Page 1

TABLE

SPECIFICATION ............................................................................................

2

MAIN PARTS COMPONENTS ..................................................................................

2

BASIC OPERATION..................................................................................

3

RESISTANCE VALUE ..................................................................................

4

ERROR CODE ..................................................................................

5

CIRCUIT DIAGRAM ..............................................................................

6

PARTS CONSTITUTION

MODEL:R-T310ERU1 .............................................................................................

7-18

SPECIFICATIONS

TYPEDOUBLE DOOR

MODEL

POWER SOURCE 1Ø,220V-240V,50Hz

POWER INPUT ( W )120

TOTAL CURRENT ( A )0.9

VOLUME260L

600

1560

655

NET WEIGHT ( Kgs )54

NO. 2022E

REFRIGERATOR

H.C.P.T.

OCT'2010

R-T310ERU1 (SLS,PWH,PBK)

R-T310ERU1

SERVICE MANUAL

DIMENSIONS

(mm)

TOTALNET

W

H

D

HITACHI

PT

NO. 2022E

R-T310ERU1 (SLS,PWH,PBK)

GENERAL SERVICE

Page 2

1.

In order to disassemble and repair the

unit in question, be sure to disconnect

the power cord plug from the power

outlet before starting the work.

2.

If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit, and the

replacement must be effected in correct manner according to the instructions in the Service Manual of the unit.

3.

After completion of repairs, the initial state should be restored.

4.

Lead wires should be connected and laid as in the initial state.

5.

Modification of the unit by the user himself should absolutely be

prohibited.

6.

Tools and measuring instruments for use in repairs or inspection should be accurately calibrated in advance.

7.

In installing the unit having been repaired, be careful to prevent the occurrence of any accident such as electrical

shock, leak of current, or bodily injury due to the drop of any part.

8.

To check the insulation of the unit, measure the insulation resistance between the power cord plug and grounding

terminal of the unit.

The insulation resistance should be 1M

or more as measured by a 500V DC megger.

9.

The initial location of installation such as window, floor or the other should be checked for being safe enough to

support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location after reinforced or at a new location.

10.

Any inflammable object must not be placed

about the location of installation.

11.

Check the grounding to see whether it is proper

or not, and if it is found improper, connect the

grounding terminal to the earth.

SAFETY DURING REPAIR WORK

First, I must disconnect

from the power outlet.

If the contacts of electrical parts are

defective, replace the electrical parts

without trying to repair them.

DANGER

the power cord plug

Ω

1

Page 3

SPECIFICATION

MODEL

COMPRESSORPTR-T310EM 001(FL1152-SH)

STARTING DEVICEPTR-250EX 021(PGT0SAT)

OVERLOAD RELAYPTR-200WGX 037(1.4C36A3)

STARTING CAPACITORPTR-47KP 003(3μF/400V)

AMBIENT TEMPERATURE SENSOR

REFRIGERATOR SENSORPTR-T300W 034R (O°C) = 6.35 k Ω ± 2 %

REFRIGERATOR CHARGING R-134a (kg)

TEMPERATURE FRESH FOOD

CONTROL FREEZER

DEFROSTING WAY

DEFROSTING INITIATION

SYSTEM TERMINATION

EVAPORATION

FREEZER ****

PTR-Z400V 050

R-T310ERU1

R (21°C) = 12 k Ω ± 3 %

R (25°C) = 10 k Ω ± 2 %

0.095

DIAL

SELECT DAMPER DIAL

HEATER

F:AUTOMATIC,R:AUTOMATIC

F:AUTOMATIC,R:AUTOMATIC

FORCED

YES

OTHER FEATURE

MINUS-ZERO COOLING

NANOTITANIUM

NO

YES

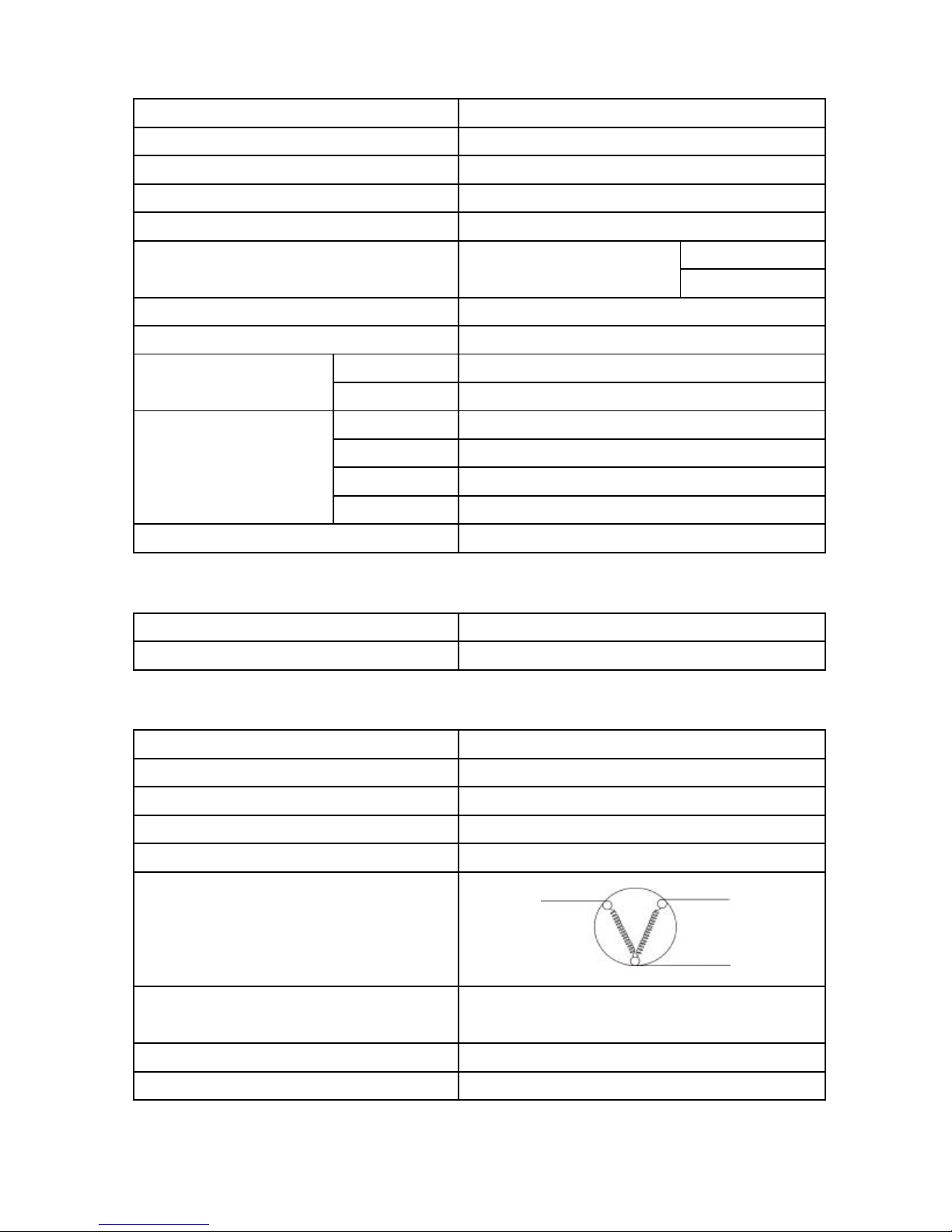

MAIN PARTS COMPONENTS

COMPRESSORPTR-T310EM 001(FL1152-SH)

PHASESINGLE PHASE

RATE VOLTAGE ( V )220

RATE FREQUENCY ( Hz )50

POLE NUMBER2

MS

CONNECTION

RESISTANCE VALUE 75°C

MAIN COILSTARTING COIL

C

M - C = 23.8 Ω

S - C = 42.4 Ω

STARTING CURRENT (A)

DEFROST HEATER

6.0

230V/165W/322.7 Ω

2

Page 4

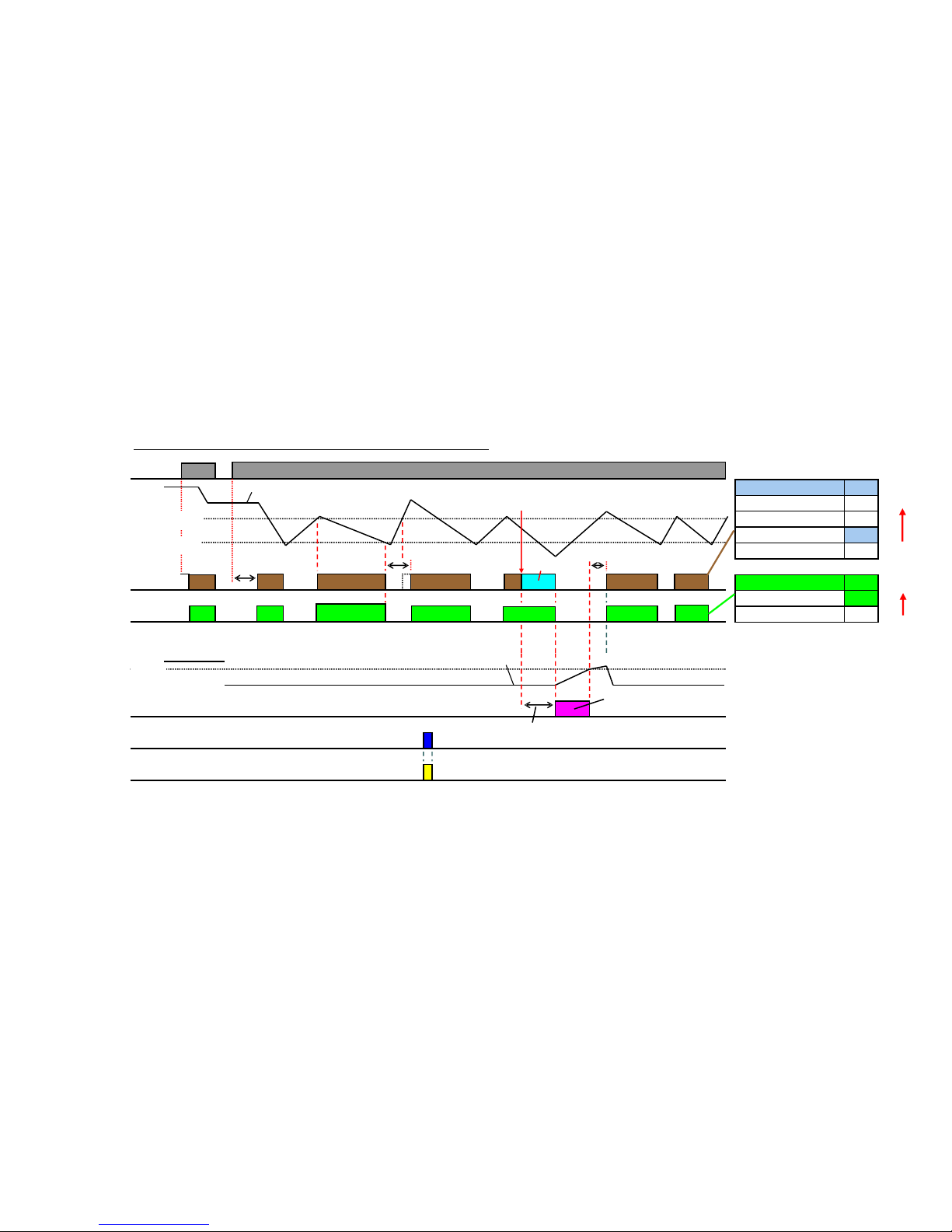

Off-time

Defrosting

R-sensor≧High temp.

R-sensor≦Low temp.

Comp. on

Comp. off

Off

3

Comp.Condition

Off

Off

On

Off

ConditionR-Fan

On

●Comp.

●Power

supply

●R-Room

Temp.

●R-Fan

●Evaporator

Temp.

●Defrost

heater

●R-Lamp

High temp.(4℃)

Low temp.(2℃)

On

R-sensor

On

Open

On

●R-Door

(R-Door sw)

8.5℃

D-sensor

On

On

~~~~~~~~

Off-time

10min

~

t1t2t3t4

Pre-Cool

Off-time

10min

Pre-Cool time≦30min

Basic operation(time chart) of 260-290L (STD) REF.

Comp. On-time:

t1+t2+t3+t4+…≧12h

High

Priority

Off-time

10min

High

Priority

Defrosting

25 s

Page 5

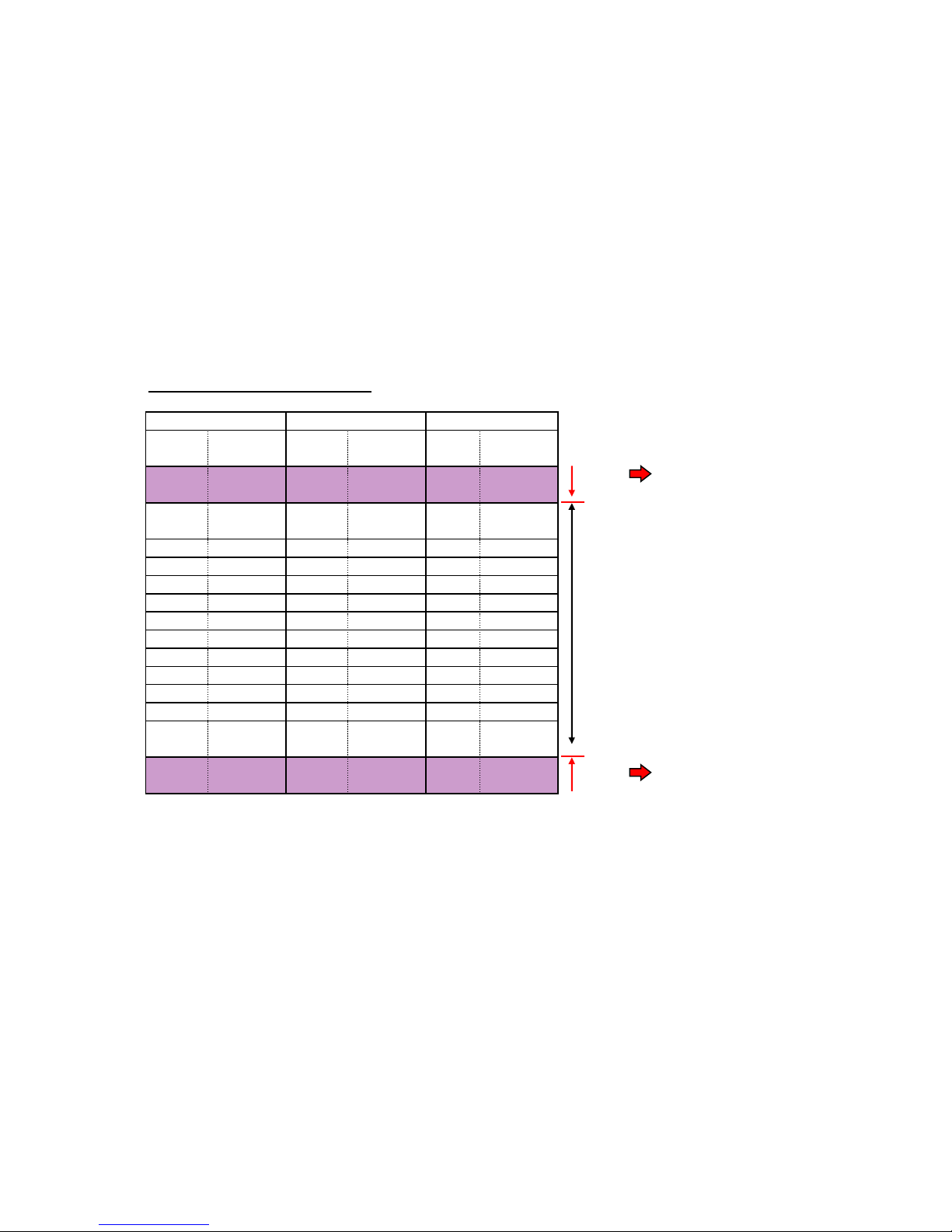

RESISTANCE VALUE RESISTANCE

Temp.ResistanceTemp.ResistanceTemp.Resistance

(℃)(Ω)(℃)(Ω)(℃)(Ω)

~~~~~~

-2019.23k-58271.14k-20105.38k

~~~~~~

-1514.26k-2019.17k-1582.03k

-1010.78k-1010.83k-1060.86k

-58.23k-58.27k-545.67k

06.35k06.38k034.62k

54.94k54.97k526.52k

103.88k103.90k1020.50k

153.08k153.09k1515.99k

202.46k202.47k2012.00k

251.98k251.98k259.97k

301.60k301.61k307.97k

351.31k401.08k356.42k

401.07k500.74k405.20k

~~~~~~

600.51k610.50k622.32k

~~~~~~

R-sensorD-sensorTC-sensor

4

Normal

range

Abnormal

range

Abnormal

range

Display

Error code

Display

Error code

Page 6

ERROR CODE

Priority

sequence

Error code

(LED on PCB)

Breakdown

list

Breakdown

description

Operation

11s ON + Blink twiceR-sensor abnormalR-sensor value abnormalProvisional mode

21s ON + Blink 3 timesTC-sensor abnormalTC-sensor value abnormalDisplay error code

31s ON + Blink 4 timesD-sensor abnormalD-sensor value abnormalNo defrosting

4Blink twice

EEPROM data

abnormal

EEPROM data

abnormal

Display error code

5Blink 4 times

Defrosting circuit

abnormal

Defrosting continues

even after 2 hours

After 2 hours,stop defrosting

and display error code

63s ON + Blink twiceRefrigerator not cool

R-sensor stays over 10℃

for 72 hours

Display error code

5

Page 7

MODEL : R-T310ERU1 (SLS,PWH,PBK)

6

Page 8

6

2

3

4

5

8

7

9

10

10

11

12

12

13

13

1

Page 9

14

23

26

27

15

16

70

69

72

71

74

79

76

75

78

77

88

73

10

10

16

85

28

17

21

22

19

52

86

87

50

51

49

48

46

47

38

29

31

32

33

34

35

36

37

55

61

53

54

62

57

56

56

58

59

63

60

68

67

66

65

64

39

30

40

41

42

43

44

45

18

20

24

25

84

83

82

81

80

Page 10

92

89

90

91

93

94

95

Page 11

MODEL: R-T310ERU1 (SLS)

Q'TY/SET

R-T310ERU1

1PTR-Z307AM 001DOOR-BADGE1

2PTR-T300W 001DOOR-PANEL-F-ASS'Y (SLS)1**

3PTR-T270W 013DOOR-GASKET-F1**

4PTR-T300W 004DOOR-PANEL-F (SLS)1**

5PTR-25A3P 021DOOR STOPPER (PMG,PGR,STL,SLS)1

6PTR-T270W 001DOOR-PANEL-R-ASS'Y (SLS)1**

7PTR-T270W 003DOOR-GASKET-R1**

8PTR-T270W 004DOOR-PANEL-R (SLS)1**

9PTR-200WKX 060DOOR STOPPER1

10PTR-T300W 011DOOR-RACK-F2

11PTR-44A4P 003E-CASE-4751

12PTR-T300W 012DOOR-RACK-R12

13PTR-T300W 013DOOR-RACK-R22

14PTR-T300W 014PLA-SHELF-F1

15PTR-T300W 015CHILLER1

REMARKSNO.SERVICE NO.SERVICE NAME

16PTR-T300W 016GLASS-SHELF-R2

17PTR-T300W 017GLASS-SHELF-CRISPER-ASS'Y1

18PTR-T300W 018GLASS-SHELF CRISPER1

19PTR-T300W 019FRAME-BUTTON1

20PTR-T300W 020V-SHUTTER1

21PTR-T300W 021CRISPER1

22PTR-T310ERU 001INSTRUCTION-BOOK1

23PTR-T300W 023ICE-CORNER1

24PTR-610AS3T 021ICE-MAKER-SPRING2

25PTR-200WKX 013ICE TRAY2

26PTR-T300W 024ICE-MAKER-SUPPORT1

27PTR-190NX 006ICE-BANK-04 TB1

28PTR-T300W 025F-GRILL1

29PTR-T300W 026FAN-GUARD-ASS'Y1

30PTR-Z380RX 046DIAL-F1

31PTR-T300W 027MOUTH-PLATE1

32PTR-923V 050BANE MOTOR1

33PTR-Z400R 004FAN1

** : RELATED PART FOR COOLING SYSTEM

10

Page 12

MODEL: R-T310ERU1 (SLS)

Q'TY/SET

R-T310ERU1

34PTR-200WGX 015MOTOR BUSH1

35PTR-Z580AM 013MOTOR-R1**

36PTR-12A9HD 029RUBBER-R1

37PTR-190N 032RM-FIXER1

38PTR-Z470EG9 008PCB-PANEL-395L-STD1**

39PTR-Z470EG9 009C-PANEL-STD1

40PTR-Z470EG9 010STICKER-CP-STD-NW-091

41PTR-Z400V 046TEMP-CTL-DIAL1

42PTR-578AM 048SCREW-COVER (SLS,TIS)1

43PTR-T270W 014CENTER-HINGE-SHEET1

44PTR-208A1HE 025CENTER HINGE-NF-011

45PTR-25A3P 022DOOR SWITCH1**

46PTR-600ET3X 016LAMP1

47PTR-T270W 006R-PANEL-ASS'Y1

48PTR-T270W 007R-DUCT1

REMARKSNO.SERVICE NO.SERVICE NAME

49PTR-T270W 008R-PANEL1

50PTR-T300W 034R-SENSOR1**

51PTR-T300W 035R-PANEL-SENSOR-COVER1

52PTR-T300W 036LAMP-COVER1

53PTR-T300W 037HEATER-COVER-31

54PTR-T300W 038HEATER-220V1**

55PTR-T300W 039HEATER-COVER-21

56PTR-T300W 061EVAP-SUPPORT2

57PTR-T300W 040EVAPORATOR1**

58PTR-208A1HE 010SENSOR HOLDER1

59PTR-Z400V 030D-SENSOR1**

60PTR-T300W 062FUSE1**

61PTR-T300W 041UP-HINGE-COVER1

62PTR-T300W 063UP-HINGE1

63PTR-T310EG1 002POWER CORD1**

64PTR-SBS6200T 027HOLE-CAP1

65PTR-T300W 044PCB-COVER1

66PTR-T300W 045PCB-290L-10-STD1**

** : RELATED PART FOR COOLING SYSTEM

11

Page 13

MODEL: R-T310ERU1 (SLS)

Q'TY/SET

REMARKSNO.SERVICE NO.SERVICE NAME

R-T310ERU1

67PTR-T300W 046PCB-CASE1

68PTR-Z400V 050TC-SENSOR1**

69PTR-47KP 003CAPA-47KP1**

70PTR-T300W 047DRAIN-PAN1

71PTR-Z610EG9 002CORD-CASE1

72PTR-14MX7 008DRYER KMP (NON-CFC)1**

73PTR-S700EUK8 132DRYER-FIXER1

74PTR-200WGX 037OVERLOAD RELAY1**

75PTR-S37NVH 018CORD-COMP1

76PTR-250EX 021STARTING DEVICE1**

77PTR-13EP 034TERMINAL-COVER1

78PTR-923V 068COMP COVER LOCK1

79PTR-T310EM 001COMPRESSOR1**

80PTR-SF37WVPH 108HEX NUT M63

81PTR-Z470AUK6K 018WASHER3

82PTR-T270W 009PIPE3

83PTR-N39WS 061HEX-BOLT (UP HING)3

84PTR-T270W 010R-GROMMET4

85PTR-T300W 049COMPRESSOR-BASE1

86PTR-T300W 050LO-HINGE1

87PTR-400WP 039ADJUSTER-R1

88PTR-400WP 038ADJUSTER-L1

89PTR-T300W 055UP-CARTON1

90PTR-T300W 056UP-CUSHION1

91PTR-570EN4 006SIDE CUSHION1

92PTR-T300W 057FRONT-CUSHION1

93PTR-T310ERU 002CARTON-BOX-R-T310ERU1 (SLS)1

94PTR-Z410AM-1 007POLY-BAG '081

95PTR-T300W 060CARTON-BASE1

** : RELATED PART FOR COOLING SYSTEM

12

Page 14

MODEL: R-T310ERU1 (PWH)

Q'TY/SET

R-T310ERU1

1PTR-Z307AM 001DOOR-BADGE1

2PTR-T310E1H 001DOOR-PANEL-F-ASS'Y (PWH)1**

3PTR-T270W 013DOOR-GASKET-F1**

4PTR-T310E1H 002DOOR-PANEL-F (PWH)1**

5PTR-25A3P 021DOOR STOPPER (PMG,PGR,STL,SLS)1

6PTR-T310E1H 003DOOR-PANEL-R-ASS'Y (PWH)1**

7PTR-T270W 003DOOR-GASKET-R1**

8PTR-T310E1H 004DOOR-PANEL-R (PWH)1**

9PTR-200WKX 060DOOR STOPPER1

10PTR-T300W 011DOOR-RACK-F2

11PTR-44A4P 003E-CASE-4751

12PTR-T300W 012DOOR-RACK-R12

13PTR-T300W 013DOOR-RACK-R22

14PTR-T300W 014PLA-SHELF-F1

15PTR-T300W 015CHILLER1

REMARKSNO.SERVICE NO.SERVICE NAME

16PTR-T300W 016GLASS-SHELF-R2

17PTR-T300W 017GLASS-SHELF-CRISPER-ASS'Y1

18PTR-T300W 018GLASS-SHELF CRISPER1

19PTR-T300W 019FRAME-BUTTON1

20PTR-T300W 020V-SHUTTER1

21PTR-T300W 021CRISPER1

22PTR-T310ERU 001INSTRUCTION-BOOK1

23PTR-T300W 023ICE-CORNER1

24PTR-610AS3T 021ICE-MAKER-SPRING2

25PTR-200WKX 013ICE TRAY2

26PTR-T300W 024ICE-MAKER-SUPPORT1

27PTR-190NX 006ICE-BANK-04 TB1

28PTR-T300W 025F-GRILL1

29PTR-T300W 026FAN-GUARD-ASS'Y1

30PTR-Z380RX 046DIAL-F1

31PTR-T300W 027MOUTH-PLATE1

32PTR-923V 050BANE MOTOR1

33PTR-Z400R 004FAN1

** : RELATED PART FOR COOLING SYSTEM

13

Page 15

MODEL: R-T310ERU1 (PWH)

Q'TY/SET

R-T310ERU1

34PTR-200WGX 015MOTOR BUSH1

35PTR-Z580AM 013MOTOR-R1**

36PTR-12A9HD 029RUBBER-R1

37PTR-190N 032RM-FIXER1

38PTR-Z470EG9 008PCB-PANEL-395L-STD1**

39PTR-Z470EG9 009C-PANEL-STD1

40PTR-Z470EG9 010STICKER-CP-STD-NW-091

41PTR-Z400V 046TEMP-CTL-DIAL1

42PTR-610AS3T 067SCREW-COVER (PWH,SWH,TWH)1

43PTR-T270W 014CENTER-HINGE-SHEET1

44PTR-208A1HE 025CENTER HINGE-NF-011

45PTR-25A3P 022DOOR SWITCH1**

46PTR-600ET3X 016LAMP1

47PTR-T270W 006R-PANEL-ASS'Y1

48PTR-T270W 007R-DUCT1

REMARKSNO.SERVICE NO.SERVICE NAME

49PTR-T270W 008R-PANEL1

50PTR-T300W 034R-SENSOR1**

51PTR-T300W 035R-PANEL-SENSOR-COVER1

52PTR-T300W 036LAMP-COVER1

53PTR-T300W 037HEATER-COVER-31

54PTR-T300W 038HEATER-220V1**

55PTR-T300W 039HEATER-COVER-21

56PTR-T300W 061EVAP-SUPPORT2

57PTR-T300W 040EVAPORATOR1**

58PTR-208A1HE 010SENSOR HOLDER1

59PTR-Z400V 030D-SENSOR1**

60PTR-T300W 062FUSE1**

61PTR-T310E1H 005UP-HINGE-COVER 1

62PTR-T300W 063UP-HINGE1

63PTR-T310EG1 002POWER CORD1**

64PTR-SBS6200T 027HOLE-CAP1

65PTR-T300W 044PCB-COVER1

66PTR-T300W 045PCB-290L-10-STD1**

** : RELATED PART FOR COOLING SYSTEM

14

Page 16

MODEL: R-T310ERU1 (PWH)

Q'TY/SET

R-T310ERU1

67PTR-T300W 046PCB-CASE1

68PTR-Z400V 050TC-SENSOR1**

69PTR-47KP 003CAPA-47KP1**

70PTR-T300W 047DRAIN-PAN1

71PTR-Z610EG9 002CORD-CASE1

72PTR-14MX7 008DRYER KMP (NON-CFC)1**

73PTR-S700EUK8 132DRYER-FIXER1

74PTR-200WGX 037OVERLOAD RELAY1**

75PTR-S37NVH 018CORD-COMP1

76PTR-250EX 021STARTING DEVICE1**

77PTR-13EP 034TERMINAL-COVER1

78PTR-923V 068COMP COVER LOCK1

79PTR-T310EM 001COMPRESSOR1**

80PTR-SF37WVPH 108HEX NUT M63

81PTR-Z470AUK6K 018WASHER3

REMARKSNO.SERVICE NO.SERVICE NAME

82PTR-T270W 009PIPE3

83PTR-N39WS 061HEX-BOLT (UP HING)3

84PTR-T270W 010R-GROMMET4

85PTR-T300W 049COMPRESSOR-BASE1

86PTR-T300W 050LO-HINGE1

87PTR-400WP 039ADJUSTER-R1

88PTR-400WP 038ADJUSTER-L1

89PTR-T300W 055UP-CARTON1

90PTR-T300W 056UP-CUSHION1

91PTR-570EN4 006SIDE CUSHION1

92PTR-T300W 057FRONT-CUSHION1

93PTR-T310ERU 003CARTON-BOX-R-T310ERU1 (PWH)1

94PTR-Z410AM-1 007POLY-BAG '081

95PTR-T300W 060CARTON-BASE1

** : RELATED PART FOR COOLING SYSTEM

15

Page 17

MODEL: R-T310ERU1 (PBK)

Q'TY/SET

R-T310ERU1

1PTR-Z307AM 001DOOR-BADGE1

2PTR-T300W 002DOOR-PANEL-F-ASS'Y (PBK)1**

3PTR-T270W 013DOOR-GASKET-F1**

4PTR-T300W 005DOOR-PANEL-F (PBK)1**

5PTR-25A3P 021DOOR STOPPER (PMG,PGR,STL,SLS)1

6PTR-T270W 002DOOR-PANEL-R-ASS'Y (PBK)1**

7PTR-T270W 003DOOR-GASKET-R1**

8PTR-T270W 005DOOR-PANEL-R (PBK)1**

9PTR-200WKX 060DOOR STOPPER1

10PTR-T300W 011DOOR-RACK-F2

11PTR-44A4P 003E-CASE-4751

12PTR-T300W 012DOOR-RACK-R12

13PTR-T300W 013DOOR-RACK-R22

14PTR-T300W 014PLA-SHELF-F1

15PTR-T300W 015CHILLER1

REMARKSNO.SERVICE NO.SERVICE NAME

16PTR-T300W 016GLASS-SHELF-R2

17PTR-T300W 017GLASS-SHELF-CRISPER-ASS'Y1

18PTR-T300W 018GLASS-SHELF CRISPER1

19PTR-T300W 019FRAME-BUTTON1

20PTR-T300W 020V-SHUTTER1

21PTR-T300W 021CRISPER1

22PTR-T310ERU 001INSTRUCTION-BOOK1

23PTR-T300W 023ICE-CORNER1

24PTR-610AS3T 021ICE-MAKER-SPRING2

25PTR-200WKX 013ICE TRAY2

26PTR-T300W 024ICE-MAKER-SUPPORT1

27PTR-190NX 006ICE-BANK-04 TB1

28PTR-T300W 025F-GRILL1

29PTR-T300W 026FAN-GUARD-ASS'Y1

30PTR-Z380RX 046DIAL-F1

31PTR-T300W 027MOUTH-PLATE1

32PTR-923V 050BANE MOTOR1

33PTR-Z400R 004FAN1

** : RELATED PART FOR COOLING SYSTEM

16

Page 18

MODEL: R-T310ERU1 (PBK)

Q'TY/SET

R-T310ERU1

34PTR-200WGX 015MOTOR BUSH1

35PTR-Z580AM 013MOTOR-R1**

36PTR-12A9HD 029RUBBER-R1

37PTR-190N 032RM-FIXER1

38PTR-Z470EG9 008PCB-PANEL-395L-STD1**

39PTR-Z470EG9 009C-PANEL-STD1

40PTR-Z470EG9 010STICKER-CP-STD-NW-091

41PTR-Z400V 046TEMP-CTL-DIAL1

42PTR-T300W 028SCREW-COVER1

43PTR-T270W 014CENTER-HINGE-SHEET1

44PTR-208A1HE 025CENTER HINGE-NF-011

45PTR-25A3P 022DOOR SWITCH1**

46PTR-600ET3X 016LAMP1

47PTR-T270W 006R-PANEL-ASS'Y1

48PTR-T270W 007R-DUCT1

REMARKSNO.SERVICE NO.SERVICE NAME

49PTR-T270W 008R-PANEL1

50PTR-T300W 034R-SENSOR1**

51PTR-T300W 035R-PANEL-SENSOR-COVER1

52PTR-T300W 036LAMP-COVER1

53PTR-T300W 037HEATER-COVER-31

54PTR-T300W 038HEATER-220V1**

55PTR-T300W 039HEATER-COVER-21

56PTR-T300W 061EVAP-SUPPORT2

57PTR-T300W 040EVAPORATOR1**

58PTR-208A1HE 010SENSOR HOLDER1

59PTR-Z400V 030D-SENSOR1**

60PTR-T300W 062FUSE1**

61PTR-T300W 042UP-HINGE-COVER1

62PTR-T300W 063UP-HINGE1

63PTR-T310EG1 002POWER CORD1**

64PTR-SBS6200T 027HOLE-CAP1

65PTR-T300W 044PCB-COVER1

66PTR-T300W 045PCB-290L-10-STD1**

** : RELATED PART FOR COOLING SYSTEM

17

Page 19

MODEL: R-T310ERU1 (PBK)

Q'TY/SET

R-T310ERU1

67PTR-T300W 046PCB-CASE1

68PTR-Z400V 050TC-SENSOR1**

69PTR-47KP 003CAPA-47KP1**

70PTR-T300W 047DRAIN-PAN1

71PTR-Z610EG9 002CORD-CASE1

72PTR-14MX7 008DRYER KMP (NON-CFC)1**

73PTR-S700EUK8 132DRYER-FIXER1

74PTR-200WGX 037OVERLOAD RELAY1**

75PTR-S37NVH 018CORD-COMP1

76PTR-250EX 021STARTING DEVICE1**

77PTR-13EP 034TERMINAL-COVER1

78PTR-923V 068COMP COVER LOCK1

79PTR-T310EM 001COMPRESSOR1**

80PTR-SF37WVPH 108HEX NUT M63

81PTR-Z470AUK6K 018WASHER3

REMARKSNO.SERVICE NO.SERVICE NAME

82PTR-T270W 009PIPE3

83PTR-N39WS 061HEX-BOLT (UP HING)3

84PTR-T270W 010R-GROMMET4

85PTR-T300W 049COMPRESSOR-BASE1

86PTR-T300W 050LO-HINGE1

87PTR-400WP 039ADJUSTER-R1

88PTR-400WP 038ADJUSTER-L1

89PTR-T300W 055UP-CARTON1

90PTR-T300W 056UP-CUSHION1

91PTR-570EN4 006SIDE CUSHION1

92PTR-T300W 057FRONT-CUSHION1

93PTR-T310ERU 004CARTON-BOX-R-T310ERU1 (PBK)1

94PTR-Z410AM-1 007POLY-BAG '081

95PTR-T300W 060CARTON-BASE1

** : RELATED PART FOR COOLING SYSTEM

18

Loading...

Loading...