Hitachi RCI-6.0FSN4, RCI-2.0FSN4, RCIM-0.6FSN4, RCI-2.5FSN4, RCI-1.5FSN4 Service Manual

...Page 1

INDOOR UNITS SYSTEM FREE SERIES

& COMPLEMENTARY SYSTEMS

Service Manual

RCI - FSN4

RCIM - FSN4(E)

RCD - FSN3

RPC - FSN3(E)

RPI - FSN(3/4)(P)E(-f)

RPIM - FSN4E(-DU)

RPK - FSN(H)3M

RPF - FSN2E

RPFI - FSN2E

KPI - (E/X)4E

DX - Interface - EXV-E2

Econofresh - EF-456NE

Page 2

Page 3

Contents

Contents

General information

Unit installation

Piping work and refrigerant charge

Electrical and control settings

Control system

Optional functions

Commissioning

1

2

3

4

5

6

7

Electrical check of main parts

Servicing

Troubleshooting

Maintenance notes

8

9

10

11

I

SMGB0099 rev.0 - 12/2016

Page 4

Page 5

General Index

General Index

1. General information ................................................................................................... 1

1.1 General information ................................................................................................................................. 2

1.1.1 Introduction ...................................................................................................................................................... 2

1.2 Applied symbols ...................................................................................................................................... 3

1.3 Productclassicationandline-up ............................................................................................................ 4

1.3.1 Classicationofindoorunitmodels ................................................................................................................. 4

1.3.2 ClassicationofKPImodels ............................................................................................................................ 4

1.3.3 ClassicationofDX-Interfacemodels ............................................................................................................. 4

1.3.4 ClassicationofEconofreshmodels ............................................................................................................... 4

1.3.5 Productline-up:indoorunits ............................................................................................................................ 5

1.3.6 Productline-up:KPIenergyrecoveryunit ....................................................................................................... 9

1.3.7 Productline-up:DX-Interface .......................................................................................................................... 9

1.3.8 Productline-up:Econofresh ............................................................................................................................ 9

1.3.9 Accessory code list ........................................................................................................................................ 10

1.3.10 Multi-Kits .......................................................................................................................................................11

1.3.11 Individualremotecontrols ............................................................................................................................ 12

1.3.12 Receiverkitforcombinationwithwirelessremotecontrolswitch ................................................................ 12

1.3.13 Centralised remote controls ........................................................................................................................ 13

1.3.14 Buildingairconditioningcontrols ................................................................................................................. 13

1.3.15 Gatewaysforbuildingmanagementsystems(BMS) .................................................................................. 14

1.3.16 Controlsupportdevices ............................................................................................................................... 14

1.3.17 Control accessories ..................................................................................................................................... 15

1.3.18 OtherdevicescompatiblewithHITACHIAirConditioningsystems ............................................................. 15

2. Unit installation ........................................................................................................ 17

2.1 RCI-4-waycassette ............................................................................................................................. 19

2.1.1 Accessoriessuppliedwiththeunit ................................................................................................................. 19

2.1.2 Unit installation .............................................................................................................................................. 20

2.1.3 Airpanelinstallation:P-N23NA2 ................................................................................................................... 22

2.1.4 AccessoriessuppliedwiththeairpanelP-N23NA2 ...................................................................................... 26

2.2 RCIM-4-waycassette(compact) ......................................................................................................... 27

2.2.1 Accessoriessuppliedwiththeunit ................................................................................................................. 27

2.2.2 Unit installation .............................................................................................................................................. 28

2.2.3 Accessoriessuppliedwiththeairpanel:P-AP56NAM .................................................................................. 30

2.2.4 Air panel installation ...................................................................................................................................... 31

2.3 RCD-2-waycassette ...........................................................................................................................35

2.3.1 Accessoriessuppliedwiththeunit ................................................................................................................. 35

2.3.2 Unit installation .............................................................................................................................................. 36

2.3.3 Accessoriessuppliedwiththeairpanel:P-N23DWA/P-N46DWA ............................................................... 39

III

SMGB0099 rev.0 - 12/2016

Page 6

General Index

2.3.4 Air panel installation ...................................................................................................................................... 39

2.4 RPC-Ceiling.........................................................................................................................................41

2.4.1 AccessoriessuppliedwiththeunitRPC-FSN3 .............................................................................................. 41

2.4.2 Unit installation .............................................................................................................................................. 42

2.4.3 SuspensionbracketinstallationRPC-FSN3E ............................................................................................... 42

2.4.4 SuspensionforFSN3units ............................................................................................................................ 43

2.4.5 Indoor unit installation ................................................................................................................................... 45

2.5 RPI(M)-Ductedindoorunit(0.6-6.0)FSN4E(-DU)................................................................................48

2.5.1 Accessoriessuppliedwiththeunit ................................................................................................................. 48

2.5.2 Unit installation .............................................................................................................................................. 48

2.5.3 Air duct connection ........................................................................................................................................ 50

2.5.4 Maintenanceofthesuctionairlter ............................................................................................................... 51

2.6 RPI-Ductedindoorunit(8/10)FSN3E(-f) .............................................................................................53

2.6.1 Accessoriessuppliedwiththeunit ................................................................................................................. 53

2.6.2 Unit installation .............................................................................................................................................. 53

2.6.3 Air duct connection ........................................................................................................................................ 55

2.6.4 Maintenanceofthesuctionairlter ............................................................................................................... 55

2.7 RPI-Ductedindoorunit(16/20)FSN3PE(-f) ......................................................................................... 56

2.7.1 Unit installation .............................................................................................................................................. 56

2.8 RPK-FSN(H)3MWallmounted ............................................................................................................ 58

2.8.1 Accessoriessuppliedwiththeunit ................................................................................................................. 58

2.8.2 Unit installation .............................................................................................................................................. 58

2.8.3 Mountingbracketdimensions ........................................................................................................................ 62

2.9 RPF-Floortype,RPFI-Floorconcealedtype ..................................................................................... 64

2.9.1 Accessoriessuppliedwiththeunit ................................................................................................................. 64

2.9.2 Unit installation .............................................................................................................................................. 64

2.9.3 Changeintheairoutletdirection(RPFIunits) .............................................................................................. 66

2.9.4 RPF:OptionalPC-ARFPEremotecontrollocation ....................................................................................... 66

2.10 KPIenergyandKPIactiveunit.............................................................................................................. 67

2.10.1 Accessoriessuppliedwiththeunit ............................................................................................................... 67

2.10.2 Unit installation ............................................................................................................................................ 67

2.10.3 Ductconnection ........................................................................................................................................... 70

2.11 EconofreshKit ....................................................................................................................................... 72

2.11.1 Accessoriessuppliedwiththeunit ............................................................................................................... 72

2.11.2 Unit installation ............................................................................................................................................ 72

2.11.3 Mountingtheunit ......................................................................................................................................... 73

2.11.4 Exampleofinstallation ................................................................................................................................. 74

2.12 DX-Interface .......................................................................................................................................... 75

2.12.1 Accessoriessuppliedwiththeunit ............................................................................................................... 75

2.12.2 Unit installation ............................................................................................................................................ 75

IV

SMGB0099 rev.0 - 12/2016

Page 7

General Index

2.12.3 Mountingmethod ......................................................................................................................................... 76

2.12.4 Thermistorinstallation ................................................................................................................................. 77

2.13 Optional accessories ............................................................................................................................. 79

2.13.1 Outdoor air inlet ........................................................................................................................................... 79

2.13.1.1 ForRCI-FSN4indoorunits:OACI-160K2andPD-75A .................................................................. 81

2.13.2 Ductadapters .............................................................................................................................................. 83

2.13.2.1 ForRCIM-FSN4(E)indoorunits:PD-75C ...................................................................................... 83

2.13.2.2 ForRCD-FSN3indoorunits:PD-150D .......................................................................................... 83

2.13.3 T-ductconnectionposition ........................................................................................................................... 84

2.13.3.1 ForRCI-FSN4indoorunits:TKCI-160k ......................................................................................... 84

2.13.3.2 Branchpipe(PDF-71C,PDF-160CI) .............................................................................................. 85

2.13.4 Outletairowinterlock ................................................................................................................................ 87

2.13.4.1 ForRCI-FSN4indoorunits:PI-160SL1 .......................................................................................... 87

2.13.5 Filterbox ...................................................................................................................................................... 89

2.13.5.1 ForRCI-FSN4indoorunits:B-160H2 ............................................................................................ 89

2.13.5.2 ForRCD-FSN3Eindoorunits:BD-90HandBD-160HD ............................................................... 90

2.13.6 Anti-bacterialter ........................................................................................................................................ 91

2.13.6.1 ForRCI-FSN4:F-160L-K ............................................................................................................... 91

2.13.6.2 ForRCD-FSN3Eindoorunits:F-90MD-K1andF-160MD-K1(Antibacteriallonglifeairlter) ...... 92

2.13.7 Deodorisinglter ......................................................................................................................................... 92

2.13.7.1 ForRCI-FSN4indoorunits:F-71L-D1andF-160L-D1 .................................................................. 92

3. Piping work and refrigerant charge ....................................................................... 95

3.1 Refrigerantpipeselection......................................................................................................................96

3.1.1 Refrigerantpipeselection .............................................................................................................................. 96

3.2 Copperpipes,sizes,connectionandinsulation .................................................................................... 97

3.2.1 Copperpipesandsizes ................................................................................................................................. 97

3.2.2 Pipe connection ............................................................................................................................................. 98

3.2.3 Insulationofmultikitsand/orbranches .......................................................................................................... 98

3.3 Generalinstructionsontheinstallationofrefrigerantpipes ..................................................................99

3.4 Copperrefrigerantpipe .......................................................................................................................100

3.4.1 Threeprinciplesonworkwithrefrigerantpipes ........................................................................................... 100

3.4.2 Preparingandcuttingcopperrefrigerationpipes ........................................................................................ 101

3.4.3 Bendingcopperpipes .................................................................................................................................. 102

3.4.4 Brazingcopperrefrigerationpipes .............................................................................................................. 103

3.4.5 Flaredconnectionmounting ........................................................................................................................ 104

3.4.6 Refrigerantpipesuspension ........................................................................................................................ 105

3.5 Refrigerantanddrainhoseinstallation ................................................................................................ 106

3.5.1 RCI-(1.0-6.0)FSN4-4-waycassette ........................................................................................................... 106

3.5.2 RCIM-(0.6-2.5)FSN4(E)-4-waycassette(compact) .................................................................................. 108

3.5.3 RCD-(0.8-6.0)FSN3-2-waycassette ......................................................................................................... 109

3.5.4 RPC-(3.0-6.0)FSN3E-Ceilingtype .............................................................................................................110

V

SMGB0099 rev.0 - 12/2016

Page 8

General Index

3.5.5 RPC-(1.5-6.0)FSN3E-Ceilingtype .............................................................................................................112

3.5.6 RPI-(0.6-1.5)FSN4E-Ductedindoorunit .....................................................................................................116

3.5.7 RPI-(2.0-6.0)FSN4E-Ductedindoorunit .....................................................................................................118

3.5.8 RPI-(8.0/10.0)FSN3E-(f)-Ductedindoorunit ............................................................................................. 120

3.5.9 RPI-(16.0/20.0)FSN3PE(-f)-Ductedindoorunit ......................................................................................... 121

3.5.10 RPIM-(0.6-1.5)FSN4E(-DU)-Ductedindoorunit ...................................................................................... 123

3.5.11 RPK-(0.6-4.0)FSN(H)3M-Walltype ......................................................................................................... 125

3.5.12 RPF(I)-(1.0-2.5)FSN2E-Floortype .......................................................................................................... 128

3.6 Refrigerantcharge...............................................................................................................................129

3.7 Precautionsintheeventofrefrigerantleaks ....................................................................................... 129

3.7.1 Maximumpermissibleconcentrationofhydrouorocarbon(HFC) .............................................................. 129

3.7.2 Calculationoftheconcentrationofrefrigerant ............................................................................................. 129

3.7.3 Countermeasuresintheeventofrefrigerantleaks ..................................................................................... 129

4. Electrical and control settings .............................................................................. 131

4.1 Unitelectricalwiringandconnection ................................................................................................... 132

4.1.1 Wiringsize ................................................................................................................................................... 132

4.1.2 Minimumrequirementsoftheprotectiondevices ........................................................................................ 133

4.1.3 Transmissionwiringbetweenoutdoorandindoorunit ................................................................................ 134

4.1.4 ElectricalconnectionofRCIunits ................................................................................................................ 134

4.1.5 ElectricalconnectionofRCIMunits ............................................................................................................. 136

4.1.6 ElectricalconnectionofRCDunits .............................................................................................................. 138

4.1.7 ElectricalconnectionofRPCunits .............................................................................................................. 140

4.1.8 ElectricalconnectionofRPIunits ................................................................................................................ 141

4.1.9 ElectricalconnectionofRPIMunits ............................................................................................................. 145

4.1.10 ElectricalconnectionofRPKunits ............................................................................................................ 147

4.1.11 ElectricalconnectionofKPIunits .............................................................................................................. 152

4.1.12 Econofreshelectricalwiringconnection .................................................................................................... 153

4.1.13 DX-Interfaceelectricalwiring ..................................................................................................................... 154

4.1.14 Networksystemconnection(CS-NETWEB) ............................................................................................ 157

4.1.15 ConnectionbetweenunitsH-LINKandH-LINKII ..................................................................................... 157

4.2 SettingofDIPswitchesandRSWswitches ........................................................................................158

4.2.1 LocationofDIPswitchesandRSWswitches .............................................................................................. 159

4.2.2 FunctionsoftheDIPswitchesandRSWswitches(Indoorunits) ................................................................ 161

4.2.3 FunctionsoftheDIPswitchesandRSWswitches(KPIunits) .................................................................... 164

4.2.4 FunctionsoftheDIPswitchesandRSWswitches(Econofreshkit) ............................................................ 166

4.2.5 FunctionsoftheDIPswitchesandRSWswitches(DX-Interface) .............................................................. 166

4.3 Wiringdiagramsforindoorunitsandcomplementarysystems ........................................................... 169

4.3.1 Wiringdiagramsforindoorunits .................................................................................................................. 169

4.3.2 Wiringdiagramsforcomplementarysystems ............................................................................................. 182

VI

SMGB0099 rev.0 - 12/2016

Page 9

General Index

5. Control system ....................................................................................................... 185

5.1 PrintedcircuitboardsforRCI-FSN4indoorunits ................................................................................ 186

5.1.1 PrintedcircuitboardsforRCI-(1.0-6.0)FSN4 .............................................................................................. 186

5.2 PrintedcircuitboardsforRCIM-FSN4(E)indoorunits ........................................................................187

5.3 PrintedcircuitboardsforRCD-FSN3indoorunits...............................................................................188

5.4 PrintedcircuitboardforRPC-FSN3E,RPF(I),units............................................................................189

5.5 PrintedcircuitboardforRPC-FSN3 .................................................................................................... 190

5.6 PrintedcircuitboardforRPI(M)-(0.6-6.0)FSN4E ................................................................................191

5.7 PrintedcircuitboardforRPI-(8.0-20.0)FSN3(P)E(-f)units .................................................................. 192

5.8 PrintedcircuitboardforRPK-FSN(H)3Munits .................................................................................... 193

5.8.1 ForRPK-(0.6-1.5)FSN(H)3M ....................................................................................................................... 193

5.8.2 ForRPK-(2.0-4.0)FSN3M ............................................................................................................................ 194

5.9 Printed circuit board for complementary systems ...............................................................................195

5.9.1 PrintedcircuitboardforKPI ........................................................................................................................ 195

5.9.2 PrintedcircuitboardforDX-Interface .......................................................................................................... 196

5.10 Safetyprotectionandcontrol............................................................................................................... 197

5.11 Indoorelectronicexpansionvalvecontrol ........................................................................................... 198

6. Optional functions ................................................................................................. 199

6.1 Indoorunitsinputandoutputsignals...................................................................................................200

6.1.1 Availableports ............................................................................................................................................. 200

6.1.2 Optionalsignalconguration ....................................................................................................................... 202

6.1.3 Programmingwithremotecontroller ........................................................................................................... 204

6.1.4 Descriptionofoptionalinputsignals ............................................................................................................ 204

6.1.5 Descriptionofoptionaloutputsignals .......................................................................................................... 208

6.2 OptionalfunctionsthroughRemotecontrol ......................................................................................... 209

6.2.1 Listofoptionalremotecontrolfunctions.(PC-ARFPE) ............................................................................... 209

6.2.2 Descriptionoftheoptionalremotecontrolfunctions(PC-ARFPE) .............................................................. 217

6.2.3 OptionalfunctionsforPC-ARHremotecontrols .......................................................................................... 225

6.2.4 Settingsonwirelessremotecontrols ........................................................................................................... 226

6.3 Complementary systems ..................................................................................................................... 227

6.3.1 KPIandDX-Interface .................................................................................................................................. 227

6.3.1.1 DX-Interface ................................................................................................................................... 228

6.3.2 EconofreshKit ............................................................................................................................................. 230

7. Commissioning ...................................................................................................... 233

7.1 Checkspriortothetestrun ................................................................................................................. 234

7.1.1 Checkpoints ................................................................................................................................................ 234

7.1.2 Checkprocedure ......................................................................................................................................... 234

VII

SMGB0099 rev.0 - 12/2016

Page 10

General Index

7.1.3 PC-ARFPEremotecontrol .......................................................................................................................... 235

7.2 Testprocedureusingthewirelessremotecontrol ............................................................................... 237

7.2.1 PC-AWRwirelessremotecontrol ................................................................................................................ 237

7.3 Testrunchecklist ................................................................................................................................ 238

8. Electrical check of main parts .............................................................................. 239

8.1 Thermistor ...........................................................................................................................................240

8.2 Electronicexpansionvalve .................................................................................................................. 240

8.3 Automaticlouvermechanism .............................................................................................................. 241

8.3.1 RCI indoor units ........................................................................................................................................... 241

8.3.2 RCIM indoor units ........................................................................................................................................ 242

8.3.3 RCDindoorunits ......................................................................................................................................... 243

8.3.4 RPC-FSN3Eindoorunits ............................................................................................................................ 244

9. Servicing ................................................................................................................. 245

9.1 RCI-(1.0-6.0)FSN4-4-waycassette ................................................................................................... 248

9.1.1 RemovingAirFilterandAirInletGrille .........................................................................................................248

9.1.2 RemovingElectricalBoxCover ................................................................................................................... 248

9.1.3 RemovingOptionalAirPanel ...................................................................................................................... 249

9.1.4 Removingturbofanandfanmotor .............................................................................................................. 250

9.1.5 RemovingPrintedCircuitBoard(PCB1) ..................................................................................................... 251

9.1.6 RemovingDrainPan ................................................................................................................................... 252

9.1.7 RemovingAntibacterialAgent .....................................................................................................................252

9.1.8 RemovingDrain-UpMechanism ................................................................................................................. 253

9.1.9 RemovingFloatSwitch ................................................................................................................................ 254

9.1.10 RemovingThermistorsforLiquidPipeandGasPipe ............................................................................... 255

9.1.11 RemovingElectronicExpansionValveCoil ............................................................................................... 256

9.1.12 RemovingAutoLouverMotors .................................................................................................................. 257

9.1.13 RemovingLouver ...................................................................................................................................... 258

9.2 RCIM-(0.6-2.5)FSN4(E)-4-waycassette(compact) .......................................................................... 259

9.2.1 Removaloftheairlter ............................................................................................................................... 259

9.2.2 Removaloftheairinletgrille ....................................................................................................................... 259

9.2.3 Removaloftheelectricalboxcover ............................................................................................................ 259

9.2.4 Removaloftheoptionalairpanel ................................................................................................................ 260

9.2.5 Removalofthefanrunnerandthefanmotor .............................................................................................. 261

9.2.6 Removaloftheprintedcircuitboard(PCB) ................................................................................................. 262

9.2.7 Removalofthedrainpan ............................................................................................................................ 263

9.2.8 Removalofthedrainmechanism ................................................................................................................ 264

9.2.9 Removaloftheoatswitch ......................................................................................................................... 264

9.2.10 Removalofthethermistorsfromtheliquidandgaspipes ........................................................................ 265

9.2.11 Removaloftheelectronicexpansionvalvecoil ......................................................................................... 265

VIII

SMGB0099 rev.0 - 12/2016

Page 11

General Index

9.2.12 Removaloftheinletairthermistor ............................................................................................................. 266

9.2.13 Removaloftheautomaticlouvermotor ..................................................................................................... 267

9.3 RCD-(0.8-6.0)FSN3-2-waycassette .................................................................................................268

9.3.1 RemovaloftheAirlterandtheAirinletgrille ............................................................................................. 268

9.3.2 Removaloftheelectricalbox ...................................................................................................................... 268

9.3.3 Removaloftheoptionalairpanel ................................................................................................................ 269

9.3.4 Removalofthefanductandthefan ........................................................................................................... 269

9.3.5 Removaloftheprintedcircuitboard(PCB) ................................................................................................. 271

9.3.6 Removaloftheoatswitch ......................................................................................................................... 272

9.3.7 Removalofthedrainmechanism ................................................................................................................ 272

9.3.8 Removalofthedrainpan ............................................................................................................................ 272

9.3.9 Removalofthethermistorsfromtheliquidandgaspipes .......................................................................... 273

9.3.10 Removaloftheelectronicexpansionvalvecoil ......................................................................................... 274

9.3.11 Removaloftheautomaticlouvermotor ..................................................................................................... 274

9.3.12 RemovetheAntibacterialagentcase ....................................................................................................... 275

9.4 RPC-(3.0-6.0)FSN3E-Ceilingtype ....................................................................................................276

9.4.1 Removaloftheairlter ............................................................................................................................... 276

9.4.2 Removalofthesidepanel ........................................................................................................................... 276

9.4.3 Removaloftheairoutletgrille ..................................................................................................................... 276

9.4.4 Removalofthefanmotor ............................................................................................................................ 277

9.4.5 Removalofthefanshaftsupport ................................................................................................................ 278

9.4.6 Removalofthecoupling .............................................................................................................................. 278

9.4.7 Removaloftheautomaticlouvermotor ....................................................................................................... 278

9.4.8 Removalofthethermistorsfromtheliquidandgaspipes .......................................................................... 279

9.4.9 Removaloftheprintedcircuitboard(PCB) ................................................................................................. 280

9.5 RPC-(1.5-6.0)FSN3-Ceilingtype ....................................................................................................... 281

9.5.1 RemovingAirFilterandAirInletGrille .........................................................................................................281

9.5.2 RemovingSideCover ................................................................................................................................. 281

9.5.3 RemovingLouver ........................................................................................................................................ 282

9.5.4 Removalofthefanmotor ............................................................................................................................ 282

9.5.5 RemovingBearing(ExceptforRPC-1.5and2.0FSN3) .............................................................................. 284

9.5.6 RemovingCoupling(ExceptforRPC-1.5and2.0FSN3) ............................................................................ 285

9.5.7 RemovingAutoLouverMotor ...................................................................................................................... 286

9.5.8 Removalofthethermistorsfromtheliquidandgaspipes .......................................................................... 286

9.5.9 RemovingElectronicExpansionValveCoil ................................................................................................. 287

9.5.10 Removaloftheprintedcircuitboard(PCB) ............................................................................................... 289

9.6 RPI-(0.6-6.0)FSN4E-Ductedindoorunit............................................................................................290

9.6.1 Removaloftheelectricalbox ...................................................................................................................... 290

9.6.2 Removaloftheinletandoutletairthermistors ............................................................................................ 291

9.6.3 Removalofthethermistorsfromtheliquidandgaspipes .......................................................................... 292

9.6.4 Removalofthefanparts ............................................................................................................................. 292

9.6.5 Removalofthedrainmechanism ................................................................................................................ 293

IX

SMGB0099 rev.0 - 12/2016

Page 12

General Index

9.6.6 Removaloftheoatswitch ......................................................................................................................... 294

9.6.7 Removaloftheairlter ............................................................................................................................... 294

9.7 RPI-(8.0-20.0)FSN3(P)E(-f)-Ductedindoorunit ................................................................................ 295

9.7.1 Removaloftheelectricalboxcover ............................................................................................................ 295

9.7.2 Removalofelectricalcomponents .............................................................................................................. 295

9.7.3 Removaloftheinletandoutletairthermistors ............................................................................................ 295

9.7.4 Removalofthethermistorsfromtheliquidandgaspipes .......................................................................... 297

9.7.5 Removalofthedrainpan ............................................................................................................................ 297

9.7.6 Fanremoval ................................................................................................................................................ 298

9.7.7 Removaloftheoatswitch ......................................................................................................................... 301

9.7.8 Removaloftheairlter ............................................................................................................................... 302

9.8 RPIM-(0.6-1.5)FSN4E-Ductedindoorunit.........................................................................................303

9.8.1 Removaloftheelectricalbox ...................................................................................................................... 303

9.8.2 Removaloftheinletandoutletairthermistors ............................................................................................ 303

9.8.3 Outletairthermistor ..................................................................................................................................... 304

9.8.4 Removalofthefanparts ............................................................................................................................. 305

9.8.5 Removaloftheoatswitch ......................................................................................................................... 306

9.8.6 Removaloftheairlter ............................................................................................................................... 306

9.9 RPK-FSN(H)3M-Wallmounted .........................................................................................................307

9.9.1 Removaloftheairlter ............................................................................................................................... 307

9.9.2 Removalofthefrontpanel .......................................................................................................................... 307

9.9.3 ElectricalBoxStructure ................................................................................................................................311

9.9.4 Removetheelectricalboxcover ................................................................................................................. 312

9.9.5 Removetheswitchcover ............................................................................................................................ 312

9.9.6 ReplacingPCB1forControl ........................................................................................................................ 313

9.9.7 RemovingElectricalBox ............................................................................................................................. 315

9.9.8 RemovingASMotor .................................................................................................................................... 317

9.9.9 RemovingDrainPan ................................................................................................................................... 317

9.9.10 RemovingHeatExchanger ....................................................................................................................... 320

9.9.11 RemovingThermistorsforFreezeProtection,GasPipe,OutletAirandInletAir ...................................... 323

9.9.12 RemovingFanandFanMotor ................................................................................................................... 327

9.9.13 RemovingElectronicExpansionValveCoil ............................................................................................... 329

9.9.14 RemovingHorizontalLouver ..................................................................................................................... 331

9.10 RPF(I)-(1.0-2.5)FSN2E-FloorandFloorconcealedtype................................................................... 332

9.10.1 Removaloftheairinletgrille ..................................................................................................................... 332

9.10.2 Removaloftheairlter ............................................................................................................................. 332

9.10.3 Removaloftheairoutletgrille ................................................................................................................... 332

9.10.4 Removalofthefrontpanel ........................................................................................................................ 333

9.10.5 Removalofthefanmotor .......................................................................................................................... 333

9.10.6 Removaloftheprintedcircuitboard(PCB) ............................................................................................... 334

9.10.7 Removalofthethermistorsfromtheliquidandgaspiping ....................................................................... 334

9.11 KPI-(252-2002)(E/X)4E-Energyrecoveryandactiveenergyrecoveryventilationunits .................... 335

X

SMGB0099 rev.0 - 12/2016

Page 13

General Index

9.11.1 Systemdescription .................................................................................................................................... 335

9.11.2 Structureandpartnames .......................................................................................................................... 335

9.11.3 Servicecoverlocation ............................................................................................................................... 335

9.11.4 RemovalofHeatExchanger ...................................................................................................................... 336

9.11.5 Removaloftheairlter .............................................................................................................................. 336

9.11.6 Removaloftheoatswitch(X4Eseriesonly) ........................................................................................... 337

9.11.7 Removalofthedampermotor ................................................................................................................... 338

9.11.8 Removaloftheelectricalbox .................................................................................................................... 339

9.11.9 RemovalofthePCB .................................................................................................................................. 339

9.11.10 Removalofthefanmotor ........................................................................................................................ 340

9.11.11 RemovaloftheDX-CoilModule(X4Eseriesonly) .................................................................................. 341

9.12 DX-Interface ........................................................................................................................................ 342

9.12.1 Structureandpartnames .......................................................................................................................... 342

9.12.2 Removaloftheelectricalcomponents ...................................................................................................... 342

10. Troubleshooting ..................................................................................................... 343

10.1 Electronicexpansionvalvecheckprocedure ...................................................................................... 344

10.2 Procedureforcheckingfanmotorsinindoorunits .............................................................................. 344

10.3 Inspectionofothercomponents .......................................................................................................... 346

10.4 Outdoor and indoor alarm codes ......................................................................................................... 347

10.5 DX-InterfaceEXV-(2.0-10.0)E2orKPI-(E/X)4Ealarmcodes..............................................................349

11. Maintenance notes ................................................................................................. 351

11.1 Regularequipmentmaintenance ........................................................................................................352

11.1.1 Necessarytools,equipmentandconsumableforregularmaintenance .................................................... 352

11.2 Indoorcleaning .................................................................................................................................... 353

11.2.1 Cleaningthebuilt-in4-wayindoorunitRCI(M) .......................................................................................... 353

11.2.2 Cleaningthebuilt-in2-wayindoorunit(RCD) ........................................................................................... 356

11.2.3 Cleaningofthewall-typeindoorunit(RPK) ............................................................................................... 358

11.2.4 CleaningtheoorconsoleandoorconcealedconsoleindoorunitRPF(I) .............................................. 359

11.2.5 Cleaningoftheceiling-typeindoorunit(RPC) .......................................................................................... 360

11.3 CleaningofKPIunits ........................................................................................................................... 363

11.4 Econofreshkit......................................................................................................................................365

11.5 Collectionofrefrigeranttoreplacetheindoorunit...............................................................................365

11.6 Cleaningagentsforheatexchanger ...................................................................................................366

11.6.1 Recommendedspecicationsofcleaningagentsforaluminiumns ........................................................ 366

11.6.2 Particularitiesandbenets ........................................................................................................................ 366

11.6.3 Toconsider ................................................................................................................................................ 366

XI

SMGB0099 rev.0 - 12/2016

Page 14

Page 15

1 General information

1. General information

Index

1.1 General information ................................................................................................................................. 2

1.1.1 Introduction ...................................................................................................................................................... 2

1.2 Applied symbols ...................................................................................................................................... 3

1.3 Productclassicationandline-up ............................................................................................................ 4

1.3.1 Classicationofindoorunitmodels ................................................................................................................. 4

1.3.2 ClassicationofKPImodels ............................................................................................................................ 4

1.3.3 ClassicationofDX-Interfacemodels ............................................................................................................. 4

1.3.4 ClassicationofEconofreshmodels ............................................................................................................... 4

1.3.5 Productline-up:indoorunits ............................................................................................................................ 5

1.3.6 Productline-up:KPIenergyrecoveryunit ....................................................................................................... 9

1.3.7 Productline-up:DX-Interface .......................................................................................................................... 9

1.3.8 Productline-up:Econofresh ............................................................................................................................ 9

1.3.9 Accessory code list ........................................................................................................................................ 10

1.3.10 Multi-Kits .......................................................................................................................................................11

1.3.11 Individualremotecontrols ............................................................................................................................ 12

1.3.12 Receiverkitforcombinationwithwirelessremotecontrolswitch ................................................................ 12

1.3.13 Centralised remote controls ........................................................................................................................ 13

1.3.14 Buildingairconditioningcontrols ................................................................................................................. 13

1.3.15 Gatewaysforbuildingmanagementsystems(BMS) .................................................................................. 14

1.3.16 Controlsupportdevices ............................................................................................................................... 14

1.3.17 Control accessories ..................................................................................................................................... 15

1.3.18 OtherdevicescompatiblewithHITACHIAirConditioningsystems ............................................................. 15

1

1

SMGB0099 rev.0 - 12/2016

Page 16

1 General information

General information

1.1 General information

©Copyright2016JohnsonControls-HitachiAirConditioningSpain,S.A.U.-Allrightsreserved.

Nopartofthispublicationmaybereproduced,copied,lmedortransmittedinanyshapeorformwithoutthepermission

ofJohnsonControls-HitachiAirConditioningSpain,S.A.U.

Withinthepolicyofcontinuousimprovementofitsproducts,JohnsonControls-HitachiAirConditioningSpain,S.A.U.

reservestherighttomakechangesatanytimewithoutpriornoticationandwithoutbeingcompelledtointroducethem

intoproductssubsequentlysold.Thisdocumentmaythereforehavebeensubjecttoamendmentsduringthelifeofthe

product.

HITACHImakeseveryefforttooffercorrect,up-to-datedocumentation.Despitethis,printingerrorscannotbecontrolled

byHITACHIandarenotitsresponsibility.

Asaresult,someoftheimagesordatausedtoillustratethisdocumentmaynotrefertospecicmodels.Noclaimswill

beacceptedbasedonthedata,illustrationsanddescriptionsincludedinthismanual.

Notypeofmodicationmustbemadetotheequipmentwithoutprior,writtenauthorizationfromthemanufacturer.

1.1.1 Introduction

HITACHIofferstheSYSTEMFREErangeofindoorunits,themainadvantageofwhichisthattheycanbecombinedwith

UTOPIAandSET-FREEseriesoutdoorunits.

Thiseliminatestheneedtoduplicatemodelsofindoorunitsandreducesstock.

SYSTEM FREE

Line up of Indoor Units

RCI-FSN4

RCIM-FSN4(E)

RCD-FSN3

RPC-FSN3

RPC-FSN3E

RPI-FSN(3/4)(P)E(-f)

RPIM-FSN4E(-DU)

RPK-FSN(H)3M

RPF-FSN2E

RPFI-FSN2E

Complementary systems

KPI-(E/X)4E

DX-InterfaceEXV-E2

EconofreshEF-456NE

? NOTE

For RCI-FSN4, RCIM-FSN4(E), RCD-FSN3 , RPC-FSN3 and RPK-FSN3M, combinations with IVX Premium and IVX Standard series 1,

as well as SET FREE FSXN1E and FSXNH(E) series, are recommended in order to obtain the maximum performance.

2

SMGB0099 rev.0 - 12/2016

Page 17

1 General information

Applied symbols

1.2 Applied symbols

Duringnormalairconditioningsystemdesignworkorunitinstallation,greaterattentionmustbepaidincertainsituations

requiringparticularcareinordertoavoiddamagetotheunit,theinstallationorthebuildingorproperty.

Situationsthatjeopardisethesafetyofthoseinthesurroundingareaorthatputtheunititselfatriskwillbeclearly

indicatedinthismanual.

Toindicatethesesituations,aseriesofspecialsymbolswillbeusedtoclearlyidentifythesesituations.

Paycloseattentiontothesesymbolsandtothemessagesfollowingthem,asyoursafetyandthatofothersdependson

it.

! DANGER

• The text following this symbol contains information and instructions relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to serious, very serious or even fatal injuries to you and others in the

proximities of the unit.

Inthetextsfollowingthedangersymbolyoucanalsondinformationonsafeproceduresduringunitinstallation.

! CAUTION

• The text following this symbol contains information and instructions relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to minor injuries to you and others in the proximities of the unit.

• Not taking these instructions into account could lead to unit damage.

Inthetextsfollowingthecautionsymbolyoucanalsondinformationonsafeproceduresduringunitinstallation.

? NOTE

• The text following this symbol contains information or instructions that may be of use or that require a more thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems may also be included.

1

3

SMGB0099 rev.0 - 12/2016

Page 18

1 General information

Productclassicationandline-up

1.3 Product classication and line-up

1.3.1 Classication of indoor unit models

Unittype(indoorunit):RCI,RCIM,RCD,RPC,RPI,RPIM,RPK,RPF,RPFI

Position-separatinghyphen(xed)

Capacity(HP):0.6,0.8,1.0,1.5,2.0,2.5,3.0,4.0,5.0,6.0,8.0,10.0,16.0,20.0

FS=SYSTEMFREE

N=R410Arefrigerant

H=Hotel(RPK-(0.6-1.5)only)

2/3/4=series

P=Pair

E=MadeinEurope

M=MadeinMalaysia

–=MadeinJapanorChina

(-DU)=DrainUp(RPIMonly)

(-f)=Non-ammableinsulation(RPI-(8.0-20.0)FSN3E-fonly

XXX – X.X FS N (H) X (P) (X) (-xx)

1.3.2 Classication of KPI models

KPI-Ventilationsystem

Position-separatinghyphen(xed)

Capacity(m3/h):250,500,800,1000,1500,2000

2=1~230V50Hz

E=Energyrecovery

X=Active(Energyrecovery+DXsection)

4=series

E=MadeinEurope

KPI – (Y)YY 2 Y 4 E

1.3.3 Classication of DX-Interface models

DX-Interfacetype

Position-separatinghyphen(xed)

Capacity(HP):2.0,2.5,3.0,4.0,5.0,6.0,8.0,10.0

E=MadeinEurope

2=series

EXV – X.X E 2

1.3.4 Classication of Econofresh models

Econofreshunittype

Position-separatinghyphen(xed)

Capacity(HP):4.0,5.0,6.0

N:R410Arefrigerant

E=MadeinEurope

EF - 456 N E

4

SMGB0099 rev.0 - 12/2016

Page 19

1 General information

Productclassicationandline-up

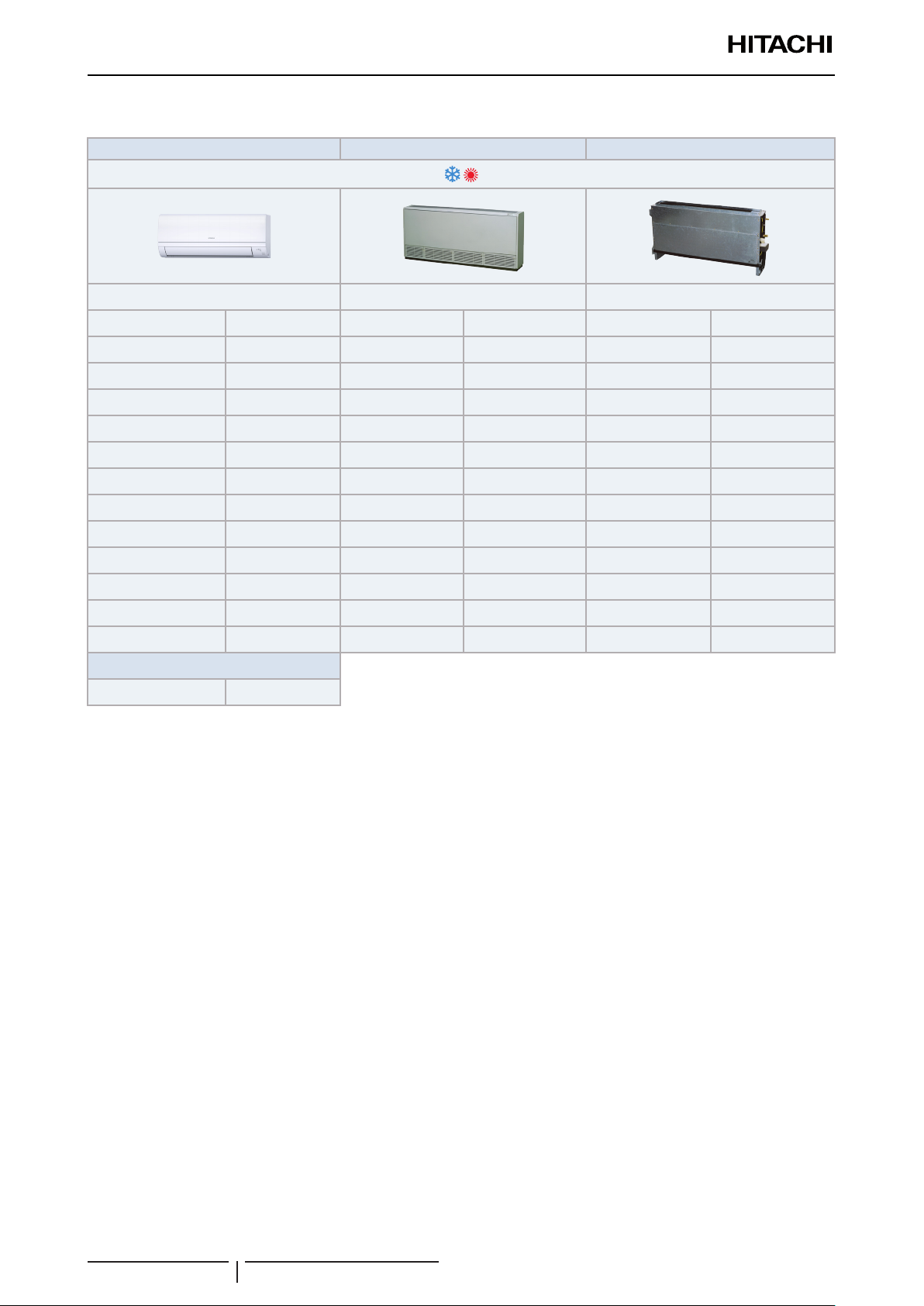

1.3.5 Product line-up: indoor units

? NOTE

• The indoor unit models and codes are the last updated at time of publication; other previous models and coming developments could

be available for combination with the outdoor unit series.

• Check the exact classication for each unit (model, type, power and series) in “1.3.1 Classication of indoor unit models”.

RCI and RCIM indoor units

RCI RCIM

1

4-waycassette 4-waycassette(compact)

Unit Code Unit Code

RCIM-0.6FSN4(E)(*) 60278215(7E411137)

RCIM-0.8FSN4(E) 60278216(7E411100)

RCI-1.0FSN4 70405001 RCIM-1.0FSN4(E) 60278217(7E411101)

RCI-1.5FSN4 70405002 RCIM-1.5FSN4(E) 60278218(7E411102)

RCI-2.0FSN4 70405003 RCIM-2.0FSN4(E)(**) 60278219(7E411103)

RCI-2.5FSN4 70405004 RCIM-2.5FSN4(E)(**) 60278220(7E411104)

RCI-3.0FSN4 70405005

RCI-4.0FSN4 70405007

RCI-5.0FSN4 70405008

RCI-6.0FSN4 70405009

Panel Panel

P-N23NA2

(withoutMotionSensor)

70532000

P-AP56NAM

(withoutMotionSensor)

60297297

? NOTE

• The RCI and RCIM models must be used in combination with the indicated panels.

• (*): 0.6 HP Indoor Units can only be used in combination with SET FREE FSXN1E, FSXNH(E) and FSN3E series.

• (**): 1 indoor unit combinations with IVX Premium / Standard series not allowed.

5

SMGB0099 rev.0 - 12/2016

Page 20

1 General information

Productclassicationandline-up

RCD and RPC indoor units

RCD RPC

2-waycassette Ceilingtype

Unit Code Unit Code Unit Code Unit Code

RCD-0.8FSN3(*) 60278242

RCD-1.0FSN3(*) 60278243

RCD-1.5FSN3(*) 60278244 RPC-1.5FSN3 60278164

RCD-2.0FSN3(*) 60278245 RPC-2.0FSN3 60278165

RCD-2.5FSN3(*) 60278246 RPC-2.5FSN3 60278166

RCD-3.0FSN3(*) 60278247 RPC-3.0FSN3E 7E443005 RPC-3.0FSN3 60278167

RCD-4.0FSN3(*) 60278248 RPC-4.0FSN3E 7E443007 RPC-4.0FSN3 60278168

RCD-5.0FSN3(*) 60278249 RPC-5.0FSN3E 7E443008 RPC-5.0FSN3 60278169

RCD-6.0FSN3(*) 60278250 RPC-6.0FSN3E 7E443009 RPC-6.0FSN3 60278170

Panel Panel

P-AP90DNA 60297300 P-AP160DNA 60297301

? NOTE

• The RCD models must be used in combination with the indicated panels.

• (*): 1 indoor unit combinations with IVX Premium / Standard series not allowed.

6

SMGB0099 rev.0 - 12/2016

Page 21

1 General information

Productclassicationandline-up

RPI and RPIM indoor units

Unit Code Unit Code Unit Code

RPI-0.6FSN4E(*) 7E424037

RPI-0.8FSN4E 7E424013

RPI-1.0FSN4E 7E424014

RPI-1.5FSN4E 7E424015

RPI RPIM

1

Indoor ducted unit Indoorductedunit(compact)

RPIM-0.6FSN4E(*) 7E430037

RPIM-0.6FSN4E-DU(*) 7E431037

RPIM-0.8FSN4E 7E430013

RPIM-0.8FSN4E-DU 7E431013

RPIM-1.0FSN4E 7E430014

RPIM-1.0FSN4E-DU 7E431014

RPIM-1.5FSN4E 7E430015

RPIM-1.5FSN4E-DU 7E431015

RPI-2.0FSN4E 7E424016

RPI-2.5FSN4E 7E424017

RPI-3.0FSN4E 7E424018

RPI-4.0FSN4E 7E424020

RPI-5.0FSN4E 7E424021

RPI-6.0FSN4E 7E424022

RPI

Indoor ducted unit

Unit Code Unit Code Unit Code Unit Code

RPI-8.0FSN3E

RPI-10.0FSN3E

7E424010

(**)

7E424011

(**)

RPI-8.0FSN3E-f

RPI-10.0FSN3E-f

7E424410

(**)

7E424411

(**)

RPI-

16.0FSN3PE

RPI-

20.0FSN3PE

7E425038

(***)

7E425039

(***)

RPI-16.0FSN3PE-f

RPI-20.0FSN3PE-f

7E425438

(***)

7E425439

(***)

? NOTE

• (*): 0.6 HP Indoor Units can only be used in combination with SET FREE FSXN1E and FSXNH(E) series.

• (**): In combination with UTOPIA IVX Premium/Standard series: 1 indoor unit system only.

• (***): RPI-FSN3PE(-f) can only be used in combination with SET FREE FSXN1E , FSXNH(E) and FSN3 series.

7

SMGB0099 rev.0 - 12/2016

Page 22

1 General information

Productclassicationandline-up

RPK, RPF and RPFI indoor units

RPK RPF RPFI

Wall type Floortype Floorconcealedtype

Unit Code Unit Code Unit Code

RPK-0.6FSN3M(*) 60278145

RPK-0.6FSNH3M(*) 60278153

RPK-0.8FSN3M 60278146

RPK-0.8FSNH3M 60278154

RPK-1.0FSN3M 60278147

RPK-1.0FSNH3M 60278155 RPF-1.0FSN2E 7E450001 RPFI-1.0FSN2E 7E460001

RPK-1.5FSN3M 60278148

RPK-1.5FSNH3M 60278156 RPF-1.5FSN2E 7E450002 RPFI-1.5FSN2E 7E460002

RPK-2.0FSN3M 60278149 RPF-2.0FSN2E(**) 7E450003 RPFI-2.0FSN2E(**) 7E460003

RPK-2.5FSN3M 60278150 RPF-2.5FSN2E(**) 7E450004 RPFI-2.5FSN2E(**) 7E460004

RPK-3.0FSN3M 60278151

RPK-4.0FSN3M 60278152

Expansion valve kit

EV-1.5N1

(1)

(1)

60921791

? NOTE

• (*) 0.6 HP Indoor Units can only be used in combination with SET FREE FSXN1E and FSXNH(E) series.

• (**) 1 indoor unit combinations with IVX Premium / Standard series not allowed.

(1)

•

For RPK-(0.6-1.5)FSNH3M models only.

8

SMGB0099 rev.0 - 12/2016

Page 23

1 General information

Productclassicationandline-up

1.3.6 Product line-up: KPI energy recovery unit

KPI

Energyrecovery Active(EnergyRecovery+DXsection)

Unit Code Unit Code

KPI-252E4E 70603000

KPI-502E4E 70603001 KPI-502X4E 70603201

KPI-802E4E 70603002 KPI-802X4E 70603202

KPI-1002E4E 70603003 KPI-1002X4E 70603203

KPI-1502E4E 70603004

KPI-2002E4E 70603005

1

1.3.7 Product line-up: DX-Interface

Controlbox

Expansionvalvebox

1.3.8 Product line-up: Econofresh

DX-Interface

Unit Code

EXV-2.0E2 7E611000

EXV-2.5E2 7E611001

EXV-3.0E2 7E611002

EXV-4.0E2 7E611003

EXV-5.0E2 7E611004

EXV-6.0E2 7E611005

EXV-8.0E2 7E611006

EXV-10.0E2 7E611007

Econofresh

Unit Code

EF-456NE 7E560000

? NOTE

The EF-456NE unit can only be installed in combination with the following units (Sales from April 2014):

• RPI-4.0FSN4E (7E424020)

• RPI-5.0FSN4E (7E424021)

• RPI-6.0FSN4E (7E424022)

9

SMGB0099 rev.0 - 12/2016

Page 24

1 General information

Productclassicationandline-up

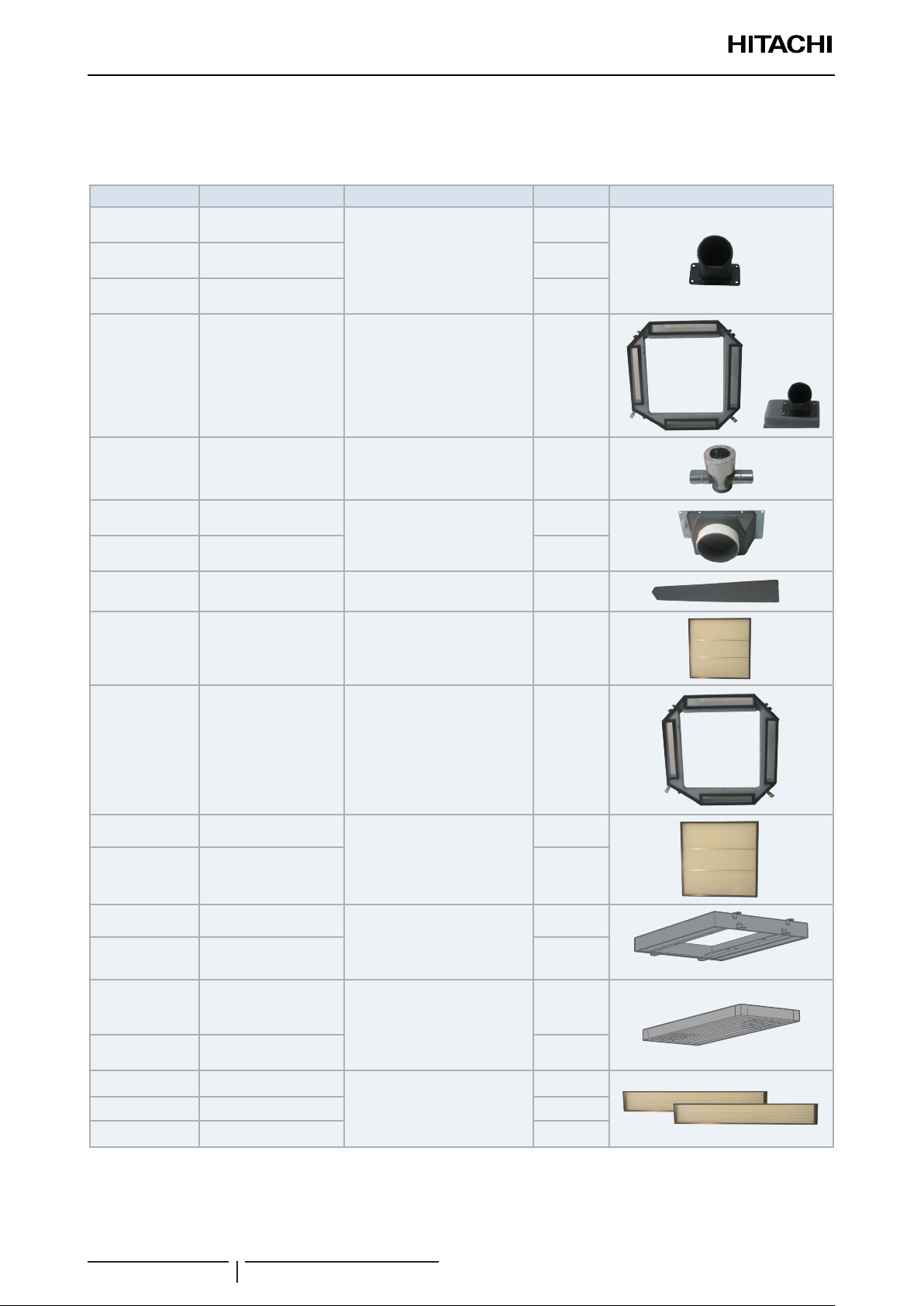

1.3.9 Accessory code list

HITACHIhasawiderangeofaccessoriesandremotecontrolsystemsthatcanbeusedwiththeSETFREEandUTOPIA

outdoorunits.ConsulttheTechnicalCatalogueforcontrolsandforthecorrespondingoutdoorunits.

Name Unit Reference Description Code Figure

PD-75A RCI-FSN4

PD-75C RCIM-FSN4(E) 60292014

PD-150D RCD-FSN3 60292064

OACI-160K2 RCI-FSN4 Freshoutdoorairintakekit 60291761

TKCI-160K RCI-FSN4

PDF-71C1 RCI-(1.0-2.5)FSN4

PDF-160C1 RCI-(3.0-6.0)FSN4 60299437

PI-160LS1 RCI-FSN4 3-wayoutletpartsset 60291756

F-160LK RCI-FSN4

Ductadapter

forfreshoutdoorairintakekit

T-shapedductconnectionkit

forfreshoutdoorairintakeki

Ductconnectingangefor

indoor air outlet

Antibacteriallonglifeairlter

(installationonthepanel)

60291763

60291762

60299436

60291760

B-160H2 RCI-FSN4

F-71L-D1 RCI-(1.0-2.5)FSN4

F-160L-D1 RCI-(3.0-6.0)FSN4 60291758

B-90HD RCD-(0.8-3.0)FSN3

B-160HD RCD-(4.0-6.0)FSN3 60292062

F-90MD-K1 RCD-(0.8-3.0)FSN3

F-160MD-K1 RCD-(4.0-6.0)FSN3 60292059

F-56LPC1 RPC-(1.5-2.0)FSN3

F-90LPC1 RPC-(2.5-3.0)FSN3 60299280

F-160LPC1 RPC-(4.0-6.0)FSN3 60299281

(Adapterfordeodorisinglter)

(installationontheFilterBox

(Adapterforantibacteriallong

Antibacteriallonglifeairlter

(installationonthelterbox

(Installationontheindoorunit)

FilterBox

Deodorantairlter

B-160H2)

FilterBox

lifeairlter)

highperformancelter

F-90MD-K1→B-90HD

F-160MD-K1→B-160HD)

Longlifelter

60291759

60291757

60292061

60292058

60299279

10

SMGB0099 rev.0 - 12/2016

Page 25

1 General information

Productclassicationandline-up

Name Unit Reference Description Code Figure

DUPC-63K1

DUPC-71K1 60291936

DUPC-160K1 60291937

PS-MSK2 RCI-FSN4

SOR-NEP RPC-FSN3 60291825

SOR-NEC RCIM-FSN4(E) 60292011

SOR-NED RCD-FSN3 60292055

SLT-30-200-L600

SLT-30-250-L600 70550201

SLT-30-300-L600 70550202

SLT-30-355-L600 70550203

HEF-252

HEF-502 70552202

RPC-FSN3 Drain-upMechanism

Motionsensorkit

KPI Noise damper

60291935

70590903

70550200

70552201

1

HEF-802 70552203

KPI Highefciencylter

HEF-1002 70552204

HEF-1502 70552205

HEF-2002 70552206

1.3.10 Multi-Kits

Name Unit Reference Description Code Figure

E-102SN4

E-162SN4 70524202

E-242SN3 70524104

E-302SN3 70524105

E-52XN3 70525100

SETFREE LineBranch

E-102XN3 70525101

E-162XN3 70525102

E-202XN3 70525103

E-242XN3 70525104

70524201

E-322XN3 70525106

MH-84AN1

MH-108AN 70522008

MH-108XN 70523108

SETFREE HeaderBranch

11

SMGB0099 rev.0 - 12/2016

70522009

Page 26

1 General information

Productclassicationandline-up

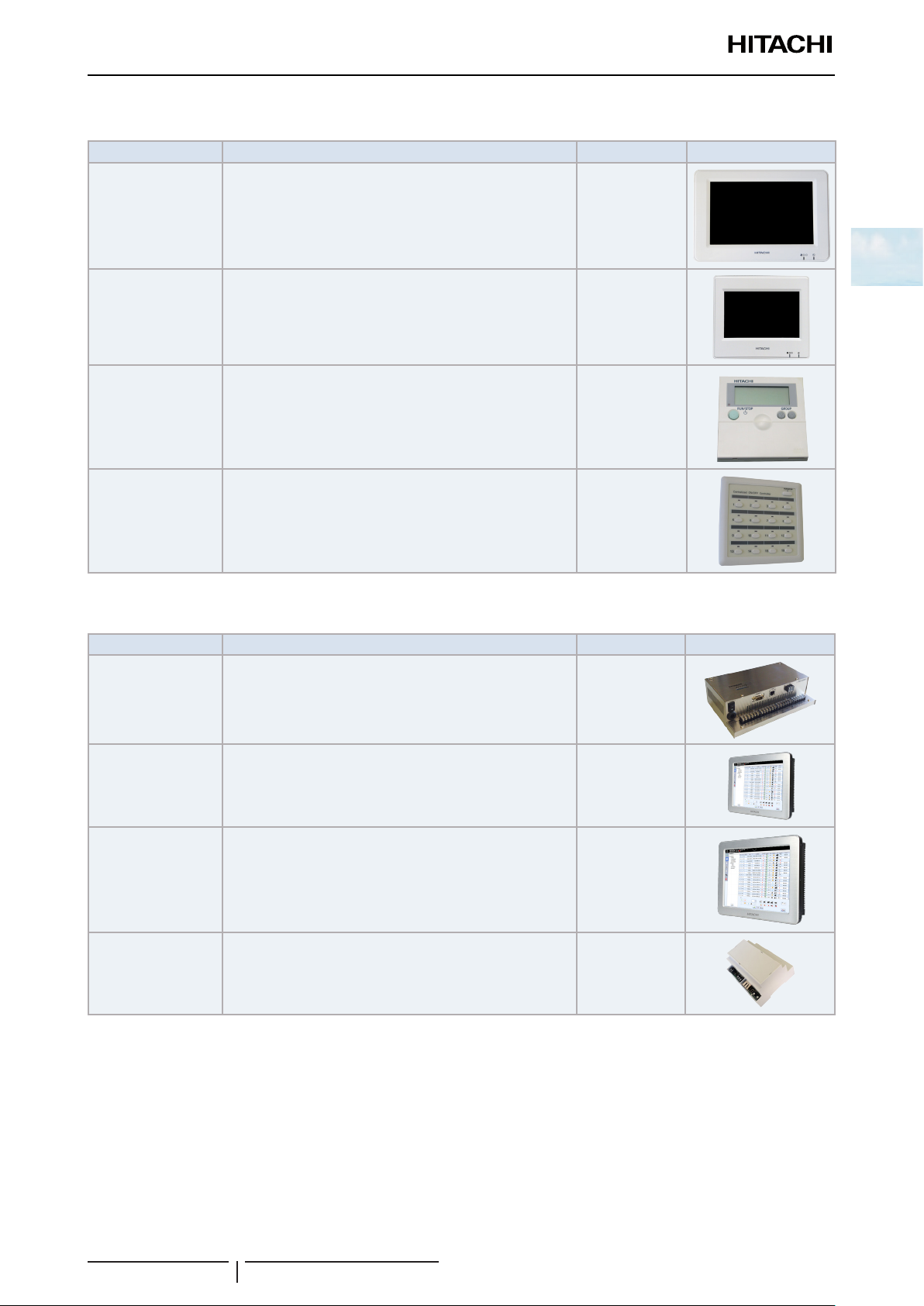

1.3.11 Individual remote controls

Name Description Code Figure

PC-ARFPE Remotecontrolwithtimer 70510002

PC-ARH Simpliedremotecontrol 60291486

PC-AWR Wireless remote control 60291056

1.3.12 Receiver kit for combination with wireless remote control switch

Receiver kit name Indoor Unit application

PC-ALH3 RCI-FSN4 PC-AWR 60291767

PC-ALHC1 RCIM-FSN4(E) PC-AWR 60292003

PC-ALHD1 RCD-FSN3 PC-AWR 60292053

PC-ALHP1 RPC-FSN3 PC-AWR 60291823

PC-ALHZ

PC-ALHZF

RPI-FSN(3/4)(P)E,

RPIM-FSN4E(-DU),

RPF(I)-FSN2E

RCI-FSN4,

RCIM-FSN4(E),

RCD-FSN3,

RPK-FSN(H)3M

RPC-FSN3

Compatible Wireless

remote control

PC-AWR 60291473

PC-AWR 60291789

Code Figure

onthepanel

onthewall

12

SMGB0099 rev.0 - 12/2016

Page 27

1 General information

Productclassicationandline-up

1.3.13 Centralised remote controls

Name Description Code Figure

PSC-A64GT Touchscreencentralstation 60291730

PSC-A32MN Touchscreencentralstationmini 60291966

PSC-A64S Centralised remote control 60291479

1

PSC-A16RS CentralisedON/OFFcontrol 60291484

1.3.14 Building air conditioning controls

Name Description Code Figure

CSNETWEB

(PSC-A160WEB1)

CSNETManagerLT

CSNETManagerXT

HC-A64NET

CentralisedcontrolsystemwhichrunsCSNETWEBsoftware

tocontroltheindoorunits

Centralisedcontrolwithatouchinterfaceof12incheswhich

runsCSNETMANAGERsoftwaretocontroltheindoorunits.

Centralisedcontrolwithatouchinterfaceof17incheswhich

runsCSNETMANAGERsoftwaretocontroltheindoorunits.

H-LINKgatewayusedbyCSNETMANAGERScreensto

communicatewithindoorunits

(Max.64indoorunits)

7E512000

7E512201

7E512202

7E512200

13

SMGB0099 rev.0 - 12/2016

Page 28

1 General information

Productclassicationandline-up

1.3.15 Gateways for building management systems (BMS)

Name Description Code Figure

HC-A8MB

HC-A64MB

Integrationwithinstallationwithintelligentcontrol(Building

ManagementSystem)GatewayInterfacetoMODBUS

systems(Max.8indoorunits).

Integrationwithinstallationwithintelligentcontrol(Building

ManagementSystem)GatewayInterfacetoMODBUS

systems(Max.64indoorunits).

7E513204

7E513205

HC-A16KNX

KNX001

HARC-BXE(A)

HARC-BXE(B)

Integrationwithinstallationswithintelligentcontrol(BMS).

GatewayInterfacetoKNXsystems.

Integrationwithinstallationswithintelligentcontrol(BMS)

throughCSNETWEB.GatewayInterfacetoKNXsystems.

Integrationwithinstallationwithintelligentcontrol(Building

ManagementSystem)GatewayInterfacetoLONWORKS

systems.(H-LINKIcommunication)(Max.64unitswith8

Integrationwithinstallationwithintelligentcontrol(Building

ManagementSystem)GatewayInterfacetoLONWORKS

systems.(H-LINKIcommunication)(Max.32unitswith16

1.3.16 Control support devices

Name Description Code Figure

7E513300

7E5121000

60290874

parameters)

60290875

parameters)

PSC-A1T Programmabletimer 60291482

PSC-6RAD H-LINKRACAdapter 60063017

PC-A1IO IntegrationofexternalequipmentintoH-LINK 7E519000

PSC-5HR H-LINKRelay 60291105

THM-R2AE Remotetemperaturesensor(THM4) 7E299907

14

SMGB0099 rev.0 - 12/2016

Page 29

1 General information

Productclassicationandline-up

1.3.17 Control accessories

Name Description Code Figure

Wall support

Standsupport

PCC-1A Optional function connector 70590901

PRC-10E1 2P-Extensioncord(10metres) 7E790211

PRC-15E1 2P-Extensioncord(15metres) 7E790212

PRC-20E1 2P-Extensioncord(20metres) 7E790213

PRC-30E1 2P-Extensioncord(30metres) 7E790214

NetCongurationKit NetcongurationkitforHC-A(8/64)MBandHC-A64NET 7E512306

Wall mounted support

(forbothCSNETMANAGERLT/XT)

Standmountedsupport

(forbothCSNETMANAGERLT/XT)

7E512300

7E512301

1.3.18 Other devices compatible with HITACHI Air Conditioning systems

InadditiontoalltheaforementionedHITACHIcontrols,therearesomenon-HITACHIdevicesforcombinationwith

HITACHIAirConditioningsystems.Thesearethefollowing:

• HITACHI-AIRZONEgateway(HTI11001):ApplicabletoHITACHIRPI(M)unitsprovidingcompatibilitywiththe

AIRZONEsystems,zone-basedclimate-controlsystems.

• Powermeter:SiemenspowermeterforCSNETWEBandCSNETManager.

• MODBUS-BACNETgateway:SolutionofferedbyIntesisSoftwarecompanywhichtransfersMODBUSdatainto

BACNETdata.

• MODBUS-FIDELIOgateway:SolutionofferedbyIntesisSoftwarecompanywhichtransfersMODBUSdatainto

FIDELIOdata.

1

15

SMGB0099 rev.0 - 12/2016

Page 30

Page 31

2 Unit installation

2. Unit installation

Index

2.1 RCI - 4-way cassette ............................................................................................................................. 19

2.1.1 Accessories supplied with the unit ................................................................................................................. 19