Page 1

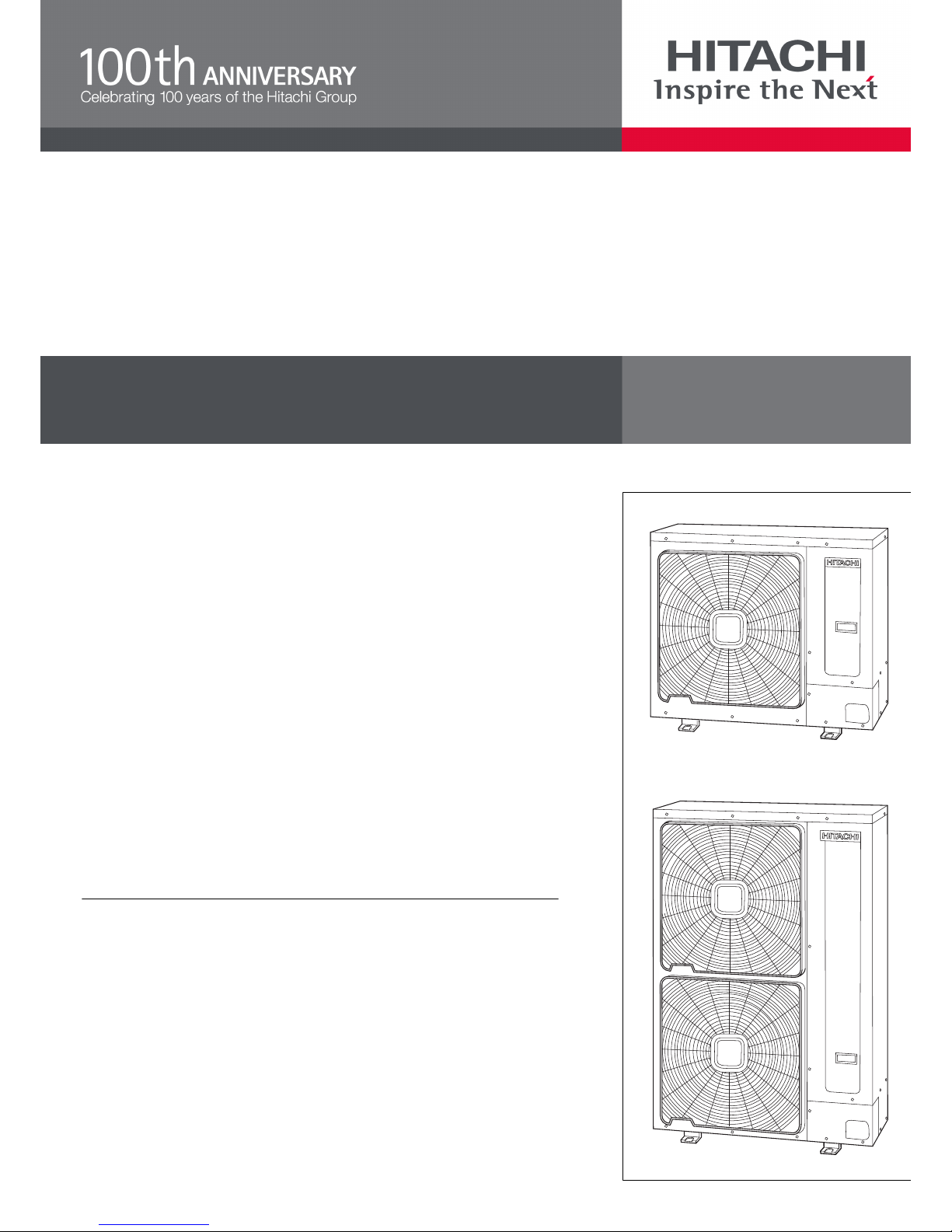

UTOPIA DC-INVERTER IVX/ES SERIES

H(V)RN(1)(S)(1)(E)

H(V)RNM(1)(E)

Service Manual

RAS-(3-6)HVRNM(1)E

RAS-(4-12)HRNM(1)(E)

RAS-(2-3)HVRN(1)(E)(S)

RAS-(4-6)HVRNS1E

RAS-(8/10)HRNSE

Page 2

Page 3

I n d e x

Index

i

SMGB0060 rev. 1- 12/2010

General information

1

Unit Installation

2

Piping work and refrigerant charge

3

Electrical Wiring

4

Control System

5

Optional functions

6

Test Run

7

Troubleshooting

8

Spare Parts

9

Servicing

10

Electrical checks of main parts

11

Maintenace notes

12

Page 4

Index

ii

SMGB0060 rev. 1- 12/2010

Page 5

Index

1 General information......................................................................................... 1

1.1 General information.................................................................................................................... 2

1.1.1 Copyright..................................................................................................................................... 2

1.1.2 Introduction................................................................................................................................. 2

1.1.3 Environment-friendly units.......................................................................................................... 2

1.2 Safety......................................................................................................................................... 3

1.2.1 Applied symbols.......................................................................................................................... 3

1.3 Product guide ............................................................................................................................ 4

1.3.1 Classification of IVX series outdoor unit models......................................................................... 4

1.3.2 Classification of ES series outdoor unit models.......................................................................... 4

1.3.3 Product guide: Outdoor units...................................................................................................... 5

1.3.4 Accessory code list..................................................................................................................... 6

2 Unit Installation................................................................................................ 7

2.1 Safety summary......................................................................................................................... 8

2.2 Transportation of outdoor unit.................................................................................................... 9

2.3 Center of gravity......................................................................................................................... 10

2.4 Factory-supplied accessories for RAS-(8-12)HRNM.................................................................. 11

2.5 Installation space (Initial ckeck).................................................................................................. 12

2.5.1 RAS-(2-3)HVRN(1)(E)(S)............................................................................................................ 12

2.5.2 RAS-(3-6)H(V)RNM(1)E / RAS-(4-10)HVRNS(1)E..................................................................... 16

2.5.3 RAS-(8-12)HRNM....................................................................................................................... 20

2.6 Place provision........................................................................................................................... 22

2.6.1 Place provision for RAS-(3-12)H(V)RNM(1)(E) and RAS-(4-10)H(V)RNS(1)E.......................... 22

2.6.2 Place provision only for RAS-(2-3)HVRN(1)(E)(S)..................................................................... 25

2.7 Optional parts and installation.................................................................................................... 28

2.7.1 Optional parts and installation for RAS-(2-3)HVRN(1)(E)(S)...................................................... 28

2.7.2 Optional parts and installation RAS-3HVRNME / RAS-(4-6)HVRNS1E..................................... 33

2.7.3 Optional parts and installation RAS-(4-6)H(V)RNM1E / RAS-(8/10)HRNSE.............................. 37

2.7.4 Optional parts and installation RAS-(8-12)HRNM....................................................................... 42

3 Piping work and refrigerant charge............................................................... 49

3.1 General notes............................................................................................................................. 50

3.2 Piping work connection considerations...................................................................................... 52

3.2.1 Piping Materials.......................................................................................................................... 52

3.2.2 Three principles on refrigerant piping work................................................................................. 54

3.2.3 Suspension of refrigerant piping................................................................................................. 54

3.2.4 Brazing work............................................................................................................................... 55

3.2.5 Refrigerant charge...................................................................................................................... 56

3.2.6 Caution of the pressure by check joint........................................................................................ 56

3.2.7 Refrigerant charge quantity......................................................................................................... 57

3.2.8 Pump down refrigerant................................................................................................................ 59

3.3 Outdoor Units IVX Series........................................................................................................... 60

3.3.1 Piping connection........................................................................................................................ 60

3.3.2 Refrigerant piping length............................................................................................................. 65

3.3.3 Refrigerant piping selection........................................................................................................ 66

Index

iii

SMGB0060 rev. 1- 12/2010

Page 6

3.3.4 Twin and triple system installation.............................................................................................. 67

3.3.5 Drain discharging boss............................................................................................................... 68

3.4 Outdoor Units ES Series............................................................................................................ 70

3.4.1 Piping connection........................................................................................................................ 70

3.4.2 Refrigerant piping length............................................................................................................. 75

3.4.3 Refrigerant piping selection........................................................................................................ 76

3.4.4 Twin and triple system installation.............................................................................................. 78

3.4.5 Connecting flare adapter (only for RAS-(2/2.5)HVRN1(E))........................................................ 79

3.4.6 Drain discharging boss............................................................................................................... 79

4 Electrical Wiring............................................................................................... 81

4.1 General check............................................................................................................................ 82

4.2 Electrical wiring for the outdoor unit IVX Series......................................................................... 83

4.2.1 Electrical wiring connection for the outdoor unit......................................................................... 83

4.2.2 Setting the DIP switches for the outdoor unit.............................................................................. 84

4.3 Electrical wiring for the outdoor unit ES Series.......................................................................... 88

4.3.1 Electrical wiring connection for the outdoor unit......................................................................... 88

4.3.2 Setting the DIP switches for the outdoor unit.............................................................................. 89

4.4 Electrical wiring between indoor unit and outdoor unit............................................................... 93

4.5 Wire sizes................................................................................................................................... 95

4.5.1 Wire sizes for IVX Series............................................................................................................ 95

4.5.2 Wire sizes for ES Series............................................................................................................. 97

4.5.3 H-LINK System........................................................................................................................... 98

4.6 Electrical wiring diagrams........................................................................................................... 108

4.6.1 Electrical wiring diagrams for IVX Series.................................................................................... 108

4.6.2 Electrical wiring diagrams for ES Series..................................................................................... 112

5 Control System................................................................................................ 117

5.1 Device control system................................................................................................................ 118

5.1.1 Device control system for IVX Series.......................................................................................... 118

5.1.2 Device control system for ES Series........................................................................................... 120

5.2 Outdoor units PCB..................................................................................................................... 122

5.2.1 Outdoor units PCB for IVX Series............................................................................................... 122

5.2.2 Outdoor units PCB for ES Series................................................................................................ 123

5.3 Protection and safety control...................................................................................................... 126

5.3.1 Protection and safety control for IVX Series............................................................................... 126

5.3.2 Protection and safety control for ES Series................................................................................ 127

5.4 Standard operation sequence.................................................................................................... 128

5.4.1 Standard operation sequence for IVX Series.............................................................................. 128

5.4.2 Standard operation sequence for ES Series............................................................................... 135

5.5 Standard control functions.......................................................................................................... 142

5.5.1 Standard control functions for IVX Series................................................................................... 142

5.5.2 Standard control functions for ES Series.................................................................................... 151

6 Optional functions........................................................................................... 161

6.1 Outdoor units IVX and ES series................................................................................................ 162

6.1.1 Available ports............................................................................................................................ 162

6.1.2 Configuration............................................................................................................................... 163

6.1.3 Description of optional input signals........................................................................................... 165

Index

iv

SMGB0060 rev. 1- 12/2010

Page 7

6.1.4 Description of optional output signals......................................................................................... 166

6.1.5 Optional functions....................................................................................................................... 167

7 Test Run........................................................................................................... 173

7.1 Checking procedure before the test run..................................................................................... 174

7.2 Test run procedure using the remote control switch.................................................................. 176

7.3 Test run procedure using the wireless remote control switch.................................................... 178

7.4 Test run procedure from the outdoor unit side........................................................................... 180

7.5 Check list.................................................................................................................................... 181

7.5.1 Check list for IVX Series............................................................................................................. 181

7.5.2 Check list for ES Series.............................................................................................................. 189

8 Troubleshooting.............................................................................................. 195

8.1 Initial troubleshooting for IVX an ES Series............................................................................... 196

8.1.1 Checking by means of the 7-segment display............................................................................ 196

8.1.2 Failure of the power supply to the indoor unit and the remote control switch............................. 197

8.1.3 Abnormal transmission between the remote control switch and the indoor unit......................... 198

8.1.4 Abnormal operation of the devices............................................................................................. 198

8.2 Troubleshooting procedure for IVX an ES Series...................................................................... 204

8.2.1 Alarm code ................................................................................................................................. 204

8.2.2 Troubleshooting in check mode.................................................................................................. 283

8.2.3 Troubleshooting by means of the 7-segment display................................................................. 290

8.2.4 Troubleshooting by means of the flashing alarm LEDs for RPK-FSNM..................................... 294

8.2.5 Cause of inverter stoppage......................................................................................................... 295

8.3 Procedure for checking each main part ..................................................................................... 299

8.3.1 Self-checking procedure of PCB by means of the Remote Control Switch................................ 299

8.3.2 Self-checking of the remote control switch................................................................................. 301

8.3.3 Self-Checking procedure of the Indoor Unit PCB (only for RPK)................................................ 303

9 Spare Parts....................................................................................................... 325

9.1 Spare parts for IVX Series.......................................................................................................... 326

9.2 Spare parts for ES Series........................................................................................................... 341

10 Servicing........................................................................................................... 353

10.1 Introduction................................................................................................................................. 354

10.2 Servicing for IVX series.............................................................................................................. 355

10.2.1 Outdoor unit RAS-3HVRNME..................................................................................................... 355

10.2.2 Outdoor units RAS-(4-6)H(V)RNM1E......................................................................................... 366

10.2.3 Oudoor units RAS-(8-12)HRNM................................................................................................. 379

10.3 Servicing for ES Series.............................................................................................................. 395

10.3.1 Outdoor Units RAS-(2/2.5)HVRN1(E) and RAS-3HVRNS.......................................................... 395

10.3.2 Outdoor Units RAS-(4-6)HVRNS1E............................................................................................ 402

10.3.3 Outdoor Units RAS-(8/10)HRNSE.............................................................................................. 414

11 Electrical checks of main parts...................................................................... 433

11.1 Inverter....................................................................................................................................... 434

11.1.1 Inverter for IVX Series................................................................................................................. 434

11.1.2 Inverter for ES Series.................................................................................................................. 439

11.2 Thermistor.................................................................................................................................. 445

11.3 Electronic expansion valve......................................................................................................... 447

Index

v

SMGB0060 rev. 1- 12/2010

Page 8

11.4 High pressure protection device................................................................................................. 448

11.5 Noise filter (NF).......................................................................................................................... 449

11.5.1 Noise filter for IVX Series............................................................................................................ 449

11.5.2 Noise filter for ES Series............................................................................................................. 450

11.6 Capacitor (CB1, CB2)................................................................................................................. 452

11.7 Reactor (DCL)............................................................................................................................ 453

11.7.1 Reactor (DCL) for IVX Series ..................................................................................................... 453

11.7.2 Reactor (DCL) for ES Series ...................................................................................................... 453

11.8 Scroll compressor....................................................................................................................... 455

11.8.1 Reliable mechanism for low vibrating and low sound................................................................. 455

11.8.2 Principle of compression............................................................................................................. 455

12 Maintenace notes............................................................................................. 457

12.1 Checking the power source and the wiring connection.............................................................. 458

12.2 Burnt-out compressor due to an insufficient refrigerant charge................................................. 459

12.3 Insufficient cooling performance when a long piping is applied................................................. 460

12.4 Abnormally high operation sound (in the ceiling type indoor unit).............................................. 461

12.5 Alarm code "31".......................................................................................................................... 462

12.6 Not cooling well due to insufficient installation space for the outdoor unit................................. 463

12.7 Caution with the refrigerant leakage........................................................................................... 464

12.7.1 Maximum permissible concentration of the HCFC gas............................................................... 464

12.7.2 Calculation of the refrigerant concentration................................................................................ 464

12.7.3 Countermeasure for the refrigerant leakage according to the KHK standard............................. 464

12.8 Maintenance work...................................................................................................................... 465

12.9 Service and maintenance record................................................................................................ 466

12.10 Service and maintenance record using the 7-segment display.................................................. 468

12.11 Service and maintenance record by remote control switch........................................................ 470

12.12 Pump-down method for replacing the compressor..................................................................... 472

Index

vi

SMGB0060 rev. 1- 12/2010

Page 9

1. G e n e r a l i n f o r m a t i o n

Index

1.1 General information.................................................................................................................... 2

1.1.1 Copyright....................................................................................................................................... 2

1.1.2 Introduction................................................................................................................................... 2

1.1.3 Environment-friendly units............................................................................................................. 2

1.2 Safety......................................................................................................................................... 3

1.2.1 Applied symbols............................................................................................................................ 3

1.3 Product guide ............................................................................................................................ 4

1.3.1 Classification of IVX series outdoor unit models........................................................................... 4

1.3.2 Classification of ES series outdoor unit models............................................................................ 4

1.3.3 Product guide: Outdoor units........................................................................................................ 5

1.3.4 Accessory code list....................................................................................................................... 6

1 General information

1

SMGB0060 rev. 1- 12/2010

1

Page 10

1.1 General information

1.1.1 Copyright

© Copyright 2010 HITACHI Air Conditioning Products Europe, S.A. – All rights reserved.

No part of this publication may be reproduced, copied, filed or transmitted in any shape or form without the permission of

HITACHI Air Conditioning Products Europe, S.A.

Within the policy of continuous improvement of its products, HITACHI Air Conditioning Products Europe, S.A. reserves the

right to make changes at any time without prior notification and without being compelled to introducing them into products

subsequently sold. This document may therefore have been subject to amendments during the life of the product.

HITACHI makes every effort to offer correct, up-to-date documentation. Despite this, printing errors cannot be controlled

by HITACHI and are not its responsibility.

As a result, some of the images or data used to illustrate this document may not refer to specific models. No claims will be

accepted based on the data, illustrations and descriptions included in this manual.

No type of modification must be made to the equipment without prior, written authorisation from the manufacturer.

1.1.2 Introduction

HITACHI offers the IVX and ES range of outdoor units, the main advantage of which is that they can be combined with

UTOPIA series indoor units.

1.1.3 Environment-friendly units

This range of HITACHI outdoor units uses environmentally-friendly

R410A gas refrigerant, and the RoHS and Green Dot regulations

are applied throughout the manufacturing and installation process

to reflect HITACHI's awareness of environmental respect and

commitment.

1 General information

2

SMGB0060 rev. 1- 12/2010

Page 11

1.2 Safety

1.2.1 Applied symbols

During normal air conditioning system design work or unit installation, greater attention must be paid in certain situations

requiring particular care in order to avoid damage to the unit, the installation or the building or property.

Situations that jeopardise the safety of those in the surrounding area or that put the unit itself at risk will be clearly indicated

in this manual.

To indicate these situations, a series of special symbols will be used to clearly identify these situations.

Pay close attention to these symbols and to the messages following them, as your safety and that of others depends on it.

D A NG ER

• The text following this symbol contains information and instructions relating directly to your safety and

physical wellbeing.

• Not taking these instructions into account could lead to serious, very serious or even fatal injuries to you and

others in the proximities of the unit.

In the texts following the danger symbol you can also find information on safe procedures during unit installation.

C A UT IO N

• The text following this symbol contains information and instructions relating directly to your safety and

physical wellbeing.

• Not taking these instructions into account could lead to minor injuries to you and others in the proximities of

the unit.

• Not taking these instructions into account could lead to unit damage.

In the texts following the caution symbol you can also find information on safe procedures during unit installation.

N O TE

• The text following this symbol contains information or instructions that may be of use or that require a more

thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems may also be included.

1 General information

3

SMGB0060 rev. 1- 12/2010

1

Page 12

1.3 Product guide

1.3.1 Classification of IVX series outdoor unit models

Unit type (Outdoor unit): RAS

Position-separating hyphen (fixed)

Capacity (HP): 3, 4, 5, 6, 8, 10, 12

H = Heat Pump

V=Single fase(1~)

R= Inverter system

N=R410A refrigerant

M=High Efficiency

Series

E = Made in Europe

– = Made in Japan

XXX – XX H V R N M 1 (X)

1.3.2 Classification of ES series outdoor unit models

Unit type (outdoor unit): RAS

Position-separating hyphen (fixed)

Capacity (HP): 2, 2.5, 3, 4, 5, 6, 8, 10

H = Heat Pump

V=Single Phase (1~)

R= Inverter system

N=R410A refrigerant

S= Eco&Small

Series

E = Made in Europe

– = Made in Japan

XXX – XX H V R N S 1 (X)

1 General information

4

SMGB0060 rev. 1- 12/2010

Page 13

1.3.3 Product guide: Outdoor units

¿ IVX series outdoor units

Outdoor Units IVX

Single Fase (1~) Three fase (3~)

HVRNME HVRNM1E HRNM1E HRNM

Unit Code Unit Code Unit Code Unit Code

RAS-3HVRNME 7E300005 RAS-4HVRNM1E 7E305007 RAS-4HRNM1E 7E305107 RAS-8HRNM 60278972

RAS-5HVRNM1E 7E305008 RAS-5HRNM1E 7E305108 RAS-10HRNM 60278973

RAS-6HVRNM1E 7E305009 RAS-6HRNM1E 7E305109 RAS-12HRNM 60278974

N O TE

• Check the exact classification for each unit (model, type, power and series) in Classification of IVX series

outdoor unit models, see on page 4.

¿ ES series outdoor units

Outdoor Units ES

Single Fase (1~) Three Fase (3~)

HVRN(1)(E)(S) HVRNS1E HRNSE

Unit Code Unit Code Unit Code

RAS-2HVRN1E 60288093 RAS-4HVRNS1E 7E306007 RAS-8HRNSE 7E314110

RAS-2.5HVRN1 60288094 RAS-5HVRNS1E 7E306008 RAS-10HRNSE 7E314111

RAS-3HVRNS 60288101 RAS-6HVRNS1E 7E306009

N O TE

• Check the exact classification for each unit (model, type, power and series) in Classification of ES series

outdoor unit models, see on page 4 .

1 General information

5

SMGB0060 rev. 1- 12/2010

1

Page 14

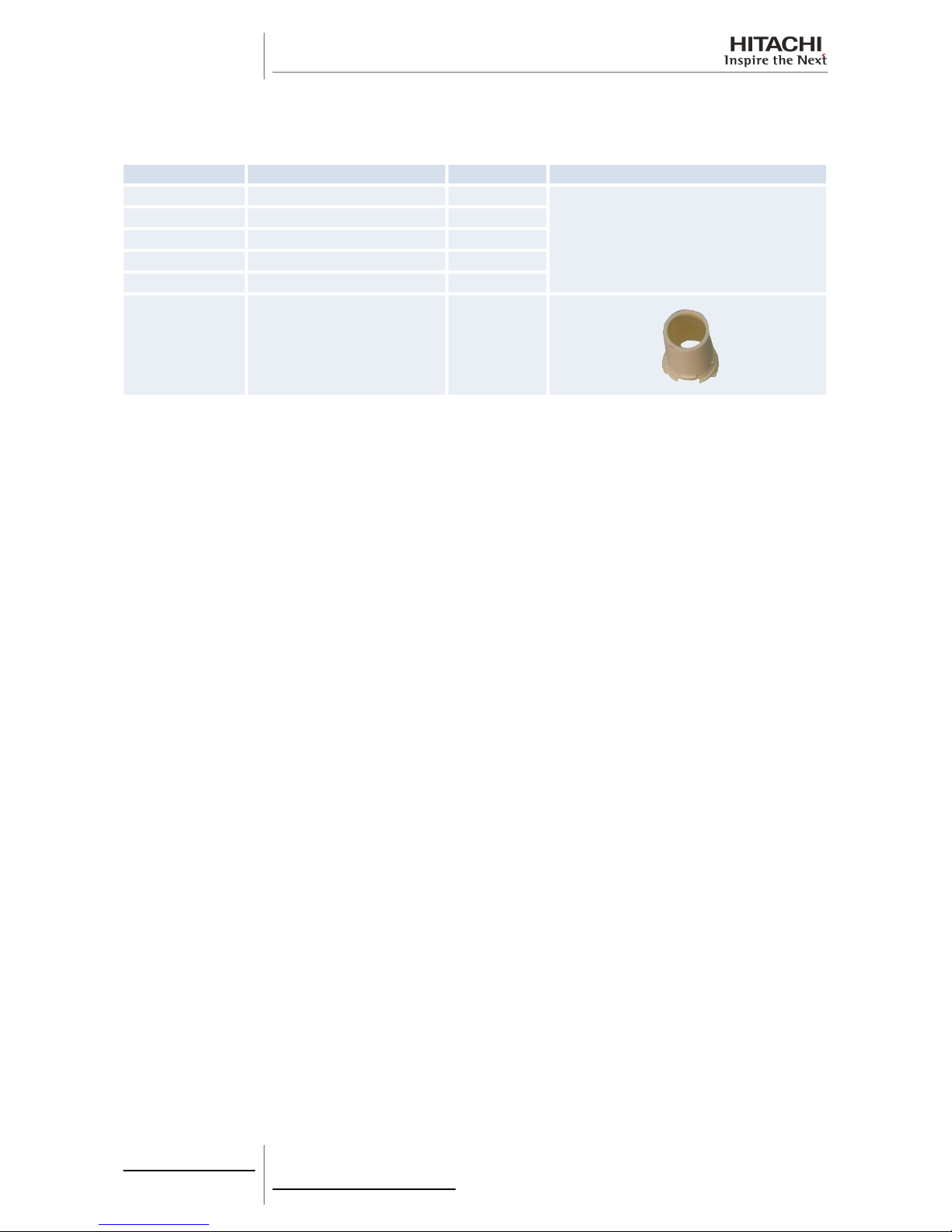

1.3.4 Accessory code list

HITACHI has a range of accessories and remote control systems that can be used with the UTOPIA outdoor units. Consult

the Controls Technical Catalogue.

Name Description Code Figure

AG-335A Air outlet diffuser (one for each fan) 60291431

Images not available

WSP-335A Wind guard 60291432

ASG-NP335F Snow guard (one for each fan) 60291433

ASG-NP335B Snow guard (one for each fan) 60291434

ASG-NP335L Snow guard 60291435

DBS-26 Drain discharge connection 60299192

1 General information

6

SMGB0060 rev. 1- 12/2010

Page 15

2. U n i t I n s t a l l a t i o n

Index

2.1 Safety summary......................................................................................................................... 8

2.2 Transportation of outdoor unit.................................................................................................... 9

2.3 Center of gravity......................................................................................................................... 10

2.4 Factory-supplied accessories for RAS-(8-12)HRNM.................................................................. 11

2.5 Installation space (Initial ckeck).................................................................................................. 12

2.5.1 RAS-(2-3)HVRN(1)(E)(S).............................................................................................................. 12

2.5.2 RAS-(3-6)H(V)RNM(1)E / RAS-(4-10)HVRNS(1)E....................................................................... 16

2.5.3 RAS-(8-12)HRNM......................................................................................................................... 20

2.6 Place provision........................................................................................................................... 22

2.6.1 Place provision for RAS-(3-12)H(V)RNM(1)(E) and RAS-(4-10)H(V)RNS(1)E............................. 22

2.6.2 Place provision only for RAS-(2-3)HVRN(1)(E)(S)........................................................................ 25

2.7 Optional parts and installation.................................................................................................... 28

2.7.1 Optional parts and installation for RAS-(2-3)HVRN(1)(E)(S)........................................................ 28

2.7.2 Optional parts and installation RAS-3HVRNME / RAS-(4-6)HVRNS1E....................................... 33

2.7.3 Optional parts and installation RAS-(4-6)H(V)RNM1E / RAS-(8/10)HRNSE................................ 37

2.7.4 Optional parts and installation RAS-(8-12)HRNM......................................................................... 42

2 Unit Installation

7

SMGB0060 rev. 1- 12/2010

2

Page 16

2.1 Safety summary

D A NG ER

• Install the outdoor unit with sufficient clearance around it for operation and maintenance as shown in the next

pages.

• Install the outdoor unit where good ventilation is available.

• Do not install the outdoor unit where exists a high level of oil mist, salty air or sulphurous atmosphere.

• Install the outdoor unit as far as practical (being at least 3 meters) from electromagnetic wave radiator, such

as medical equipment.

• Keep clearance between units of more than 50 mm, and avoid obstacles that could hamper air intake, when

installing more than one unit together.

• Install the outdoor unit in the shade or not exposed to direct sunshine or direct radiation from high temperature

heat source.

• Do not install the outdoor unit in a place where a seasonal wind directly blows into the outdoor fan.

• For cleaning, use non-inflammable and nontoxic cleaning liquid. Use of inflammable agent may cause

explosion or fire.

• Work with sufficient ventilation, for working in an enclosed space could cause oxygen deficiency. Toxic gas

may be produced when cleaning agent is heated to high temperature by, e.g., being exposed to fire.

• Cleaning liquid shall be collected after cleaning.

• Pay attention not to clamp cables when attaching the service cover to avoid electric shock or fire.

C A UT IO N

• Check the foundation to be flat, leveled and strongly enough.

• Install the unit in a restricted area not accessible by the general public.

• Aluminium fins have very sharp edges. Pay attention to the fins in order to avoid injury.

• Do not install the indoor units in a flammable environment to avoid a fire or an explosion.

• Check to ensure that the ceiling slab is strong enough. If not strong enough, the indoor unit may fall down on

you.

• Do not install the indoor units, outdoor unit, remote control switch and cable within approximately 3 meters

from strong electromagnetic wave radiators, such as medical equipment.

• Do not install the indoor units in a machinery shop or kitchen, where vapour from oil or mist flows to the indoor

units. The oil will deposit on the heat exchanger, thereby reducing the indoor unit performance, and may

deform. In the worst case, the oil damages the plastic parts of the indoor unit.

• To avoid any corrosive action to the heat exchangers, do not install the indoor units in an acid or alkaline

environment.

• When lifting or moving the indoor unit, use appropriate slings to avoid damage and be careful not to damage

the insulation material on units surface.

• This appliance must be used only by adult and capable people, having received the technical information or

instructions to handle properly and safely this appliance.

• Turn OFF all power switches before maintenance is performed.

• Do not start the cleaning procedures before 5 minutes of the stop of the unit.

D A NG ER

• Avoid obstacles which may hamper the air intake or the air discharge flow.

• Children must be supervised to ensure that they do not play with the electrical appliances.

• Before obtaining access to terminals, all supply circuits bust be disconnected.

2 Unit Installation

8

SMGB0060 rev. 1- 12/2010

Page 17

2.2 Transportation of outdoor unit

D AN GE R

• Do not put any foreign material into the outdoor unit and check to ensure that none exists in the outdoor unit

before the installation and test run. Otherwise, a fire or failure will occur.

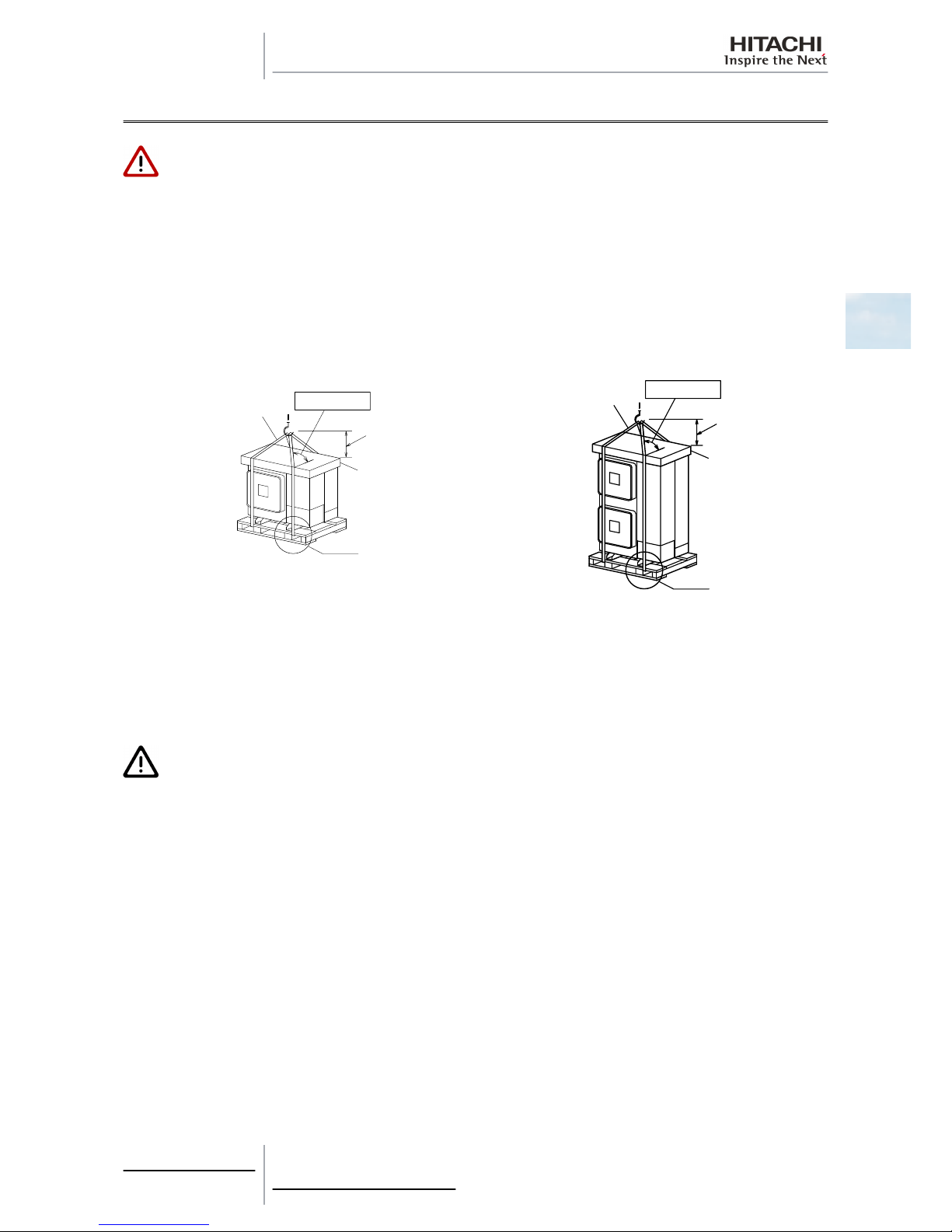

Hanging Method

When hanging the unit, ensure the balance of the unit, check safety and lift it up smoothly. Do not remove any packing

materials and hang the unit under packing condition with two ropes, as shown below.

RAS-3HVRNME RAS-(4-6)H(V)RNM1E

RAS-(2-3)HVRN(1)(E)(S) RAS-(8-12)HRNM

RAS-(4-6)HVRNS1E RAS-(8/10)HRNSE

1ABCD1ABC

D

1. Wire rope.

A. Over 60º.

B. 0.7 to 1.0 m.

C. Do not remove the plastic band or the corrugate paper frame.

D. Pass the wire ropes through each lifting hole in the wooden base as shown.

C A UT IO N

• Lift the outdoor unit in its factory packaging with 2 wire ropes.

• For safety reasons ensure that the outdoor unit is lifted smoothly and does not lean.

• Do not attach lifting equipment to the plastic band or the corrugated paper frame, because of the ropes will slip

or break the materials.

• Ensure that the exterior of the unit is adequately protected with cloth or paper.

2 Unit Installation

9

SMGB0060 rev. 1- 12/2010

2

Page 18

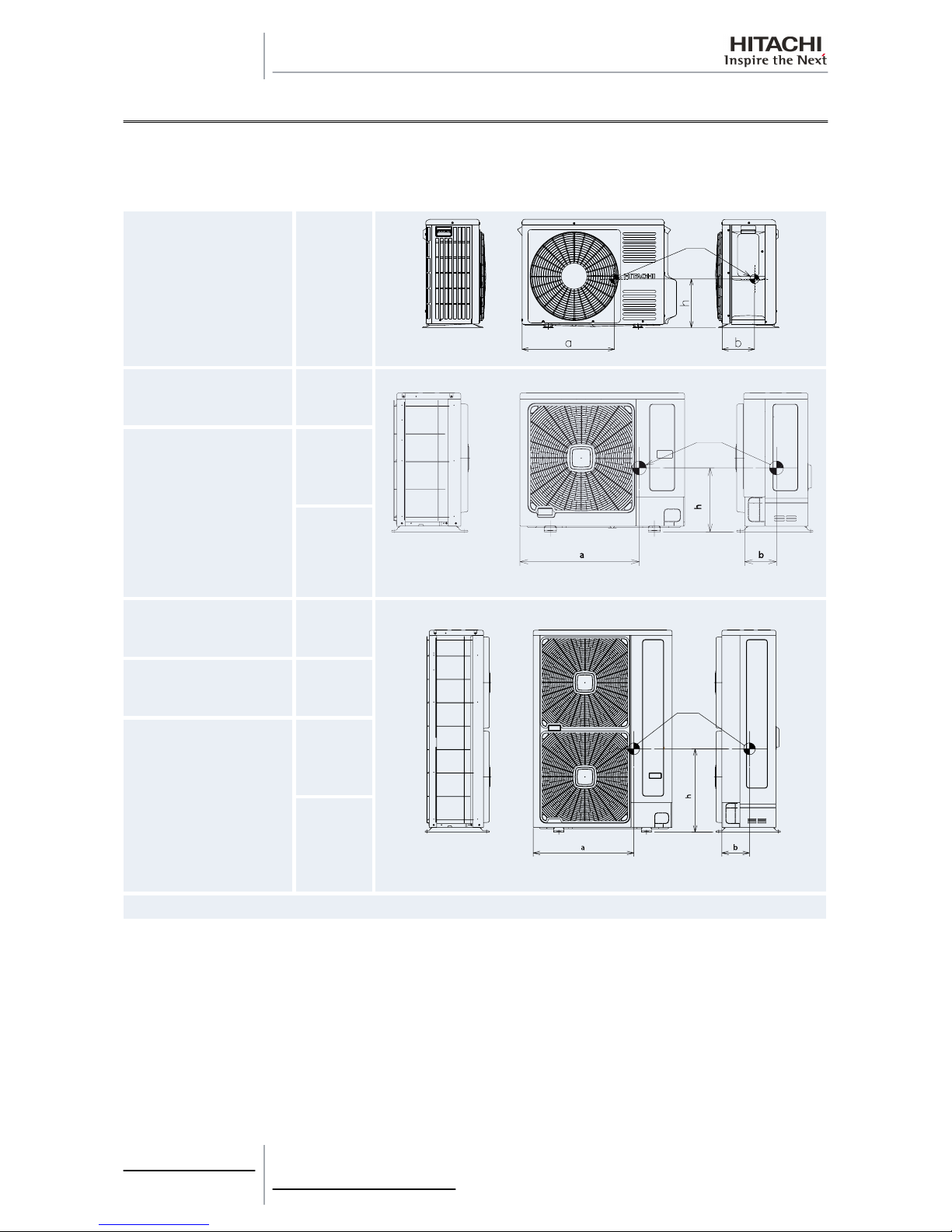

2.3 Center of gravity

Hanging Method

When hanging the unit, ensure the balance of the unit, check safety and lift it up smoothly. Do not remove any packing

materials and hang the unit under packing condition with two ropes, as shown below. At leat two persons are needed to

move the unit.

RAS-(2-3)HVRN(1)(E)(S)

a. 515 mm

b. 180 mm

h. 275 mm

1

RAS-3HVRNME

a. 590 mm

b. 185 mm

h. 370 mm

1

RAS-(4-6)HVRNS1E

For 4 HP:

a. 635 mm

b. 180 mm

h. 335 mm

For 5-6 HP:

a. 630 mm

b. 190 mm

h. 360 mm

RAS-(4-6)H(V)RNM1E

a. 615 mm

b. 190 mm

h. 570 mm

1

RAS-(8-12)HRNM

a. 615 mm

b. 190 mm

h. 570 mm

RAS-(8/10)HRNSE

For 8 HP:

a. 325 mm

b. 206 mm

h. 565 mm

For 10HP:

a. 325 mm

b. 213 mm

h. 585 mm

1 Center of gravity

2 Unit Installation

10

SMGB0060 rev. 1- 12/2010

Page 19

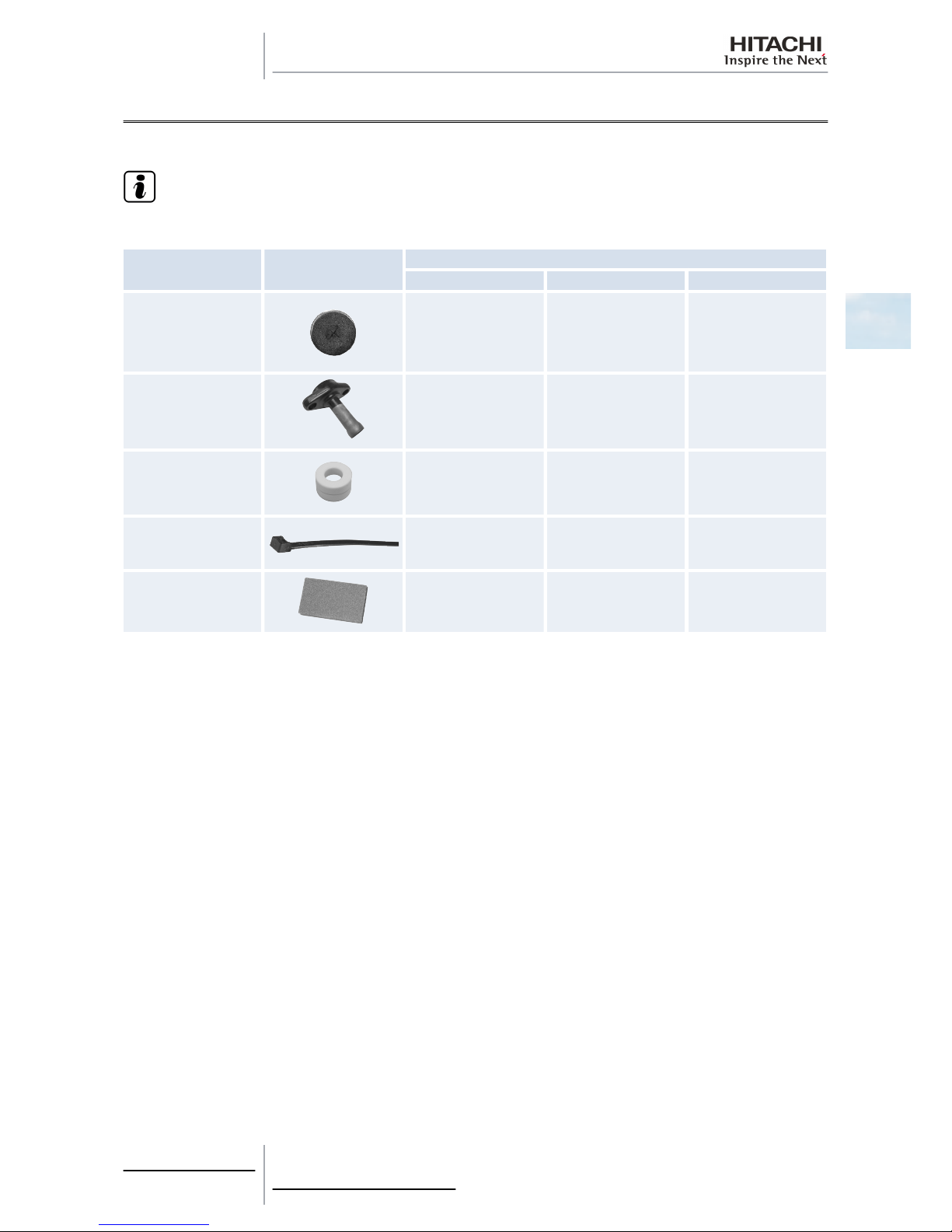

2.4 Factory-supplied accessories for RAS-(8-12)HRNM

Make sure that the following accessories are packed with the unit.

N O TE

• If any of these accessories are not packed with the unit, please contact your dealer.

Accessory Appearance

Quantity

RAS-8HRNM RAS-10HRNM RAS-12HRNM

Gasket 1 1 1

Pipe flange for refrigerant

gas piping

1 1 1

Ring core 1 1 1

Cable tie 1 1 1

Compressed sheet 1 1 1

2 Unit Installation

11

SMGB0060 rev. 1- 12/2010

2

Page 20

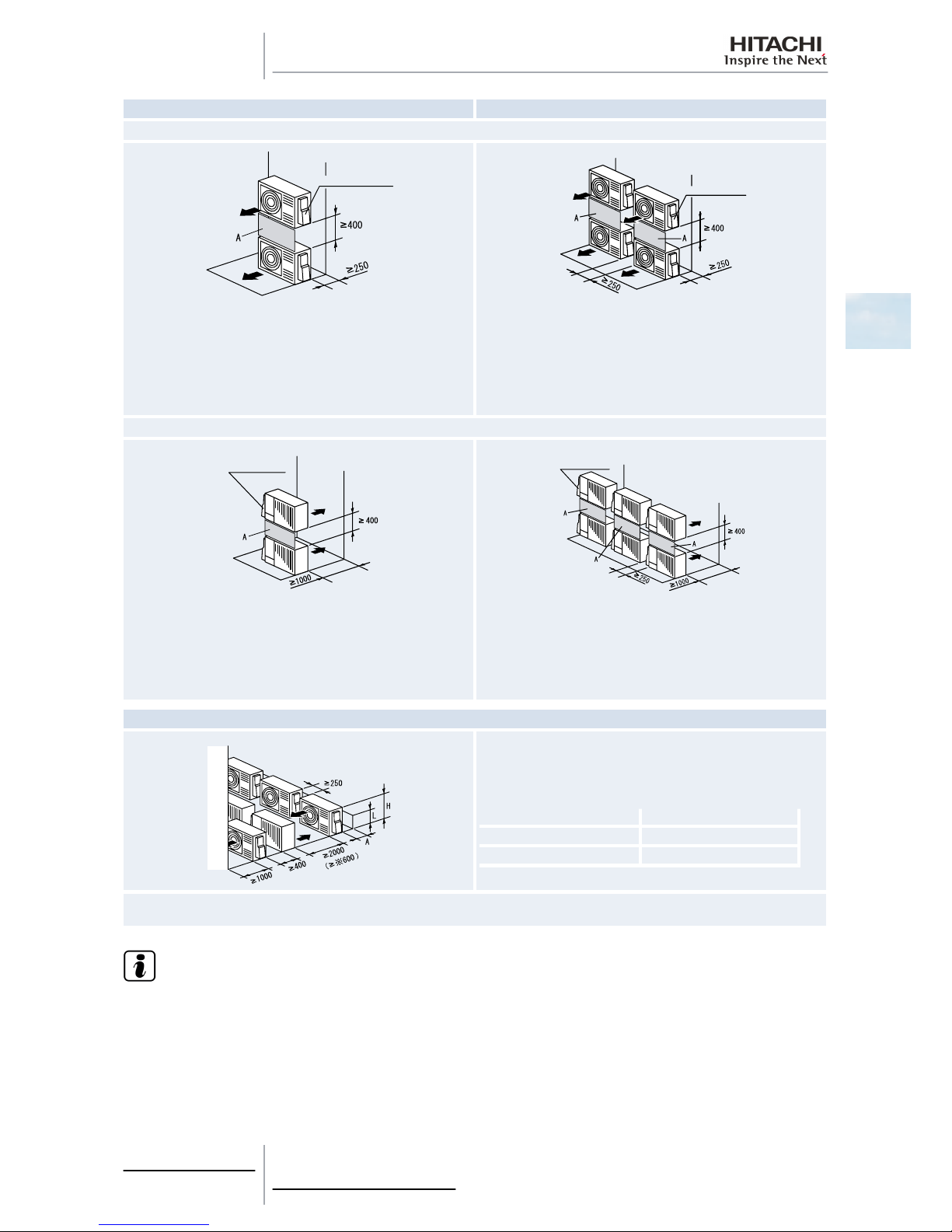

2.5 Installation space (Initial ckeck)

2.5.1 RAS-(2-3)HVRN(1)(E)(S)

Blocked in Inlet Side

Upper Side Open

Single Installation Multiple Installation (Two units or more)

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side. Allow 250 mm of space between units. Leave open both right and left sides.

Pipe Cover

Pipe Cover

Be sure to use the fan direction guide. Leave open both right and left sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Be sure to use the fan direction guide.

Allow 250 mm of service space between units. Leave open both right and

left sides. When subject to direct sunlight on the back wall, ensure the

length marked with . be 400 or greater.

Ensure 250 mm or more of the side space on the pipe cover side.

Upper Side Blocked

Single Installation Multiple Installation (Two units or more)

Pipe Cover

Pipe Cover

Fifteen mm of space is acceptable for one of the lateral sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 250 mm of service space between units. Leave open both right and

left sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Be sure to use the fan direction guide. Leave open both right and left sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Be sure to use the fan direction guide.

Allow 250 mm of service space between units. Leave open both right and

left sides. Serial installation allowed up to two units.

Ensure 250 mm or more of the side space on the pipe cover side.

2 Unit Installation

12

SMGB0060 rev. 1- 12/2010

Page 21

Blocked in Inlet Side

The length A is as show in the following table:

L A

0<L=1/2H 500 or greater

1/2H<L≤H

1000 or greater

When L > H, use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

Outlet Side Blocked

Upper Side Open

Single Installation Multiple Installation (Two units or more)

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 250 mm of service space between units. Both right and left sides

shall be open.

Pipe Cover

Pipe Cover

Be sure to use the fan direction guide. Leave open both right and left sides.

Be sure to use the fan direction guide. Allow 250 mm of service space

between units. Serial installation allowed up to two units.

Leave open both right and left sides.

The length A is as show in the following table:

L A

0<L=1/2H 100 or greater

1/2H<L≤H

200 or greater

When L > H, use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

The length A is as show in the following table:

L A

0<L=1/2H 150 or greater

1/2H<L≤H

250 or greater

When L > H, use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

2 Unit Installation

13

SMGB0060 rev. 1- 12/2010

2

Page 22

Lateral Side Blocked

Upper Side Open

Single Installation

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side. Ensure 250 mm or more of the side space on the pipe cover side.

Upper Side Blocked

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side. Ensure 250 mm or more of the side space on the pipe cover side.

2 Unit Installation

14

SMGB0060 rev. 1- 12/2010

Page 23

Single Installation Multiple Installation

Blocked in Inlet Side

Pipe Cover

Pipe Cover

Close the part A not to allow the outlet air bypassed. Install to avoid the

drain water from upper unit falling on the lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Allow 250 mm of service space between units. Serial sideways installation

allowed up to two units.

Leave open both right and left sides. Close the part A not to allow the outlet

air bypassed. Install to avoid the drain water from upper unit falling on the

lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Outlet Side Blocked

Pipe Cover

Pipe Cover

Be sure to use the fan direction guide. Close the part A not to allow the

outlet air bypassed. Install to avoid the drain water from upper unit falling

on the lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Be sure to use the fan direction guide. Allow 250 mm of service space

between units. Serial side way installation allowed, but leave open both

right and left sides. Close the part A not to allow the outlet air bypassed.

Install to avoid the drain water from upper unit falling on the lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Multiple Installation in Multiple Rows

Ensure 250 mm or more of the side space on the pipe cover side. Allow

400 mm of service space above the top board.

The length A is as show in the following table:

L A

0<L=1/2H 150 or greater

1/2H<L≤H

250 or greater

When L > H, use a base for outdoor unit to make L ≤ H. Close the base not to allow the outlet air bypassed. Be sure to use the fan direction guide in

order to ensure the length marked with ..

N O TE

• All units are in (mm).

• Do not stack more than two units in height.

• Close gap (*) to avoid recirculating discharge air flow.

2 Unit Installation

15

SMGB0060 rev. 1- 12/2010

2

Page 24

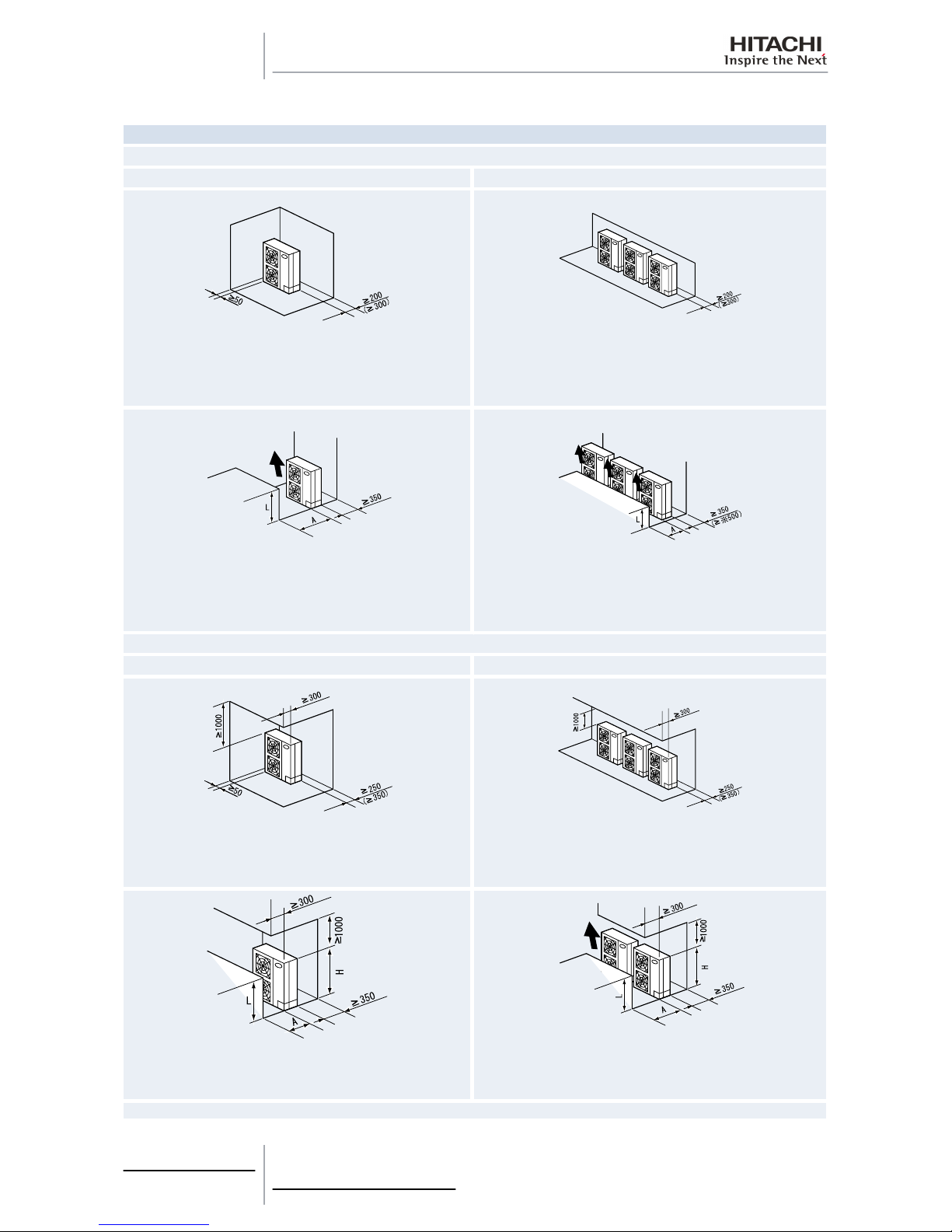

2.5.2 RAS-(3-6)H(V)RNM(1)E / RAS-(4-10)HVRNS(1)E

Blocked in Inlet Side

Upper Side Open

Single Installation Multiple Installation (Two units or more)

100 mm or more of the side space is acceptable on the service cover side.

Dimensions in ( ) shows numbers especially for IVX 4-10 HP and ES

8/10 HP. 150 or more (200 or more) of the back space is acceptable when

the right and left sides are open.

Allow 100 mm of space between units. Leave open both right and left sides.

Dimensions in ( ) shows numbers especially for IVX 4-10 HP and ES

8/10 HP.

Be sure to use the fan direction guide. Leave open both right and left sides.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Leave open both right and left sides.

When subject to direct sunlight on the back wall, ensure the length marked

with . be 500 or greater.

Upper Side Blocked

Single Installation Multiple Installation (Two units or more)

100 mm or more of the side space is acceptable on the service cover side.

Dimensions in ( ) shows numbers especially for IVX 4-10 HP and ES

8/10 HP.

Allow 100 mm of space between units. Leave open both right and left sides.

Dimensions in ( ) shows numbers especially for IVX 4-10 HP and ES

8/10 HP.

Be sure to use the fan direction guide.

Leave open both right and left sides.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Leave open both right and left sides.

Serial installation allowed up to two units.

2 Unit Installation

16

SMGB0060 rev. 1- 12/2010

Page 25

Blocked in Inlet Side

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H

600 or greater

1/2H < L≤ H

1200 or greater

Be sure to use the fan direction guide. Allow 100 mm of space between units. Leave open both right and left sides. Serial installation allowed up to two

units.

Outlet Side Blocked

Upper Side Open

Single Installation Multiple Installation (Two units or more)

Allow 100 mm of space between units. Both right and left sides shall be

open.

Be sure to use the fan direction guide. Leave open both right and left sides.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Serial installation allowed up to two units. Leave open both right and

left sides.

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H ≤ 200

1/2H < L≤ H ≤ 300

When L > H, use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H ≤ 250

1/2H < L≤ H ≤ 350

When L > H, use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

2 Unit Installation

17

SMGB0060 rev. 1- 12/2010

2

Page 26

Lateral Side Blocked

Upper Side Open

Single Installation

Upper Side Blocked

Stack installation (allowed up to 2 Units)

Upper Side Open

Single Installation Multiple Installation

Close the part A not to allow the outlet air bypassed. Install to avoid the

drain water from upper unit falling on the lower unit.

Allow 100 mm of space between units. Serial sideways installation allowed

up to two units. Leave open both right and left sides. Close the part A not

to allow the outlet air bypassed. Install to avoid the drain water from upper

unit falling on the lower unit.

Upper Side Blocked

Single Installation Multiple Installation

Be sure to use the fan direction guide. Close the part A not to allow the

outlet air bypassed. Install to avoid the drain water from upper unit falling

on the lower unit.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Serial side way installation allowed. but leave open both right and left

sides. Close the part A not to allow the outlet air bypassed. Install to avoid

the drain water from upper unit falling on the lower unit.

2 Unit Installation

18

SMGB0060 rev. 1- 12/2010

Page 27

Multiple Installation in Multiple Rows

Serial Installation in Multiple Rows (E.g. Rooftop)

Allow approx. 100 mm of space from the side unit. Leave open both right

and left sides.

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H ≤ 200

1/2H < L≤ H ≤ 300

N O TE

When L > H, use a base for outdoor unit to make L = H. Close the base not to allow the outlet air bypassed. Be

sure to use the fan direction guide in order to ensure the length marked with ..

2 Unit Installation

19

SMGB0060 rev. 1- 12/2010

2

Page 28

2.5.3 RAS-(8-12)HRNM

Single installation

Around sides are open Around sides are open with obstacles above

Around sides are closed

Around sides are open with obstacles above

Multiple installation

Around sides are open

Around sides are open with obstacles above

Multi-Row

2 Unit Installation

20

SMGB0060 rev. 1- 12/2010

Page 29

N O TE

• All units are in mm.

• Do not stack more than two units in the height.

• If L is larger than H, mount the units on a base so that H is equal or greater than L.

– H: Unit height (1650 mm) + base concret height

L A B

0 < L ≤ 1/2 H

600 or more 300 or more

1/2H < L ≤ H

— —

• In this situation, ensure that the base is closed and does not allow the airflow to short circuit.

• In each case, install the outdoor unit so that the discharge flow is not short-circuited.

• When the installation dimension results the one marked with an (*), mount the air flow guide.

2 Unit Installation

21

SMGB0060 rev. 1- 12/2010

2

Page 30

2.6 Place provision

2.6.1 Place provision for RAS-(3-12)H(V)RNM(1)(E) and RAS-(4-10)H(V)RNS(1)E

¿ Concrete foundation

• Foundation could be on flat and it is recommended to be 100-300 mm higher than ground level.

• Install a drainage around foundation for smooth drain.

• When installing the outdoor unit, fix it by M10 anchor bolts.

• When installing the unit on a roof or a veranda, drain water sometimes turns into ice on a cold morning. Therefore, avoid

draining in an area that people often use because it may become slippery.

Metal plate for RAS-(3-6)H(V)RNM(1)E and RAS-(4-10)H(V)RNS(1)E

1 Outdoor unit.

2 Cut this portion of bolt If not, it’s difficult to remove Service

cover.

3 Mortar hole (Ø100 x Depth 150).

4 Anchor bolt M10 (Ø12.5 Hole).

5 Drainage (Wide 100 x Depth 150).

6 Drainage.

7 Vibration-proof rubber.

N O TE

• (*): Space for downward piping space.

Anchor bolt location in case of RAS-(8–12)HRNM

(1)

.

The whole base of the outdoor unit should be installed on a foundation. When using vibration-proof material, it should also

be positioned in the same place. When installing the outdoor unit on a fieldsupplied frame, use metal plates to adjust the

frame width for stable installation as shown in the figure below.

1. Outdoor unit is unstable

2. Frame.

3. Outdoor unit is stable.

4. Metal plate.

A. For RAS-(3-6)H(V)RNM(1)E 57 mm. Base width for outdoor unit.

For RAS-(4-10)H(V)RNS(1)E 70 mm. Base width for outdoor

unit.

For RAS-(8-12)HRNM: 100 mm. Base width for outdoor unit.

B. 60 mm. Frame width (Field supplied).

C. For RAS-(3-12)H(V)RNM(1)(E) 100 mm or more Metal plate.

For RAS-(4-10)H(V)RNS(1)E: 70 mm or more Metal plate.

1234567

4

(1)

AB21AC234

INCORRECT CORRECT

2 Unit Installation

22

SMGB0060 rev. 1- 12/2010

Page 31

Recommended Metal Plate Size

• (Field-Supplied) Material: Hot-Rolled Mild Steel.

• Plate (SPHC) Plate Thickness: 4.5 T.

¿ Example of fixing outdoor unit by anchor bolts

1. Max. 21 mm (After cut “A”)

2. Concrete

3. Anchor bolt

B. Cut this portion when this type of anchor bolt is used. If not done,

it will be dificult to remove the service cover

¿ Fix unit to the wall

1 Fix the unit onto the wall as shown in the figures (Field supplied bracket).

2 Secure the foundation to avoid noise and warping

3 To avoid vibrations transferring to the building, use a rubber mat.

RAS-3HVRNME

RAS-(4-6)H(V)RNM1E

RAS-(4-6)HVRNS1E RAS-(8-12)HRNM

RAS-(8/10)HRNSE

A

1

2

*

2

1

1. Rubber material

2. Fixing plate

N O TE

• (*): In RAS-(8-12)HRNM are 110 mm

Model

RAS-3HVRNME RAS-(4-6)HVRNS1E

RAS-

(4-6)H(V)RNM1E

RAS-(8-12)HRNM RAS-(8/10)HRNSE

A (mm) 529 796 529 1173 1109

B12

3

2 Unit Installation

23

SMGB0060 rev. 1- 12/2010

2

Page 32

¿ Suspended unit

1 Suspend the unit as shown in the figures.

2 Ensure that wall can withstand the weight of the outdoor unit indicated on the specifications plate.

3 It is advisable that each foot support should bear the full weight of the unit (in order take account of applied stress fatigue

when unit is operating).

RAS-3HVRNME

RAS-(4-6)H(V)RNM1E

RAS-(4-6)HVRNS1E RAS-(8-12)HRNM

RAS-(8/10)HRNSE

12312

3

1. Wall support

2. Anchor bolts

3. Supplied by the installer

C A UT IO N

• Follow these installation procedures carefully

– The installation must be done so as to ensure that the outdoor unit does not lean, vibrate, make a noise or

fall in the event of strong gusts of wind or earthquakes. Calculate the resistance to vibration (caused by

earthquakes) to guarantee that the installation is sturdy enough to prevent falls. Secure the unit with cables

(field-supplied) when installing the unit in a place without walls or wind protection, and where it is likely to

be exposed to gusts of wind.

– When using the vibration-proof rubber mat, secure it at four points on the front and back.

2 Unit Installation

24

SMGB0060 rev. 1- 12/2010

Page 33

¿ Installing location where the unit will be exposed to strong wind

Follow the instructions below to install on the roof or in a place which is not surrounded by buildings, and where the product

may be buffeted by strong winds.

1 Select a place where the input or outlet side of the product is exposed to strong winds.

2 When the outlet is exposed to strong winds: Strong direct winds may cause a lack of air flow and negative effects on

the unit operation.

RAS-3HVRNME RAS-(4-6)H(V)RNM1E

RAS-(4-6)HVRNS1E RAS-(8-12)HRNM

RAS-(8/10)HRNSE

C A UT IO N

• An excessively strong wind blowing against the outlet of the outdoor unit may cause reverse rotation and

damage to the fan motor.

2.6.2 Place provision only for RAS-(2-3)HVRN(1)(E)(S)

1 Secure the outdoor unit with the anchor

1. Base of outdoor unit

2. Nut

3. Special washer (M12)

4. Anchor bolts

5. Filled mortar

6. Concrete

A. Max. 17 mm

Fix the outdoor unit to the anchor bolts by special washer of

factory-supplied accessory.

2 When installing the outdoor unit, fix the unit by anchor bolts.

Regarding the location of fixing holes.

1. M10 Hole for anchor bolt (Ø12)

2. Pipe cover

3. Front side

123

4

5

6

A

1

2

3

2 Unit Installation

25

SMGB0060 rev. 1- 12/2010

2

Page 34

3 Example of fixing outdoor unit by anchor bolts.

1. Max. 17 mm (After cut “A”)

2. Concrete

3. Anchor bolt

B: Cut this portion when this type of anchor bolt is used. If not

done, it will be difficult to remove the service cover

4 Provide an adequate drainage around the foundation. When installing the unit on a roof or a veranda, drain water may

turn to ice in a cold morning. Therefore, avoid draining in an area where people often use because it is slippery. In case

of installing such a place, provide the additional drainage around the foundation.

1. Drain hole (30x80)

2. Drain hole (3-30x80)

3. Front side

5 The whole of the base of the outdoor unit should be installed on a foundation. When using vibration-proof mat, it should

also be positioned the same way. When installing the outdoor unit on a field-supplied frame, use metal plates to adjust

the frame width for stable installation as shown in Figure.

1. Outdoor unit is unstable

2. Frame

3. Outdoor unit is stable

4. Metal plate

A. 57 mm. Base width of outdoor unit

B. 40 mm Frame width (Field-supplied)

C. 100 mm or more Metal plate

• Recommended Metal Plate Size:

– (Field-Supplied) Material: Hot-Rolled Mild Steel.

– Plate (SPHC) Plate Thickness: 4.5 T

B12

3

1

2

3

AB21AC234

INCORRECT CORRECT

120

60

(560)

70

420

70

20

14

R

4-C10

2 Unit Installation

26

SMGB0060 rev. 1- 12/2010

Page 35

Installing location where the unit will be exposed to strong wind

Follow the instructions below to install on the rooftop or a location without surrounding buildings, where strong wind is

expected against the product.

1 Choose a location where the outlet or inlet side of the product

will not be exposed to strong wind.

2 When the outlet is exposed to strong wind: Direct strong wind

may cause lack of air flow and adversely affect to normal

function.

C A UT IO N

• Excessive strong wind against the outdoor unit outlet may cause inverse rotation and damage the fan and

motor.

2 Unit Installation

27

SMGB0060 rev. 1- 12/2010

2

Page 36

2.7 Optional parts and installation

2.7.1 Optional parts and installation for RAS-(2-3)HVRN(1)(E)(S)

¿ Air flow guide, wind guard and snow protection hood

Optional parts HP Model

Air flow guide

2-3

AG-264

1 2

3

1 Air flow guide

2 Wind Guard

3 Snow protection hood

Wind guard

WSP-264

Snow protection

hood

Zinc Plate

Air outlet

2-3

ASG-NP80F

Air inlet of rear side ASG-NP56B

Air inlet of side face ASG-NP56L

Stainless plate

(NSSC180)

Air outlet

2-3

ASG-NP80FS2

Air inlet of rear side ASG-NP63B52

Air inlet of side face ASG-NP63LS2

¿ Air flow guide

Model

AG-264

Quantity 1 per unit

1

1

2

1 Mounting dimension

2 Air flow guide

Air discharge

direction

Upward (downward), left & right

Material Weather proof polypropylene resin

Color Gray

Weight 1.4 kg

Accessories

Fixing screw

4x [M5 (SUS) x 12]+4x [M5 (SUS) x 30]

Installation manual

Self-screw 2x [M4 x 13]

Installation

restriction

“Wind Guard” or “Snow protection hood” is not

available to install with air flow guide. (“Guard net” is

available to be installed together.)

Attaching example of air flow guide

• Attach the air flow guide to the air discharge grille with four (4) screws (supplied).

• The fixing holes are located at 4 positions on the grille. (Screw tightening torque 2.4 ~ 3.1 N.m)

• Do not remove the air discharge grille for air flow guide installation.

C A UT IO N

• If the air guide is installed without discharge grille, it may cause injury due to rotating fan.

2 Unit Installation

28

SMGB0060 rev. 1- 12/2010

Page 37

Locations of fixing holes

The holes Location shall be made by using self-screws (M4x13)

and later shall be used SUS screw (M5x12) for fixing air flow guide.

1 Outdoor Unit

2 Hole (4 locations)

One flow guide installation

1 Air discharge grille

2 Air flow

3 Outdoor unit

4 M5 fixing screw x4 (Accessories)

5 Air flow guide

Service space (In case of upward air discharge)

• In case of right and left sides air discharge, enough space for

air discharge is required.

• The downward air discharge is also available. In such case,

install the base under the unit to secure enough space for air

discharge.

• In case of serial units installation, air discharge should be

upward.

1 Min.150 mm

2 Outdoor unit

3 Air flow guide

4 Passage side

12123445123

4

2 Unit Installation

29

SMGB0060 rev. 1- 12/2010

2

Page 38

¿ Wind guard

Specifications

Model WSP-264

Quantity 1 per unit

1

2

1

4-6x10 Long Hole

2

5 (Both Sides) - M5 Screw (attachement)

Material Galvanized sheet metal + baked painting

Color UTOPIA Beige

Weight 4.0 kg

Accessories

Fixing screw x 4 [M5 (SUS) x 30]- Unit

Fixing Screw x 10 [M5 (SUS) x 12]- Wind Ward

Installation manual

Installation

restriction

“Guard net”, “Air flow guide” or “Snow protection hood” is

not available to install with Wind guard

Attaching example of air wind guard

• Attach the air flow guide to the air discharge grille with four (4) screws (supplied).

• The fixing holes are located at 4 positions on the grille. (Screw tightening torque 2.4 ~ 3.1 N.m)

• Do not remove the air discharge grille for air flow guide installation.

C A UT IO N

• If the air guide is installed without discharge grille, it may cause injury due to rotating fan.

Two windguard covers installation

1 Air discharge grille

2 Outdoor unit

3 M5 fixing screw x4 (Accessories)

Service space

• Both sides of the outdoor unit should be open.

• No obstacles should be placed in the air discharge side.

1 Min.150 mm

2 Outdoor unit

3 Wind guard

1123123

2 Unit Installation

30

SMGB0060 rev. 1- 12/2010

Page 39

¿ Snow protection hood

Air discharge hood

Nº

Part name Quantity

1 Right side plate 1

2 Left side plate 1

3 Front panel 1

4 Fixing screw (Accessories)

5 Hole for safety wire rope to prevent overturning

Rear suction hood

Nº

Part name Quantity

1 Right side plate 1

2 Left side plate 1

3 Upper front panel (Upside) 1

4 Upper front panel (Downside). 1

5 Hole for safety wire rope to prevent overturning

6 Fixing screw (Accessories)

Left suction hood

Nº

Part name Quantity

1 Right side plate 1

2 Left side plate 1

3 Upper front panel (Upside) 1

4 Upper front panel (Downside). 1

12345

123

4

2 Unit Installation

31

SMGB0060 rev. 1- 12/2010

2

Page 40

Attaching example of snow protection hood

1

1

2

3

1 1

4

2 1

5

1

BA C

1. Fixing screw (accessories)

2. Air inlet hood

3. Wire rope (optional for over turning protection)

4. Air discharge hood

5. Outdoor unit

A. Rear side

B. Left side

C Front side

N O TE

• The holes locations marked with a mark shall be made by using sel screw (M4X13) and later shall be used SUS

Screw for fixing protection hood.

Specifications of snow protection hood

Product name Air discharge hood Rear suction hood Left suction hood

Model ASG-NP80F ASG-NP80FS ASG-NP56B ASG-NP63BS2 ASG-NP56L ASG-NP63LS2

Quantity 1 per unit

Material

Bonderized steel

sheet

Iron

Stainless

(NSSC180)

Bonderized steel

sheet

Iron

Stainless

(NSSC180)

Bonderized steel

sheet

Iron

Stainless

(NSSC180)

Color

Gray (1.0Y8.5/0.5

or approximation)

—

Gray (1.0Y8.5/0.5

or approximation)

—

Gray (1.0Y8.5/0.5

or approximation)

—

Weight 3 kg 6 kg 3 kg

Assembling Knockingdown parts (assembled at field)

Components

Hood For air discharge part x 1 For rear side air intake x 1 For left side air intake x 1

Unit

Fixing screw

4 (M5x12 tapping screw) 5 (M5x12 tapping screw) 4 (M5x12 tapping screw)

Hood

Fixing screw

(SUS)

6 (M5x12 tapping

screw)

6 (M5x14)

14 (M5x12 tapping

screw)

14 (M5x14)

10 (M5x12 tapping

screw)

10 (M5x14)

Self-screw 2 (M4x13) 2 (M4x13) 2 (M4x13)

Installation manual

Installation restriction

Installation with “Guard net”, “Wind

guard” or is not available

Installation with “Guard net” is not available

Safety wire rope for overturning

prevention (optional parts)

ASG-SW20A

2 Unit Installation

32

SMGB0060 rev. 1- 12/2010

Page 41

2.7.2 Optional parts and installation RAS-3HVRNME / RAS-(4-6)HVRNS1E

¿ Air flow guide, wind guard and snow protection hood

Optional parts HP Model

Air flow guide

4-6

AG-335A

1 2

3

1 Air flow guide

2 Wind Guard

3 Snow protection hood

Wind guard

WSP-335A

Snow protection

hood

Zinc plate

Air outlet

4-6

ASG-NP335F

Air inlet of rear side ASG-NP80B

Air inlet of side face ASG-NP80L

Stainless plate

(SUS304)

Air outlet

4-6

ASG-NP335F52

Air inlet of rear side ASG-NP160BS2

Air inlet of side face ASG-NP160LS2

¿ Air flow guide

Specifications

Model

AG-335A

Quantity 1 per unit

1

1

2

1 Mounting dimension

2 Air flow guide

Air discharge

direction

Upward (downward), left & right

Material Weather proof polypropylene resin

Color Gray

Weight 1.9 kg

Accessories

Fixing screw x 4 [M5 (SUS) x 20]

Installation manual

Installation

restriction

“Wind Guard” or “Snow protection hood” is not

available to install with air flow guide. (“Guard net”

is available to be installed together.)

Attaching example of air flow guide

• Attach the air flow guide to the air discharge grille with four (4) screws (supplied).

• The fixing holes are located at 4 positions on the grille. (Screw tightening torque 2.4 ~ 3.1 N.m)

• Do not remove the air discharge grille for air flow guide installation.

C A UT IO N

• If the air guide is installed without discharge grille, it may cause injury due to rotating fan.

2 Unit Installation

33

SMGB0060 rev. 1- 12/2010

2

Page 42

One flow guide installation

1 Air discharge grille

2 Air flow

3 Air flow guide

4 Outdoor unit

5 M5 fixing screw x4 (Accessories)

Service space (In case of upward air discharge)

• In case of right and left sides air discharge, enough space for

air discharge is required.

• The downward air discharge is also available. In such case,

install the base under the unit to secure enough space for air

discharge.

• In case of serial units installation, air discharge should be

upward.

1 Min. 200 mm

2 Outdoor unit

3 Air flow guide

4 Passage side

¿ Wind guard

Specifications

Model

WSP-335A

Quantity 1per unit

1

1

2

2

2

2

3

1 Mounting dimension

2 Air flow

3 3 4xØ7

Material

Galvanized sheet metal +

baked painting

Color Gray (1.0Y8.5/0.5)

Weight 5.5 kg

Accessories

Fixing screw

x 4 [M5 (SUS) x 12]

Installation manual

Installation

restriction

“Guard net”, “Air flow guide” or “Snow protection

hood” is not available to install with Wind guard

4

1

3

2

5

123

4

2 Unit Installation

34

SMGB0060 rev. 1- 12/2010

Page 43

Attaching example of air wind guard

• Attach the air flow guide to the air discharge grille with four (4) screws (supplied).

• The fixing holes are located at 4 positions on the grille. (Screw tightening torque 2.4 ~ 3.1 N.m)

• Do not remove the air discharge grille for air flow guide installation.

C A UT IO N

• If the air guide is installed without discharge grille, it may cause injury due to rotating fan.

One windguard cover installation

1 Air discharge grille

2 Wind guard

3 Air discharge grille

4 Outdoor unit

5 M5 fixing screw x4 (Accessories)

Service space

• Both sides of the outdoor unit should be open.

• No obstacles should be placed in the air discharge side.

1 Min. 200 mm

2 Outdoor unit

3 Wind guard

¿ Snow protection hood

Air discharge hood

Nº

Part name Quantity

1 Right side plate 1

2 Left side plate 1

3 Front panel 1

4 Stay 4

5 Fixing screw (Accessories)

6 Hole for safety wire rope to prevent overturning

1

2

3

4

5

123

12345

6

2 Unit Installation

35

SMGB0060 rev. 1- 12/2010

2

Page 44

Rear suction hood

Nº Part name Quantity

1 Right side plate 1

2 Left side plate 1

3 Upper front panel (Upside) 1

4 Upper front panel (Downside) 1

5 Fixing screw (Accessories)

6 Hole for safety wire rope to prevent overturning

Left suction hood

Nº

Part name Quantity

1 Right side plate 1

2 Left side plate 1

3 Front panel (Upside) 1

4 Front panel (Downside) 1

5 Fixing hole x 2

6 Fixing screw (Accessories)

A Enlarged view of A (Fixing Hole)

Attaching example of snow protection hood

11111234ABC56

7

1. Fixing screw (Accessories).

2. Rear suction hood

3. Wire rope (Optional. For overturning protection)

4. Air discharge grille

5. Left suction hood

6. Air discharge hood

A. Left side

B. Front side

C. Rear side

12345621345

6

AAA

2 Unit Installation

36

SMGB0060 rev. 1- 12/2010

Page 45

Specifications of snow protection hood

Product name Air discharge hood Rear suction hood Left suction hood

Model ASG-NP335F ASG-NP335FS2 ASG-NP80B ASG-NP160BS2 ASG-NP80L ASG-NP160LS2

Quantity 2 per unit 1 per unit

Material

Bonderized steel

sheet

Iron

Stainless

(NSSC 180)

Bonderized steel

sheet

Iron

Stainless (NSSC

180)

Bonderized steel

sheet

Iron

Stainless (NSSC

180)

Color

Gray (1.0Y8.5/0.5

or approximation)

—

Gray (1.0Y8.5/0.5

or approximation)

—

Gray (1.0Y8.5/0.5

or approximation)

—

Weight 3 kg 14 kg 8 kg

Assembling Knockingdown parts (assembled at field)

Components

Hood For air discharge part x 1

For rear side air intake x 1

(Upper side x 1, lowe side x 1)

For left side air intake x 1

Unit Fixing

screw

4 (M5x12 tapping screw) 5 (M5x14 tapping screw) 6 (M5x12 tapping screw)

Unit Fixing

screw (SUS)

6 (M5x12 tapping

screw)

6 (M5x14)

12 (M5x12 tapping

screw)

12 (M5x14)

10 (M5x12 tapping

screw)

10 (M5x14)

Installation manual

Installation restriction

Installation with “Guard net” or “Wind guard”

is not available

Installation with “Guard net” is not available

Safety wire rope for overturning

prevention (optional parts)

ASG-SW20A

2.7.3 Optional parts and installation RAS-(4-6)H(V)RNM1E / RAS-(8/10)HRNSE

¿ Air flow guide, wind guard and snow protection hood

Optional parts

Model

Air flow guide AG-335A X 2

1 2

3

1 Air flow guide

2 Wind Guard

3 Snow protection hood

Wind guard

WSP-335A X 2

Snow

protection

hood

Zinc plate

Air outlet ASG-NP335F X 2

Air inlet of rear side ASG-NP280B

Air inlet of side face ASG-NP280L

Stainless plate

(NSSC 180)

Air outlet ASG-NP335FS 2X 2

Air inlet of rear side ASG-280BS2

Air inlet of side face ASG-NP280LS2

2 Unit Installation

37

SMGB0060 rev. 1- 12/2010

2

Page 46

¿ Air flow guide

Specifications

Model

AG-335A Image

Quantity 2 per unit

1

1

2

1 Mounting dimension

2 Air flow guide

Air discharge

direction

Upward (downward),

left & right

Material

Weather proof

polypropylene resin

Color Gray

Weight 1.9 kg

Accessories

Fixing screw x 4

[M5 (SUS) x 20]

Installation manual

Installation

restriction

“Wind Guard” or “Snow protection hood” is not

available to install with air flow guide. (“Guard net” is

available to be installed together.)

Attaching example of air flow guide

• Attach the air flow guide to the air discharge grille with four (4) screws (supplied).

• The fixing holes are located at 4 positions on the grille. (Screw tightening torque 2.4 ~ 3.1 N.m)

• Do not remove the air discharge grille for air flow guide installation.

C A UT IO N

• If the air guide is installed without discharge grille, it may cause injury due to rotating fan.

Two flow guides installation

1 Air discharge grille

2 Air flow

3 Air flow guide (see the note)

4 Outdoor Unit

5 M5 fixing screw x4 (Accessories)

N O TE

• Air flow direction of both air flow guides should be the

same.

Service space (In case of upward air discharge)

• In case of right and left sides air discharge, enough space for

air discharge is required.

• The downward air discharge is also available. In such case,

install the base under the unit to secure enough space for air

discharge.

• In case of serial units installation, air discharge should be

upward.

1 Min. 200 mm

2 Outdoor unit

1223355

4

123

4

2 Unit Installation

38

SMGB0060 rev. 1- 12/2010

Page 47

3 Air flow guide

4 Passage side

¿ Wind guard

Specifications

Model WSP-335A

Quantity 2 per unit

1

1

2

2

2

2

3

1 Mounting dimension

2 Air flow

Material

Galvanized sheet metal +

baked painting

Color Gray (1.0Y8.5/0.5)

Weight 5.5 kg

Accessories

Fixing screw

x 4 [M5 (SUS) x 12]

Installation manual

Installation

restriction

“Guard net”, “Air flow guide” or “Snow protection

hood” is not available to install with Wind guard

Attaching example of air wind guard

• Attach the air flow guide to the air discharge grille with four (4) screws (supplied).

• The fixing holes are located at 4 positions on the grille. (Screw tightening torque 2.4 ~ 3.1 N.m)

• Do not remove the air discharge grille for air flow guide installation.

C A UT IO N