Page 1

Actual Size (SJ100-004NFE, 004NFU)

Sensorless Vector Control

All Rights Reserved,Copyright ©2002,Hitachi,Ltd.

Page 2

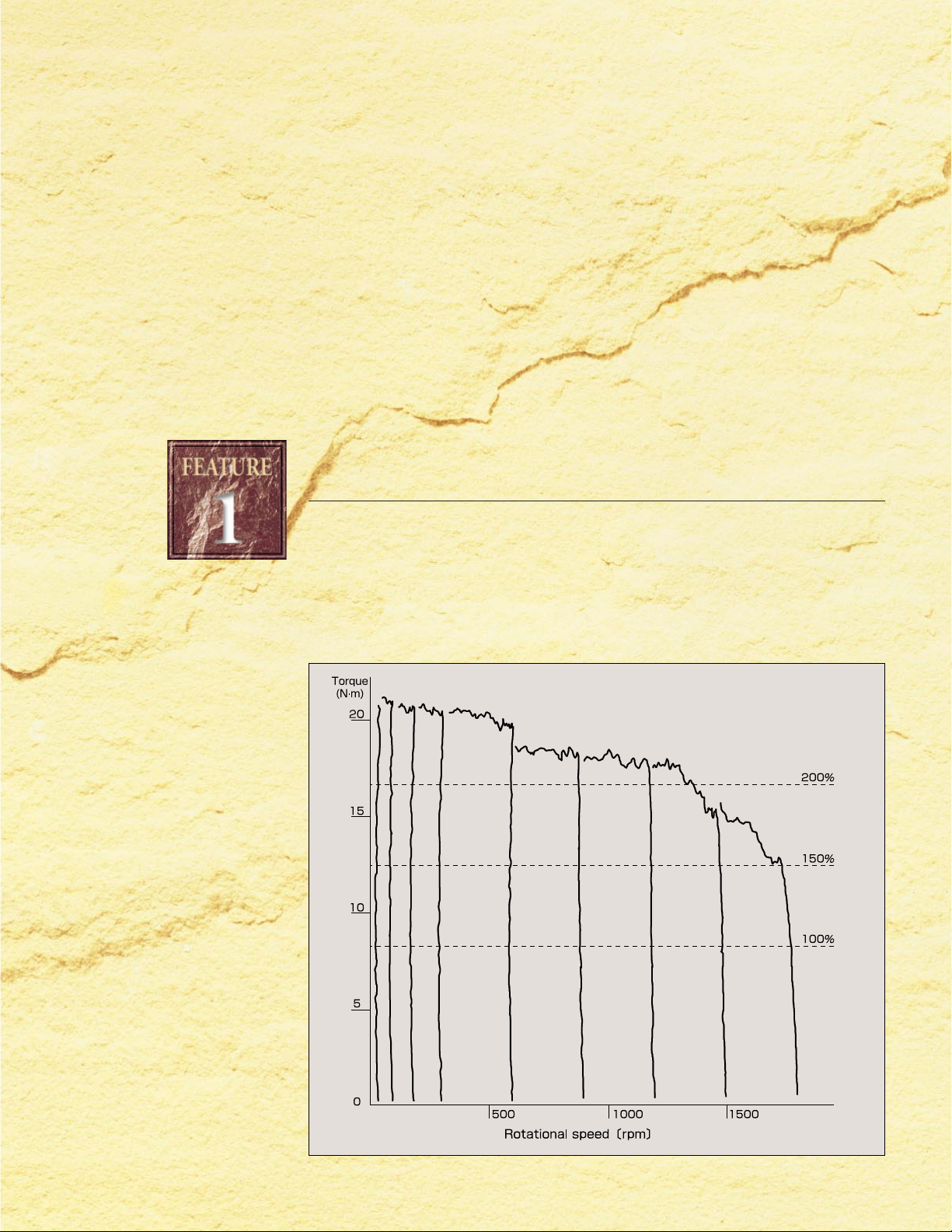

The torque calculation software (sensorless vector control) developed by Hitachi

ensures accurate torque control throughout the entire frequency range, even with

general purpose motors.

• High starting torque of 200%or more (3.7kW~ : 180% or more)

• 100% continuous operating torque within a 1:10 speed range (6 to 60 Hz/5 to 50

Hz) without motor de-rating. (3.7kW~: 1:3

(

20~60Hz))

Precise torque regulation using senseless

vector control!

The small inverter

with the power of a big one

The small inverter

with the power of a big one

1

Example of SJ100-015NFE with Hitachi 1.5kW 4 pole totally enclosed type motor

Page 3

P1~4

P5

P6~7

P8

P9~12

P13

P14

P15

P16

P17~18

W Features

W Standard Specifications

W Dimensional Drawings

W Operation

W Function List

W Terminal Functions

W Protective Functions

W Connection Diagram

W Applicable Wiring Apparatus and Options

W For Correct Operation

C ONTENTS

XAuto tuning to set motor constants

X Second motor setting (Provision to set second motor constants)

X PID control provided as standard

X 16–stage multispeed operation

X Instantaneous power failure retry

(frequency stabilization)

X Intelligent terminal system

allows you to select only the

necessary functions

from a full lineup of

enhanced functions.

X FAN ON/OFF selection

to provide longer cooling

fan life

X Incorporated rush current

prevention circuit

Advanced Functions Condensed in One Unit

2

Page 4

3

The SJ100 can be started by pressing

the RUN button or receiving an

external signal through the terminal.

Speed can be changed by standard

potentiometer, keypad or external

signals. Functions are grouped for

quick, easy setting.

Simple Operation By keypad or external

input signals

Installation space is reduced by

56% from the J100 Series and

11% from the compact L50 Series.

This allows downsizing of your

system installation.

Compact Size Saves Space

The powerful and intelligent SJ100 inverter series solves your

applications requirements for high torque at low speeds.

[Dynamic braking circuit incorporated as standard]

X CONVEYOR X TRUCK

X EXTRUDER X MIXER

X LIFT etc.

Perfect matching to Constant torque load

Compact, Powerful, Intelligent

and Easy to Use

Compact, Powerful, Intelligent

and Easy to Use

Page 5

4

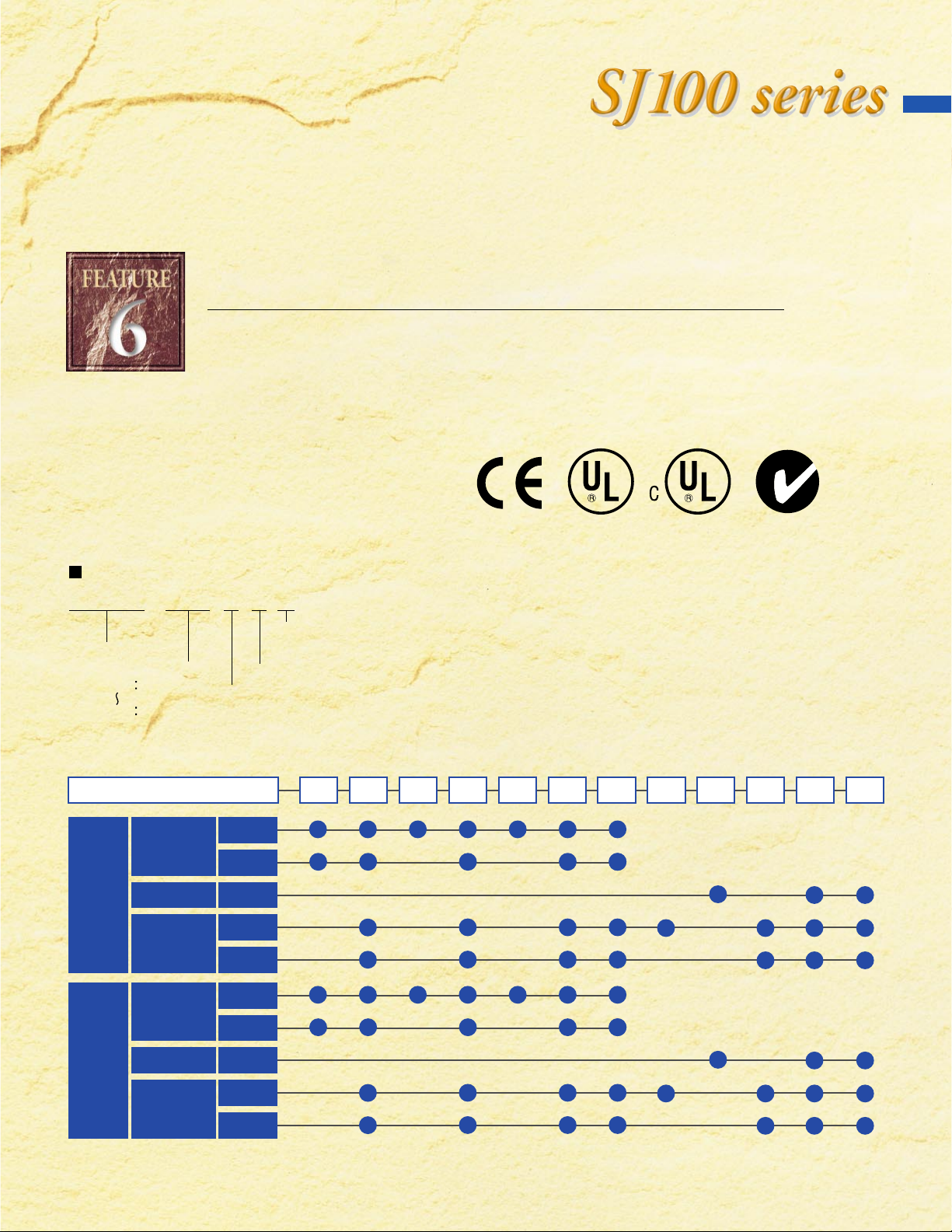

Applicable motor rating (kW)

Series name

E:European version for Europe, Australia, Singapore,etc.

U:UL version for North America

F:Operator panel equipped

Input power specification

L:Three-phase 200V class

N:Single-/three-phase 200V class

H:Three-phase 400V class

Applicable motor rating

SJ100-004 N F E

Single-/Threephase 200V

Eurpean

Version

(xxE type)

UL

Version

(xxUtype)

NFE type

LFU type

Three-phase

200V

NFU type

Three-phase

400V

HFE type

HFU type

Single-/Threephase 200V

Device Net

Compatible

[

SJ100DN

]

(xxE type)

(xxUtype)

NFE type

LFU type

Three-phase

200V

NFU type

Three-phase

400V

HFE type

HFU type

Model Type List

0.2 0.4 0.55 0.75 1.1 1.5 2.2 3.0 3.7 4.0 5.5 7.5

002 0.2kW

075 7.5kW

The SJ100 Series of world standard machines provide global performance.

X European low–voltage directive compliant, EMC directive compliant

(with dedicated noise filter)

X UL, c–UL standards

X C–Tick (Australian EMC requirment, with dedicated noise filter)

The line-up includes models

compatible with DeviceNet.

Network-Compatible World Standard Machine

Expands Global Business

<CE > <UL>

<C–UL>

<C–Tick>

Page 6

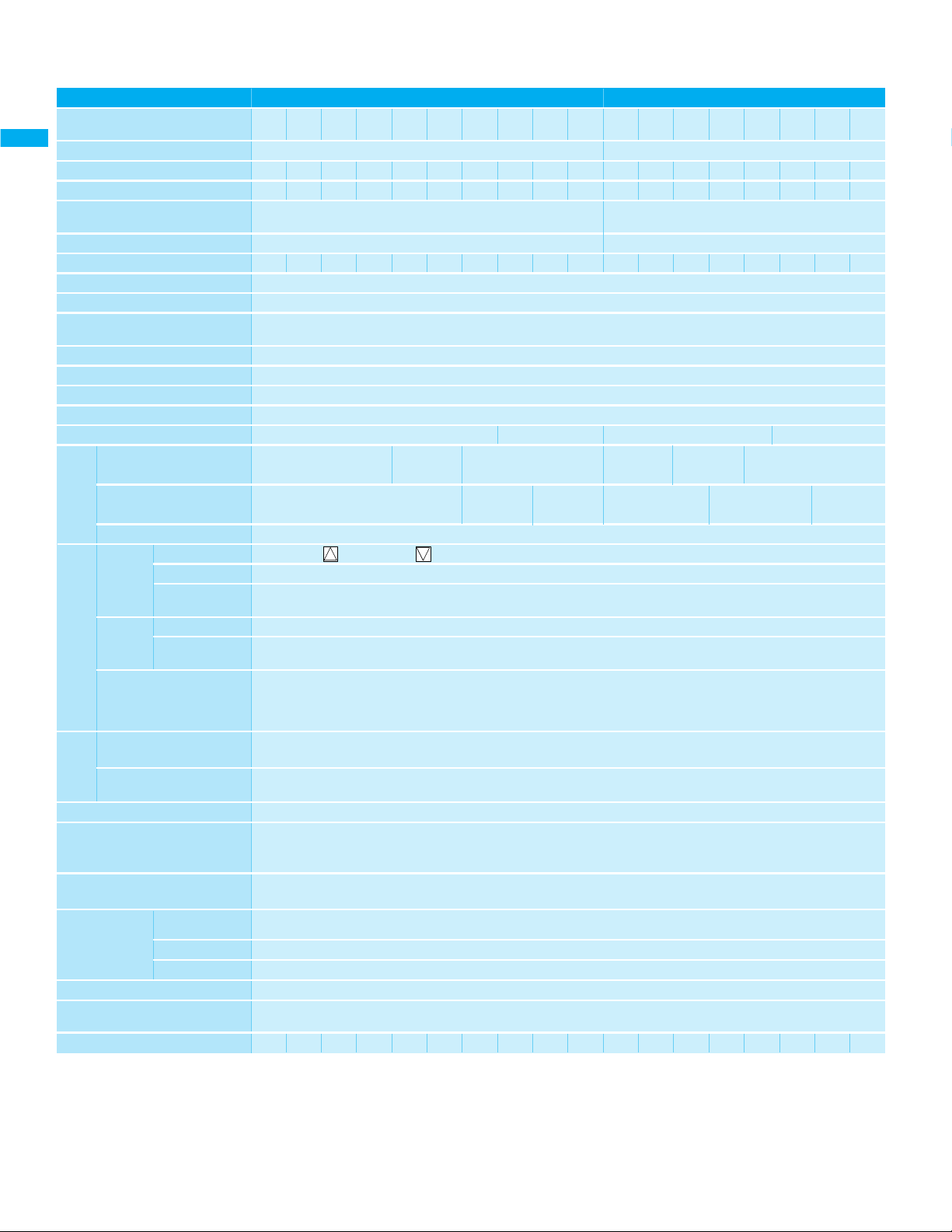

Standard Specifications

Item 200 V Class 400 V Class

Model (SJ100-)

Protective structure:

IP20

Applicable motor(kW)

Rated capacity(kVA)(240V/460V)

Rated input voltage

1-phase : 200~240V+5%/-10%, 50/60Hz +/-5%

3-phase380~460+/-10%,50/60Hz+/-5%

3-phase : 200~230V+10%/-10%,50/60Hz+/-5% (037~075LFU :3-phase only)

Rated output voltage

3-phase 200~240V (corresponding to input voltage)

3-phase 380~460V (corresponding to input voltage)

Rated output current (A)

Control method Sine-wave pulse width modulation (PWM) control

Output frequency range* 4 0.5 ~ 360 Hz

Frequency accuracy

Digital command:

w 0.01% of the Max. frequency

Analog command: w 0.1% (25

!

Cw10!C) of the Max. frequency

Frequency setting resolution

Digital: 0.1 Hz, Analog: Max. frequency/1000

Volt./Freq. characteristic*5 V/F optionally variable, V/F control (constant torque, reduced torque), sensorless vector control

Overload current rating 150%, 60 seconds

Acceleration/deceleration time

0.1~3000 sec. (linear or S-curve acceleration/deceleration), second acceleration/deceleration setting available

Starting torque*6

200%or more 180%or more 200%or more 180%or more

Dynamic braking *7

Approx. 100%

Approx.70%

Approx.20%

Approx. 100% Approx. 70%

Approx.20%

(without external resistor)

Dynamic braking *7

Approx. 150%

Approx.100% Approx.80%

Approx.150% Approx.100%

Approx.80%

(with external resistor)

Operating frequency, time, and braking force variable

Up ( ) and down ( ) keys/Value setting keys

Analog setting

0~10 VDC (input impedance 10k

Ω)

4~20mA (input impedance 250Ω), Potentiometer: 1kΩ to 2kΩ (2W) Variable resister

Run/Stop (Forward/Reverse run change by command)

Forward run/stop, Reverse run/stop

Operation command available at terminal assignment (1a/1b selectable)

FW ( Forward run comand) , RV ( reverse run command), CF1~CF4 (multi-stage speed setting ) , JG ( jogging command ),

2CH (2-stage acceleration/deceleration command), FRS (free run stop command ), EXT (external trip), USP (USP function ), SFT (

software lock

),

AT (analog current input select signal), RS (Reset), PTC (Thermal protection), DB(external DC braking command), SET(2nd setting selection),

UP (remote control, acceleration), DWN (remote control, deceleration)

RUN (running signal), FA1,2 (frequency arrival signal), OL (overload advance notice signal), OD

(deviation signal at PID control), AL (alarm signal)

PWM output; Select analog output frequency monitor, analog output current monitor or digital

output frequency monitor

Alarm output contact OFF for the inverter alarm (1C contact output) (possible to change to ON for the alarm)

Other functions

AVR function, curved acceleration/deceleration, upper and lower limiters, 16-stage speed, fine adjustment of start

frequency, carrier frequency change (0.5to16Kz ) frequency jump, gain and bias settung, process jogging, electronic

thermal level adjustment, retry function, trip history monitor, 2nd setting selection, auto tuning, fan on/off selection

Protective function

Overcurrent, overvoltage, undervoltage, overload, extreme high temperature, CPU error, memory

error, ground fault detection at startup, internal communication error,electronic thermal, CT error

-

10~50!C (*9)/-25~70!C (*10)/20~90% (no condensation)

5.9 m/s

2

(0.6G), 10~55 Hz

Altitude 1,000 m or less, indoors (no corrosive gases or dust)

Coating color Munsell 8.5YR6.2/0.2,cooling fins in base color of aluminum

Option

Remote operator unit, copy unit, cables for the units, braking unit, braking resistor, AC reactor,

DC reactor, noise filter

Weight(kg)

Input

signal

Output

signal

Operating

environment

Frequency

setting

Forward

/Reverse

run

DC braking

Digital operator panel

Potentiometer

External signal *8

Digital operator panel

External signal

Intelligent input terminal

Intelligent output terminal

Frequency monitor

Ambient/storage

temperature/humidity

Vibration *11

Location

*1: The protection method conforms to JEM1030.

*2: The applicable motor refers to Hitachi standard 3-phase motor (4-pole). To use

other motors, care must be taken to prevent the rated motor current from exceeding

the rated output current of the inverter.

*3: The output voltage decreases as the main power supply voltage decreases. (Except

for use of the AVR function)

*4: To operate the motor beyond 50/60 Hz, consult the motor manufacturer about the

maximum allowable rotation speed.

*5: SLV selected, set carrier frequency more than 2.1kHz.

*6: At the rated voltage when using a Hitachi standard 3-phase, 4-pole moter.(When

selecting high starting torque flux vector contlrol)

*7: The braking torque at capacitive feedback is the average deceleration torque at the

shortest deceleration (stoppage from 50 Hz) of the motor itself. It is not the

continuous regenerative braking torque. And the average deceleration torque

varies with motor loss. This value decreases when operating beyond 50/60 Hz. If a

large regeneration torque is required, the optional braking resistor should be used.

*8: The frequency command is the maximum frequency at 9.8 V for input voltage 0 ~ 10

VDC, or at 19.6 mA for input current 4 ~ 20 mA. If this characteristic is not

convenient, contact your Hitachi sales representative.

*9: To use the inverter at 40

!

C or higher, reduce carrier frequency 2.1kHz and derate

output current 80%, and remove the top cover.

*10: The storage temperature refers to the short-term temperature during transport.

*11: Conforms to the test method specified in JIS C0040 (1999). For the model types

excluded in the standard specifications, contact your Hitachi sales representative.

5

1

2

5.5

10.3

7.5

12.7

4.0

6.8

3.0

6.2

2.2

4.3

1.5

3.0

0.75

1.9

0.4

1.1

7.5

13.3

5.5

9.9

3.7

7.2

2.2

4.5

1.5

3.3

1.1

2.0

0.75

1.6

0.55

1.2

0.4

1.0

0.2

0.6

13 168.67.85.53.82.51.5322417.511.08.05.04.03.02.61.6

055HFE

055HFU

075HFE

075HFU

040HFE

040HFU

030HFE

-

022HFE

022HFU

015HFE

015HFU

007HFE

007HFU

004HFE

004HFU

-

075LFU

-

055LFU

-

037LFU

022NFE

022NFU

015NFE

015NFU

011NFE

-

007NFE

007NFU

005NFE

-

004NFE

004NFU

002NFE

002NFU

5.75.52.82.81.81.71.71.35.75.52.82.82.21.31.30.850.850.7

Braking

Page 7

6

Dimensional Drawings

V

SJ100-002NFE, 004NFE, 005NFE

002NFU, 004NFU

V

SJ100- 015NFE,015NFU

V

SJ100-022NFE, 030HFE, 040HFE

022NFU, 037LFU, 040HFU

V

SJ100-007HFE, 015HFE, 022HFE

007HFU, 015HFU, 022HFU

V

SJ100-007NFE, 011NFE, 004HFE

007NFU, 004HFU

✽

007HFE, 007HFU

with out FAN

model

002NFE

002NFU

004NFE

005NFE

004NFU

D

93

107

V

SJ100-055LFU,055HFE,055HFU,

075HFE,075HFU

V

SJ100- 075LFU

Page 8

7

V

FFL100-SB3, LB3

V

FFL100-HB32

V

FFL100-SB5, HB6

V

FFL100-SB11, HB11, HB17

Noise filter

Inverter model

SJ100-002NF

*

004NF

*

SJ100-005NFE

007NF

*

SJ100-011NFE

015NF

*

022NF

*

SJ100-037LFU

SJ100-055LFU

075LFU

SJ100-004HF

*

007HF

*

015HF

*

SJ100-022HF

*

030HFE

040HF

*

SJ100-055HF

*

075HF

*

Input Power Source

1-phase 200V class

3-phase 200V class

1-phase 200V class

3-phase 200V class

1-phase 200V class

3-phase 200V class

3-phase 200V class

3-phase 200V class

3-phase 400V class

3-phase 400V class

3-phase 400V class

Inverter model

FFL100-SB3

FFL100-LB3

FFL100-SB5

FFL100-HB6

FFL100-SB11

FFL100-HB11

FFL100-HB17

FFL100-HB32

FFL100-HB6

FFL100-HB11

FFL100-HB32

Dimensional Drawings

Page 9

Operation

The SJ100 Series can be easily operated with the digital operator panel equipped as standard in the main unit.

For remote operation, the remote operator unit is available as an option.

Displays the monitored frequency,

motor current, motor rpm, or alarm

condition.

Indicates the monitor item.

Press to start the motor.

Press to stop the motor or to cancel

the alarm.

Indicates ON/OFF of the control

circuit power supply.

Indicates the monitor item.

Use to store the set data.

Scroll the function code No. or

change the setting.

1

1

1

1

2

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

STR

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

or the previously

monitored value is displayed.

or the previously

monitored value is displayed.

or the previously

monitored value is displayed.

(1) Setting the maximum frequency

appears.

Function code appears.

Function code appears.

The previous set value

is displayed.

The set value is updated.

The setting is complete

( appears).

The motor rotates at the frequency

set by the potentiometer.

The motor stops.

(3) Monitoring the output current value

Output current value is

displayed.

(2) Running the motor (using the Potentiometer)

FUNC

Press the

key.

FUNC

Press the

key.

FUNC

Press the

key.

FUNC

Press the

key.

FUNC

Press the

key.

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

appears.

Display

using the up

and down keys.

Press the

up key

three times.

Change the set value

using the up and

down keys.

Press the

key to

enter the value.

Press the key

and rotate the

Potentiometer.

Press the key

to stop the motor.

(Operating frequency monitor)

Turn on the

power.

Turn on the

power.

Turn on the

power.

1

2

Display

using the up

and down keys.

appears.

RUN

STOP

RESET

STR

FUNC

RUN

Hz

A

PRG

MIN

MAX

POWER

1

2

appears.

RUN

Monitor section (LED)

Power lamp

Monitor lamp

Store key

Up/down keys

Frequency setting Potentiometer

Monitor lamp

Run key

Stop/Reset key

Function key

1 when running the motor, return to Monitor Mode or Basic Setting Mode.

8

Page 10

Code Function Monitor/Setting Range Initial Setting

A Group: Standard Functions

Code Function Monitor/Setting Range Initial Setting

d01

Output frequency monitor 0.0 ~ 360.0 Hz

-

d02 Output current monitor 0.00 ~ 999.9 A

-

F (forward run)

d03 Running direction monitor

r (reverse run)

-

w

(stop)

d04 Process variable (PV), PID feedback value monitor 0 ~ 9999

-

d05 Intelligent input terminal status monitor

-

d06 Intelligent output terminal status monitor

-

d07 Scaled output freguency monitor

-

d08 Trip event monitor

--

d09 Trip history monitor

--

F01 Output frequency setting 0.5 ~ 360 Hz

-

F02 Acceleration time 1 setting 0.1 ~ 3000 s 10.0s

F202 2ndsetting acceleration time 1 setting 0.1 ~ 3000 s 10.0s

F03 Deceleration time 1 setting 0.1 ~ 3000 s 10.0 s

F203 2ndsetting deceleration time 1 setting 0.1 ~ 3000 s 10.0s

F04 Motor direction setting 00:Forward/01:Reverse 00:Forward

A

--

Extented function of A group setting A01 ~ A98

-

B

--

Extented function of B group setting b01 ~ b92

-

C

--

Extented function of C group setting C01 ~ C95

-

H

--

Extented function of H group setting H01 ~ H234

-

Monitoring Functions and Main Profile Parameters

Monitor

Setting

Expanded

Function

.

Potentiometer (Front Case)

A01 Frequency Commanding

.

Control terminal

Control terminal

.

Digital panel

A02 Run Commanding

.

Control terminal

.

Digital panel

A03 Base frequency setting 50 ~ 360 Hz

xxE type:50Hz

xxU type:60Hz

A203 2nd setting base frequency setting 50 ~ 360 Hz

xxE type:50Hz

xxU type:60Hz

A04 Maximum frequency setting 50 ~ 360 Hz

xxE type:50Hz

xxU type:60Hz

A204 2nd setting maximun frequency setting 50 ~ 360 Hz

xxE type:50Hz

xxU type:60Hz

A11 External frequency setting start 0.0 ~ 360 Hz 0.0 Hz

A12 External frequency setting end 0.0 ~ 360 Hz 0.0 Hz

A13 External frequency start rate setting 0 ~ 100% 0%

A14 External frequency end rate setting 0 ~ 100% 100%

A15 External frequency start pattern setting

Set frequency of A11 / 0 Hz

0 Hz

A16 External frequency sampling count setting 1 ~ 8 times 8 times

A20 Multispeed frequency setting (Speed 0)

A220 2nd setting multispeed frequency setting (Speed 0)

0 ~ 360 Hz 0 Hz

A21

Multispeed frequency setting (Speed 1~ Speed 15)

A35

A38 Jogging frequency setting 0.00 ~ 9.99 Hz 1.0 Hz

.

Free-run stop

A39 Jogging stop operation selection

.

Controlled deceleration

Free-run stop

.

DC braking to stop

Basic

Setting

Analog

Input

Setting

Multispeed

Freq.

Setting

~

Function List

‘‘ xxE type’’ and ‘‘ xxU type’’ in the tables below refer to the model types for Europe and North America, respectively.

Display the status of the intelligent terminals

(Input, Output)

(Output frequency (Hz))

T

(frequency converted value b86 )

Control terminal

9

Page 11

Code Function Setting Range Initial Setting

A61 Frequency upper limiter setting

0.0, 0.5 ~ 360(Disable when 0.0) Hz

0.0 Hz

A62 Frequency lower limiter setting

0.0, 0.5 ~ 360(Disable when 0.0) Hz

0.0 Hz

A63 Jump frequency setting 1 0.0 ~ 360 Hz 0.0 Hz

A64 Jump frequency width setting 1 0 ~ 10 Hz 0.5 Hz

A65 Jump frequency setting 2 0 ~ 360 Hz 0 Hz

A66 Jump frequency width setting 2 0 ~ 10 Hz 0.5 Hz

A67 Jump frequency setting 3 0 ~ 360 Hz 0 Hz

A68 Jump frequency width setting 3 0 ~ 10 Hz 0.5 Hz

A71 Enable PID function ON/OFF OFF

A72 P gain setting 0.2 ~ 5 times 1.0

A73 I gain setting 0.0 ~ 150 s 1.0 s

A74 D gain setting 0.0 ~ 100 s 0.0 s

A75 PV scale conversion 0.01 ~ 99.99 1.00

A76 PV source setting Current/Voltage Current

A81 AVR function selection

ON/OFF/OFF at xxE type:OFF at decel.

deceleration xxU type:ON

A82 AVR voltage selection

200/220/230/240 xxE type:230/400

380/400/415/440/460 xxU type:230/460

A92 Second acceleration time setting 0.1 ~ 3000 s 15.0 s

A292 2nd setting second acceleration time setting 0.1 ~ 3000 s 15.0 s

A93 Second deceleration time setting 0.1 ~ 3000 s 15.0 s

A293 2nd setting second deceleration time setting 0.1 ~ 3000 s 15.0 s

A94

Second acceleration/deceleration Terminal /switching

Terminal

switching method frequency

A294

2nd setting second acceleration/deceleration Terminal /switching

Terminal

switching method frequency

A95 Acceleration switching frequency 0 ~ 360 Hz 0 Hz

A295 2nd setting acceleration switching frequency 0 ~ 360 Hz 0 Hz

A96 Deceleration switching frequency 0 ~ 360 Hz 0 Hz

A296 2nd setting deceleration switching frequency 0 ~ 360 Hz 0 Hz

A97 Acceleration pattern selection Linear/S-curve Linear

A98 Deceleration pattern selection Linear/S-curve Linear

PID

Control

AVR

2nd

Acceleration/

Deceleration

Function

Upper/Lower

Limiter,Jump

Frequency

A41 Torque boost mode selection Manual/Auto Manual

A241 2nd setting torque boost mode selection Manual/Auto Manual

A42 Manual torque boost setting 0 ~ 99 11

A242 2nd setting manual torque boost setting 0 ~ 99 11

A43 Boost frequency setting 0.0 ~ 50.0% 10%

A243 2nd setting boost frequency setting 0.0 ~ 50.0% 10%

A44 Control method setting Sensorless vector

A244 2nd setting Control method setting Sensorless vector

A45 Output voltage gain setting 50 ~ 100% 100%

A51 DC braking enable ON/OFF OFF

A52 DC braking frequency setting 0.5 ~ 10Hz 0.5Hz

A53 DC braking output delay time setting 0.0 ~ 5 s 0.0 s

A54 DC braking force setting 0 ~ 100% 0%

A55 DC braking time setting 0.0 ~ 60 s 0.0 s

V/F

Characteristics

DC

Braking

•Constant torque

•Reduced torque

•Sensorless vector

(*)

•Constant torque

•Reduced torque

•Sensorless vector

(*)

10

(*) Sensorless vector selected, set carrier frequency more than 2.1kHz by b83

Page 12

Code Function Setting Range Initial Setting

Code Function Setting Range Initial Setting

Trip/0Hz start

b01 Selection of restart mode /interrupt start Trip

/interrupt stop

b02 Allowable instantaneous power failure time setting 0.3 ~ 25 s 1.0 s

b03

Time and delay enforced before motor restarts

0.3 ~ 100 s 1.0 s

b12 Electronic thermal level setting

Rated

current value

b212 2nd setting electronic thermal level setting

Rated

current value

b13 Electronic thermal characteristic selection

Reduced torque Reduced torque

/constant torque characteristic

b213

2nd setting electronic thermal characteristic selection

Reduced torque Reduced torque

/constant torque characteristic

b21 Overload restriction operation mode 00 ~ 02 (code)

01

:ON only at acceleration

and constant speed

b22 Overload restriction setting

Rated

current x1.25

b23 Deceleration rate at overload restriction 0.3 ~ 30.0 1.0

b31 Software lock selection 00 ~ 03 (code) 01

b81 Analog meter adjustment 0 ~ 255 80

b82 Start frequency adjustment 0.5 ~ 9.9 Hz 0.5 Hz

b83 Carrier frequency setting 0.5 ~ 16 kHz 5 kHz

b84 Initialization mode selection Trip history clear /Parameter initialization Trip history clear

b85 Country code for initialization 01, 02

xxE type: 01

xxU type: 02

b86 Frequency conversion value setting 0.1 ~ 99.9 1.0

b87

Stop key validity selection during terminal operation

Enabled/disabled Enabled

b88 Resume on FRS cancellation mode selection

0Hz start/frequency

0Hz start

matching start

b89 Monitoring selection 01 ~ 07 (code) 01

b90 Dynaimic braking use time(ratio)setting 00 ~ 100.0 00

b91 Deceleration mode selection Deceleration stop/free run stop Deceleration stop

b92 FAN ON/OFF selection ON/OFF at inverter stop ON

B Group: Fine Tuning Functions

Instantaneous

Stop Restart

Electronic

Thermal

Overload

Limit

Lock

Others

50 ~120% of the rated

inverter current value

Differs depending

on model type

50 ~120% of the rated

inverter current value

Differs depending

on model type

50 ~150% of the rated

inverter current value

Differs depending

on model type

C01 Input terminal 1 setting FW

C02 Input terminal 2 setting RV

C03 Input terminal 3 setting

xxE type:CF1

xxU type:AT

C04 Input terminal 4 setting

xxE type:CF2

xxU type:USP

C05 Input terminal 5 setting

C06 Input terminal 6 setting

C11 Input terminal 1 active state NO

C12 Input terminal 2 active state NO

C13 Input terminal 3 active state NO

C14 Input terminal 4 active state

xxE type:NO

xxU type:NC

C15 Input terminal 5 active state NO

C16 Input terminal 6 active state NO

C Group: Intelligent Terminal Functions

Intelligent

Input

Terminal

Setting

Intelligent

Input

Terminal

Active

State

Input terminal active state

NO: Normally open

NC: Normally closed

V

Input ON State

Code Function

00 FW (Forward run)

01 RV (Reverse run)

02 CF1 (Multispeed 1)

03 CF2 (Multispeed 2)

04 CF3 (Multispeed 3)

05 CF4 (Multispeed 4)

06 JG (Jogging operation )

07 DB (External DC braking)

08 SET (2nd setting selection)

09 2CH

(Second acceleration/deceleration command)

11 FRS (Free run stop command)

12 EXT (External trip)

13 USP (Unattended start protection)

15 SFT (Software lock)

16 AT (Analog current input selection signal)

18 RS (Reset)

19

PTC (Thermistor trip)[Assignable to C05 only]

27 UP

(Remote control function, Acceleration)

28 DWN

(Remote control function, Decceleration)

11

xxE type:RS

xxU type:2CH

xxE type:

2CH

xxU type:

RS

Page 13

12

Code Function Setting Range Initial Setting

Intelligent

Output

Terminal

Setting

Function

Relation

with

Output

Terminal

Others

Output terminal active state

NO: Normally open

NC: Normally closed

Output terminal active state

NO: Normally open

NC: Normally closed

NO: AL0-AL2 is closed at alarm NC: AL0-AL2 opens at alarm

Intelligent

Output

Terminal

Active

State

- -

Function Setting Range

H01

H02

H202

H03

H203

H04

H204

H05

H205

H06

H206

H20

H220

H21

H221

H22

H222

H23

H223

H24

H224

H30

H230

H31

H231

H32

H232

H33

H233

H34

H234

00~02(code)

Hitachi standard/auto

Hitachi standard/auto

0.1~7.5

0.1~7.5

2 / 4 / 6 / 8

2 / 4 / 6 / 8

0~99

0~99

0~255

0~255

0~65.53

0~65.53

0~65.53

0~65.53

0~655.35

0~655.35

0~655.35

0~655.35

0~655.35

0~655.35

0~65.53

0~65.53

0~65.53

0~65.53

0~655.35

0~655.35

0~655.35

0~655.35

0~655.35

0~655.35

00

Hitachi standard

Hitachi standard

Factoty set

4

4

20

20

100

100

Factoty set

Auto-tuning setting

Motor data

Motor data, 2nd motor

Motor capacity

Motor capacity, 2nd motor

Motor poles setting

Motor polesetting, 2nd motor

Speed control response constant (Kp)

Speed control response constant (Kp), 2nd motor

Moter stabilization constant

Motor stabilization coustant, 2nd motor

Motor constant R1

Motor constant R1, 2nd motor

Motor constant R2

Motor constant R2, 2nd motor

Motor constant L

Motor constant L, 2nd motor

Motor constant Io

Motor constant Io, 2nd motor

Inertia (J)

Inertia (J), 2nd motor

Motor constant R1

Motor constant R1, 2nd motor

Motor constant R2

Motor constant R2, 2nd motor

Motor constant L

Motor constant L, 2nd motor

Motor constant Io

Motor constant Io, 2nd motor

Inertia (J)

Inertia (J), 2nd motor

H Group: Sensorless Vector Functions

Sensorless

Vectol

Contorol

Motor

Constant

Initial SettingCode

Auto

Tuning

Motor

Constant

0~200% of the inverter rated current

0.0 ~ 360.0 Hz

0.0 ~ 360.0 Hz

0.0 ~100.0%

0.0 ~255

0.0 ~255

(Reserved) Do not edit.

Differs depending on models

Inverter rated current

NC

NO

NO

0 Hz

0 Hz

3.0%

Code Function

00 RUN (Running signal)

01 FA1 (Frequency arrival signal:command arrival)

02 FA2 (Frequency arrival signal:setting or more)

03 OL (Overload advance notice signal)

04 OD (Output deviation for PID control)

05 AL (Alarm signal)

Code Function

00 RUN (Running signal)

01 FA1 (Frequency arrival signal:command arrival)

02 FA2 (Frequency arrival signal:setting or more)

03 OL (Overload advance notice signal)

04 OD (Output deviation for PID control)

05 AL (Alarm signal)

C21

Output terminal 1 setting

Output terminal 11 active state

Output terminal 12 active state

Alarm relay active state

Overload advance notice signal

Acceleration arrival signal frequency setting

Deceleration arrival signal frequency setting

PID deviation limit signal level setting

Frequency command adjust.(0-L terminal)

Frequency command adjust.(OI-L terminal)

C22

C23

FM terminal setting

A-F (Analog output frequency monitor)

A (Analog output current monitor)

D-F (Digital output frequency monitor)

Output terminal 2 setting

C24

C31

C32

C33

C41

C42

C43

C44

C81

C82

C91~C95

Alarm relay output terminal setting

Factoty set

Factoty set

AL

A-F

RUN

FA1

Page 14

Function

L1,L2,L3

G

T1,T2,T3

+, +1

+,

-

+, RB

Symbol

007~022NFE

007~022NFU

037LFU

004~040HFE

004~040HFU

055~075LFU

055~075HFE

055~075HFU

002~005NFE

002~004NFU

M3.5 M4 M5

Main

circuit

terminal

Alarm

terminal

Control

circuit

terminal

M2 (press-tight type)

M3 (press-tight type)

Terminal Functions

Main circuit

terminal

Main power supply input

terminals

Inverter output terminals

DC reactor connection

terminals

External braking resistor

connection terminals

External braking unit

connection terminals

Ground connection terminal

Main Circuit Terminals

Control Circuit Terminals

Connect the input power

supply.

Connect the motor.

Connect the DC reactor for

harmonic suppression, power

factor improvement.

Connect the optional

regenerative braking resistor

when braking torque required

Connect the optional

regenerative braking unit

when braking torque required

Ground to prevent electric

shock and reduce noise

FM

L

P24

6

5

4

3

2

1

H

O

OI

L

12

11

CM2

AL2

AL1

AL0

Symbol

Frequency

command

Alarm output

Output signal

Input/Monitor

signal

Signal

Monitor terminal (frequency, current, etc.)

Common terminal for monitor and frequency command

Common terminal for the intelligent input terminal

Power supply (10VDC) for frequency command

Frequency command input (voltage command) (0 ~ 10VDC)

Frequency command input (current command) (4 ~ 20mADC)

Common terminal for frequency command

Intelligent output terminal, selection from:

Run signel (RUN), Freguency arrival at the set freguency signal (FA1), Freguency arrival at

or aboue the set freguency signal (FA2), Overload advanced notice signal (OL), Output

deviation for PID control (OD), and Alarm signal (AL).

Intelligent input terminals, selection from:

Forward run command (FW), Reverse run command (RV), Multispeed

commands 1~4 (CF1~CF4), 2-stage acceleration/deceleration command (2CH), Free-run

stop (FRS), External trip (EXT), Unattended start protection (USP), Jogging (JG),

Analog input selection (AT), Software lock (SFT), Reset (RS), PTC Thermistor thermal

protection (PTC), External DC braking (DB), Set second motor (SET), and

Remote control acceleration/deceleration(UP/DWN)

Terminal Name

Open collector output

L level at operation (ON)

PWM output

-

24 VDC

-

Input impedance 10 kΩ

Input impedance 250Ω

-

Contact input

Operated by SW (closed)

Remarks

Front case (right open)

Terminal section cover (left open)

[Main Circuit Terminal] [Control Circuit Terminal]

Terminal Screw Diameter

Control circuit

terminal

LOWER

L1RBL2

+1 +

-

N/L3 T1/U T2/V T3/W

UPPER

Short bar

Motor

Ground

Power supply

(Power source)

SW

P24

6

1

Contact rating

0.4

AC250V 2.5A

resistor load

DC30V

0.2A

cos 0.4

3.0A

resistor load

cos0.7A

Alarm output terminal:

NO-NC contact (relay) output

Common with intelligent output terminal

<Initial Setting>

Normal:AL0–AL1 closed

Trip/Power OFF:AL0–AL2

closed

13

Terminal Name

Page 15

Name

Overcurrent

protection

Overload protection

(*1)

Braking resistor

overload protection

Overvoltage

protection

EEPROM error(*2)

Undervoltage

protection

CT error

CPU error

External trip

USP error

Ground fault

protection

Input overvoltage

protection

Temperature error

PTC error

Digital operator

Description

When the motor is restrained or suddenly reduced in

speed, a large current is charged to the inverter,

causing a fault. When the inverter detects 205% peak

current for the rated current of the inverter,Over current

is occurred.

When the inverter output current causes the motor to overload, the electronic

thermal trip in the inverter cuts off the inverter output.

If the duty rating for the regenerative braking resistor has been exceeded,an overvoltage is detected

by stopping BRD(regenerative braking unit)operation and the inverter output is turned off.

If regenerative energy from the motor or the main power supply voltage is high,

the protective circuit activates to cut off the inverter output when the voltage of

the converter section exceeds the specification.

The inverter output is cut off when EEPROM in the inverter has an error due to

external noise, excessive temperature rise, or other factor.

When the input voltage received by the inverter decreases, the control circuit

does not function normally. When the input voltage is below the

specification, the inverter output is cut off.

Turns off the output if CT in the inverter has become abnormal.

The inverter output is cut off when the inverter CPU has a malfunction or an

error.

When the external equipment or unit has an error, the inverter receives the

corresponding signal and cuts off the output.

The USP error is indicated when the power is turned on with the inverter in

RUN state. (Enabled when the USP function is selected.)

Ground fault is detected between the inverter output section and the motor

when the power is turned on, to protect the inverter.

When the input voltage is higher than the specified value, it is detected 100

seconds after power is turned on and the output is cut off.

When the temperature in the main circuit increases due to cooling fan stop,

the inverter output is cut off. (Only for the model type with cooling fan)

When the resistance value of the external thermistor is too large, the equipment

detects the abnormal condition of the thermistor and then cut off the output

(when PTC function is selected)

Constant speed

Deceleration

Acceleration

Others

Trip Monitoring Method

FUNC

FUNC FUNC

FUNC

FUNC FUNC

Trip cause Trip frequency Trip current

Trip History Monitoring Method

Previous trip cause

Trip cause before the previous

FUNC

Trip +-(DC) voltage

1: is indicated when there is no trip.

Note

OC.Drive

OC.Decel

OC.Accel

Over.c

Over.L

OL.BLD

Over.V

EEPROM

Under.V

CT

CPU

CPU2

EXTERNAL

USP

GND.Flt

OV.SRC

OH FIN

PTC

Remote operator

/copy unit

ERR1 ****

Protective Functions

Waiting on account

of undervoltage

Waiting with the output turned off, because the inverter receiving Voltage has

dropped.

UV.WAIT

Notes

1.Press the reset key 10 seconds after the alarm has occurred.

2.If an EEPROM error occurs,be sure to comfirm the seting value again.

14

Page 16

Connection Diagram

Main power

supply

3-phase

200~230V

50/60 Hz

Inverter

Class 3 grounding

Main circuit power

RUN command

Output frequency

Motor rpm

(*3)

Motor

DCL

(DC reactor) (option)

Frequency setting

device

1kΩ~2kΩ

Dynamic

braking

resistor (option)

Dynamic

braking

unit (option)

Alarm relay output

Turn on the main power at the timing shown below.

*1: Note that the common terminal differs depending on

the terminal name.

1, 2, 3, 4, 5, 6 FM, H, O, OI 11, 12

P24 L CM2

Terminal

Name

*2: The braking resistor is equipped with a

thermosensor. If it is activated, turn off the main

power or extend the deceleration time.

*3: Use the above timing to turn on the main power and

input the RUN command. If the main power ON

and the RUN command input occur simultaneously,

the motor starts to run 2 sec. later because the

control power supply boot is delayed.

Common

15

<Connection to the Programmable Controller>

When the internal interface

power source is used

Note 1:

Do not short circuit the terminals

P24 and L by mistake.

The control power supply may

cause a failure

(0.3W or more

is recommended)

Current input

4~20mA

L1

L2

L3

P24

1

2

3

4

5

6

FM

L

H

O

O

L

L

L

L

L

L

DC10V

5V

L

T1

T2

T3

+1

+

RB

-

AL0

AL1

AL2

11

12

CM2

RY

RY

DC24V

COM

1

2

3

4

5

6 6

S

EH-YT P16 type

trans ist or output mod ule

INVER TER

L1

L2

L3

P24

1

2

3

4

5

L

Inver ter common

24 VD C

1

+1

RB

AL0

AL1

AL2

U

V

W

+

Motor

Alarm ou tput

conta ct

t 2.0

Page 17

Applicable Wiring Apparatus and Options

(Power supply)

L1 L2 L3

T1 T2 T3

+1

+

-

RB

Inverter

Motor

Thermal

relay

IM

Fuse

Function

This is useful when harmonic suppression measures must be taken,

when the main power voltage unbalance rate exceeds 3% and the

main power capacity exceeds 500kVA, or when a sudden power

voltage variation occurs.It also helps to improve the power factor.

Noise may occur in a nearby radio, etc., via the mainpower supply

side wiring when using the inverter. This filter helps to reduce the

noise; radiated noise reduction.

Reduces the conductive noise on the main power wires generated

from the main power supply. Connect to the inverter primary side

(input side).

Reduces noise radiated from the main power wiring on the input side.

Suppresses harmonics generated by the inverter.

This is useful for increasing the control torque of the inverter, for

frequently repeating ON-OFF of the inverter, or for decelerating the

load with a large inertial moment (GD

2

).

This is installed between the inverter and the motor to reduce noise

radiated from the control power wiring. It is useful for reducing

radio-wave disturbance in a radio or TV set and for preventing

malfunction of measuring instruments or sensors

Useful for reducing noise produced in the inverter output side.

(It is usable on either the input or output side.)

Vibration may increase when driving a general-purpose motor with an

inverter as compared with operation on commercial power.

Connecting this reactor between the inverter and the motor allows

reduction of motor pulsation. When the wiring between the inverter and

the motor is 10 m or more, inserting the reactor prevents thermal relay

malfunction caused by harmonics resulting from inverter switching.

A current sensor can be used instead of the thermal relay.

Output-side sine wave generating filter

Name

Input-side AC reactor for

harmonicsuppression/power

coordination/powerfactor

improvement

(ALI-

w w w

2

)

Radio noise filter

<zerophase reactor>

(ZCL-

w

)

EMI filter for Inverter

(FFL100-

w w

)

Input-side radio noise filter

(capacitive filter)

(CFI-

w

)

DC reactor

Output-side noise filter

(ACF-C

w

)

Radio noise filter

<zero-phase reactor>

(ZCL-

w w w

)

AC reactor for vibration

reduction/thermal relay

malfunction prevention

(ACL-L2-

w w w

)

(ACL-H2-

w w w

)

LCR filter

Standard Apparatus

Options

Note 1: FFL100 series filter is required for EMC directive(Europe),C-Tick(Australian EMC requirment) but the other

options are not for these purpose. Reactors and filters except for EMI filter listed above are for general use in

noise reduction.

Note 2: Fieldbus communications -Please consult your sales representative or distributor for available options.

Motor

Output

(kW)

Inverter model

Wiring

Applicable equipment

Power lines

Signal lines

Fuse(class J)

rated 600V

0.2

0.4

0.55

0.75

1.1

1.5

2.2

3.7

5.5

7.5

0.4

0.75

1.5

2.2

3.0

4.0

5.5

7.5

AWG14/2.1mm

2

AWG16/1.3mm

2

AWG14/2.1mm

2

AWG12/3.3mm

2

AWG12/3.3mm

2

AWG12/3.3mm

2

AWG10/5.3mm

2

AWG8/ 8.4mm

2

AWG10/5.3mm

2

AWG16/1.3mm

2

10A

15A

30A

6A

3A

50A

40A

10A

10A

15A

20A

25A

25A

(

single ph.

)

15A(three ph.

)

30A(single ph.

)

20A(three ph.

)

NOTE1: Field wiring connection must be made by a UL Listed and CSA Certified closed-loop terminal connector sized for the wire

gauge involeved. Connector must be fixed using the crimp tool specified by the connector manufacturer.

NOTE2: Be sure to consider the capacity of the circuit breaker to be used.

NOTE3: Be sure to use bigger wires for power lines if the distance exceeds 20 m.

(*) Use 0.75 mm2wire for the alarm signal wire.

(*)

0.14 to 0.75

mm

2

Shielded wire

SJ100-002NFE/NFU

SJ100-004NFE/NFU

SJ100-005NFE

SJ100-007NFE/NFU

SJ100-011NFE

SJ100-015NFE/NFU

SJ100-022NFE/NFU

SJ100-037LFU

SJ100-055LFU

SJ100-075LFU

SJ100-004HFE/HFU

SJ100-007HFE/HFU

SJ100-015HFE/HFU

SJ100-022HFE/HFU

SJ100-030HFE

SJ100-040HFE/HFU

SJ100-055HFE/HFU

SJ100-075HFE/HFU

16

Braking resistor

Braking unit

Page 18

For Correct Operation

Application to Motors

[Application to general-purpose motors]

Operating frequency

Torque characteristics

Motor loss and

temperature increase

Noise

Vibration

Power transmission mechanism

Gear motor

A system applying a voltage-type PWM inverter with IGBT may have surge voltage at the motor terminals resulting from the cable constants including

the cable length and the cable laying method. Depending on the surge current magnification, the motor coil insulation may be degraded. In

particular, when a 400V-class motor is used, a longer cable is used, and critical loss can occur, take the following countermeasures:

(1) install the LCR filter between the inverter and the motor,

(2) install the AC reactor between the inverter and the motor, or

(3) enhance the insulation of the motor coil.

Brake-equipped motor

Run/Stop

Emergency motor stop

High-frequency run

Pole-change motor

Submersible motor

Explosion-proof motor

Synchronous (MS) motor

High-speed (HFM) motor

Single-phase motor

[Application to the 400V-class motor]

Notes on Use

[

Drive

]

The overspeed endurance of a general-purpose motor is 120% of the rated speed for 2 minutes (JIS C4004). For

operation at higher than 60 Hz, it is required to examine the allowable torque of the motor, useful life of bearings,

noise, vibration, etc. In this case, be sure to consult the motor manufacturer as the maximum allowable rpm differs

depending on the motor capacity, etc.

The torque characteristics of driving a general-purpose motor with an inverter differ from those of driving it with

commercial power (starting torque decreases in particular). Carefully check the load torque characteristic of a

connected machine and the driving torque characteristic of the motor.

An inverter-driven general-purpose motor heats up swiftly at lower speeds. Consequently, the torque level permitting

continuous use decreases with lower motor speeds. Carefully check the torque characteristics.

When run by an inverter, a general-purpose motor generates noise slightly greater than with commercial power.

When run by an inverter at variable speeds, the motor may generate vibration, especially because of (a) unbalance of

the rotor including a connected machine, or (b) resonance caused by the natural vibration frequency of a mechanical

system. Particularly, be careful of (b) when operating at variable speeds a machine previously fitted with a constant

speed motor. Vibration can be minimized by (1) avoiding resonance points using the frequency jump function of the

inverter, (2) using a tire-shaped coupling, or (3) placing a rubber shock absorber beneath the motor base.

Under continued, low-speed operation, oil lubrication can deteriorate in a power transmission mechanism with an oiltype gear box (gear motor) or reducer. Check with the motor manufacturer for the permissible range of continuous

speed. To operate at more than 60 Hz, confirm the machine

’s ability to withstand the centrifugal force generated.

The allowable rotation range of continuous drive varies depending on the lubrication method or motor manufacturer.

(Particularly in case of oil lubrication, pay attention to the low frequency range.) The Hitachi CX/CA gear motors are of a

grease lubrication type. Their grease lubrication capability remains unchanged even if the motor rotating speed

decreases.

For use of a brake-equipped motor, be sure to connect the braking power supply from the primary side of the inverter.

There are different kinds of pole-change motors, constant output characteristic type, constant torque characteristic

type, etc., and with different rated current values. In motor selection, check the maximum allowable current for each

motor of a different pole count. At the time of pole changing, be sure to stop the motor.

The rated current of a submersible motor is significantly larger than that of the general-purpose motor. In inverter

selection, be sure to check the rated current of the motor.

Inverter drive is not suitable for a safety-enhanced explosion-proof type of motor. The inverter should be used in

combination with a pressure-proof explosion-proof type of motor.

* Explosion-proof verification is not available for SJ100 Series. For explosion-proof operation, use other series of motors.

In most cases, the synchronous (MS) motor and the high-speed (HFM) motor are designed and manufactured to meet

the specifications suitable for a connected machine. As to inverter selection, consult the manufacturer.

A single-phase motor is not suitable for variable-speed operation by inverter drive. Therefore, use a three-phase motor.

Run or stop of the inverter must be done with the keys on the operator panel or through a control circuit terminal.

Do not operate by installing a electromagnetic contactor (Mg) in the main circuit.

When the protective function is operating or the power supply stops, the motor enters the free run stop state. When

an emergency stop is required or when the motor should be kept stopped, use the mechanical brake.

A max. 360 Hz can be selected on the SJ100 Series. However, a two-pole motor can attain up to approx. 21,600

rpm, which is extremely dangerous. Therefore, carefully make selection and settings by checking the mechanical

strength of the motor and connected machines. Consult the motor manufacturer when it is necessary to drive a

standard (general-purpose) motor at over 60 Hz. A full line of high-speed motors is available from Hitachi.

[Installation location and operating environment]

Avoid installation in areas of high temperature, excessive humidity, or where moisture can easily collect, as well as areas that are dusty, subject to corrosive

gasses, mist of liquid for grinding, or salt. Install the inverter away from direct sunlight in a well-ventilated room that is free of vibration. The inverter can be

operated in the ambient temperature range from -10 to 50

!

C

.(carrier frequency and output current must be reduced in the range of 40 to 50

!

C

)

[Application to special motors]

17

Page 19

V

Before use, be sure to read through the Instruction Manual to insure proper use of the inverter.

V

Note that the inverter requires electrical wiring; a specialist should carry out the wiring.

V

The inverter in this catalog is designed for general industrial applications. For special applications in fields such as aircraft, outer space, nuclear

power, electrical power, transport vehicles, clinics, and submarine relay equipment, please consult with us in advance.

V

For application in a facility where human life is involved or serious losses may occur, make sure to provide safety devices to avoid a serious

accident.

V

The inverter is intended for use with a three-phase AC motor. For use with a load other than this, please consult with us.

Installation of an

AC reactor on the

input side

Using a private power

generator

Wiring connections

Installing a circuit breaker

Wiring distance

Earth leakage relay

Phase advance capacitor

Wiring

between

inverter and

motor

Electromagnetic contactor

Thermal relay

Notes on Peripheral Equipment Selection

An inverter run by a private power generator may overheat the generator or suffer from a deformed output voltage

waveform of the generator. Generally, the generator capacity should be five times that of the inverter (kVA) in a

PWM control system, or six times greater in a PAM control system.

(1) Be sure to connect main power wires with R, S, and T (input) terminals and motor wires to U, V, and W terminals

(output). (Incorrect connection will cause a breakdown.)

(2) Be sure to provide a grounding connection with the ground terminal ( ).

When an electromagnetic contactor is installed between the inverter and the motor, do not perform on-off switching

during running operation.

When used with standard applicable output motors (Hitachi standard three-phase squirrel-cage four-pole motors), the

SJ100 Series do not need a thermal relay for motor protection due to the internal electronic protective circuit. A

thermal relay, however, should be used:

●

during continuous running at a range beyond 30 to 60 Hz.

●

for motors exceeding the range of electronic thermal adjustment (rated current).

●

when several motors are driven by the same inverter; install a thermal relay for each motor.

●

The RC value of the thermal relay should be more than 1.1 times the rated current of the motor. Where the wiring

length is 10 m or more, the thermal relay tends to turn off readily. In this case, provide an AC reactor on the output

side or use a current sensor. See the item for the thermal relay malfunction preventive AC reactor on page 16.

Install a circuit breaker on the main power input side to protect inverter wiring and ensure personal safety. Choose an

inverter-compatible circuit breaker. The conventional type may malfunction due to harmonics from the inverter. For

more information, consult the circuit breaker manufacturer.

The wiring distance between the inverter and the remote operator panel should be 20 meters or less. When this

distance is exceeded, use CVD-E (current-voltage converter) or RCD-E (remote control device). Shielded cable

should be used on the wiring. Beware of voltage drops on main circuit wires. (A large voltage drop reduces torque.)

If the earth leakage relay (or earth leakage breaker) is used, it should have a sensitivity level of 15 mA or more (per

inverter). The leakage current differs depending on the cable length; see page xx.

Do not use a capacitor for power factor improvement between the inverter and the motor because the high-frequency

components of the inverter output may overheat or damage the capacitor

(1) High-frequency components are included in the input/output of the inverter main circuit, and they may cause interference in a transmitter, radio,

or sensor if used near the inverter. The interference can be minimized by attaching noise filters (option) in the inverter circuitry.

(2) The switching action of an inverter causes an increase in leakage current. Be sure to ground the inverter and the motor.

Because a smoothing capacitor deteriorates as it undergoes internal chemical reaction, it should normally be

replaced every five years. Be aware, however, that its life expectancy is considerably shorter when the inverter is

subjected to such adverse factors as high temperatures or heavy loads exceeding the rated current of the inverter.

The approximate lifetime of the capacitor is as shown in the figure at the right when it is used 12 hours daily

(according to the

‘‘ Instructions for Periodic Inspection of General-Purpose Inverter’’ (JEMA).)

Also, such consumable parts as a cooling fan should be replaced. (Maintenance inspection and parts replacement

must be performed by only specified trained personnel.)

In the cases below involving a general-purpose inverter, a large peak current flows on the main power supply side,

and is able to destroy the converter module. Where such situations are foreseen or the connected equipment must

be highly reliable, install an AC reactor between the power supply and the inverter. Also, where influence of

indirect lightning strike is possible, install a lightning conductor.

(A) The unbalance factor of the power supply is 3% or higher. (Note)

(B) The power supply capacity is at least 10 times greater than the inverter capacity (the power supply capacity is

500 kVA or more).

(C) Abrupt power supply changes are expected.

Examples:

(1) Several inverters are interconnected with a short bus.

(2) A thyristor converter and an inverter are interconnected with a short bus.

(3) An installed phase advance capacitor opens and closes.

In cases (A), (B) and (C), it is recommended to install an AC reactor on the main power supply side.

Note: Example calculation with V

RS = 200V, VST = 203V, VTR = 197V

V

RS : R-S line voltage, VST : S-T line voltage, VTR : T-R line voltage

Unbalance factor of voltage =

-----------------------------------------------------------------

- T 100

=

---------------------------------

- T 100 =

---------------

- T 100 = 1.5 (%)

[Main power supply]

High-frequency Noise and Leakage Current

Lifetime of Primary Parts

Precaution for Correct Usage

Ambient temperature

)

(

Capacitor lifetime (years)

Max. line voltage (min.) - Mean line voltage

Mean line voltage

V

RS

-

(VRS + VST + VTR )/3

(V

RS + VST + VTR )/3

205 - 202

202

18

Page 20

Printed in Japan(H)SM-E229R 0602

Loading...

Loading...