Page 1

NO. 0019E

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

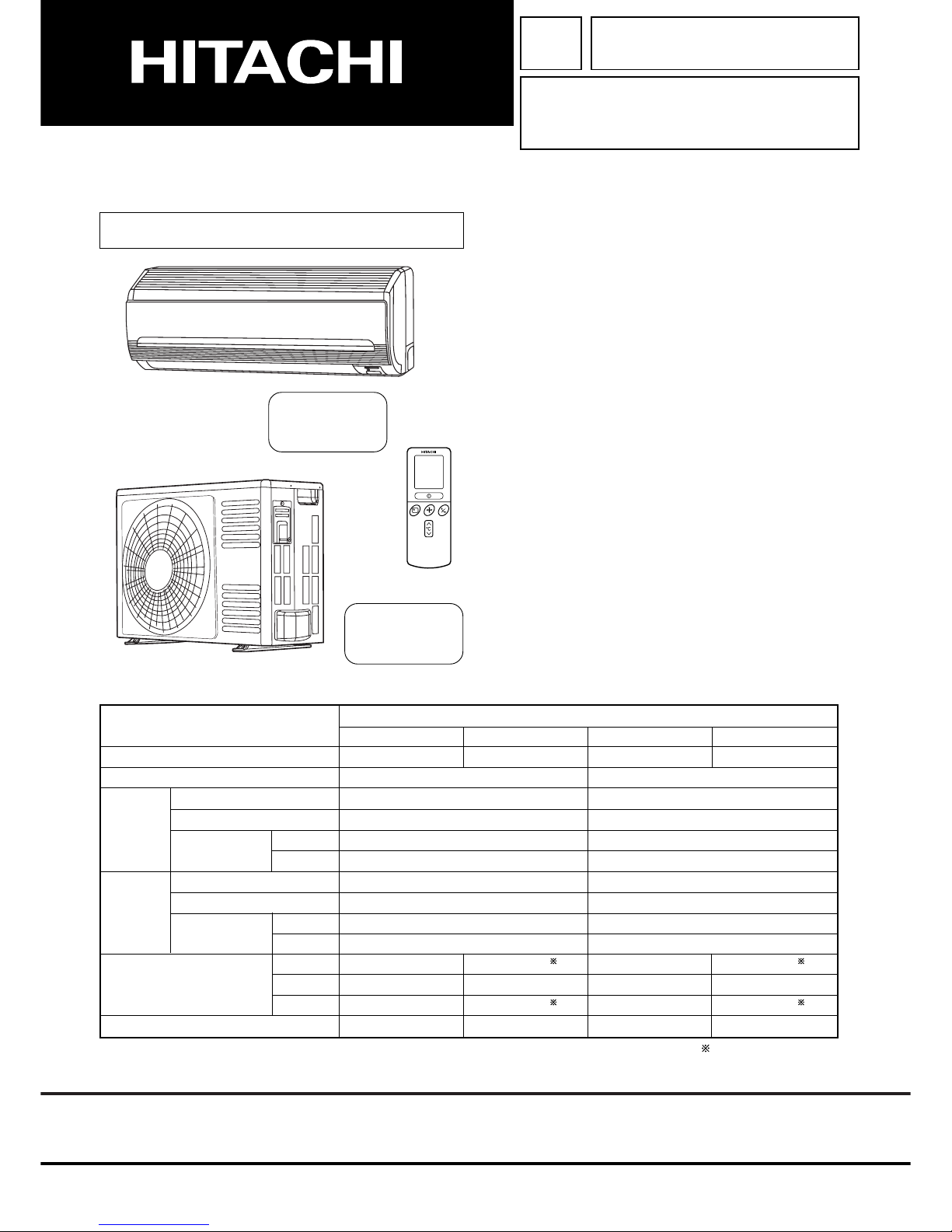

ROOM AIR CONDITIONER

INDOOR UNIT + OUTDOOR UNIT

DECEMBER 2006 Hitachi Household Appliances(Wuhu) Co.,Ltd.

SERVICE MANUAL

AW

REFER TO THE FOUNDATION MANUAL

TECHNICAL INFORMATION

FOR SERVICE PERSONNEL ONLY

(W)

(A)

(kW)

(B.T.U./h)

(W)

(A)

(kW)

(B.T.U./h)

W

H

D

(kg)

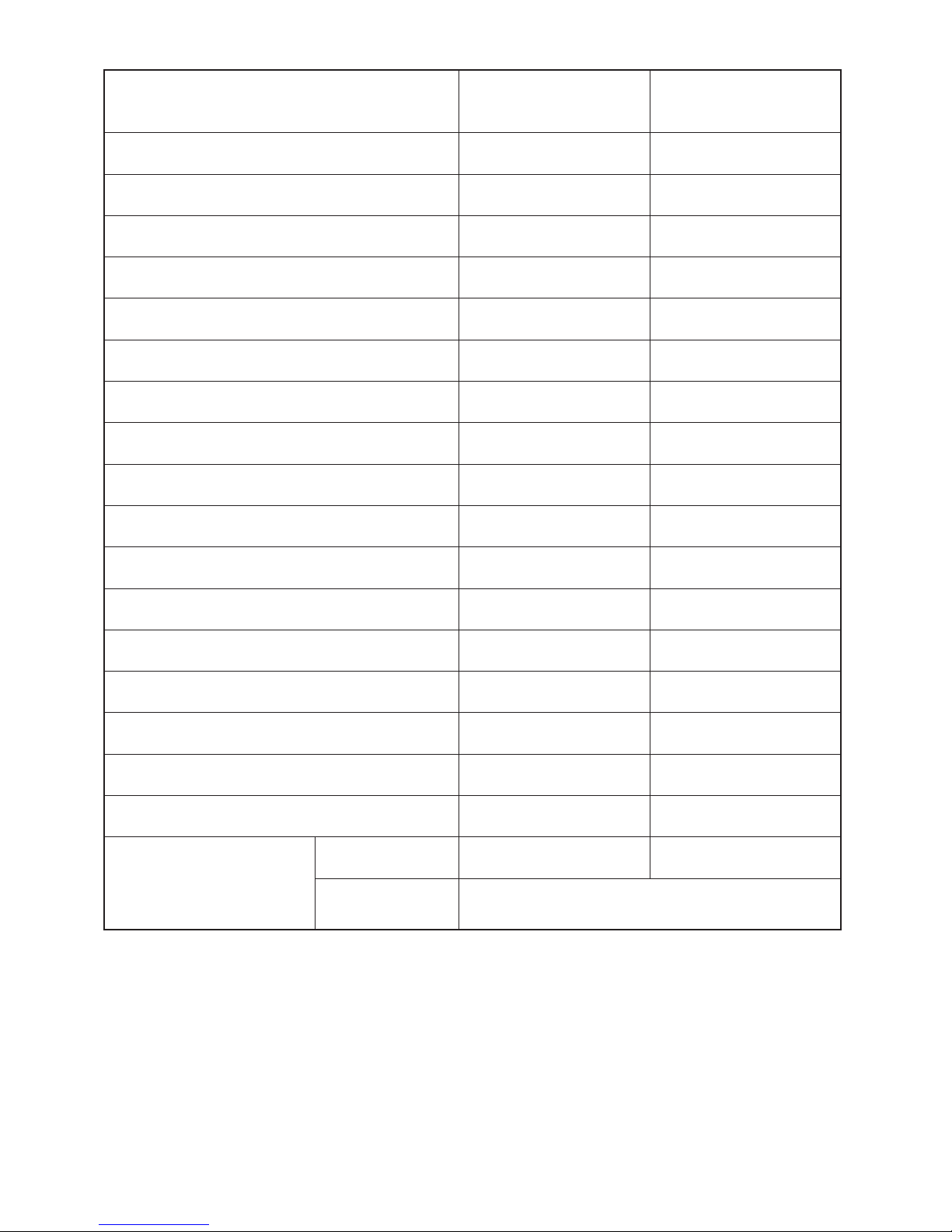

RAS-18YH6 RAC-18YH6

DC INVERTER (WALL TYPE)

TYPE

MODEL

POWER SOURCE

TOTAL INPUT

TOTAL AMPERES

CAPACITY

TOTAL INPUT

TOTAL AMPERES

CAPACITY

DIMENSIONS

(mm)

NET WEIGHT

SPECIFICATIONS

780

280

210

9.5

RAS-18YH6

RAS-25YH6

CONTENTS

SPECIFICATIONS ------------------------------------------------------------------- 4

HOW TO USE ----------------------------------------------------------------------- 5

CONSTRUCTION AND DIMENSIONAL DIAGRAM --------------------- 15

MAIN PARTS COMPONENT --------------------------------------------------- 17

WIRING DIAGRAM ---------------------------------------------------------------- 19

CIRCUIT DIAGRAM --------------------------------------------------------------- 20

RAS-18YH6/RAC-18YH6

RAS-25YH6/RAC-25YH6

RAC-18YH6

RAC-25YH6

COOLING

HEATING

INDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

1 PHASE, 50 Hz, 220-230V

550 (155 ~ 1,010)

2.95-2.81

2.00 (0.90 ~ 2.50)

6,820 (3,070 ~ 8,530)

580 (115 ~ 970)

2.93-2.81

2.50 (0.90 ~ 3.20)

8,530 (3,070 ~ 10,920)

505

27

780

280

210

9.5

505

27

1 PHASE, 50 Hz, 220-230V

700 (155 ~ 1,290)

3.75-3.59

2.50 (0.90 ~ 3.10)

8,530 (3,070 ~ 10,580)

880 (115 ~ 1,250)

4.45-4.26

3.40 (0.90 ~ 4.40)

11,600 (3,070 ~ 15,010)

After installation

RAS-25YH6 RAC-25YH6

BLOCK DIAGRAM ----------------------------------------------------------------- 22

BASIC MODE ----------------------------------------------------------------------- 23

REFRIGERATING CYCLE DIAGRAM --------------------------------------- 29

DESCRIPTION OF MAIN CIRCUIT OPERATION ----------------------- 30

SERVICE CALL Q & A ---------------------------------------------------------- 60

TROUBLE SHOOTING ----------------------------------------------------------- 63

PROCEDURE FOR DISASSEMBLY AND REASSEMBLY ------------ 87

PARTS LIST AND DIAGRAM -------------------------------------------------- 89

700 (+68) 700 (+68)

258 (+48) 258 (+48)

Page 2

SAFETY DURING REPAIR WORK

First, I must disconnect

the power cord plug

from the power outlet.

1. In order to disassemble and repair the unit

in question, be sure to disconnect the power

cord plug from the power outlet before

starting the work.

2. If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit, and

the replacement must be effected in correct manner according to the instructions in the Service Manual of the

unit.

If the contacts of electrical

parts are defective, replace the

electrical parts without trying to

repair them.

3. After completion of repairs, the initial state should

be restored.

4. Lead wires should be connected and laid as in the

initial state.

5. Modification of the unit by user himself should

absolutely be prohibited.

6. Tools and measuring instruments for use in repairs or inspection should be accurately calibrated in advance.

7. In installing the unit having been repaired, be careful to prevent the occurence of any accident such as

electrical shock, leak of current, or bodily injury due to the drop of any part.

8. To check the insulation of the unit, measure the insulation resistance between the power cord plug and grounding

terminal of the unit. The insulation resistance should be 1MΩ or more as measured by a 500V DC megger.

9. The initial location of installation such as window, floor or the other should be checked for being and safe

enough to support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location reinforced or at a new

location.

10. Any inflammable thing should never be placed about the location of installation.

11. Check the grounding to see whether it is

proper or not, and if it is found improper,

connect the grounding terminal to the earth.

DANGER

Page 3

– 1 –

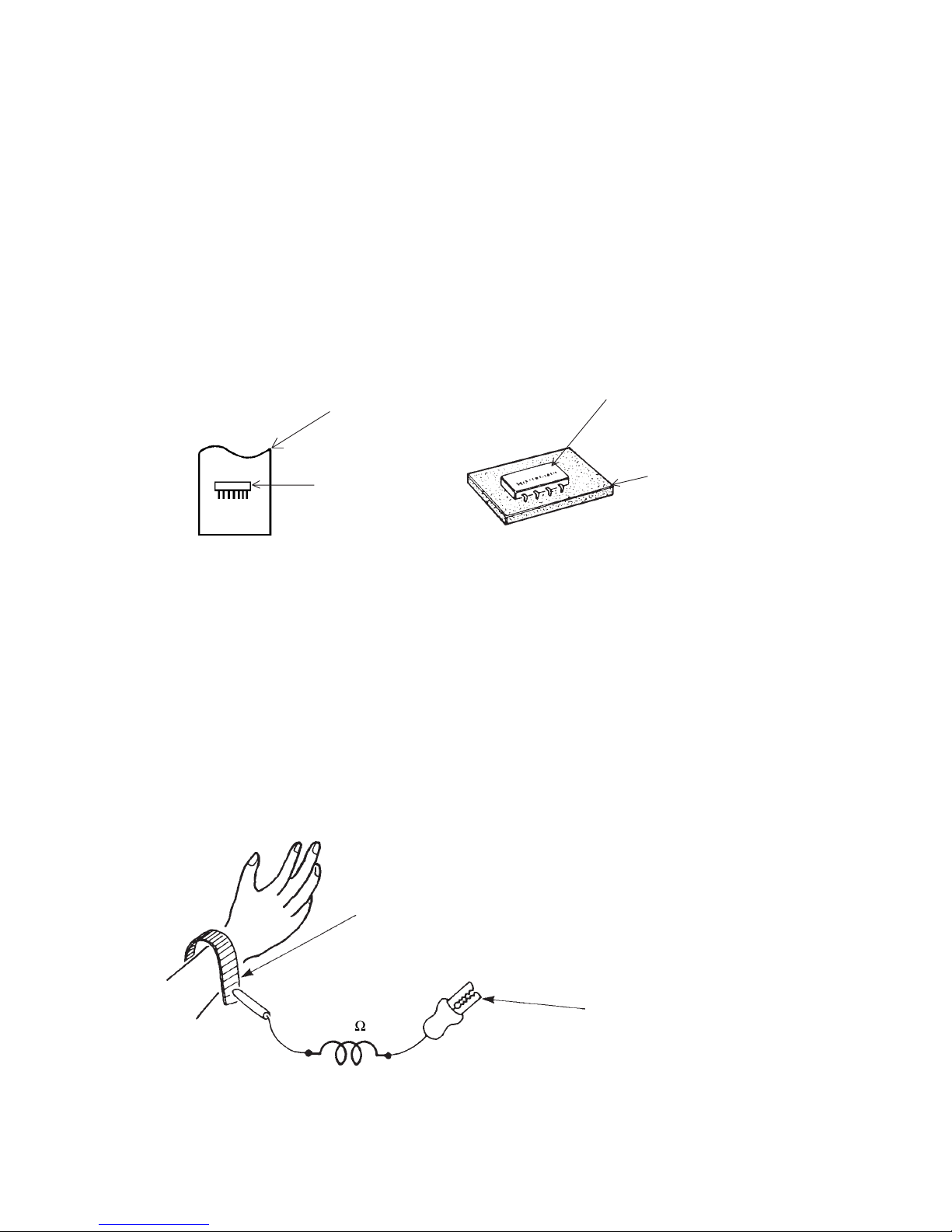

WORKING STANDARDS FOR PREVENTING BREAKAGE OF SEMICONDUCTORS

1. Scope

The standards provide for items to be generally observed in carrying and handling semiconductors in relative

manufacturers during maintenance and handling thereof. (They apply the same to handling of abnormal

goods such as rejected goods being returned).

2. Object parts

(1) Micro computer

(2) Integrated circuits (IC)

(3) Field-effect transistors (FET)

(4) P.C. boards or the like on which the parts mentioned in (1) and (2) of this paragraph are equipped.

3. Items to be observed in handling

(1) Use a conductive container for carrying and storing of parts. (Even rejected goods should be handled in

the same way).

Fig. 1 Conductive Container

IC

A conductive polyvinyl bag

IC

Conductive sponge

(2) When any part is handled uncovered (in counting, packing and the like), the handling person must always

use himself as a body earth. (Make yourself a body earth by passing one M ohm earth resistance through

a ring or bracelet).

(3) Be careful not to touch the parts with your clothing when you hold a part even if a body earth is being

taken.

(4) Be sure to place a part on a metal plate with grounding.

(5) Be careful not to fail to turn off power when you repair the printed circuit board. At the same time, try to

repair the printed circuit board on a grounded metal plate.

1M

Fig. 2 Body Earth

Body earth

(Elimik conductive band)

Clip for connection with a

grounding wire

Page 4

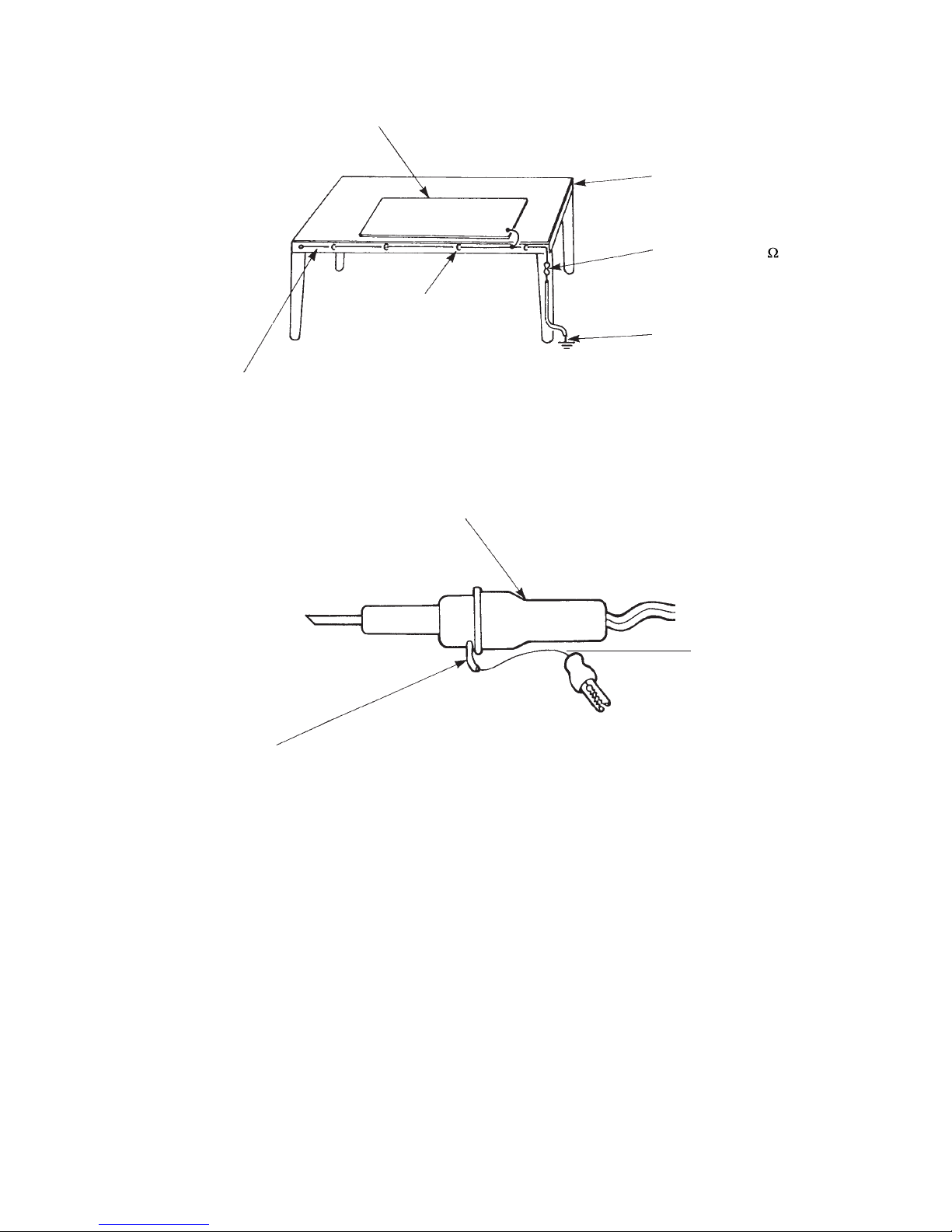

– 2 –

(6)Use a three wire type soldering iron including a grounding wire.

Use a high insulation mode (100V, 10M or higher) when ordinary iron is to be used.

(7) In checking circuits for maintenance, inspection or some others, be careful not to have the test probes of

the measuring instrument shortcircuit a load circuit or the like.

Bare copper wire (for body earth)

Working

table

Resistor of 1 M

(1/2W)

Earth wire

Fig. 3 Grounding of the working table

Metal plate (of aluminium, stainless steel, etc.)

Staple

Screw stop at the screwed

part using a rag plate

Soldering iron

Grounding

wire

Fig. 4 Grounding a soldering iron

Page 5

– 3 –

1. In quiet operation or stopping the running, slight flowing noise of refrigerant in the refrigerating cycle is

heard occasionally, but this noise is not abnormal for the operation.

2. When it thunders near by, it is recommend to stop the operation and to disconnect the power cord plug from

the power outlet for safety.

3. The room air conditioner does not start automatically after recovery of the electric power failure for prevent-

ing fuse blowing. Re-press START/STOP button after 3 minutes from when unit stopped.

4. If the room air conditioner is stopped by adjusting thermostat, or missoperation, and re-start in a moment,

there is occasion that the cooling and heating operation does not start for 3 minutes, it is not abnormal and

this is the result of the operation of IC delay circuit. This IC delay circuit ensures that there is no danger of

blowing fuse or damaging parts even if operation is restarted accidentally.

5. This room air conditioner should not be used at the cooling operation when the outside temperature is

below -10°C (14°F).

6. This room air conditioner (the reverse cycle) should not be used when the outside temperature is below

–15°C (5°F).

If the reverse cycle is used under this condition, the outside heat exchanger is frosted and efficiency falls.

7. When the outside heat exchanger is frosted, the frost is melted by operating the hot gas system, it is not

trouble that at this time fan stops and the vapour may rise from the outside heat exchanger.

!

CAUTION

Page 6

– 4 –

SPECIFICATIONS

MODEL

FAN MOTOR

FAN MOTOR CAPACITOR

FAN MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR MOTOR CAPACITOR

OVERLOAD PROTECTOR

OVERHEAT PROTECTOR

FUSE (for MICROPROCESSOR)

POWER RELAY

POWER SWITCH

TEMPORARY SWITCH

SERVICE SWITCH

TRANSFORMER

VARISTOR

NOISE SUPPRESSOR

THERMOSTAT

REMOTE CONTROL SWITCH (LIQUID CRYSTAL)

40 W

NO

NO

NO

ASC092CD

YES

YES

3.0A

G4A

NO

NO

YES

NO

450NR

YES

YES(IC)

NO

WITHOUT REFRIGERANT BECAUSE

COUPLING IS FLARE TYPE.

UNIT

PIPES (MAX. 20m)

REFRIGERANT CHARGING

VOLUME

(Refrigerant 410A)

RAC-18YH6

RAC-25YH6

820g

RAS-18YH6

RAS-25YH6

PWM DC35V

NO

NO

–

NO

NO

NO

NO

NO

YES

NO

NO

NO

NO

YES(IC)

YES

----------

YES

Page 7

– 2 –

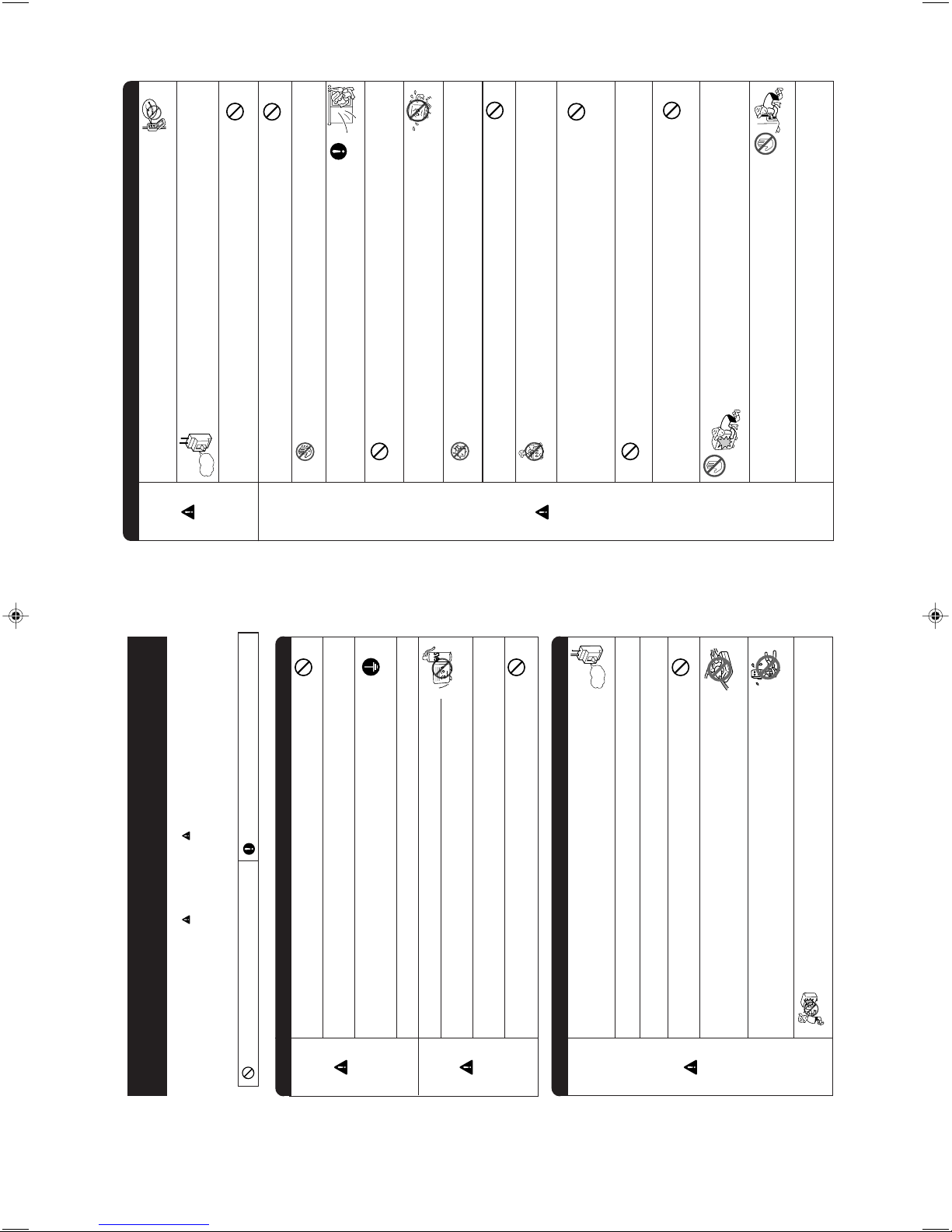

SAFETY PRECAUTION

• Please read the “Safety Precaution” carefully before operating the unit to ensure correct usage of the unit.

• Pay special attention to signs of “

Warning” and “ Caution”. The “Warning” section contains

matters which, if not observed strictly, may cause death or serious injury. The “Caution” section

contains matters which may result in serious consequences if not observed properly. Please observe

all instructions strictly to ensure safety.

• The signs indicate the following meanings. (The following are examples of signs.)

• Please keep this manual after reading.

This sign in the figure indicates prohibition. Indicates the instructions that must be followed.

WARNING

CAUTION

• Do not reconstruct the unit.

Water leakage, fault, short circuit or fire may occur if you reconstruct the unit by

yourself.

• Please ask your sales agent or qualified technician for the installation of your

unit.

Water leakage, short circuit or fire may occur if you install the unit by yourself.

• Please use earth line.

Do not place the earth line near water or gas pipes, lightning-conductor, or the

earth line of telephone. Improper installation of earth line may cause electric

shock.

• Be sure to use the specified piping set for R410A. Otherwise, this may result in

broken copper pipes or faults.

• A circuit breaker should be installed depending on the mounting site of the unit.

Without a circuit breaker, the danger of electric shock exists.

• Do not install the unit near a location where there is flammable gas.

The outdoor unit may catch fire if flammable gas leaks around it. Piping shall be

suitable supported with a maximum spacing of 1m between the supports.

• Please ensure smooth flow of water when installing the drain hose. If any failure

is found in the drain path, water drops from the indoor and outdoor units, causing

wet household effects.

• Make sure that a single phase 230V power source is used.

The use of other power sources may cause electrical components to overheat

and lead to fire.

PROHIBITION

CONNECT EARTH LINE

PROHIBITION

PROHIBITION

• Should abnormal situation arise (like burning smell), please stop operating the

unit and remove plug from the socket or turn off the circuit breaker. Contact your

agent. Fault, short circuit or fire may occur if you continue to operate the unit

under abnormal situation.

• Please contact your agent for maintenance.

Improper self maintenance may cause electric shock and fire.

• Please contact your agent if you need to remove and reinstall the unit.

Electric shock or fire may occur if you remove and reinstall the unit yourself improperly.

WARNING

PRECAUTIONS DURING INSTALLATION

PRECAUTIONS DURING SHIFTING OR MAINTENANCE

“OFF”

PROHIBITION

• Avoid an extended period of direct air flow for your health.

• Do not connect the power calbe with an extension cable or do not plug too many

leads of the other electric appliance into the socket where this cable is plugged.

In addition, wire the cable with some allowances to prevent the cable from stretching.

Not doing so will cause an electrical shock, heat generation or fire.

PROHIBITION

• Do not put objects like thin rods into the panel of blower and suction side

because the high-speed fan inside may cause danger.

• Do not bundle the power cable, pull it, put something on it, heat it, process it, or

put it between things. Breakage of the power cable may result.

Use of a damaged cable may cause an electrical shock or a fire.

PROHIBITION

PROHIBITION

HOW TO USE

– 3 –

WARNING

PRECAUTIONS DURING OPERATION

• Do not use any conductor as fuse wire, this could cause fatal accident.

PROHIBITION

• During thunder storm, disconnect the plug top or turn off the circuit breaker.

• Spray cans and other combustibles should not be located within a meter of the air

outlets of both indoor and outdoor units.

As a spray can’s internal pressure can be increased by hot air, a rupture may result.

“OFF”

CAUTION

PROHIBITION

• The product shall be operated under the manufacturer specification and not for

any other intended use.

PROHIBITION

DON’T WET

• Do not attempt to operate the unit with wet hands, this could cause fatal accident.

STRICTLY OBSERVE

PRECAUTIONS

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

• When operating the unit with burning equipments, regularly ventilate

the room to avoid oxygen insufficiency.

• Do not direct the cool air coming out from the air-conditioner panel to

face household heating apparatus as this may affect the working of

apparatus such as the electric kettle, oven etc.

• Do not wash the unit with water or place a water container such as a

vase on the indoor unit.

Electrical leakage could be present and cause electric shock.

• Please ensure that outdoor mounting frame is always stable, firm and

without defect. If not, the outdoor unit may collapse and cause danger.

• Do not place plants or animals directly under the air flow as it is bad for the plants or

animals.

• Do not climb on the outdoor unit or put objects on it.

PROHIBITION

PROHIBITION

PROHIBITION

DON’T TOUCH

DON’T TOUCH

• When operating the unit with the door and windows opened, (the room humidity

is always above 80%) and with the air deflector facing down or moving automati-

cally for a long period of time, water will condense on the air deflector and drips

down occasionally. This will wet your furniture. Therefore, do not operate under

such condition for a long time.

• If the amount of heat in the room is above the cooling or heating capability of the

unit (for example: more people entering the room, using heating equipments and

etc.), the preset room temperature cannot be achieved.

• This appliance especially indoor unit cleaning must be performed by authorized

personnel only. Consult your sales agent.

Using a commercially available detergent or similar can damage the plastic parts

or clog the drain pipe, causing water to drip with potential electric shock hazard.

• Do not touch the air outlet, bottom surface and aluminum fin of the outdoor

unit.

You may get hurt.

• Do not touch the refrigerant pipe and connecting valve.

Burns may result.

• This appliance is not intended for use by young children or infirm persons unless they have been

adequately supervised by a responsible person to ensure that they can use this appliance safely.

• Young children should be supervised to ensure that they do not play with the appliance.

– 5 –

Page 8

– 4 –

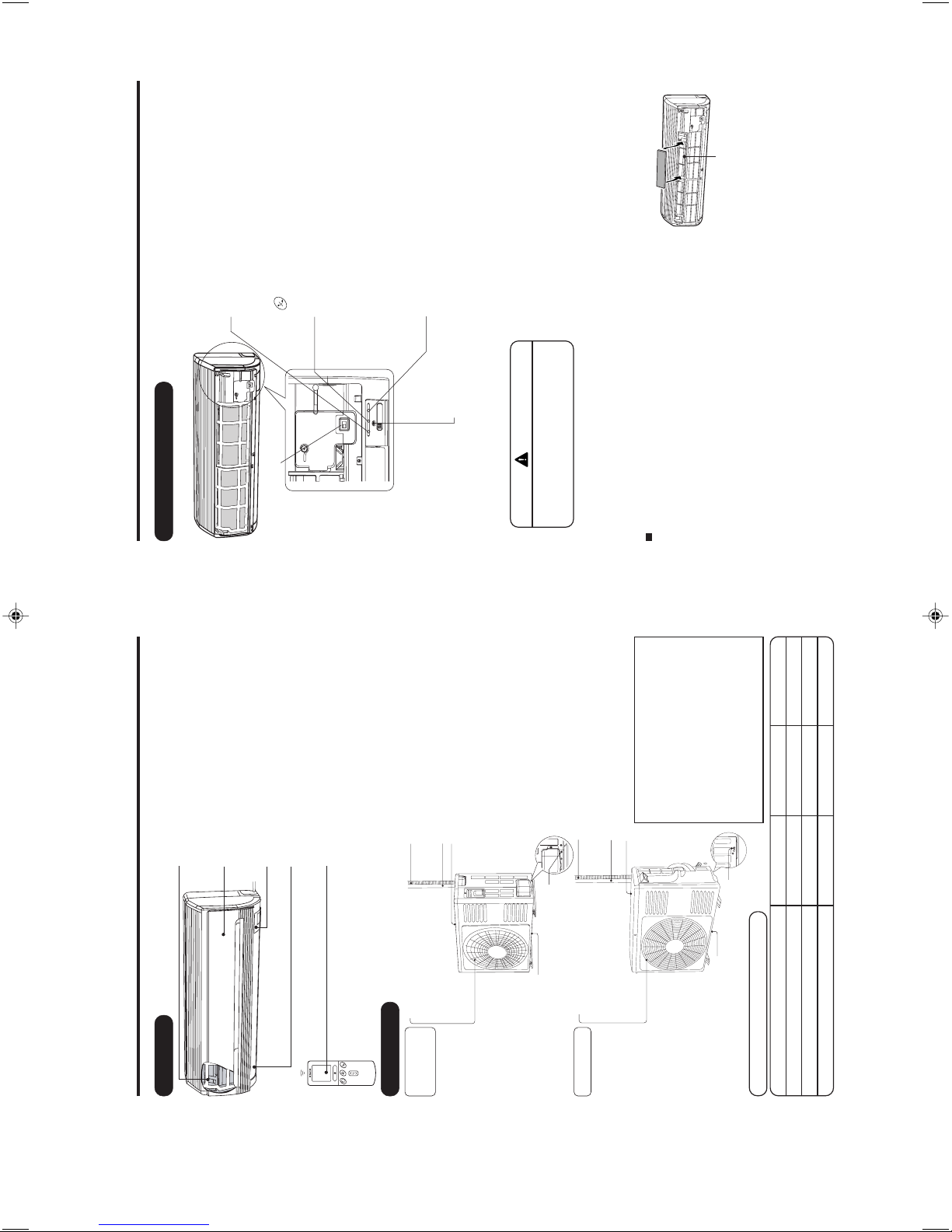

NAMES AND FUNCTIONS OF EACH PART

INDOOR UNIT

Air filter

To prevent dust from coming into the indoor unit.

(Refer page 16)

Front panel

Indoor unit indicators

Light indicator showing the operating condition.

(Refer page 5)

Horizontal deflector Vertical deflector

(Air Outlet)

(Refer page 15)

Remote controller

Send out operation signal to the indoor unit. So as

to operate the whole unit.

(Refer page 6)

MODEL NAME AND DIMENSIONS

About the outdoor unit:

• When “Stop” is selected during operation

of the indoor unit, the fan of the outdoor

unit continues turning for 10 to 60

seconds to cool the electric parts down.

• In heating operation, condensate or

water due to defrosting will flow.

Do not cover the drain port of the outdoor

unit because such water may freeze in

the chilly area.

• When the outdoor unit is hung on the

ceiling, install the bush and drain pipe

on the drain port and drain water.

MODEL WIDTH (mm) HEIGHT (mm) DEPTH (mm)

RAS-18YH6, RAS-25YH6, RAS-35YH6 780 280 210

RAC-18YH6, RAC-25YH6 700 505 258

RAC-35YH6 750 548 288

Air outlet

When “ heating” operation is

performed, cool air blows and

when “cooling” or “dehumidifying”

operation is performed, warm air

blows.

Drain hose

Drains the dehumidified water from the indoor unit to the

outdoor during “cooling” or “dehumidifying” operation.

Piping and Wiring

Air inlets (Rear and left sides)

Drain port

(Bottom)

Earth terminal

(Lower section of the side)

Air outlet

When “ heating” operation is

performed, cool air blows and

when “cooling” or “dehumidifying”

operation is performed, warm air

blows.

Drain hose

Drains the dehumidified water from the indoor unit to the

outdoor during “cooling” or “dehumidifying” operation.

Piping and Wiring

Air inlets (Rear and left sides)

Drain port

(Bottom)

Earth terminal

(Lower section of the side)

RAC-35YH6

RAC-18YH6

RAC-25YH6

OUTDOOR UNIT

– 5 –

NAMES AND FUNCTIONS OF EACH PART

INDOOR UNIT INDICATIONS

TIMER LAMP (Orange)

This lamp lights when the timer is working.

FILTER LAMP (Green)

When the device is operated for a total of about 200

hours, the FILTER lamp lights indicates that it is time

to clean the filter.The lamp goes out when the

“

(AUTO SWING)” button is pressed while the

operation is stopped.

OPERATION LAMP (Yellow)

This lamp lights during operation.

The OPERATION LAMP flashes in the following

cases during heating.

(1) During preheating

For about 2-3 minutes after starting up.

(2) During defrosting

Defrosting will be performed about once an hour

when frost forms on the heat exchanger of the

outdoor unit, for 5-10 minutes each time.

TEMPORARY SWITCH

●

Use this switch to start and stop when the remote controller does not work.

●

This temporary operation will be at the most recent setting made. (The unit

will immediately go into automatic operation once power is switched on.)

CAUTION

Turn off the circuit breaker or pull out

the power plug if the unit is not be

operated for a long period.

✩ If the power stays on and the unit is not operated, power is slightly consumed in the control circuit.

The power is saved by turning off the power switch (or the circuit breaker when the power is supplied

from the outdoor unit).

Attaching the air cleansing and deodorizing filters (Accessories) to the filter frame.

• Attach the air cleansing and deodorizing filters to the frame by

gently compress its both sides and release after insertion into

filter frame.

• The cooling capacity is slightly weakened and the cooling speed

becomes slower when the air cleansing and deodorizing filters

are used.

• Air cleansing and deodorizing filters are washable and reusable up to 20 times by using vacuum

cleaner or water rinse under running tap water. When you want to renew it, please ask your sales

agent.

Frame

POWER SWITCH

– 6 –

Page 9

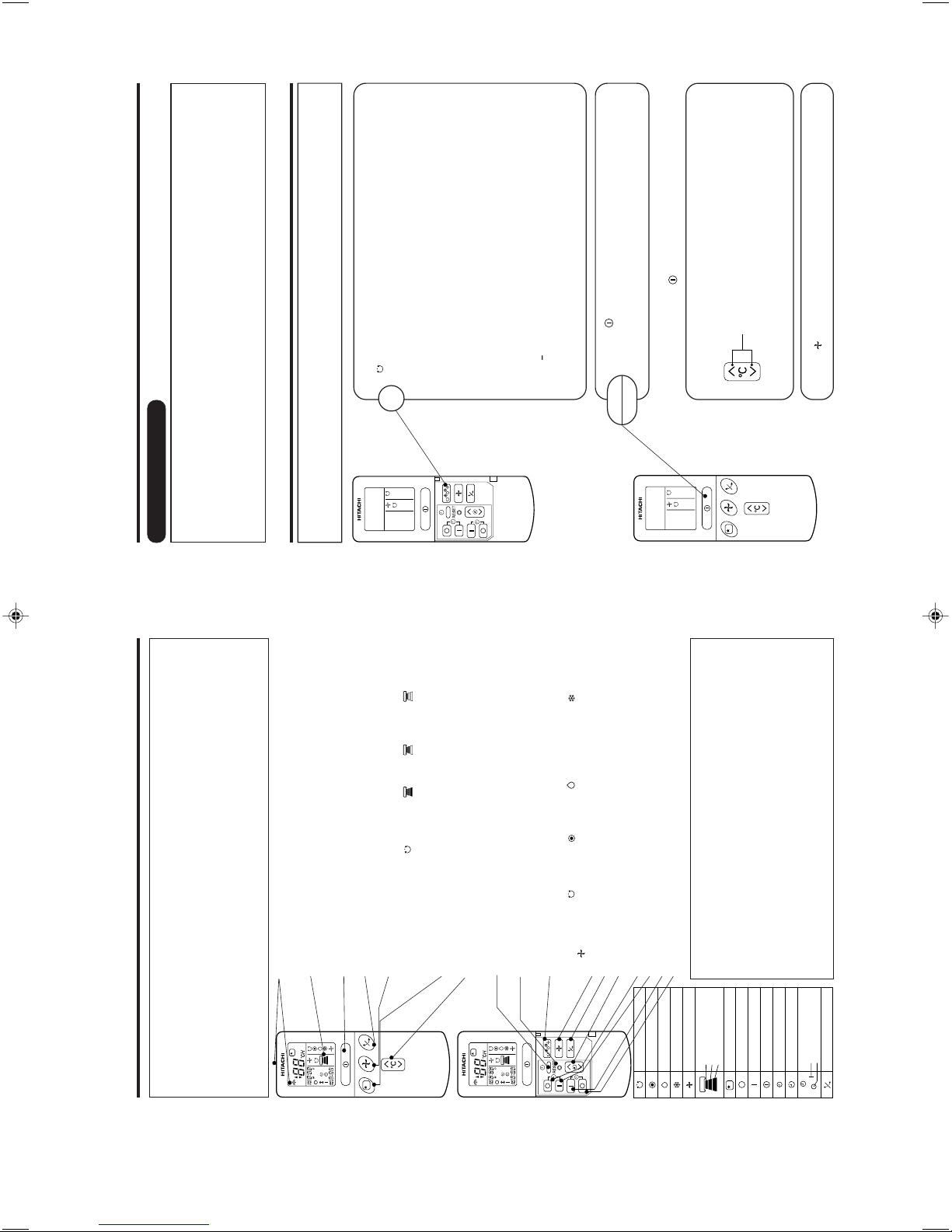

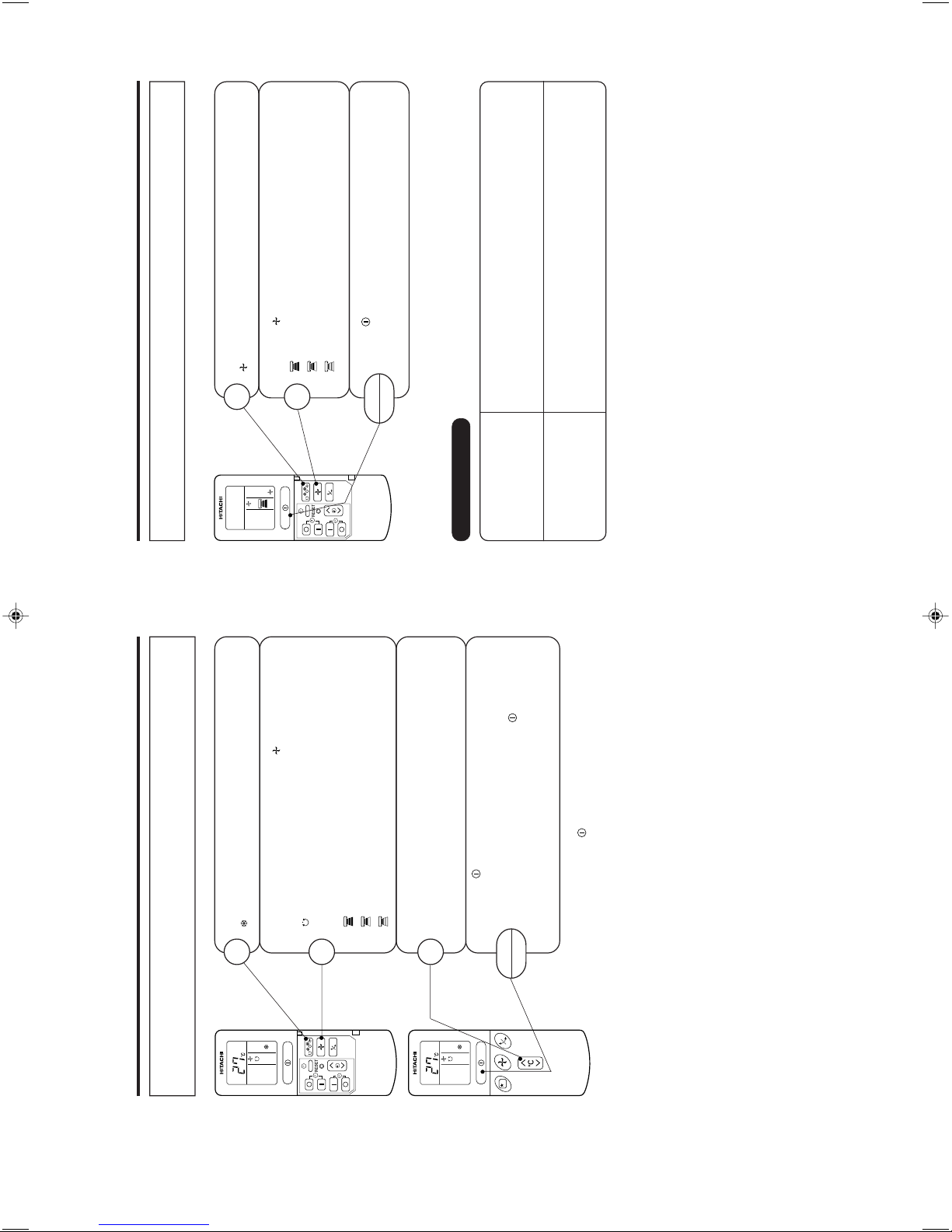

– 6 – – 7 –

● Signal emitting window/transmission sign

Point this window toward the indoor unit when controlling it.

The transmission sign blinks when a signal is sent.

● Display

This indicates the room temperature selected, current time, timer status,

function and intensity of circulation selected.

● START/STOP button

Press this button to start operation. Press it again to stop operation.

● AUTO SWING button

Controls the angle of the horizontal air deflector.

● FAN SPEED selector

This determines the fan speed. Every time you press this button, the intensity of

circulation will change from (AUTO) to (HI) to (MED) to (LOW).

(This button allows selecting the optimal or preferred fan speed for each

operation mode.)

● SLEEP button

Use this button to set the sleep timer.

● TEMPERATURE buttons

Use these buttons to raise or lower the temperature setting. (Keep pressed, and

the value will change more quickly.)

● TIME button

Use this button to set and check the time and date.

● RESET button

Press this button after the batteries are replaced or when some irregular

operation is found.

● FUNCTION selector

Use this button to select the operating mode. Every time you press it, the mode

will change from (AUTO) to (HEAT) to (DEHUMIDIFY) to (COOL) and

to (FAN) cyclically.

● FAN SPEED selector

● AUTO SWING button

● TIMER control

Use these buttons to set the timer.

● OFF-TIMER button Select the turn OFF time.

● ON-TIMER button Select the turn ON time.

● RESERVE button Time setting reservation.

● CANCEL button Cancel time reservation.

VARIOUS FUNCTIONS

■ Auto Restart Control

• If there is a power failure, operation will be automatically restarted when the power is resumed with

previous operation mode and airflow direction.

(As the operation is not stopped by remote controller.)

• If you intend not to continue the operation when the power is resumed, switch off the power supply.

When you switch on the circuit breaker, the operation will be automatically restarted with previous

operation mode and airflow direction.

Note: 1. If you do not require Auto Restart Control, please consult your sales agent.

2. Auto Restart Control is not available when Timer or Sleep Timer mode is set.

AUTOMATIC OPERATION

The device will automatically determine the mode of operation, HEAT or COOL depending on the

initial room temperature. The selected mode of operation will change when the room temperature

varies.

Press the FUNCTION selector so that the display indicates the

(AUTO) mode of operation.

• When AUTO has been selected, the device will automatically

determine the mode of operation, HEAT or COOL depending

on the current room temperature.

• When AUTO is first selected, the device will determine the

current room temperature and select the proper operation

mode accordingly.

• When the air conditioner has adjusted the room's temperature

to the near preset temperature, it will begin to monitor

operation. If the room temperature subsequently changes,

the air conditioner will once again select the appropriate

operation (heating or cooling) to adjust the temperature to

the preset temperature. The monitoring operation range is

+

3°C relative to the preset temperature.

• If the mode automatically selected by the unit is not

satisfactory, manually change the mode setting (heat,

dehumidify, cool or fan).

1

NAMES AND FUNCTIONS OF EACH PART

REMOTE CONTROLLER

• This controls the operation of the indoor unit.

The range of control is about 7 meters. If indoor lighting is controlled electronically, the range of

control may be shorter, in some cases, the control signal may not be received.

This unit can be fixed on a wall using the fixture provided. Before fixing it, make sure the indoor unit

can be controlled from the remote controller.

• Handle the remote controller with care.

Dropping it or getting it wet may compromise its signal transmission capability.

• After new batteries are inserted into the remote controller, the unit will initially require approximately

10 seconds to respond to commands and operate.

Precautions for Use

• Do not put the remote controller in the following places.

• In direct sunlight

• In the vicinity of a heater.

• Handle the remote controller carefully. Do not drop it on the floor, and

protect it from water.

• Once the outdoor unit stops, it will not restart for about 3 minutes (unless

you turn the power switch off and on or unplug the power cord and plug

it in again).

This is to protect the device and does not indicate a failure.

• If you press the FUNCTION selector button during operation, the device

may stop for about 3 minutes for protection.

AUTO

HEAT

DEHUMIDIFY

COOL

FAN

FAN SPEED

LOW

MED

HI

SLEEPING

STOP (CANCEL)

START (RESERVE)

START/STOP

TIME

TIMER SET

TIMER SELECTOR

ON TIMER

OFF TIMER

AUTO SWING

Press the (START/STOP) button.

Operation starts with a beep.

Press the button again to stop operation.

Press the (FAN SPEED) button, AUTO and LOW is available.

■ As the settings are stored in memory in the remote controller, you

only have to press the

(START/STOP) button next time.

You can raise or lower the temperature setting as necessary by

maximum of 3°C.

Press the temperature button and the temperature

setting will change by 1°C each time.

• The preset temperature and the actual room temperature may

vary somewhat depending on conditions.

START

STOP

– 7 –

Page 10

– 8 –

Press the (START/STOP) button. Heating operation starts

with a beep. Press the button again to stop operation.

START

STOP

HEATING OPERATION

• Use the device for heating when the outdoor temperature is under 21°C.

When it is too warm (over 21°C), the heating function may not work in order to protect the device.

• In order to keep reliability of the device, please use this device above -15°C of the outdoor

temperature.

Press the FUNCTION selector so that the display indicates

(HEAT).

1

Set the desired FAN SPEED with the (FAN SPEED) button

(the display indicates the setting).

(AUTO) : The fan speed changes automatically according

to the temperature of the air which blows out.

(HI) : Economical as the room will become warm

quickly.

But you may feel a chill at the beginning.

(MED) : Quiet.

(LOW) : More quiet.

2

Set the desired room temperature with the TEMPERATURE

buttons (the display indicates the setting).

The temperature setting and the actual room temperature may

vary somewhat depending on conditions.

3

■ As the settings are stored in memory in the remote controller, you

only have to press the

(START/STOP) button next time.

■ Defrosting

Defrosting will be performed about once an hour when frost forms on the heat exchange of the outdoor unit,

for 5~10 minutes each time.

During defrosting operation, the operation lamp blinks in cycle of 3 seconds on and 0.5 second off.

The maximum time for defrosting is 20 minutes.

(If the piping length used is longer than usual, frost will likely to form.)

– 9 –

DEHUMIDIFYING OPERATION

Use the device for dehumidifying when the room temperature is over 16°C.

When it is under 15°C, the dehumidifying function will not work.

Press the (START/STOP) button.

START

STOP

Press the FUNCTION selector so that the display indicates

(DEHUMIDIFY).

The FAN SPEED is set at LOW automatically.

The FAN SPEED button does not work.

1

■ When you want to change the operation mode, please use the

FUNCTION selector.

■ Set the desired temperature is available.

■ You also can use the FUNCTION selector to select this operation.

■ Dehumidifying Function

• Dehumidifying takes place with a target temperature which is slightly lower than the room

temperature setting. (However, target temperature is 16°C for a temperature setting of 16°C.)

If the room temperature becomes lower than the target value, operation stops. If the room

temperature becomes higher than the target value, operation restarts.

• The preset room temperature may not be reached depending on the number of people present in

the room conditions.

– 8 –

Page 11

– 10 –

Press the (START/STOP) button. Cooling operation starts

with a beep. Press the button again to stop operation. The cooling

function does not start if the temperature setting is higher than

the current room temperature (even though the (OPERATION)

lamp lights).

The cooling function will start as soon as you set the temperature

below the current room temperature.

START

STOP

COOLING OPERATION

Use the device for cooling when the outdoor temperature is -10 to 42°C.

If humidity is very high (over 80%) indoors, some dew may form on the air outlet grille of the indoor

unit.

Press the FUNCTION selector so that the display indicates

(COOL).

1

Set the desired FAN SPEED with the (FAN SPEED) button

(the display indicates the setting).

(AUTO) : The FAN SPEED is HI at first and varies to MED

automatically when the preset temperature has

been reached.

(HI) : Economical as the room will become cool quickly.

(MED) : Quiet.

(LOW) : More quiet.

2

Set the desired room temperature with the TEMPERATURE

buttons (the display indicates the setting).

The temperature setting and the actual room temperature may

vary somewhat depending on conditions.

3

■ As the settings are stored in memory in the remote controller, you

only have to press the

(START/STOP) button next time.

– 11 –

Press the (START/STOP) button. Fan operation star ts with a

beep.

Press the button again to stop operation.

START

STOP

FAN OPERATION

You can use the device simply as an air circulator. Use this function to dry the interior of the indoor unit

at the end of summer.

Press the FUNCTION selector so that the display indicates

(FAN).

1

Press the (FAN SPEED) button.

(HI) : The strongest air blow.

(MED) : Quiet.

(LOW) : More quiet.

2

FAN SPEED (AUTO)

… When the AUTO fan speed mode is set in the cooling/heating operation:

For the heating operation

• The fan speed will automatically change according to the temperature of

discharged air.

• As room temperature reaches the preset temperature, a very light breeze

will blow.

• Operation starts in the “HI” mode to reach the preset temperature.

• As room temperature approaches the preset temperature, fan speed auto-

matically switches to “LOW”.

For the cooling operation

– 9 –

Page 12

– 12 –

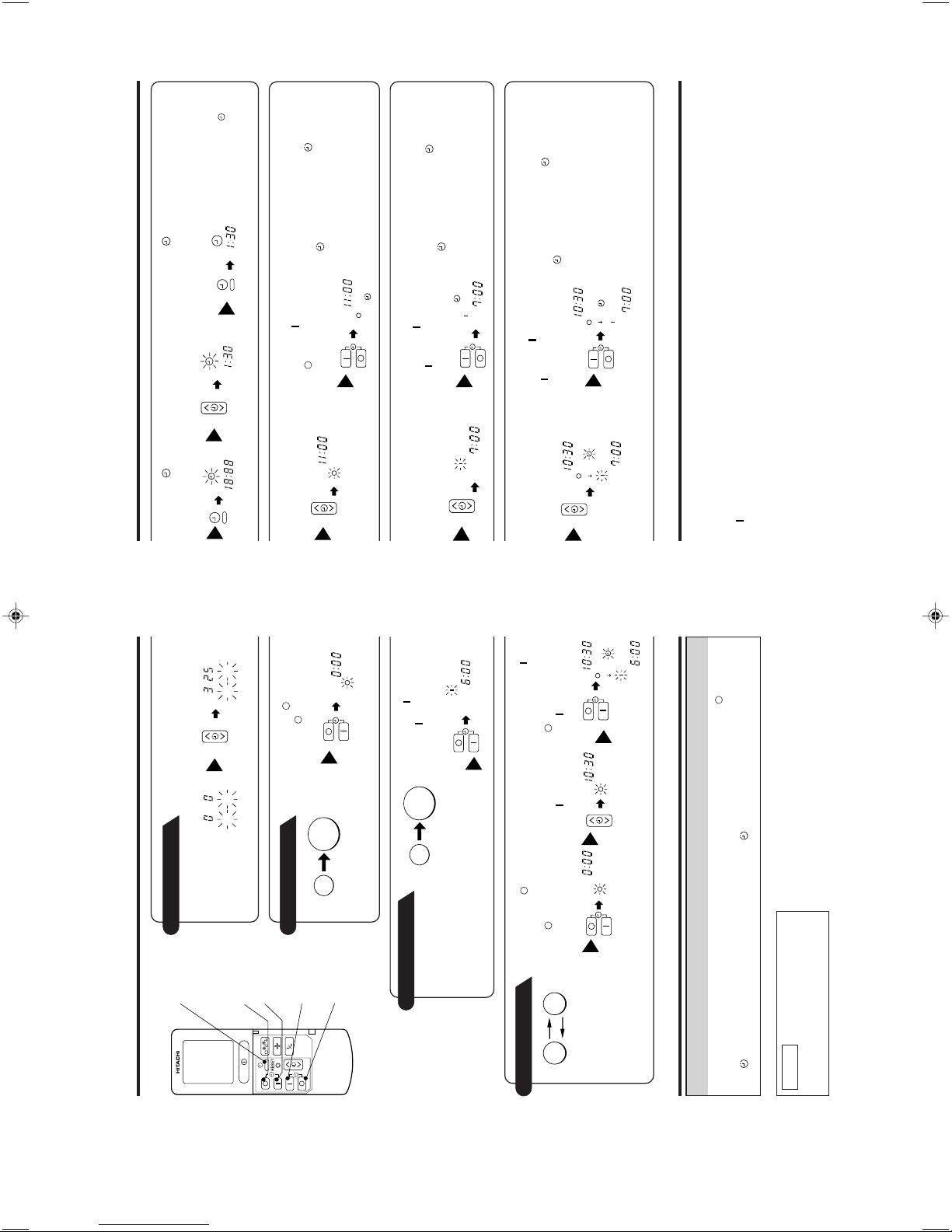

HOW TO SET THE TIMER

Time, Day, Month

TIME, DAY,

MONTH (current

time, day, month)

OFF TIMER

ON TIMER

RESERVE

CANCEL

OFF-Timer

ON-Timer

ON/OFF-Timer

1

Set the current month and day

with the TIMER control button.

DM

M D

After you change the

batteries;

Start

Stop

You can set the device to turn off at

the present time.

1

Press the (OFF-TIMER)

button. The (OFF) mar k blinks

on the display.

The device will turn on at the

designated times.

1

Press the (ON-TIMER)

button. The (ON) mark blinks on

the display.

AM

Start Stop

• The device will turn on (off) and

off (on) at the designated times.

• The switching occurs first at the

preset time that comes earlier.

• The arrow mark appear ing on the

display indicates the sequence of

switching operations.

1

Press the (OFF-

TIMER) button so that

the (OFF) mark

blinks.

2

Set the turn-off time

with the TIMER control

button.

Press the (RESERVE)

button.

PM

3

Press the (ON-

TIMER) button so that the

(OFF) mark lights and

the (ON) mark blinks.

PM

AM

How to Cancel Reservation

Point the signal window of the remote controller toward the indoor unit, and press the (CANCEL)

button.

The

(RESERVED) sign goes out with a beep and the (TIMER) lamp turns off on the indoor unit.

NOTE

You can set only one of the OFF-timer,

ON-timer and ON/OFF-timer.

Start

Stop

AM

PM

– 13 –

2

Set the

(TIME) button.

3

Set the current time with

the TIMER control button.

4

Press the (TIME)

button again. The time

indication starts lighting

instead of flashing.

• The time indication will

disappear automatically in 10

seconds.

• To check the current time

setting, press the (TIME)

button twice.

The setting of the current

time is now complete.

AM

PM

PM

PM

Example: The current time is 1:30p.m.

2

Set the turn-off time with

the TIMER control button.

PM

3

Point the signal window of the remote controller toward the indoor unit,

and press the (RESERVE) button.

The (OFF) mark starts lighting instead of flashing and the (RESERVED)

sign lights. A beep occurs and the (TIMER) lamp lights on the indoor unit.

PM

Example: The device will turn off at 11:00p.m.

The setting of turn-off time is now complete.

2

Set the turn-on time with

the TIMER control button.

AM

3

Point the signal window of the remote controller toward the indoor unit,

and press the (RESERVE) button.

The (ON) mark starts lighting instead of flashing and the (RESERVED)

sign lights. A beep occurs and the (TIMER) lamp lights on the indoor unit.

AM

Example:

The device will turn on early so that the preset

temperature be almost reached at 7:00 a.m.

The setting of the turn-on time is now complete.

4

Set the turn-on time with

the TIMER control button.

5

Point the signal window of the remote controller toward the indoor unit,

and press the (RESERVE) button.

The (ON) mark starts lighting instead of flashing and the (RESERVED)

sign lights. A beep occurs and the (TIMER) lamp lights on the indoor unit.

Example:

For heating, the device will turn off at 10:30 p.m.,

and then turn on early so that the preset

temperature be almost reached at 7:00 a.m.;

for cooling and dehumidifying, it will simply

turned on at 7:00 a.m. The settings of the turn

on/off times are now complete.

PM

AM

PM

AM

• The timer may be used in three ways: off-timer, on-timer and ON/OFF (OFF/ON)-timer. Set the

current time at first because it serves as a reference.

• As the time settings are stored in memory in the remote controller, you only have to press the

(RESERVE) button is order to use the same settings next time.

– 10 –

Page 13

– 14 –

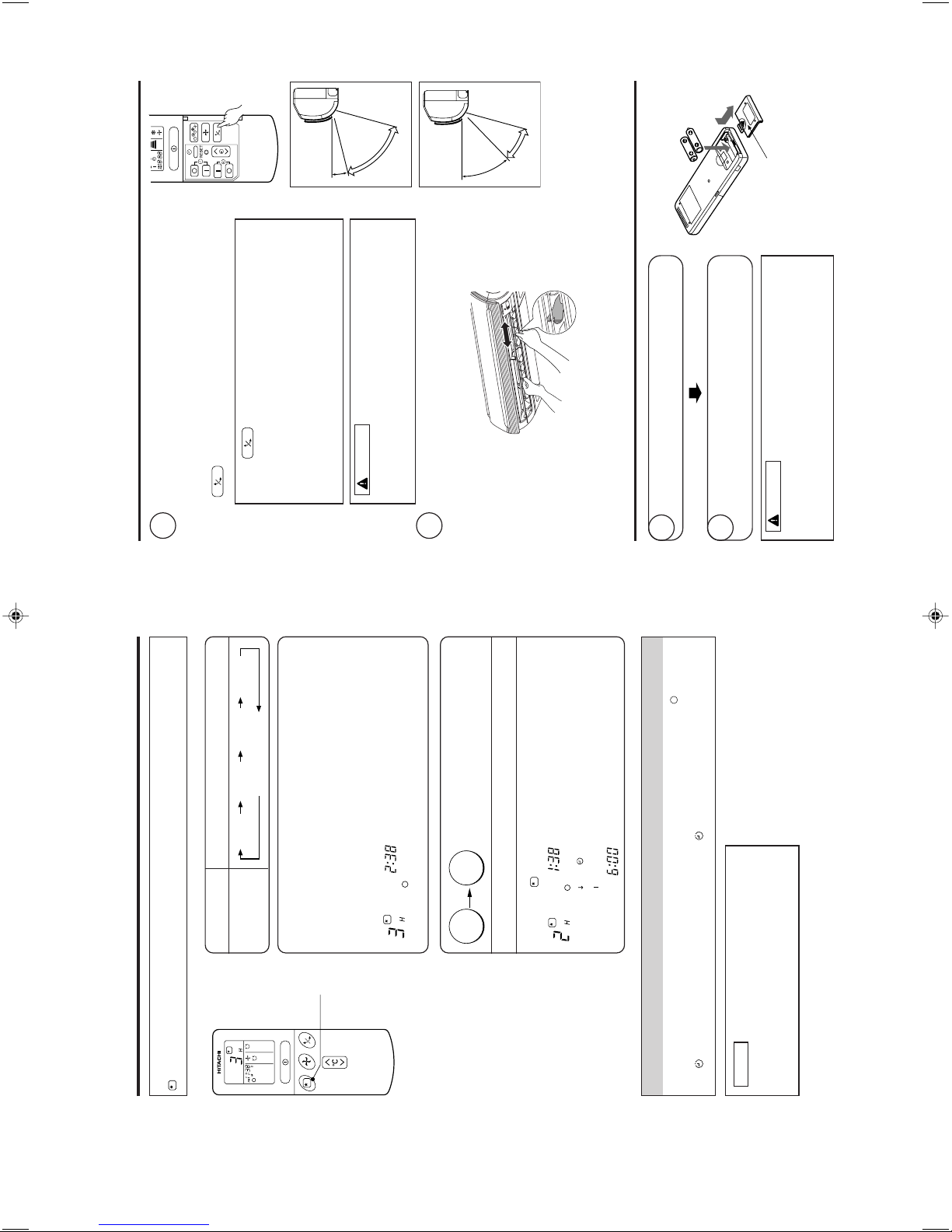

HOW TO SET THE SLEEP TIMER

Set the current time at first if it is not set before (see the pages for setting the current time). Press the

(SLEEP) button and the display changes as shown below.

●

SLEEP

Mode Indication

Sleep Timer

1 hour 2 hours 3 hours 7 hours

Sleep timer off

Sleep Timer: The device will continue working for the desired number of

hours and then turn off.

Point the signal window of the remote controller toward the indoor unit, and

press the SLEEP button.

The timer information will be displayed on the remote controller. The TIMER

lamp lights with a beep from the indoor unit. When the sleep timer has

been set, the display indicates the turn-off time.

AM

Example: If you set 3 hours sleep time at

11:38 p.m., the turn-off time is 2:38 a.m.

Sleep

timer

Start

The device will be turned off by the sleep timer

and turned on by on-timer.

1

Set the ON-timer.2 Press the (SLEEP) button and set the sleep timer.

AM

AM

For heating:

In this case, the device will turn off in

2 hours (at 1:38 a.m.) and turn on early

so that the preset temperature will be

almost reached at 6:00 next morning.

How to Cancel Reservation

Point the signal window of the remote controller toward the indoor unit, and press the (CANCEL)

button.

The

(RESERVED) sign goes out with a beep and the (TIMER) lamp turns off on the indoor unit.

NOTE

If you set the sleep timer when the off-time or on/off-

timer has been set earlier, the sleep timer becomes

effective instead of the off - or on/off-timer set earlier.

– 15 –

ADJUSTING THE AIR DEFLECTORS

1

Adjustment of the conditioned air in the upward and downward

directions.

The horizontal air deflector is automatically set to the proper angle

suitable for each operation. The deflector can be swung up and

down continuously and also set to the desired angle using the

“

(AUTO SWING)” button.

• In “Cooling” operation, do not keep the horizontal air

deflector swinging for a long time. Some dew may form on

the horizontal air deflector and dew may drop.

CAUTION

2

Adjustment of the conditioned air to the left and right.

Hold the vertical air deflector as shown in the figure and adjust

the conditioned air to the left and right.

HOW TO EXCHANGE THE BATTERIES IN THE REMOTE CONTROLLER

1

Remove the cover as shown in the figure and take out

the old batteries.2Install the new batteries.

The direction of the batteries should match the marks

in the case.

1. Do not use new and old batteries, or different kinds of

batteries together.

2. Take out the batteries when you do not use the remote

controller for 2 or 3 months.

CAUTION

Push and pull to the

direction of arrow.

Vertical

Vertical

about 15°

about 60°

about 45°

about 30°

When cooling,

dehumidifying

When heating

•

If the “ (AUTO SWING)” button is pressed once, the horizontal

air deflector swings up and down. If the button is pressed again, the

deflector stops in its current position. Several seconds (about 6

seconds) may be required before the deflector starts to move.

• Use the horizontal air deflector within the adjusting range

shown in the right.

• When the operation is stopped, the horizontal air deflector

moves and stops at the position where the air outlet closes.

Left side: Hold the third

blade from the left end

of the air deflector to

adjust the direction. The

pull for the blade is

marked.

Right side: Hold the third

blade from the right end

of the air deflector to

adjust the direction. The

pull for the blade is

marked.

– 11 –

Page 14

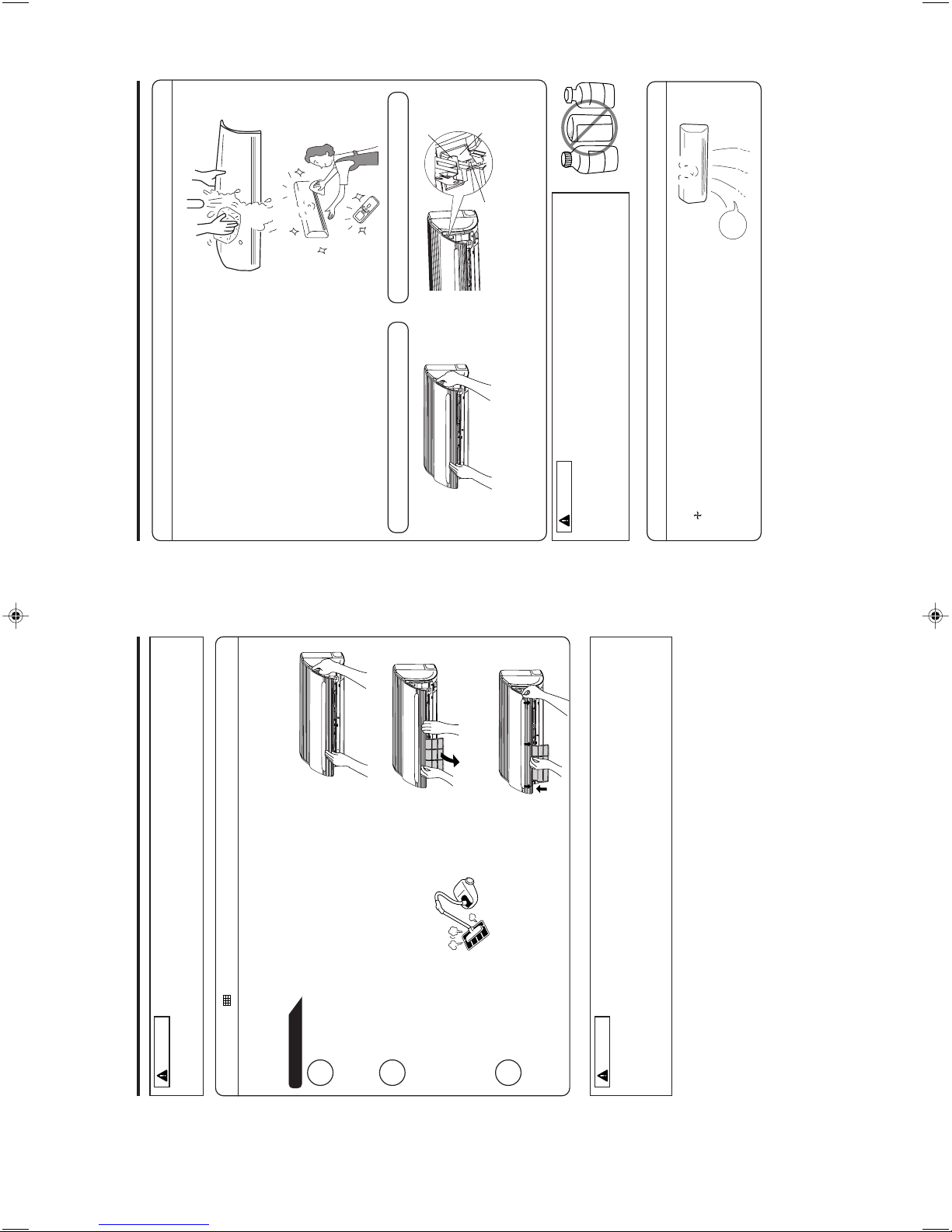

– 16 –

MAINTENANCE

Cleaning and maintenance must be carried out only by qualified service personal. Before cleaning,

stop operation and switch off the power supply.

CAUTION

1. AIR FILTER

When the filter indicator lamp comes on, be sure to clean the filter. By doing so, the power rates are

saved. In case the air filter is full of dust, the air flow will decrease and the cooling capacity will be

reduced. Further, noise may occur. Be sure to clean the filter following the procedure below.

PROCEDURE

1

Open the front panel carefully and remove the filter.

2

Vacuum dust from the air filter using vacuum cleaner.

If there is too much dust, wash the filter with a detergent

and rinse it thoroughly. After that, dry it in the shade.

3

• Set the filter with “FRONT” mark facing front, and

slot them into the original state.

• After attaching the filters, push the front panel at

three arrow portions as shown in figure and close

it.

• Do not wash with hot water at more than 40°C. The filter may shrink.

• When washing it, shake off moisture completely and dry it in the shade; do not expose it directly

to the sun. The filter may shrink.

• Don't operate the unit without filter. Fault may occur if you continue.

CAUTION

– 17 –

2. CLEANING OF FRONT PANEL

• Remove the front panel and wash with clean water.

Wash it with a soft sponge.

After using neutral detergent, wash thoroughly with

clean water.

• When front panel is not removed, wipe it with a soft

dry cloth. Wipe the remote controller thoroughly with

a soft dry cloth.

• Wipe the water thoroughly.

If water remains at indicators or signal receiver of

indoor unit, it causes trouble.

Method of removing the front panel.

Be sure to hold the front panel with both hands to

detach and attach it.

CAUTION

Removing the Front Panel Attaching the Front Panel

• When the front panel is fully opened with both

hands, push the right arm to the inside to

release it, and while closing the front panel

slightly, put it out forward.

• Move the shafts of the left and right arms into

the steps in the unit and securely insert them

into the holes.

Shaft

Step

Hole

B

E

N

Z

I

N

E

T

H

I

N

N

E

R

A

CID

• Do not splash or direct water to the body of the unit when cleaning it as

this may cause short circuit.

• Never use hot water (above 40°C), benzine, gasoline, acid, thinner or a

brush, because they will damage the plastic surface and the coating.

3. MAINTENANCE AT BEGINNING OF LONG OFF PERIOD

• Run the unit by setting the operation mode to

(FAN) and the fan speed to HI for about half a day

on a fine day, and dry the whole of the unit.

• Switch off the power plug or turn off the circuit breaker.

Air

Blow

– 12 –

Page 15

– 18 –

INFORMATION

CAPABILITIES

Heating Capability

• This room air conditioner utilizes a heat pump system that absorbs

exterior heat and brings it into a room to be heated. As the ambient

temperature gets lower, heating capability will also lower. In such a

situation, the inverter work to increase compressor rpm to keep the

unit’s heating capability from decreasing. If the unit’s heating perfor-

mance is still unsatisfactory, other heating appliances should be used

to augment this unit’s performance.

• The air conditioner is designed to heat an entire room so that it may take some time before you feel warm.

Timer operation is recommended for effective preheating ahead of the desired time.

Cooling and Dehumidifying Capabilities

• If the heat present in a room exceeds the unit’s cooling capacity (for example, if there are many people in

the room or other heating appliances are used), the preset room temperature may not be reached.

CAUTION

Do not use a stove

or any other

hightemperature

devices in proximity

to the indoor unit.

• When fan speed, room temperature are set with the remote controller before starting manual operation and

the buttons are released, the indication of settings will go off in 10 seconds and only the operation mode

will be displayed.

• Pressing the button while the unit is in operation will let the protective circuit work so that the unit will

not operate for approximately 3 minutes.

• During heating operation, the indoor unit’s color indicator lamp may flash with no air emitted for a while.

• If you feel cold wind during heating operation with the (HI) fan speed or want to make the unit operation

quieter after the room is heated, use of (AUTO) setting is recommended.

• With the (LOW) setting, the unit’s cooling capability will lower slightly.

• With the (LOW) setting, the unit’s heating capacity will vary with the operating conditions.

VARIOUS FUNCTIONS

• When the timer has been programmed, the unit will not operate even if the set time is reached unless the

unit receives a signal from the remote controller. Confirm that timer programming is complete (beep) and

the TIMER lamp of the indoor unit lights.

• If the (SLEEP) button is pressed while the ON/OFF timer is programmed, the sleep timer takes priority.

• During sleep timer operation, the fan speed sets to (LOW) regardless of the preset speed. The remote

controller display indication will remain unchanged even with the (LOW) setting.

TIMER PROGRAMMING/SLEEP TIMER OPERATION

PROHIBITION

– 19 –

REGULAR INSPECTION

PLEASE CHECK THE FOLLOWING POINTS EVERY EITHER HALF YEARLY OR YEARLY. CONTACT

YOUR SALES AGENT SHOULD YOU NEED ANY HELP.

1

2

3

WARNING

WARNING

Check to see if the unit’s earth line has been con-

nected correctly.

If the earth line is disconnected or faulty, unit failure or

electric shock hazard may result.

Check to see if the mounting frame has rusted ex-

cessively or if the outdoor unit has tilted or become

unstable.

It could collapse or fall, causing injury.

AFTER SALES SERVICE AND WARRANTY

WHEN ASKING FOR SERVICE, CHECK THE FOLLOWING POINTS.

CONDITION CHECK THE FOLLOWING POINTS

• Do the batteries need replacement?

• Is the polarity of the inserted batteries correct?

• Is the fuse all right?

• Is the voltage extremely high or low?

• Is the circuit breaker “ON”?

• Is the power plug inserted?

• Do you have any power cut?

• Is the air filter blocked with dust?

• Is the set temperature suitable?

• Have horizontal air deflectors been adjusted to their correct

positions according to the operation mode selected?

• Are the air inlets or air outlets of indoor and outdoor units

blocked?

• Is the fan speed “LOW”?

When it does not operate.

When it does not cool well.

When it does not heat well.

If the remote controller is not

transmitting a signal.

(Remote controller display is

dim or blank.)

■ The following phenomena do not indicate unit failure.

<Operation start>

The unit is preparing to blow warm air. Please wait.

<In operation>

The outdoor unit is defrosting. Please wait.

Refrigerant flow noise in the pipe or valve sound generated when flow rate is

adjusted.

Noise generated when the unit expands or contracts due to temperature changes.

Noise generated with the indoor unit fan’s rpm changing such as operation start

times.

Noise of the motorized valve when the unit is switched on.

During heating, the operation

indicator blinks and air blow stops

Hissing or fizzy sounds

Squeaking noise

Rustling noise

WARNING

Clicking noise

Check to see if the power plug is securely inserted

into the wall socket.

If the power plug is not inserted into the wall socket

securely or becomes hot, an electric shock or fire may result.

If dust or dirt is found on the power plug, clean the plug

and insert it into the wall socket.

– 13 –

Page 16

– 20 –

• If the unit still fails to operate

normally after performing the

above inspections, turn the

circuit breaker off, or pull the

power plug out, and contact

your sales agent immediately.

Contact your sales agent immediately if the

following phenomena should occur:

•

The circuit breaker switches off or the fuse blows

frequently.•The switch operation is not stable.•Foreign matter or water accidentally enters the unit interior.•The power cord gets excessively hot or its insulation is torn or stripped.•TIMER lamp on the indoor unit display blinks.

As the nature of the failure can be identified by the blinking cycle,

check the blinking cycle before turning off the circuit breaker.

(

)

Notes

• In quiet operation or stopping the running, the following phenomena may

occasionally occur, but they are not abnormal for the operation.

(1) Slight flowing noise of refrigerant in the refrigerating cycle.

(2) Slight rubbing noise from the fan casing which is cooled and then

gradually warmed as operation stops.

• The odor will possibly be emitted from the room air conditioner because

the various odor, emitted by smoke, foodstuffs, cosmetics and so on,

sticks to it. So please clean the air filter and the evaporator regularly to

reduce the odor.

Noise of the ventilation fan sucking in air present in the drain hose and blowing out

dehumidifying water that had accumulated in the condensed water collector. For

details, consult your sales agent.

Operation noise changes due to power variations according to room temperature

changes.

Mist is generated as the air within the room is suddenly cooled by conditioned air.

Water generated during defrosting operation evaporates and steam is emitted.

Caused as the smells and particles of smoke, food, cosmetics, etc. present in room

air become attached the unit and blown off into the room again.

Defrosting is underway (as the heating operation is stopped, the microcomputer

checks frost accumulated in the outdoor unit and instructs the unit to perform

automatic defrosting if necessary).

Shows preheating or defrosting operation is underway.

As the protective circuit or preheat sensor operates when unit operation is stopped

during preheating and then restarted, or when operation mode is switched from cooling

to heating, the lamp continues to blink.

Actual room temperature may deviate slightly from the remote controller's

temperature setting depending on the number of people in the room, indoor or

outdoor conditions.

• Please contact your sales agent immediately if the air conditioner still fails to operate normally after

the above inspections. Inform your agent of the model of your unit, production number, date of

installation. Please also inform him regarding the fault.

Please note:

On switching on the equipment, particularly when the room light is dimmed, a slight brightness

fluctuation may occur. This is of no consequence.

The conditions of the local Power Supply Companies are to be observed.

Does not reach the temperature

setting

Mist emission

Perking noise

Changing operation noise

Steam emitted from the outdoor unit

The outdoor unit continues to operate

even if operation is stopped.

Odors

The OPERATION lamp is blinking.

– 14 –

Page 17

– 15 –

About

70

Warning

About 108

70

70

(190)

190

400

47

22

81.5

60

30

60

47

210

47

5

60

11

60

5

47

280

780

About 370

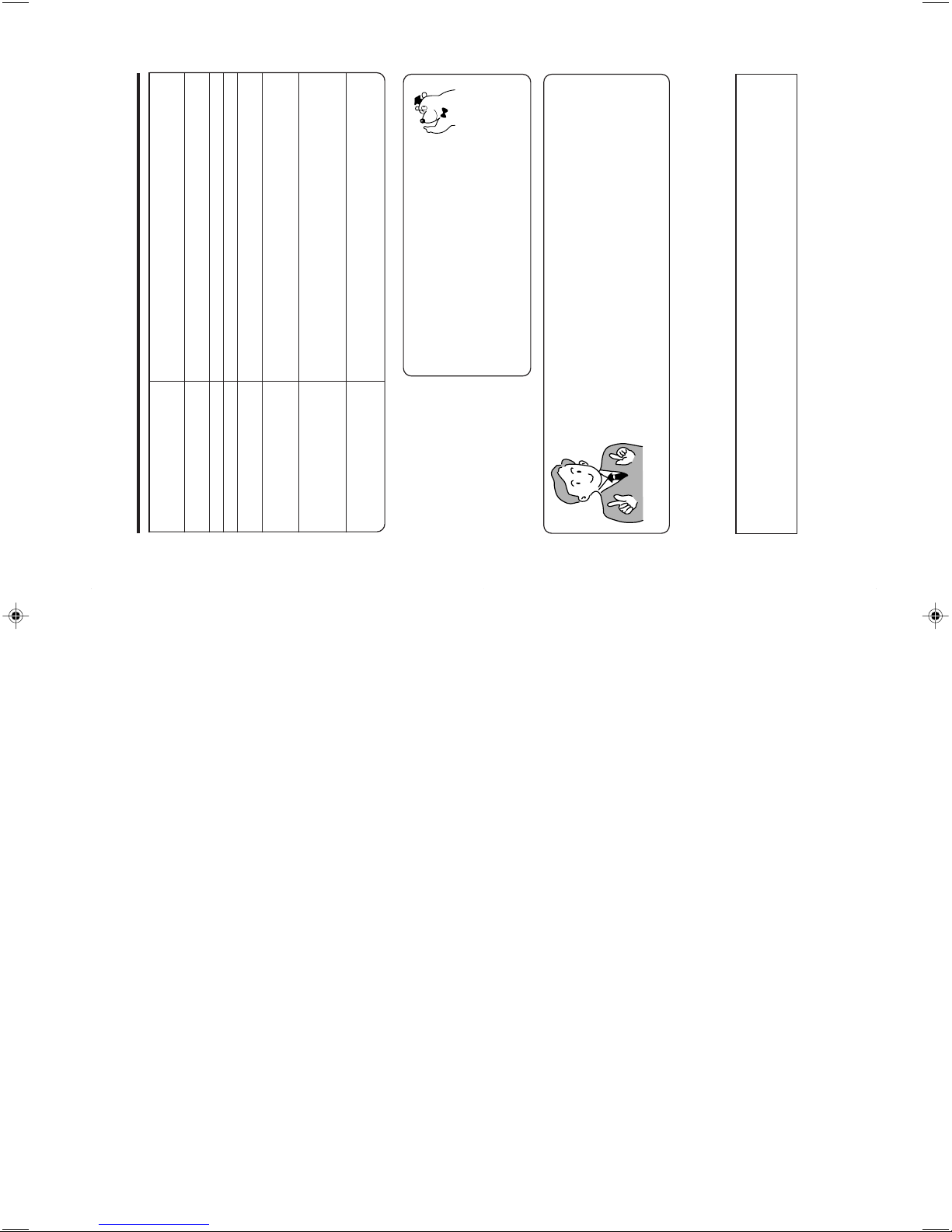

CONSTRUCTION AND DIMENSIONAL DIAGRAM

MODEL RAS-18YH6, RAS-25YH6

Top air suction grill

147

56 17.5

When piping is

drawn from the left side

,

exchange the drain

hose for the dr

ain cap

Mounting plate

Air outlet

Horizontal air diflector

Front panel

Cabinet

Drain

Drain cap connection port

Narrow pipe (ø6.35)

Wide pipe (ø9.52)

Drain hose

Power cord

Connecting cable

Vertical air deflector

INDOOR UNIT

Page 18

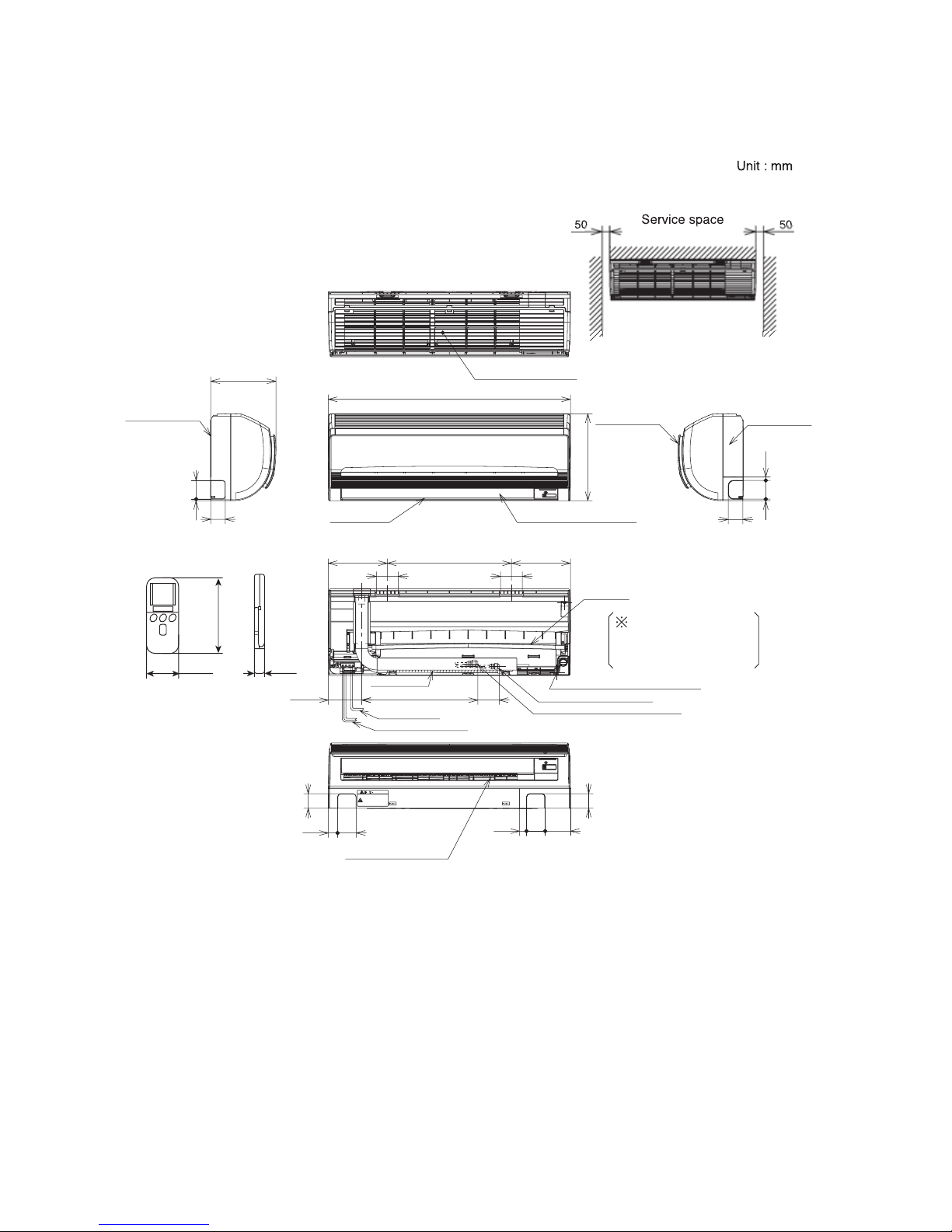

– 16 –

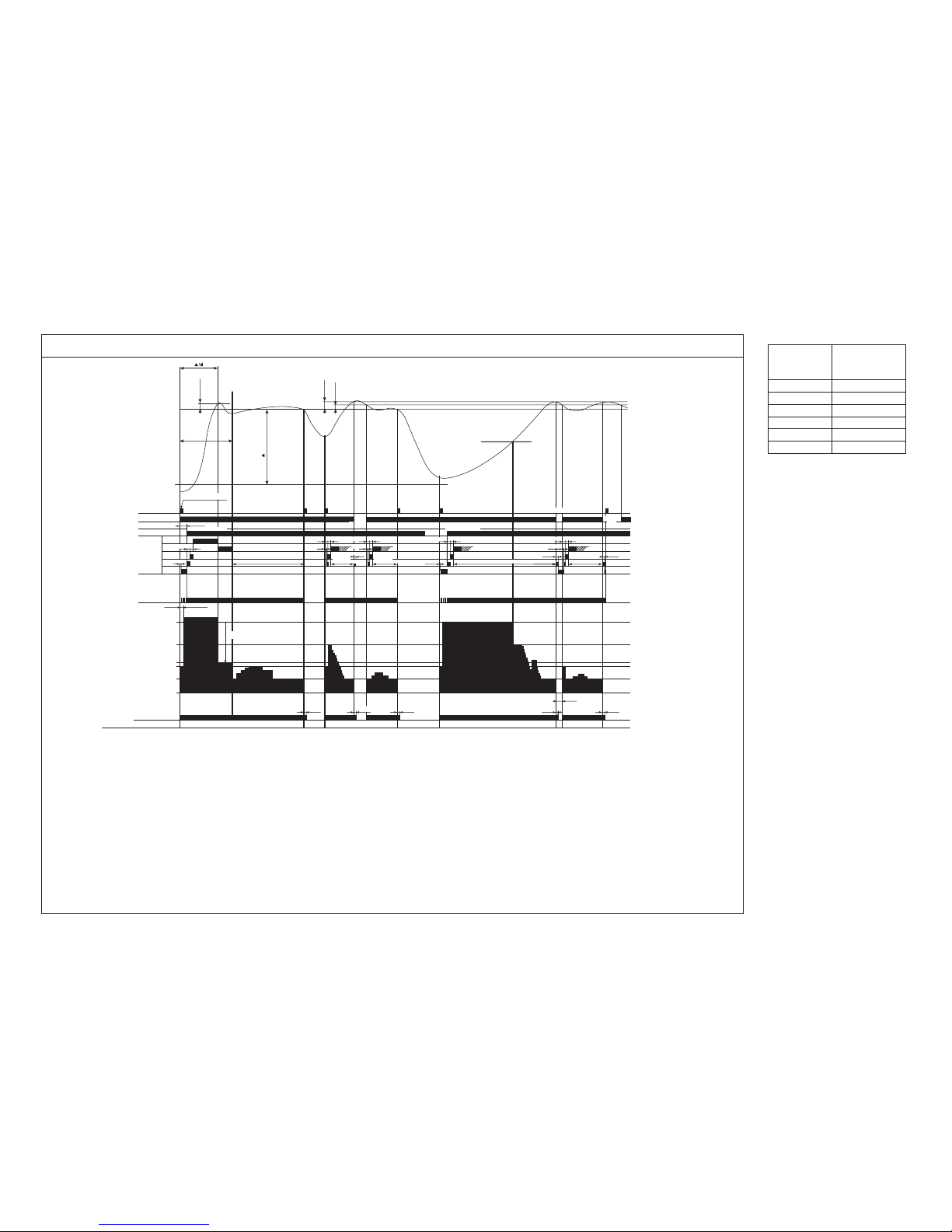

CONSTRUCTION AND DIMENSIONAL DIAGRAM

MODEL RAC-18YH6, RAC-25YH6

OUTDOOR UNIT

Page 19

– 17 –

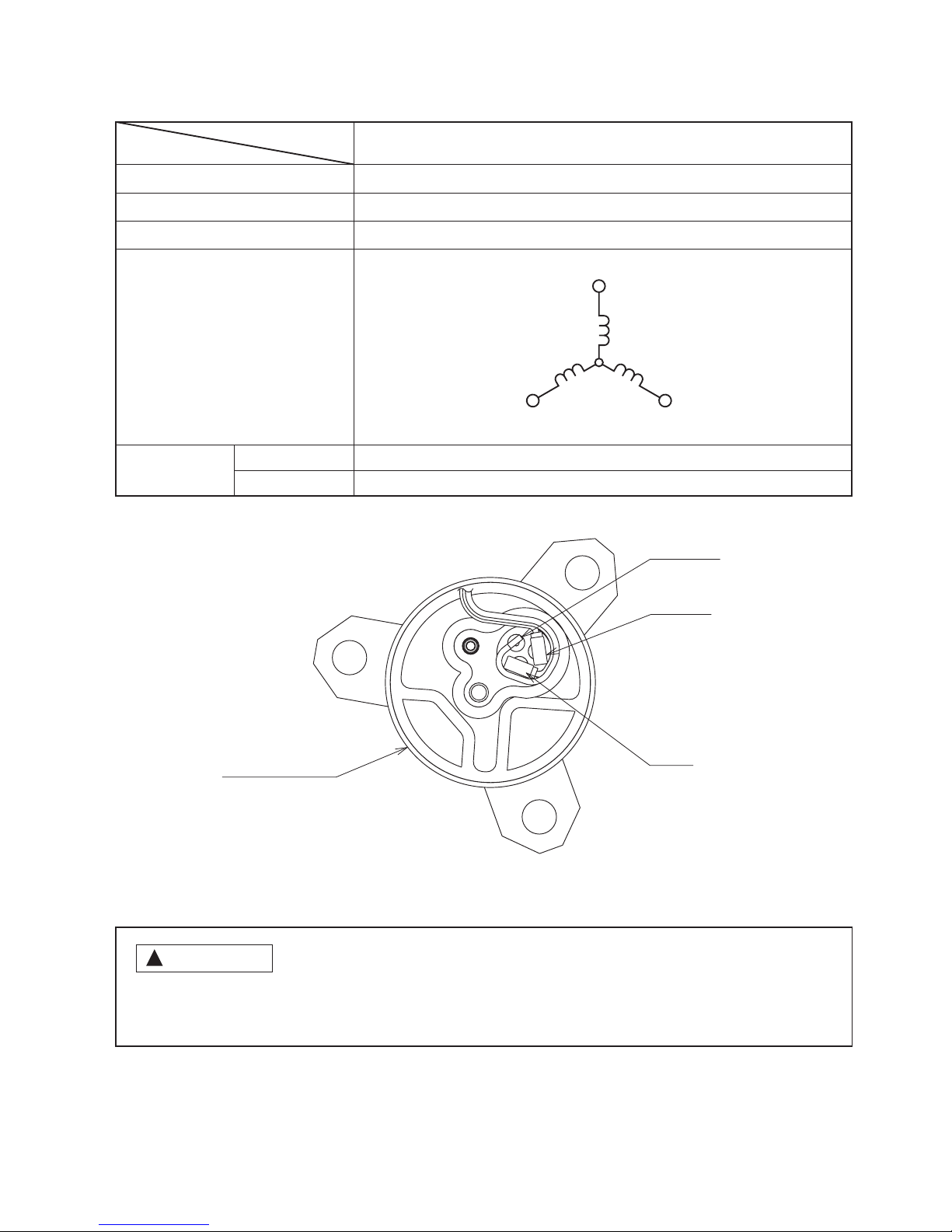

MAIN PARTS COMPONENT

THERMOSTAT

Thermostat Specifications

FAN MOTOR

MAIN ELECTRIC COMPONENTS FOR OUTDOOR UNIT

Fan Motor Specifications

CONNECTION

TEMPERATURE

°C (°F)

INDICATION

16

INDICATION

24

INDICATION

32

MODEL RAS-18YH6, RAS-25YH6

THERMOSTAT MODEL IC

OPERATION MODE COOL HEAT

ON 16.7 (62.1) 18.7 (65.7)

OFF 16.0 (60.8) 19.3 (66.7)

ON 24.7 (76.5) 26.7 (80.1)

OFF 24.0 (75.2) 27.3 (81.1)

ON 32.7 (90.9) 34.7 (94.5)

OFF 32.0 (89.6) 35.3 (95.5)

M

RED

BLK

WHT

YEL

BLU

35V

5V

0V

0 - 5V

FG

MODEL

NAME RATING APPLICABLE MODELS

REVERSING VALVE COIL 135 Ω (20 ˚C) RAC-18YH6, 25YH6

REACTOR L1 13 (mH), 0.224 Ω RAC-18YH6, 25YH6

REACTOR L2 25.5 (mH), 0.37 Ω RAC-18YH6, 25YH6

FILM CAPACITOR 45 (µF) RAC-18YH6, 25YH6

RAS-18YH6, RAS-25YH6

POWER SOURCE DC 5V, 35V

DC 140

- 350

V

OUTPUT 25W

40W

(Control circuit built in)

BLU : BLUE YEL : YELLOW BRN : BROWN WHT : WHITE

GRY : GRAY ORN : ORANGE GRN : GREEN RED : RED

BLK : BLACK PNK : PINK VIO : VIOLET

RED

140 350V

BLK

0V

WHT

15V

M

YEL

0-6V

BLU

0-15V

RAC-18YH6, RAC-25YH6

Page 20

– 18 –

WHITE

COMPRESSOR

YELLOW

RED

FRONT SIDE OF OUTDOOR UNIT

MODEL

ITEM

COMPRESSOR TYPE

POWER SOURCE

OUTPUT

COMPRESSOR MOTOR

Compressor Motor Specifications

WINDING

20°C

75°

C

RESISTANCE

(Ω)

!

CAUTION

When the refrigerating cycle has been operated for a long time with the capillary tubes clogged or crushed

or with too little refrigerant, check the color of the refrigerating machine oil inside the compressor. If the

color has been changed conspicuously, replace the compressor.

2M=1.15

2M=1.40

(U)

(V)

(W)

M

M

M

WHITE

YELLOW

RED

RAC-18YH6, RAC-25YH6

ASC092CD

800W

DC 270 - 350 V

Page 21

– 19 –

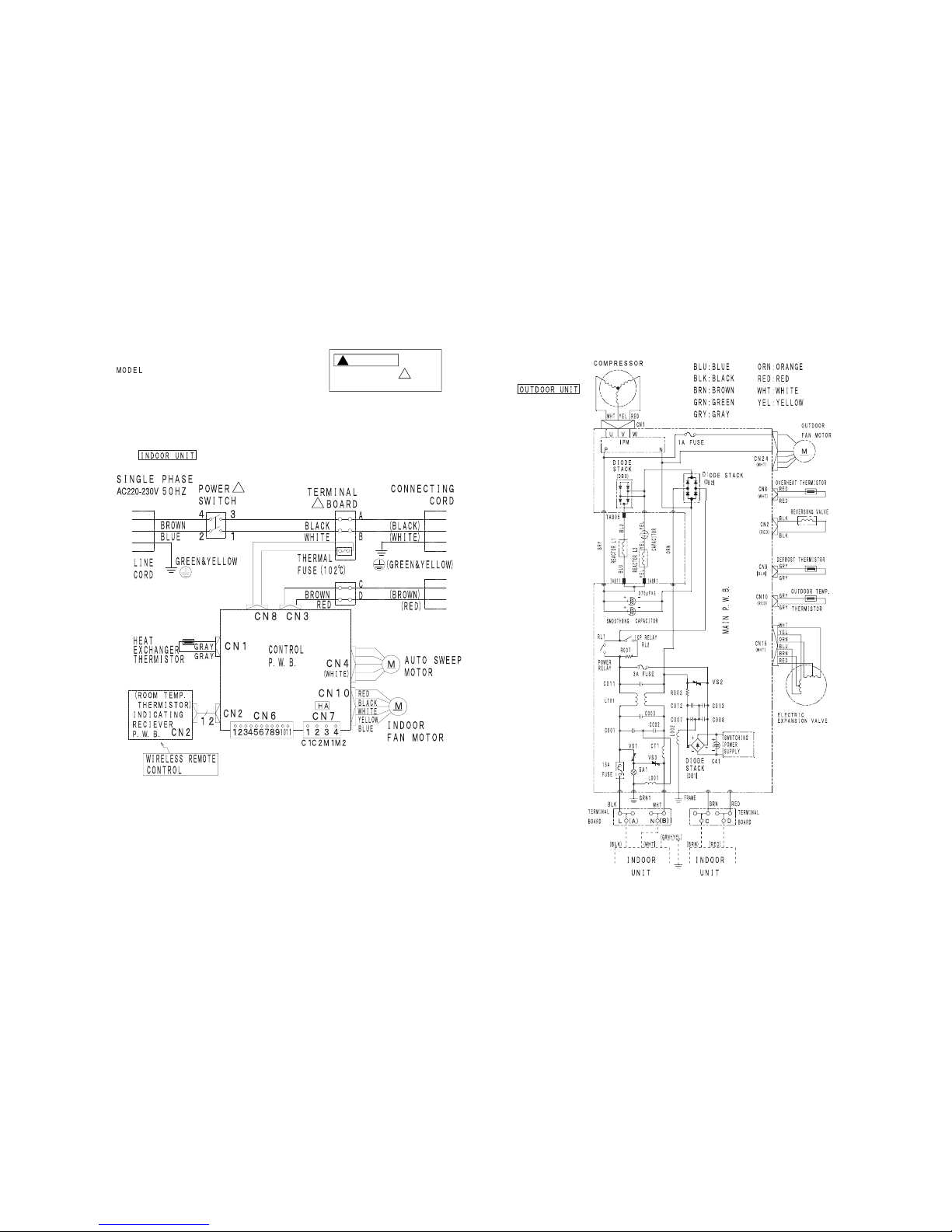

WIRING DIAGRAM

RAS-18YH6 / RAC-18YH6

RAS-25YH6 / RAC-25YH6

!

!

CAUTION

The marked parts are

very important ones for safety.

!

!

Page 22

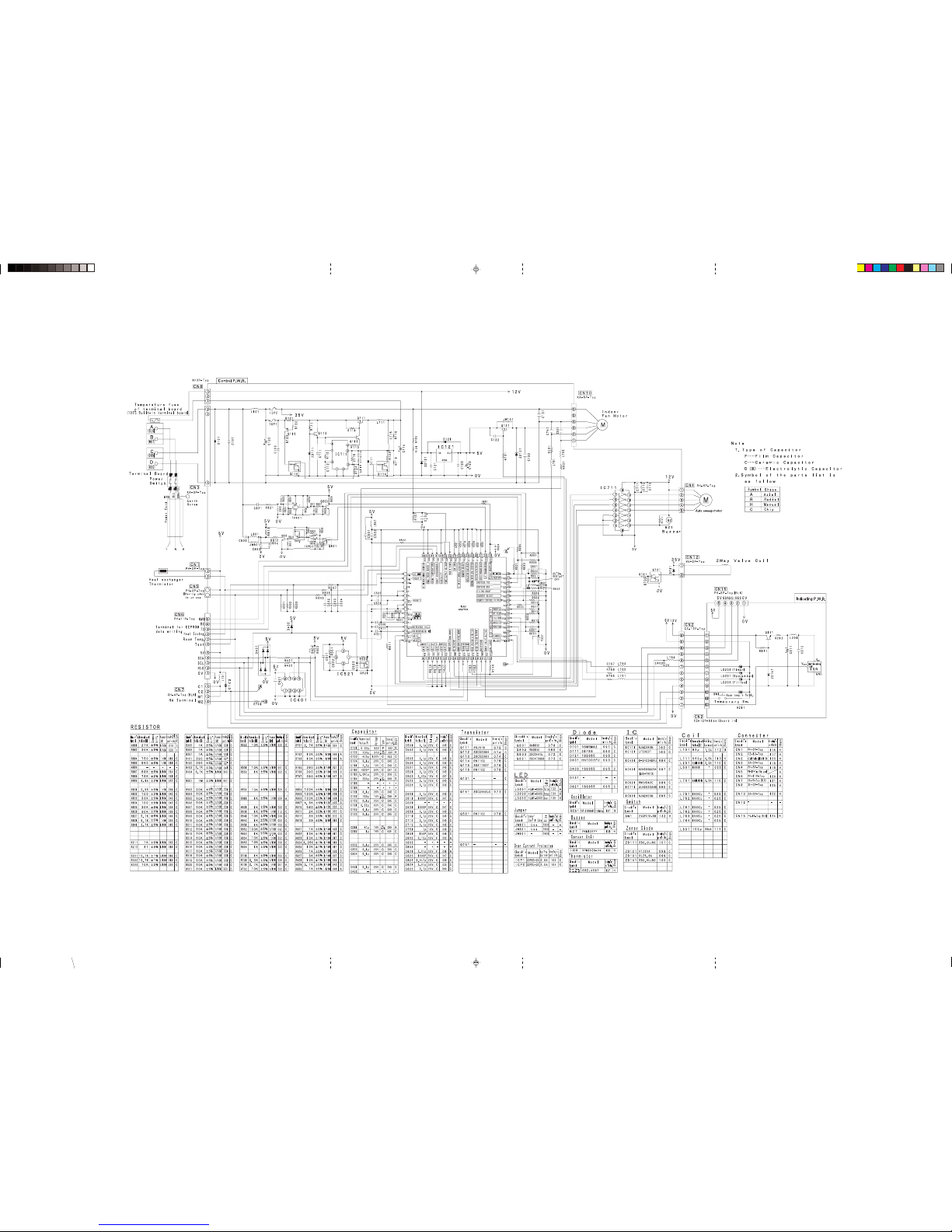

– 20 –

CIRCUIT DIAGRAM

MODEL RAS-18YH6, RAS-25YH6

RAS_AW_020-021_A2 11/17/06, 11:18 AM20

Page 23

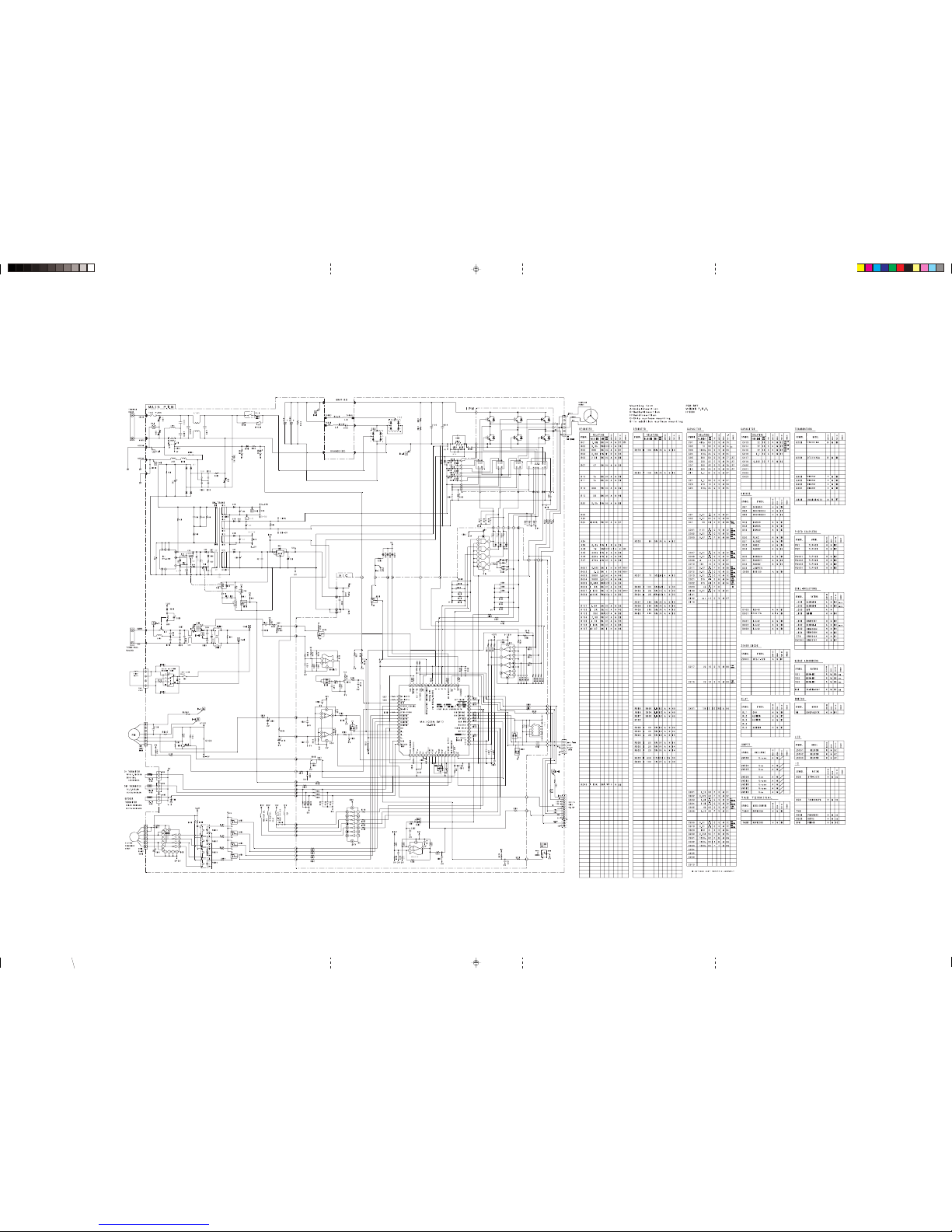

– 21 –

RAC-18YH6, RAC-25YH6

MODEL

RAS_AW_020-021_A2 11/17/06, 11:18 AM21

Page 24

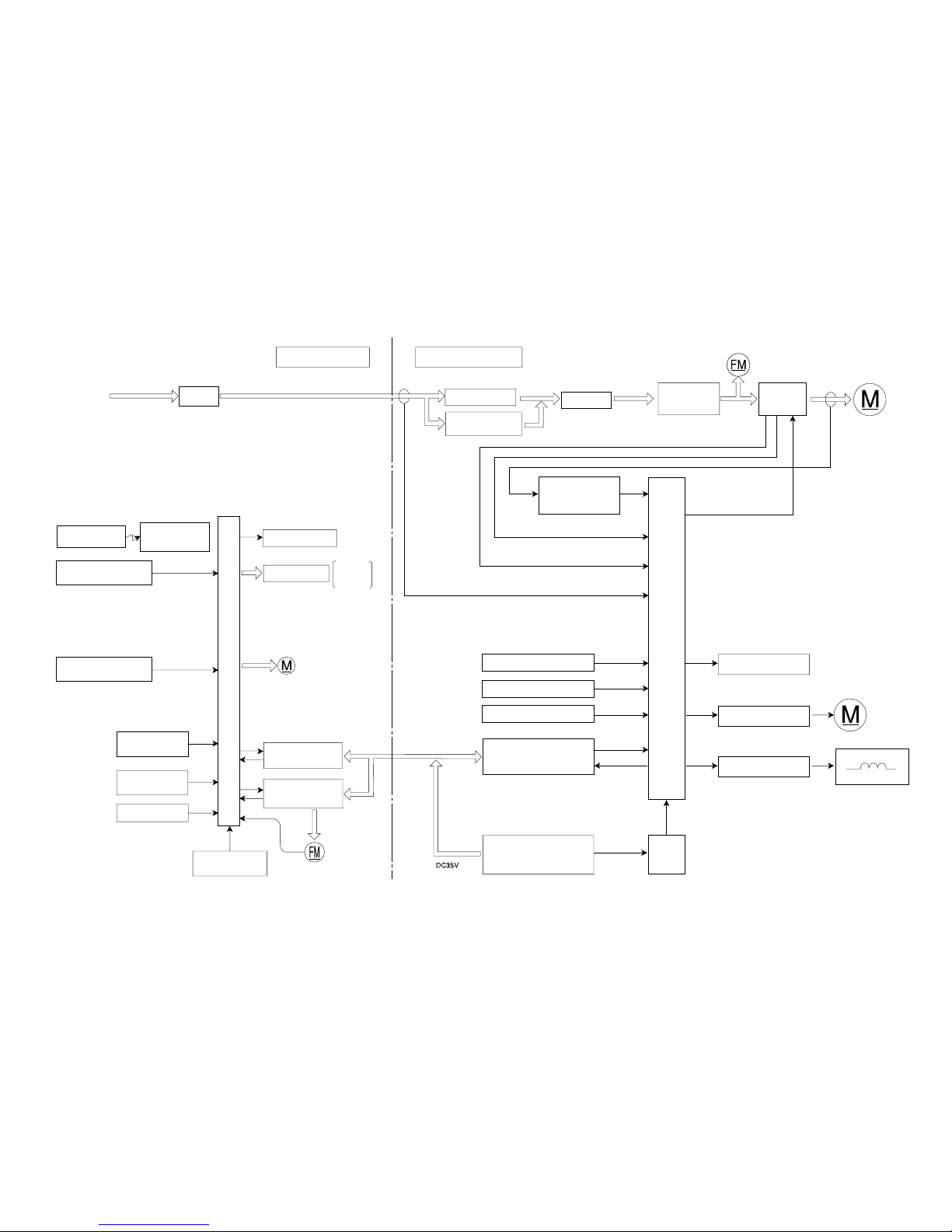

Wireless receive

circuit

Filter.

Operation.

Timer.

Auto sweep motor for

Air deflector

Remote controller

Heat exchanger

thermistor

Room temperature

thermistor

Reset circuit

Initial setting circuit

Temporary switch

Outdoor microcomputer (AX-8V11)

RAS-18YH6 / RAC-18YH6MODEL

RAS-25YH6 / RAC-25YH6

Indoor microcomputer (AX-7R13)

BLOCK DIAGRAM

INDOOR UNIT OUTDOOR UNIT

POWER RELAY

POWER

SWITCH

Inrush current

Protection circuit

HARMONICS

IMPROVEMENT

CIRCUIT

IPM

Rotor magnetic

pole position

detection circuit

lp

ld

ls

Buzzer circuit

Indicating lamp

Indoor/Outdoor

interface circuit

DC fan motor drive

circuit

Microcomputer clock

circuit

Indoor DC

fan motor

Overheat thermistor

Defrost thermistor

Outdoor temperature thermistor

Indoor/Outdoor

interface circuit

Reversing valve coil

Power circuit

Reset

circuit

Outdoor DC fan motor

RECTIFIER

DC compressor

motor

Relay drive circuit

Electric expansion valve

Reversing valve

control circuit

Power source

1ø 50Hz 220-230V

– 22 –

Page 25

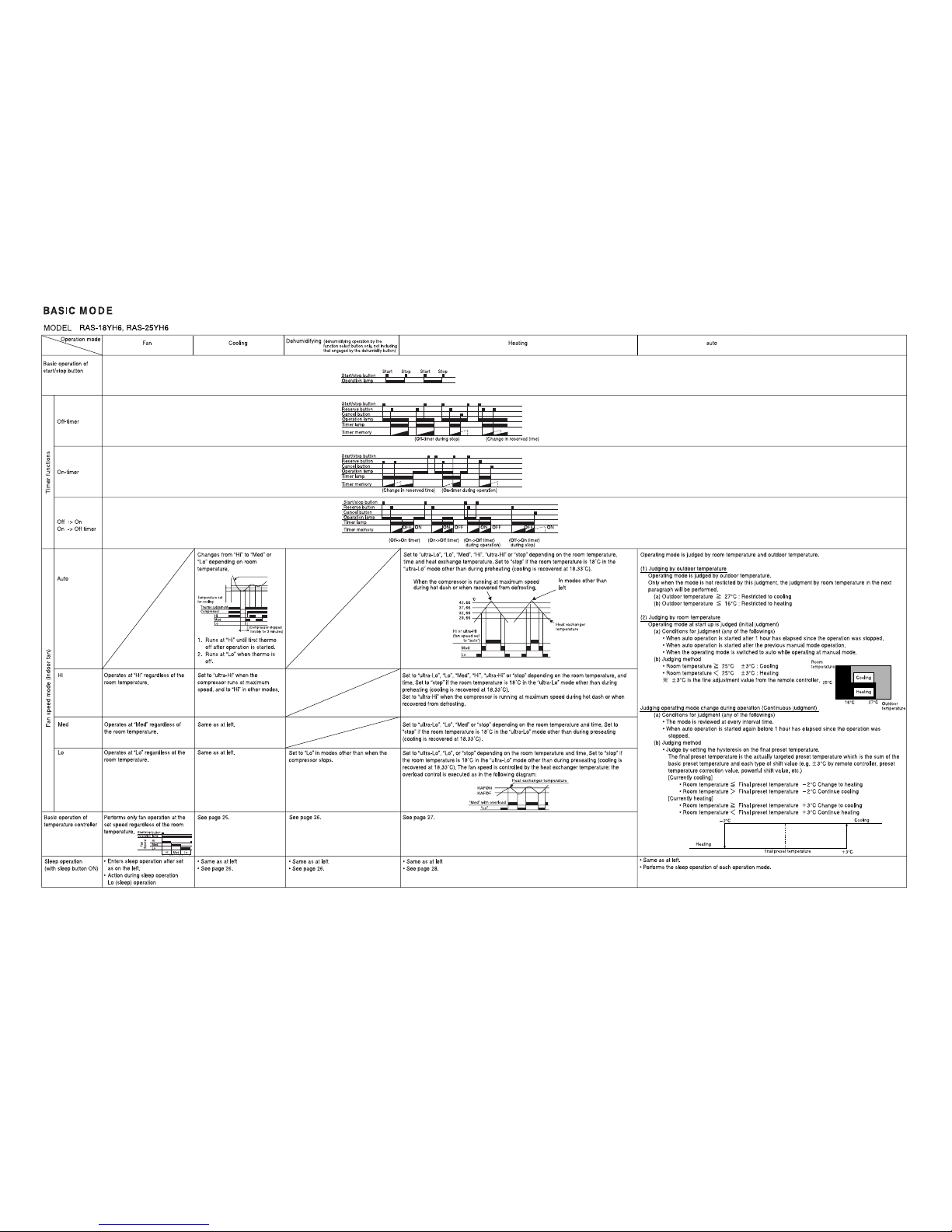

– 23 –

Page 26

– 24 –

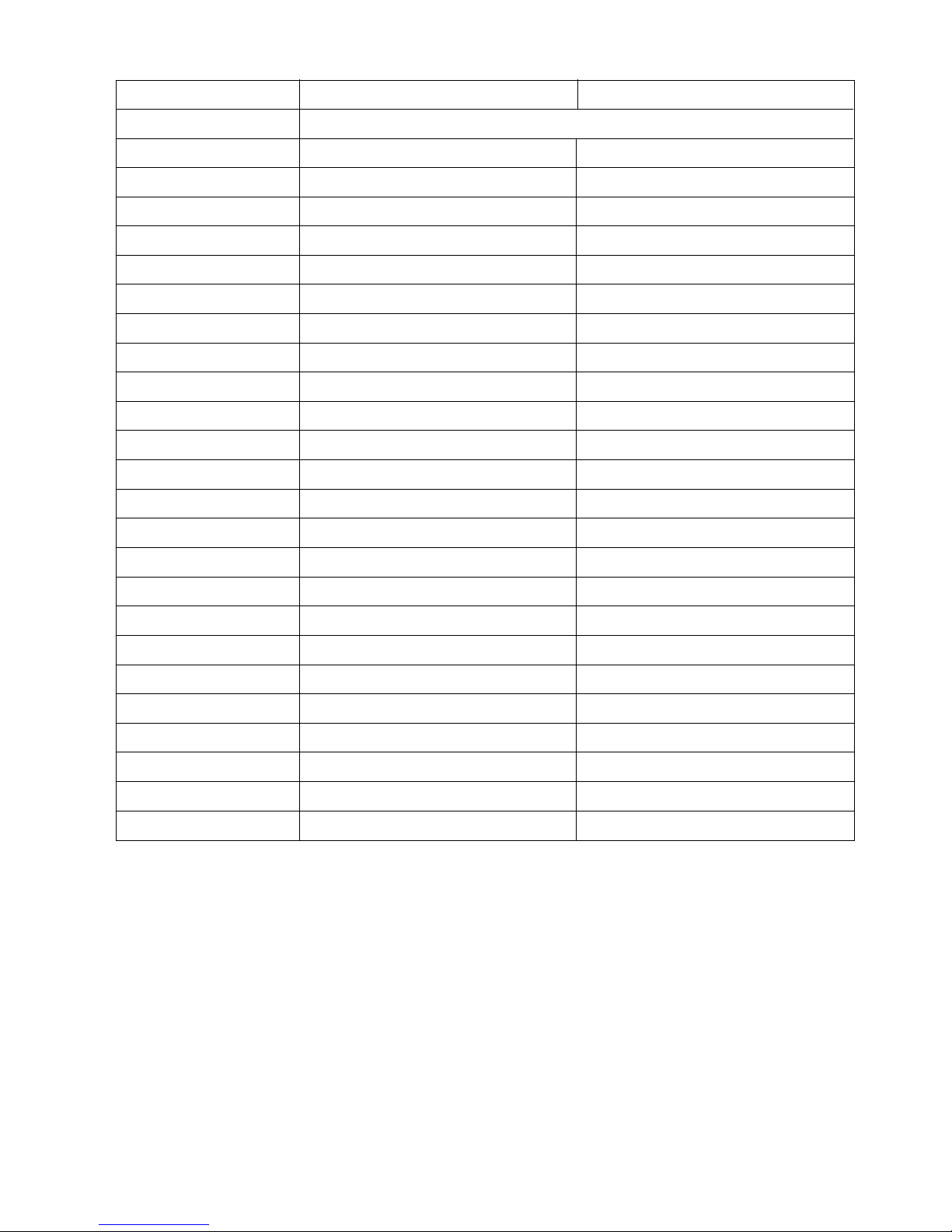

Table 1 Mode data file

RAS-18YH6 RAS-25YH6

LABEL NAME VALUE

WMAX

3500 min

–1

4400 min

–1

WMAX2

3500 min

–1

4400 min

–1

WSTD

2950 min

–1

4200 min

–1

WBEMAX

2800 min

–1

3200 min

–1

CMAX

3200 min

–1

3200 min

–1

CMAX2

3200 min

–1

3200 min

–1

CSTD

2400 min

–1

2900 min

–1

CKYMAX

2300 min

–1

2700 min

–1

CJKMAX

2300 min

–1

2500 min

–1

CBEMAX

2300 min

–1

2300 min

–1

WMIN

2200 min

–1

2200 min

–1

CMIN

2200 min

–1

2200 min

–1

STARTMC

90 Seconds 90 Seconds

DWNRATEW

80% 80%

DWNRATEC

60% 60%

SHIFTW

2.00°C 2.00°C

SHIFTC

1.33°C 1.33°C

CLMXTP

30.00°C 30.00°C

YNEOF

25.00°C 25.00°C

TEION

2.00°C 2.00°C

TEIOF

9.00°C 9.00°C

SFTDSW

1.00°C 1.00°C

DFTIM1

43 Minutes 43 Minutes

DFTIM2

60 Minutes 60 Minutes

Page 27

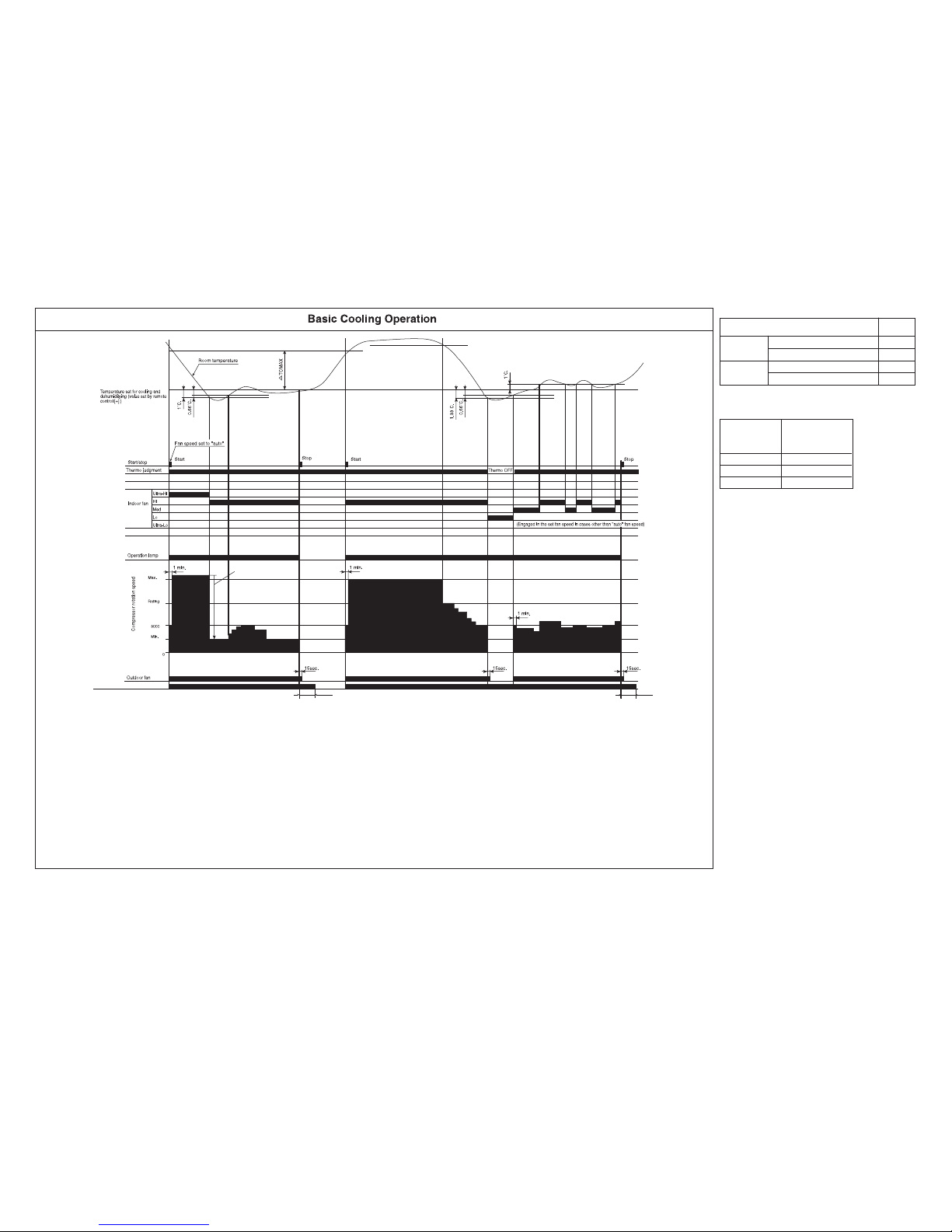

Reversing valve (cooling “on” mode)

NO

TE (9)

Notes:

(1) Condition for entering into Cool Dashed mode. When fan set to “Hi” or “Auto mode” and temperature difference between indoor temperature and set temperature has a

corresponding compressor rpm (calculated value in Table 2) larger than CMAX.

(2) Cool Dashed will release when i) a maximum 25 minutes is lapsed and ii) room temperature is lower than set temperature –3°C (thermo off) and iii) when room temperature

has achieved setting temperature –1°C then maximum Cool Dashed time will be revised to 20 minutes. And iv) indoor fan is set to Lo and Med fan mode and v) change operation

mode.

(3) During Cool Dashed operation, thermo off temperature is set temperature (with shift value) –3°C. After thermo off, operation continue in Fuzzy control mode.

(4) Compressor minimum “ON” time and “OFF” time is 3 minutes.

(5) During normal cooling mode, compressor maximum rpm CMAX will maintain for 60 minutes if indoor temperature is lower than CLMXTP. No time constrain if indoor temperature

is higher than CLMXTP.

(6)

(7) When fan is set to “Med”, compressor rpm will be limited to CJKMAX.

(8) When fan is set to “Lo”, compressor rpm will be limited to CBEMAX.

(9) During Cool Dashed, when room temperature reaches set temperature –1°C compressor rpm is actual rpm x DWNRATEC.

Temperature

Calculated

difference

compressor rpm

1.66°C

2200 min

–1

2.00°C

2600 min

–1

2.33°C

3000 min

–1

CLMXTP

2min. 30sec.

2min. 30sec.

(with shift value)

Table 2 Compressor rpm

Item

Temperature

Room

temperature

Outdoor

temperature

30°C

32°C

32°C

33°C

Thermo judgment (ON)

Thermo judgment (OFF)

Thermo judgment (ON)

Thermo judgment (OFF)

Table 1 Thermo judgment

button

When fan speed setting on remote control is “Hi” or “Auto” mode, and both room and outdoor temperatures (data based on out door unit) meet temperature judgment

(Off) shown in the table 1, the compressor rpm will be limited to CKYMAX.

– 25 –

Page 28

Sleep button

Notes:

(1) The sleep operation starts when the sleep button is pressed.

(2) When the sleep button is set, the maximum compressor speed is limited to CBEMAX, and the

indoor fan is set to "sleep Lo".

(3) The indoor fan speed does not change even when the fan speed mode is changed.

(4)

If sleep operation is canceled by the cancel button or sleep button, all data is cleared.

1min.

Compressor speed

Horiz

ontal air

deflector

Shut

Horizontal

Facing down

Indoor fan

Outdoor fan

Timer lamp

Remote control (Sleep) ON

Hi

Med

Lo

Set to 7 hours

See basic

operation

Notes:

(1) The sleep operation starts when the sleep button is pressed.

(2) When the sleep button is set, the indoor fan is set to “sleep Lo”.

(3) The indoor fan speed does not change even when the fan speed mode

is changed.

(4)

If sleep operation is canceled by the cancel button or sleep button, all

data is cleared.

+

+

–1.33˚C

–0.66˚C

Notes:

(1) The operation is done assuming as the preset temperature

= (room temperature at the time) – (2°C).

(2) The indoor fan is operated in the “Lo” mode. During thermo OFF indoor fan will be OFF for 5

(3) When the operation is started by the themostat turning ON, the start of the indoor fan is

delayed 32 seconds after the start of compressor operation.

(4) The compressor is operated forcedly for 3 minutes after operation is started.

(5) The minimum ON time and OFF time of the compressor are 3 minutes.

minutes and ON for 1 minute.

Cooling Sleep Operation

Operation lamp

Cooling Defrost

Dehumidifying Operation

Start Stop

Dehumidifying Sleep Operation

Sleep button

Operation lamp

Timer lamp

Remote control (Sleep) ON

Indoor fan

See basic

operation

Hi

Med

Lo

Sleep Lo

Outdoor fan

Horizontal

air deflector

Shut

Horizontal

Facing down

Compressor speed

Set to 7 hours

SDMAX or SDRPM

7hr

STARCP

1hr

Sleep Lo

1 hr

7 hr

Room temperature

Reversing valve

(cooling "on" model)

button

Min

Min

2 min 30 sec.

– 26 –

Page 29

1.33˚C.

SFTDSW

0.66˚

C.

Fan speed set to "auto"

1 min.

Basic Heating Operation

Start

Stop Start Start StopStop

Thermo

OFF

Thermo

OFF

Heating set temperature

(remote control set temperature

(+))

Start/stop button

Thermo judgment

Indoor fan

Ultra-Hi

Hi

Med

Lo

Ultra-Lo

Operation lamp

Max.

Rating

3000

0

Compressor speed

Outdoor fan

Reversing valve (cooling "on" model)

Ther

mo OFF

Dash period

TWMAX

Wtd

Defrost signal

Preheating judgment

30sec.

30sec.

10sec.

15sec. 15sec.

15sec. 15sec. 15sec.

10sec.

15sec.

15sec.

3min.

Max. 3 min.

Preheating released

Control by

heat exchanger temperature

Control by

heat exchanger temperature

15sec.

Control by

heat exchanger temperature

Control by

heat exchanger temperature

Control by

heat exchanger temperature

18˚C

10sec.

30sec.

30sec.

10sec.

30sec.

30sec.30sec. 30sec. 30sec. 30sec.

10sec.

Preheat released

WMIN

(WSTD)

(WMAX)

NOTE (10)

WMAX2

Notes:

(1) Condition for entering into Hot Dashed mode. When fan set to “Hi” or “Auto mode” and i) Indoor temperature is lower than 18°C, and ii) outdoor temperature is lower than 10°C,

and iii) Temperature difference between indoor temperature and set temperature has a corresponding compressor rpm (calculated value in Table 3) larger than WMAX.

(2) Hot Dashed will release when i) Room temperature has achieved the set temperature + SFTDSW. ii) Thermo off.

(3) During Hot Dashed operation, thermo off temperature is set temperature (with shift value) +3°C. After thermo off, operation continue in Fuzzy control mode.

(4) Compressor minimum “ON” time and “OFF” time is 3 minutes.

(5) During normal heating mode, compressor maximum rpm WMAX will maintain for 120 minutes if indoor temperature is higher than 18°C. No time limit constrain if outdoor temperature is

lower than 4°C.

(6) During Hotkeep or Defrost mode, indoor operation lamp will blink at interval of 0.5 seconds “ON” and 0.5 second “OFF”.

(7) When heating mode starts, it will enter into Hotkeep mode if indoor heat exchanger temperature is lower than YNEOF + 0.33°C.

(8) When fan is set to “Lo”, compressor rpm will be limited to WBEMAX. When fan is set to "Med", compressor rpm will be limited to WJKMAX.

(9) In “Ultra-Lo” fan mode, if indoor temperature is lower than 18°C, indoor fan will stop. If indoor temperature is higher than 18°C + 0.33°C, fan will continue in “Ultra-Lo” mode.

During Hotkeep or Defrost mode, fan will continue in “Ultra-Lo” mode.

(10) During Hot Dashed, when room temperature reaches set temperature + SFTDSW compressor rpm is actual rpm x DWNRATEW.

Temperature

Calculated

difference

compressor rpm

1.66°C2200 min

–1

2.00°C2600 min

–1

2.33°C3000 min

–1

2.66°C3400 min

–1

3.00°C3800 min

–1

3.33°C4200 min

–1

Table 3 Compressor rpm

Notes:

1. See the data in Table 1-Table 2 on

page 47 & 49 for each constant in

capital letters in the diagrams.

(with shift value)

– 27 –

Page 30

2min. 30sec.

Notes:

(1) The defrosting inhibit period is set as shown in the diagram below. When defrosting has finished once, the

inhibit period is newly set, based on the outdoor temperature when the compressor was started. During this

period, the defrost signal is not accepted.

(2) If the difference between the room and outdoor temperature is large when defrosting is finished, the

maximum compressor speed (WMAX) or (WMAX2) can be continued for 120 minutes maximum.

(3) The defrosting period is 12 minutes maximum.

(4) When operation is stopped during defrosting, it is switched to auto refresh defrosting.

(5) Auto refresh defrosting cannot be engaged within 15 minutes after operation is started or defrosting is

finished.

Sleep Lo

Notes:

(1) The sleep operation starts when the sleep button is pressed.

(2) When the sleep button is set, the maximum compressor speed is limited to WBEMAX, and the indoor fan is

set to "sleep Lo".

(3) The indoor fan speed does not change even when the fan speed mode is changed. (Sleep Lo)

(4) When defrosting is to be set during sleep oepration, defrosting is engaged and sleep operation is restored

after defrosting.

(5) If sleep operation is cancelled by the cancel button or sleep button, all data is cleared.

Reversing Valve Defrosting

Preheating released

Reversing valve

(cooling "on" model)

Heating Sleep Operation

Upper limit WBEMAX

Sleep button

– 28 –

Page 31

– 29 –

Page 32

– 30 –

2

1

7

3

5

NORMAL : HI

RESET : LO

RES

Microcomputer

C524

C522

C521

R551

IC521

0V

R552

5V

Power "OFF"

Power "ON"

Reset enter at 4.2V

Reset release at 4.4V

Voltage

Voltage

Voltage supply to

pin 2 of IC521

Voltage at pin 7

of microcomputer

5.0V

Fig. 1-2

Fig. 1-1

5.0V

DESCRIPTION OF MAIN CIRCUIT OPERATION

MODEL RAS-18YH6, RAS-25YH6

1. Reset Circuit

The reset circuit initializes the microcomputer program when power is ON or OFF.

Low voltage at pin

77

77

7 resets the microcomputer and Hi activates the microcomputer.

When power “ON” 5V voltage rises and reaches 4.4V, pin

11

11

1 of IC521 is set to “Hi”. At this time the microcomputer

starts operation.

When power “OFF” voltage drops and reaches 4.2V, pin

11

11

1 of IC521 is set to “Low”. This will RESET the

microcomputer.

Page 33

– 31 –

2. Receiver Circuit

IRR (light receiver unit) receives the infrared signal from the wireless remote controller. The receiver

amplifies and shapes the signal and outputs it.

3. Buzzer Circuit

When the buzzer sounds, an approx 3.9kHz

square signal is output from buzzer output pin

TT

TT

T

of the microcomputer. After the amplitude of this

signal has been set to 12Vp-p by IC711, it is

applied to the buzzer. The piezoelectric element in

the buzzer oscillates to generate the buzzer’s

sound.

Q141

L201

12V

IRR

VDD

Fig.2-1

Fig.3-1 Buzzer circuit

GND

V

OUT

C212

C211

R212

0V

0V

0V

R211

0V

ZD141

R141

R611

C611

0V

RECEIVER I/P

Microcomputer

13

BZ1

R721

12V

IC711

Microcomputer

Buzzer output

16130

BZ

Sound wave

Metal diaphragm

V

Pizoelectric element

V

Fig. 3-2 Buzzer Operation

Page 34

– 32 –

Micro computer pins

Step width : 10ms

Horizontal air deflectors

15

16

17

18

123456 78

Fig.4-2 Microcomputer Output Signals

Table 4-1 Auto sweep Motor Rotation

Mi

crocompute

r

7

1

N4

Roto

r

Auto sweep motor for

horizontal air defectors

Fig.4-1

Rotation angle per step ) Time per step (ms.)

0.0882 10Horizontal air deflectors

4. Auto Sweep Motor Circuit

Fig. 4-1 shows the Auto sweep motor drive circuit; the signals shown in Fig.4-2 are output from pin

EE

EE

E~

HH

HH

H of

microcomputer.

As the microcomputer’s outputs change as shown in Fig.4-2, the coils of the auto sweep motor is excite to turn the

rotor. Table 4-1 shows the rotation angle of horizontal air deflectors.

Page 35

– 33 –

5. Initial Setting Circuit (IC401)

• When power is supplied, the microcomputer reads the data in IC401 or IC402 (E2PROM) and sets

the preheating activation value and the rating and maximum speed of the compressor, etc. to their

initial values.

• Data of self-diagnosis mode is stored in IC401 or IC402; data will not be erased even when power is

turned off.

6. Power Supply

First, 35V power which operates the indoor unit is generated by the power source section of the outdoor unit and

supplied to the indoor unit through the C and D lines of the connecting cable.

Second, use the DC/DC converter and the 35 V power supply from the outdoor unit to generate 12 V control

power, which drives the stepping motor during the operation.

In addition, use the regulator IC 121 to generate 5 V power required for driving the micro computer and controlling

fan motor.

If the terminal block was overheated due to a connecting cable improper connection, the thermal fuse built in the

terminal block will burnt to shut off the 12 V line and stop the operation of the indoor unit. Then, the outdoor unit

cannot be communicated with the indoor unit and a communication error occurs (the outdoor LD301 will blink 9

times), stop all operations.

Fig. 6-1

Fig. 5-1

Microcomputer

External ROM

SCL

SDA

0V

0V

0V

5V

5V 5V

C401

IC401 or IC402 (E

2

PROM)

R404

R403

27

26

1

2

3

4

8

7

6

5

}

Page 36

– 34 –

7

51

7

51

63

1

N1

0

V

V

Micro computer

Fan motor

Fig. 7-1

DC fan

motor output

DC fan motor

Speed

feedback

Voltage at point A

Waveform

T2

T1

Voltage at point B

Waveform

T1

Voltage at point C

Waveform

T2

Fig. 7-2

Voltage at point B (V)

Fig. 7-3

7. Fan Motor Drive Circuit

• For the point A , 15.7 kHz PWM pulse will be output from

the pin

NN

NN

N on the micro computer as shown in Fig. 7-2.

The pulse range will vary with different command speed.

• The pulse is converted into the analog voltage by the

R751 and C751 and applied to the fan motor as the speed

command voltage.

Fig. 7-3 shows the relation between the voltage at the

point B and the speed. (Some differences will occur

due to the condition of the unit.)

• The fan motor outputs the feedback pulse of the speed,

which is input into the pin

DD

DD

D on the micro computer. This

pulse is equivalent to a frequency of 12/60 speed.

(Example: 1000 min-1 x 12/60 = 200 Hz)

The micro computer monitors the frequency and adjusts

the output pulse range of the pin

NN

NN

N so as to keep the

command speed.

• If the feedback pulse is 100 min-1 or less due to a locked fan motor or failure, the fan output will be

stopped temporarily as fan lock error. After 10 seconds, restart the output of the pulse. If fan lock

error is detected twice within 30 minutes, all units are stopped and the unit will come in the failure

mode. (The timer lamp will blink 10 times.)

Page 37

– 35 –

MODEL RAC-18YH6 RAC-25YH6

1. Power circuit

This circuit is to convert the power from AC which is provided from the terminal A and B to DC voltage.

And produces an AC current which does not exceed the harmonic amplitude limit of the IEC61000-3-2.

When the compressor is stopped, the AC voltage becomes about 300 V and while the compressor

operates, it is about 280 V.

Main parts

(1) DB2

The DB2 rectifies the AC voltage.

The possible causes for the DB2 failure are as follows. The 15 A fuse may be blown out or the IPM

for the main P.W.B. may have a failure. In such a case, check the 15 A fuse for blowout and replace

the main P.W.B. if necessary.

(2) DB3, L1, C023 and L2

The DB3, L1, C023 and L2 shape waveform of the input current.

When the current runs through the L1 is taken for I1 and the current runs through the L2 is taken for

I2 as shown in Fig. 1-2, I1 becomes an input current to the capacitor which peak value was crushed

by the L1 and I2 becomes a resonance current which causes the LC resonance using the L2 and

C023. By combining the I1 and I2, the input current from the main power shapes a waveform shown

in the right side of Fig. 1-3, indicating that the waveform is similar to sine wave. The more the

waveform is similar to the sine wave, the lower the harmonic current becomes.

If the C023 has any failure, the protection unit activates and the C023 in open mode. In such a case,

replace the failed parts.

1-2 1-3

+

I

1

I

2

I

S

I

1

I

2

L1

L2

DB3

C023

Page 38

– 36 –

Input

Voltage

0V

0V

0V

Voltage

Smoothed

Voltage

Fig. 1-4

(3) C021 and C022

This smoothes the voltage rectified for operating the

compressor.

When the input voltage is taken for the sine wave as

shown in the top of Fig. 1-4, it is rectified by the DB2