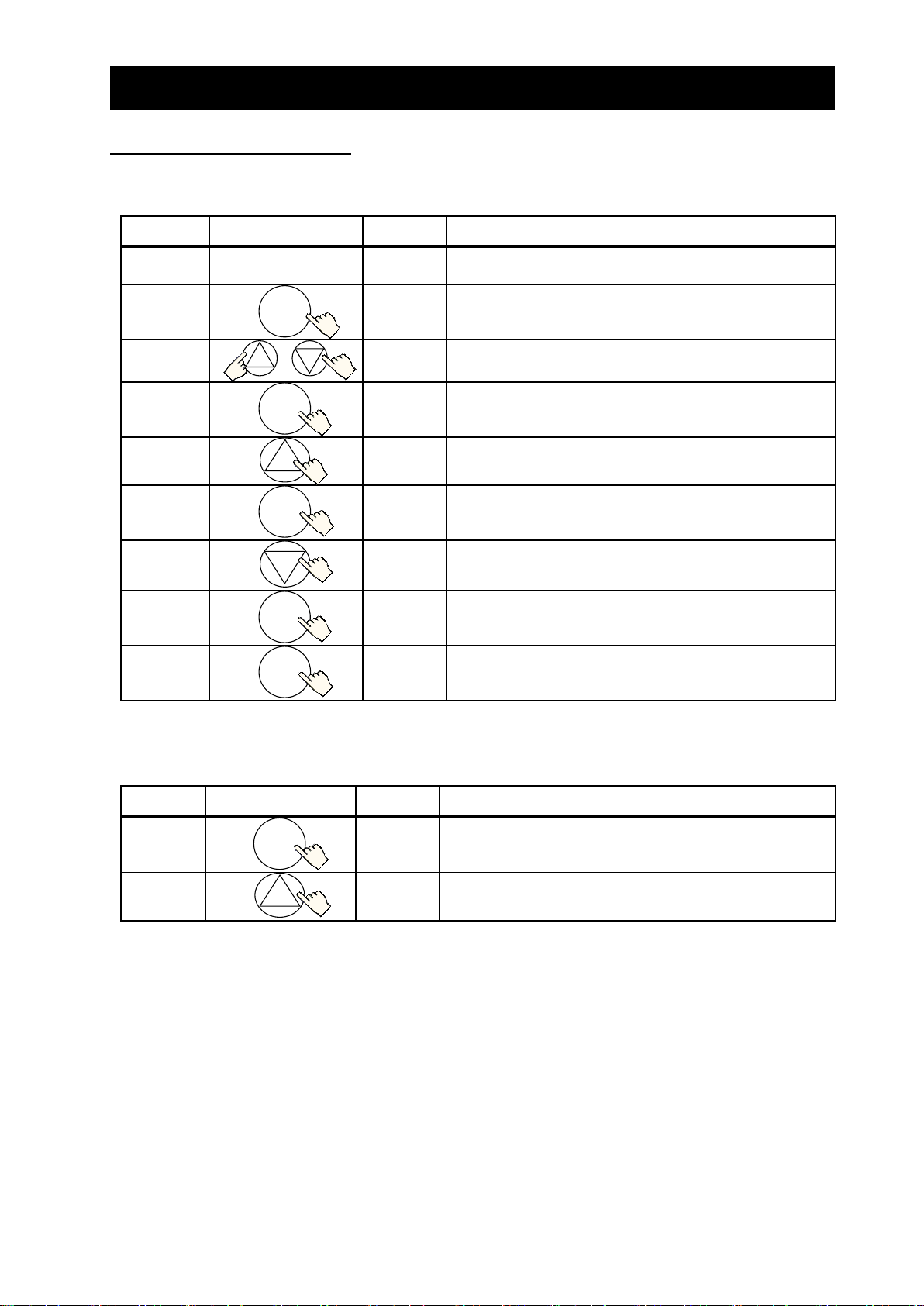

Start-up Commissioning the drive

Procedure

Key operation

Indication

Details

1-1

.

After powering up of the inverter, the operator displays 0.00,

output frequency monitor (d001)

1-2

Indication changes from data display (0.00) to parameter

display (d001).

1-3

or

Push the key and select the head of Group A.

1-4

Push the key and indication changes from A--- to A001.

1-5

Push the key and indication changes to 02(operator).

1-6

Push the key and change from 02 to 01 (control circuit

terminal block).

1-7

Push the key and indication changes A001 (Data save).

1-8

.

By pushing the key for more than three seconds,

indication changes to the output frequency data (d001).

(It depends on b038 setting)

Procedure

Key operation

Indication

Details

1-5’

Push the key and indication changes to 01(control circuit

terminal block).

1-6’

Push the key and change the data to 02 (operator).

FUNC

2

1

FUNC

FUNC

2

STR

FUNC

FUNC

1

S.4.2 Frequency command source selection

Key operation to set A001

****FF3 : Change A001 from 02 (operator) to 01 (control circuit terminal block).

****FEF3/FUF3 : Change from 01 (control circuit terminal block) to 02 (operator).

*) Replace the procedure 1-5 and 1-6 in the list above with 1-5’ and 1-6’ in the list below.

S - 9

Start-up Commissioning the drive

Procedure

Key operation

Indication

Details

1

.

After powering up of the inverter, the operator displays

0.00, output frequency monitor (d001)

2

Indication changes from data (0.00) to parameter (d001).

3

or

Push the key and select F001 (setting frequency).

4

.

Push the key and indication changes setting frequency.

5

or

.

(Example) Set the frequency to 40Hz.

6

Push the key and indication goes back to F001 (Data save).

note)

7

.

By pushing the key for more than three seconds,

the indication changes to the output frequency data.

(It depends on b038 setting)

Parameters

Condition

Setting

A001

Operator

*1)

A020

Multi speed 1 and 2 are not active.

.*2)

A021

Multi speed 1is active and

multi speed 2 is not active.

.*2)

A022

Multi speed 1is not active and

multi speed 2 is active.

.*2)

FUNC

2

1

FUNC

2

1

STR

FUNC

Setting frequency command

(A) A001=02: Digital operator

With this setting, the value set in the parameter F001 defines the target frequency of the inverter.

The procedure below shows an example of a procedure to set F001=40Hz.

note) In case of the setting A001=02, on displaying the output frequency, the setting frequency can change by the

up and down keys.

(B) A001=01: Control terminal

The frequency command can be changed in accordance with the analog input given to the O/OI terminal on the

control terminal by using a potentiometer (connected to H/O/L terminal) or an analog voltage / current supply.

With this setting, the parameter F001 indicates the frequency command value given via the control terminal.

Please refer to the instruction manual for the detailed information about the analog input (e.g. adjustment of he

start / end value).

(C) Multi-speed selection – Binary operation

The inverter can store several target frequencies (up to 16), which is useful to define such low / middle / high

frequencies and those frequencies are switched by external signals. The actual target frequency is selected from

those pre-set frequencies in accordance with the signal status of the multi speed inputs. This part describes an

example using 3 frequency sets.

*1) In case multi speed 1 and 2 are not active, the setting of A001 defines the frequency command source.

In case of A001=02, and if multi speed 1 and 2 are not active, F001 adopts the A020 value.

*2) Initial settings are 0.00Hz. You should set the appropriate data.

S - 10

Start-up Commissioning the drive

Procedure

Key operation

Indication

Details

2-1

.

After powering up of the inverter, the operator displays

0.00, output frequency monitor (d001)

2-2

Indication changes from data (0.00) to parameter (d001).

2-3

or

Push the key and select the head of Group A.

2-4

Push the key and indication changes to A001.

2-5

Push the key and select A002 (Run command source).

2-6

Push the key and indication changes to 02(operator).

2-7

Push the key and change the data to 01 (control circuit

terminal block).

2-8

Push the key and indication changes to A002 (Data save).

2-9

.

By pushing the key for more than three seconds,

indication changes to the output frequency data.

(It depends on b038 setting)

Procedure

Key operation

Indication

Details

2-6’

Push the key and indication changes to 01 (control circuit

terminal block).

2-7’

Push the key and change to 02(operator).

FUNC

2

1

FUNC

1

FUNC

2

STR

FUNC

FUNC

1

S.4.3 Run command source selection

Key operation to set A002

****FF3 : Change from 02 (operator) to 01 (control circuit terminal block).

****FEF3/FUF3 : Change 01 (control circuit terminal block) to 02 (operator).

*) Replace the procedure 2-6 and 2-7 on the list above with 2-6’ and 2-7’ in the list below.

S - 11

Start-up Commissioning the drive

RUN

STOP/

ON

Motor

Speed

Time

RUN

command

Frequency

command

Motor

speed

Operating run command

(A) A001=02: Digital operator

RUN and STOP key on the digital operator allows you to start and stop the motor respectively.

RUN: STOP:

RESET

*) Changing the rotatory direction can be done by changing the parameter F004, keypad run key routing or to

exchange any two phases of the wiring to the motor. Before wiring, you should confirm that the power supply

to the inverter has been cut off.

(B) A001=01: Control terminal

You can start and stop the motor operation via the FW terminal (forward rotation) or RV terminal (Reverse

rotation).

In case of terminal FW:

Sink logic (short between P24 and PLC)

FW-CM1 short: The inverter runs the motor in the forward direction --- RUN command is active.

FW-CM1 open: The inverter decelerates and stops the motor --- RUN command is not active.

Source logic (short between CM1 and PLC)

FW-P24 short: The inverter runs the motor in the forward direction --- RUN command is active.

FW-P24 open: The inverter decelerates and stops the motor --- RUN command is not active.

S - 12

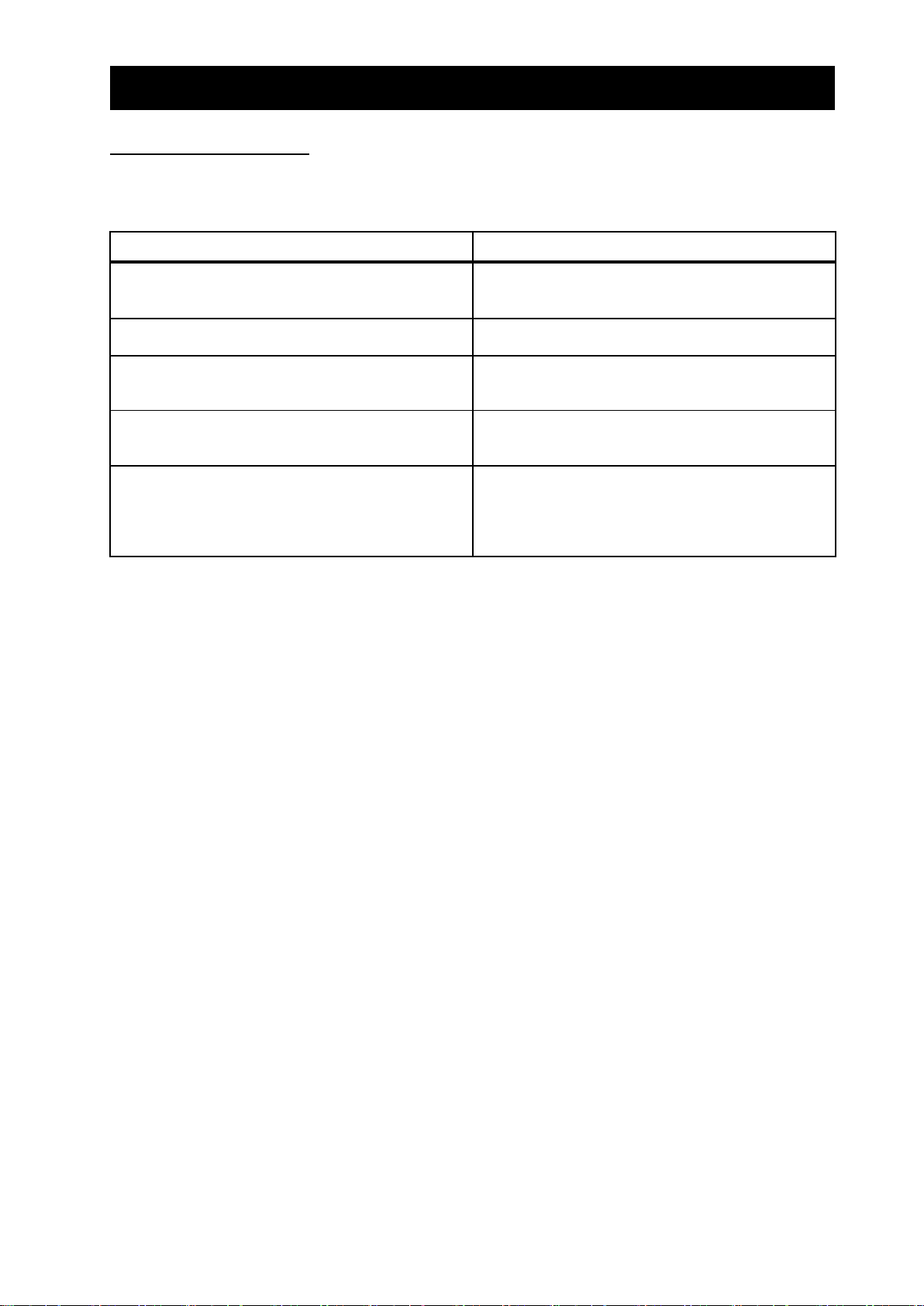

Start-up Commissioning the drive

Check

In case you want to drive fun, pump or light load

application :

-Using the reduced torque mode (A044=01)

-Use the light load mode (b049=01) to drive the motor

with the one size smaller inverter.

In case you want to set the characteristic of

voltage/frequency freely :

-Using Free V/f mode (A044=02)

In case you want to drive the application which

requires high torque control without the motor

feedback :

-Using sensor-less vector mode (A044=03)*

In case you want to drive the application which

requires the high torque control at low frequency range

without the motor feedback.

-Using 0Hz sensor-less vector mode (A044=04)*

In case you want to

- drive the application which requires high torque

control

- drive the application which requires the position

control with the motor feedback :

-Using vector control mode (A044=05)*

S.5 Selecting the control mode

The SJ700D-3 inverter series provides several options for motor control to satisfy various application

requirements. Please choose a suitable control mode for your application by referring to the table below.

Initial setting of A044 is 00 (V/f control mode).

*) Depending on the load, applying the one size bigger inverter may be required. For more information,

refer to SJ700D-3 manual.

S - 13

Start-up Commissioning the drive

(Memo)

S - 14

Chapter 1 Overview

This chapter describes the inspection of the purchased product, the product warranty, and the

names of parts.

1.1 Inspection of the Purchased Product ······· 1 - 2

1.2 Method of Inquiry and Product Warranty · 1 - 3

1.3 Exterior Views and Names of Parts ········ 1 - 4

Chapter 1 Overview

Specification label

Figure 1 Location of the specifications label

Figure 1-2 Contents of the specifications label

Inverter model

Input ratings

Output ratings

Serial number

Model: SJ700D-150HFF3

50Hz,60Hz 380-480V 3 Ph 35/41A

Output/Sortie: 0 - 400Hz 380-480V 3 Ph 32/37A

Input/Entree: 50Hz,60Hz V 1 Ph A

MFGNo. 44A T12345AA 001 Date: 1404

Hitachi Industrial Equipment

MADE IN JAPAN

NE18238-29

INVERTER

1.1 Inspection of the Purchased Product

1.1.1 Inspecting the product

After unpacking, inspect the product as described below.

If you find the product is abnormal or defective, contact your supplier or local Hitachi Distributor.

(1) Check the product for damage (including falling of parts and dents in the inverter body) caused during

transportation.

(2) Check that the product package contains an inverter set, this Quick Reference Guide and a CD (including the

SJ700D-3 Instruction Manual).

(3) Check the specification label to confirm that the product is the one you have ordered.

Systems Co.,Ltd.

1.1.2 Quick Reference Guide and Instruction Manual

This Quick Reference Guide describes how to handle and maintain the Hitachi SJ700D-3 Series Inverter briefly and

"SJ700D-3 series Instruction Manual" on CD bundled with inverter describes the more detailed information. Read

these manuals carefully before using the inverter, and then keep it handy for those who operate, maintain, and

inspect the inverter. When using the inverter together with optional products, also read the manuals for those

products.

Note that these manuals and the manual for each optional product to be used should be delivered to the end user

of the inverter.

1 - 2

Chapter 1 Overview

1.2 Method of Inquiry and Product Warranty

1.2.1 Method of inquiry

For an inquiry about product damage or faults or a question about the product, notify your supplier of

the following information:

(1) Model of your inverter

(2) Serial number (MFG No.)

(3) Date of purchase

(4) Content of inquiry

- Location and condition of damage

- Content of your question

1.2.2 Product warranty

The product will be warranted under the term described in the next section “1.2.3 Warranty Terms”.

Even within the warranty period, repair of a product fault will not be covered by the warranty (but the repair will be

at your own cost) if:

(1) the fault has resulted from incorrect usage not conforming to the instructions given in this Instruction Manual

or the repair or modification of the product carried out by an unqualified person,

(2) the fault has resulted from a cause not attributable to the delivered product,

(3) the fault has resulted from use beyond the limits of the product specifications, or

(4) the fault has resulted from disaster or other unavoidable events.

The warranty will only apply to the delivered inverter and excludes all damage to other equipment and facilities

induced by any fault of the inverter.

Repair at the user's charge :

Following the warranty period, any examination and repair of the product will be accepted at your charge. Even

during the warranty period, examination and repairs of faults, subject to the above scope of the warranty disclaimer,

will be available at charge. To request a repair at your charge, contact your supplier or local Hitachi Distributor.

1.2.3 Warranty Terms

The warranty period under normal installation and handling conditions shall be two (2) years from the date of

manufacture (“DATE” on product nameplate), or one (1) year from the date of installation, whichever occurs first.

The warranty shall cover the repair or replacement, at Hitachi’s sole discretion, of ONLY the inverter that was

installed.

(1) Service in the following cases, even within the warranty period, shall be charged to the purchaser:

a. Malfunction or damage caused by mis-operation or modification or improper repair

b. Malfunction or damage caused by a drop after purchase and transportation

c. Malfunction or damage caused by fire, earthquake, flood, lightening, abnormal input voltage,

contamination, or other natural disasters

(2) When service is required for the product at your work site, all expenses associated with field repair shall be

charged to the purchaser.

(3) Always keep this manual handy; please do not lose it. Please contact your Hitachi distributor to purchase

replacement or additional manuals.

1 - 3

Chapter 1 Overview

Option slot 1

Main circuit terminals

Backing plate

Control circuit terminals

Option slot 2

POWER lamp

ALARM lamp

Digital operator

Spacer cover

Specification label

Terminal block cover

Front cover

1.3 Exterior Views and Names of Parts

The figure below shows an exterior view of the inverter.

For the wiring of the main circuit and control circuit terminals, open the terminal block cover.

For mounting optional circuit boards, open the front cover.

Exterior view of inverter with the removed front and terminal block covers

Exterior view of inverter

1 - 4

Chapter 2 Installation and Wiring

This chapter describes how to install the inverter and the wiring of main circuit and control

signal terminals with typical examples of wiring.

2.1 Installation ····································· 2 - 2

2.2 Wiring ··········································· 2 - 6

Chapter 2 Installation and Wiring

CAUTION

- Install the inverter on a non-flammable surface, e.g., metal. Otherwise, you run the risk of fire.

- Do not place flammable materials near the installed inverter. Otherwise, you run the risk of fire.

- When carrying the inverter, do not hold its top cover. Otherwise, you run the risk of injury by dropping the

inverter.

- Prevent foreign matter (e.g., cut pieces of wire, sputtering welding materials, iron chips, wire, and dust) from

entering the inverter. Otherwise, you run the risk of fire.

- Install the inverter on a structure able to bear the weight specified in this Instruction Manual. Otherwise, you

run the risk of injury due to the inverter falling.

- Install the inverter on a vertical wall that is free of vibrations. Otherwise, you run the risk of injury due to the

inverter falling.

- Do not install and operate the inverter if it is damaged or its parts are missing. Otherwise, you run the risk of

injury.

- Install the inverter in a well-ventilated indoor site not exposed to direct sunlight. Avoid places where the

inverter is exposed to high temperature, high humidity, condensation, dust, explosive gases, corrosive gases,

flammable gases, grinding fluid mist, or salt water. Otherwise, you run the risk of fire.

- The inverter is precision equipment. Do not allow it to fall or be subject to high impacts, step on it, or place a

heavy load on it. Doing so may cause the inverter to fail.

2.1 Installation

2 - 2

Chapter 2 Installation and Wiring

5 cm or more

5 cm or more

(*1)

(*2)

Inverter

Keep enough clearance between the

inverter and the wiring ducts located

above and below the inverter to prevent

the latter from obstructing the ventilation

of the inverter.

(*1) 10 cm or more : ~ 55kW

(*2) 10 cm or more : ~ 55kW

But for exchanging the DC bus capacitor,

take a distance.

22cm or more : 15kW ~ 55kW

30cm or more : 75kW ~

Inverter

Air flow

Wall

2.1.1 Precautions for installation

(1) Transportation

The inverter uses plastic parts. When carrying the inverter, handle it carefully to prevent damage to the parts.

Do not carry the inverter by holding the front or terminal block cover. Doing so may cause the inverter to fall.

Do not install and operate the inverter if it is damaged or its parts are missing.

(2) Surface on which to install the inverter

The inverter will reach a high temperature (up to about 150°C) during operation. Install the inverter on a vertical

wall surface made of nonflammable material (e.g., metal) to avoid the risk of fire.

Leave sufficient space around the inverter. In particular, keep sufficient distance between the inverter and other

heat sources (e.g., braking resistors and reactors) if they are installed in the vicinity.

(3) Ambient temperature

Avoid installing the inverter in a place where the ambient temperature goes above or below the allowable range

(-10°C to +40°C), as defined by the standard inverter specification.

Measure the temperature in a position about 5 cm distant from the bottom-center point of the inverter, and check

that the measured temperature is within the allowable range.

Operating the inverter at a temperature outside this range will shorten the inverter life (especially the capacitor

life).

(4) Humidity

Avoid installing the inverter in a place where the relative humidity goes above or below the allowable range (20%

to 90% RH), as defined by the standard inverter specification.

Avoid a place where the inverter is subject to condensation.

Condensation inside the inverter will result in short circuits and malfunctioning of electronic parts. Also avoid

places where the inverter is exposed to direct sunlight.

(5) Ambient air

Avoid installing the inverter in a place where the inverter is subject to dust, corrosive gases, combustible gases,

flammable gases, grinding fluid mist, or salt water.

Foreign particles or dust entering the inverter will cause it to fail. If you use the inverter in a considerably dusty

environment, install the inverter inside a totally enclosed panel.

30cm or more : 75kW ~

30cm or more : 75kW ~

2 - 3

Chapter 2 Installation and Wiring

Inverter

Inverter

Enclosure

Horizontal mounting

Inverter

Inverter

Enclosure

Guide

Plate

Vertical mounting

(Unacceptable)

Ventilation fan

Inverter

(Acceptable)

Ventilation fan

Inverter

(6) Installation method and position

Install the inverter vertically and securely with screws or bolts on a surface that is free from vibrations and that

can bear the inverter weight. If the inverter is not installed vertically, its cooling performance may be degraded

and tripping or inverter damage may result.

(7) When mounting multiple inverters in an enclosure with a ventilation fan, carefully design the layout of the

ventilation fan, air intake port, and inverters. An inappropriate layout will reduce the inverter-cooling effect and

raise the ambient temperature. Plan the layout so that the inverter ambient temperature will remain within the

allowable range.

Position of ventilation fan

(8) Mounting in an enclosure

The internal fan releases the heat generated by the inverter from the upper part of the inverter. When it is

necessary to install a device above the inverter, please ensure that the device is protected against this heat.

When several inverters are mounted in the same cabinet the standard arrangement of the inverters is side-by-side

with certain space as shown in the figure on the left below. If the inverters must be mounted one above the other

in order to save the cabinet space or similar, the heat from the lower inverter may lead to temperature rise and

breakdown of the higher inverter. Please ensure that the heat generated by the lower inverter does not affect the

one above by installing a mechanical separation or similar (e.g. guide plate between the inverters as shown in the

figure below right).

When mounting several inverters in the same cabinet, design the cabinet so that the temperature inside the

cabinet does not exceed the allowable specific range for the inverter (by using increased ventilation and/or

enlarging the size of cabinet etc.)

2 - 4

Chapter 2 Installation and Wiring

Section to be cut off

Joint

Inverter capacity (kW)

0.4

0.75

1.5

2.2

3.7/4.0

5.5

7.5

11

15

18.5

Loss with 70% load (W)

64

76

102

127

179

242

312

435

575

698

Loss with 100% load (W)

70

88

125

160

235

325

425

600

800

975

Efficiency at rated output (%)

85.1

89.5

92.3

93.2

94.0

94.4

94.6

94.8

94.9

95.0

Inverter capacity (kW)

22

30

37

45

55

75

90

110

132/150

Loss with 70% load (W)

820

1100

1345

1625

1975

2675

3375

3900

4670

Loss with 100% load (W)

1150

1550

1900

2300

2800

3800

4800

5550

6650

Efficiency at rated output (%)

95.0

95.0

95.1

95.1

95.1

95.2

95.2

95.2

95.2

Backing plate

Rubber bushing

(9) Reduction of enclosure size

If you mount the inverter inside an enclosure such that the heat sink of the inverter is positioned outside the

enclosure, the amount of heat produced inside the enclosure can be reduced and likewise the size of the

enclosure. Mounting the inverter in an enclosure with the heat sink positioned outside requires an optional

dedicated special metal fitting. To mount the inverter in an enclosure with the heat sink positioned outside, cut

out the enclosure panel according to the specified cutting dimensions. The cooling section (including the heat

sink) positioned outside the enclosure has a cooling fan. Therefore, do not place the enclosure in any

environment where it is exposed to waterdrops, oil mist, or dust.

(10) Approximate loss by inverter capacity

2.1.2 Backing plate

(1) For models with 30 kW or less capacity

On the backing plate, cut the joints around each section to be cut off with cutting pliers or a cutter, remove them,

and then perform the wiring.

(2) For the models with 37 kW to 75kW

1) For wiring without using conduits

Cut an X in each rubber bushing of the backing plate with cutting pliers or a cutter, and then perform the wiring.

2) For wiring using conduits

Remove the rubber bushings from the holes to be used for wiring with conduits, and then fit conduits into the

holes.

Note: Do not remove the rubber bushing from holes that are not used for wiring with a conduit.

If a cable is connected through the plate hole without a rubber bushing and conduit, the cable insulation

may be damaged by the edge of the hole, resulting in a short circuit or ground fault.

2 - 5

Chapter 2 Installation and Wiring

WARNING

- Be sure to ground the inverter. Otherwise, you run the risk of electric shock or fire.

- Commit wiring work to a qualified electrician. Otherwise, you run the risk of electric shock or fire.

- Before wiring, make sure that the power supply is off. Otherwise, you run the risk of electric shock or fire.

- Perform wiring only after installing the inverter. Otherwise, you run the risk of electric shock or injury.

- Do not remove rubber bushings from the wiring section. Otherwise, the edges of the wiring cover may damage

the wire, resulting in a short circuit or ground fault.

CAUTION

- Make sure that the voltage of AC power supply matches the rated voltage of your inverter. Otherwise, you run

the risk of injury or fire.

- Do not input single-phase power into the inverter. Otherwise, you run the risk of fire.

- Do not connect AC power supply to any of the output terminals (U, V, and W). Otherwise, you run the risk of

injury or fire.

- Do not connect a resistor directly to any of the DC terminals (PD, P, and N). Otherwise, you run the risk of fire.

- Connect an earth-leakage breaker to the power input circuit. Otherwise, you run the risk of fire.

- Use only the power cables, earth-leakage breaker, and magnetic contactors that have the specified capacity

(ratings). Otherwise, you run the risk of fire.

- Do not use the magnetic contactor installed on the primary and secondary sides of the inverter to stop its

operation.

- Tighten each screw to the specified torque. No screws must be left loose. Otherwise, you run the risk of fire.

- Before operating, slide switch SW1 in the inverter, be sure to turn off the power supply. Otherwise, you run the

risk of electric shock and injury.

- Since the inverter supports two modes of cooling-fan operation, the inverter power is not always off, even when

the cooling fan is stopped. Therefore, be sure to confirm that the power supply is off before wiring. Otherwise,

you run the risk of electric shock and injury.

2.2 Wiring

2 - 6

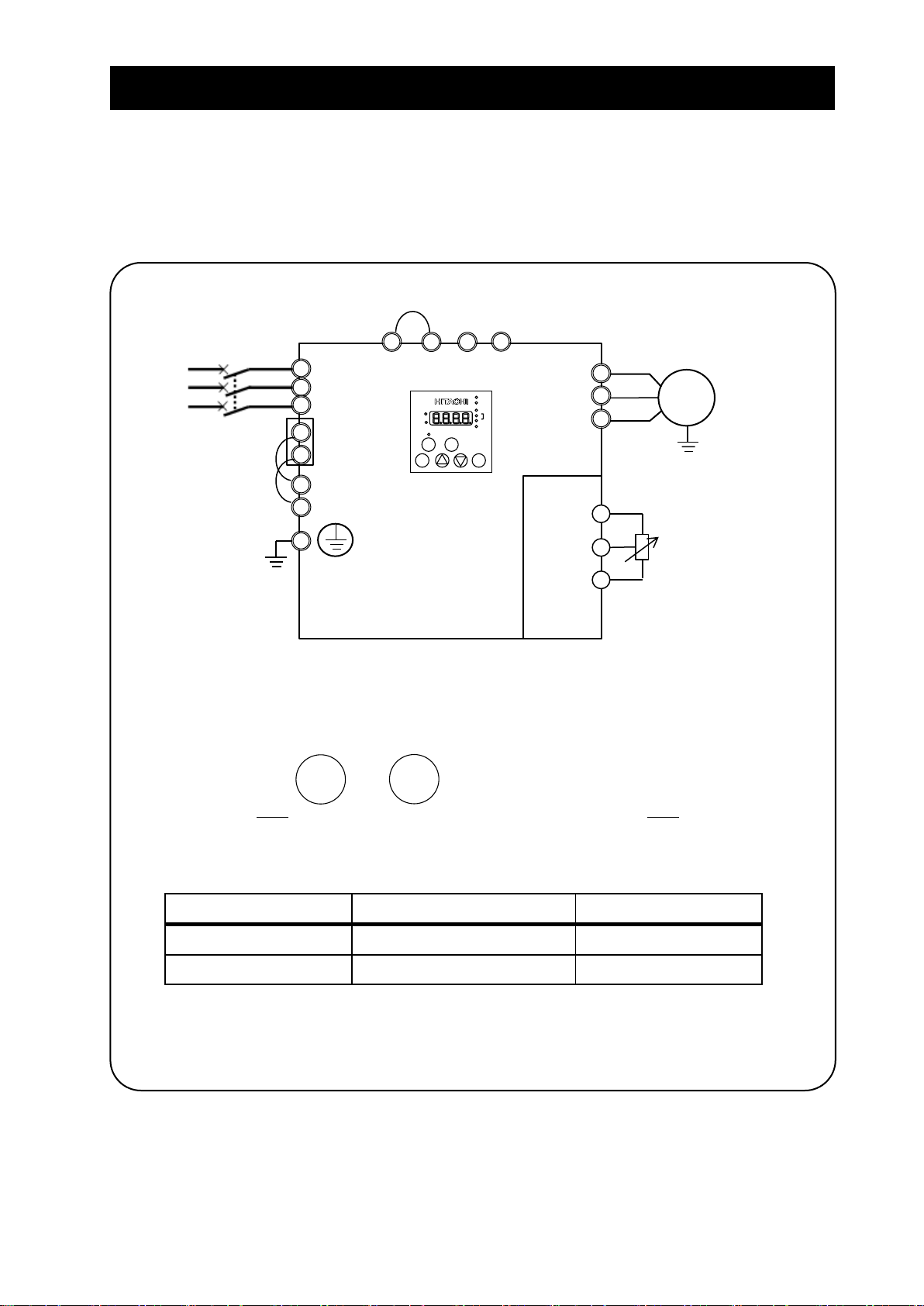

Chapter 2 Installation and Wiring

3-phase power supply

(50/60 Hz ±5%)

Jumper

When connecting separate power

cables beforehand.

Power supply for

control circuit

Forward rotation

Intelligent input

Digital monitor output

(PWM output)

Thermistor

Frequency

500 to 2,000Ω

0 to 10 VDC (12 bits)

-10 to +10 VDC (12 bits)

4 to 20 mA (12 bits)

Analog monitor

Analog monitor

0 to 10 V (10 bits)

4 to 20 mA (10 bits)

Motor

Jumper bar

Braking resistor

The dotted line indicates

terminal board.

Intelligent relay output contact

Intelligent output

For terminating

resistor

Option 1

Option 2

Type-D grounding (for 200 V class model)

(See page 2-12.)

PLC

P24

DC24V

CM

R S T

R0

T0 U V

W

PD

P

RB

N

FW

7

6

1

8

FM

CM1

H

O

O2

OI

L

AM

AMI

SP

SN

RP

SN

RS485

AL0

AL1

AL2

1

2

HITACHI

POWER

ALARM

Hz

V

A

%

kW

RUN

PRG

RUN

FUNC

STR

DC10V

100Ω

10kΩ

10kΩ

15

11

CM2

R

T

TH

J51

STOP/

RESET

M

100Ω

Default jumper position

(source type : FEF)

DCL

(without jumper bar)

BRD

2.2.1 Terminal connection diagram and explanation of terminals and switch settings

200 V class: 200 to 240 V +10%, -15%

(50/60 Hz ±5%)

400 V class: 380 to 480 V +10%, -15%

supplies to main and control

circuits, remove J51 connector

(sinking type : FUF/FF)

Default jumper position

(Models with 22kW

or less capacity )

the detachable control

command

(8 contacts)

setting circuit

(default: alarm output)

(5 terminals)

output

(voltage output)

output

(current output)

Type-C grounding (for 400 V class model)

2 - 7

Chapter 2 Installation and Wiring

Symbol

Terminal name

Description

R, S, T

(L1, L2, L3)

Main power input

Connect to the AC power supply.

Leave these terminals unconnected when using a regenerative converter (HS900 series).

U, V, W

(T1, T2, T3)

Inverter output

Connect a 3-phase motor.

PD, P

(+1, +)

DC reactor connection

Remove the jumper from terminals PD and P, and connect the optional power factor reactor (DCL).

P, RB

(+, RB)

External braking resistor

connection

Connect the optional external braking resistor.

(The RB terminal is provided on models with 30 kW or less capacity.)

P, N

(+, -)

Regenerative braking unit

connection

Connect the optional regenerative braking unit (BRD).

G

Inverter ground

Connect to ground for grounding the inverter chassis by type-D grounding (for 200 V class models)

or type-C grounding (for 400 V class models).

Symbol

Terminal name

Description

Electric property

Analog

Power

supply

L

Analog power

supply (common)

This common terminal supplies power to frequency command terminals (O, O2,

and OI) and analog output terminals (AM and AMI). Do not ground this terminal.

H Frequency setting

power supply

This terminal supplies 10 VDC power to the O, O2, OI terminals.

Allowable load current:

20 mA or less

Frequency setting input

O

Frequency

command

(voltage)

Input a voltage (0 to 10 VDC) as a frequency command. 10 V specifies the

maximum frequency.

To specify the maximum frequency with a voltage of 10 V or less, set the voltage

using function "A014".

Input impedance: 10kΩ

Allowable input voltages: -0.3

to +12 VDC

O2

Auxiliary

frequency

command

(voltage)

Input a voltage (0 to ±10 VDC) as a signal to be added to the frequency command

input from the O or OI terminal. You can input an independent frequency

command from this terminal (O2 terminal) alone by changing the setting.

Input impedance: 10kΩ

Allowable input voltages:

0 to 12 VDC

OI

Frequency

command

(current)

Input a current (4 to 20 mA DC) as a frequency command. 20 mA specifies the

maximum frequency.

The OI signal is valid only when the AT signal is on. Assign the AT function to an

intelligent input terminal.

Input impedance: 10kΩ

Maximum allowable current:

24 mA

Monitor output

AM

Analog monitor

(voltage)

This terminal outputs one of the selected "0 to 10 VDC voltage output"

monitoring items. The monitoring items available for selection include output

frequency, output current, output torque (signed or unsigned), output voltage,

input power, electronic thermal overload, LAD frequency, motor temperature,

heat sink temperature, and general output.

Maximum allowable current:

2 mA

Output voltage accuracy

±20%

(Ta=25±10 degrees C)

AMI

Analog monitor

(current)

This terminal outputs one of the selected "4 to 20 mA DC current output"

monitoring items. The monitoring items available for selection include output

frequency, output current, output torque (unsigned), output voltage, input power,

electronic thermal overload, LAD frequency, motor temperature, heat sink

temperature, and general output.

Allowable load impedance:

250Ω or less

Output current accuracy

±20%

(Ta=25±10 degrees C)

Digital (contact)

Monitor output

FM

Digital monitor

(voltage)

This terminal outputs one of the selected "0 to 10 VDC voltage output (PWM

output mode)" monitoring items. The monitoring items available for selection

include output frequency, output current, output torque (unsigned), output voltage,

input power, electronic thermal overload, LAD frequency, motor temperature,

heat sink temperature, general output, digital output frequency, and digital current

monitor.

For the items "digital output frequency" and "digital current monitor," this

terminal outputs a digital pulse signal at 0/10 VDC with a duty ratio of 50%.

Maximum allowable current:

1.2 mA

Maximum frequency:

3.6 kHz

Power supply

P24

Interface power

supply

This terminal supplies 24 VDC power for contact input signals.

If the source logic is selected, this terminal is used as a common contact input

terminal.

Maximum allowable output

current: 100 mA

CM1

Interface power

supply (common)

This common terminal supplies power to the interface power supply (P24),

thermistor input (TH), and digital monitor (FM) terminals. If the sink logic is

selected, this terminal is used as a common contact input terminal. Do not ground

this terminal.

Contact input

Operation

command

FW

Forward rotation

command

Turn on this FW signal to start the forward rotation of the motor; turn it off to stop

forward rotation after deceleration.

[Conditions for turning

contact input on]

Voltage across input and PLC:

18 VDC or more

Input impedance between

input and PLC: 4.7kΩ

Maximum allowable voltage

across input and PLC:

27 VDC

Load current with 27 VDC

power: about 5.6 mA

Function selection and logic

switching

1

2

3

4

5

6

7

8

Intelligent input

Select eight of a total 56 functions, and assign these eight functions to terminals 1

to 8.

Note:

If the emergency stop function is used, terminals 1 and 3 are used exclusively for

the function. For details, refer to the SJ700D-3 instruction manual.

(1) Explanation of main circuit terminals

(2) Explanation of control circuit terminals

2 - 8

Chapter 2 Installation and Wiring

Symbol

Terminal name

Description

Electric property

Digital (contact)

Contact input

Function selection and

logic switching

PLC

Intelligent input

(common)

To switch the control logic between sink logic and source logic, change the

jumper connection of this (PLC) terminal to another terminal on the control

circuit terminal block.

Jumper terminals P24 and PLC for the sink logic; jumper terminals CM1 and PLC

for the sink logic.

To use an external power supply to drive the contact inputs, remove the jumper,

and connect the PLC terminal to the external interface circuit.

Open collector

output

Status and factor

11

12

13

14

15

Intelligent output

Select five of a total 51 functions, and assign these five functions to terminals 11

to 15.

If you have selected an alarm code using the function "C062", terminals 11 to 13

or 11 to 14 are used exclusively for the output of cause code for alarm (e.g.,

inverter trip). The control logic between each of these terminals and the CM2

terminal always follows the sink or source logic.

Voltage drop between each

terminal and CM2 when

output signal is on: 4 V or less

Maximum allowable voltage:

27 VDC

Maximum allowable current:

50 mA

CM2

Intelligent output

(common)

This terminal serves as the common terminal for intelligent output terminals [11]

to [15].

Relay contact output

Status and alarm

AL0

AL1

AL2

Intelligent relay

output

Select functions from the 43 available, and assign the selected functions to these

terminals, which serve as C contact output terminals.

In the initial setting, these terminals output an alarm indicating that the inverter

protection function has operated to stop inverter output.

(Maximum contact capacity)

AL1-AL0: 250 VAC, 2 A

(resistance) or 0.2 A

(inductive load)

AL2-AL0: 250 VAC, 1 A

(resistance) or 0.2 A

(inductive load)

(Minimum contact capacity)

100 VAC, 10 mA

5 VDC, 100 mA

Analog

Analog input

Sensor

TH

External

thermistor input